Water source heat pump system

A technology of water source heat pump and heat source side, which is applied in lighting and heating equipment, refrigeration components, mechanical equipment, etc., and can solve problems such as inability to evaporate temperature and improve system energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

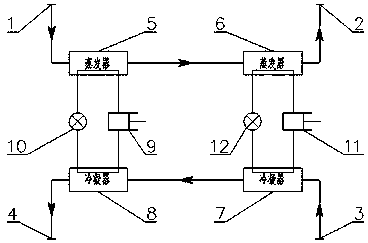

[0034] Such as figure 1 As shown, the water source heat pump system includes a primary evaporator 5, a secondary evaporator 6, a primary condenser 7, a secondary condenser 8, a first compressor 9, a second compressor 11, a first expansion valve 10 and a second Two expansion valves 12;

[0035] The primary evaporator 5 and the secondary evaporator 6 are arranged between the water inlet 1 on the heat source side and the water outlet 2 on the heat source side;

[0036] The water inlet of the primary evaporator 5 is connected to the heat source side water inlet 1 through a pipeline, and the water outlet is connected to the water inlet of the secondary evaporator 6 through a pipeline;

[0037] The water outlet of the secondary evaporator 6 is connected to the heat source side water outlet 2 through a pipeline;

[0038] The primary condenser 7 and the secondary condenser 8 are arranged between the user-side water inlet 3 and the user-side water outlet 4;

[0039] The water inlet ...

Embodiment 2

[0047] Based on the water source heat pump system of Embodiment 1, the first compressor 9 and the first expansion valve 10 connected by pipelines between the primary evaporator 5 and the secondary condenser 8 form the first heat pump cycle system; the secondary evaporator 6 A second compressor 11 and a second expansion valve 12 communicated with the primary condenser 7 form a second heat pump cycle system;

[0048] N evaporators are also connected in series between the primary evaporator 5 and the secondary evaporator 6, and N condensers are also connected in series between the primary condenser 7 and the secondary condenser 8. The N evaporators and the N The condensers are in one-to-one correspondence with a compressor and an expansion valve connected through pipelines to form N heat pump circulation systems, where N is a positive integer.

Embodiment 3

[0050] Based on the water source heat pump system of Embodiment 1, the water inlet 1 on the heat source side communicates with mid-deep geothermal water, and the mid-deep geothermal water is used as heat source water.

[0051] In the water source heat pump system of Embodiment 3, the medium-deep geothermal water at 40°C enters the water inlet on the heat source side and first flows through the primary evaporator 5 to drop to 30°C, then flows through the secondary evaporator 6 to drop to 20°C, and then flows from the heat source The side water outlet flows out; the user-side water at 45°C enters the user-side water inlet, first flows through the primary condenser 7 and is heated to 50°C, then flows through the secondary condenser 8 and is heated to 55°C, and then flows out from the user-side water outlet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com