Spinneret for preparing reinforced hollow fiber membrane, membrane manufacturing method and hollow fiber membrane

A spinneret and fiber membrane technology, which is applied in the field of hollow fiber membrane preparation, can solve the problems of difficult to control precoating liquid seepage, difficult operation and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

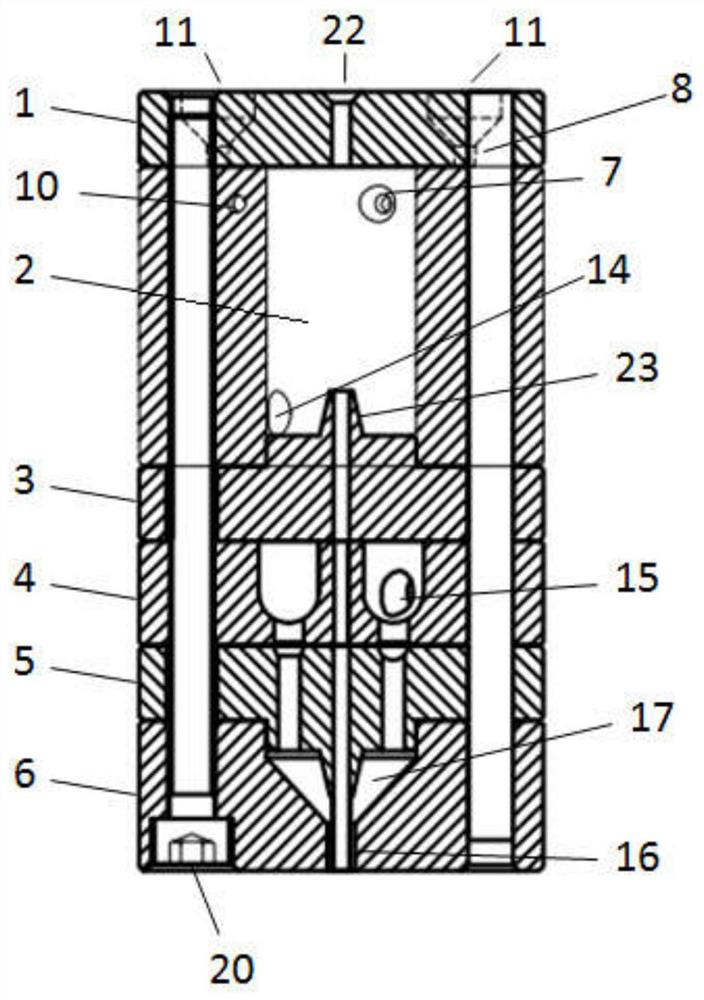

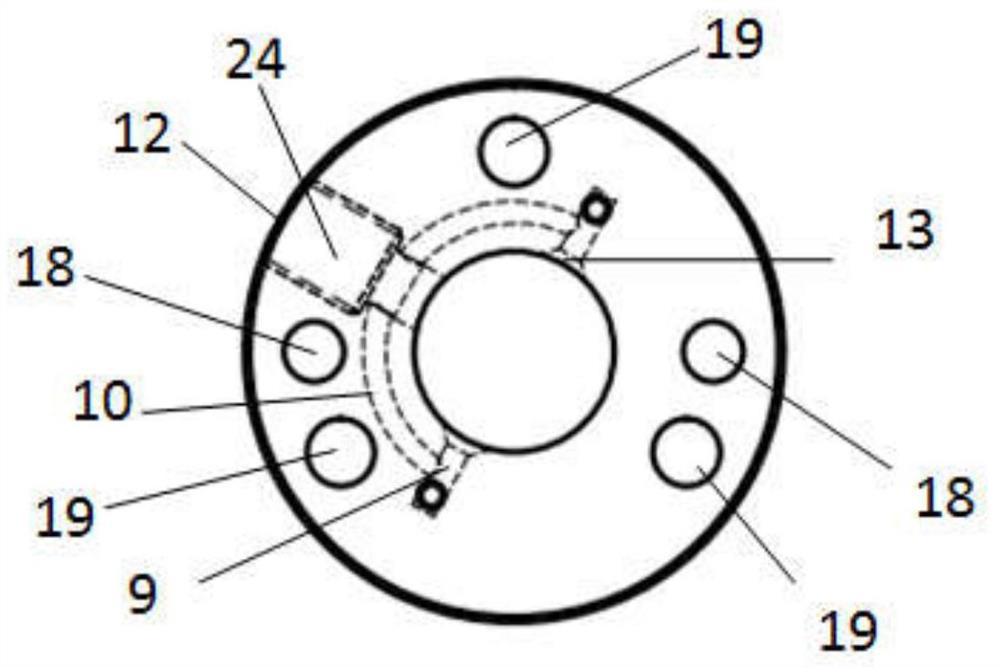

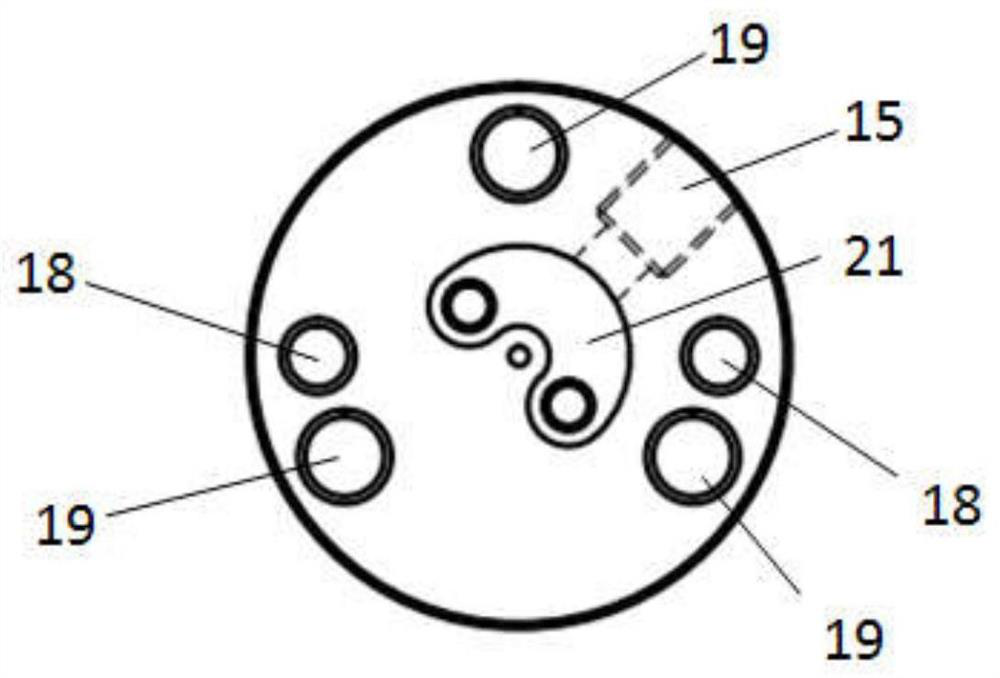

[0032] refer to Figure 1-3 , the spinneret for preparing reinforced hollow fiber membranes of the present invention comprises a coating spinneret and a pre-coating device arranged on the top of the first coating spinneret, and the primary coating spinneret includes passing through the rope hole 22 successively Connected baffle plate 3 , primary distribution plate 4 , secondary distribution plate 5 and bottom plate 6 .

[0033] The pre-coating device includes a cover plate 1 and a pre-coating chamber 2 located below the cover plate 1. The bottom of the wall of the pre-coating chamber 2 is set on the baffle plate 3; The hole 8 and the air inlet hole 8 are symmetrically distributed on both sides of the rope hole 22. The inner radial direction of the air inlet hole 8 gradually becomes larger and an air inlet 11 is formed on the upper surface of the cover plate, and the air inlet 11 is connected to the air compressor. . Two atomizing holes 7 leading to the precoating chamber 2 a...

Embodiment 2

[0043] The method for preparing reinforced hollow fiber membrane using spinneret of the present invention comprises the following steps:

[0044] Support tube pretreatment: the support tube is passed through the threading hole 22 of the spinneret of the present invention, the coating liquid is supplied to the liquid inlet hole 24 by a metering pump, and the high-speed airflow is supplied to the air inlet hole 8 by an air compressor. Spinneret atomization holes 9 meet and are atomized and sprayed into the pre-coating cavity 2, evenly wetting the surface of the support tube;

[0045] Hollow fiber membrane preparation: the pretreated support tube is coated with casting solution, and then immersed in a coagulation bath for phase inversion to obtain a reinforced hollow fiber membrane.

[0046] Figure 4 It is a flow chart of the film making process of the present invention. In this embodiment, the support body is woven or knitted from polyester fiber filaments, the weaving densit...

Embodiment 3

[0054] In Example 2, the composition ratio in the coating liquid is set to PMMA:NMP=15:85, the feed rate of the coating liquid is set to 10 ml / min, the compressed air is set to 0.2MPa, except Otherwise, the operation was carried out in the same manner as in Example 2 to obtain a reinforced hollow fiber membrane 2 comprising a reinforcing layer, a coupling layer, and a separation layer connected from the inside to the outside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com