Patents

Literature

63 results about "Joint coordinate system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The joint coordinate system is defined by two independent body-fixed axes and the common perpendicular. Angular rotation of the bodies is about one or more ot these spatial axes. Grood and Suntay (1983) indicate that it is necessary to specify: the bone coordinate system the body-fixed axes and the reference axes,...

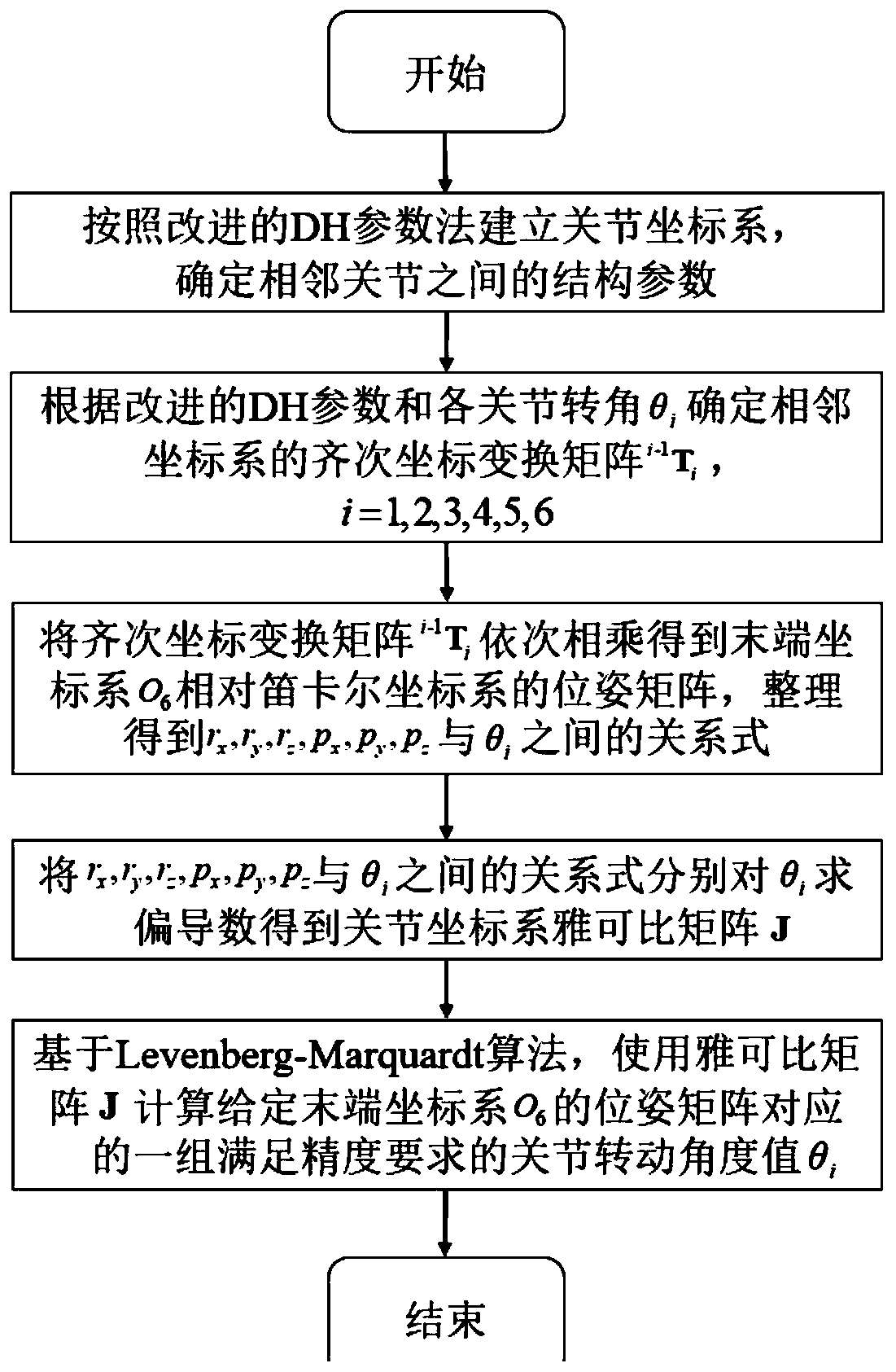

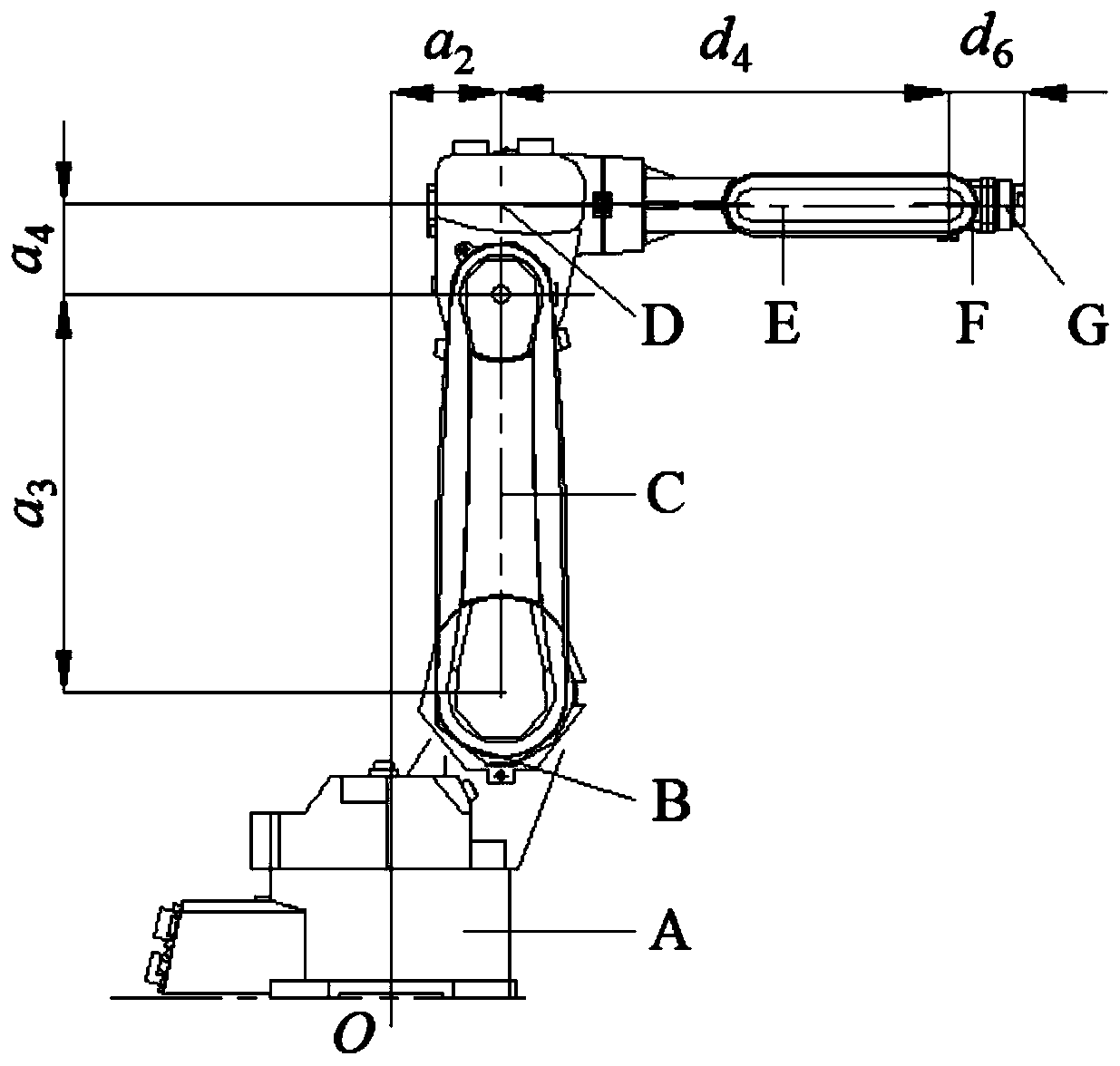

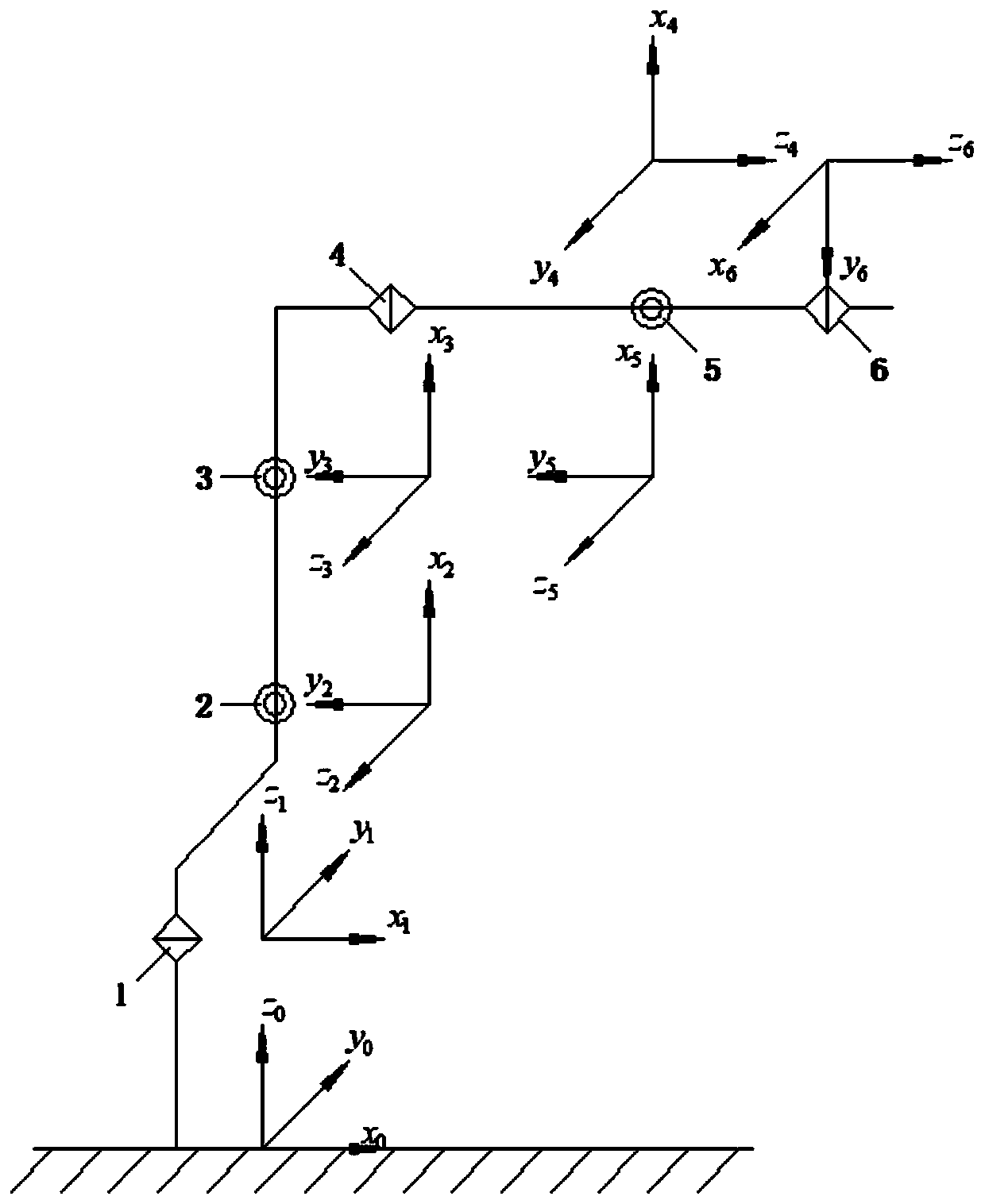

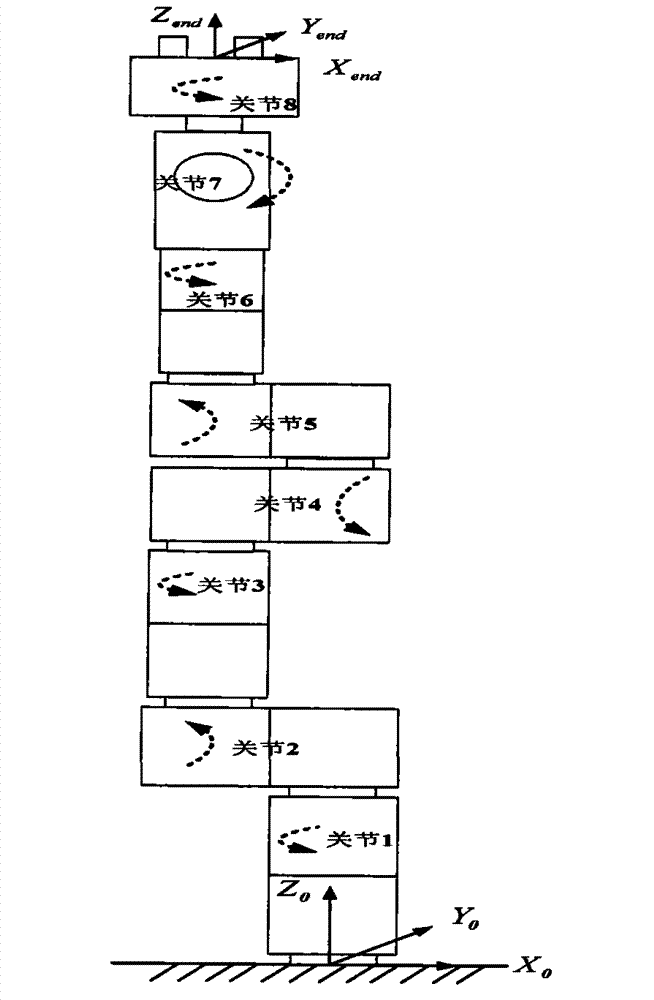

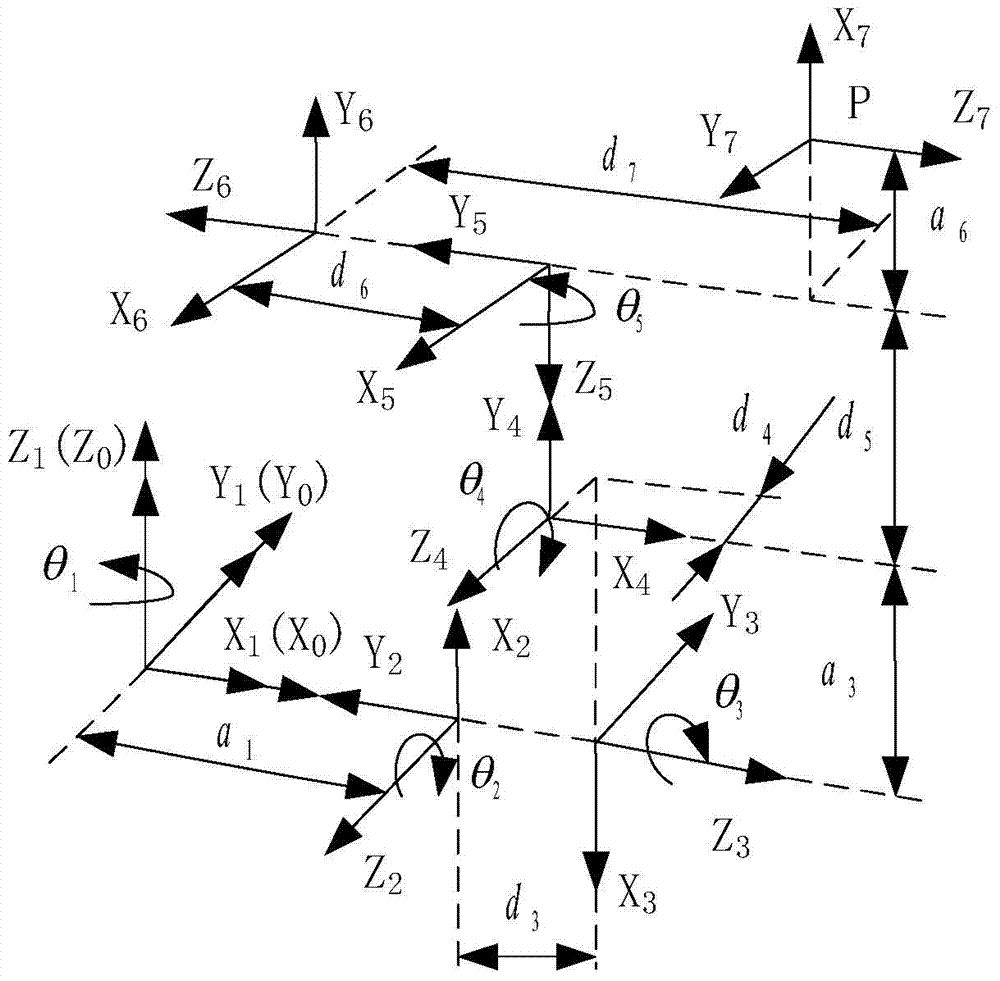

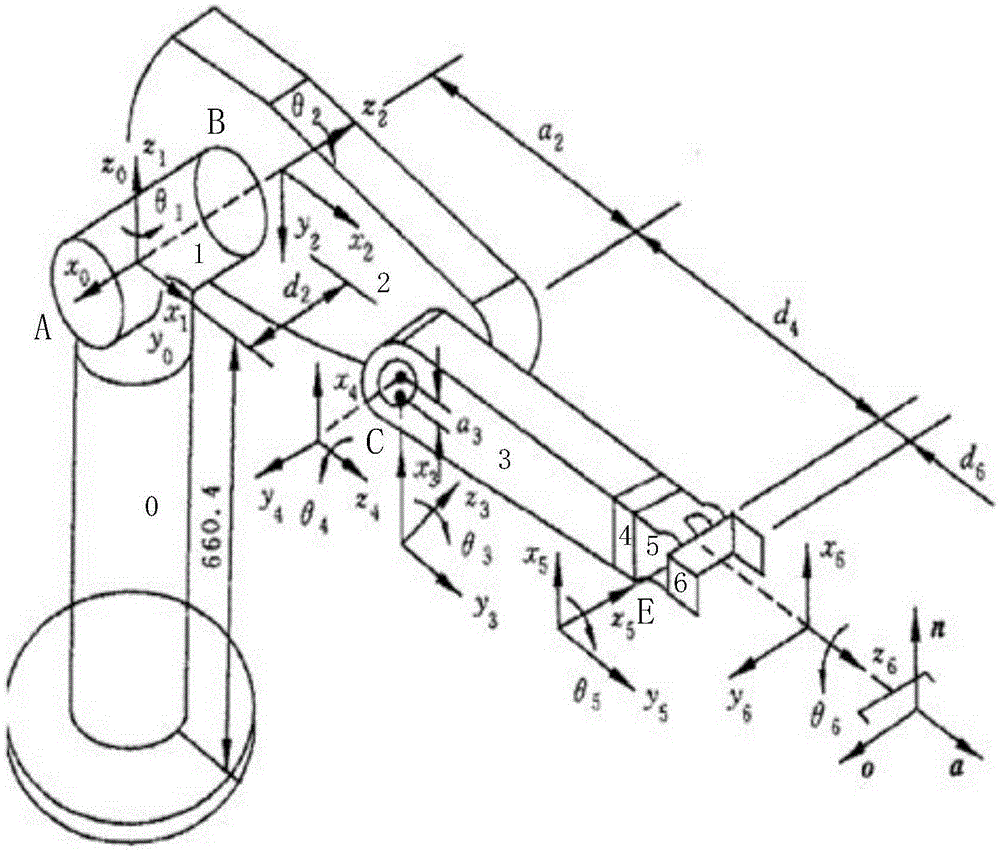

Method for uniquely solving inverse kinematics numerical value of joint type mechanical arm

ActiveCN109895101AOvercoming the requirement of full rankSimple modeling methodProgramme-controlled manipulatorJoints typesEngineering

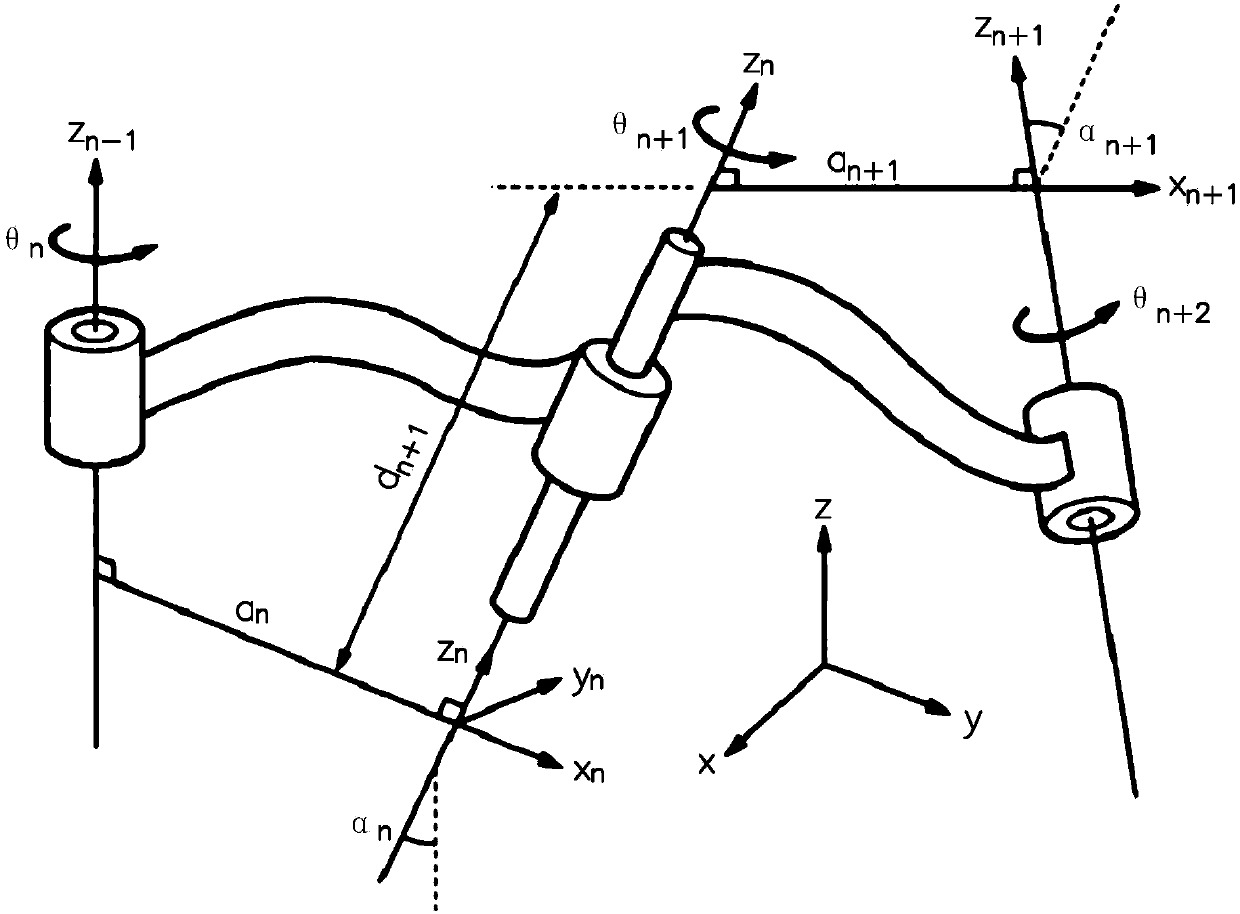

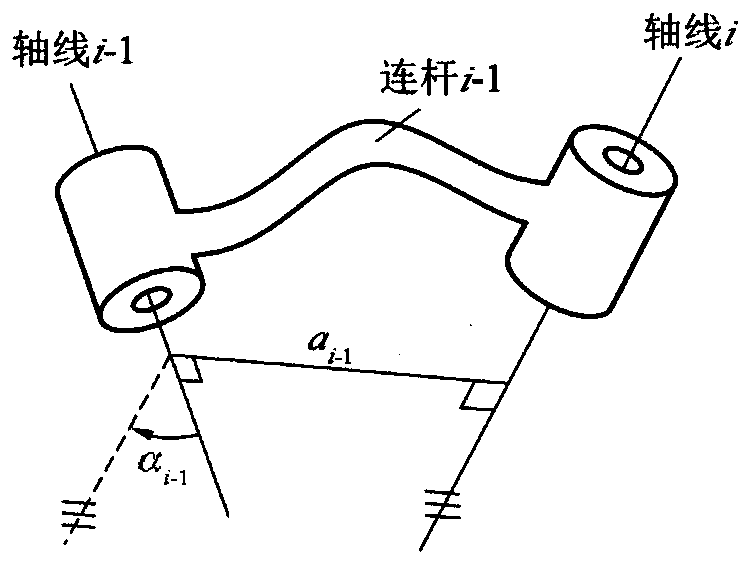

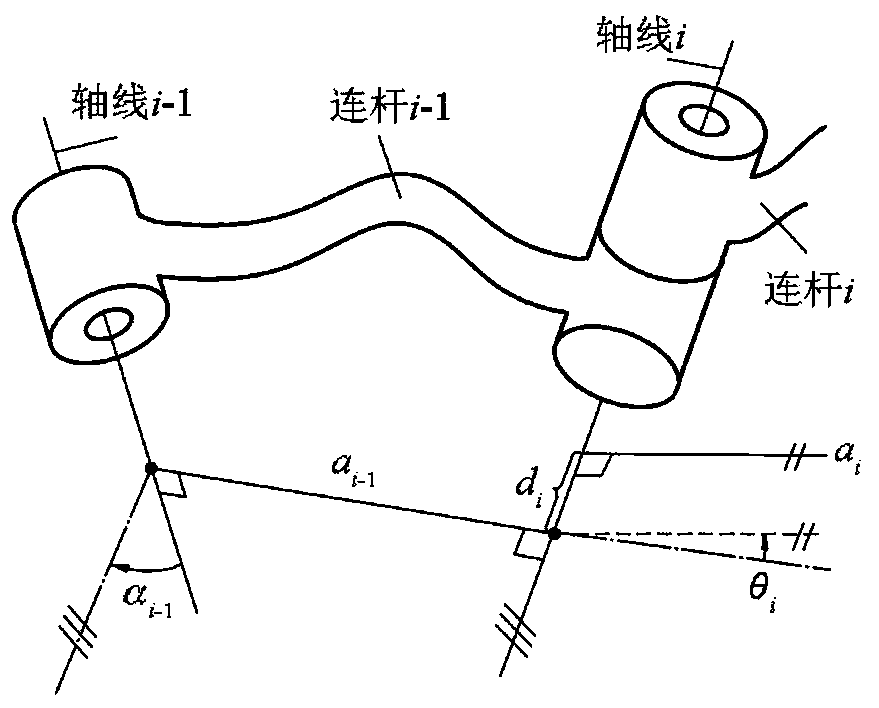

The invention discloses a method for uniquely solving the inverse kinematics numerical value of the joint type mechanical arm, belongs to the technical field of modern intelligent manufacturing, relates to the technical field of industrial robots, relates to a method for uniquely solving the inverse kinematics numerical value of a joint type six-degree-of-freedom mechanical arm with shoulder joints facing forward. According to the method, a mechanical arm joint coordinate system is built according to an improved DH parameter method, four structural geometrical parameters between adjacent joints of the mechanical arm are determined, a homogeneous coordinate transformation matrix of two adjacent coordinate systems is calculated. For a given pose matrix of a tail end coordinate system O6, animproved newton iteration method, namely a Levenberg marquardt iterative algorithm is adopted, the inverse kinematics solution of the joint coordinate system is calculated by using a jacobian matrix J, and the six joint rotation angle values theta i which correspond to the pose matrix and meet the precision requirement are obtained. The method overcomes the requirement that a traditional newton iteration method needs to fully rank the jacobian matrix j, the modeling method is simple, clear and effective, the method has the characteristics of being high in solving precision, high in solving speed and simple and feasible in solving process.

Owner:DALIAN UNIV OF TECH

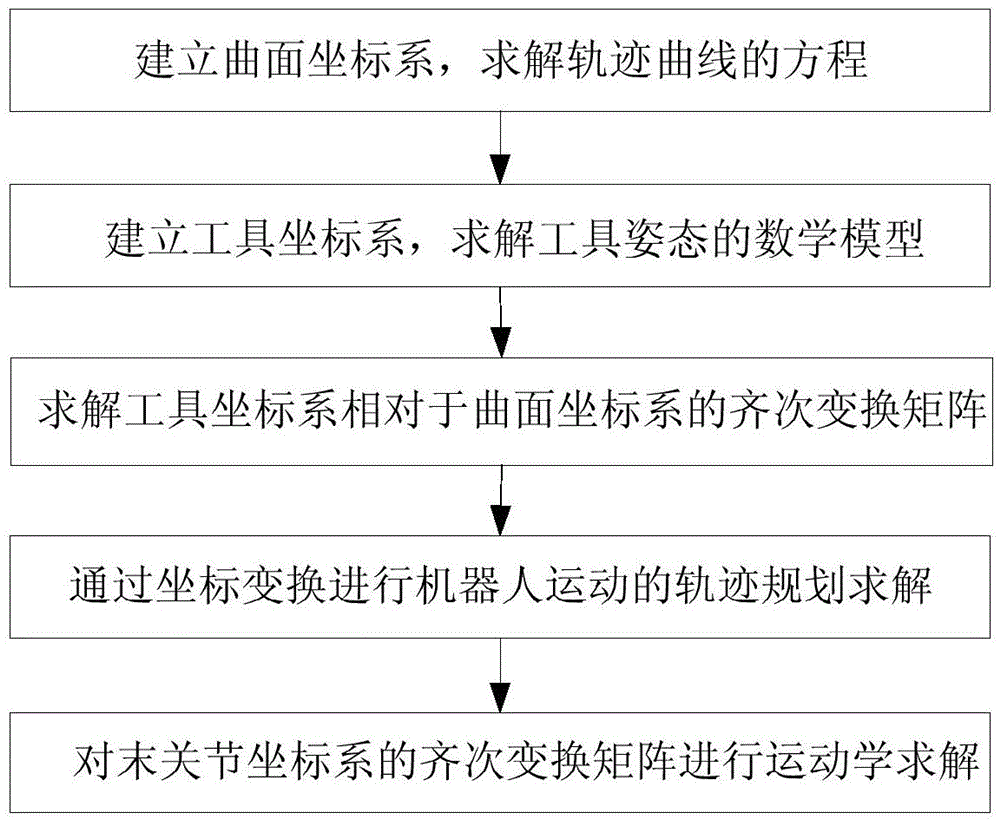

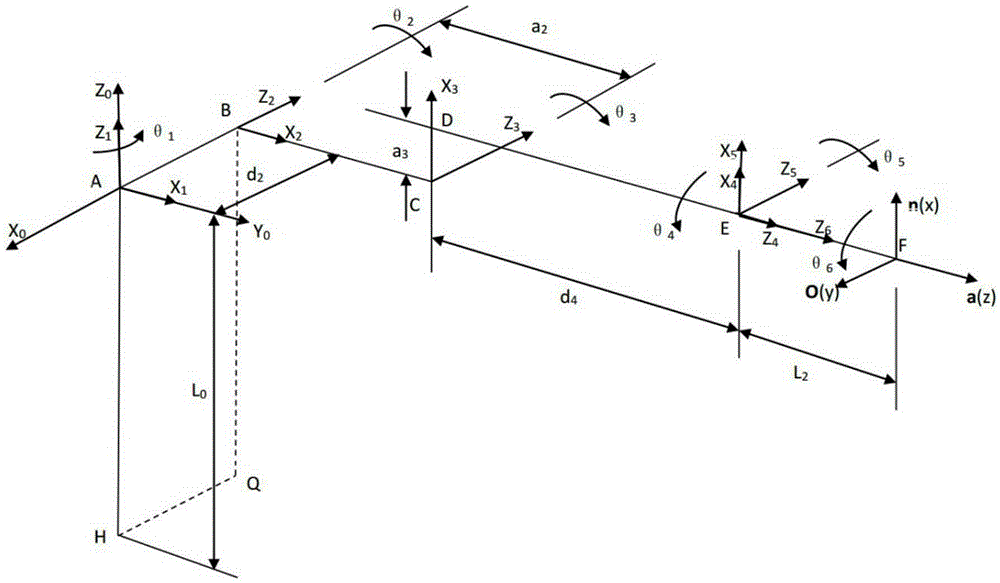

Pipeline insertion intersecting line track planning method orientated to laser machining robot

InactiveCN104827479ASave imputation calculation timeReduce difficultyProgramme-controlled manipulatorMetal working apparatusLaser processingMathematical model

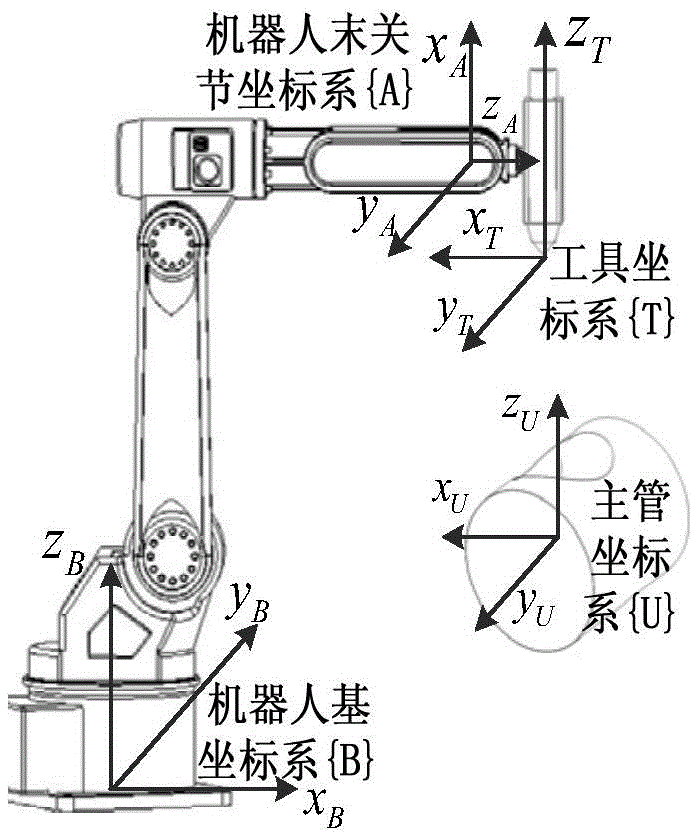

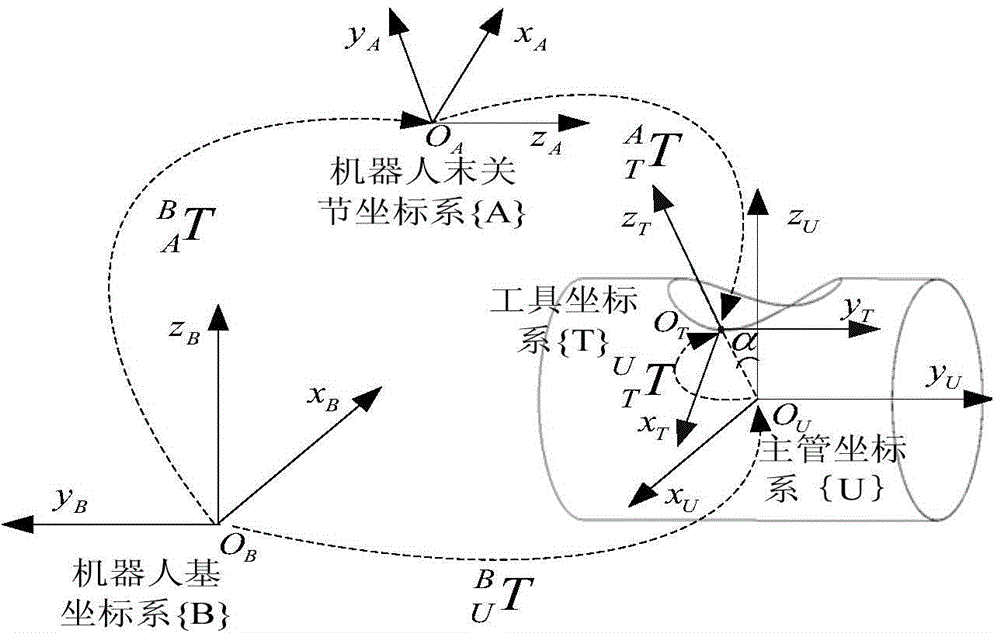

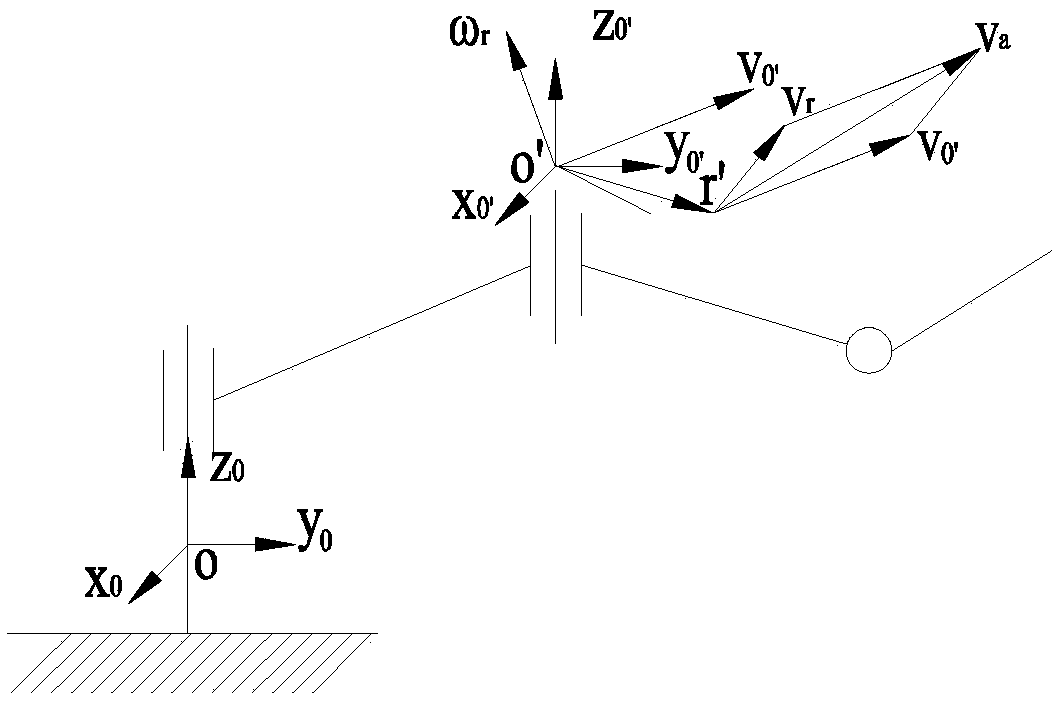

The invention discloses a pipeline insertion intersecting line track planning method orientated to a laser machining robot. According to the method, through coincidence of the axis of a laser head of the laser machining robot and the normal vector of a curved surface of a workpiece, it is guaranteed that the laser machining head and the surface of the workpiece are perpendicular, a mathematic model of the position and the posture of the laser machining head in the pipeline insertion intersecting line cutting process is established, a homogeneous transformation matrix of a tail joint coordinate system relative to a robot base coordinate system is acquired when the laser machining robot cuts an intersecting line, and finally the position of the intersecting line is rapidly calibrated through a position interpolation algorithm for determining the intersecting line track. By the adoption of the track planning method, the position and the posture of the laser machining head can be effectively controlled in the intersecting line cutting process of the laser machining robot, compared with a traditional track planning method, the track planning method can greatly shorten operation time of track planning of a motion controller and the responding speed of a whole system is increased.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

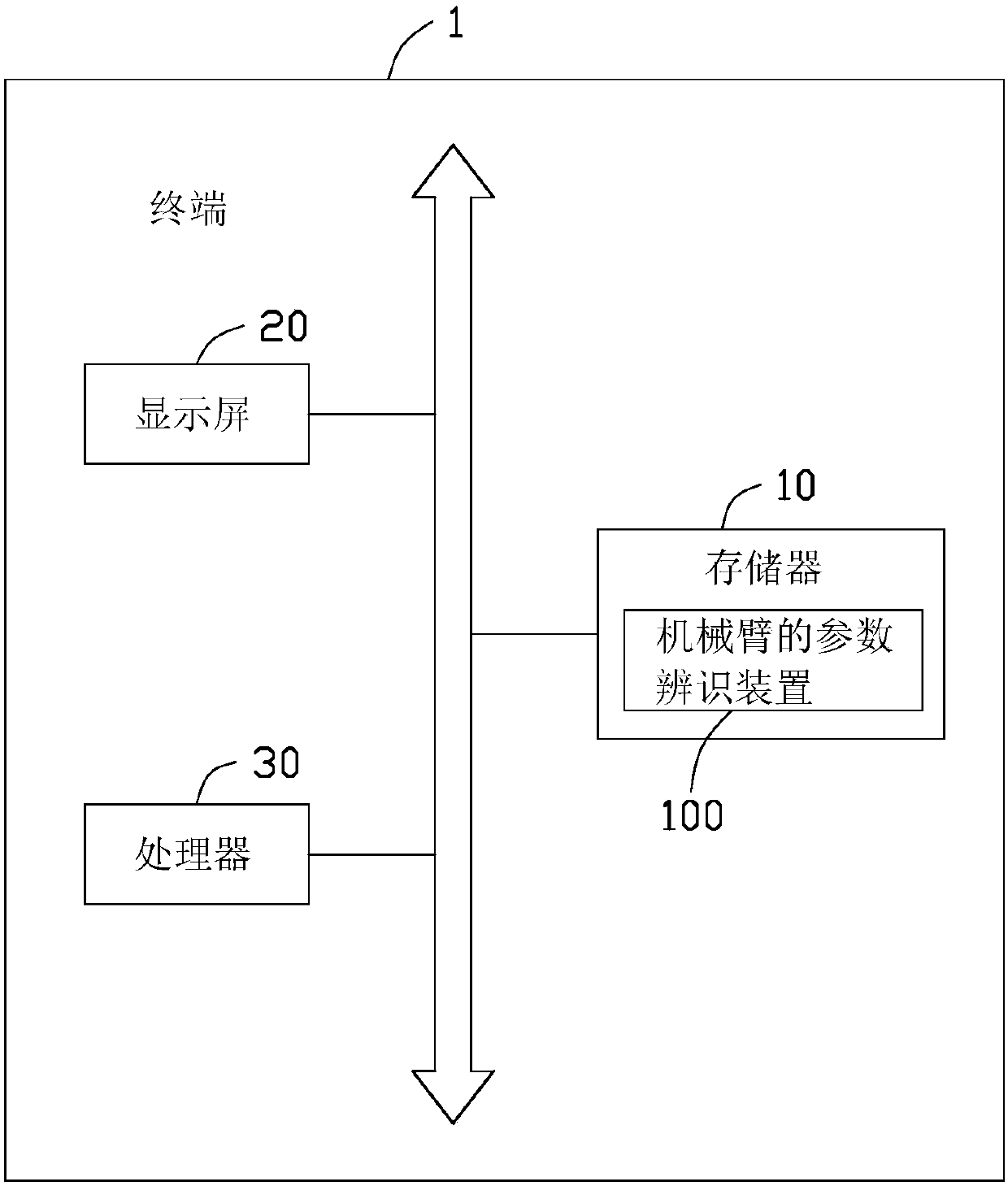

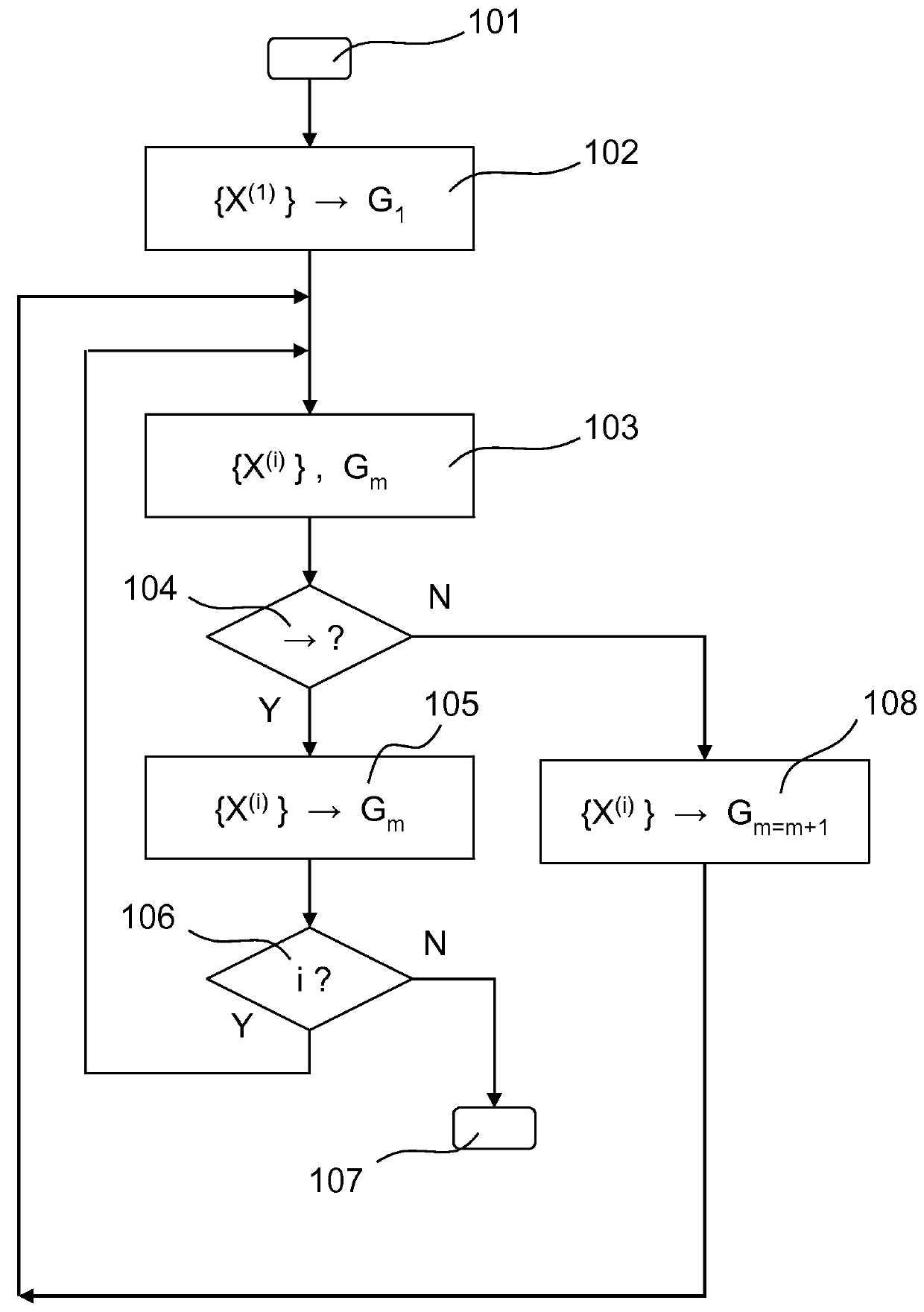

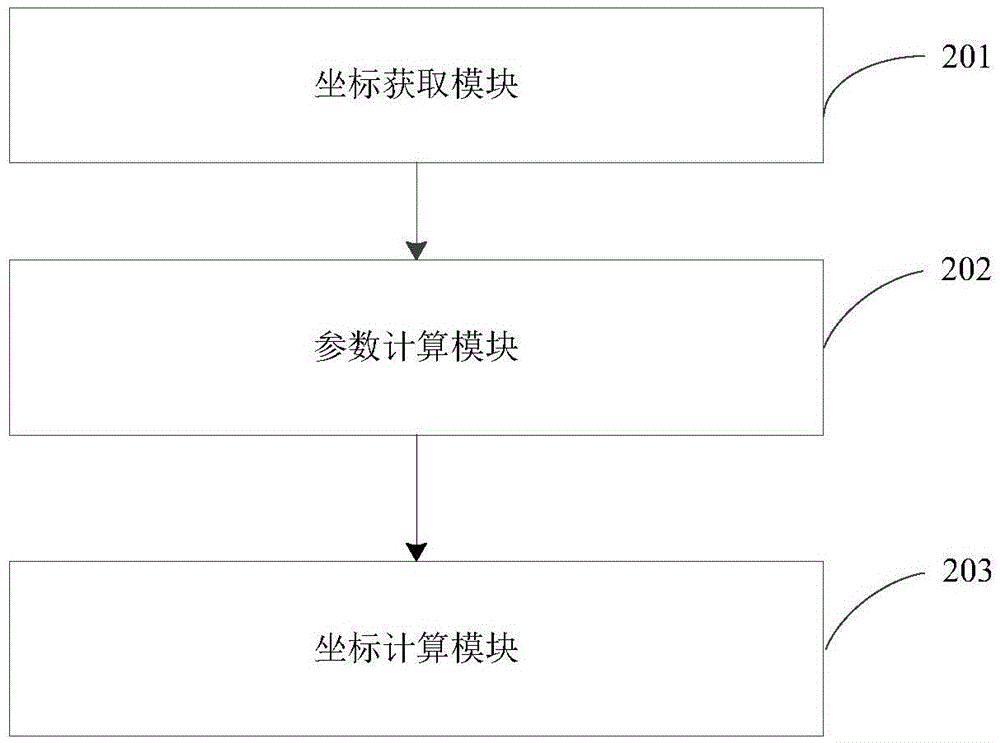

Parameter measurement and identification method and device of mechanical arm, terminal, and storage medium

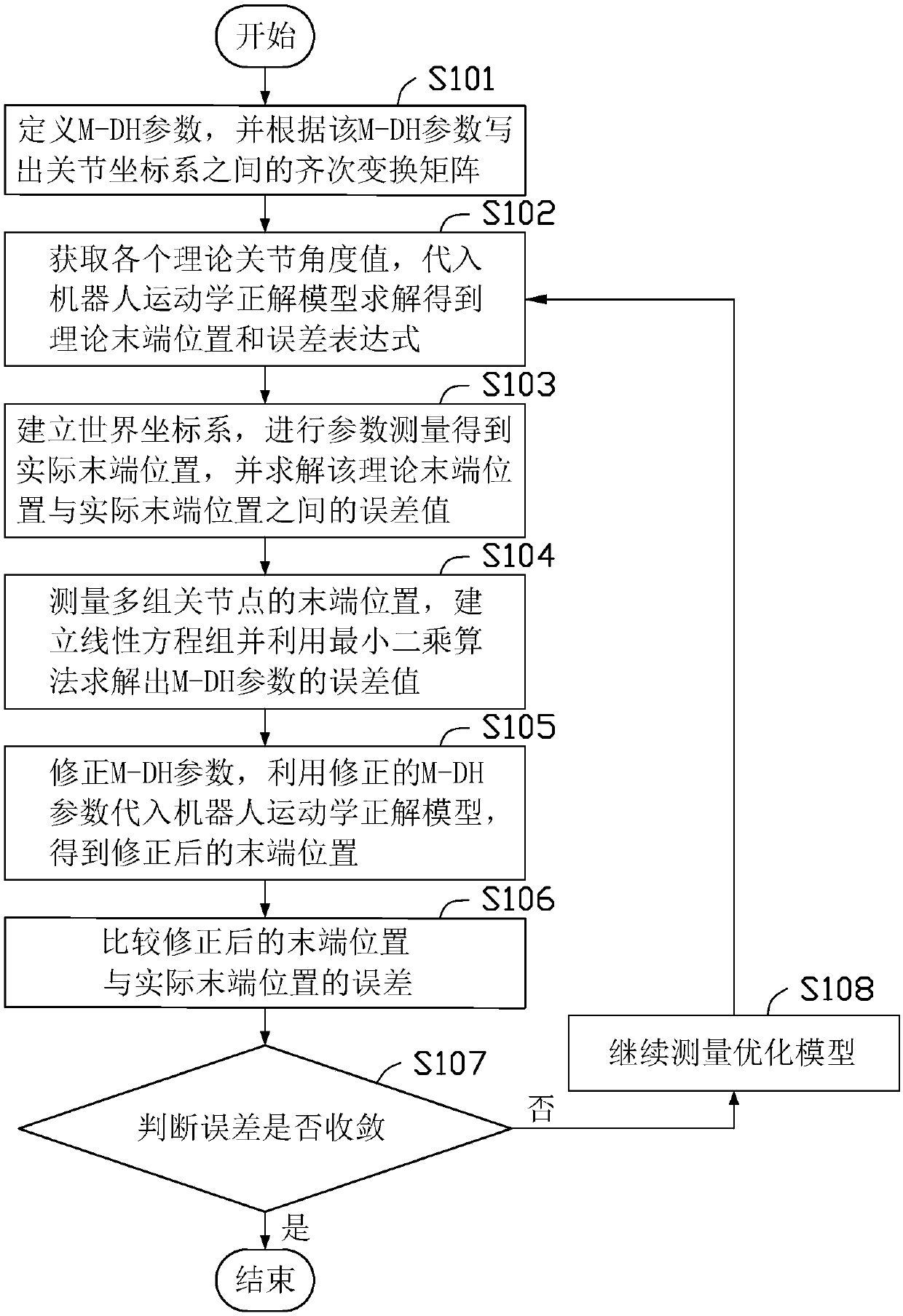

InactiveCN108527373AHigh precisionProgramme-controlled manipulatorMeasurement deviceJoint coordinates

The invention provides a parameter identification method of a mechanical arm. The parameter identification method of the mechanical arm comprises the steps of defining an M-DH parameter, and writing out a homogeneous transformation matrix between joint coordinate systems; acquiring each theoretical joint angle value, substituting into a robot kinematics forward analysis model, and solving to obtain a theoretical terminal position and an error expression; measuring a practical terminal position, and solving an error value between the theoretical terminal position and the practical terminal position; measuring terminal positions of multiple groups of joint points, building a system of linear equations, and utilizing a least squares algorithm for solving an error value of the M-DH parameter;correcting the M-DH parameter, and utilizing the corrected M-DH parameter to obtain a corrected terminal position; and judging whether an error between the corrected terminal position and the practical terminal position is converged or not, and if yes, finishing the flow. The invention further provides a parameter measurement method and a parameter measurement device of the mechanical arm, a parameter identification device of the mechanical arm, a terminal device and a storage medium. By utilizing the embodiment of the invention, the parameter identification accuracy can be improved.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

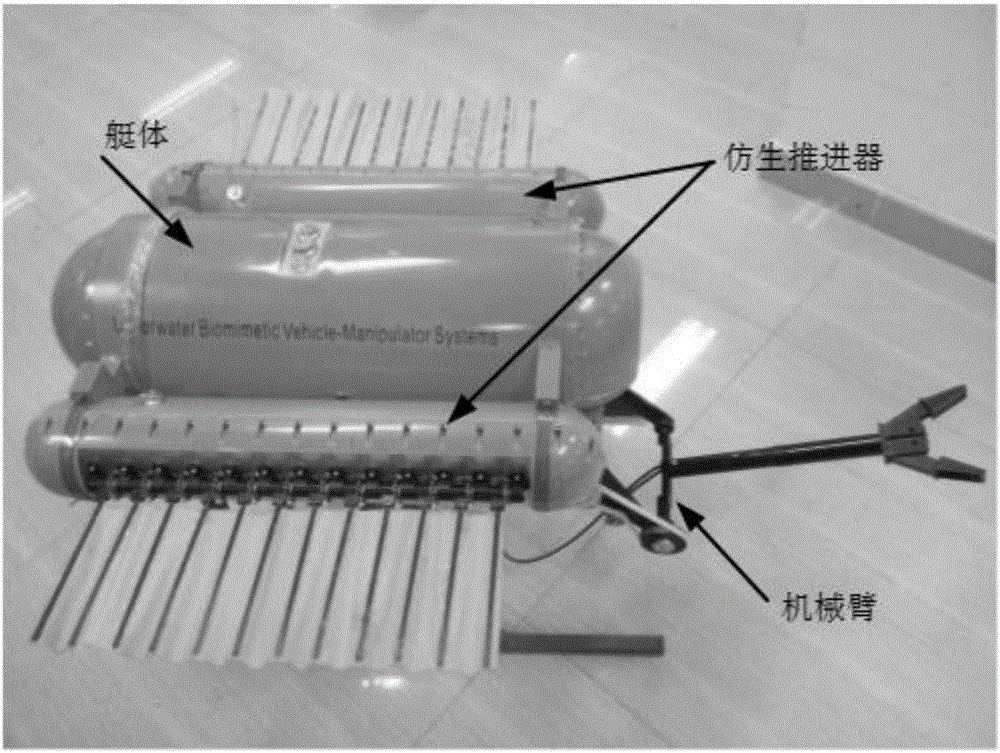

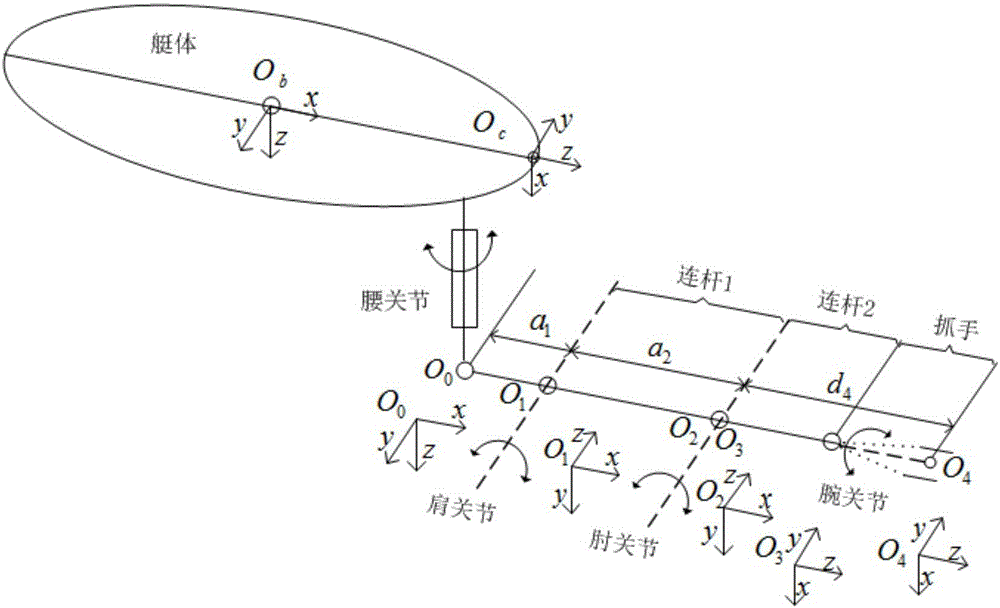

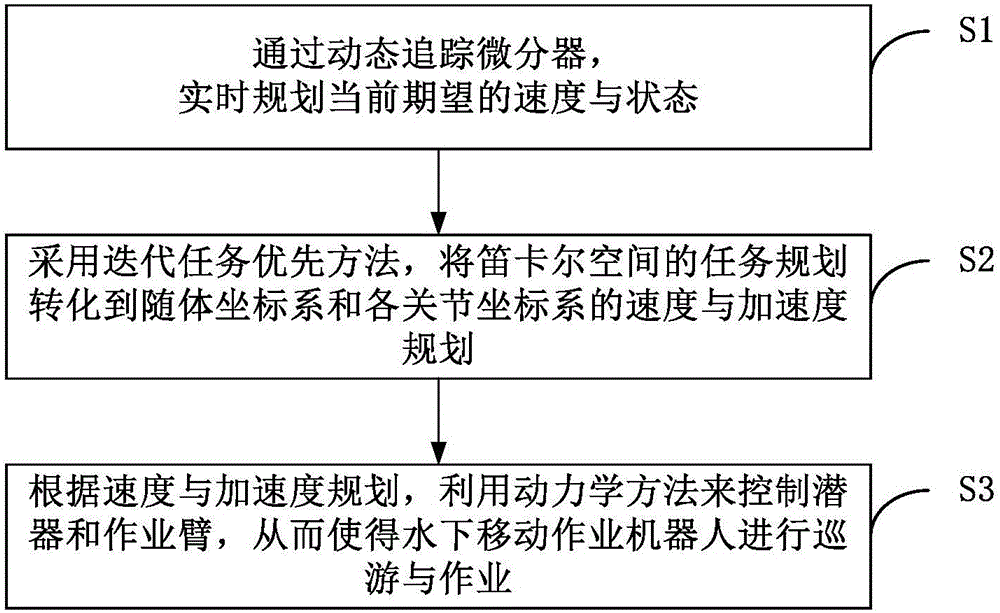

Coordinated planning and control method of underwater mobile operation robot

ActiveCN106708069AIncrease the level of autonomyAchieve homeworkAdaptive controlAltitude or depth controlDynamic methodDifferentiator

The present invention discloses a coordinated planning and control method of an underwater mobile operation robot. The method includes the following steps that: a currently desired velocity and state are planned in real time through a dynamic tracing differentiator; an iterative task priority method is adopted to transform task planning in the Cartesian space into velocity and accelerated velocity planning of the Lagrangian coordinate system and each joint coordinate system; and a dynamics method is adopted to control a submersible vehicle and an operating arm according to the velocity and accelerated velocity planning, and therefore, the underwater mobile operation robot can cruise and operate. According to the coordinated planning and control method of the underwater mobile operation robot of the present invention, the desired velocity and desired state of each task at present are planned; a state observer is adopted to estimate the state and velocity of a current task and feed back the state and velocity to control input; the robust iterative task priority method is adopted to achieve closed-loop control; and therefore, the autonomous level of the underwater mobile operation robot is improved, and therefore, fully-autonomous cruise and operation of the underwater mobile operation robot can be realized.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

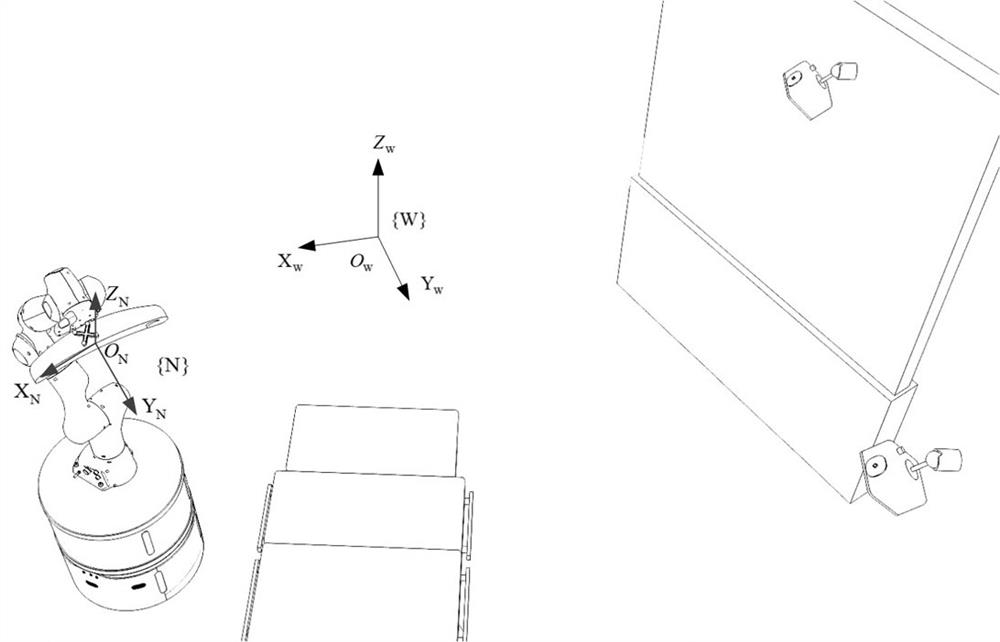

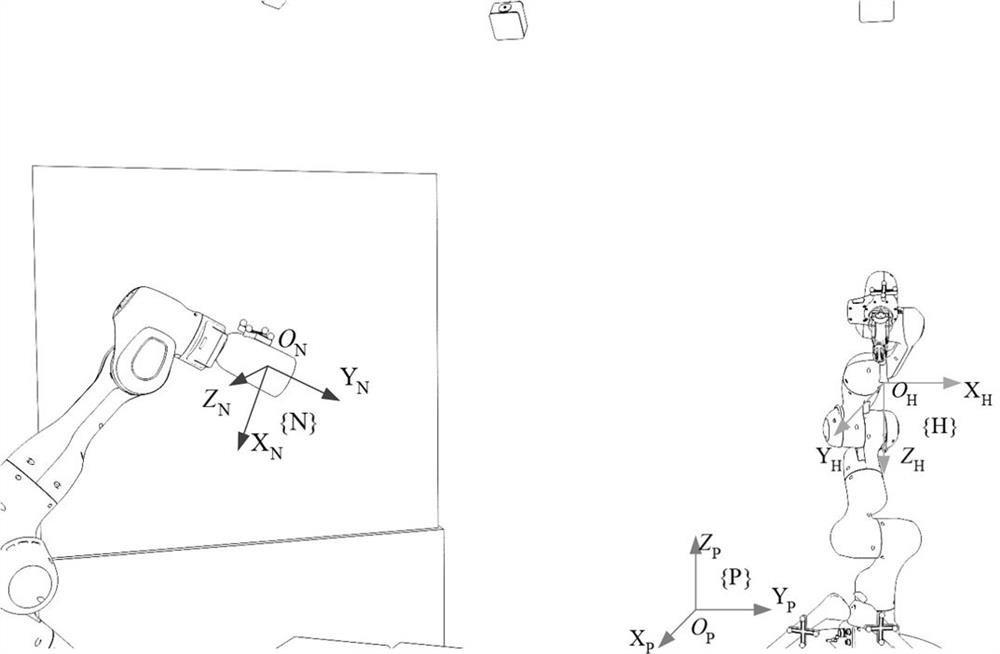

Calibration method suitable for visual servo plug-pull operation

ActiveCN109318234AIncreased durabilityGood Visual Servo EffectProgramme-controlled manipulatorVisual servoingImaging Feature

The invention relates to a calibration method suitable for a visual servo plug-pull operation, and belongs to the field of image identification. The problems that servo alignment control precision based on the visual servo is low, and the effect of the plug-pull operation controlled by an open loop is poor in a plug-pull stage are solved; the calibration method suitable for the visual servo plug-pull operation is provided, an image containing pins, a socket and a plug clamping device is collected by using a camera; a depth learning algorithm is utilized to obtain a center point of each pin inthe socket and the center point of each calibration board on the plug clamping device; then a socket middle point coordinate, a socket deflection angle, a plug clamping device middle point and a plugclamping device deflection angle are calculated; the point coordinate is transferred into a joint coordinate system at the tail end of a mechanical arm of a robot; the socket middle point coordinatesin a tail end coordinate system of the robot is obtained; a visual servo image feature error is calculated in the tail end coordinate system; and a visual servo feature is sent to a robot visual servoalgorithm, and the robot is controlled to move. According to the method, the operation precision in visual servo plug-pull operation is improved.

Owner:HARBIN INST OF TECH

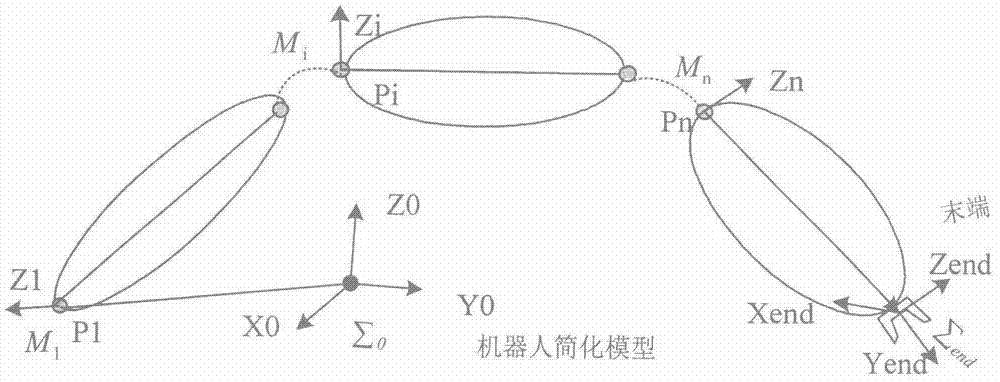

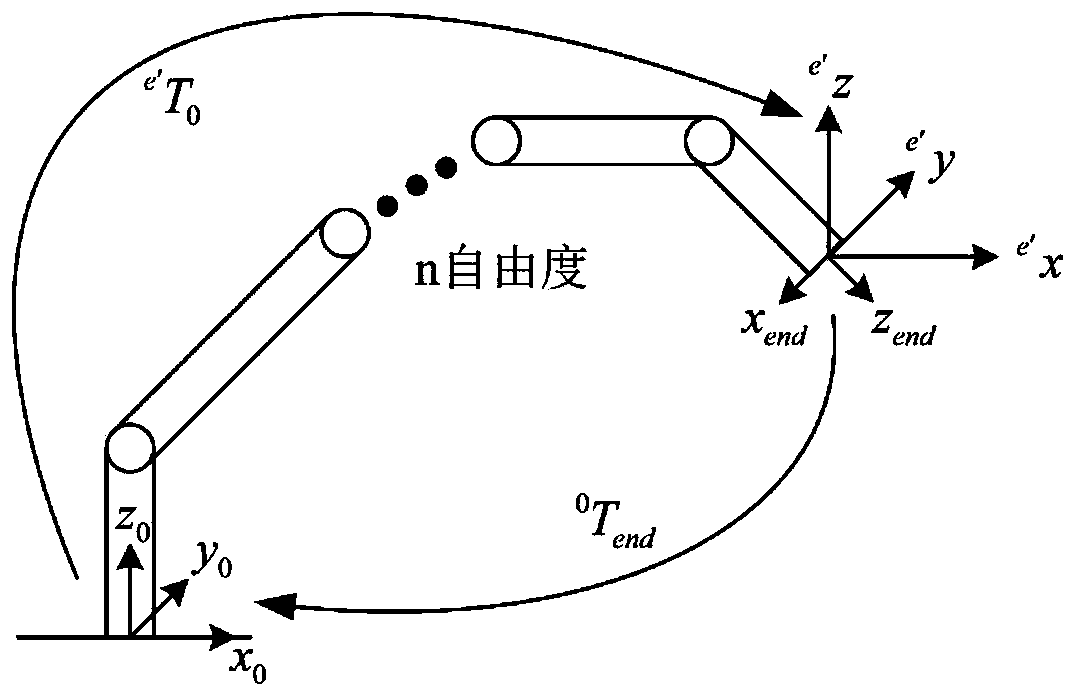

Novel robot kinematics modeling method

InactiveCN103085069AExpress clearly and conciselyEasy programmingProgramme-controlled manipulatorModel methodSimulation

The invention discloses a novel robot kinematics modeling method. The method comprises the following steps of: establishing a robot reference coordinate system and an end-of-arm tooling coordinate system only, and representing robot kinematics model parameters through a position vector and a pointing vector; deducing a transformation relation between joints by utilizing an implied joint coordinate system; and solving a pose transformation matrix and a Jacobian matrix of the robot end-of-arm tooling coordinate system relative to the reference coordinate system under the specific joint position through the matrix transformation relationship. By the novel robot kinematics modeling method, the robot kinematics modeling is realized, the modeling process is simple and high-efficiency, only the reference coordinate system and the end-of-arm tooling coordinate system are required to be modeled, and the method has an intuitive expression form and clear physical significance.

Owner:BEIJING UNIV OF POSTS & TELECOMM

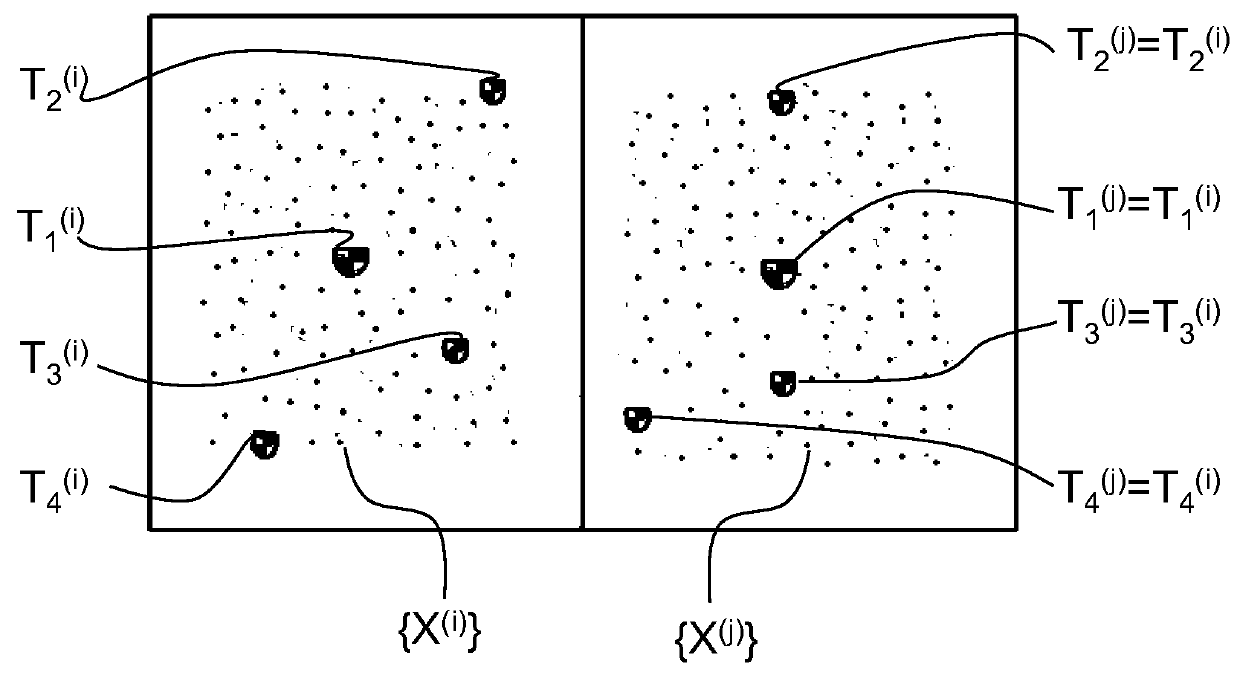

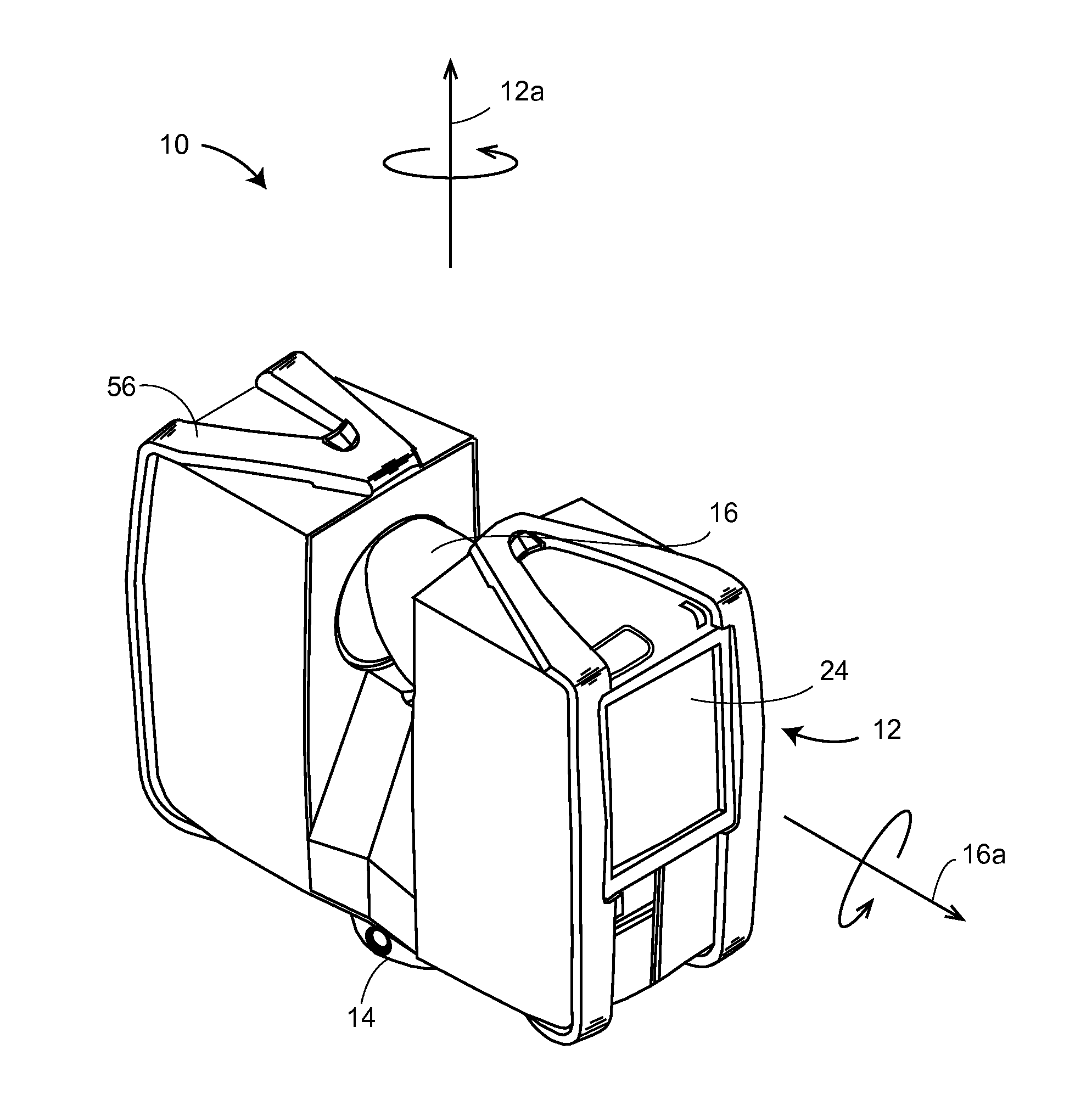

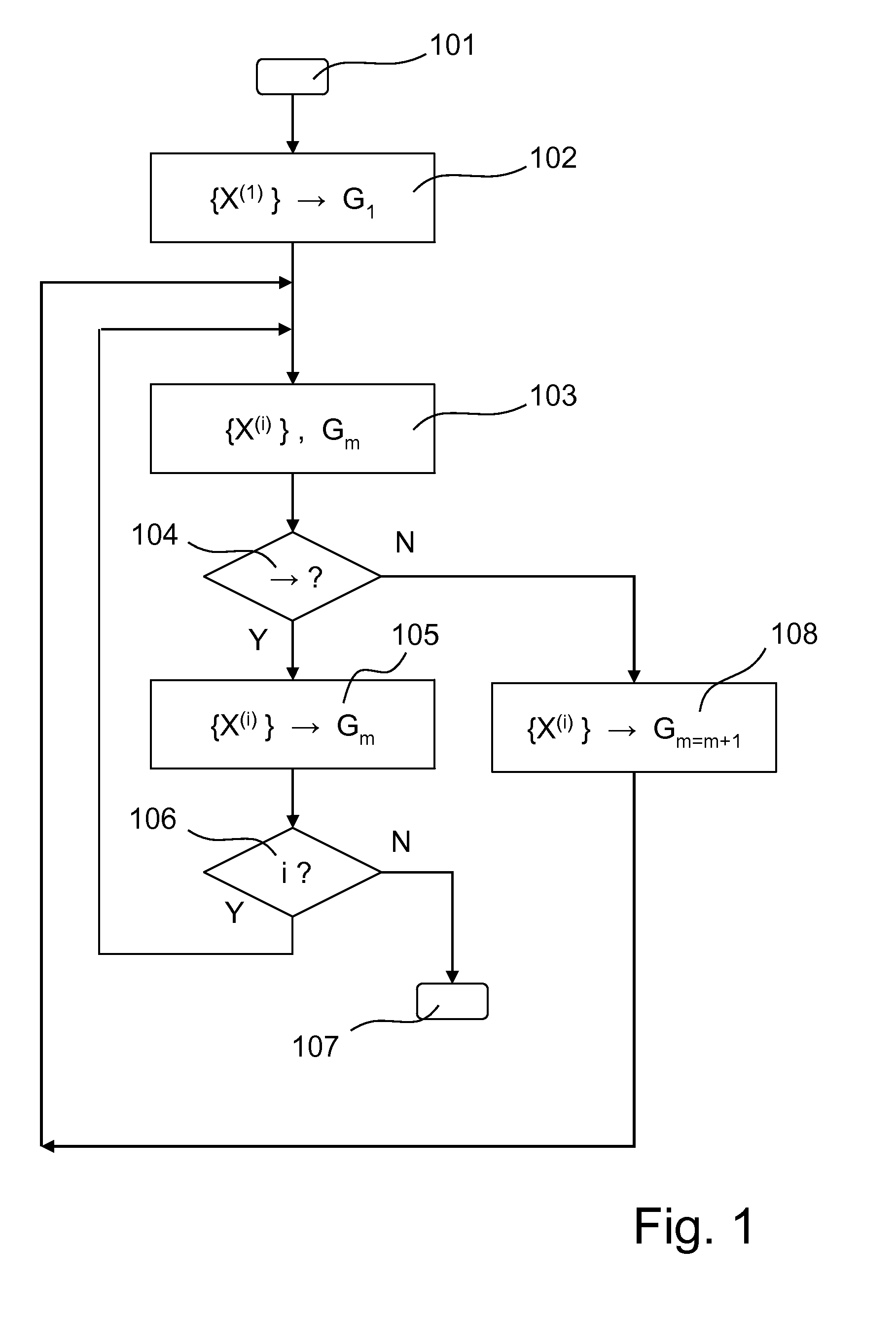

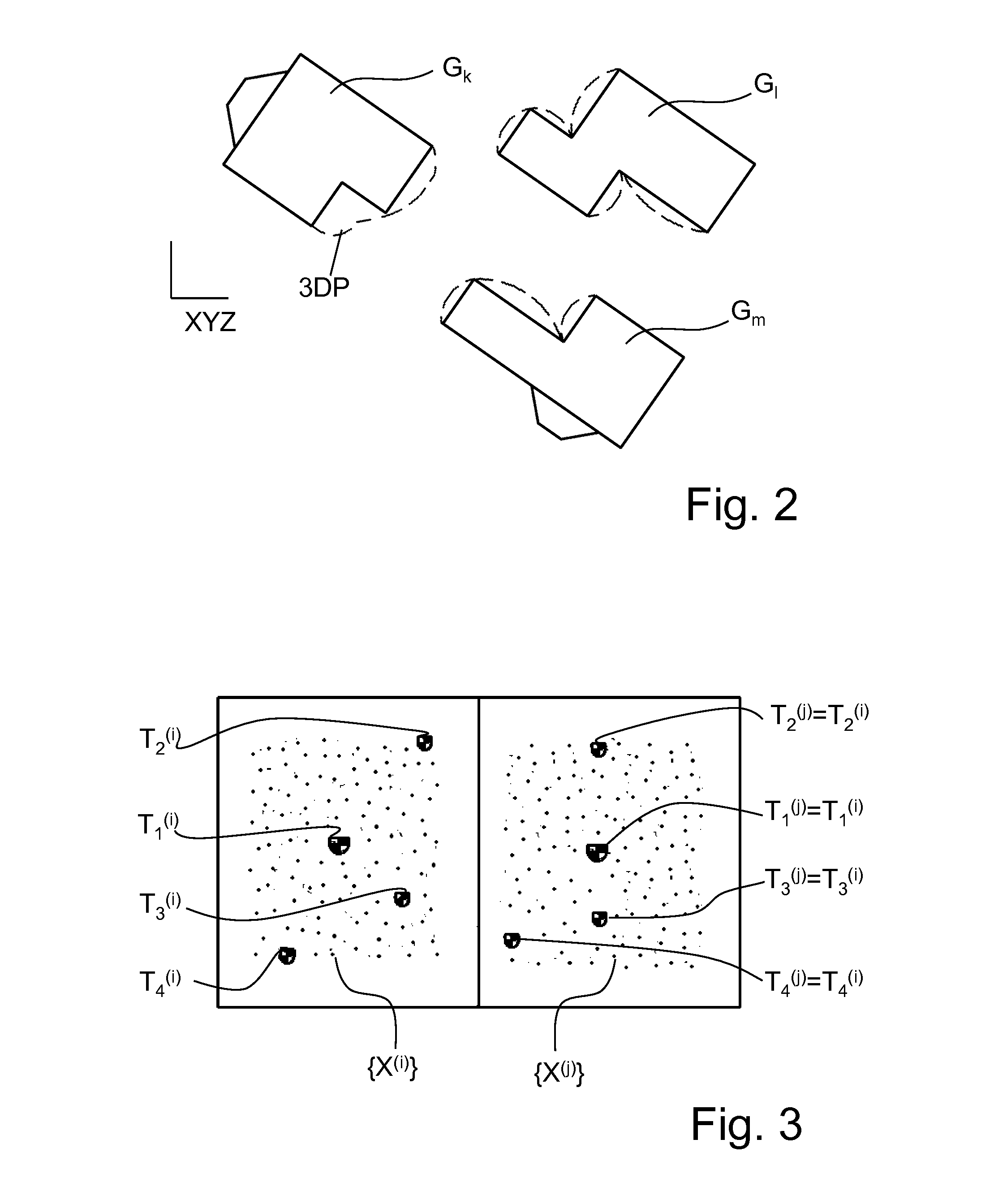

Registering of a scene disintegrating into clusters with visualized clusters

A method for optically scanning and measuring a scene by a three-dimensional (3D) measurement device in which multiple scans are generated to then be registered in a joint coordinate system of the scene. At first at least one cluster is generated from at least one scan, further scans are registered for test purposes in the coordinate system of the cluster, if specified quality criteria are fulfilled and the generated clusters are then joined, for which purpose clusters are selected, registered for test purposes and registering is confirmed if appropriate, wherein the clusters to be joined are visualized with an optional possibility for the user to intervene, for supporting the selection of clusters.

Owner:FARO TECH INC

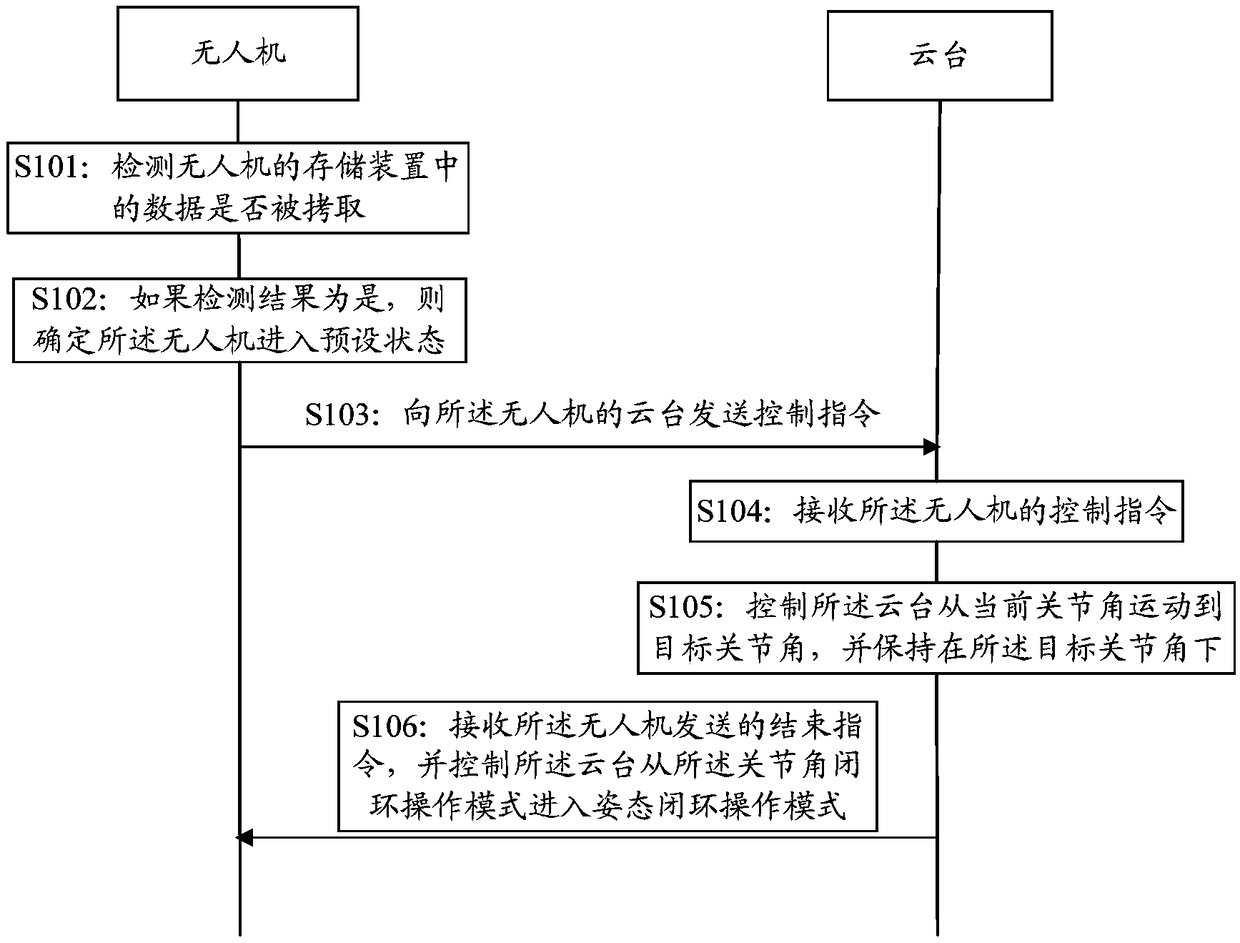

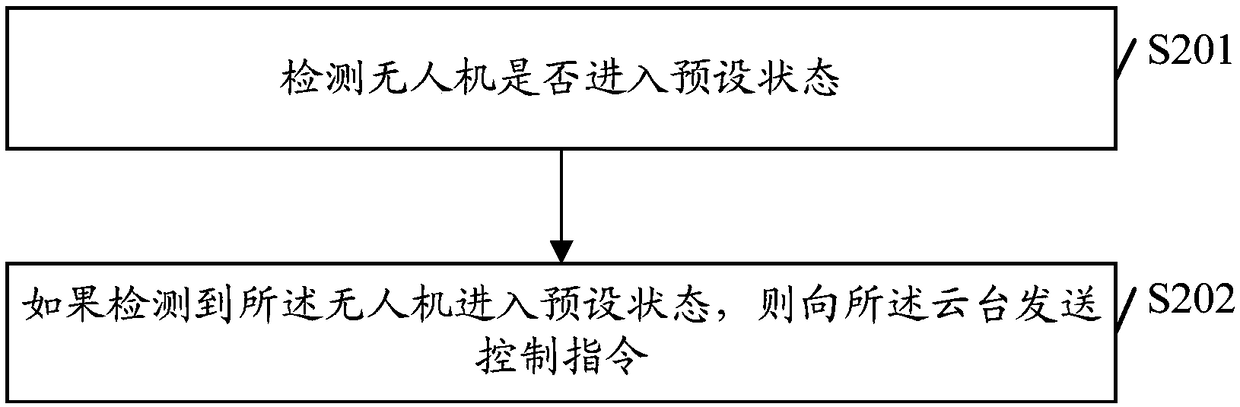

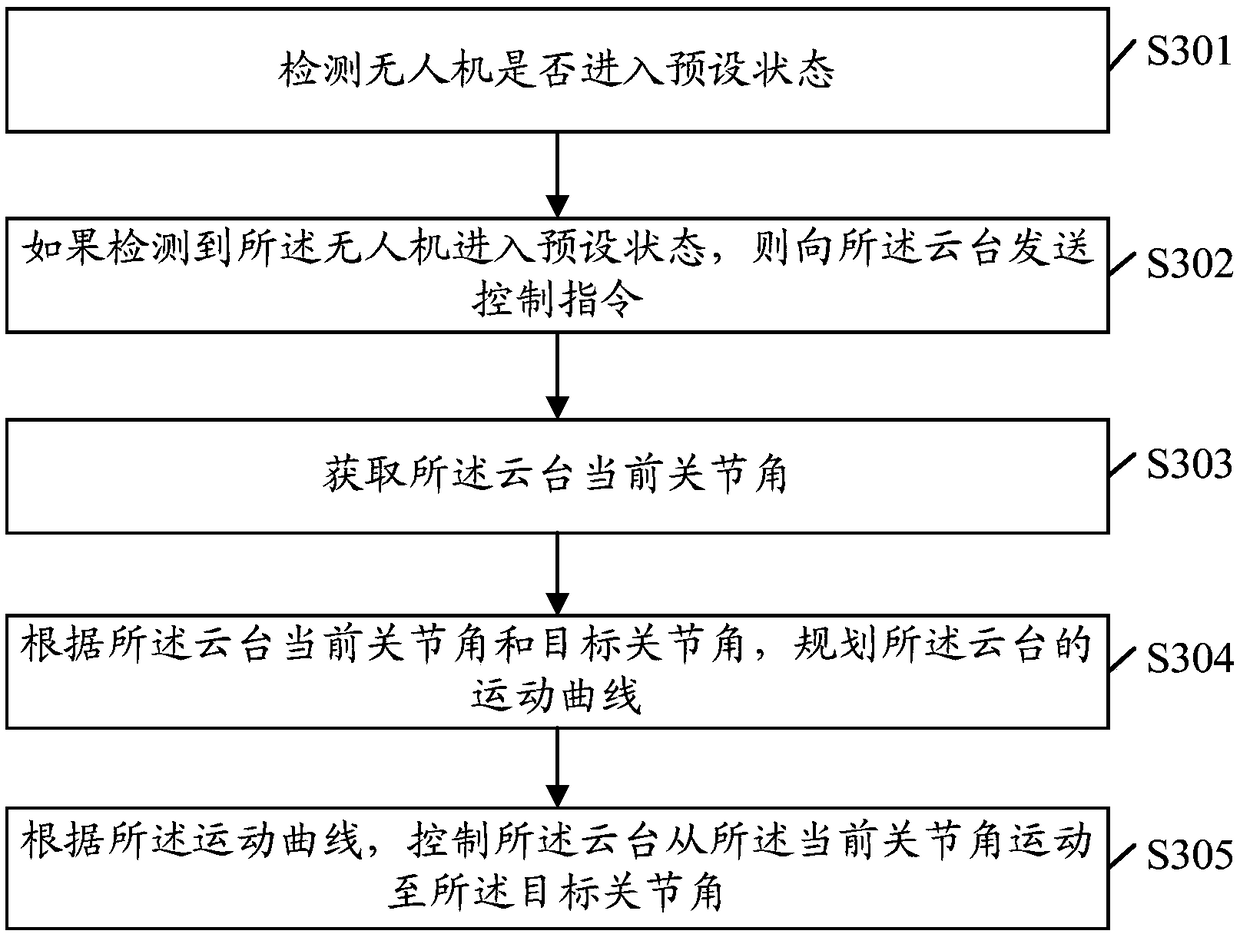

PTZ control method, drone, pan/tilt and storage medium

PendingCN108780328AGuaranteed not to reach the limit positionRealize protection controlPosition/course control in three dimensionsComputer scienceJoint angle

The embodiment of the invention provides a cloud platform control method, a drone, a cloud platform and a storage medium, which are applied to a drone. The drone is equipped with a Pan / Tilt. The method comprises: detecting whether the drone enters a preset state; if detecting that the drone enters a preset state, sending a control instruction to the pan / tilt; the control command is used to instruct the pan / tilt to move from a current joint angle to a target joint angle and remain under the target joint angle. The joint angle refers to an angle of a pan / tilt axis with respect to a joint coordinate system of the pan / tilt. In the embodiment of the present invention, by controlling the manner in which the pan / tilt moves from the current joint angle to the target joint angle, it is possible toeffectively ensure that the pan / tilt does not reach the limit position, realize the protection control of the pan / tilt, and ensure the safety of the pan / tilt.

Owner:SZ DJI OSMO TECH CO LTD

Registering of a scene disintegrating into clusters with visualized clusters

A method for optically scanning and measuring a scene by a three-dimensional (3D) measurement device in which multiple scans are generated to then be registered in a joint coordinate system of the scene. At first at least one cluster is generated from at least one scan, further scans are registered for test purposes in the coordinate system of the cluster, if specified quality criteria are fulfilled and the generated clusters are then joined, for which purpose clusters are selected, registered for test purposes and registering is confirmed if appropriate, wherein the clusters to be joined are visualized with an optional possibility for the user to intervene, for supporting the selection of clusters.

Owner:FARO TECH INC

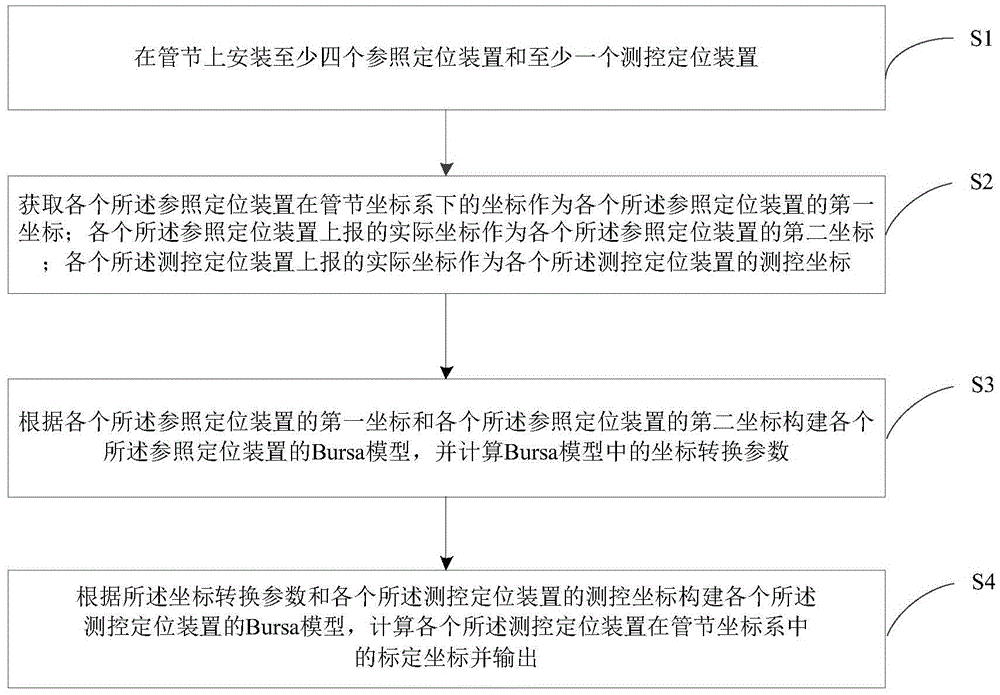

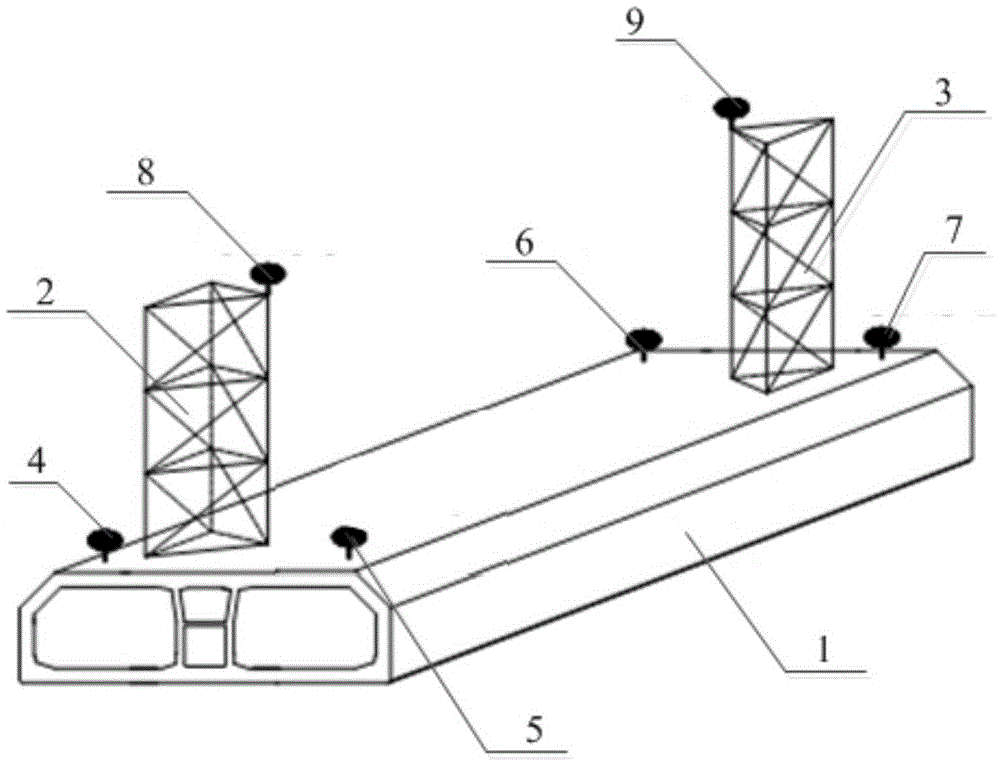

Position calibration method and system for measurement and control positioning devices

ActiveCN105588582AImprove accuracyMeasurement devicesTransformation parameterJoint coordinate system

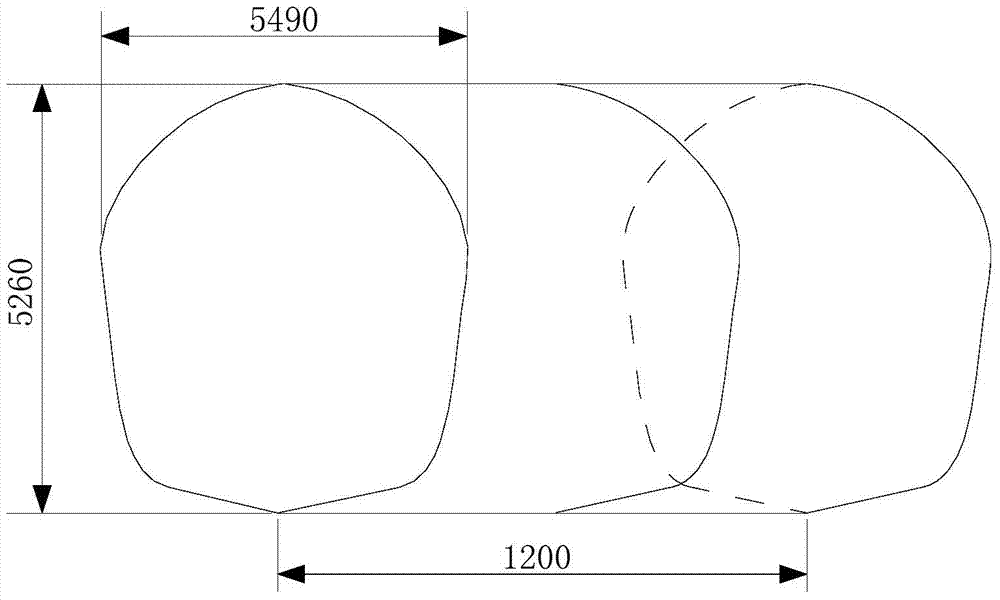

The invention relates to the technical field of engineering survey, in particular to a position calibration method and system for measurement and control positioning devices. The position calibration method for the measurement and control positioning devices comprises the following steps: at least four reference positioning devices and at least one measurement and control positioning device are mounted on a pipe joint; a Bursa model of each reference positioning device is established according to first coordinates and second coordinates of the reference positioning device, and a coordinate transformation parameter in the Bursa model is calculated; a Bursa model of each measurement and control positioning device is established according to the coordinate transformation parameter and measurement and control coordinates of the measurement and control positioning device, and calibration coordinates of the measurement and control positioning device in a pipe joint coordinate system are calculated and output. The method can improve the accuracy of position calibration of the measurement and control positioning devices in the pipe joint coordinate system, so that the obtained calibration coordinates of the measurement and control positioning devices in the pipe joint coordinate system more meet the actual state.

Owner:CCCC FIRST HARBOR ENG +1

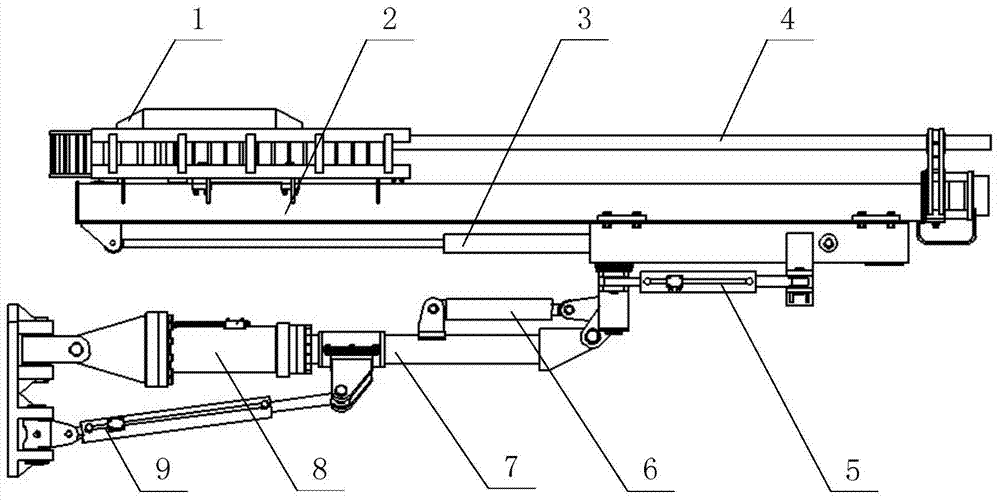

Method for achieving automatic positioning of cross section parallel hole for rock drilling machine rapidly and accurately

InactiveCN104265274AEasy to control intelligentlySimple calculationSurveyAutomatic control for drillingHydraulic cylinderClosed loop

The invention discloses a method for achieving automatic positioning of a cross section parallel hole for a rock drilling machine rapidly and accurately. The method for achieving automatic positioning of the cross section parallel hole for the rock drilling machine rapidly and accurately comprises the steps that the structural components of a drilling arm positioning mechanism of the hydraulic rock drilling machine and the movement of all mechanisms are analyzed, the joint coordinate system of the drilling arm positioning mechanism of the hydraulic rock drilling machine is established according to a structure model of a drilling arm system of the hydraulic rock drilling machine by means of the D-H method, the coordinate system of a drilling arm positioning system and connecting rod parameters are analyzed, and the functional relationships between the coordinates of a positioning tail end in a base coordinate system and all joint variables are calculated; cross section parallel hole regional planning for the hydraulic rock drilling machine is conducted; all the joint variables are solved; the pre-positioned position of the positioning tail end during drilling of the rock drilling machine is determined, the pre-positioned coordinates of the positioning tail end in the base coordinate system and all target joint variables are calculated, and a control module is driven in real time through a closed loop to adjust all hydraulic cylinders, so that whether the positioning tail end reaches a preset position is judged. By the adoption of the method for achieving automatic positioning of the cross section parallel hole for the rock drilling machine rapidly and accurately, the difficulty of solving the joint variables of the drilling arm system of the hydraulic rock drilling machine is greatly lowered.

Owner:YANSHAN UNIV

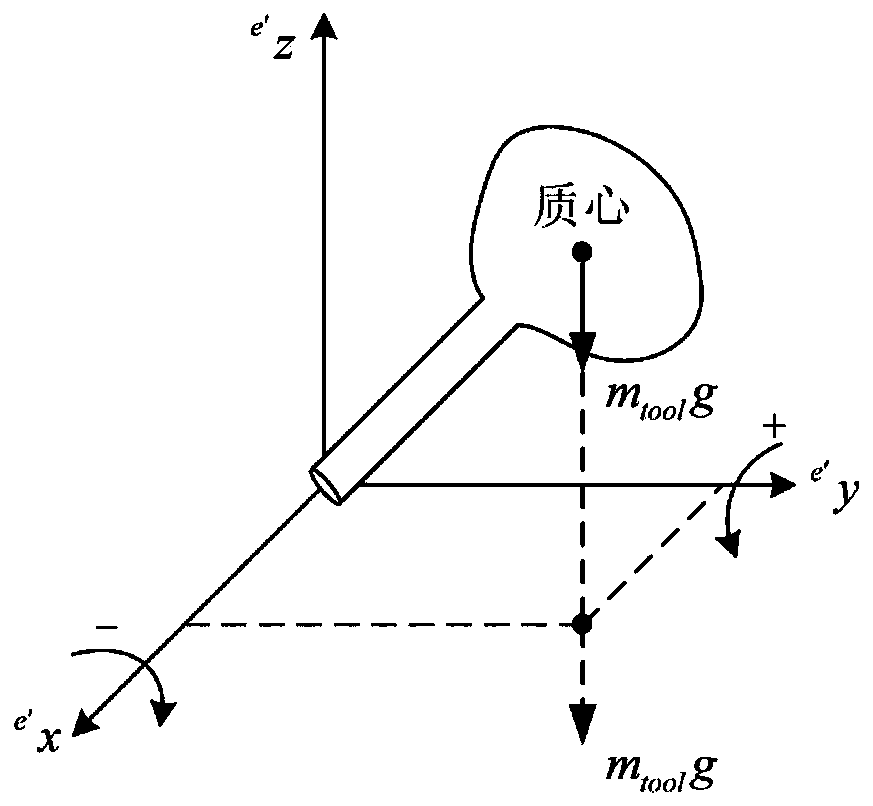

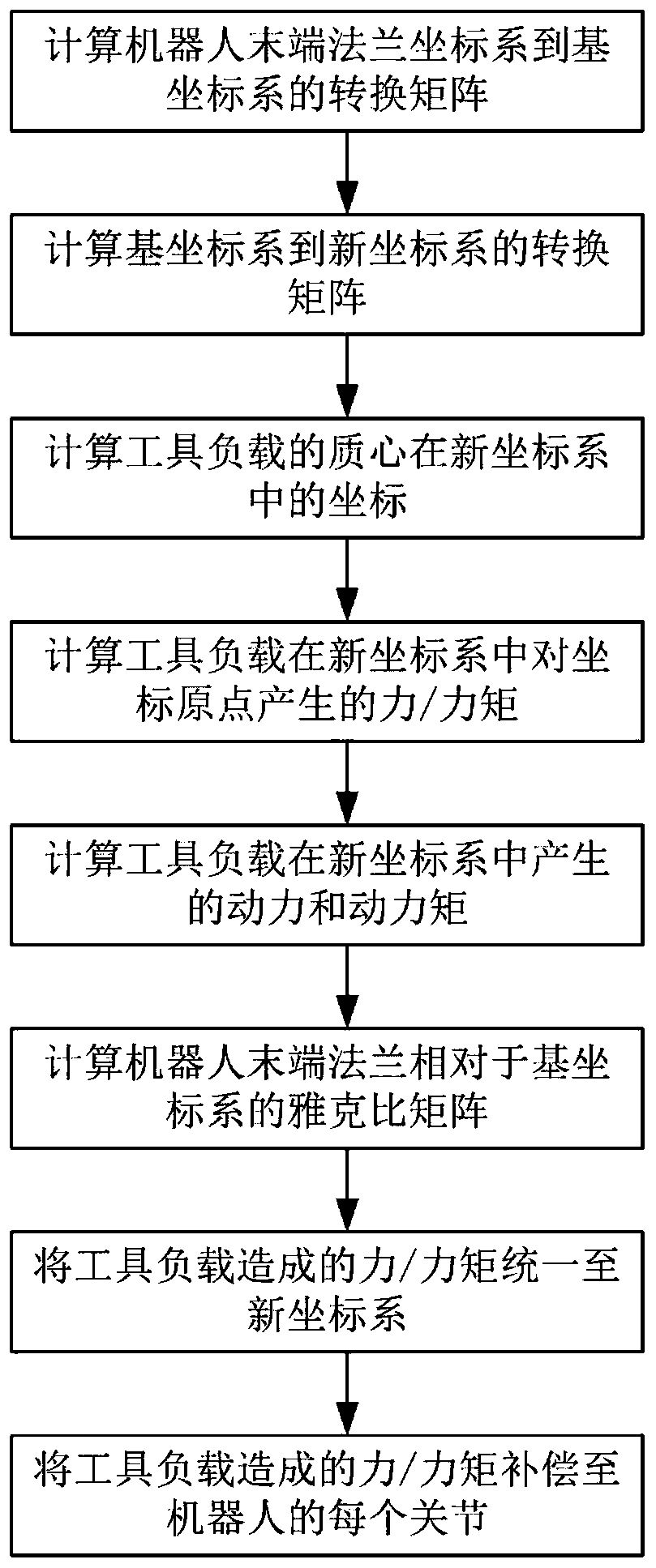

Tail-end load compensating method dragged by multi-degree-of-freedom cooperation robot

ActiveCN110666794AEasy to dragEasy load draggingProgramme-controlled manipulatorClassical mechanicsControl theory

The invention discloses a tail-end load compensating method dragged by a multi-degree-of-freedom cooperation robot. The method comprises the steps of 1, building a robot tail-end flange stress and torque mathematic model; 2, building a joint coordinate system, a base coordinate system, a tail end flange coordinate system of the robot and calculating transition matrixes for transition among the coordinate systems; 3, measuring load mass center parameters; 4, building a new coordinate system and calculating static force and static torque generated by a tool loaded at the original point of the new system; 5, calculating dynamic force and dynamic torque generated by the tool loaded at the original point of the new system; 6, calculating a Jacobian matrix of the robot tail-end coordinate systemrelative to the base coordinate system; 7, compensating for torque and force caused by the load of the tool to each joint of the robot. By compensating for force and torque generated by the load, therobot with the load is dragged more portably, and no extra force or torque sensor needs to be added.

Owner:TIANJIN UNIV

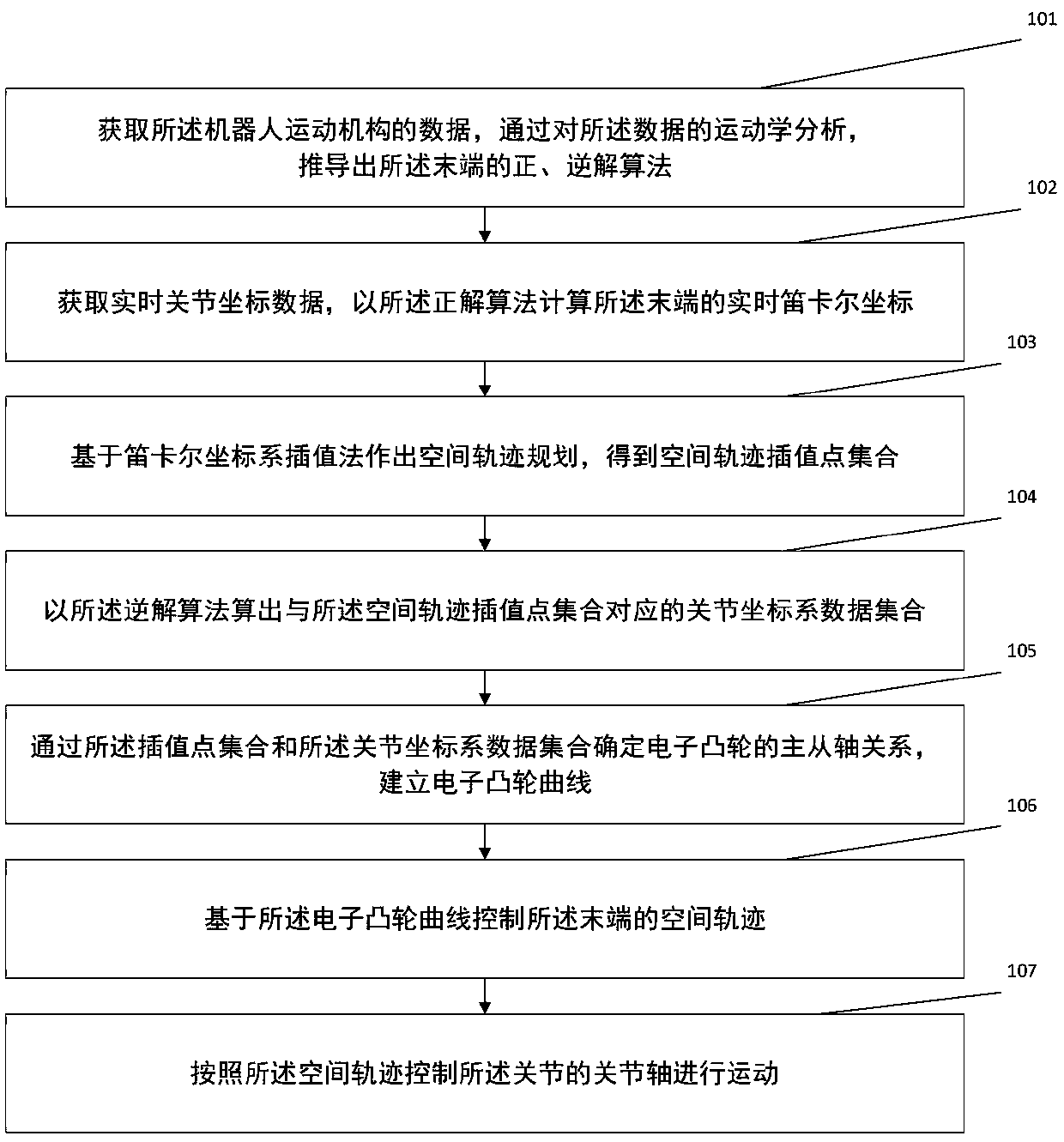

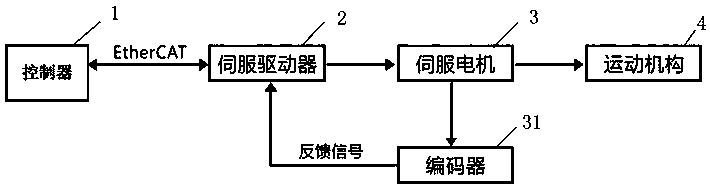

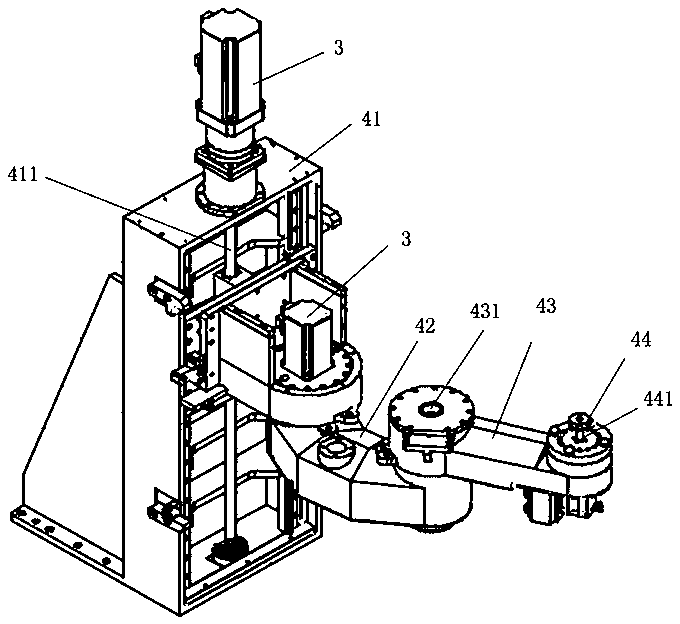

Robot motion control method based on electronic cam and control system

ActiveCN111002306AImprove compatibilityImprove acceleration performanceProgramme-controlled manipulatorLinear motionData set

The invention provides a robot motion control method based on an electronic cam and a control system. The method comprises the steps of obtaining data of a robot motion mechanism, and through kinematics analysis of the data, deducing a positive solution algorithm and an inverse solution algorithm of a tail end; obtaining real-time joint coordinate data, and calculating real-time Cartesian coordinates of the tail end with the positive solution algorithm; based on the Cartesian coordinate system, making spatial trajectory planning, and obtaining a space trajectory point set; working out a jointcoordinate system data set corresponding to the space trajectory point set with the inverse solution algorithm; through a point set and the joint coordinate system data set, determining a master and slave shaft relation of the electronic cam, and building an electronic cam curve; based on the electronic cam curve, controlling the spatial trajectory of the tail end; and according to the spatial trajectory, controlling a joint shaft of a joint to move. Robot non-linear motion control is converted into linear motion control, smooth connection between spatial trajectory points can be achieved, andequipment running smoothness and stability can be improved.

Owner:项淮智能科技(长兴)有限公司

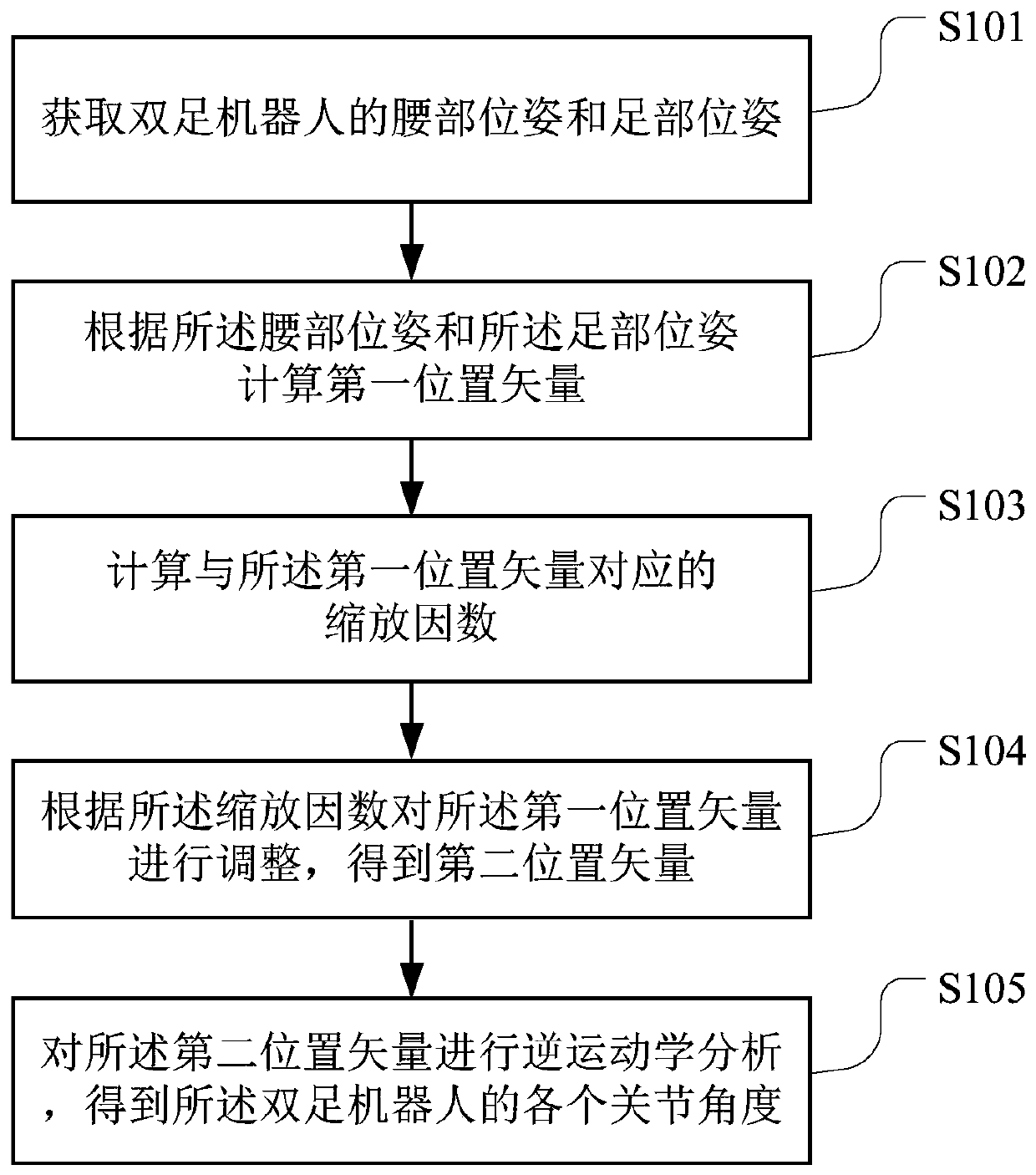

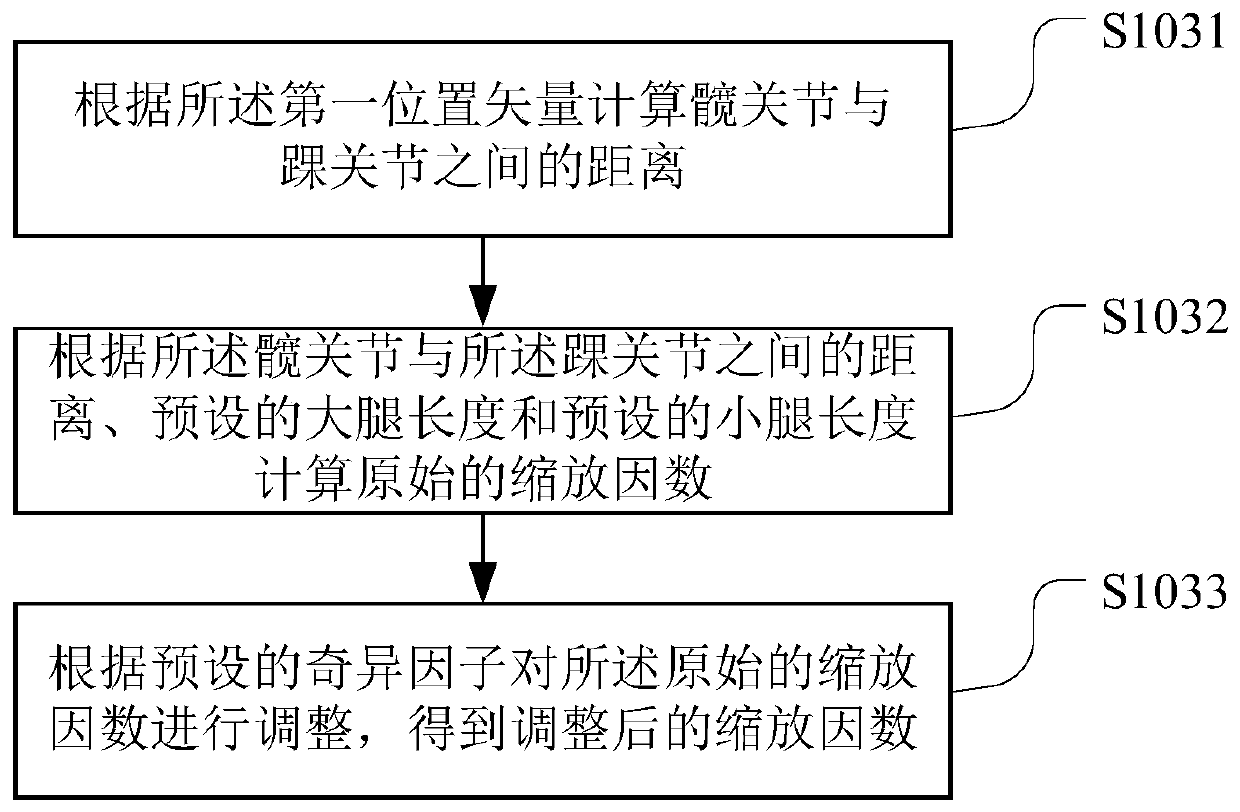

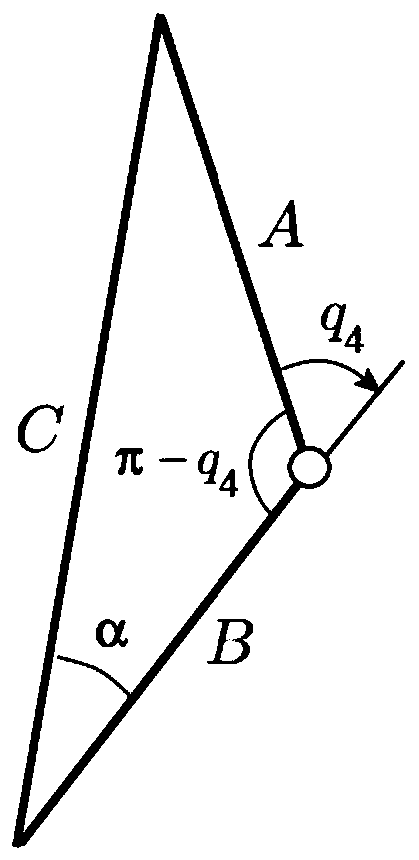

Singular-avoiding gait planning method and device, readable storage medium and robot

PendingCN110989585AAvoid singularity problemsPosition/course control in two dimensionsVehiclesGait planningSimulation

The invention belongs to the technical field of computers, and particularly relates to a singularity-avoiding gait planning method and device, a computer readable storage medium and a robot. The method comprises the steps of acquiring the waist posture and the foot posture of the biped robot; calculating a first position vector according to the waist pose and the foot pose, wherein the first position vector is a hip joint position vector in an ankle joint coordinate system; calculating a scaling factor corresponding to the first position vector; if the scaling factor meets a preset singularityjudgment condition, adjusting the first position vector according to the scaling factor to obtain a second position vector; and performing inverse kinematics analysis on the second position vector toobtain each joint angle of the biped robot. According to the embodiment of the invention, on the basis of the prior art, the consideration of a singular problem is added, and the possible singular problem is effectively avoided through the adjustment of the hip joint position vector.

Owner:UBTECH ROBOTICS CORP LTD

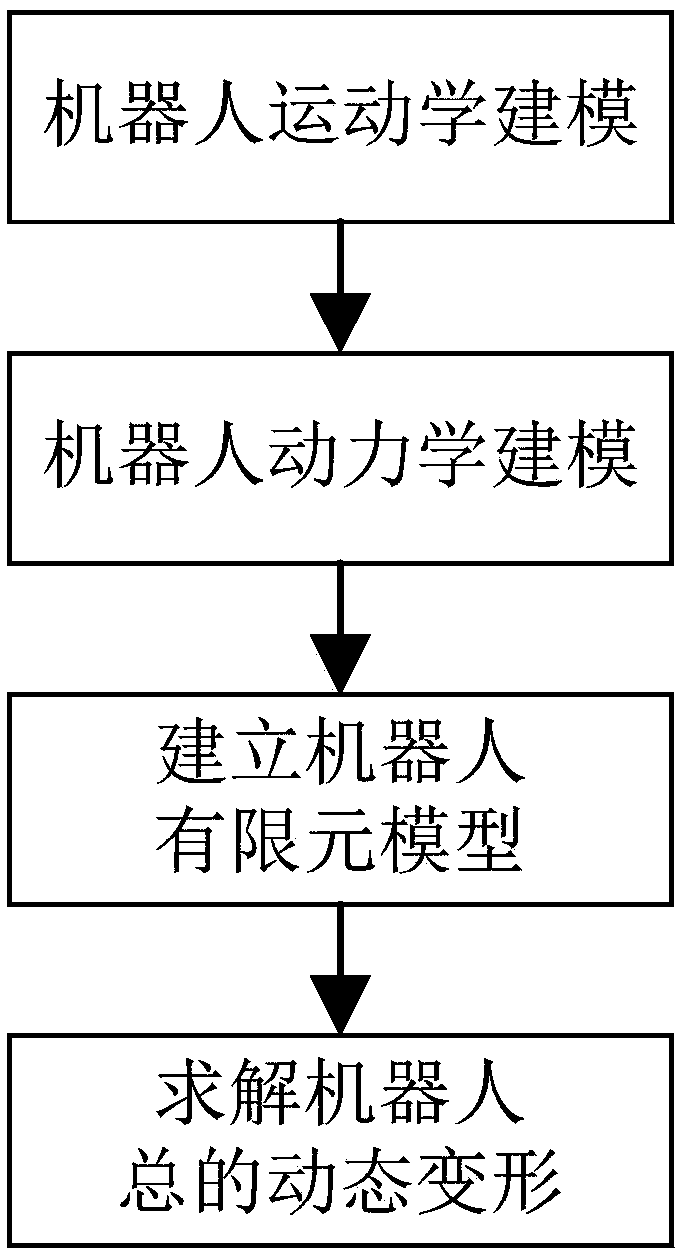

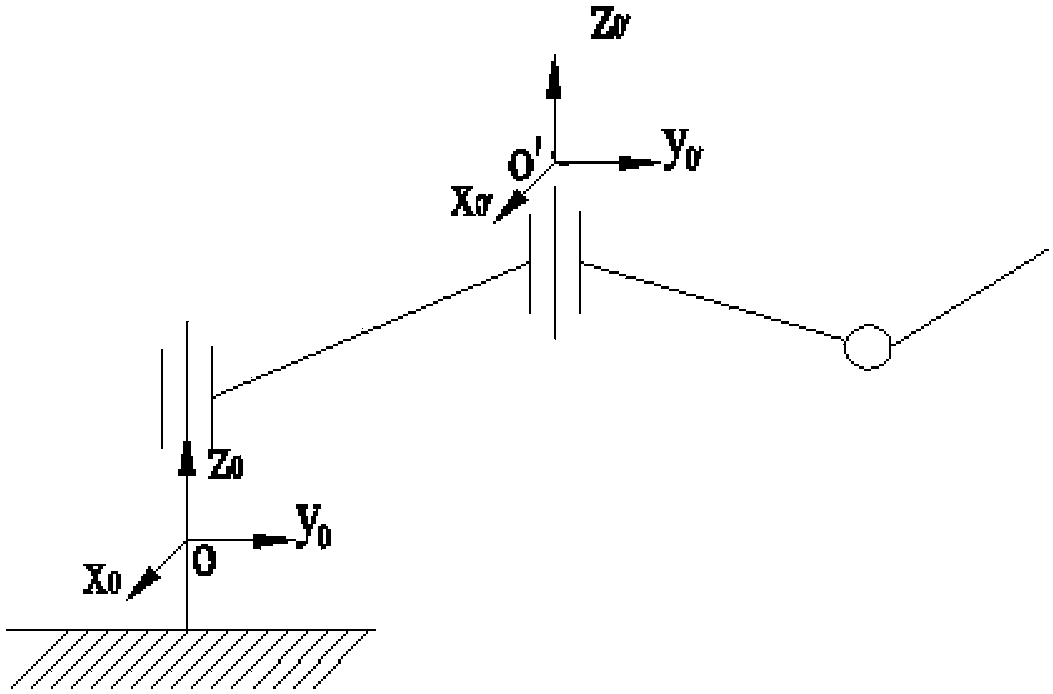

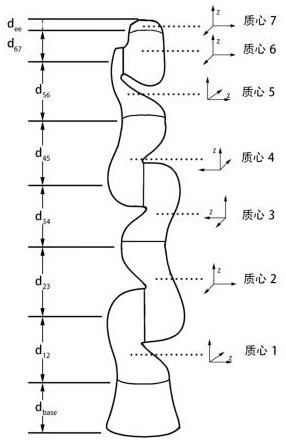

Dynamic deformation calculation method for high-speed heavy-load robot

ActiveCN109634111AEasy to analyze one by oneProof of validityAdaptive controlElement modelKinematics equations

The invention relates to a dynamic deformation calculation method for a high-speed heavy-load robot. The method comprises the following steps that according to design features of a robot body, a basecoordinate system is established at the position of a robot base, robot joint coordinate systems are established at joints of the robot, and D-H parameters at the joints are acquired; a kinematics equation of a tail end device is calculated, the tail end position and posture of the robot is acquired, recurrence on angular velocity and angular acceleration are sequentially conducted, recurrence onvelocity and acceleration are sequentially conducted, and the motion state of each connecting rod in the base coordinate system is calculated; and the inertia force and the inertia moment of each connecting rod are solved, a finite element model of the robot is established, and the total dynamic deformation, stress and strain of the robot are solved. According to the method, a kinetic model of therobot is applied to the finite element model, the deformation situation caused by dead weight, loads and all the inertia force and the inertia moments of the robot is analyzed, various influence factors of the deformation of a tail end point are researched, and a basis is provided for modeling design and parameter optimization of the robot.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

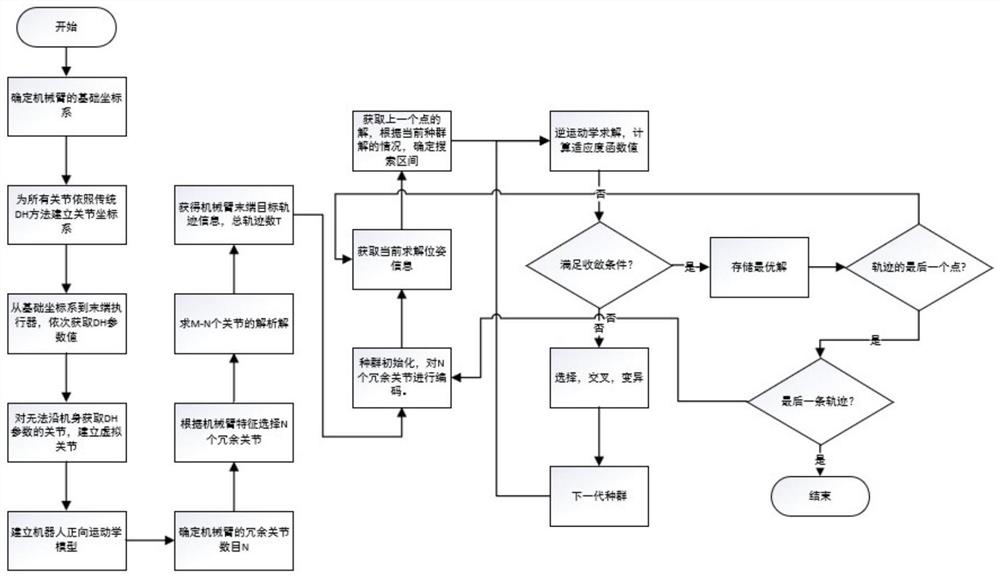

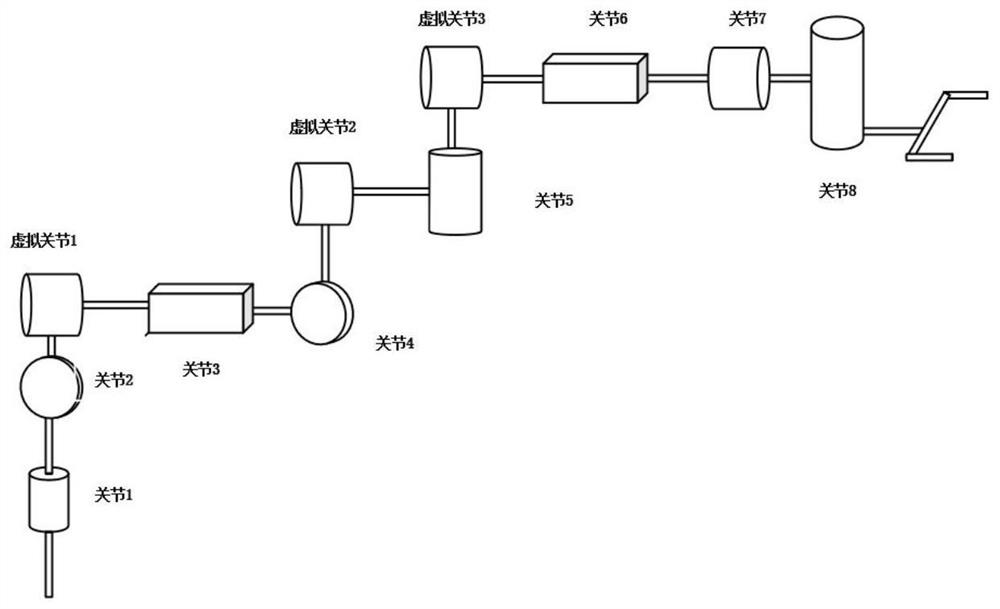

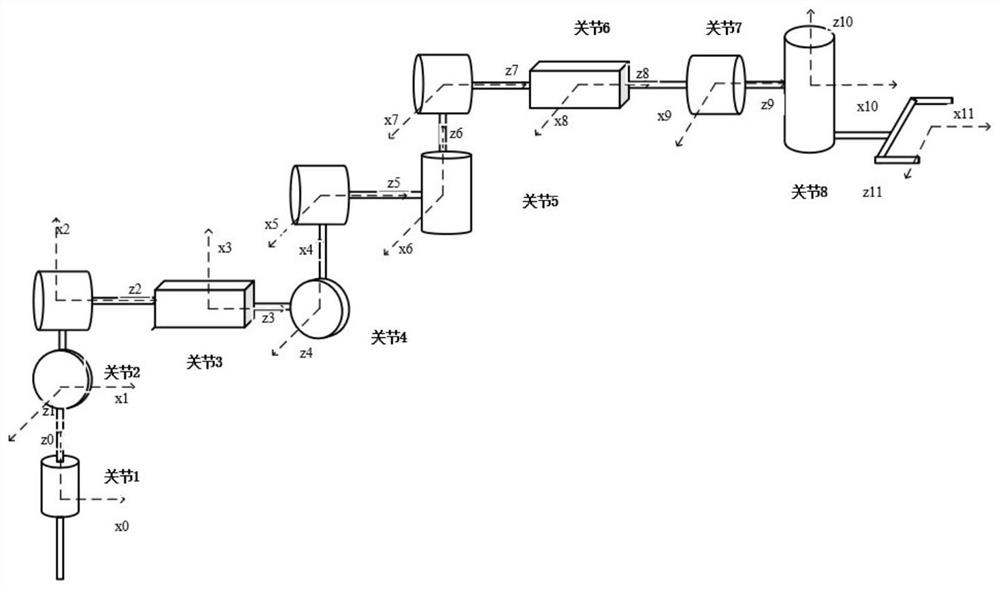

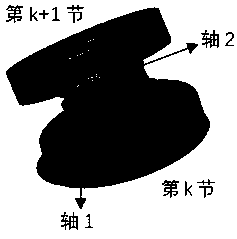

Redundant mechanical arm kinematics solving method based on analytical solution and improved genetic algorithm

PendingCN111914980AAvoid finding pseudo-inverse matricesSmall amount of calculationProgramme-controlled manipulatorArtificial lifeAlgorithmGenetics algorithms

The invention discloses a redundant mechanical arm kinematics resolving method based on an analytical solution and an improved genetic algorithm, which comprises the following steps: A, improving a traditional DH method, and introducing a virtual joint to establish a joint coordinate system; B, constructing a mechanical arm forward kinematics model based on the improved DH parameter table; C, dividing the M joints into N redundant joints and MN non-redundant joints; D, solving an analytical solution of the non-redundant joint; E, generating an initial population of the genetic algorithm by taking the N redundant joints as variables; F, making inverse kinematics calculation with the track as a unit, and using variable interval search in the process of solving one track through the genetic algorithm; and G, repeating the steps E and F until all tracks are solved. Solving is carried out by taking the trajectory as a unit, the use of the evolutionary population is continued, the search speed and solution quality of the genetic algorithm are effectively improved, and the solution continuity is ensured; and meanwhile, a strategy of variable interval search and reference points is introduced to improve the understanding search speed and the self-adaptive degree.

Owner:CENT SOUTH UNIV

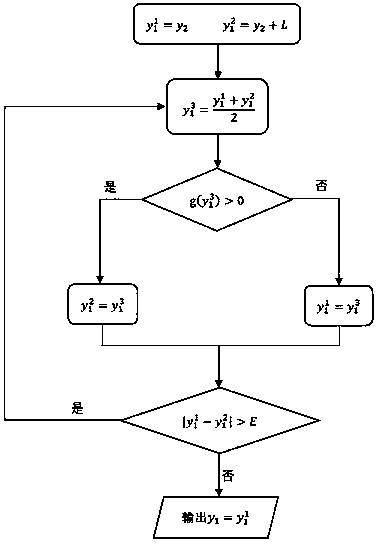

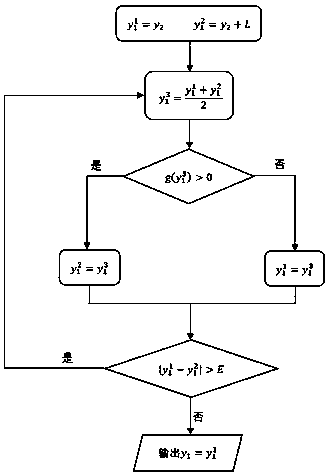

Inverse kinematic solving method of manual operation and control of multi-joint mechanical arm

The invention provides an inverse kinematic solving method of manual operation and control of a multi-joint mechanical arm. The method is characterized in that the posture of each joint and the lengthof each driving rope in each time can be output after space trajectory functions are set; the mapping relation between an operation space and a joint space is solved by dichotomy in the numerical method while being settled; the transfer matrix of each joint coordinate system relative to a base coordinate system can be solved while the mapping relation between the joint space and a driving space is settled, and thus the length of each driving rope can be obtained. According to the method, the posture information of the mechanical arm and the length of the driving ropes in each time in the whole movement process can be obtained under the condition that the basic information of the mechanical arm are known.

Owner:ZHEJIANG UNIV

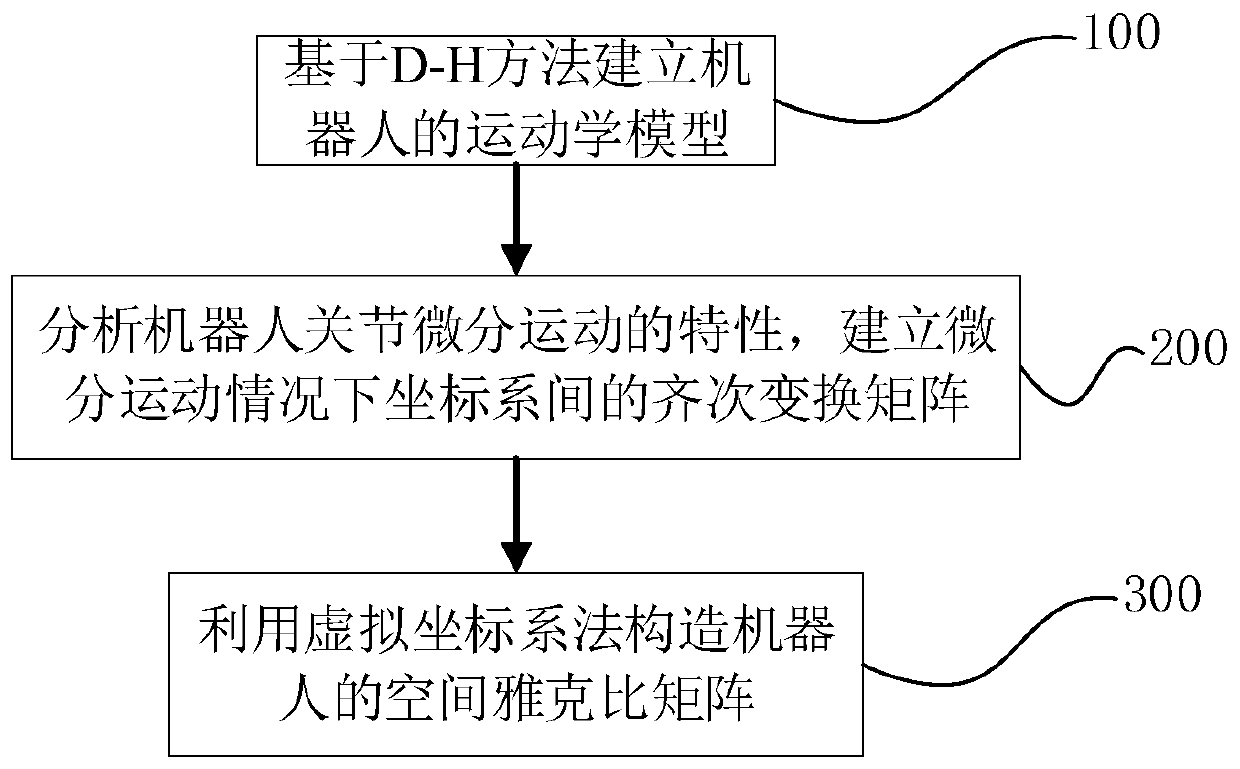

Space Jacobian matrix establishing method for robot parameter identification

ActiveCN110722562AFast constructionRealize parameter identificationProgramme-controlled manipulatorVirtual coordinate systemsRobot kinematics

The invention discloses a space Jacobian matrix establishing method for robot parameter identification. The method includes the steps of S100, establishing a robot kinematic model; S200, analyzing robot joint differential movement characteristics on the basis of the robot kinematic model, and establishing a homogeneous transformation matrix in a coordinate system under the differential movement conditions; S300, establishing a virtual coordinate system corresponding to a joint on the basis of assuming that differential movements happen to a certain joint coordinate system, establishing a transformation matrix between the joint and the coordinate system, then calculating the attained pose of the tail end of the robot relative to a base coordinate system, comparing the attained pose with anexisting theoretical pose to obtain the pose error, caused by the movement quantity error of the joint coordinate system, of the tail end of the robot relative to the base coordinate system, and establishing a space Jacobian matrix of the robot. The robot space Jacobian matrix establishing method based on the differential movement principle and the virtual coordinate system method has lower time consumption and can rapidly establish the space Jacobian matrix of the robot.

Owner:HUAZHONG UNIV OF SCI & TECH

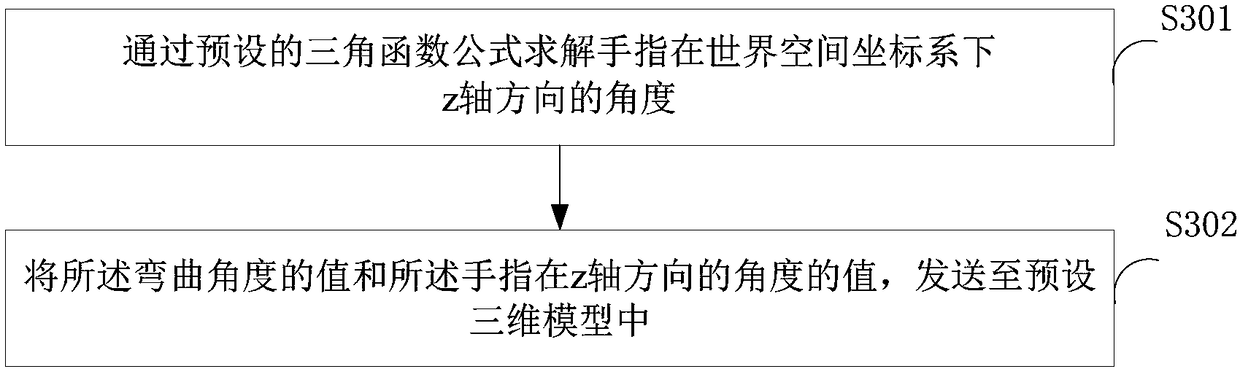

Gesture recognition method, device and system

InactiveCN108693958AReduce in quantitySimple structureInput/output for user-computer interactionGraph readingRelevant informationMathematical model

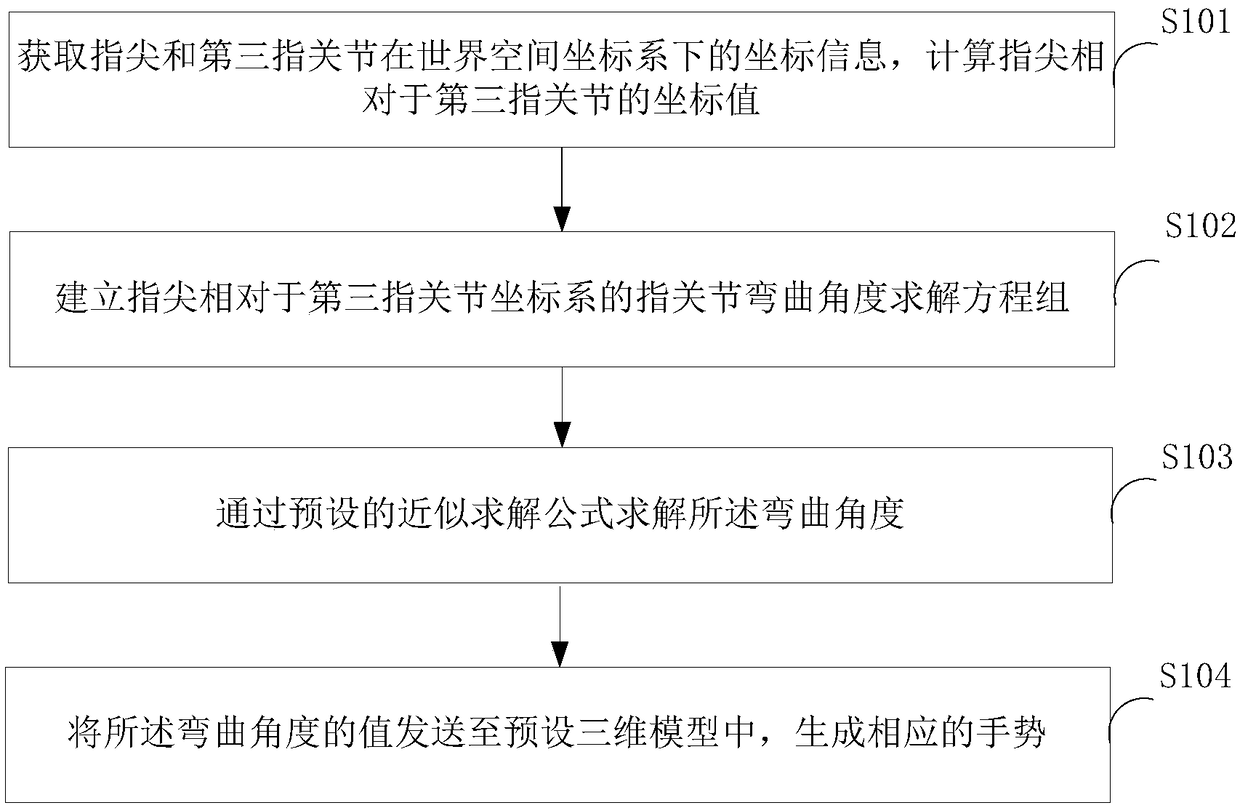

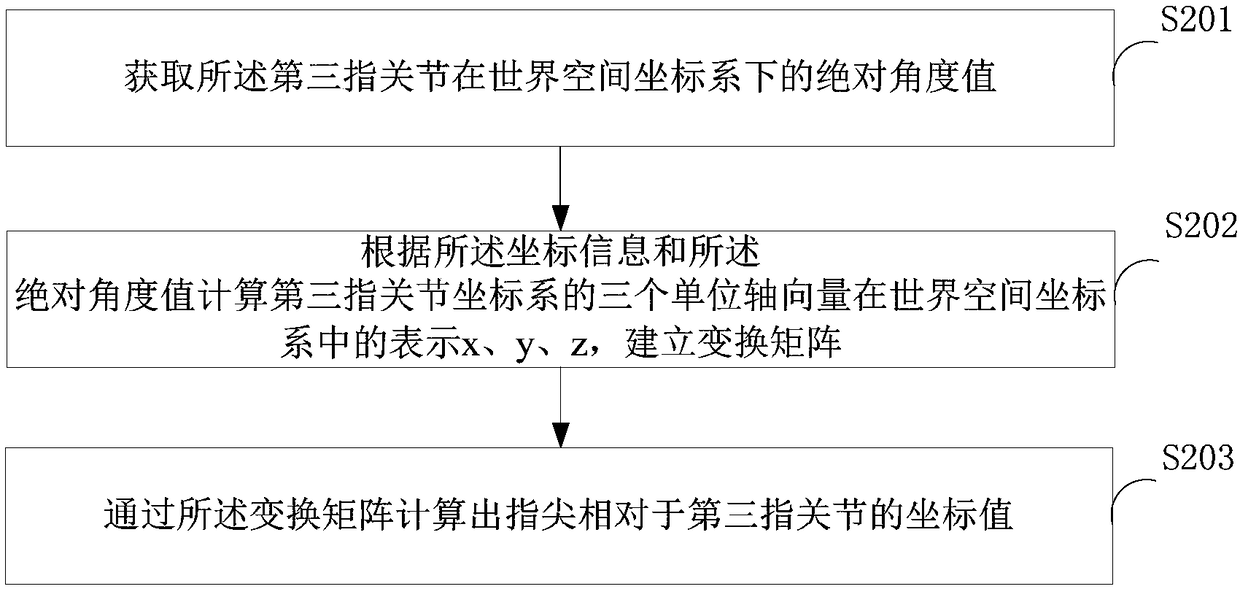

The invention provides a gesture recognition method, device and system. The method comprises the steps of acquiring coordinate information of the fingertip and the third finger joint in a world spacecoordinate system by inertial sensors arranged at the fingertip and the third finger joint; obtaining an established finger joint bending angle solving equation set of the fingertip relative to a third finger joint coordinate system according to a preset approximate solution formula; and sending bending angles Theta 1, Theta 2 and Theta 3 obtained by calculation to a preset three-dimensional modelto generate the corresponding gesture. By means of a mathematical model of solving the bending angle backwards through the coordinate information, accurate bending angle information can be efficiently calculated and obtained, the number of inertial sensors used in the traditional gesture recognition method is reduced, the structure of a gesture recognition product, for example, the structure of adata glove is simplified, and at the same time, the portability and the operability of the data glove are greatly improved due to the reduction of the number of the inertial sensors, and the manufacturing difficulty and the cost of the data glove are reduced, and the user experience is better.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

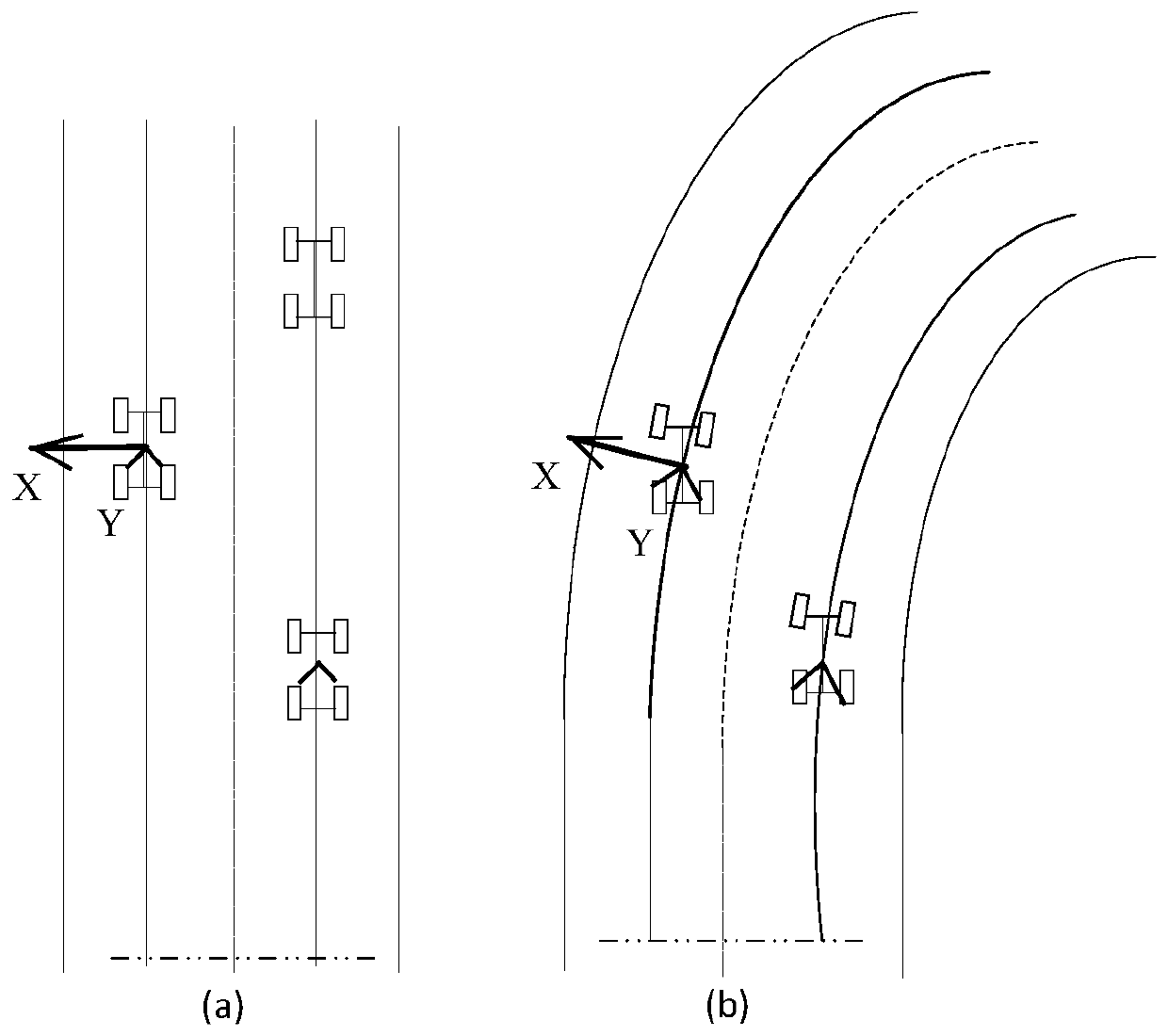

A peripheral vehicle behavior identification method based on an HMM-SVM double-layer improved model under a complex road condition

PendingCN109886304AExcellent timing modeling abilityStrong binary classification abilityInternal combustion piston enginesRoad vehicles traffic controlFeature vectorVehicle behavior

The invention discloses a peripheral vehicle behavior identification method based on an HMM-SVM double-layer improved model under complex road conditions. The method comprises the following steps of 1) offline training, dividing typical surrounding vehicle behaviors, extracting state feature information of surrounding vehicles, transmitting the state feature information to a vehicle through the Internet of Vehicles, converting the vehicle information into state feature information under a road joint coordinate system, generating a feature vector X, and respectively inputting the X into an HMMand SVM parameter learning; 2) carrying out the model improvement which is characterized in that a threshold processor is arranged between the HMM and the SVM, an NSGA-II algorithm is used for optimization to obtain an optimal difference factor, and an HMM-SVM double-layer improved model is obtained; and 3) online testing characterized in that the vehicle utilizes an HMM-SVM double-layer improvedmodel to identify the behavior mode of the tracked vehicle. According to the invention, the application occasion of a surrounding vehicle behavior system is expanded by using a road joint coordinate system constructed by a high-precision map; the excellent time sequence modeling capability of the HMM and the extremely high binary classification capability of the SVM are organically combined, and the double-layer model is improved, so that the accuracy rate and the recognition speed of vehicle behavior recognition are improved.

Owner:JIANGSU UNIV

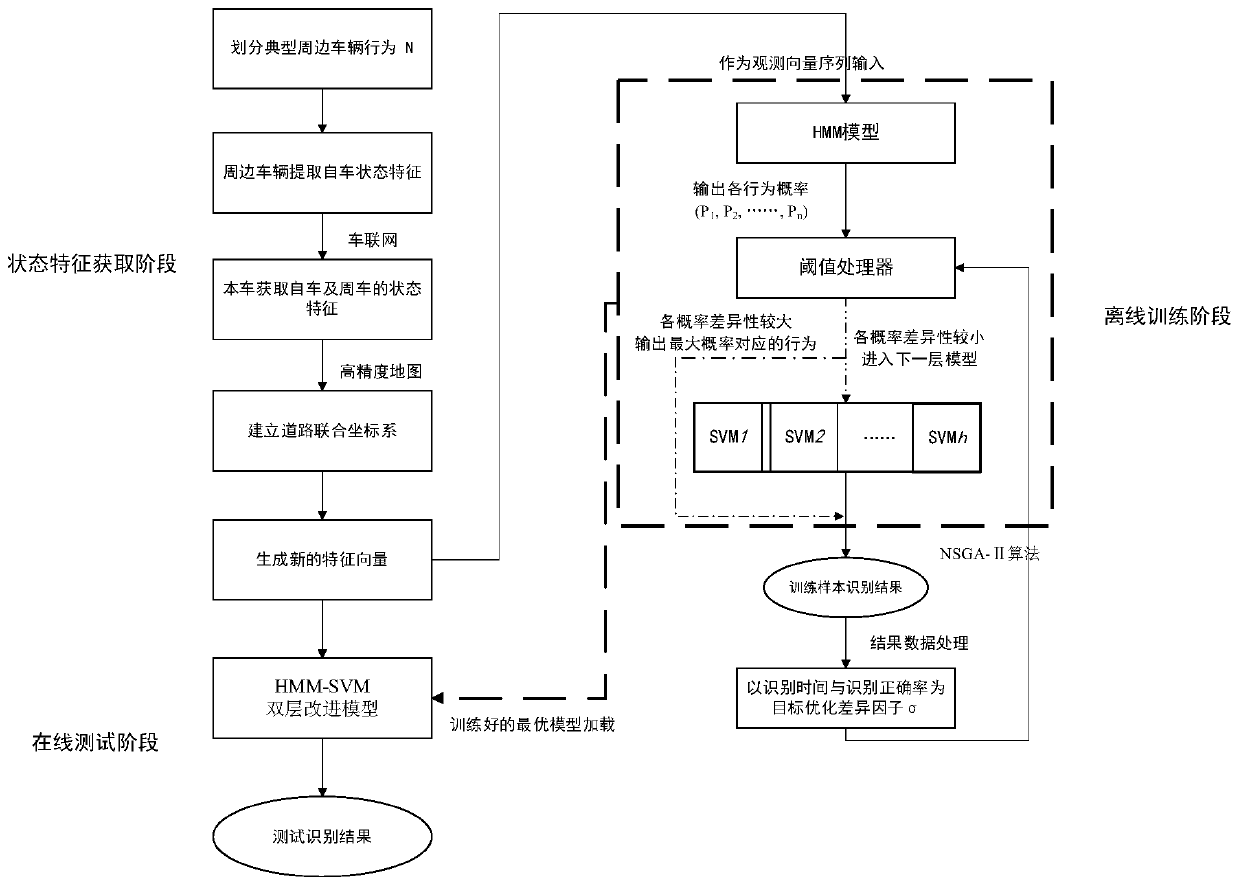

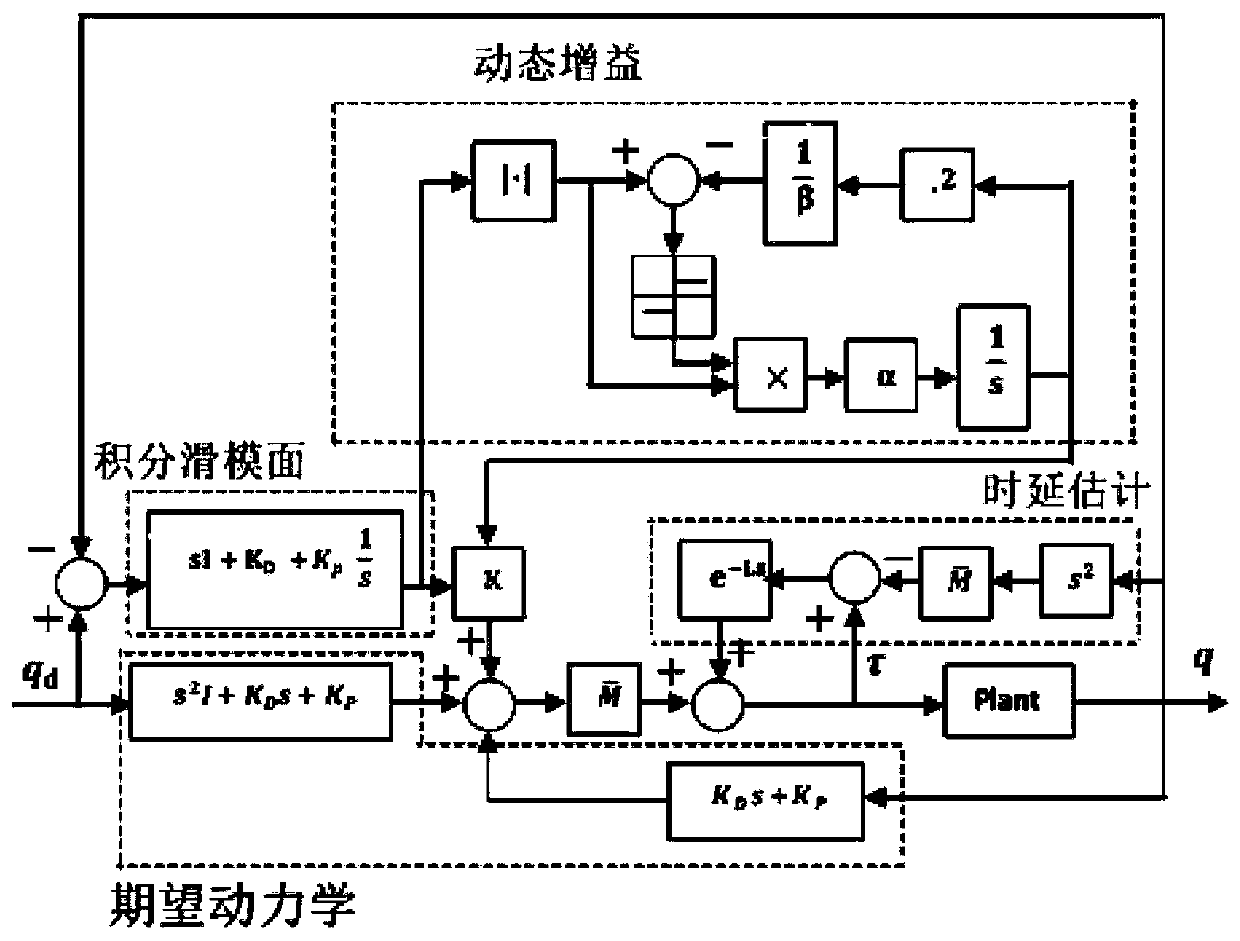

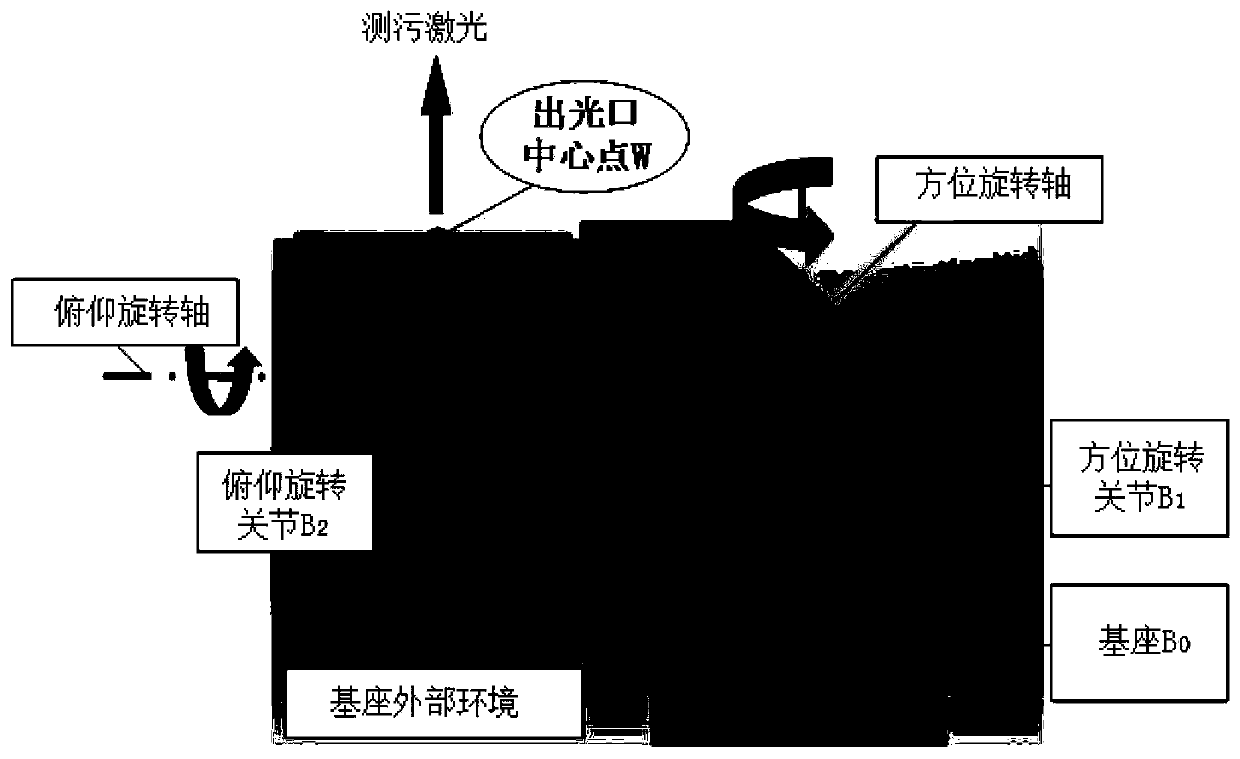

Self-adaptive integral sliding mode control method and system for laser radar scanning mechanism

ActiveCN110007599AFast track targetAccurately track targetsElectromagnetic wave reradiationAdaptive controlJoint coordinatesAngular degrees

The invention discloses a self-adaptive integral sliding mode control method and system of a laser radar scanning mechanism. The laser radar scanning mechanism comprises a base B0, an azimuth rotationjoint B1 and a pitching rotation joint B2, wherein the base B0, the azimuth rotating joint B1 and the pitching rotating joint B2 are sequentially connected in a rotating mode, and the method comprises the steps that a DH modeling method is utilized, the base B0, the azimuth rotating joint B1 and the pitching rotating joint B2 serve as joint points, and joint coordinate systems are established respectively; according to the established joint coordinate system and the power parameters of the laser radar scanning mechanism, a torque-joint angle kinetic equation of the laser radar scanning mechanism is established; and a sliding mode angle controller is established to adjust the actual angle of the joint angle, and the torque applied to the laser radar scanning mechanism by the motor is obtained. According to the method, integral sliding mode control is adopted, the problems of flutter and noise sensitivity in the arrival stage are solved, the uncertainty of the system dynamics of the laser radar scanning mechanism is eliminated, and the robustness of the system is improved.

Owner:UNIV OF SCI & TECH OF CHINA

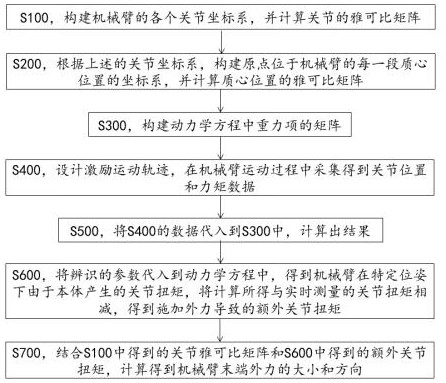

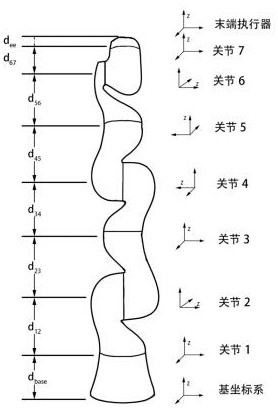

Method of high precision force feedback of mechanical arm in stationary or low speed working condition

ActiveCN111618859AReduce the amount of parametersReduce computing power requirementsProgramme-controlled manipulatorJoint coordinatesKinetics equation

The invention discloses a method of high precision force feedback of a mechanical arm in a stationary or low speed working condition. The method comprises the following steps of S100, establishing joint coordinate systems of the mechanical arm and calculating a jacobian matrix of joints; S200, establishing a coordinate system of an origin located at the center of mass of each section of the mechanical arm according to the joint coordinate systems and calculating a jacobian matrix of the center of mass; S300, establishing a matrix of gravity items in a kinetic equation; S400, collecting joint positions and torque data in the moving process of the mechanical arm; S500, introducing data of S400 in S300 to calculate a result; S600, obtaining an extra joint torque caused by applying an externalforce; and S700, calculating amplitude and direction of an external force at the tail end of the mechanical arm by combining the jacobian matrix of joints in S100 and the extra joint torque in S600.The invention provides the method of high precision force feedback of the mechanical arm in the stationary or low speed working condition, so that the calculating steps are simplified and the force feedback precision is improved.

Owner:HANGZHOU JOINTECH LTD

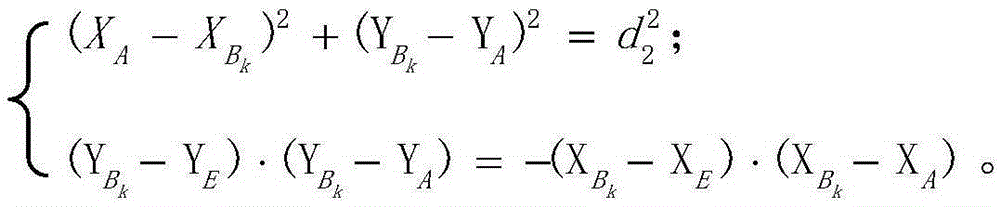

Solving method for six-degree-of-freedom series robot inverse kinematics solution

ActiveCN105404174AReduce complexityPrevent inversionSimulator controlJoint coordinatesRobot kinematics

Owner:HUAZHONG UNIV OF SCI & TECH

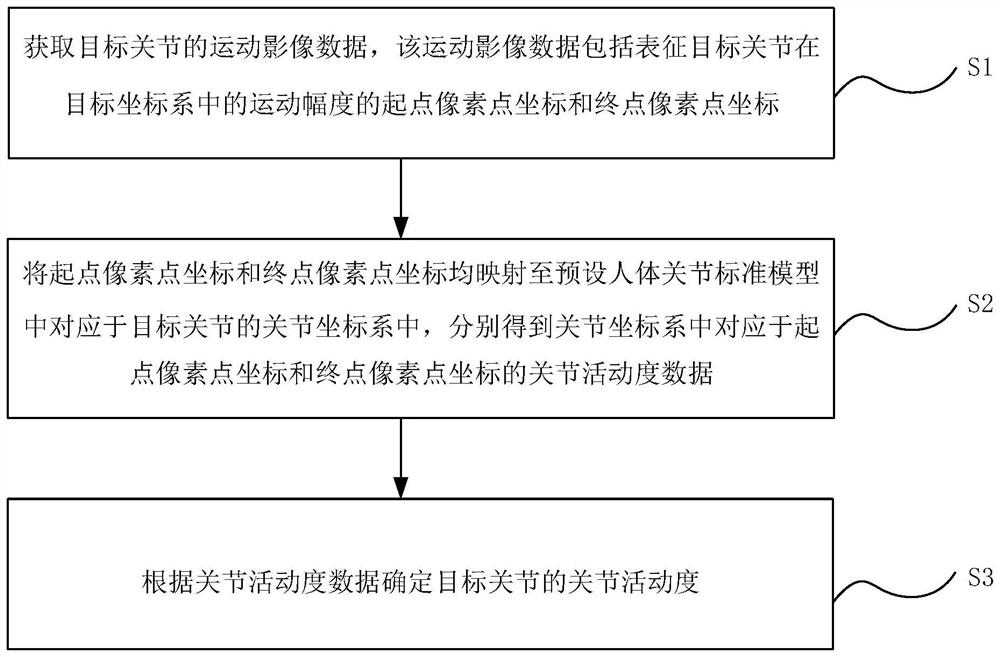

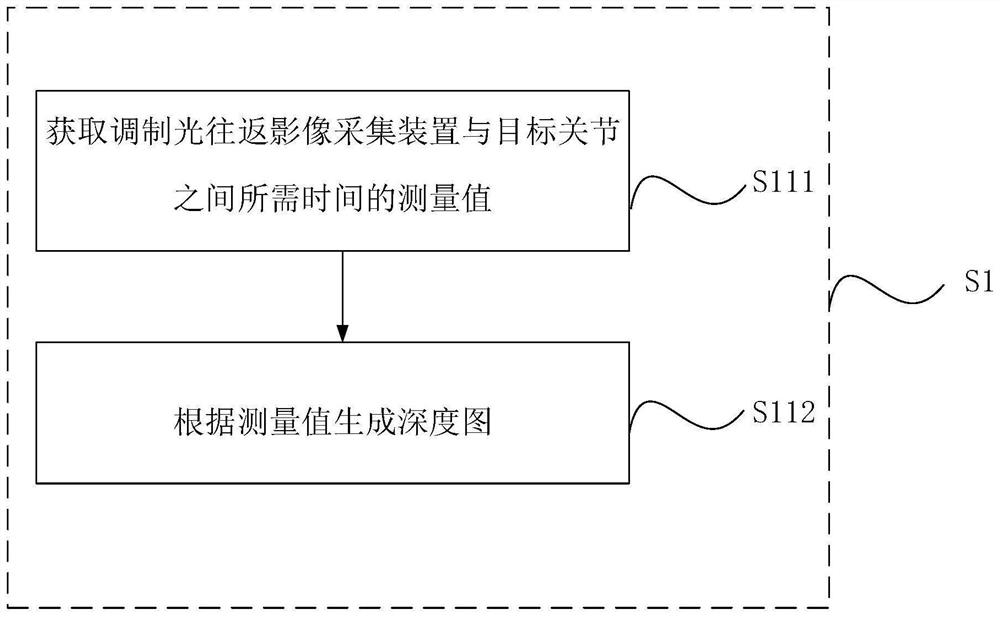

Joint motion range measuring method, system and equipment, electronic equipment and storage medium

PendingCN114663463AMaintain consistencyMaintain objectivityImage enhancementImage analysisHuman bodyData pack

The invention discloses a joint motion range measuring method, system and device, an electronic device and a storage medium, the joint motion range measuring method comprises the following steps: obtaining motion image data of a target joint, the motion image data comprising a starting point pixel point coordinate and an end point pixel point coordinate representing the motion amplitude of the target joint in a target coordinate system; mapping the starting point pixel point coordinate and the ending point pixel point coordinate to a joint coordinate system corresponding to the target joint in a preset human body joint standard model, and respectively obtaining joint activity data corresponding to the starting point pixel point coordinate and the ending point pixel point coordinate in the joint coordinate system; and determining the joint motion range of the target joint according to the joint motion range data. According to the joint motion range measuring method provided by the invention, the coordinates of the pixel points corresponding to the space motion starting point and the space motion ending point of the target joint are mapped to the corresponding joint coordinate systems in the human body joint standard model to represent the joint motion range of the target joint, so that the consistency of measuring results is effectively kept.

Owner:SHANGHAI ELECTRICGROUP CORP

Inverse kinematics solution method for spatial function track movement of multi-joint mechanical arm

The invention provides an inverse kinematics solution method for spatial function track movement of a multi-joint mechanical arm. The mapping relations between operating space and joint space, and thejoint space and driving space during the movement of the multi-joint mechanical arm according to an established trajectory function are solved. After the spatial trajectory function is established, the inverse kinematics solution method for the spatial function track movement of the multi-joint mechanical arm is capable of outputting postures of all joints at all time (specifically, the end positions of all the joints) and the rope length of each driving rope. When solving the mapping relation between the operating space and the joint space, the relation is numerically solved by a dichotomy in numerical methods. When solving the mapping relation between the joint space and the driving space, a transformation matrix of each joint coordinate system relative to a base coordinate system can be obtained by an algorithm, so that the rope length of each driving rope is obtained.

Owner:ZHEJIANG UNIV

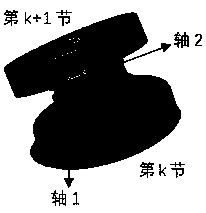

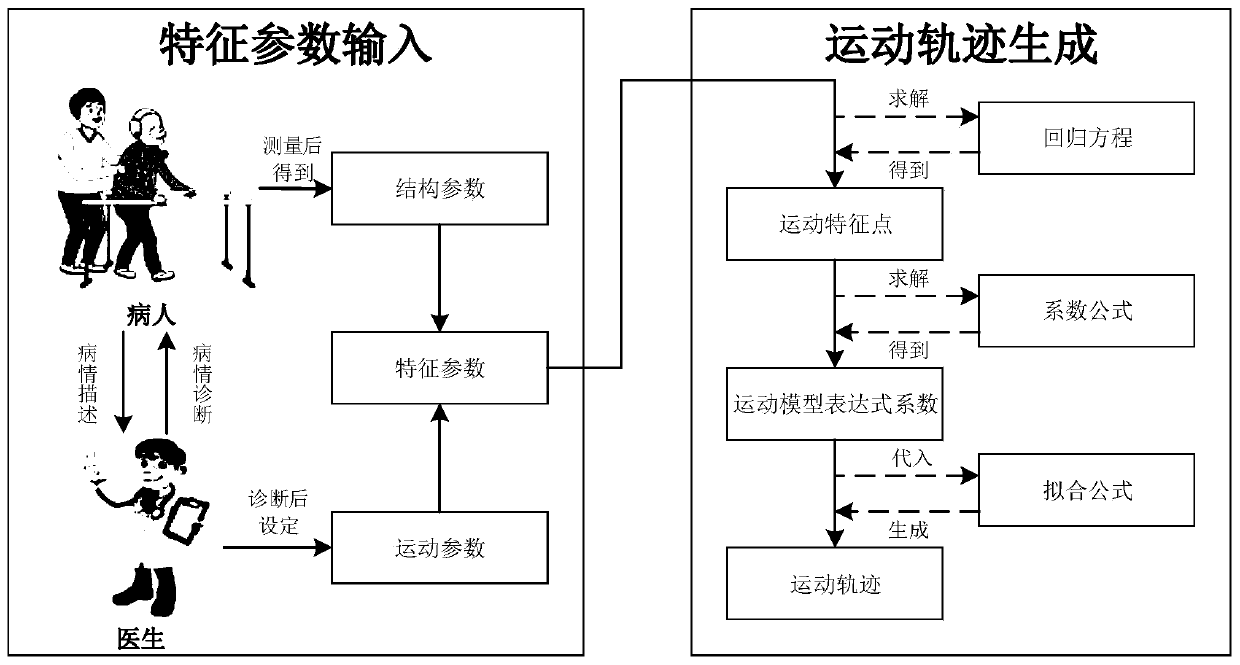

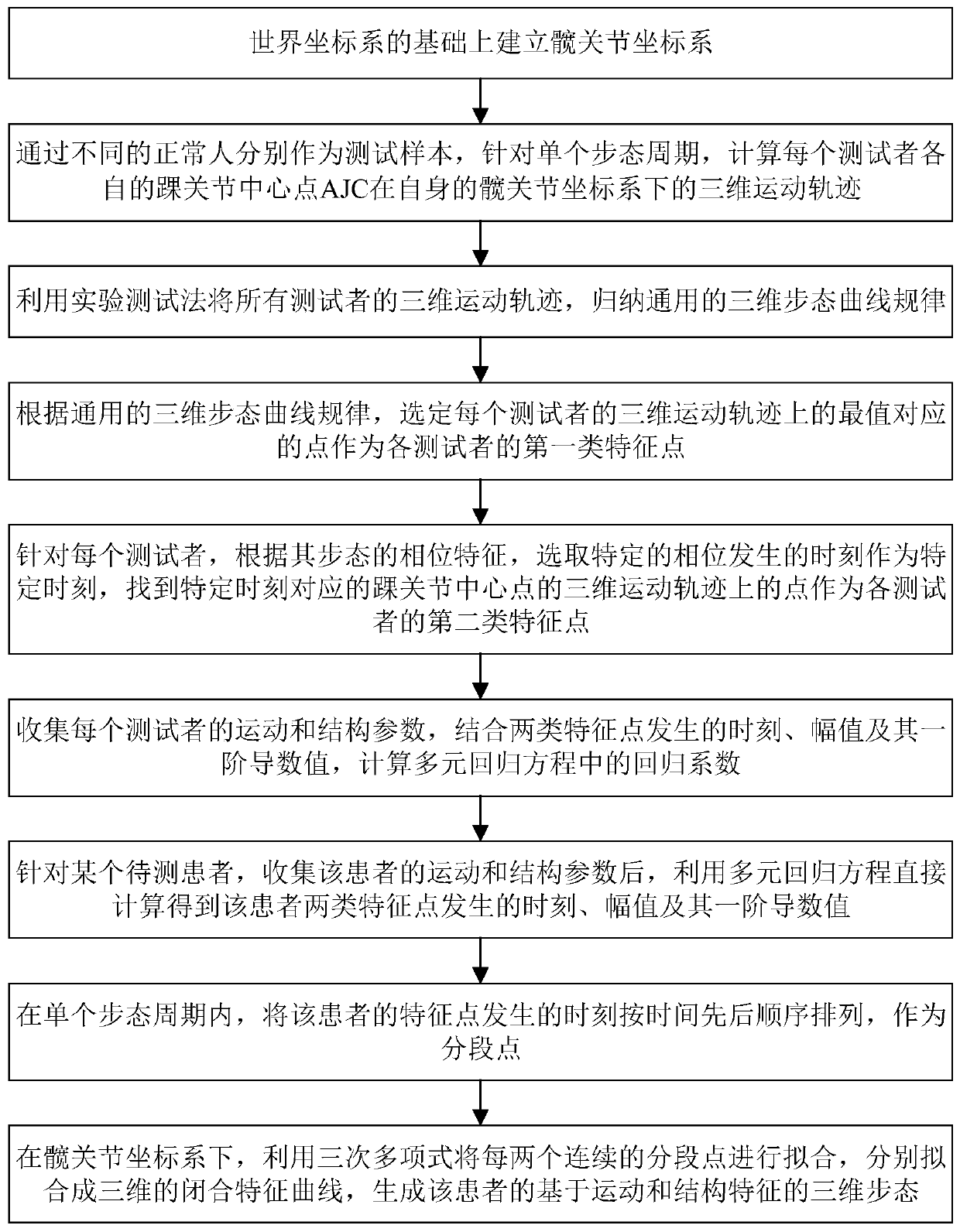

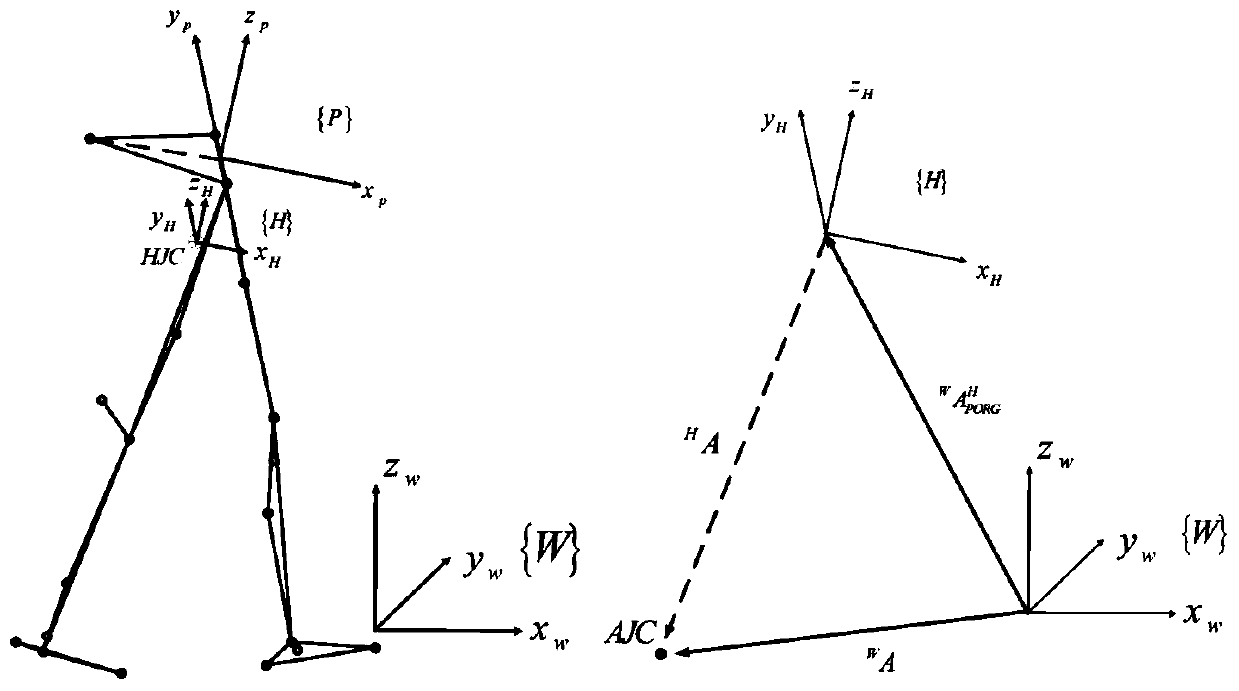

Three-dimensional gait generating method based on human body motion structure characteristic

The invention discloses a three-dimensional gait generating method based on a human body motion structure characteristic, wherein the method relates to robot control technology. The method comprises the steps of firstly establishing a hip joint coordinate system, and calculating a three-dimensional motion track of an AJC in a self hip joint coordinate system in the single gait period of differentnormal persons; concluding a general three-dimensional gait curve rule, selecting a point which corresponds with a limit value on each three-dimensional motion track as a first-class characteristic point; selecting points on the three-dimensional motion track of an ankle joint central point which corresponds with the generating time of the specific phase of each testee as second-class characteristic points; calculating a regression coefficient in a multivariable regression equation according to the two classes of characteristic points; and finally calculating the generating time of two classesof characteristic points of a certain to-be-tested patient by means of the regression equation, performing sequencing and using the time as a segmenting point, and fitting every two continuous segmenting points for obtaining a three-dimensional closed characteristic curve, and generating the three-dimensional gait of the patient. The three-dimensional gait generating method can perform customization according to the motion and structure characteristics of different persons for generating the adapted three-dimensional gait.

Owner:BEIHANG UNIV

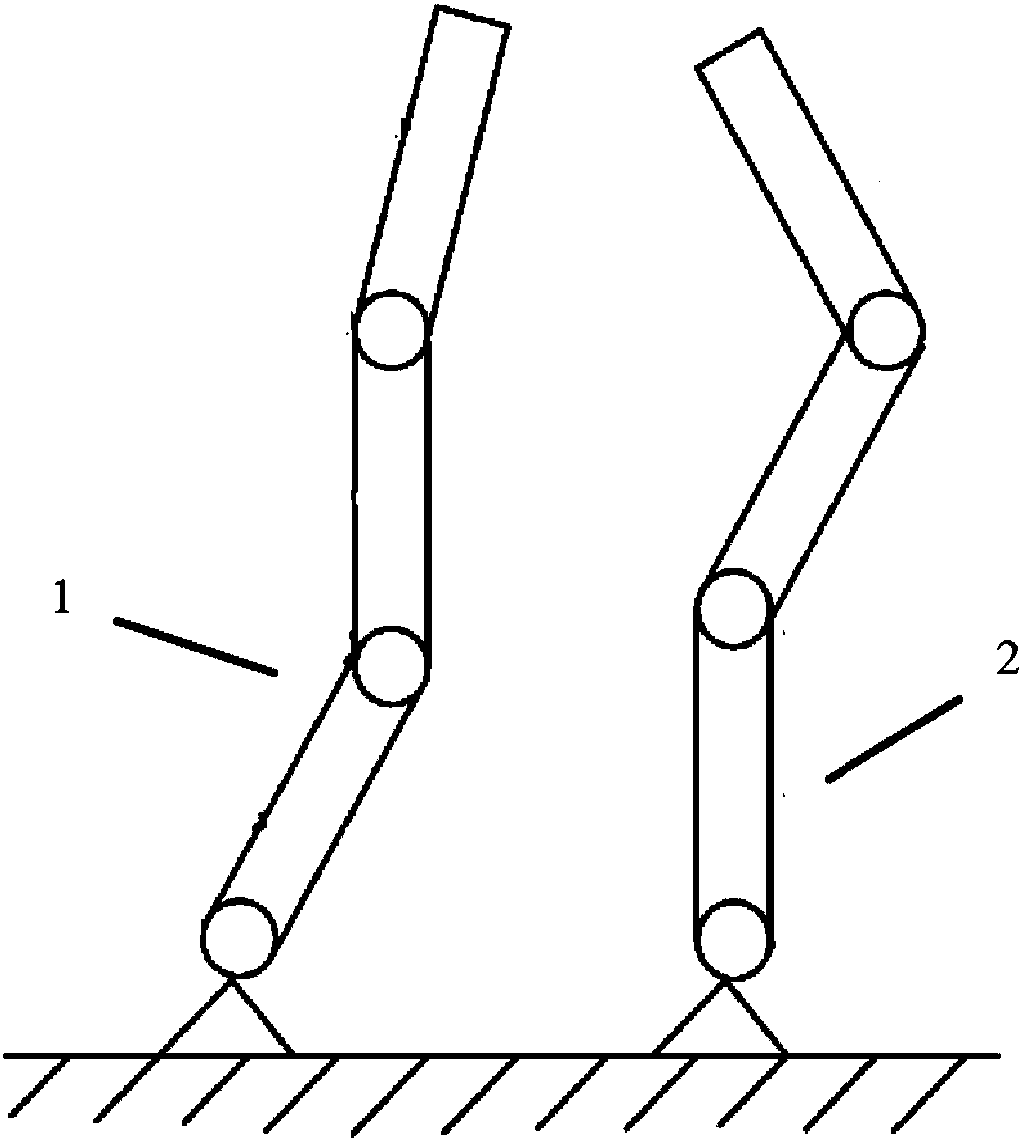

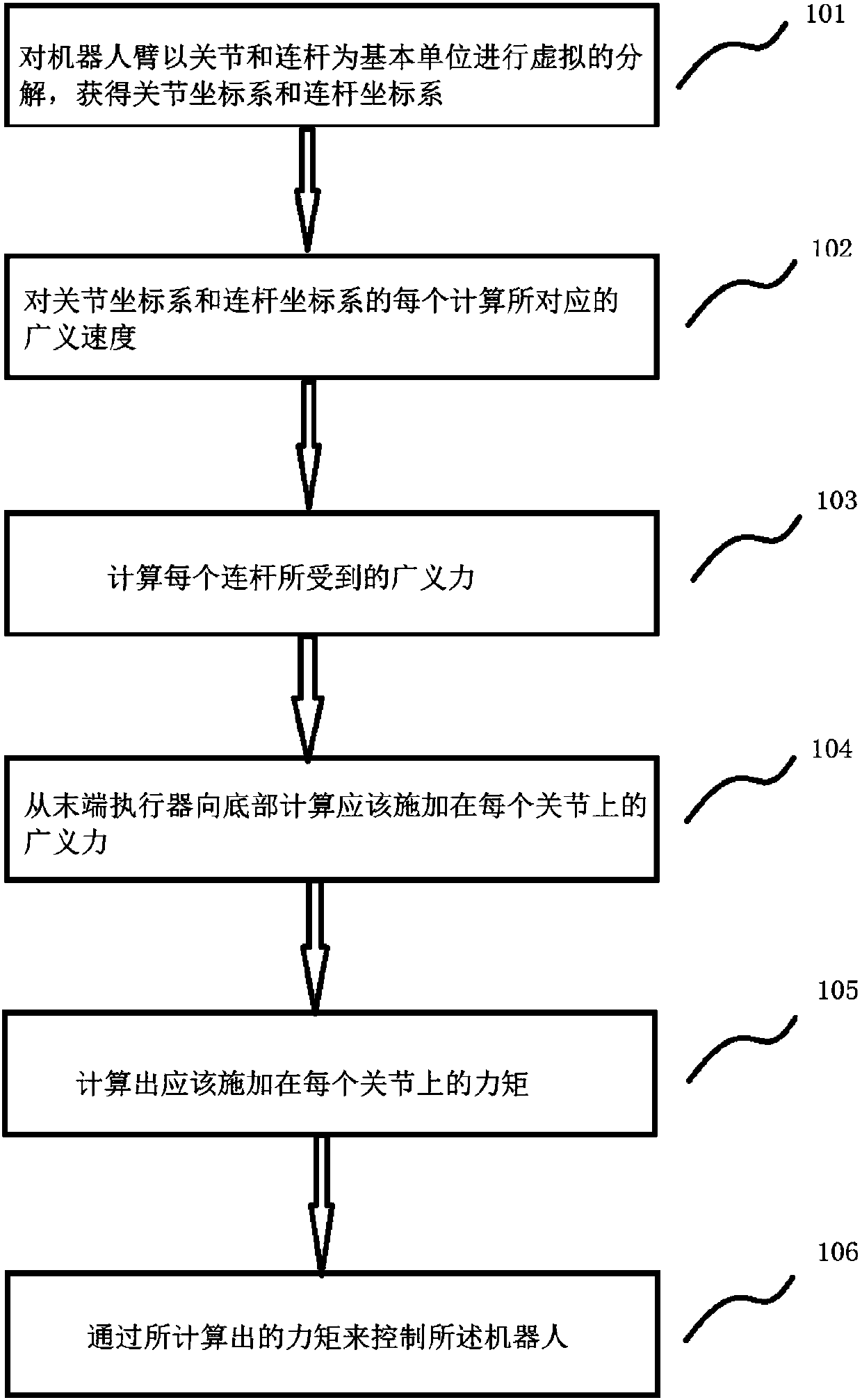

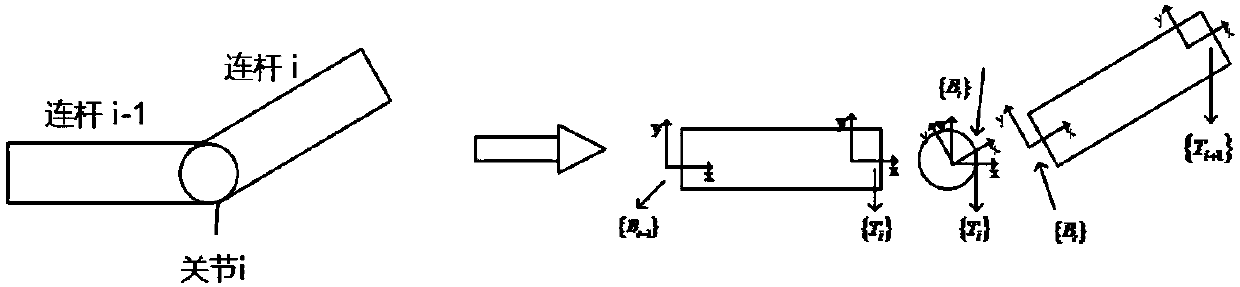

Control method for robot

ActiveCN107650121ASmall amount of calculationGuaranteed stabilityProgramme-controlled manipulatorJoint coordinatesEngineering

The invention discloses a control method for a robot. The robot comprises at least one arm. Each arm comprises a bottom, joints, connection rods and an end executor. The control method comprises the steps that the arms are decomposed with the joints and the connection rods as basic units so that joint coordinate systems and connection rod coordinate systems can be obtained; corresponding generalized velocities of each joint coordinate system and each connection rod coordinate system are calculated; the generalized force subjected by each connection rod is calculated; according to the calculated generalized force borne by each connection rod, the generalized force needing to be applied to each joint is calculated from the corresponding end executer to the corresponding bottom; the moment offorce to be applied to each joint is worked out; and the robot is controlled through the calculated moment of force. By adopting the control method, the calculated amount in real-time control can beeffectively reduced, and the real-time control purpose is achieved.

Owner:深圳力合精密装备科技有限公司

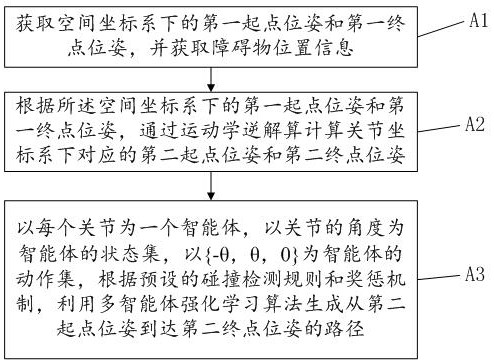

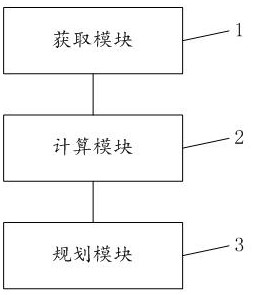

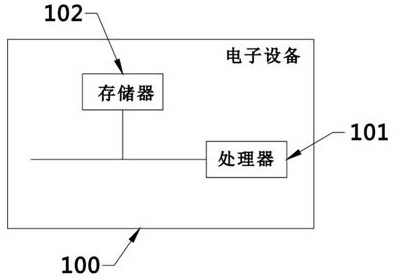

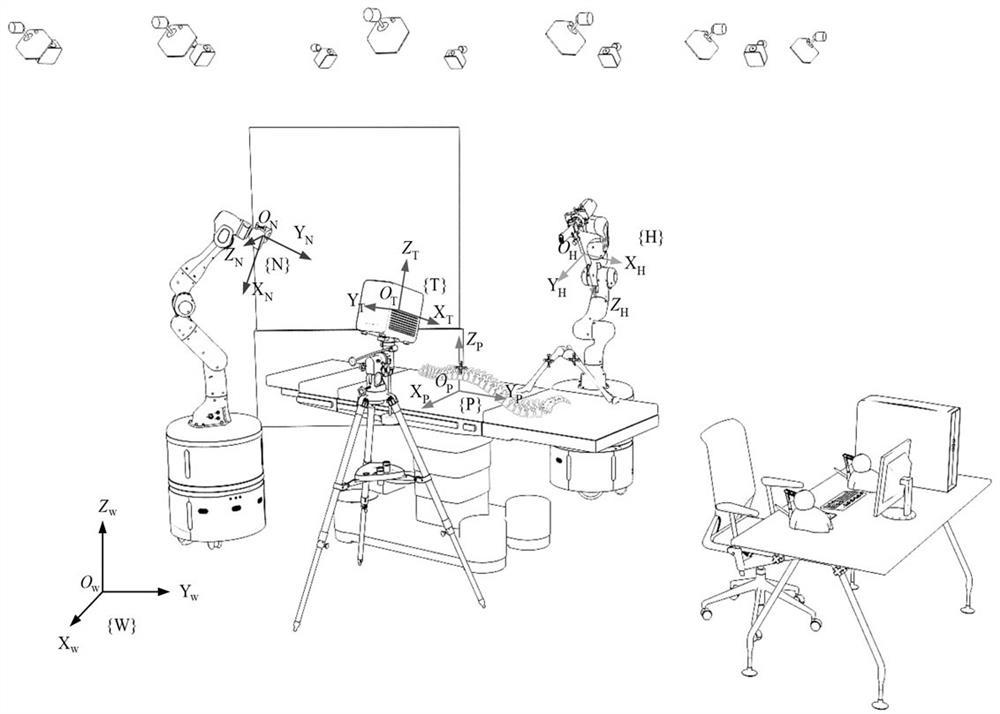

Mechanical arm path planning method and device, electronic equipment and storage medium

ActiveCN113459109AGuaranteed stabilityAvoid Mutation SituationsProgramme-controlled manipulatorCollision detectionClassical mechanics

The invention relates to the technical field of mechanical arm control, and provides a mechanical arm path planning method and device, electronic equipment and a storage medium. A first starting point pose and a first end point pose under a space coordinate system are obtained, and position information of an obstacle is obtained; according to the first starting point pose and the first end point pose under the space coordinate system, a corresponding second starting point pose and a corresponding second end point pose under a joint coordinate system are calculated through inverse kinematics calculation; and each joint is taken as an agent, the angles of the joints are taken as state sets of the agents, {-theta, theta, 0} is as an action set of the agents, and a multi-agent reinforcement learning algorithm is utilized to generate a path from the second starting point pose to the second end point pose according to a preset collision detection rule and a reward and punishment mechanism, wherein theta is the preset minimum movement step length of each joint. Therefore, the singular solution and multi-solution problems caused by the fact that the angles of all the joints are calculated through inverse kinematics calculation by space coordinates can be avoided, and the stability of operation of a mechanical arm is guaranteed.

Owner:JIHUA LAB

Surgery and image integrated surgical planning and navigation method

ActiveCN113940755AGuaranteed high precision positioningSurgical navigation systemsComputer-aided planning/modellingSurgical operationOperating theatres

The invention discloses a surgery and image integrated surgical planning and navigation method, which comprises the following steps of step 1, collecting a patient preoperative CT image with a positioning mark; step 2, establishing a surgery and image integrated joint coordinate system according to a three-dimensional optical tracker coordinate determined by an environmental motion capture system, and a medical instrument and surgical area coordinate positioned by a three-dimensional optical tracker, and carrying out registration on the surgery and image integrated joint coordinate system and the patient preoperative CT image with the positioning mark, wherein the surgery coordinate system is an operating room coordinate system, and the image coordinate system is a virtual image coordinate system; step 3, converting a surgery path under a virtual image coordinate system planned before surgery into the operating room coordinate system to realize intraoperative active navigation of a mechanical arm and a surgical instrument; and step 4, projecting a planned section to the surgical area, carrying out dynamic following, and performing an auxiliary surgical operation by combining with a force feedback device. The surgery and image integrated surgical planning and navigation method provided by the invention belongs to a marked registration method, and can be used for carrying out integrated spatial relation description on the environment of a surgical operating room, the surgical operation, a navigation arm and human-computer interaction equipment, pre-operative medical images and surgical operation orientation registration and planning path transmission are used, and therefore, accurate active navigation in the surgery is realized.

Owner:NANKAI UNIV

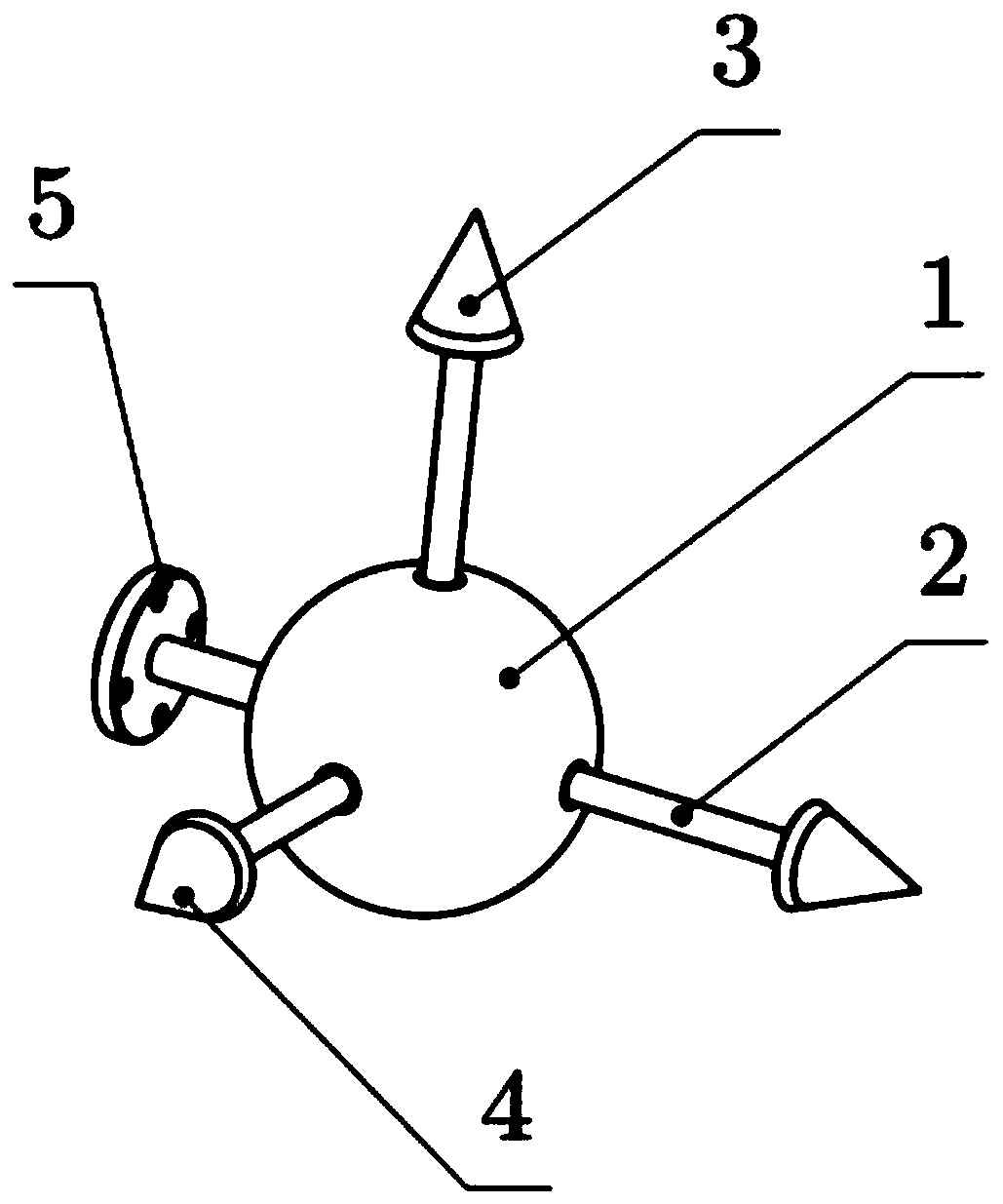

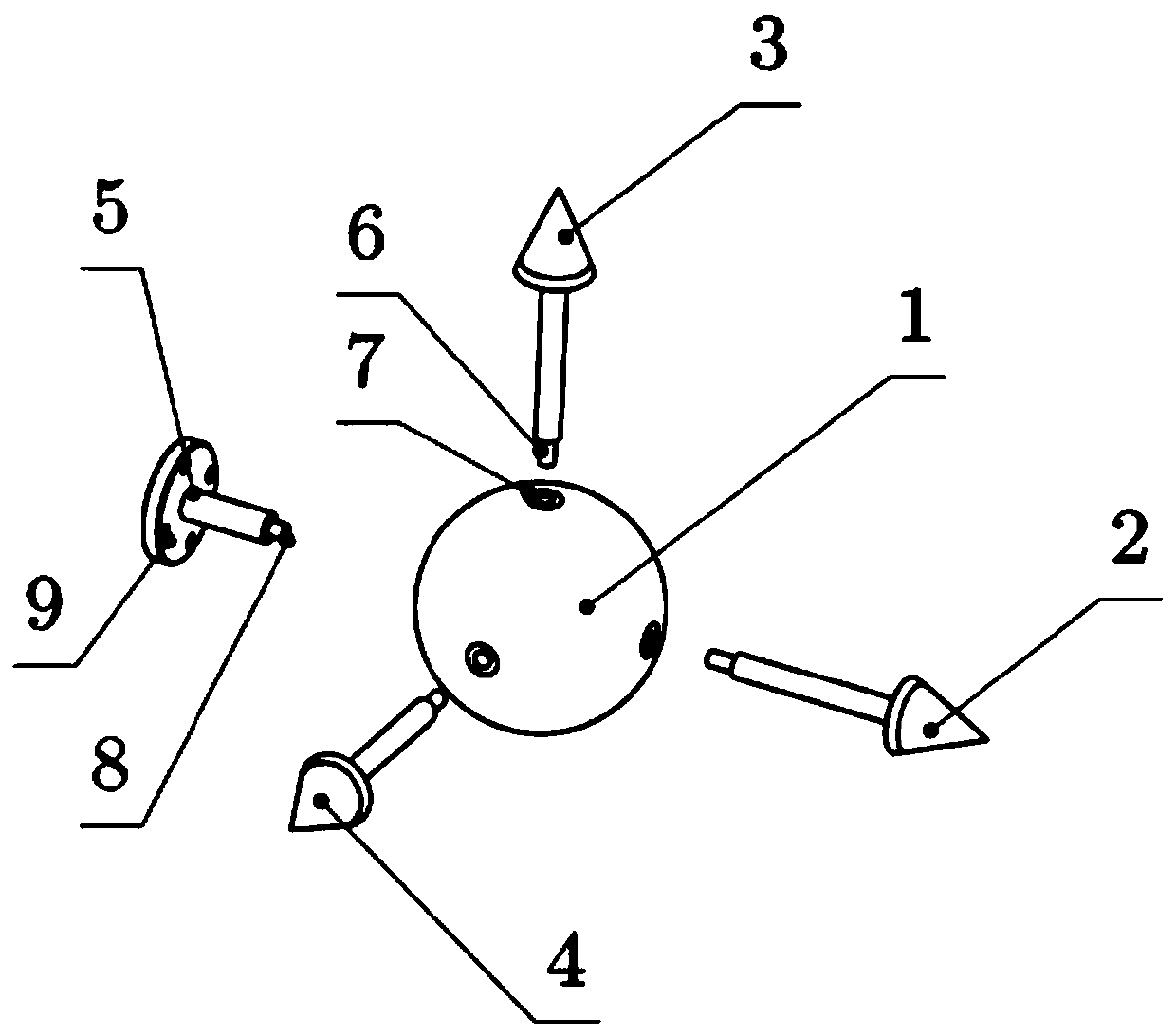

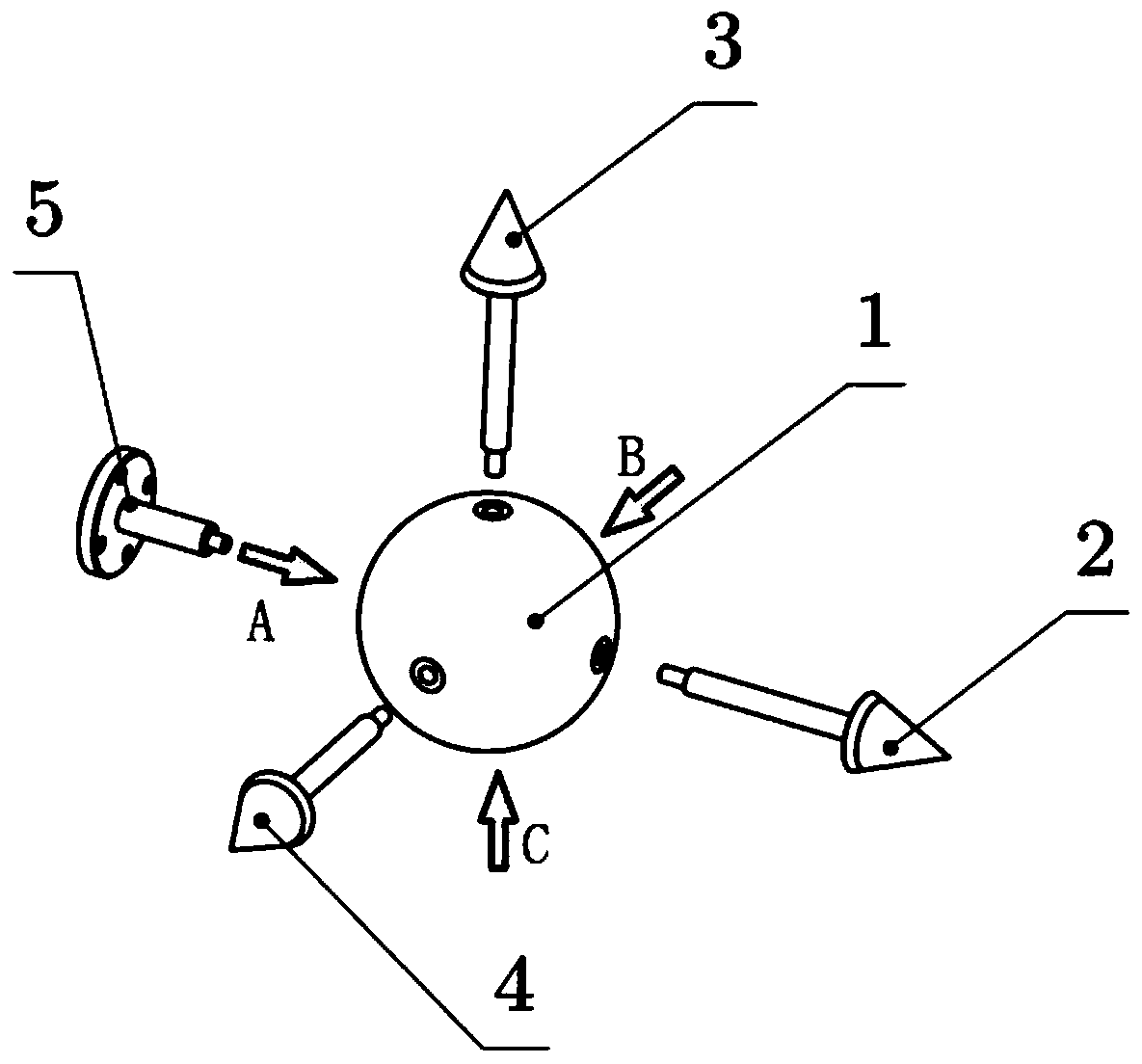

Tail end coordinate ball for robot demonstration

InactiveCN110977946AImprove debugging efficiencyImprove accuracyProgramme-controlled manipulatorRectangular coordinatesJoint coordinates

The invention discloses a tail end coordinate ball for robot demonstration. The tail end coordinate ball comprises a central ball body, an x-axis coordinate, a y-axis coordinate, a z-axis coordinate and a connecting flange; the central ball body is provided with a plurality of threaded mounting holes which are mutually perpendicular in pairs, the x-axis coordinate, the y-axis coordinate, the z-axis coordinate and the connecting flange, the x-axis coordinate, the y-axis coordinate and the z-axis coordinate are respectively connected with the central ball body through the threaded mounting holes, one end of the connecting flange is connected with the central ball body through the threaded mounting holes which are mutually perpendicular in pairs on the central ball body, the other end of theconnecting flange is connected with a robot rail end joint, and the x-axis coordinate, the y-axis coordinate, the z-axis coordinate and the connecting flange are assembled to form a Descartes rectangular coordinate system. The tail end coordinate ball for robot demonstration is convenient to install and adjust, can adapt to different robot joint coordinate systems, and can conveniently and visually display the space position and posture of the tail end joint of the robot, so that the debugging efficiency and accuracy of the robot can be effectively improved.

Owner:CHANGZHOU INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com