Device for coating liquid, which is such as adhesive agent, especially hot melt adhesive

A technology of hot-melt adhesives and adhesives, applied to devices for coating liquids, liquids such as adhesives, especially in the field of hot-melt adhesives, can solve the problems of expensive and troublesome operations, and avoid flow variables Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

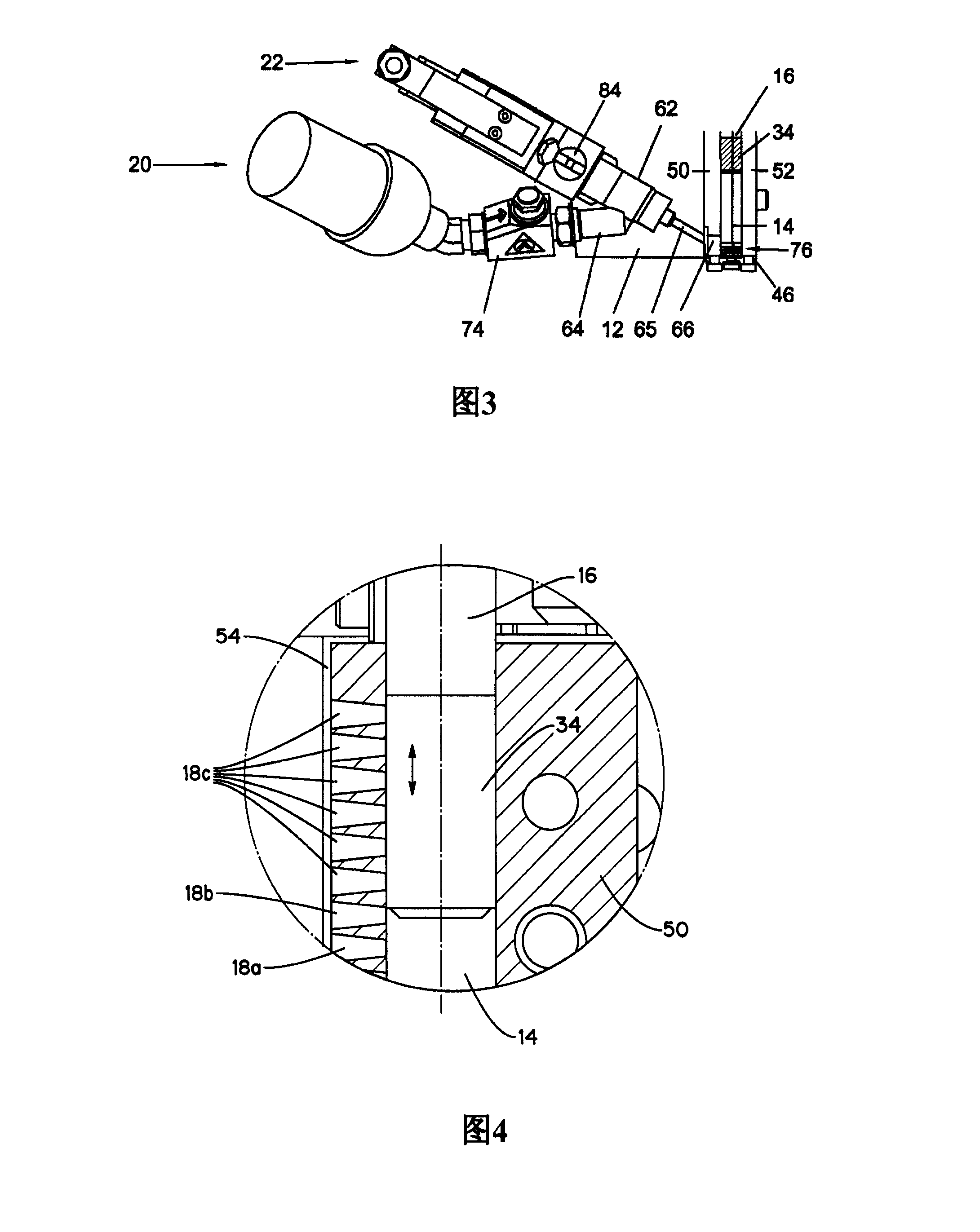

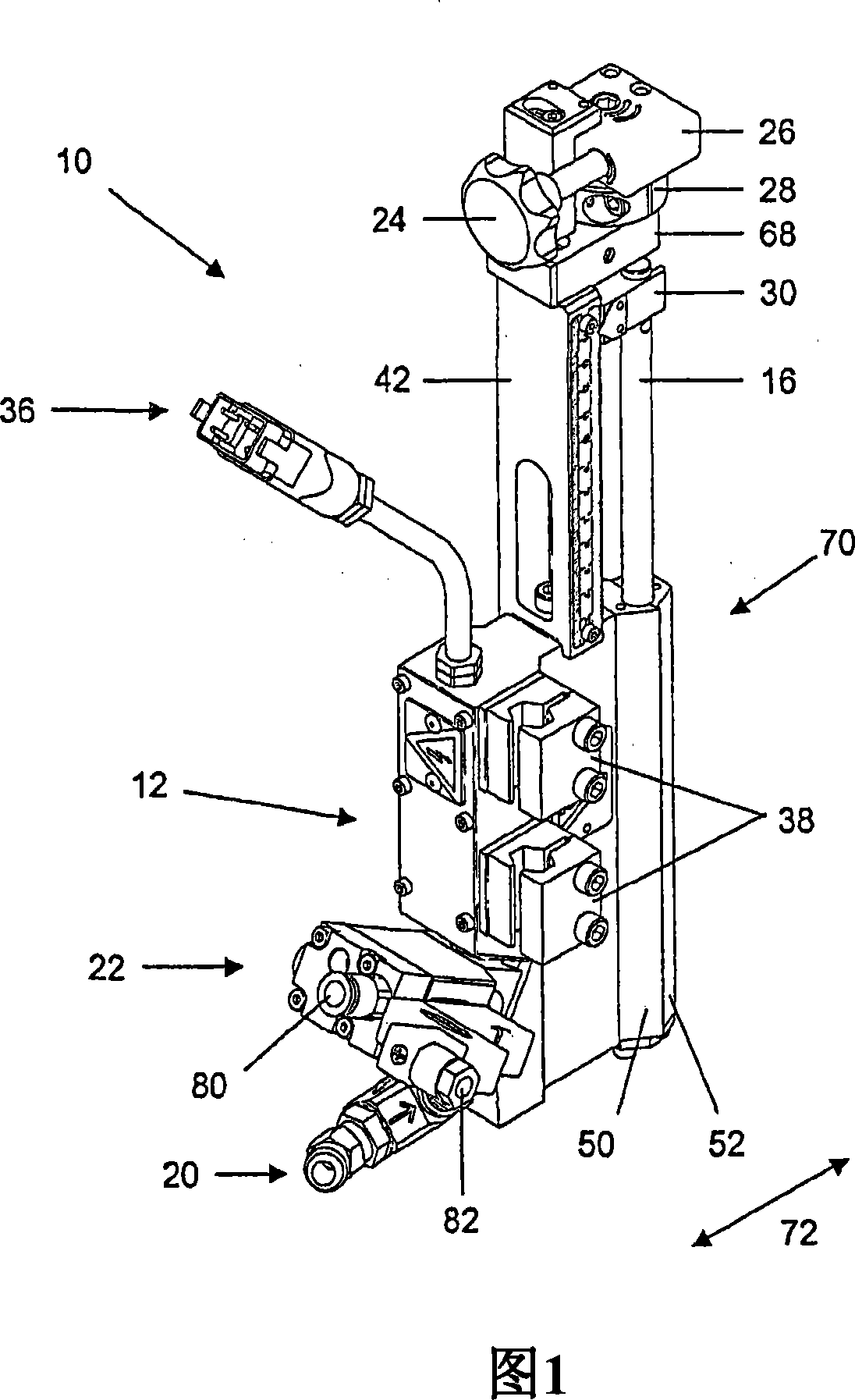

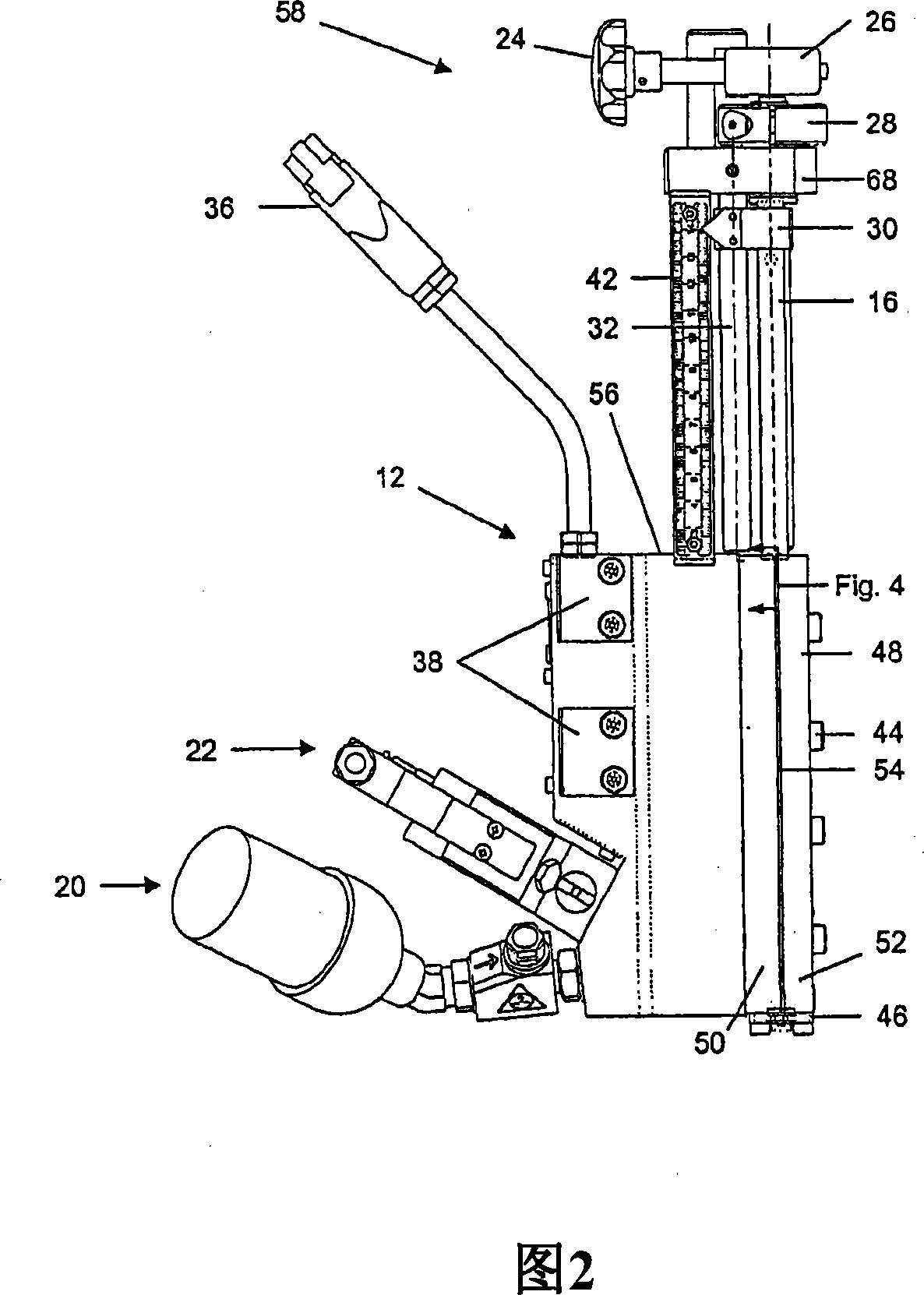

[0026] The device 10 shown in FIG. 1 is used to apply a liquid, such as an adhesive, especially hot melt, to a substrate that is movable relative to the device 10 in the direction of the arrow 72 shown. The device comprises an electropneumatically operated delivery valve 22 connected to the base body 12 . On one side of the base body 12 , the nozzle arrangement 70 is detachably fastened by means of screw connections 44 and centered by means of screws 48 ( FIG. 2 ). The nozzle assembly consists of two building blocks 50 and 52 . The device 10 can be connected via a conduit 20 to a source of liquid, not shown. The device 10 is supplied with electrical energy via the connecting element 36 . The device 10 can be fixed in its position by means of the fixing element 38 .

[0027] The electrically operable delivery valve 22 has an electrical connection 82 and a compressed gas connection 80 , by means of which a compressed gas source (not shown) can be connected. In this way, it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com