Novel cataplasm coating forming device

A molding device, the technology of babble paste, applied in the direction of coating, the device for coating liquid on the surface, etc., to achieve the effect of smooth distribution, high applicability, stable and accurate temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

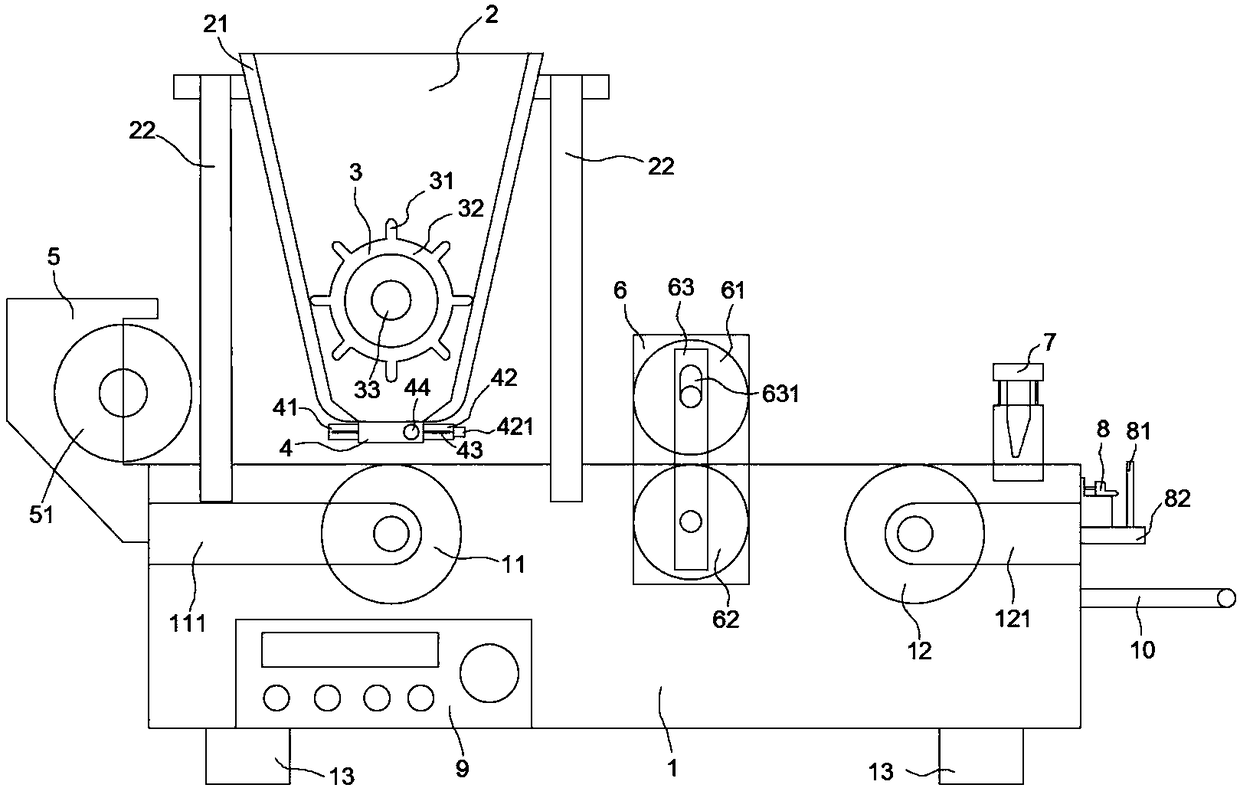

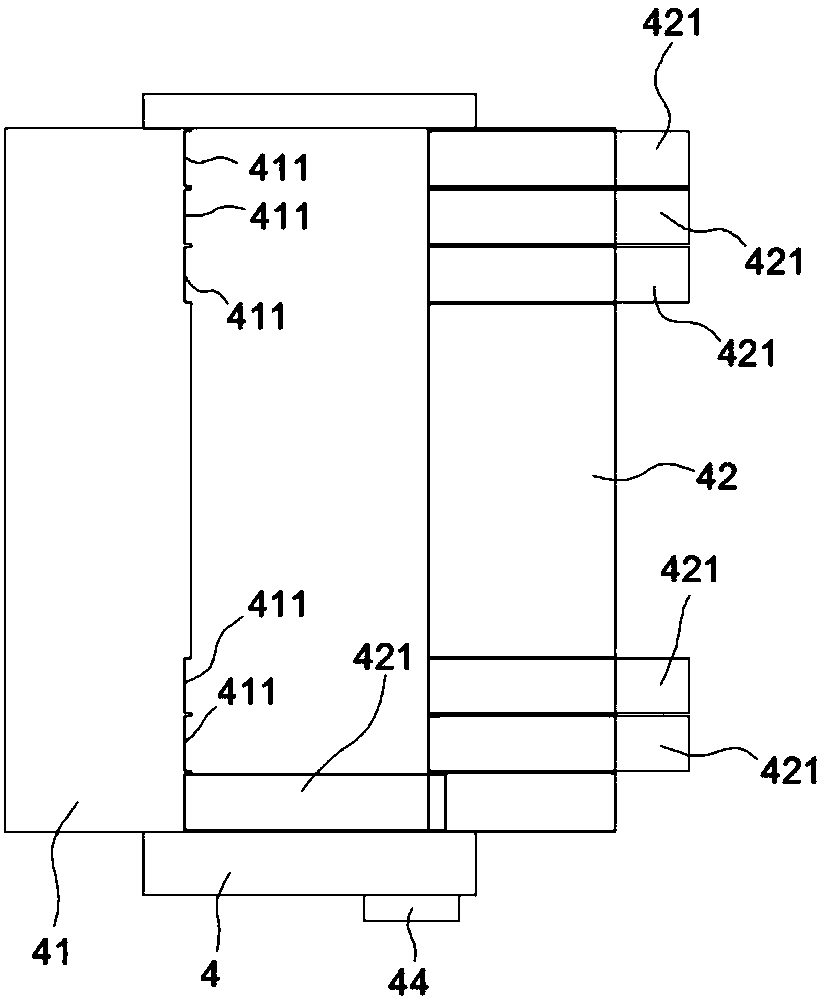

[0019] like figure 1 and 2 As shown, a new type of Babu paste coating forming device mainly includes a device main body 1, a constant temperature lower hopper 2, a constant temperature speed control wheel 3, a feeding control port 4, a cloth releasing device 5, a double pressure roller feeding device 6, a longitudinal Cutting device 7, cross-cutting device 8, control panel 9 and conveying device 10; the inner upper left of device main body 1 is provided with conveying roller a 11, and is fixed with the inner wall of the upper left end of device main body 1 by fixing bracket a 111, device main body 1 There is a conveying roller b 12 on the upper right inside of the interior, and it is fixed with the inner wall of the upper right end of the device main body 1 through the fixing frame b 121. The lower bottom end of the device main body 1 is provided with support blocks 13 at the left and right ends; the outer side of the constant temperature lower hopper 2 One week is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com