Graphite pot and making method thereof

A production method and technology of graphite pots, which are applied in the field of cooking utensils, can solve the problems of poor coating hardness and poor wear resistance, and achieve the effects of ensuring adhesion, uniform heating, and good air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

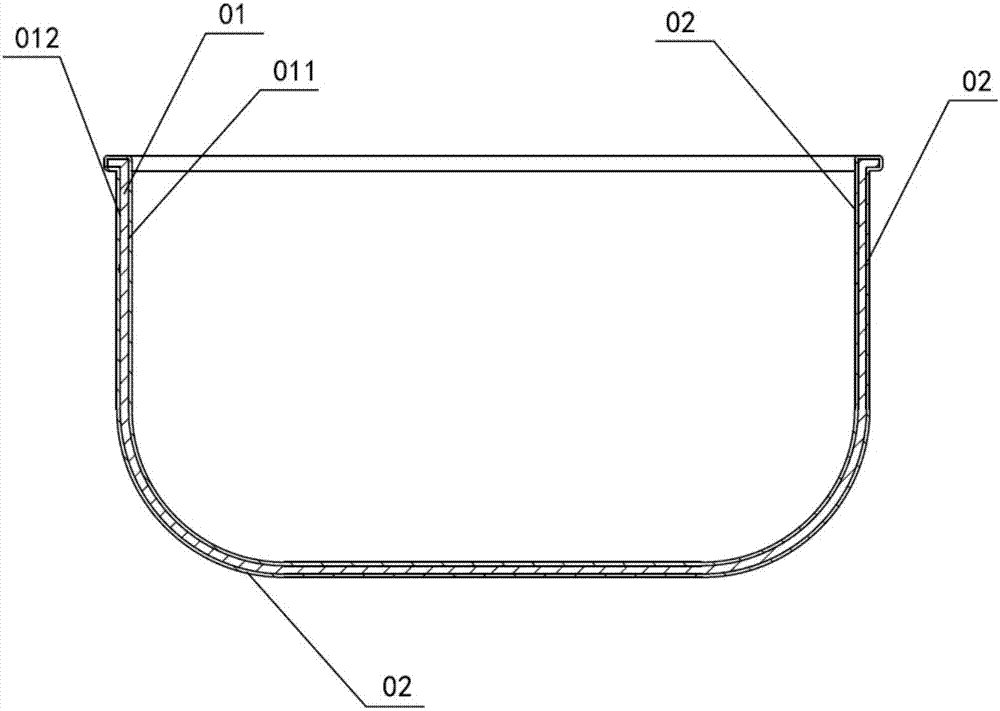

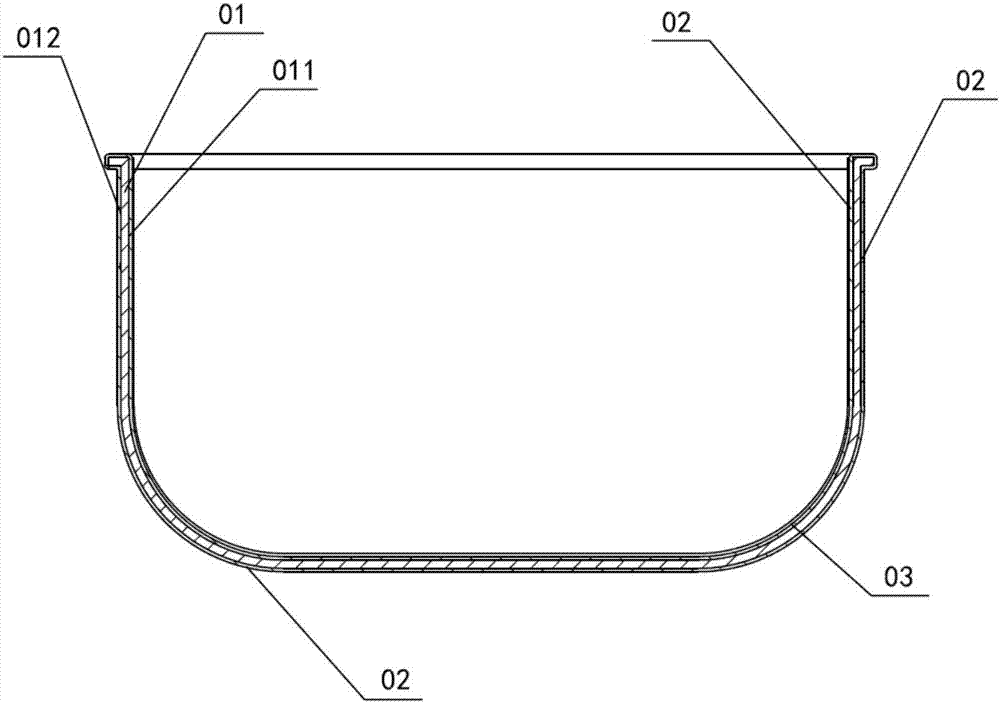

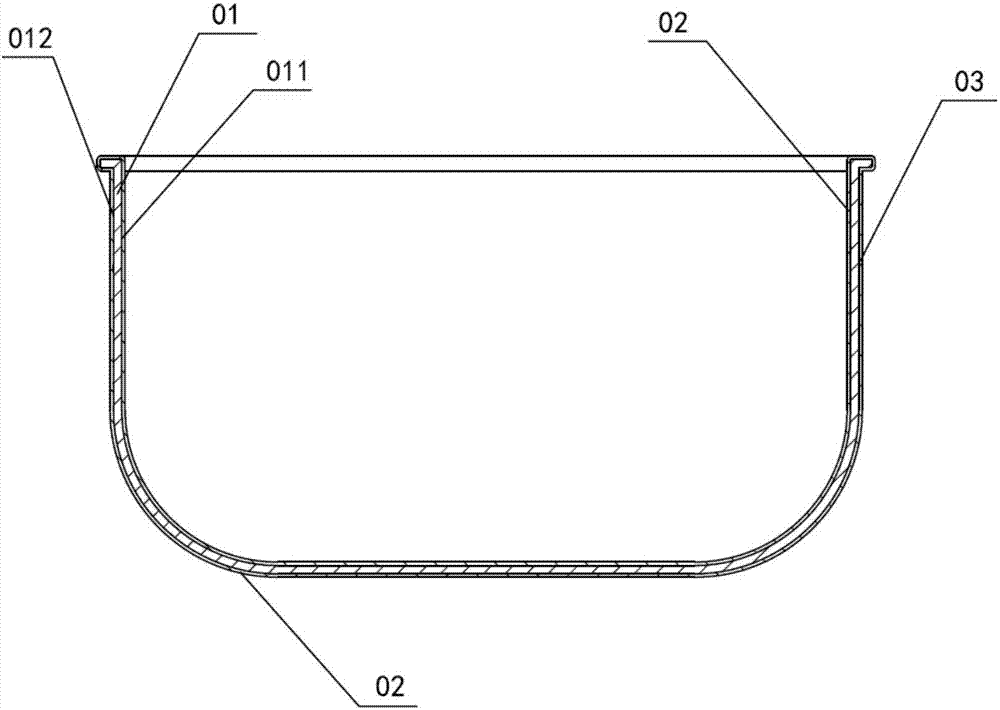

[0046] For the structural diagram of Embodiment 1 of the graphite cookware of the present invention, see figure 1 , including a pot body 01 made of graphite, the pot body 01 has an inner wall 011 and an outer wall 012, a covalent carbide film 02 is attached to the inner wall 011, and a covalent carbide film 02 is also attached to the outer wall 012, Wherein, the covalent carbide film 02 is a silicon carbide film, and the thickness of the silicon carbide film is 3.0 μm.

[0047]Since there is a covalent carbide film attached to the surface of the inner wall, that is, a silicon carbide film, the hardness of the silicon carbide film is much higher than that of the existing PTFE resin film layer, and the film layer will not appear until it is used tens of thousands of times. The wear-through phenomenon ensures the wear resistance of the graphite cookware a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com