Factory prefabricated construction method for immersed tube joints

A construction method and factory-like technology, applied in the field of factory prefabrication of immersed pipe sections, can solve the problems of difficult crack control of concrete, difficult prefabrication of curved pipe sections, large factory area, etc. The effect of space utilization and increased prefabrication cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

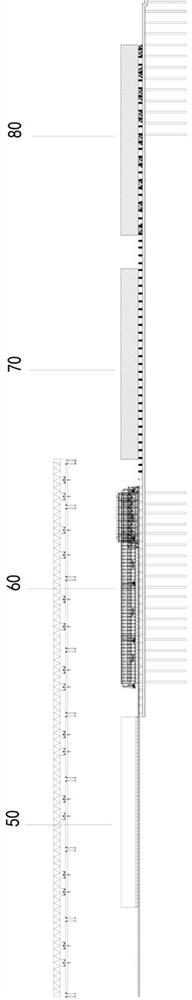

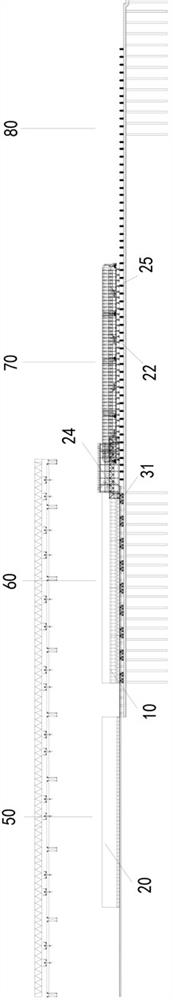

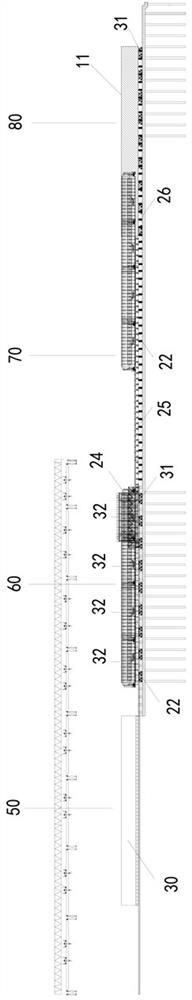

[0059] The section of the immersed tube tunnel in this embodiment adopts the scheme of two holes and one pipe gallery. The main line of the standard road section adopts two-way 6 lanes. The total length of the tunnel is 935m. 85m. The width of the immersed pipe section is 30.6m, the height is 8.9m, the thickness of the top and bottom plates of the pipe section structure is 1.2m, the thickness of the side wall is 1m, and the thickness of the partition wall is 0.6m. A single pipe section is divided into 4 pouring sections along the longitudinal direction of the pipe section. The section is about 21.25m long.

[0060] A single pipe joint adopts an immersed pipe joint factory prefabrication method according to the present invention, and the specific construction steps are as follows:

[0061] The ground prefabrication factory adopts a vertical line-shaped production line layout, according to the following figure 1 The layout of the industrialized site of immersed tube joints sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com