Method for preparing material with holographic patterns

A holographic pattern and holographic technology, applied in the field of material preparation, can solve the problems of insufficient wear resistance and corrosion resistance, large volume change, excellent wear resistance and corrosion resistance, etc., to improve product quality, avoid deformation, Guaranteed effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

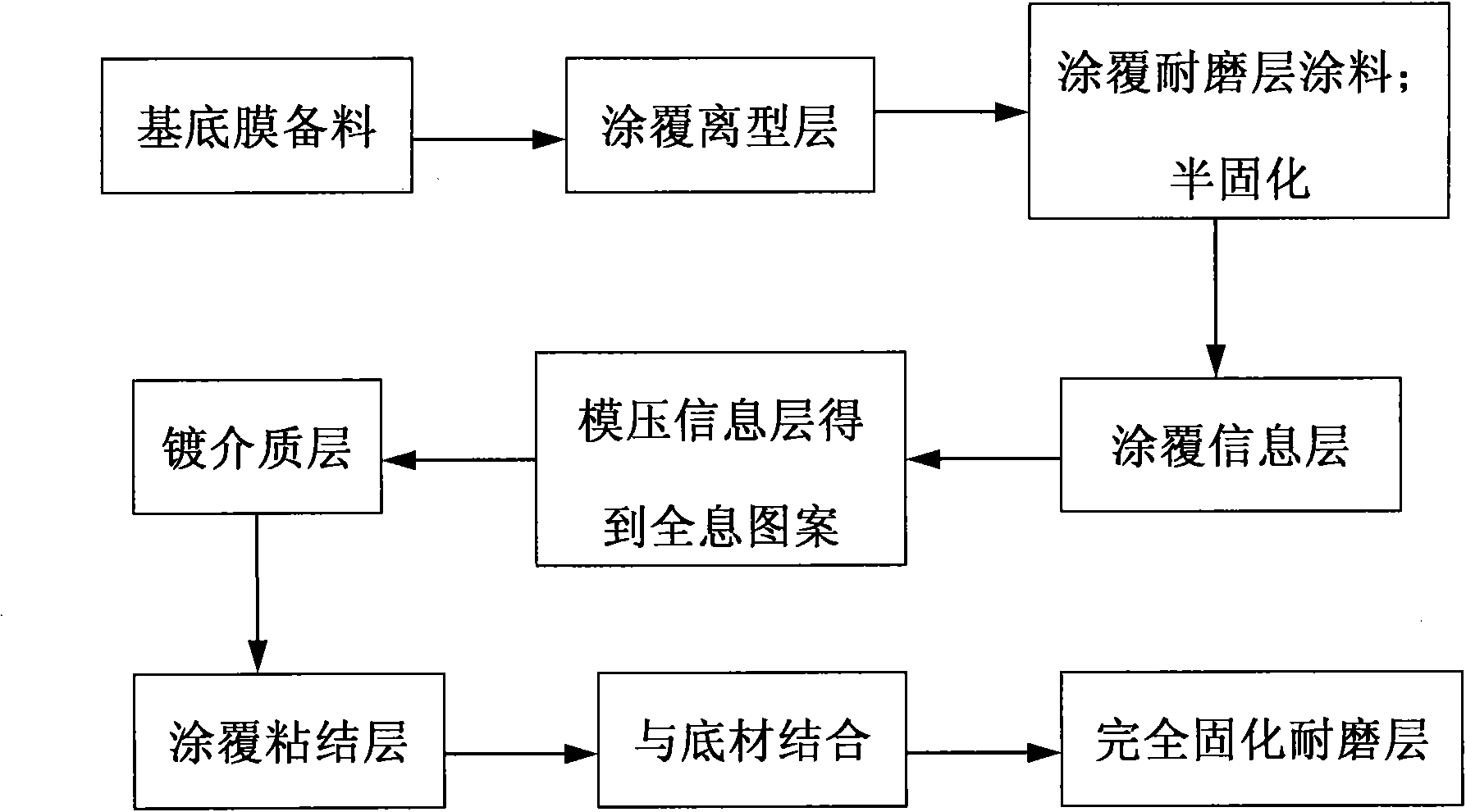

Method used

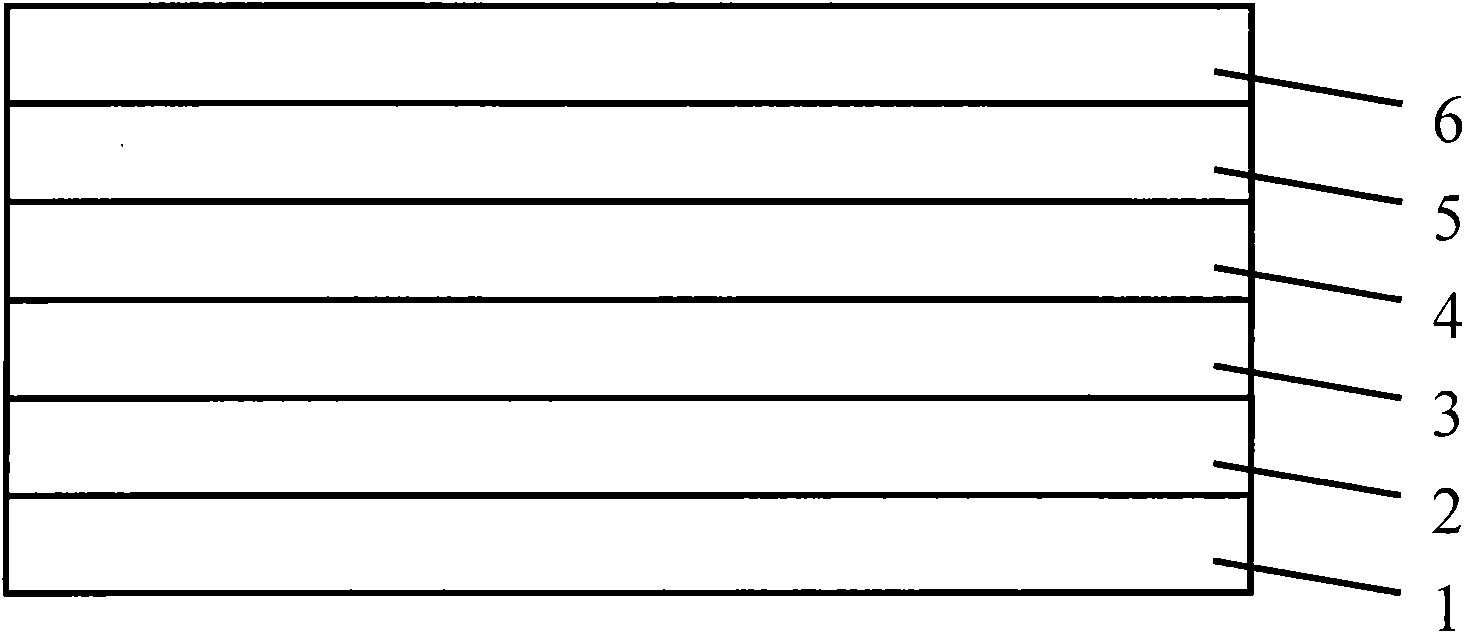

Image

Examples

Embodiment 1

[0040] This example is used to illustrate the method provided by the present invention.

[0041] Coat the release layer slurry (weight ratio of butyl acetate cellulose to acetone 40:60) by gravure printing on a base film with a width of 800mm (PET base film produced by Foshan Dupont Hongji Film Co., Ltd., with a thickness of 18um) , based on the total weight of the wear-resistant layer coating to be coated, the weight of the release layer slurry is 30wt%; then bake at 80°C for 15s to obtain a release layer with a thickness of 0.5um.

[0042] The above-mentioned release layer was coated with a dual-curing coating by gravure printing, and then cured at 70°C for 5 minutes in a combined drying tunnel produced by Shantou Far East Machinery Co., Ltd. to obtain a 4um thick semi-cured wear-resistant layer.

[0043] The composition of the above-mentioned dual-curing coating is: based on the total weight of the dual-curing coating, it includes 30wt% aliphatic urethane acrylate resin, 38...

Embodiment 2

[0052] This example is used to illustrate the method provided by the present invention.

[0053] The preparation method of the material with holographic pattern is the same as that of Example 1, the difference is:

[0054] The weight of the release layer slurry is 50wt%, and the thickness of the obtained release layer is 1.5um.

[0055] The dual-curing coating is composed of: based on the total weight of the dual-curing coating, it includes 20wt% aliphatic urethane acrylate resin, 32wt% xylene, 4wt% benzophenone, and 18wt% trimethylolpropane Triacrylate, 25wt% isophorone diisocyanate trimer, 0.3wt% BYK366 (leveling agent produced by BYK company), 0.2wt% BYK354 (defoamer produced by BYK company), 0.5wt% Kerper-602 (dispersant produced by Kerper Company). The thickness of the wear-resistant layer is 6um.

[0056] The weight of the information layer slurry is 70wt%, and the obtained information layer has a thickness of 3um.

[0057] The dielectric layer is a 0.5um thick silic...

Embodiment 3

[0061] This example is used to illustrate the method provided by the present invention.

[0062] The preparation method of the material with holographic pattern is the same as that of Example 2, the difference is:

[0063] The semi-curing method is: use the F300 ultraviolet curing lamp system produced by FUSION to semi-cure the wear-resistant layer. The curing conditions are: wavelength 365nm, curing energy 500mj / cm 2 .

[0064] Material A3 with a holographic pattern was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com