Polycarboxylic acid high-slump-retaining zero-bleeding high-performance water reducing agent

A technology of polycarboxylic acid series and water reducing agent, which is applied in the fields of high performance concrete, ultra-high strength concrete, self-compacting concrete, polycarboxylic acid series high performance water reducing agent with high slump retention and zero bleeding, and can solve the problems of low energy consumption and so on. , to achieve the effect of improving later strength, improving workability, and high water reduction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

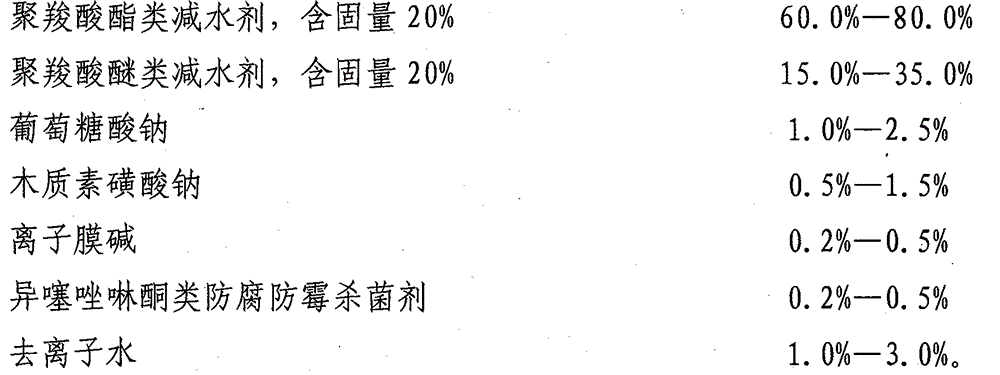

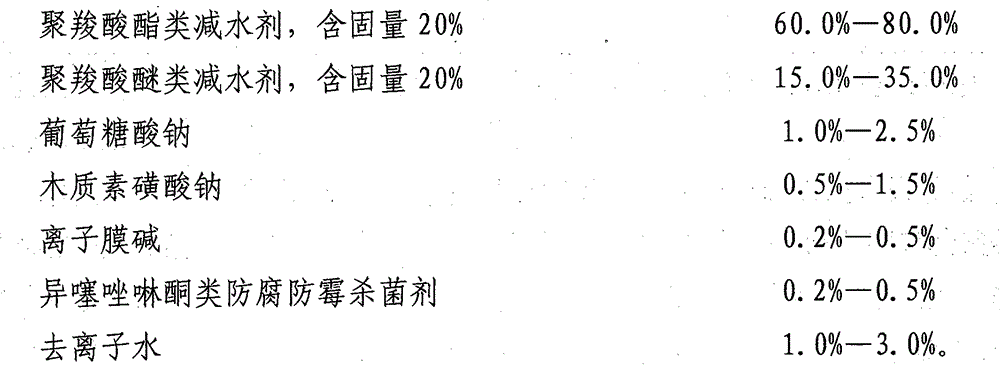

[0017] Example 1: Add 1.9kg of deionized water with the above composition and ratio into the reaction pot and raise the temperature to 30°C-50°C, add 60kg of polycarboxylate water reducer, and add 35kg of polycarboxylate ether type water reducer , keep the temperature, add 1.0kg of sodium gluconate and 1.5kg of sodium lignosulfonate as activators, and stir for 30 minutes to form a synthetic product with a specific structure. After cooling to normal temperature, add 0.3kg of ion-exchange membrane alkali to adjust the pH, add 0.3kg of anti-corrosion, anti-mildew and fungicide and continue to stir for 30 minutes, which is the finished product.

Embodiment 2

[0018] Example 2: Add 1.6kg of deionized water with the above composition and ratio into the reaction pot and raise the temperature to 30°C-50°C, add 60kg of polycarboxylate water reducer, and add 35kg of polycarboxylate water reducer , keep the temperature, add 2.0kg of sodium gluconate and 0.5kg of sodium lignosulfonate as activators, and stir for 30 minutes to form a synthetic product with a specific structure. After cooling to normal temperature, add 0.5kg of ion-exchange membrane alkali to adjust the pH, add 0.4kg of anti-corrosion, anti-mildew and fungicide, and continue stirring for 30 minutes to obtain the finished product.

Embodiment 3

[0019] Example 3: Add 1.8kg of deionized water with the above composition and ratio into the reaction pot and raise the temperature to 30°C-50°C, add 70kg of polycarboxylate water reducer, and add 25kg of polycarboxylate ether type water reducer , keep the temperature, add 1.5kg of sodium gluconate and 1.0kg of sodium lignosulfonate as activators, and stir for 30 minutes to form a synthetic product with a specific structure. After cooling to normal temperature, add 0.4kg of ion-exchange membrane alkali to adjust the pH, add 0.3kg of anti-corrosion, anti-mildew and fungicide, and continue stirring for 30 minutes to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com