Patents

Literature

67 results about "Dry dock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A dry dock (sometimes dry-dock or drydock) is a narrow basin or vessel that can be flooded to allow a load to be floated in, then drained to allow that load to come to rest on a dry platform. Dry docks are used for the construction, maintenance, and repair of ships, boats, and other watercraft.

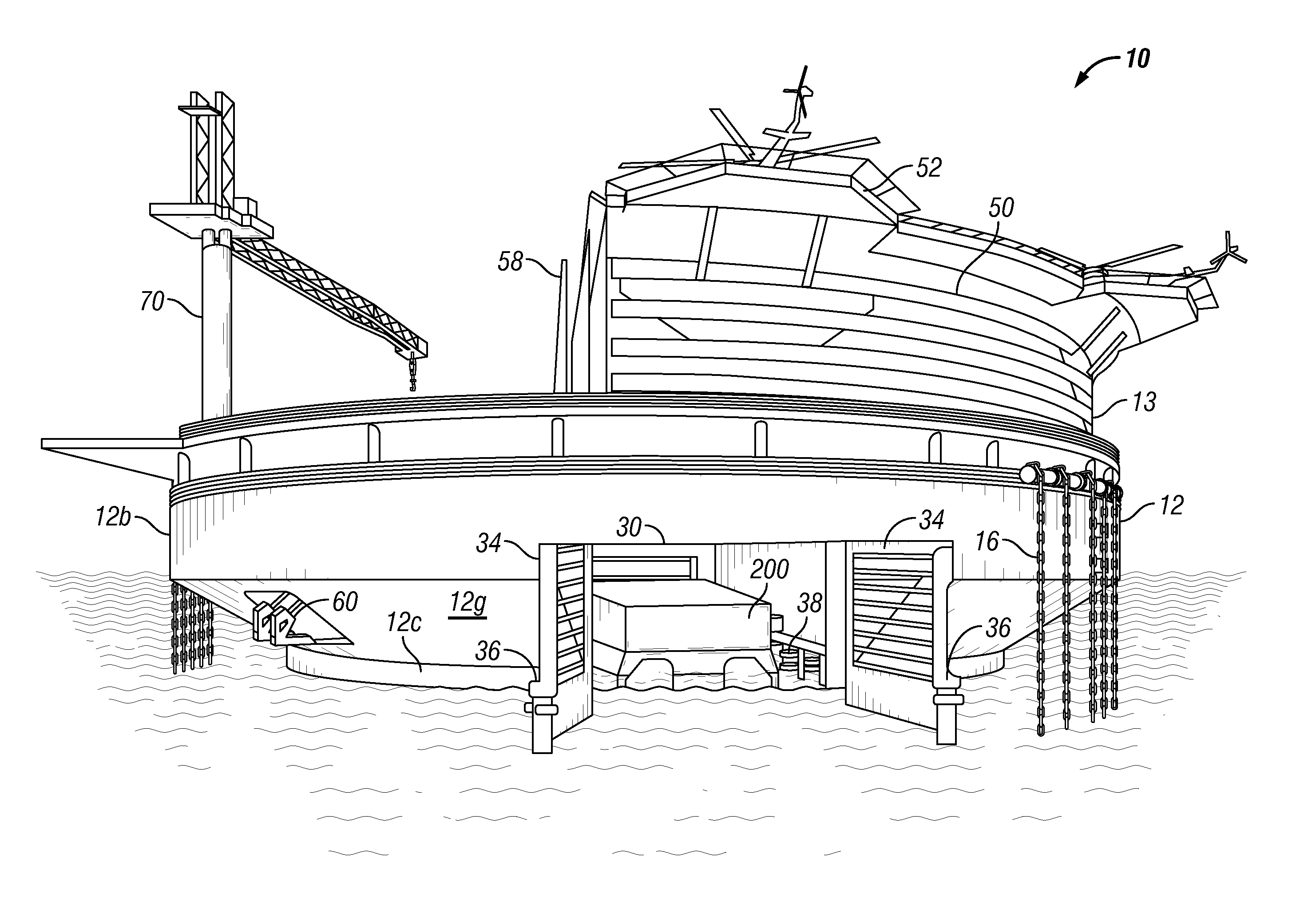

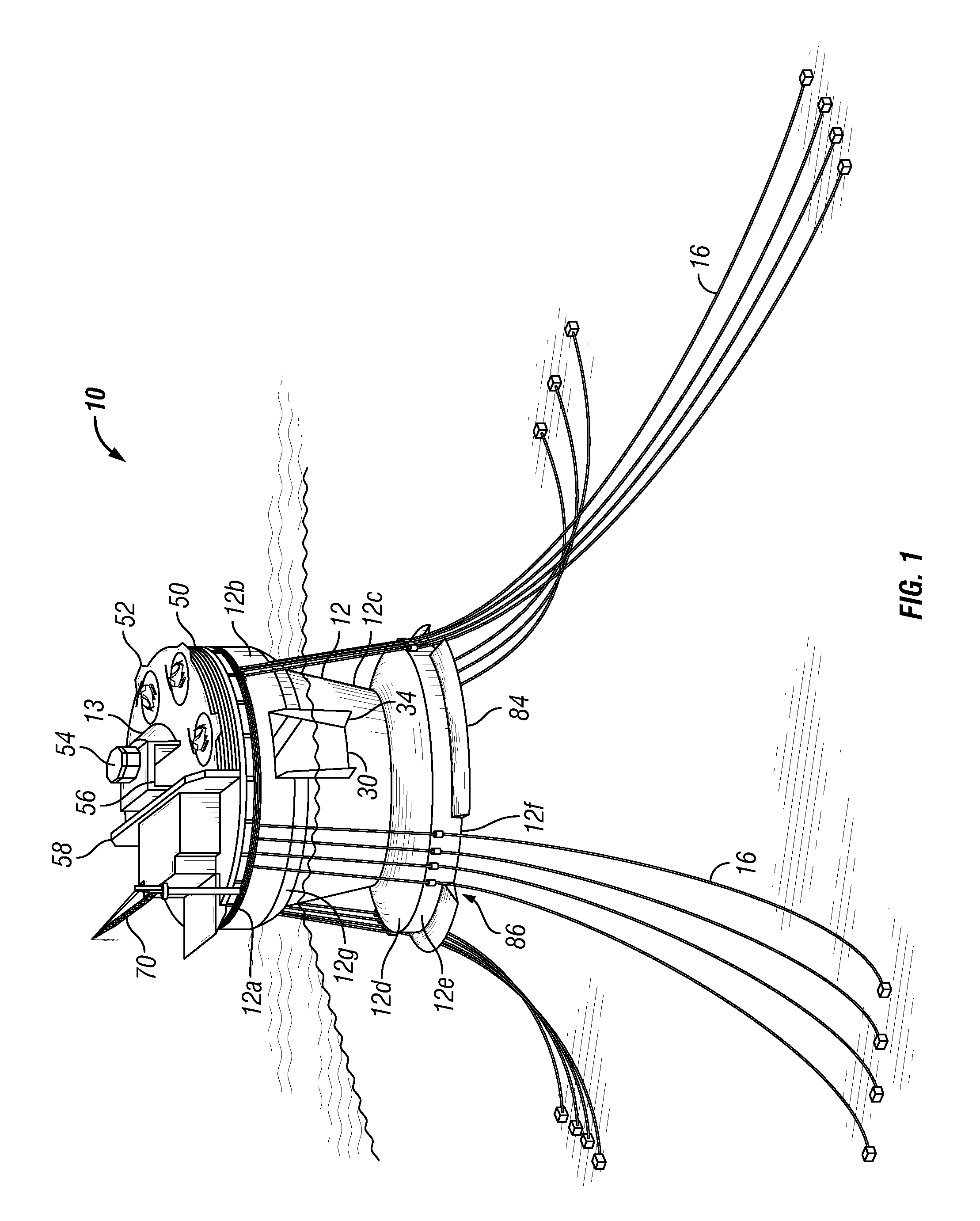

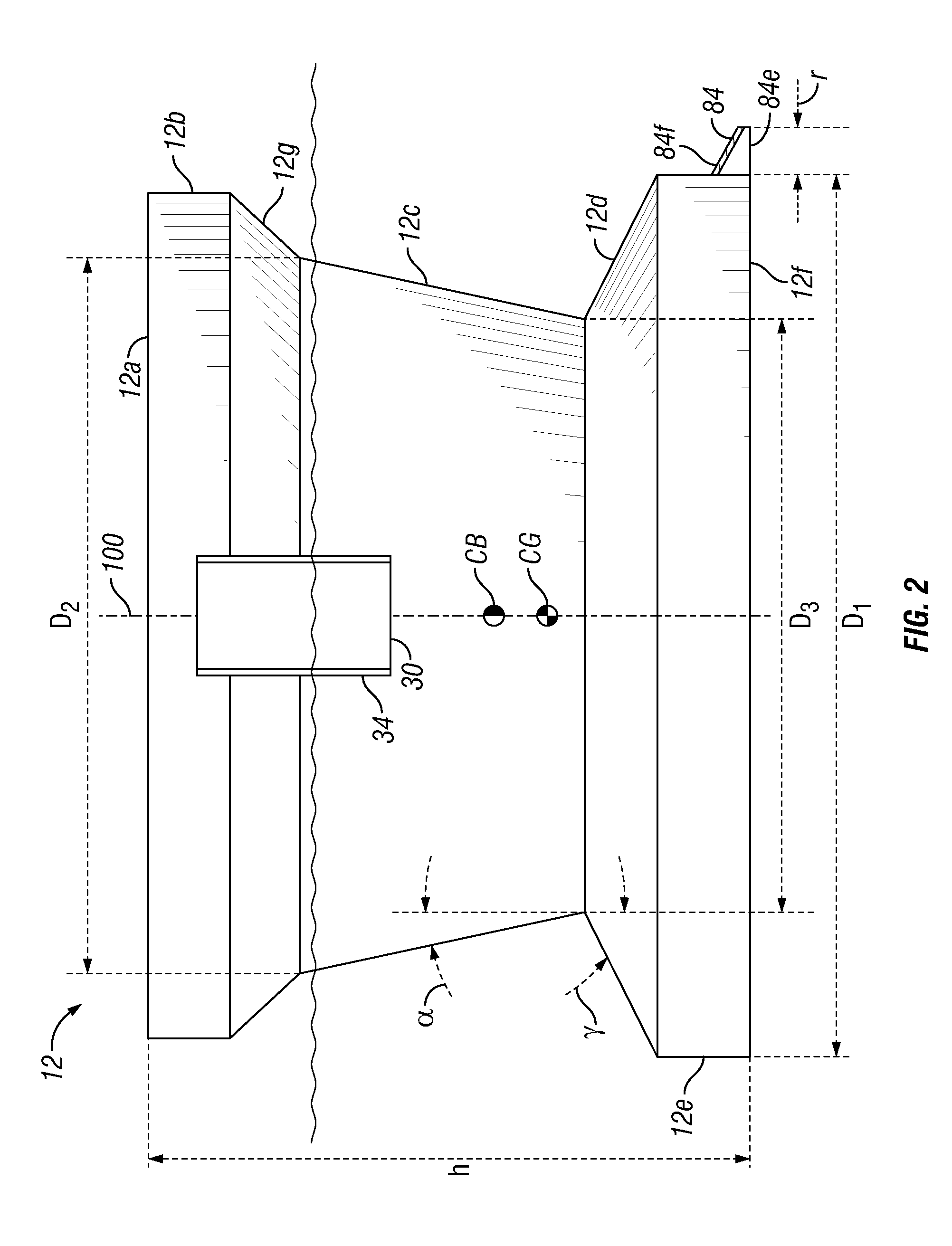

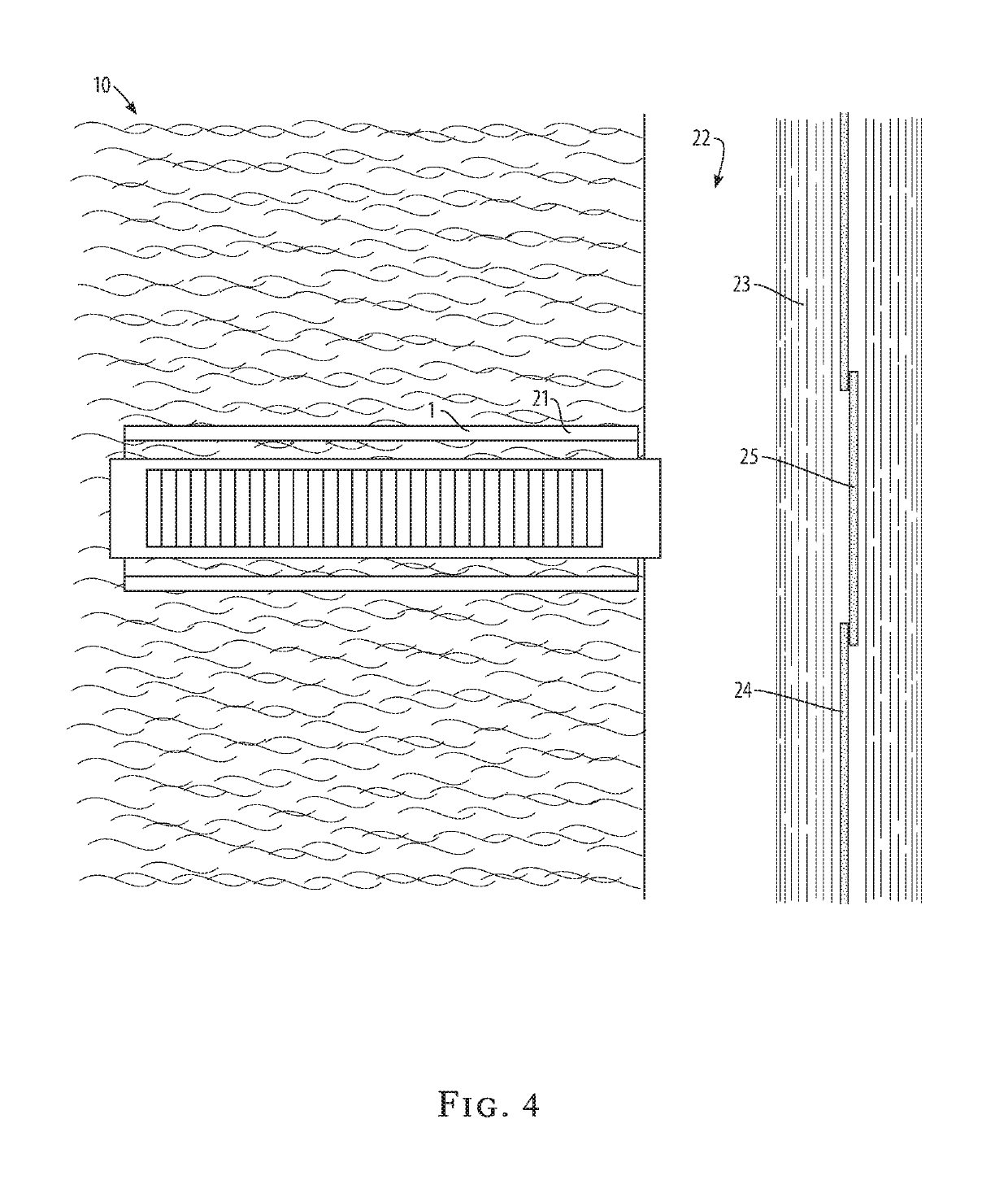

Stable offshore floating depot

ActiveUS8662000B2Exceptional heave damping characteristicsSteering by propulsive elementsAircraft carriersMachine shopMarine engineering

An offshore depot having a vertically symmetric hull, an upper inwardly-tapered wall and a lower outwardly-tapered wall that produce significant heave damping in response to heavy wave action. Ballast is added to the lower and outermost portions of the hull to lower the center of gravity below the center of buoyancy. The offshore depot includes a tunnel formed within or through the hull at the waterline that provides a sheltered area inside the hull for safe and easy launching / docking of boats and embarkation / debarkation of personnel. When the watertight tunnel doors are all shut, the tunnel may be drained to create a dry dock environment within the hull. The offshore depot includes berthing and dinning accommodations, medical facilities, workshops, machine shops, a heliport, and the like.

Owner:JURONG SHIPYARD

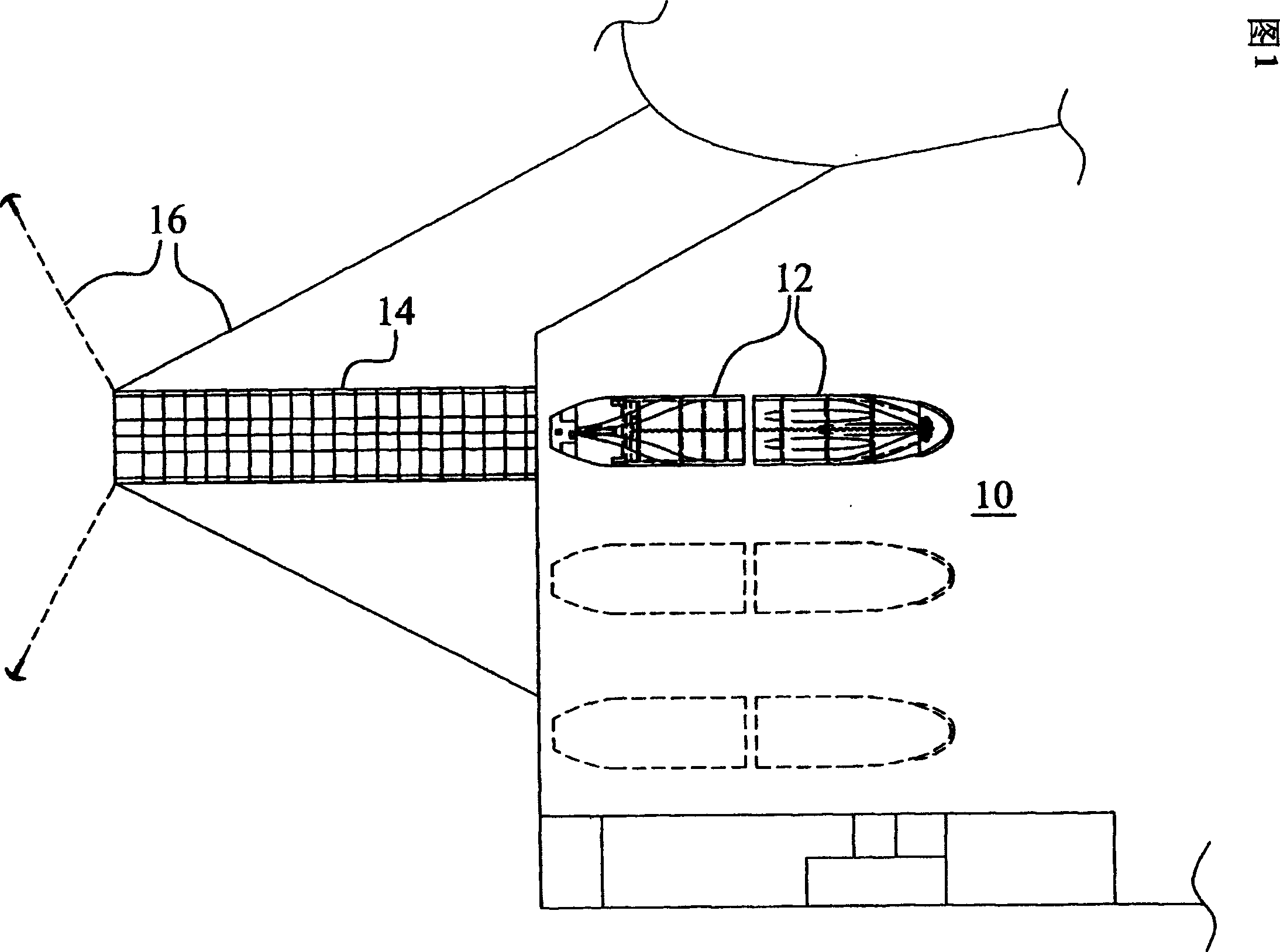

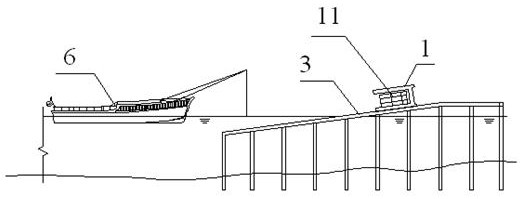

Method for building ship on ground and launching ship using skid launching system

Provided is a method for building a ship on the ground and launching a ship using a skid launching system. The method includes dividing the ship into two through four sections and semi-assembling the divided sections into hull blocks in a hull block assembly yard on the ground, fixing a barge at a quay wall adjacent to the hull block assembly yard in a longitudinal direction, transporting the semi-assembled hull blocks to the barge in a longitudinal direction, completing a hull by assembling the semi-assembled hull blocks on the barge, moving the barge to a launching point and sinking the barge through ballasting, and launching the built ship and floating the barge. Therefore, large-scale ships can be constructed without a dry dock facility while improving the efficiency of shipbuilding.

Owner:STX OFFSHORE & SHIPBUILDING CO LTD

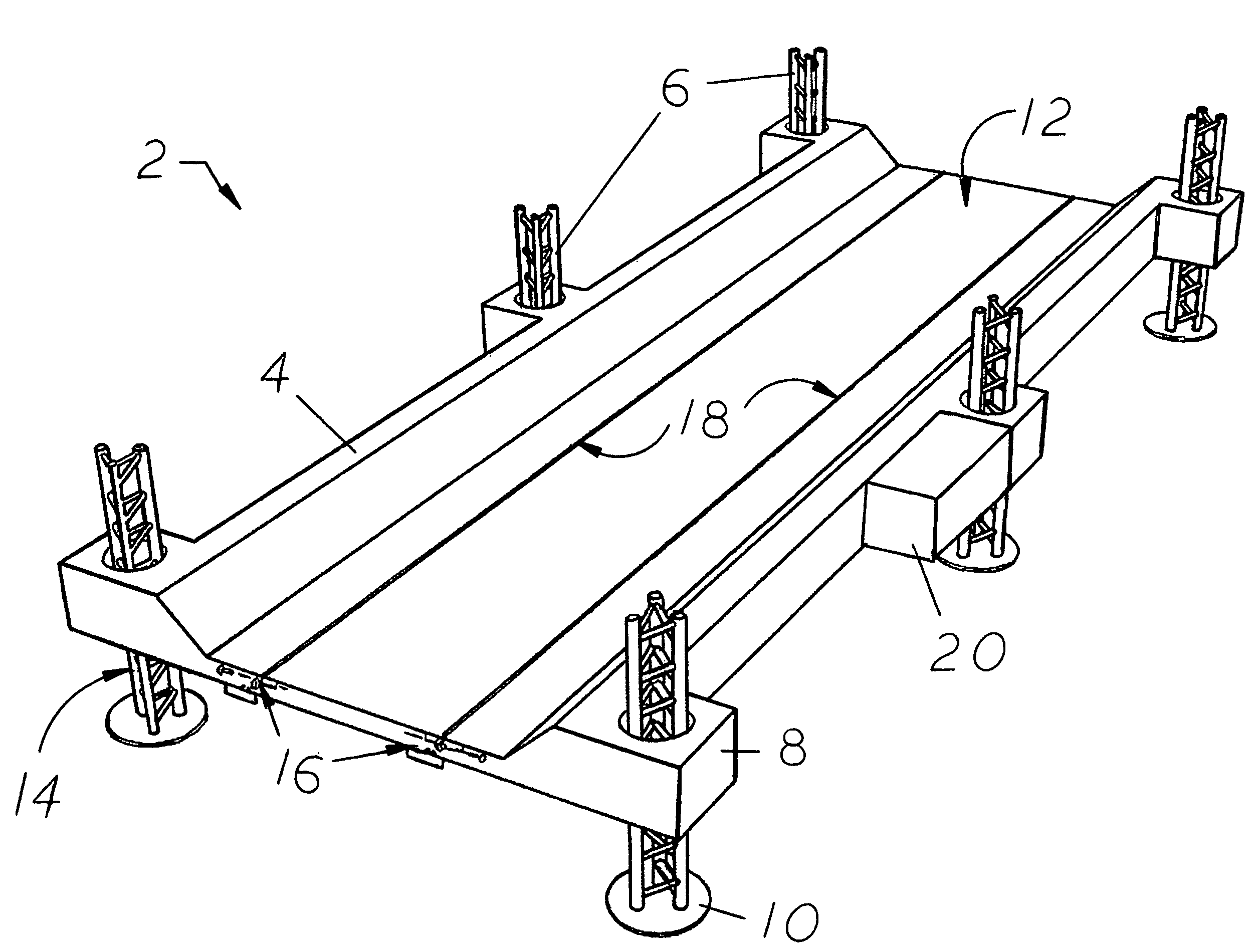

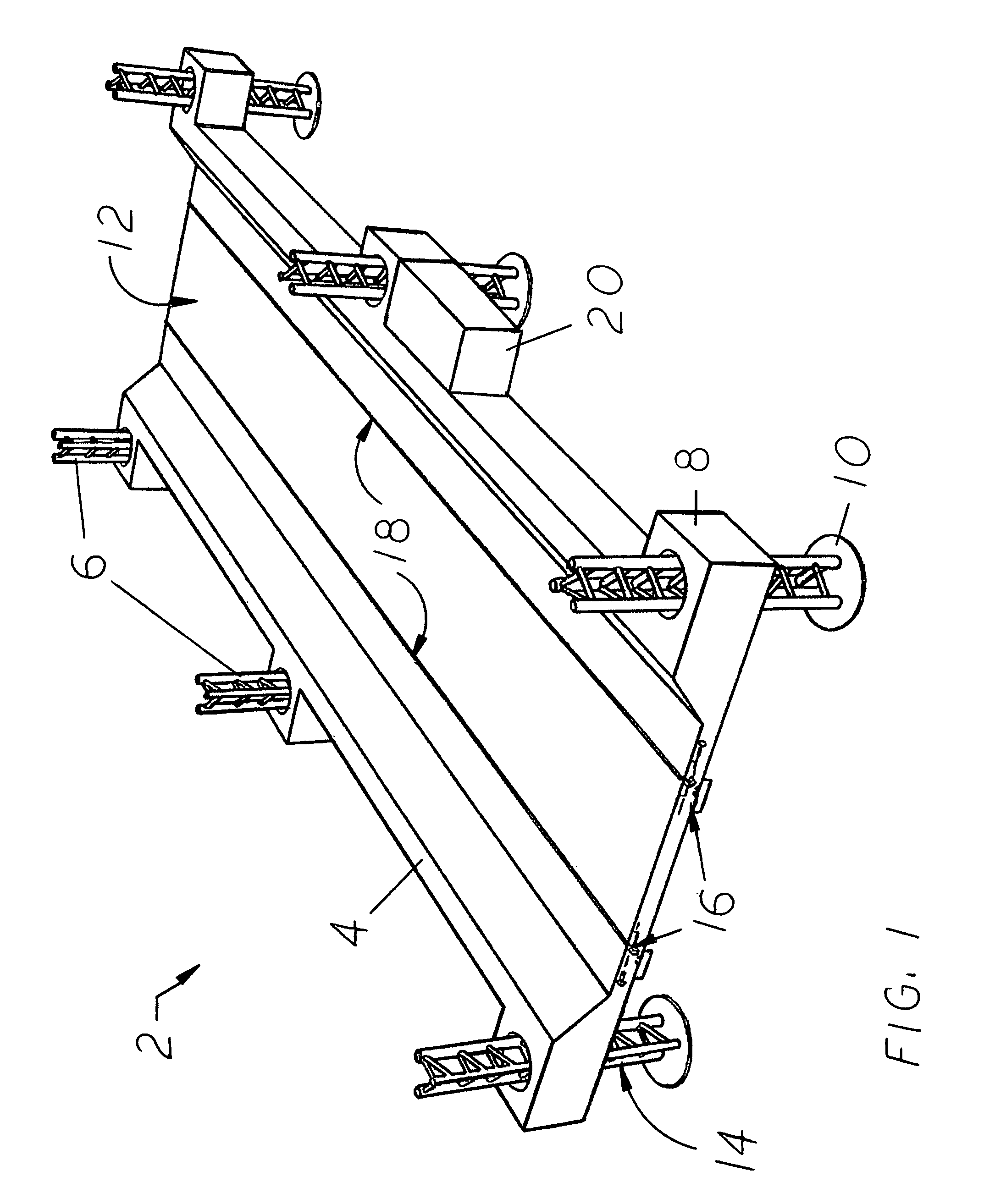

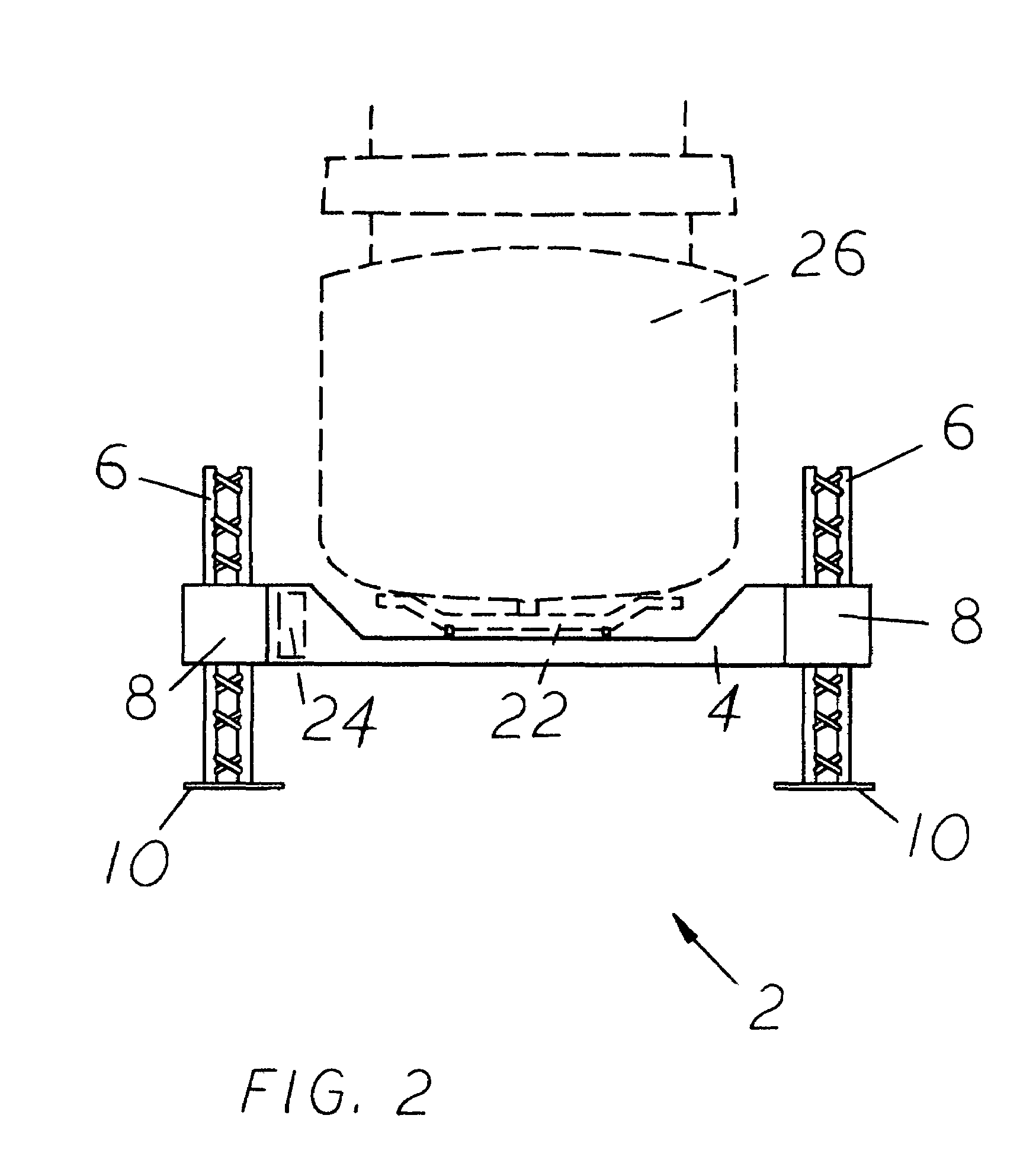

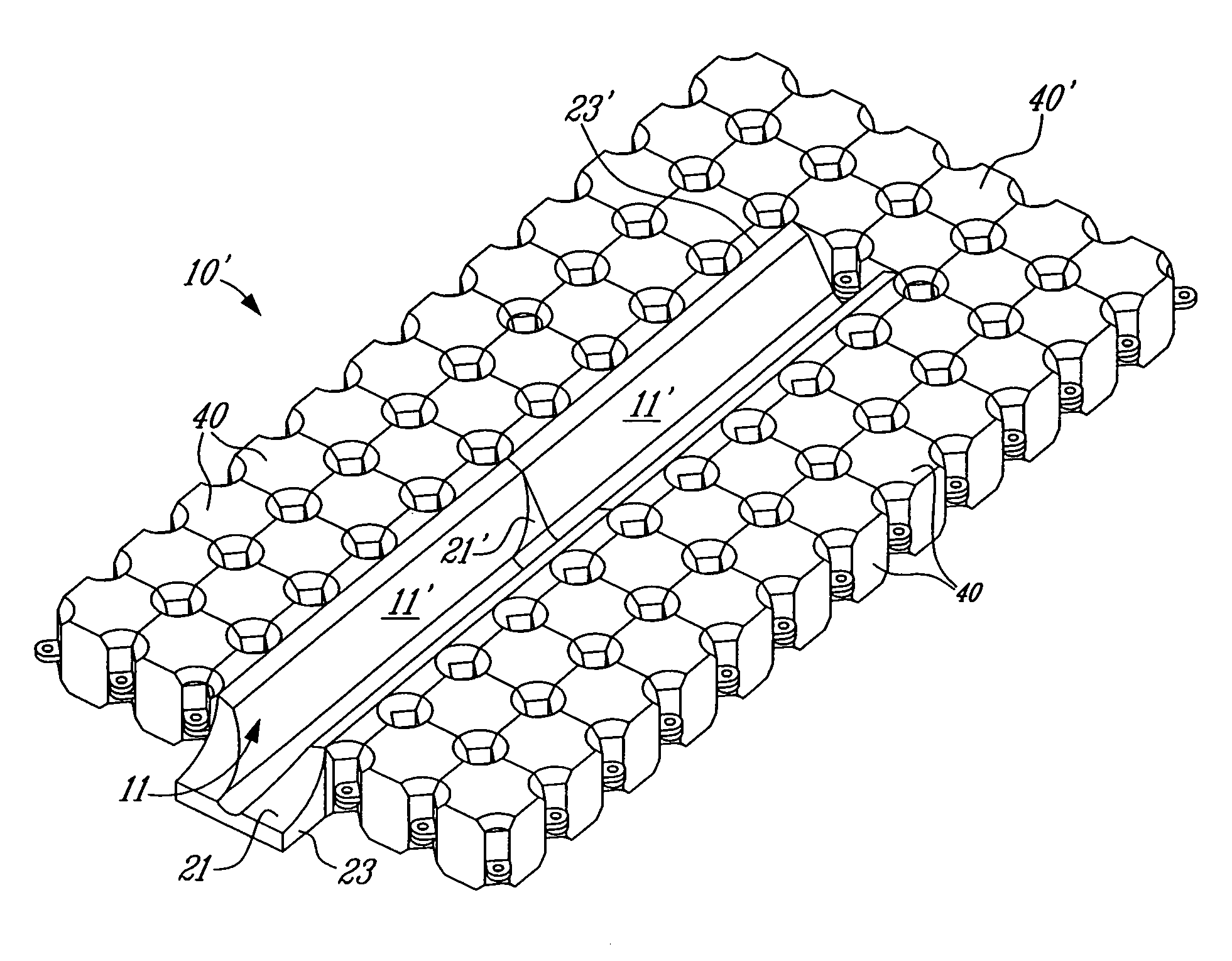

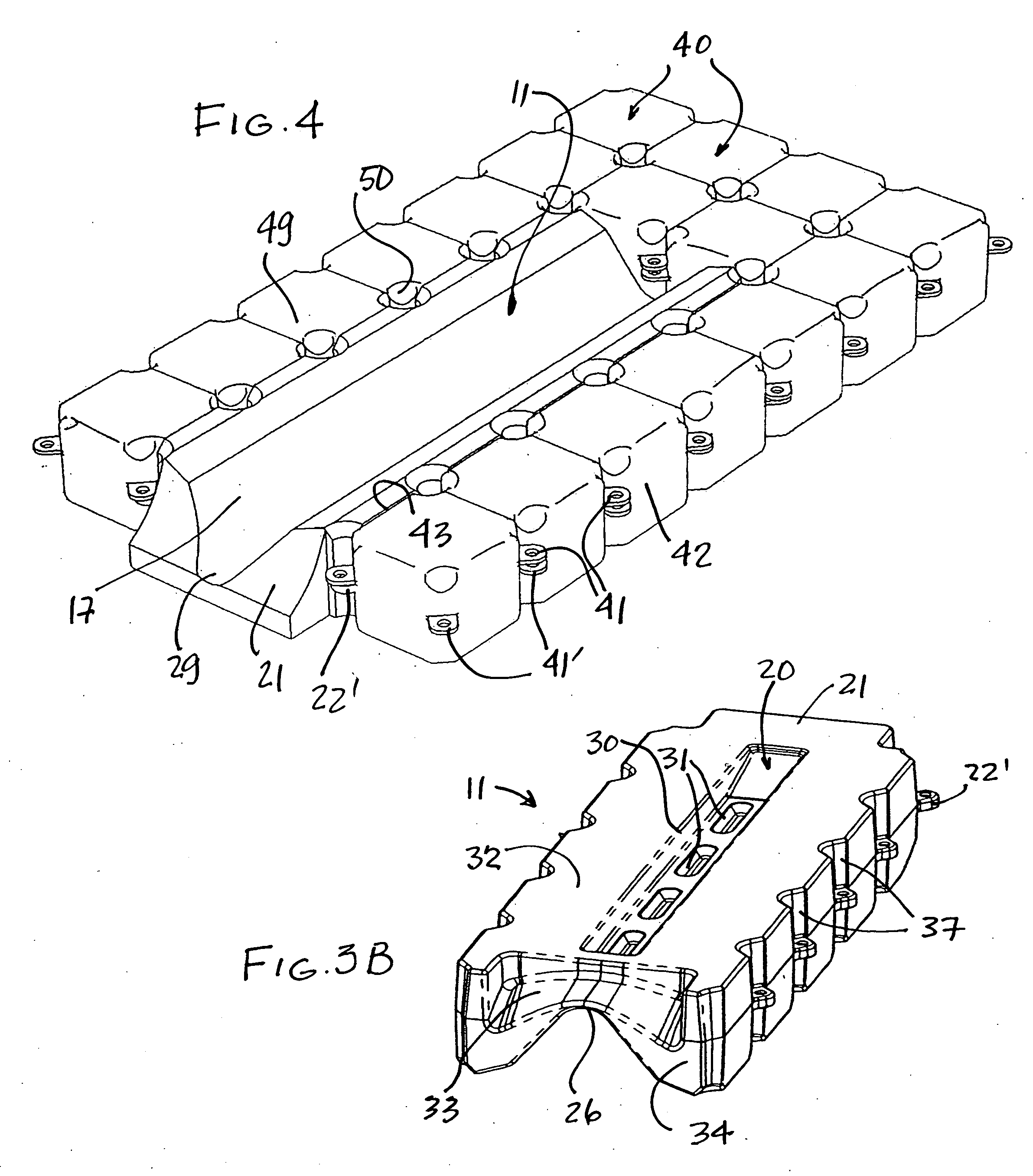

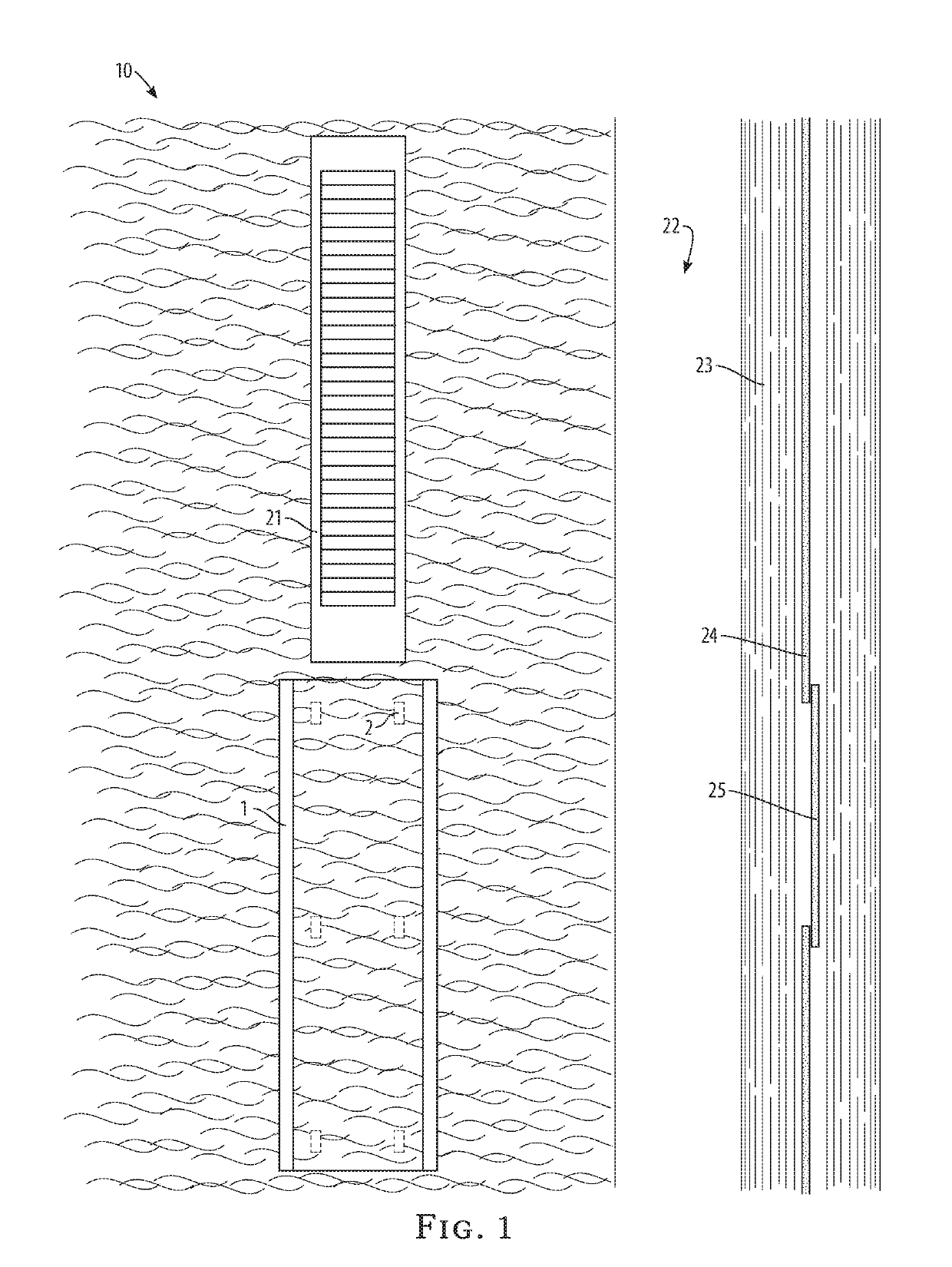

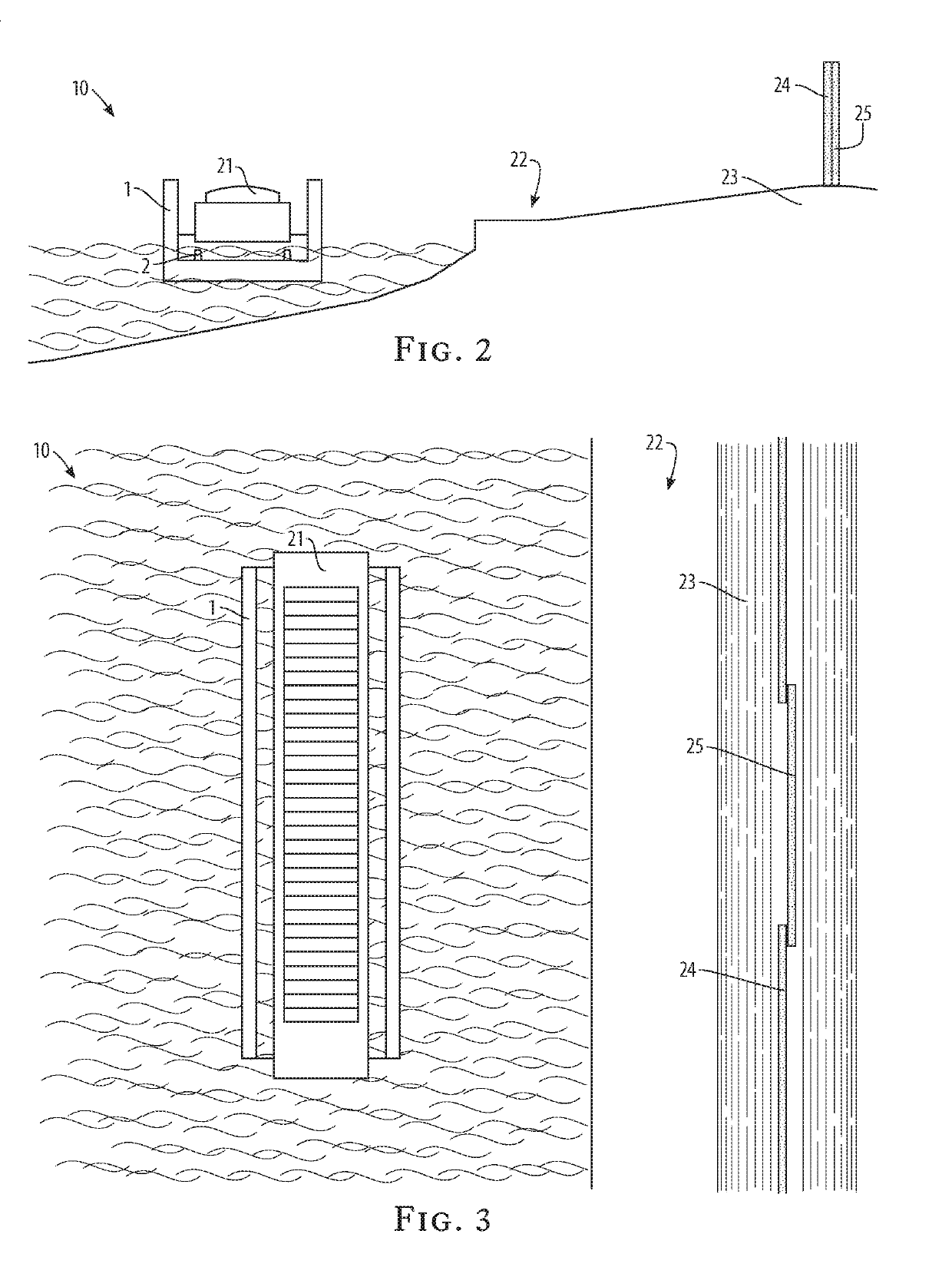

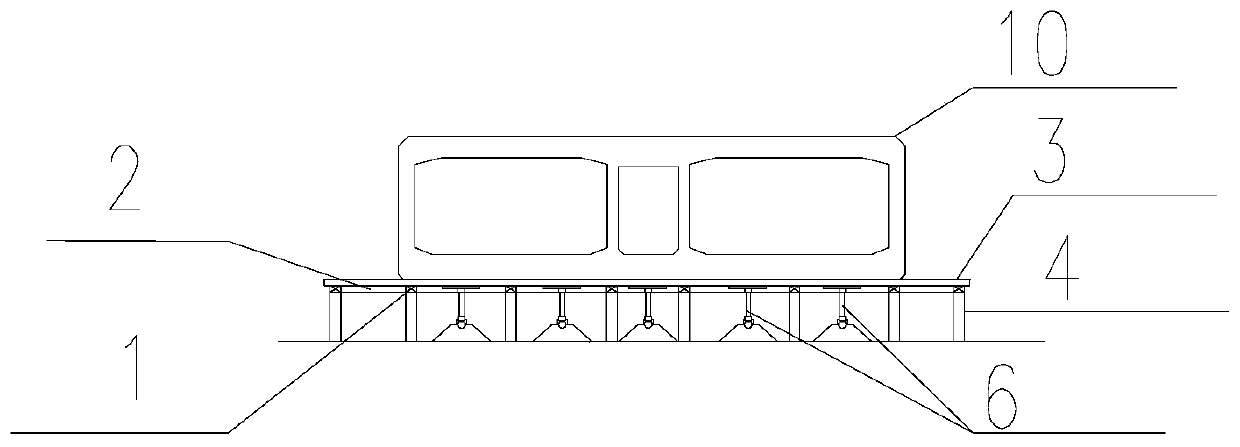

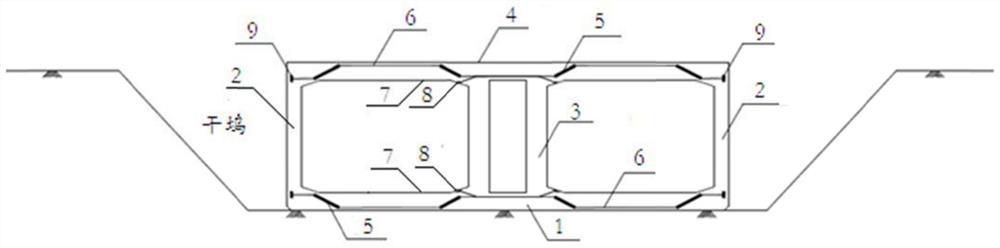

Semi-submersible dry-docking lift apparatus

A portable marine lift capable of multi-directional off-loading of yachts, ships, and other marine vessels at ground level to dry-dock them. It is compact and barge-like, and can be shared by independent shipyards, or used to expand the work area within a single port facility or shipyard. It is also self-contained when fitted with generators and / or propulsion means via add-on pods, and comprises independent platform sections joined together to meet any hull design, length and water depth. Platform sections have the ability to submerge, and may also be employed to capture and temporarily contain environmentally hazardous materials commonly produced by shipyards. In addition, the platform sections are preferably open-framed for weight savings. Computerized lifting, via multiple lift modules secured to platform sections, assures lifting of vessels in substantially level orientation. Optionally, platform sections can be configured for shallow water operation, with locking devices, and / or guides usable for off-loading railway alignment.

Owner:TAFOYA CRAIG ALLEN

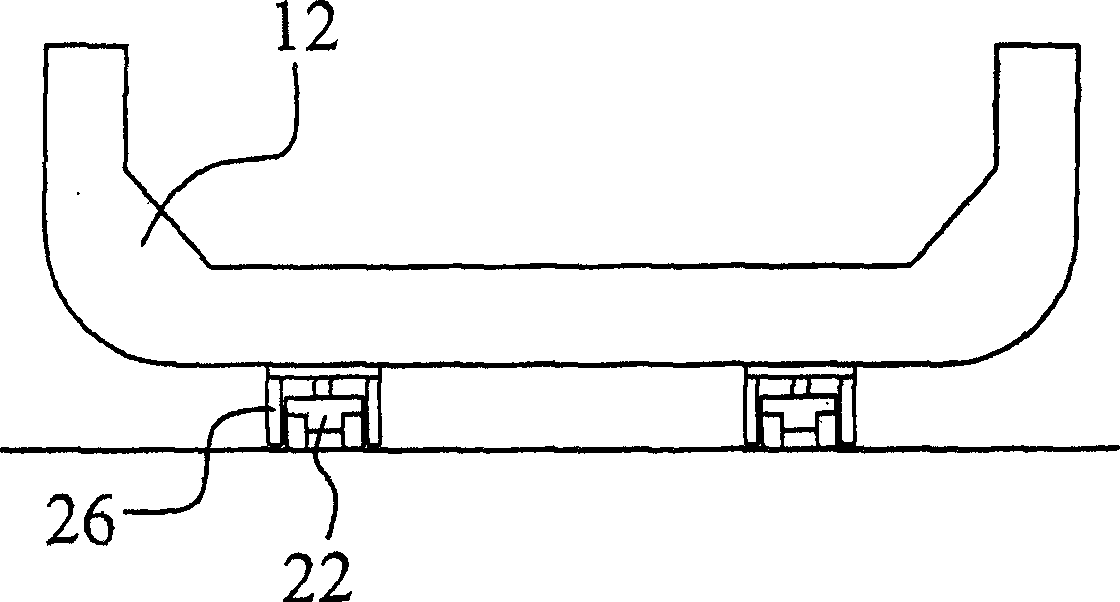

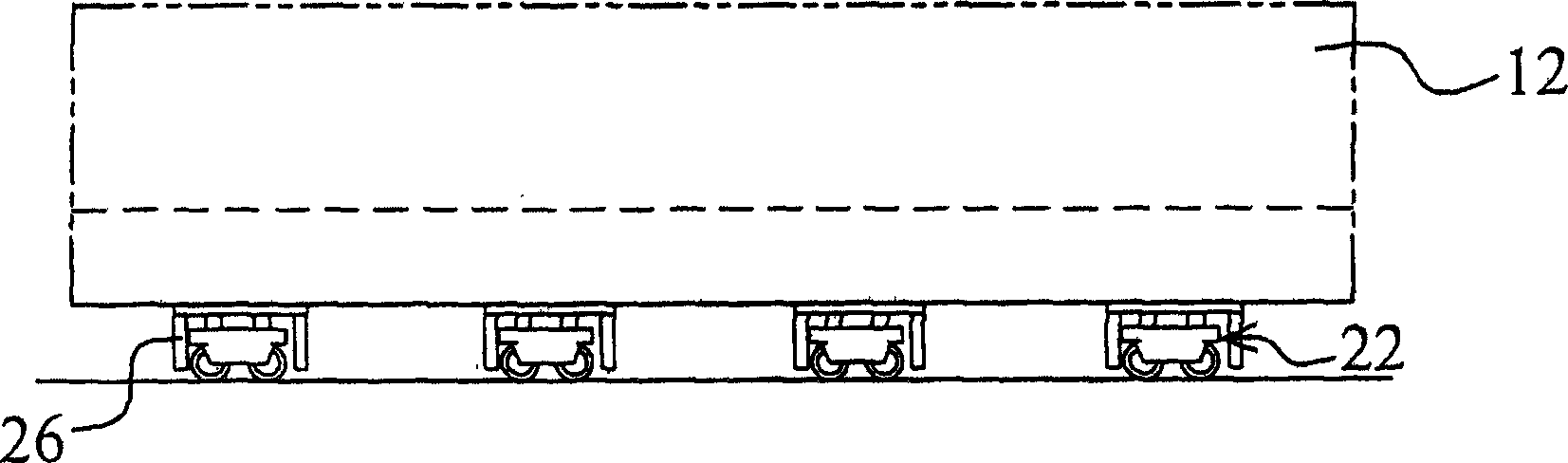

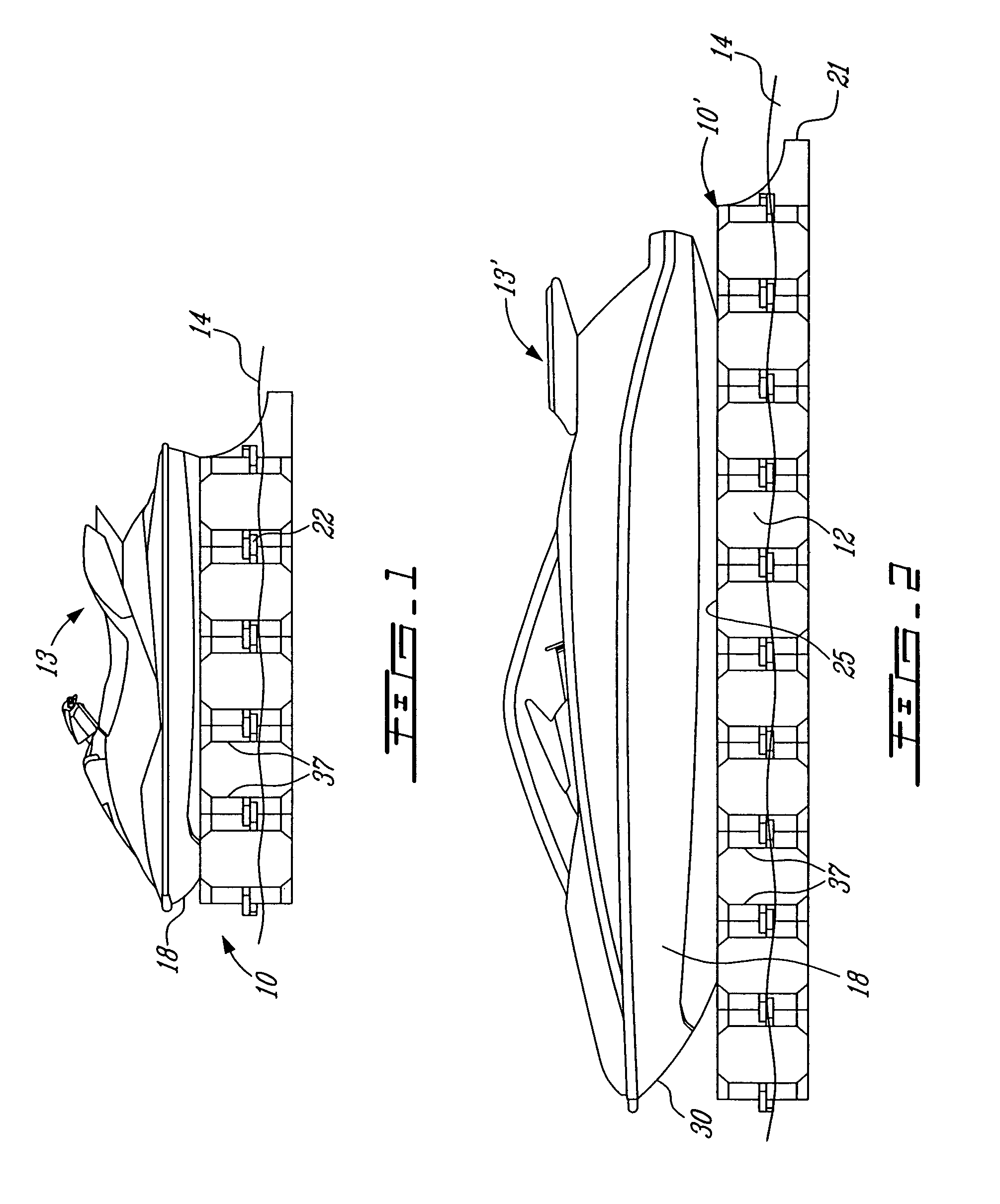

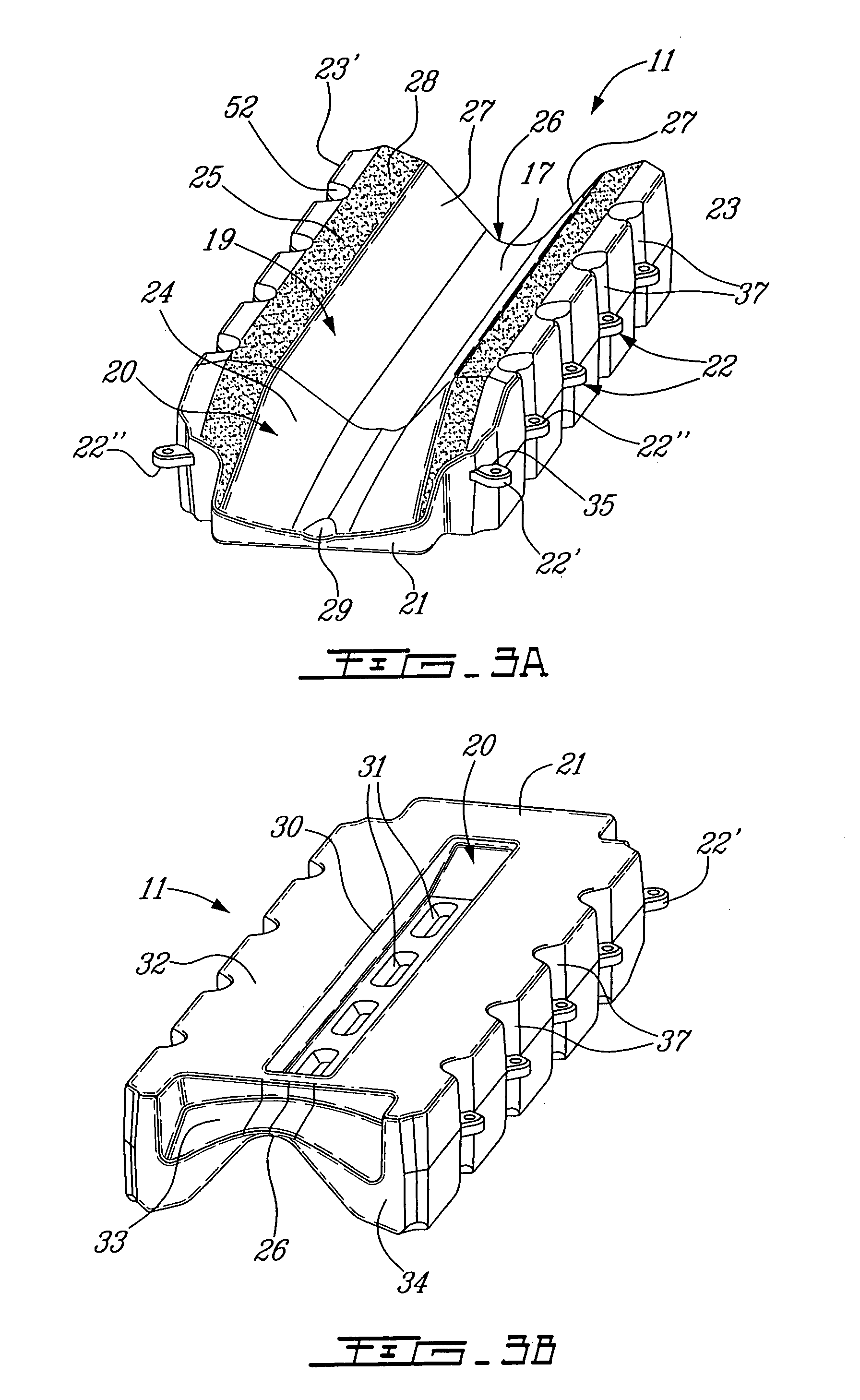

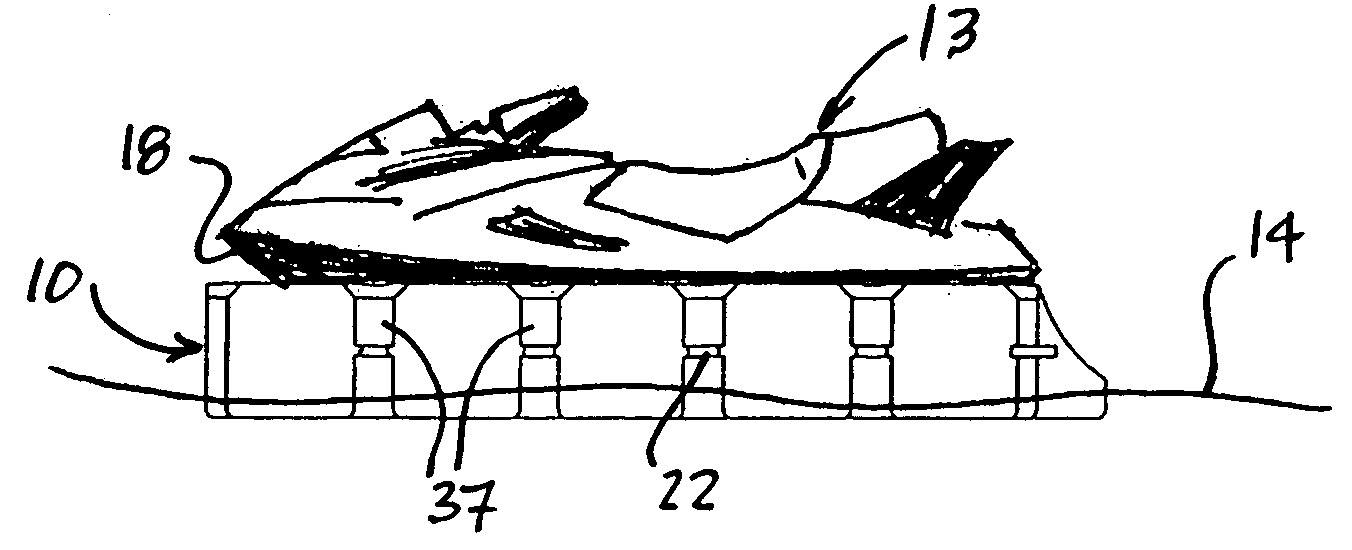

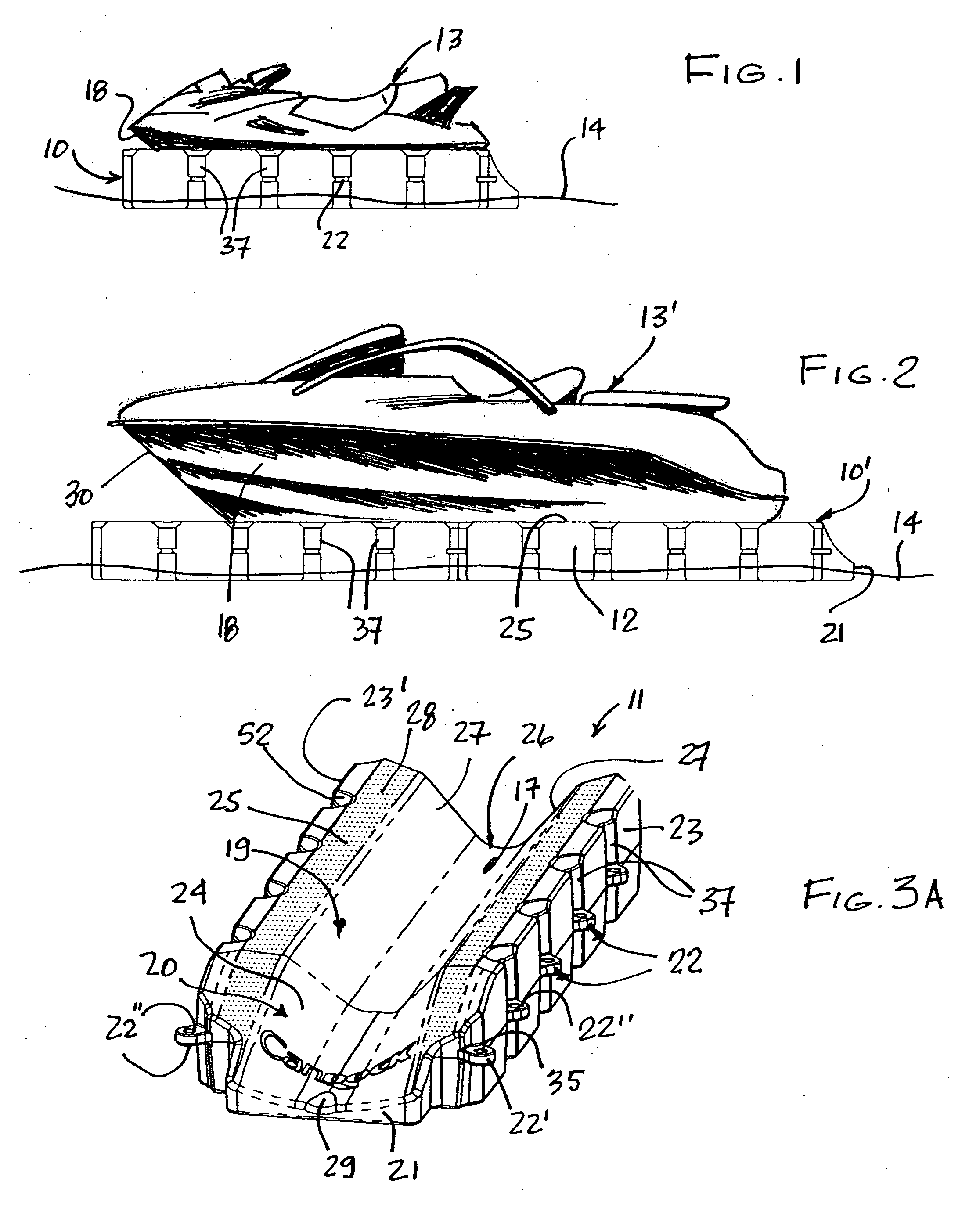

Floating dry dock for light watercrafts

A watercraft support platform casing for a floating dry dock for light weight watercrafts is described. The support platform casing has integrally formed floatation chambers and an elongated central ramp is formed in the top surface of the casing to support the hull of a watercraft positioned thereon. The ramp has a trough-like upper surface with a sloped forward entry way formed integral therewith and terminates in a lower forward projecting edge. The support platform is provided with connectors on opposed side walls thereof for a rigid connection with a plurality of floatation casings to support the platform casing on a water surface with the entry way positioned to receive the bow of a watercraft in movement whereby the watercraft can project itself on the central ramp above the water surface.

Owner:CANDOCK

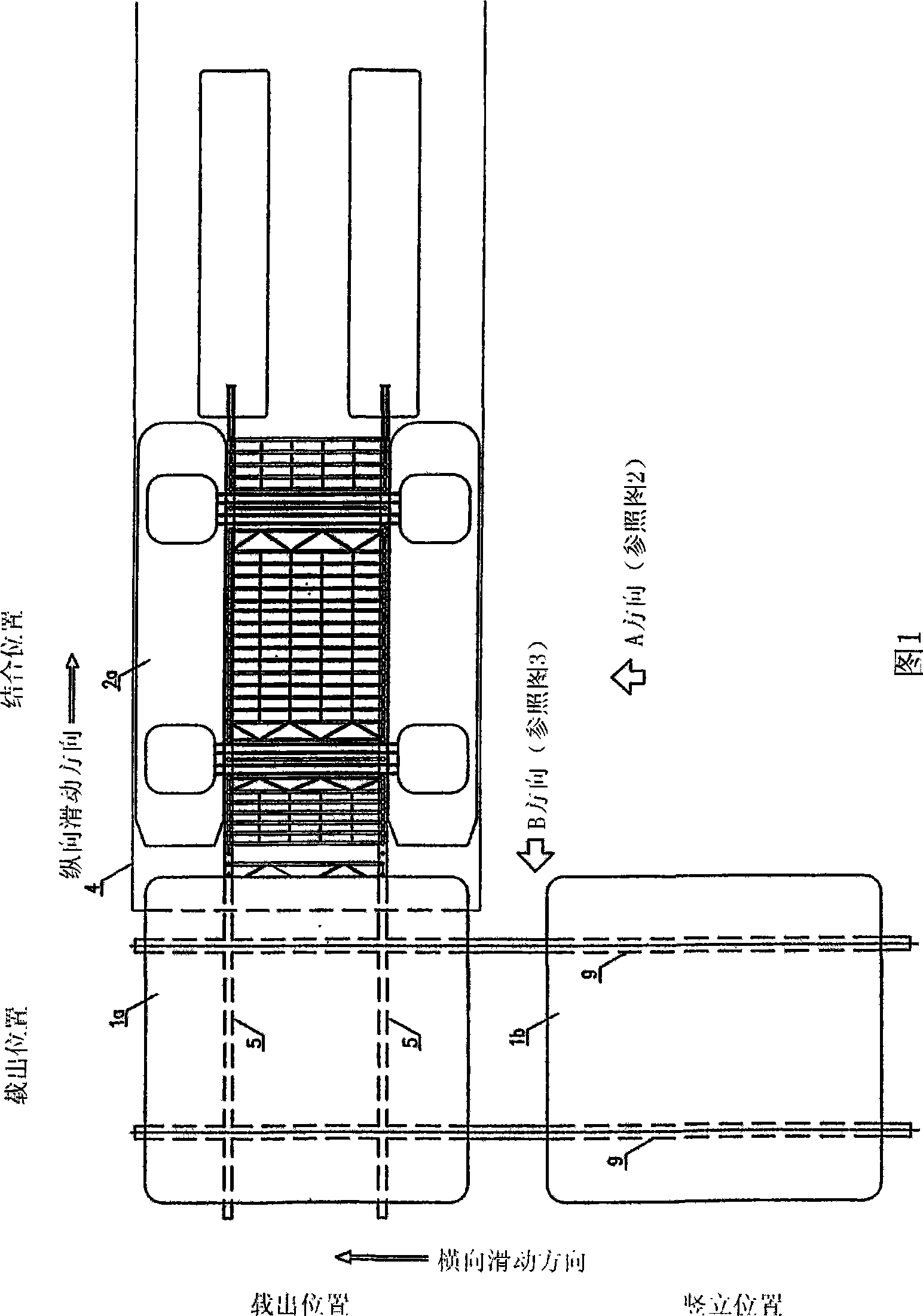

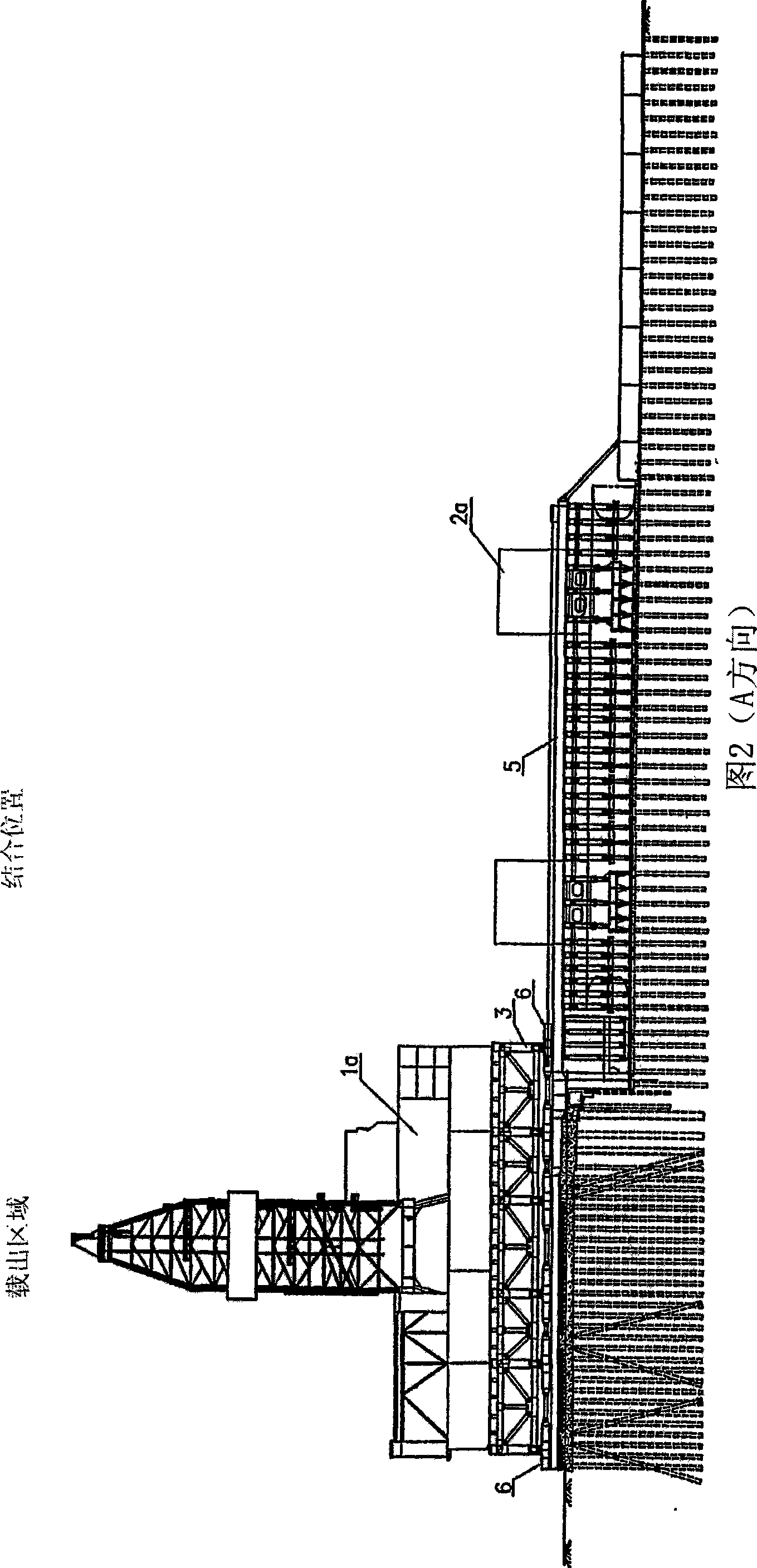

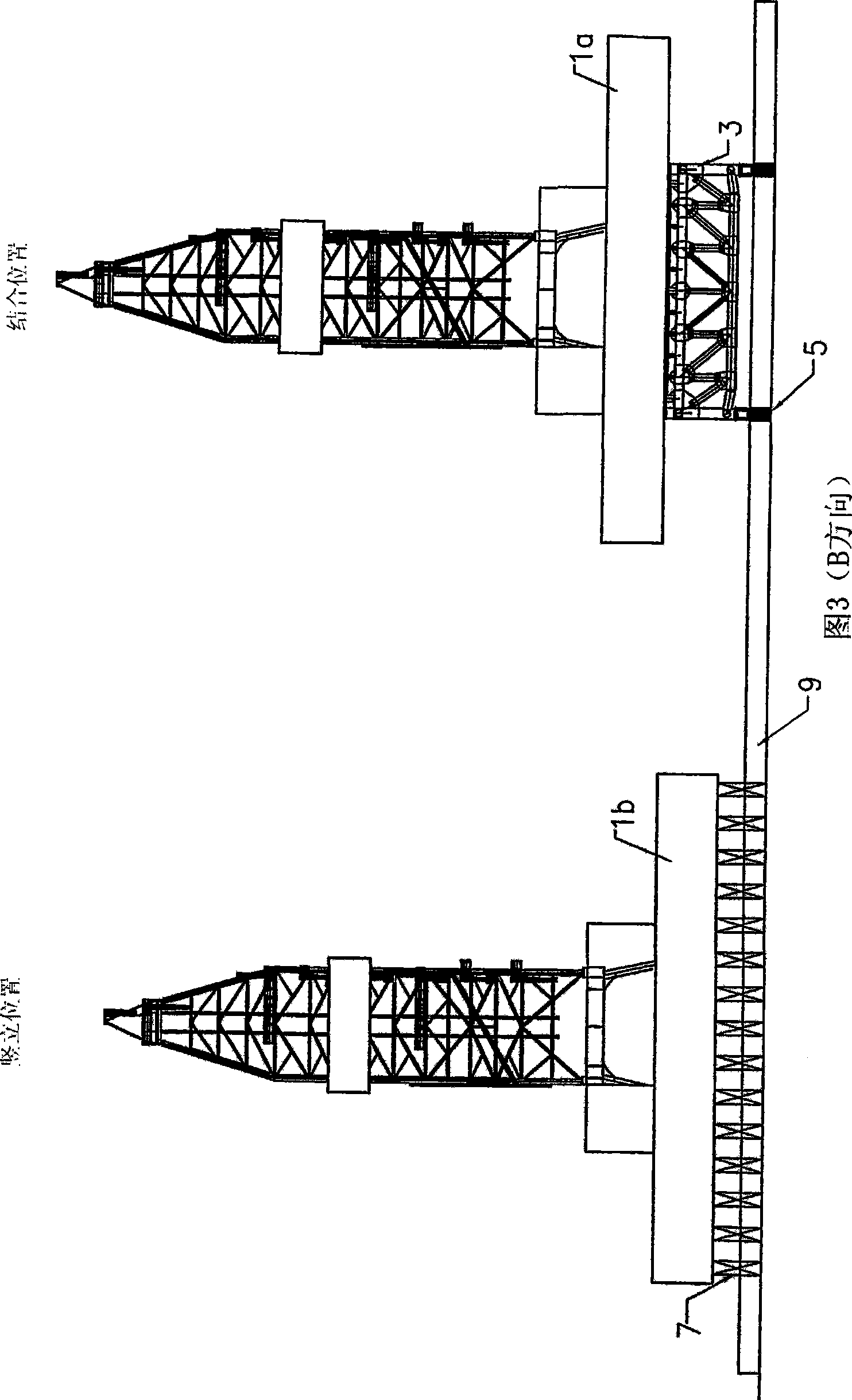

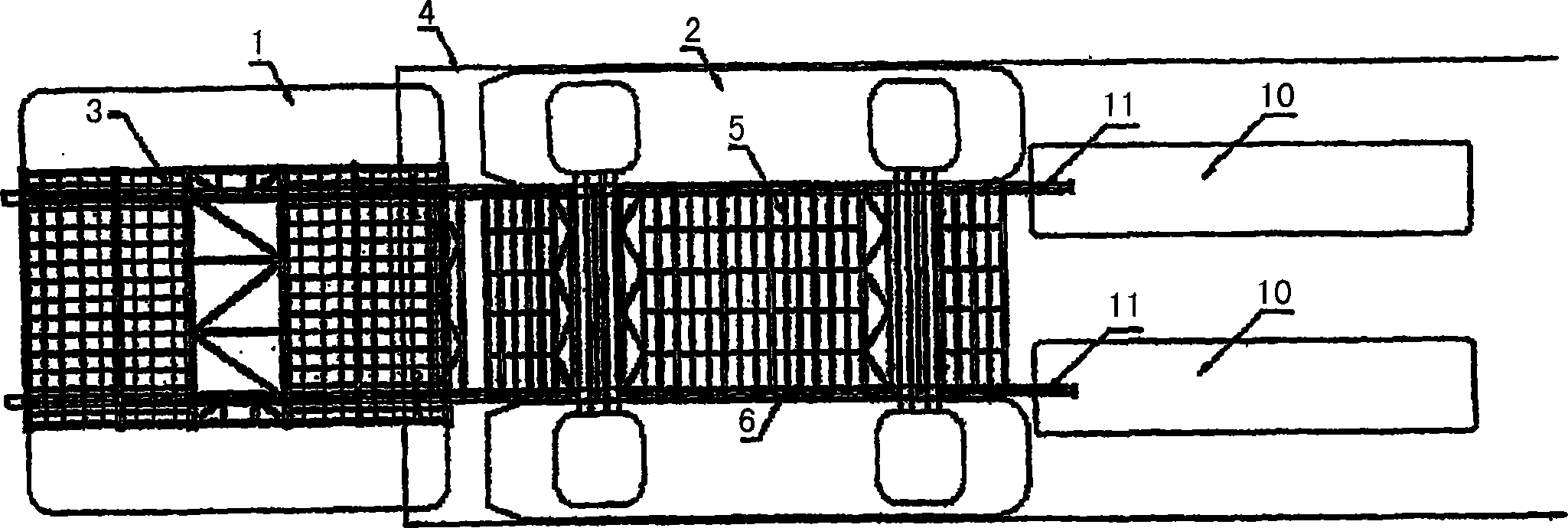

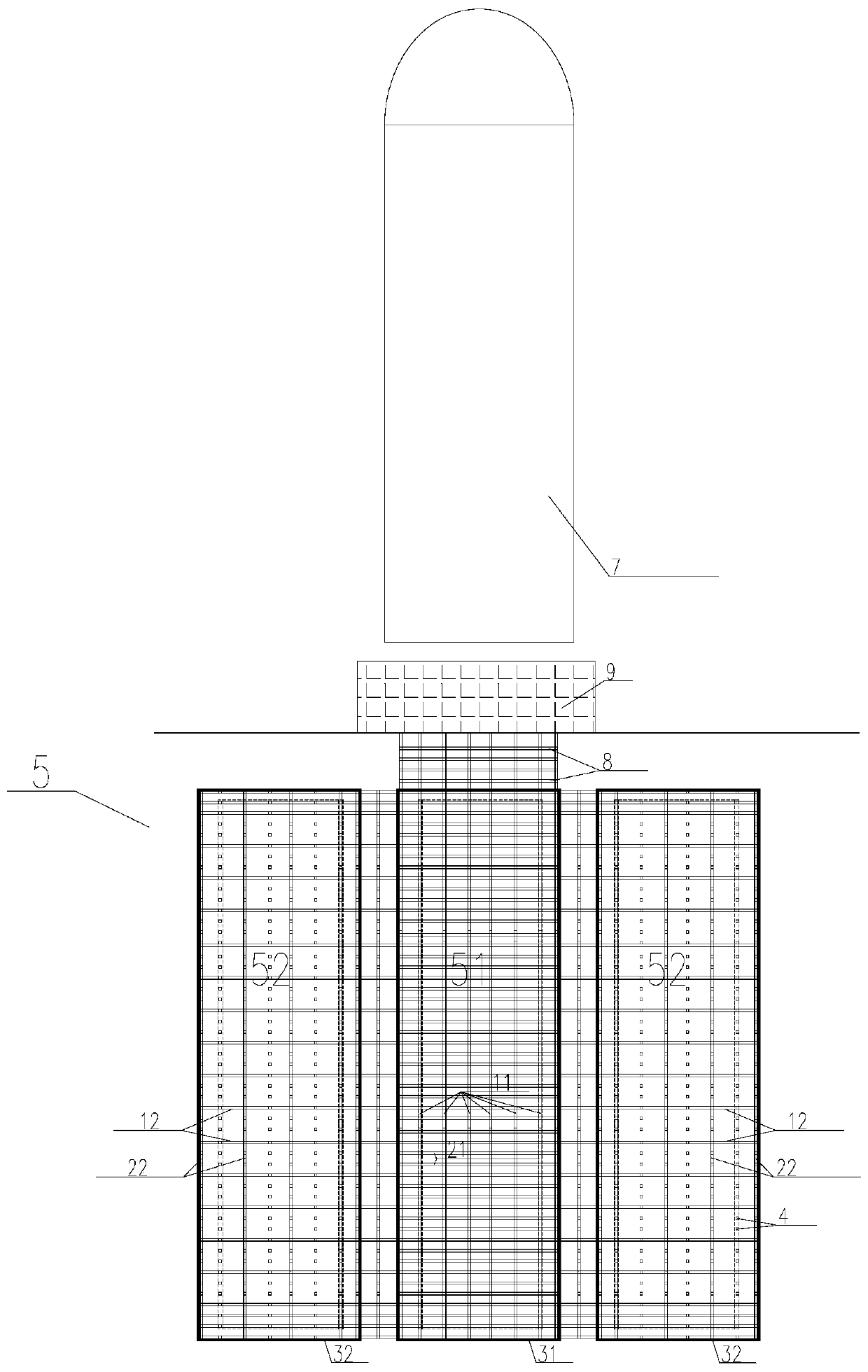

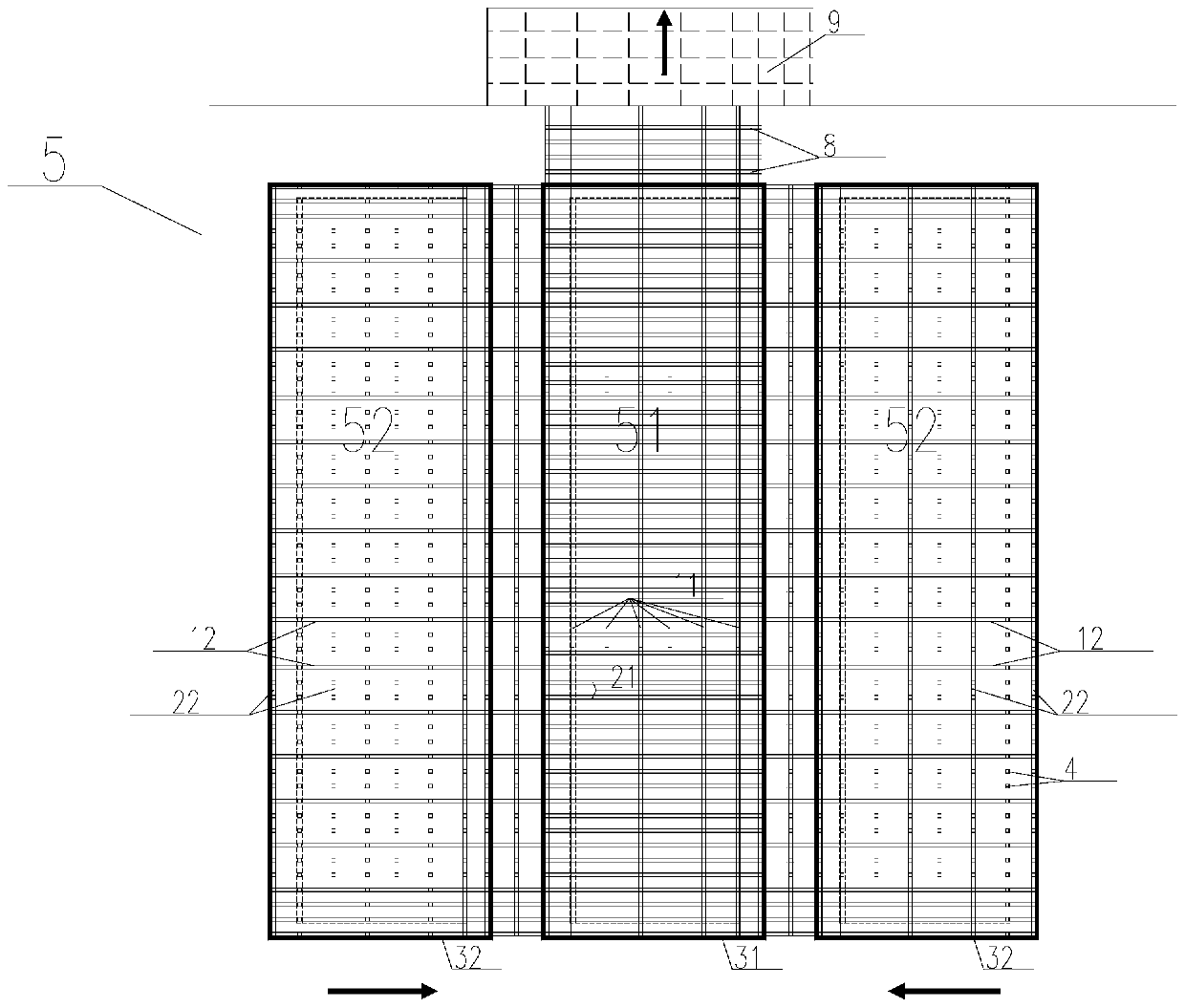

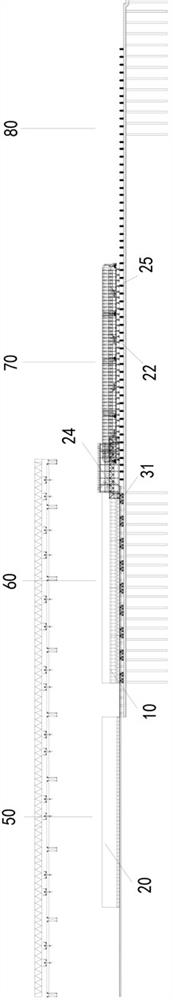

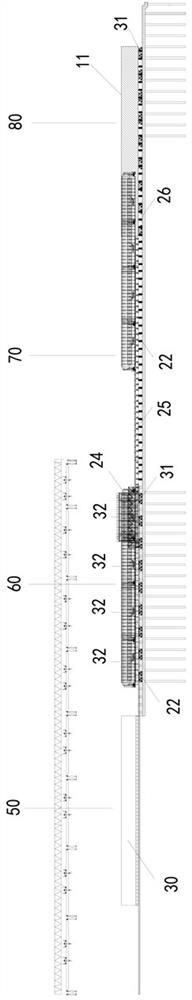

A method of contemporaneously constructing more than one semi-submersible rig using transverse skidding

A method of constructing two (or more) semi-submersible rigs simultaneously in a shipyard and completely assembling the rigs sequentially at the shipyard is disclosed. Two upper hulls of separate rigs are constructed side by side on land next to a dry dock, where the lower hulls are constructed. The first upper hull is then skidded longitudinally to a position above the first lower hull. The lower hull is floated by flooding the dry dock, and position of the lower hull is adjusted using the ballast tanks of the lower hull. Once the upper hull and the lower hull are aligned, they are permanently welded together, completing the first rig assembly in the dry dock. Concurrently, the second upper hull is then skidded transversely to the load-out position and subsequently jacked up to the required height. It is resting on the skidding truss after the truss is pulled back from the first rig's mating location. The load-out and mating operation is then repeated to assemble the second semi-submersible rig in the dry dock.

Owner:JURONG SHIPYARD

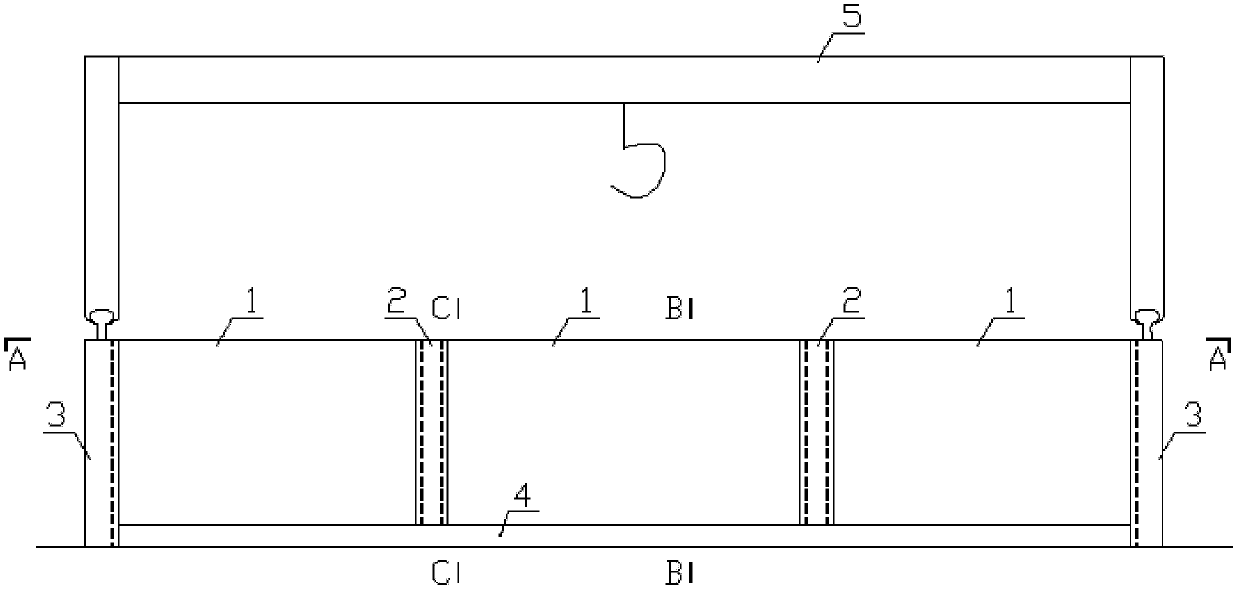

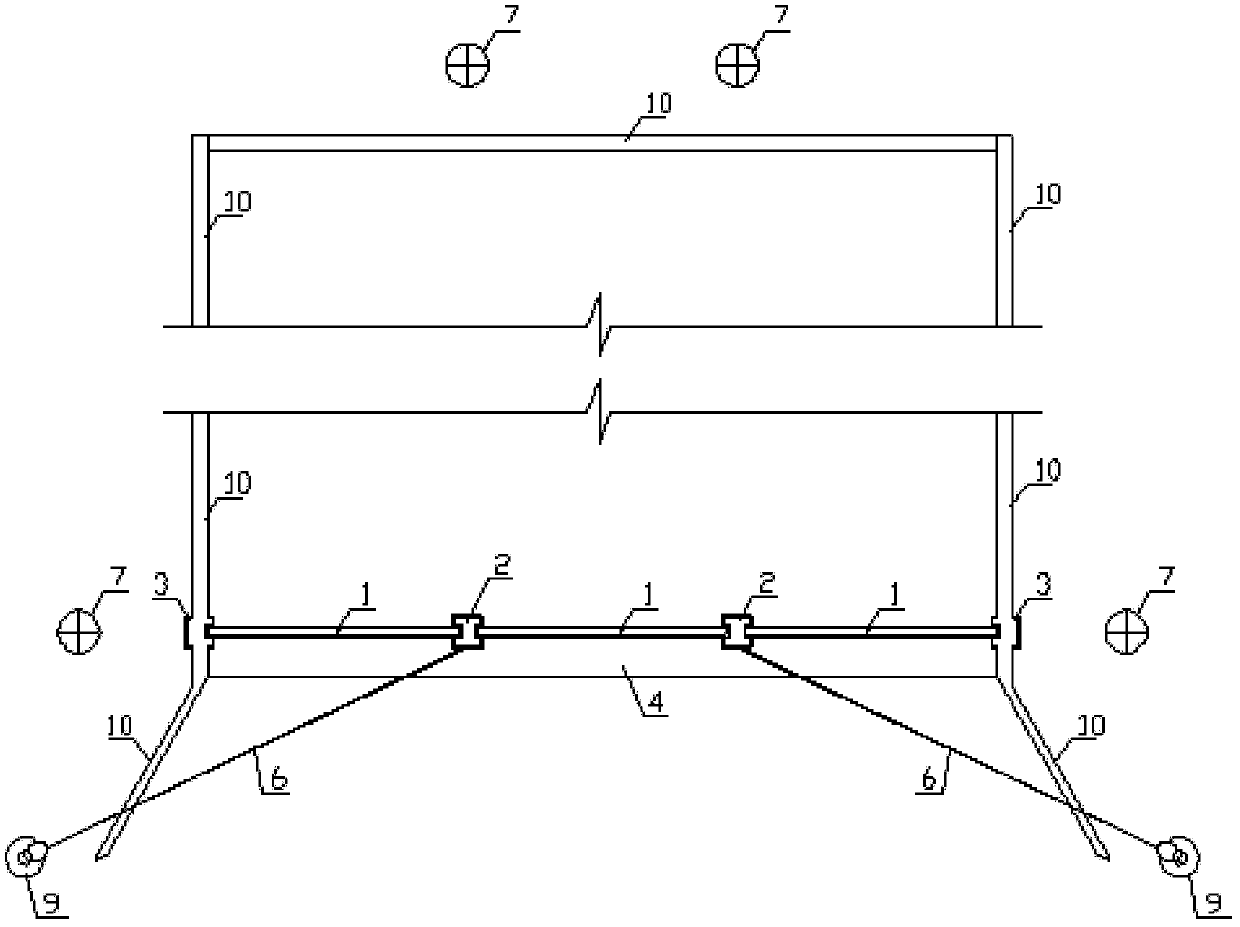

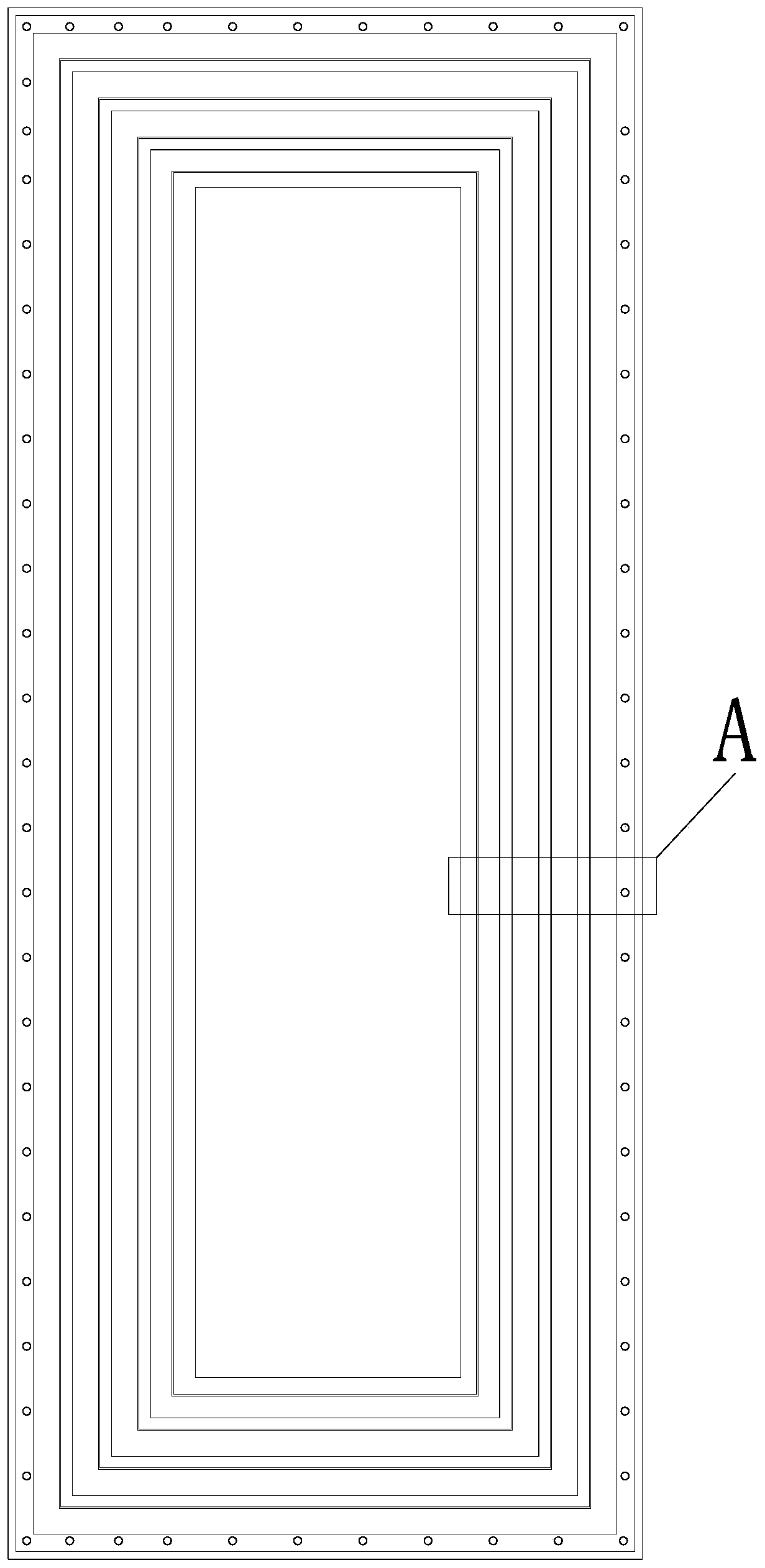

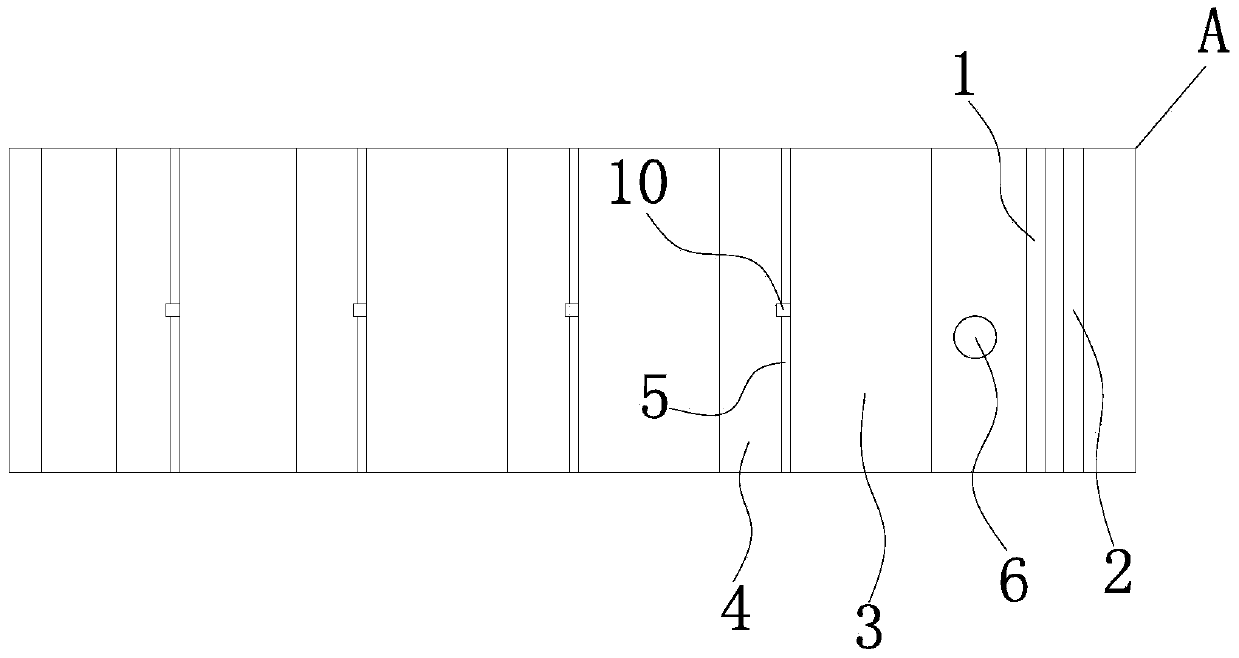

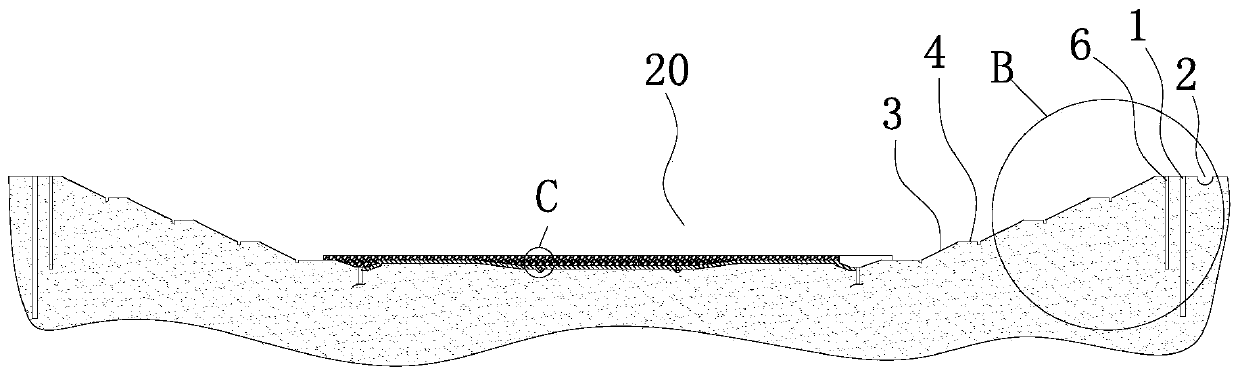

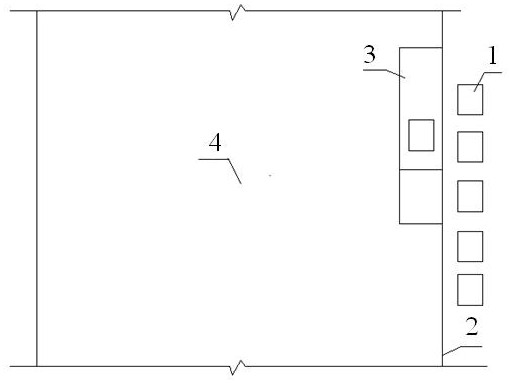

Combined gate-type dry dock door

The invention discloses a combined gate-type dry dock door which comprises gates, two fixed gate piers, a dock sill and a hoist. A plurality of movable gate piers are arranged between the two fixed gate piers, and the lower ends of the movable gate piers are movably connected with the dock sill; the gates are arranged between the fixed gate piers and the movable gate piers and between two movable gate piers; the upper ends of the movable gate piers are provided with cables, and the cables are connected with ground anchors which are arranged on the left riverside and the right riverside; and the cable and the gate form an included angle. The combined gate-type dry dock door has low manufacturing cost, is convenient to operate and easy to maintain and is suitable for the large and medium-size dry dock.

Owner:东兴市鸿生实业有限公司

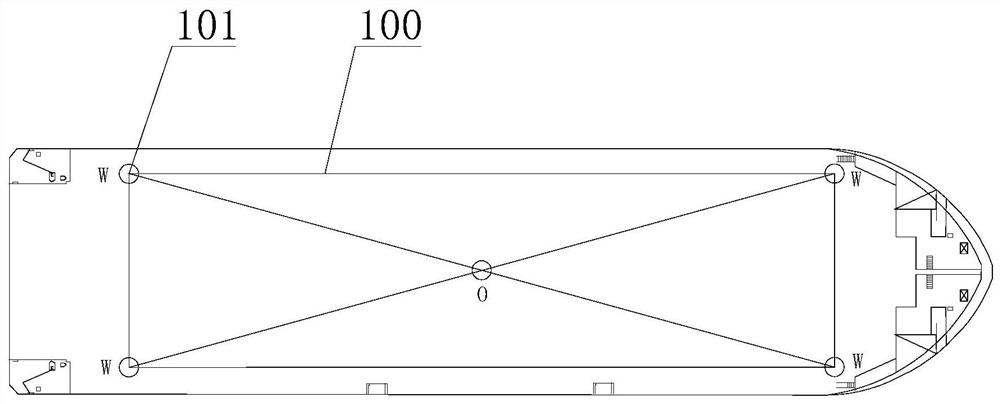

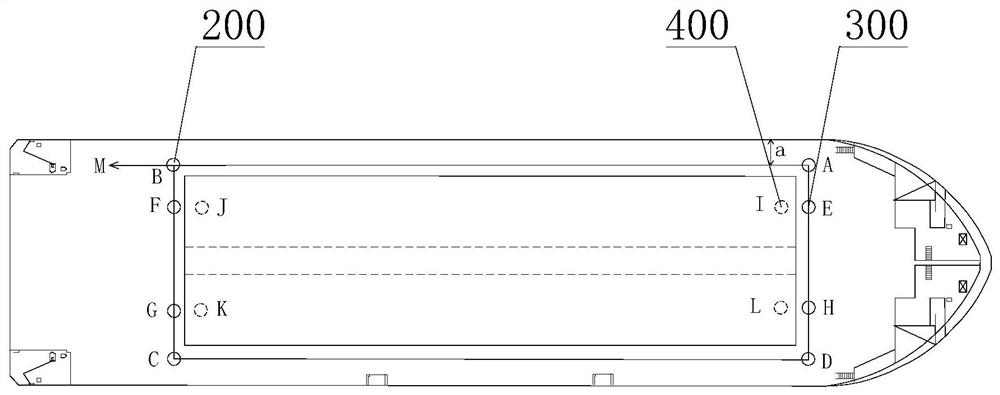

In-dock super-large ship floating secondary positioning process

The invention relates to an in-dock super-large ship floating secondary positioning process, which comprises the following steps of: ensuring that a ship meets an requirement on integrity before water enters a dock; making a ballasting and pier adding scheme and a dock pier fixing scheme before water enters the dry dock; arranging folding piers at right positions at the bottoms of ballast tanks of the whole ship and a half ship according to a requirement of a folding pier arrangement diagram; before water in the dock is drained, making preparation; marking water gauges on the front, tail, and left and right gunwales of the half ship respectively by using a paint, and using the water gauges as basis for observing longitudinal and transverse inclination of a ship body; observing and measuring in the process of introducing water into the dock; when the water begins entering the dock, gradually loosening a cable manually, and measuring and secondarily positioning the half ship; checking and arranging the dock piers; and washing the bottom of the dock and cleaning a cargo room. In the process, when the whole ship is launched, the half ship immediately moves to the position of the whole ship to be continuously hoisted and folded, the folding period of a ship under construction in the dock is shortened, and precious resources of gantry cranes are utilized to the greatest extent.

Owner:江苏新世纪造船有限公司

Floating dry dock for light watercrafts

A watercraft support platform casing for a floating dry dock for light weight watercrafts is described. The support platform casing has integrally formed floatation chambers and an elongated central ramp is formed in the top surface of the casing to support the hull of a watercraft positioned thereon. The ramp has a thraugh-like upper surface with a sloped forward entry way formed integral therewith and terminates in a lower forward projecting edge. The support platform is provided with connectors on opposed side walls thereof for a rigid connection with a plurality of floatation casings to support the platform casing on a water surface with the entry way positioned to receive the bow of a watercraft in movement whereby the watercraft can project itself on the central ramp above the water surface.

Owner:CANDOCK

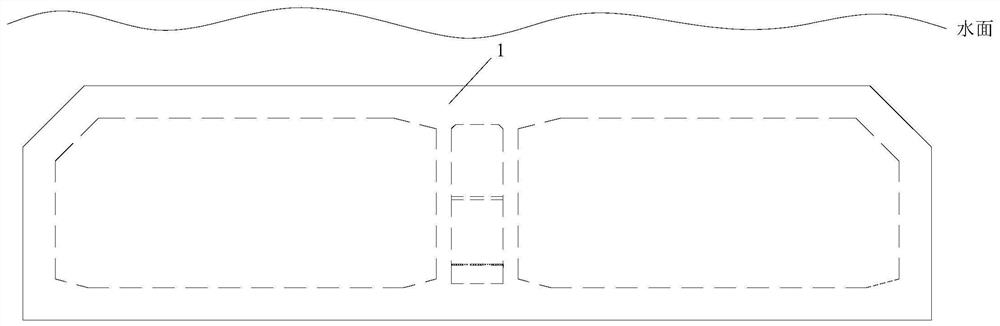

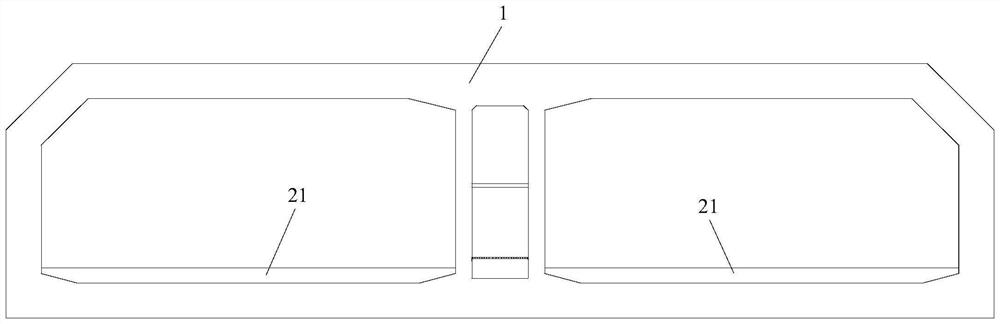

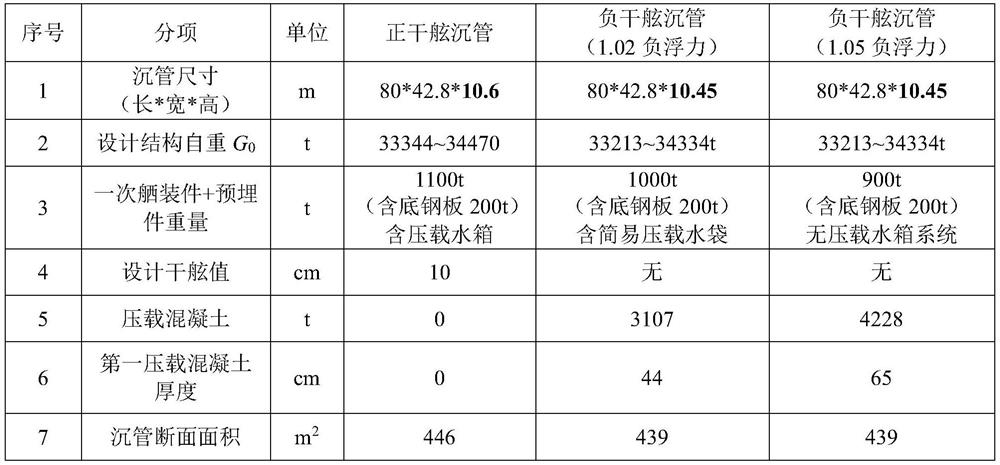

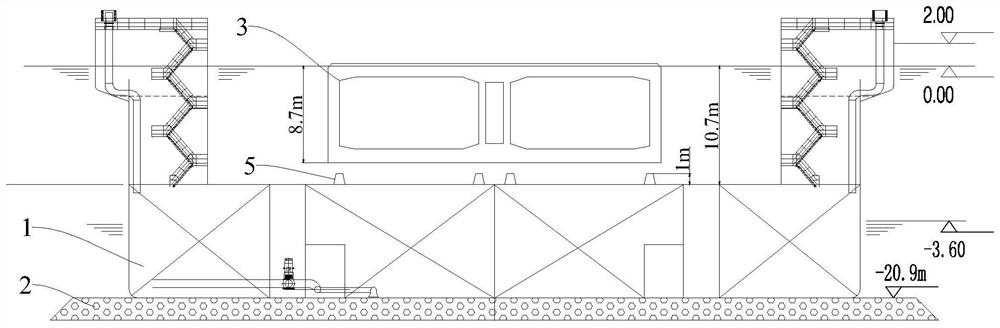

Negative buoyancy immersed tube and prefabricating method thereof

PendingCN112252367AIncrease Section HeightSmall amount of workArtificial islandsUnderwater structuresFreeboardImmersed tube

The invention relates to the technical field of immersed tube tunnel construction, in particular to a negative buoyancy immersed tube and a prefabricating method thereof. The immersed tube comprises abody, wherein the designed freeboard value of the body is smaller than 0. According to the negative buoyancy immersed tube, pipe joints do not need to be designed to be capable of self-floating in acorresponding water area, therefore, the section height of the immersed pipe does not need to be increased for guaranteeing the minimum freeboard value during floating transportation, the design contradiction between freeboard value consideration and anti-floating in the operation period in the design link is avoided, a dry dock does not need to be set for freeboard value detection, the method isparticularly suitable for engineering projects with limited fields, the design concept that a self-floating immersed tube must be adopted in the prior art is broken through, the structural height canbe reduced to the maximum extent, the engineering amount of a main body structure, foundation trench backfilling and the like is reduced, a freeboard adjusting layer does not need to be arranged, theprefabricating cost and the construction cost are effectively reduced, design difficulty and prefabricating difficulty are reduced, the cumbersome operation of adjusting the freeboard value in water in the floating transportation link is avoided, the transportation time can be shortened, and the method has important popularization significance and good application prospects.

Owner:CCCC FOURTH HARBOR ENG CO LTD +2

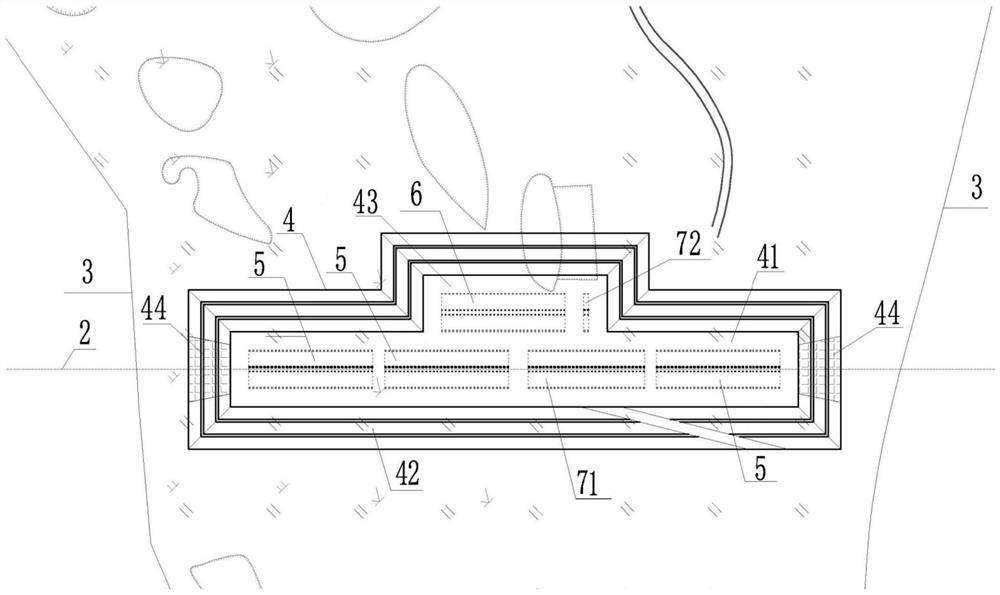

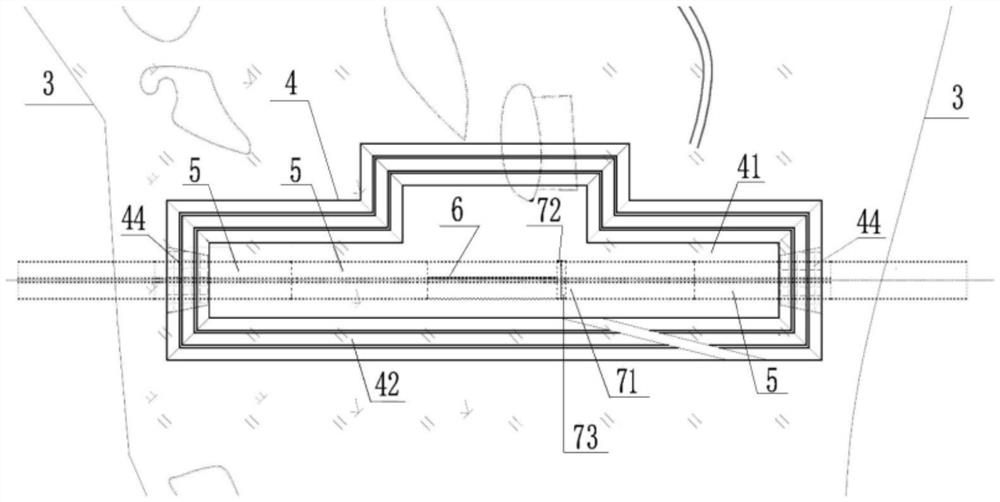

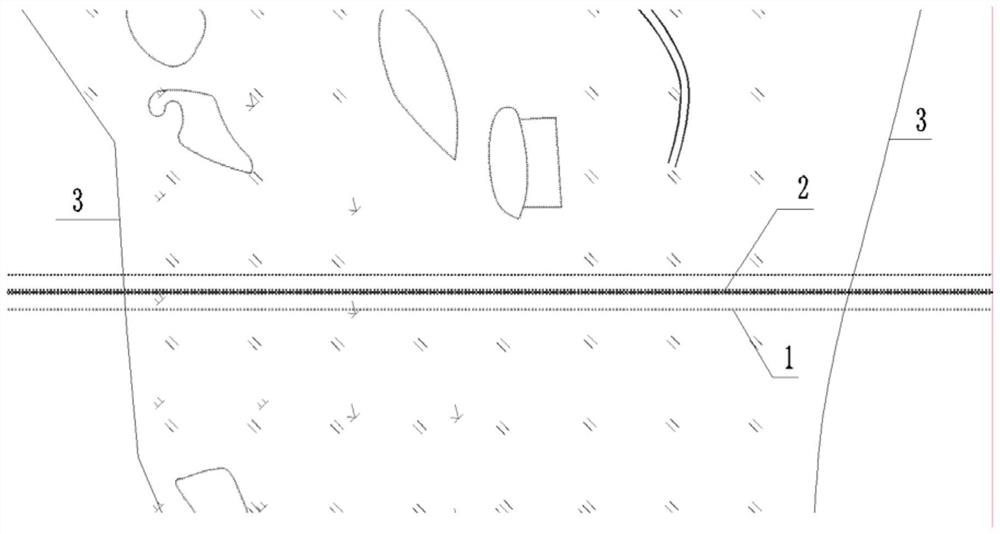

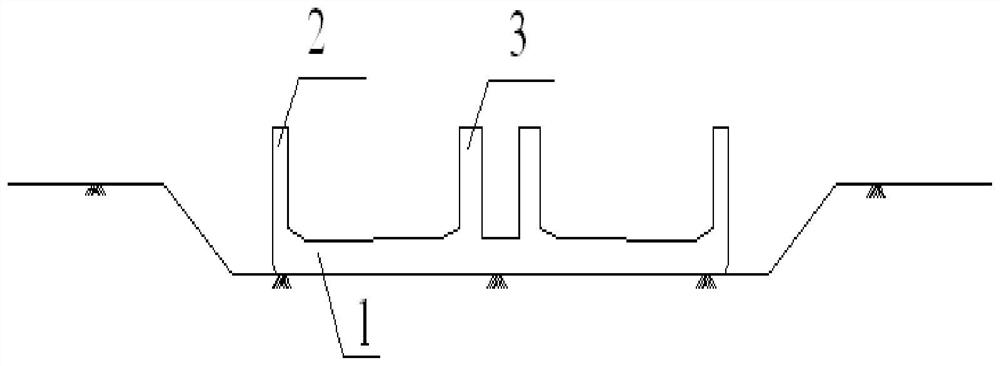

Construction method of dry dock foundation pit and dry dock foundation pit structure

The invention discloses a construction method of a dry dock foundation pit. The construction method comprises the steps that A, a cutoff wall is built outside a foundation pit construction area, wherein the cutoff wall surrounds the foundation pit construction area, and the bottom of the cutoff wall reaches an impermeable layer; a drainage ditch is dug in the surface outside the cutoff wall; a plurality of vertical dewatering wells are dug between the cutoff wall and the foundation pit construction area; the foundation pit is excavated; and a drainage cushion layer is laid at the pit bottom ofthe foundation pit, a drainage pipe is installed in the drainage cushion layer, and then a concrete layer is poured on the upper surface of the drainage cushion layer. The invention further disclosesa dry dock foundation pit structure which can be constructed by adopting the construction method. According to the construction method, rainwater, groundwater, surface water and the like can be prevented from entering the foundation pit and generating accumulated water, so that the construction is continuously and normally carried out, the construction efficiency is improved, and the constructionquality is ensured.

Owner:SEPCO ELECTRIC POWER CONSTR CORP

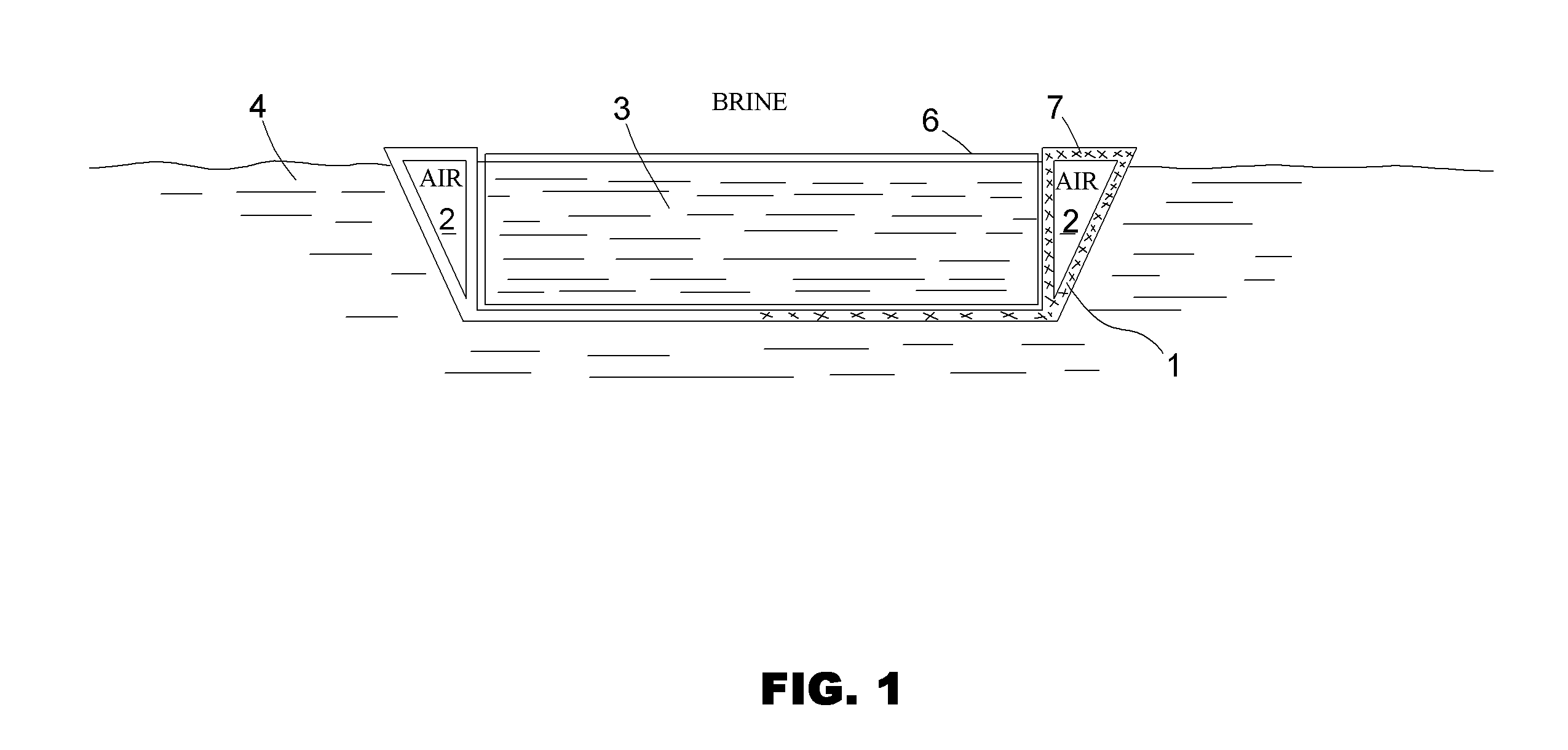

Floating canal system for seas with tendency to freeze

A system of floating canal sections that connect end-to-end along a route to form a shipping canal and contain brine to prevent freezing. The canal sections of the present invention resemble floating dry-docks that are filled with the brine solution rather than with normal sea water. Sections can be floated into place and connected. Sections can be anchored to the sea floor. A typical section can be around 1000 feet long, 150 feet wide and about 50 feet deep. The sections can be manufactured anywhere and towed to the Arctic and connected. The use of brine prevents pollution if there should be a leak.

Owner:LAWES ROLAND

System for conveying a barge over a levee in a level attitude

A system for conveying a barge over a levee in a level attitude providing for safety and avoidance of damage to the barge, the levee, and of persons, where a barge is to be conveyed from a waterway, over a levee, through a floodgate in a floodwall, and into a maintenance building, and the reverse operation, by placing a barge in a drydock, resting on support blocks, aligning the drydock with the floodgate, placing level-raising tractors with tractor controllers underneath the barge, raising the barge off of the support blocks, and rolling and lifting the barge over the levee while keeping the barge in a level attitude, optionally under the additional control of a person using a hand-remote tractor controller.

Owner:CIBILICH ANTHONY

Method for prefabricating pipe joints of immersed tube tunnel

PendingCN111350208AReduced Depth RequirementsReduced time requirementsArtificial islandsCeramic shaping apparatusImmersed tubeRebar

The invention discloses a method for prefabricating pipe joints of an immersed tube tunnel. The method comprises the following steps that 1, steel bars are bound in a shallow dry dock, and the pipe joints are poured; 2, a steel end shell, a steel end sealing wall and a guiding device are arranged at the two ends of each pipe joint; 3, a waterproof layer of each pipe joint is constructed; 4, prefabricated plates are prefabricated in a prefabricated site beside an assembling platform; 5, a dock door is opened, the pipe joints are conveyed to the assembling platform in a floating mode, and a hoisting system is arranged on the assembling platform; 6, the prefabricated plates are hoisted to the corresponding positions of the pipe joints through the hoisting system; 7, the waterproof layers areapplied above the prefabricated plates; and 8, the pipe joints are dragged to designated positions for reassembling and then sinking. According to the method, the pipe joint floating process is shallow in draft depth, the temporary project is little, the dredging amount in water or dredging is not needed, the environment influence is small, and streamlined operation can be carried out.

Owner:CHINA RAILWAY TUNNEL SURVEY & DESIGN INST +1

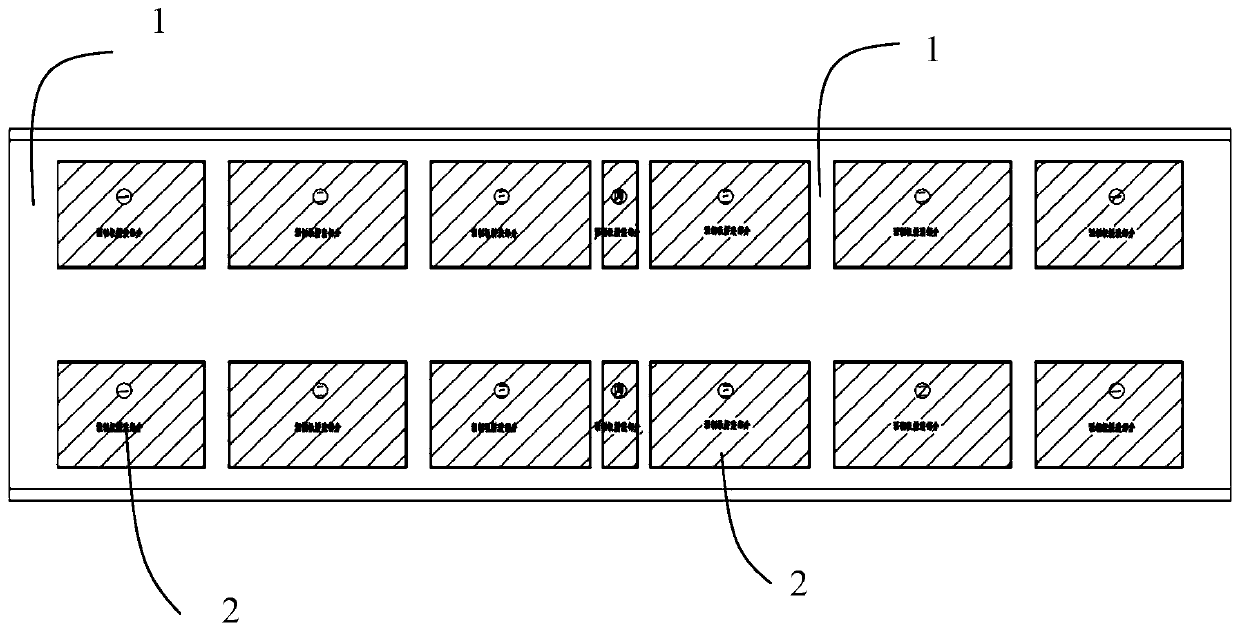

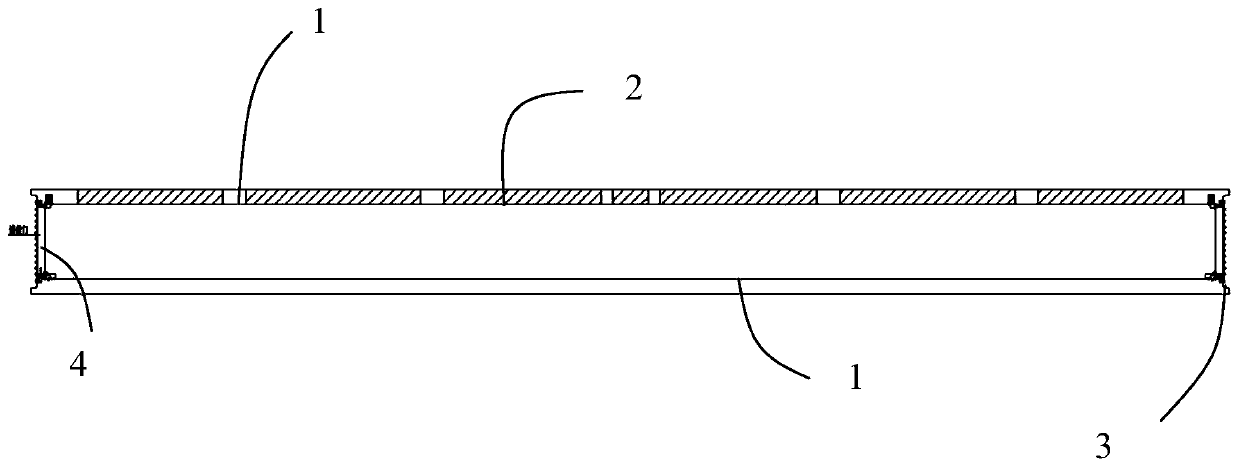

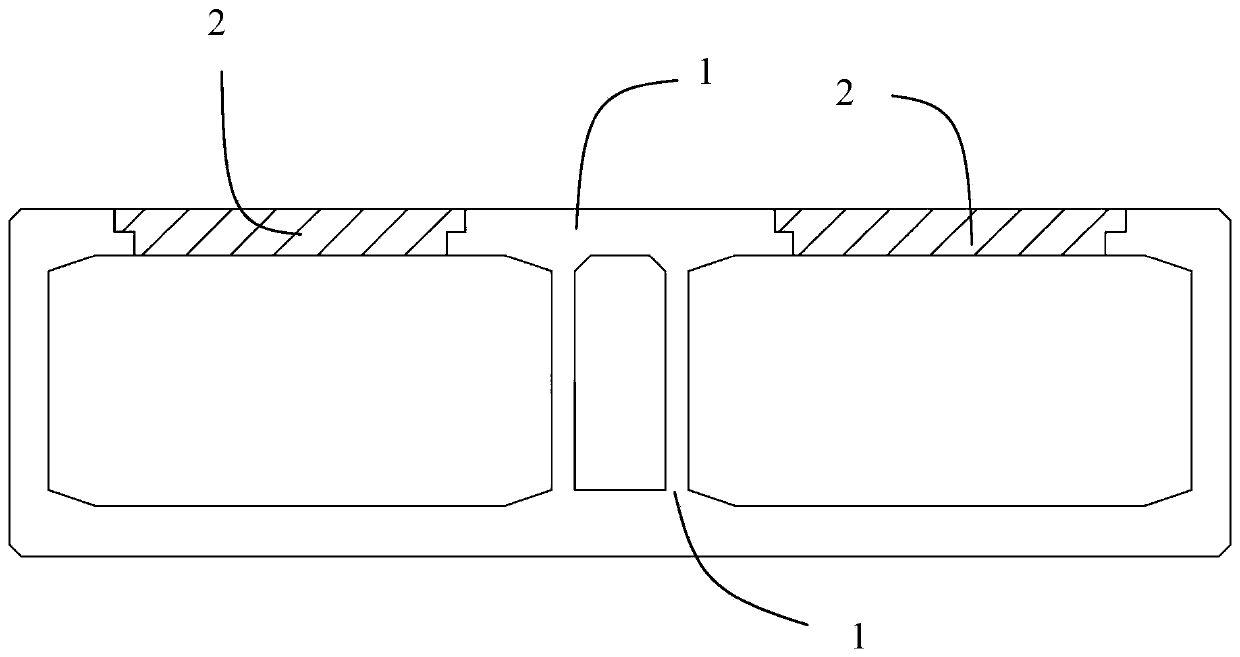

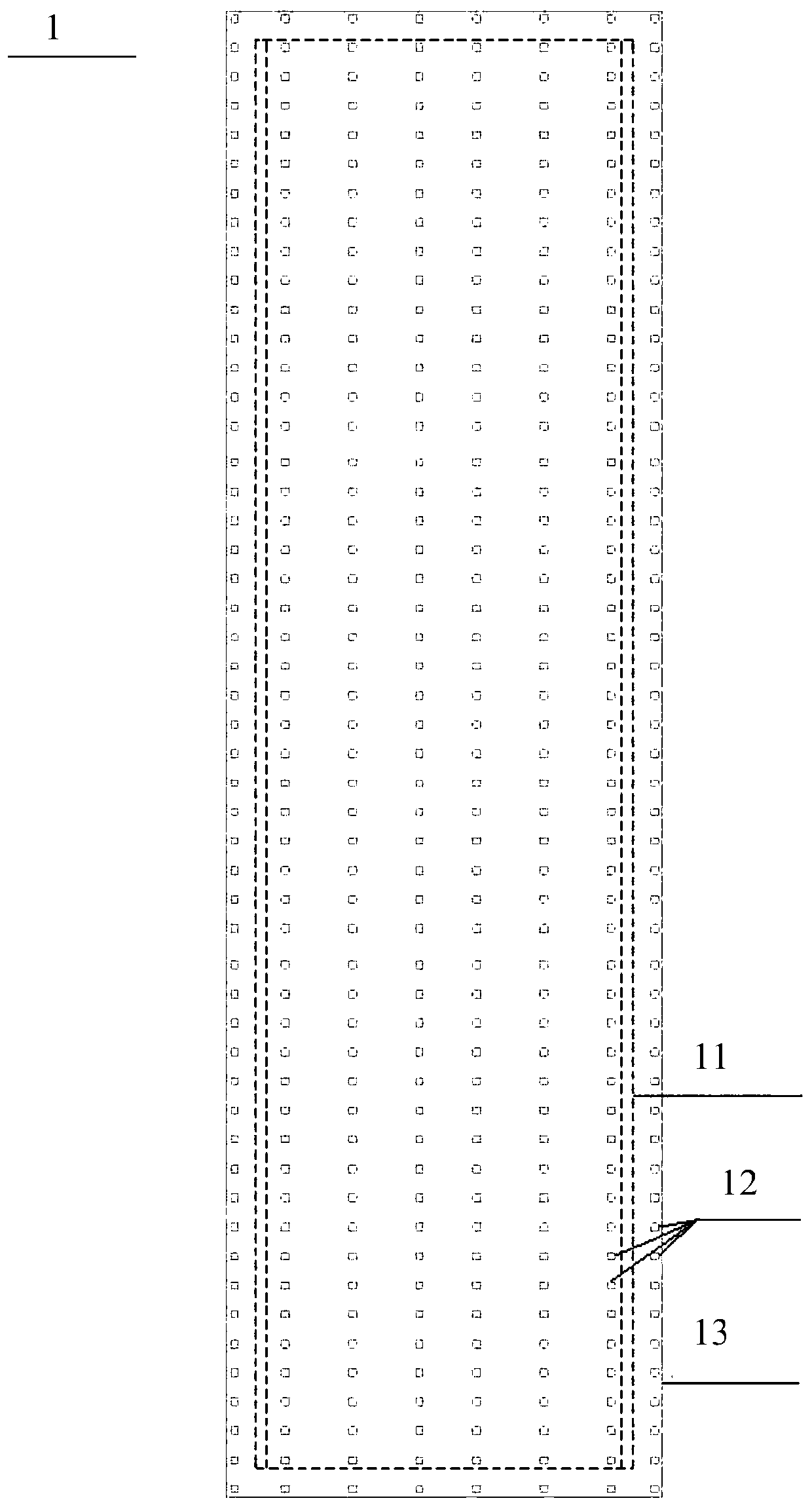

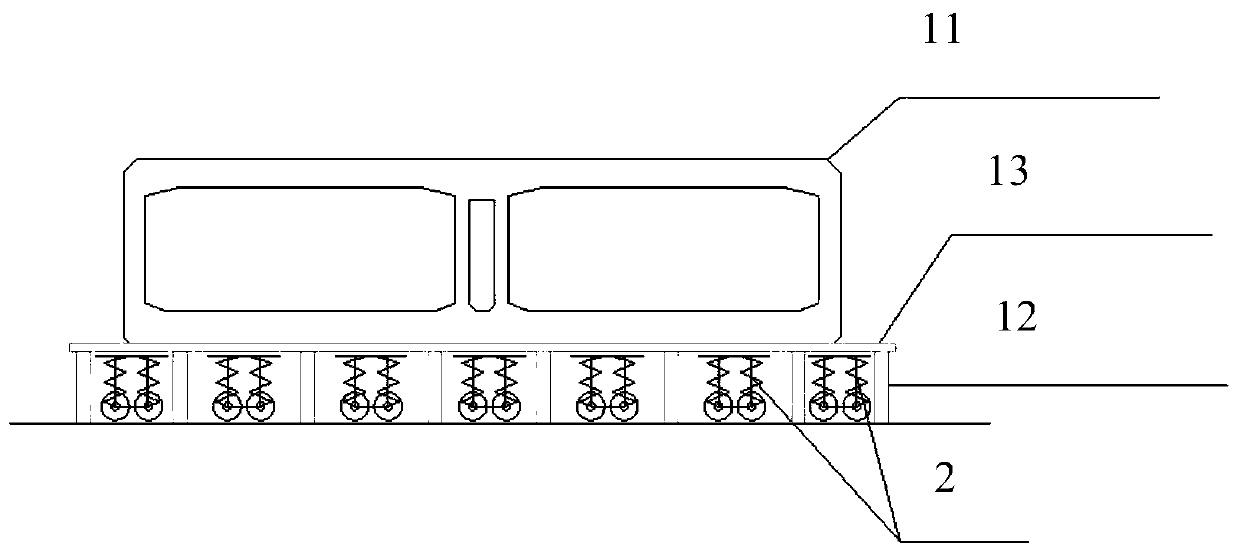

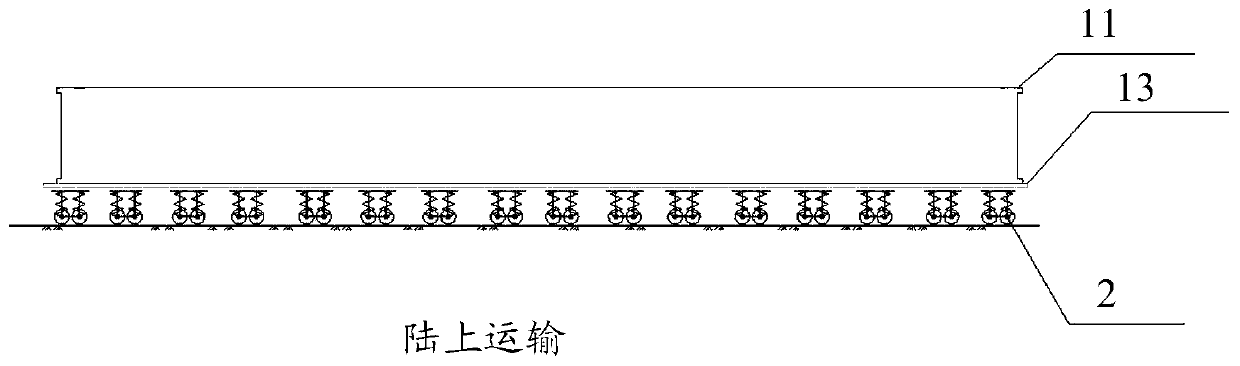

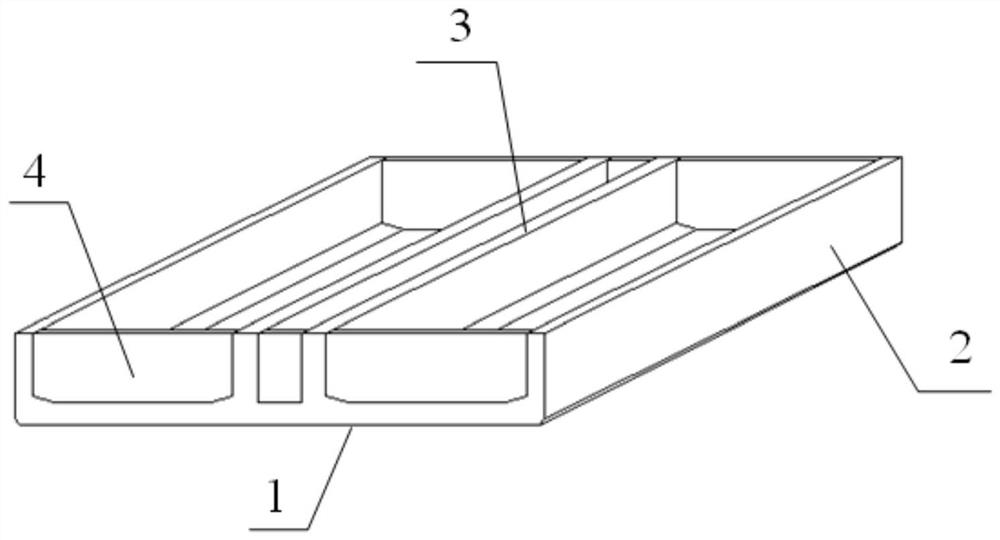

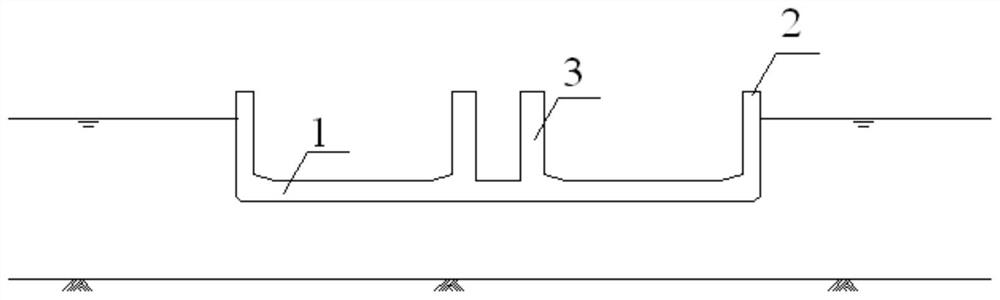

Structural system for flatly prefabricating and modularly transporting large-scale immersed tube tunnel tube section

PendingCN111206585AReduce investmentCost savingArtificial islandsUnderwater structuresMode of transportArchitectural engineering

The invention discloses a structural system for flatly prefabricating and modularly transporting a large-scale immersed tube tunnel tube section. The structural system for flatly prefabricating and modularly transporting the large-scale immersed tube tunnel tube section comprises a land area prefabrication platform, a modular transportation platform, and an ultra-large type pipe section transportation barge, wherein the land area prefabrication platform comprises a bottom steel plate for supporting the tunnel tube section and multiple rows of support pillars; the tunnel tube section is transported by land through the land area prefabrication platform; the modular transportation platform is used for sending the tunnel tube section to the transportation barge and then retreating, is capableof automatically adjusting the height, and comprises multiple communicated transportation modules; the transportation modules are arranged on the bottom part of the bottom steel plate and are locatedbetween the adjacent support pillars; and the ultra-large type pipe section transportation barge is used for transporting the tunnel tube section in a water area. According to the structural system for flatly prefabricating and modularly transporting the large-scale immersed tube tunnel tube section provided by the invention, a dry dock has no need to be built, so that the input of an immersed tube tunnel construction temporary project is reduced, the immersed tube tunnel cost and the construction period are saved; the requirement on the floor space required for tube section prefabrication issmall, so that the applicability of the immersed tube tunnel is higher; the tube section is transferred through the modular transportation platform, so that the transportation modes are flexible; andthe requirement on the fairway depth is low, so that the dredging of an existing fairway can be avoided or reduced.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD +1

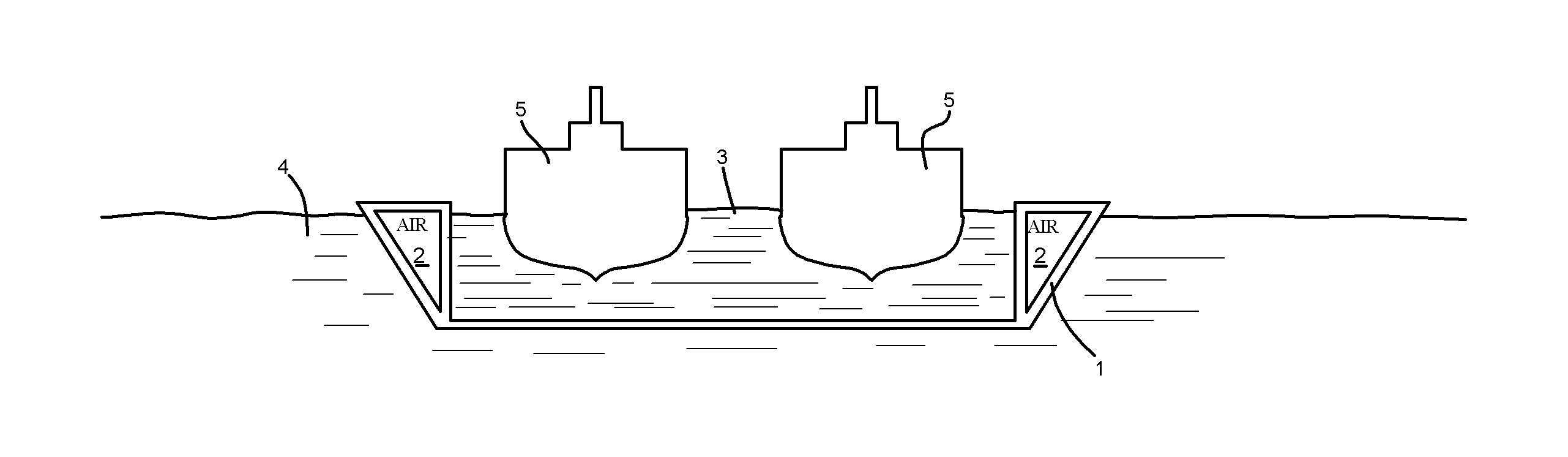

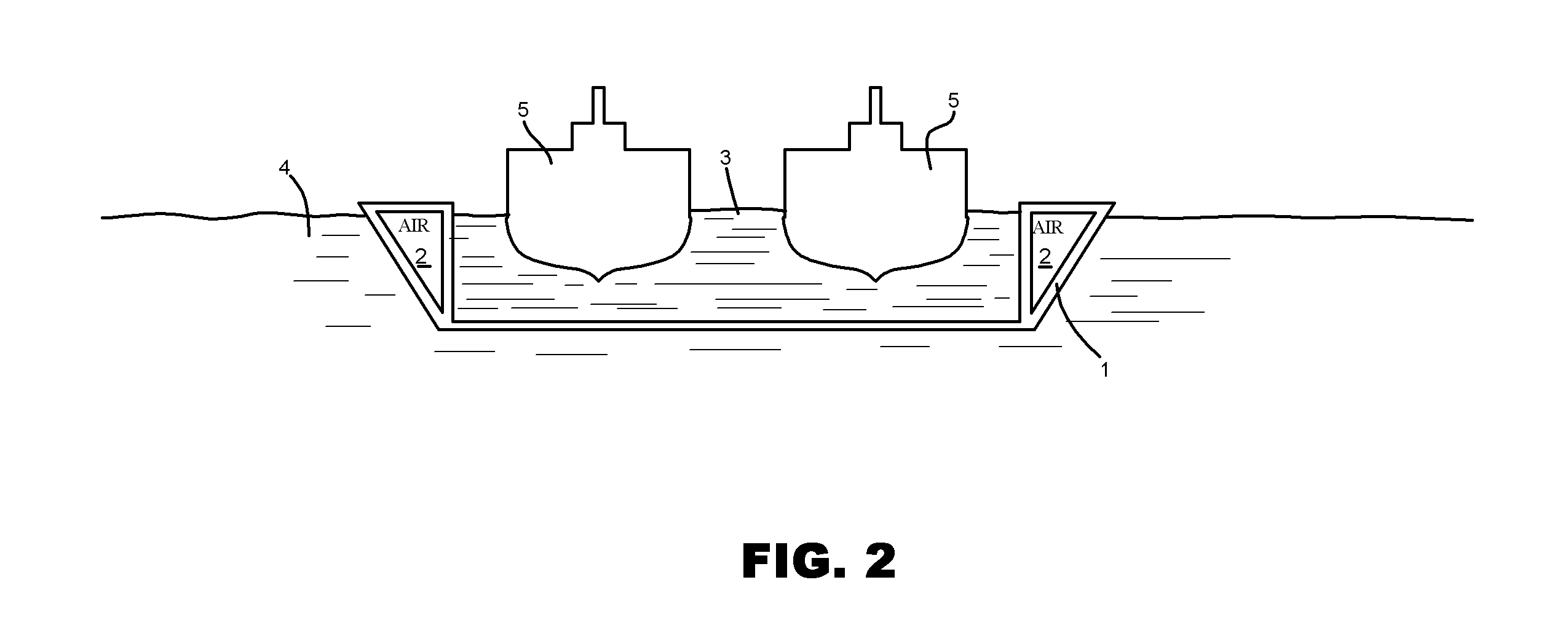

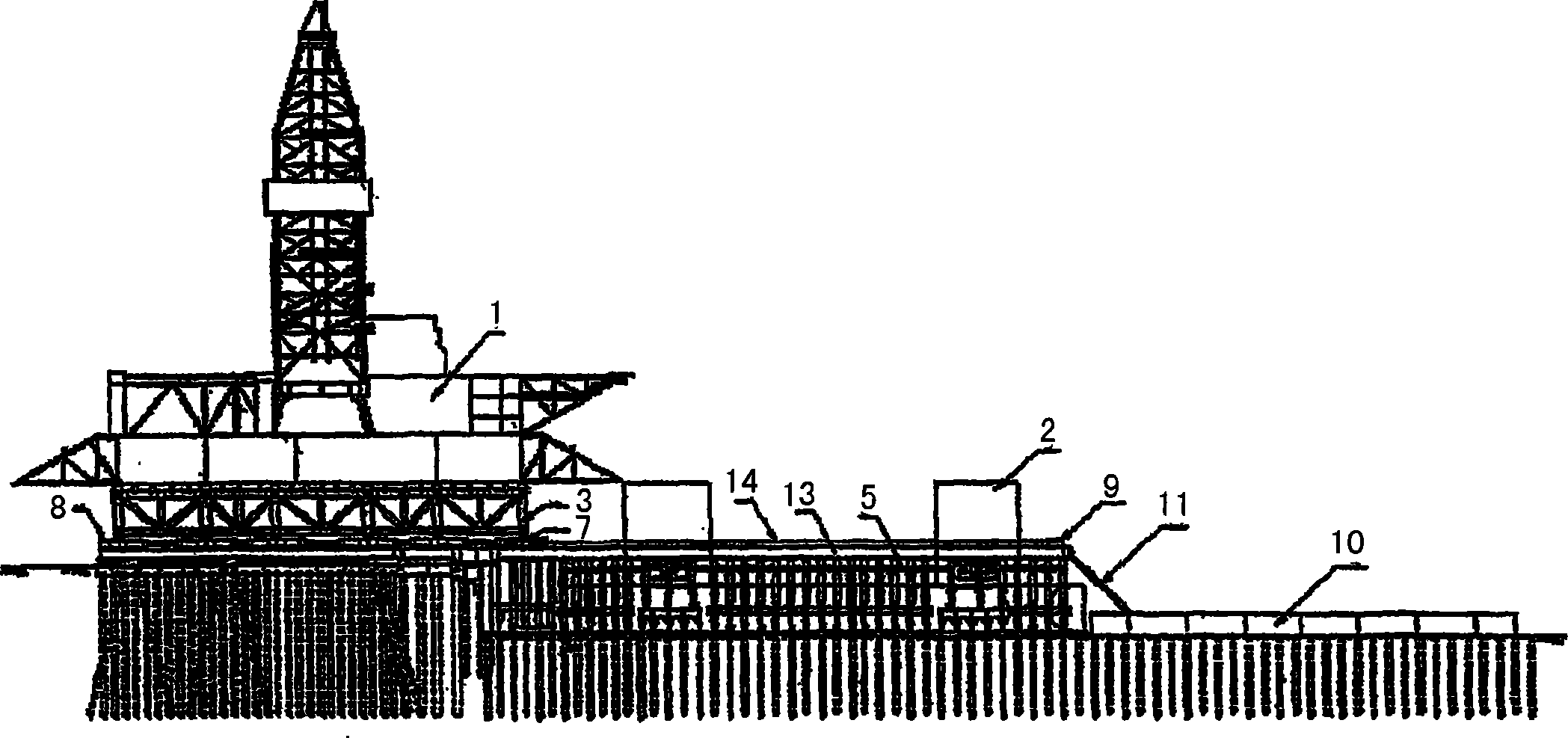

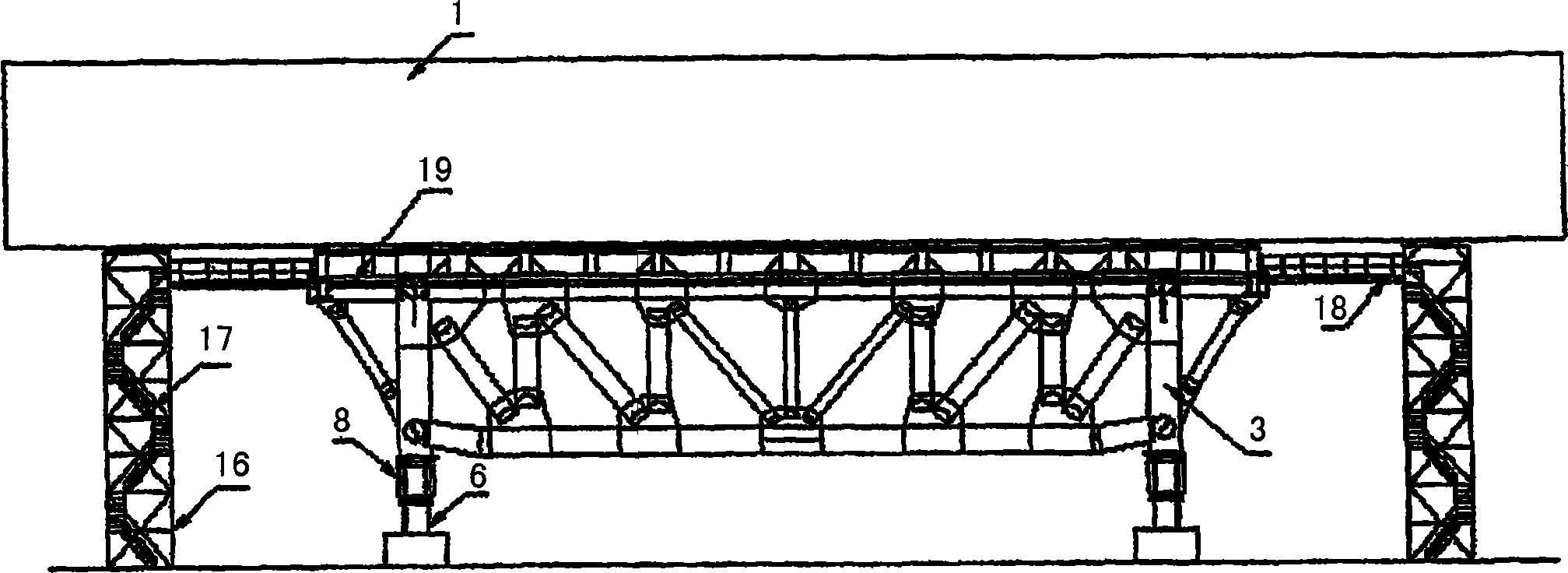

A method of constructing a semi-submersible vessel using dry dock mating

A method of constructing a semi-submersible drilling rig in a shipyard and fully assembling it in a shipyard. The upper hull (1) is built on land adjacent to the dry dock in which the lower hull (2) is built and the joining of the upper and lower hulls is finally done in the dry dock. The upper shell slides to a position above the lower shell, and the lower shell is floated up by injecting water into the dry dock, and the position of the lower shell is adjusted through the ballast tank in the lower shell. Once the upper and lower hulls are in contact alignment, they are permanently welded together, completing the rig assembly in dry dock.

Owner:JURONG SHIPYARD

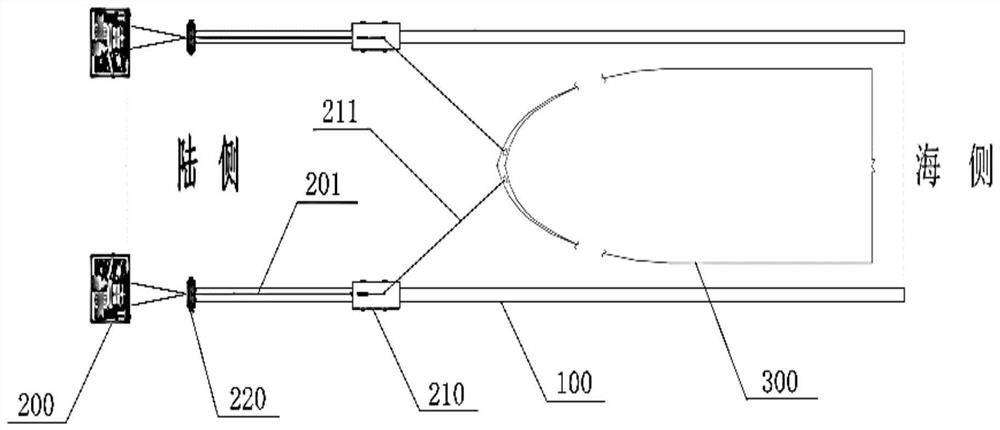

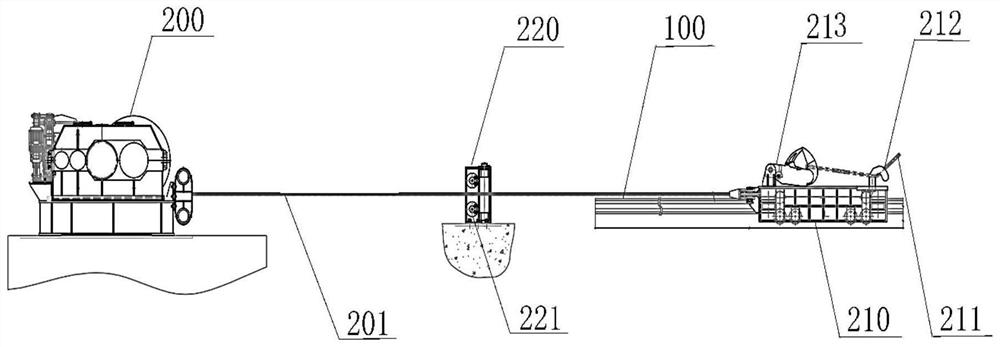

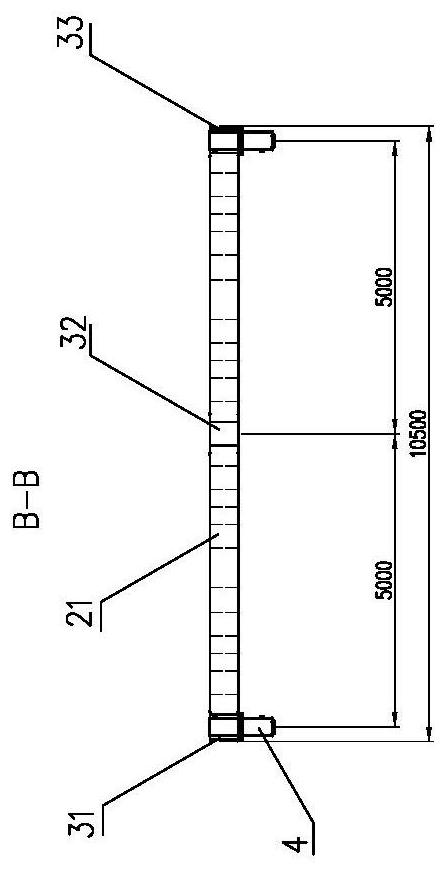

Dry dock ship guiding system

The invention provides a dry dock ship guiding system, and the system comprises two traction rails, wherein the two traction rails are symmetrically arranged on two sides of a dry dock; two traction winches which are arranged at the tail ends, facing the land side, of the two traction rails correspondingly; two small rail cars which are respectively arranged on the traction rail, wherein the traction winches are connected with the small rail cars through the traction rope, so the small rail cars moves along the traction rails under the traction of the traction winches; and a rigging, wherein one end of the rigging is connected with the rail trolley, and the other end of the rigging is used for being connected with a ship. According to the dry dock ship guiding system, the track trolley is driven by the traction winch to drag a ship to enter the dry dock, and meanwhile the ship can stably and safely enter the dry dock through cooperation of the traction track.

Owner:SHANGHAI ZHENHUA HEAVY IND

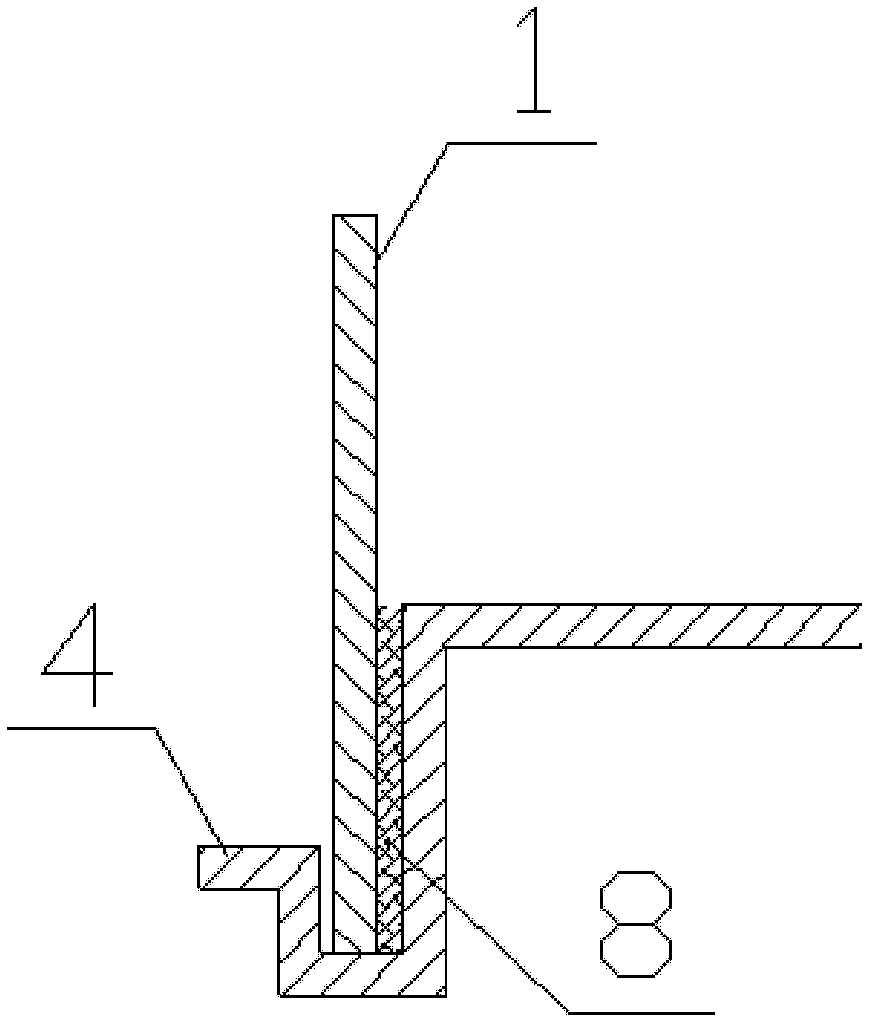

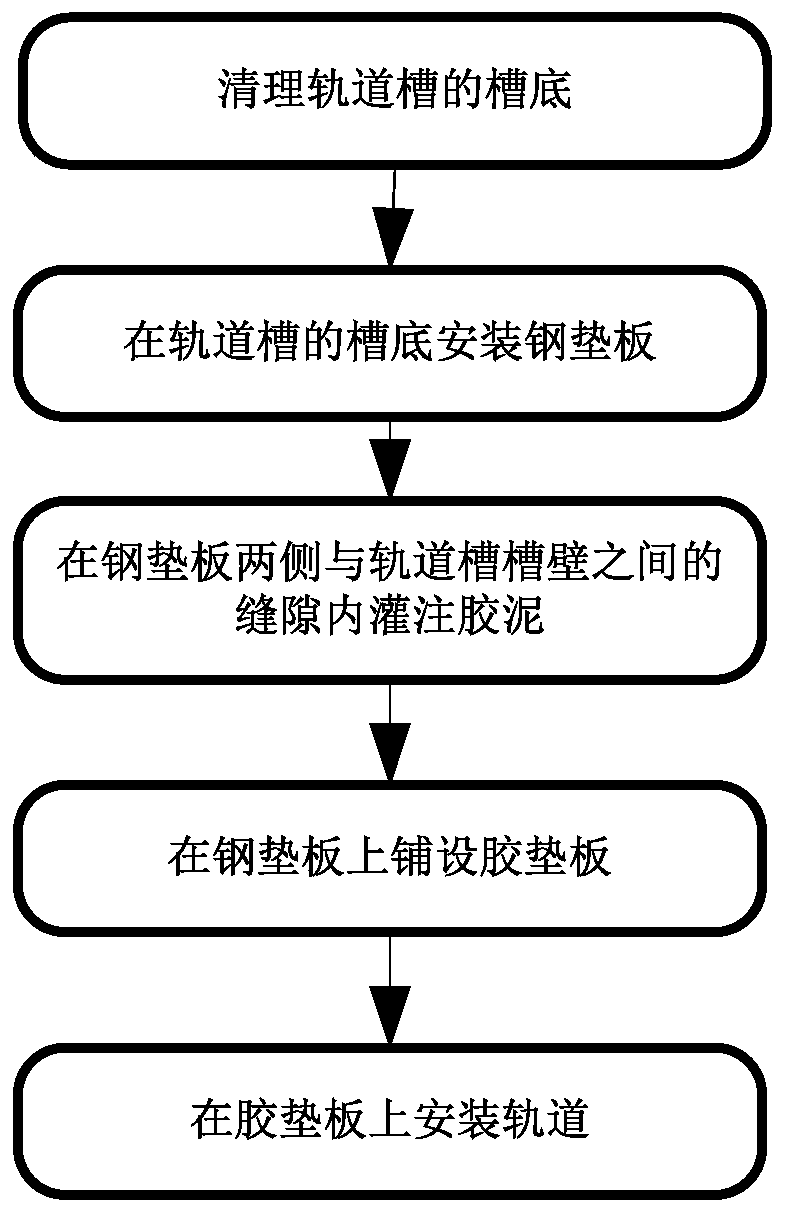

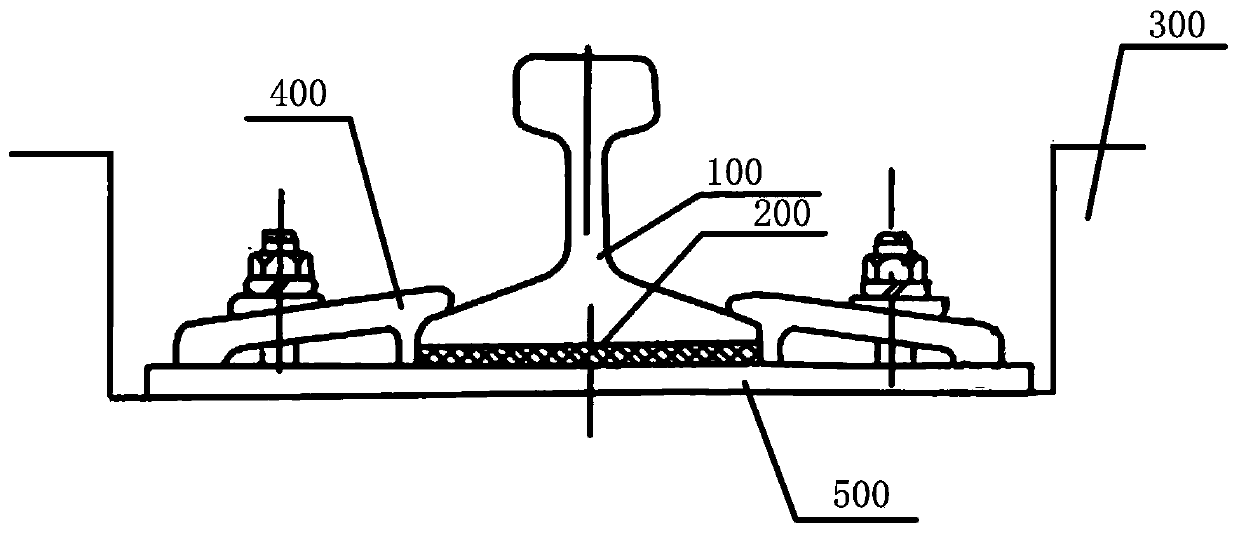

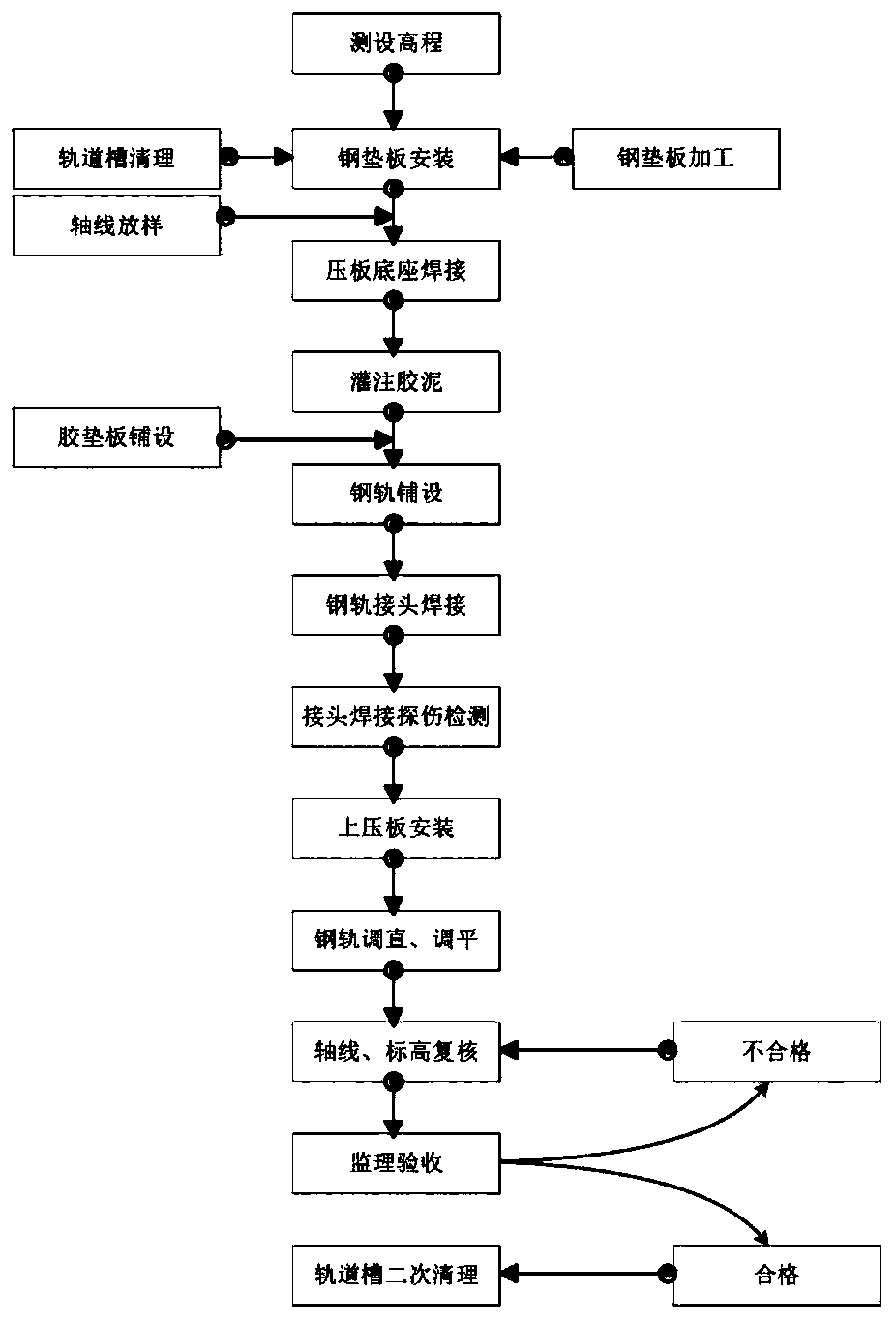

Dry dock track mounting method

InactiveCN111395073AGuaranteed installation qualityImprove stabilityDry-dockingMovable tracksTrackwayStructural engineering

The invention provides a dry dock track mounting method. The dry dock track mounting method comprises the steps that the groove bottom of a track groove is cleaned; a steel base plate is mounted at the bottom of the track groove; cement is poured into gaps between the two sides of the steel base plate and the groove wall of the track groove; a rubber base plate is laid on the steel base plate; anda track is arranged on the rubber base plate. On the premise of simplifying the track mounting process, the track mounting quality is guaranteed, and the track mounting stability and mounting efficiency are improved.

Owner:CCCC THIRD HARBOR ENG

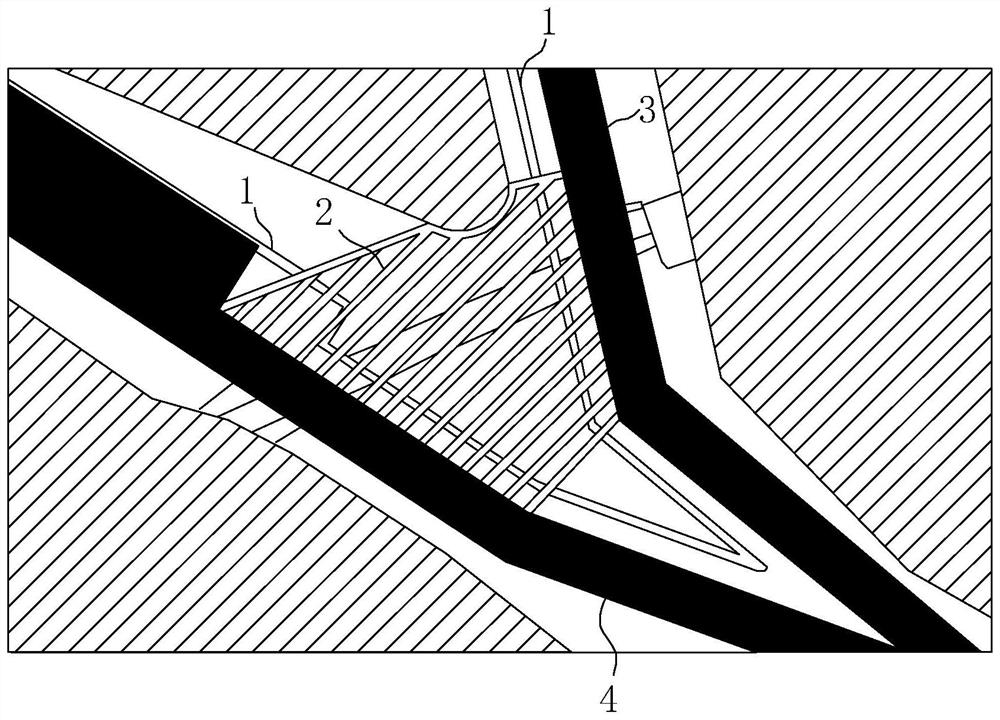

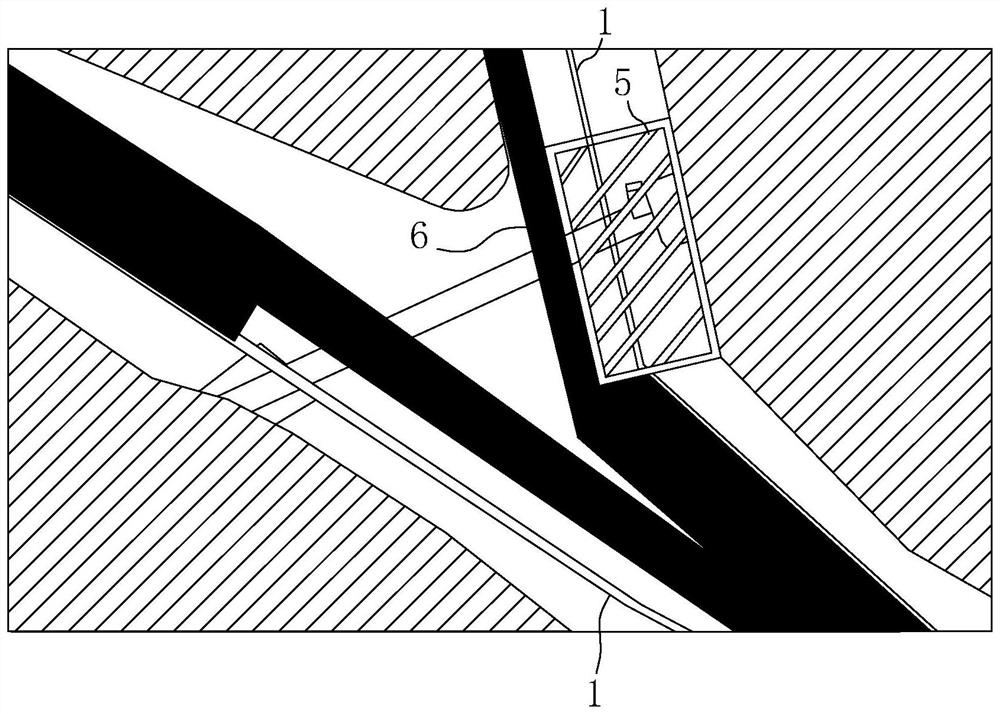

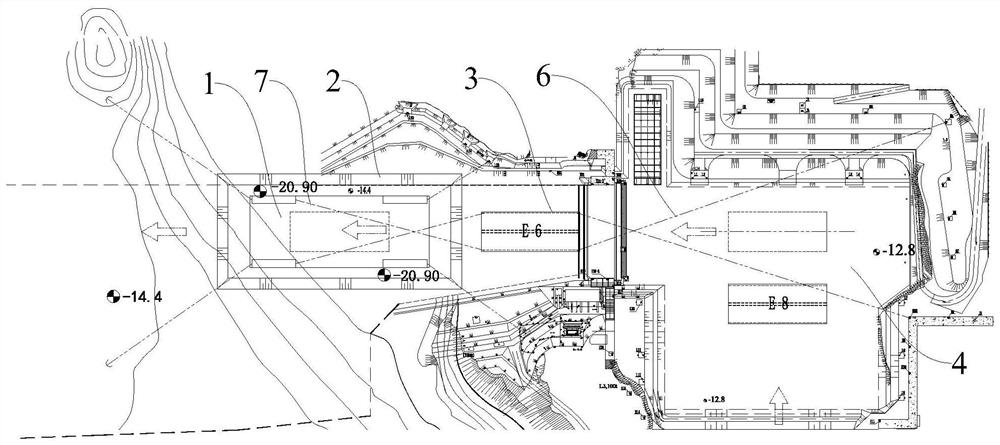

Dry dock arrangement method based on immersed tunnel crossing river

PendingCN114837226AReduce floating riskAvoid the problem of difficult site selectionArtificial islandsClimate change adaptationButt jointUnderwater

The invention provides a dry dock arrangement method based on an immersed tunnel crossing a centerline, which comprises the following steps of: taking a foundation trench excavated in the middle line of a tunnel line on the upper edge of the centerline as a dry dock prefabricated pipe joint, dragging a first batch of pipe joints out of the dock through dock gate hinges arranged at two ends of the foundation trench to carry out sinking butt joint, and prefabricating subsequent batches of pipe joints after a dock gate is recovered; and the last batch of pipe joints are foundation trench inner pipe joints, sinking butt joint is carried out through ground anchor hinge dragging, final joints are poured in an underwater joint mode, and finally construction of the immersed tunnel is completed. According to the method, a dry dock does not need to be independently built, the problem that the site selection difficulty of a different-place dry dock is large is solved, long-distance floating transportation is not needed, large-range channel dredging is avoided, the pipe section floating transportation risk is reduced, the project investment is greatly reduced, and meanwhile, the underwater final joint is adopted, and the problem that the construction period of a conventional axis dry dock is long is solved.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD +1

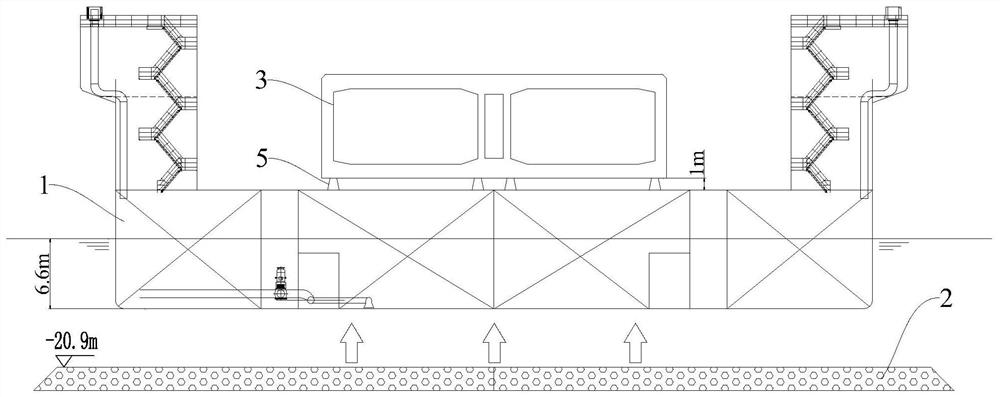

Immersed tube segment batch prefabricating method capable of reducing scale of dry dock

ActiveCN113638446ALight weightReduce draftArtificial islandsUnderwater structuresReinforced concreteImmersed tube

The invention relates to an immersed tube segment batch prefabricating method capable of reducing the scale of a dry dock. The method comprises the following steps that (1) in a small temporary dry dock, part of components of an immersed tube segment are prefabricated for the first time, the components comprising a bottom plate, part of a sidewall, a middle partition wall and sealing doors at two ends, an open type tube segment similar to a ship is formed, the dead weight of the tube segment is reduced as much as possible, and the draft depth of the tube segment is reduced as much as possible; (2) the tube segment is towed to the position near a tunnel site; (3) a prefabricated site without silt accumulation is selected in water and leveled, a plurality of uninflated air bags are immersed in the site and anchored to the river bottom, and the air bags are inflated; (4) the tube segment is slowly located on the inflated air bag structure; and (5) the rest part of the side wall and top plate reinforced concrete part of the tube segment are poured and constructed for the second time, and overall prefabrication of the immersed tube segment is completed. According to the immersed tube segment batch prefabricating method, the work amount is small, the influence on the environment is small, and the site area of the temporary dry dock, the foundation pit depth and the tube segment hauling difficulty can be effectively reduced.

Owner:CHINA RAILWAY TUNNEL SURVEY & DESIGN INST +1

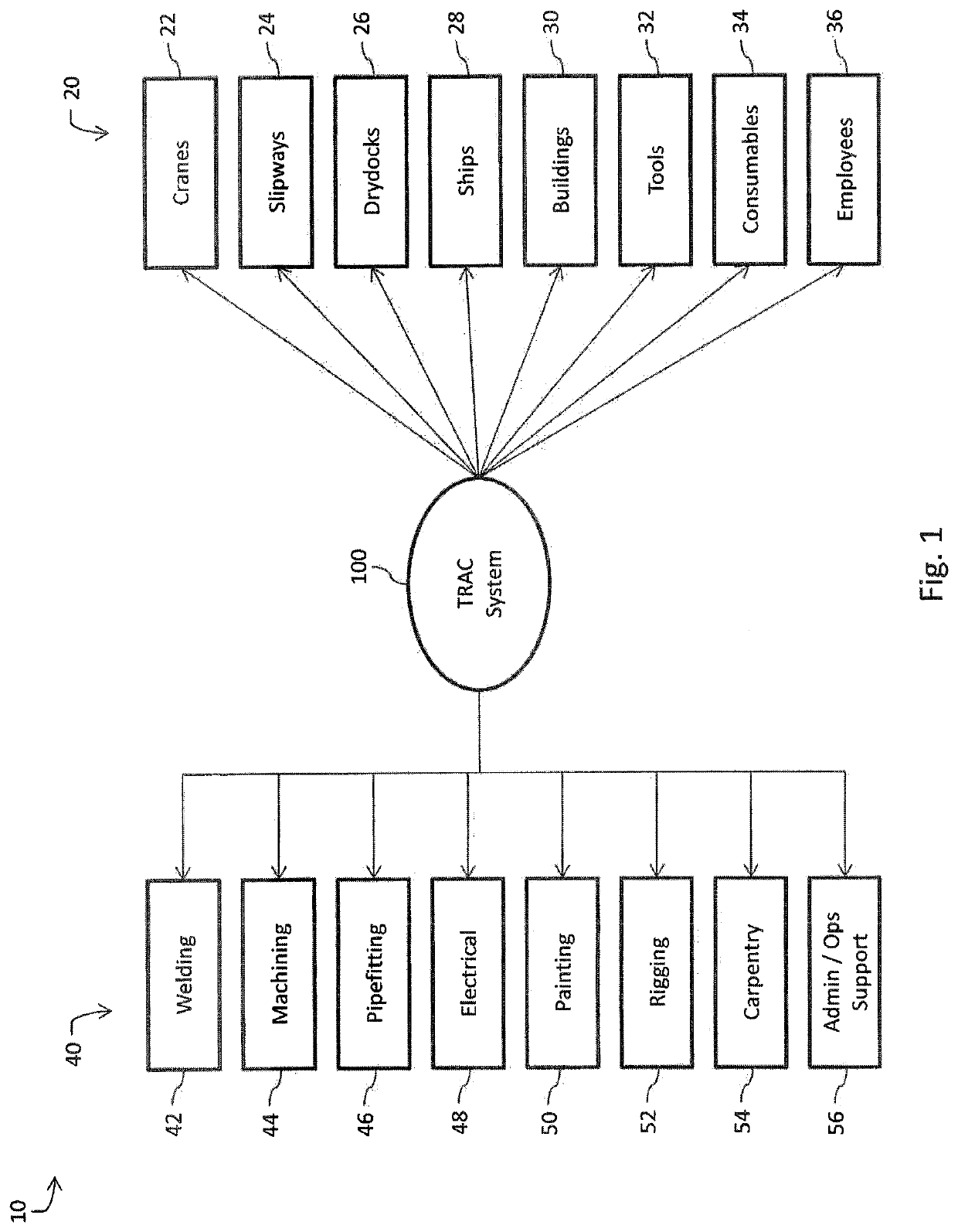

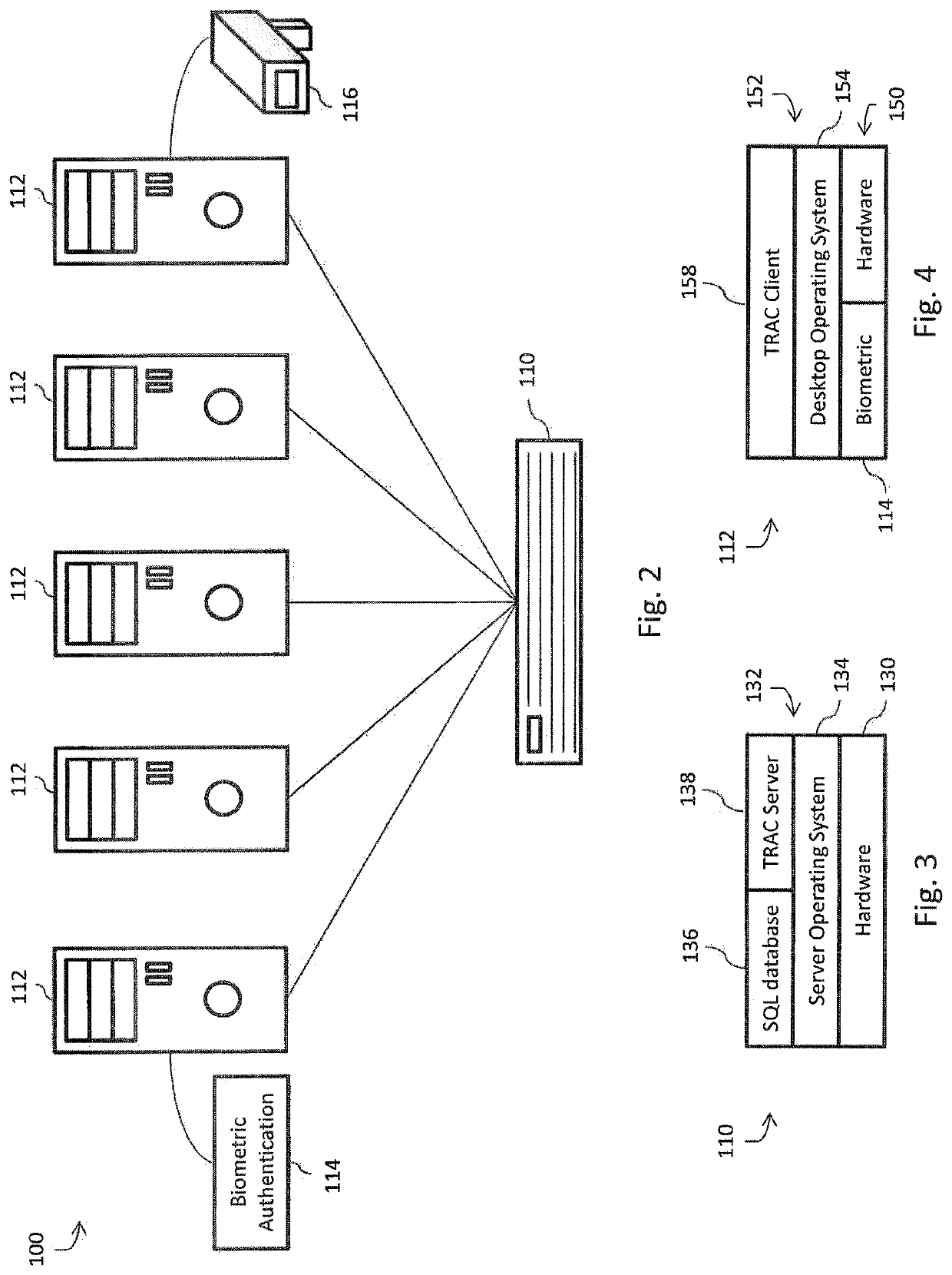

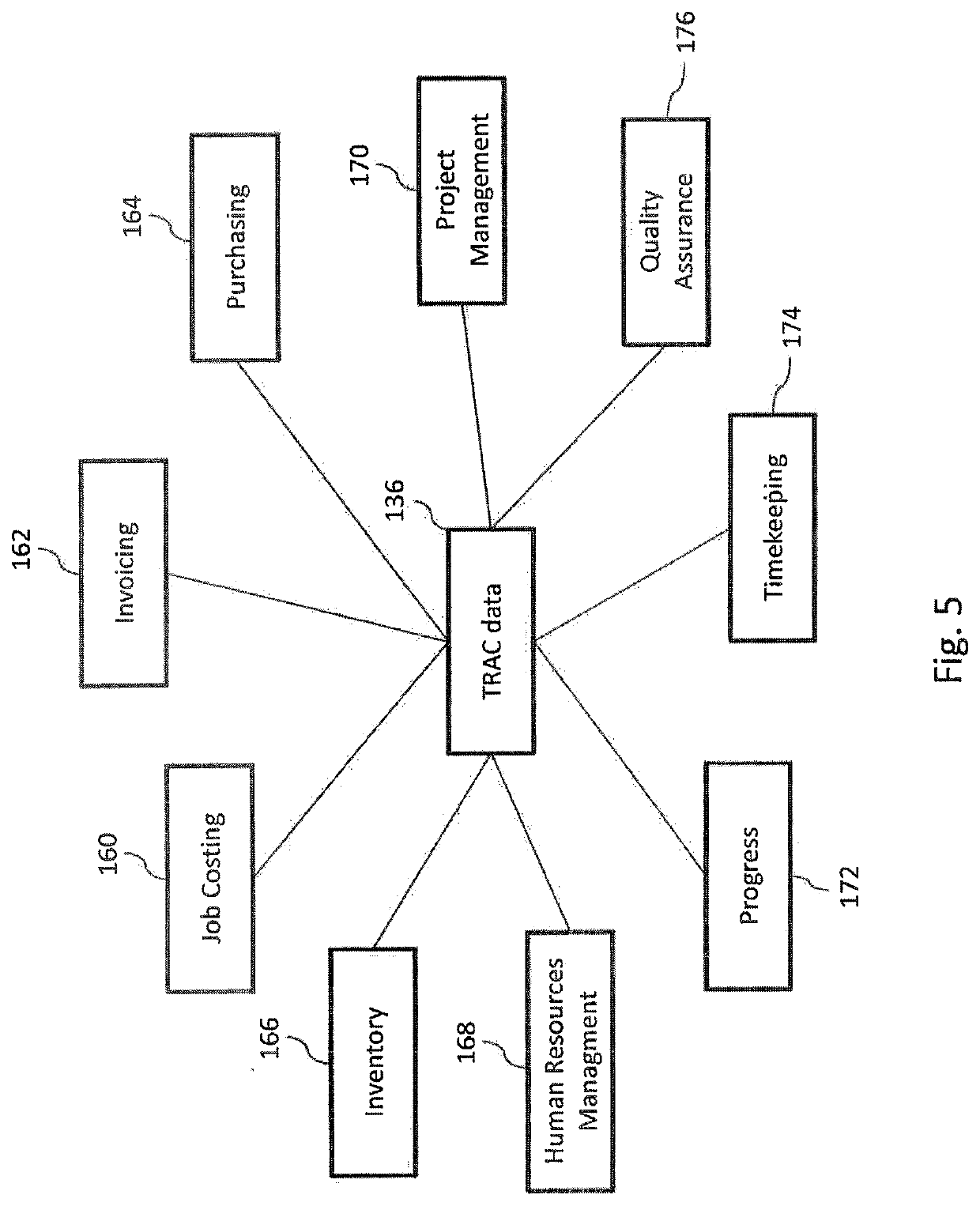

Auditable Networked Enterprise Oversight System

PendingUS20200118062A1Facilitating resource planningFacilitating oversightFinanceNetwork topologiesBusiness enterpriseConstruction engineering

Disclosed is an auditable networked shipyard capable of building and / or repairing ships with real-time progress and cost tracking, as well as instant and efficient auditability. The shipyard provides standard shipyard components such as cranes, drydocks or syncrolifts, tools, and consumable items such as paint and parts. The shipyard is configured to provide welding, machining, pipefitting, electrical, rigging, and other relevant functions for the building and / or repair of ships. In order to match resources to functions, track availability of resources, and generally oversee operations of the shipyard, a totally reliable auditable contracting enterprise resource planning system (“TRAC system”) is configured to allow real-time oversight of each work item on each job of a business in the ship repair or ship support industry. The TRAC system consolidates all business management and production functions into a single enterprise resource planning (“ERP”) system.

Owner:TRAC CONSULTING LLC

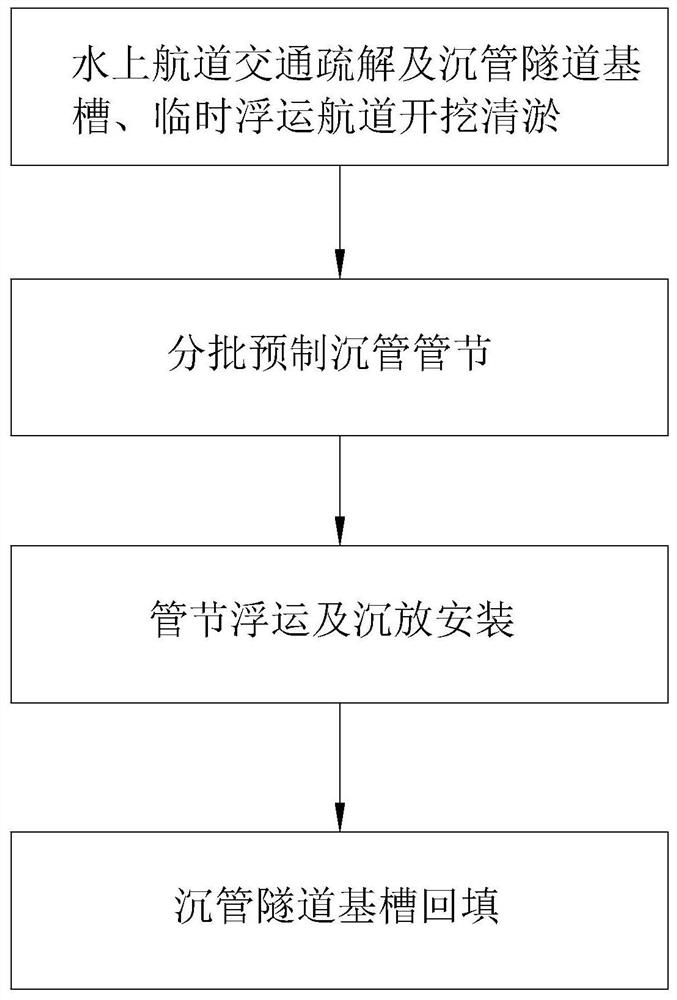

Offshore inland river intersection area immersed tube tunnel construction technology

ActiveCN113585345ALess impact due to limited navigationSmooth navigationArtificial islandsExcavationsRiver routingWater transport

The invention discloses an offshore inland river intersection area immersed tube tunnel construction technology. The offshore inland river intersection area immersed tube tunnel construction technology comprises the following steps that S1, water channel traffic reconciliation and immersed tube tunnel foundation trench excavation and desilting construction are carried out, the immersed tube tunnel foundation trench is excavated and constructed stage by stage, and smooth navigation of at least one side of a water channel is kept; S2, immersed tube joints are prefabricated in a river bank dry dock in batches; S3, floating transportation and sinking installation construction of immersed tube joints are carried out; and S4, immersed tunnel foundation trench backfilling construction is carried out. The problem of navigation coordination of all the river channels in the river intersection area is solved, foundation trench staged construction is carried out according to the floating transportation scheme and the water transportation condition, smooth navigation of at least one side channel is kept during foundation trench construction in each stage, so that the influence of construction on navigation of all the river channels in the river intersection area is effectively reduced, and the river channels can still be kept in a normal navigation state; and in addition, the pipe joints are prefabricated, subjected to floating transportation and sinking, and installed in batches, and the construction efficiency is effectively improved.

Owner:CENT SOUTH UNIV +1

Device and method for manufacturing immersed tube tunnel pipe section without dry dock and using hydraulic jacking

The invention discloses a device and a method for manufacturing an immersed tube tunnel pipe section without a dry dock and using hydraulic jacking. The device comprises a dry dock-free pipe section prefabrication platform, a wharf and a transportation immersion ship which are sequentially connected; the dry dock-free pipe section prefabrication platform comprises a middle flat prefabricated platform, a plurality of flat prefabricated platforms on two sides, a bottom steel plate, rail beams and stiffening beams; the middle flat prefabricated platform is connected with the wharf through a sliding rail arranged on a parallel water front and is used for transporting the pipe section onto the transportation immersion ship through the wharf; the plurality of flat prefabricated platforms on twosides are separately arranged on the two sides of the middle flat prefabricated platform, are arranged perpendicular to the middle flat prefabricated platform, and are used for conveying the pipe section to the middle flat prefabricated platform; and a plurality of rows of rail beams and a plurality of rows of stiffening beams are arranged perpendicular to each other to form a rectangular dry dock-free pipe section prefabrication platform. According to the device and the method, different from the conventional mode that after a large foundation pit is excavated in a dry dock, the pipe sectionis subjected to flotation conveying after water injection, a single section of an immersed tube tunnel pipe section main body structure is poured on flat ground, and the sliding rail and a hydraulic jacking device are used as land area transport carriers of the pipe section, so that the transition from the land area to the water area is completed.

Owner:CHINA RAILWAY TUNNEL SURVEY & DESIGN INST +1

Factory prefabricated construction method for immersed tube joints

ActiveCN113635439AWide range of adaptabilityEasy constructionShaping reinforcementsArchitectural engineeringImmersed tube

The invention discloses a factory prefabricated construction method for immersed tube joints. The method is characterized in that a steel bar binding area, a tube joint pouring area and 2-4 one-time outfitting areas are arranged on a construction site, an immersed tube joint bottom plate and a side wall steel reinforcement cage are bound and formed in the steel bar binding area and then transferred to the tube joint pouring area through a hydraulic traveling car and a steel bar binding moving trolley, full-section integral mass concrete sequential pouring construction is conducted on a plurality of pouring sections in the tube joint pouring area, and the concrete is moved from the tube joint pouring area to a primary outfitting area by adopting the hydraulic traveling car for subsequent construction after the concrete reaches the strength. Compared with traditional dry dock tube joint prefabricated construction, factory prefabricated construction of the method has the advantages that interval-free flow construction of all subareas and procedures is achieved, the prefabricated construction period of the tube joints is short, construction is convenient, safety is good, quality control of the immersed tubes is facilitated, and referential experience is provided for later factory prefabricated construction of the immersed tubes.

Owner:中铁十八局集团第五工程有限公司 +1

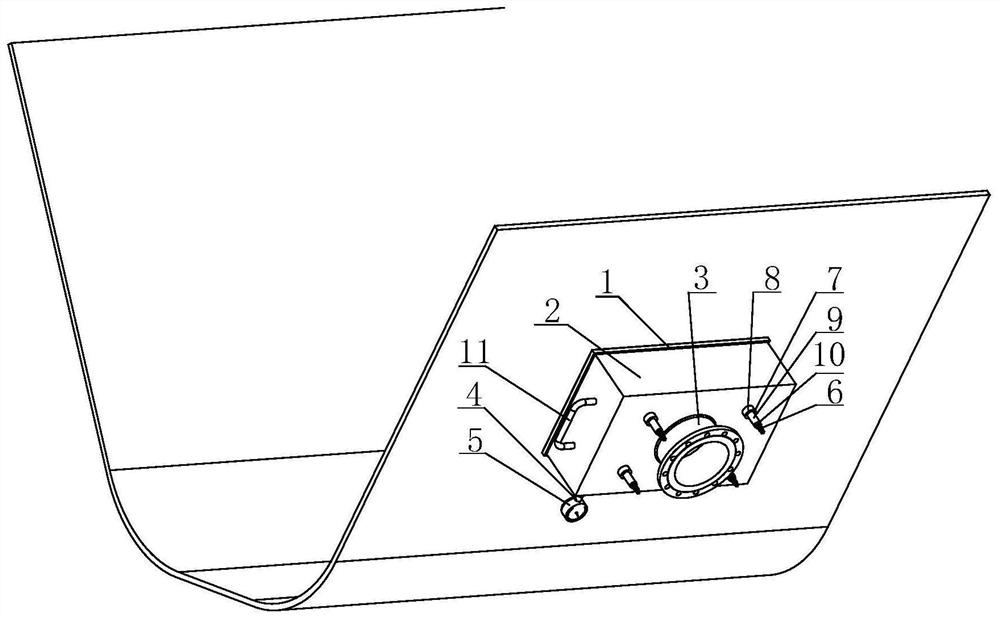

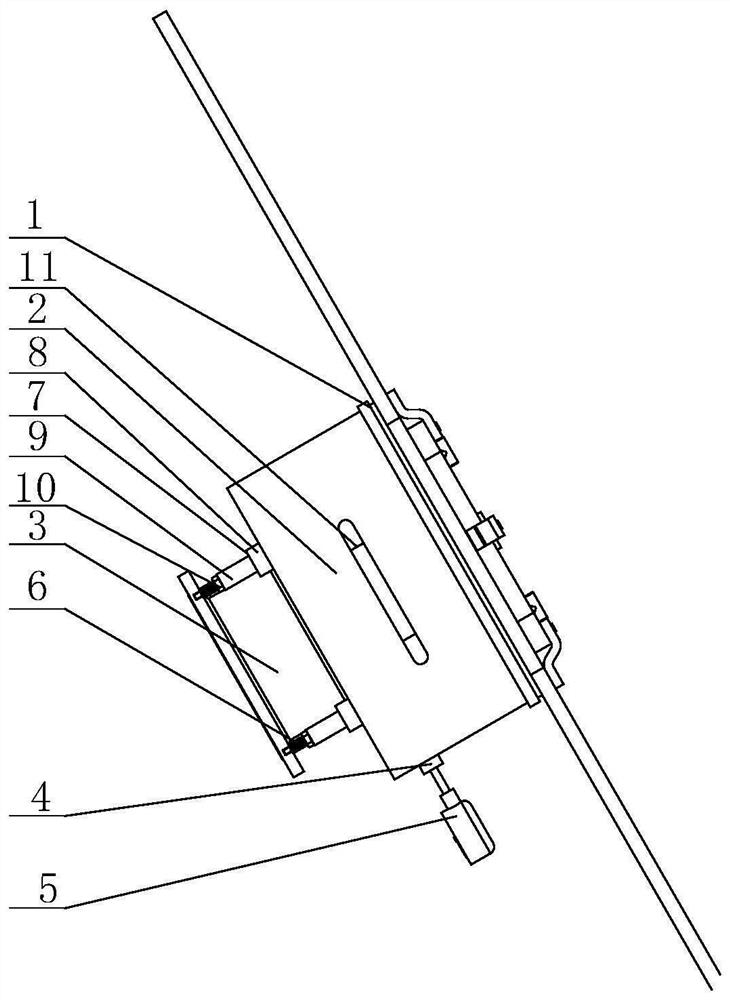

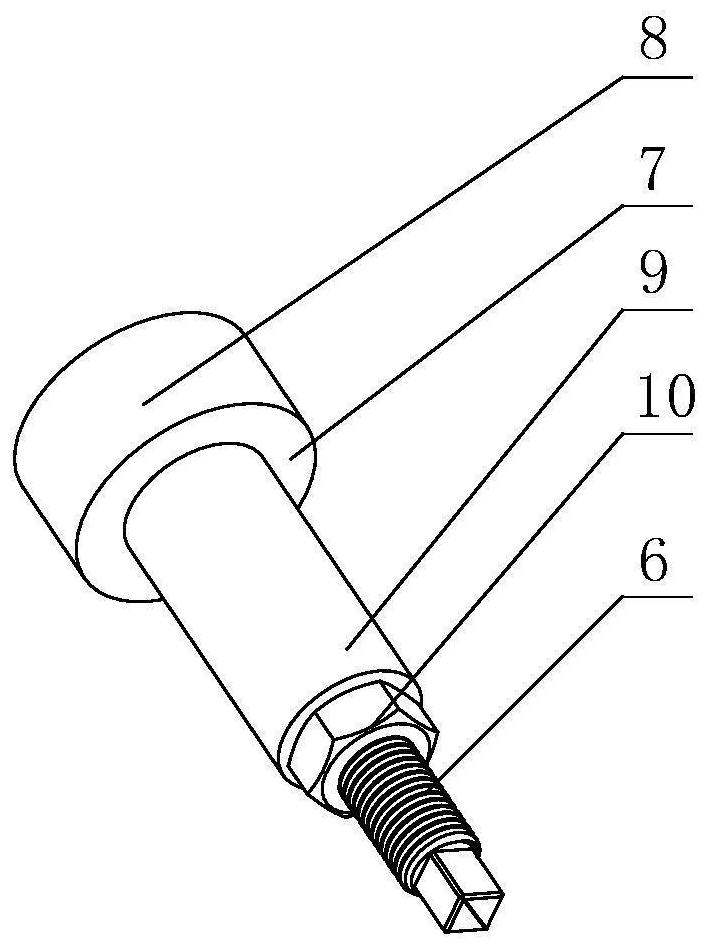

Sea chest rapid water supply device during ship dry dock

InactiveCN112389583AShorten the construction periodImprove performanceVessel partsStructural engineeringBiology

The invention provides a sea chest rapid water supply device during ship dry dock period. The device comprises a water supply valve box arranged on a sea chest, a plurality of connecting pull rods penetrating into the water supply valve box are arranged on the water supply valve box, the inner ends of the connecting pull rods are arranged in a T-shaped state and hooked on the edge opening of the sea chest, and nuts are arranged at the outer ends of the connecting pull rods. The water supply valve box is fixed on the sea chest through nuts. The sea chest rapid water supply device has the beneficial effects of being stable in performance, convenient to operate and implement and capable of meeting the water supply requirement for normal operation and use of ship equipment and a system of a ship in the dry dock period; meanwhile, the technical defects that in a traditional construction method, many types of work are involved, procedures are complex, the labor input is large, the period islong, and ship body outer plate base metal damage is caused to a certain degree can be effectively overcome, production cost saving, labor efficiency improving and product construction quality improving are facilitated, and the construction period of ships in dock engineering is shortened.

Owner:JIANGNAN SHIPYARD GRP CO LTD

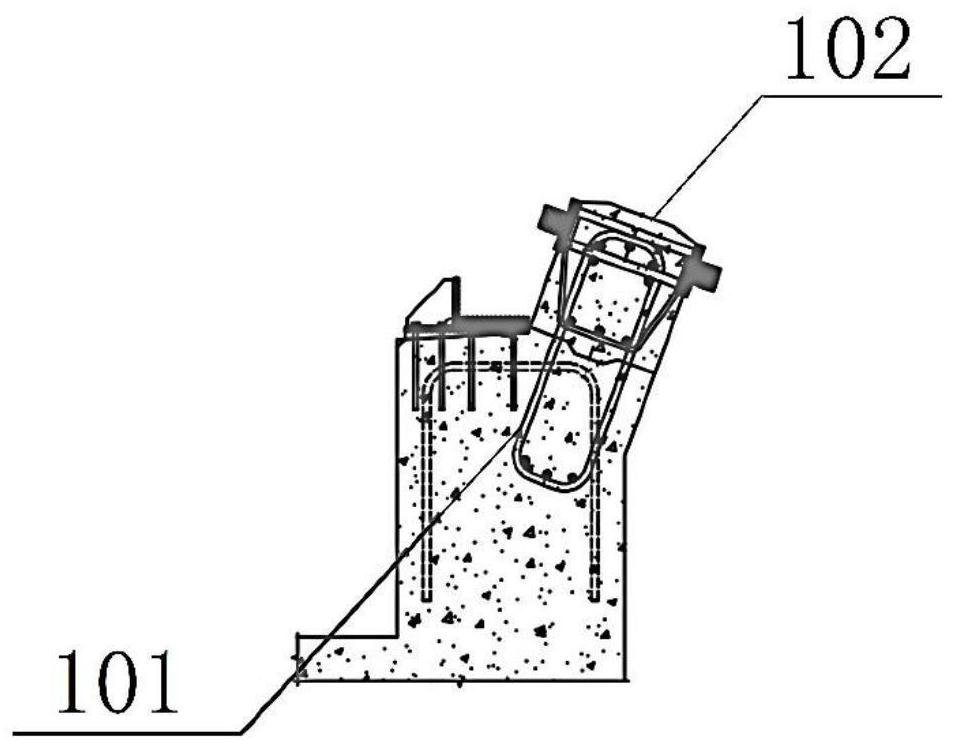

Immersed tube floating-state barge-up method

ActiveCN113911271AWork around site constraintsEasy to operateCaissonsBarges/lightersImmersed tubeDry dock

The invention relates to the technical field of immersed tube transportation, and discloses an immersed tube floating-state barge-up method which comprises the following steps: A, constructing a submerged bottom sitting area of a semi-submersible barge, and arranging a buttress system on the semi-submersible barge; b, operating the semi-submersible barge to dive and sit on the bottom, and floating the immersed tube in the dry dock; c, after the semi-submersible barge sits on the bottom, transporting the immersed tube to the position over the buttress system in a floating mode; and D, positioning and mooring the semi-submersible barge and the immersed tube, operating the semi-submersible barge to drain and float, supporting the immersed tube by the buttress system, supporting the immersed tube out of the water surface, and completing the barge-up work of the immersed tube. According to the immersed tube floating-state barge-up method, immersed tube barge-up can be completed through floating transportation, site limitation of construction of the barge-up wharf is avoided, transportation through the barge-up wharf, the rail and the trolley is not needed, immersed tube barge-up operation is easy, and the construction cost is also controlled.

Owner:CCCC FOURTH HARBOR ENG CO LTD

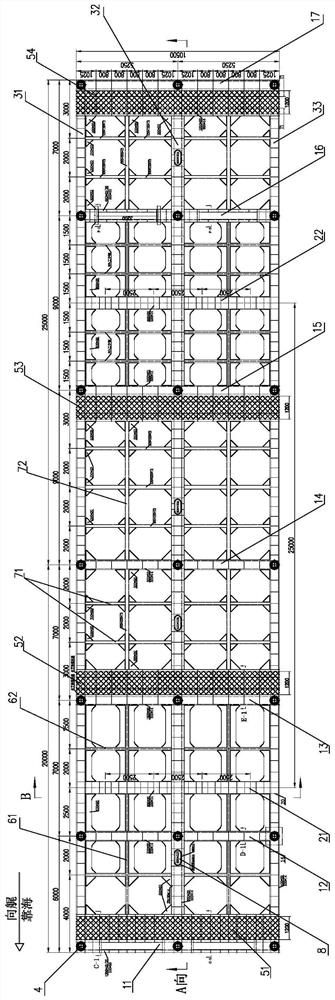

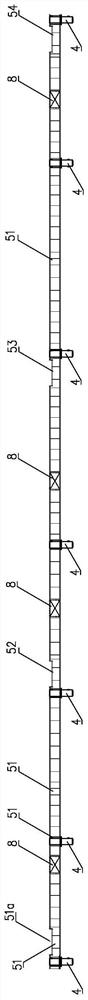

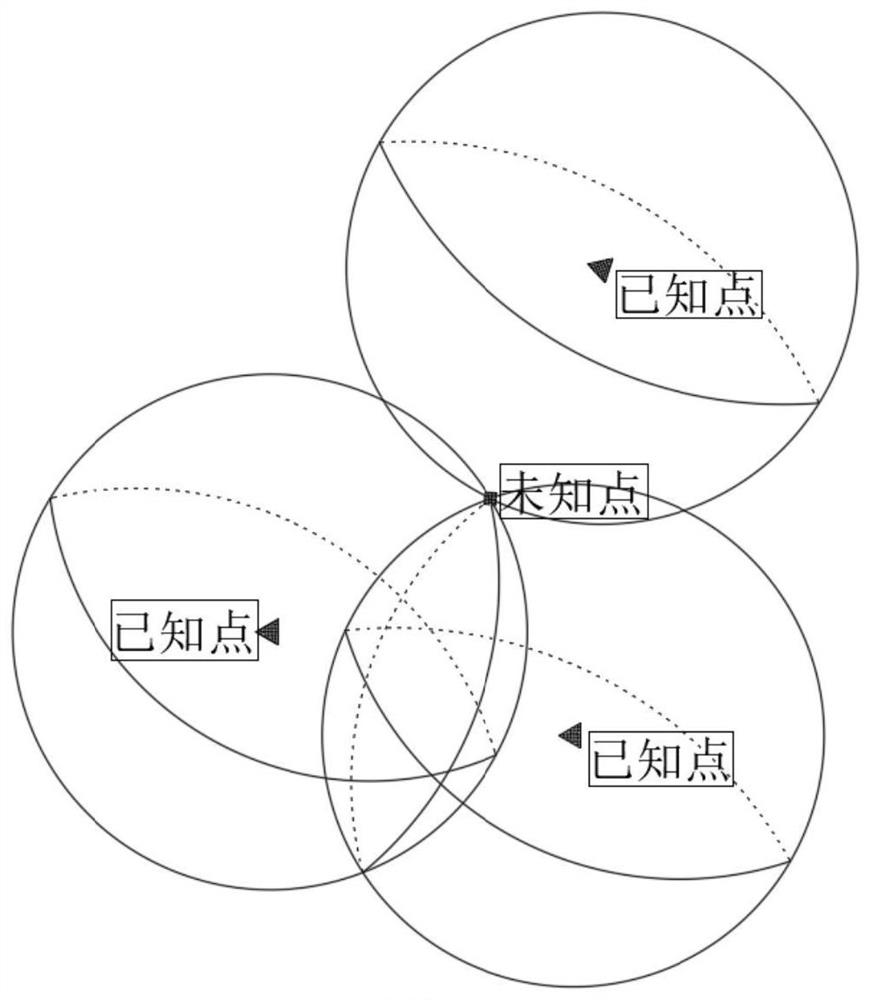

Mobile dry dock prefabricated immersed tube joint measuring method

The invention discloses a mobile dry dock prefabricated immersed tube joint measuring method. The method comprises the steps of S1 establishing a measurement plane above a deck surface of a mobile dry dock, and enabling the measurement plane to be parallel to the deck surface; S2 establishing a plurality of main control points on the deck surface, the main control points being located on the outer side of the projection of an immersed tube joint needing to be prefabricated on the deck surface, and arranging a main observation station at the main control points based on the measurement plane; and S3 placing an adjusted theodolite on the main observation station, and measuring the prefabricated immersed tube joint through the theodolite based on the measurement plane. According to the movable dry dock prefabricated immersed tube joint measuring method, the immersed tube joint can be accurately measured in the process of prefabricating the immersed tube joint.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

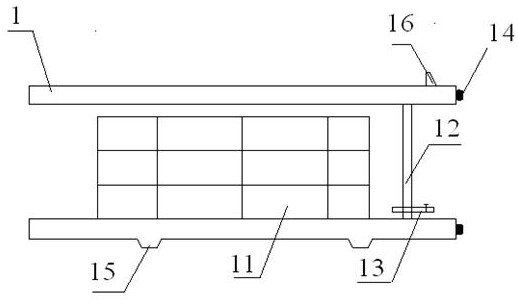

Slipway and ship transfer method

The invention provides a slipway and a ship transfer method, and belongs to the technical field of ships, the slipway comprises a frame body with an upper surface for berthing of a ship, a connecting structure matched with a carrying device and detachably or movably connected, and a lifting mechanism for lifting the frame body and the ship on the frame body together. By applying the slipway, the ship can be stably transferred to the shore without deformation, the operation cost can be greatly reduced, damage to natural ecology due to construction of a dry dock and use of a floating dock is avoided, and the slipway is economical, environmentally friendly, low in energy consumption and practical.

Owner:浙江华航实业有限公司

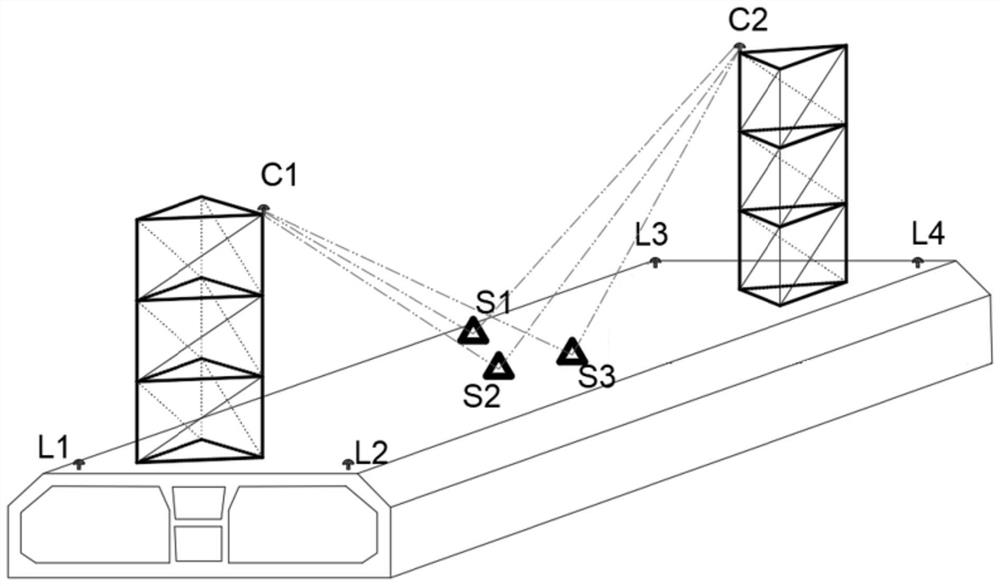

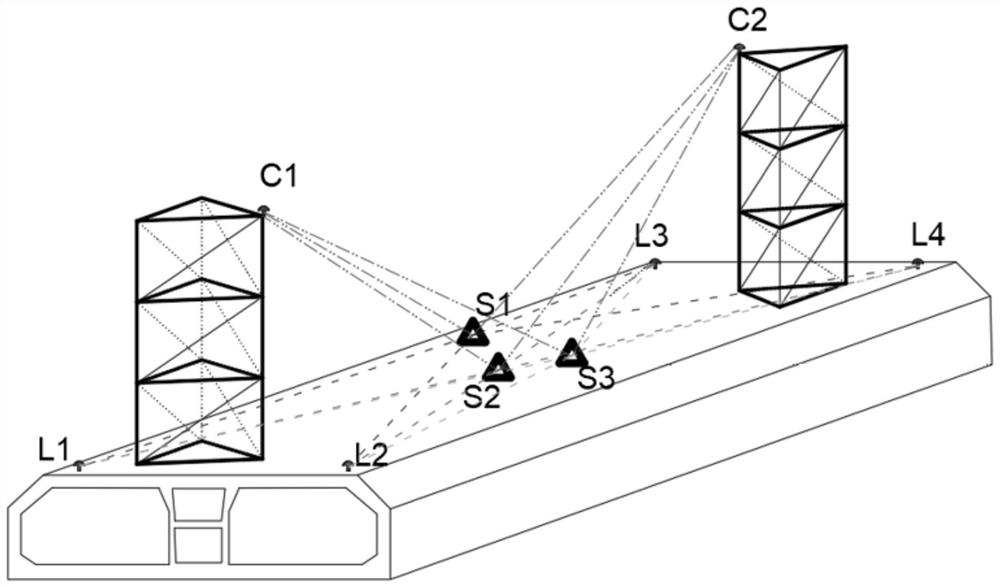

Immersed tube joint floating condition calibration method

PendingCN114858108AImprove the installation accuracy of sinkingLow costMeasurement devicesComplex mathematical operationsClassical mechanicsEngineering

The invention belongs to the technical field of engineering measurement, and relates to an immersed tube joint floating state calibration method. The floating state calibration method comprises the steps that a pipe joint coordinate system is established in a dry dock area, at least three non-collinear pipe top middle section feature points are arranged on the middle section of the top face of a pipe joint, and three-dimensional coordinates of the non-collinear pipe top middle section feature points in the pipe joint coordinate system are calibrated; the pipe joint is moved to an outfitting area, the head end and the tail end of the top face of the pipe joint are each provided with a measuring tower, tower top feature points are arranged, the spatial distances between the three pipe top middle section feature points and the two tower top feature points are measured, the three-dimensional coordinates of the three pipe top middle section feature points in a pipe joint coordinate system are combined, calculation is carried out through a spatial distance intersection method, and the three-dimensional coordinates of the three pipe top middle section feature points in the pipe joint coordinate system are calculated. And three-dimensional coordinates of the two tower top feature points in the pipe joint coordinate system are obtained. The method is easy to operate, calibration of the tower top feature points of the measuring tower can be completed only through distance measurement, the problem that the floating state calibration precision is poor due to the fact that an existing pipe joint calibration method is affected by posture changes when the pipe joint floats is solved, and the measurement calibration cost and difficulty are reduced.

Owner:CCCC FIRST HARBOR ENG +1

Dry-dock-free underwater shallow-buried open-cut large channel basic structure unit and construction method

ActiveCN112982476AReduce the difficulty of site selectionAvoid influenceArtificial islandsUnderwater structuresAir volumeMarine engineering

The invention relates to a dry-dock-free underwater shallow-buried open-cut large channel basic structure unit and a construction method. The basic structure unit used in the method has the following characteristics that the length of each basic structure unit is 20-25m, a sealing door is arranged at one end of each basic structure unit, the other end of each basic structure unit is of an open structure, and a drainage pressure relief valve is arranged at the lower end of each sealing door; a rubber water stop belt is arranged at the end of each basic structure unit in a surrounding mode, and a floating and ballasting cabin capable of adjusting the water inlet and drainage capacity is fixed in each basic structure unit; and at least four axis positioning foot stands are arranged at the bottom of each basic structure unit. The channel basic structure unit can be directly prefabricated on the flat ground, a large temporary dry dock does not need to be built, the temporary engineering investment is reduced, the manufacturing cost of an underwater channel is reduced, and the construction period of the underwater channel is shortened; and the basic structure unit can slide into a water area from a land area through a slideway, the basic structure unit is kept in a suspended state in water by adjusting the air volume in the floating and ballasting cabin, the basic structure unit is pulled and sunk by a floating crane ship, the construction efficiency is improved, and the water construction difficulty is reduced.

Owner:CHINA RAILWAY LIUYUAN GRP CO LTD +1

Construction method of prestressed immersed tunnel pipe joint

InactiveCN112942428AIncreased durabilityEasy to pourArtificial islandsUnderwater structuresReinforced concretePre stress

The invention provides a construction method of a prestressed immersed tunnel pipe joint. The construction method comprises the following steps of: binding pipe joint bottom plate steel bars in a dry dock, laying prestressed tensioned sleeves and steel strands, and pouring pipe joint bottom plate concrete; constructing pipe joint side wall and middle partition wall reinforced concrete; binding pipe joint top plate steel bars, laying prestressed tensioned sleeves and steel strands, and pouring top plate concrete; constructing door sealing structures at two ends of the pipe joint; locking the steel strands in anchoring ends on the pipe joint side walls, after the strength of the pipe joint concrete reaches a design value, horizontally tensioning the steel strands of the top plate and the bottom plate at the middle partition wall from the tensioning ends, and after the steel strands reach a tensioning preset value, locking the steel strands; grouting in the embedded sleeves, blocking the sleeves, and blocking anchorage device hand holes; and constructing a pipe joint outer waterproof layer, floating the pipe joint in the dry dock, mounting fitting-out components, and preparing pipe joint floating transportation. The construction method is suitable for reinforced concrete pipe joints with larger spans, and the adaptability of an immersed tunnel is enhanced; and the durability of the pipe joint can be improved, and the total construction cost of the immersed tunnel can be greatly reduced.

Owner:CHINA RAILWAY TUNNEL SURVEY & DESIGN INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com