Method for coating substrate with coating

A technology for substrates and coatings, applied in coatings, devices for coating liquids on surfaces, measuring devices, etc., can solve the problems that cannot be said to provide methods for effectively controlling the formation of coatings, and achieve the effect of quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

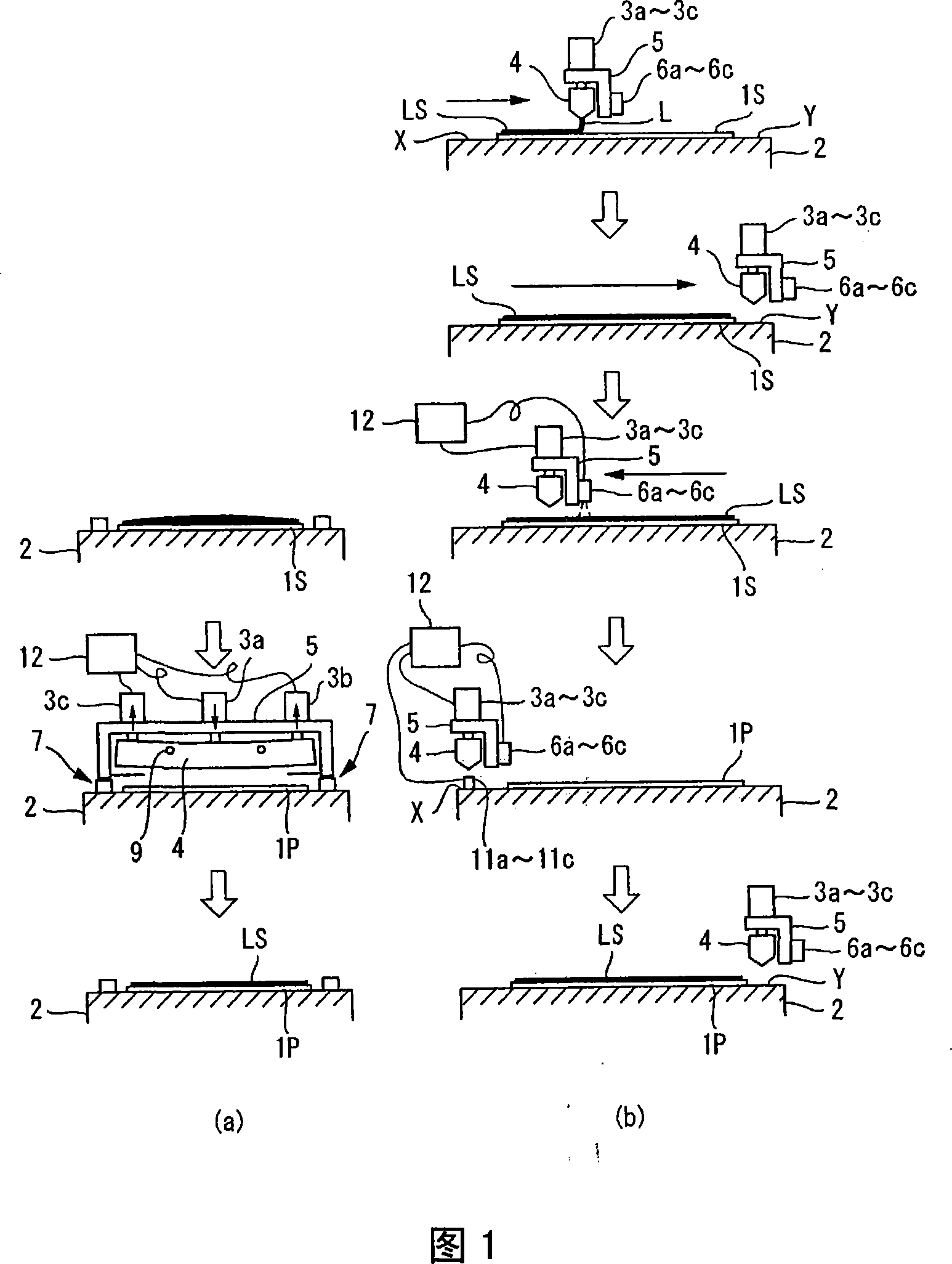

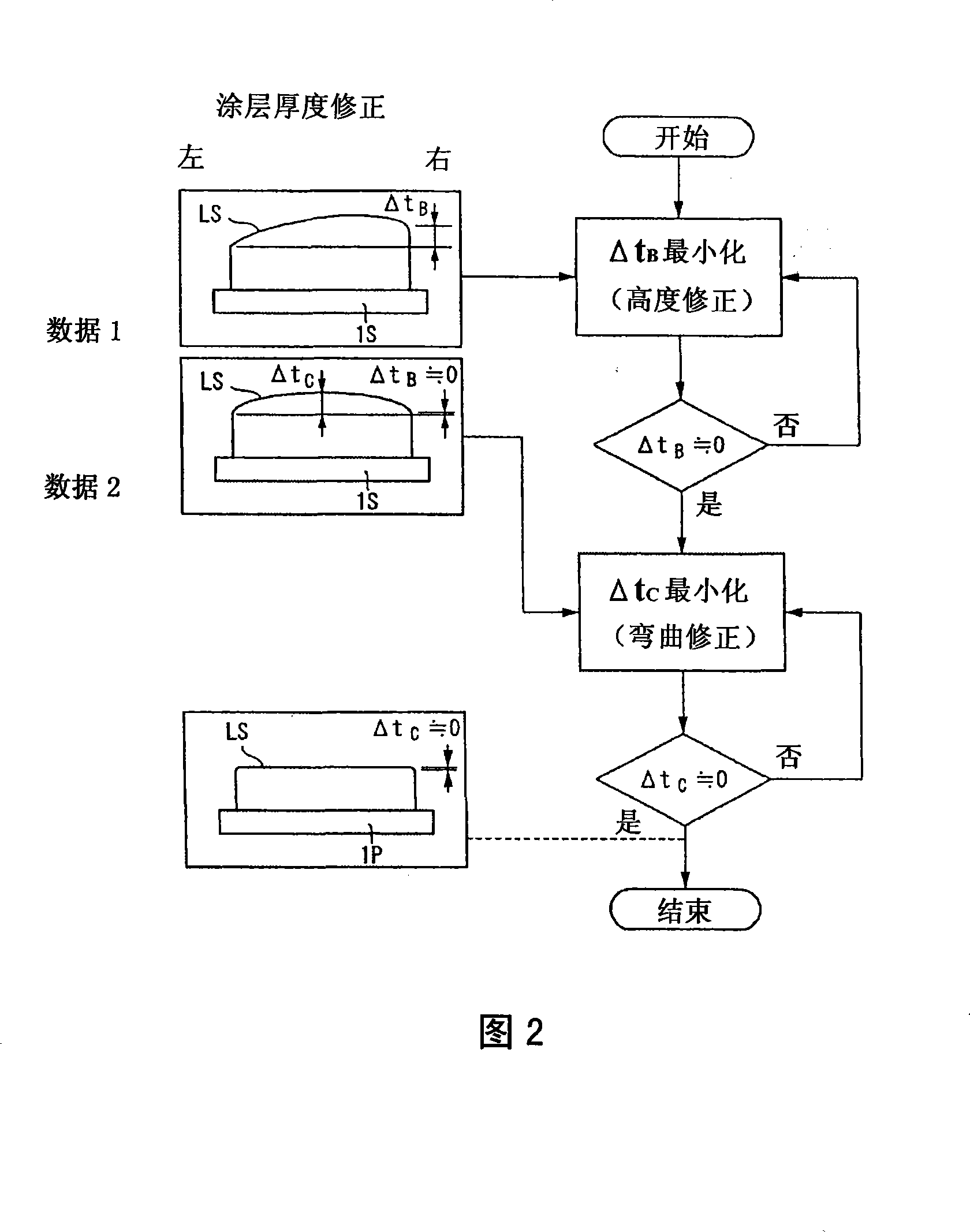

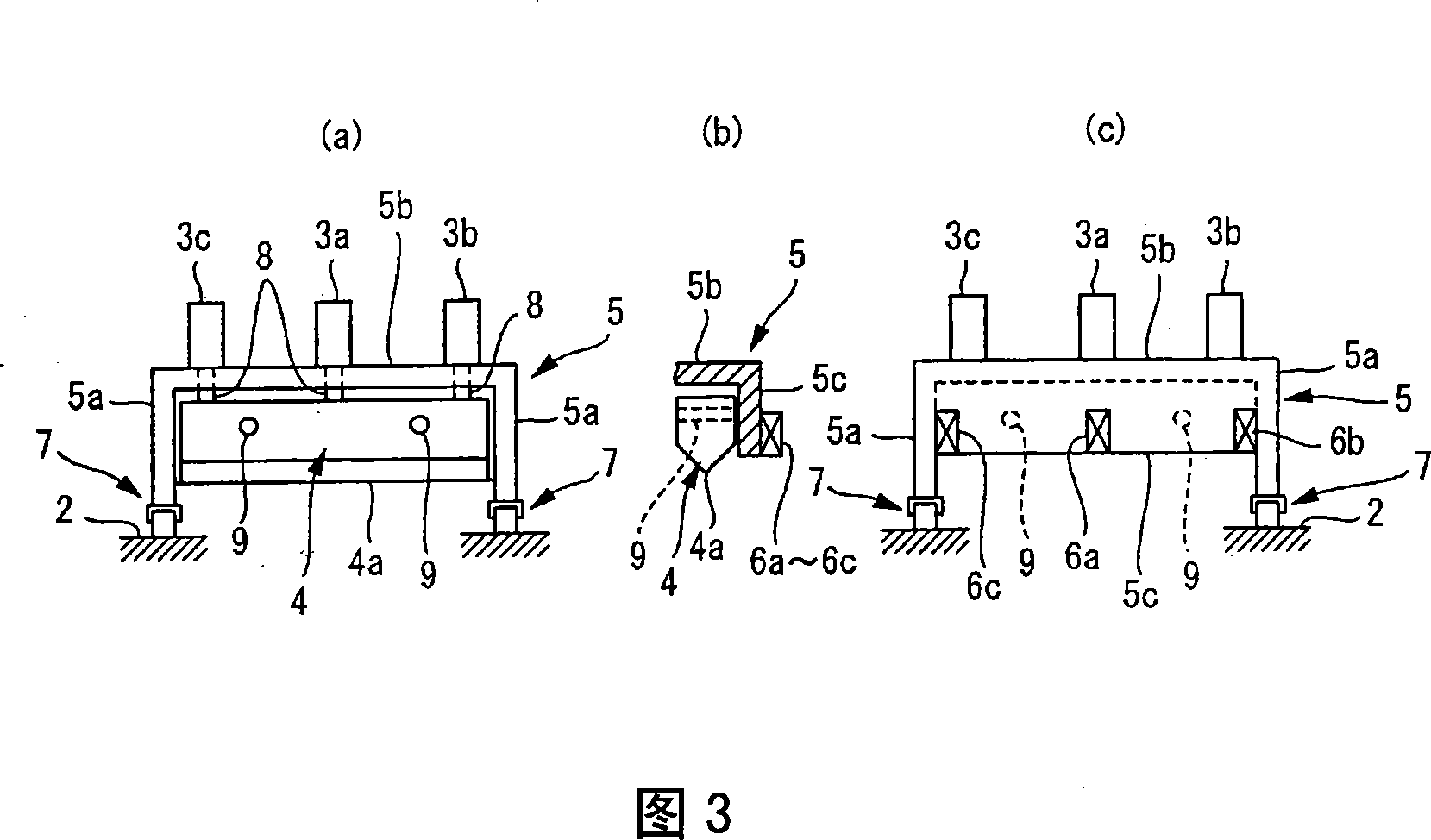

[0028] A detailed description of preferred embodiments of the present invention is provided below with reference to the accompanying drawings. The present invention is a method of applying a coating to a substrate, wherein, as shown in FIG. The liquid medium L is applied to the substrates 1S (sample for test coating) and 1P (product) located on the stage 2 . In this method, distance sensors 6 a - 6 c installed before processing are used to measure the distance between the surface LS of the coating on the substrate 1S and the nozzle 4 . To start the process, the test substrate 1S is placed on the table 2 and the test liner is tentatively coated by the nozzle 4 while the nozzle holder 5 is moving on the table 2 in a forward direction relative to the table 2. Bottom 1S. Then, the distance sensors 6a-6c perform a measuring operation while the nozzle holder 5 is moved in the backward direction relative to the table 2. Then, in order to obtain the desired coating surface LS, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com