Patents

Literature

385results about How to "Easy to move and adjust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

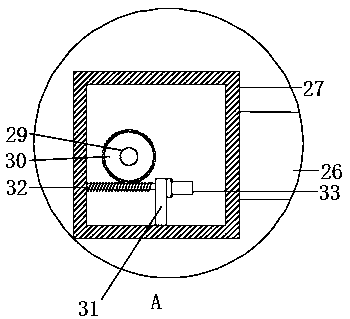

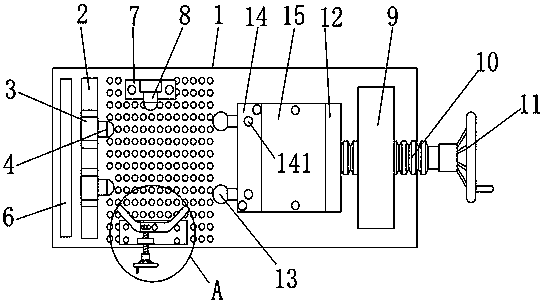

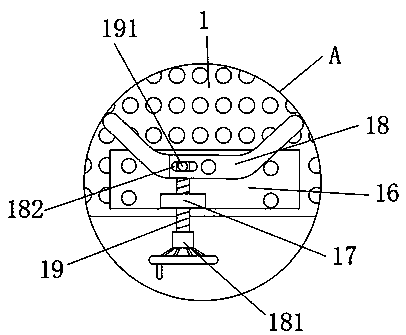

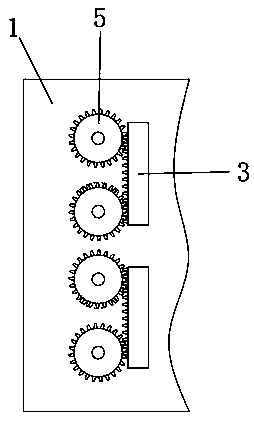

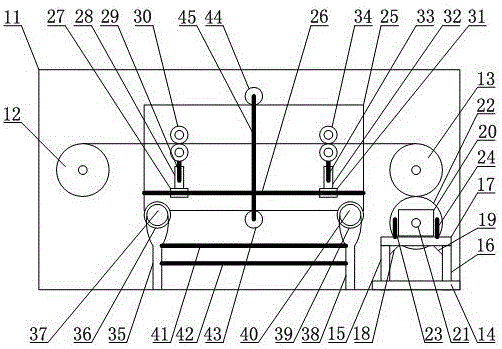

Rapid diluting and mixing device for agricultural agent

InactiveCN107398204AImprove the mixing effectImprove mixing efficiencyRotary stirring mixersTransportation and packagingEngineeringDrive shaft

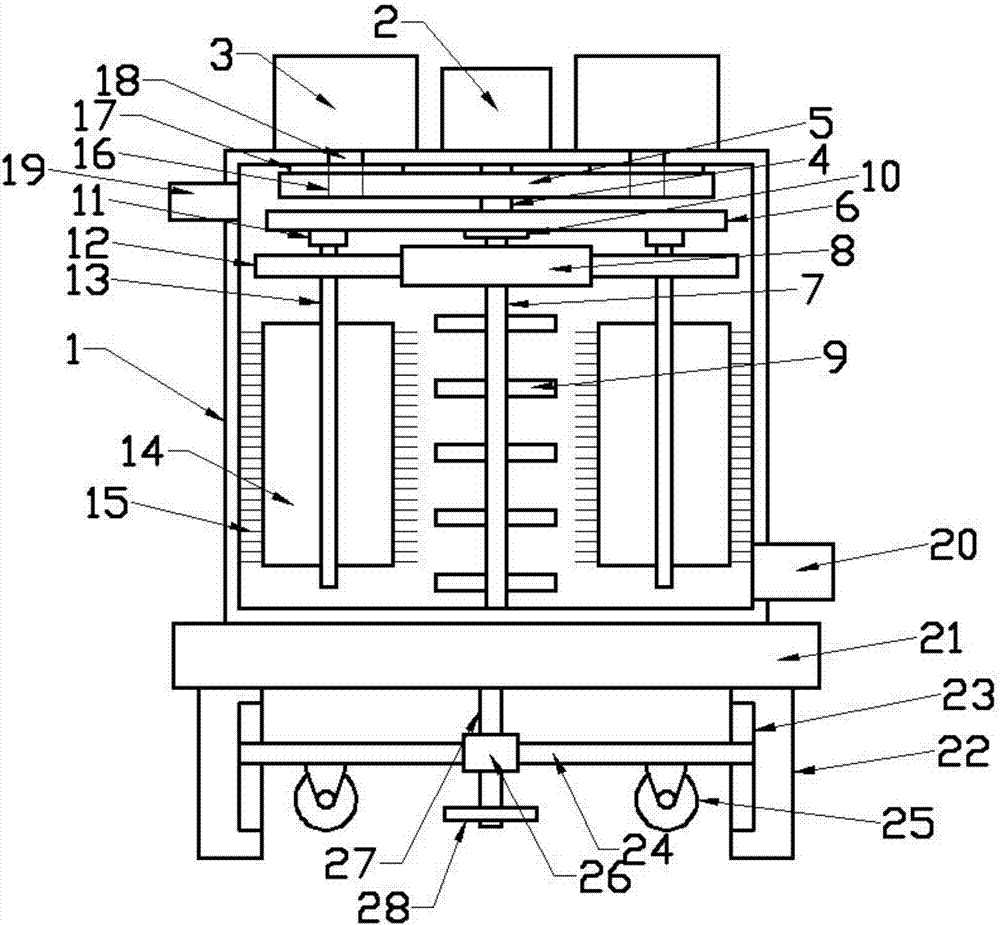

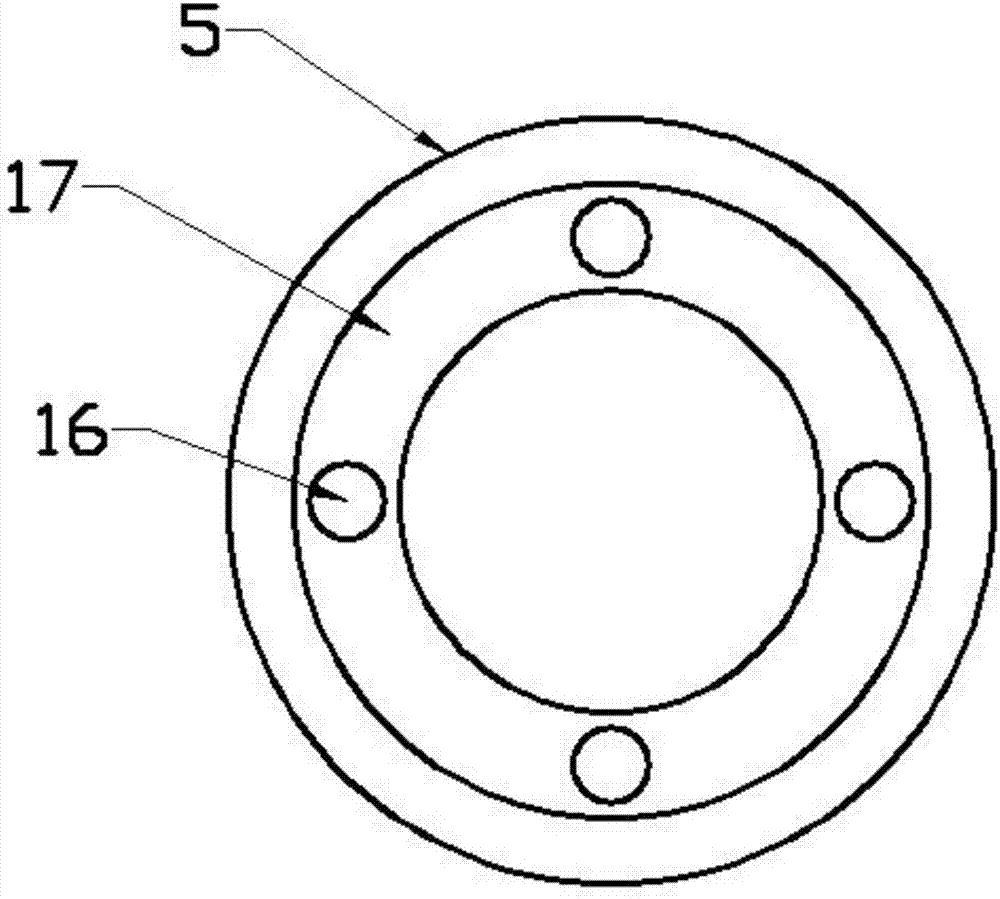

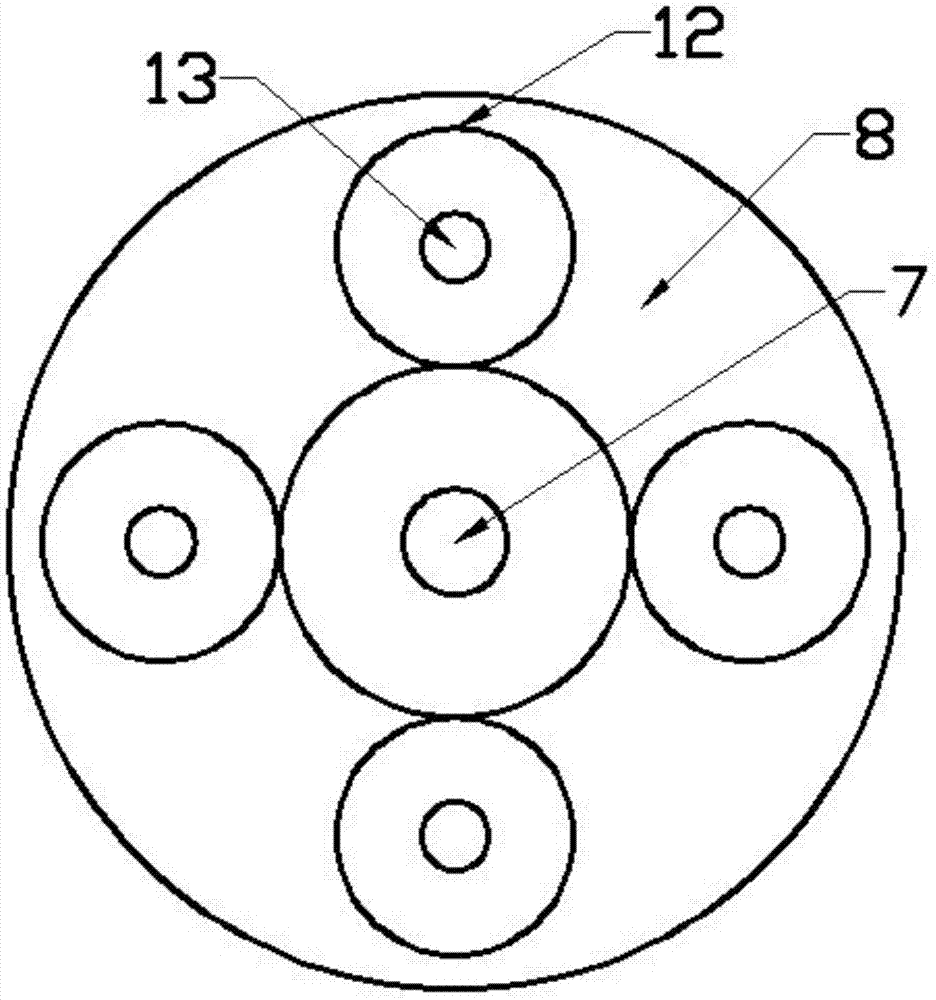

The invention discloses a rapid diluting and mixing device for an agricultural agent. The rapid diluting and mixing device comprises a shell, a motor, a medicine kit and a base, wherein a horizontal rotating disk is fixed at the lower end of a transmission shaft; a vertical first stirring shaft is fixedly inserted into a first bearing; a plurality of horizontal stirring rods are fixed on the side wall of the first stirring shaft; a driven gear is meshed with a horizontal driving gear; a mixing blade is fixed at the lower end of a second stirring shaft; vertical connection openings are formed in a seal ring and a seal plate; a mobile regulating mechanism comprises a slide chute, a support rod, a mobile wheel, a threaded tube, a screw rod and a handle. The mixing blade and the stirring rods are driven to rotate simultaneously through the arranged turn plate, and internal different positions are stirred, so that the mixing effect of a liquid medicine is improved and the uniform mixing of the liquid medicine is ensured; and the liquid medicine in the medicine kit falls off through the rotating connection openings, the agent discontinuously falls off and the agent can be quickly mixed with water, so that the mixing efficiency is improved.

Owner:广西综改咨询服务有限公司

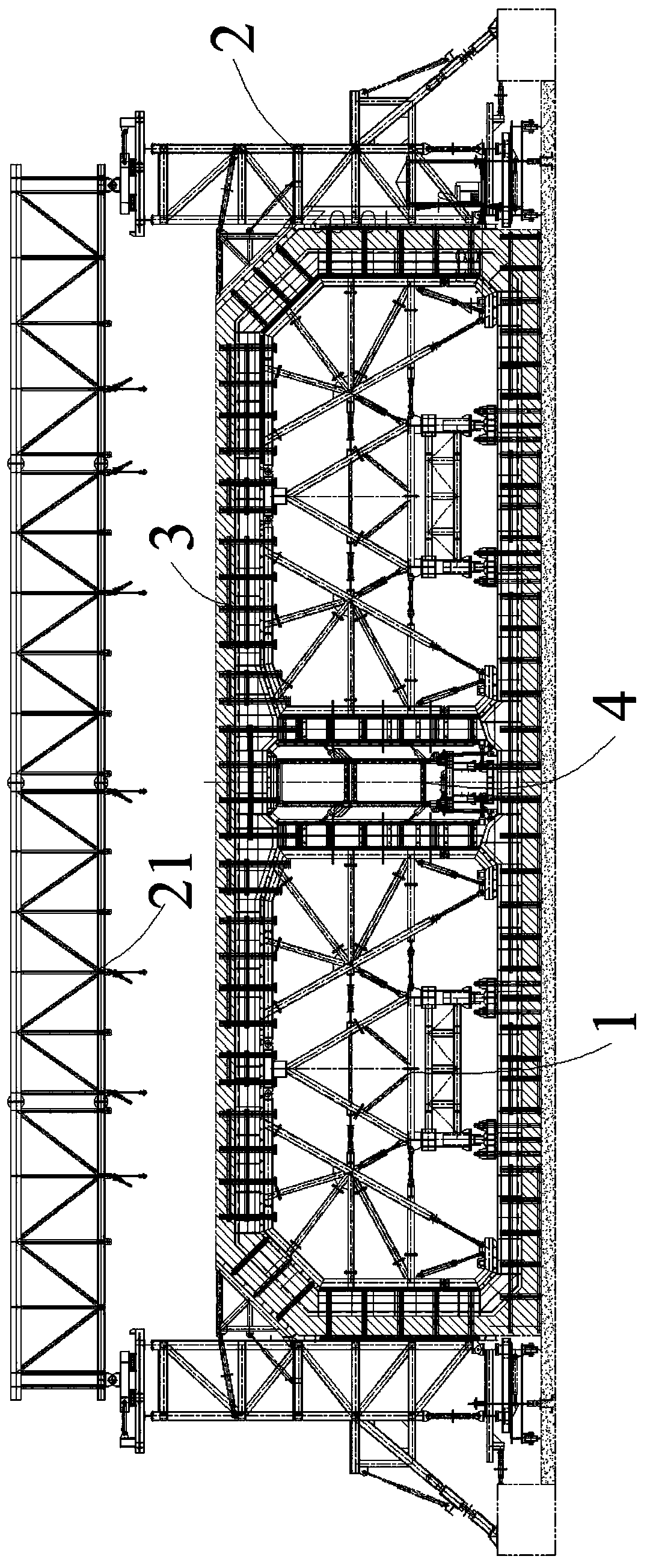

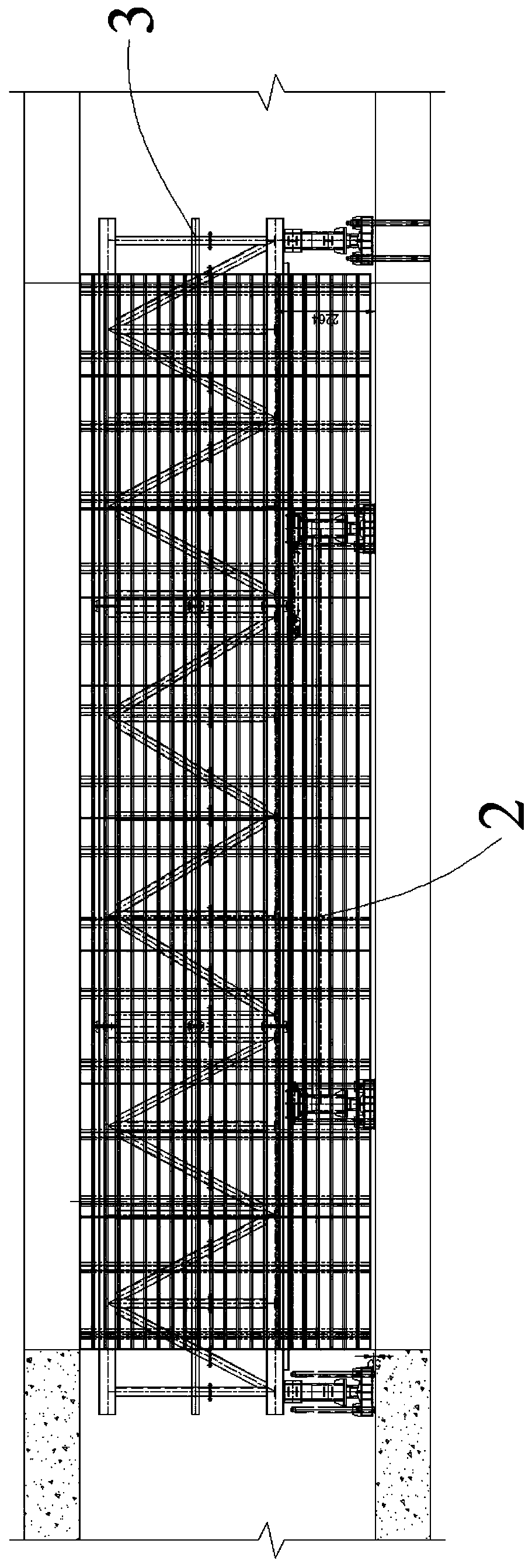

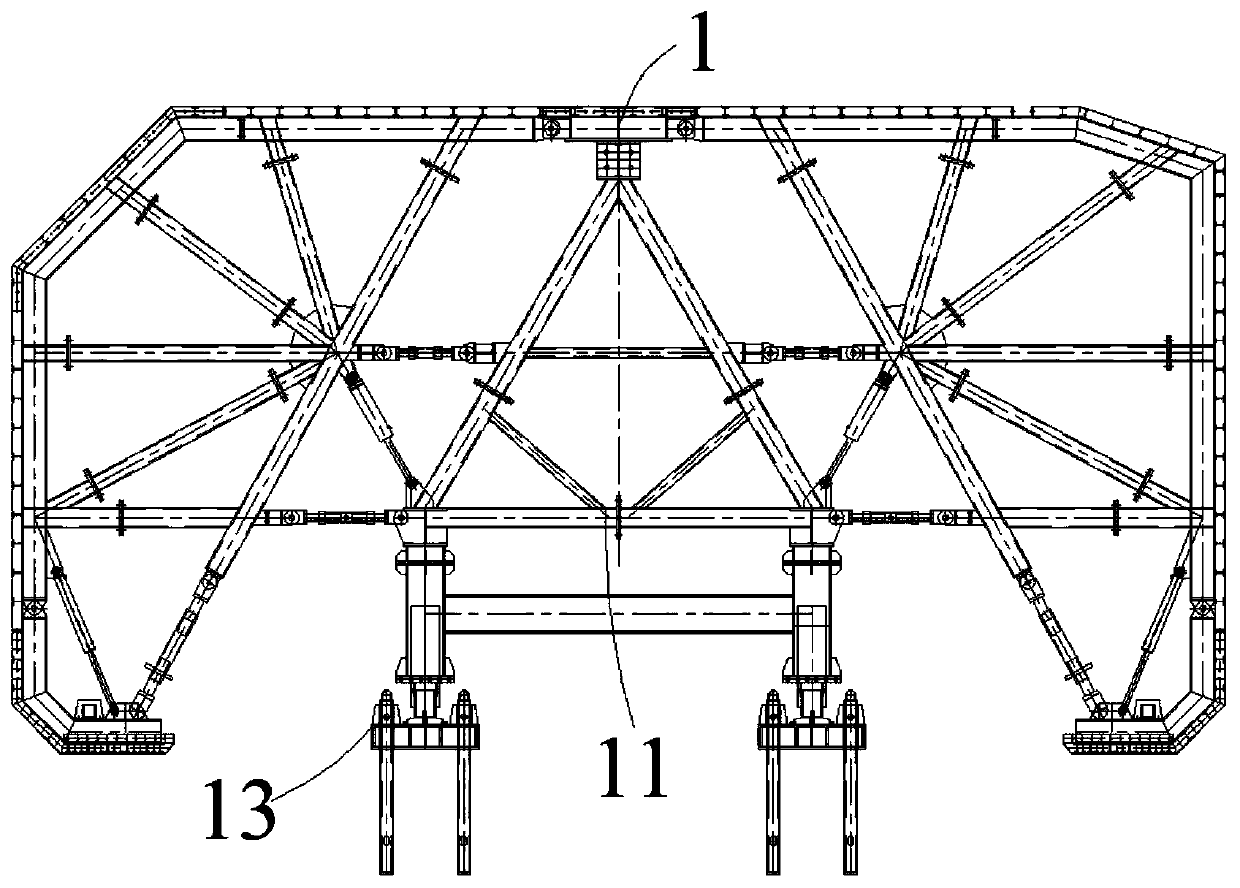

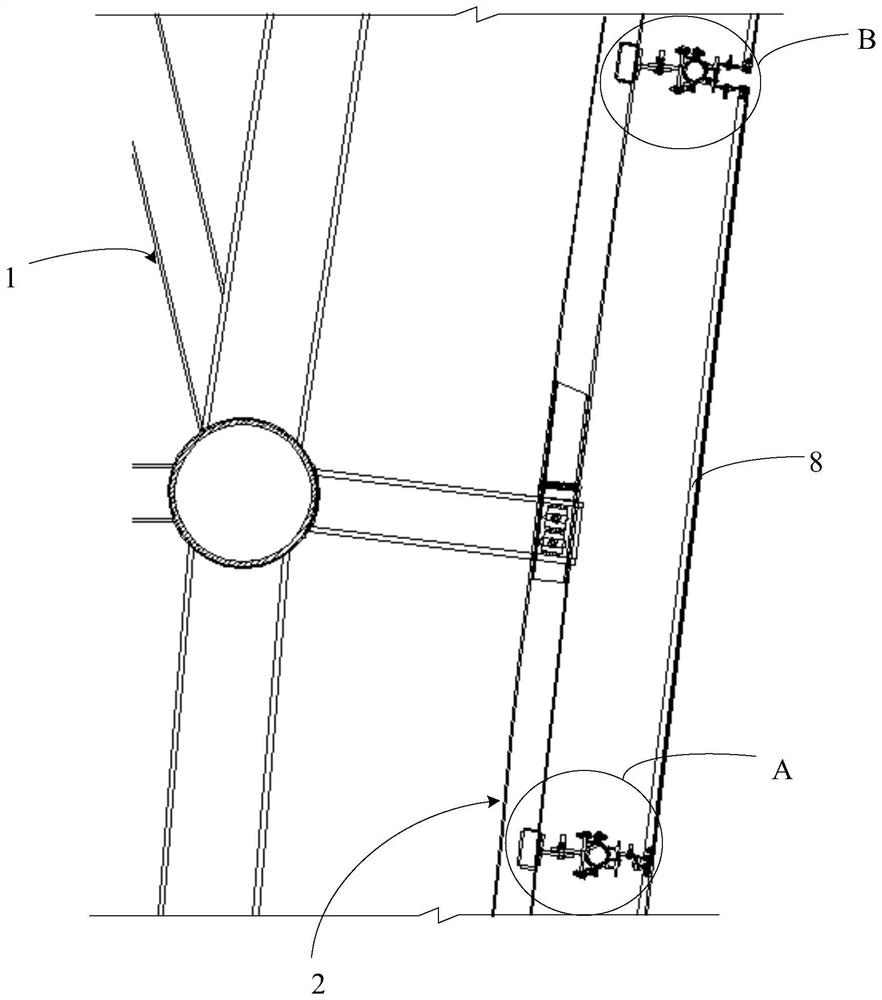

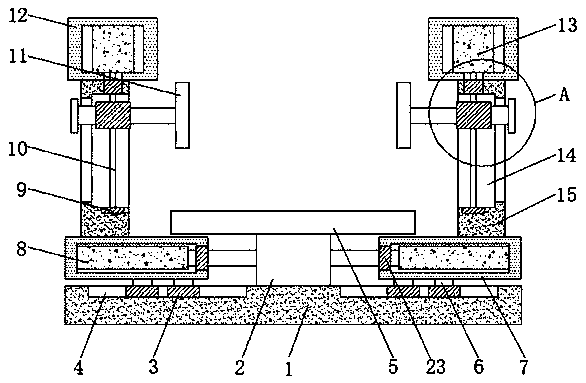

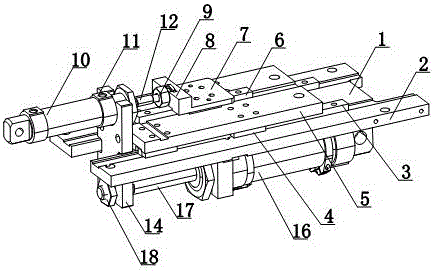

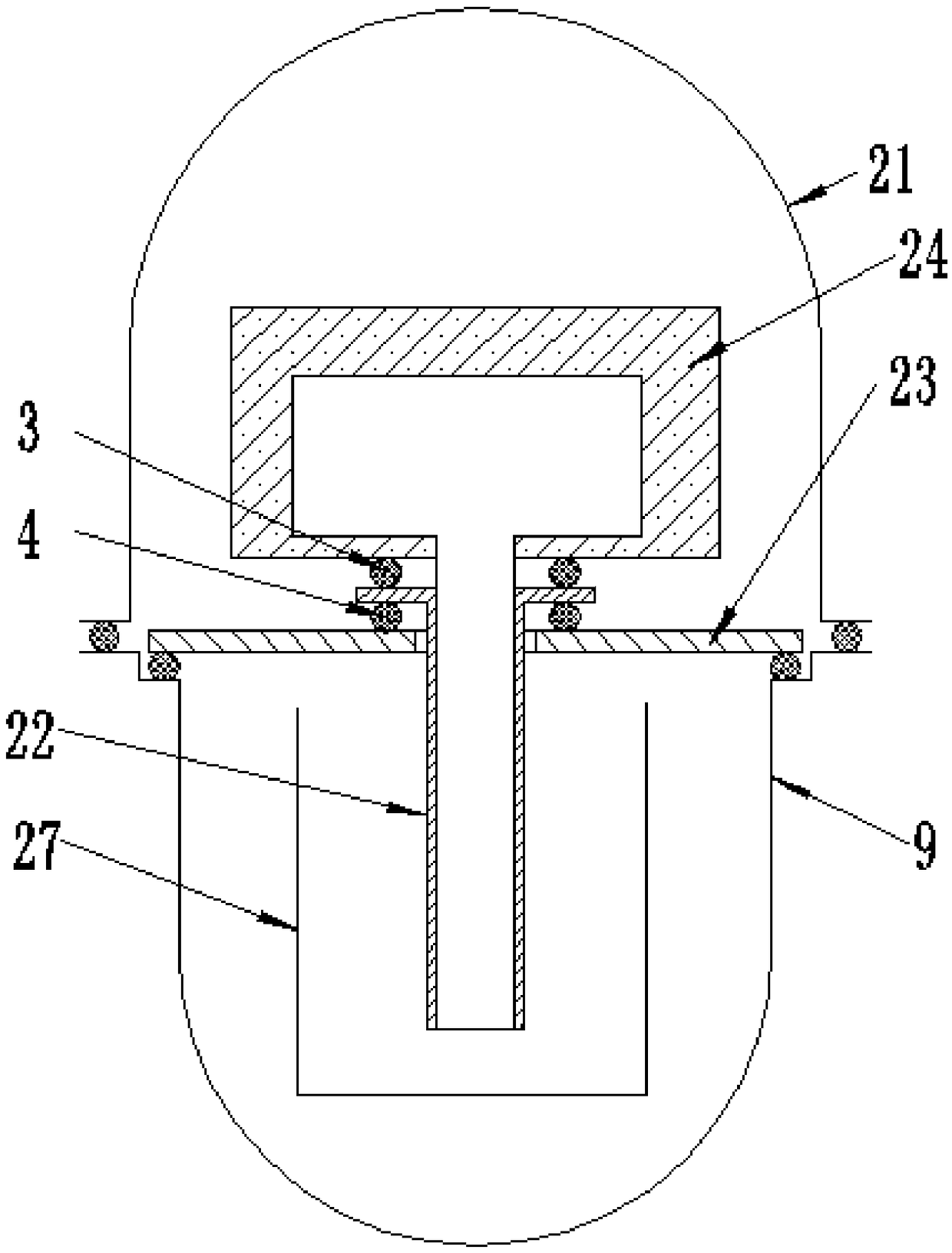

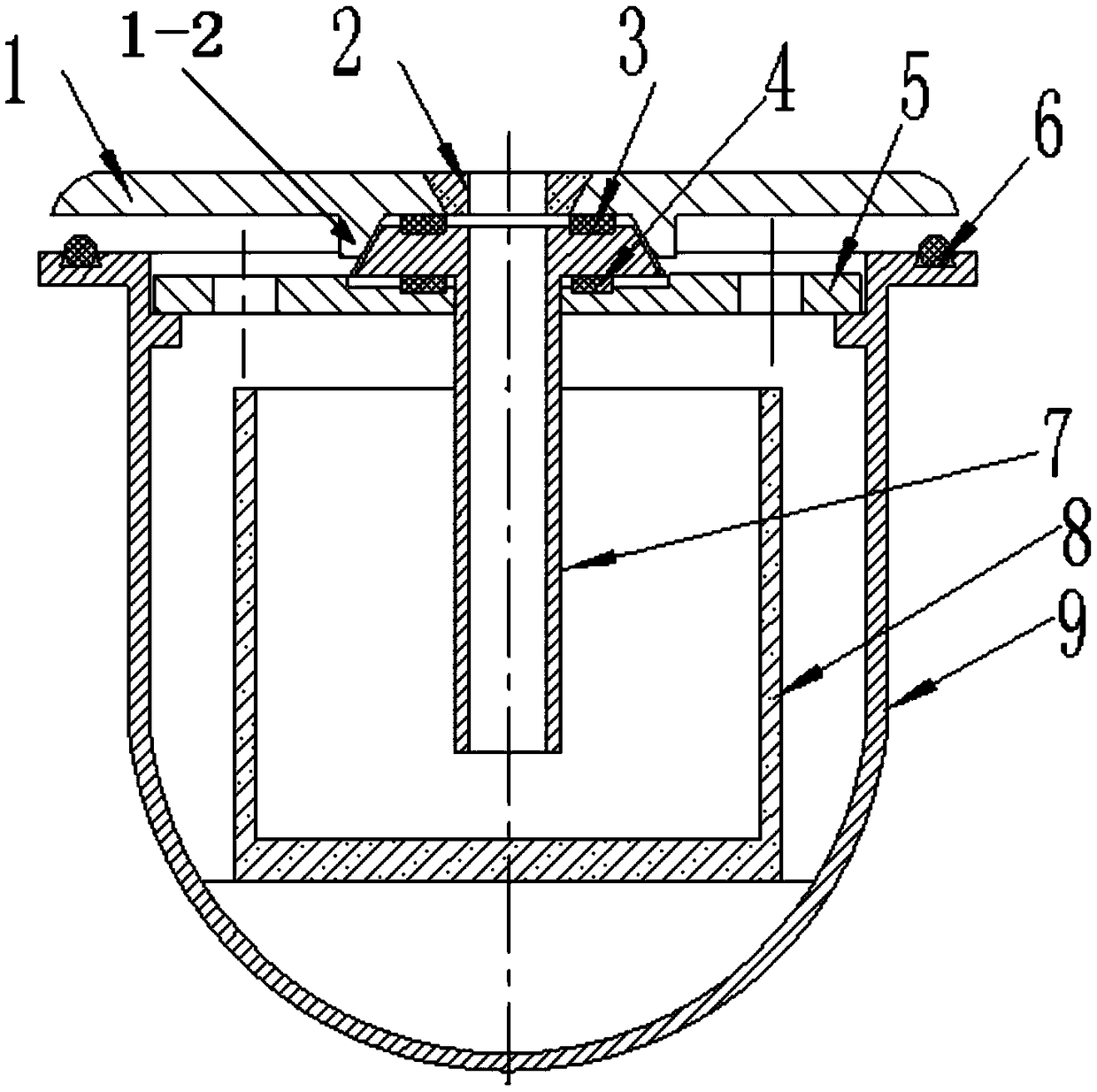

Dry dock sequential method full-section integral immersed tube prefabrication formwork system

PendingCN110076889AEasy to adjustSimple travel adjustmentDischarging arrangementMouldsSequential methodEngineering

The invention relates to the technical field of immersed tube prefabrication construction, in particular to a dry dock sequential method full-section integral immersed tube prefabrication formwork system. The system comprises an inner mold system, an outer mold system and an end mold system, wherein the inner mold system is located on the inner side of an immersed tube casting space and is connected with the outer mold system located outside the immersed tube casting space into a whole through the end mold system positioned at the longitudinal end part of the immersed tube casting space, the lower end of the inner mold system is provided with an inner mold travelling support device which is used for carrying out longitudinal, transverse and vertical position adjustment on the inner mold system, and the outer mold system is an outer side formwork structure capable of being adjusted in the longitudinal direction, the transverse direction and the vertical position. The immersed tube prefabrication method has the advantages of being accurate in position adjusting, less in main body structure damage and capable of operating all weather, so that the technical problems of sequential prefabrication, adjacent operation, compact space, longitudinal long-distance travel of an ultra-large super-heavy formwork is long, being prone to deviation and the like which occur to a sequential methodare solved.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES +1

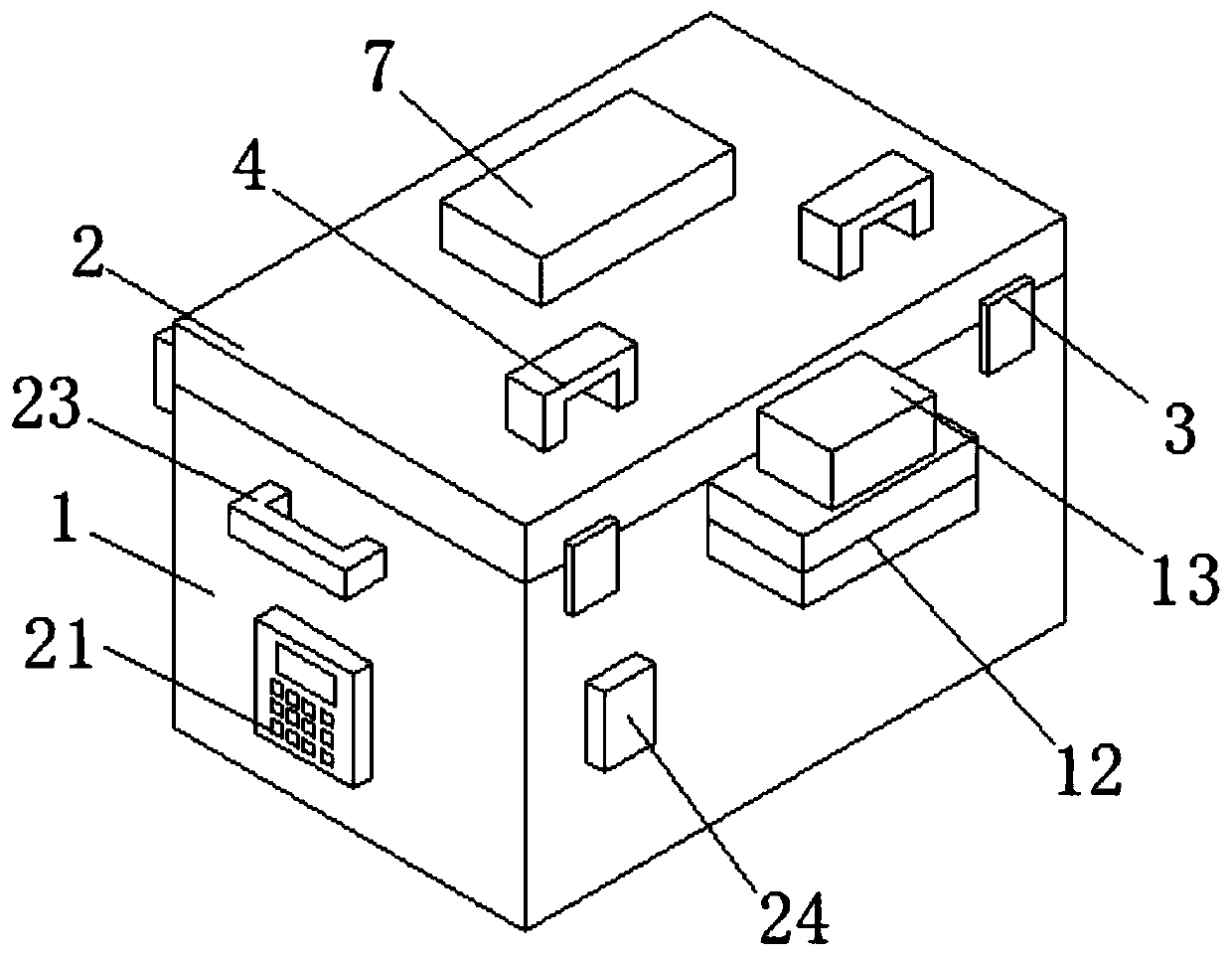

Electric power distribution box used for constructional engineering

InactiveCN107946964AAvoid Equipment DamageGood protectionSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsCushionElectric power distribution

The present invention relates to the technical field of distribution boxes, and discloses a power distribution box for construction engineering, including a bottom plate, the top of the bottom plate is fixedly connected with a card seat, and the inside of the card seat is clamped with a box body, One side of the front of the box is hinged with a box door, the bottom of one side of the box is fixedly connected with a heat dissipation pipe, the top of the box is fixedly connected with a top plate, and the top of the top plate is fixedly connected with a buffer The two sides of the top of the buffer seat are sleeved with telescopic columns, and the outer sides of the telescopic columns are sleeved with shock-absorbing springs. The power distribution box used in construction projects, through the buffer seat on the top of the roof, when the rainproof plate is subjected to the impact of heavy objects, the telescopic column and the spring cooperate to expand and contract up and down, disperse the force in the vertical direction, and reduce the vibration. The buffer spring and shock absorbing plate in the inner cavity of the box reduce the force in the left and right directions through the buffer spring when the distribution box moves, so as to avoid damage to the internal equipment and achieve the purpose of good protection effect.

Owner:江苏丰禾食品有限公司

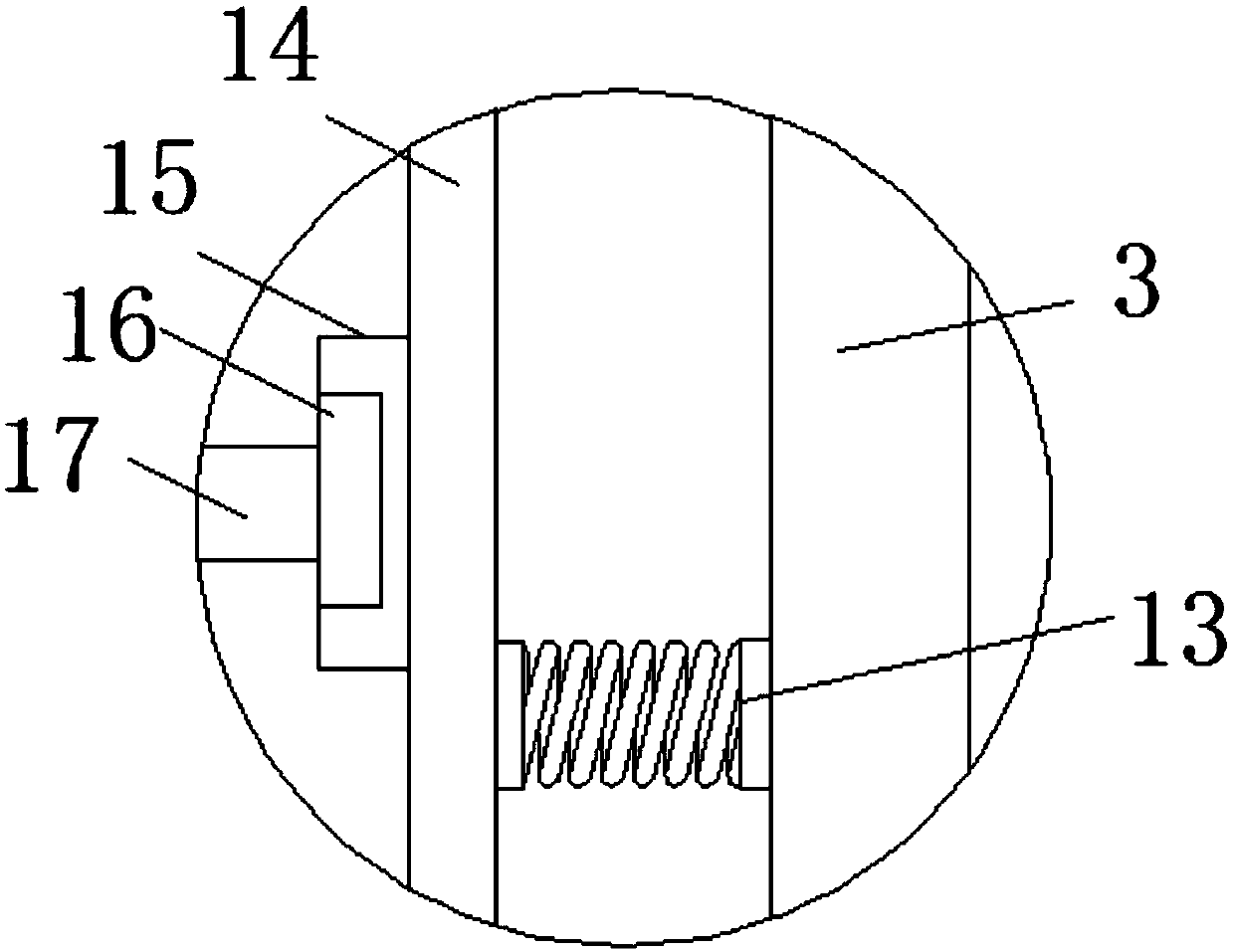

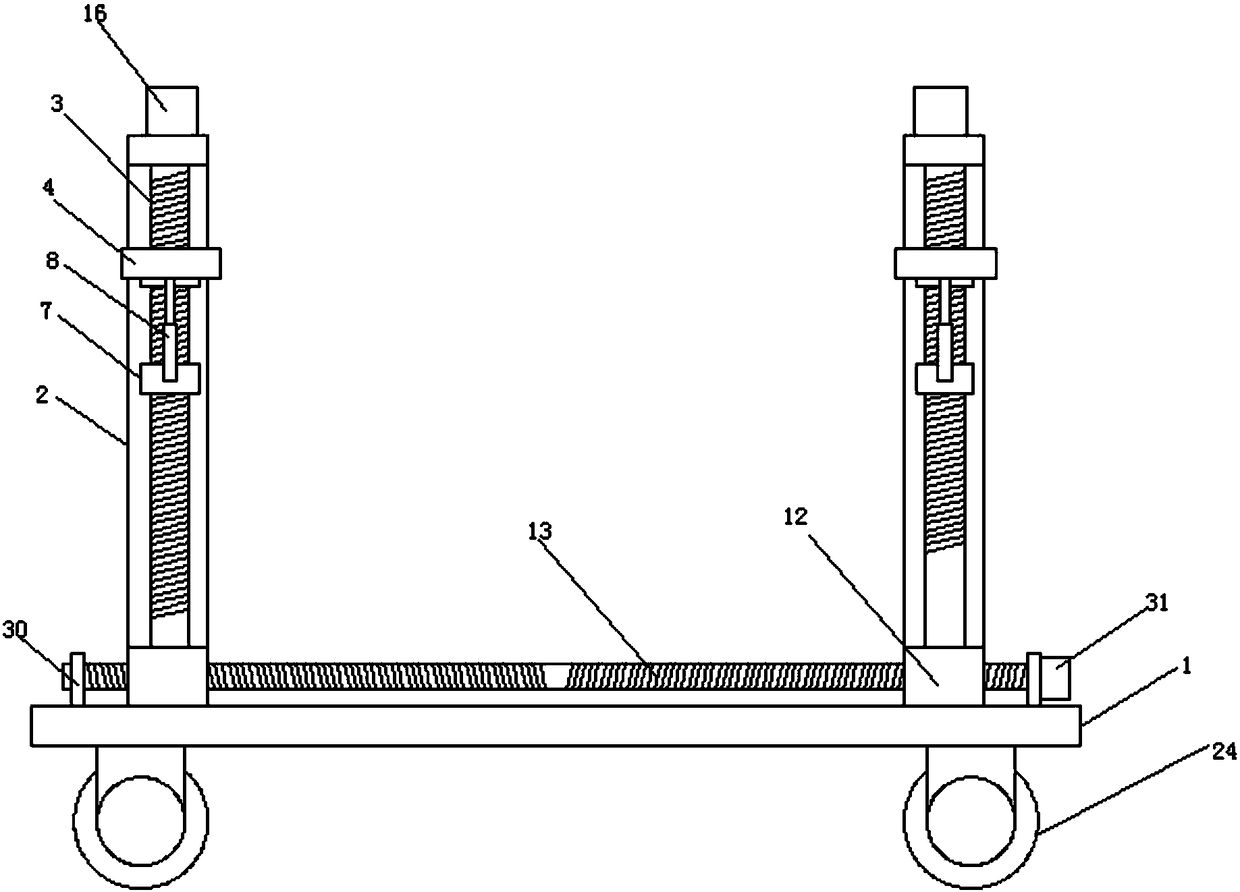

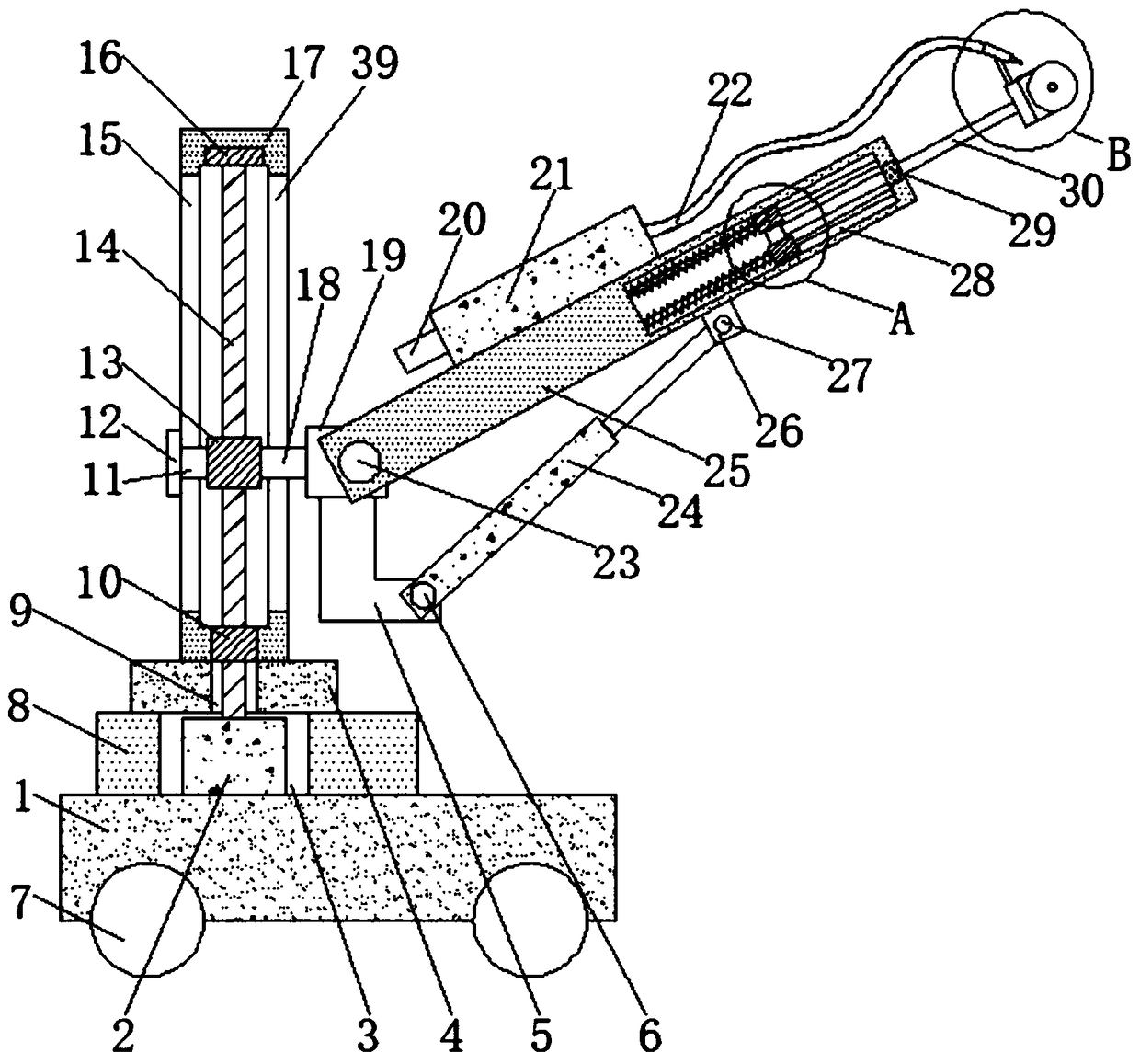

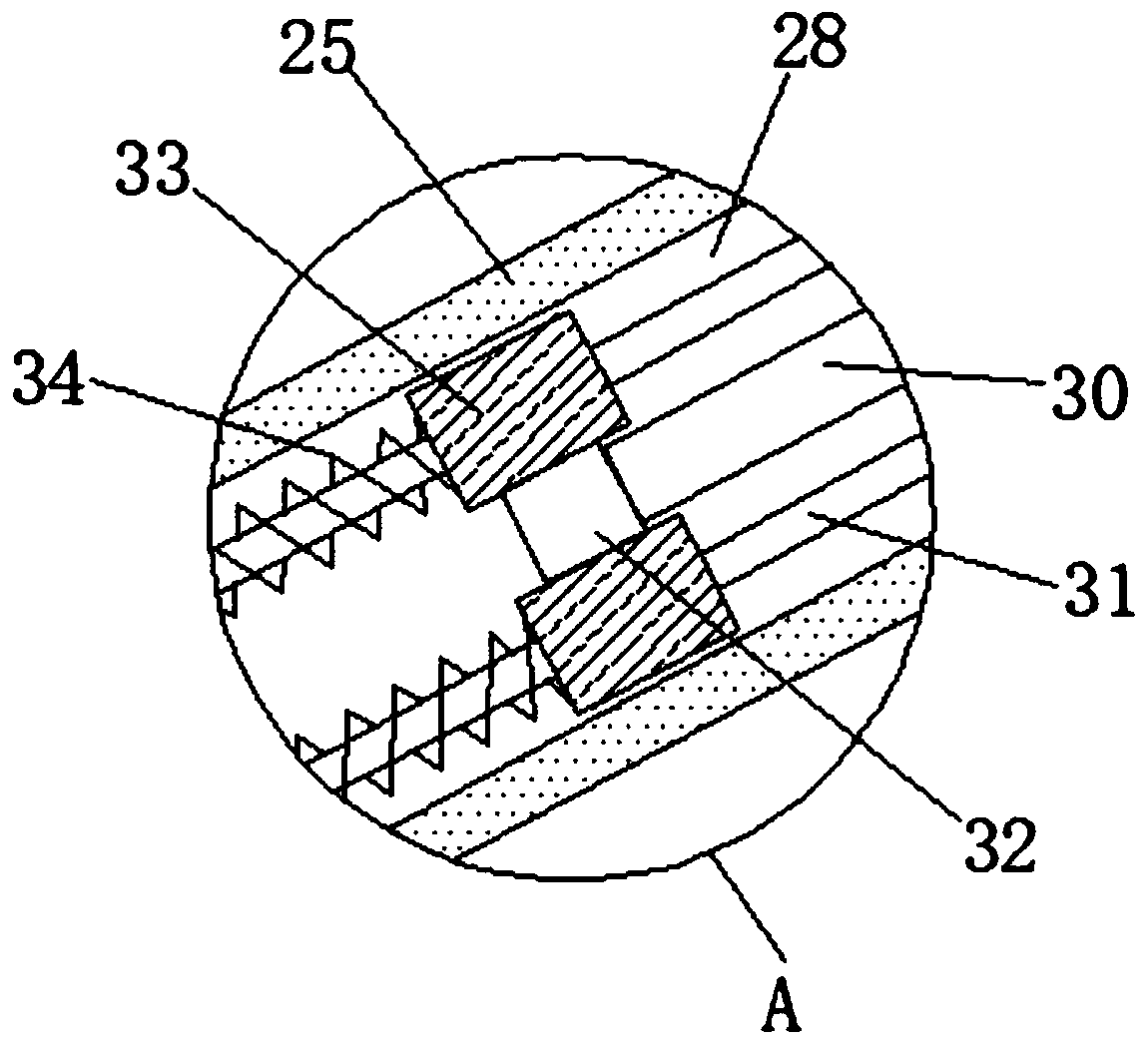

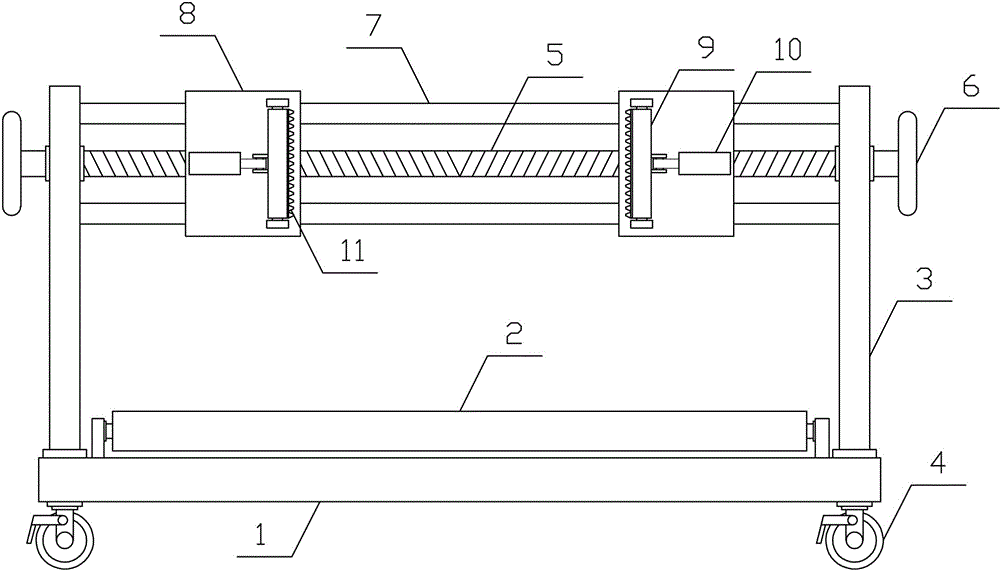

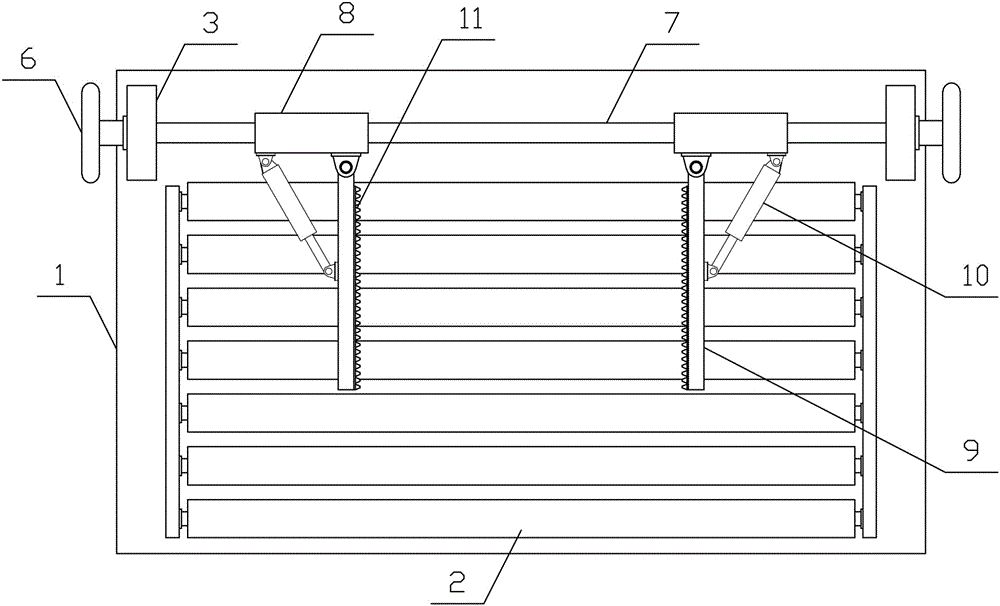

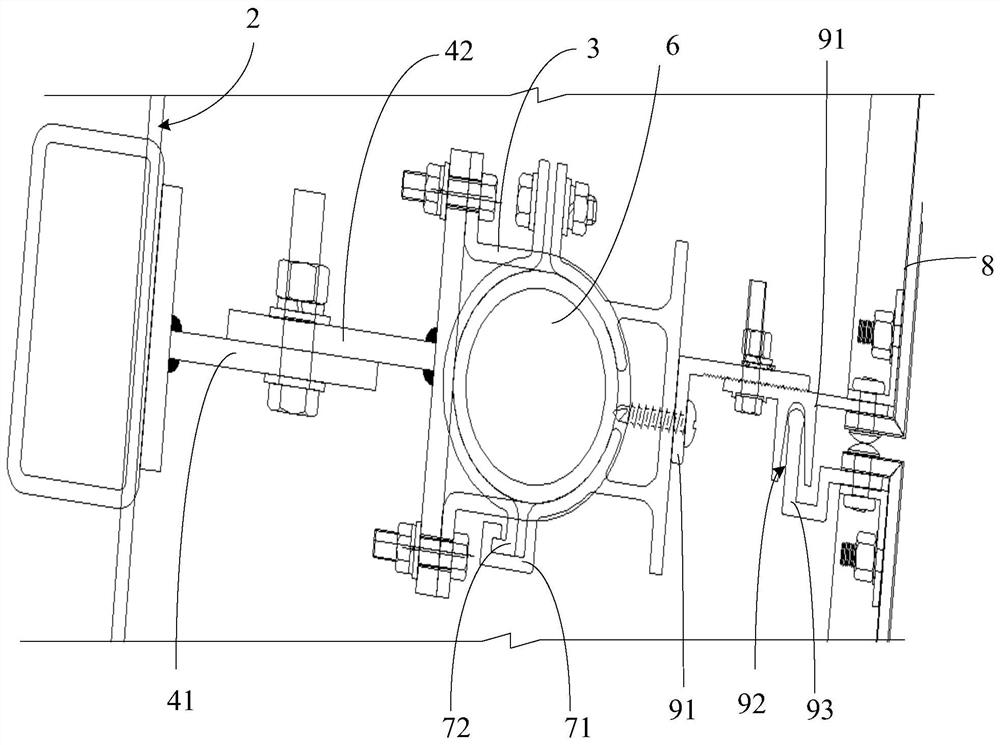

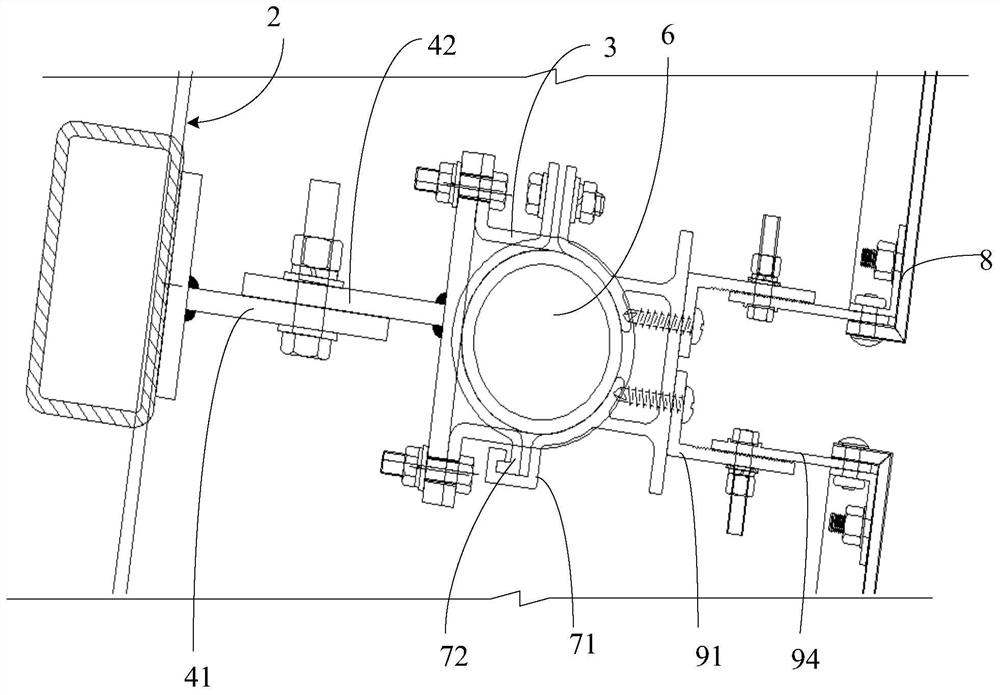

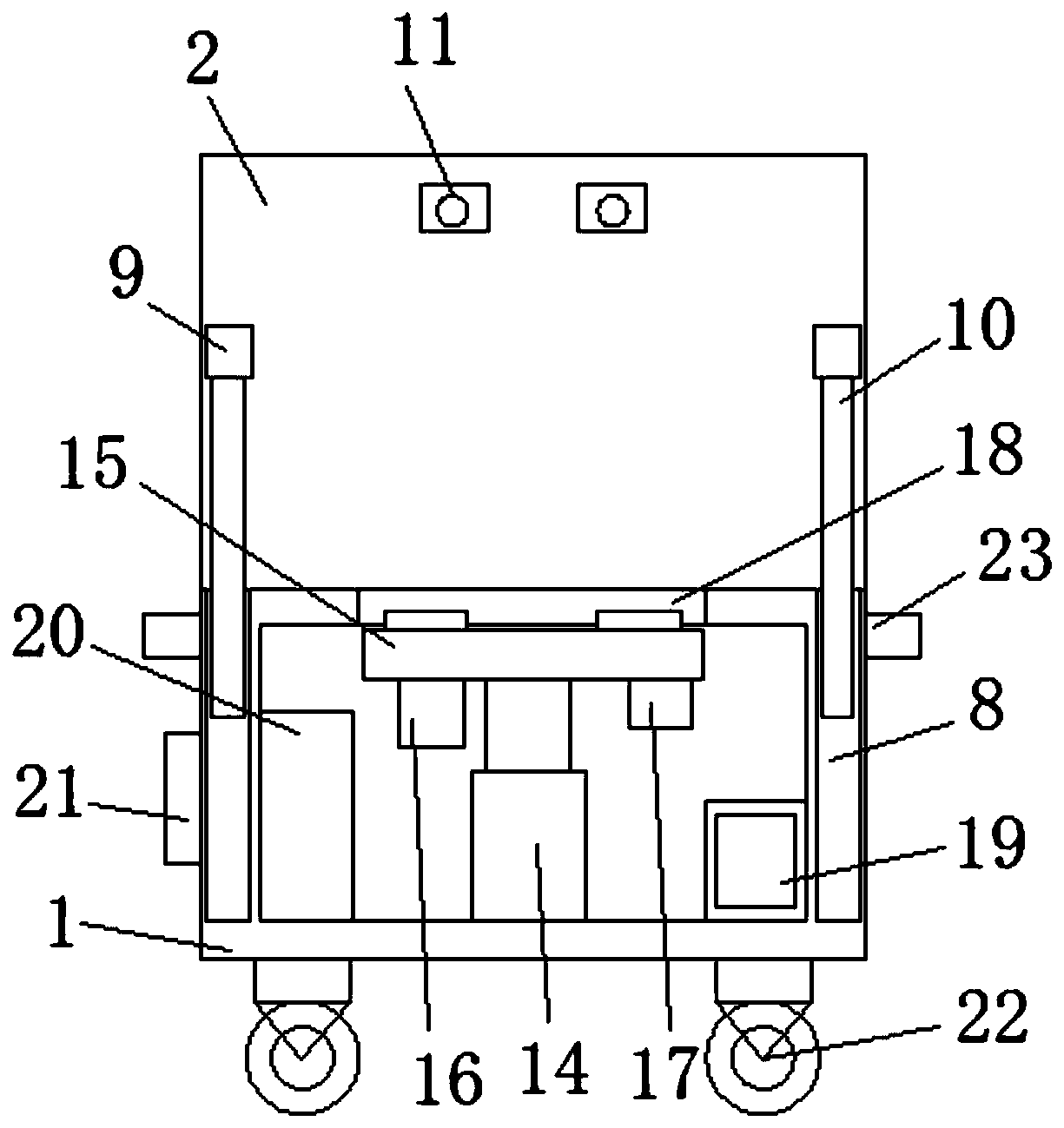

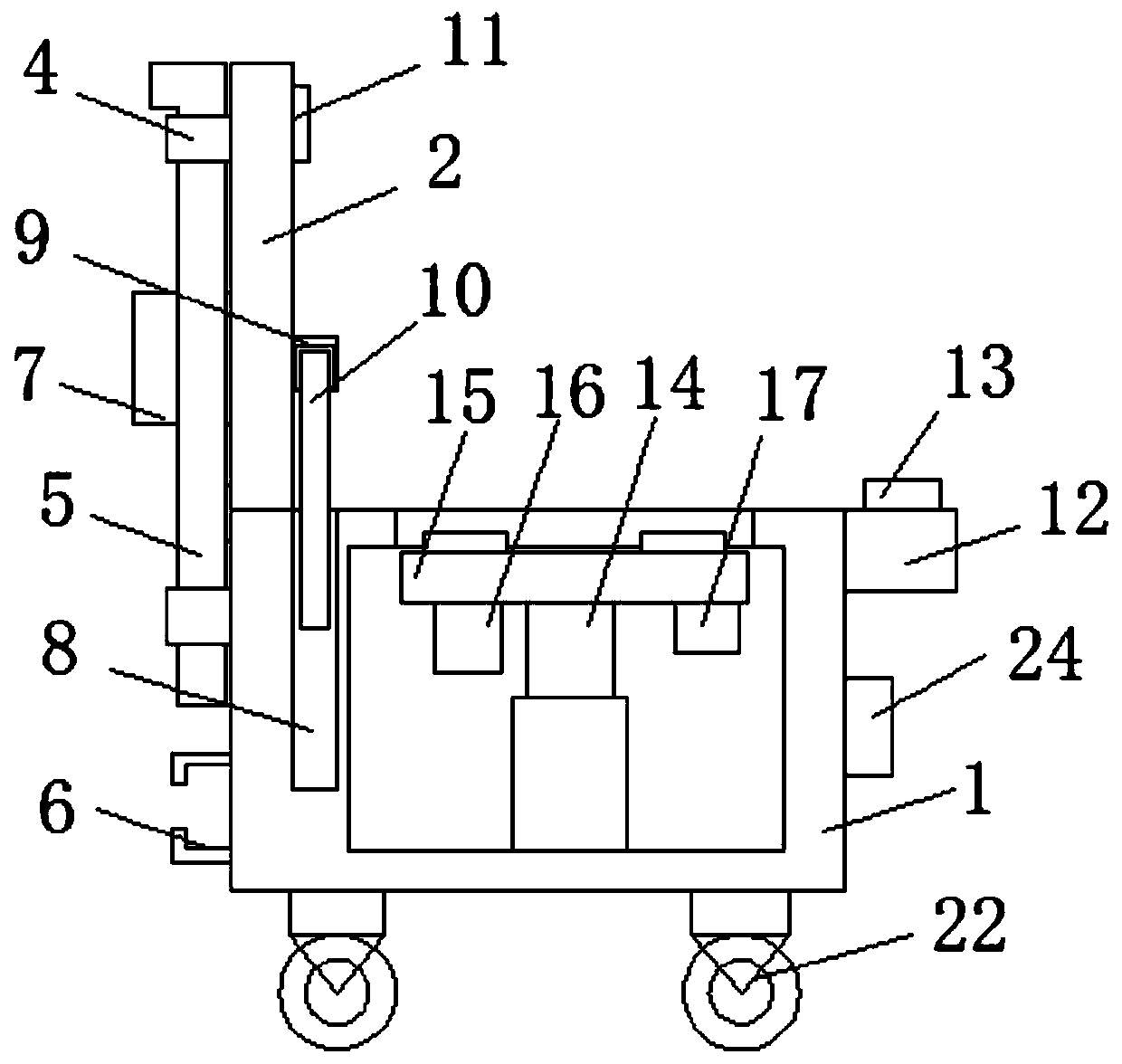

Hydraulic engineering pipe transfer device with good feeding and discharging convenience

InactiveCN108146481ATransport stableImprove transport efficiencyHand carts with multiple axesEngineeringHydraulic engineering

The invention discloses a hydraulic engineering pipe transfer device with good feeding and discharging convenience, comprising a transverse support plate; a support rod rack that is vertical is arranged on each side of the upper end face of the transverse support plate; a lift screw rod is arranged in each support rod rack; the top ends of the lift screws are connected with lift motors arranged atthe top ends of the support rod racks, each lift screw is provided with a first support driving sleeve and a second support driving sleeve, an adjusting screw that is transverse is arranged above thetransverse support plate, two ends of the adjusting screw pass through two adjusting driving blocks, the two adjusting driving blocks are connected with the adjusting screw in threaded fit manner, the two ends of the adjusting screw are fixed to the transverse support plate through bearing blocks, the two ends of the adjusting screw have opposite thread directions, the lower ends of the two adjusting driving blocks are connected with the upper end face of the transverse support plate through a guide mechanism. The hydraulic engineering pipe transfer device with good feeding and discharging convenience is simple in structure, allows hydraulic pipes of different lengths to be transferred stably, allows good convenience for moving and adjusting and is highly practical.

Owner:COMMON TECH DEV CO LTD

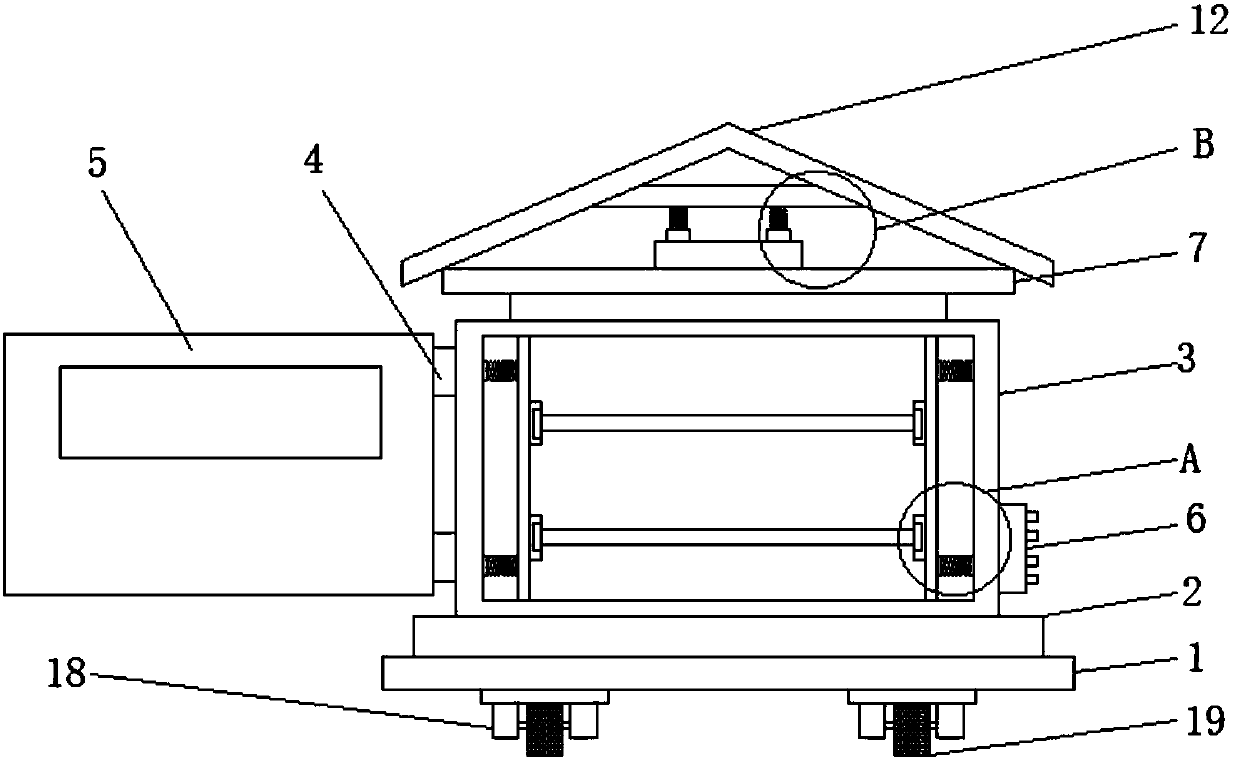

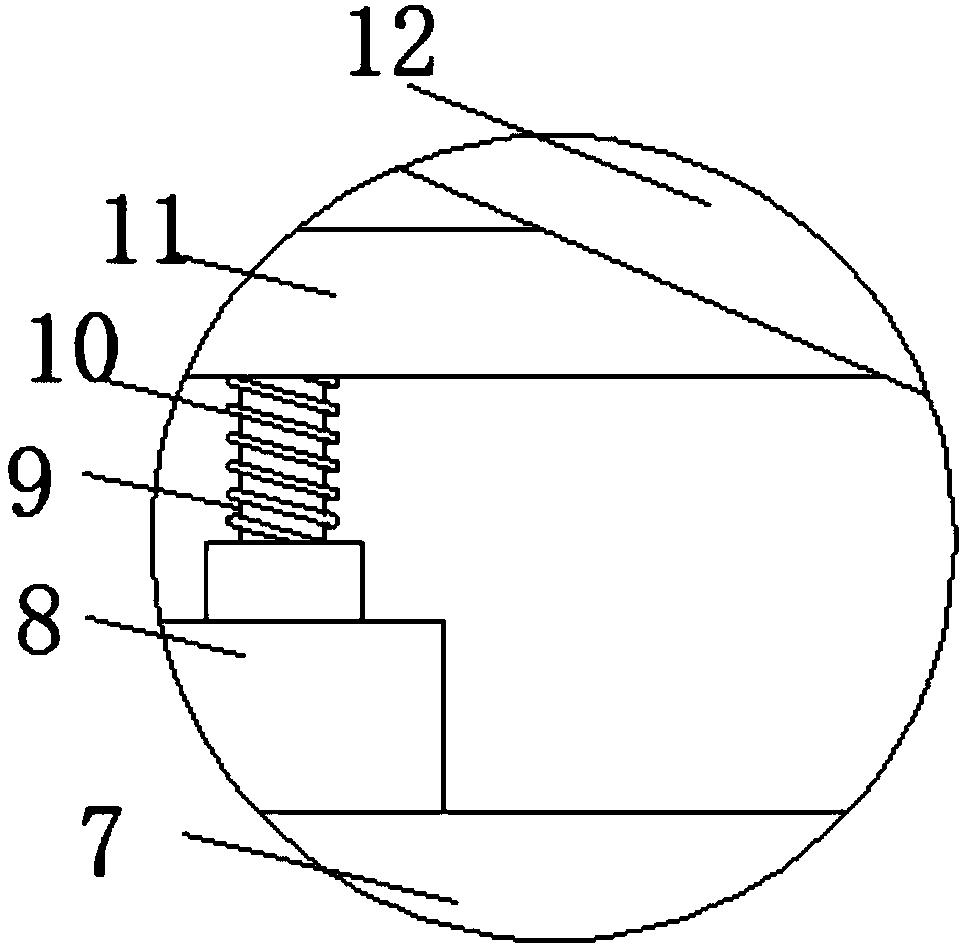

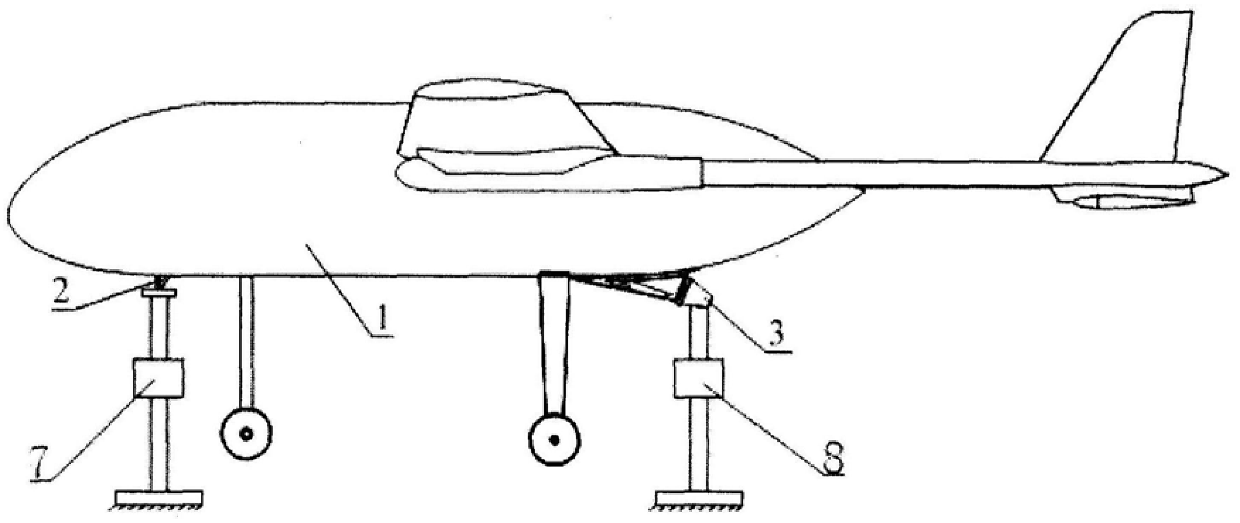

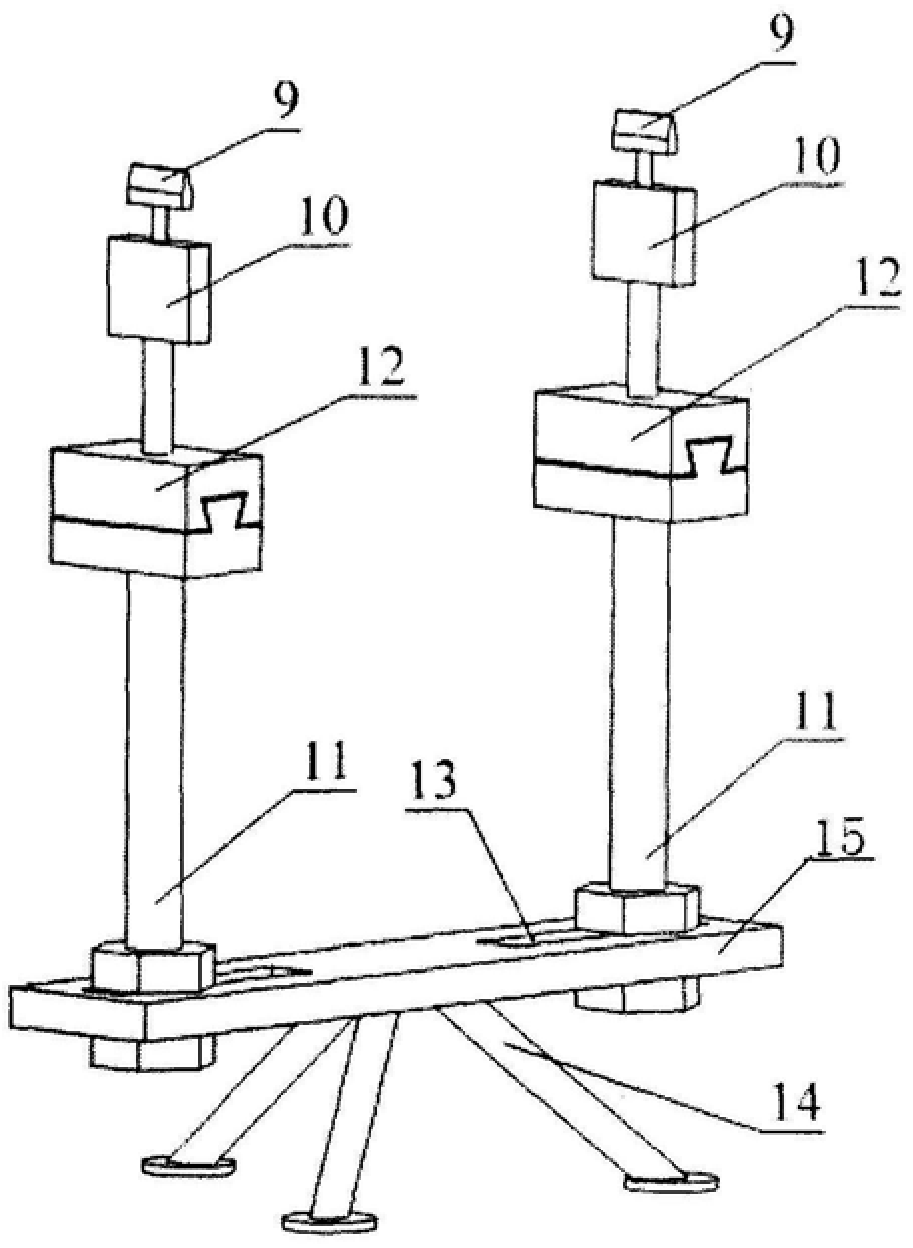

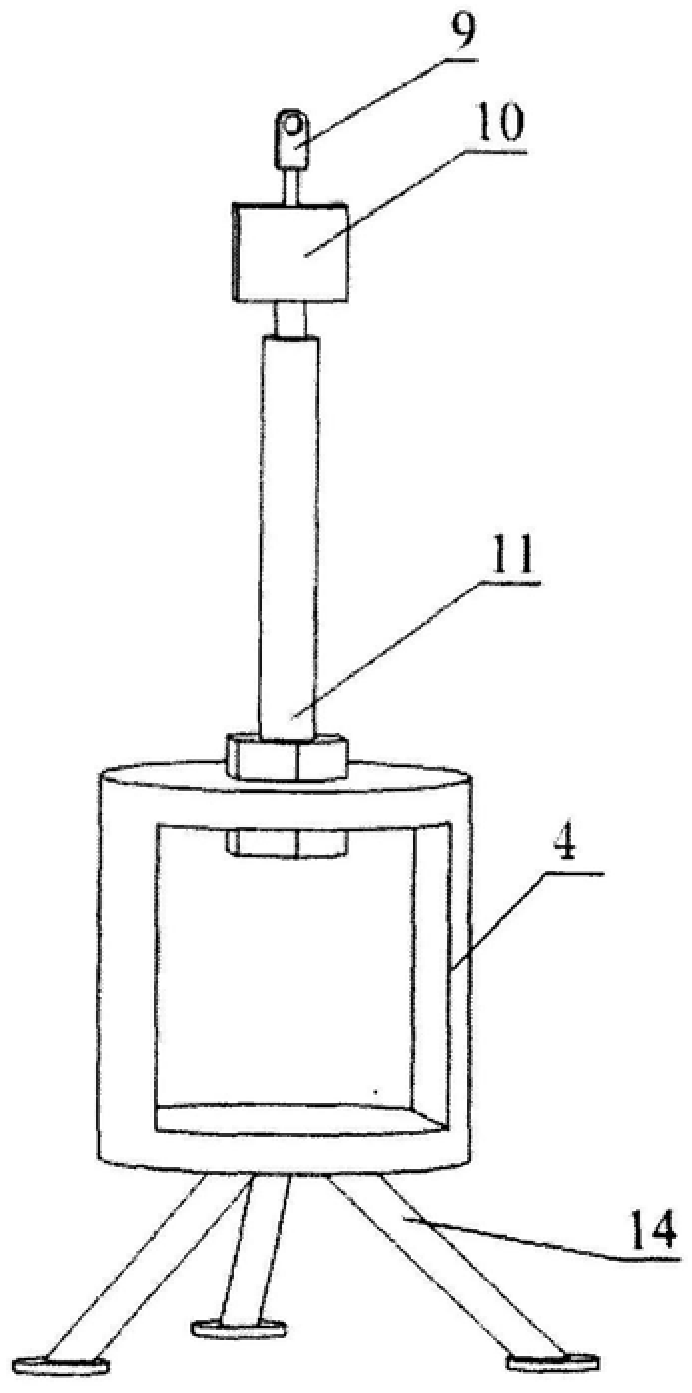

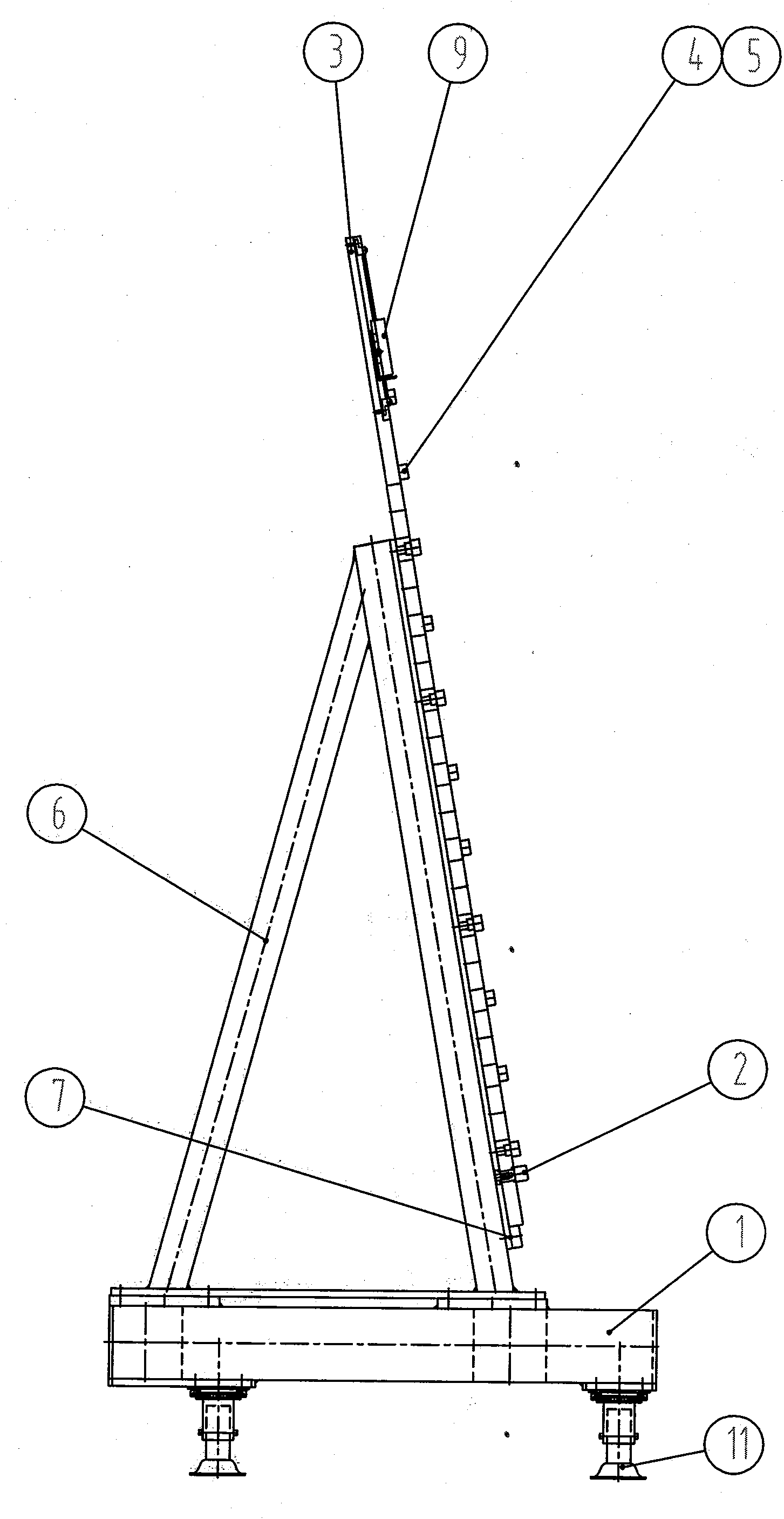

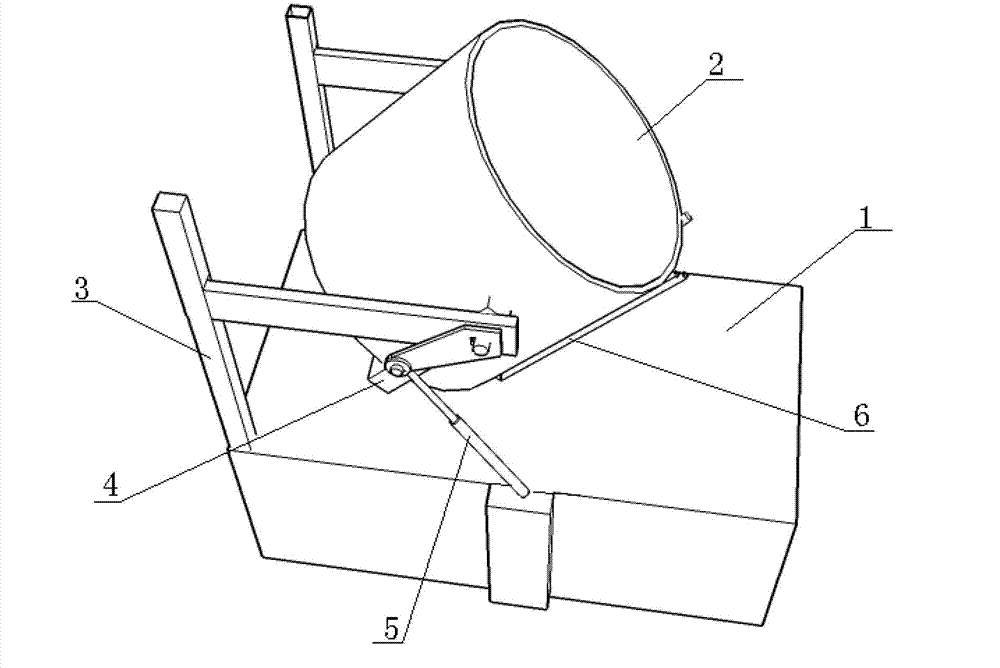

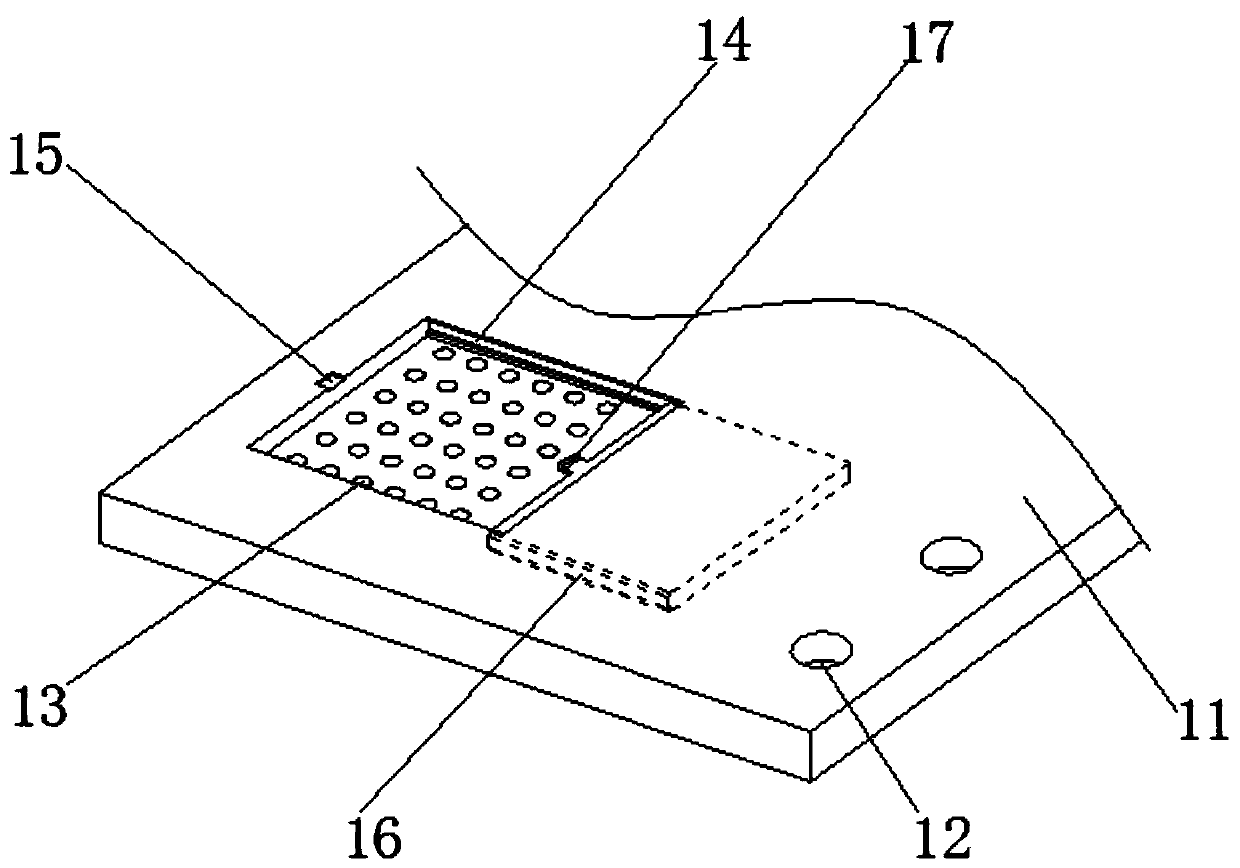

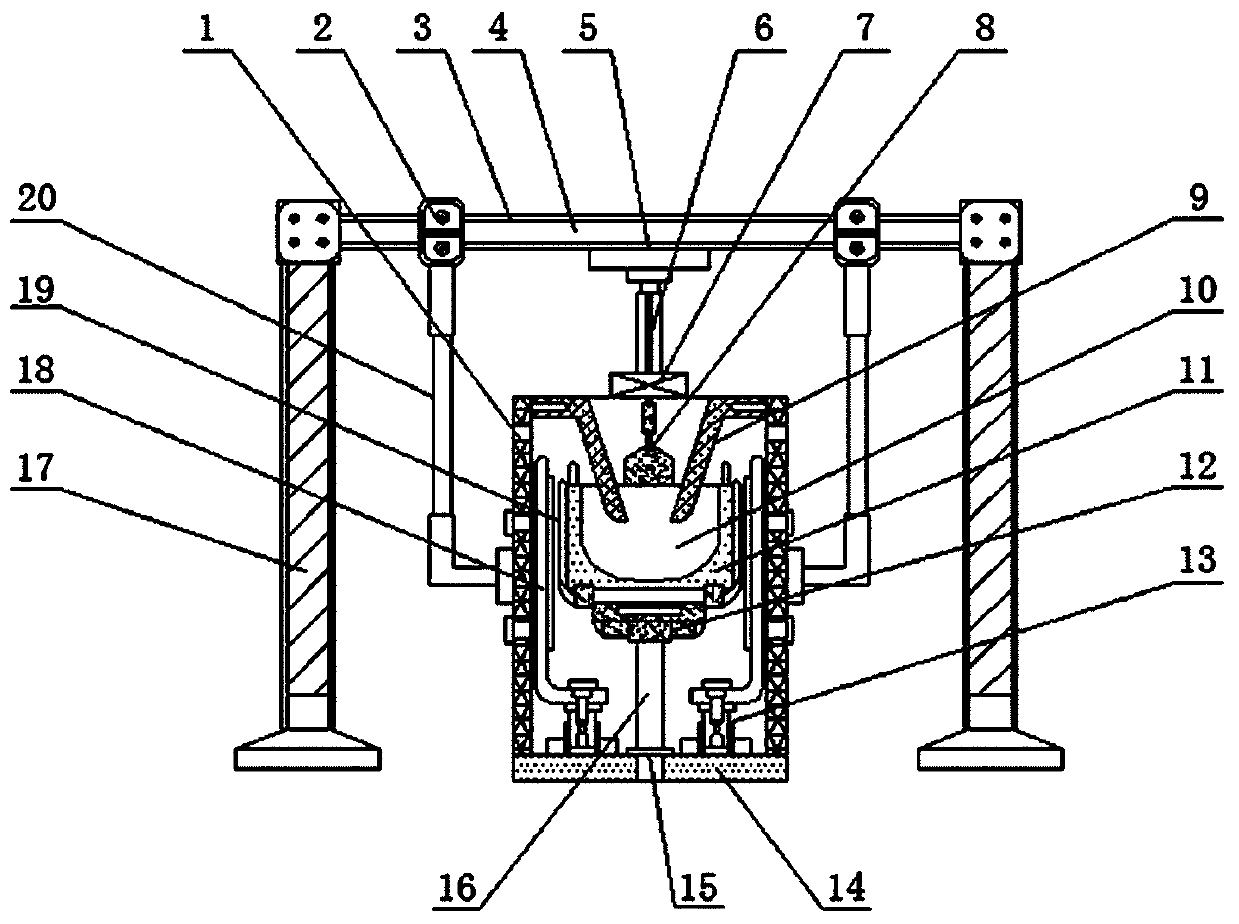

Analyzing the Method of Hanging Weighing Aircraft to Determine the Center of Gravity and the Compound Weighing Device

ActiveCN106507918BSimple weighing methodImprove efficiencySpecial purpose weighing apparatusAirplaneTilt sensor

The present invention proposes a method for determining the position of the center of gravity of an analytically hanging weighing aircraft and its compound weighing device. By using the compound analytical weighing method of the present invention in combination with the hanging weighing method and its compound weighing device, it is only necessary to One time of horizontal weighing and one time of hanging, the position of the center of gravity of the aircraft in three directions can be obtained. The present invention is achieved through the following technical solutions. Use the compound weighing device with three-dimensional adjustable three-point support to adjust the plane level, and pass the known coordinates of the front support and the rear support, through the pressure sensors of the front scale and the rear scale on the compound weighing device From the readings, the position of the center of gravity of the aircraft heading is calculated. Suspend the aircraft on the truss by a sling, install an inclination sensor between the sling and the rear support, and measure the relative angle between the axes of the above sling and the rear support in the pitch and yaw directions through the inclination sensor; according to "Aircraft Calculate the position of the center of gravity of the aircraft in the vertical direction and yaw direction by using the drawing method in the Design Manual.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

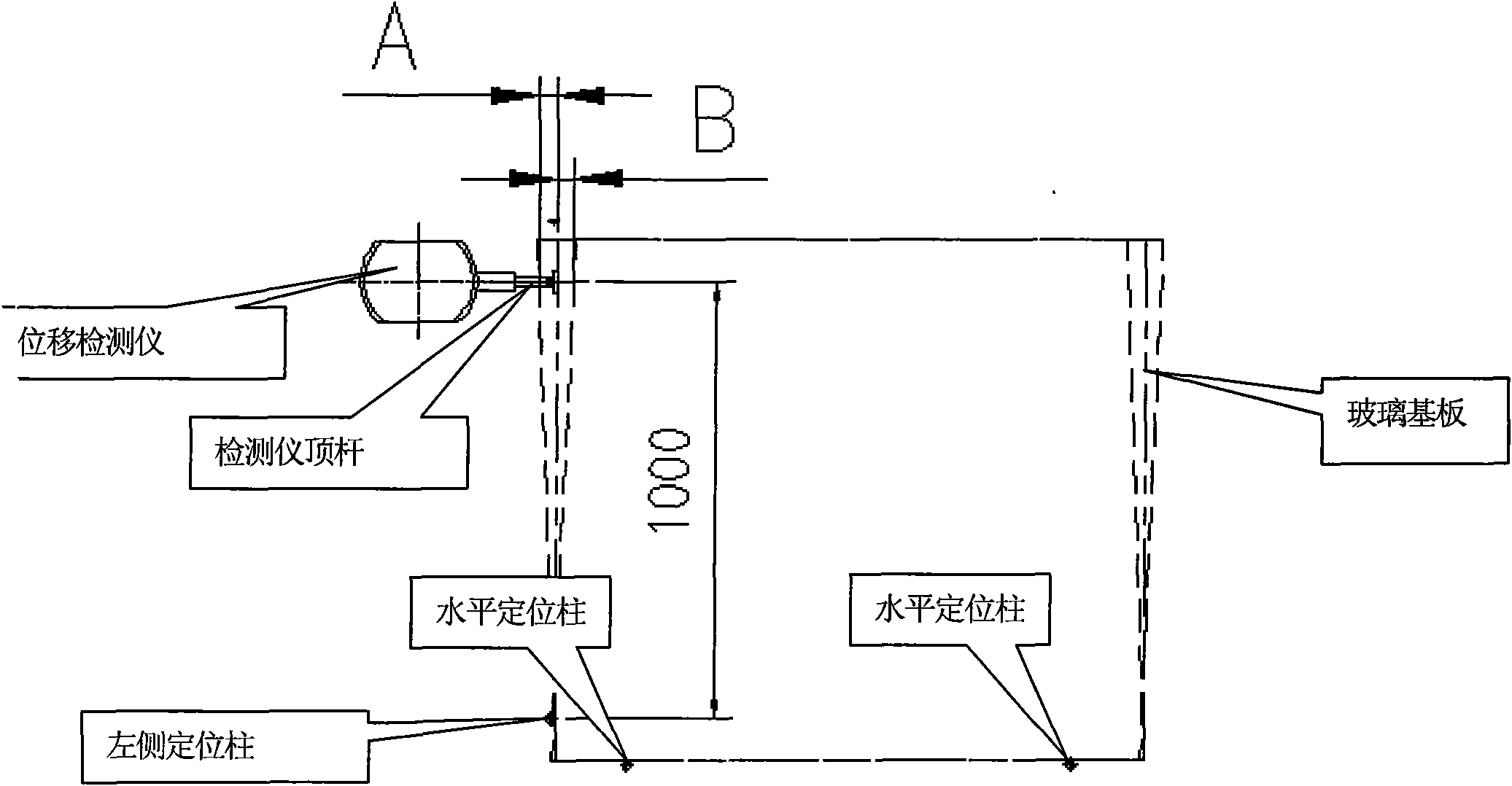

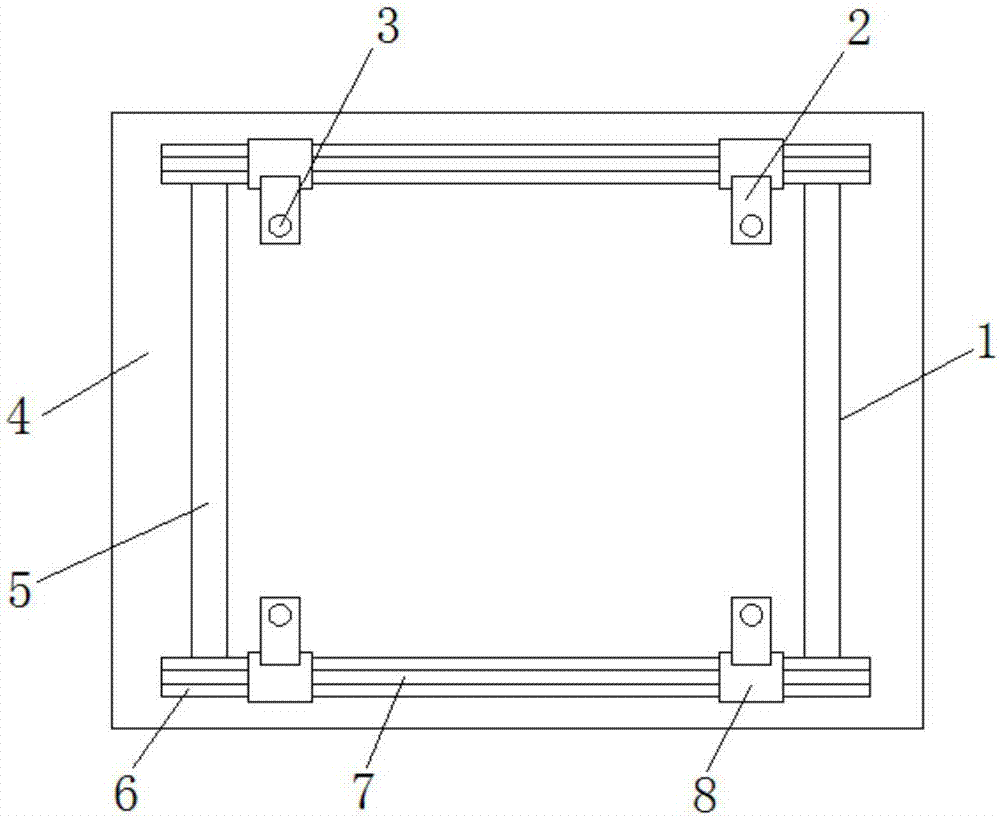

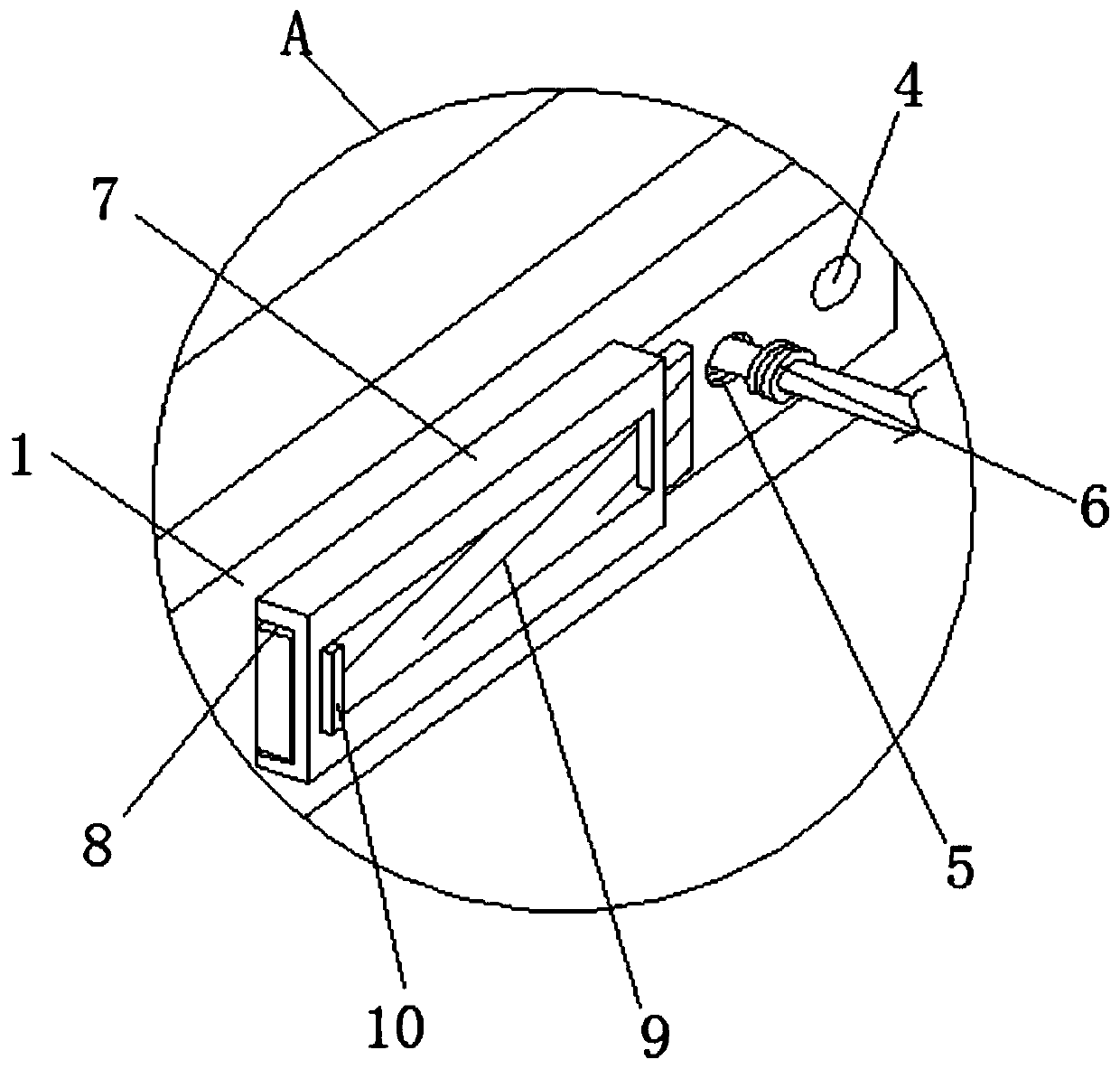

Fast measuring method of right angle of large-sized rectangular glass substrate and measuring instrument thereof

InactiveCN101886918AAdapt to the requirements of streamlined operationsQuick and easy to measureUsing optical meansMeasuring instrumentLinear displacement

The invention relates to a method for measuring the right angle of a large-sized rectangular glass substrate by utilizing a plane geometry principle and a linear displacement sensor and singlechip technology and measuring the displacements of two parallel edges of glass as well as a measuring instrument thereof. The accurate positioning of the glass substrate is realized by utilizing upper buses of two positioning columns positioned at the bottom of equipment and a side bus of a positioning column positioned at the left side of the equipment as standards; a part to be measured of the left side surface of the glass substrate stresses a mandril of the measuring instrument to generate the displacement; if the bottom edge of the glass substrate is not perpendicular to the side edge of the glass substrate, the reading value of the measuring instrument can be different by overturning the glass substrate by the displacement of 180 degrees, and a half of a difference value is right angle measuring data. The invention can fast and conveniently measure whether the right angle of the adjacent edges of the glass is in a range of 1 / 1000 or not; and in addition, the measuring method can realize the fast, efficient and easy operation in the production of the large-sized rectangular glass substrate, is convenient and fast, is lower in cost and better meets the requirements for the flow operation of a glass production line.

Owner:TUNGHSU GRP

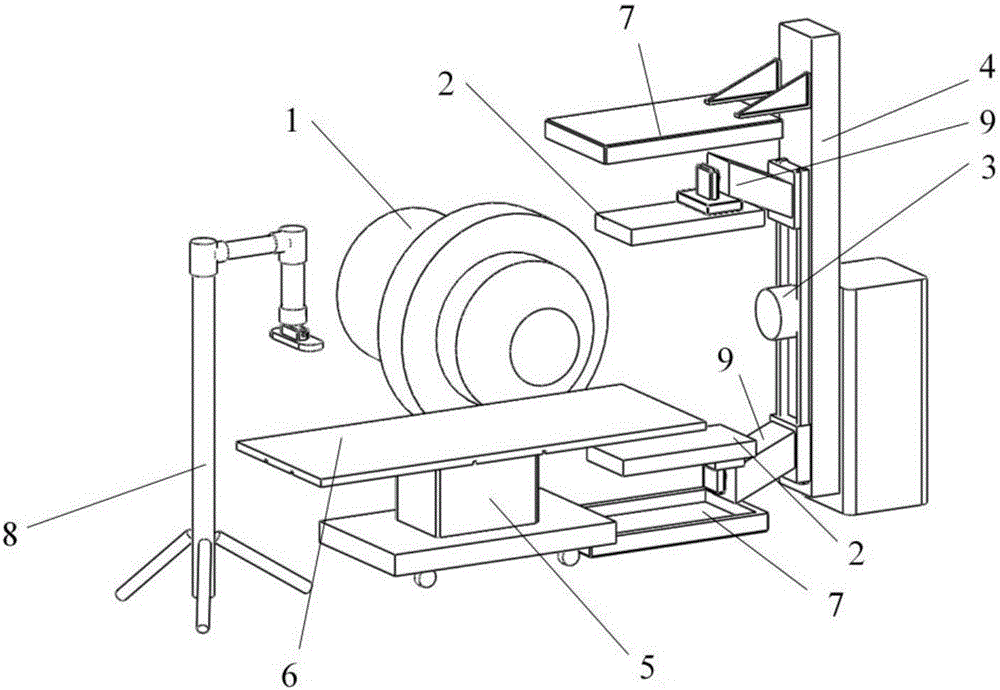

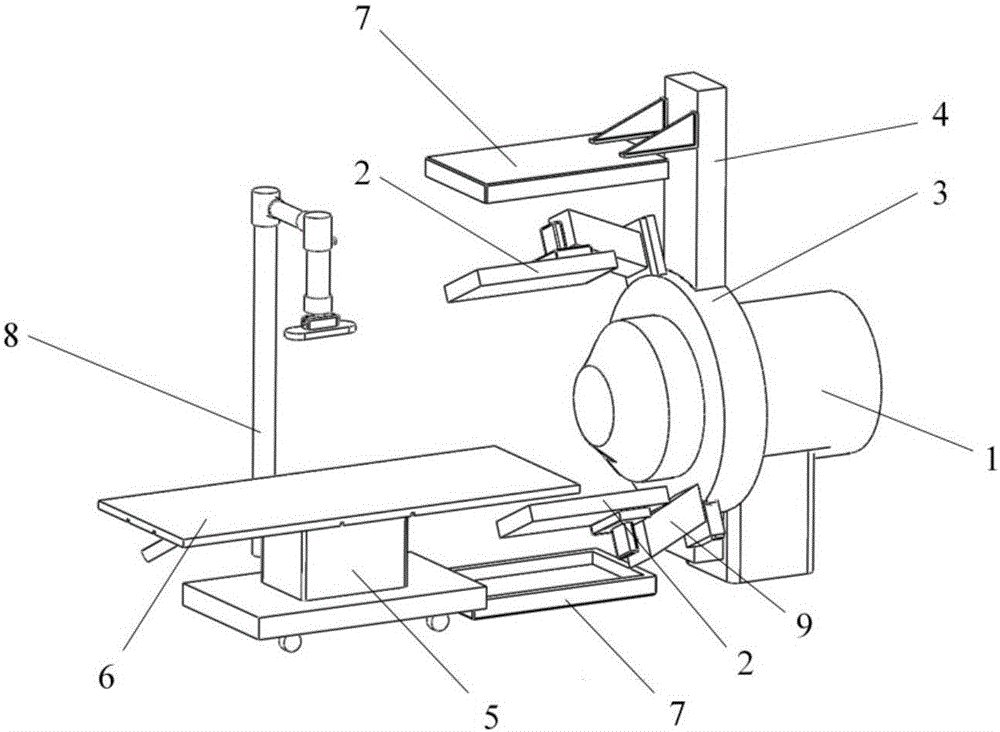

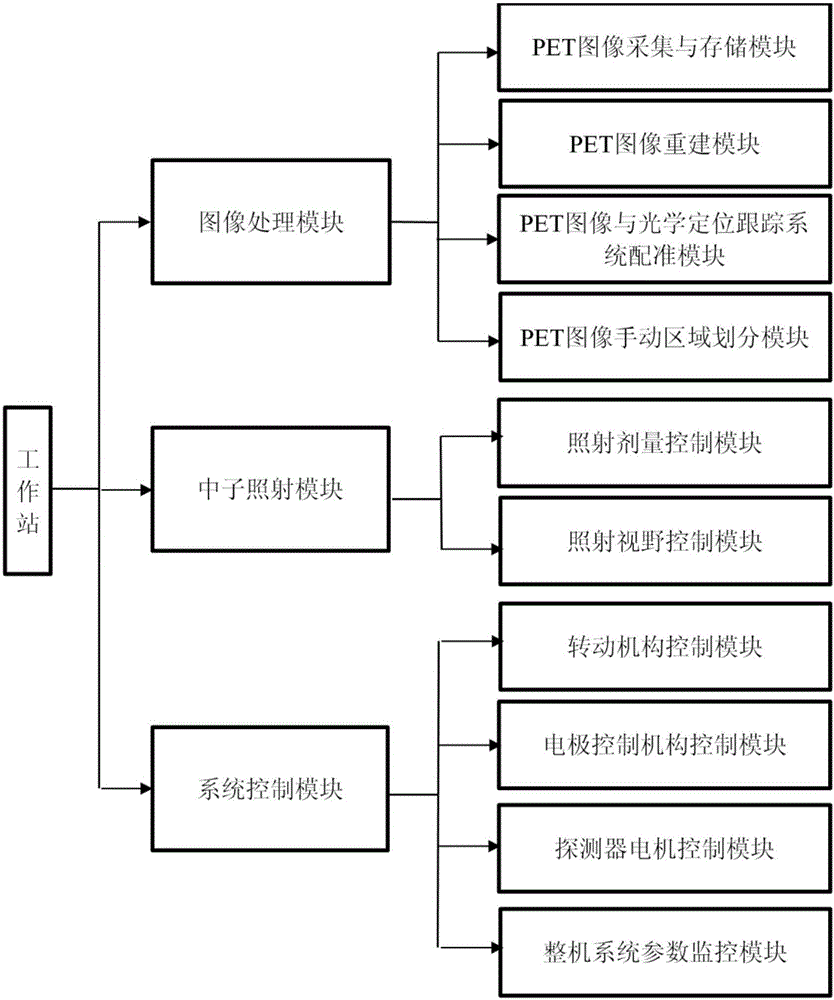

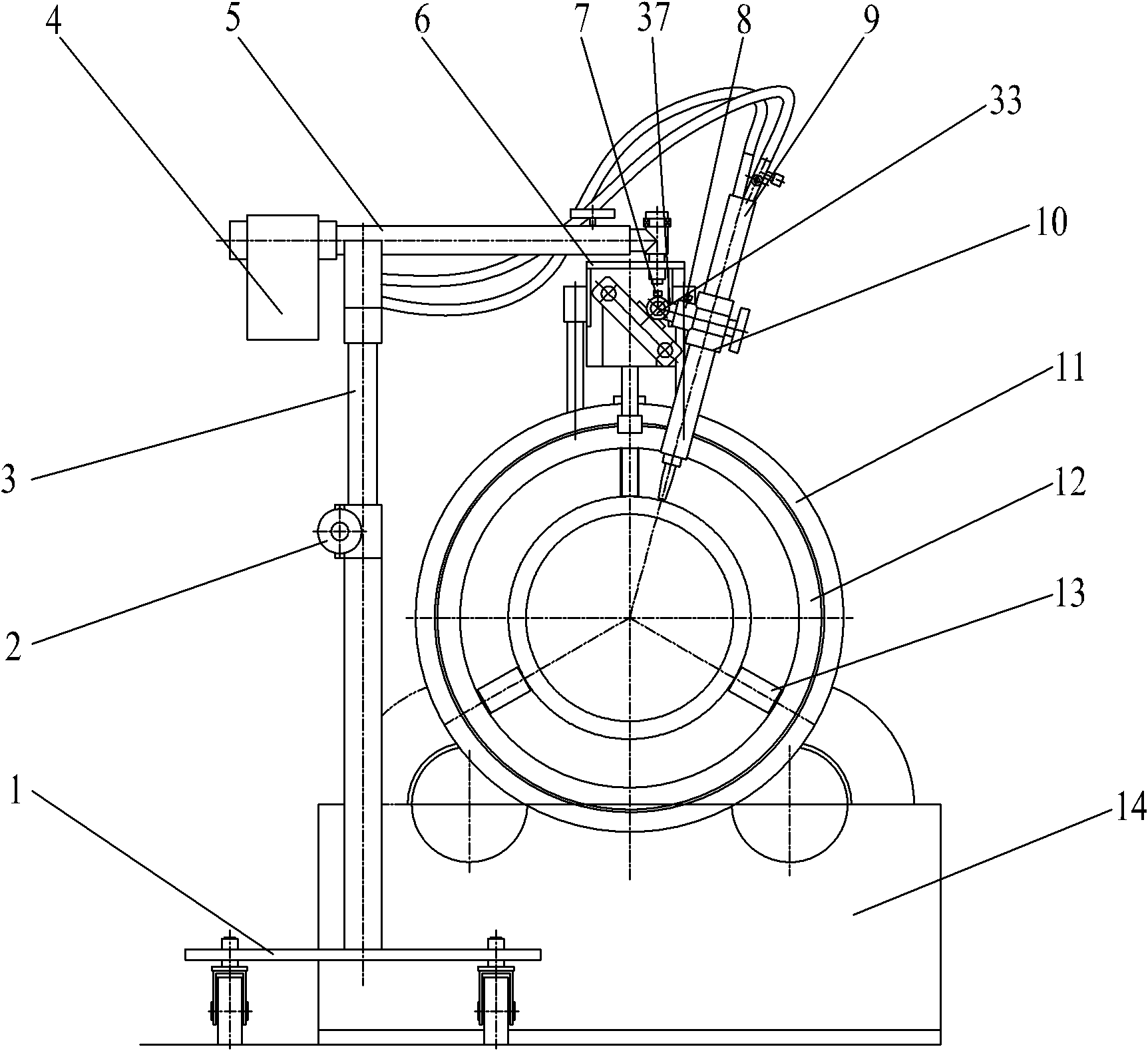

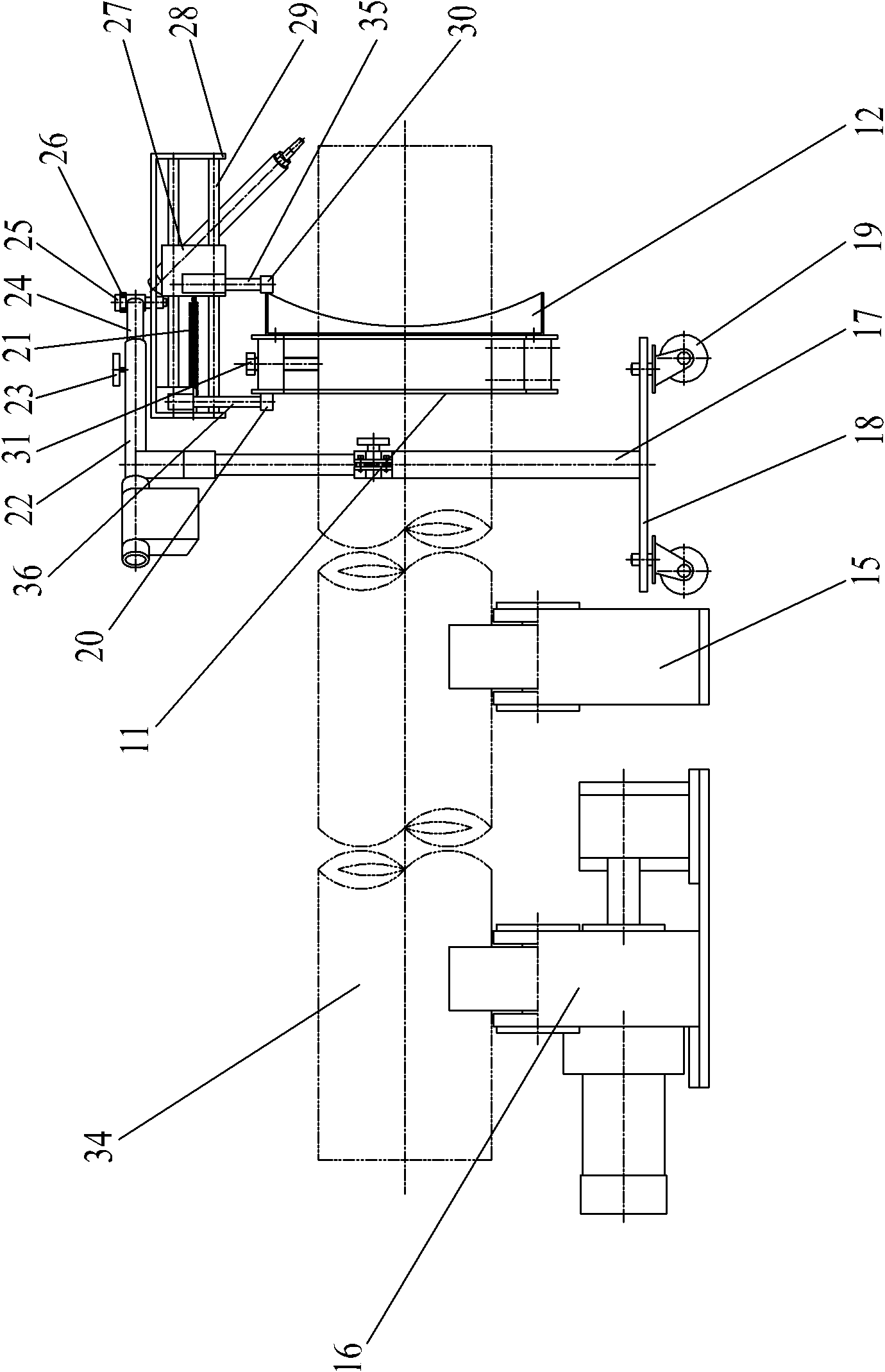

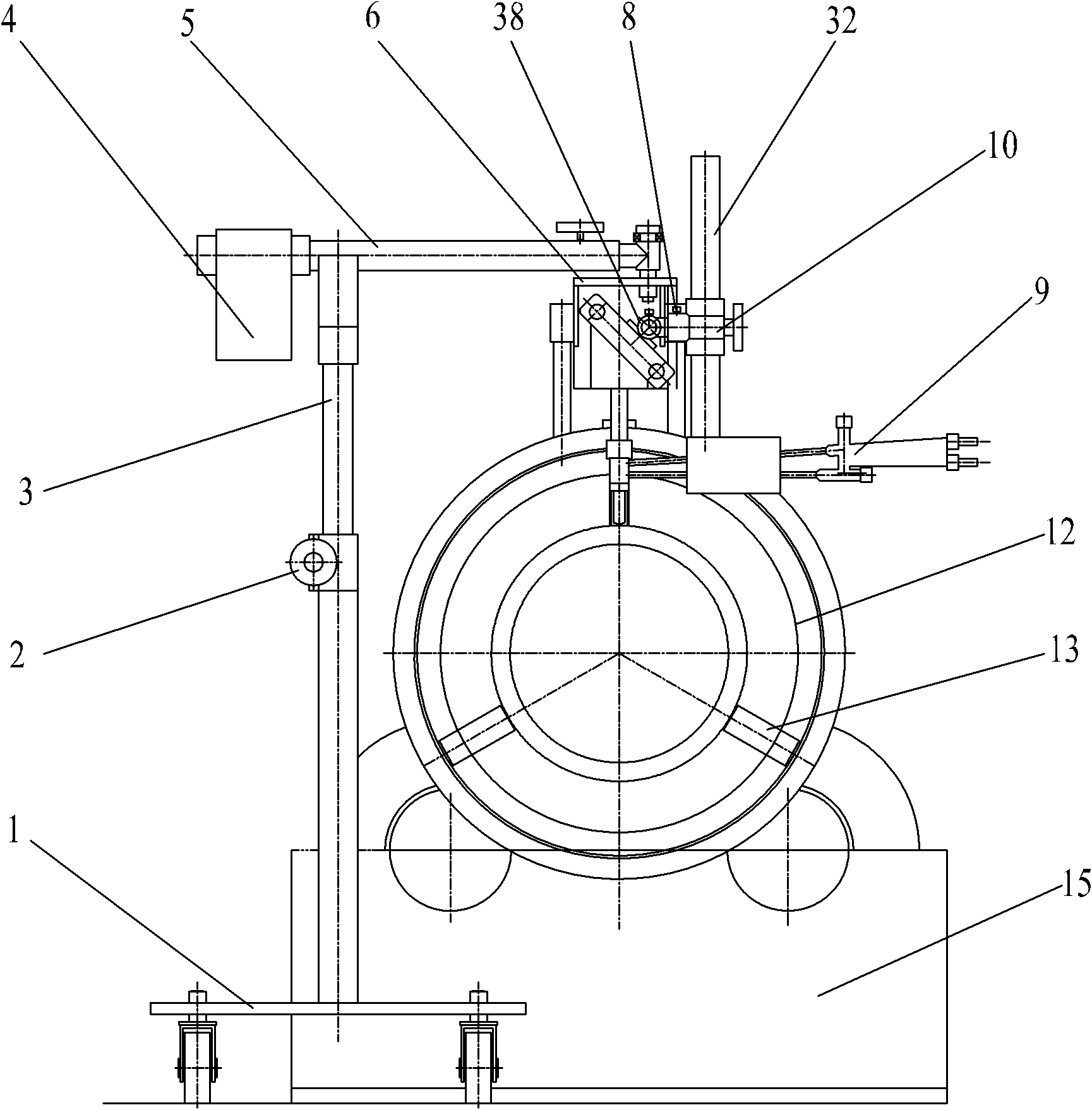

Panel PET-led boron neutron capturing therapeutic system and neutron beam flow control method

ActiveCN106264585AGuaranteed accuracyReduce Radiation DamageNuclear energy generationComputerised tomographsNeutron captureEngineering

The invention discloses a panel PET-led boron neutron capturing therapeutic system and a neutron beam flow control method. Precise image information can be provided by utilizing a panel PET detector, and precise irradiation time information can be provided for BNCT (boron neutron capturing therapeutic system) so as to conduct the precision does delivery aiming at specific target area and reduce the irradiation damage of sensitive areas; the system can conduct neutron targeting irradiation under horizontal and vertical postures, and the distance away from a beam outlet device can be conveniently moved and adjusted by utilizing a motor control device; and the precise space alignment on movement of an irradiated sample can be conducted by utilizing a high-precision optical positioning and tracking system, so as to ensure the positioning accuracy of the target area.

Owner:PEKING UNIV

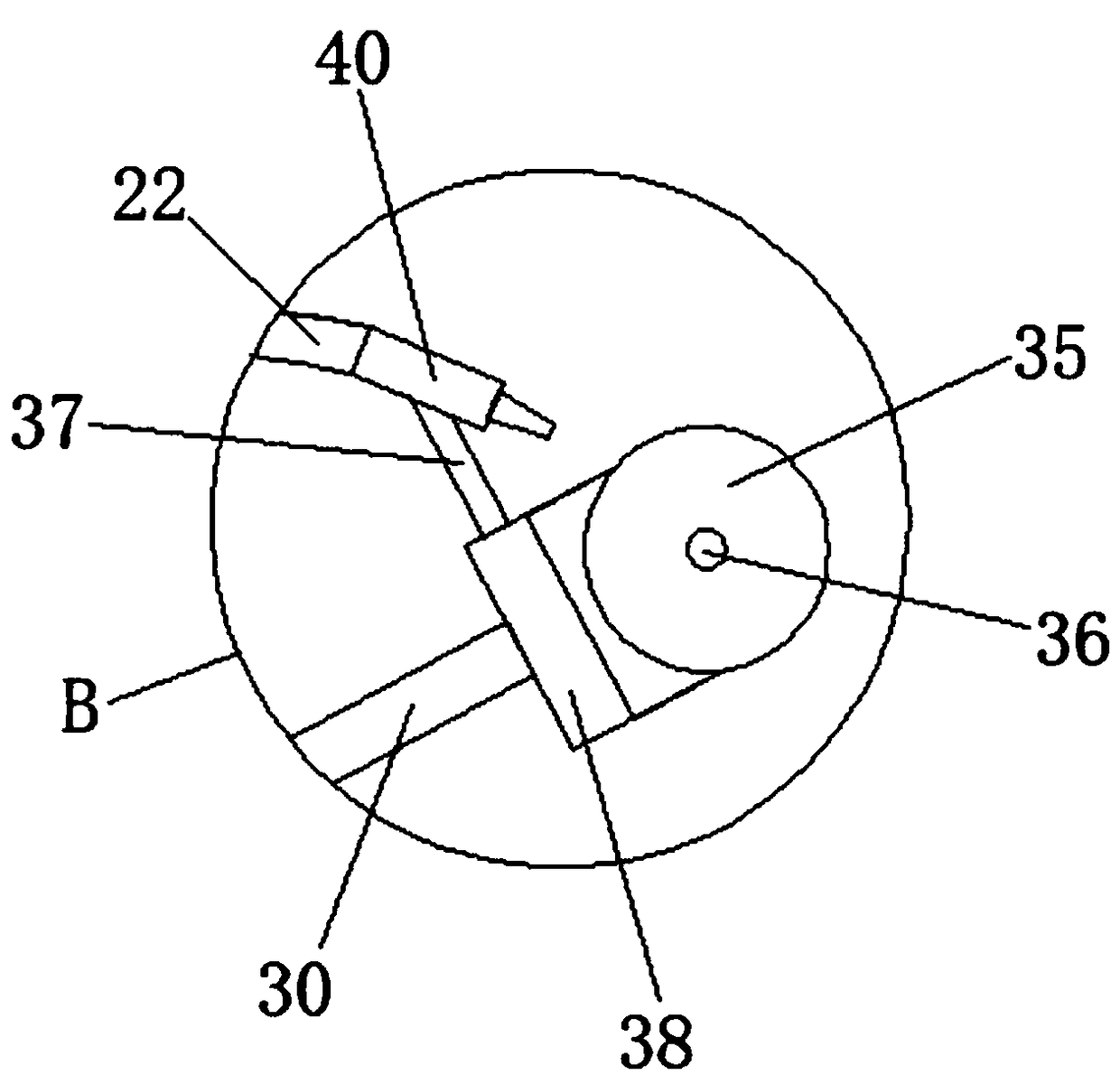

Saddle-shaped pipe end cutting device

The invention relates to a saddle-shaped pipe end cutting device, comprising a roll-over stand and a base, wherein the base is provided with a stand column which is provided with a cross arm; end part of the cross arm is provided with a hanging bracket by a pin roll; the hanging bracket comprises a s bracket body which is provided with a slider shaft; the slide shaft is in slip connection with a slider which is provided with a regulating spring; the slider is provided with a cutting torch adjusting sleeve in a hinged mode, and the cutting torch adjusting sleeve is provided with a cutting torch; a fixed pinch roller and a movable pinch roller are arranged at the lower part of the bracket body; a locating sleeve is arranged between the movable pinch roller and the fixed pinch roller; the locating sleeve is provided with an explorator; the fixed pinch roller and the locating sleeve are in rolling contact opposite to the other side the side in which the explorator is arranged; and the movable pinch sleeve and the explorator are in rolling contact. The saddle-shaped pipe end cutting device of the invention has the advantages of compact structure, low processing cost and high processingprecision and is convenient to process and operate, is used for saddle-shaped pipe ends and cutting processing of beveled edges of the saddle-shaped pipe ends, and processing of parallel and level pipe ends and cutting processing of beveled edges of the flush pipe ends.

Owner:WUXI HUAGUANG IND BOILER

Detecting device and method for machining

InactiveCN106271884ASensitive displacementEfficient detectionMeasurement/indication equipmentsMachining processMachine tool

The invention discloses a detecting device and method for machining and belongs to the field of detection. The detecting device for machining comprises measuring probes and a control circuit. The measuring probes are arranged on supports of magnetic force gauge stands. The measuring probes are pointed to the surface of a workpiece to be detected. The control circuit comprises a controller and an alarming device. The controller is in signal connection with the measuring probes. The measuring probes convert collected information and send the converted information to the controller. The alarming value of deviation of the workpiece to be detected is stored in the controller. The controller is also connected with an indication device. The detecting device can detect the movement condition of the workpiece in real time in the machining process of a machine tool, and the problem that in the prior art, detection only depends on regular checking conducted by operation personnel, so that the real-time performance is low is effectively solved.

Owner:HIMILE MECHANICAL MFG

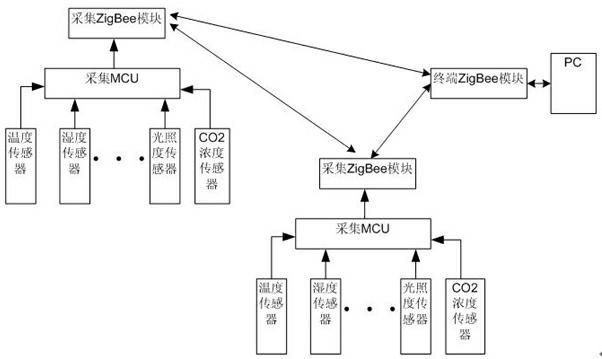

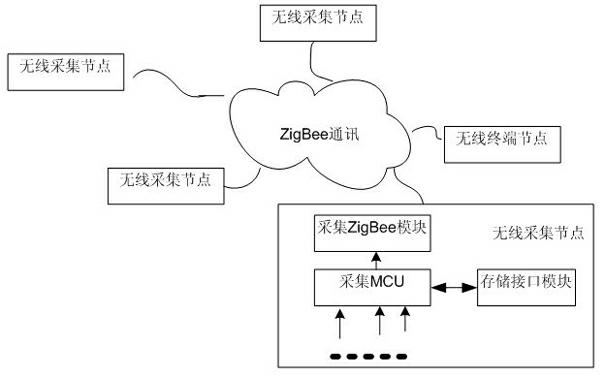

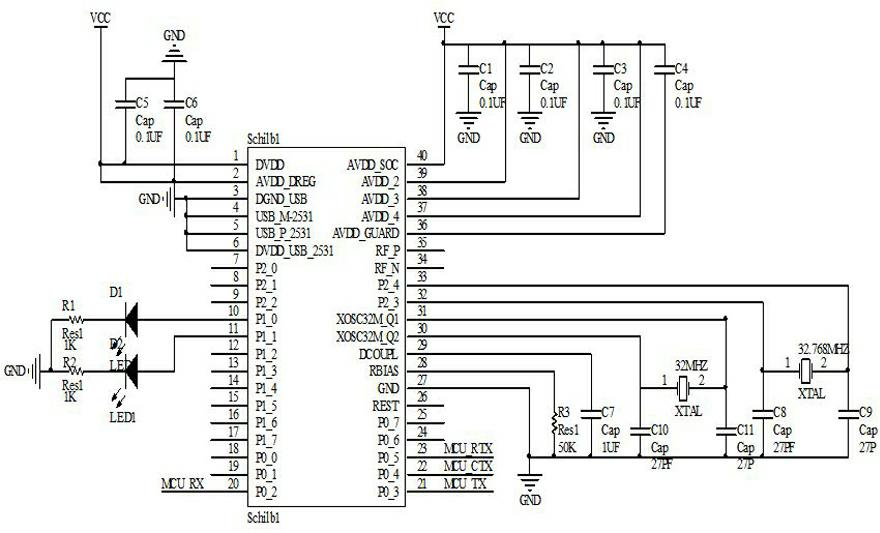

System for monitoring farmland based on ZigBee technology

InactiveCN102685930ASolve the costSolve complexityTransmission systemsNetwork topologiesSelf-healingPersonal computer

The invention relates to a system for monitoring farmland based on a ZigBee technology. The system is characterized in that at least two wireless acquisition nodes which are used for acquiring farmland information in real time and a wireless terminal node are distributed in the farmland, and each node forms a wireless network; each wireless acquisition node consists of an acquisition ZigBee module, a micro controller unit (MCU) and sensors, wherein the outputs of the sensors are connected with the MCU, the MCU and the acquisition ZigBee module are in communication connection, the farmland information acquired by the sensors is transmitted to the acquisition ZigBee module through the MCU, and the farmland information is transmitted to the wireless network by the acquisition ZigBee module; and the wireless terminal node comprises a terminal ZigBee module and a user terminal personal computer (PC) which is in communication connection with the terminal ZigBee module, and the terminal ZigBee module transmits the farmland information received from the wireless network to the user terminal PC. The system has the advantages of convenience of mounting, and high adaptability and self-healing ability, and is easy to use.

Owner:HENAN UNIV OF SCI & TECH

Automatic painting device

InactiveCN108930393AAvoid issues affecting height adjustmentEasy to moveBuilding constructionsThreaded pipeEngineering

The invention discloses an automatic painting device. The automatic painting device comprises a base plate. A connecting plate is fixedly connected with the left side of the upper surface of the baseplate. A fixing plate is fixedly connected with the middle of the upper surface of the connecting plate. A groove is formed in the middle of the upper surface of the connecting plate. A positive and negative motor is fixedly connected with the left side of the upper surface of the base plate. The end, away from the base plate, of the positive and negative motor extends into the groove. According to the automatic painting device, better movement can be achieved, a threaded rod can be better driven to rotate by rotation of the positive and negative motor, and therefore a threaded pipe can conduct sliding adjustment at the threaded rod, and position of the threaded pipe can be better limited to avoid the problem of influencing height adjustment due to threaded pipe rotating caused by threadedrod rotating. The telescopic end of an electric telescopic rod can better extend out and retract back to drive a supporting rod to conduct angle adjustment, and therefore a cotton brush cylinder canbe better pulled to pain a wall body in an up and down mode, and the painting effect of the device can be improved.

Owner:FOSHAN UNIVERSITY

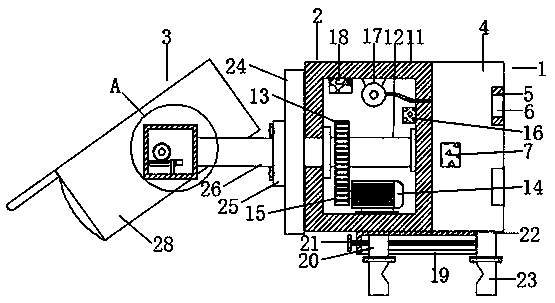

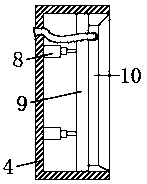

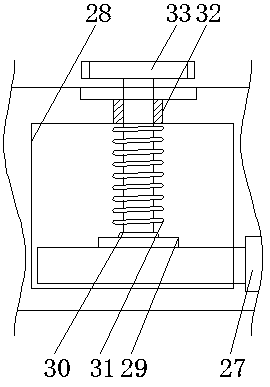

Fixing device of video surveillance camera

InactiveCN110307461ACompact structureEasy to move and adjustStands/trestlesSurveillance cameraEngineering

The invention discloses a fixing device of a video surveillance camera. The fixing device of the video surveillance camera comprises a fixing mechanism, a rotating mechanism and an elevation adjustingmechanism, wherein the rotating mechanism is arranged on one side of the fixing mechanism, the elevation adjusting mechanism is arranged on the side, away from the fixing mechanism, of the rotating mechanism. According to the fixing device, the structure is compact, through arrangement of the fixing mechanism, the camera can be fixed on a smooth wall through a vacuum sucker, so that the camera can be moved and adjusted conveniently, the camera can be mechanically fixed through bolts and fixing holes, the camera can be clamped and fixed to the required position through a fixing screw rod, so that the problem that the installation is inconvenient due to the fixing plate is inflexible is avoided, multimode fixing installation improves the mounting efficiency; and through arrangement of the rotating mechanism and the elevation adjusting mechanism, the camera can be conveniently adjusted in multiple angles, the problem that the angle adjustability of the camera is poor due to inflexible ofthe structure is avoided, the angle positions of the camera can be flexibly adjusted, and the practicability of the fixing device is improved.

Owner:YANTAI SANXIN NEW ENERGY TECH CO LTD

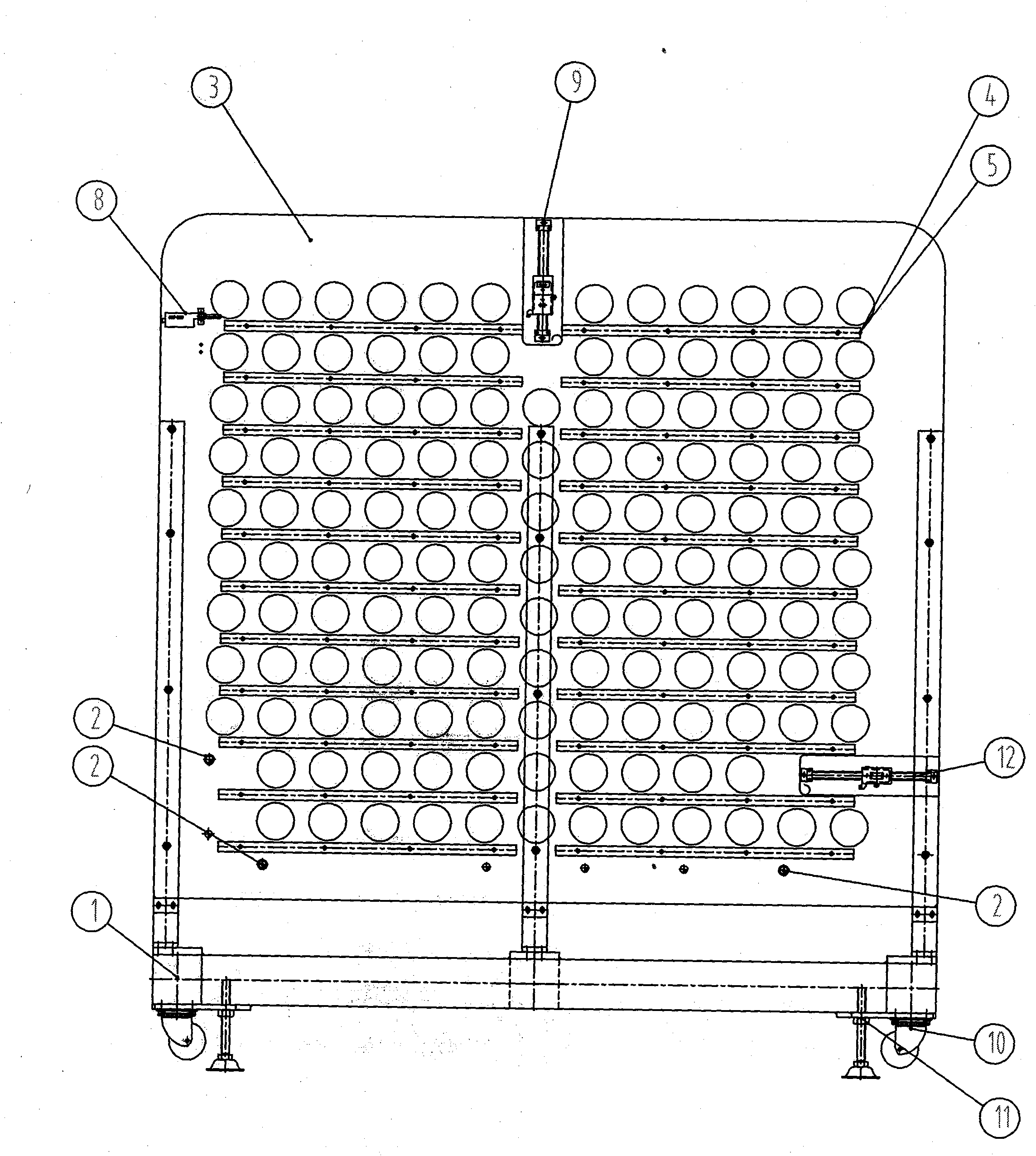

Packing box fixing and conveying device

InactiveCN105858054AEasy to fixEfficient and convenient mobile adjustmentConveyorsSupporting framesHydraulic cylinderEngineering

The invention discloses a packing box fixing and conveying device, and belongs to the field of conveying mechanical devices. The packing box fixing and conveying device comprises a horizontal moving base, box bearing rollers, a fixing support and clamping mechanisms. A plurality of brake-carrying universal wheels are evenly arranged on the lower side of the horizontal moving base. The box bearing rollers are horizontally, evenly and rotationally connected with the upper side of the horizontal moving base. The clamping mechanisms are symmetrically arranged on the two sides of a horizontal moving lead screw. Each clamping mechanism comprises a horizontal moving plate, a clamping plate and a clamping hydraulic cylinder. The two sides of the horizontal moving lead screw are provided with thread surfaces with opposite spiral directions respectively. The two horizontal moving plates are connected to the two sides of the horizontal moving lead screw in a threaded mode respectively. The horizontal moving plates can move horizontally along horizontal moving guide rods. Each clamping plate is arranged on one side of the corresponding horizontal moving plate. One end of each clamping plate is hinged to the corresponding horizontal moving plate. Each clamping hydraulic cylinder is arranged between the corresponding clamping plate and the corresponding horizontal moving plate. The packing box fixing and conveying device is reasonable in structural design, can rapidly and efficiently convey packing boxes stably, and can meet use requirements.

Owner:晋正正

Novel three-roller grinding mill

InactiveCN102950047AEasy to move and adjustEasy to operateGrain treatmentsEngineeringInjection device

The invention aims to solve the problem to provide a novel three-roller grinding mill, which comprises a grinding mill body, wherein a support is arranged on the grinding mill body; an ink injection device is arranged on the support, and comprises a feed cylinder, a base and a hydraulic system, wherein the base is fixedly supported on an outer side of the feed cylinder; two ends of the base are rotatably connected with the support; and parts of the two ends of the base, which are stretched out of the support, are connected with a piston of hydraulic steel of the hydraulic system through connecting pieces. The novel three-roller grinding mill has the beneficial effects that: due to the adoption of the technical scheme, the grinding mill body is assembled with the ink injection device, so that the movement and the adjustment are convenient; and the ink injection device is adjusted by adopting the hydraulic system and is charged automatically, so that the operation is convenient, the structure is simple, and the manufacturing cost is low.

Owner:TIANJIN ANGUANG INK FACTORY

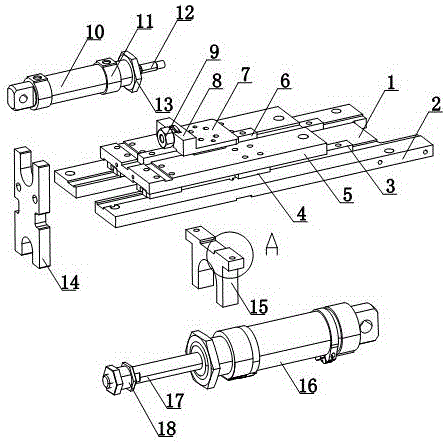

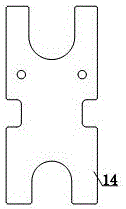

Adjustment-convenient material clamping device for plasma cutting equipment

InactiveCN107470831AEasy to adjustEasy to move and adjustWelding/cutting auxillary devicesAuxillary welding devicesEngineeringPlasma cutting

The invention relates to the technical field of plasma cutting equipment, in particular to a conveniently adjustable material clamping device for plasma cutting equipment, which includes a support platform on the plasma cutting equipment, and the upper surface of the support platform is provided with two symmetrically arranged strips block, so that the long block slides along the upper surface of the support platform, and the upper surface of the support platform is provided with two long holes corresponding to the position of the long block, and a fixing rod is provided under the two long holes, Both ends of the two fixed rods are provided with fixed blocks, the tops of the fixed blocks are installed on the bottom surface of the support platform, and the fixed rods are sleeved with pipe fittings corresponding to the positions of the long strips, so that the pipe fittings are fixed along the The surface of the rod slides, and a plurality of second through holes are opened on the fixed rod. The present invention is simple in structure, easy to use, not only convenient to adjust and fix according to the size of the material, but also convenient to the operation of staff, and improves the practicability of the clamping device.

Owner:湖北敏丰机电设备有限公司

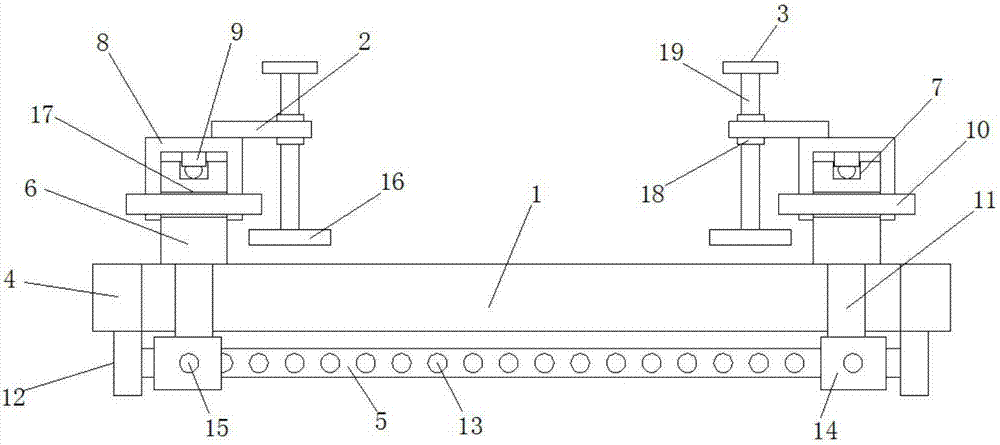

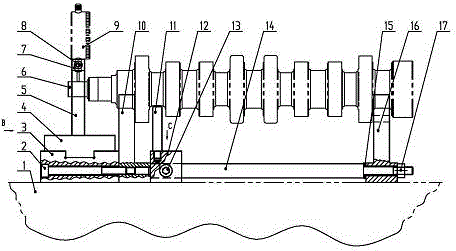

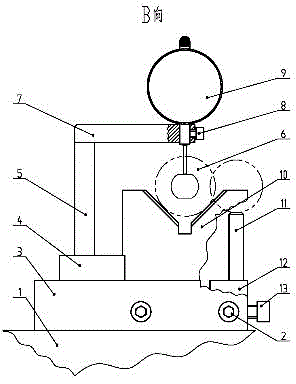

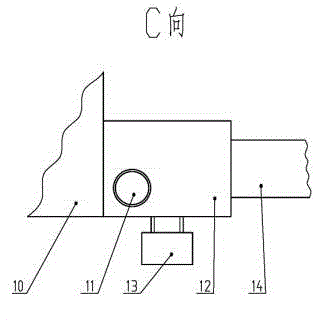

Crankshaft plane parallelism detection device

InactiveCN104089567AImprove detection efficiencyReasonable structureAngles/taper measurementsEngineeringSlide plate

The invention relates to a crankshaft plane parallelism detection device. The crankshaft plane parallelism detection device comprises a platform, V-shaped blocks, a positioning and supporting block, a positioning column, a sliding table, a sliding plate and a dial indicator. The V-shaped blocks, the positioning and supporting block and the sliding table are placed on the platform. Two connection pull rods are connected between the two V-shaped blocks. A circular through hole is formed in the positioning and supporting block in the direction of the connection pull rods. A smooth cylinder through which the connection pull rods are connected is movably sleeved with the positioning and supporting block, and a positioning screw is arranged in the positioning and supporting block. The sliding table is fixed to the left side of the V-shaped block at the left end through two lengthened screws. The sliding plate is movably arranged on the sliding table. A stand column is fixed to the sliding plate. The dial indicator is arranged on the stand column through a dial indicator connection rod. By means of the crankshaft plane parallelism detection device, a read number is obtained when the contact of the dial indicator makes contact with the plane at the small end of a crankshaft, and the crankshaft plane parallelism detection result can be obtained when the read number is compared with that of a standard crankshaft. The crankshaft plane parallelism detection device is reasonable in structure, easy and convenient to move and regulate, high in detection efficiency and particularly suitable for detecting the parallelism of a plane machined on a small-end cylinder of the crankshaft.

Owner:TIANRUN IND TECH CO LTD

Clamping device for automobile irregular metal component machining and clamping method

ActiveCN109333115AImprove efficiencyEasy to move and adjustPositioning apparatusMetal-working holdersMachiningThreaded rod

The invention discloses a clamping device for automobile irregular metal component machining in the technical field of component clamping. The clamping device comprises a clamp body with the top evenly provided with screw connecting holes. The top of the clamp body is provided with two longitudinal parallel rectangular grooves. A front T-shaped plate and a rear T-shaped plate are arranged on the right rectangular groove. Transverse first round head positioning pins are arranged on the tops of the T-shaped plates. A lead screw transversely penetrates through the middle portion of a fixing basethrough a threaded hole. The left end of the lead screw is connected with a clamping block through a bearing. The front side of the top of the clamp body is connected with a rectangular block througha screw. A supporting base is arranged on the front side of the top of the rectangular block. The rear side of the top of the rectangular block is rotationally connected with a pressing rod through avertical shaft. The supporting base is provided with a longitudinal threaded rod through a threaded hole in a penetrating manner. The rear end of the threaded rod is connected with the pressing rod. According to the device, automatic balanced clamping is achieved during clamping, the irregular component clamping precision is improved, and accordingly the component machining precision is improved.

Owner:重庆万象津专专用汽车有限责任公司

Curved roof curtain wall system

PendingCN112726909ARealize rotation adjustmentSolve the problem that the installation cannot be adjustedRoof coveringWallsClassical mechanicsMechanical engineering

The invention relates to a curved roof curtain wall system. The curved roof curtain wall system comprises a main framework arranged on a main body structure, a plurality of first adapting pieces arranged on the side, away from the main body structure, of the main framework at intervals, second adapting pieces installed on the sides, away from the main framework, of the first adapting pieces in a swinging mode, secondary frameworks detachably installed on the sides, away from the main framework, of the second adapting pieces, a plurality of installing bases arranged at intervals and detachably arranged on the secondary frameworks in a sleeving mode, and curtain wall plates detachably installed on the sides, away from the secondary frameworks, of the installing bases. The second adapting pieces are moved and adjusted in the length direction of the first adapting pieces so that the distance between the secondary frameworks and the main framework can be adjusted, and the posture of the secondary frameworks is adjusted by adjusting the second adapting pieces in a swinging mode. A plurality of curtain wall plates are spliced and connected to form the curved roof curtain wall system, adjusting and installing can be conducted according to the design modeling of the curved roof curtain wall system, and construction is more flexible, easier and more convenient.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

A computer software and hardware detection device convenient to move and adjust

InactiveCN109885445AEasy to move and adjustAvoid enteringError detection/correctionData connectionComputer software

The invention discloses a computer software and hardware detection device convenient to move and adjust. The device comprises a computer software and hardware detection device body, a data connectionport, a sealing block and a protective shell, wherein a data connection port is formed in one end of the computer software and hardware detection device main body; the sealing block is arranged on theside face of the data connection port, the protection shell is arranged in the computer software and hardware detection device body, the two ends of a baffle are arranged in second sliding grooves, aclamping block is fixed to one side of the baffle, and a clamping groove is formed in the side, away from the baffle, of the clamping block. In the computer software and hardware detection device convenient to move and adjust, the protective shell is provided with the ventilation opening, the second sliding groove, the baffle and the clamping block, the clamping block is pushed to drive the baffle to slide in the second sliding groove according to different wind power areas needing to be used, then the baffle slides out of the protective shell, and therefore the area of the ventilation opening is adjusted, and calculation software and hardware of different sizes can be detected through the device.

Owner:ZHEJIANG BOLUONI ELECTRONICS

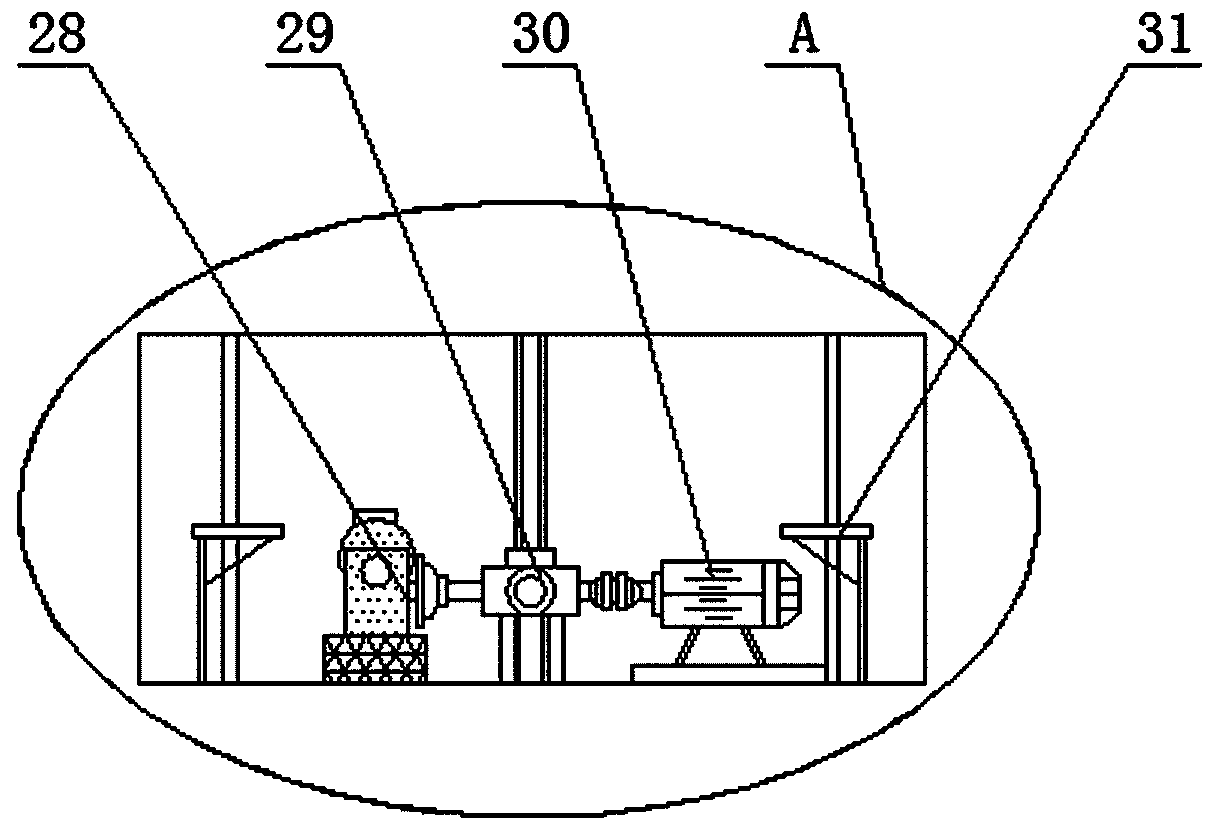

Electrostatic treatment device of plastic thin film

PendingCN108100736AEasy to transportEasy to move and adjustElectrostatic chargesWebs handlingEngineeringPlastic film

The invention discloses an electrostatic treatment device of a plastic thin film. The electrostatic treatment device comprises a base. A rack is arranged on the base. A mounting shaft is arranged on one side of the bottom of the rack. Moving wheels are arranged at the two ends of the mounting shaft. A first traction roller is arranged on the upper side of the rack, and a second traction roller isarranged on the lower side of the rack. A first transmission roller is arranged on the upper portion of the rack and is mounted on the upper portion of the rack through a first mounting shaft. A second transmission roller is arranged on the lower portion of the rack and is mounted on the lower portion of the rack through a second mounting shaft. A guide pipe is arranged on one side of the rack, amoving shaft is arranged in the guide pipe in a sleeved manner, an electrostatic removal brush is arranged at the inner end of the moving shaft, and the outer end of the moving shaft is a free end. According to the electrostatic treatment device, the electrostatic removal brush can be conveniently moved and adjusted, and electrostatic removal treatment can be conveniently carried out on the frontface of the plastic thin film through the electrostatic removal brush.

Owner:苏州星火丰盈环保包装有限公司

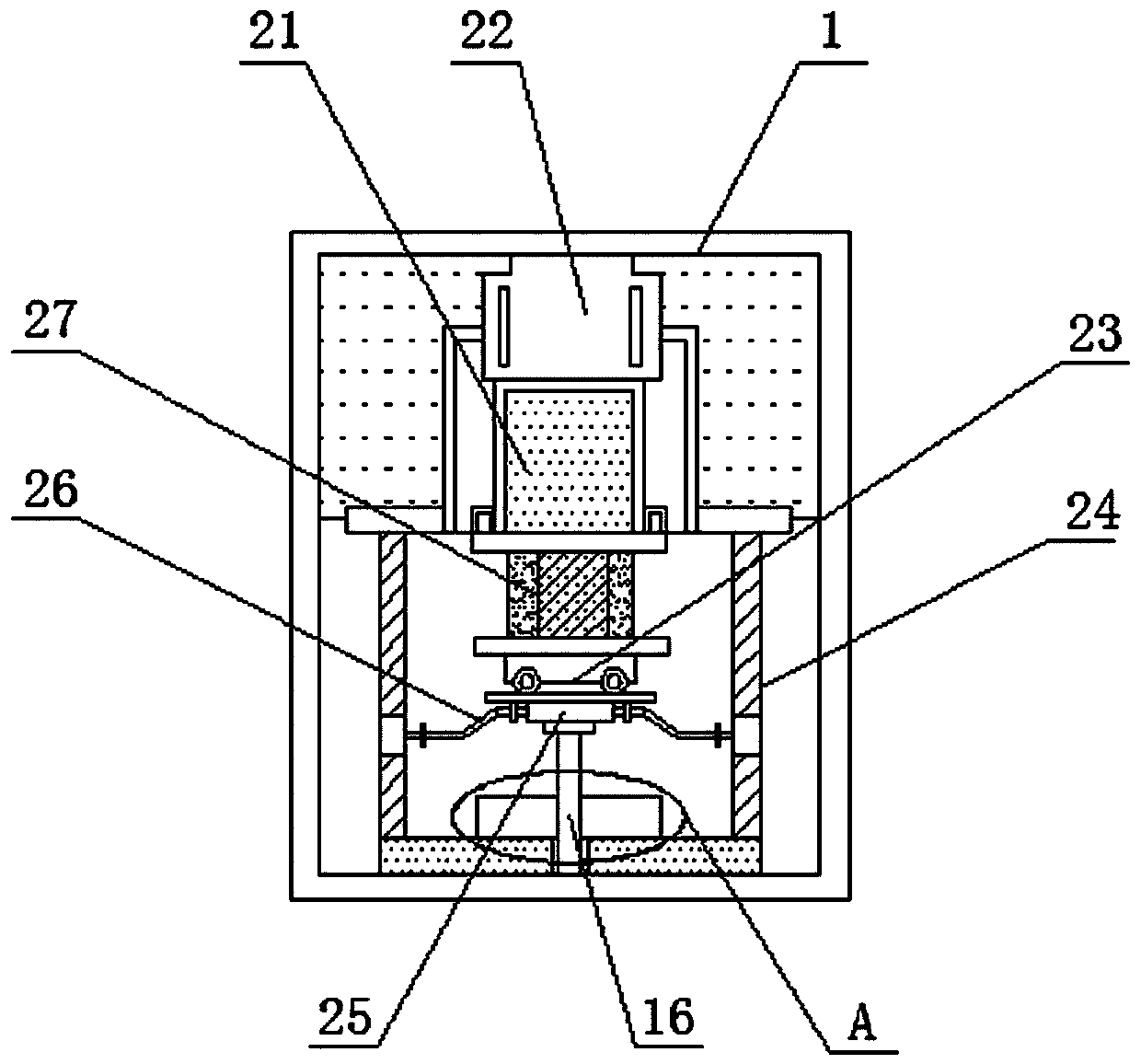

Intelligent production processing equipment for single product silicon hot field crucible and processing method of intelligent production processing equipment

InactiveCN110685011AReduce stepsReduce security risksPolycrystalline material growthBy pulling from meltCrucibleProcess engineering

The invention discloses intelligent production processing equipment for a single product silicon hot field crucible. The intelligent production processing equipment comprises a heat preservation cylinder and a mechanical truss, wherein a fixed transverse beam is arranged above the mechanical truss; a transverse beam sliding track is arranged on the fixed transverse beam; fixed sliding bases are arranged on both the left end and the right end of the fixed transverse beam; telescopic clamping arms are arranged below the fixed sliding bases; a top bearing is arranged below the middle position ofthe fixed transverse beam; and an upper furnace cavity is formed below the top bearing. The invention further discloses a processing method of the intelligent production processing equipment for the single product silicon hot field crucible. By adopting the equipment, not only is the problem that the equipment is inconvenient to move because of a high temperature in a preparation process solved, but also conventional equipment for processing single product silicon is improved, the processed single product silicon can be high in purity and small in impurity, convenience can be brought to processing and production, and thus the purposes that the equipment is conveniently moved and adjusted and the prepared product is high in quality can be achieved.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

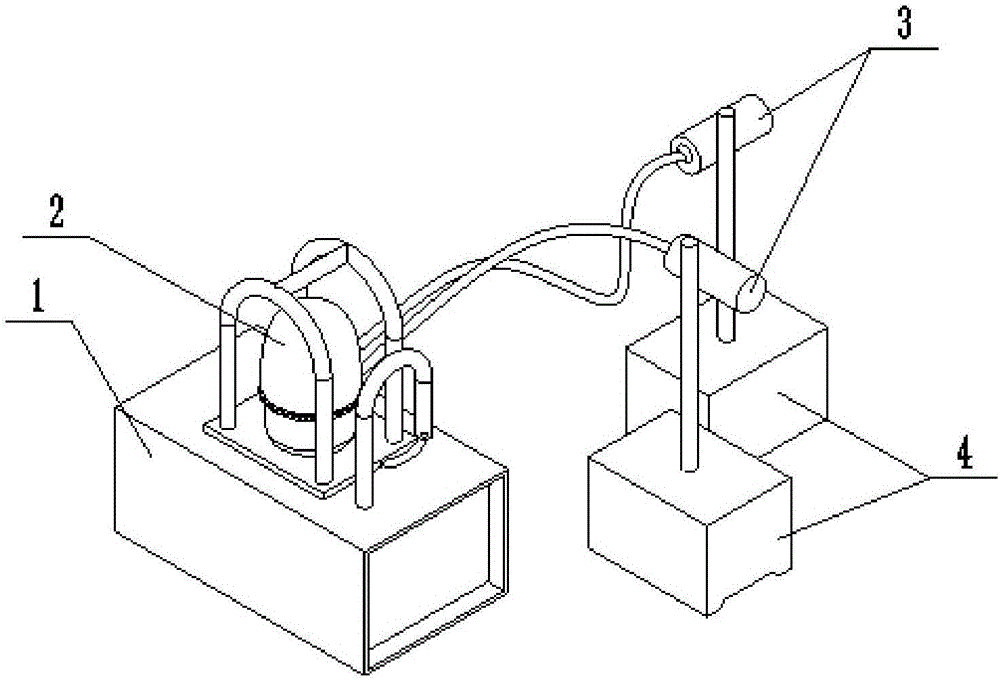

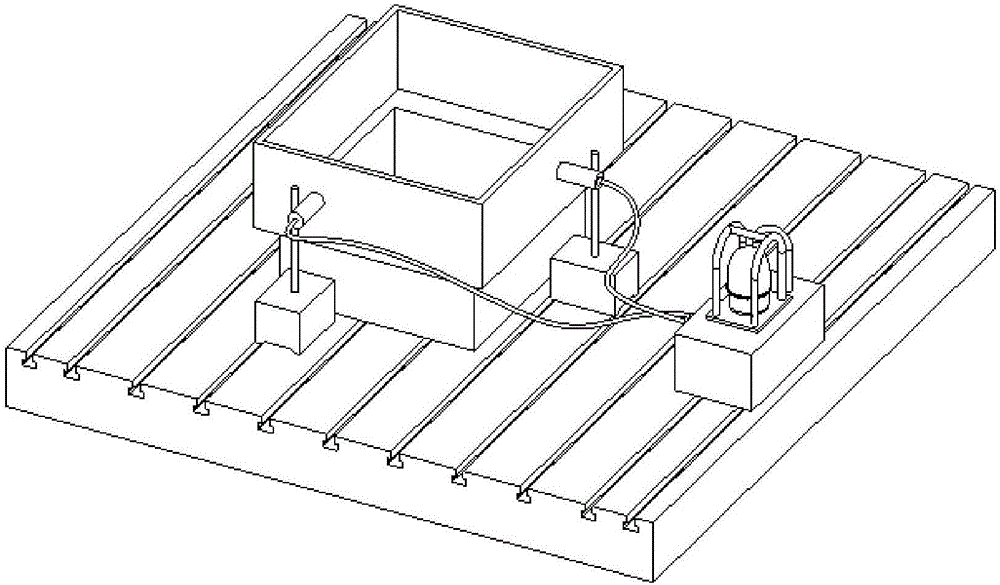

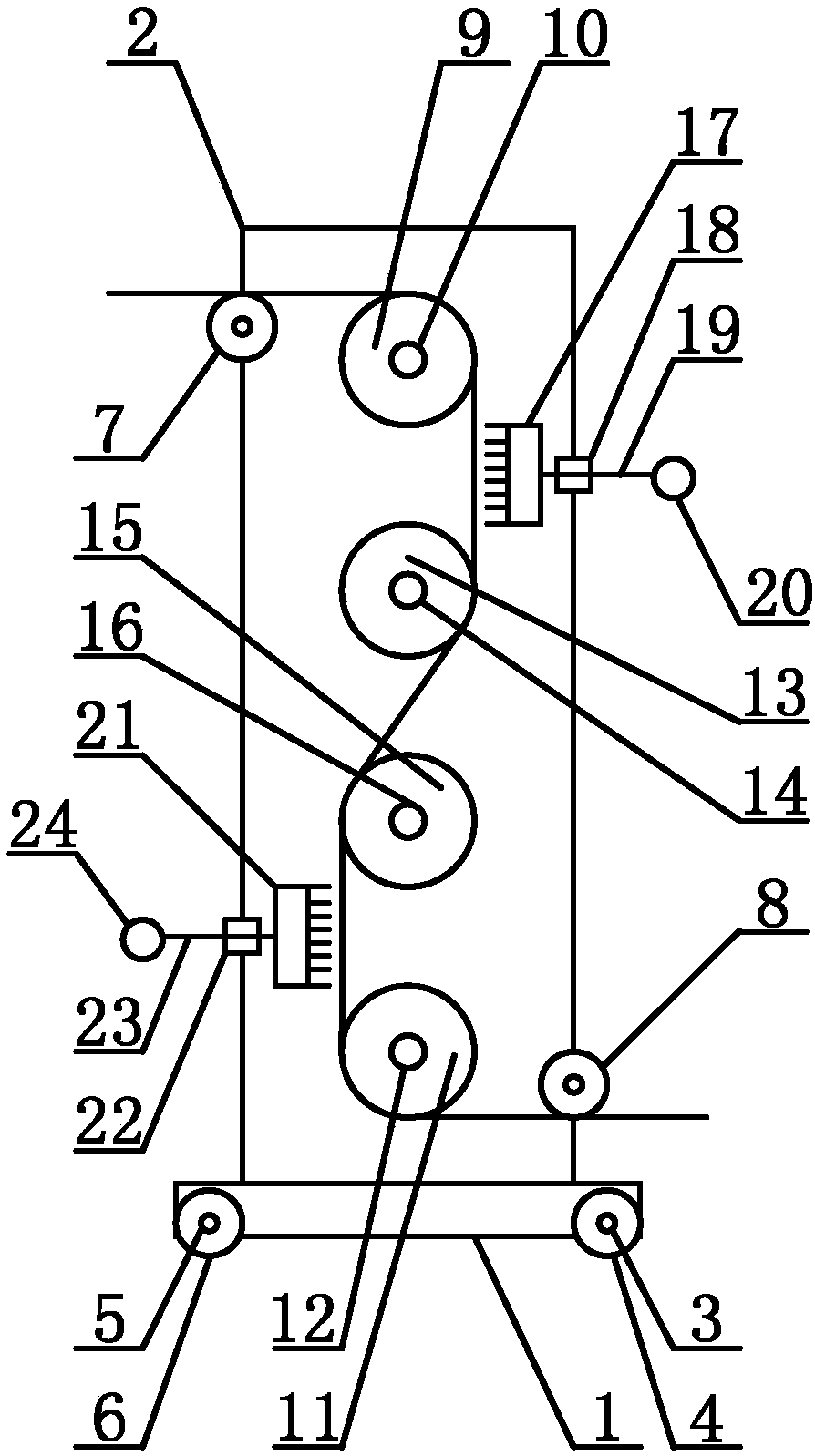

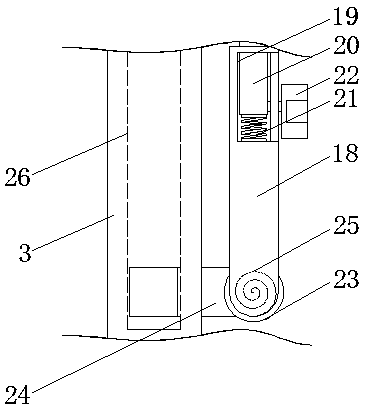

Guide pipe adjusting type radio-frequency cable take-up device

The invention discloses a guide pipe adjusting type radio-frequency cable take-up device. The guide pipe adjusting type radio-frequency cable take-up device comprises a rack, a pay-off reel and a take-up reel are arranged on the rack, a fixing plate is arranged on the inner bottom of the rack, side plates are arranged on the fixing plate, and a carrying plate is arranged between the ends of the side plates. A driving motor is arranged on the carrying plate, a driving shaft is arranged on the front portion of the driving motor, one end of the driving shaft is connected with the driving motor, and the other end of the driving shaft is sleeved with a driving wheel. The driving wheel is engaged with the take-up reel. A moving frame is arranged in the rack, a guide shaft is arranged in the moving frame, the peripheral surface of the guide shaft is sleeved with sliding pipes, guide pipes are arranged on the sliding pipes, cyclophons are sleeved with the guide pipes, and traction wheels are arranged at the ends of the cyclophons. According to the guide pipe adjusting type radio-frequency cable take-up device, the moving frame is convenient to move and adjust, the traction wheels can be moved and adjusted, and thus a radio-frequency cable can be wound in the axial position of the peripheral surface of the take-up reel and can be wound on the whole outer surface of the take-up reel.

Owner:SUZHOU HONGYE LAMP EQUIP CO LTD

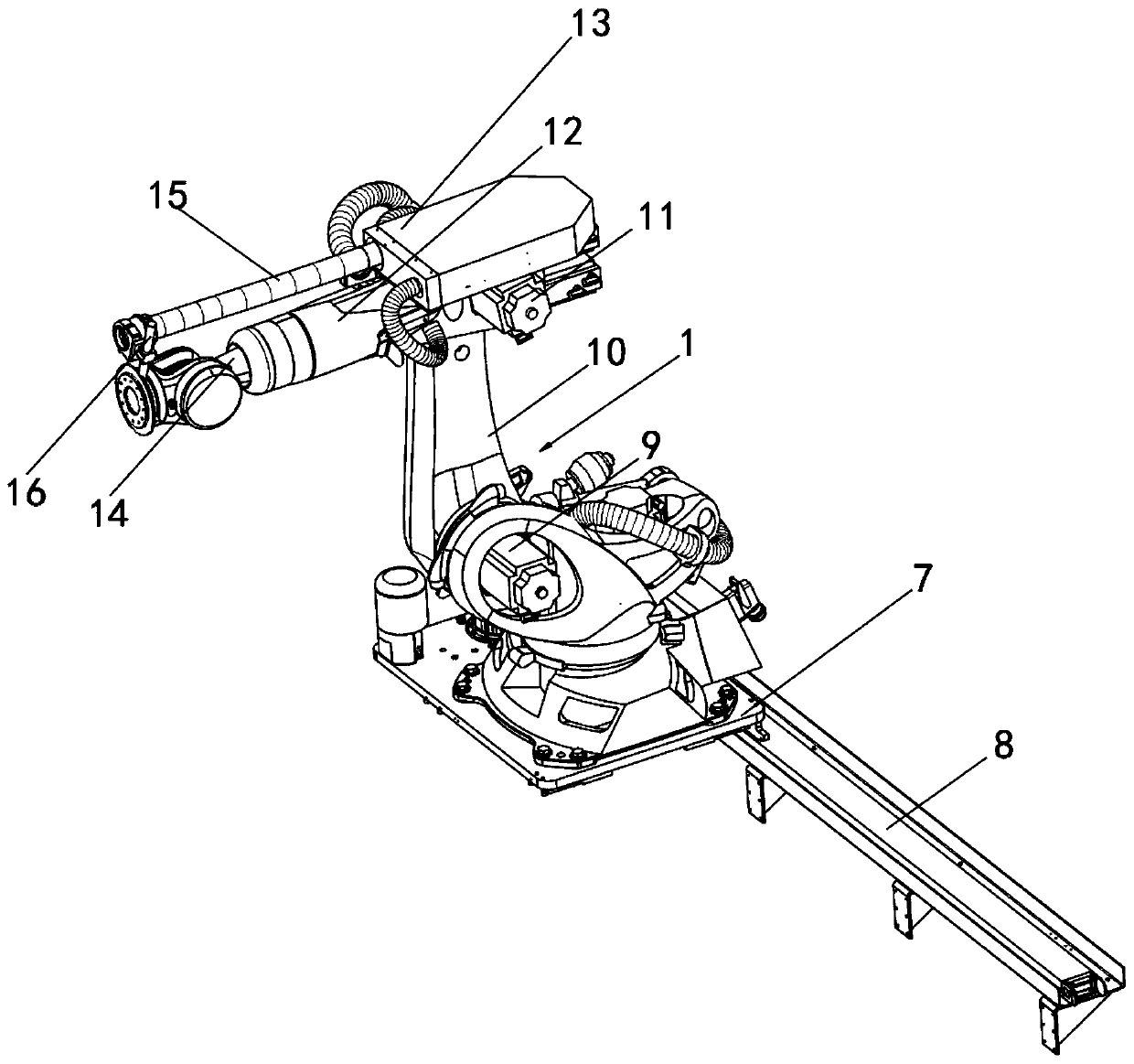

Electrical automatic mechanical arm bracket

InactiveCN111958572AEasy to move and adjustEasy to operateProgramme-controlled manipulatorControl engineeringControl theory

Owner:谢欢

Heavy mechanical equipment clamping device

InactiveCN108679371AAvoid the problem that the clamping height cannot be adjustedAvoid height adjustmentMachine framesStands/trestlesEngineeringMechanical equipment

The invention discloses a heavy mechanical equipment clamping device which comprises a bottom plate. A supporting column is fixedly connected to the middle of the upper surface of the bottom plate, aplacing plate is fixedly connected to the side face, away from the bottom plate, of the supporting column, and two symmetric sliding grooves are formed in the upper surface of the bottom plate; and two symmetric sliding blocks are clamped in each sliding groove, and a connecting column is fixedly connected to the middle of the upper surface of each sliding block. The heavy mechanical equipment clamping device can better place heavy mechanical equipment, and the position of a moving box can be better slid, so that two fixing rods are driven to move, and two clamping plates are used for clampingand stabilizing the mechanical equipment; and operation of a motor can better drive threaded tubes to slide on threaded rods to be adjusted, so that connecting rods and the clamping plates are drivento adjust the height, the problem that the clamping height cannot be adjusted during clamping is avoided, the threaded rods can be better rotated, and the problem that the threaded rods are clamped during rotation is avoided.

Owner:芜湖市涵润智能科技有限公司

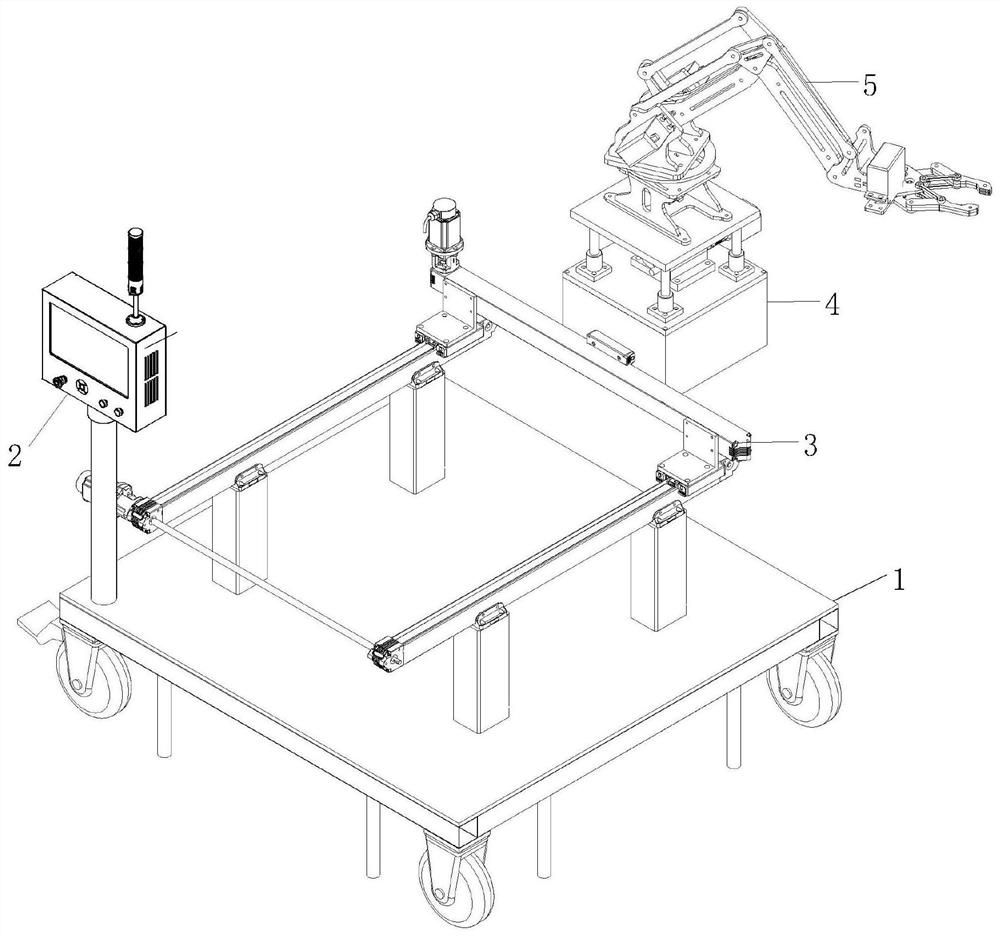

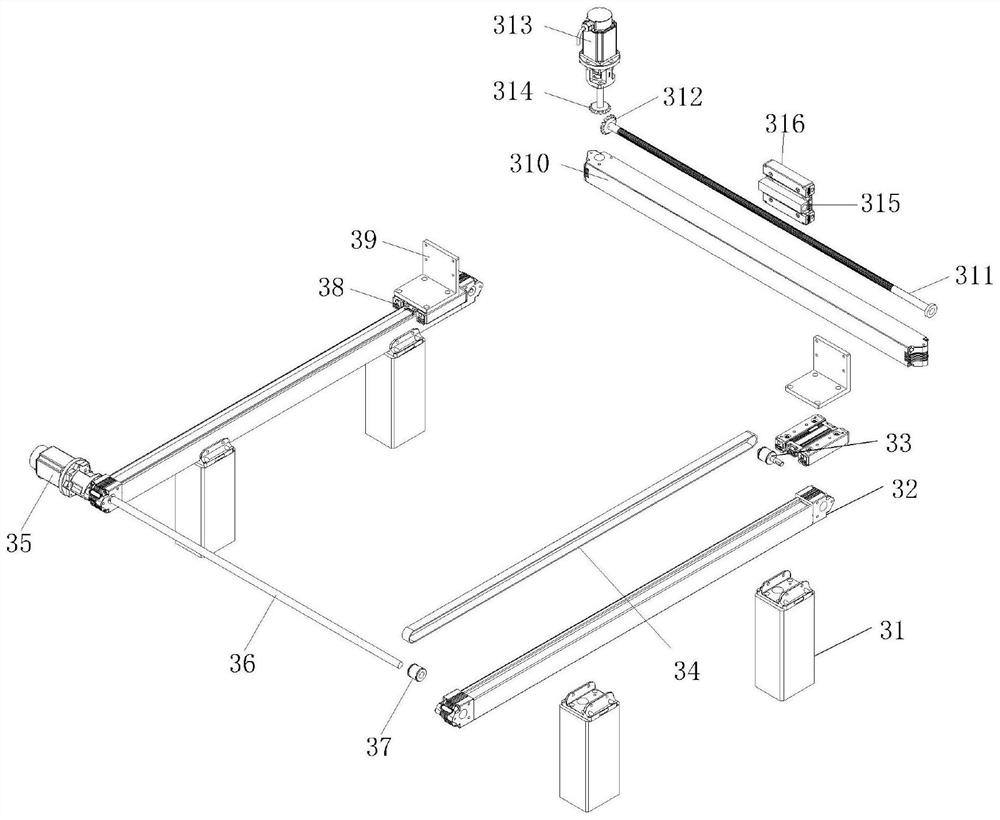

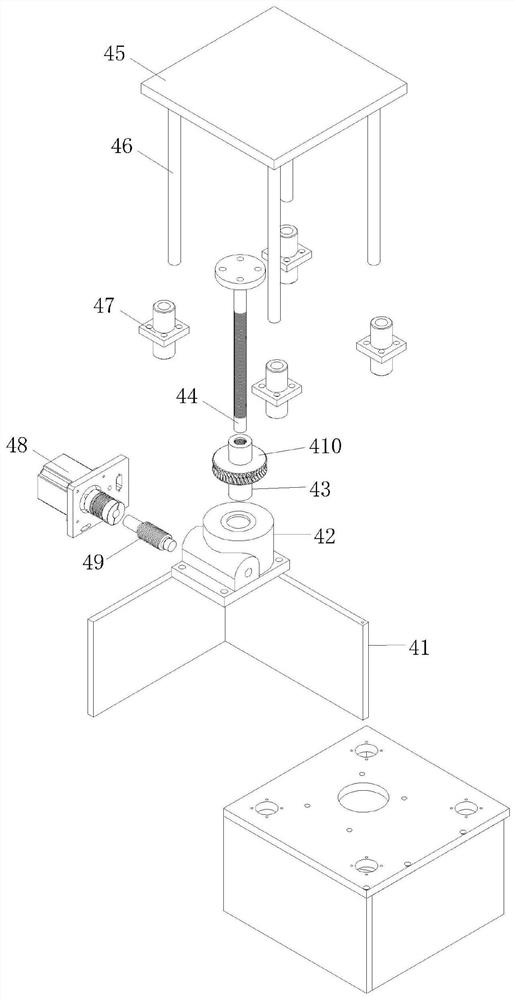

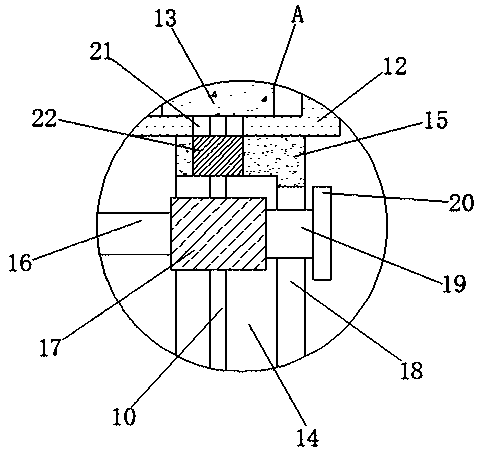

Automatic loading and unloading robot for part machining

ActiveCN109794924AWidely applicableGuaranteed universalityProgramme-controlled manipulatorGripping headsHydraulic pumpAutomation

The invention discloses an automatic loading and unloading robot for part machining. The robot comprises a moving and adjusting frame, a hydraulic pump I, a grabbing disk and a machine base; the machine base is arranged below the moving and adjusting frame; a moving platform is horizontally arranged at the bottom of the moving and adjusting frame; a motor I is arranged at one end of the moving platform; and a motor IV is arranged above the moving platform. The robot has the beneficial effects as follows: the robot is widely applicable, can perform loading grabbing and movement on materials required before part machining and can also perform unloading grabbing, movement and adjustment on part products after part machining, so that the adaptation universality is guaranteed; the robot is highin automation degree of working and is time-saving and labor-saving in use, a motor II drives a turning plate and the grabbing disk for rotation adjustment, a motor III drives a hydraulic pump II andthe grabbing disk for up-and-down turning adjustment, and a motor VI below the hydraulic pump I drives the grabbing disk through a swinging rod I to rotate to adjust the dropping angle and height, sothat the robot can drop different kinds of parts or required materials more accurately and appropriately.

Owner:AVIC POWER SCI & TECH ENG

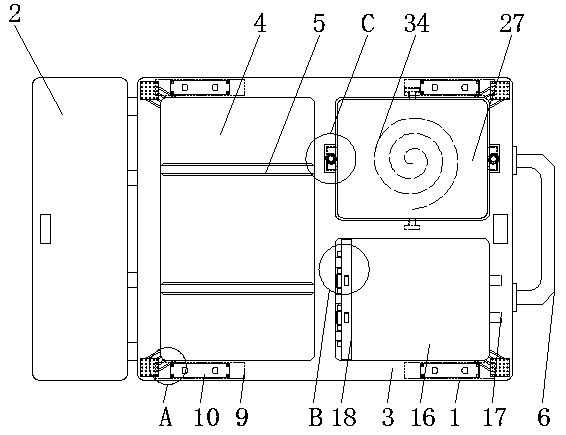

Portable fault-detection maintenance support toolbox with sorting function

The invention relates to a portable fault-detection maintenance support toolbox with a sorting function. The portable fault-detection maintenance support toolbox comprises a box body and grooves, a box door is arranged on the outer side of the left end of the box body, and a frame body is connected to the outer side of the box body. A side chamber is formed in the left end of the box body, and theinner end of the side chamber is connected with horizontal partition plates. An outer handle is fixed to the outer side of the right end of the box body. Air holes are formed in the inner sides of the grooves, and the grooves are located around the frame body. Storage compartments are connected to the bottom ends of the air holes, and openings are formed in the tops of the right ends of the storage compartments. The portable fault-detection maintenance support toolbox has the beneficial effects that the portable fault-detection maintenance support toolbox with the sorting function is providedwith the openings through which drying materials such as a desiccant can be added to the storage compartments, and the interior of the box body is dried through the air holes; and through the clamping between clamping columns and clamping grooves, sealing covers can be firmly fixed to the outer sides of the openings to seal and fix the openings.

Owner:DONGGUAN UNIV OF TECH

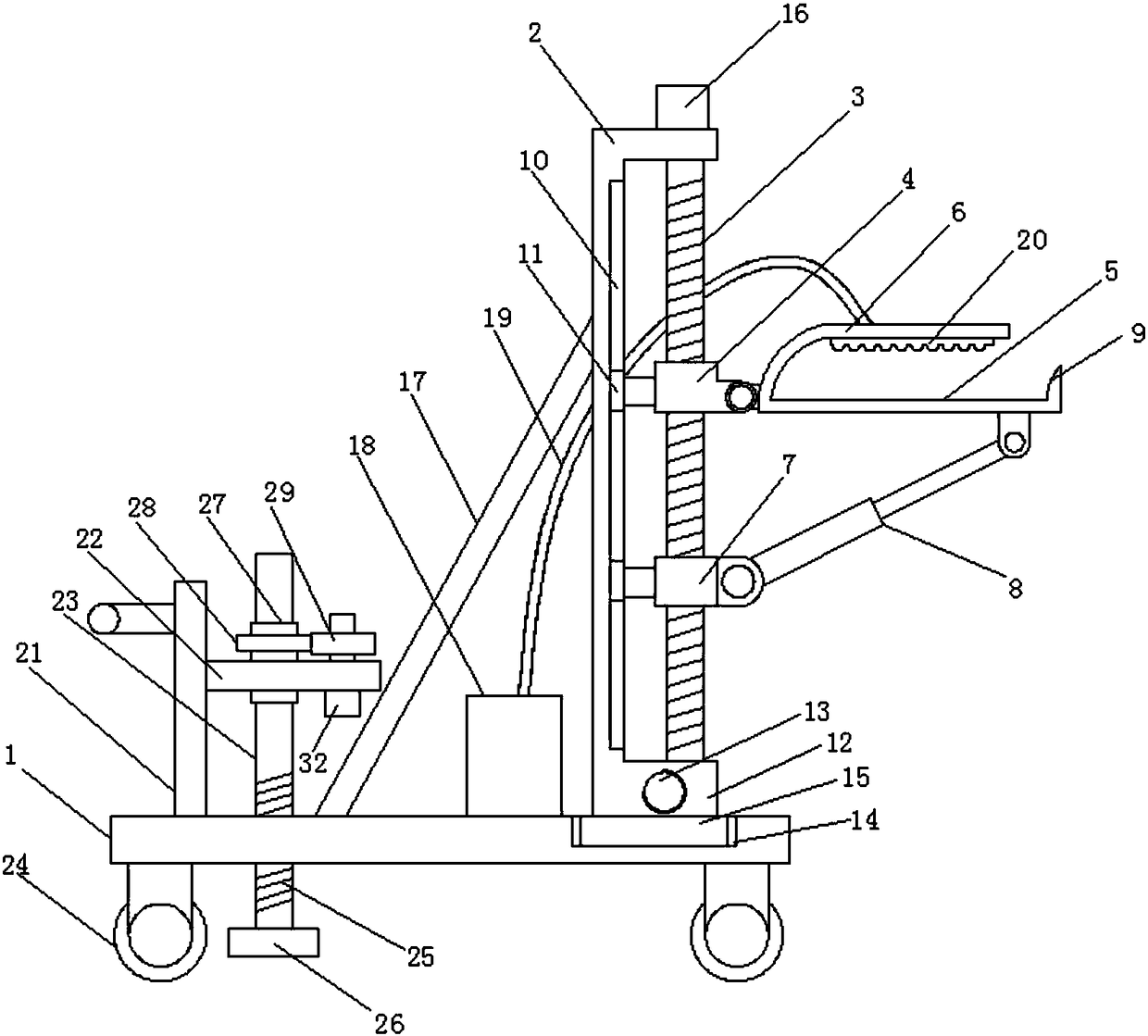

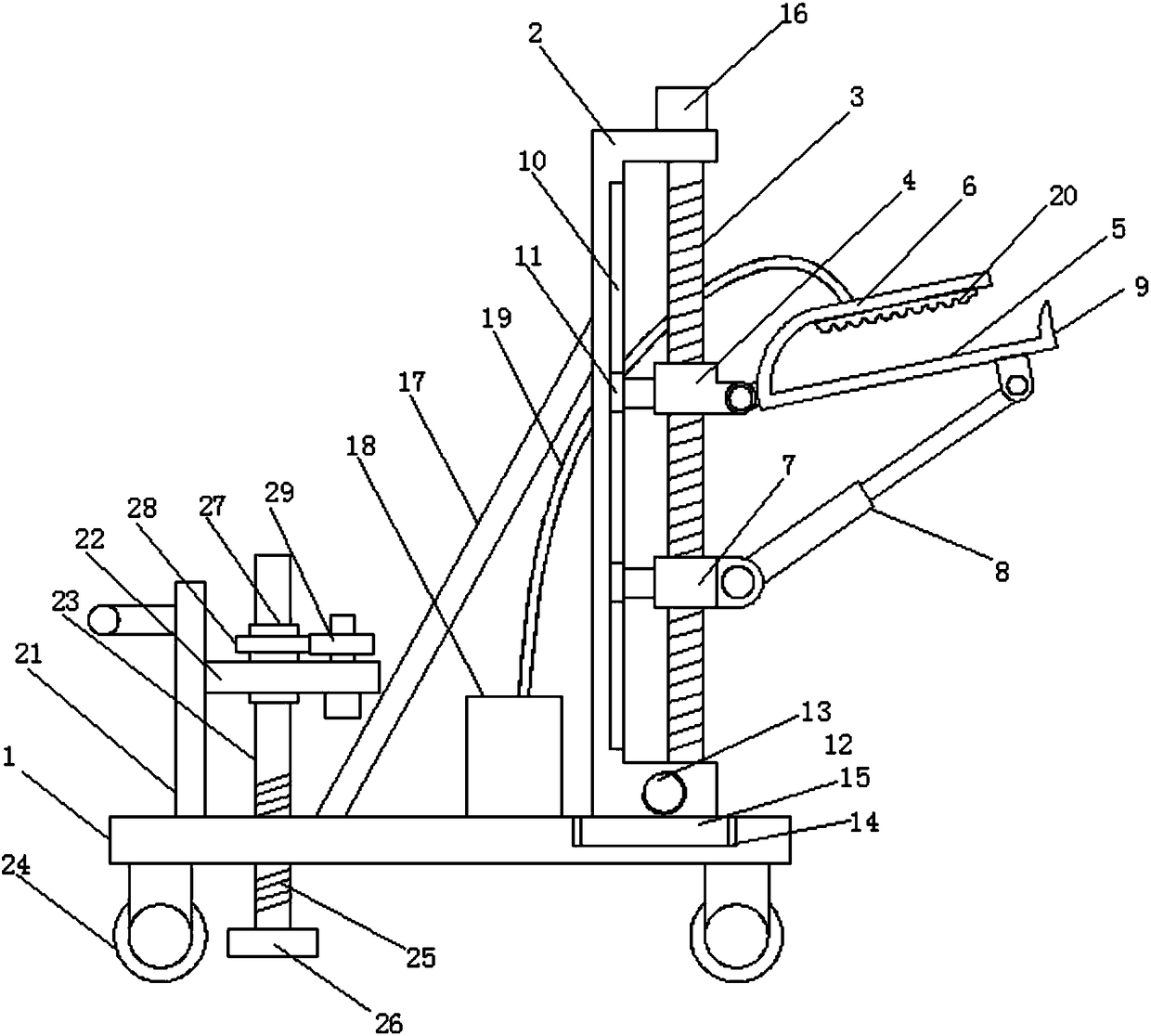

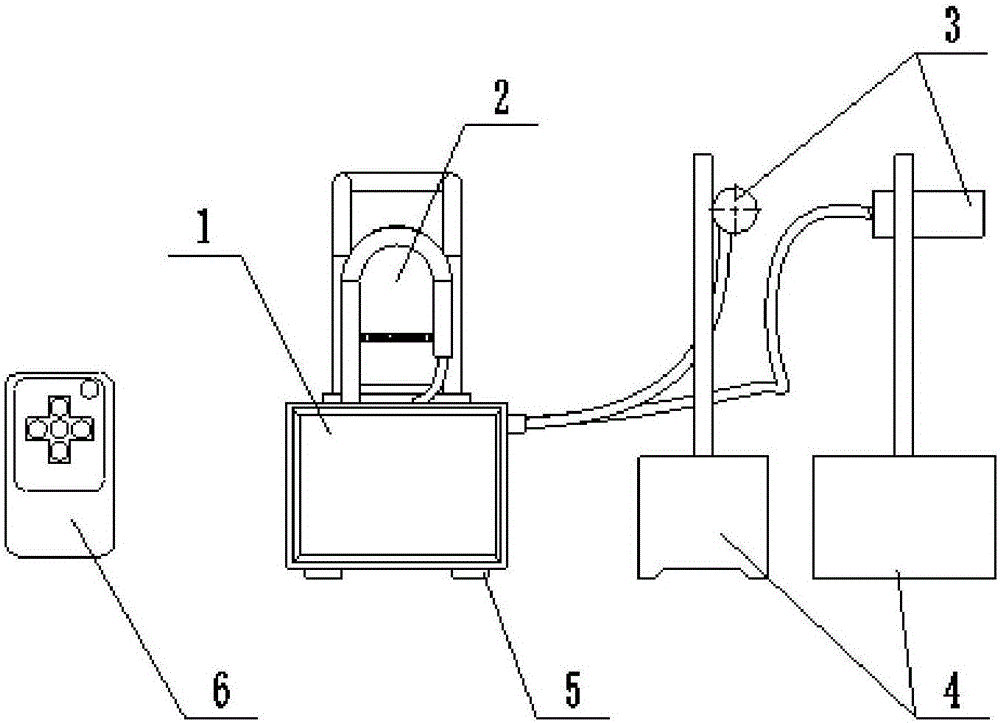

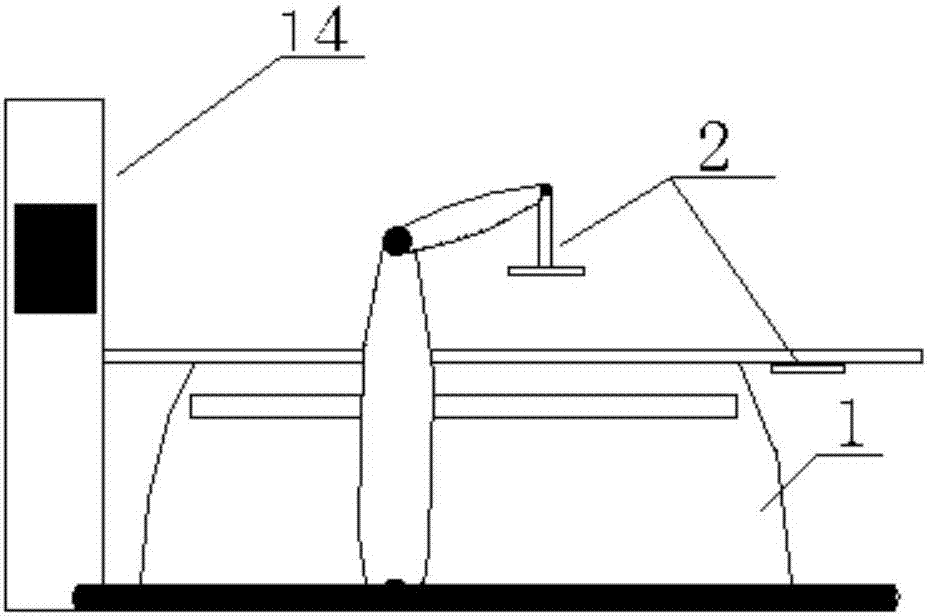

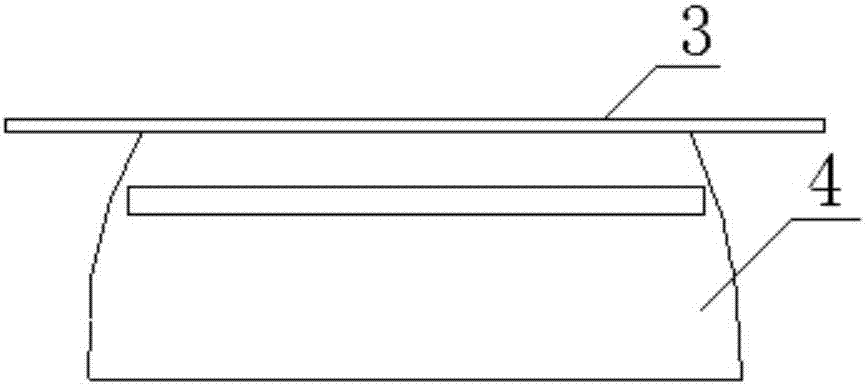

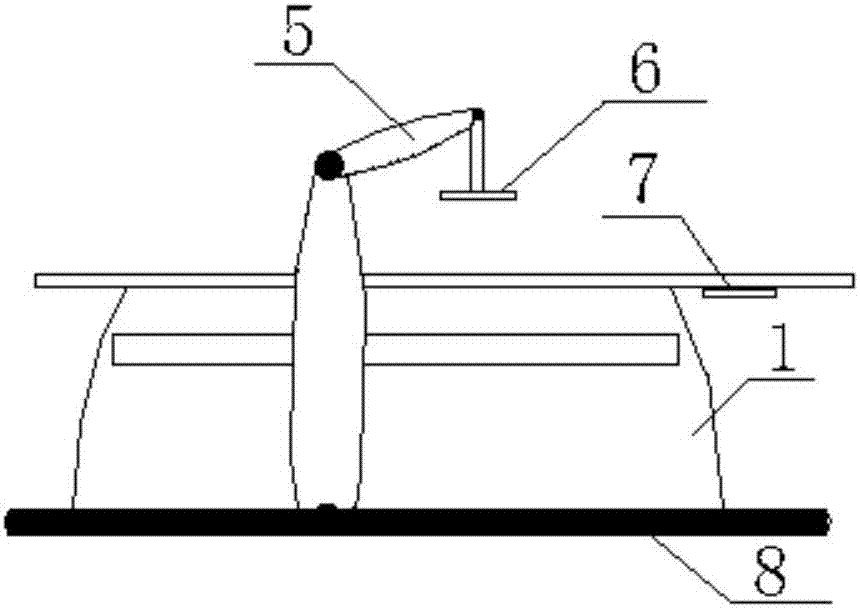

Terahertz module-based intelligent physiotherapy system and physiotherapy method

PendingCN107308547AImprove experienceImprove the effect of physical therapyRadiation therapyHuman bodyPhysical medicine and rehabilitation

The present invention discloses a terahertz module-based intelligent physiotherapy system and physiotherapy method. The system includes a human body lying system (1) and a physiotherapy system (2); the human body lying system (1) includes a lying platform (3) and a lying platform auxiliary supporting block (4); the lying platform (3) is arranged on the lying platform auxiliary supporting block (4); and the physiotherapy system (2) includes a joint arm (5), an A terahertz module (6) and a B terahertz module (7), wherein the A terahertz module (6) is fixedly connected with the joint arm (5), and the B terahertz module (7) is arranged below the lying platform (3). According to the terahertz module-based intelligent physiotherapy system and physiotherapy method of the invention, by means of the A terahertz module (6) connected with the joint arm and the B terahertz module (7) arranged under the lying platform (3), terahertz waves can simultaneously act on portions requiring physiotherapy from the front side and back side of a human body, and therefore, a physical therapy can be greatly improved.

Owner:成都清大华科微晶材料有限责任公司 +1

Auxiliary pushing device for aluminum panel processing

ActiveCN106695426AAuxiliary push for processing is convenientEasy to pushMetal working apparatusSlide plateEngineering

The invention discloses an auxiliary pushing device for aluminum panel processing. The auxiliary pushing device comprises a fixed plate, and fixed tracks are arranged on the two sides of the fixed plate. First guide rails are arranged between the fixed tracks and the fixed plate, and sliding blocks are arranged on the first guide rails. Sliding plates are arranged on the sliding blocks, and second sliding rails are arranged on the sliding plates. A slide rest is arranged on the second sliding rails, and a pushing block is arranged on the slide rest. A supporting frame is arranged between the fixed tracks and the fixed plate, and the upper part of the supporting frame is provided with a first air cylinder. The front part of the first air cylinder is provided with a first telescopic shaft, and the first telescopic shaft is connected with the slide rest. The lower part of the fixed plate is provided with a second air cylinder, and the front part of the second air cylinder is provided with a second telescopic shaft. The end part of the second telescopic shaft is provided with a clamping sleeve, and the clamping sleeve is arranged at the lower part of the supporting frame. The bottom of the fixed plate is provided with a supporting seat, and the second air cylinder is arranged on the supporting seat. An aluminum panel to be processed is put on the sliding plates, and the aluminum panel can be conveniently pushed through the slide rest. The auxiliary pushing device is convenient to process and push the aluminum panel as an auxiliary way.

Owner:GUANGDONG WHOLETOPS BUILDING MATERIALS IND

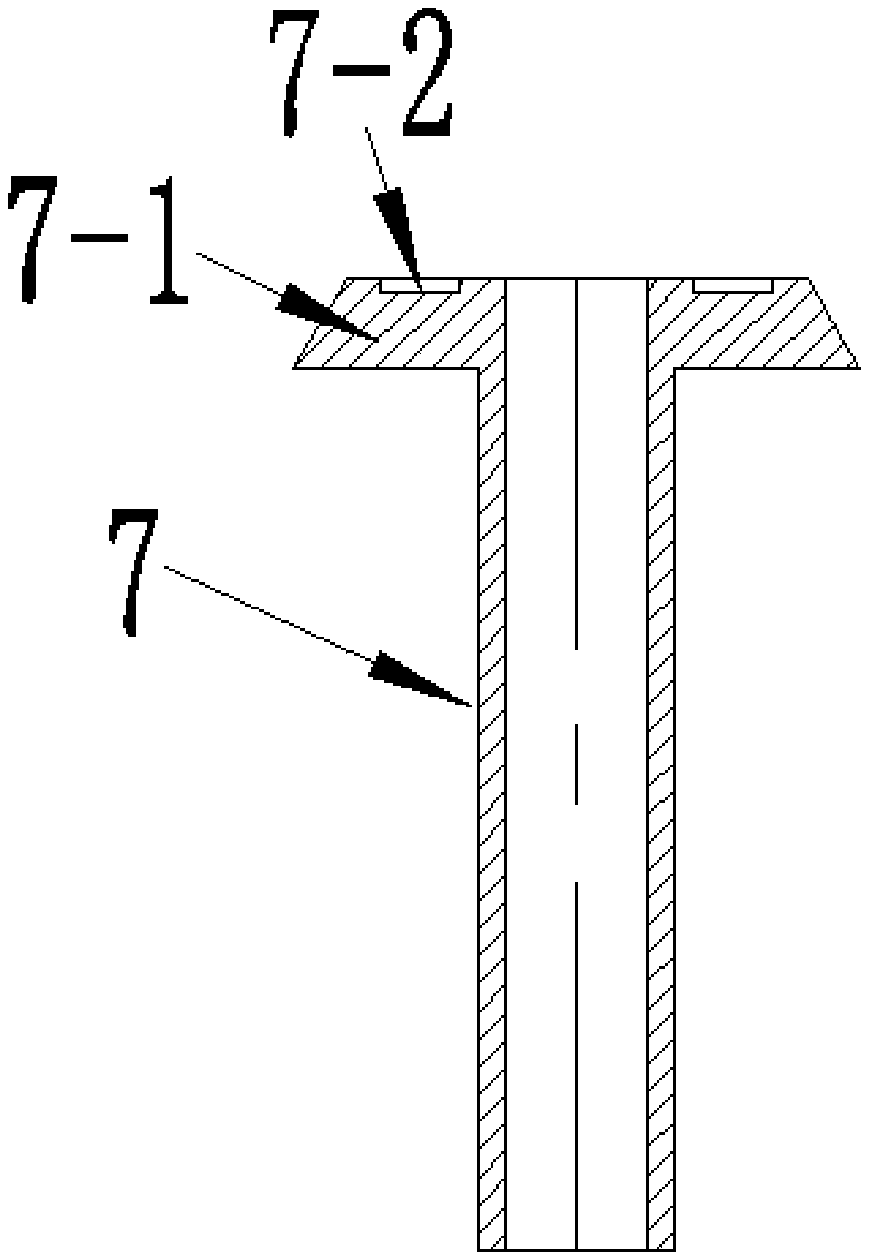

Riser tube placing device of double-station anti-gravity casting machine for large copper alloy propellers

The invention discloses a riser tube placing device of a double-station anti-gravity casting machine for large copper alloy propellers and relates to a riser tube placing device of a double-station anti-gravity casting machine. The invention solves the problem that a riser tube of the anti-gravity casting machine interferes with movement of a lower tank. The riser tube placing device comprises a middle partition plate, an upper seal ring, a lower seal ring, a supporting plate, the riser tube and a molten copper ladle. The molten copper ladle is arranged in the lower tank, a riser tube insertion hole is formed in the center of circle of the supporting plate, the supporting plate is arranged on a positioning protruding edge of the lower tank, the riser tube flange is arranged at one tube endof the tube body of the riser tube, the riser tube is vertically inserted into the riser tube insertion hole of the supporting plate and stretches into the molten copper ladle, a flange seat matchedwith the riser tube flange is arranged on a lower panel of the middle partition plate, and an orthogonal mouth sleeve is arranged in the thickness direction of the middle partition plate. The riser tube is integrally arranged below the middle partition plate, so that the lower tank drives the riser tube to move on a bed body guide rail to adjust different stations.

Owner:HARBIN INST OF TECH

Multimedia display device for computer research and development and operation method thereof

InactiveCN109938527AStable projectionImprove display effectShow shelvesShow hangersDisplay deviceEngineering

The invention discloses a multimedia display device for computer research and development. The multimedia display device comprises a shell, wherein four groups of universal wheels are symmetrically mounted at the bottom corners of the shell; the rear end of the top of the shell is hinged with an end cover through a hinge; a mounting seat is mounted at the top end of the front surface of the shell;a projector body is movably mounted at the top of the mounting seat; a spotlight body is embedded into the front end of the bottom of the end cover; an electric cylinder body is fixedly mounted at the internal bottom end of the shell; the top of the electric cylinder body is fixedly connected with a clamping device for placing a product; an air pump subassembly and a wiring box are respectively mounted on two sides of the bottom of the clamping device; a computer host is fixedly mounted on one side in the shell; a wireless communicator connected with the computer host in a signaling manner isembedded into one side of the front surface of the shell. The multimedia display device is simple and reasonable in structural design and convenient to operate, move and adjust; by various modes fordisplaying, the multimedia display device is good in display effect, safe, stable, wide in application range and favorable for being promoted and popularized.

Owner:大连天屹网络科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com