Frame for receiving annular components and method

A component and ring-shaped technology, applied in the direction of electrolytic components, optical components, shafts and bearings, etc., can solve the problem that coating defects cannot be completely prevented, and achieve the effect of uniform coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

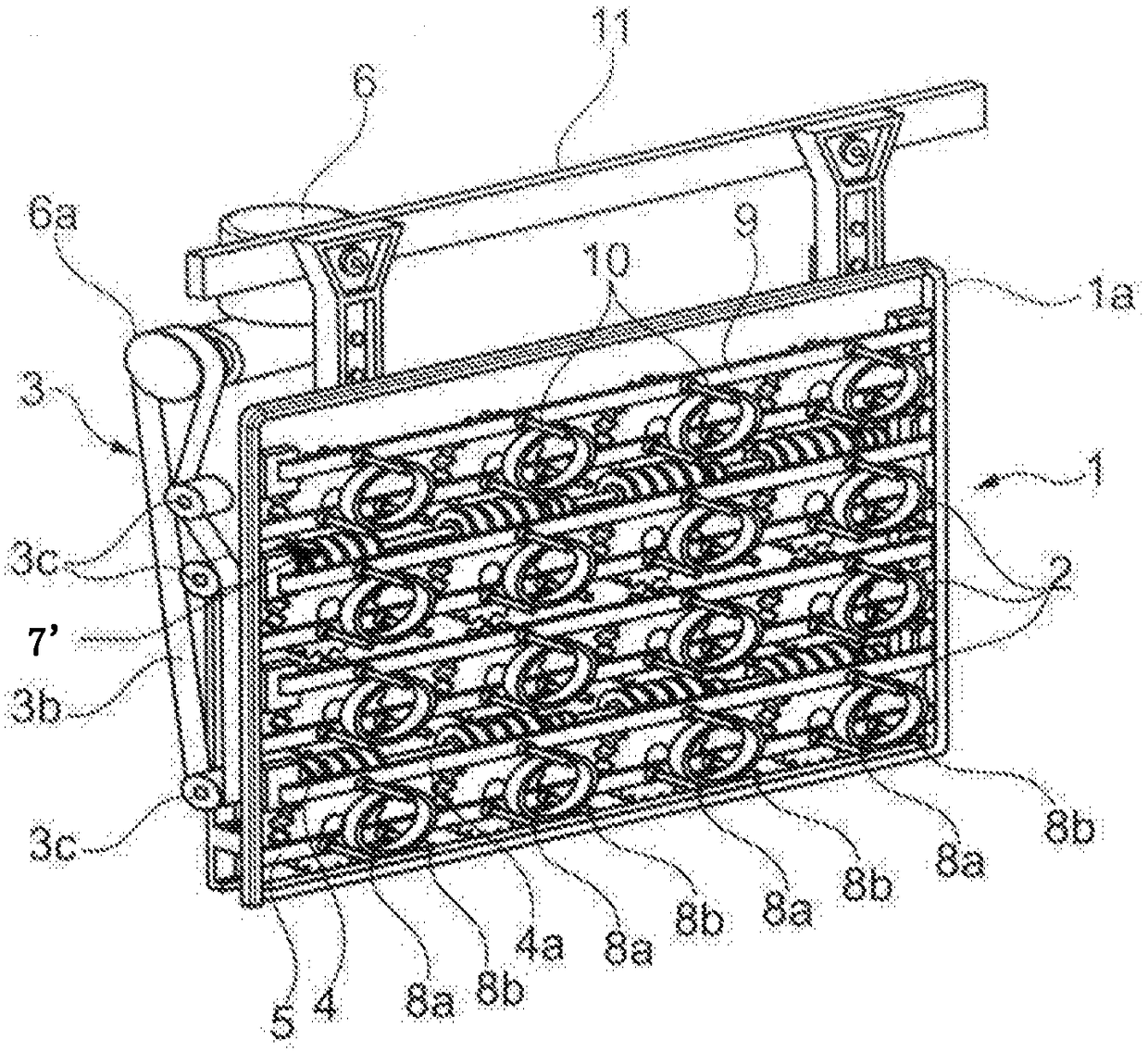

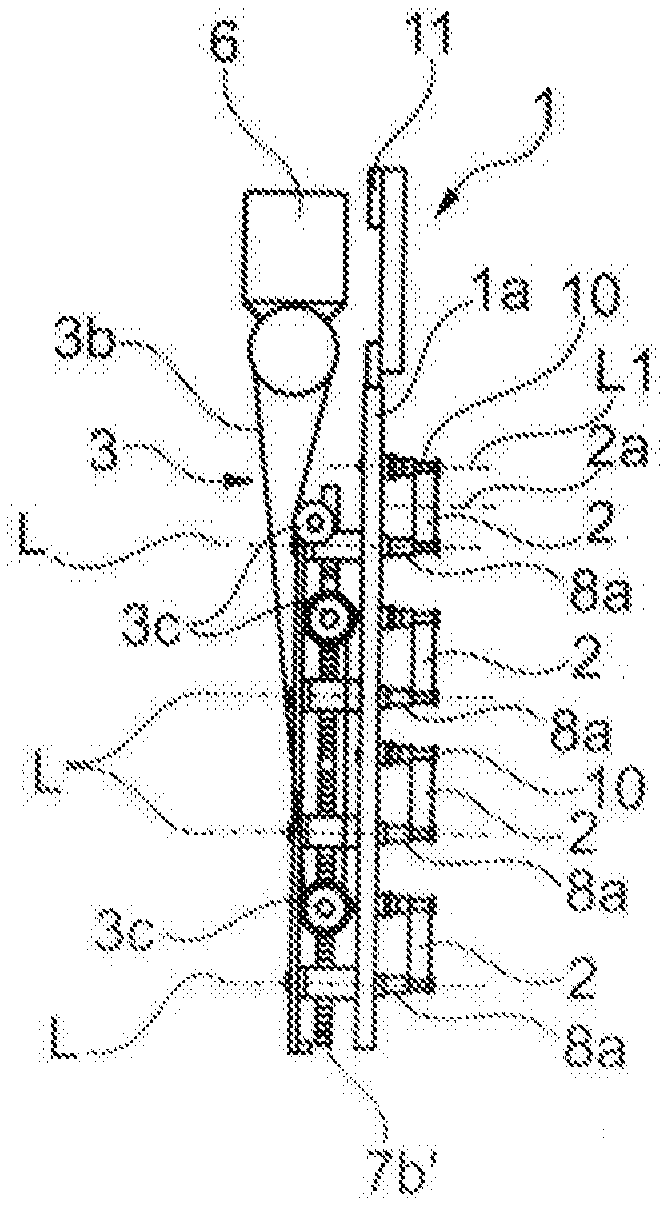

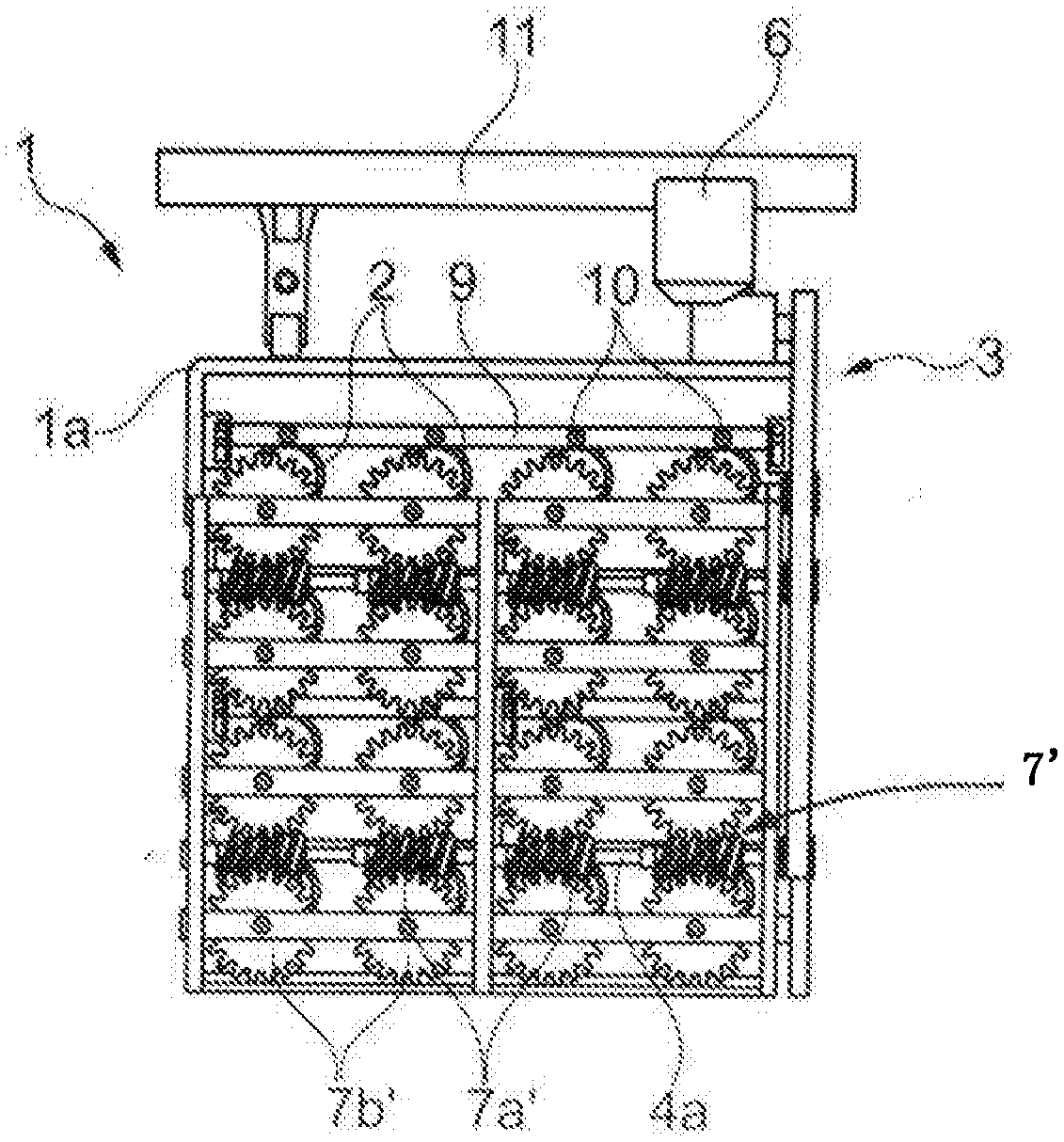

[0047] figure 1 A three-dimensional front view of a first carrier 1 for accommodating a ring-shaped component 2 in the form of a bearing ring here and for chemically or galvanically coating the component 2 in an electrolytic bath is shown. The first bracket 1 includes a carrying frame 1a, a first drive unit 3 and four second drive units 4, and each second drive unit 4 has a horizontally arranged first lateral support structure 5. The first carriage 1 further includes a driving motor 6 for driving the first driving unit 3 , wherein the first driving unit 3 is connected with four second driving units 4 in a manner of driving these second driving units. In addition, the first bracket 1 also includes pairs of longitudinal axes L of each first transverse support structure 5 that can be around the drive pin (see figure 2 ) rotating horizontally arranged driving pins 8a, 8b for accommodating the ring-shaped member 2, the driving pins are arranged on the first lateral support structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com