Gluing head capable of preventing glue from overflowing and gluing equipment of gluing head

A technology of gluing head and glue, which is used in coatings, devices that apply liquid to the surface, electrode manufacturing, etc. The effect of maintaining uniformity, preventing edges, and maintaining uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

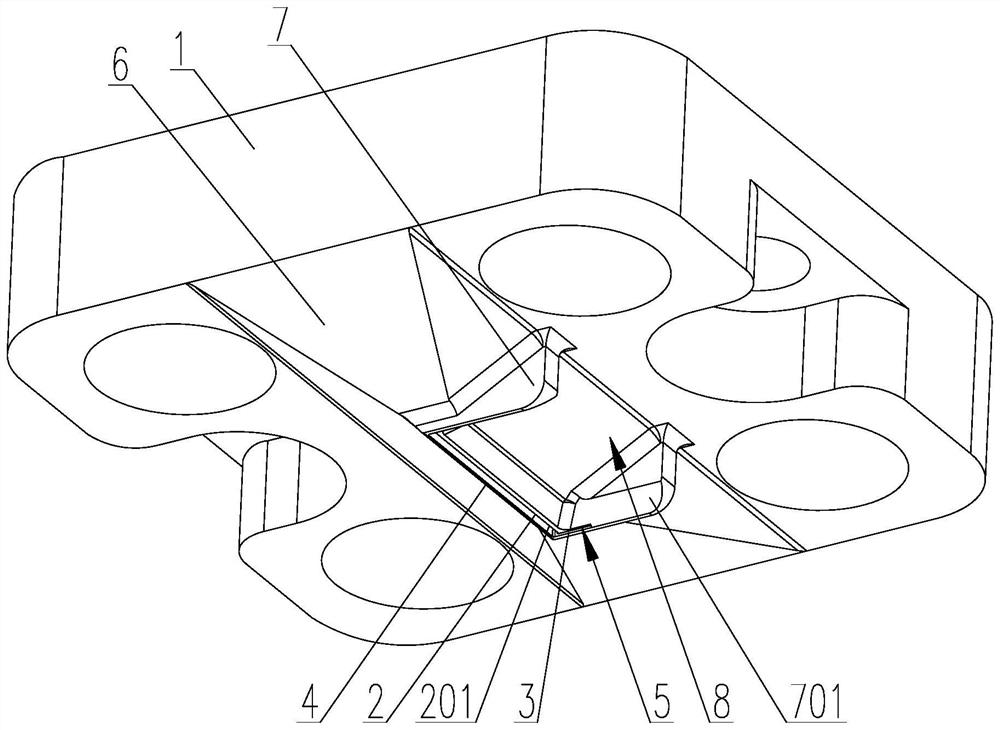

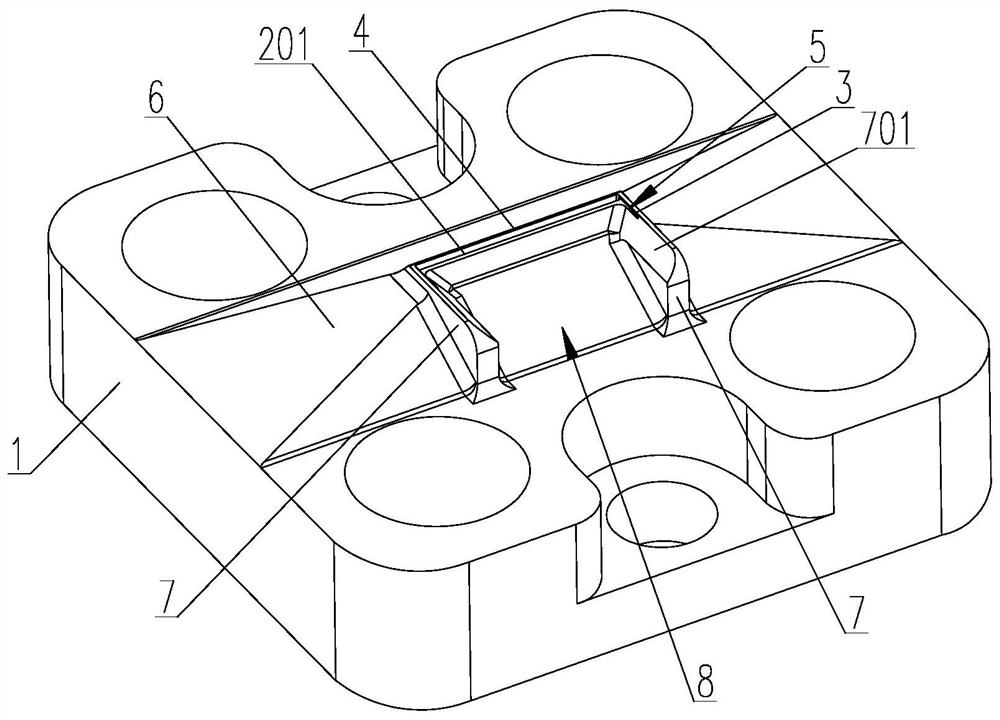

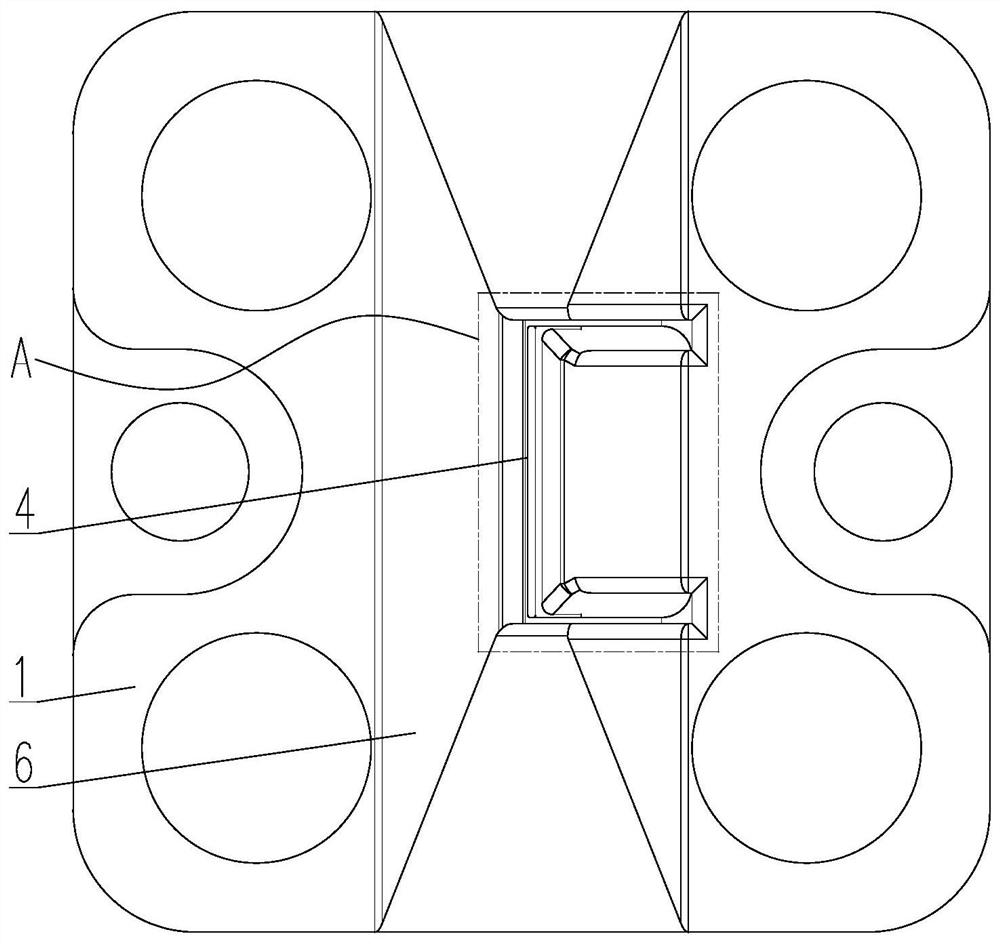

[0033] like Figure 1-6 As shown, a glue applicator for preventing glue from overflowing includes a glue head body 1, the glue head body 1 has a glue outlet hole 2 and two side ribs 3, and the glue outlet 201 of the glue outlet hole 2 is located at Between the two side ribs 3, the side ribs 3 protrude outward from the glue outlet 201 of the glue outlet hole 2;

[0034] The back side of the rubber head body 1 located at the glue outlet 2 is protruded with a rear wall 4, the rear wall 4 is located between the two side walls 3, and the two ends of the rear wall 4 are respectively connected to the The two side ribs 3 are connected to form a glue discharge groove 5 , and the glue outlet 201 of the glue outlet hole 2 is located in the glue discharge groove 5 .

[0035] In this embodiment, the glue outlet 201 may specifically be in the shape of a strip.

[0036] Specifically, the rear rib 4 and the side rib 3 are arranged perpendicular to each other.

[0037] The bottom surface of...

Embodiment 2

[0052] like Figure 7 Shown, a kind of gluing equipment comprises the gluing head that prevents glue from overflowing among the above-mentioned embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com