A preparation method of boride solid solution modified silicon-based coating on the surface of carbon material

A technology of carbon materials and borides, which is applied in the field of preparation of silicon-based coatings modified by boride solid solutions on the surface of carbon materials, can solve the problems of difficult control of the solid solubility content of boride solid solution phases in the thickness of ultra-high temperature ceramic ceramics, and achieve The effect of increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of anti-oxidation coating, first configure the ultra-high temperature ceramic boride solid solution NB with controllable content 2 Modified silicon-based composite ceramic slurry, wherein N=Zr x Ta 1-x , Hf x Ta 1-x or Zr x f 1-x , x=0~1, followed by brushing, dipping or spraying ultra-high temperature ceramic boride solid solution NB on the surface of carbon material substrate with SiC inner coating 2 The preset layer of the slurry, after the preset layer is obtained, is sintered and combined by ultra-high temperature heat treatment to form a coating.

[0033] The specific steps are:

[0034] Step 1: Grinding the carbon material with sandpaper of different roughness, followed by ultrasonic cleaning and drying, the carbon material is graphite or C / C composite material;

[0035] Step 2: Prepare the SiC inner coating: uniformly mix the C powder with a mass fraction of 10-30% and the Si powder with 70-90% and dry it, and then dry the carbon ma...

Embodiment 1

[0044] Step 1: Ultrasonic cleaning and drying of graphite after sanding with different roughnesses.

[0045] Step 2: Prepare the SiC inner coating: evenly mix Si powder with a mass fraction of 75% and C powder with 25% and dry it, then put the graphite treated in step 1 into a graphite crucible and use the dried powder Then put the graphite crucible with powder and graphite into the ultra-high temperature heat treatment furnace, pass it into the argon atmosphere for protection, and raise the temperature of the ultra-high temperature heat treatment furnace to 2000 °C at a heating rate of 10 °C / min, keep it for 3 hours, and then The graphite surface gets a SiC inner coating.

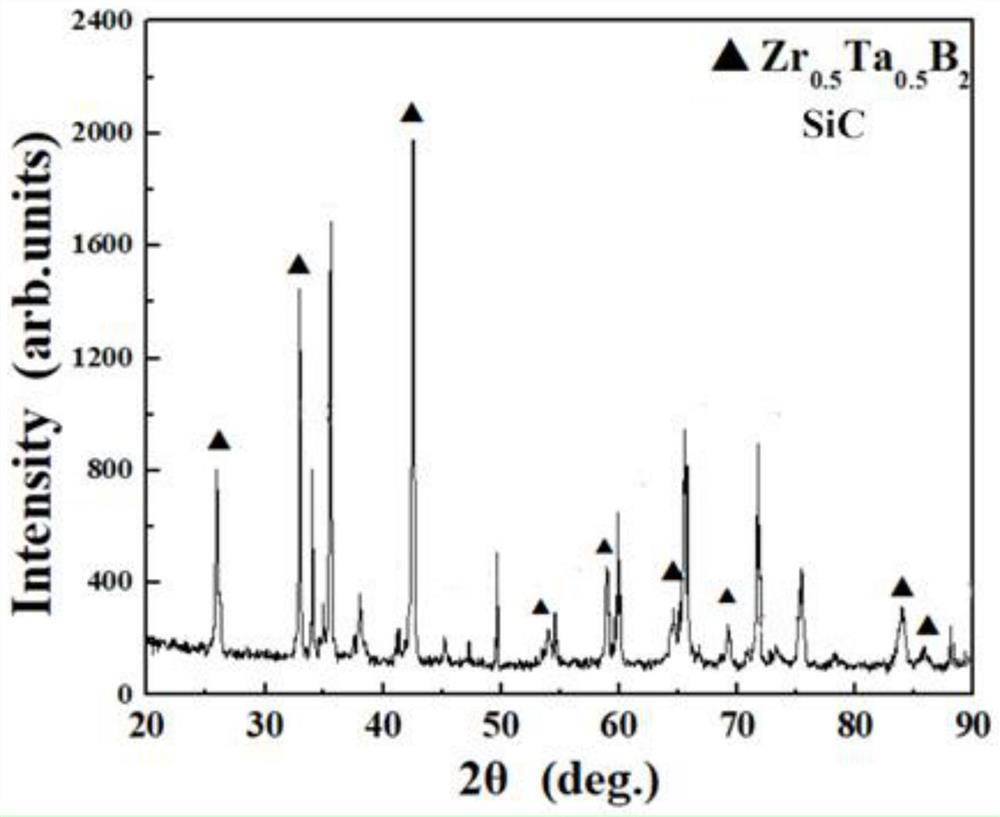

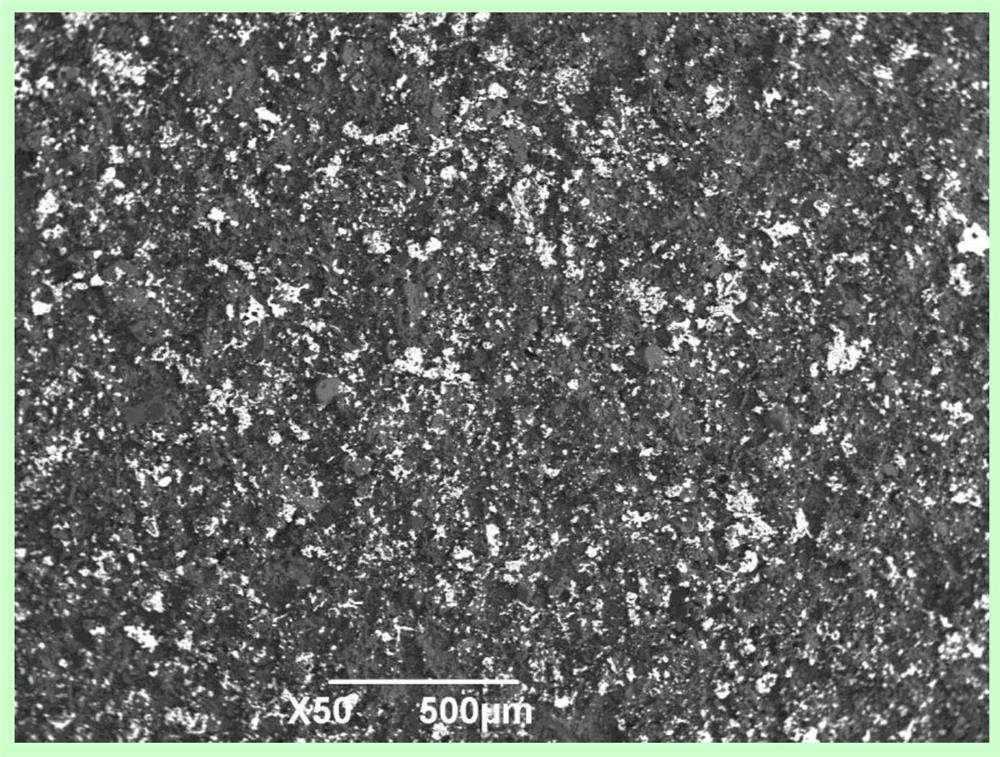

[0046] Step 3: Preparation of Zr 0.5 Ta 0.5 B 2 -SiC outer coating: Zr 0.5 Ta 0.5 B 2Powder (70wt.%), SiC powder (15wt.%), Si powder (10wt.%) and C powder (5wt.%) are evenly mixed and dried, then add a certain amount of silica sol (the volume of silica sol is mixed with The mass ratio of the powder ...

Embodiment 2

[0050] Step 1: Ultrasonic cleaning and drying of graphite after sanding with different roughnesses.

[0051] Step 2: Prepare the SiC inner coating: evenly mix Si powder with a mass fraction of 80% and C powder with 20% and dry it, then put the graphite treated in step 1 into a graphite crucible and use the dried powder Then put the graphite crucible with powder and graphite into the ultra-high temperature heat treatment furnace, pass it into the argon atmosphere for protection, and raise the temperature of the ultra-high temperature heat treatment furnace to 2100 °C at a heating rate of 15 °C / min, keep it for 2 hours, and then The graphite surface gets a SiC inner coating.

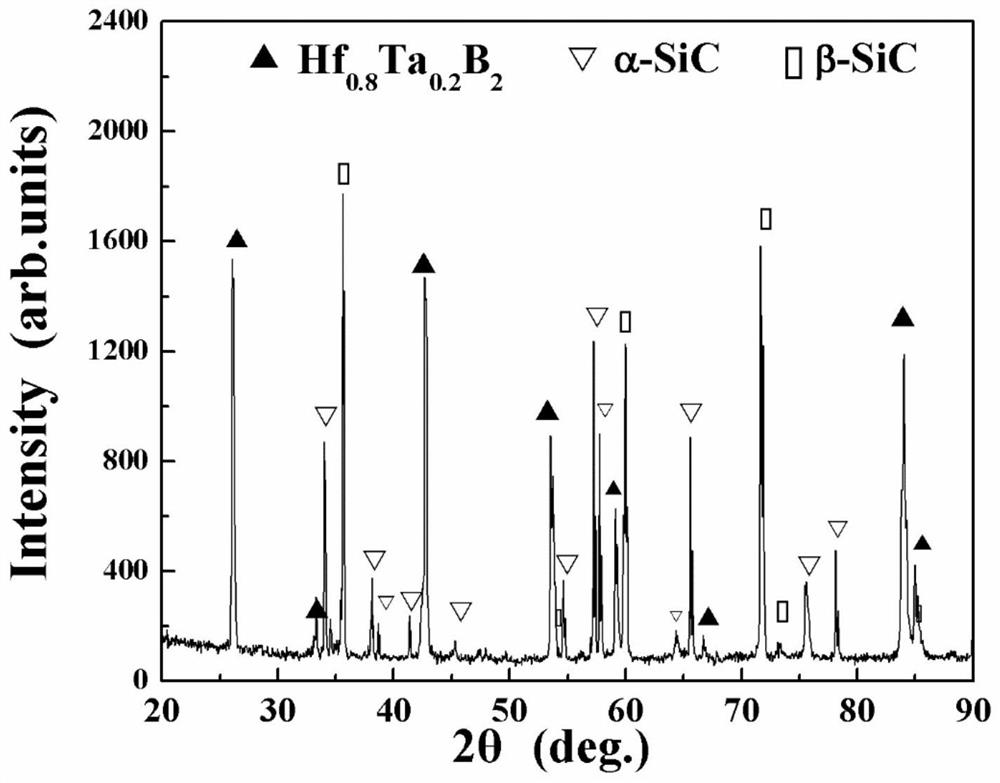

[0052] Step 3: Preparation of Hf 0.8 Ta 0.2 B 2 -SiC outer coating: Hf 0.8 Ta 0.2 B 2 Powder (20wt.%), SiC powder (60wt.%), Si powder (15wt.%) and C powder (5wt.%) are evenly mixed and dried, then add a certain amount of silica sol (the volume of silica sol is mixed with The ratio of powder mass is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com