Method for building ship on ground and launching ship using skid launching system

A slideway and ground technology, used in slipway, dry dock, ship construction, etc., can solve the problems of waste, inability to guarantee a constant ship order volume, and high operating costs in dry dock.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

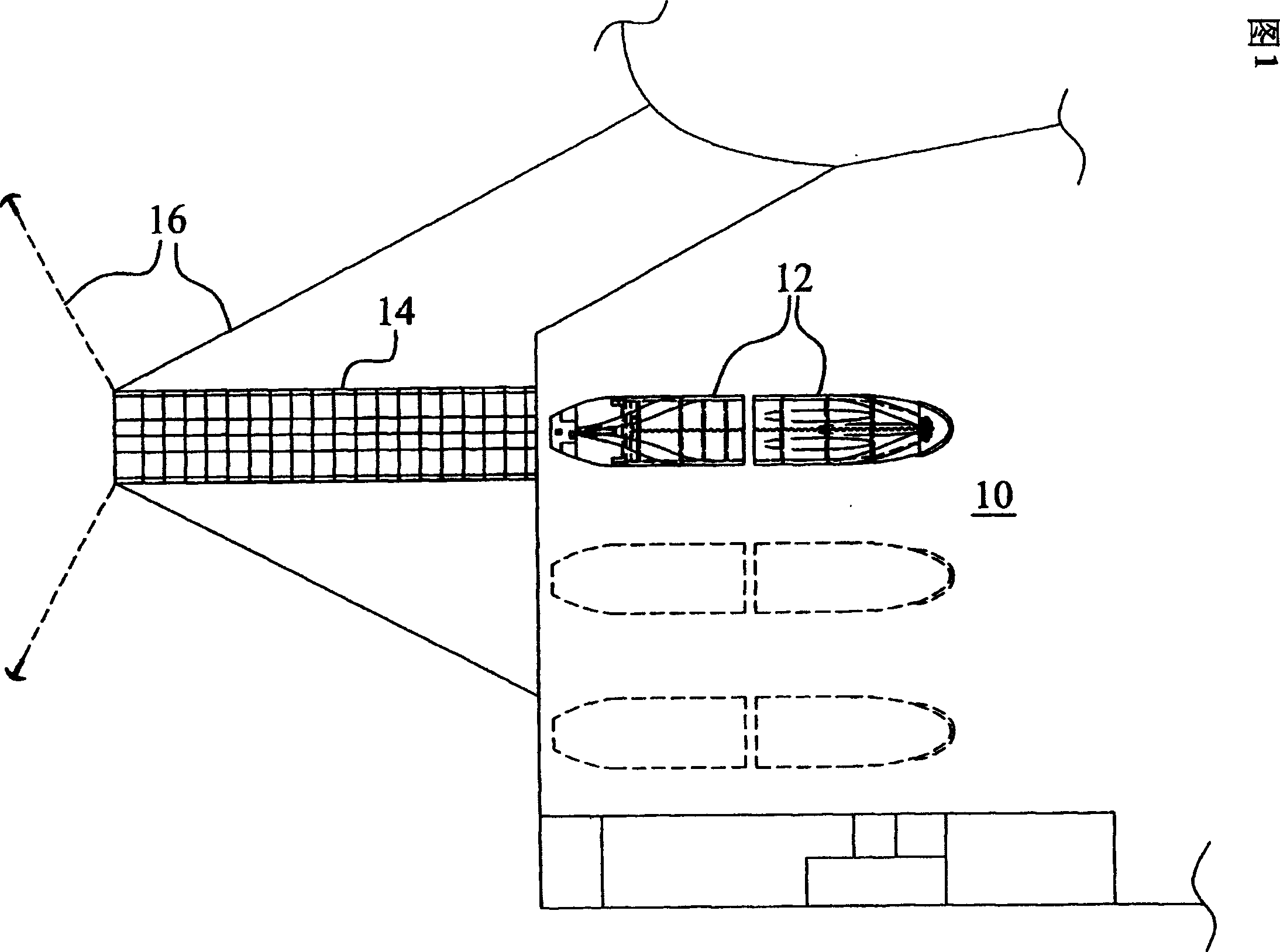

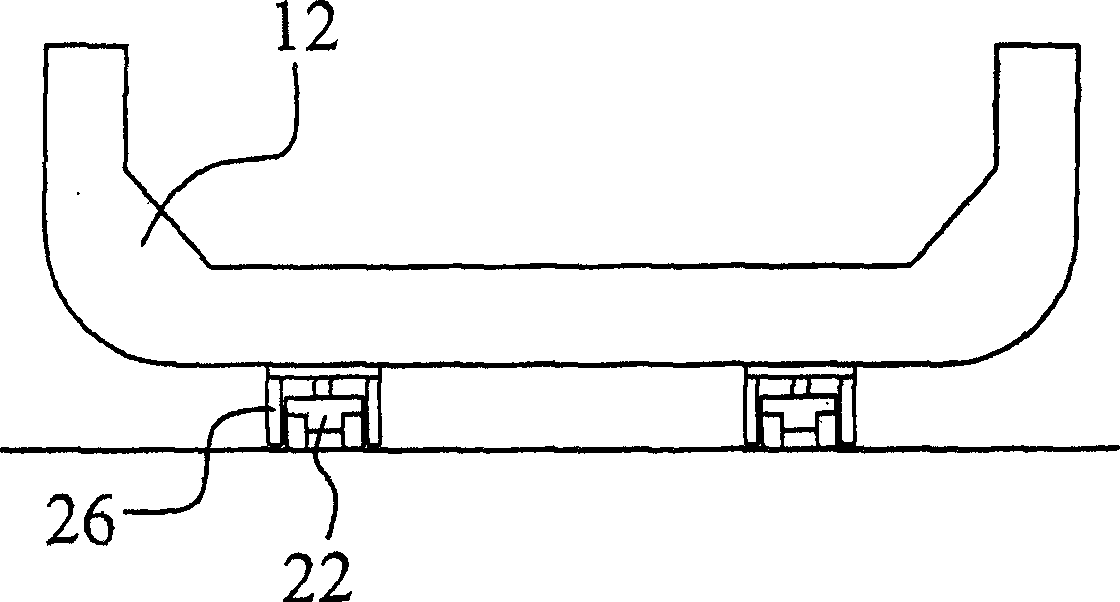

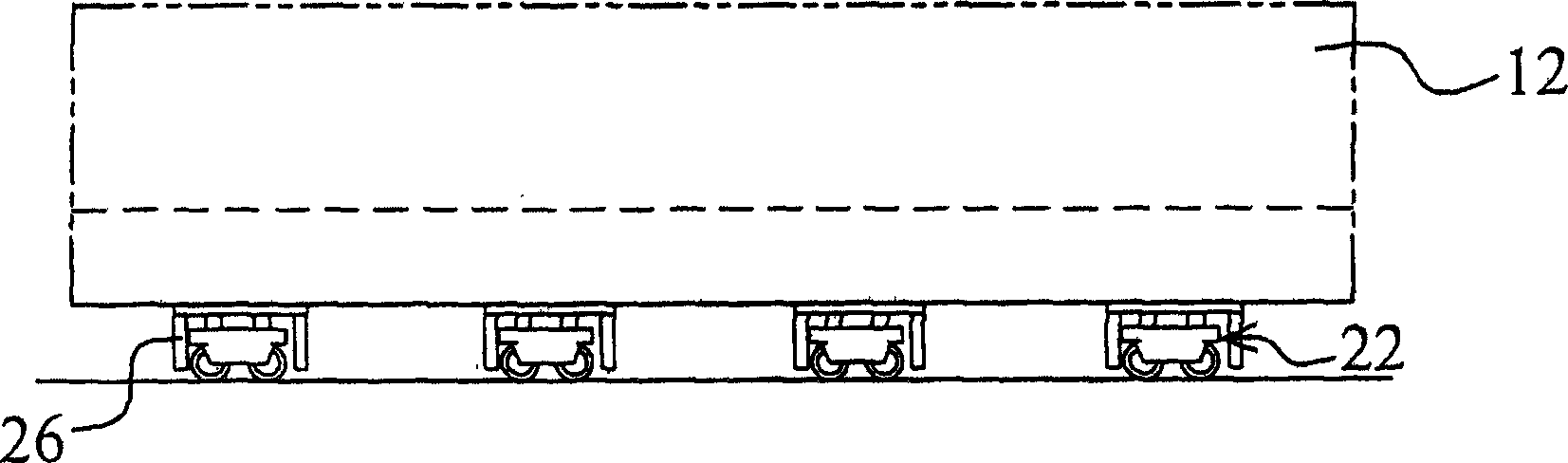

[0024] Fig. 1 is a conceptual top view schematically showing a method of building and launching a ship according to the present invention. The unit blocks manufactured in the individual hull production processes are transported to the hull section assembly point 10 and assembled by welding into hull sections 12 for each part of the hull. As shown in Figure 1, the unit blocks are assembled into two hull sections, eg a bow section and a stern section. However, the number of hull sections can be increased to 2 to 4 if desired. 2 to 4 hull sections simplifies transportation and increases utilization of hull section assembly points, thereby increasing productivity of ship construction. In other words, when the hull sections 12 of each part of the ship are assembled at the hull section assembly point 10, the assembled hull sections are transported to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com