A coating device for the surface of polymer catheter

A technology of polymers and catheters, which is applied to the device and coating of the surface coating liquid, which can solve the problems of coating waste, adhesion firmness, large coating thickness, high equipment cost, etc., and achieve production sanitation and safety Guaranteed safety, uniform coating thickness, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

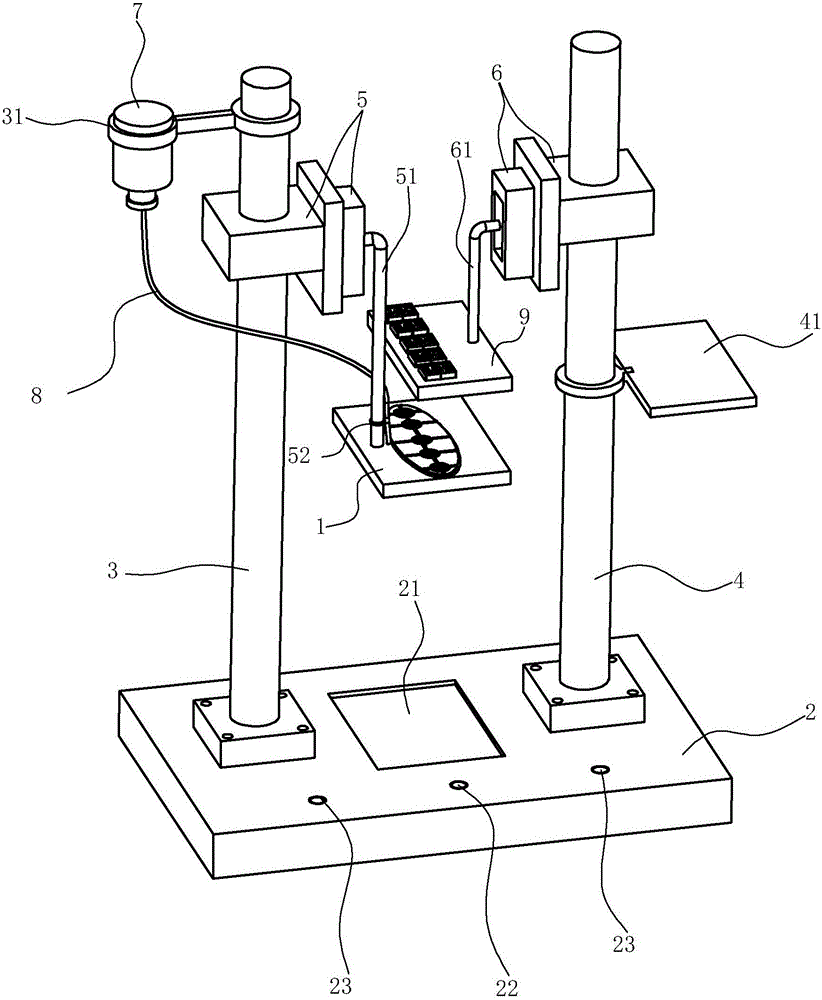

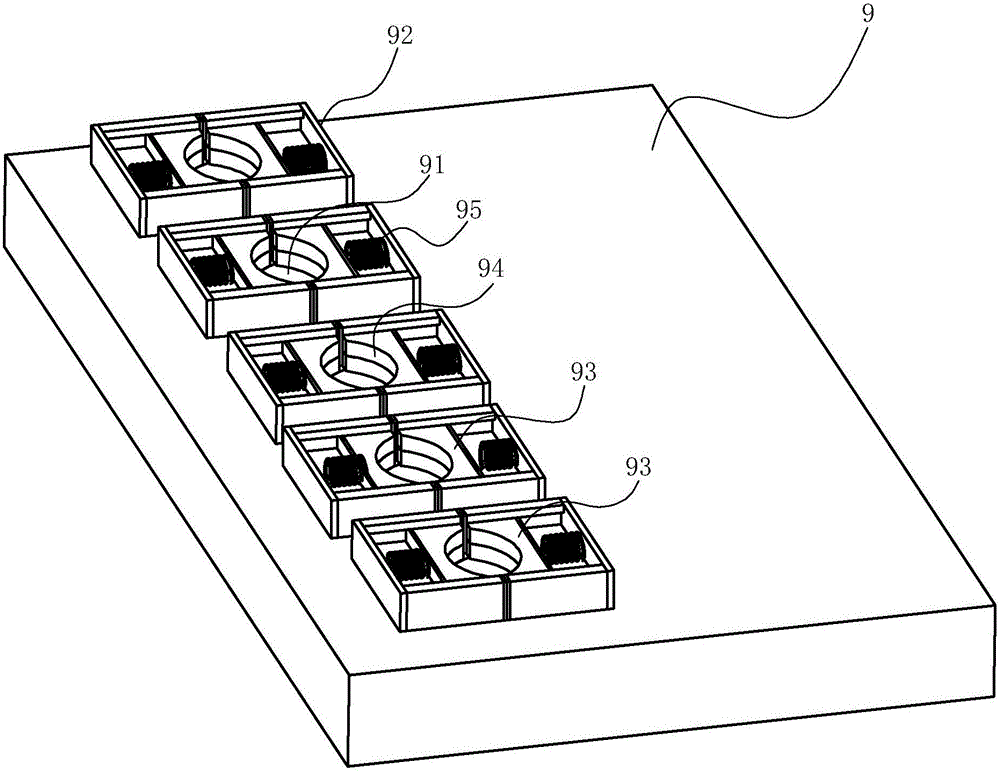

[0022] Such as Figure 1 to Figure 3 As shown, the coating equipment for the surface of polymer catheters includes:

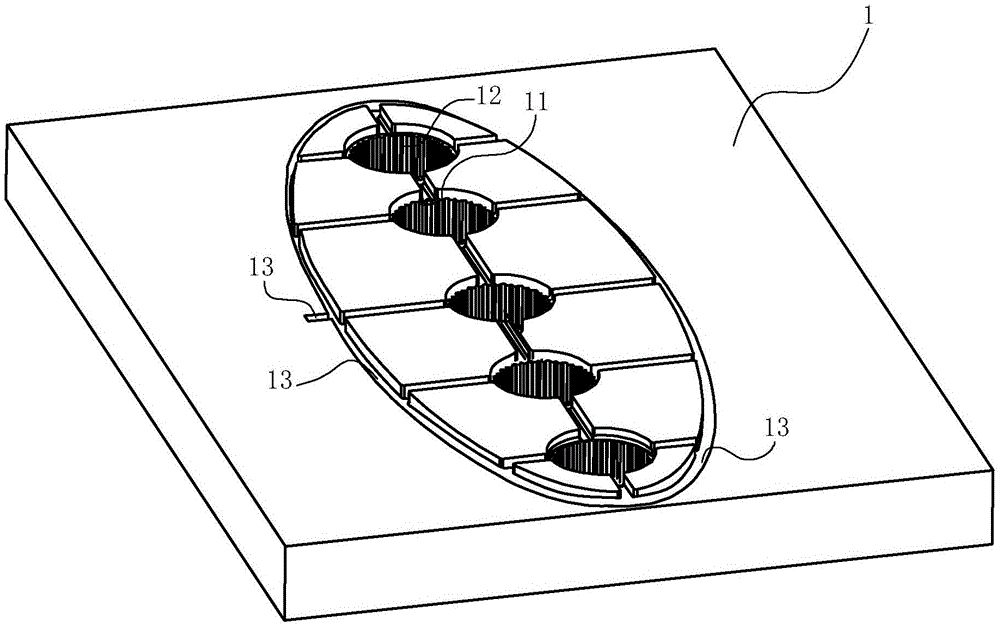

[0023] The first carrier plate 1 is provided with a plurality of through holes 11 on the first carrier plate, five in the present embodiment; a plurality of ribs 12 are longitudinally provided on the side walls of each through hole; each rib in the present embodiment There is a smooth transition between them, and the surface of the convex rib is also a curved structure. A groove 13 is opened on the surface of the first carrier, and the groove 13 communicates with five through holes. The groove is a fluid replenishment channel for replenishing fluid into each through hole.

[0024] The base 2 is the supporting seat of the coating equipment. The middle part of the base 1 is provided with a liquid storage tank 21 , and the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com