Patents

Literature

30results about How to "Control coating thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

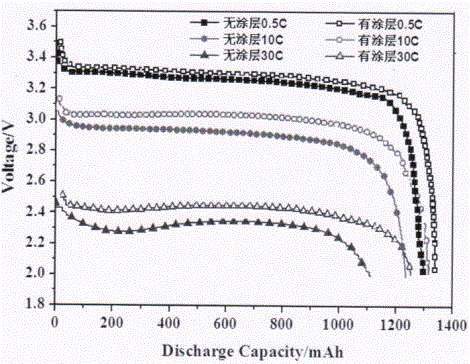

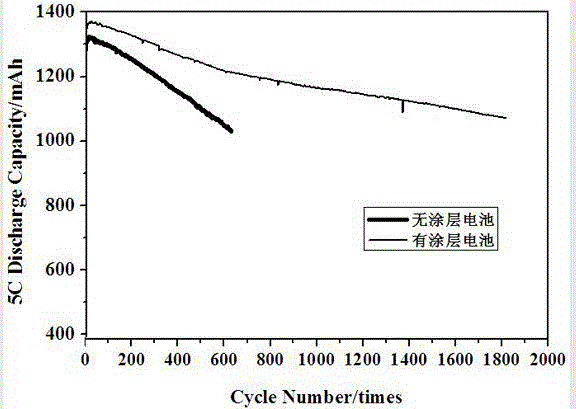

Lithium ion battery anode functional coating and preparation method thereof

ActiveCN102757700AReduce the presence of air bubblesEasy to processCell electrodesElectrically-conductive paintsLow speedSlurry

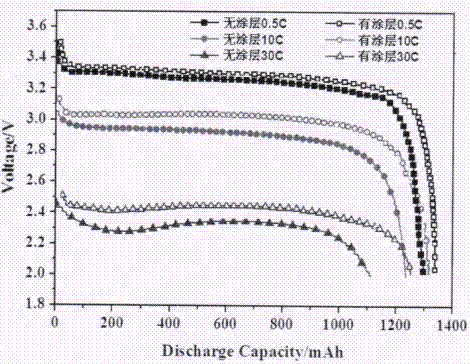

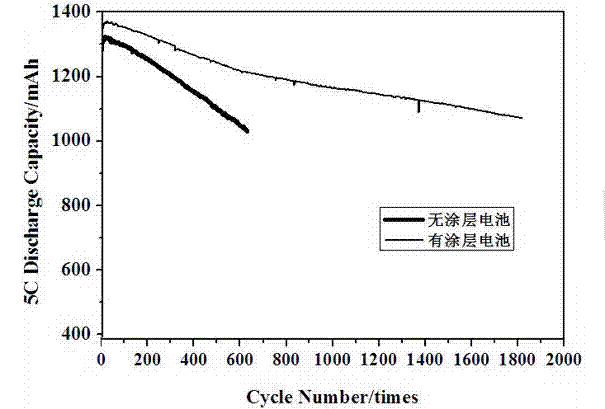

The invention provides a lithium ion battery anode functional coating and a preparation method thereof. A dispersing agent NMP (N-methyl-pyrrolidone) is stirred by a planetary stirrer at a high speed till the temperature reaches 40 to 50 DEG C; a certain proportion of a binding agent PVDF (Polyvinylidene Fluoride) is added to enable the solid content of a binding agent solution to be 1.2 to 3.5 percent; low-speed revolution is performed and then high-speed rotation is started; cold circulating water is received to control the temperature of the slurry below 50 DEG C; stirring is preformed for 2 to 6 h; a carbon black conductive agent (conductive carbon) is added to enable the solid contend of the slurry to be 20 to 30 percent; stirring is performed for 2 to 4 h; the slurry is transferred into a high-efficiency dynaflow ultrasonic slurry mixer to be subjected to ultrasonic dispersion for 1 to 2 h; after the preparation is finished, the slurry passes through a 200-mesh screen stencil and is sprayed through a spraying machine, wherein the spraying thickness is controlled within 3 to 5 Mum; and after the spraying is finished, a coated pole piece is baked for 12 to 14 h at 110 plus or minus 3 DEG C, wherein dry nitrogen is filled for replacement once each two hours, so as to obtain the lithium ion battery anode functional coating. The replacement of a current collector with an anode aluminium foil material by a current collector with the functional coating can greatly improve the electrochemical properties of lithium ion batteries.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

Damp-proof processing method of electronic circuit board

InactiveCN103108493AStable and moisture-proof requirementsAvoid spraying dead endsNon-metallic protective coating applicationElectronic circuitMechanical engineering

The invention relates to a damp-proof processing method of an electronic circuit board. The damp-proof processing method of the electronic circuit board comprises the following steps that pre-covering processing is conducted on the electronic circuit board; an automatic spray gun conducts automatic and reciprocating spraying and coating on the electronic circuit board along the horizontal direction and the perpendicular direction; a face is turned automatically according to damp-proof requirements; and the sprayed and coated electronic circuit board is automatically heated and dried. According to the damp-proof processing method of the electronic circuit board, the electronic circuit board is ideal in damp-proof effect and reliable in quality guarantee and work efficiency, and therefore good performance of the electronic circuit board is guaranteed.

Owner:SHANGHAI SHARP ELECTRONICS +1

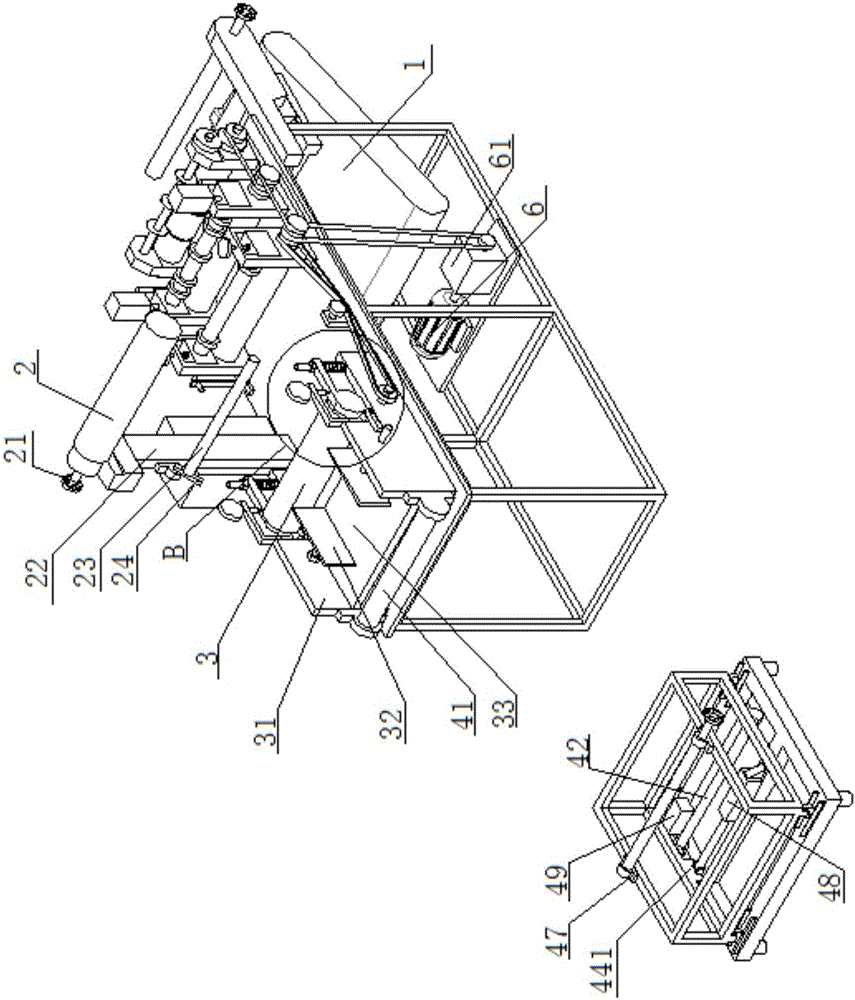

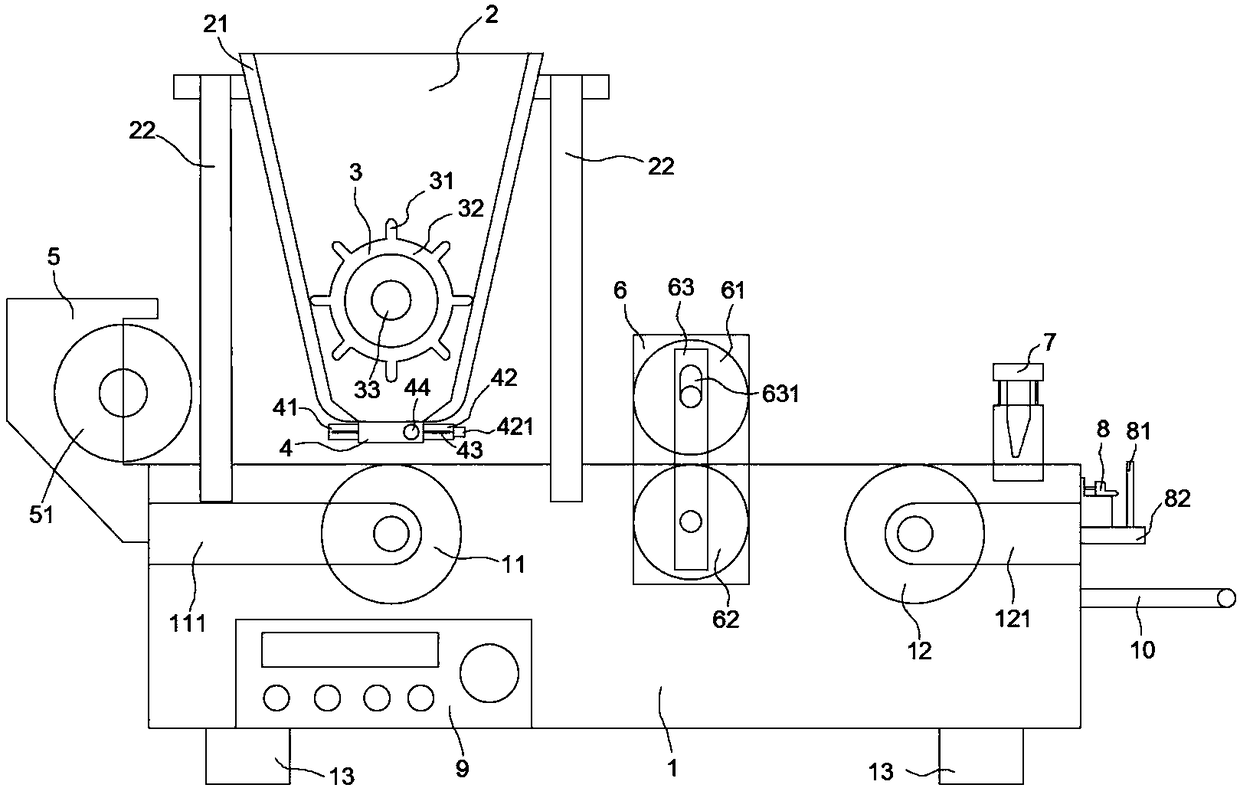

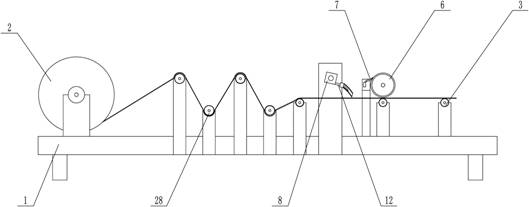

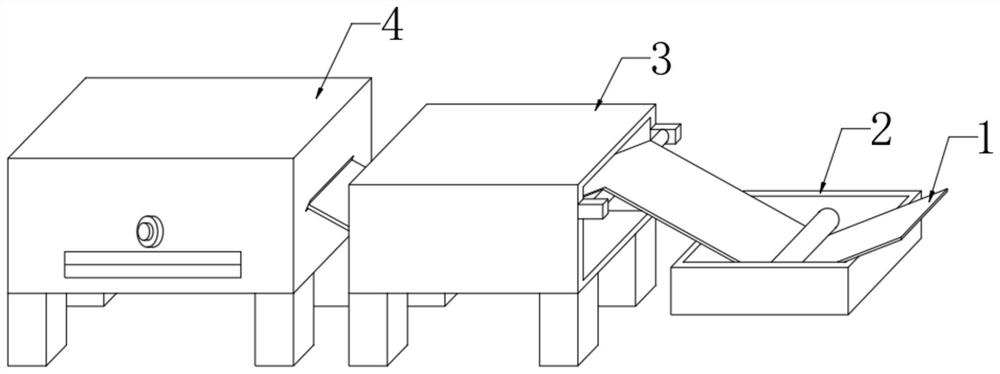

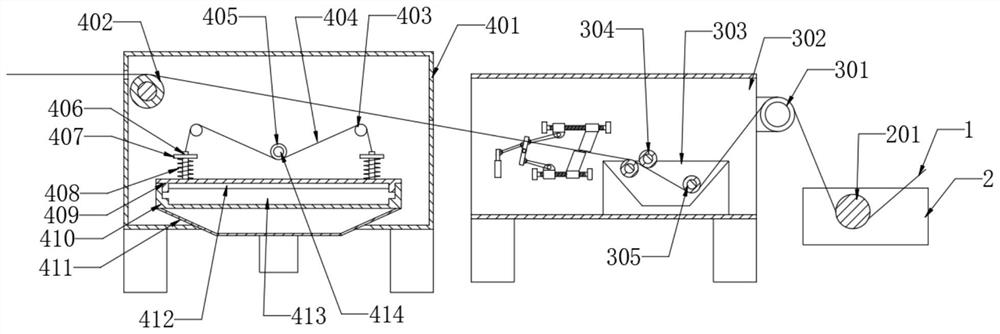

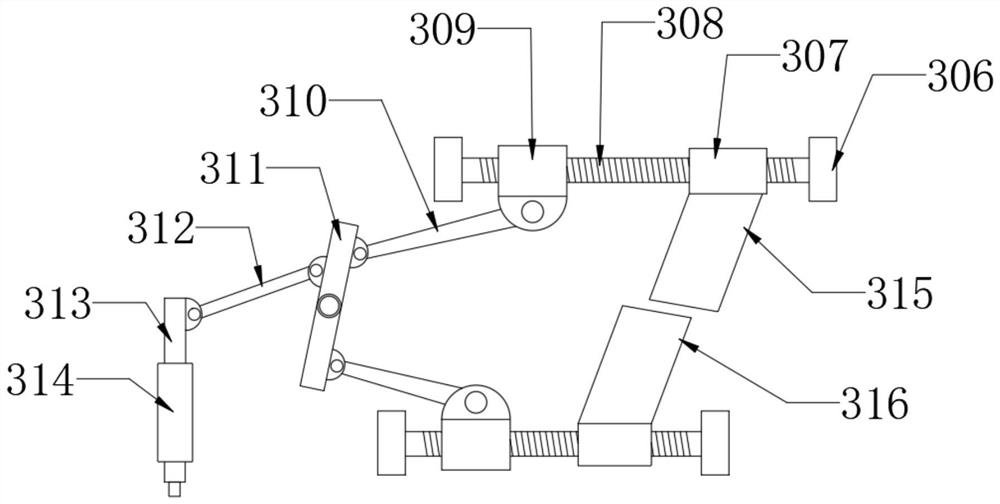

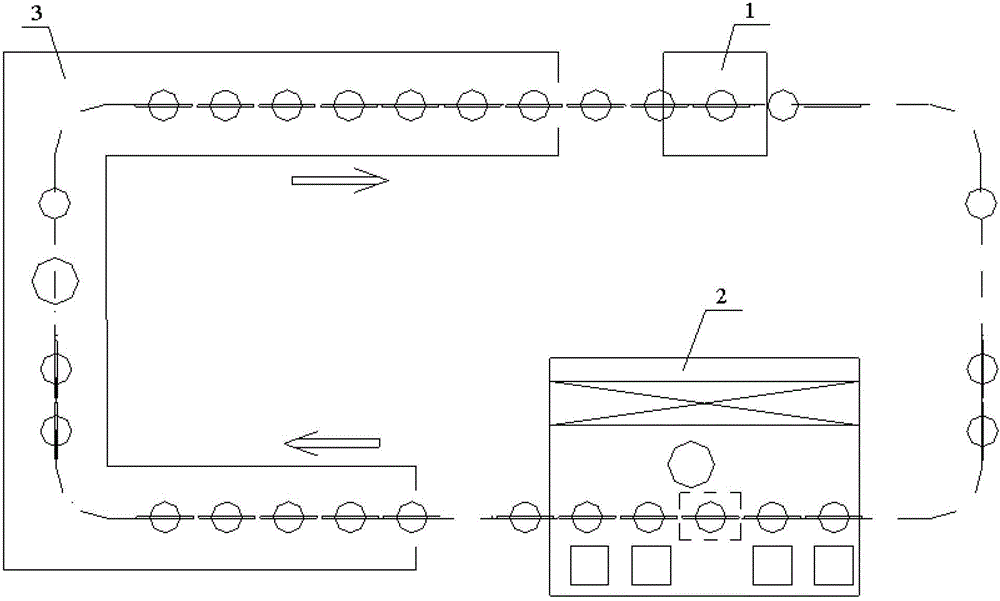

Automatically adjusted cataplasm automatic production line

InactiveCN105853230ASimple structureEasy to use and maintainPharmaceutical product form changeAutomatic tuningCoating

The invention provides an automatically adjusted cataplasm automatic production line, which comprises an automatic skew adjustment device and a spunlaced fabric unwinding device, wherein the automatic skew adjustment device comprises a base and an adjusting vehicle which is arranged on the base; the adjusting vehicle is connected to the base in a sliding mode by virtue of a guide rail which is fixedly arranged at the upper end of the base; an adjusting cylinder is arranged on the base, and a piston rod of the adjusting cylinder is hinged with the vehicle body; an opposite-side sensor is additionally fixedly connected to the lower part of the base; the spunlaced fabric unwinding device is detachably connected to a bearing base which is fixedly arranged on the vehicle body by virtue of a bearing; and a lower spunlaced fabric rolling shaft is connected to the part, close to the opposite-side sensor, of the lower side of the vehicle body in a rotatable mode by virtue of a mounted bearing. The automatically adjusted cataplasm automatic production line disclosed by the invention is simple to operate and conducive to production and maintenance. The coating width and thickness of a cataplasm body can be controlled, so that uniform coating is guaranteed; and meanwhile, the sticking amount of the cataplasm body on a cutter head can be reduced when a finished product is cut in a longitudinal direction. In addition, the position of a spunlaced fabric can be also automatically adjusted, so that product quality is guaranteed.

Owner:TIANJIN ZHUOPU MEDICAL EQUIP CO LTD

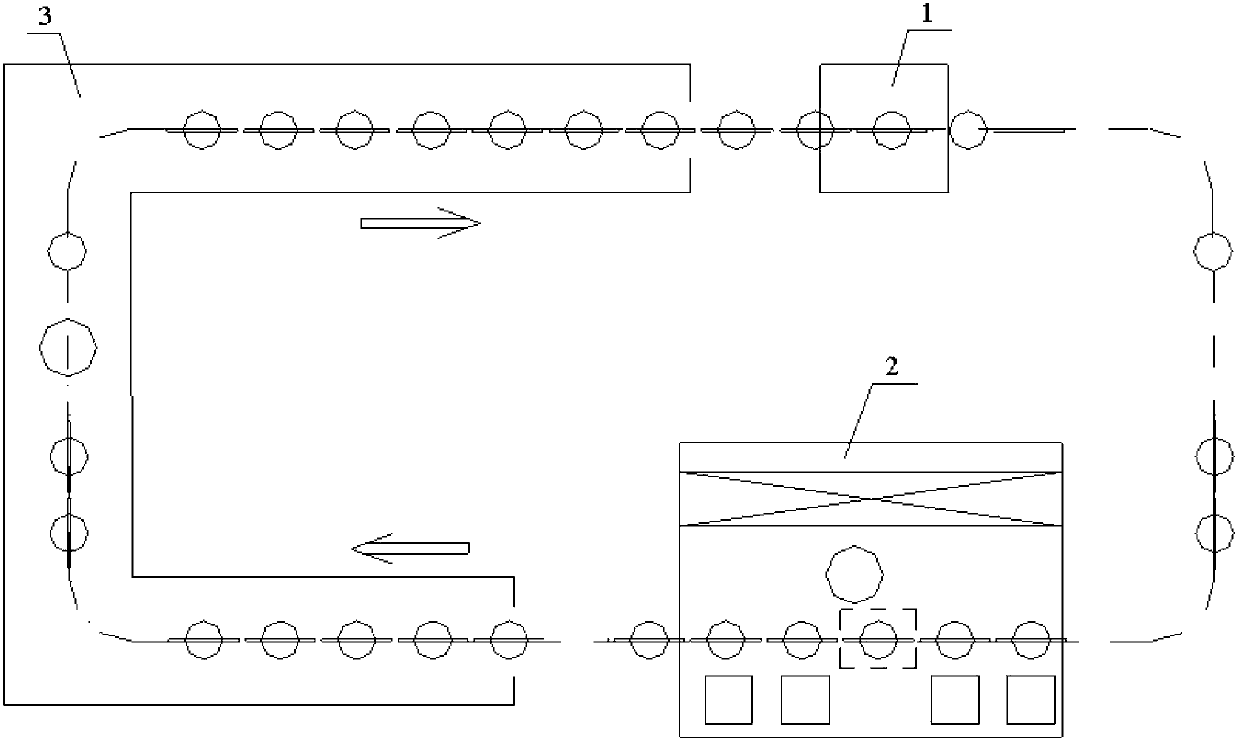

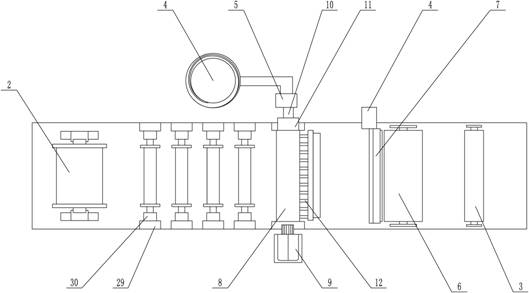

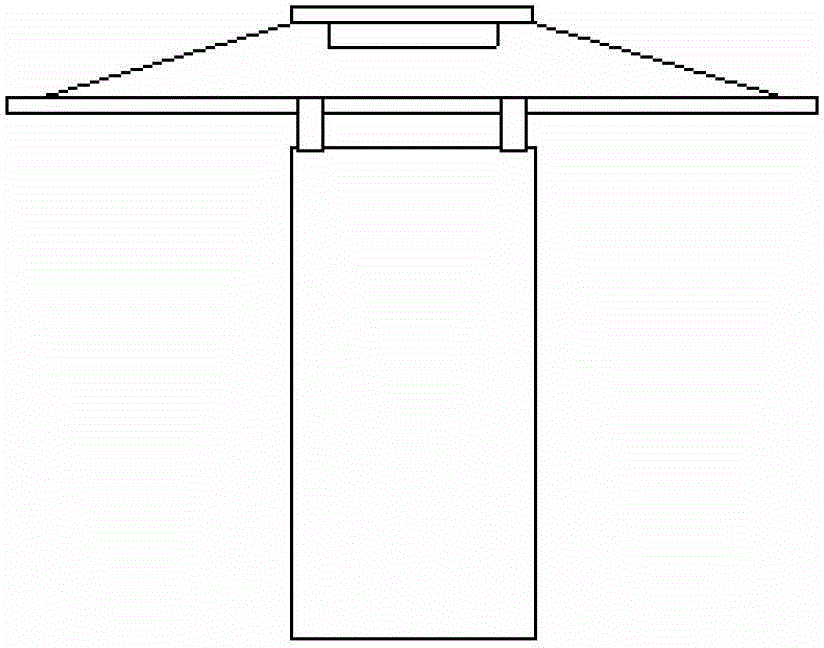

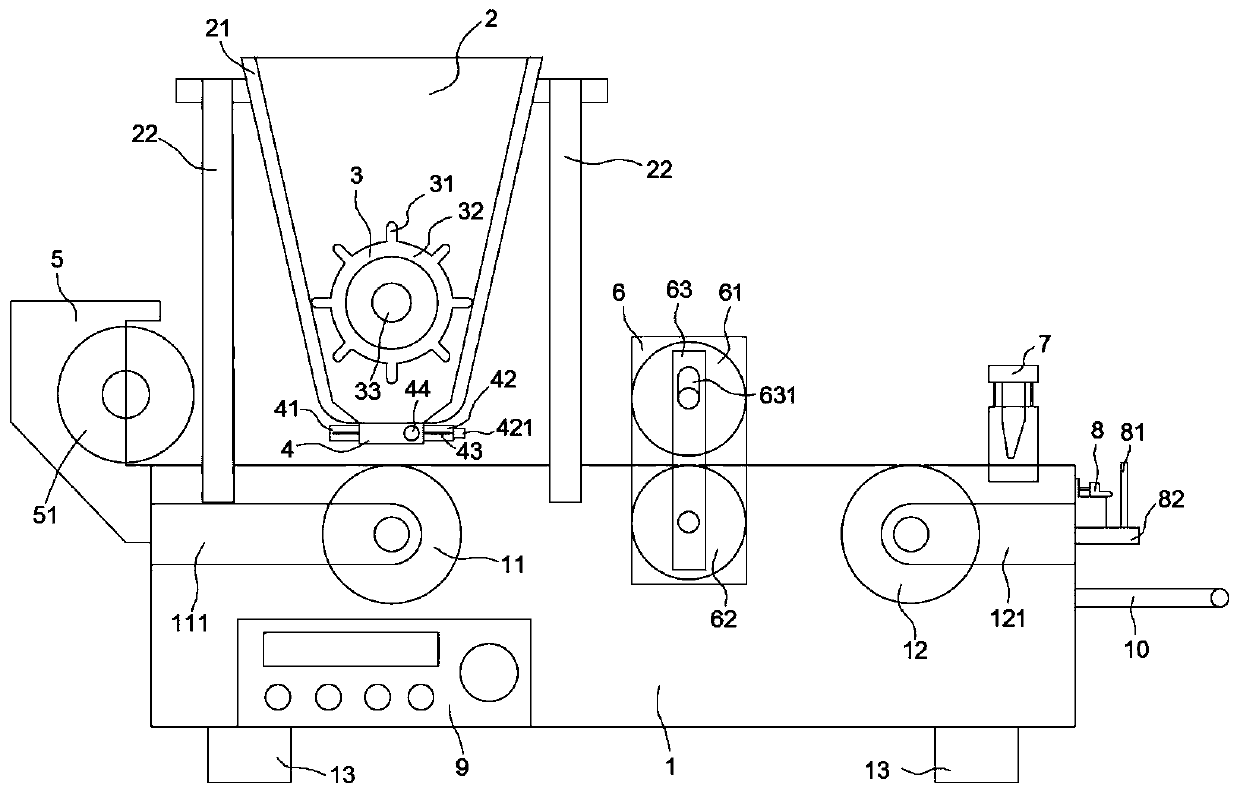

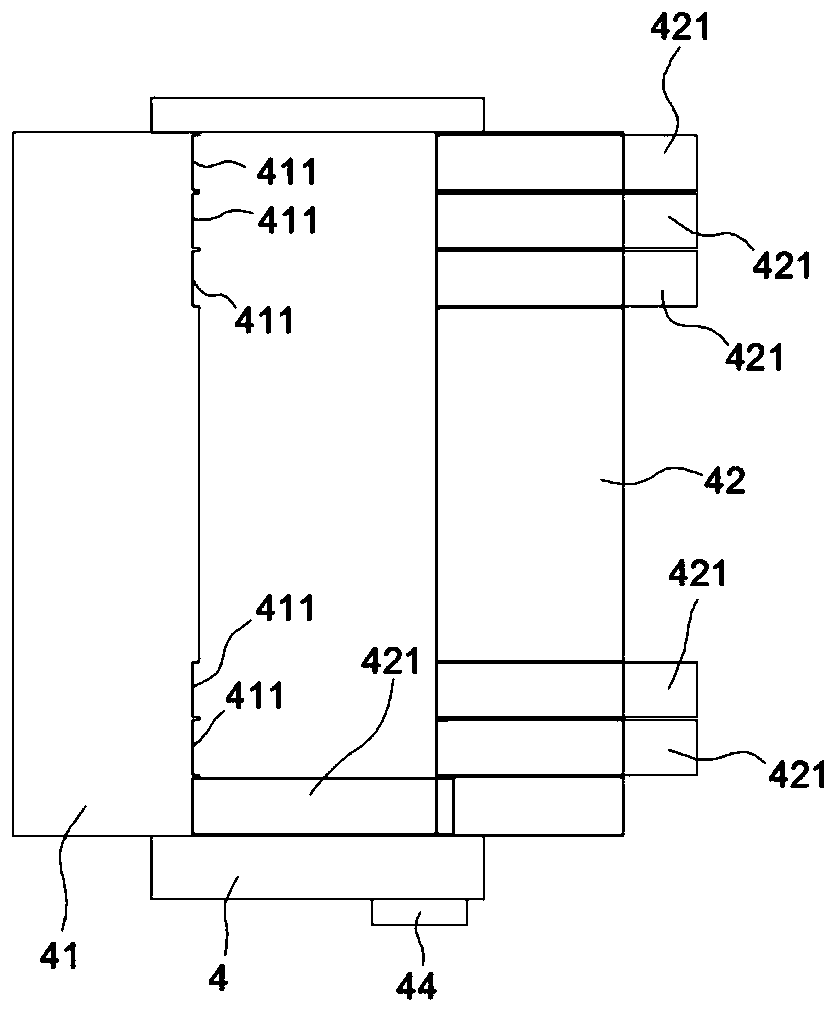

Automatic production line for producing patches

InactiveCN105380799AQuality assuranceControl coating thicknessPharmaceutical product form changeDomestic articlesBiomedical engineeringX-ray

The invention relates to the field of patch production equipment, in particular to an automatic production line for producing patches. The production line is sequentially provided with an ointment coating device, a detection device, an air-drying and cooling device, a cloth expanding device and a cloth coiling device, wherein the detection device comprises an X-ray thickness detector; the X-ray thickness detector comprises a transmitting end and a receiving end; the ointment coating device comprises a coating base plate, a scraper device, a lifting mechanism and a PC control device; and the PC control device is electrically connected to the X-ray thickness detector and the lifting mechanism respectively. The automatic production line can detect ointment thickness in a patch by virtue of X ray and can adjust the height of the scraper device according to the thickness value so as to adjust and control a scraping clearance; the automatic production line can control the coating thickness of ointment more simply, rapidly and accurately, so that the traditional Chinese medicinal ointment layer in the produced patch not only can achieve a standard national thickness value but also can avoid excessive thickness; therefore, the quality of the patch is guaranteed, and meanwhile production cost is saved.

Owner:SINOPHARM GRP DEZHONG (FOSHAN) PHARM CO LTD

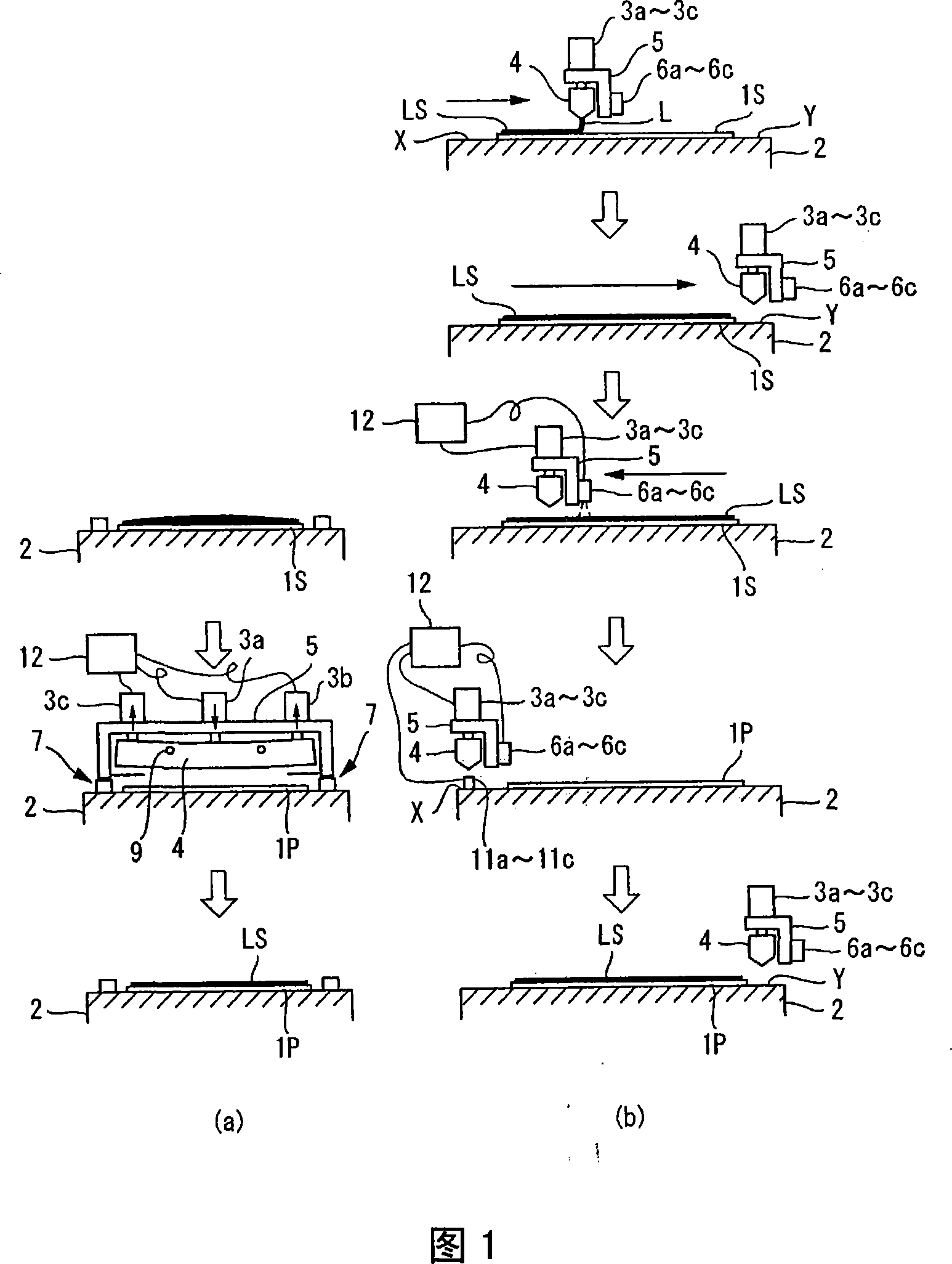

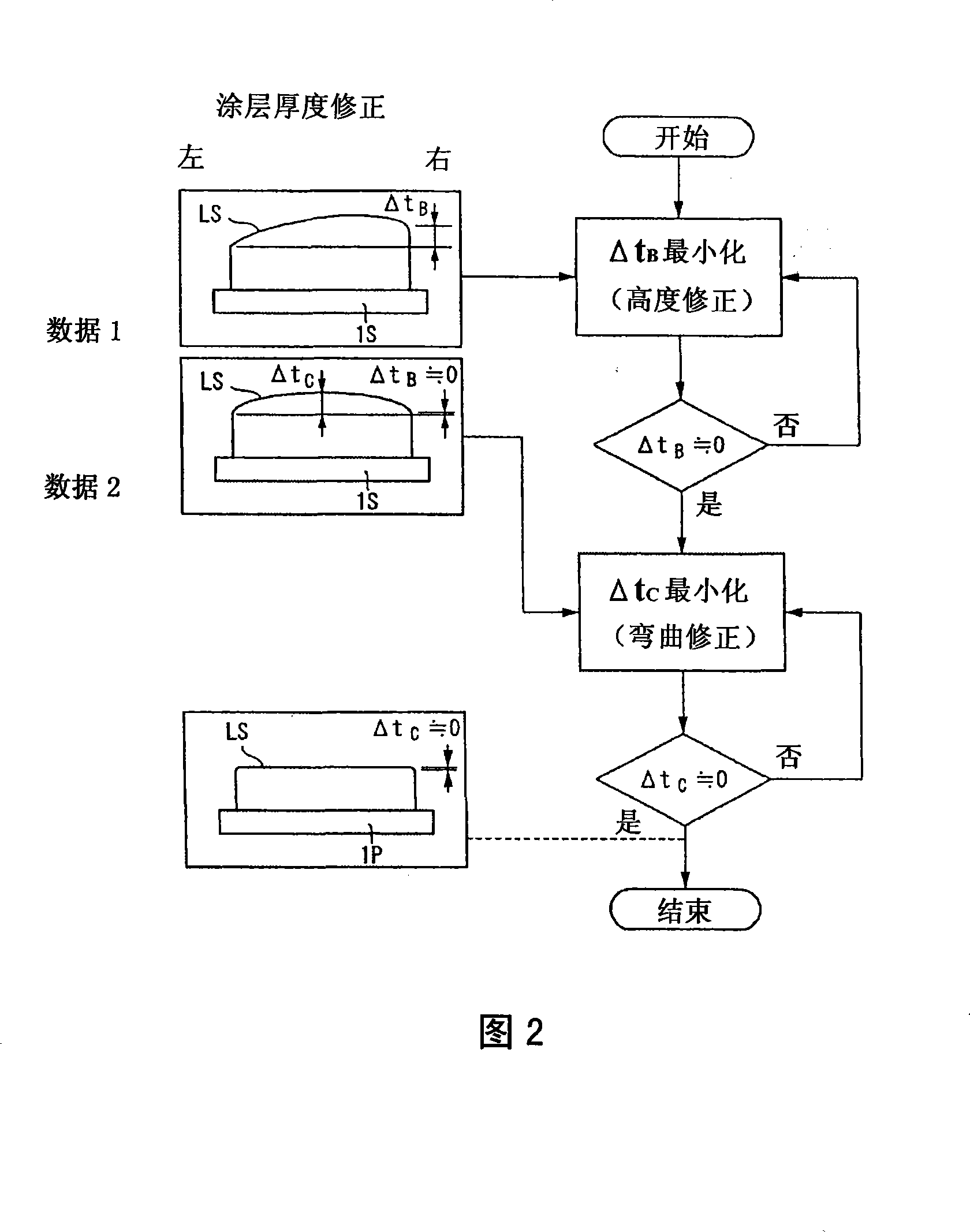

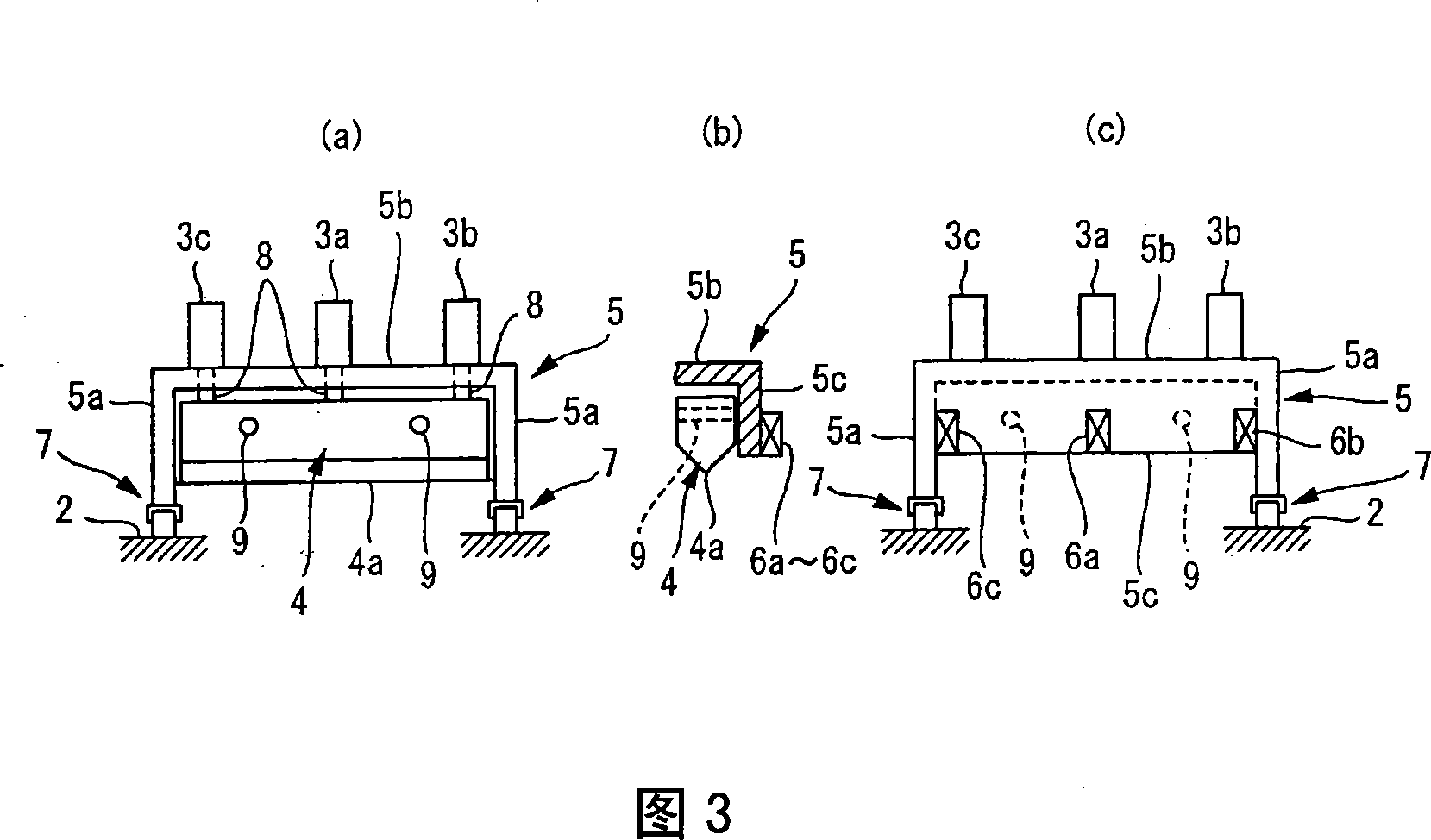

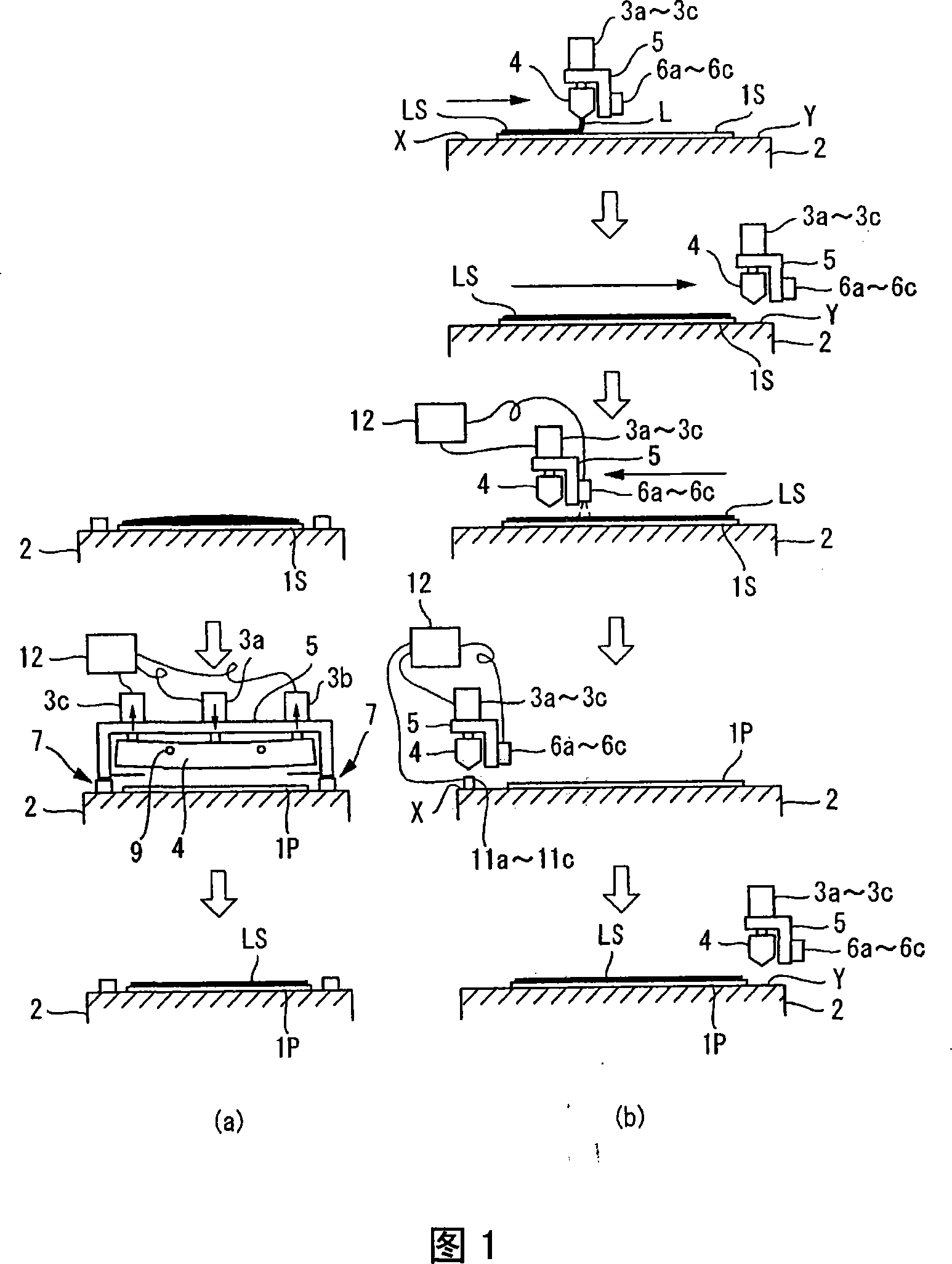

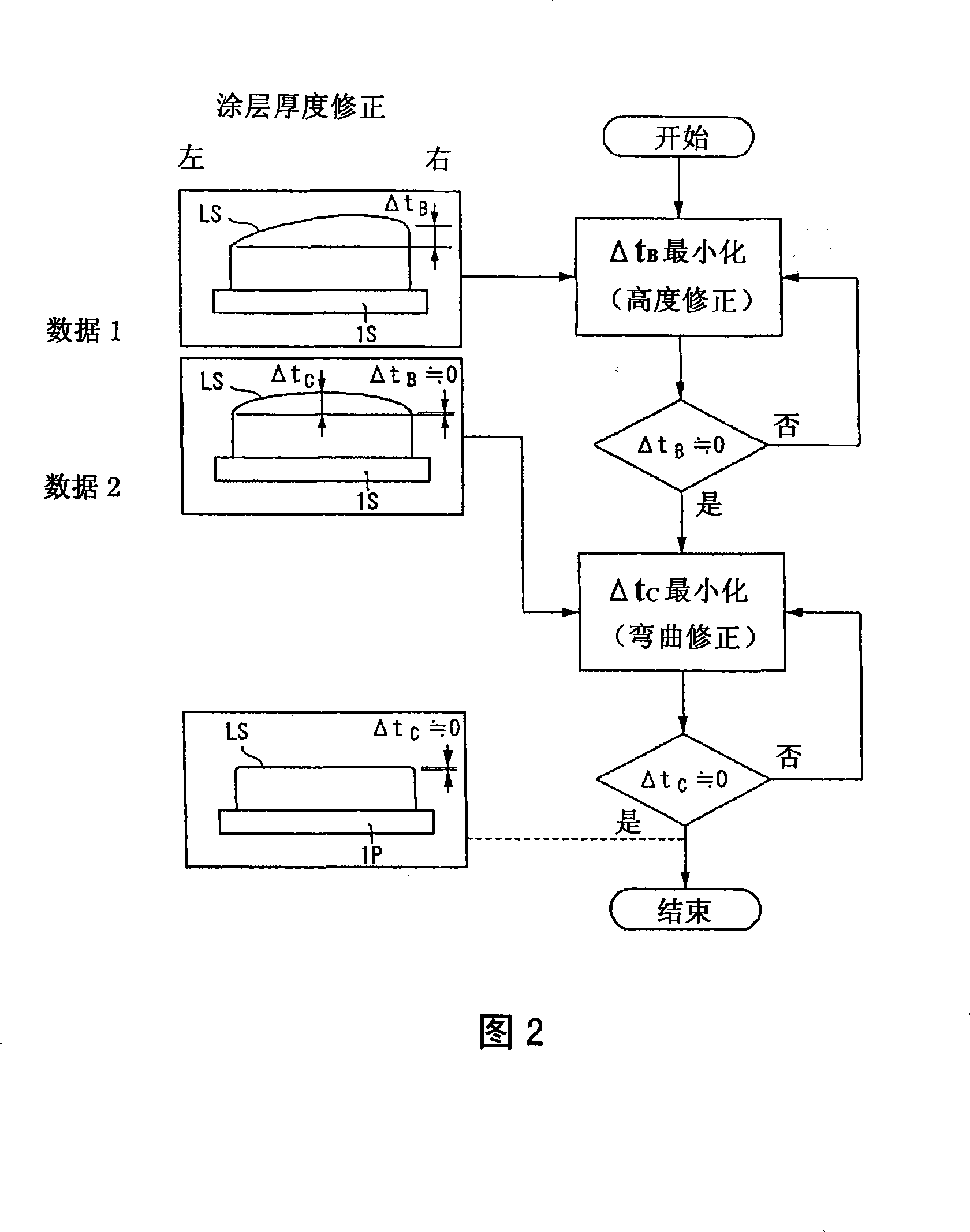

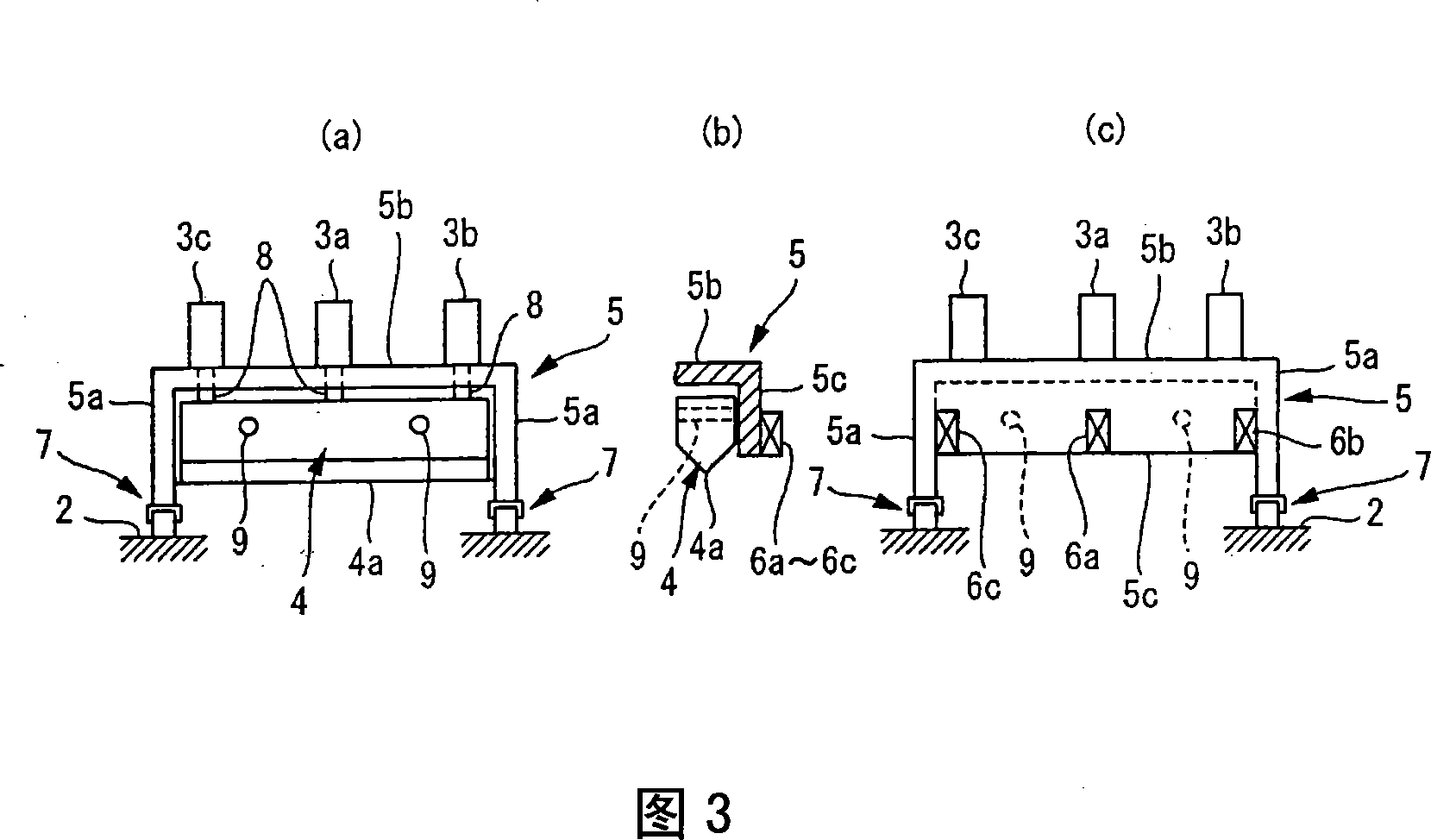

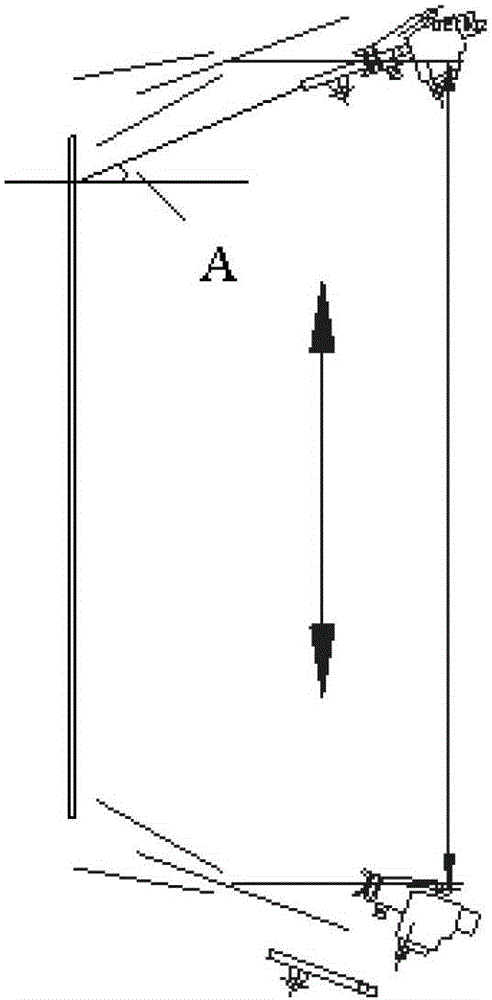

Method for coating substrate with coating

ActiveCN101229536AQuality improvementControl coating thicknessMeasurement devicesPretreated surfacesCoated surfaceLiquid medium

The invention relates to a method of applying a coating to a substrate wherein the coating surface of a sprayed liquid medium onto a substrate by a spray nozzle may be effectively controlled, the formation of the thickness of the coating formed by the liquid medium may be effectively controlled, and the quality control of the coating may be maintained with high production efficiency. The method invention has an operational sequence as follows. A distance sensor 6a to 6c is firstly installed as means of measuring the distance between a media layer surface LS formed on a substrate 1S, 1P and a spray nozzle 4. A test substrate 1S is placed on a table 2 and test coated by liquid media sprayed from the spray nozzle during a forward traverse of a nozzle holder 5 relative to the table. A measuring operation is executed by the distance sensor during a rearward traverse of the nozzle holder relative to the table. A nozzle positioner 3a to 3c is actuated based on the results of the measuring operation executed by the distance sensor as means of setting the spray nozzle position which forms a desired coating. The liquid media L is applied to a substrate 1P.

Owner:CHUGAI RO CO LTD

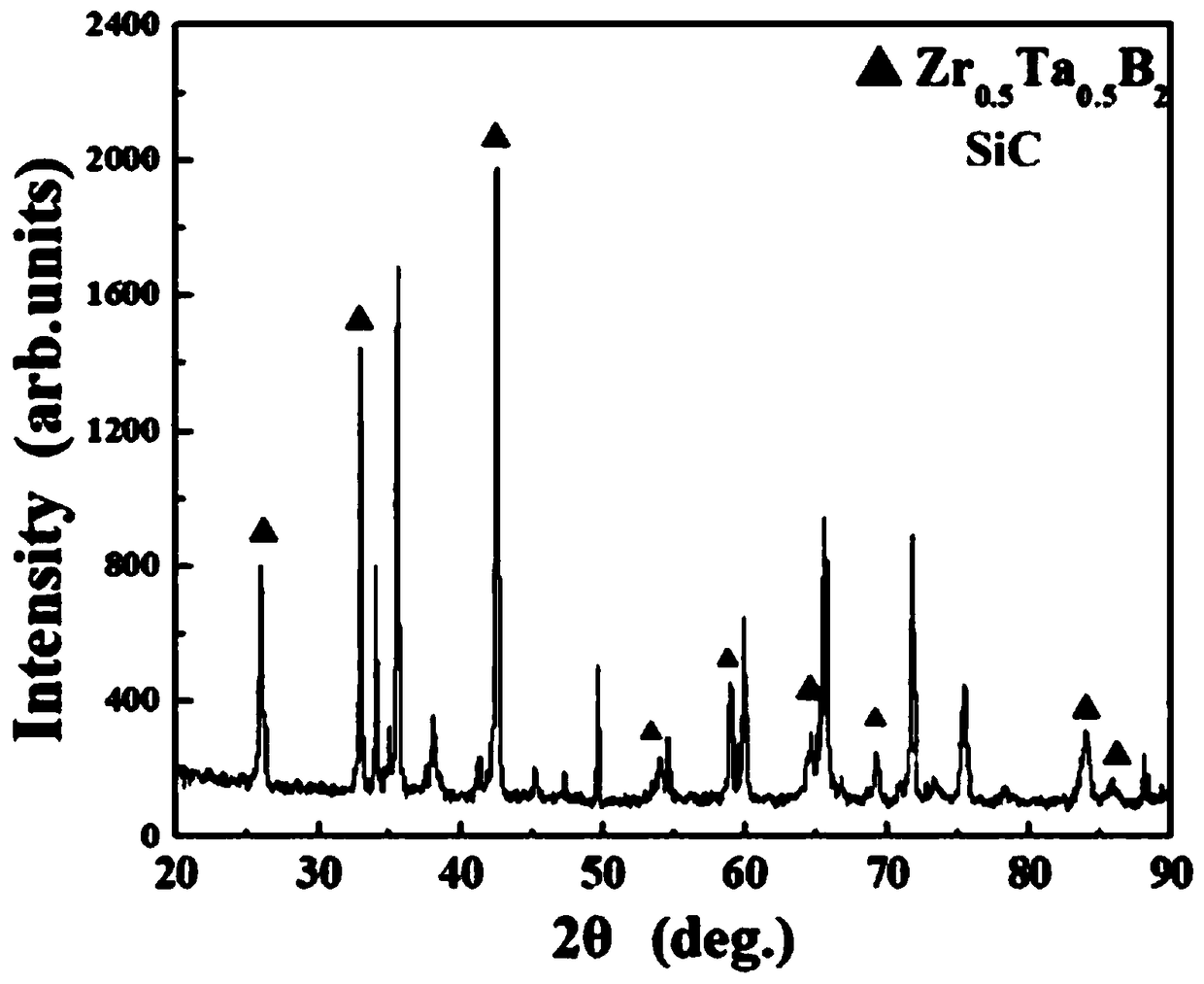

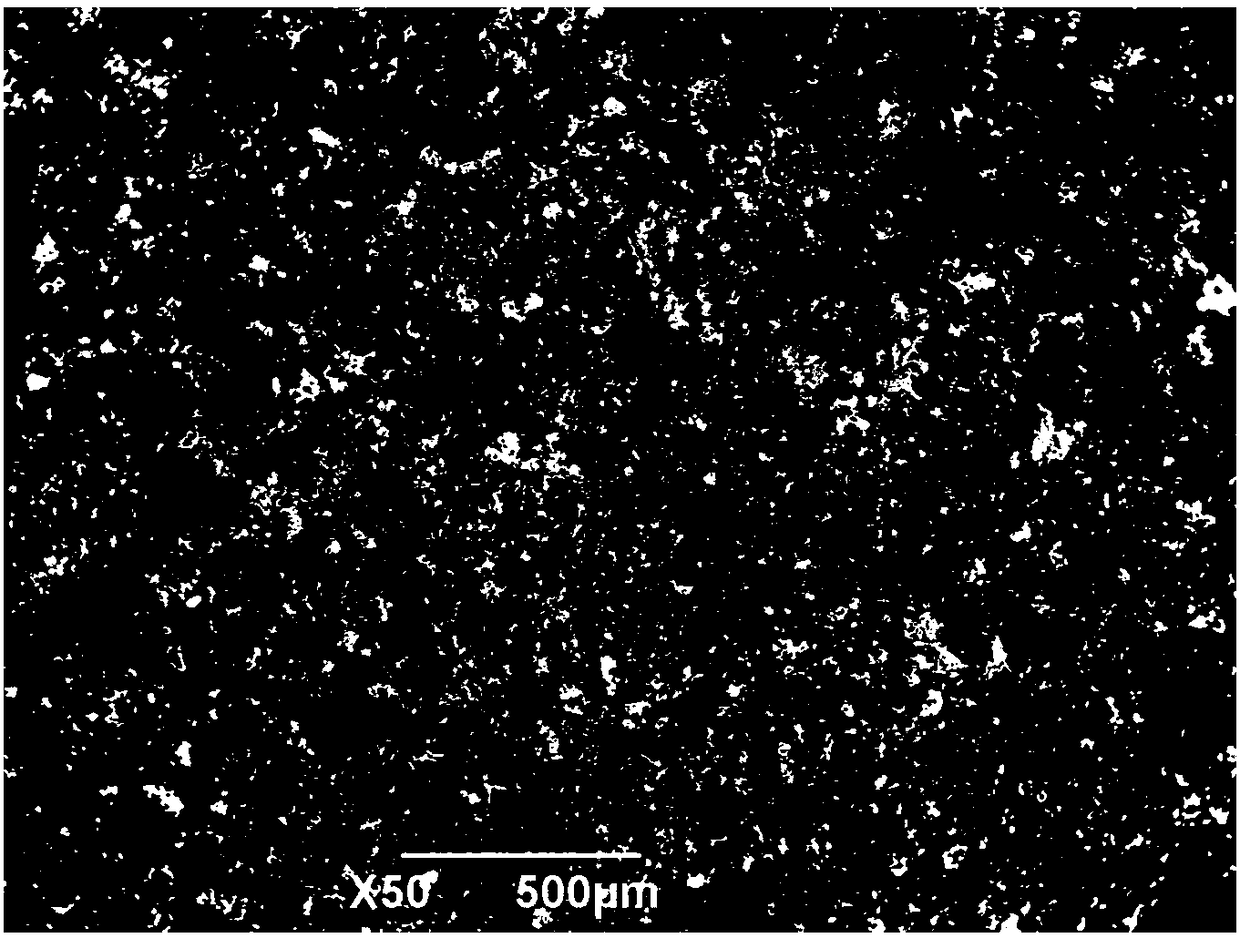

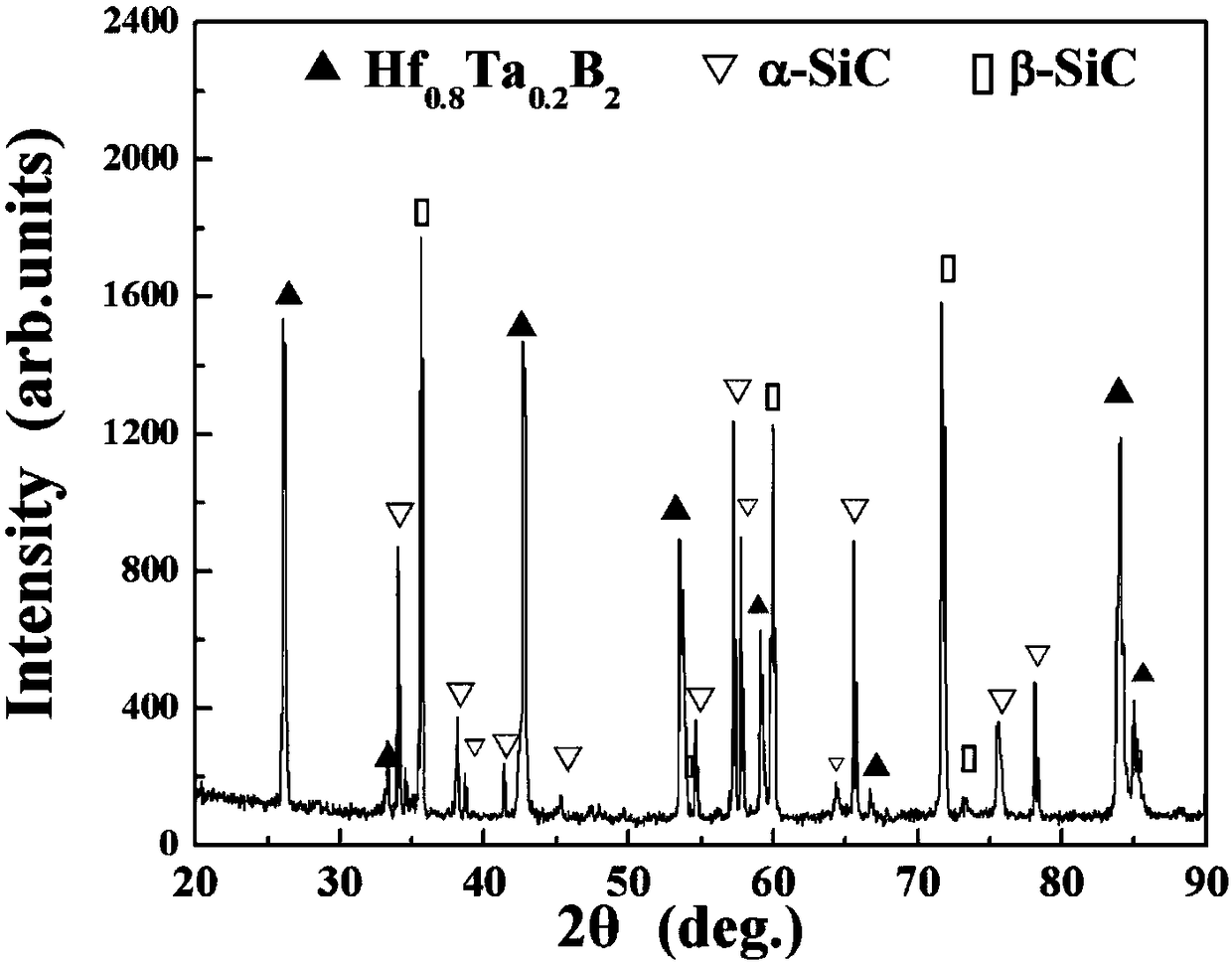

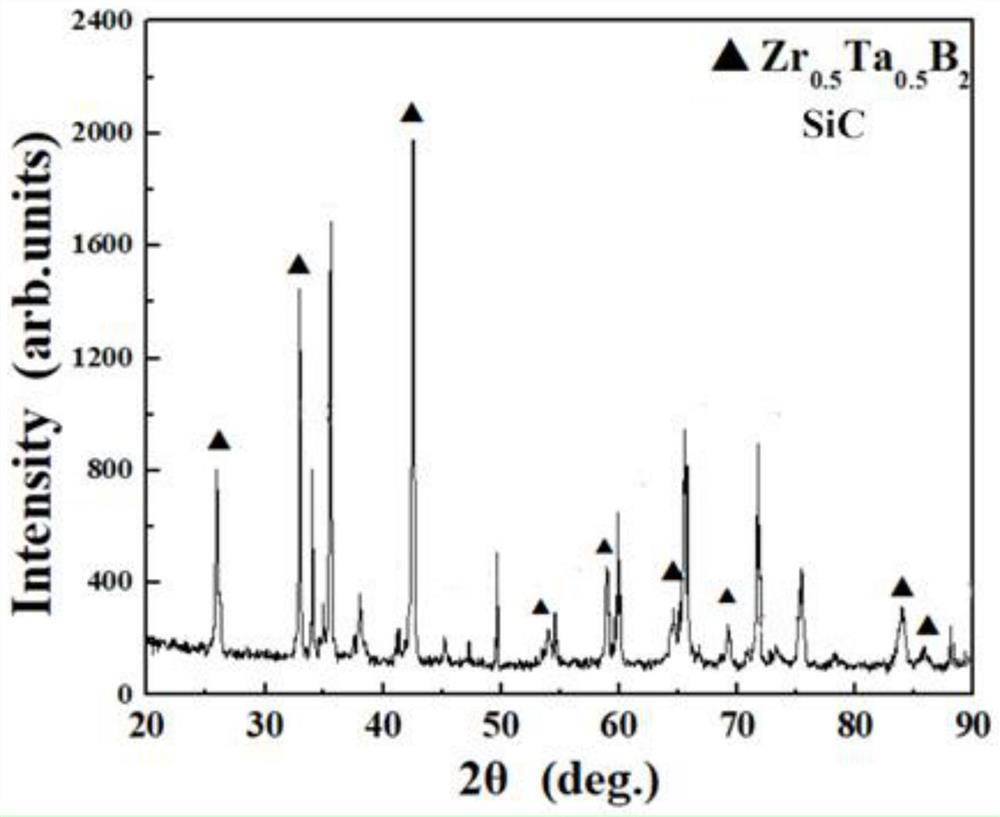

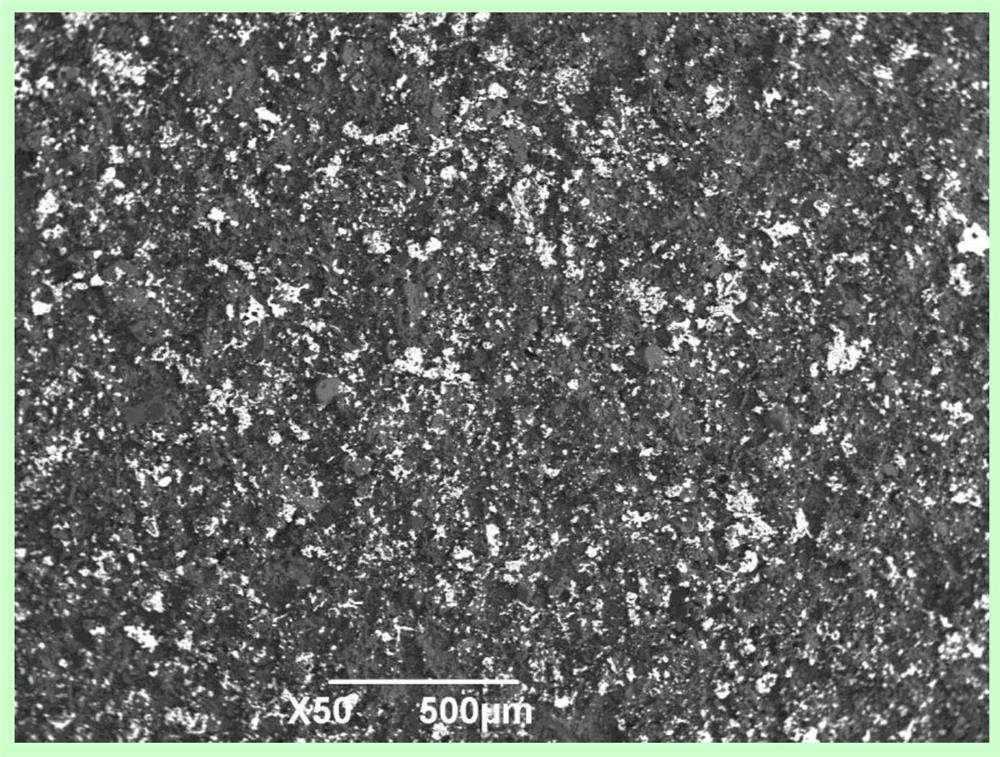

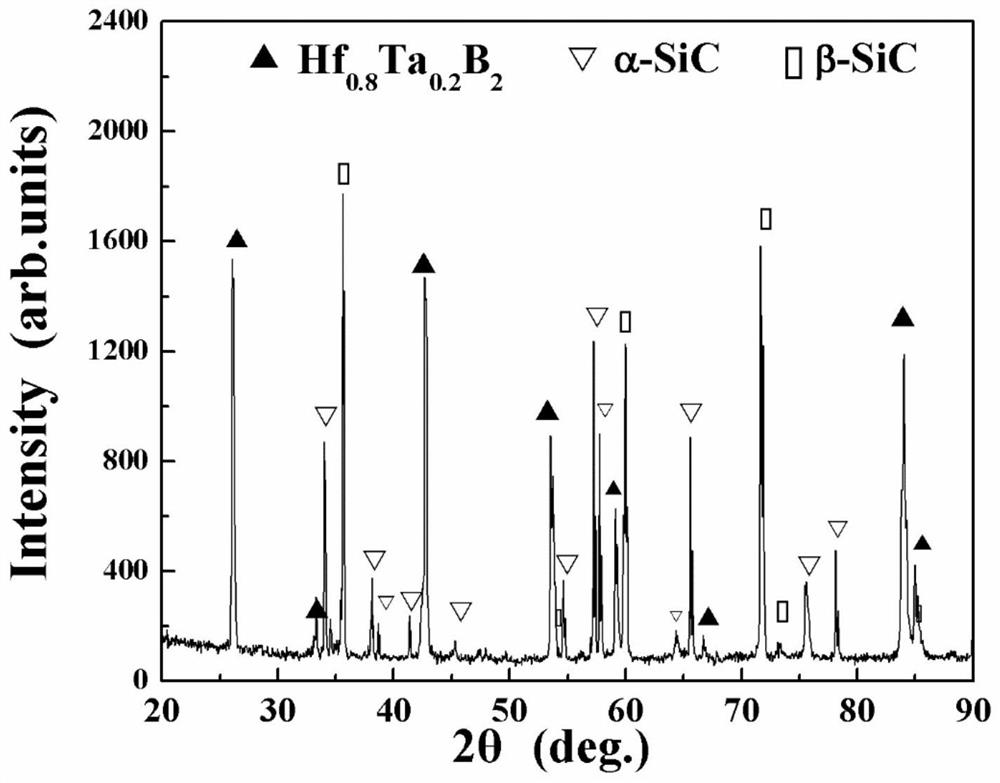

Preparation method of carbon material surface boride solid solution modified silicon-based coating

The invention discloses a preparation method of a carbon material surface boride solid solution modified silicon-based coating, and belongs to a preparation method of a carbon material surface anti-oxidation coating. The preparation method comprises the following steps: preparing content-controllable boride solid solution NB2 modified silicon-based composite ceramic slurry, wherein N is equal to ZrxTa1-x, HfxTa1-x or ZrxHf1-x, and x is equal to 0-1; applying a preset layer of the NB2 slurry, by brushing, dip coating or spraying, to the surface of a carbon material matrix with a SiC internal coating; performing heat treatment and sintering to synthesizing the coating. According to the preparation method disclosed by the invention, the solid solubility of the solid solution phase in the coating is controlled by taking boride solid solution powder as a raw material; the component content of the coating can be controlled by controlling and designing the slurry-powder ratio of composite ceramic; control on the coating thickness can be realized through control on the times of the brushing, dip coating or spraying. Through late heat treatment on the preset layer, the density of the coating and the bonding strength of the internal coating interface can be enhanced. The preparation method disclosed by the invention has the advantages of simple preparation technology, dense and uniform coating and relatively low production cost, and is suitable for carbon material components different in shape and size.

Owner:CHINA UNIV OF MINING & TECH

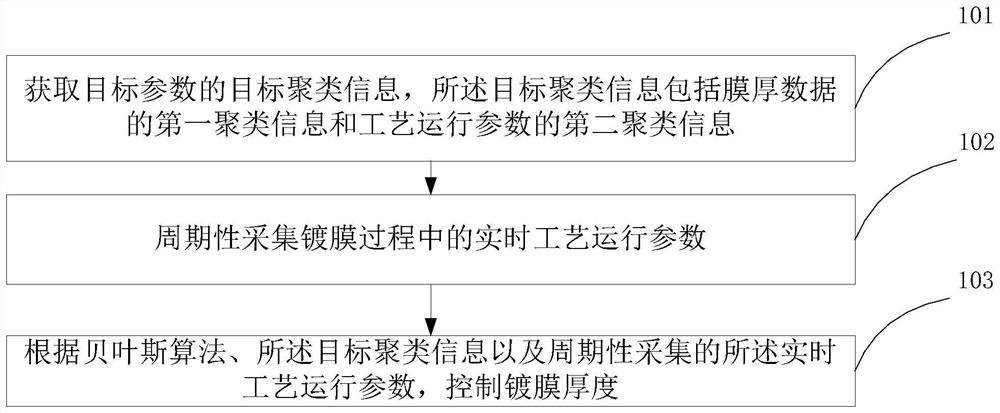

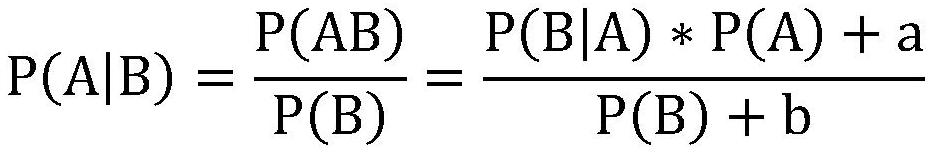

Coating thickness control method and device and storage medium

PendingCN114662056ASolve the problem of insufficient coating qualityControl coating thicknessCharacter and pattern recognitionComplex mathematical operationsControl engineeringProcess engineering

The invention discloses a coating thickness control method and device and a storage medium, and relates to the technical field of intelligent control, the method comprises the steps that target clustering information of target parameters is acquired, and the target clustering information comprises first clustering information of film thickness data and second clustering information of process operation parameters; periodically collecting real-time process operation parameters in the coating process; and controlling the coating thickness according to a Bayesian algorithm, the target clustering information and the periodically acquired real-time process operation parameters. The problem that the coating quality obtained through an existing coating control method is insufficient is solved, and the effects that the real-time process operation parameters can be periodically collected, then the coating thickness is controlled in real time, and the coating quality is improved are achieved.

Owner:无锡唯因特数据技术有限公司

Novel photovoltaic welding strip production process

InactiveCN103050566AControl coating thicknessImprove work efficiencyFinal product manufactureSemiconductor devicesCopper-wiringNitrogen gas

The invention discloses a novel photovoltaic welding strip production process and relates to the field of solar photovoltaic power generation systems. A calendering process and a tin coating process are adopted for separate treatment, wherein the oxygen-free copper line calendering process comprises the steps of calendering, quenching, nitrogen treatment, deionized water washing and copper strip winding; and the oxygen-free copper strip tin coating process comprises the following steps of copper strip unwinding, cleaning through a cleaning system, welding aid through a welding aid system, preheating and air-drying, tin coating, coating thickness adjustment, material receiving, and cutting and packaging. The novel photovoltaic welding strip production process has the advantages that the quenching process requirement can be satisfied, the physical properties of copper strips are changed, the copper strips can reach an ultra-soft state and the production efficiency is greatly improved; and by adopting a separate treatment method, the coating thickness in the copper strip tin coating process can be better controlled, the product quality is better controlled during production and the process flexibility is increased.

Owner:JIANGXI YINGNUOWEISI IND

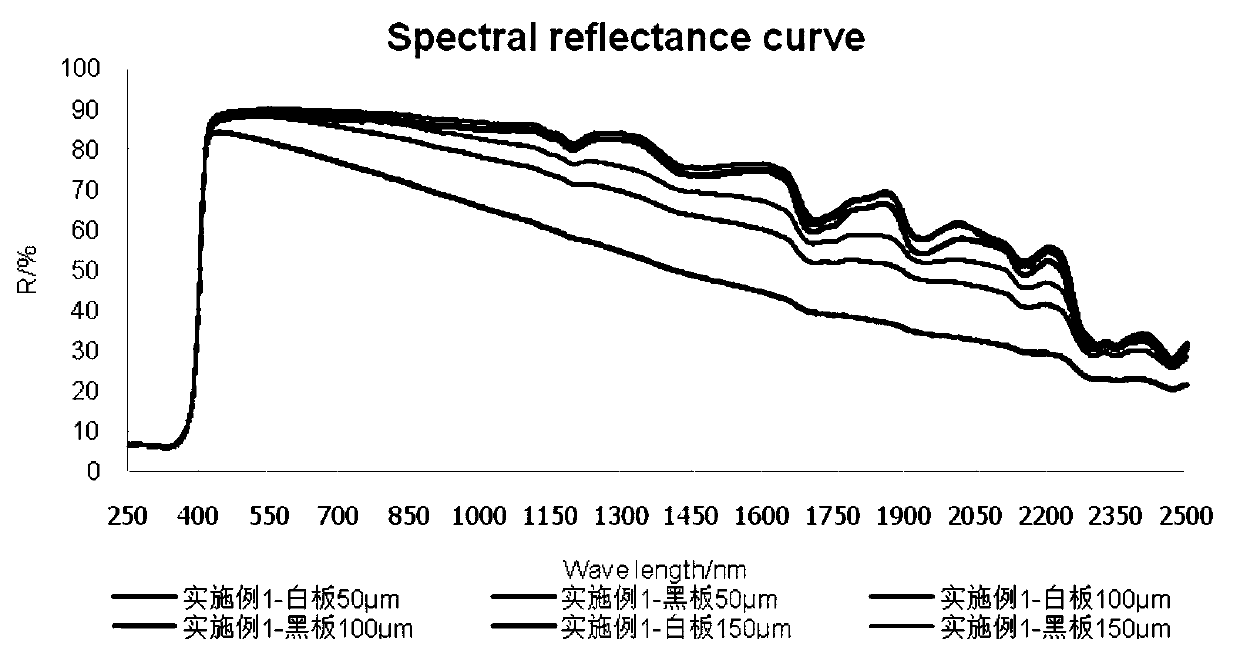

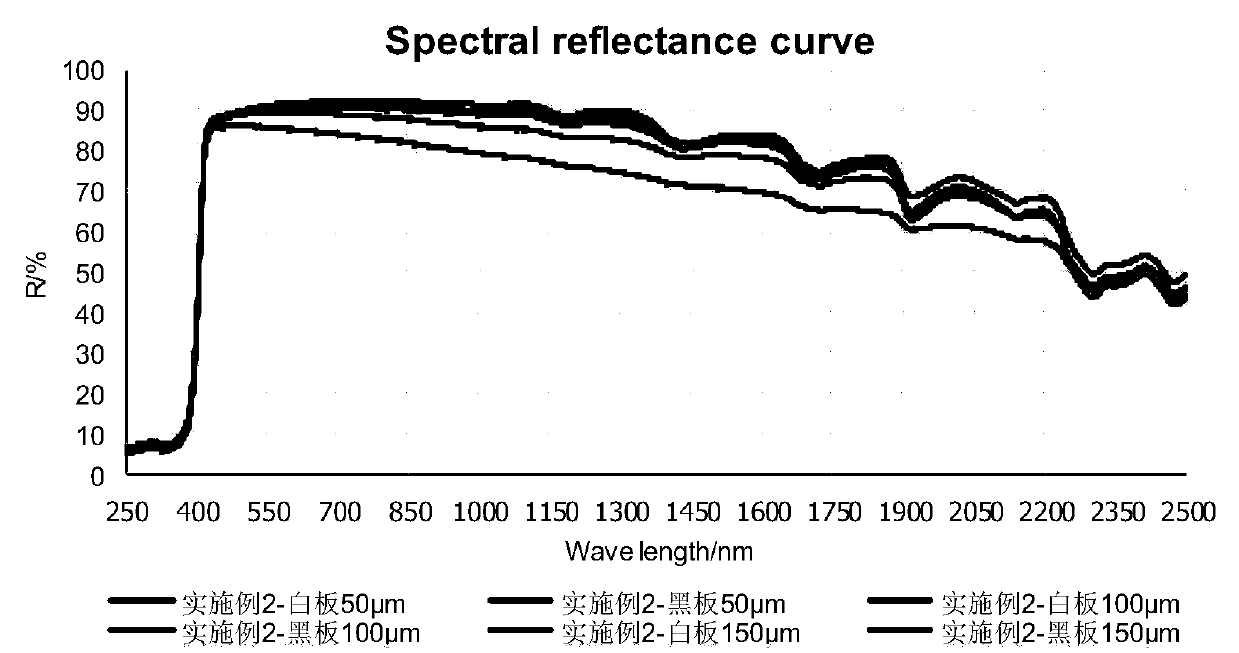

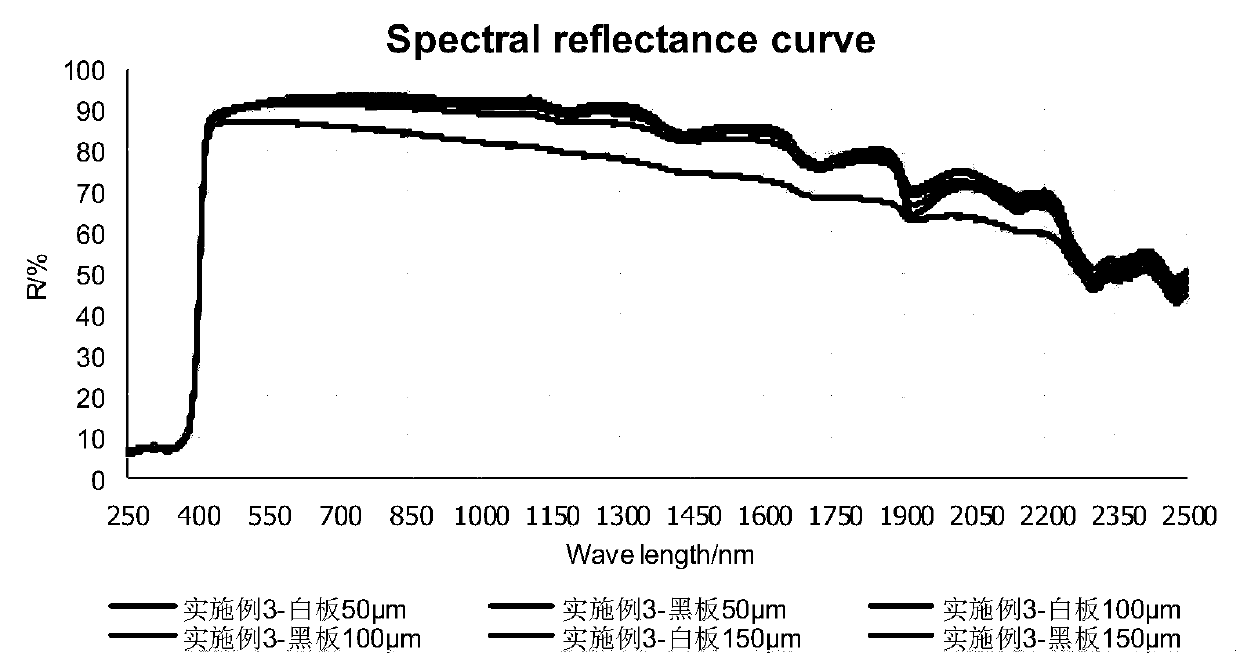

Method for detecting thermal insulation performance of building reflective thermal insulation coating (flat coating)

InactiveCN109655429AReflect the effect of heat insulationThe detection method is simpleMaterial analysis by optical meansCardboardWhiteboard

The invention relates to a method for detecting the thermal insulation performance of a building reflective thermal insulation coating (flat coating). The method is mainly characterized in that an ultraviolet-visible-near infrared spectrophotometer is used for measuring the near-infrared reflectance of the reflective thermal insulation coating on a black and white cardboard; the principle is thatthe coating has a transmission phenomenon in the near-infrared, which results in a difference in the near-infrared reflectance of the coating on a whiteboard and blackboard of the cardboard. In this way, the hiding power of the coating can be obtained by using a hiding power calculation formula. The insulation temperature difference of the coating is measured by using the same coating, and it is confirmed that the thermal insulation temperature difference and near-infrared hiding power of the coating are linearly proportional. Guidance can be provided for the actual use of the reflective thermal insulation coatings on the wall. It is avoided that high-reflectance coating obtained during laboratory testing does not achieve the desired thermal insulation effect in practical application.

Owner:镇江泛华检测科技有限公司

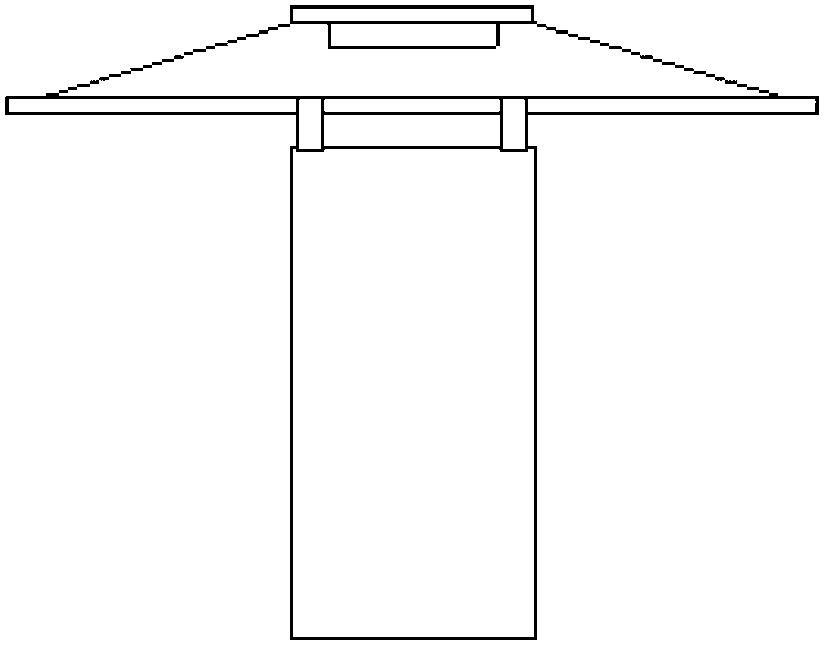

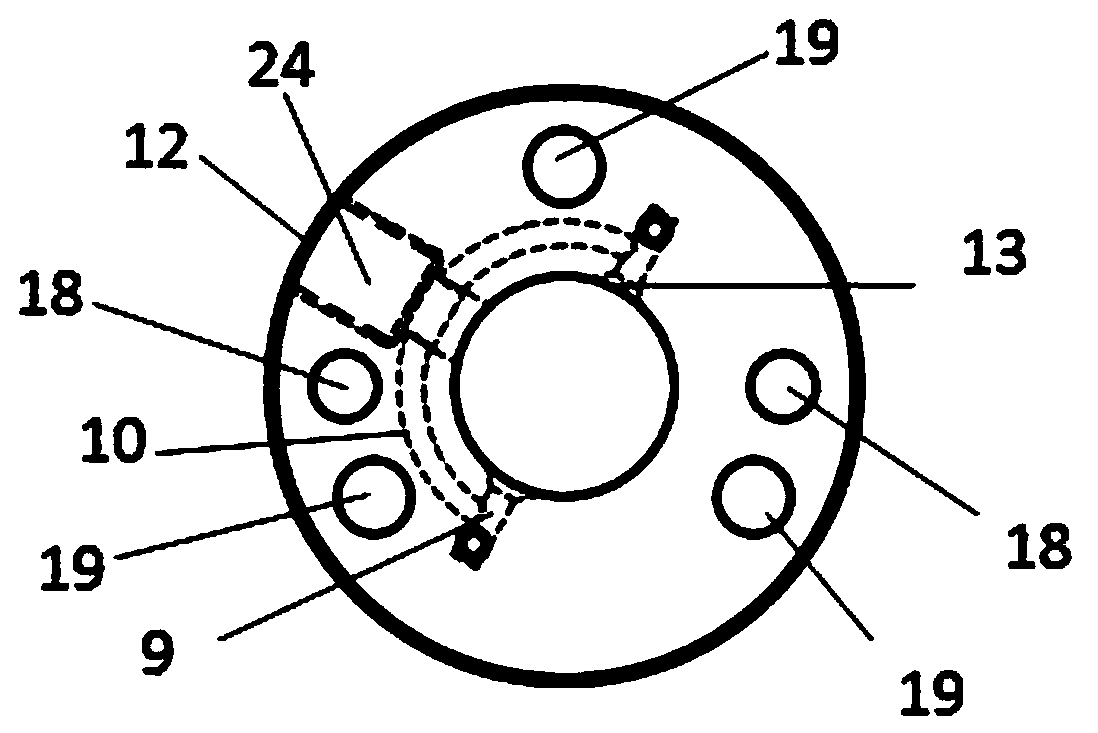

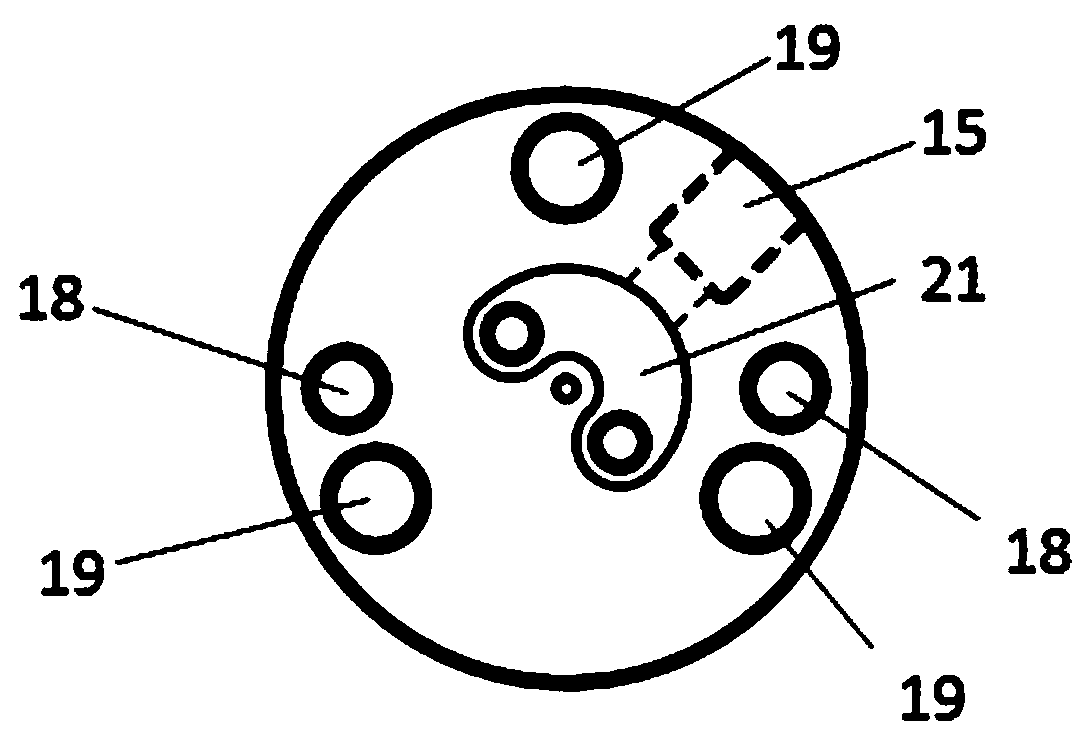

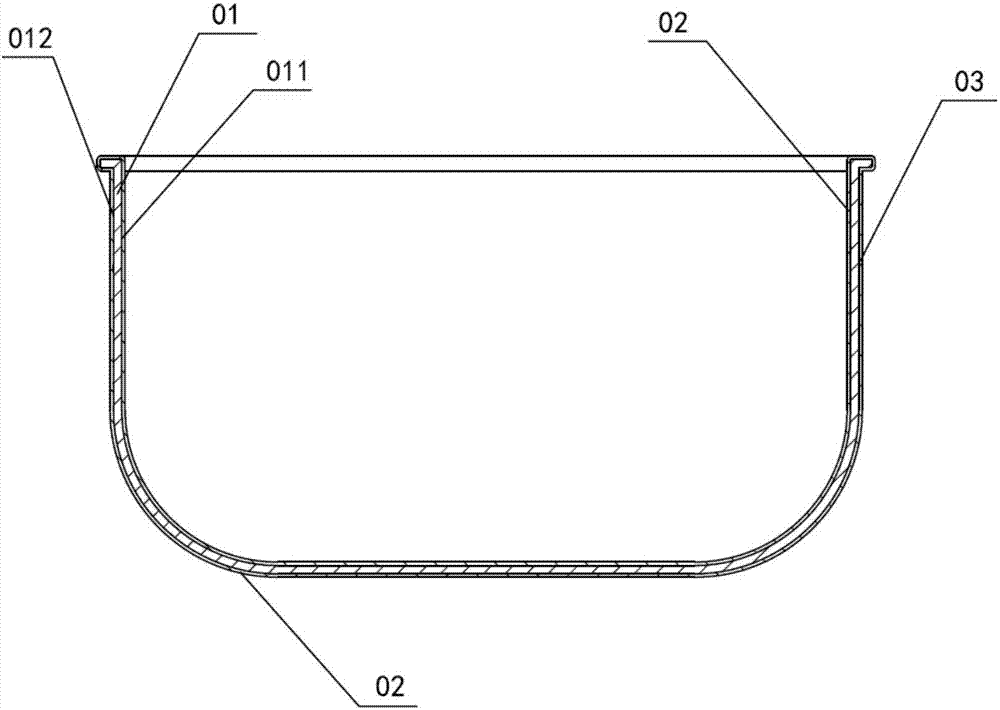

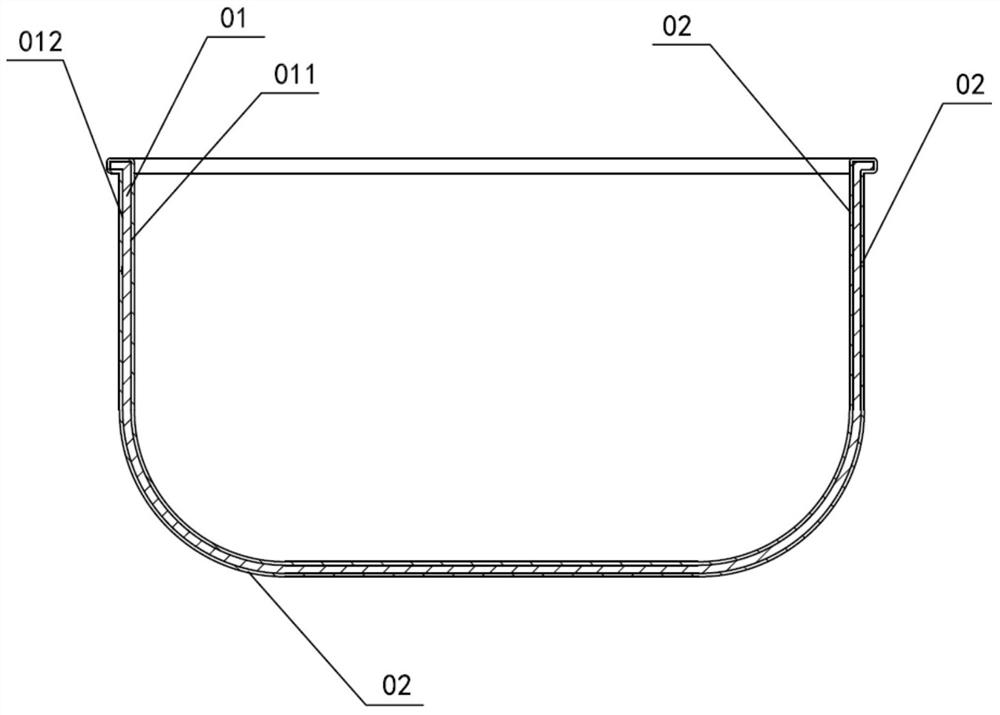

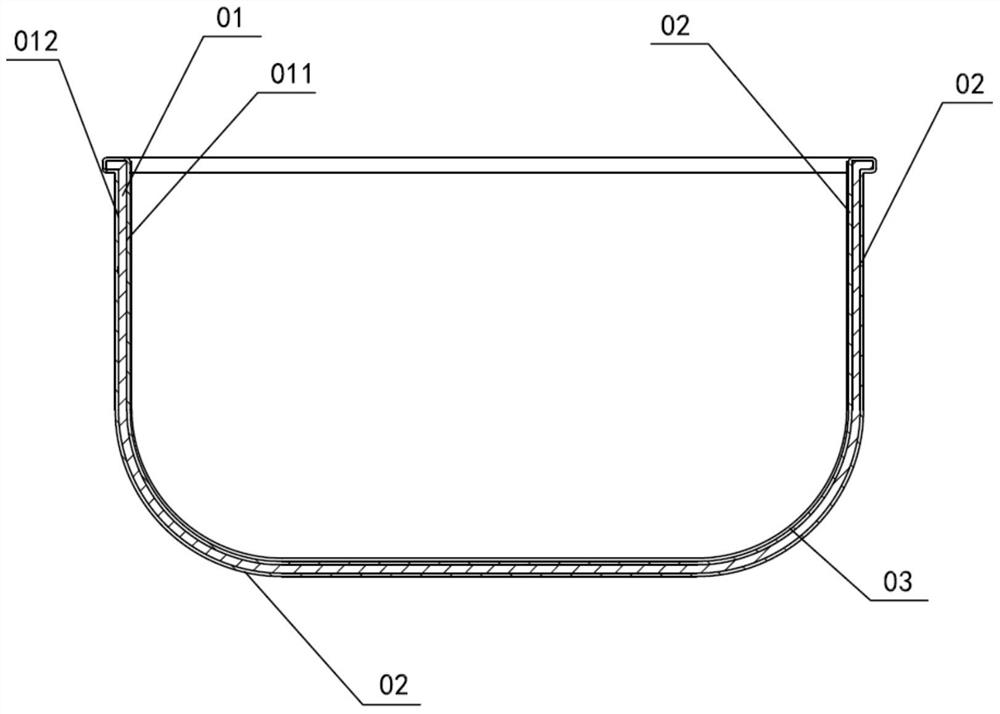

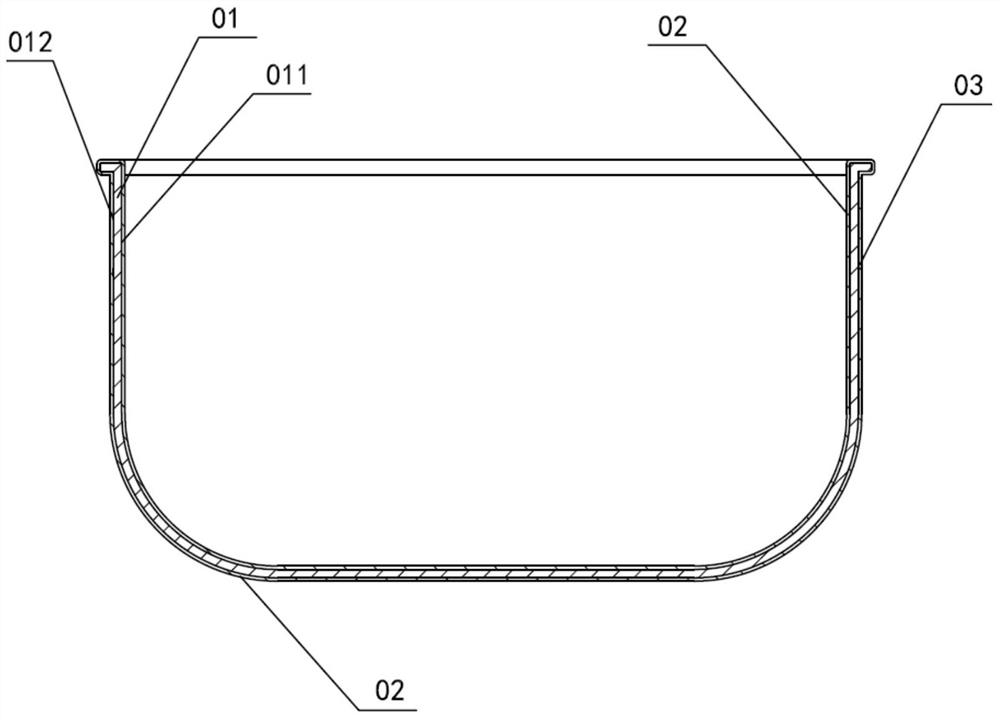

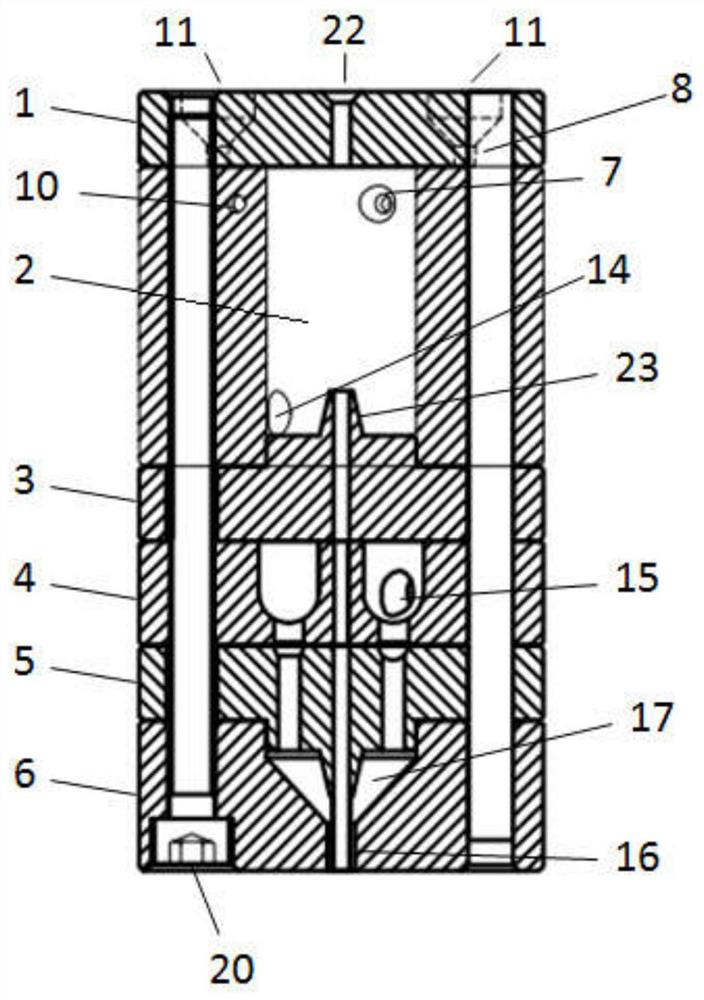

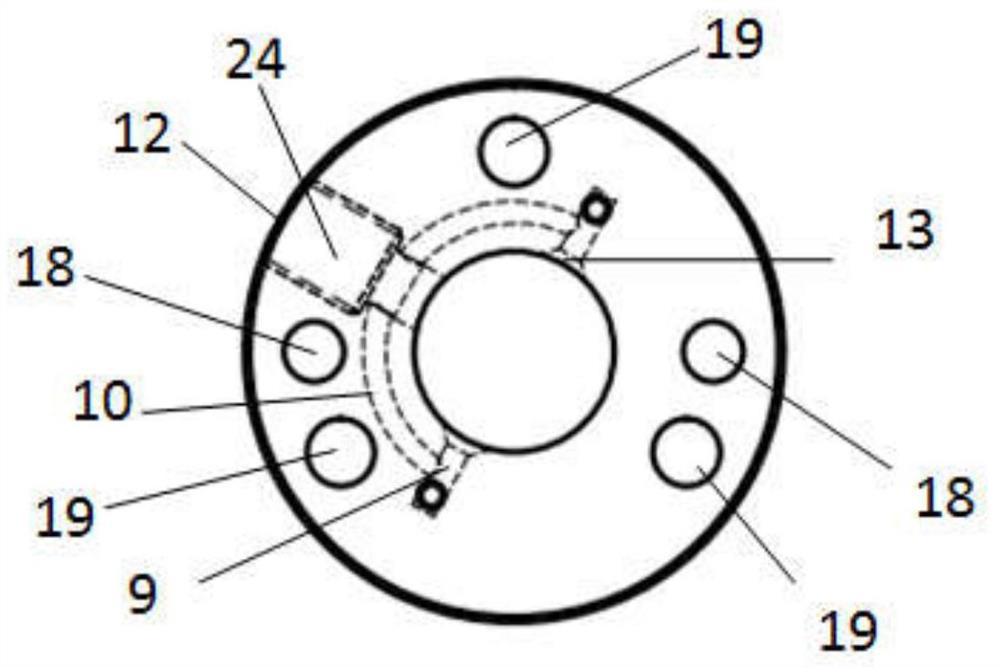

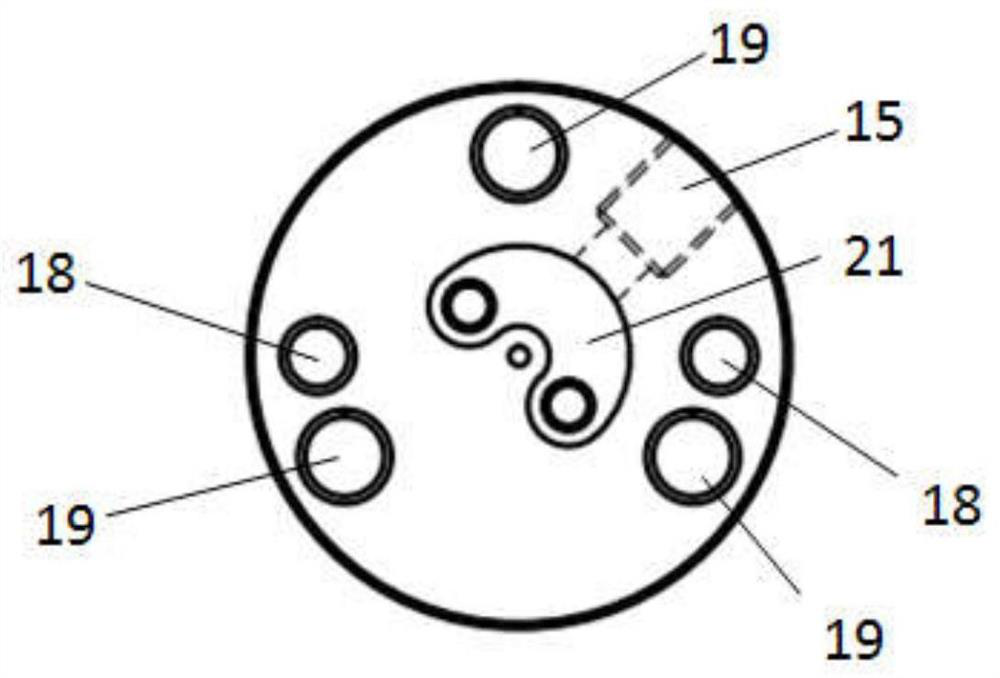

Spinneret for preparing enhanced hollow fiber membrane, membrane preparation method and hollow fiber membrane

ActiveCN111020715AControl coating thicknessAchieving controllability of seepageSpinnerette packsNon-woven fabricsStructural engineeringHollow fiber membrane

The invention discloses a spinneret for preparing an enhanced hollow fiber membrane and a membrane preparation method. The spinneret comprises a primary coating spinneret. A pre-coating device is arranged on the baffle of the primary coating spinneret; the pre-coating device comprises a cover plate and a pre-coating cavity arranged below the cover plate; the bottom of the cavity wall of the pre-coating cavity is arranged on the baffle; an air inlet hole is arranged in the cover plate; an atomizing hole is arranged in the surface in contact with the cover plate of the pre-coating cavity; the atomizing hole is communicated with the air inlet hole; a liquid inlet hole is arranged in the cavity wall of the pre-coating cavity; a gas-liquid discharge hole is arranged in the lower part of the pre-coating cavity; a liquefied droplet leakage-proof table is arranged at the bottom of the pre-coating cavity on the baffle, a positioning hole and a fixing hole are arranged in the cover plate and thewall of the pre-coating cavity in the thickness direction respectively, a rope penetrating hole is arranged in the middle of the cover plate and in the top of the leakage-proof table respectively, and the positioning hole, the fixing hole and the rope penetrating hole correspond to the positioning hole, the fixing hole and the rope penetrating hole respectively of the primary coating spinneret. The enhanced hollow fiber membrane with super-strong falling resistance and high bursting strength can be prepared.

Owner:JIANGSU KAIMI MEMBRANE TECH

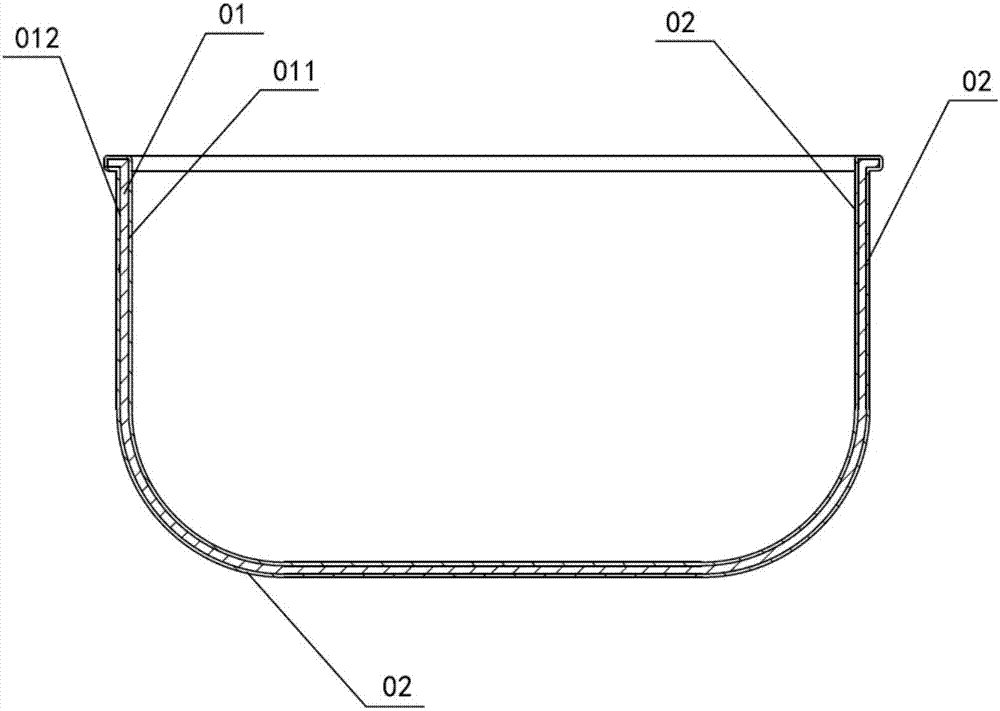

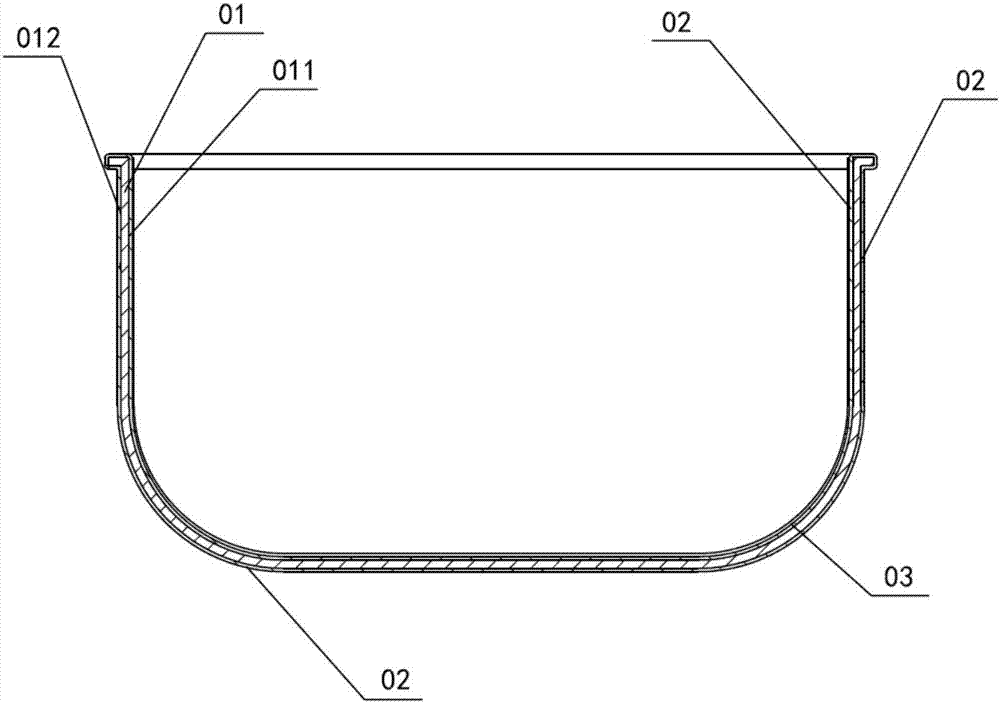

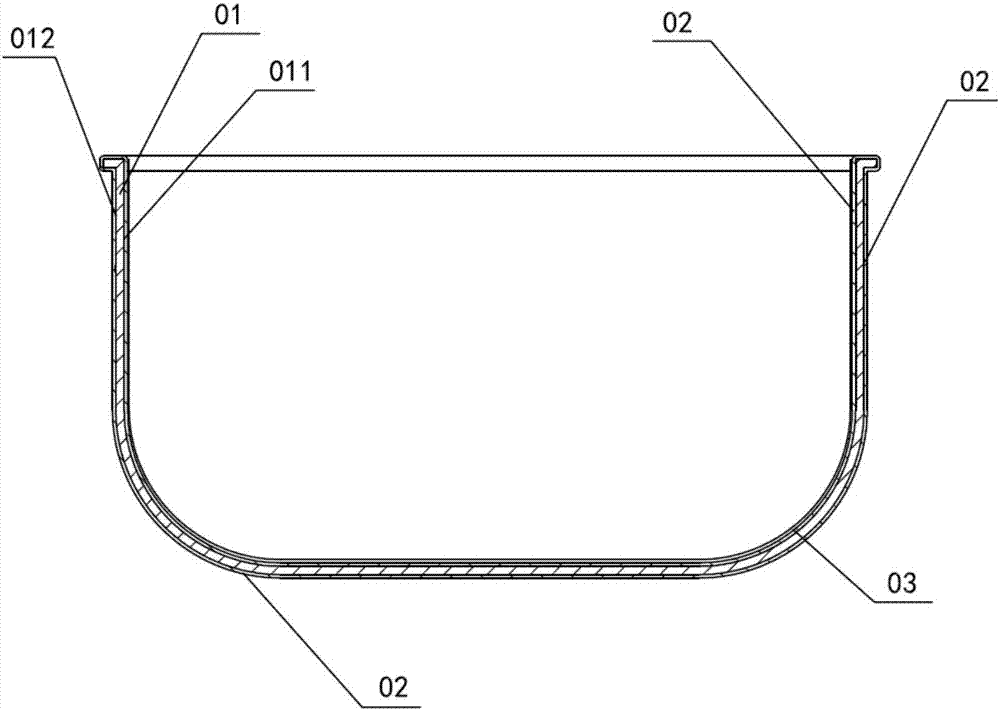

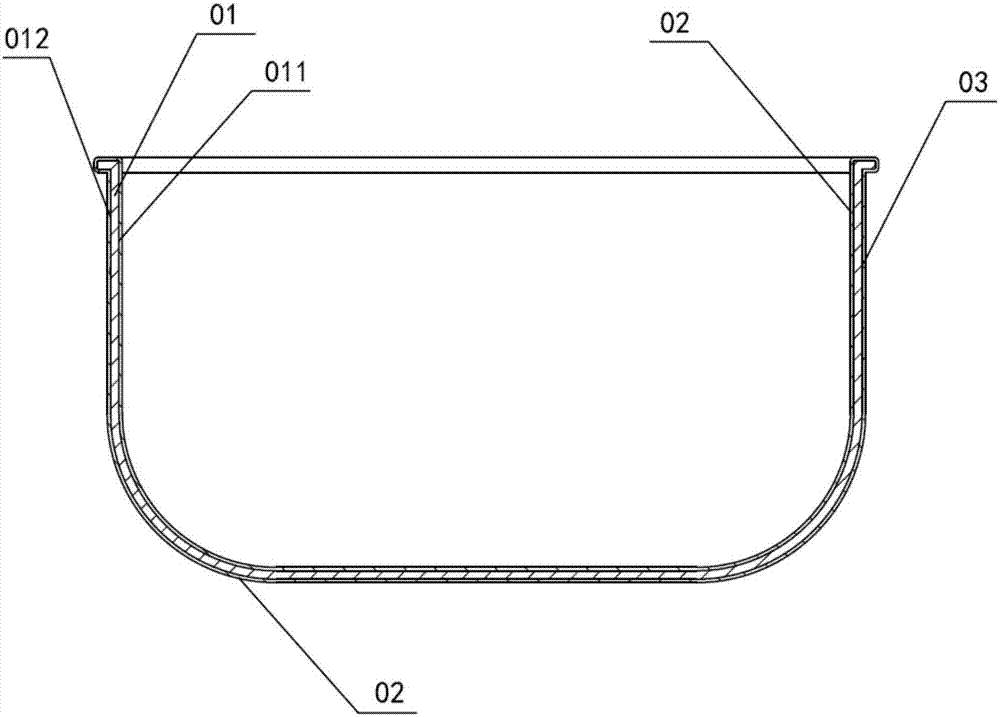

Graphite pot and making method thereof

InactiveCN107296509AGuaranteed wear resistanceExtended service lifeCooking-vessel materialsVacuum evaporation coatingCarbideGraphite

The invention provides a graphite pot which comprises a pot body made from graphite. The pot body is provided with an inner wall and an outer wall, and a covalent carbide film is attached to at least the inner wall. Due to the fact that the covalent carbide film is attached to the surface of the pot body, the hardness of the covalent carbide film is far higher than that of an existing PTFE resin film, after the graphite pot is used tens of thousands of times, the wear out phenomenon can occur on the film, the abrasion performance of the graphite pot is ensured, and the service life of the graphite pot is prolonged; the covalent carbide film has the good air permeable performance, and it is ensured that the advantages of being good in thermal conductivity, rapid in thermal transmission and uniform in heating of the graphite pot body are well embodied.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

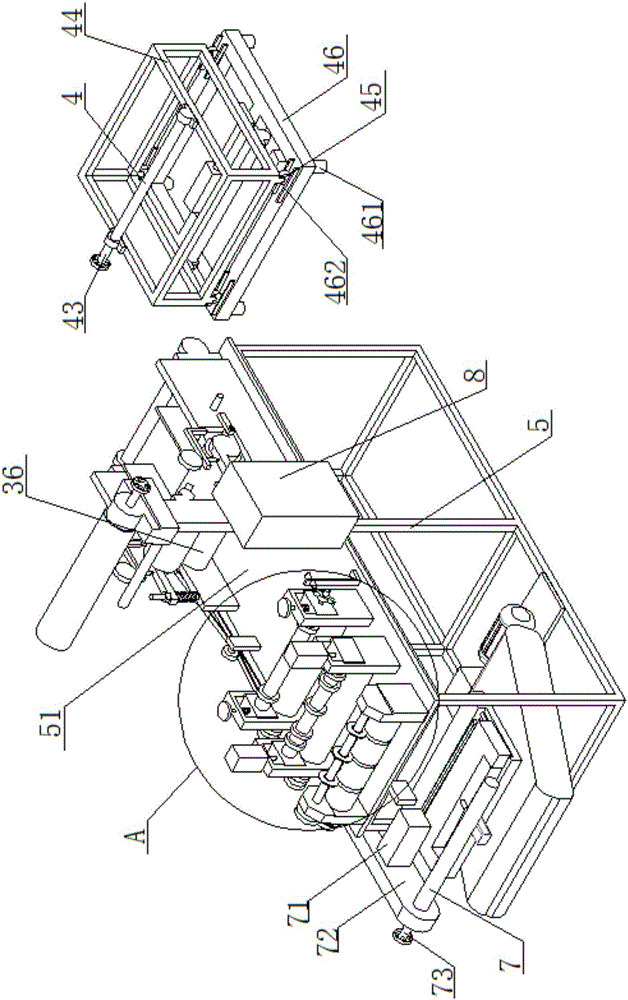

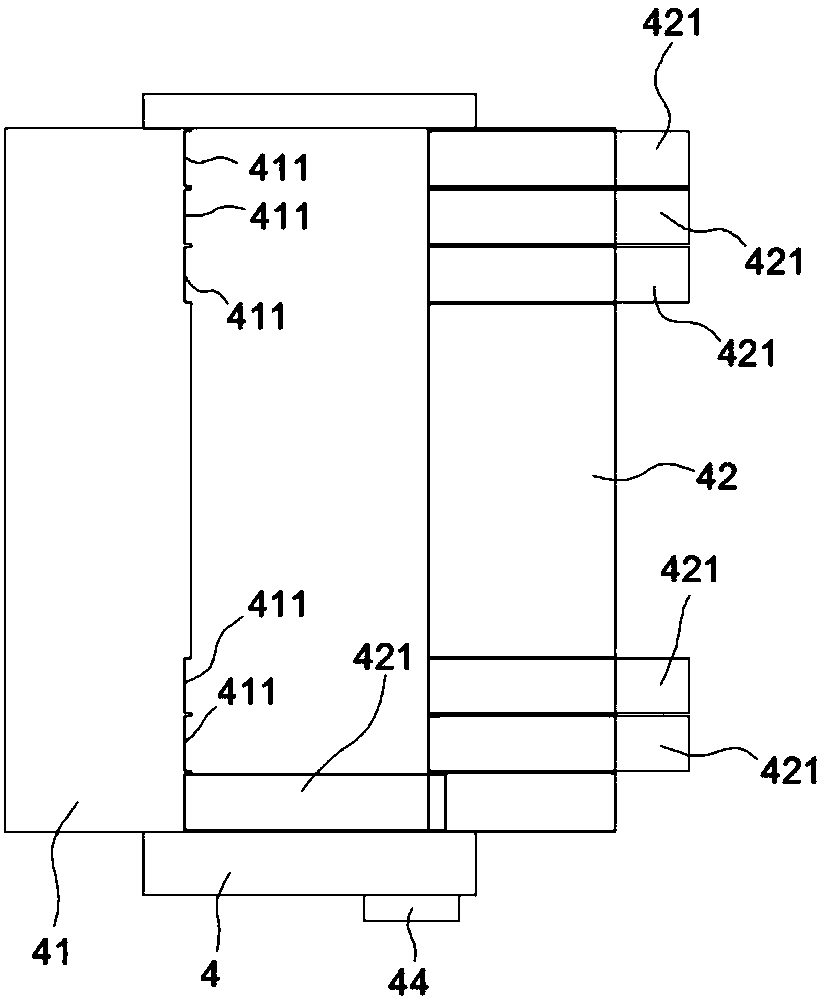

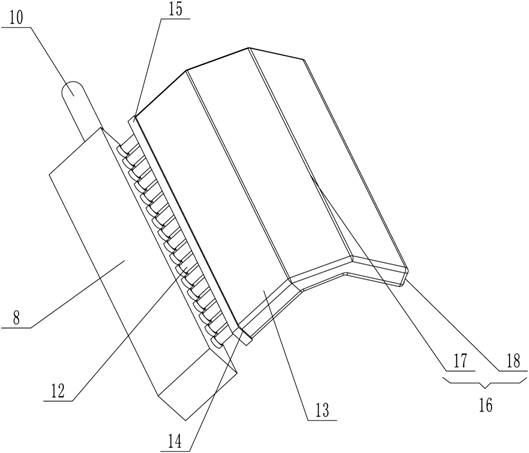

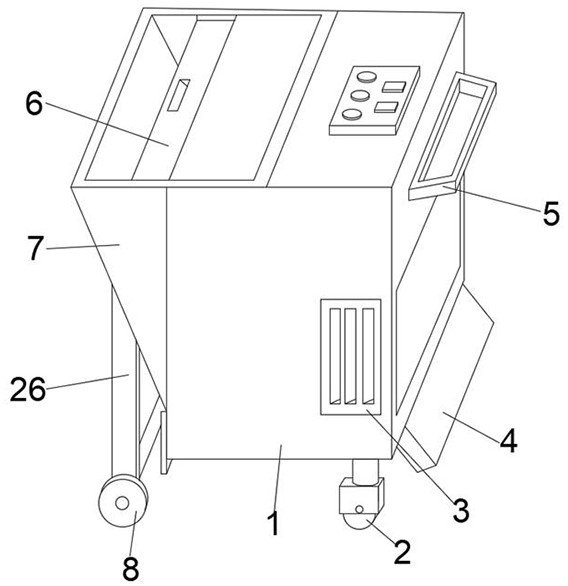

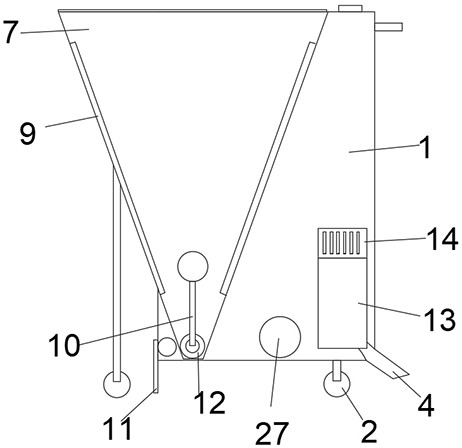

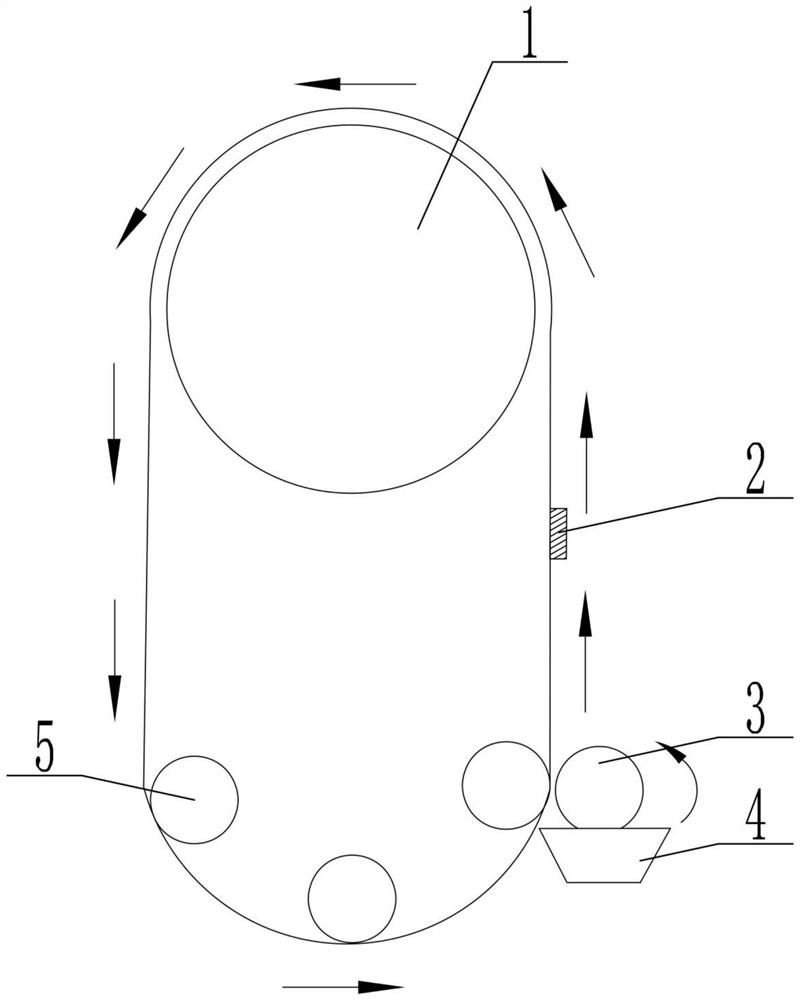

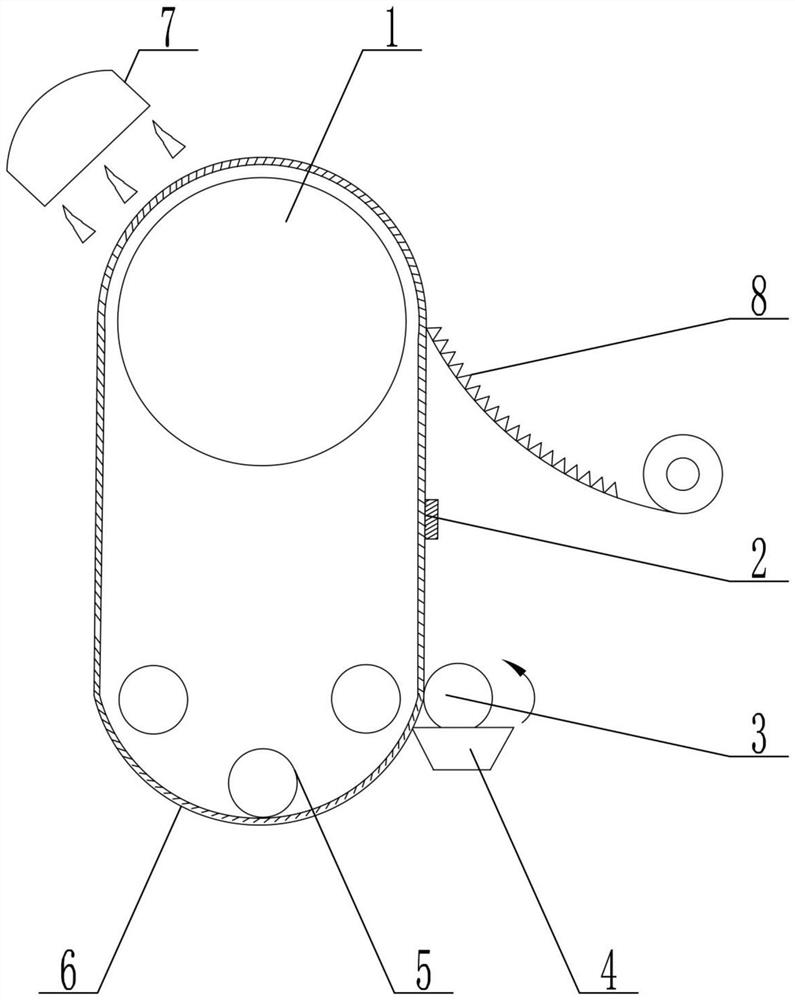

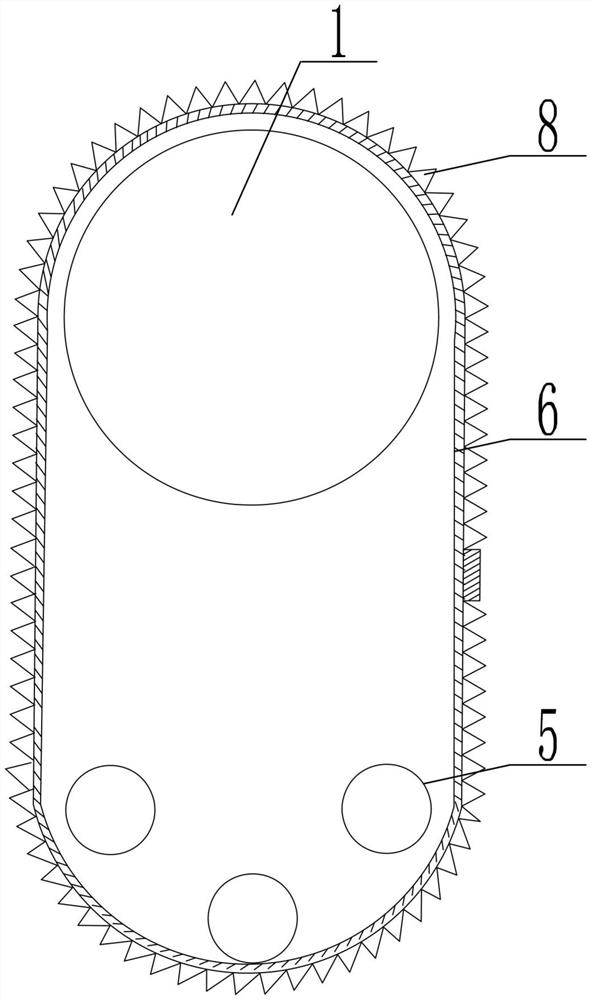

Novel cataplasm coating forming device

InactiveCN108405260AGood application effectControl cream contentLiquid surface applicatorsCoatingsWater bathsDouble compression

The invention discloses a novel cataplasm coating forming device. The novel cataplasm coating forming device mainly comprises a device main body, a constant-temperature discharging hopper, a constant-temperature speed control wheel, a discharging control opening, a cloth releasing device, a double-compression-roller feeding device, a longitudinal cutting device, a transverse cutting device, a control panel and a conveying device; the cloth releasing device, the constant-temperature discharging hopper, the double-compression-roller feeding device and the longitudinal cutting device are sequentially arranged on the upper top surface of the device main body from left to right, the transverse cutting device is fixed at the upper end of the right side surface of the device main body through a lower supporting plate, and a water bath interlayer is arranged on the periphery of the outer side of the constant-temperature discharging hopper; and the constant-temperature speed control wheel is arranged below the inner part of the constant-temperature discharging hopper, and the discharging control opening is formed in the bottom end of the constant-temperature discharging hopper. According tothe novel cataplasm coating forming device, structure is simple, and design is reasonable; the parameters of the paste content, the coating width, and the coating thickness are realized; and more uniform and smooth of the coating are guaranteed.

Owner:王传文

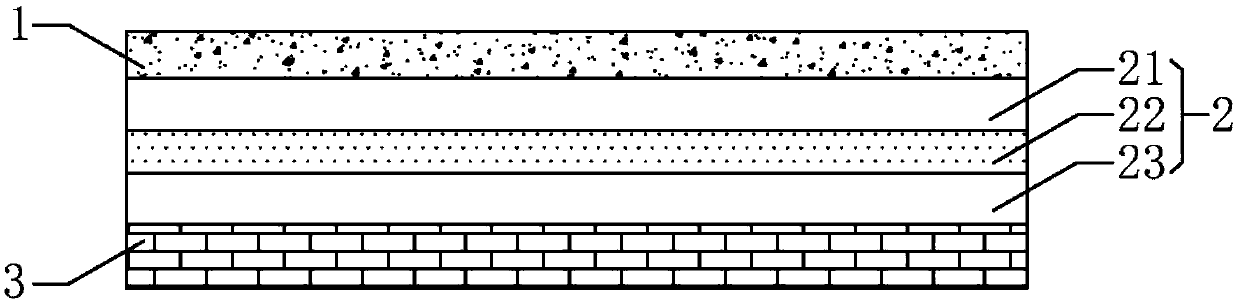

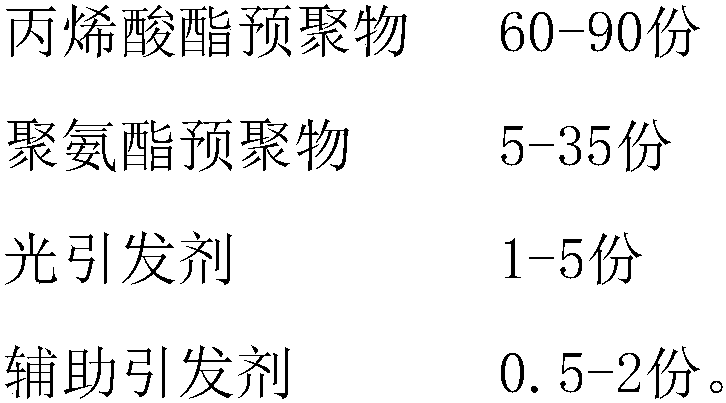

OCA optical adhesive and preparation method thereof

ActiveCN107652908AHigh tensile strengthIncrease internal stressNon-macromolecular adhesive additivesMacromolecular adhesive additivesSurface layerAdhesive

The invention relates to the technical field of optical adhesives, in particular to an OCA optical adhesive and a preparation method thereof. The OCA optical adhesive comprises a light release film, an OCA optical adhesive layer and a heavy release film sequentially fitted from top to bottom, the OCA optical adhesive layer comprises a surface layer, a middle layer and an inside layer sequentiallyfitted from top to bottom, the upper surface of the surface layer is fitted to the lower surface of the light release layer, and the lower surface of the inside layer is fitted to the upper surface ofthe heavy release layer. The OCA optical adhesive has excellent tensile strength, curing contraction rate, resistance to cold-heat impact and scraping resistance and is excellent in light transmission and high in stability; the preparation method is simple, convenient to operate and control, stable in quality, high in production efficiency, low in production cost and suitable for large-scale industrial production.

Owner:NALI OPTICAL MATERIAL DONGGUAN

Gluing device for valve bag production

PendingCN114602728APrevent slippingImprove adhesionLiquid surface applicatorsSpraying apparatusAdhesive glueIndustrial engineering

The invention relates to the technical field of valve bag production equipment, in particular to a gluing device for valve bag production, which comprises a support, one end of the support is provided with a discharging roller, the other end of the support is provided with a traction roller, a gluing assembly is arranged between the discharging roller and the traction roller, the gluing assembly comprises a gluing nozzle, and the outside of the gluing nozzle is connected with a storage box. A booster pump is arranged between the material storage box and the gluing nozzle, a pressing roller is arranged on the side, facing the traction roller, of the gluing nozzle, a cleaning scraper is arranged on one side of the pressing roller, materials are transmitted through the discharging roller and the collecting roller on the support, the gluing nozzle is installed in the middle of the support and located above the materials to be glued, the upper surfaces of the materials are coated with glue, and therefore the glue can be sprayed on the upper surfaces of the materials. According to the glue coating device, the glue on the surface of a material is prevented from slipping off after being coated, and the glue is pressed by the compression roller after being coated, so that the adhesion degree of the glue and the surface of the material is increased while the glue is uniformly distributed on the surface of the material, and the production yield of a product is further improved.

Owner:HENAN BAIJIA NEW ENERGY SAVING MATERIALS CO LTD

Gluing head capable of preventing glue from overflowing and gluing equipment of gluing head

PendingCN113289856APrevent overflowRelieve pressureLiquid surface applicatorsElectrode manufacturing processesAdhesive glueMechanical engineering

The invention relates to the technical field of gluing devices, in particular to a gluing head capable of preventing glue from overflowing and gluing equipment of the gluing head. The gluing head comprises a glue head body, the glue head body is provided with a glue outlet hole and two side flanges, a rear flange protrudes out of the position, located on the rear side of the glue outlet hole, of the glue head body, the two ends of the rear flange are connected with the two side flanges correspondingly to form glue discharging grooves, and glue outlets are located in the glue discharging grooves. The side flanges and the rear flange are arranged near the glue outlets to form the glue discharging grooves, on one hand, glue flowing out of the glue outlets can be discharged in advance, the pressure after the glue flows out is reduced, the side flanges prevent the glue from overflowing towards the two sides so as to prevent edges generated during coating, on the other hand, in the coating process, the glue stored in the glue discharging grooves can also be applied in advance, the rear flange achieves a glue scraping function, the coating thickness of the glue is controlled, the coating uniformity of the glue is maintained, and therefore gluing can be carried out in a groove, and accuracy of the gluing thickness and width is ensured.

Owner:CHANGZHOU GAO KAI PRECISION MACHINERY CO LTD

Waterproof treatment device for fabric

InactiveCN114182460AImprove waterproof performanceAdjustable spacingTextile treatment machine arrangementsLiquid/gas/vapor removal by scrapingEngineeringStructural engineering

The waterproof treatment device for the fabric comprises the fabric, a waterproof sorting box, a gluing mechanism and a baking mechanism, the gluing mechanism is arranged on the right side of the baking mechanism, the waterproof sorting box is arranged on the left side of the gluing mechanism, and a first guide roller is arranged in the waterproof sorting box; the fabric passes through the waterproof finishing box, the gluing mechanism and the baking mechanism through the guide roller I, the guide roller II, the guide roller III, the guide roller IV and the guide roller V; compared with the prior art, the device has the following beneficial effects that the distance between the upper scraping plate and the lower scraping plate can be adjusted, the thickness of a coating on the surface of fabric can be effectively controlled, so that the fabric has more durable waterproof performance, a dustproof net and a heater can be rapidly pulled out for maintenance and overhaul, the fixing effect is good, the sealing performance is good, and the practicability is high. And the working efficiency of the baking mechanism is effectively improved.

Owner:李鹏

Method for coating substrate with coating

ActiveCN101229536BQuality improvementControl coating thicknessMeasurement devicesPretreated surfacesLiquid mediumQuality control

The invention relates to a method for coating a coat onto a substrate for effectively controlling surface of the coat spraying liquid medium on the substrate through a nozzle, effectively controlling formation of thickens of the coat forming through the liquid medium, and maintaining quality control of the coat with high production efficiency, comprising the following operation steps of: firstly installing a distance sensor 6a-6c, for measuring the distance between a medium layer surface LS forming on substrate 1S and 1P and a nozzle 4; putting a measuring substrate 1S on a work bench 2, and undergoing coat measurement for the measuring substrate 1S through the liquid medium sprayed by the nozzle when a nozzle clamp holder 5 moves forwards related to the work bench, performing measurementoperation by the distance sensor when the nozzle clamp holder moves backward related to the work bench, starting a nozzle positioner 3a-3c according to a result of measurement operation performed by the distance sensor, as the device setting nozzle position for forming suitable coat, so as to coat the liquid medium L onto the substrate 1P.

Owner:CHUGAI RO CO LTD

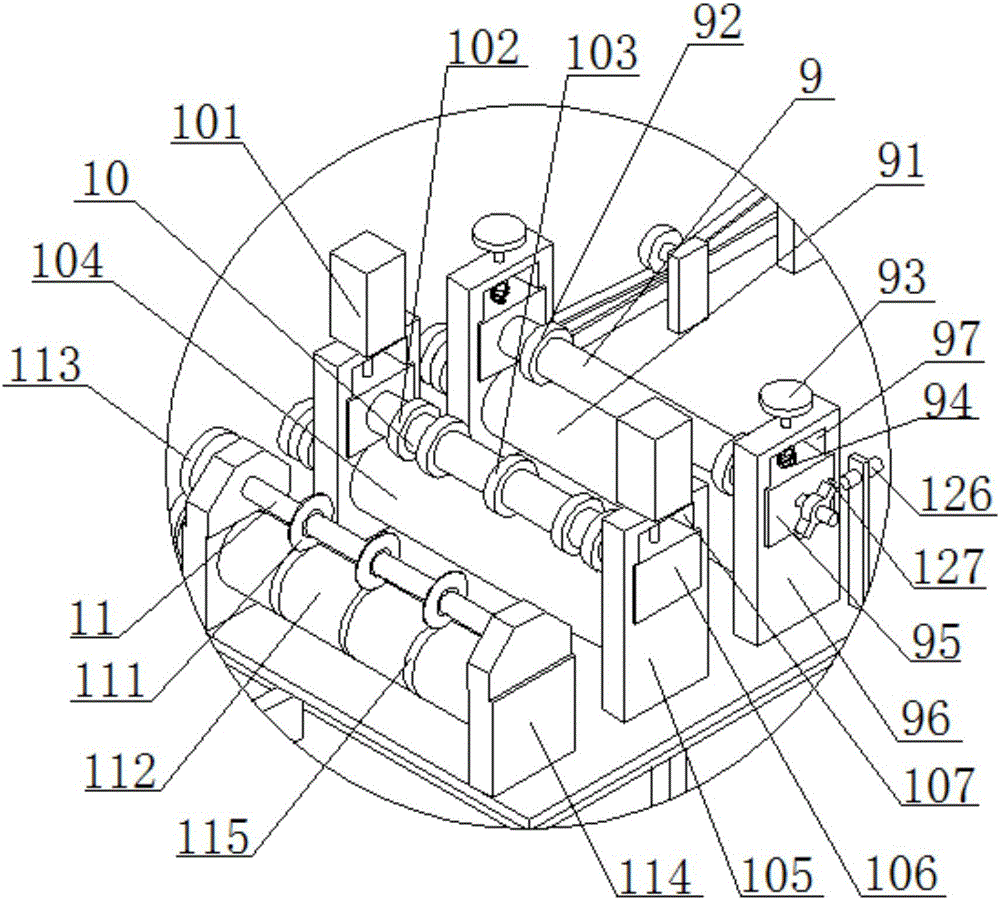

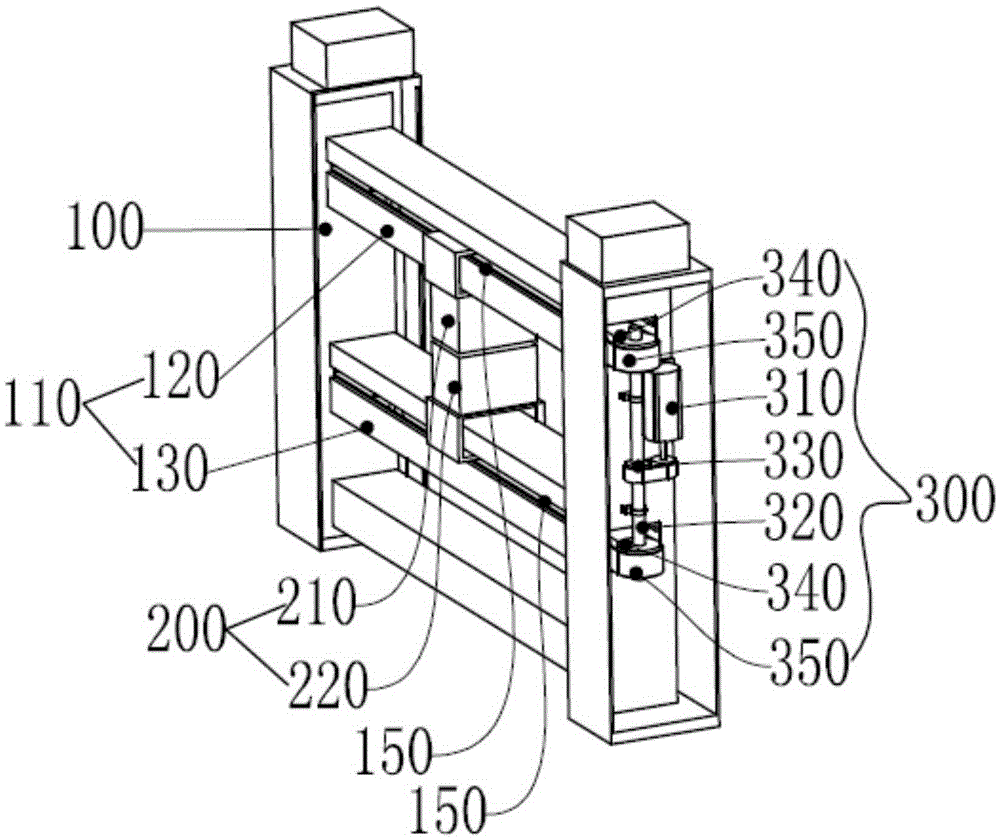

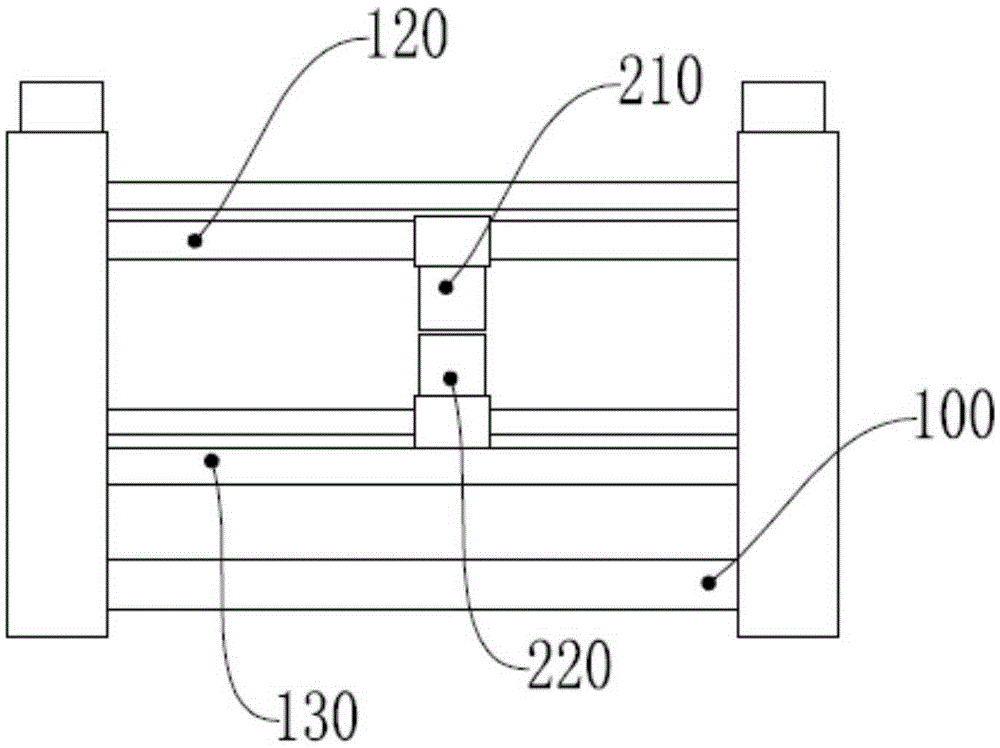

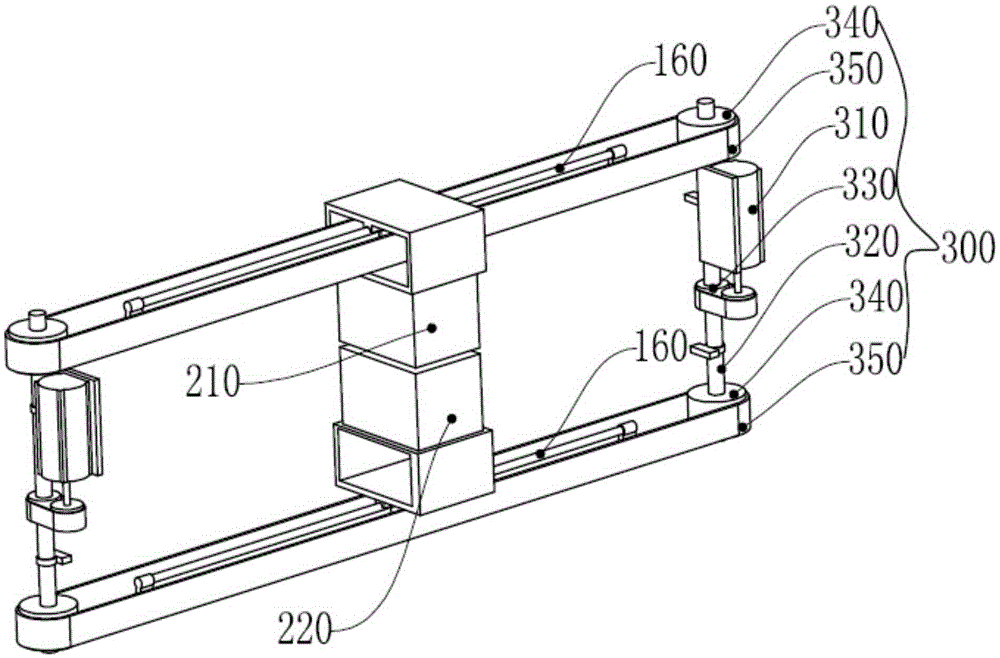

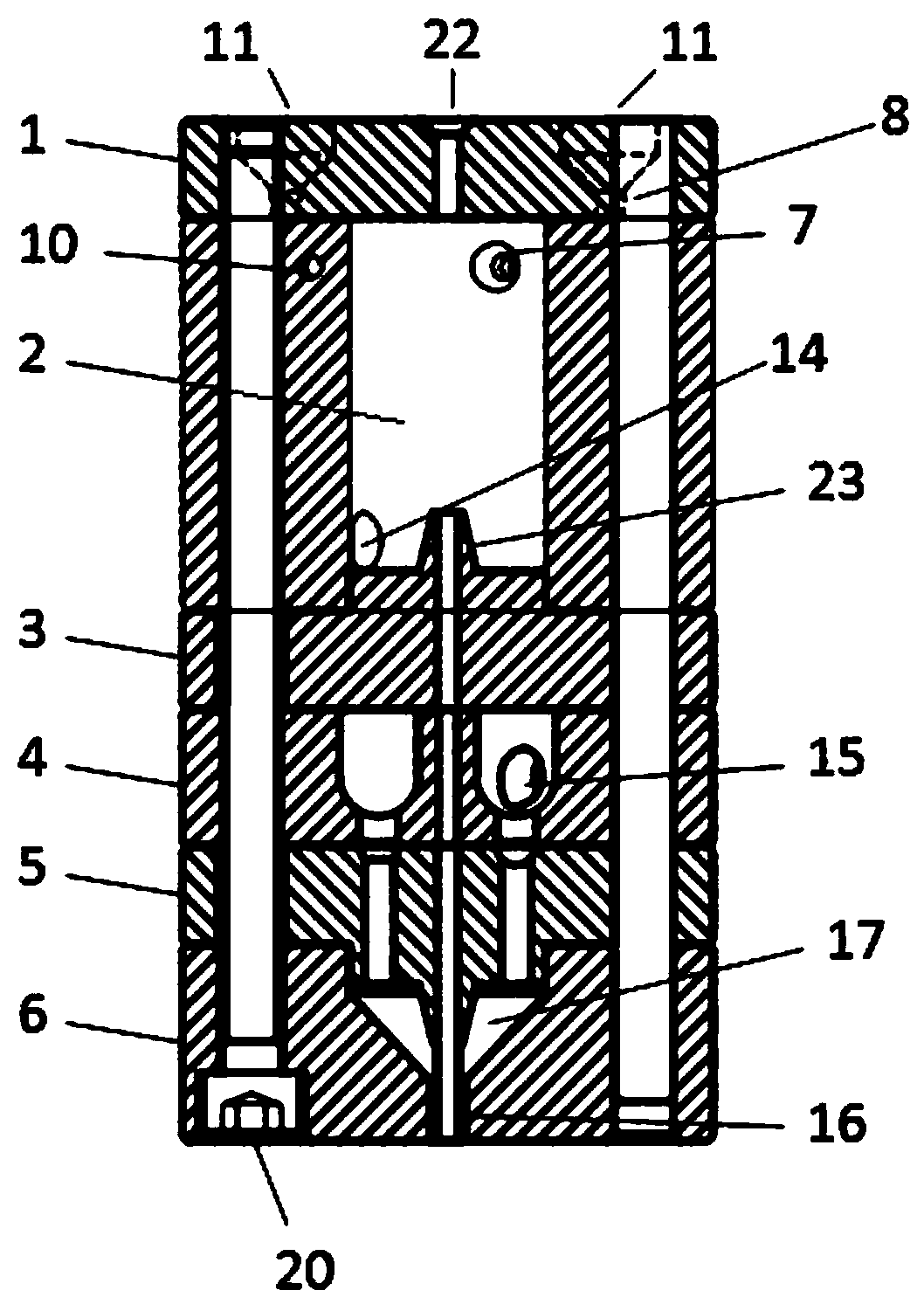

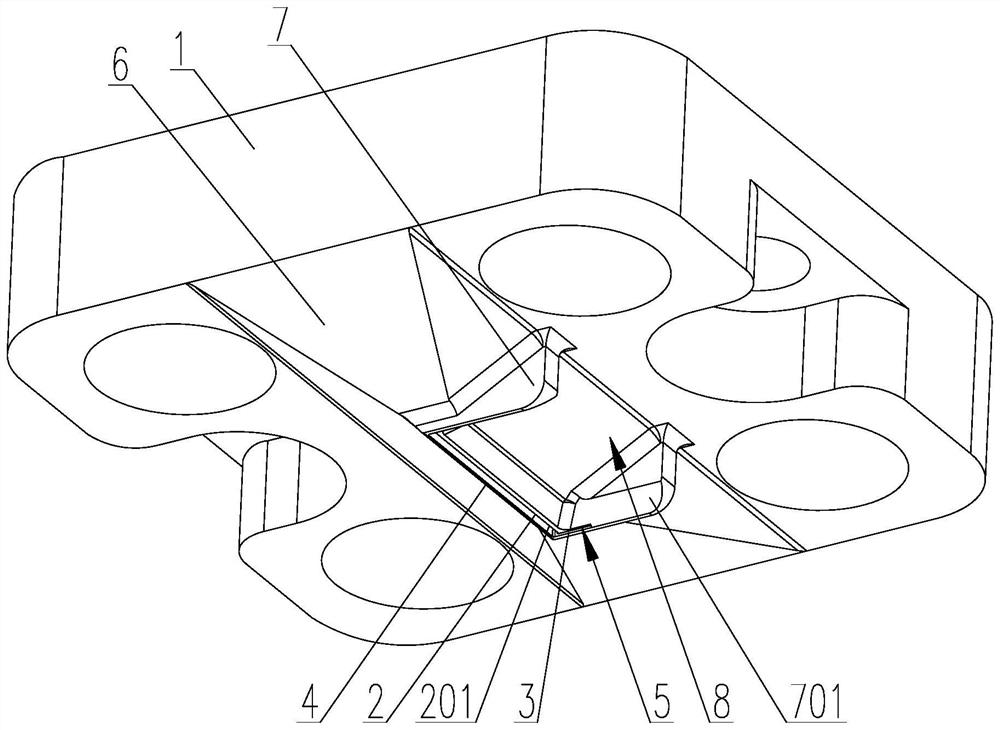

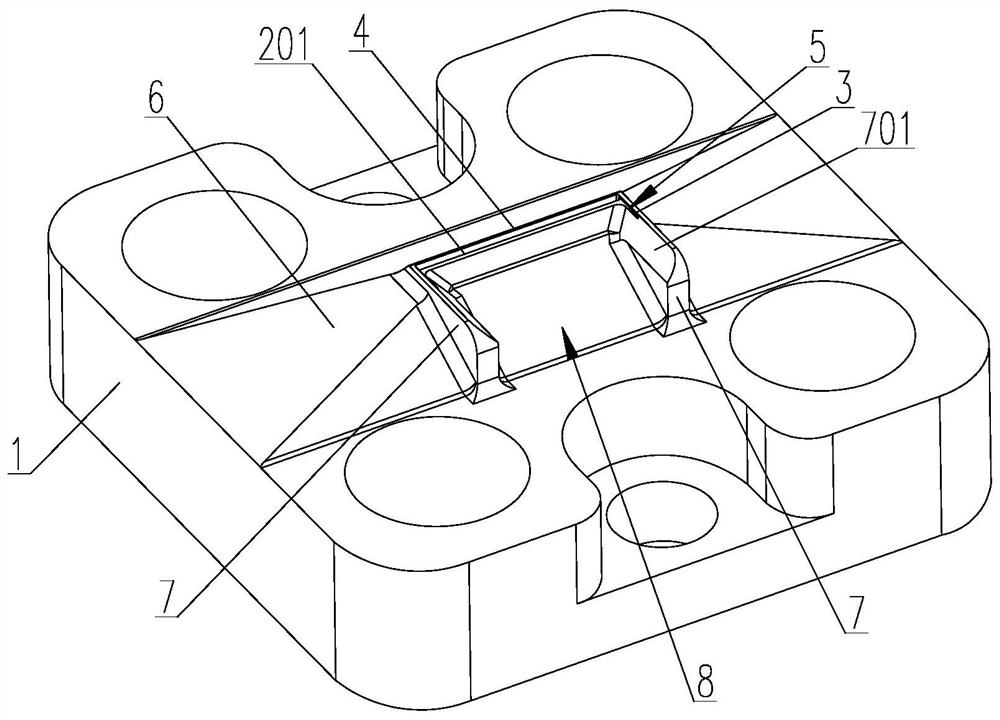

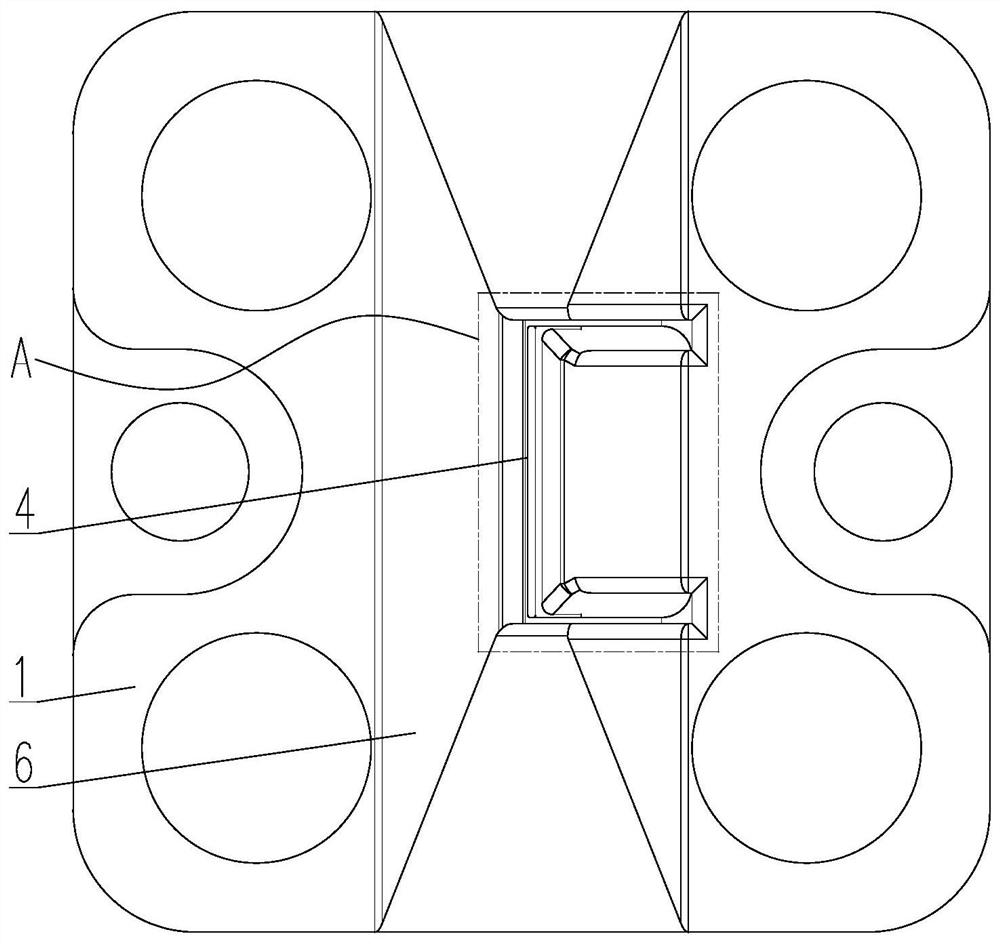

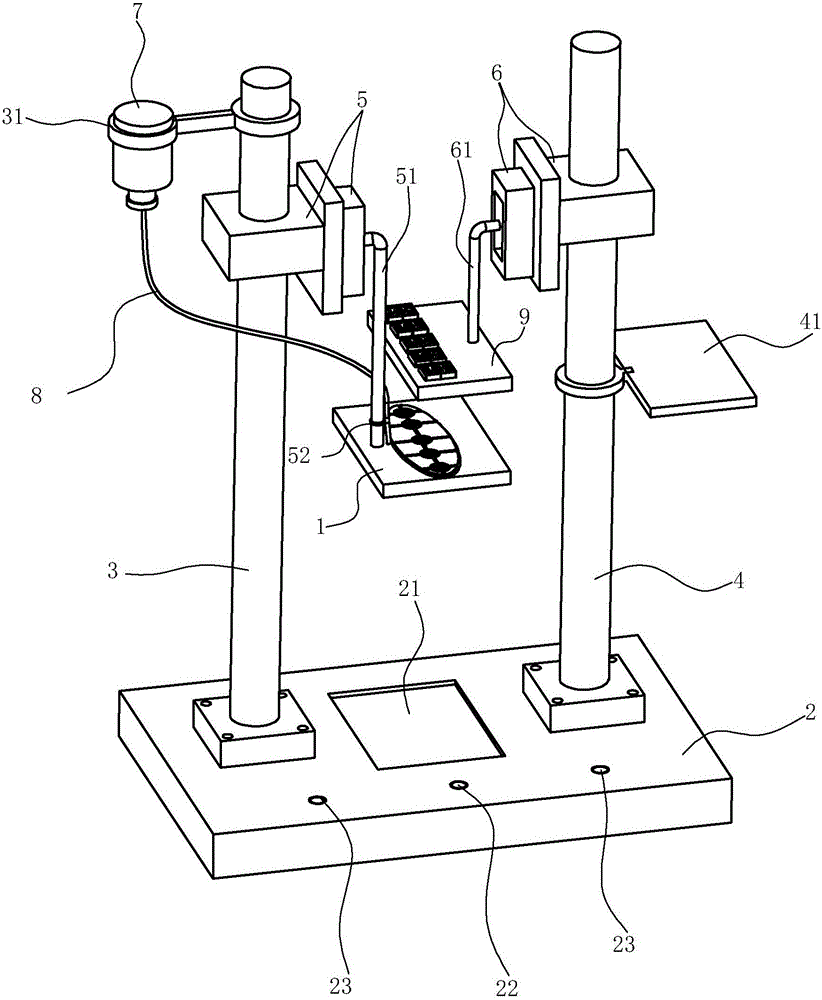

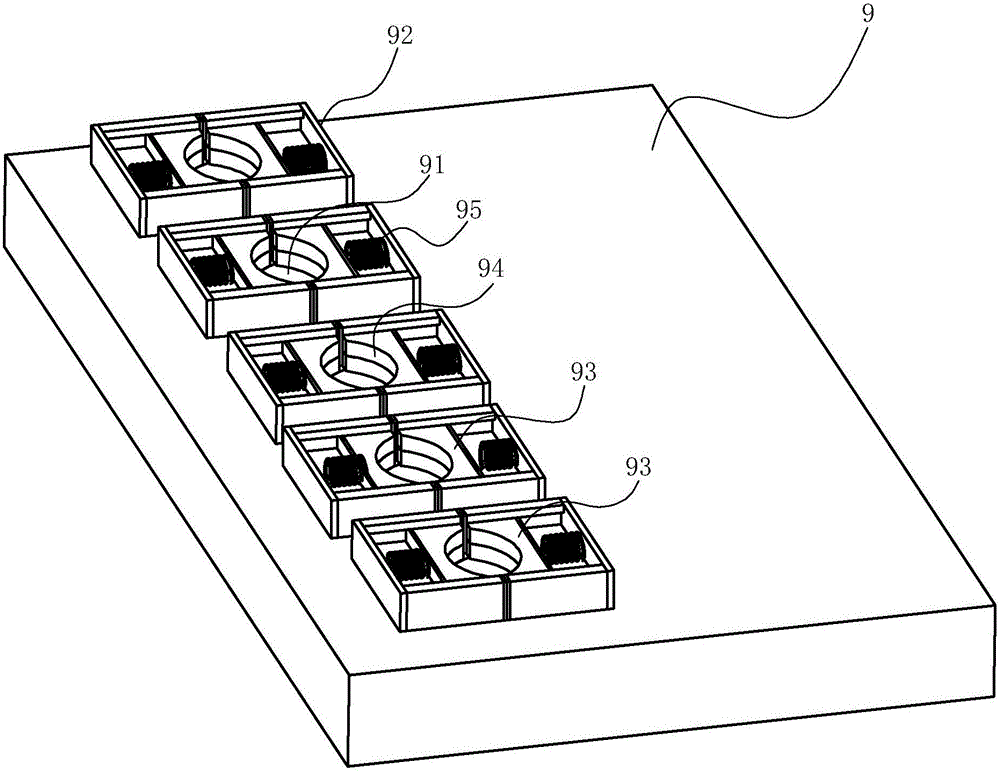

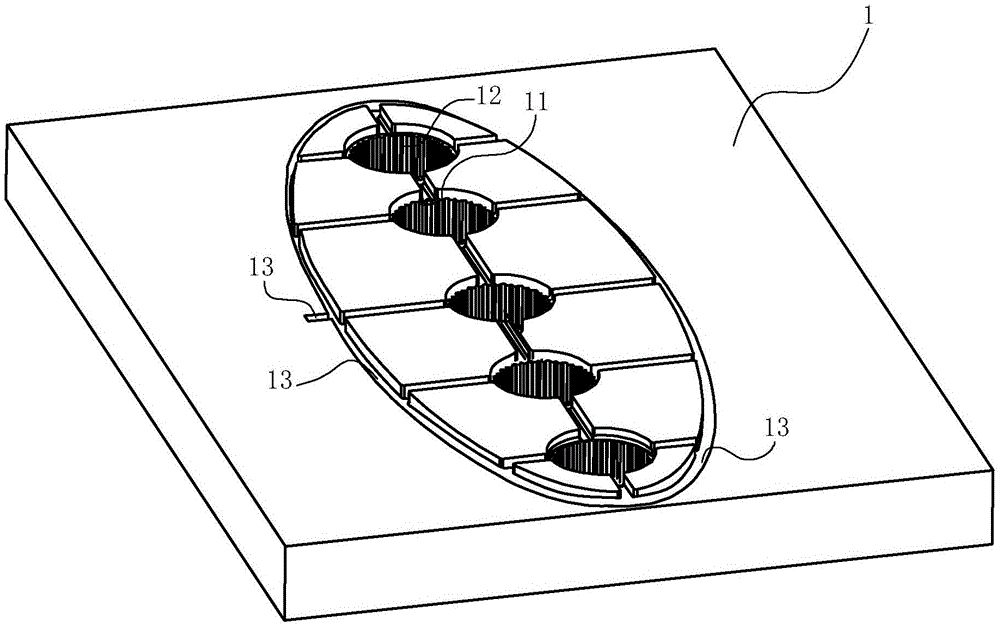

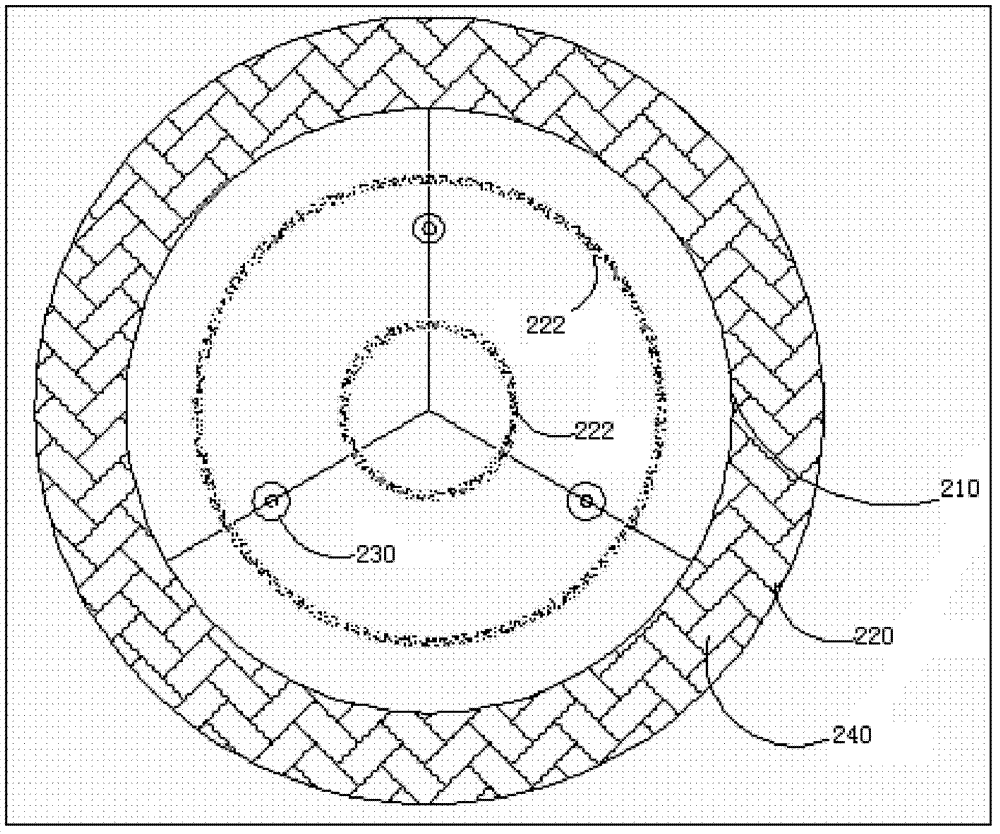

A coating device for the surface of polymer catheter

ActiveCN103817042BUniform coating thicknessControl coating thicknessLiquid surface applicatorsCoatingsLiquid storage tankEngineering

The invention relates to a coating device used for a polymer conduit surface. The coating device is characterized in that: the coating device comprises a first support plate; the first support plate is provided with a plurality of through holes and a groove; the first support plate is connected to a first support pillar through a first driving mechanism; a liquid storage tank containing a coating liquid is disposed right below the first support plate; a second support pillar is disposed in parallel with the first support pillar; a second support plate is disposed at the second support pillar through a second driving mechanism; the second support plate is provided with a plurality of limiting holes used for limiting a conduit to be coated; the second support plate is provided with a clamping and fixing device used for positioning the conduit to be coated; the second support pillar is also provided with a baffle plate used for controlling the length penetrating through the second support plate of the conduit, and the baffle plate is rotatablely connected to the second support pillar. A novel coating method is provided. The thickness of the coating is uniform. The coating has strong adhesive force with the surface of the conduit. Waste of the coating liquid is avoided. The coating process is free of contamination to the inner wall of the conduit, thus guaranteeing production sanitation and safety.

Owner:宁波保税区安杰脉德医疗器械有限公司

Lithium ion battery anode functional coating and preparation method thereof

ActiveCN102757700BReduce the presence of air bubblesEasy to processCell electrodesElectrically-conductive paintsLow speedSlurry

The invention provides a lithium ion battery anode functional coating and a preparation method thereof. A dispersing agent NMP (N-methyl-pyrrolidone) is stirred by a planetary stirrer at a high speed till the temperature reaches 40 to 50 DEG C; a certain proportion of a binding agent PVDF (Polyvinylidene Fluoride) is added to enable the solid content of a binding agent solution to be 1.2 to 3.5 percent; low-speed revolution is performed and then high-speed rotation is started; cold circulating water is received to control the temperature of the slurry below 50 DEG C; stirring is preformed for 2 to 6 h; a carbon black conductive agent (conductive carbon) is added to enable the solid contend of the slurry to be 20 to 30 percent; stirring is performed for 2 to 4 h; the slurry is transferred into a high-efficiency dynaflow ultrasonic slurry mixer to be subjected to ultrasonic dispersion for 1 to 2 h; after the preparation is finished, the slurry passes through a 200-mesh screen stencil and is sprayed through a spraying machine, wherein the spraying thickness is controlled within 3 to 5 Mum; and after the spraying is finished, a coated pole piece is baked for 12 to 14 h at 110 plus or minus 3 DEG C, wherein dry nitrogen is filled for replacement once each two hours, so as to obtain the lithium ion battery anode functional coating. The replacement of a current collector with an anode aluminium foil material by a current collector with the functional coating can greatly improve the electrochemical properties of lithium ion batteries.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

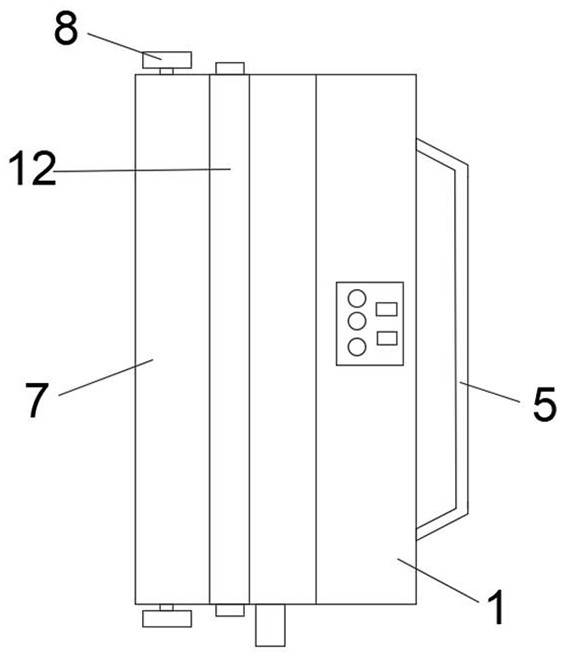

Emulsified asphalt paint coating device and construction method

PendingCN114517435AImprove construction quality and construction efficiencyControl coating thicknessRoad cleaningRoads maintainenceElectric heatingHeater Rod

The invention discloses an emulsified asphalt paint coating device which comprises a box body base and a material box body, the material box body is fixedly installed on one side of the box body base, the cross section of the material box body is of a conical structure, and a base plane scraper plate used for scraping emulsified asphalt paint is movably installed on the lower portion of one side of the material box body. A thickness determining roller for controlling the thickness of the emulsified asphalt coating is movably mounted at the lower position in the material box body, a heating rod is fixedly mounted in the thickness determining roller, two groups of electric heating plates are fixedly mounted on the inner wall of the material box body and are symmetrically arranged, and a dust collection nozzle is arranged at the bottom of a box body base; according to the emulsified asphalt coating coating device, the base surface scraping plate and the thickness determining roller are arranged, so that the emulsified asphalt coating coating device is provided with multiple adjusting structures, corresponding adjustment can be conducted according to the coating thickness and the scraping thickness, traditional manual operation is replaced, and the construction efficiency and the construction quality of emulsified asphalt coating are improved.

Owner:湖南大禹神工防水科技有限公司

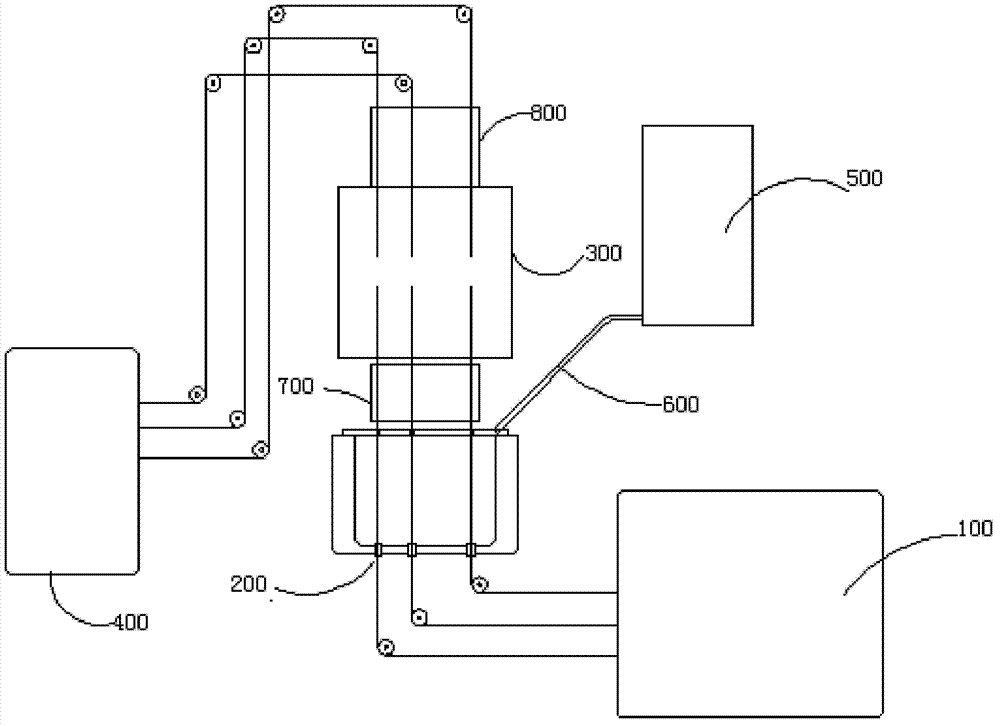

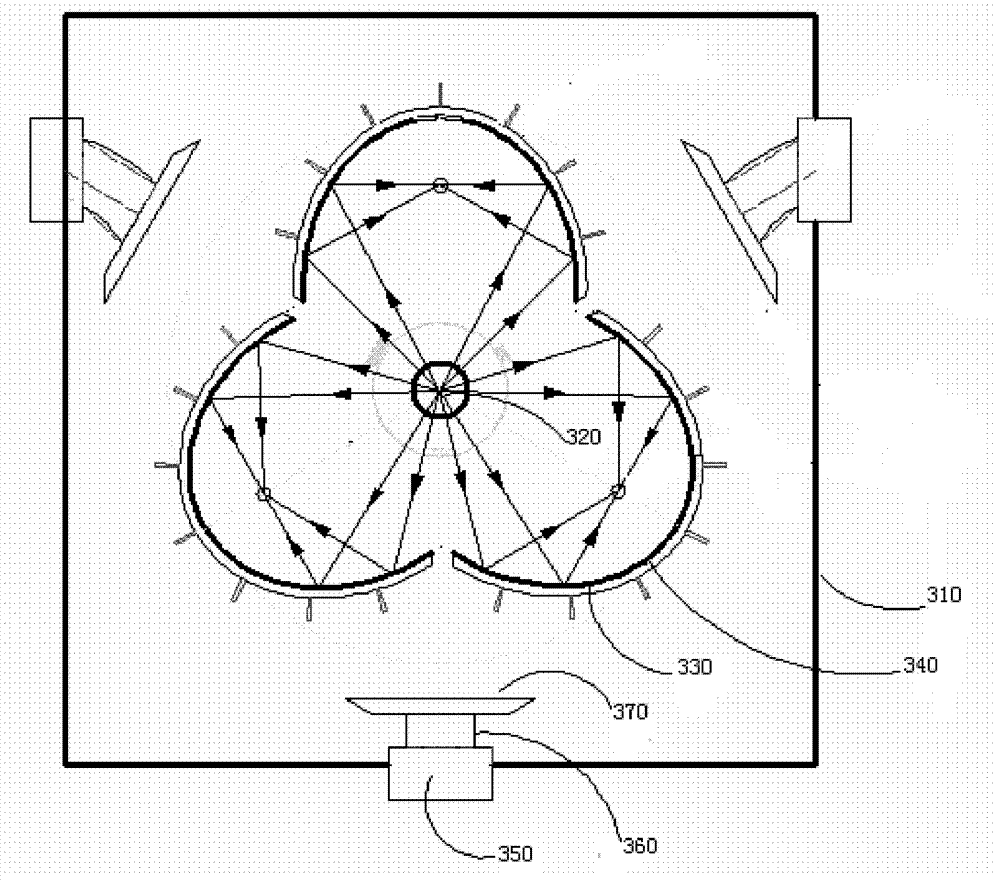

Equipment for synchronously producing multiple fiber insulating sleeves with ultraviolet light curing technology

The invention discloses equipment for synchronously producing multiple glass fiber insulating sleeves with an ultraviolet light curing technology, which comprises a blank pipe guide device, a coating device, a light source system, a sleeve traction device and a resin mixing and preheating kettle, wherein the blank pipe guide device is positioned at the foremost end, and the coating device is positioned at the rear of the blank pipe guide device; the light source system is positioned above the coating device, and the sleeve traction device is positioned at the rearmost end; and the resin mixing and preheating kettle is positioned at the inclined top of the coating device and is communicated with the coating device through a feed pipe. The light source system comprises a hood, a central fluorescent tube and reflectors, and the central fluorescent tube can generate ultraviolet light. The hood forms a closed box shape, and the central fluorescent tube and the reflectors are arranged in the hood. The number of the reflectors is at least two, and the reflectors are uniformly distributed in the same plane. The cross section of each reflector is semielliptical, and one focal point of all reflectors is superposed. The central fluorescent tube is positioned at the superposed focal point. According to the equipment, the utilization ratio of light sources and energy sources is increased.

Owner:山东佰渥康生物科技有限公司

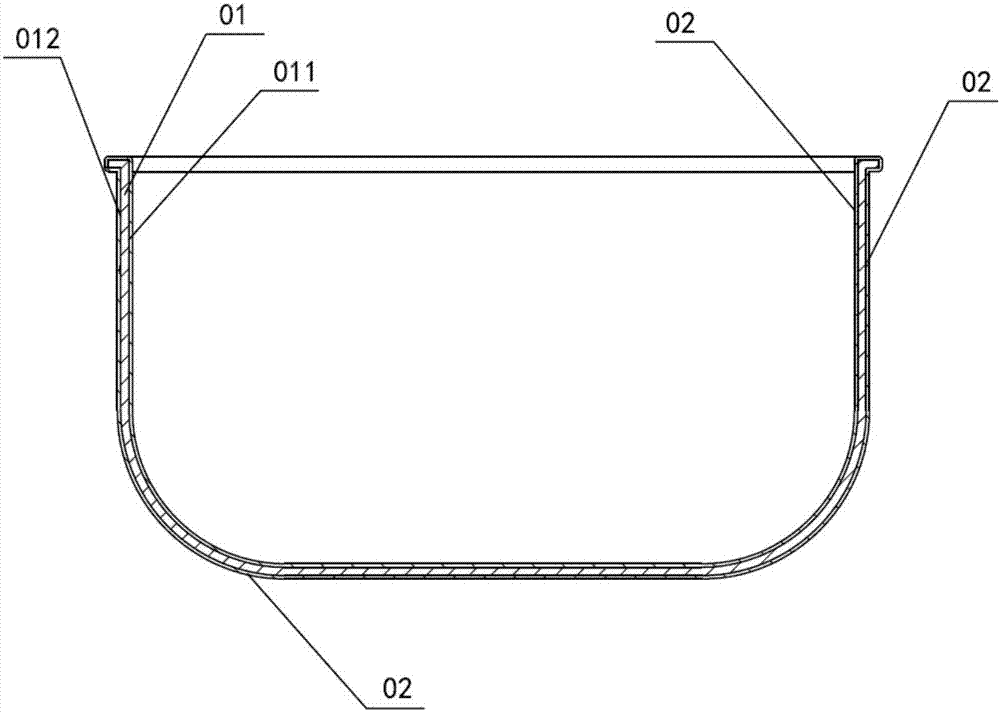

A kind of graphite cooker and manufacturing method thereof

ActiveCN107296508BImprove wear resistanceGuaranteed wear resistanceCooking-vessel materialsCarbon filmGraphite

The invention provides a graphite pot which comprises a pot body made from graphite. The pot body is provided with an inner wall and an outer wall, and a hard carbon film is attached to at least the surface of the inner wall. Due to the fact that the hard carbon film is attached to the inner wall of the pot body, the hardness of the hard carbon film is higher than that of an existing PTFE resin film, the abrasion performance of the graphite pot is ensured, the hard carbon film has the good air permeable performance, and it is ensured that the advantages of being good in thermal conductivity, rapid in thermal transmission and uniform in heating of the graphite pot body are well embodied; in the use process, the far infrared property and the adsorption property of the graphite pot body are well embodied, and the graphite pot is very environmentally friendly and healthy.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

A moisture-proof treatment method for electronic circuit boards

InactiveCN103108493BAvoid uniformityEffective control of process parametersNon-metallic protective coating applicationEngineeringHorizontal and vertical

The invention relates to a damp-proof processing method of an electronic circuit board. The damp-proof processing method of the electronic circuit board comprises the following steps that pre-covering processing is conducted on the electronic circuit board; an automatic spray gun conducts automatic and reciprocating spraying and coating on the electronic circuit board along the horizontal direction and the perpendicular direction; a face is turned automatically according to damp-proof requirements; and the sprayed and coated electronic circuit board is automatically heated and dried. According to the damp-proof processing method of the electronic circuit board, the electronic circuit board is ideal in damp-proof effect and reliable in quality guarantee and work efficiency, and therefore good performance of the electronic circuit board is guaranteed.

Owner:SHANGHAI SHARP ELECTRONICS +1

Dustproof and anti-seepage adhesive for bridge expansion joint and preparation method of dustproof and anti-seepage adhesive

PendingCN114539942AExtended service lifePlay the effect of dust and seepage preventionMineral oil hydrocarbon copolymer adhesivesFilm/foil adhesivesAdhesivePetroleum resin

The invention discloses a bridge expansion joint dustproof seepage-proof adhesive which comprises a modified asphalt cement, a base cloth, a high-temperature-resistant polyethylene (PE) film and a high-temperature-resistant PET silicone oil film, the modified asphalt cement is dip-dyed on the base cloth, the high-temperature-resistant polyethylene film is located on the lower surface of the base cloth, and the high-temperature-resistant silicone oil film is located on the upper surface of the base cloth. The modified asphalt cementing material is prepared from the following raw materials in parts by weight: 50 to 60 parts of matrix asphalt, 4 to 10 parts of SBS (Styrene Butadiene Styrene), 15 to 25 parts of rubber powder, 2 to 5 parts of petroleum resin, 13 to 18 parts of extract oil and 0.05 to 0.15 part of stabilizer, the rubber powder is 20-40-mesh desulfurized rubber powder, the stabilizer is a sulfur-containing stabilizer, the extract oil is furfural extract oil, and the petroleum resin is C9 petroleum resin.

Owner:XINJIANG MIND TECH CO LTD +1

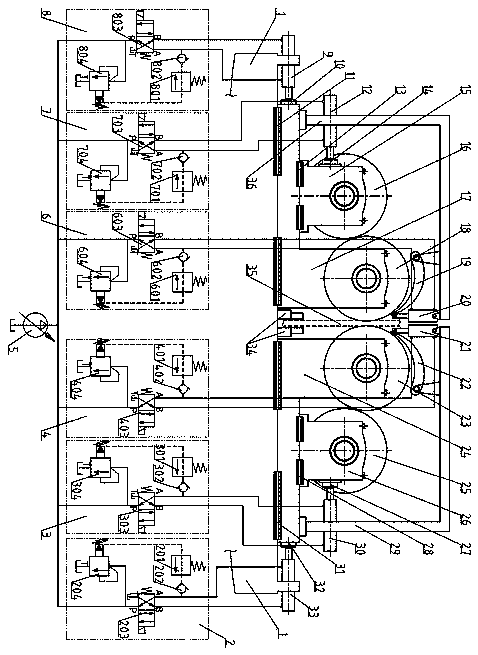

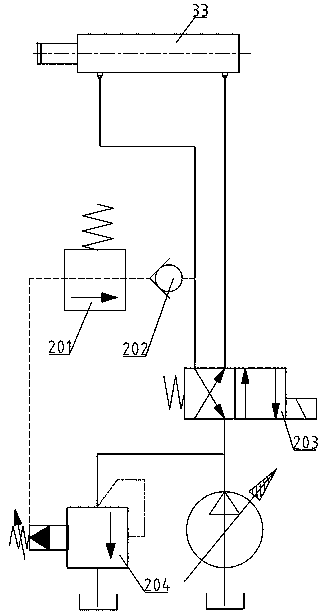

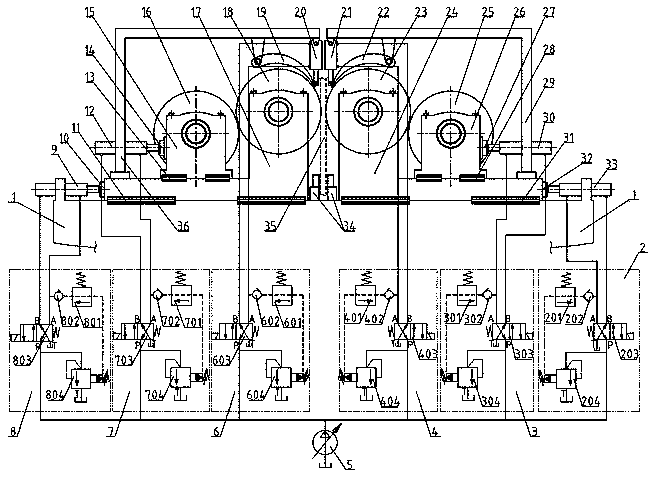

Hydraulic roller coating device with accurate coating thickness

PendingCN111135980AControl coating thicknessGuaranteed accuracyLiquid surface applicatorsCoatingsHydraulic cylinderStructural engineering

The invention discloses a hydraulic roller coating device with the accurate coating thickness. The device comprises a machine frame, a front coating roller, a back coating roller, a front dipping roller and a back dipping roller are symmetrically arranged on the machine frame, thickness measuring sensors are arranged on the two sides of the symmetrical face, the front coating roller, the back coating roller, the front dipping roller and the back dipping roller realize sliding supporting through corresponding sliding seats, corresponding pressure sensors are arranged between the sliding seats and hydraulic cylinders, the peripheries of the front coating roller and the back coating roller are each provided with corresponding uniformizing plates at intervals, the uniformizing ends of the uniformizing plates are hinged to a support through the corresponding hydraulic cylinders, the hydraulic cylinders communicate with corresponding hydraulic positioning loops, and each hydraulic positioning loop comprises an electromagnetic reversing valve, a check valve, a remote pressure regulating valve and a pilot overflow valve. The hydraulic roller coating device not only can automatically adjustthe roller gap and coating thickness, effectively ensure accuracy of the coating thickness, but also can achieve remote adjustment control, and is high in automation degree and coating thickness accuracy.

Owner:江苏君安新材料科技有限公司

Graphite pot and making method thereof

ActiveCN107296508AImprove breathabilityGuaranteed wear resistanceCooking-vessel materialsCarbon filmGraphite

The invention provides a graphite pot which comprises a pot body made from graphite. The pot body is provided with an inner wall and an outer wall, and a hard carbon film is attached to at least the surface of the inner wall. Due to the fact that the hard carbon film is attached to the inner wall of the pot body, the hardness of the hard carbon film is higher than that of an existing PTFE resin film, the abrasion performance of the graphite pot is ensured, the hard carbon film has the good air permeable performance, and it is ensured that the advantages of being good in thermal conductivity, rapid in thermal transmission and uniform in heating of the graphite pot body are well embodied; in the use process, the far infrared property and the adsorption property of the graphite pot body are well embodied, and the graphite pot is very environmentally friendly and healthy.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

Manufacturing method of PET bottom plate and mother plate combined film

ActiveCN112793283AUniform coatingThere will be no problems such as protrusions and depressionsLamination ancillary operationsLaminationAdhesive beltMechanical engineering

The invention discloses a manufacturing method of a PET bottom plate and mother plate combined film. The combined film comprises a large rubber roller assembly, a guide roller, a PET bottom plate and a mother plate, the PET bottom plate is respectively connected with the large rubber roller assembly and the guide roller, the large rubber roller assembly drives the PET bottom plate to reciprocate, the combined film further comprises a splicing fixing piece, a pre-coating roller assembly, a liquid tank assembly and an ultraviolet curing lamp, the splicing fixing piece is matched with the PET bottom plate and the mother plate, the pre-coating roller assembly is matched with the liquid tank assembly and makes contact with the PET bottom plate, and the mother plate is matched with the PET bottom plate and the ultraviolet curing lamp. According to the PET bottom plate and mother plate combined film manufactured through the method, the problem that a traditional mother plate is spliced through an adhesive tape, so that huge waste is caused in the cutting procedure is solved, a protective film does not need to be used, and the cost is low; meanwhile, the problem that the laser splicing cost is high is solved; and the PET bottom plate and mother plate combined film manufactured by the method is uniform in coating of the coating agent, so that the problems of bulges, recesses and the like cannot occur when the PET bottom plate and the mother plate are bonded, and the preparation efficiency of the combined film is improved.

Owner:CHANGZHOU HUAWEI ADVANCED MATERIAL

Spinneret for preparing reinforced hollow fiber membrane, membrane manufacturing method and hollow fiber membrane

ActiveCN111020715BControl coating thicknessAchieving controllability of seepageSpinnerette packsNon-woven fabricsStructural engineeringHollow fiber membrane

The invention discloses a spinneret for preparing an enhanced hollow fiber membrane and a membrane preparation method. The spinneret comprises a primary coating spinneret. A pre-coating device is arranged on the baffle of the primary coating spinneret; the pre-coating device comprises a cover plate and a pre-coating cavity arranged below the cover plate; the bottom of the cavity wall of the pre-coating cavity is arranged on the baffle; an air inlet hole is arranged in the cover plate; an atomizing hole is arranged in the surface in contact with the cover plate of the pre-coating cavity; the atomizing hole is communicated with the air inlet hole; a liquid inlet hole is arranged in the cavity wall of the pre-coating cavity; a gas-liquid discharge hole is arranged in the lower part of the pre-coating cavity; a liquefied droplet leakage-proof table is arranged at the bottom of the pre-coating cavity on the baffle, a positioning hole and a fixing hole are arranged in the cover plate and thewall of the pre-coating cavity in the thickness direction respectively, a rope penetrating hole is arranged in the middle of the cover plate and in the top of the leakage-proof table respectively, and the positioning hole, the fixing hole and the rope penetrating hole correspond to the positioning hole, the fixing hole and the rope penetrating hole respectively of the primary coating spinneret. The enhanced hollow fiber membrane with super-strong falling resistance and high bursting strength can be prepared.

Owner:JIANGSU KAIMI MEMBRANE TECH

A preparation method of boride solid solution modified silicon-based coating on the surface of carbon material

Owner:CHINA UNIV OF MINING & TECH

A babu paste coating forming device

InactiveCN108405260BControl cream contentControl coating widthLiquid surface applicatorsCoatingsWater bathsDouble compression

The invention discloses a novel cataplasm coating forming device. The novel cataplasm coating forming device mainly comprises a device main body, a constant-temperature discharging hopper, a constant-temperature speed control wheel, a discharging control opening, a cloth releasing device, a double-compression-roller feeding device, a longitudinal cutting device, a transverse cutting device, a control panel and a conveying device; the cloth releasing device, the constant-temperature discharging hopper, the double-compression-roller feeding device and the longitudinal cutting device are sequentially arranged on the upper top surface of the device main body from left to right, the transverse cutting device is fixed at the upper end of the right side surface of the device main body through a lower supporting plate, and a water bath interlayer is arranged on the periphery of the outer side of the constant-temperature discharging hopper; and the constant-temperature speed control wheel is arranged below the inner part of the constant-temperature discharging hopper, and the discharging control opening is formed in the bottom end of the constant-temperature discharging hopper. According tothe novel cataplasm coating forming device, structure is simple, and design is reasonable; the parameters of the paste content, the coating width, and the coating thickness are realized; and more uniform and smooth of the coating are guaranteed.

Owner:王传文

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com