Automatic production line for producing patches

An automatic production line, automatic production line technology, applied in the direction of making medicines into special physical or ingestible devices, other household appliances, household components, etc., can solve the problems of product quality risk and danger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

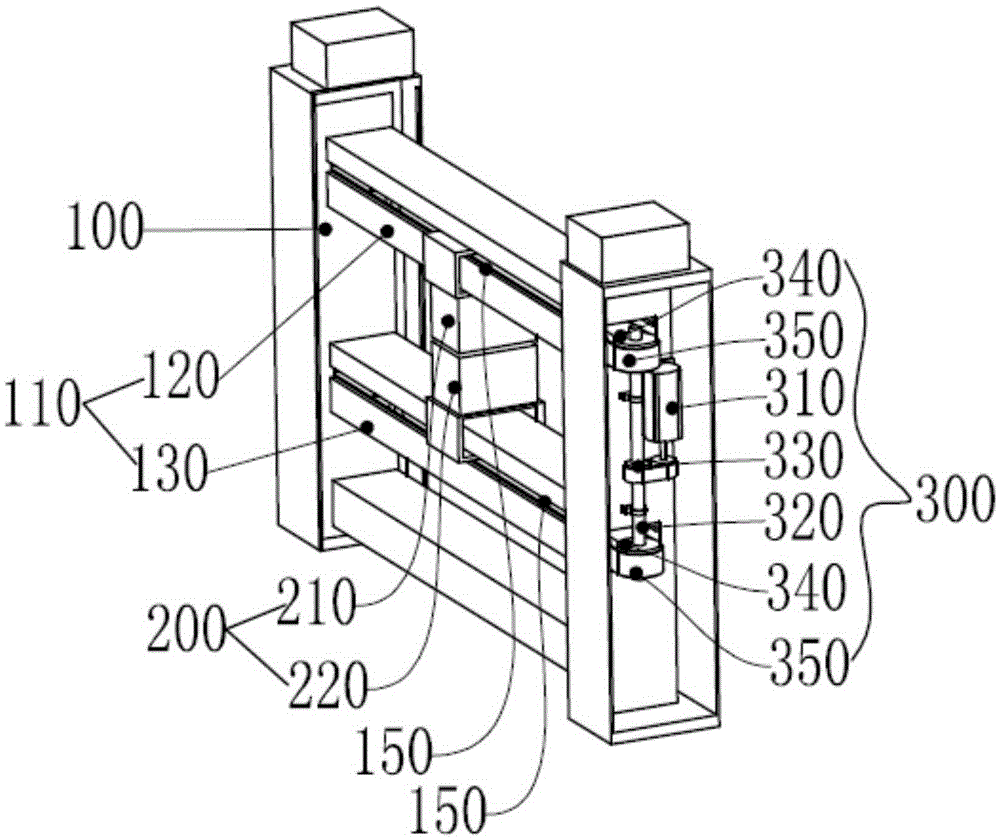

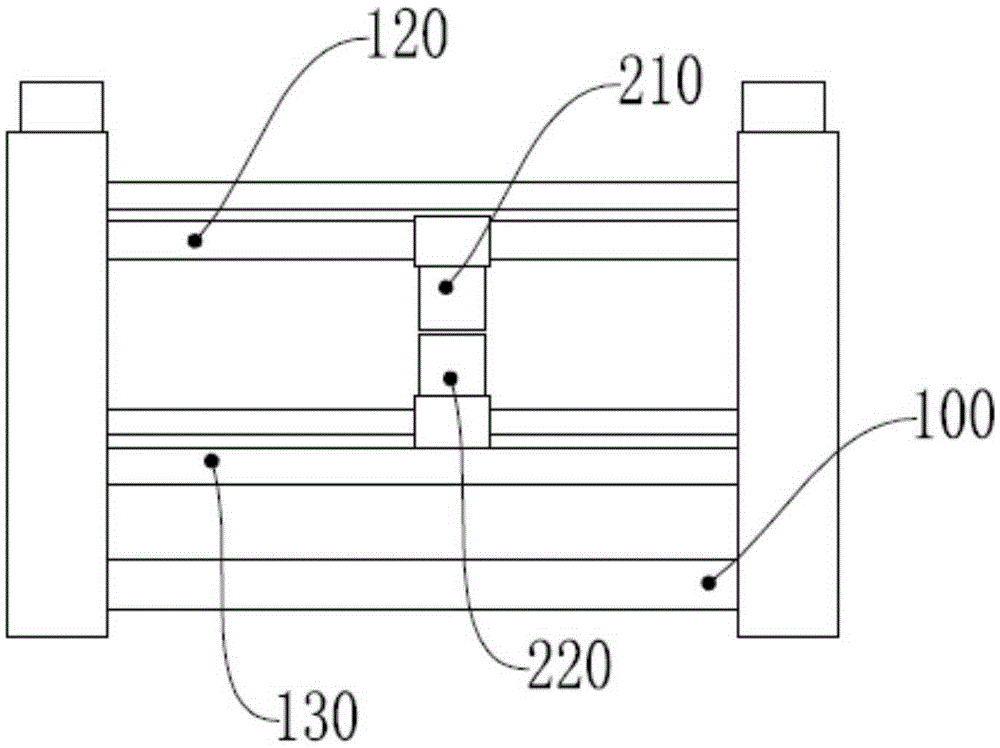

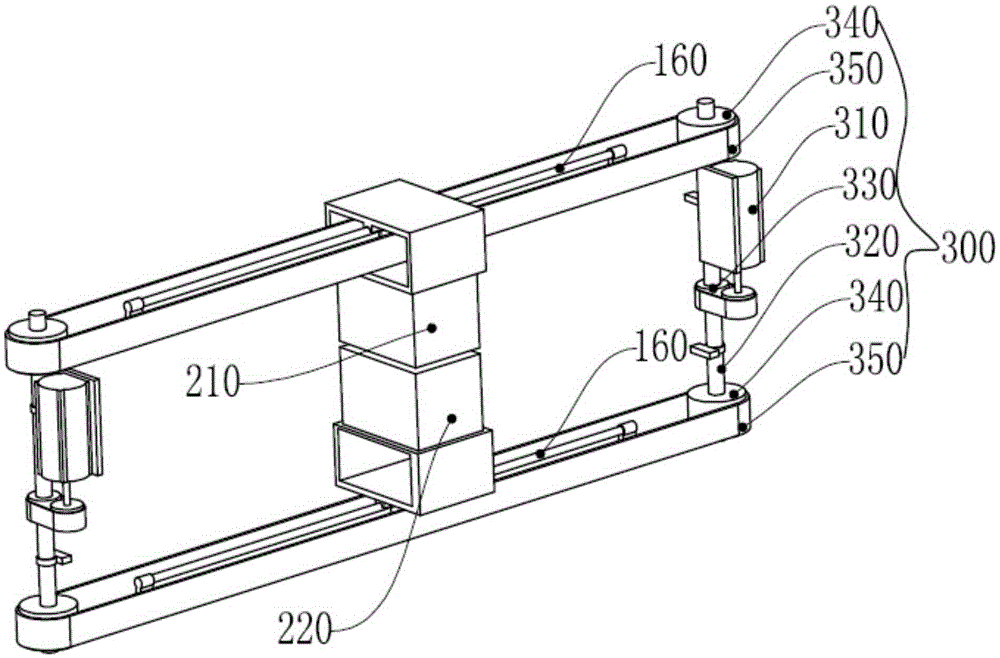

[0029] like Figure 9 As shown, an automatic production line for producing patches is provided with an automatic ointment detection and coating system, an air-dry cooling device 30, a cloth spreading device 40 and a cloth rolling device in sequence; the automatic ointment detection and coating system includes: ointment coating Device 20 and detection device 10, and described ointment coating device 20 is located at the upstream of described detection device; Figure 1-3 As shown, the detection device 10 includes a mobile support 100, an X-ray thickness detector 200, a reciprocating drive mechanism 300 and a reciprocating control system; the mobile support 100 is provided with a beam 110; 210 and the receiving end 220; the transmitting end 210 and the receiving end 220 are always facing each other a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com