Wide chord blade machining method

A processing method and blade technology, applied in the processing field of wide chord blades, can solve the problems of increasing the risk of cracking, unable to improve, and difficult to guarantee the uniformity and reliability of the truss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

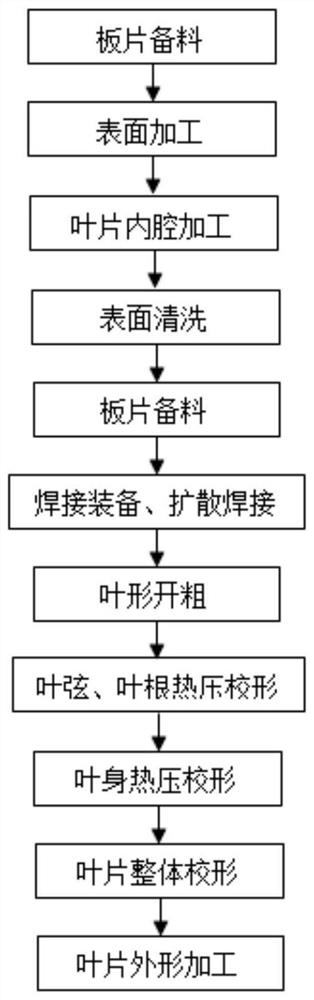

[0050] This embodiment provides a processing method for wide-chord blades, comprising the following steps:

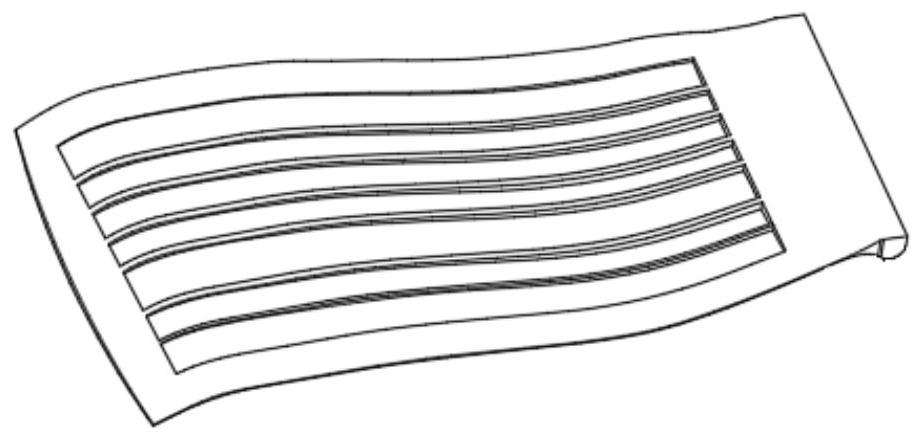

[0051] The titanium alloy forging material is cut into two sheets. The size of the sheet is 20mm allowance on each side of the final length and width direction of the blade, and 5mm allowance on each side of the thickness direction. The surface roughness Ra<0.8μm is achieved by milling. On the welding surface of the sheet metal, the inner cavity structure of the blade is processed to a hollow rate of 60%. The inner cavity adopts a support rib structure, the rib width is greater than 1mm, and the cavity shape is a blade-shaped cavity. Use hydrochloric acid to clean the surface of the two processed plates to remove the surface oxide film.

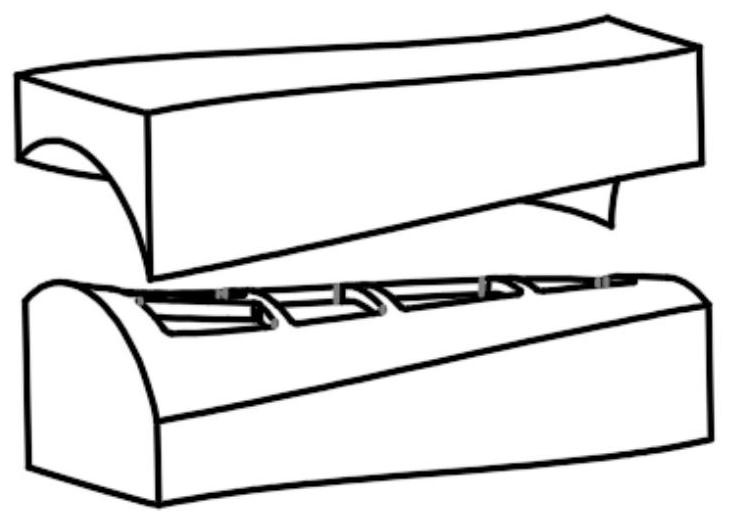

[0052] Such as Figure 4 As shown, the two cleaned sheets are butted and assembled according to the drawing, and then put into a diffusion welding furnace, vacuumed and heated to a diffusion welding temperature of titanium alloy of ab...

Embodiment 2

[0055] This embodiment provides a processing method for wide-chord blades, comprising the following steps:

[0056] The titanium alloy forging material is cut into two sheets, and the surface roughness Ra<0.8 μm is obtained by milling. On the welding surface of the sheet metal, the inner cavity structure of the blade is processed to a hollow rate of 50%. Use hydrochloric acid to clean the surface of the two processed plates to remove the surface oxide film.

[0057] Such as Figure 4 As shown, the two cleaned sheets are butted and assembled according to the drawing, and then put into a diffusion welding furnace, vacuumed and heated to a diffusion welding temperature of titanium alloy of about 950°C, and then the workpiece is pressurized to 10MPa and kept warm 240min, and finally cooled to room temperature with the furnace to form a blade blank with a vacuum inner cavity.

[0058] Take out the blade blank, process and thin its two sides to be close to the final wall thicknes...

Embodiment 3

[0060] This embodiment provides a processing method for wide-chord blades, which is different from Embodiment 1 only in the parameter control of the following steps:

[0061] The operating pressure in the vacuum diffusion welding process is 3MPa, and the operating pressure in the primary hot pressing forming and secondary hot pressing forming processes is 1MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com