Patents

Literature

49results about How to "Reduce cleanup steps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

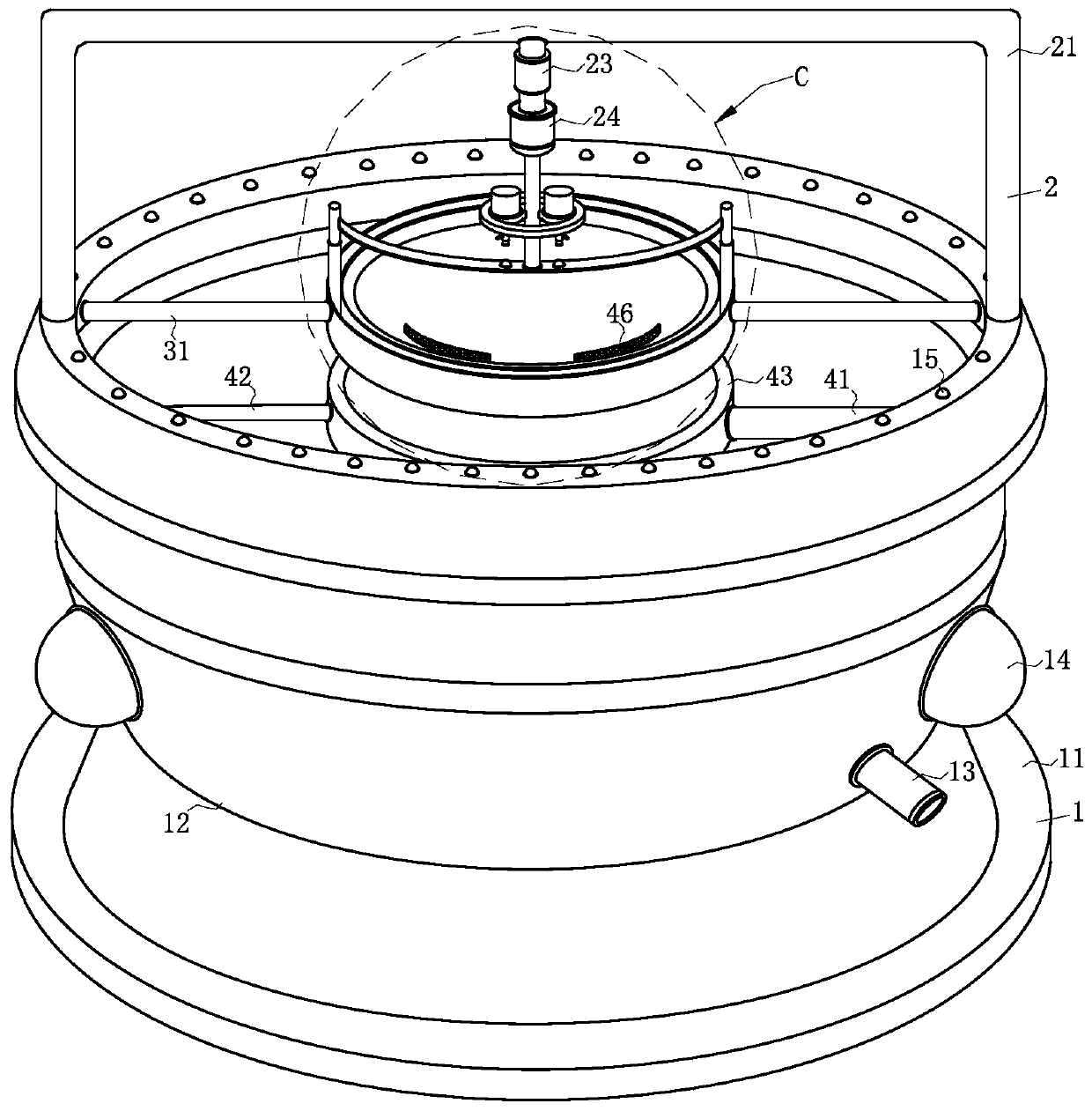

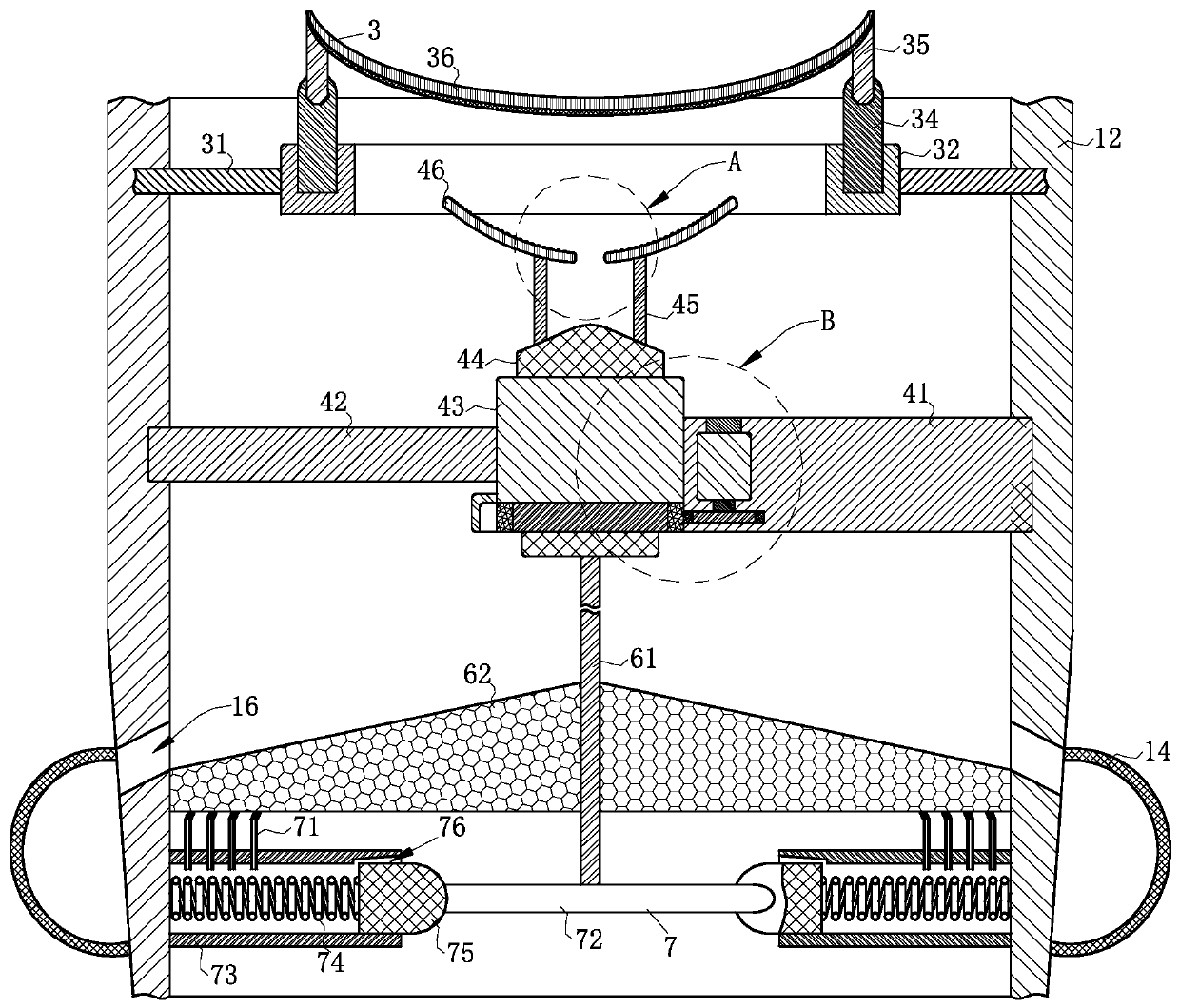

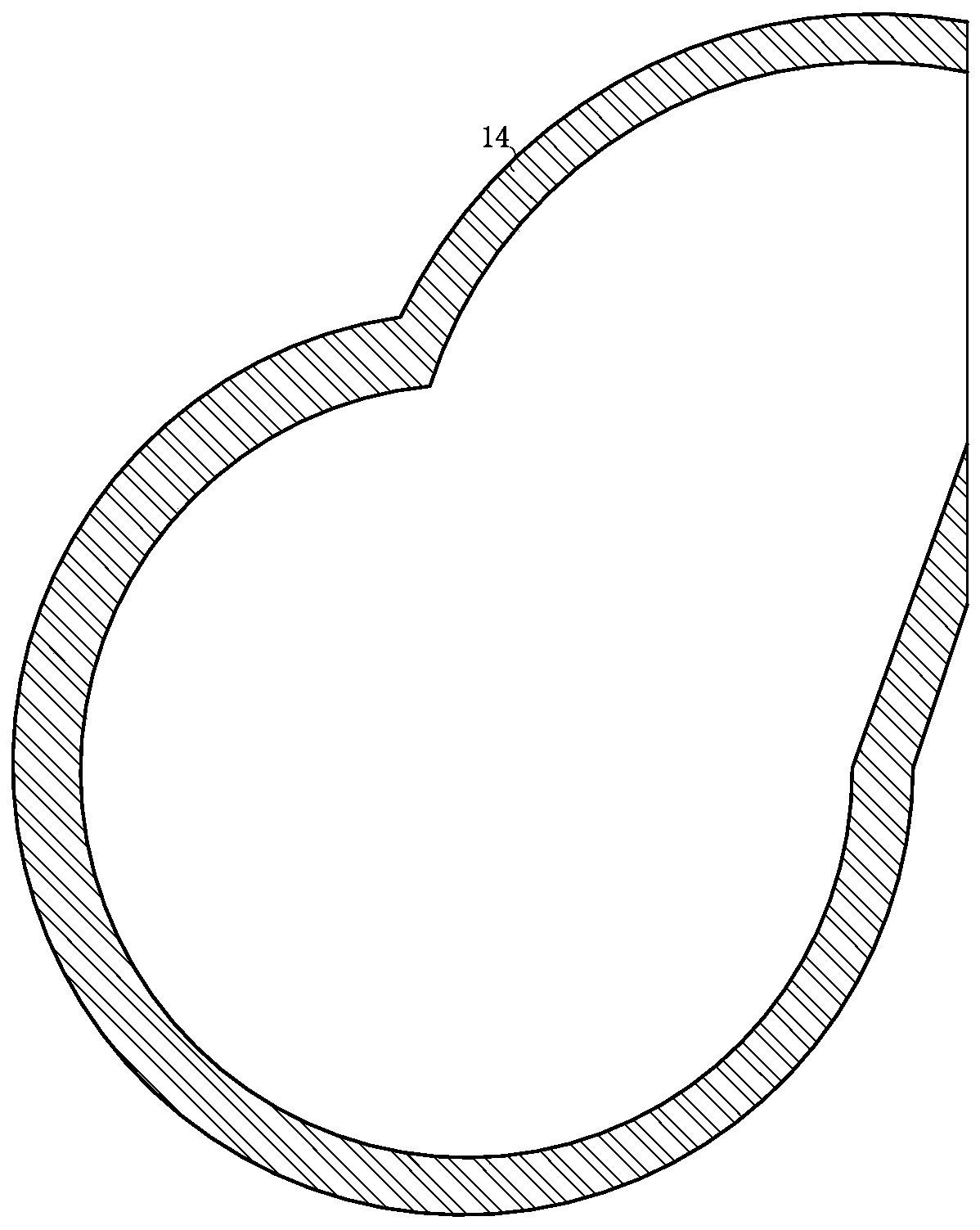

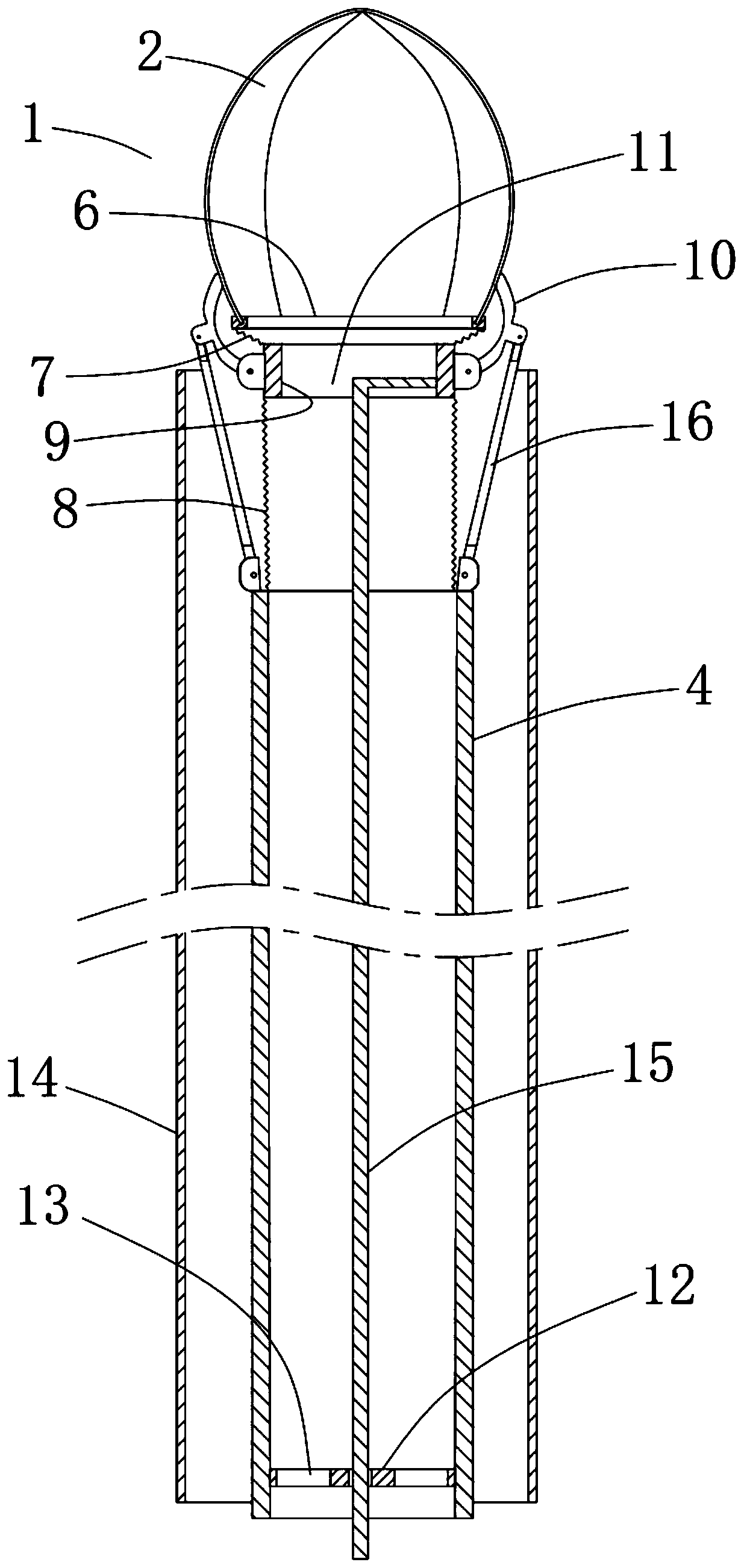

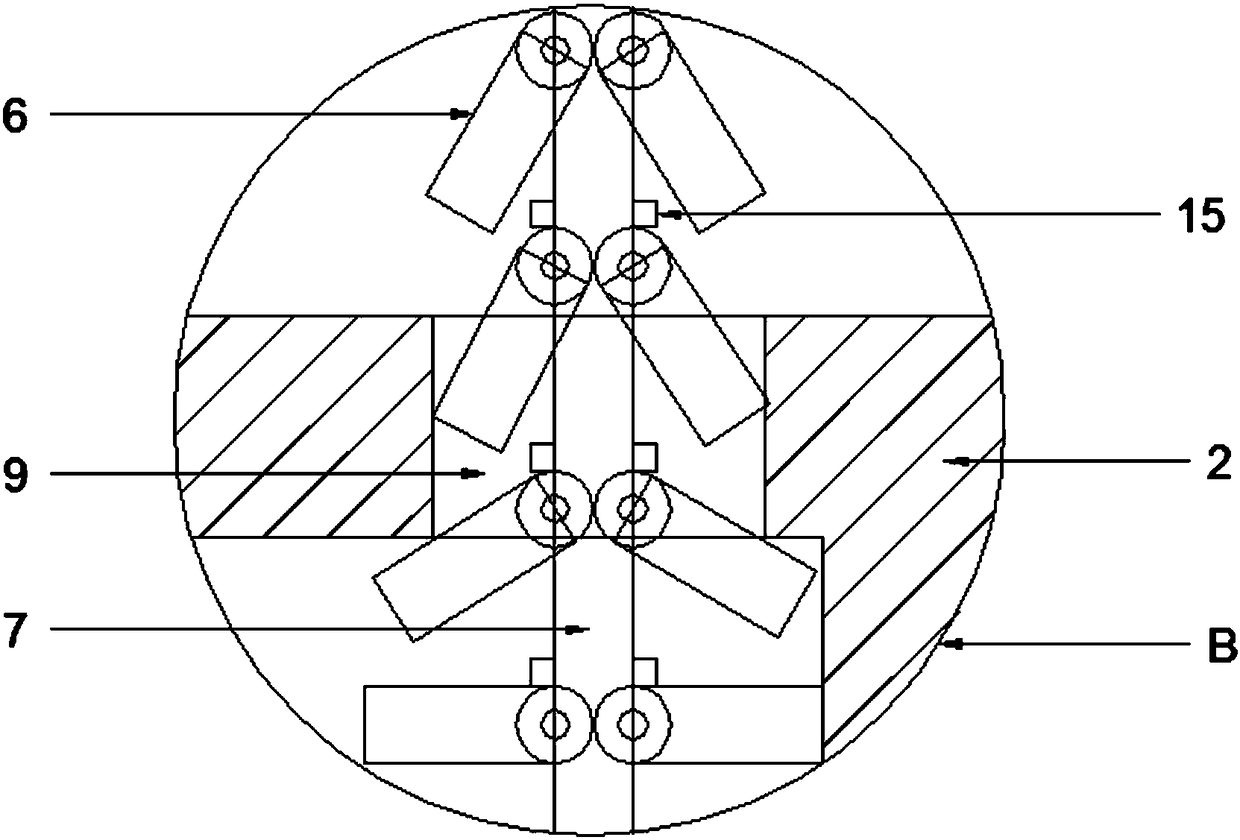

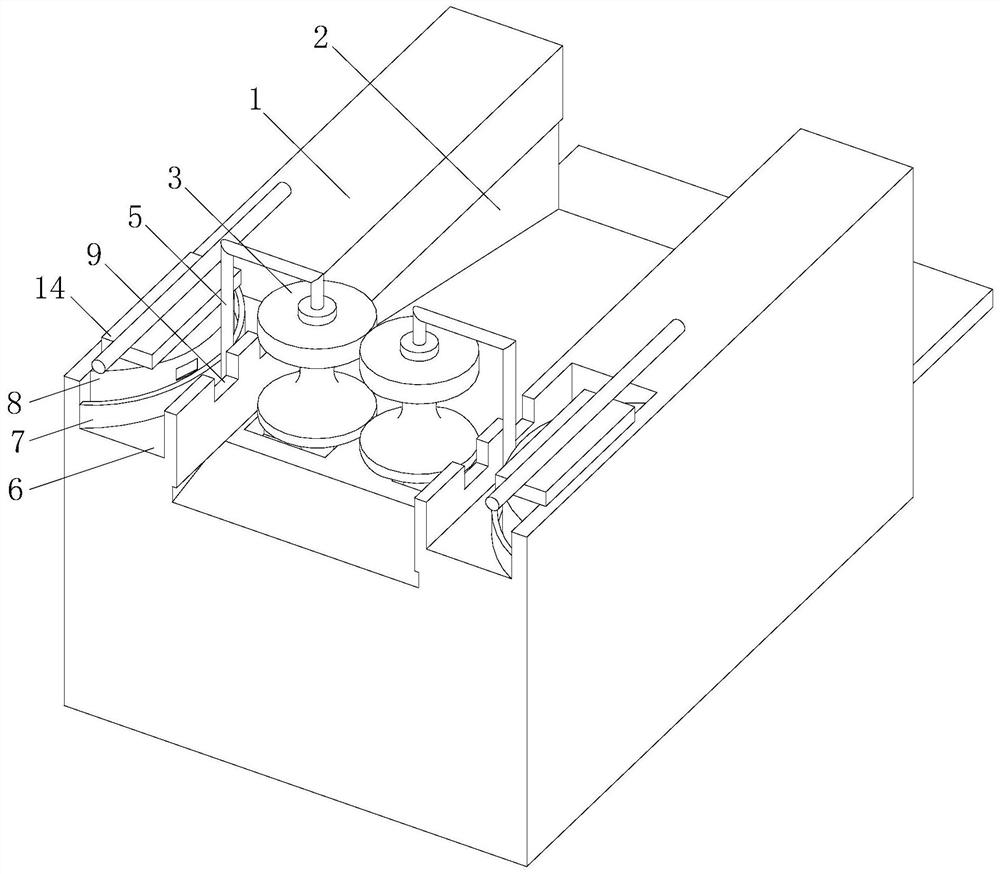

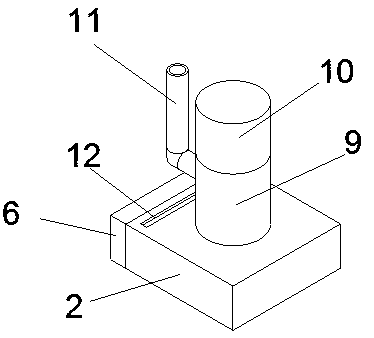

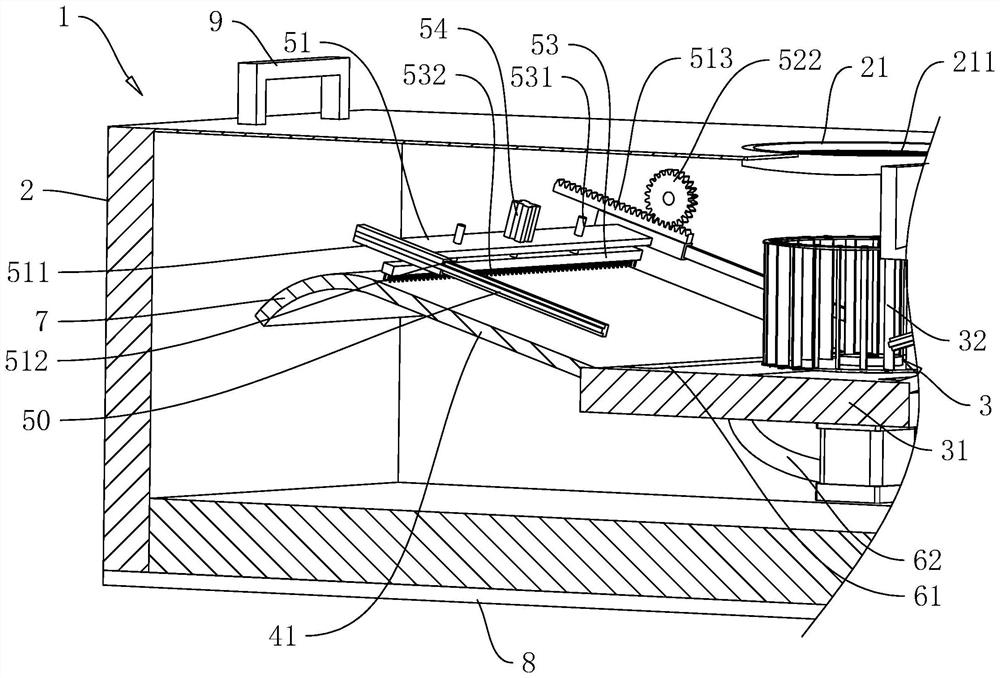

Mechanical device applied to sewage treatment

ActiveCN110368735AReduce stepsEasy to take outTableware washing/rinsing machine detailsMoving filtering element filtersEngineeringSewage

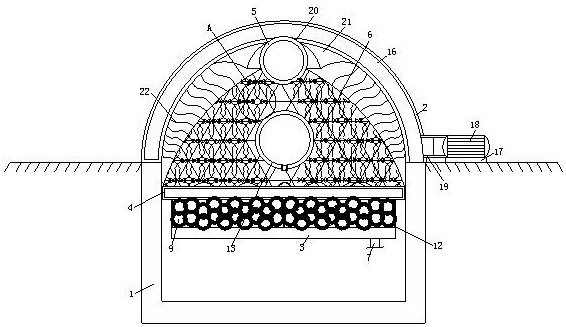

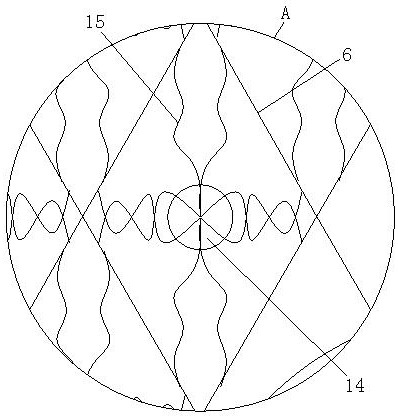

The invention relates to the field of sewage treatment, specifically to a mechanical device applied to sewage treatment. The mechanical device comprises a main body mechanism, a driving mechanism, a cleaning mechanism, a dust scraping mechanism, a linkage mechanism, a filtering mechanism and a backwashing mechanism. When the mechanical device is in use, the cleaning mechanism is arranged on the inner side wall of the main body mechanism, and the driving mechanism is connected with the top part of the main body mechanism, so the cleaning mechanism is driven by the driving mechanism to automatically clean a cookware positioned on the cleaning mechanism, and use is more convenient; meanwhile, the linkage mechanism positioned in the interior of the dust scraping mechanism is powered by a powersupply to drive the dust scraping mechanism and the filtering mechanism, and the dust scraping mechanism automatically cleans the bottom part of the cookware, so use is further convenient; and when sewage enters the filtering mechanism, the filtering mechanism is driven by the linkage mechanism to rotate, and filtered residual dirts are thrown into a storage unit located on the main body mechanism under the action of a centrifugal force to be conveniently taken out, so reduction of steps and improvement of work efficiency are realized, and use is further convenient.

Owner:广东德通水务有限公司

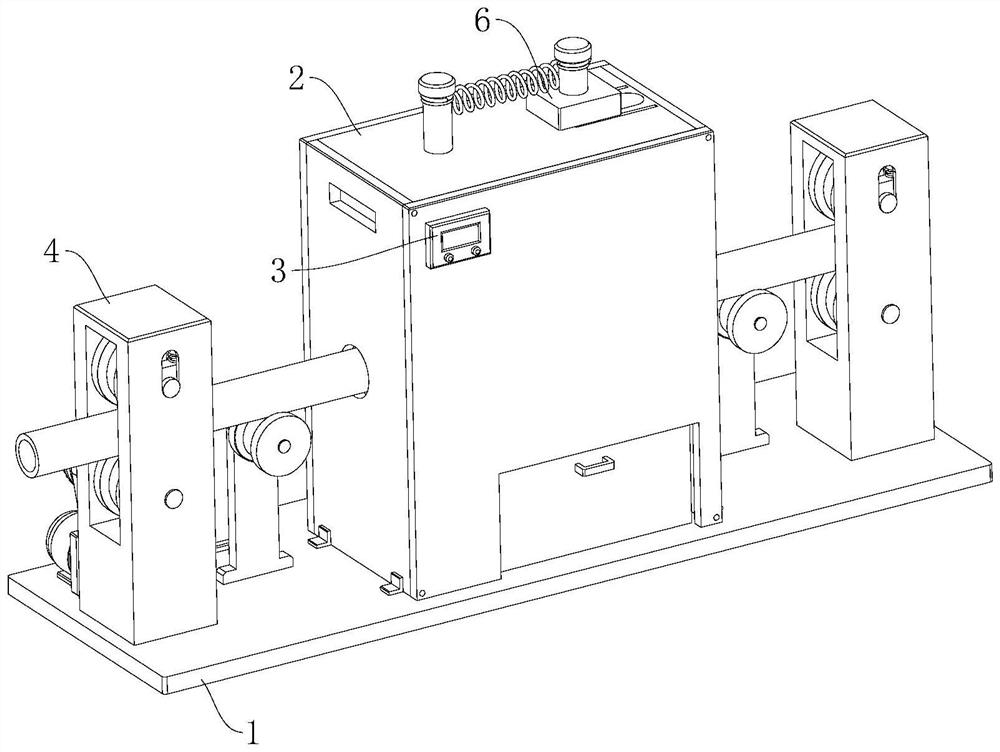

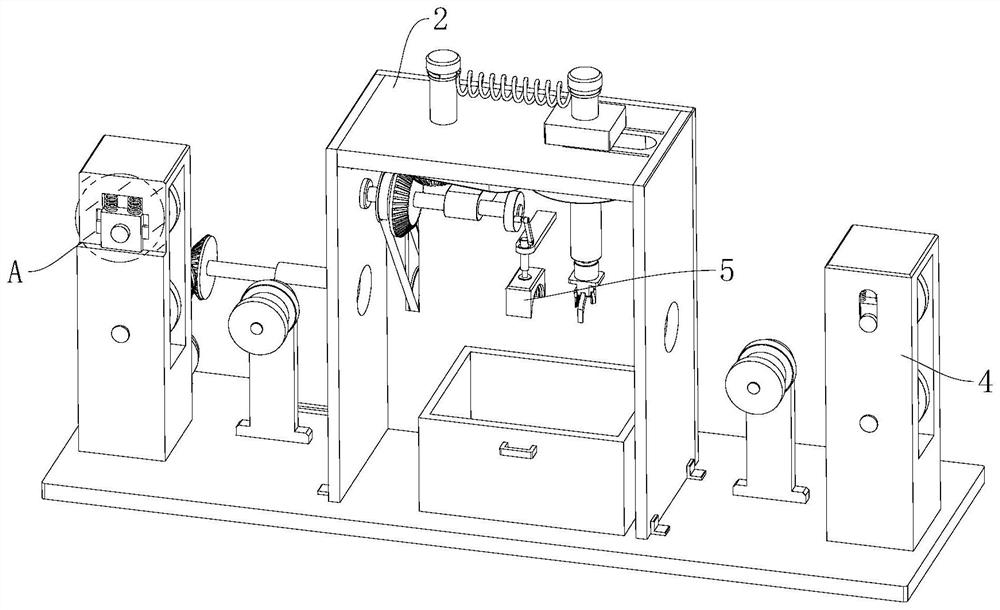

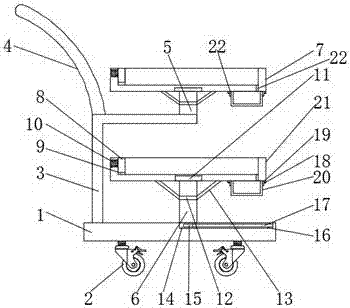

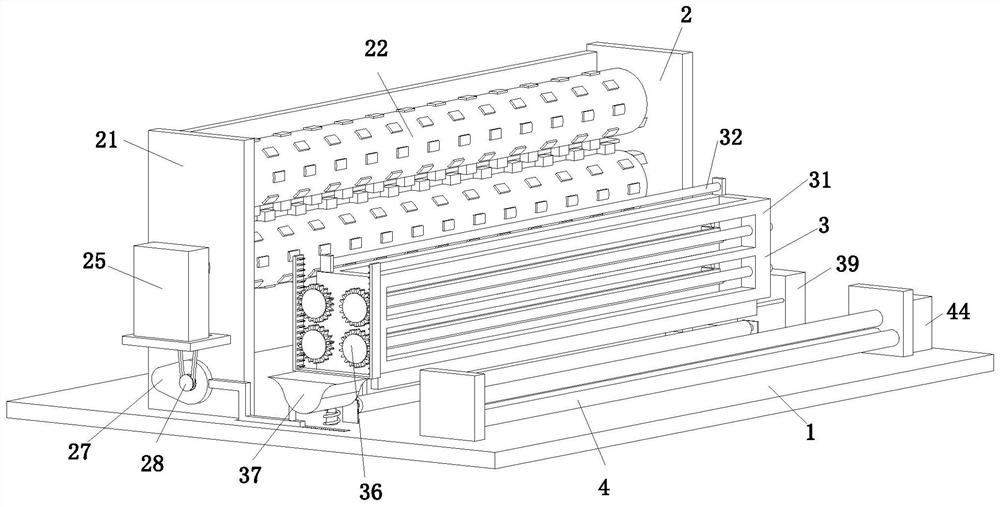

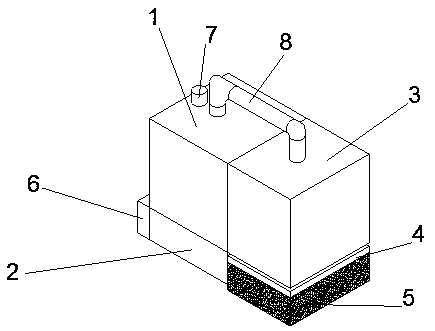

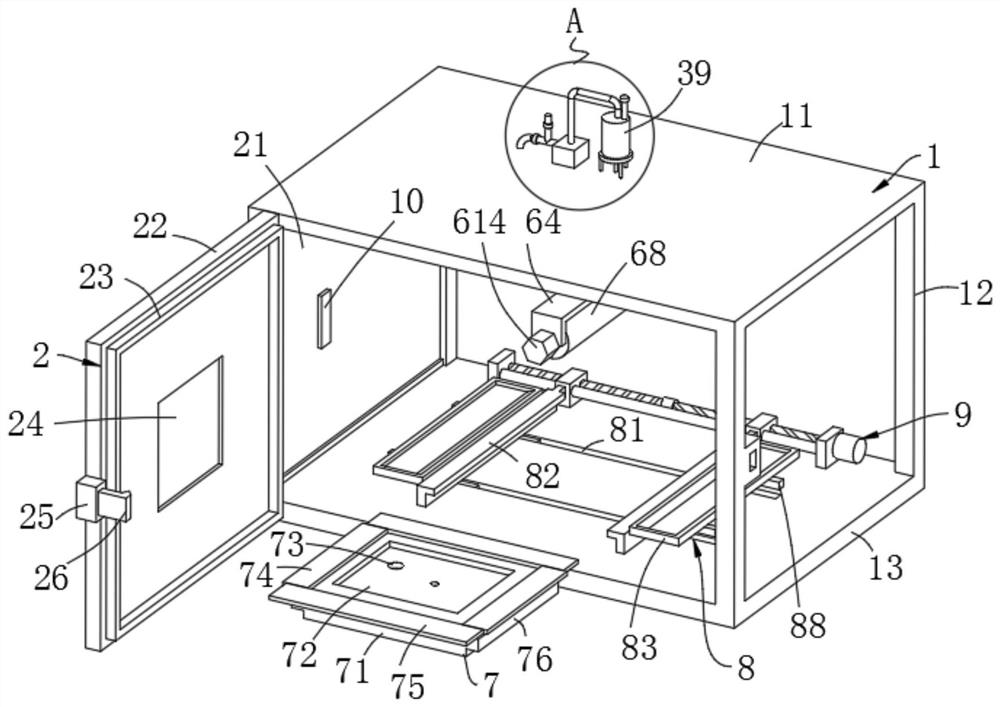

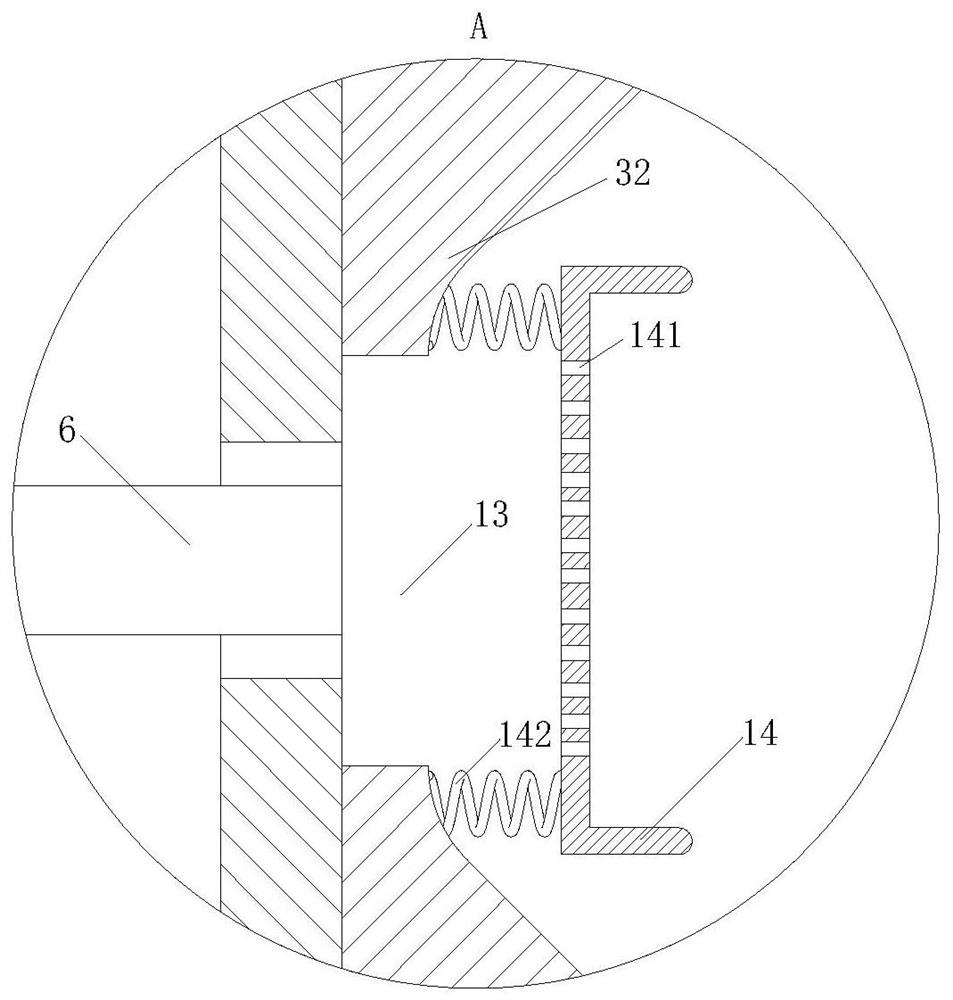

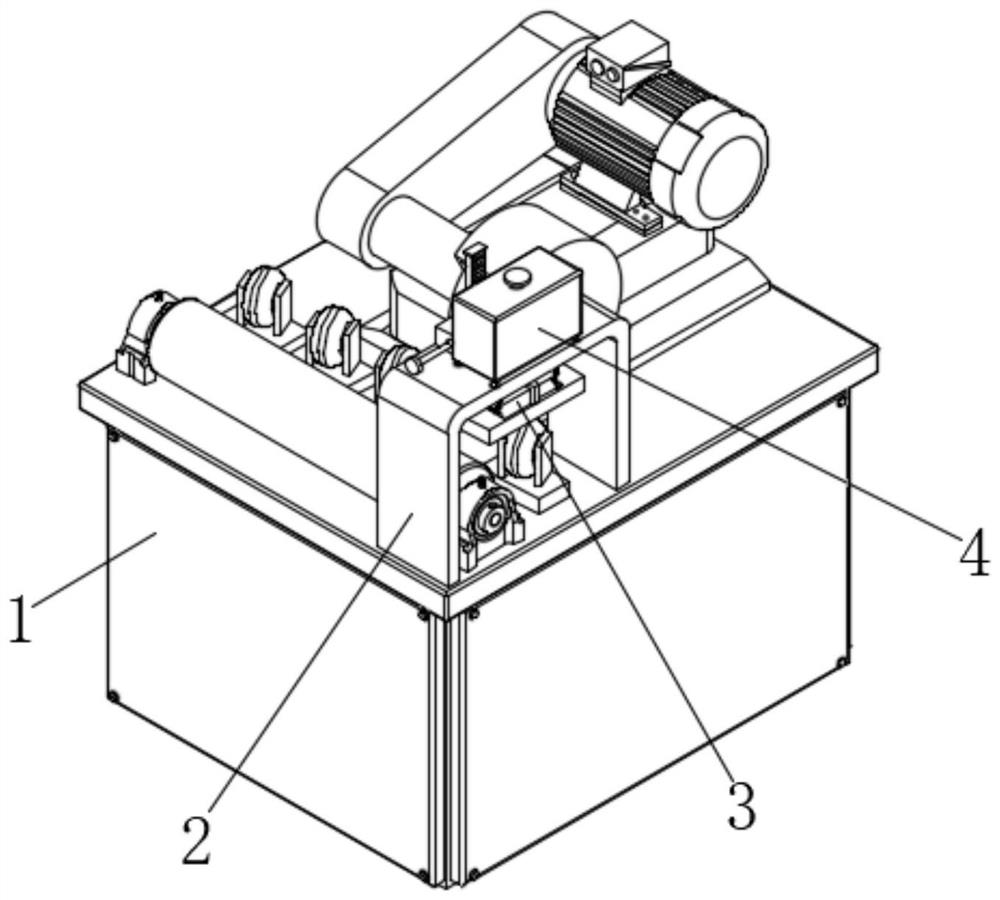

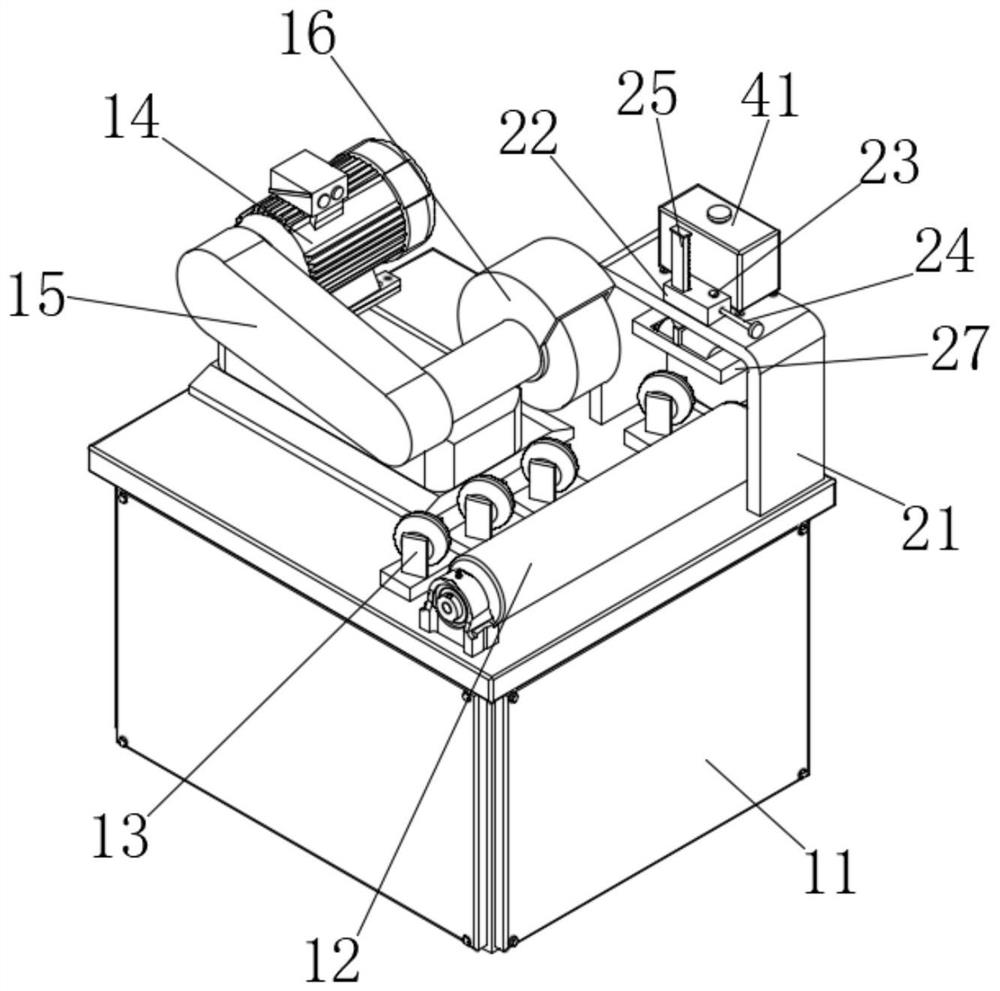

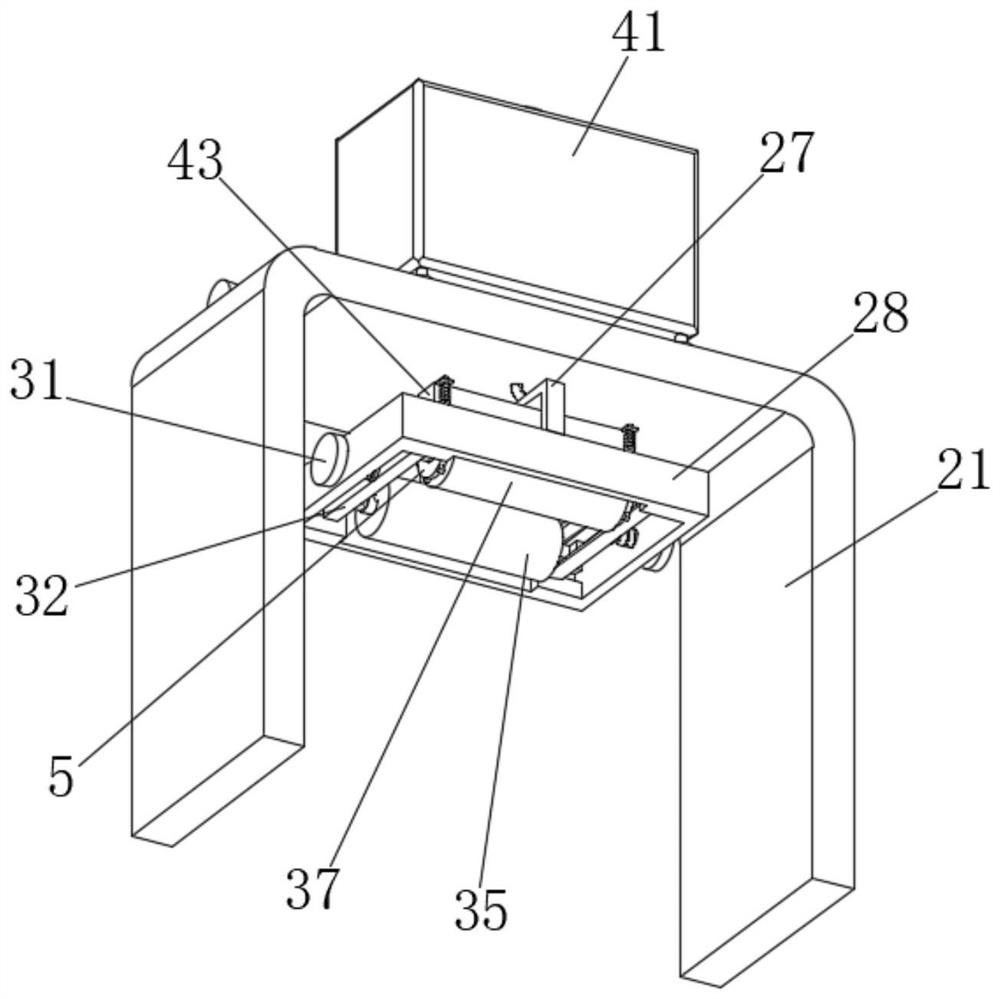

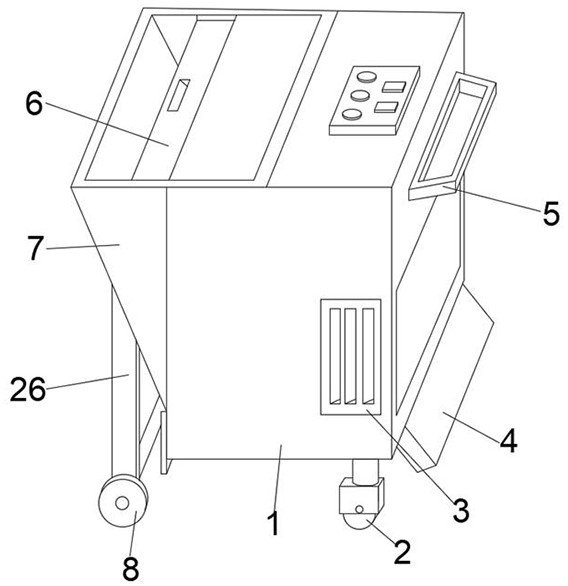

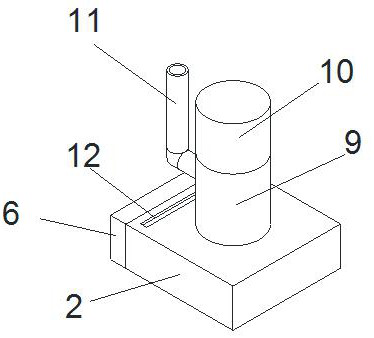

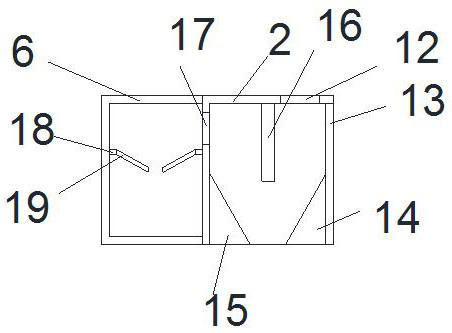

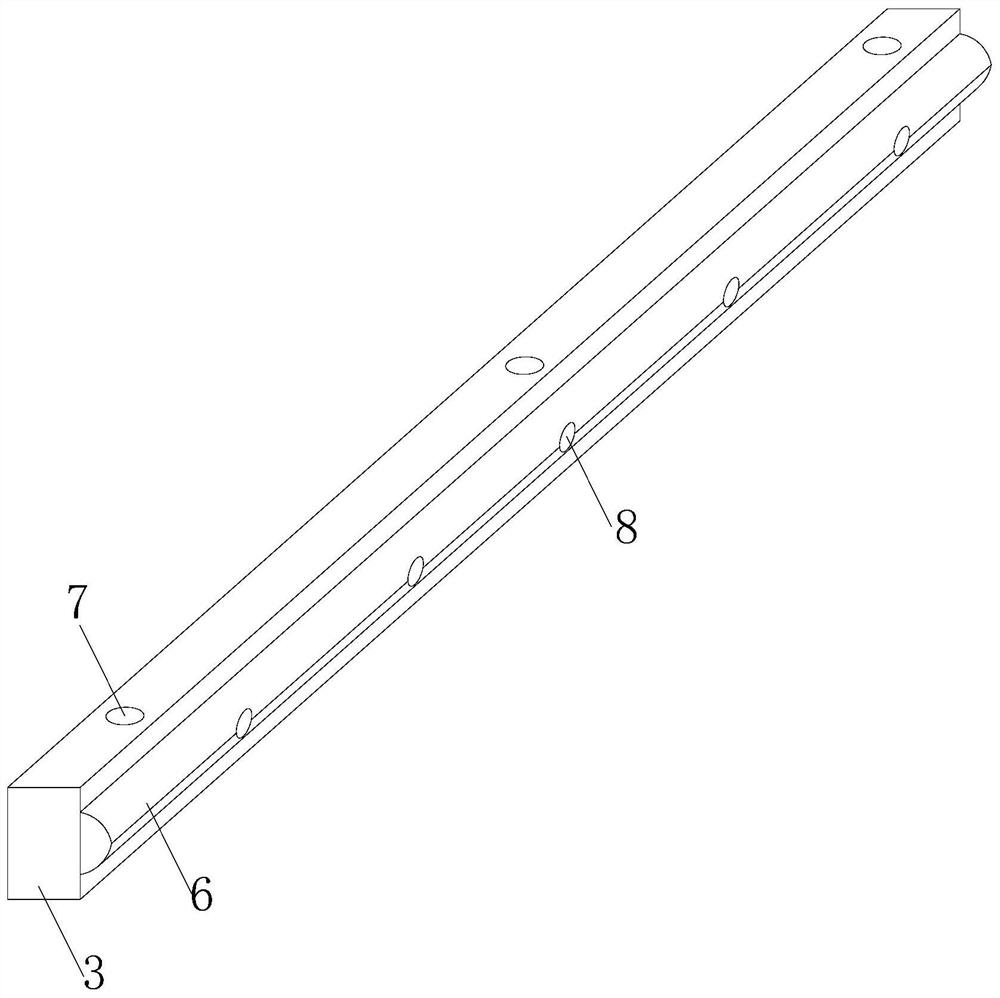

Construction site steel pipe surface cleaning equipment

ActiveCN112354979AReduce labor intensityReduce cleanup stepsHollow article cleaningDirt cleaningSurface cleaningPipe

The invention relates to the field of cleaning devices, in particular to construction site steel pipe surface cleaning equipment. The equipment comprises a base and a cleaning box and further comprises a controller, a conveying mechanism, a beating mechanism and a scraping mechanism. The conveying mechanism is arranged at the top of the base to be used for conveying steel pipes and comprises a transmission assembly and two conveying tables. The beating mechanism is arranged at the top of the inner side of the cleaning box and used for beating the steel pipes, the beating mechanism comprises ahammer head and a rotating assembly, the scraping mechanism is arranged at the top of the inner side of the cleaning box and used for scraping impurities such as concrete on the surfaces of the steelpipes, the scraping mechanism comprises a scraping head, a pushing assembly and a limiting assembly, and the transmission assembly is electrically connected with the controller. According to the construction site steel pipe surface cleaning equipment, manpower is automatically replaced, the cleaning efficiency is high, the labor intensity is low, the noise is low, meanwhile, the power consumptionis low, the cleaning cost can be reduced, the cleaned impurities can be effectively collected, and pollution is avoided.

Owner:巢湖市鼎力铁塔有限公司

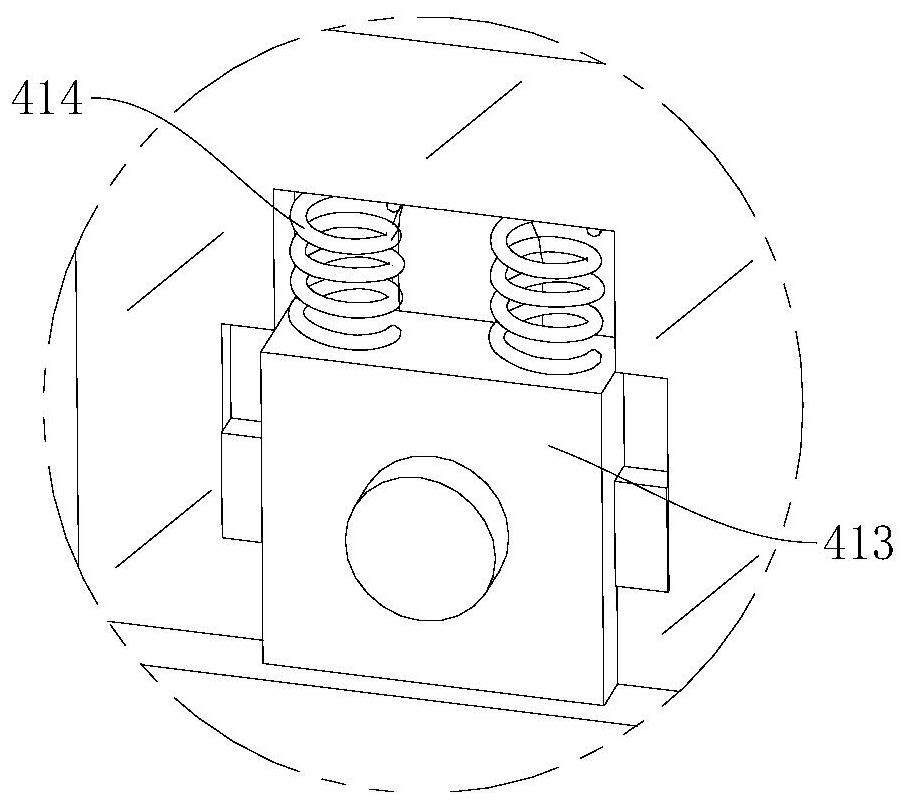

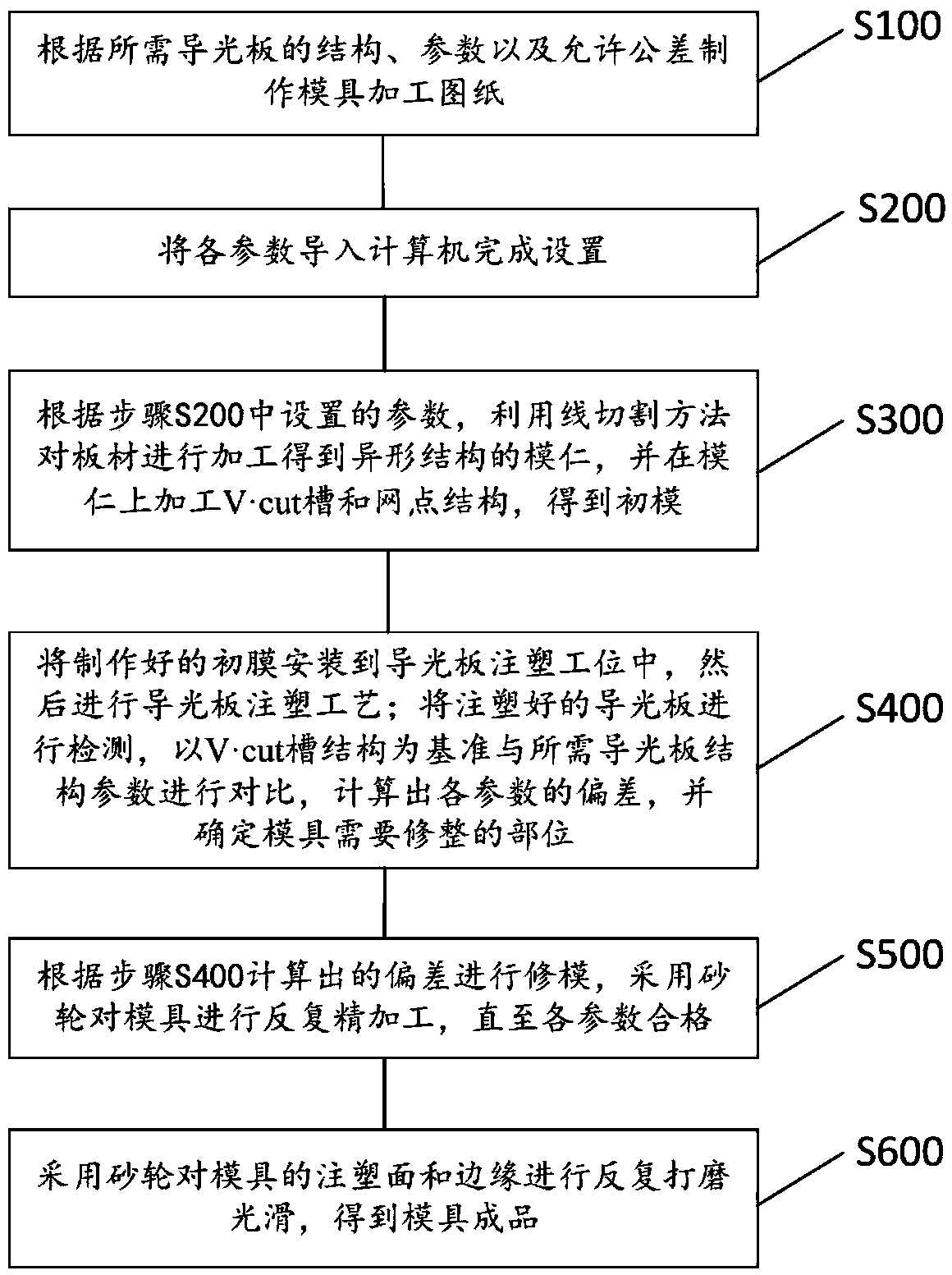

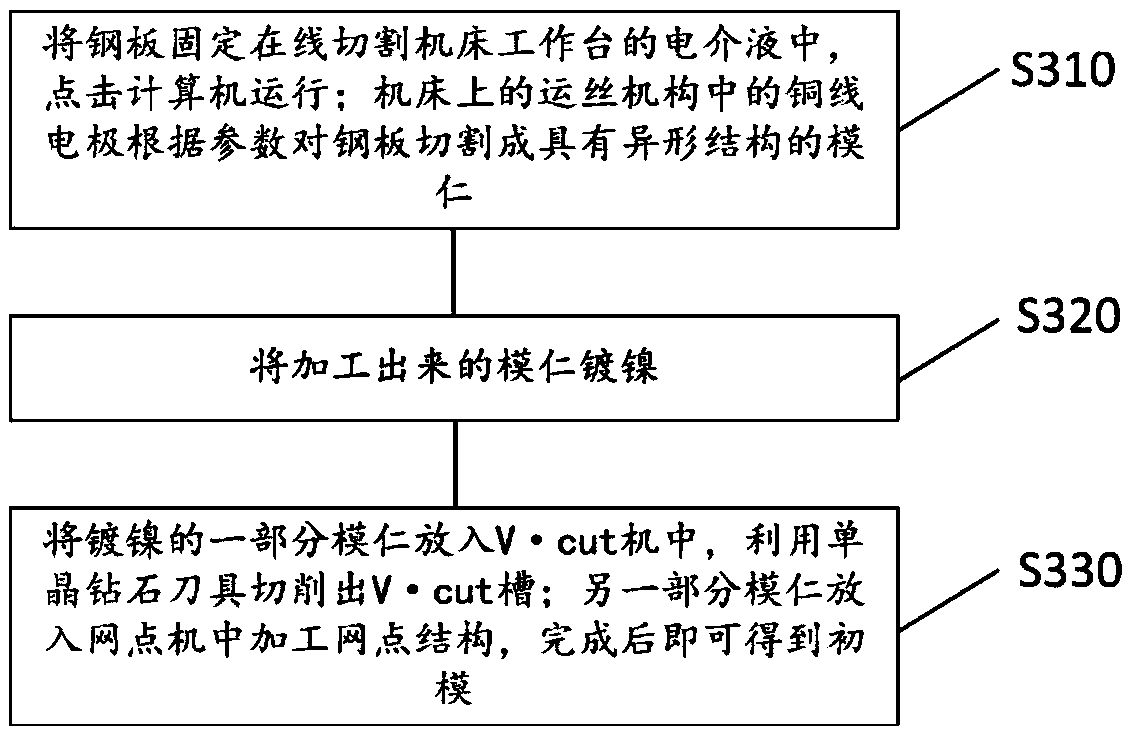

Processing method for special-shaped light guide plate injection mold

The invention discloses a processing method for a special-shaped light guide plate injection mold. The processing method for the special-shaped light guide plate injection mold comprises drawing, importing parameters into a computer, starting linear cutting equipment to manufacture a mold insert, conducting nickel plating, manufacturing a V-cut groove to obtain a primary mold, carrying out a moldtest, trimming the mold with specific grinding wheels, and removing burrs on the mold. According to the processing method for the special-shaped light guide plate injection mold, in the production process of the injection mold, a linear cutting method is adopted to manufacture the primary mold and then the grinding wheels are used for finish machining in the mold trimming process. The processing method is simple to operate and does not damage the V-cut groove, and the grinding wheels are used for trimming, so that the burrs on the edge of the mold can be all removed and the labor cost is saved.

Owner:SHENZHEN LONGLI TECH CO LTD

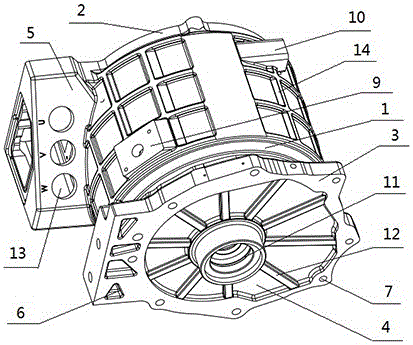

New energy source automobile spiral water cooling integral motor case and pressure casting process thereof

InactiveCN105871106AGuaranteed air tightnessImprove pass rateElectric machinesCooling/ventillation arrangementPressure castingEngineering

The invention discloses a new energy source automobile spiral water cooling integral motor case and a pressure casting process thereof. The new energy source automobile spiral water cooling integral motor case comprises a motor casing, wherein the upper end of the motor casing is provided with a casing upper edge; the lower end of the motor casing is provided with a casing lower edge and a motor back end cover; a cooling water passage is arranged inside the motor casing; a water inlet installing seat is arranged in the lower part position of the motor casing; a water outlet installing seat is arranged in the upper part position of the motor casing; the water inlet installing seat and the water outlet installing seat are respectively communicated with the cooling water passage. The processing process of the new energy source automobile spiral water cooling integral motor case is optimized; the integral casting forming is realized; the processing cost of each split body and the assembling complexity are reduced; compactness and firmness are realized; the gravity pressure casting process is used; the new energy source automobile spiral water cooling integral motor case is suitable for mass production; the forming performance is good; the product surface is smooth; the crystal particles are fine; the tissue is compact; the mechanical performance is good; the technical requirements of customers can be met; meanwhile, the production efficiency is greatly improved.

Owner:GUANGZHOU ROVMA AUTO PARTS

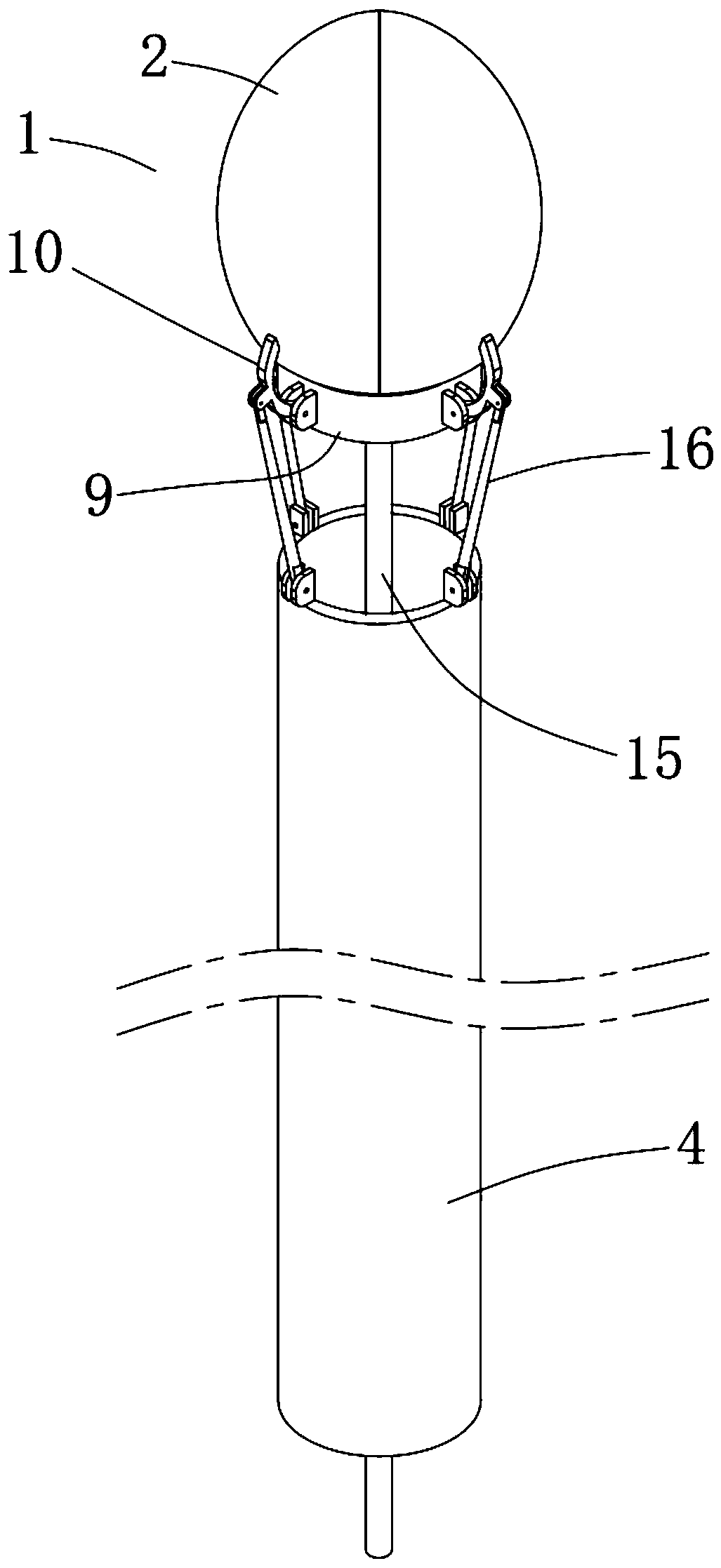

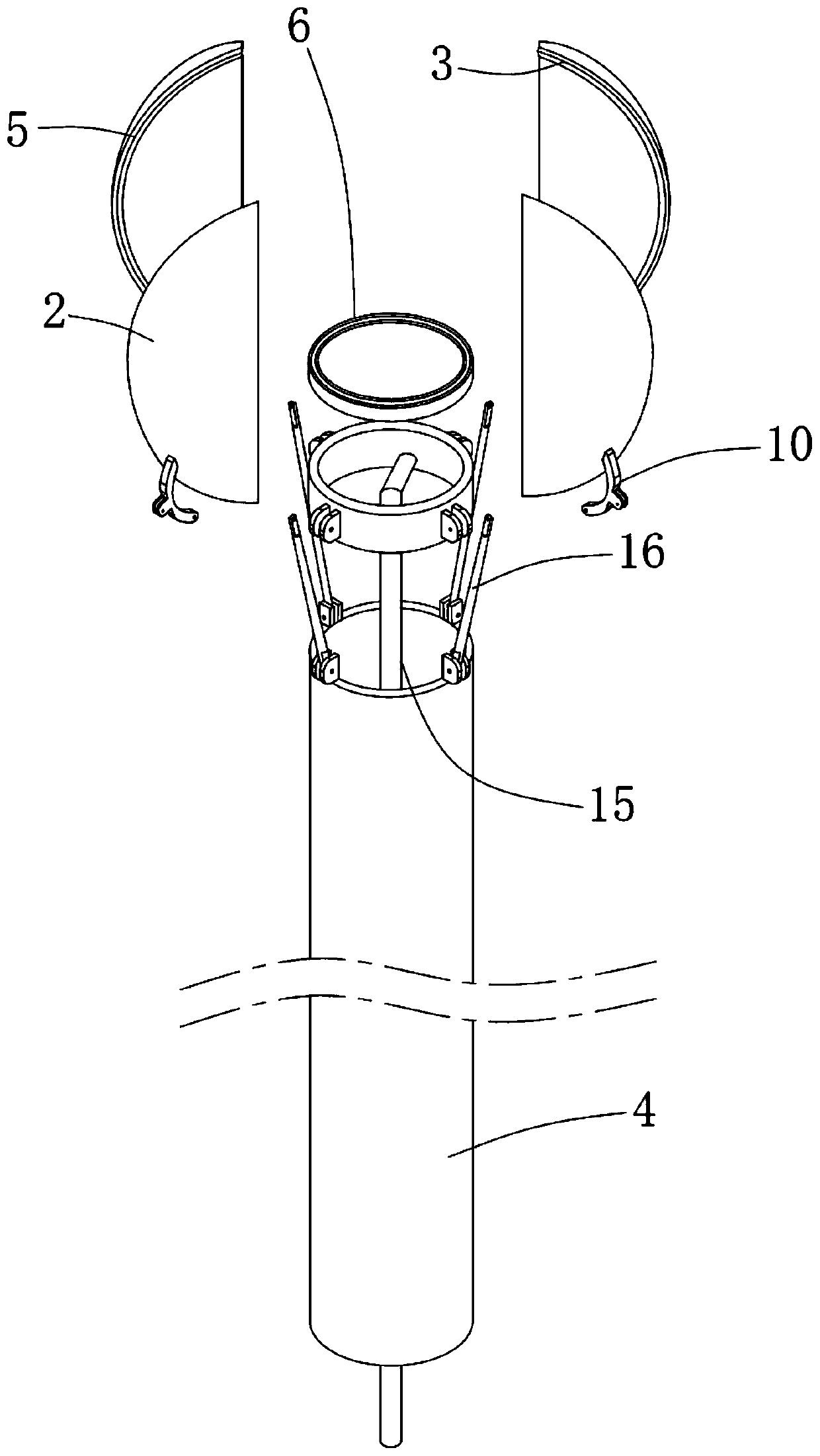

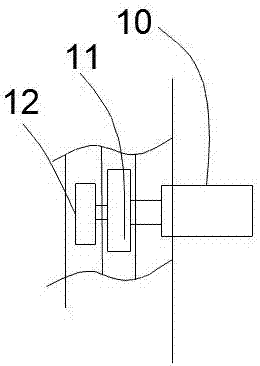

Excision device for excision of internal tissue

The invention relates to a medical instrument, in particular to an excision device for excision of internal tissue. The excision device includes a catheter, one end of the catheter is an extending endused for extending into the body of a patient. The other end is an operation end positioned outside the patient body; the extending end is provided with an opening and closing type blade end head; when the blade end head is in a closed state; a containing cavity is formed in the blade end, the containing cavity is communicated with the internal space of the catheter; the blade end head further comprises a plurality of cutting edges, when the cutting edge end is switched from the open state to the closed state, the cutting edges scratch tissue to-be-excised in the body of a patient to achievecutting of the tissue to-be-excised, and the excision device further comprises an operation component used for driving the blade end head to be switched between the open state and the closed state. According to the excision device, when tissue excision is conducted, the excised and separated tissue naturally falls into the containing cavity in the blade end, and the risk that the excised tissue isleft in the body of a patient is directly avoided.

Owner:SICHUAN PROVINCIAL PEOPLES HOSPITAL

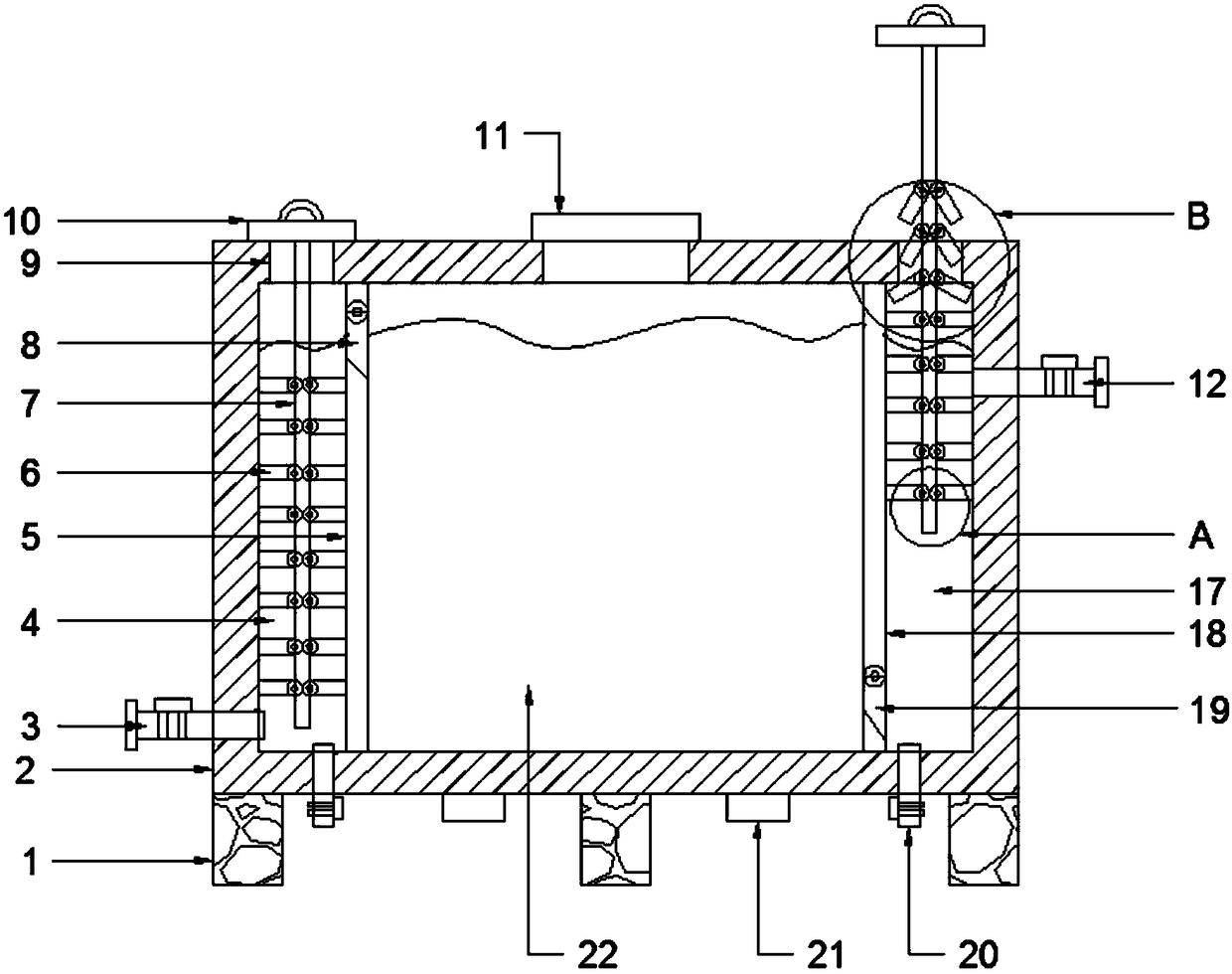

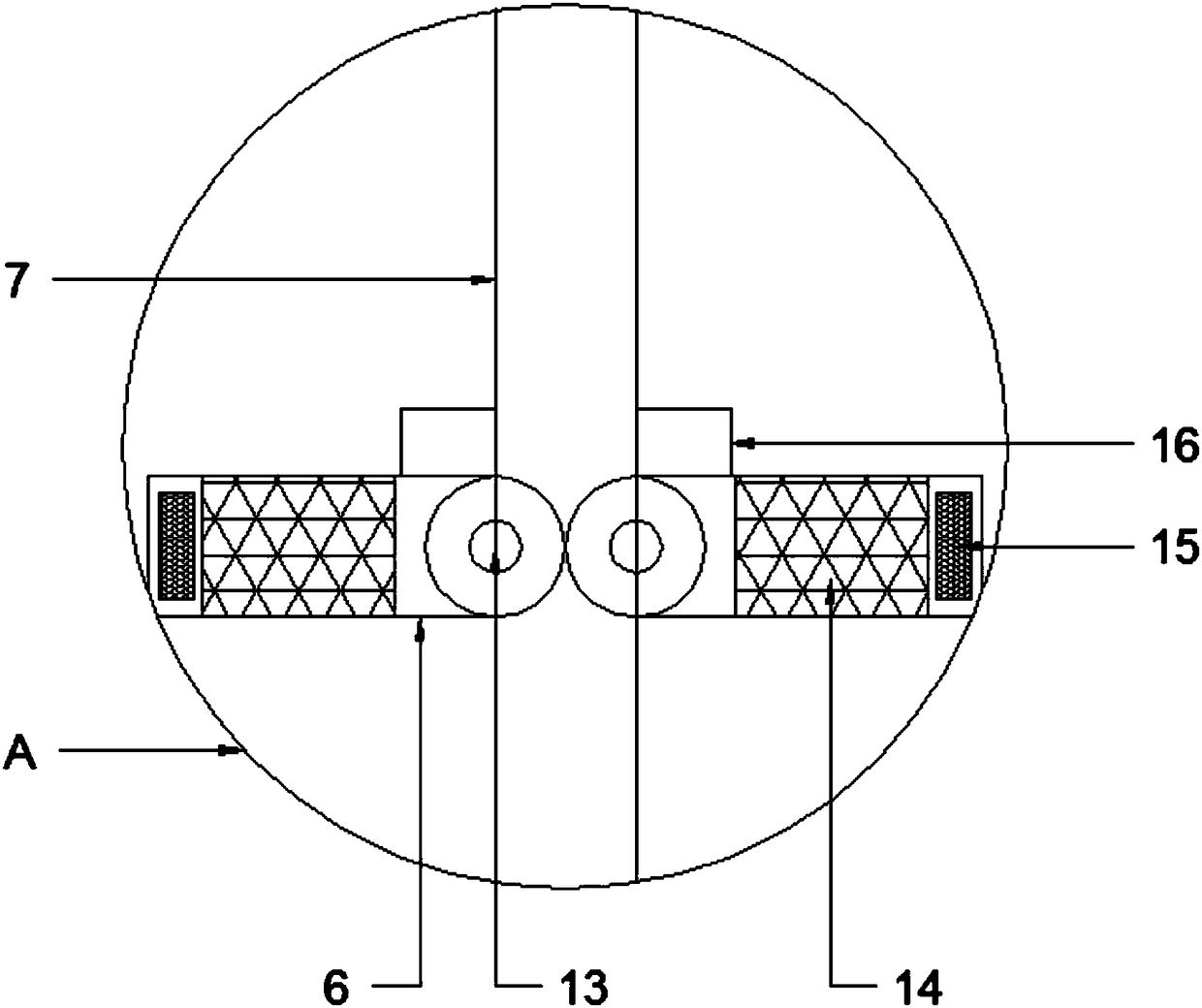

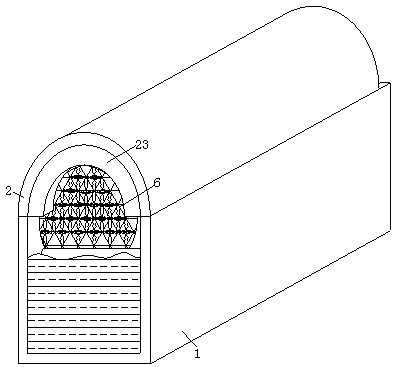

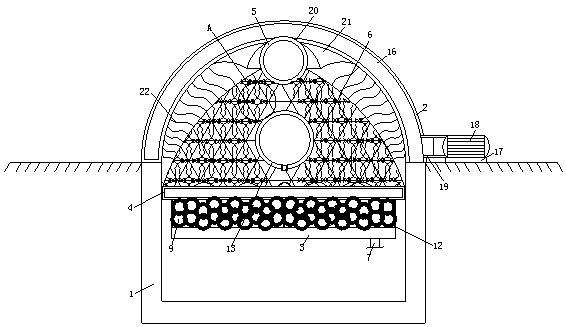

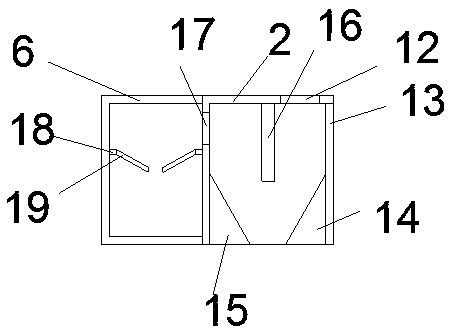

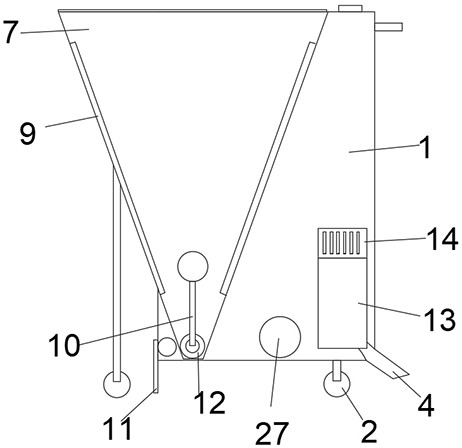

Water-saving water supply tank with adjustable filter plates

ActiveCN108118751AEasy to take outIncrease filter lengthTreatment involving filtrationWater supply tanksWater storageWater saving

The invention discloses a water-saving water supply tank with adjustable filter plates. The water-saving water supply tank comprises a water supply tank body, a water inlet pipe is arranged at the bottom of the left side wall of the water supply tank body, a water inlet chamber, a water inlet partition plate water storage chamber, a water outlet partition plate and a water outlet chamber are sequentially arranged in the water supply tank body from left to right, connecting rod openings are formed in the tops of the water inlet chamber and the water outlet chamber, pull ring cover plates are fixed at the tops of connecting rods, a plurality of rotating shafts are rotatably fixed onto walls of the connecting rods, limit blocks are fixed onto the walls of the connecting rods at the upper positions of the rotating shafts, a plurality of filter plates are fixed onto the rotating shafts, buoyancy blocks are arranged in outer side plates of the filter plates, filter screens are arranged in the middles of the filter plates, a water inlet valve is arranged at the top of a water inlet partition plate, a water outlet valve is arranged at the bottom of the water outlet partition plate, filterpipes are arranged at the bottoms of the water inlet chamber and the water outlet chamber, two water outlets are formed in the bottom of the water supply tank body, and an access hole is formed in thetop center of the water supply tank body. The adjustable filter plates are conveniently taken out and cleaned, and water resources and manpower cost are saved.

Owner:苏州斯尔斯特新材料科技有限公司

Anti-corrosion wear-resistant rotatable medical equipment

InactiveCN106867220AImprove toughnessImprove wear resistanceNursing accommodationBall bearingMedical equipment

The invention discloses an anti-corrosion and wear-resistant rotatable medical device, which comprises a fixed plate, a universal wheel is arranged on the bottom of the fixed plate, and a support plate is arranged on one side of the top of the fixed plate, and one end of the top of the support plate is An armrest is provided, and the end of the top of the support plate away from the armrest is provided with a first receiving rod, and the first receiving rod is provided with a second receiving rod corresponding to the top of the fixing plate. In the present invention, the first receiving rod, the second receiving rod, the ball bearing, the rotating collar, the supporting rod, the connecting block, the restricting block, the moving groove and the sliding groove are arranged and used in cooperation with each other, so as to realize the combination of the first placement and the second placement. The tray is rotatable, which facilitates the removal of the second placement tray, and facilitates the taking of instruments at different positions of the first placement tray and the second placement tray, which saves time, reduces the workload of medical staff, and plays an important role in the health of medical staff. protective effect.

Owner:苏州祥弘源电子科技有限公司

Rubber hose polishing device

InactiveCN113579866AAvoid grinding cornersImprove sanding effectRevolution surface grinding machinesGrinding drivesPolishingCeramic materials

The invention discloses a rubber hose polishing device, and relates to the technical field of rubber product production. The rubber hose polishing device comprises a device body, a polishing channel is formed in the center of the top of the device body, and two rotary polishing rollers are arranged in the polishing channel. According to the rubber hose polishing device, the two rotary polishing rollers on the device body can polish the surface of a rubber hose in the surface treatment process, and in the polishing process, the two rotary polishing rollers can move towards the two sides under the pushing effect of the rubber hose, and then rubber hoses with different diameters can be polished. Meanwhile, the elastic force from elastic pieces of the two rotary polishing rollers can extrude the rubber hose so that the rubber hose can deform, the rubber hose can be tightly attached to the rotary polishing rollers so that polishing dead corners caused by deformation of the rubber hose can be prevented, and the polishing effect can be improved through the extrusion force between the rubber hose and the rotary polishing rollers.

Owner:陆海平

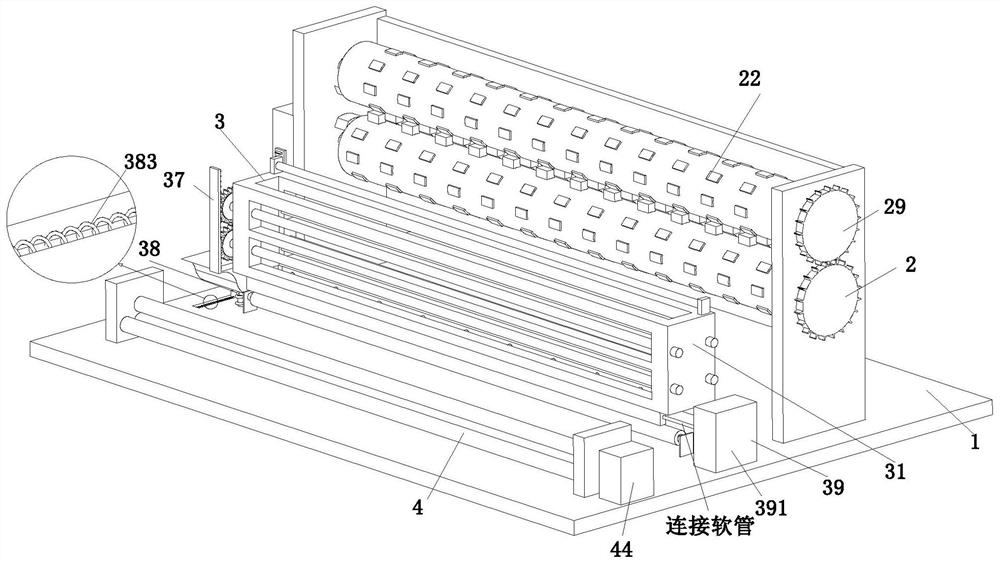

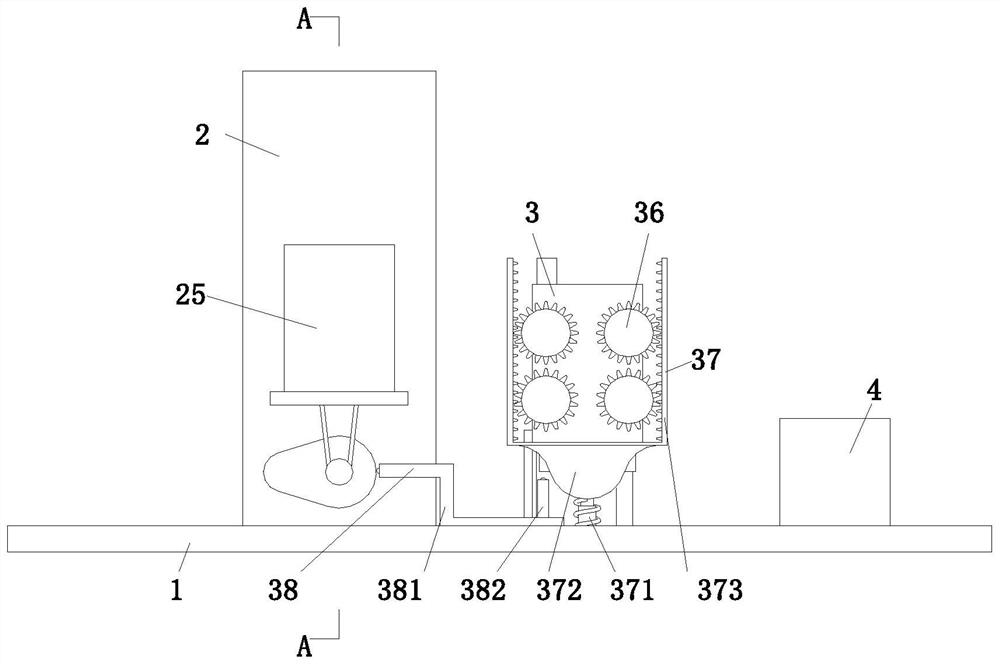

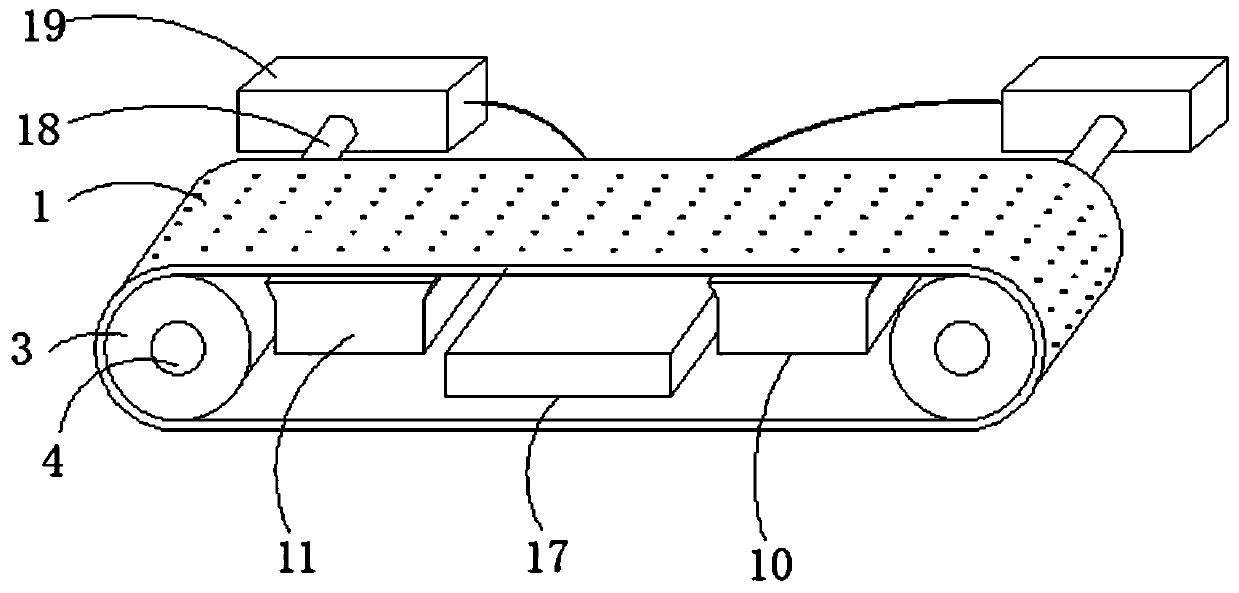

Agricultural mulching film environment-friendly recycling machining equipment

ActiveCN113352502AEasy to recycleEasy to separatePlastic recyclingDirt cleaningSoil scienceAgricultural engineering

The invention relates to agricultural mulching film environment-friendly recycling machining equipment which comprises a bottom plate, a grinding device, a beating-off device and a traction device. The grinding device, the beating-off device and the traction device are sequentially installed at the upper end of the bottom plate from left to right. The equipment can solve the problems that when existing equipment is used for removing hard soil on the surface of a mulching film, the mulching film is usually shaken in a direct shaking mode, the hard soil on the mulching film cannot be ground, the hard soil is prone to remaining on the mulching film, the cleaning effect on the surface of the mulching film is reduced, recycling of the mulching film is not facilitated, meanwhile, soil and dust fallen from the surface of the mulching film cannot be blown away after being removed, the fallen soil is likely to affect the surface of the mulching film again, and working steps are increased.

Owner:上海农林职业技术学院

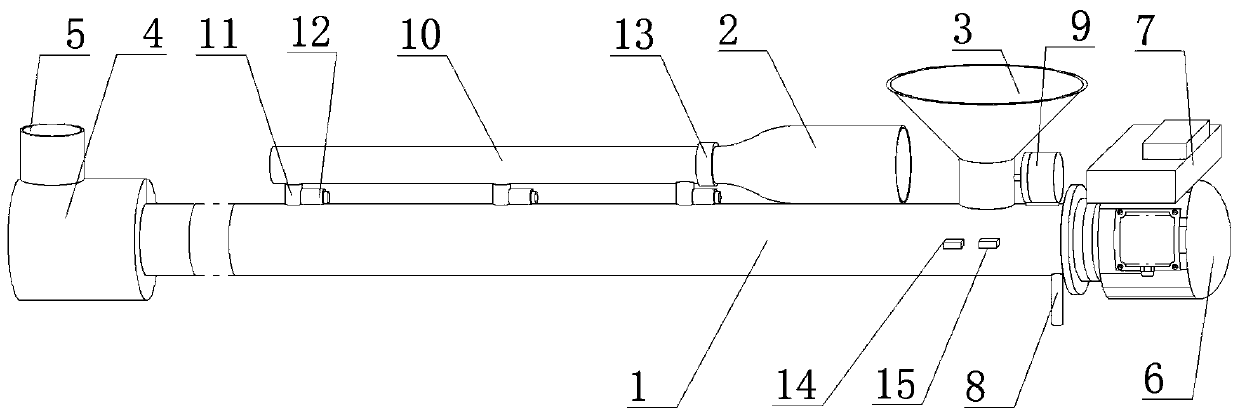

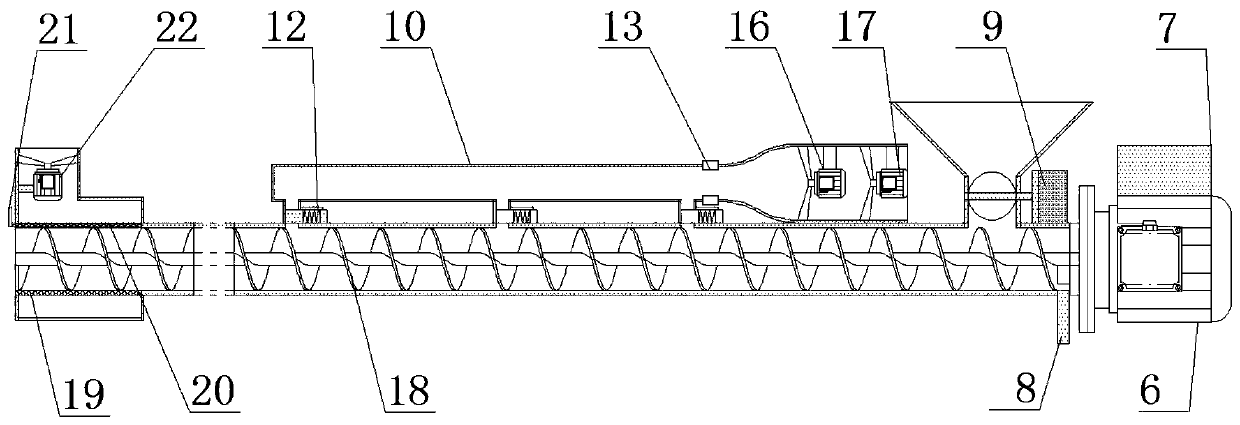

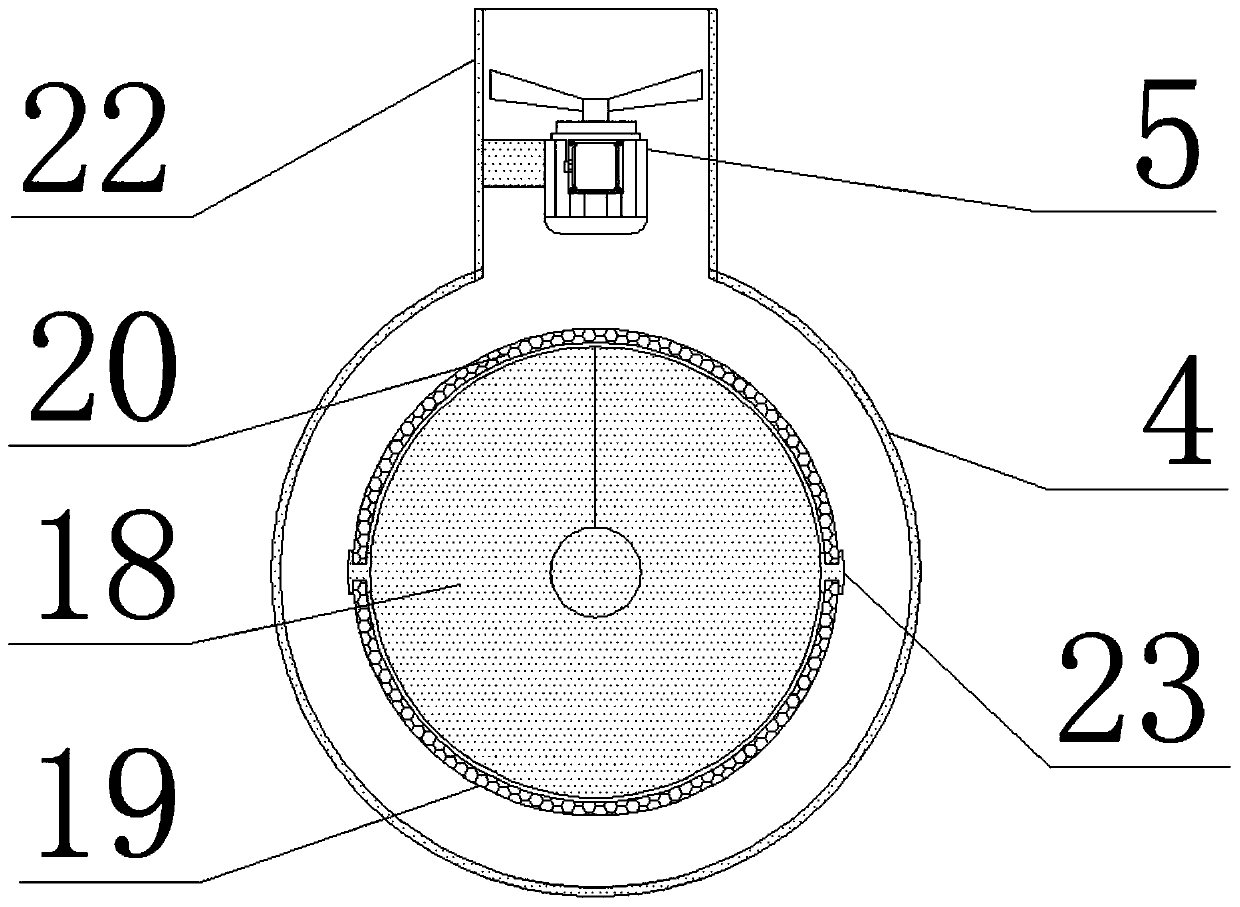

Spiral material conveyor used for agricultural product primary processing

ActiveCN111232573AImprove liquidityGuaranteed clearanceGas current separationPackagingAgricultural scienceAgricultural engineering

The invention provides a spiral material conveyor used for agricultural product primary processing. The conveyor comprises a sleeve, a wind cylinder, a hopper and a wind cover, the wind cylinder and the hopper are both welded to the top of the sleeve, the wind cylinder is mounted on one side of the hopper, the wind cover is mounted on the outer side of the sleeve in a sleeving manner, an air opening is welded to the top of the air cover, one end of the sleeve is provided with a first motor through a bolt, the top of the first motor is provided with an intelligent controller through a bolt, andthe bottom of the sleeve is provided with a rotating speed sensor through a bolt. Through the spiral material conveyor used for agricultural product primary processing, powder raw materials can be prevented from being extruded into blocks, the loose degree of the powder raw materials can be ensured, the subsequent machining is facilitated, the material can be cleaned, the subsequent cleaning stepand the input of cleaning equipment can be reduced, the phenomenon that due to equipment damage, a large amount of raw materials are left in the sleeve can be avoided, it is ensured that a spiral plate can be smoothly started, and the conveyor is suitable for material conveying use during agricultural product primary processing.

Owner:亳州中宇生物科技有限公司

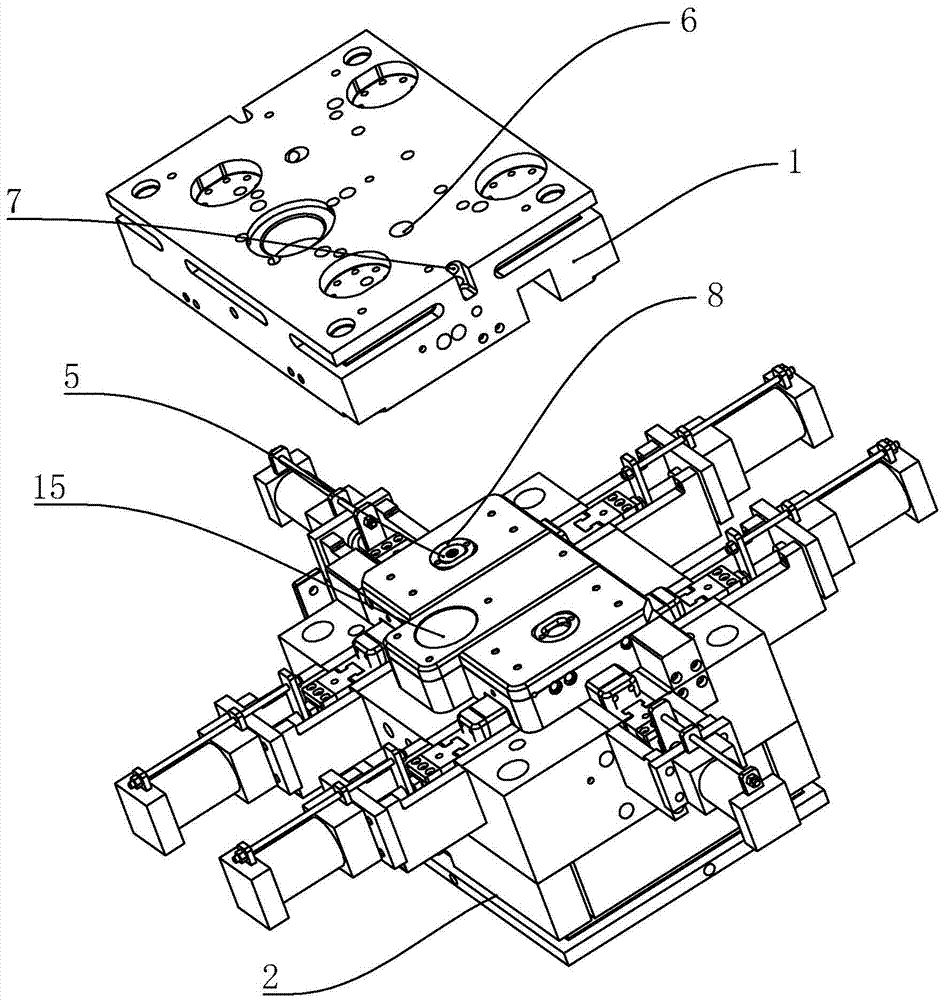

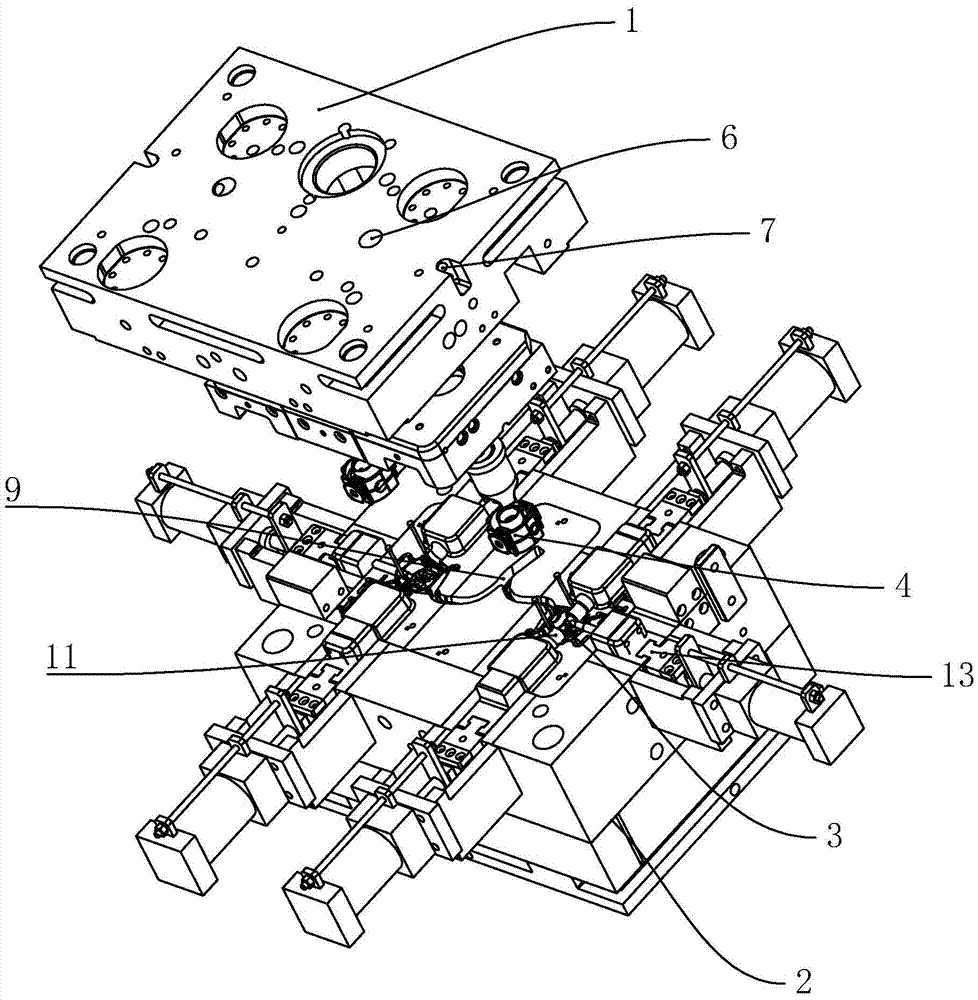

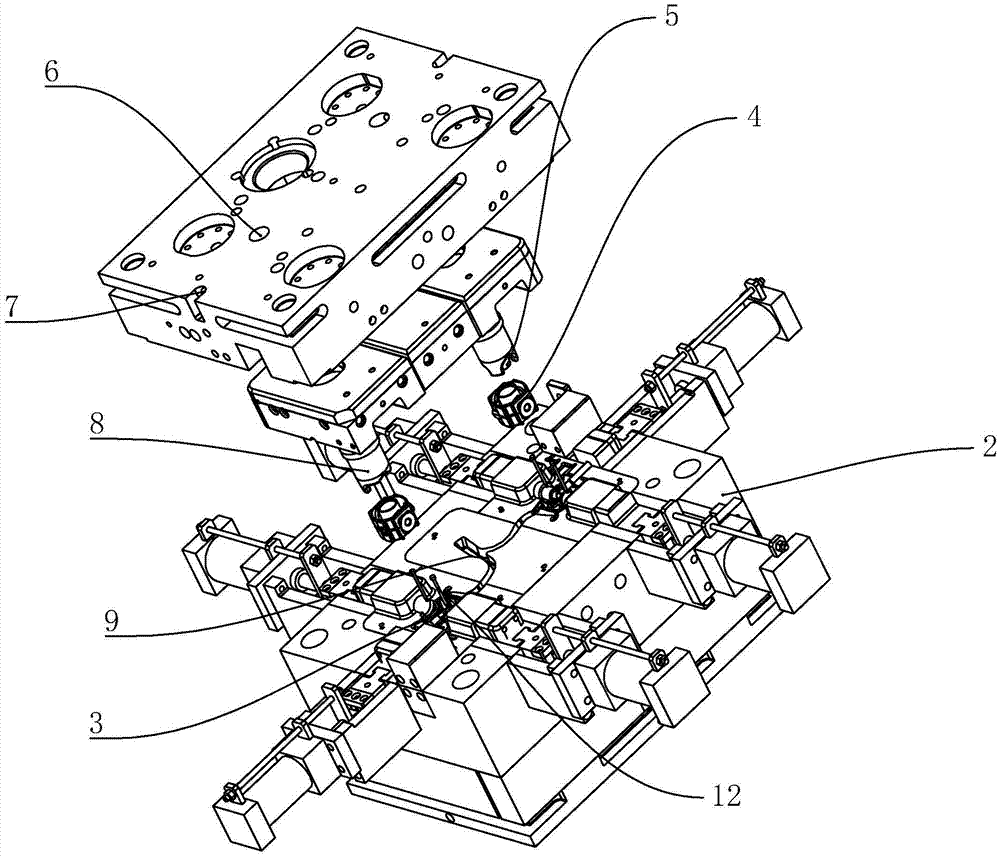

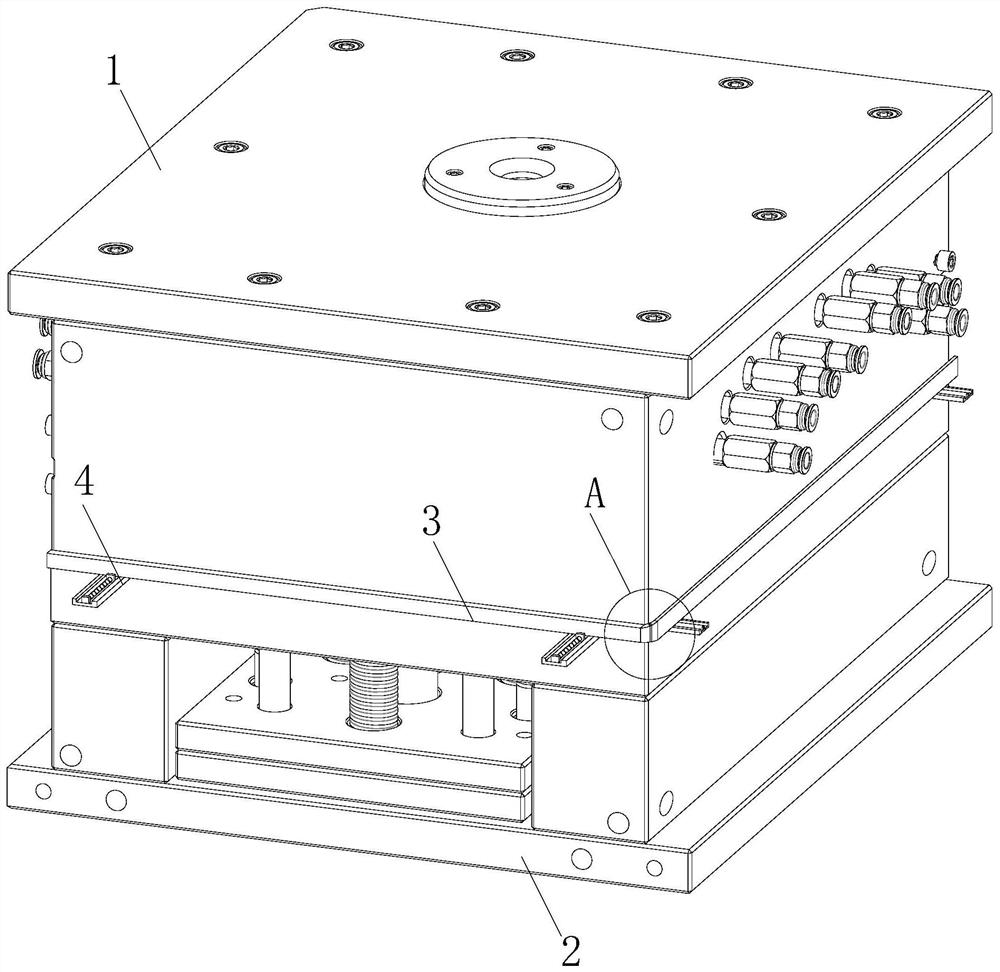

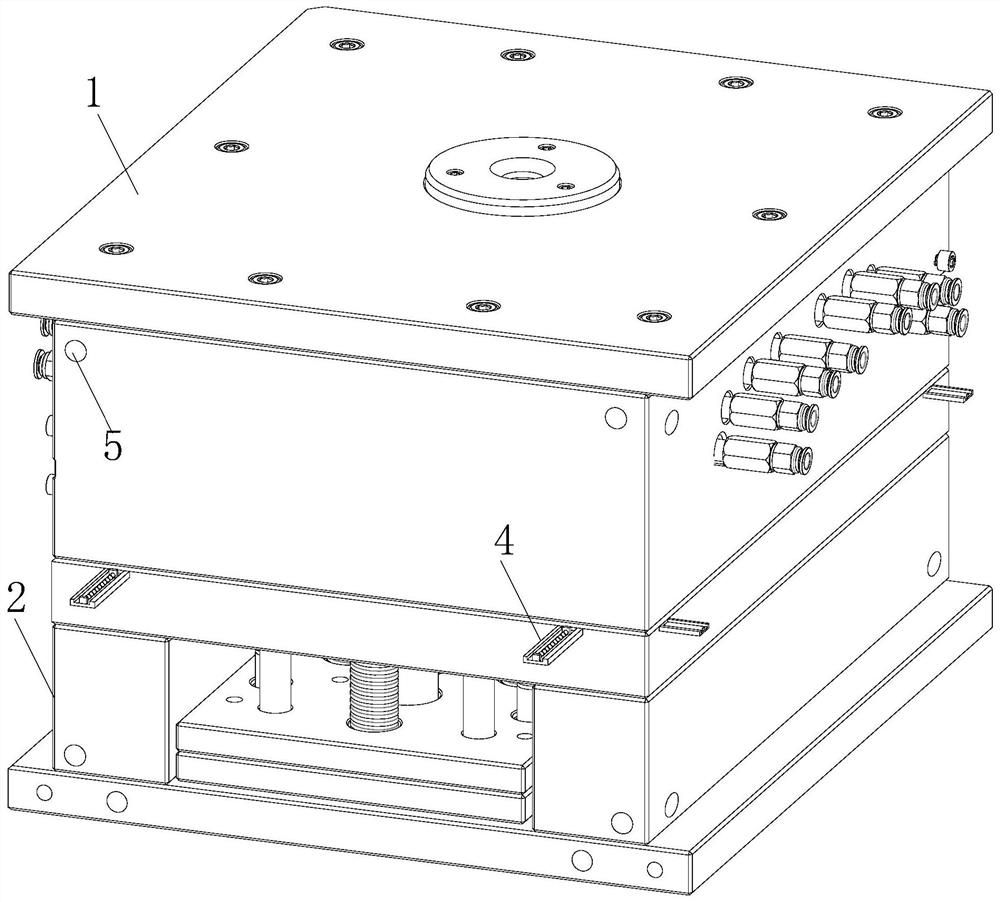

Injection mould

The invention discloses an injection mould. The injection mould comprises a fixed mould and a movable mould, wherein a plurality of movable mould cores are arranged on the movable mould; fixed mould cores which are matched with the movable mould cores are embedded into the fixed mould; an injection molding column is arranged on the top of each fixed mould core in a penetration mode; a column sleeve is arranged on the corresponding injection molding column in a sleeving mode; injection molding holes which correspond to the corresponding injection molding columns are formed in the fixed mould; an injection molding runner which is communicated with each mould core is arranged on the movable mould; and all injection molding runners are gathered on the same point. According to the injection mould, the injection molding column is arranged on each fixed mould core in the penetration mode, and therefore, during casting of each product, molten plastic can be directly injected into a mould cavity from a plastic container, so that a flow distance of a formed body plastic of each product is reduced, and therefore, heat loss when the former body plastic is unstable is reduced, and the products can be more uniform after being formed; and the injection molding runners are gathered at one point, so that the formed products are connected together, and therefore, an operator conveniently takes out the products.

Owner:浙江诺格汽车模具有限公司

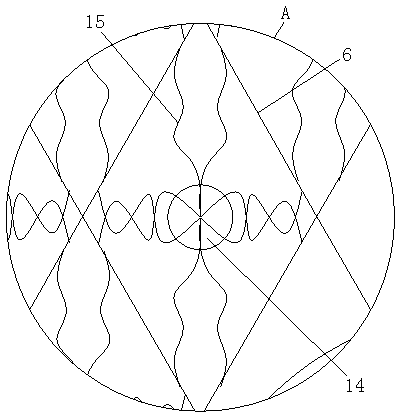

Catch type flocculation treatment device for advection section of textile wastewater

ActiveCN110273458AAvoid blockingImprove work efficiencySewer pipelinesMoving filtering element filtersFlocculationAir filter

The invention provides a catch type flocculation treatment device for an advection section of textile wastewater. The catch type flocculation treatment device comprises a drainage covered channel for draining, an arc-shaped stop shed for blocking floating flocculant in air, a balance weight lever which is sunken into water and is made of metal, a buoyancy tube, a wind jittering bag and an air filtering screen, wherein the drainage covered channel is placed inside a groove formed in the ground; the surface of the drainage covered channel is fixedly connected with the surface of the arc-shaped stop shed; the inner part of the balance weight lever is hollow; an air delivery pipe sleeves the surface of the balance weight lever. The invention relates to the field of textile. The catch type flocculation treatment device for the advection section of the textile wastewater adopts a special floating flocculant intercepting structure; the floating flocculant is intercepted and then is quickly concentrated, so that the floating flocculant is conveniently cleaned and the intercepting structure can be utilized more efficiently, and further the problems that a general floating flocculant treatment device needs to frequently clean the filter screen when being used and is lower in working efficiency, while a flocculation method for a large-area circulating pool has low recycling value of the floating flocculant and greater energy consumption are effectively solved.

Owner:东营正诺技术服务有限公司

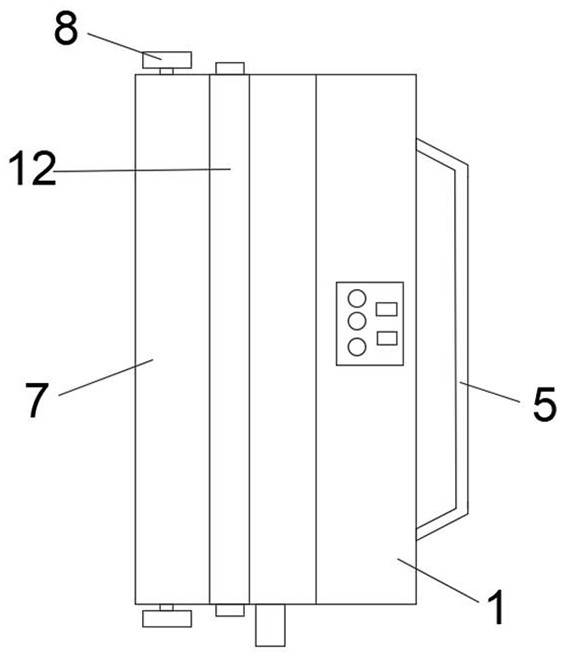

Dust remover for cleaning building curtain wall

ActiveCN111000503AEasy to cleanAvoid damageCarpet cleanersFloor cleanersElectric machineDust control

The invention relates to the field of curtain wall cleaning. The invention discloses a dust remover for cleaning a building curtain wall. The dust remover comprises a device main body, wherein the device main body is in a rectangular box shape; a cleaning box is fixedly mounted at the bottom of the device main body; the cleaning box is in a rectangular box shape with the bottom hollowed out to theinner side wall of the top of the cleaning box. In the present invention, a fan motor is started to drive fan blades to rotate to generate wind power, wind power flows into the cleaning box through ahollow area in the device main body and a dust removal wind groove in the cleaning box, and the wind power is guided and blown to dust in a corresponding position at the bottom of the cleaning box through a dust-removing guide plate, therefore, dust on the surface of the curtain wall is cleaned; a rotating shaft drives a first cleaning block to rotate so as to clean the curtain wall, the curtainwall cleaned by the first cleaning block is air-dried through air-drying holes, and the air-dried curtain wall is secondarily cleaned through a secondary cleaning block, so that the effect of cleaningthe curtain wall is achieved, and meanwhile, the effect of avoiding the situation that the curtain wall is damaged by wall scraping cleaning is achieved.

Owner:新昌县哈坎机械配件厂

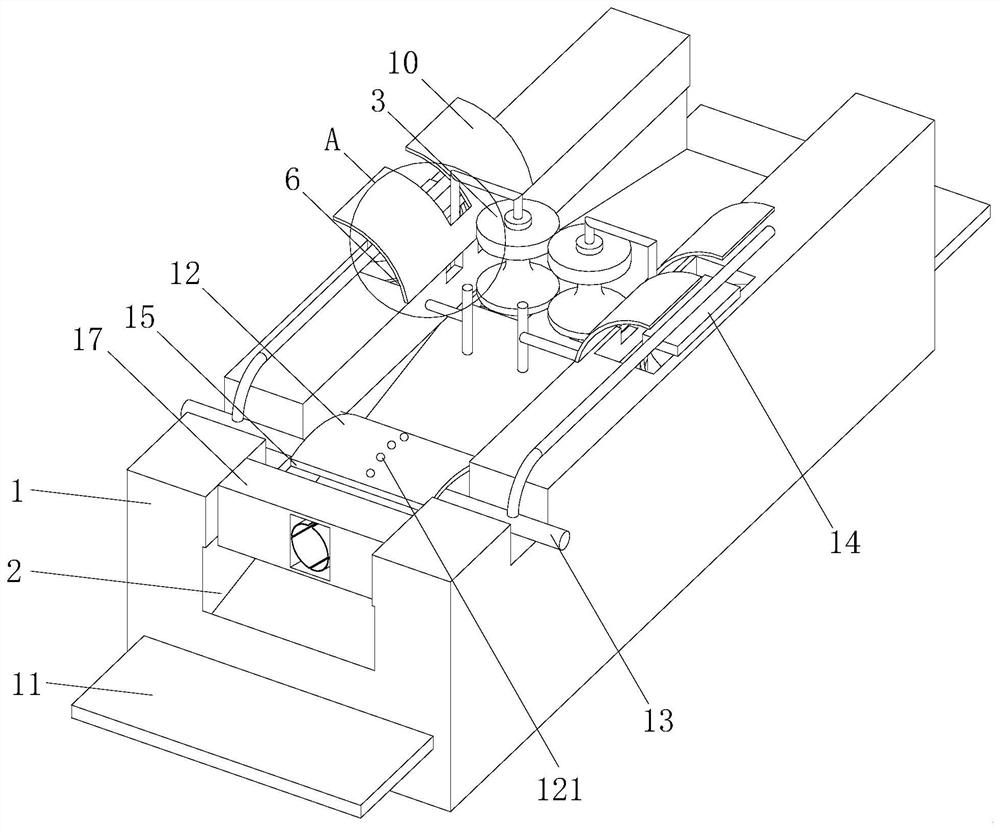

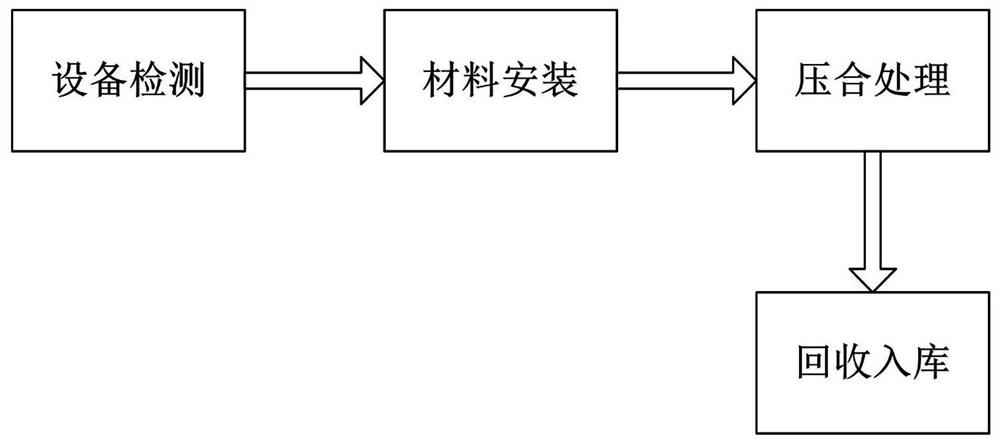

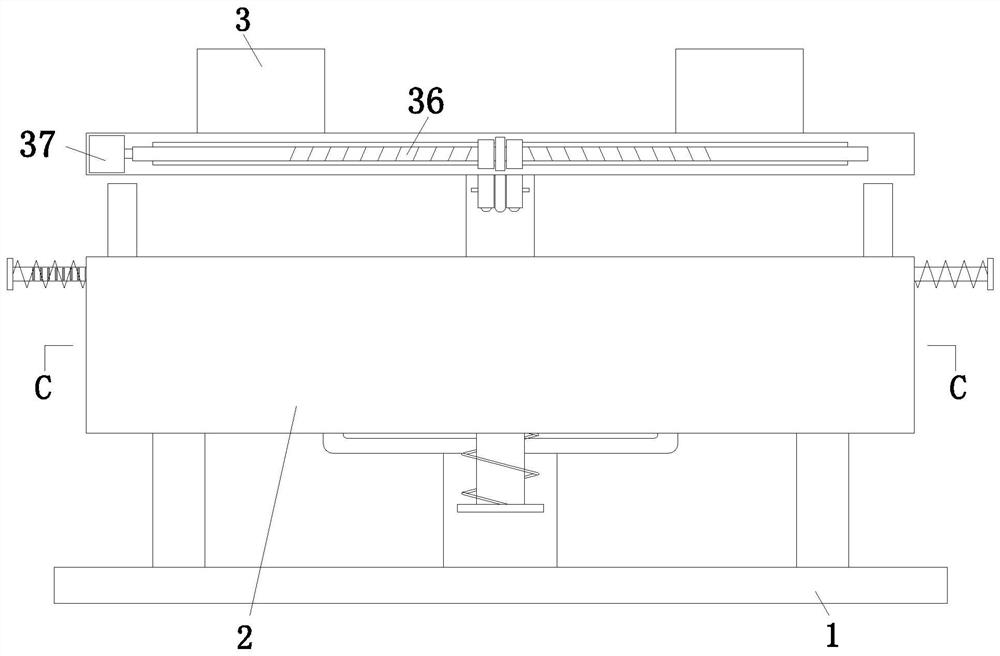

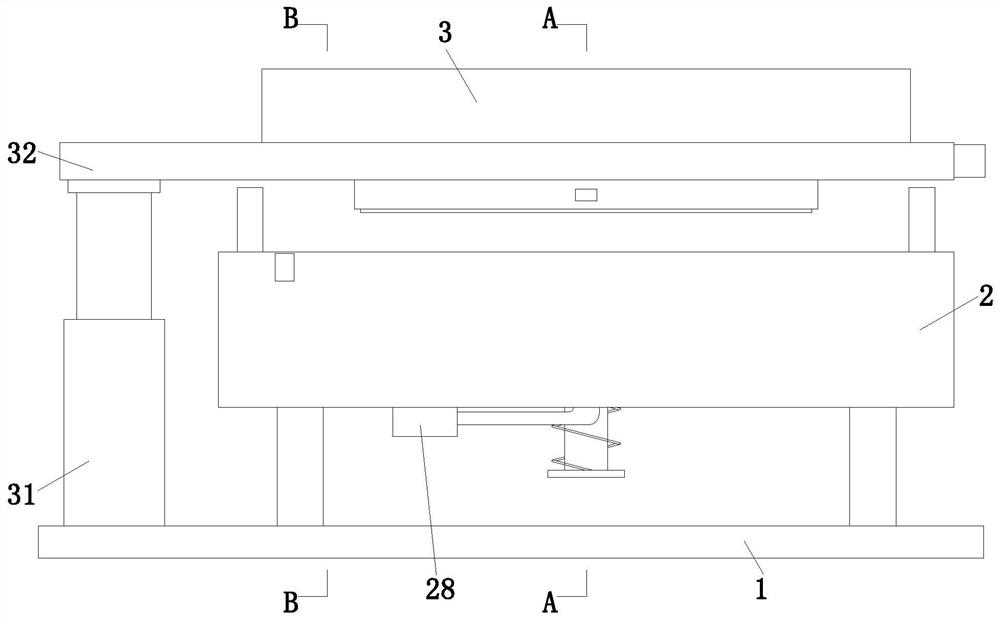

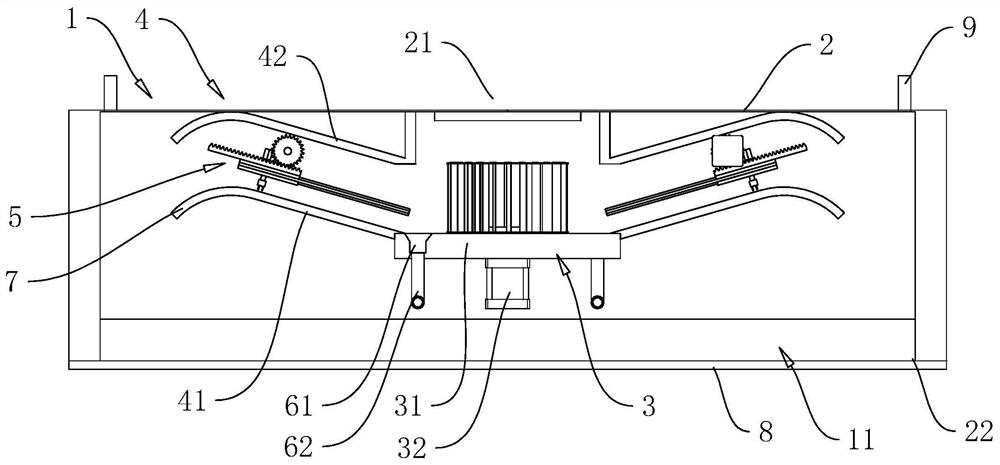

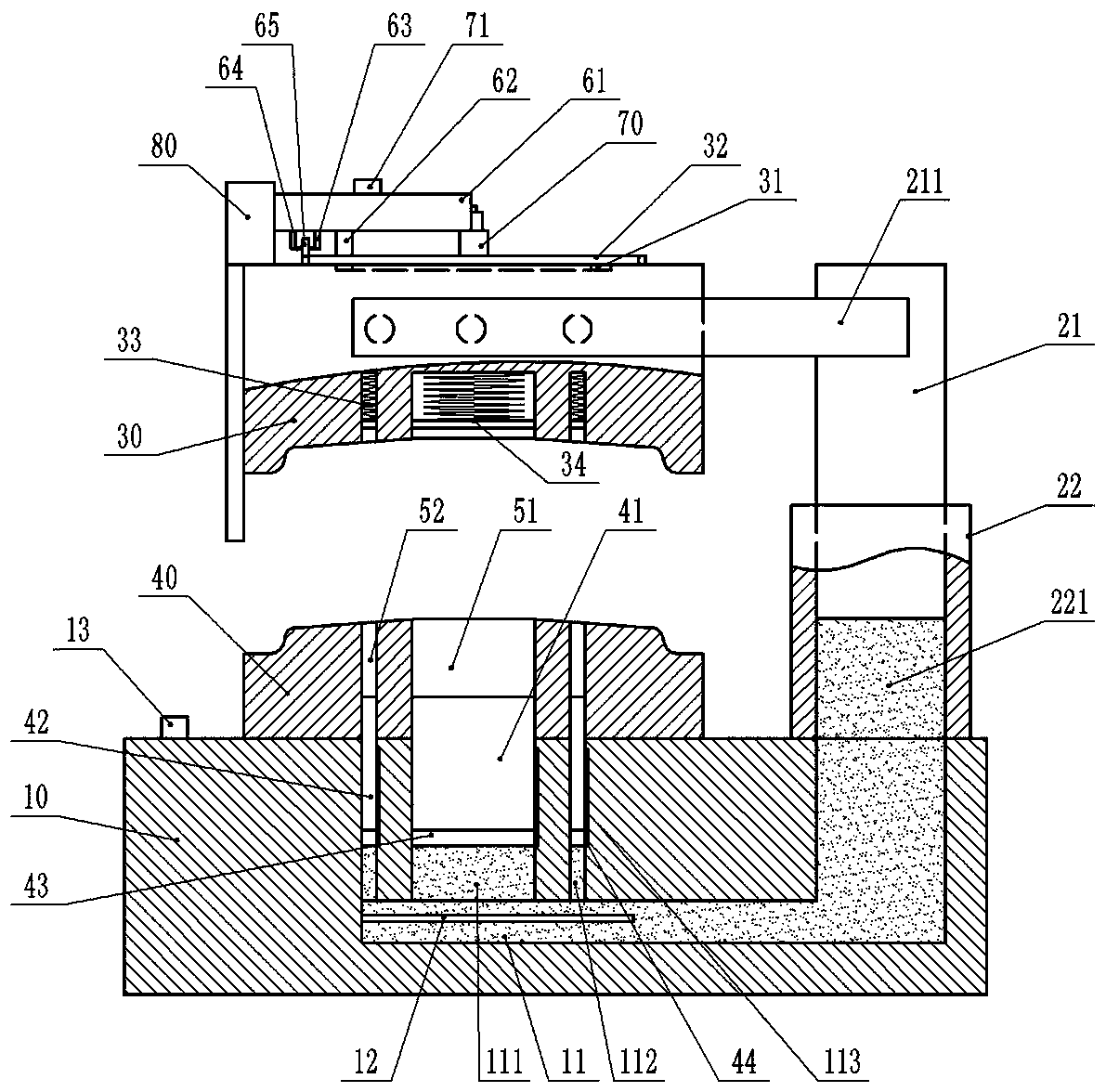

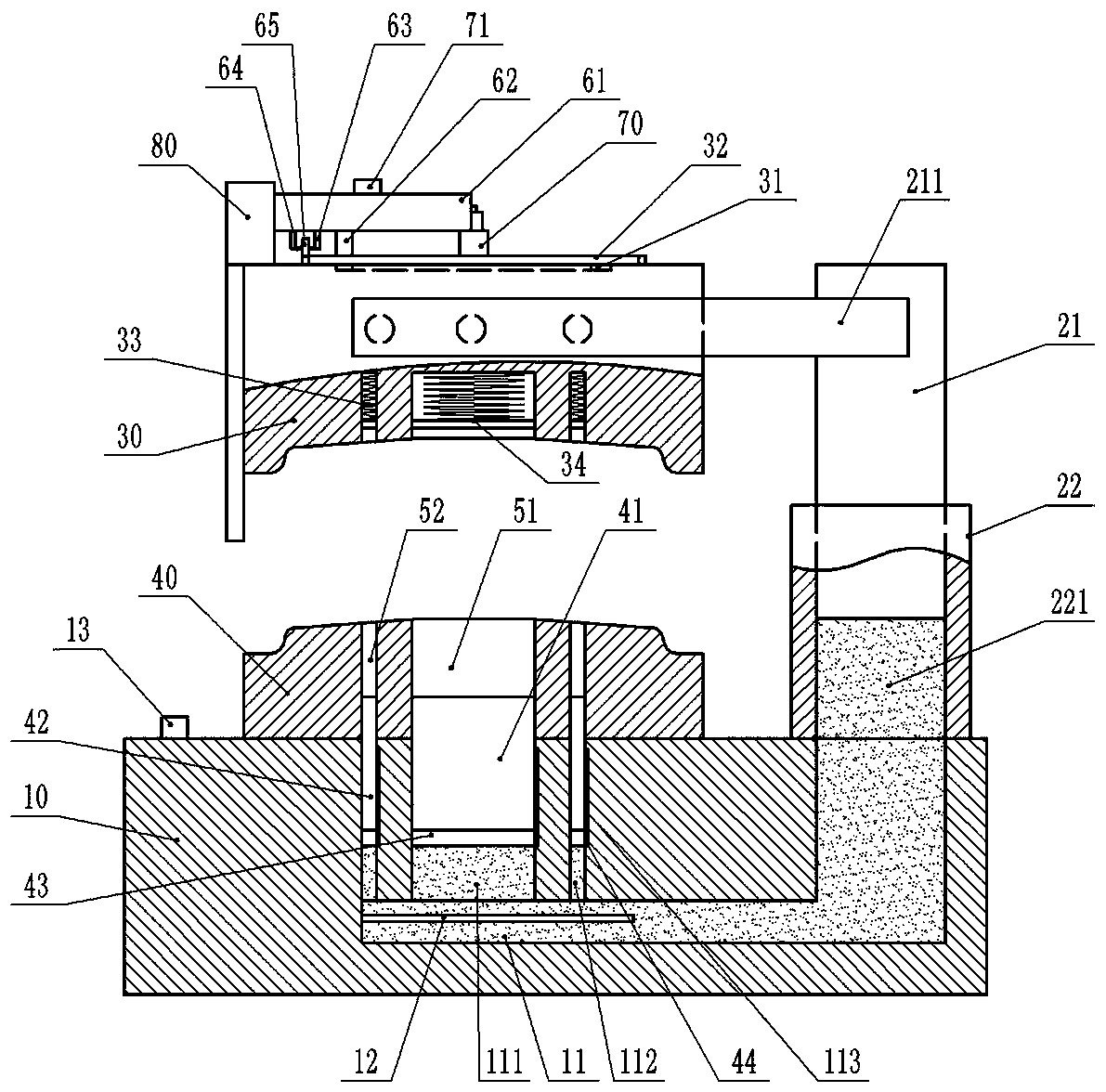

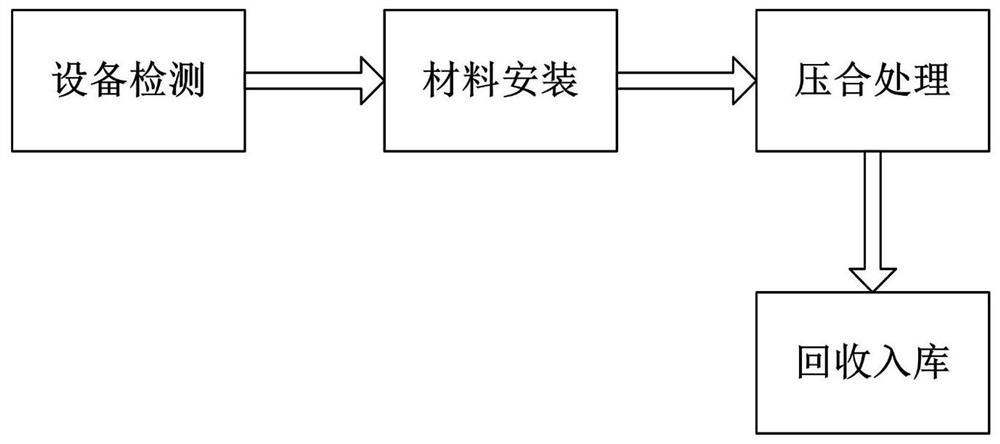

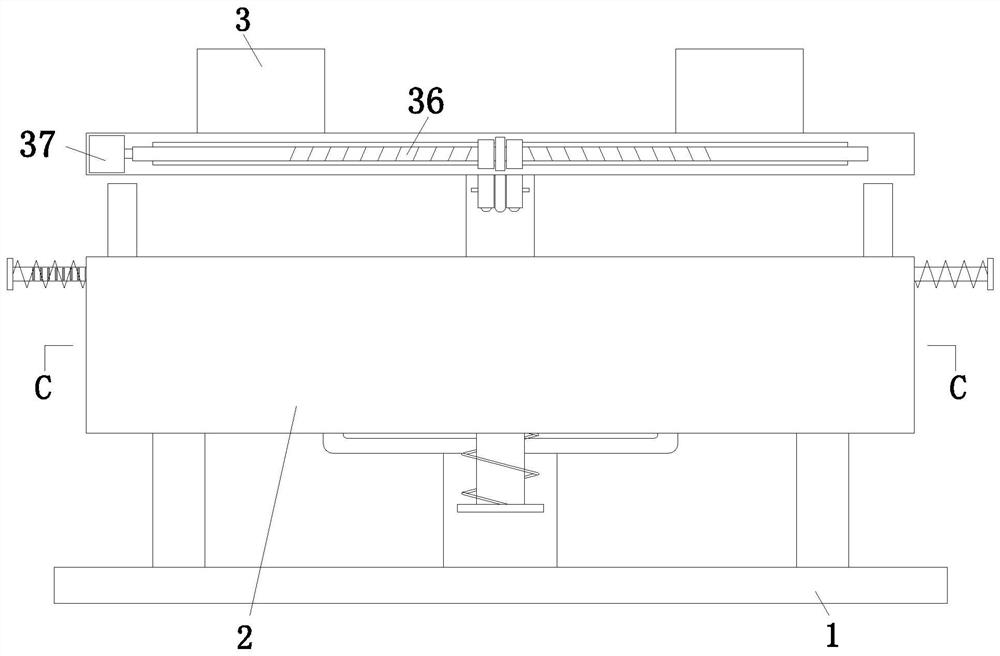

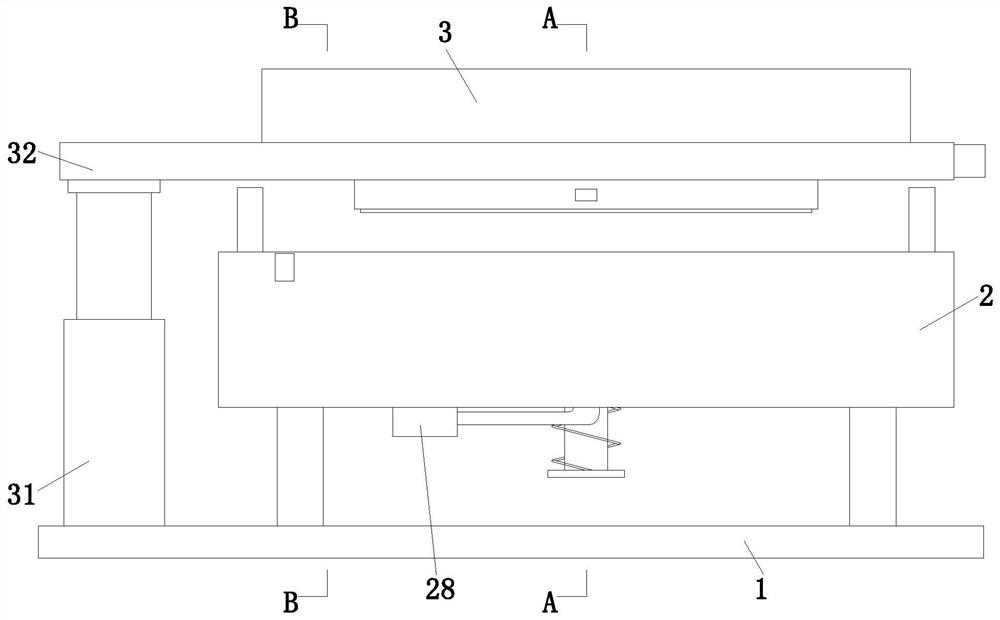

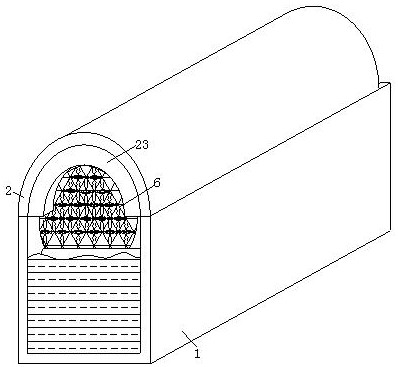

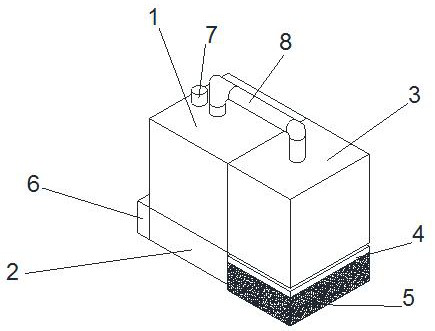

Manufacturing method of aluminum-based copper-clad plate

ActiveCN112026329AGuaranteed smoothnessReduce cleanup stepsLamination ancillary operationsLaminationCopper foilMaterial resources

The invention relates to a manufacturing method of an aluminum-based copper-clad plate. Equipment used by the method comprises a bottom plate, a bearing device and a pressing device, the bearing device is installed at the upper end of the bottom plate through a supporting column, the pressing device is arranged above the bearing device, and the pressing device is installed on the bottom plate. Thealuminum-based copper-clad plate manufacturing equipment and method can solve the problems that when existing equipment is used for manufacturing an aluminum-based copper-clad plate, redundant glue cannot be scraped off after copper foil pressing is completed, and consequently glue residues appear on the surface of a formed aluminum-based copper-clad plate, the step of cleaning the surface of thealuminum-based copper-clad plate is added, consumption of manpower and material resources is increased, the copper foil cannot be tensioned, the copper foil cannot be kept flat in the pasting process, and wrinkles are prone to occurring after the copper foil is pasted, and thus the surface smoothness of the aluminum-based copper-clad plate is reduced, and material waste is increased.

Owner:福建鑫宏华机械有限公司

Energy-efficient fan filter unit

InactiveCN112484145AReduce dust contentReduce the burden onPump componentsLighting and heating apparatusAir cleaningEngineering

The invention relates to an energy-efficient fan filter unit, and belongs to the technical field of air purification equipment. The fan filter unit comprises a filter device and a high-efficiency filter detachably mounted at the bottom of the filter device, wherein the filter device comprises a shell; an air inlet is formed in the top of the shell; a fan unit is arranged at the position, located at an air outlet end of the air inlet, of the inner side of the shell; an electrostatic dust collection device used for adsorbing dust particles is arranged at the air outlet end of the fan unit; a dust removal device used for removing dust on the electrostatic dust collection device and recycling the dust is arranged in the shell; an air outlet is formed in the bottom of the shell; and the air outlet end of the high-efficiency filter faces the air outlet. The electrostatic dust collection device is additionally arranged in the filter device, and the electrostatic dust collection device can greatly reduce the dust content in air, so that the filtering effect can be further improved, the burden of the high-efficiency filter is reduced, and the service life of the high-efficiency filter is prolonged.

Owner:深圳市赛威利华净化科技有限公司

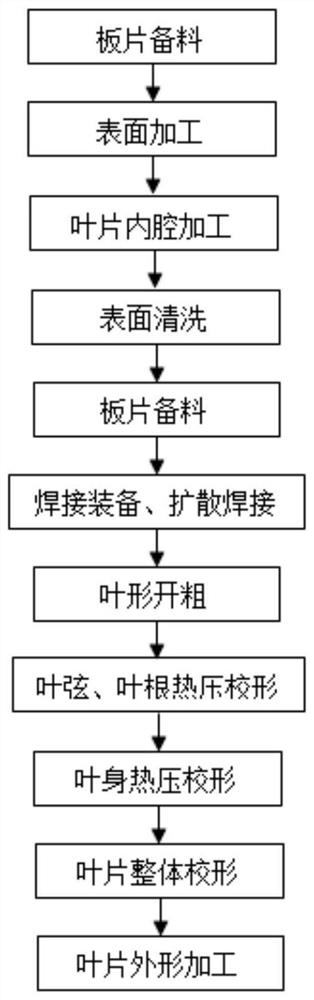

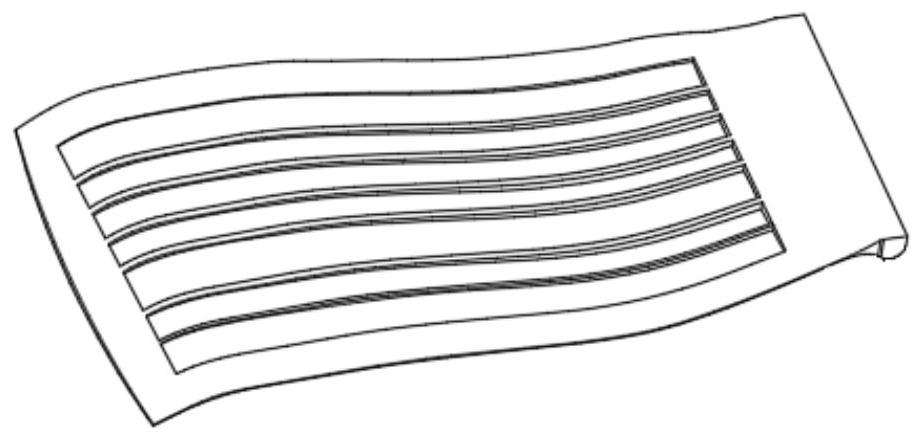

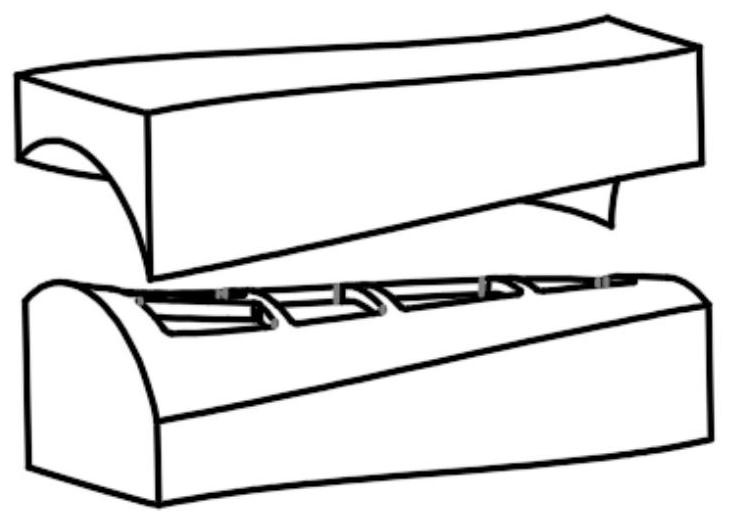

Wide chord blade machining method

The invention discloses a wide chord blade machining method, and relates to the technical field of wide chord blades. The wide chord blade machining method includes the steps that blade inner chamberstructures are machined on welded faces of two plates to be welded respectively, then the welded faces with inner chambers of the plates to be welded are closed and assembled to form base materials tobe welded, and blade billet with a vacuum inner chamber is formed after the base materials to be welded are subjected to vacuum diffusion welding. Many abuses brought in a superplastic forming process can be prevented, and particularly, blades can be effectively prevented from cracking at the same time when the vacuum inner chamber is formed, and the mechanical strength of a welding seam can be improved to some extent.

Owner:陕西智拓固相增材制造技术有限公司

Packaging mechanism and packaging method of circuit board

InactiveCN112331590AGood for tight adhesionAvoid spillingSemiconductor/solid-state device manufacturingAdhesive glueStructural engineering

The invention discloses a packaging mechanism and a packaging method of a circuit board. The packaging mechanism comprises a supporting frame, a sealing unit, a packaging adhesive extruding unit, a transverse moving unit, an adhesive coating unit, a circuit board tray, a tray fixing and residual adhesive collecting unit and a longitudinal sliding rail movable power unit. The supporting frame comprises a top plate, supporting columns and a bottom plate, wherein the four corners of the bottom of the top plate are connected with the four corners of the top of the bottom plate through the four supporting columns, the sealing unit is installed on the periphery of the supporting frame to enable the interior of the supporting frame to form a closed space, and the transverse moving unit is transversely installed in the middle of the bottom of the top plate; the gluing unit is mounted at the bottom of the transverse moving unit. According to the invention, the circuit board trays of different sizes can be fixed for different types of circuit boards, excessive glue can be prevented from being scattered by the gluing roller, excessive glue liquid outside the sizes of the circuit boards can becollected, waste is avoided, cleaning steps are reduced, and the use efficiency is improved.

Owner:简思涛

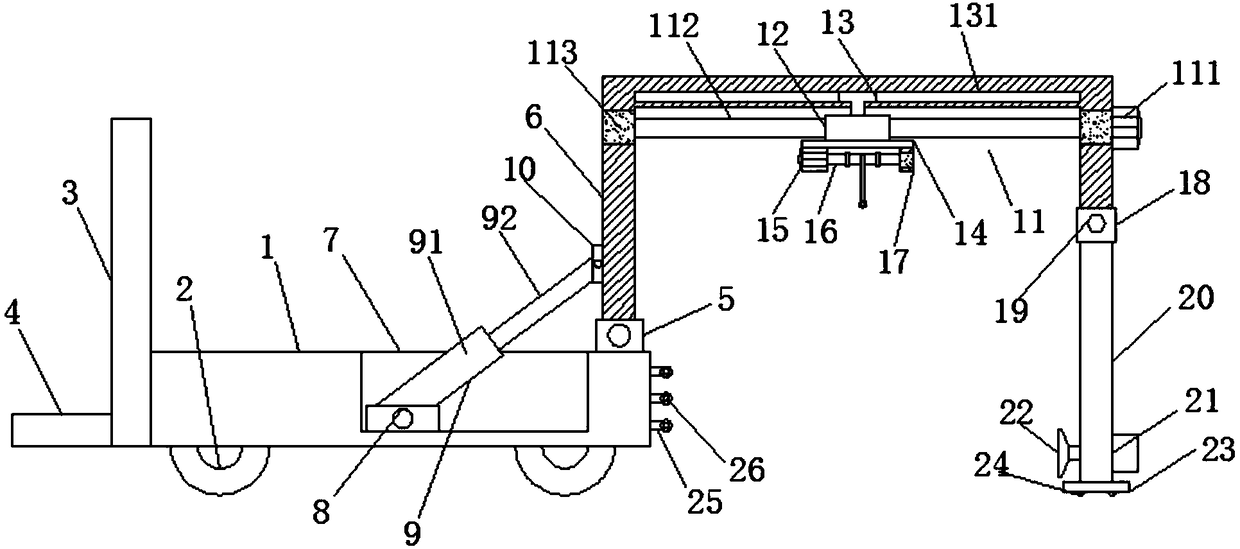

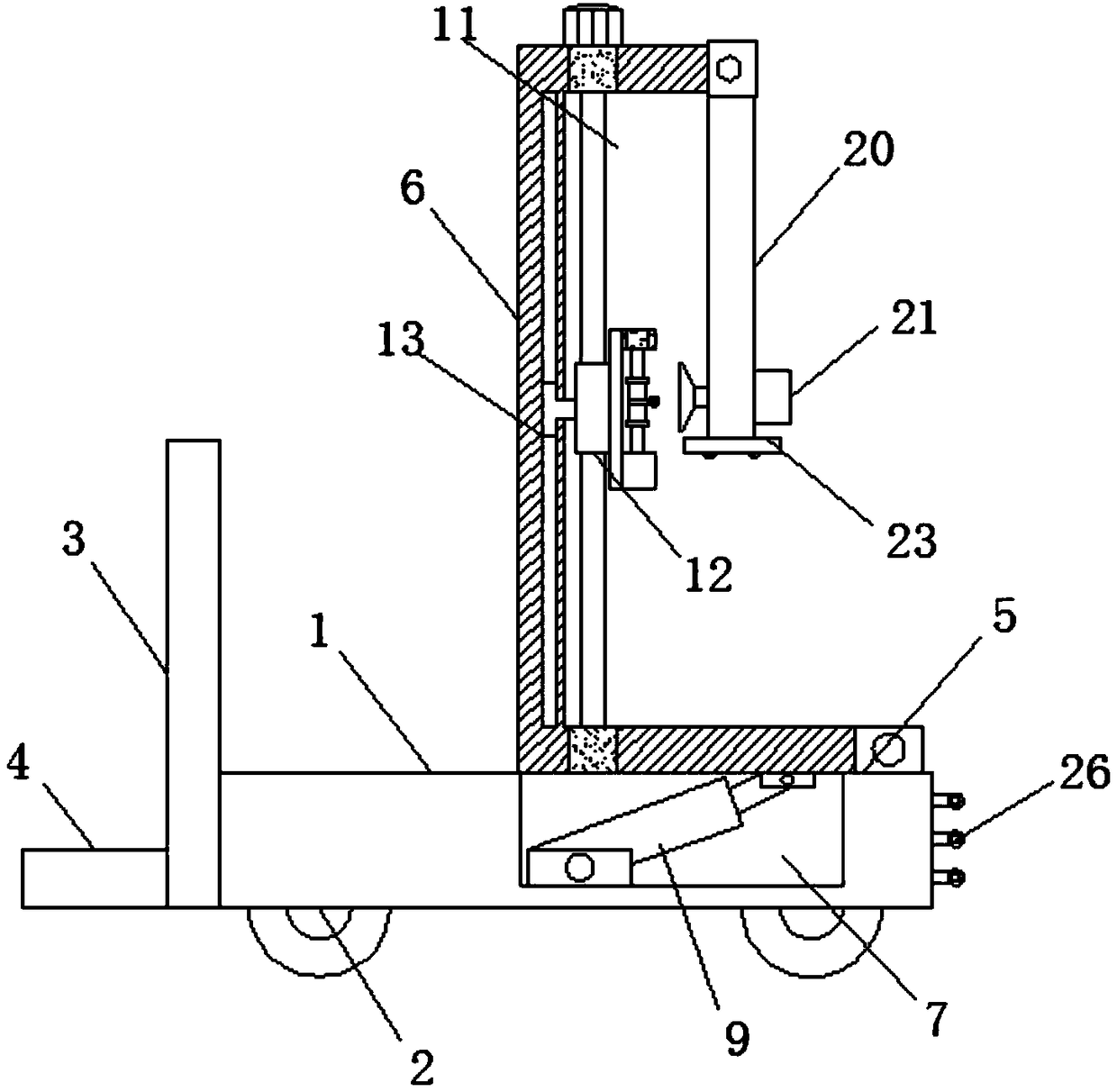

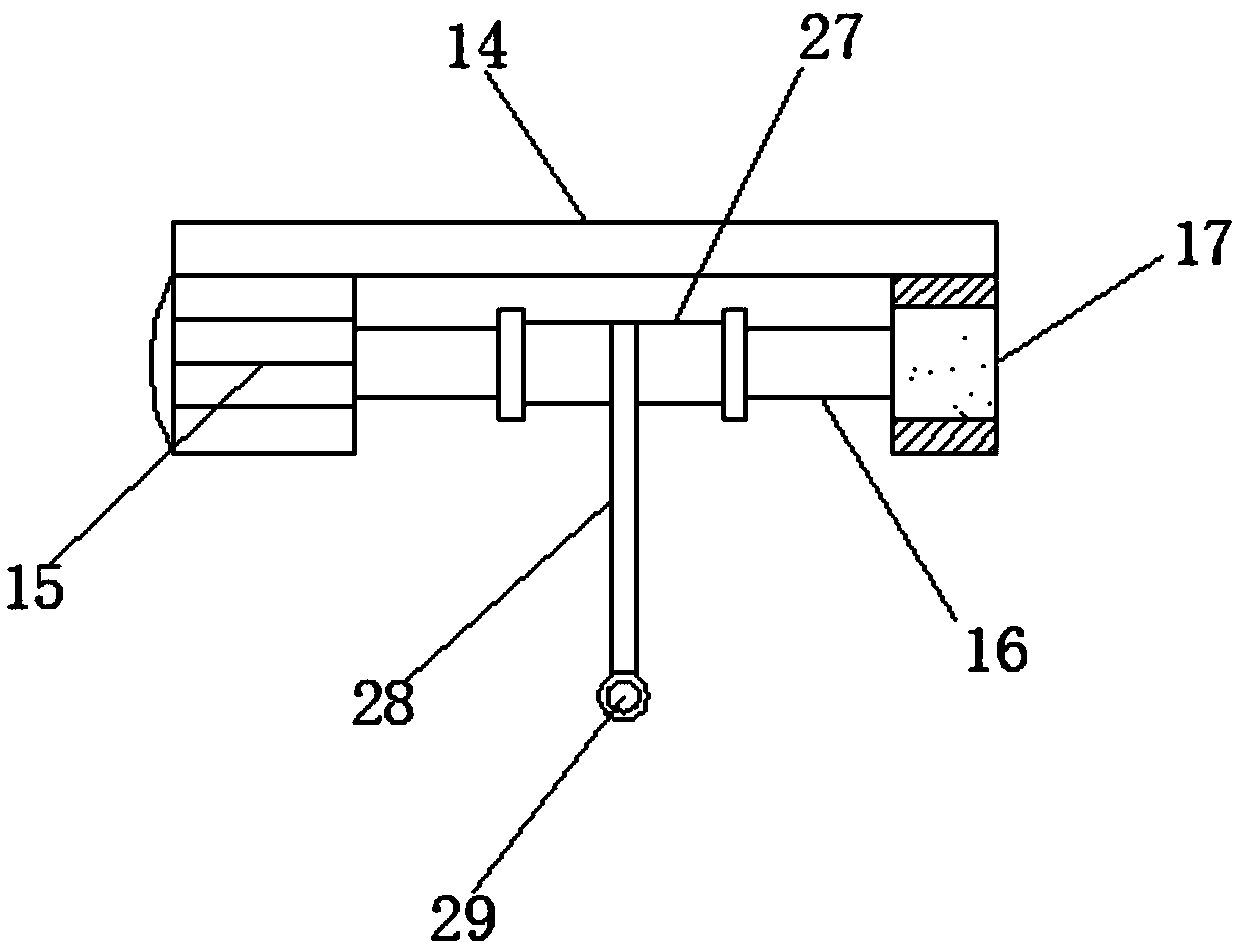

Foldable industrial lifting device convenient to move

InactiveCN108217500AEasy to move and adjustEasy to fold and storePortable liftingVehicle frameWorking environment

The invention discloses a foldable industrial lifting device convenient to move. The foldable industrial lifting device comprises a frame and wheels arranged at the bottom of the frame, a side plate is arranged on the left side of the frame, a connecting plate is welded to the left side of the side plate, a hydraulic device is connected in the groove through a second connecting pin, the hydraulicdevice is movably connected to a machine frame through a third connecting pin, a dust suction cover is arranged at the end part of the dust suction pipe on a dust collector, a machine frame is transversely provided with a servo driving device, a guide block is arranged on the servo driving device in a penetrating mode, the top of the guide block is connected to the machine frame in a sliding modethrough a sliding block, a wire wheel is arranged on the output shaft, and the wire wheel is connected with a hanging ring through a steel wire rope. The device is convenient to move and adjust, and facilitates folding and storage; the mechanical carrying mode is adopted, so that the manpower is saved, and the carrying and hoisting efficiency is improved; and after the hoisting of equipment is finished, dust adsorption is carried out on the ground by utilizing the dust collector, so that the sanitation of the working environment is guaranteed, and the subsequent cleaning steps are reduced.

Owner:高锦芳

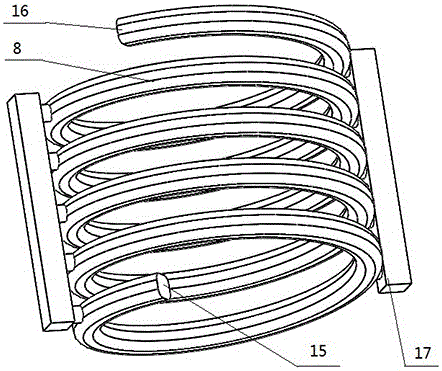

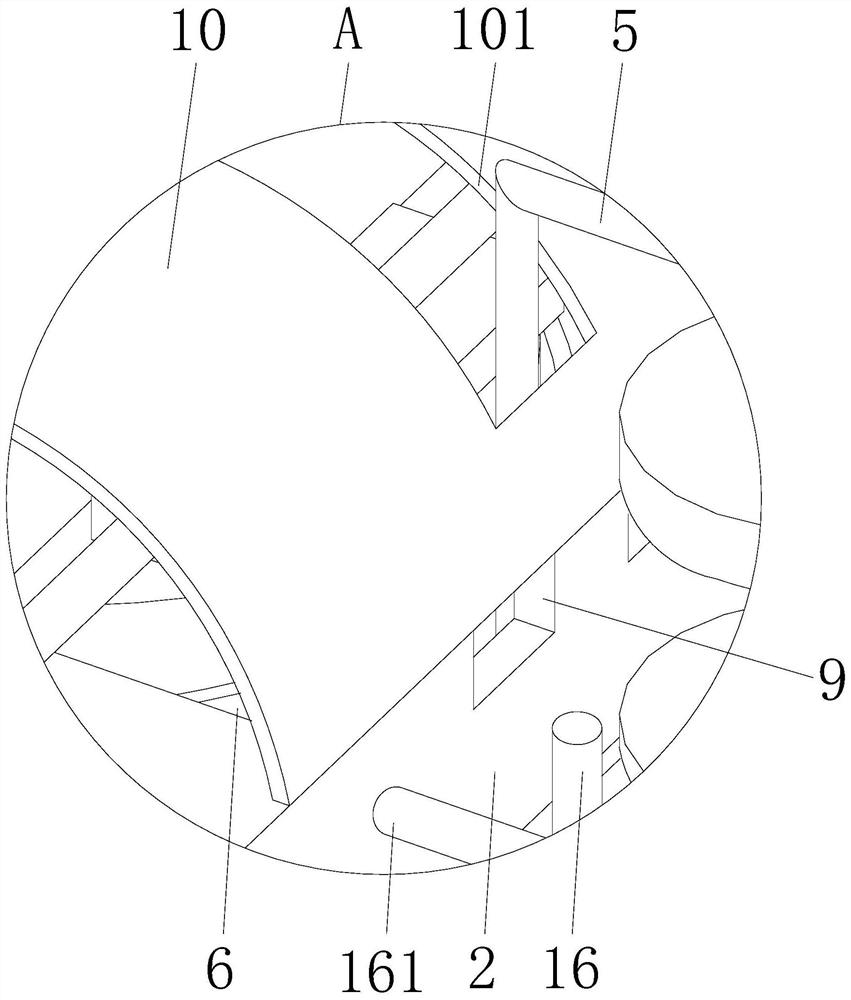

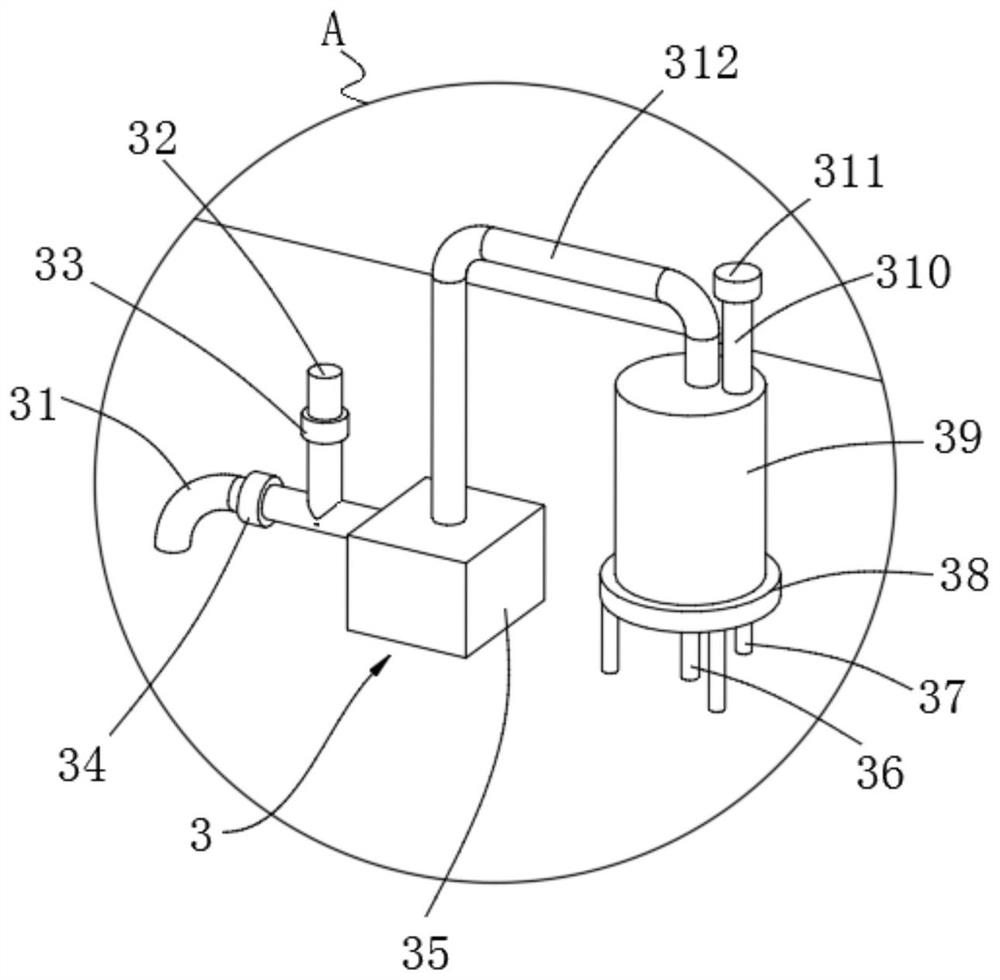

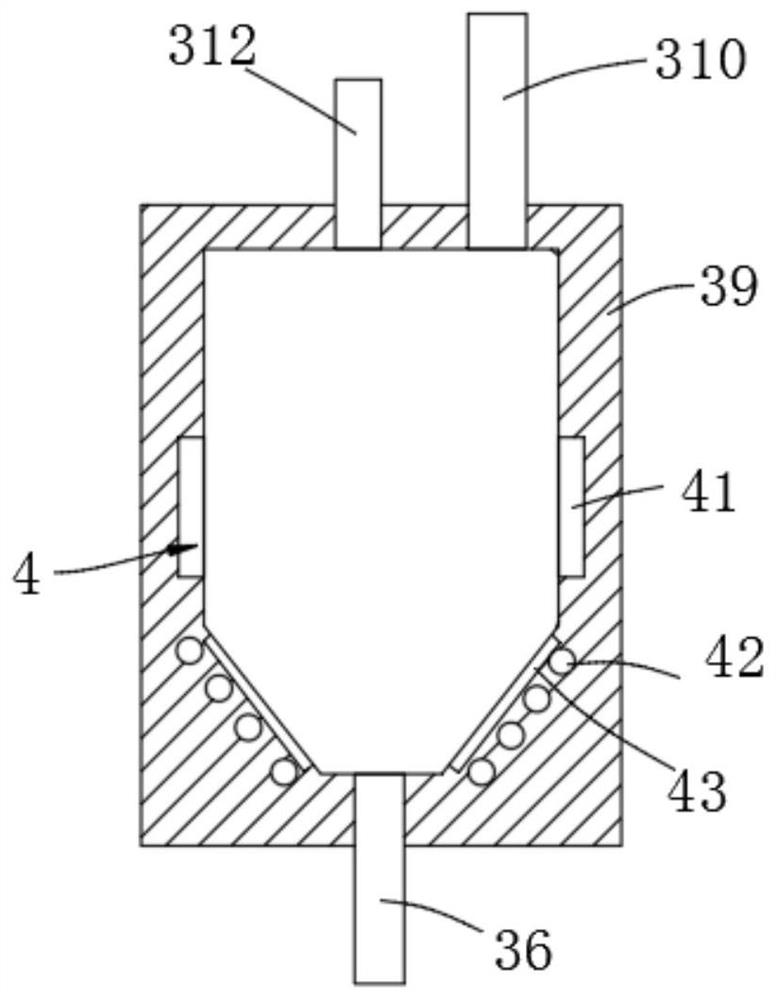

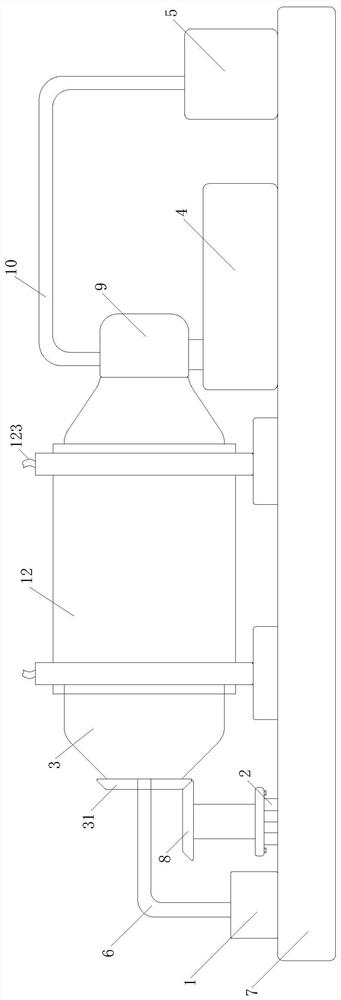

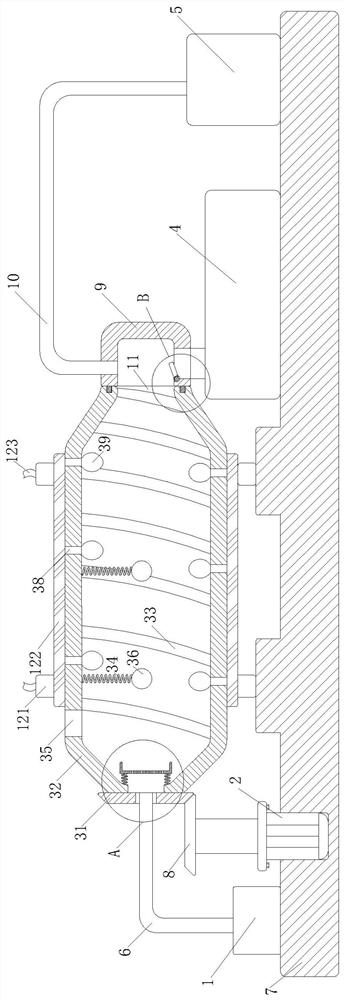

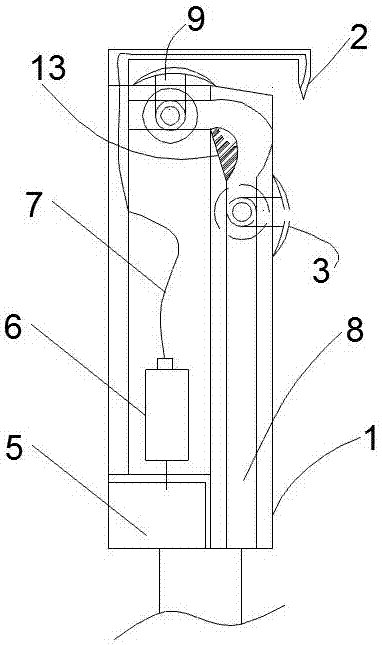

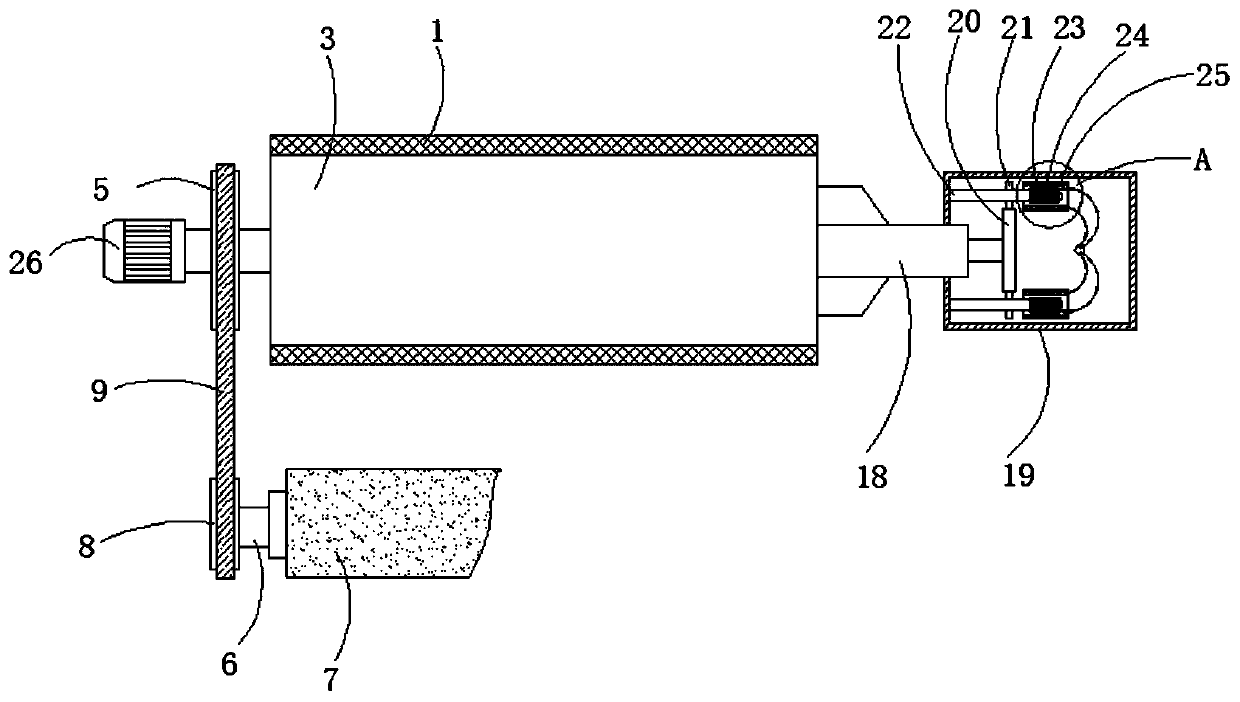

Alcohol distillation system

PendingCN113856228AEasy to cleanReduce cleanup stepsFermented solutions distillation/rectificationAlcoholic beverage preparationElectric machineryLees

The invention relates to the field of wine brewing equipment, in particular to an alcohol distillation system, which comprises a steam device, a motor, a distillation chamber, a material receiving device and a cooling liquefying device, the steam device is communicated with the distillation chamber through a first air pipe, and the distillation chamber comprises a second bevel gear, a tank body and a spiral piece. The second bevel gear is fixedly connected with the end, close to the motor, of the tank body and perpendicularly matched with the first bevel gear, a charging opening is formed in the outer side wall of the tank body, a spiral piece is fixedly connected to the inner side wall of the tank body, and the outer diameter of the spiral piece is the same as the inner diameter of the tank body; through cooperation of the spiral piece and a gas slip ring, vinasse continuously rolls in the distillation process, so that the vinasse can make full contact with water vapor, the distillation effect is improved, the vinasse can be self-cleaned under the action of the spiral piece after distillation is completed, and the distillation efficiency is improved.

Owner:赵慧

A kind of processing method of wheel spoke

Owner:CHONGQING FENGHUIDA METAL FORGING CO LTD

Method for machining spoke

The invention belongs to the technical field of machining, and particularly discloses a method for machining a spoke. The method comprises the following machining steps that (1) an upper punching dieis fixedly connected with an upper support, and an electromagnet is electrified; (2) a steel plate is placed on a lower punching die, electricity of the electromagnet is cut off, and the upper punching die is punched downwards by utilizing a press machine till a pre-formed spoke blank is punched; (3) a center hole and a mounting hole are punched while the steel plate is punched; (4) the upper punching die is dismantled from the upper support, a motor and an electric cutting saw are electrified, and waste materials on the periphery of the pre-formed spoke blank are cut away; (5) electricity ofthe motor and the electric cutting saw is cut off, the upper punching die is fixedly connected with the upper support, the electromagnet is electrified, and the spoke blank is taken out; and (6) finish machining is conducted on the spoke blank to manufacture the spoke. Compared with the prior art, the machining method mainly uses a machining device to machine the spoke, the machining process is simple in operation and convenient, and the machining efficiency and the precision of the spoke blank are greatly improved.

Owner:CHONGQING FENGHUIDA METAL FORGING CO LTD

Advertising board cleaning method adopting scraper cleaning device

InactiveCN107952706AReduce cleanup stepsAvoid blind spotsCleaning using toolsCleaning using liquidsStopped workCleaning methods

Owner:江苏飞视文化发展有限公司

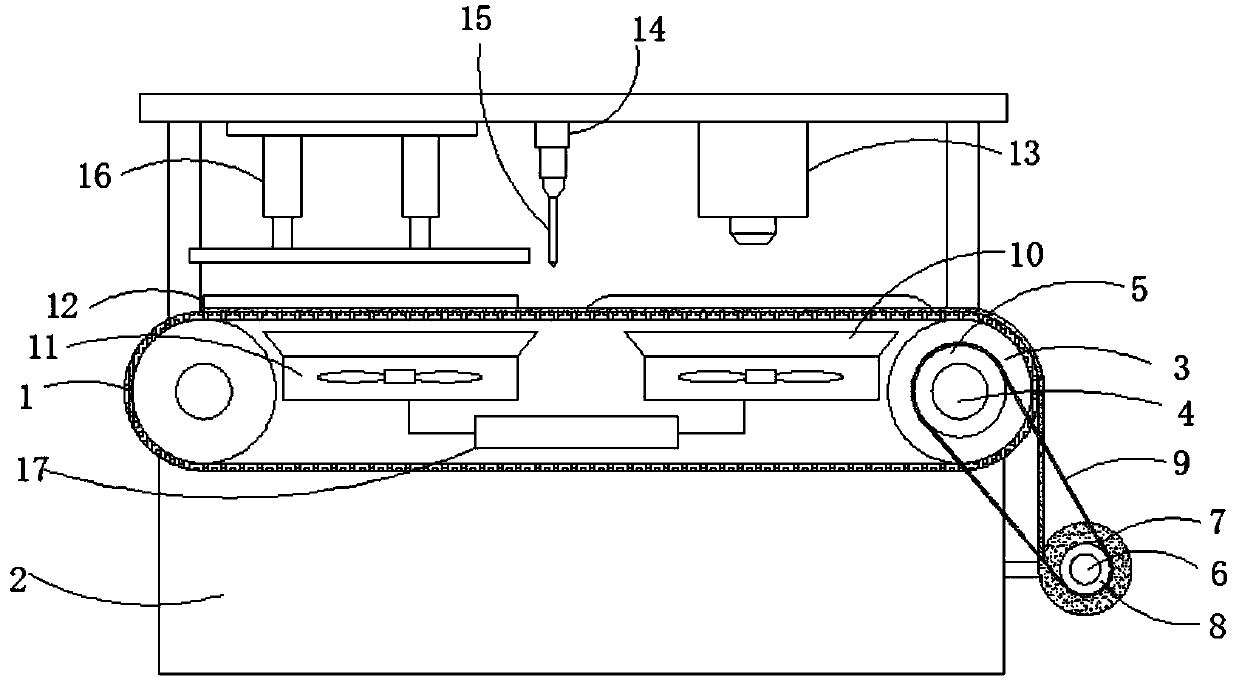

Mesh belt solid medium isolation structure for shaving board production

InactiveCN110843071ASurface quality effectReduce cleanup stepsWood working apparatusFlat articlesPulp and paper industryMechanical engineering

The invention discloses a mesh belt solid medium isolation structure for shaving board production. A layer of kraft paper is laid on a mesh belt and can be synchronously fed along with the mesh belt,wherein an auxiliary roller for bearing a kraft paper roll is rotationally connected to the feeding end of a base below the mesh belt; a kraft paper adsorption piece is arranged below the feeding endof the conveying face of the mesh belt; a cutting assembly used for cutting off the kraft paper is arranged above the conveying face of the mesh belt; and the cutting assembly is positioned between apowder laying machine and a pressing plate assembly above the mesh belt. The mesh belt solid medium isolation structure for shaving board production is used for isolating the mesh belt from wood boardraw materials, adhesion between wood boards and the mesh belt in the pressing plate process is prevented, the influence of adhesion on the surface quality of a shaving board is prevented, the cleaning steps of the mesh belt are reduced, and the production quality and efficiency are improved. In the mesh belt solid medium isolation structure for shaving board production, the auxiliary roller for bearing the kraft paper roll and a conveying wheel share one driving source, and the whole structure is compact.

Owner:益阳万维竹业有限公司

A kind of manufacturing method of aluminum-based copper-clad laminate

ActiveCN112026329BGuaranteed smoothnessReduce cleanup stepsLamination ancillary operationsLaminationCopper foilMaterial resources

Owner:福建鑫宏华机械有限公司

A capture type floating flocculation treatment device in the horizontal flow section of textile sewage

ActiveCN110273458BAvoid blockingImprove work efficiencySewer pipelinesMoving filtering element filtersFlocculationAir filter

The invention provides a catch type flocculation treatment device for an advection section of textile wastewater. The catch type flocculation treatment device comprises a drainage covered channel for draining, an arc-shaped stop shed for blocking floating flocculant in air, a balance weight lever which is sunken into water and is made of metal, a buoyancy tube, a wind jittering bag and an air filtering screen, wherein the drainage covered channel is placed inside a groove formed in the ground; the surface of the drainage covered channel is fixedly connected with the surface of the arc-shaped stop shed; the inner part of the balance weight lever is hollow; an air delivery pipe sleeves the surface of the balance weight lever. The invention relates to the field of textile. The catch type flocculation treatment device for the advection section of the textile wastewater adopts a special floating flocculant intercepting structure; the floating flocculant is intercepted and then is quickly concentrated, so that the floating flocculant is conveniently cleaned and the intercepting structure can be utilized more efficiently, and further the problems that a general floating flocculant treatment device needs to frequently clean the filter screen when being used and is lower in working efficiency, while a flocculation method for a large-area circulating pool has low recycling value of the floating flocculant and greater energy consumption are effectively solved.

Owner:东营正诺技术服务有限公司

Novel bicycle front fork outer surface polishing machine

InactiveCN114012582AIncrease productivityEasy to disassemble and replaceLiquid surface applicatorsPolishing machinesPolishingStructural engineering

The invention discloses a novel bicycle front fork outer surface polishing machine which comprises a polishing machine body. An adjusting mechanism is installed at the top end of the polishing machine body, an assembling mechanism is installed at the bottom end of the adjusting mechanism, the assembling mechanism comprises a pushing rod, and the pushing rod is installed in a clamping frame through a bearing. According to the invention, a driving strip and a cleaning roller are arranged, the driving strip drives the whole fixing frame to move, the cleaning roller can abut against the surface of a bicycle front fork, and metal particle powder left on the surface of the polished front fork can be effectively removed; and the step that follow-up production personnel need to additionally clean the surface of the front fork can be reduced, the production efficiency of the front fork is effectively improved, meanwhile, the labor intensity of the production personnel is reduced, two sets of clamping frames are arranged in the fixing frame, the cleaning roller and the oiling roller can be conveniently detached and replaced after being used for a long time, and the cleaning efficiency reduction caused by a large amount of dust adhered to the cleaning roller is avoided.

Owner:YANCHENG SIKEDA MACHINERY TECH

Liquid coating for protecting surface of aluminum substrate, and preparation method thereof

InactiveCN111117442AOvercoming the problem of insufficient hardnessImprove acid and alkali corrosion resistanceFireproof paintsPretreated surfacesPhotosensAluminum substrate

The invention discloses a liquid coating for protecting the surface of an aluminum substrate, and a preparation method thereof. The liquid coating for protecting the surface of the aluminum substrateis prepared from, by weight, 25-50 parts of UV resin, 15-30 parts of organic silicon resin, 10-30 parts of a photosensitizer, 5-10 parts of superfine talcum powder, 10-30 parts of superfine barium sulfate, 1-3 parts of a wetting dispersant, 15-30 parts of silica powder and 5-10 parts of an organic silicon defoamer. The preparation method of the liquid coating for protecting the surface of the aluminum substrate comprises the following steps: mixing the UV resin and the organic silicon resin, and uniformly stirring and mixing to obtain a first mixture; adding the photosensitizer into the firstmixture, and uniformly stirring and mixing to obtain a second mixture; adding the superfine talcum powder, the superfine barium sulfate, the silica powder and the wetting dispersant into the second mixture, and uniformly stirring and mixing to obtain a third mixture; and grinding and dispersing the third mixture, adding the organic silicon defoamer and the wetting dispersant, and uniformly mixingto obtain the liquid coating for protecting the surface of the aluminum substrate.

Owner:江门市阪桥电子材料有限公司

Emulsified asphalt paint coating device and construction method

PendingCN114517435AImprove construction quality and construction efficiencyControl coating thicknessRoad cleaningRoads maintainenceElectric heatingHeater Rod

The invention discloses an emulsified asphalt paint coating device which comprises a box body base and a material box body, the material box body is fixedly installed on one side of the box body base, the cross section of the material box body is of a conical structure, and a base plane scraper plate used for scraping emulsified asphalt paint is movably installed on the lower portion of one side of the material box body. A thickness determining roller for controlling the thickness of the emulsified asphalt coating is movably mounted at the lower position in the material box body, a heating rod is fixedly mounted in the thickness determining roller, two groups of electric heating plates are fixedly mounted on the inner wall of the material box body and are symmetrically arranged, and a dust collection nozzle is arranged at the bottom of a box body base; according to the emulsified asphalt coating coating device, the base surface scraping plate and the thickness determining roller are arranged, so that the emulsified asphalt coating coating device is provided with multiple adjusting structures, corresponding adjustment can be conducted according to the coating thickness and the scraping thickness, traditional manual operation is replaced, and the construction efficiency and the construction quality of emulsified asphalt coating are improved.

Owner:湖南大禹神工防水科技有限公司

A dust collector for building curtain wall cleaning

ActiveCN111000503BAvoid damageAchieve the effect of cleaning the curtain wallCarpet cleanersFloor cleanersThermodynamicsDust control

The invention relates to the field of curtain wall cleaning, and discloses a dust collector for building curtain wall cleaning, which includes a device body, the device body is in the shape of a rectangular box, a cleaning box is fixedly installed at the bottom of the device body, and the bottom of the cleaning box is hollowed out to The rectangular box shape of the inner side wall of the top of the cleaning box. In the present invention, the dust collector for building curtain wall cleaning, the fan motor is started to drive the fan blades to rotate to generate wind force. Inside the box, the dust is blown to the corresponding position at the bottom of the cleaning box through the guide of the dust removal guide plate, so as to clean the dust on the surface of the curtain wall, and the first cleaning block is driven by the rotating shaft to rotate to clean the curtain wall, and the first cleaning block is cleaned through the air-drying hole The curtain wall is air-dried, and the air-dried curtain wall is cleaned again through the secondary cleaning block, so as to achieve the effect of cleaning the curtain wall, and at the same time achieve the effect of avoiding the damage to the curtain wall caused by scraping the wall cleaning.

Owner:新昌县哈坎机械配件厂

Mold for injection molding

Owner:佛山市顺德区天玛仕电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com