Lithium ion battery anode functional coating and preparation method thereof

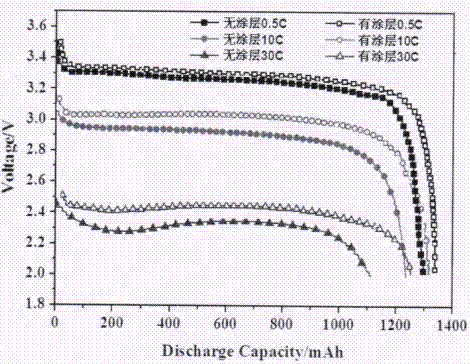

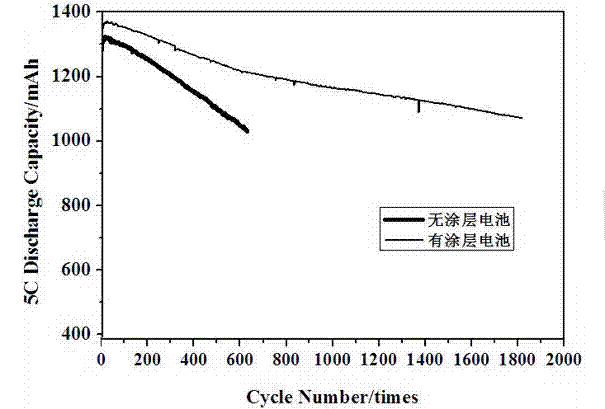

A lithium-ion battery, functional technology, applied in the direction of battery electrodes, coatings, conductive coatings, etc., can solve the problems of poor cycle performance at high rates, charge-discharge cycle life of less than 1000 times, battery damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The metered NMP is stirred at a high speed by HY-DLY100L Guangzhou Red Star Mixer, with a revolution speed of 25r / min and an autorotation speed of 2000r / min. Stop stirring when the temperature reaches 40°C~50°C, and add the metered binder PVDF (Solef5130). The mass ratio of NMP and PVDF is 80:1, and the solid content of the binder solution is 1.23%. First, it revolves at a low speed, with a speed of 15r / min. After 10 minutes, it starts to rotate at a high speed, with a speed of 1000r / min. After 10 minutes, it scrapes the wall and evacuates to a vacuum. -0.08MPa~-0.1MPa, high-speed revolution, speed 25r / min, high-speed autorotation, speed 2000r / min, connect cold circulating water, control the slurry temperature below 50°C, stir for 5h, break the vacuum to vacuum degree 0MPa~ -0.01 MPa, add metered carbon nanotubes, the mass ratio of PVDF and carbon nanotubes is 1:19, so that the solid content of the slurry is 20%, first revolve at a low speed, the speed is 15r / min, and st...

Embodiment 2

[0044] The metered NMP is stirred at a high speed by HY-DLY100L Guangzhou Hongxing Star Mixer, with a revolution speed of 25r / min and an autorotation speed of 2000r / min. When the temperature reaches 40°C~50°C, the stirring is stopped, and the metered binder PVDF (HSV900) is added. The solid content of the binder solution is 1.64%. First, it revolves at a low speed, with a speed of 15r / min. After 10 minutes, it starts to rotate at a high speed, with a speed of 1000r / min. After 10 minutes, it scrapes the wall, vacuumizes to a vacuum degree of -0.08MPa~-0.1MPa, and rotates at a high speed. , rotation speed 25r / min, high-speed autorotation, rotation speed 2000r / min, connect cold circulating water, control the slurry temperature below 50°C, stir for 5h, break the vacuum to vacuum degree 0MPa~-0.01 MPa, add metered Ketjen black The mass ratio of Super-p, PVDF, Ketjen black, and Super-p is 1:9:10, so that the solid content of the slurry is 25%. First, it revolves at a low speed at a s...

Embodiment 3

[0047] The metered NMP is stirred at a high speed by HY-DLY100L Guangzhou Hongxing Star Mixer, with a revolution speed of 25r / min and an autorotation speed of 2000r / min. When the temperature reaches 40°C~50°C, the stirring is stopped, and the metered binder PVDF (HSV900) is added. The solid content of the binder solution is 2.10%. First, low-speed revolution, the speed is 15r / min. After 10 minutes, the high-speed rotation is started, and the speed is 1000r / min. After 10 minutes, the wall is scraped, vacuumed to a vacuum degree of -0.08MPa~-0.1MPa, and high-speed revolution , rotation speed 25r / min, high-speed autorotation, rotation speed 2000r / min, connect cold circulating water, control the slurry temperature below 50°C, stir for 6h, break the vacuum to vacuum degree 0MPa~-0.01 MPa, add metered Ketjen black , the mass ratio of PVDF and Ketjen black is 1:19, so that the solid content of the slurry is 30%, first revolve at a low speed, with a speed of 15r / min, and then start hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com