Graphite pot and making method thereof

A production method and technology of graphite pot, which are applied to special materials for cooking utensils and other directions, can solve the problems of reducing the far-infrared characteristics and adsorption characteristics of graphite pots, and achieve the effects of good thermal conductivity, ensuring adhesion, and ensuring wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

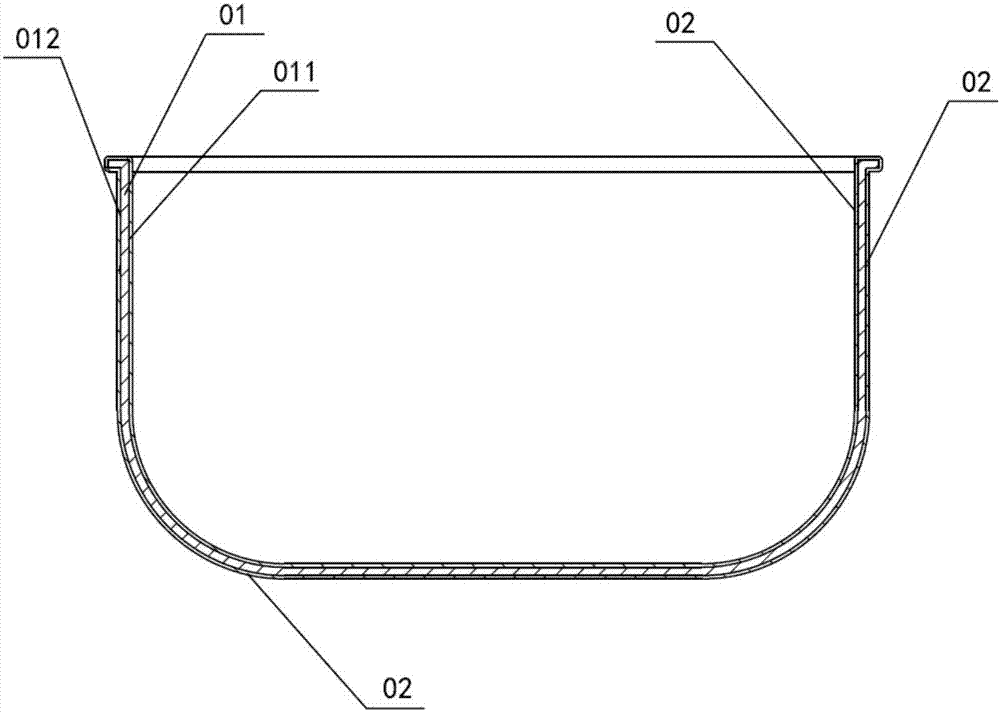

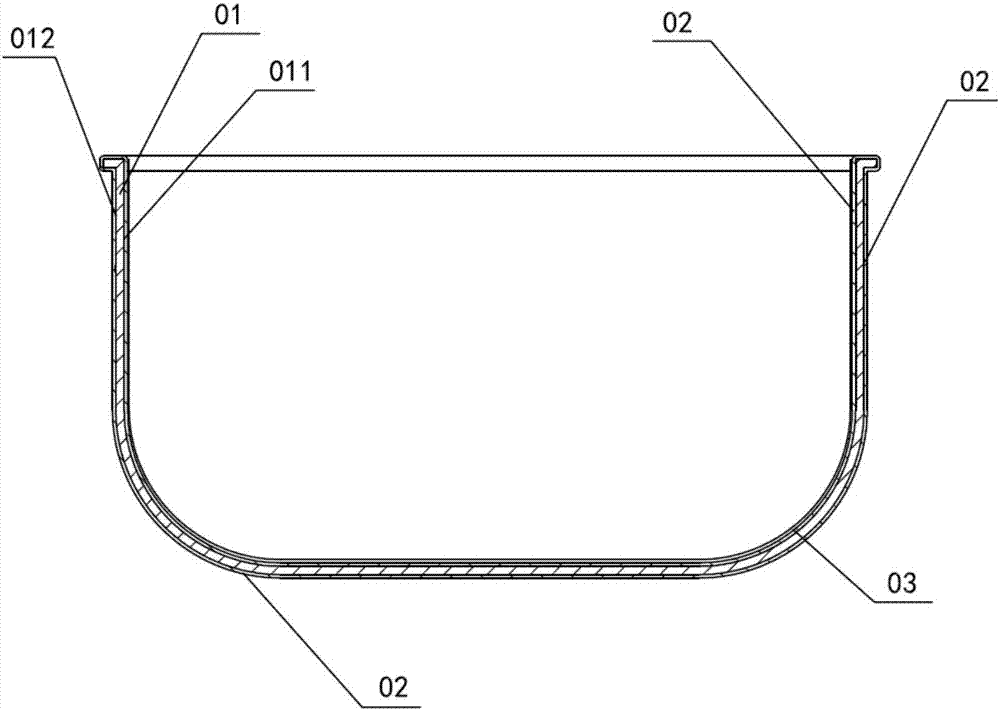

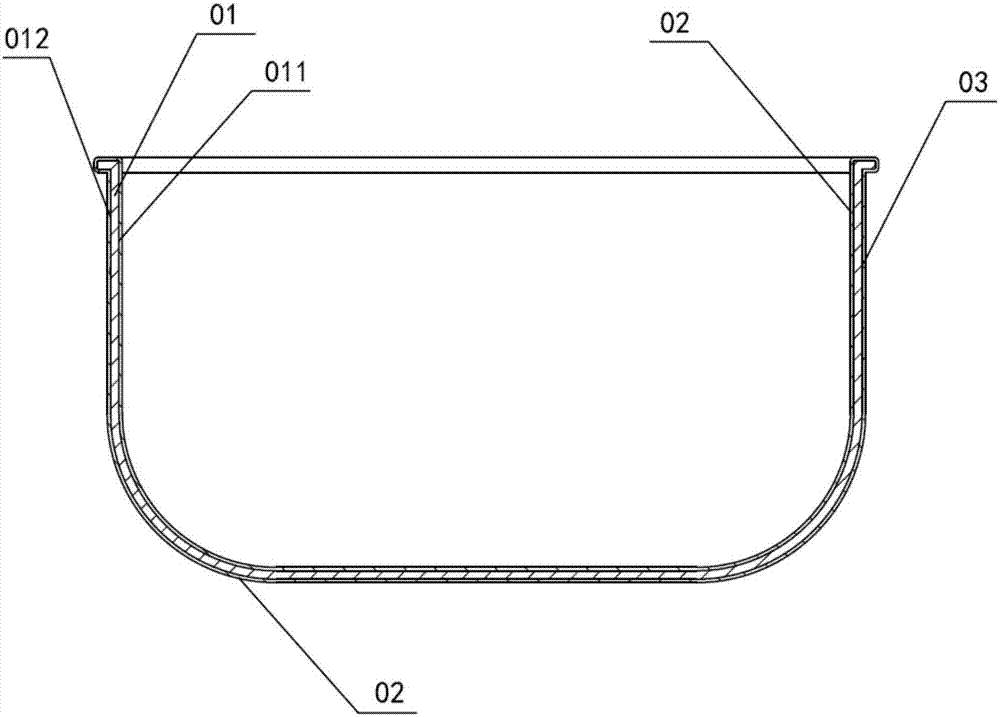

[0050] For the structural diagram of Embodiment 1 of the graphite cookware of the present invention, see figure 1 , including a pot body 01 made of graphite, the pot body 01 includes an inner wall 011 and an outer wall 012, a hard carbon film 02 is attached to the surface of the inner wall 011, and a hard carbon film 02 is also attached to the surface of the outer wall 012; The thickness of the carbon film 02 was 20 μm.

[0051] Since a hard carbon film is attached to the surface of the inner wall of the pot body, the hardness of the hard carbon film is higher than that of the existing PTFE resin film layer, which ensures the wear resistance of the graphite pot. The hard carbon film itself has Good air permeability ensures good thermal conductivity of the graphite cookware body, fast heat transfer, and uniform heating characteristics are well reflected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com