Pipeline insertion intersecting line track planning method orientated to laser machining robot

A laser processing and robot technology, applied in laser welding equipment, metal processing, metal processing equipment and other directions, can solve problems such as large amount of calculation, increasing difficulty of robot trajectory planning, and difficulty in obtaining included angles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

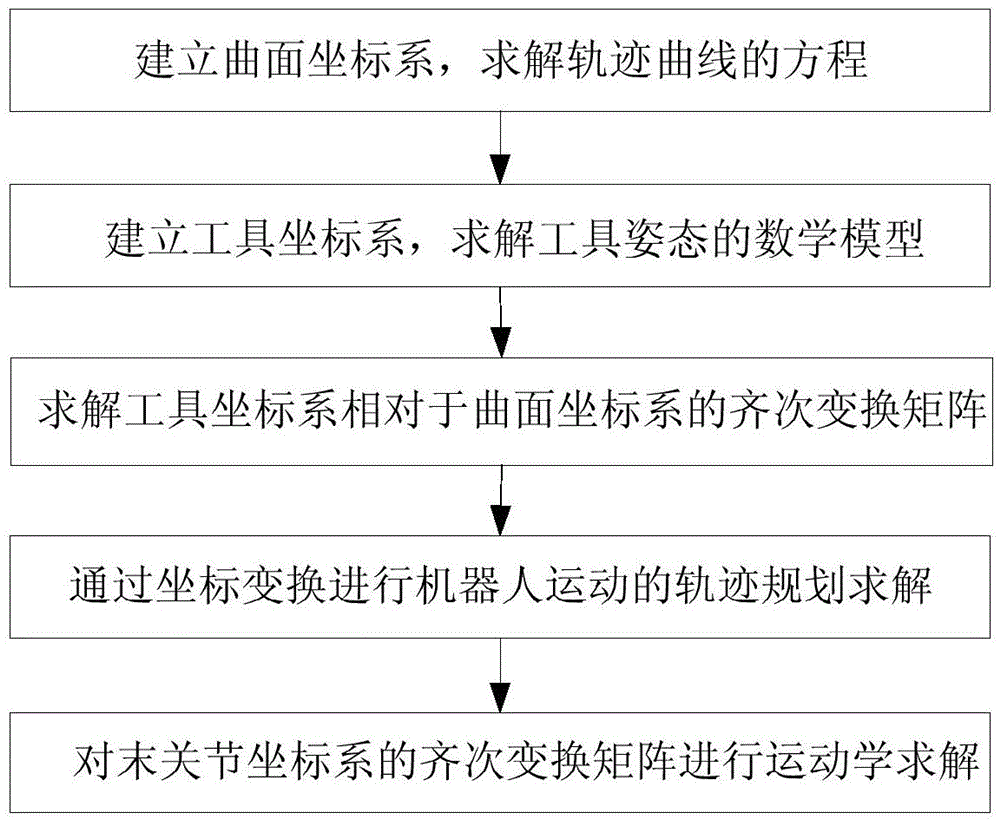

[0026] like figure 1 Shown is the trajectory planning method flow of the intersecting line of the laser processing robot, and the implementation of the present invention will be further explained according to the accompanying drawings and specific examples:

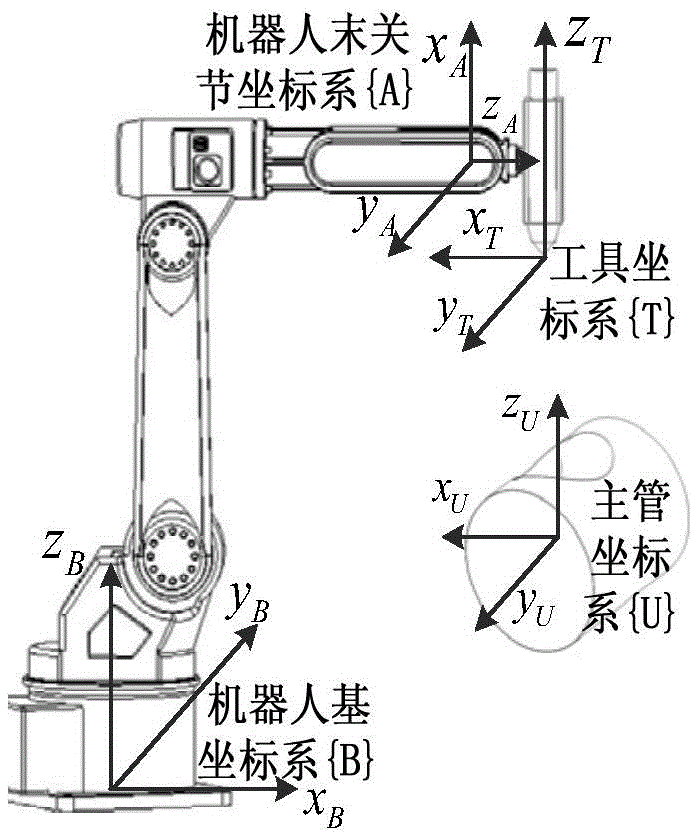

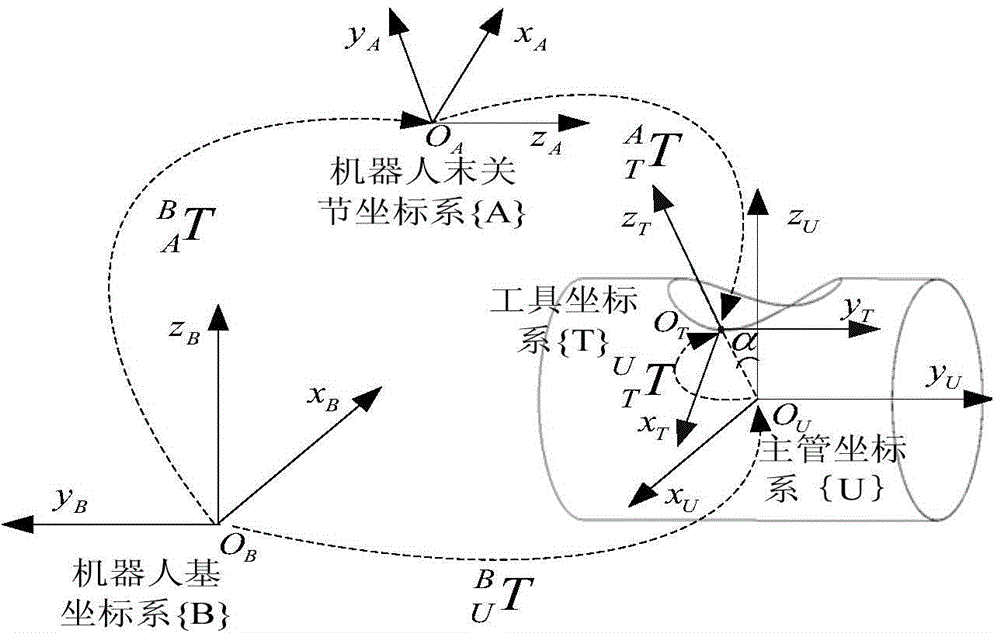

[0027] Establish a surface coordinate system and solve the curve equation of the tool end motion trajectory; establish a tool coordinate system to determine the attitude of the tool; construct a homogeneous transformation matrix corresponding to the tool position and attitude, and the homogeneous transformation matrix of the tool coordinate system relative to the surface coordinate system; solve the tool The homogeneous transformation matrix of the coordinate system relative to the end joint of the robot, and the homogeneous transformation matrix of the surface coordinate system relative to the robot base coordinate system; the position interpolation algorithm for determining the intersecting line trajectory by three point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com