Anti-flashover RTV (Room Temperature Vulcanization) coating material coating method for umbrella-shaped and bell-shaped insulators

An antifouling flashover coating and coating method technology, applied in the direction of insulators, electrical components, circuits, etc., can solve the problems of uneven spraying, complex shape, deep groove of umbrella ring, etc., and achieve smooth surface, high product quality, coating The effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

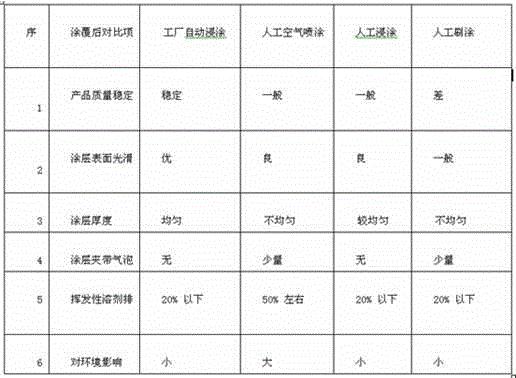

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of coating method of umbrella, bell shape insulator RTV antipollution flashover paint, the steps are as follows:

[0036] (1) Pretreatment: Clean the qualified insulators and pretreat the metal fittings; check whether the insulators have certificates of conformity, whether there are defects, cracks, damage, pores, mechanical impurities, and oil stains that are difficult to clean on the surface of the insulators;

[0037] (2) On-machine: Connect the insulator to the head of the equipment, and put the paint into the tooling equipment; it can detect whether the insulator has a certificate of conformity, whether the insulator surface has defects, cracks, damage, pores, mechanical impurities, oil stains that are difficult to clean, etc. .

[0038] (3) Coating: Dip the insulator in the paint for spin coating; paint during the spin process to prevent uneven coating, dripping and accumulation of the paint on the insulator during the coating process. The steps of spin co...

Embodiment 2

[0048] Other steps are as in Example 1, the solid content of the paint is 65%, and the surface dry time of the paint is 20 minutes.

[0049] The viscosity of the coating is tested by coating 4 cups, and the viscosity is 15 minutes.

[0050] The dipping step is that the head of the coating equipment is tilted to immerse the insulator in the paint and rotate the coating, the downward slope is 50°C, the speed is 15 rpm, and the time is 50s.

[0051] The material throwing step is to make the insulator completely leave the coating liquid surface and then rotate for 5 minutes at a speed of 90 rpm and a downward slope of 50°.

[0052] The closing step is to adjust the head of the coating equipment to raise the insulator, the inclination is 30°, the time is 90s, and the speed is 15 rpm; the edge closing step is to place the insulator in the horizontal direction during rotation, the inclination is -5°, and the surface dry time is 80min , the speed is 10 rev / min.

[0053] Curing time ...

Embodiment 3

[0055] Other steps are as in Example 1, the solid content of the coating is 55%, and the surface drying time of the coating is 45 minutes.

[0056] The viscosity of the coating is tested by coating 4 cups, and the viscosity is 50min.

[0057] The dipping step is to tilt the head of the coating equipment to immerse the insulator in the coating and rotate the coating, the downward slope is 45°, the speed is 10 rpm, and the time is 60s; the material rejection step is to make the insulator completely leave the coating liquid surface and then rotate for 3 minutes , the speed is 60 rpm, and the downward slope is 45°.

[0058] The closing step is to adjust the insulator on the head of the coating equipment, the inclination is 25°, the time is 40s, and the speed is 18 revolutions / min; The speed is 12 revolutions / min.

[0059] Curing time 24h, temperature 20°C, humidity 60%;

PUM

| Property | Measurement | Unit |

|---|---|---|

| tack-free time | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

| tack-free time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com