Packing box fixing and conveying device

A technology for conveying devices and packing boxes, which is applied in the direction of transportation and packaging, conveyors, conveyor objects, etc. It can solve the problems that cannot meet the needs of production, difficult to fix packing boxes, and high labor intensity, so as to improve efficiency and quality, Avoid slipping or rollover and reduce labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

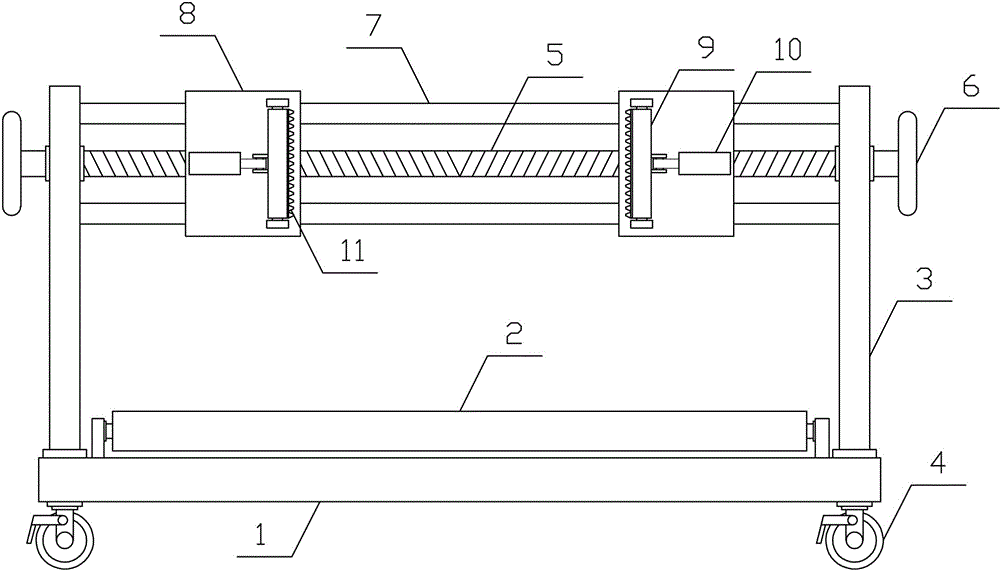

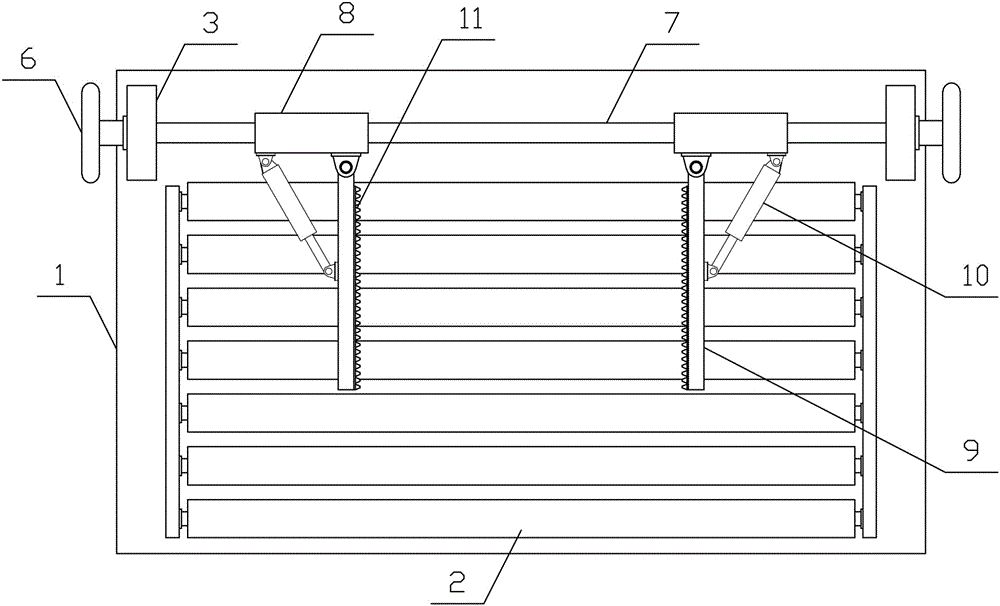

[0011] In order to further describe the present invention, a specific implementation of a packaging box fixing and conveying device will be further described below in conjunction with the accompanying drawings. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0012] Such as figure 1 , figure 2 As shown, the present invention is a fixed transport device for packing boxes, including a translation base 1, a case roller 2, a fixed bracket 3 and a clamping mechanism, a plurality of universal wheels 4 with brakes are uniformly arranged on the lower side of the translation base 1, and the translation base 1 The upper side is horizontally and uniformly rotated and connected with a plurality of bearing rollers 2, and the fixed bracket 3 is vertically arranged on the upper side of the translation base 1. Vertically be provided with rotating handwheel 6, translation screw mandrel 5 upper and lower sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com