Riser tube placing device of double-station anti-gravity casting machine for large copper alloy propellers

A technology of anti-gravity casting and riser tubes, which is applied in the field of placement devices for riser tubes of double-station anti-gravity casting machines, to achieve the effects of filling molds, shortening distances, and simple structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

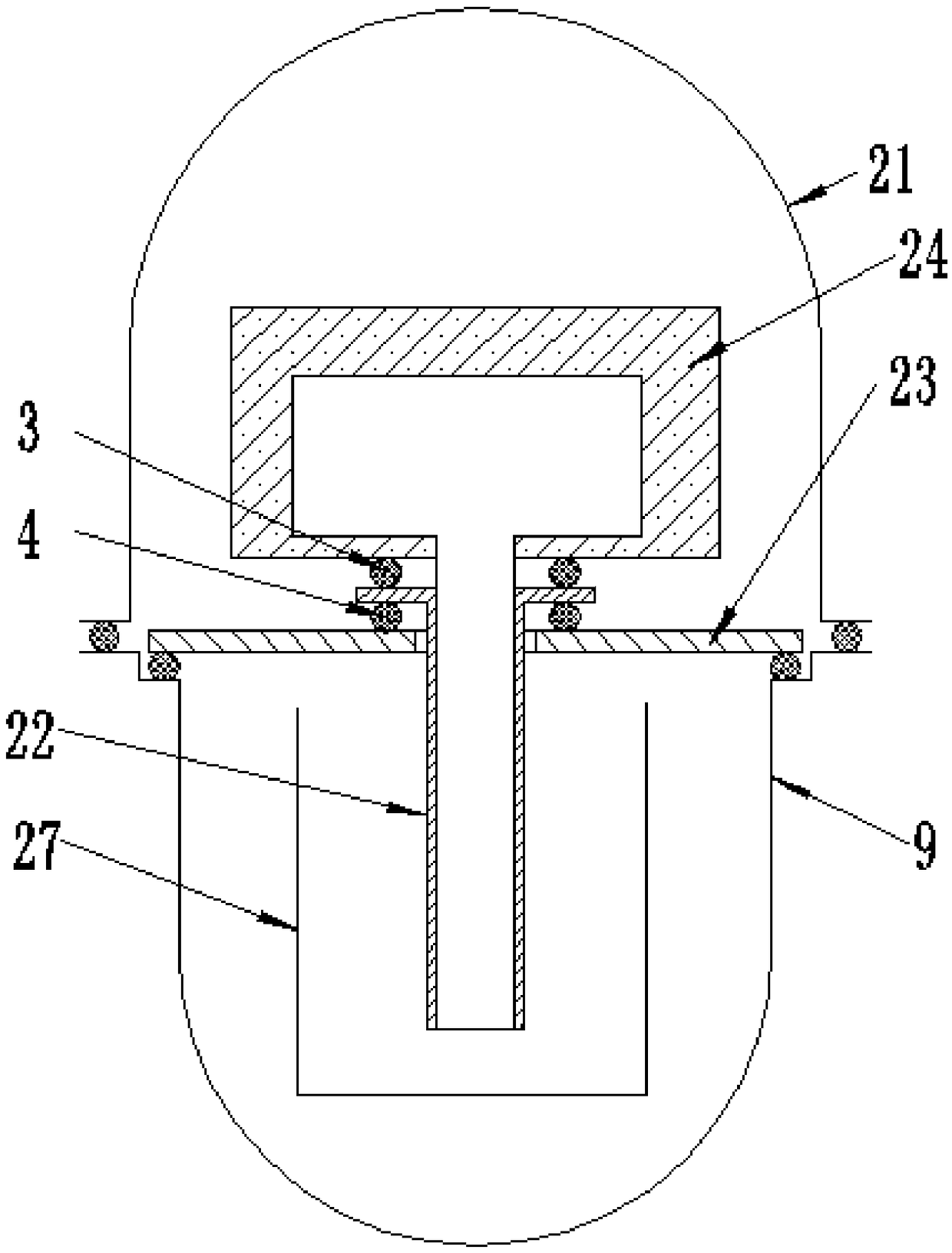

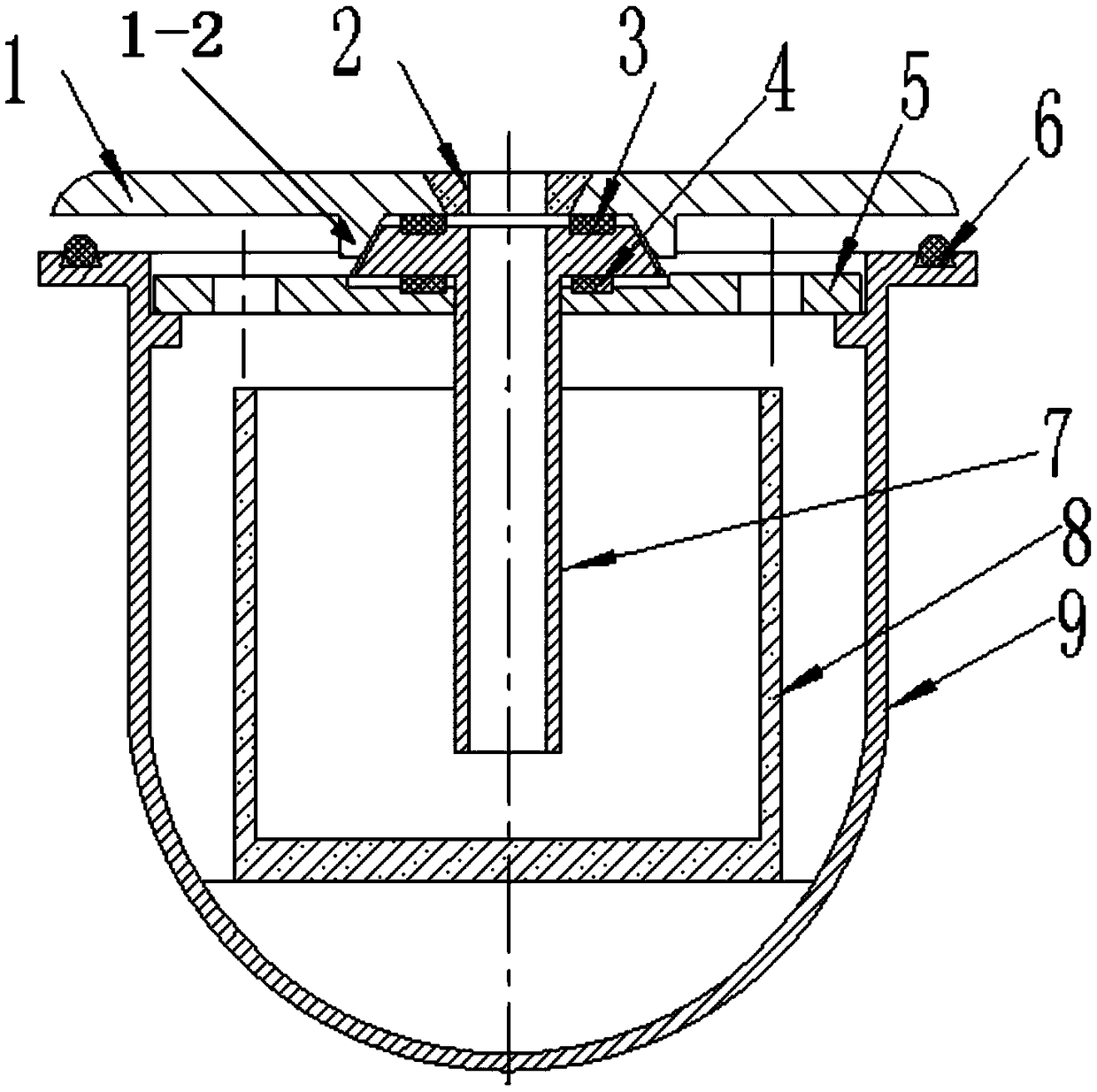

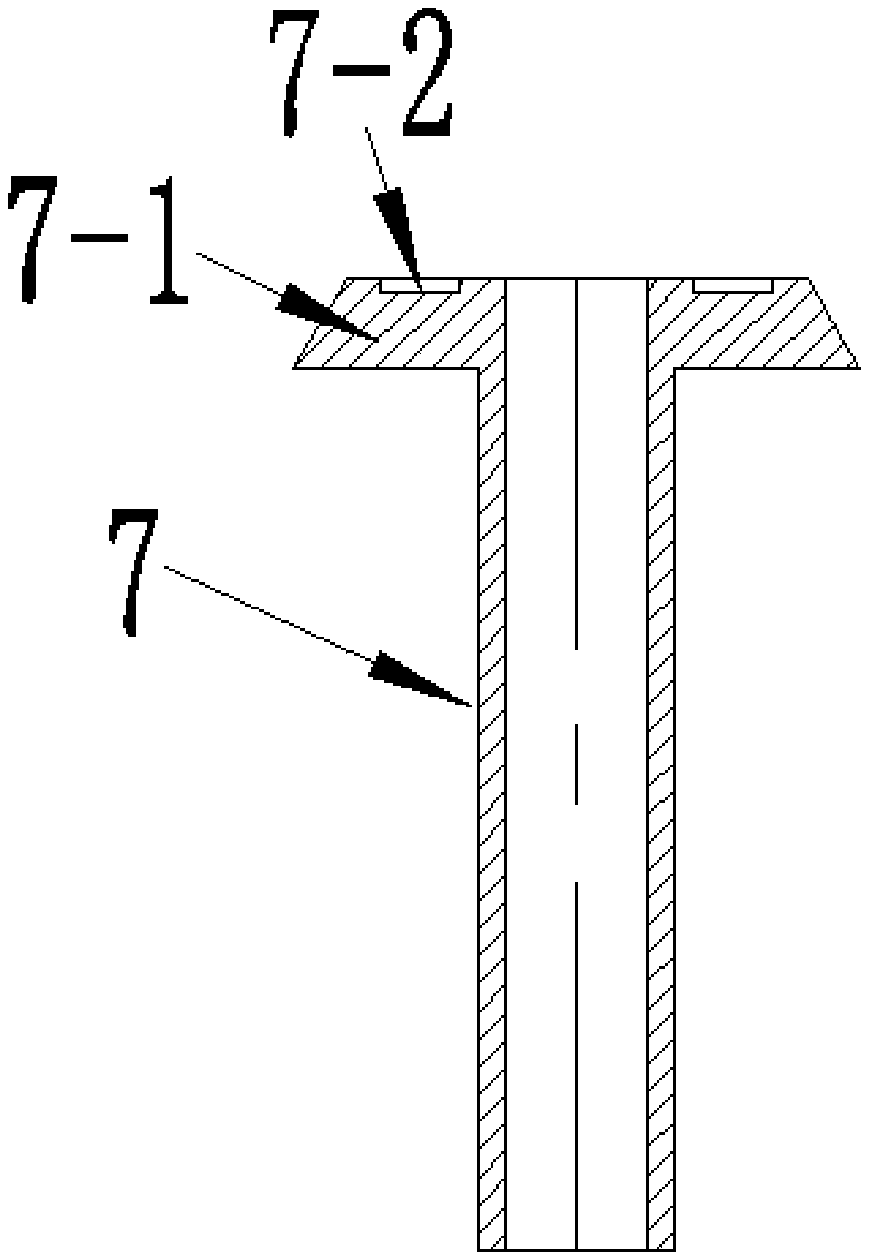

[0017] Specific Embodiment 1: In this embodiment, the large-scale copper alloy propeller double-station anti-gravity casting machine riser installation device includes a middle partition 1, an upper seal ring 3, a lower seal ring 4, a support plate 5, a riser pipe 7 and copper The water bag 8 and the copper water bag 8 are arranged in the lower tank 9, and a positioning convex edge platform 9-1 is arranged on the tank inner wall of the lower tank 9, and the support plate 5 is in the shape of a disc, and a liquid liter is opened at the center of the support plate 5. Pipe insertion hole 5-1, the upper plate surface of support plate 5 has circular positioning groove 5-2, also has sealing ring positioning groove 5-3 in the groove of circular positioning groove 5-2, circular positioning The groove 5-2, the sealing ring positioning groove 5-3 and the riser pipe insertion hole 5-1 form a concentric circle structure, and a plurality of ventilation holes 5-4 are opened in the circumfere...

specific Embodiment approach 2

[0019] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the support plate 5 is uniformly opened with four ventilation holes 5-4 in the circumferential direction.

specific Embodiment approach 3

[0020] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the lower tank flange 9-2 is arranged on the open edge of the lower tank 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com