Patents

Literature

102 results about "Homogeneous transformation matrix" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

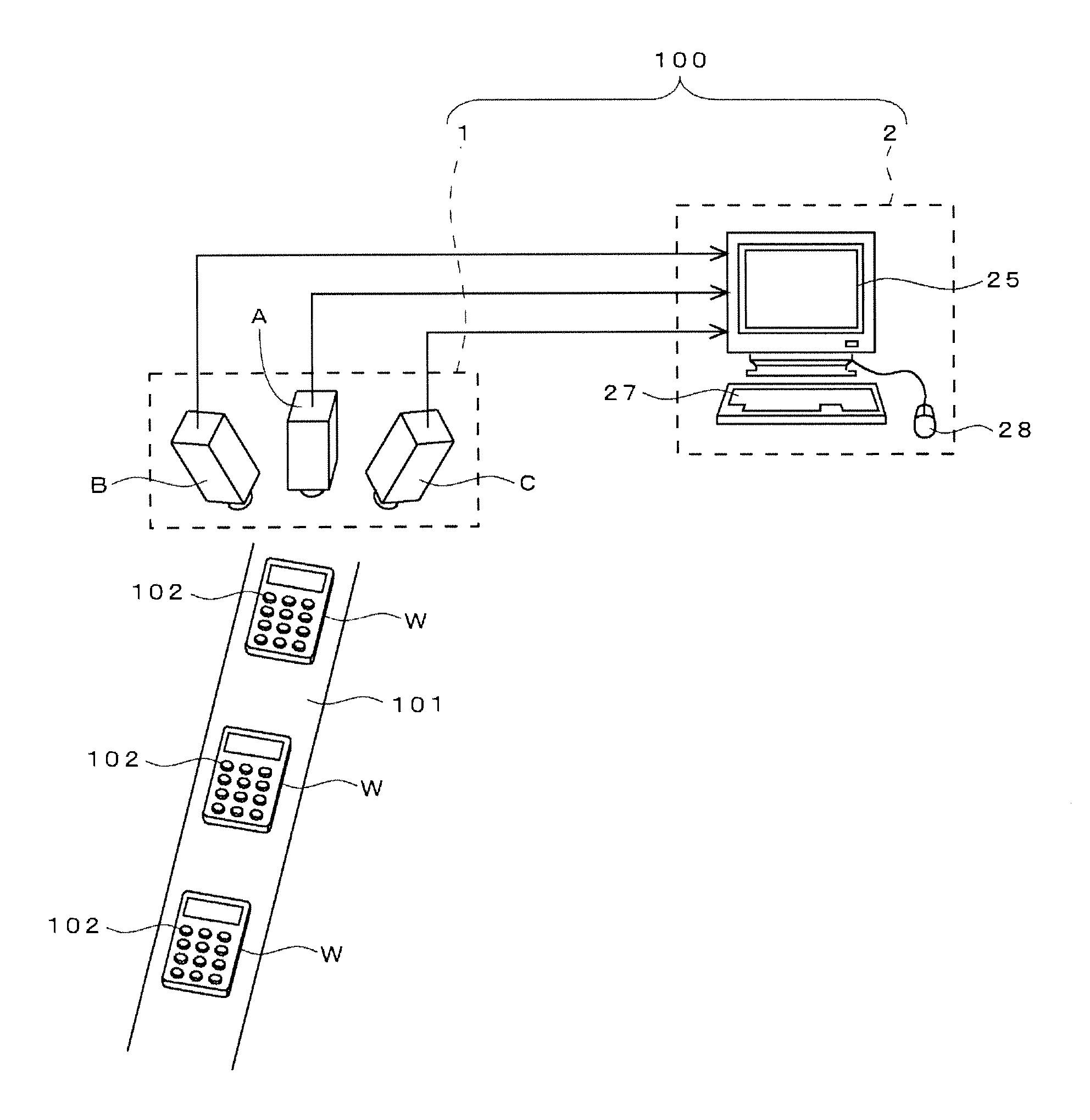

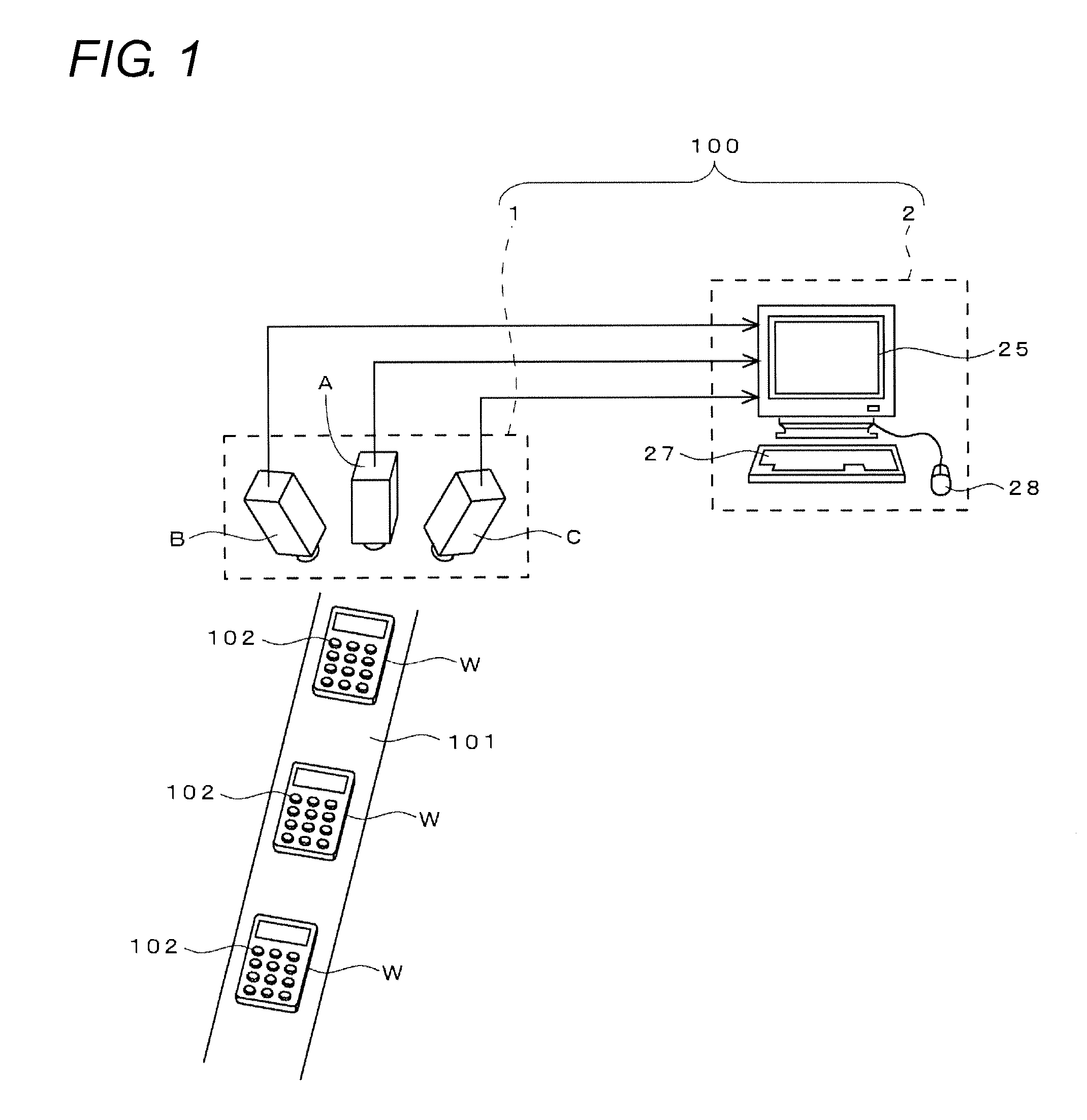

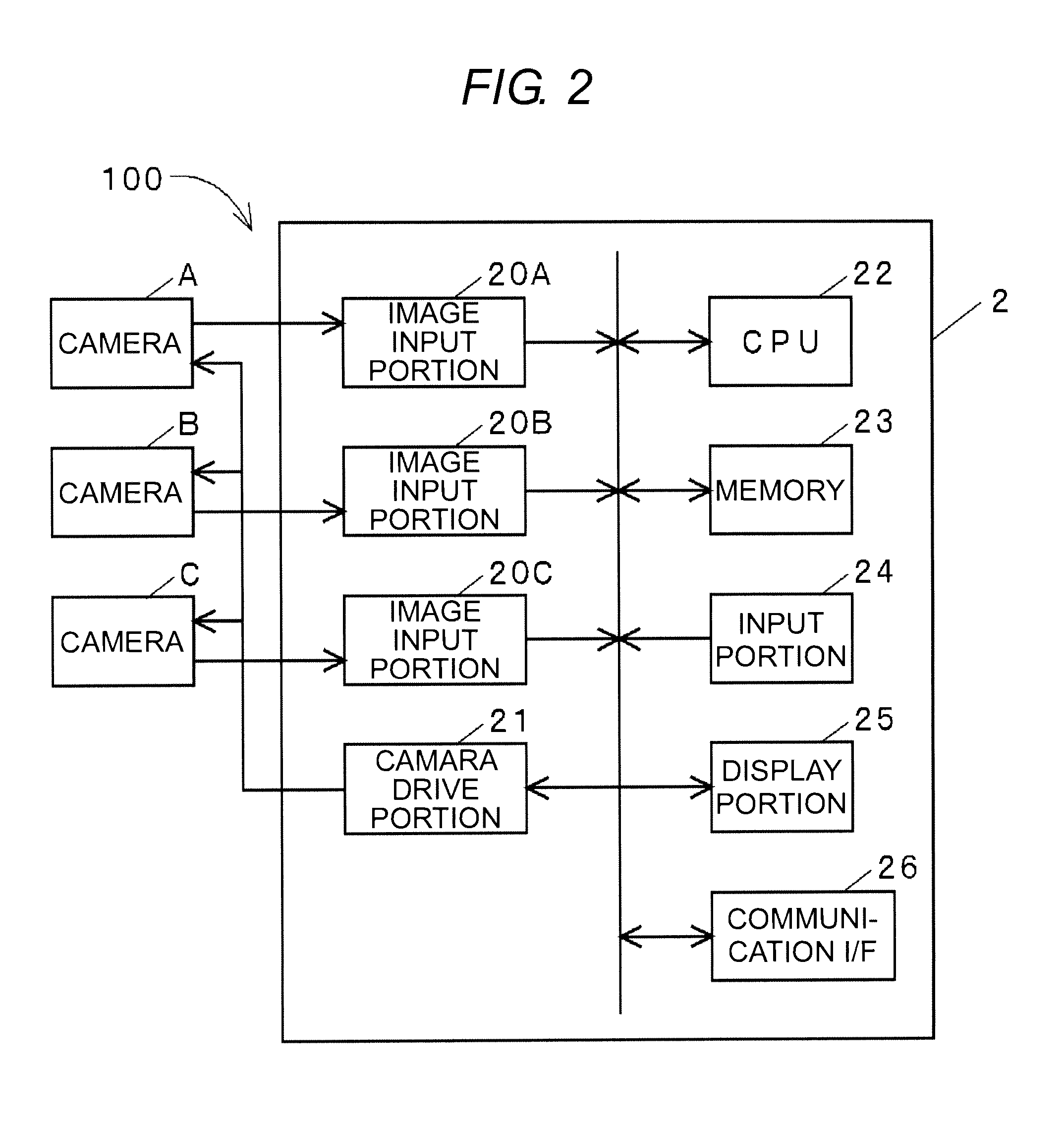

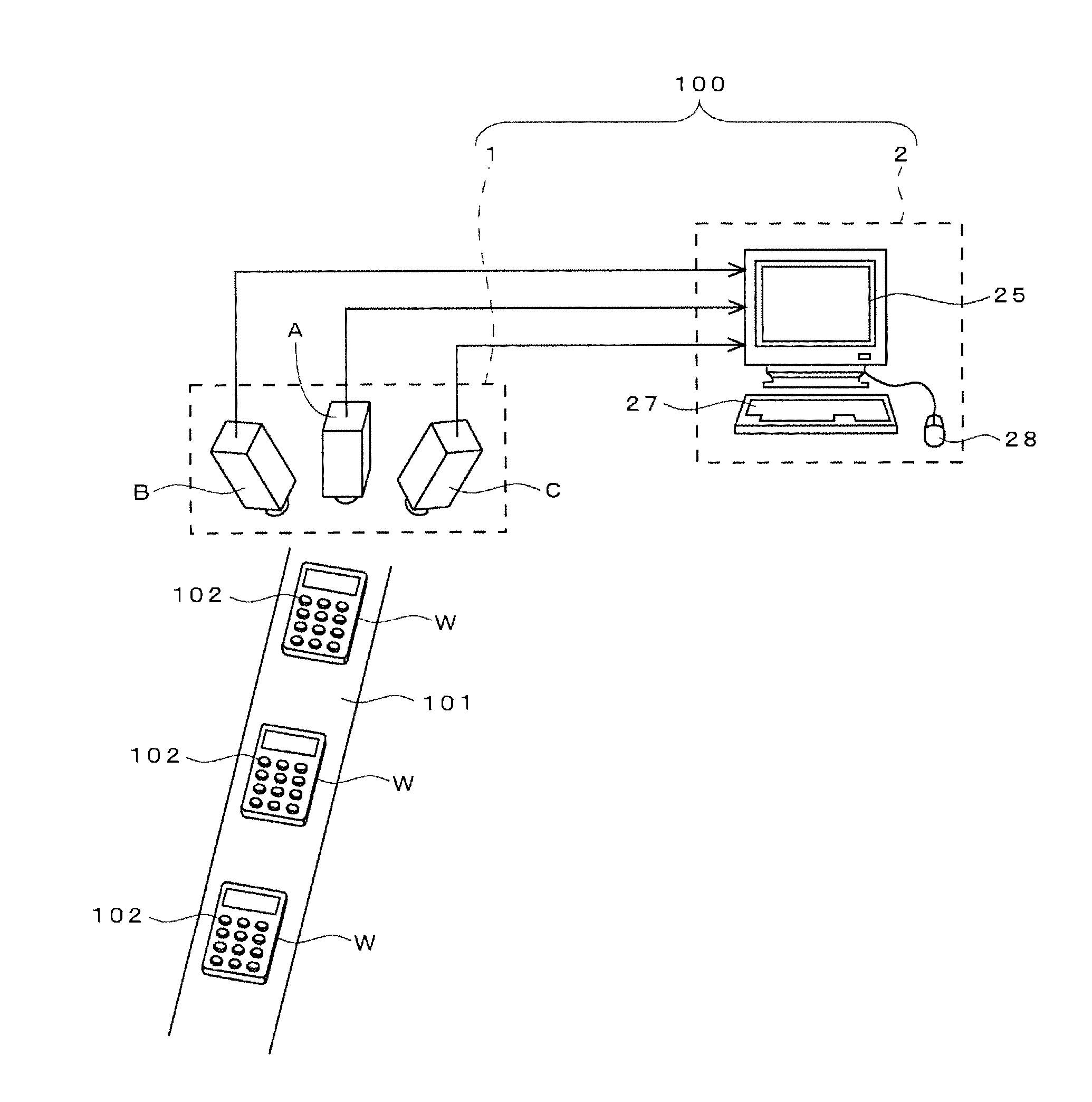

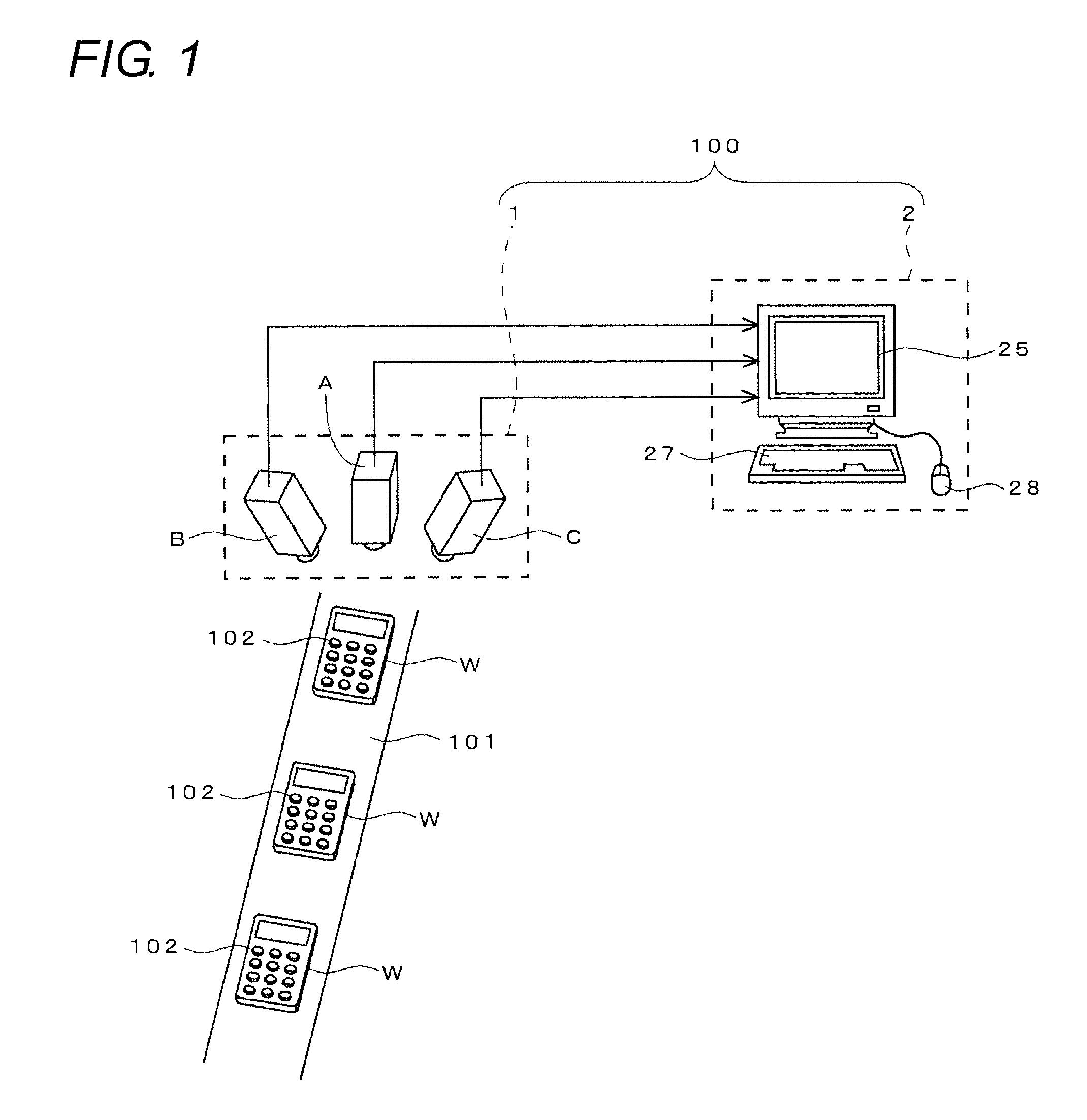

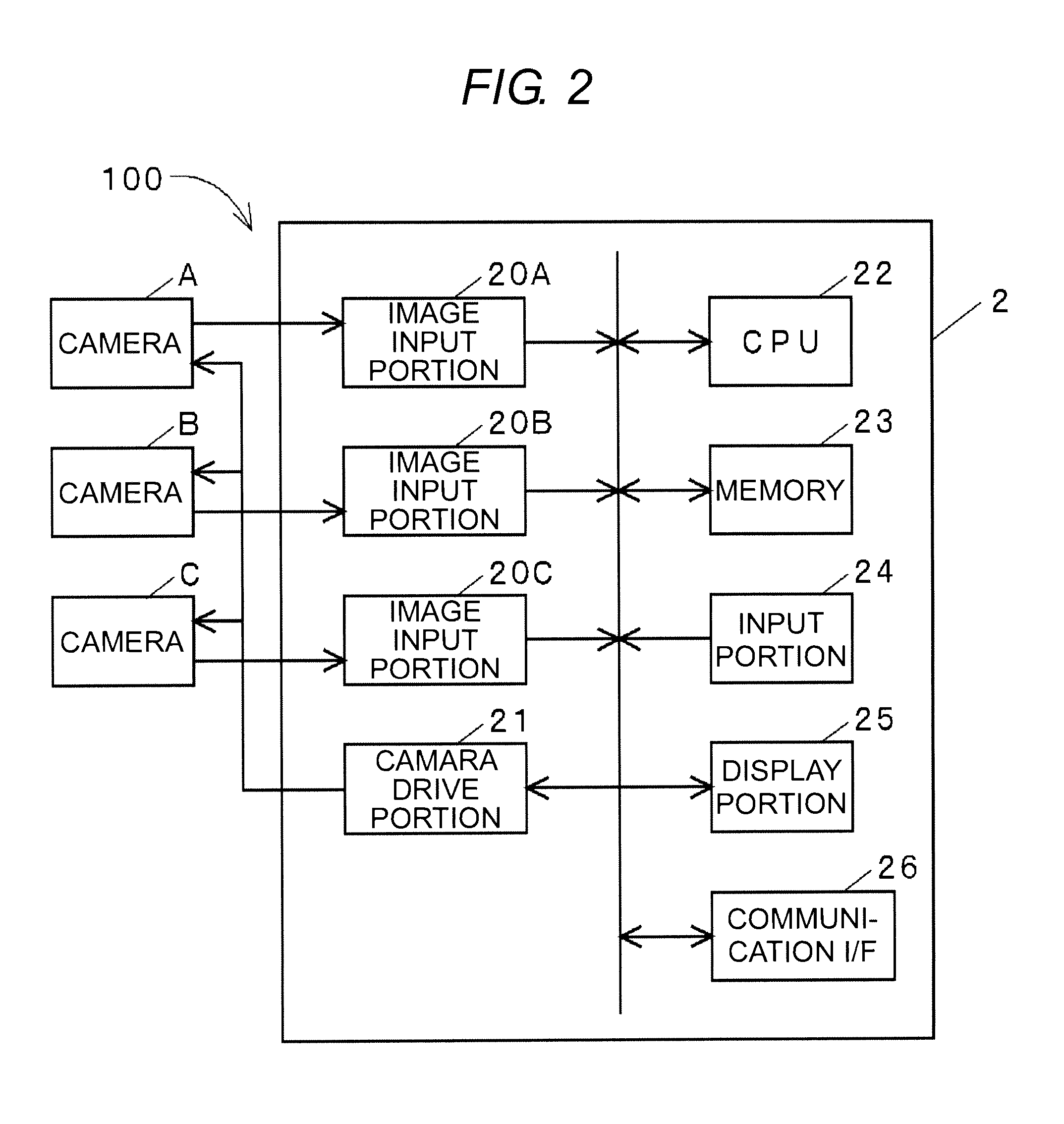

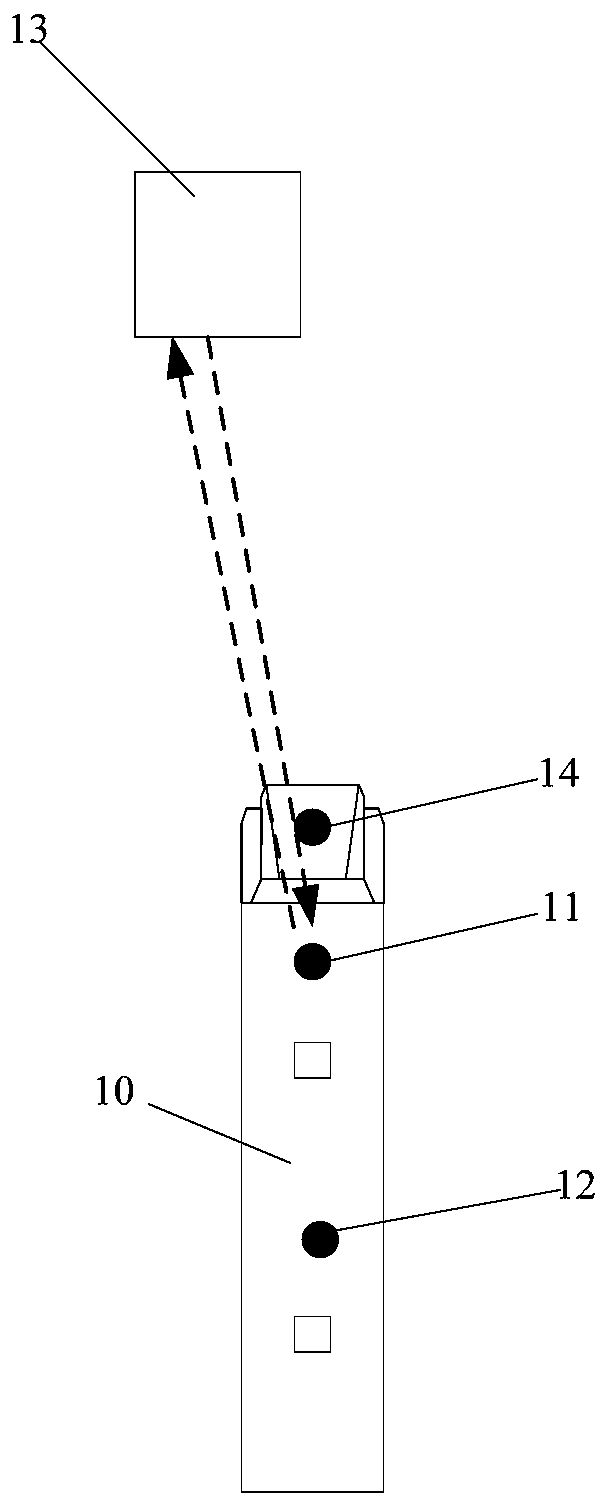

Three-dimensional vision sensor

InactiveUS20100232681A1Avoid performanceCancel noiseImage enhancementImage analysisTransformation parameterThree dimensional measurement

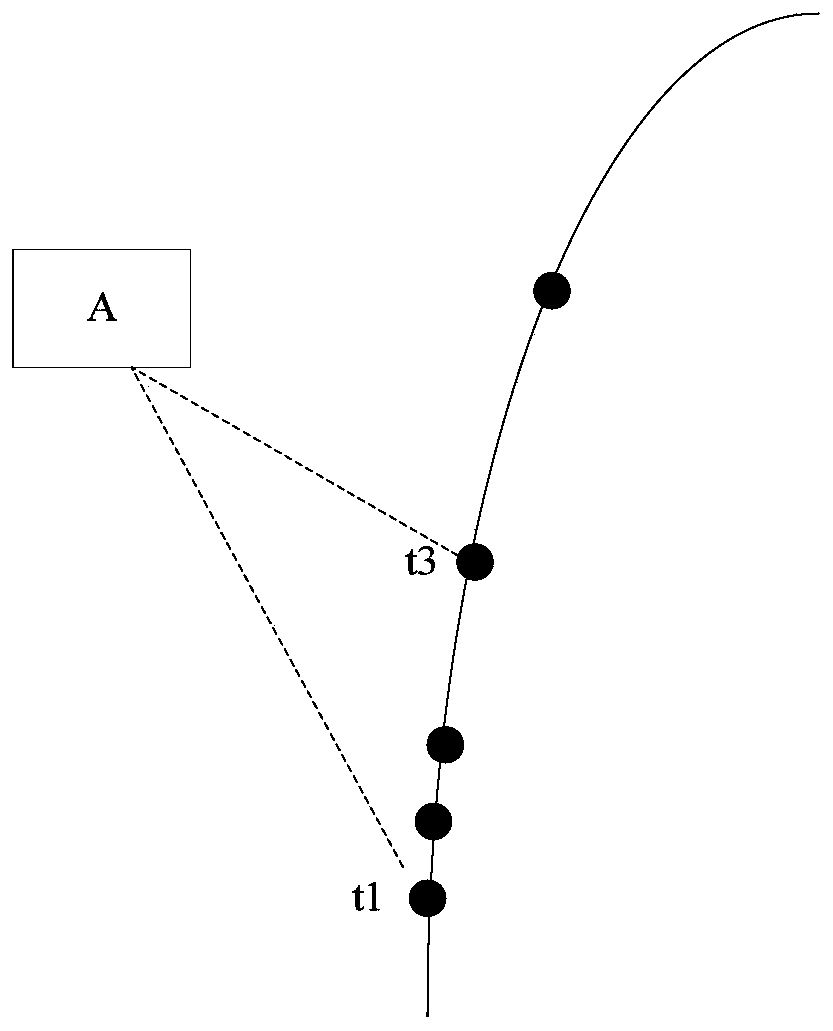

An object of the present invention is to enable performing height recognition processing by setting a height of an arbitrary plane to zero for convenience of the recognition processing. A parameter for three-dimensional measurement is calculated and registered through calibration and, thereafter, an image pickup with a stereo camera is performed on a plane desired to be recognized as having a height of zero in actual recognition processing. Further, three-dimensional measurement using the registered parameter is performed on characteristic patterns (marks m1, m2 and m3) included in this plane. Three or more three-dimensional coordinates are obtained through this measurement and, then, a calculation equation expressing a plane including these coordinates is derived. Further, based on a positional relationship between a plane defined as having a height of zero through the calibration and the plane expressed by the calculation equation, a transformation parameter (a homogeneous transformation matrix) for displacing points in the former plane into the latter plane is determined, and the registered parameter is changed using the transformation parameter.

Owner:ORMON CORP

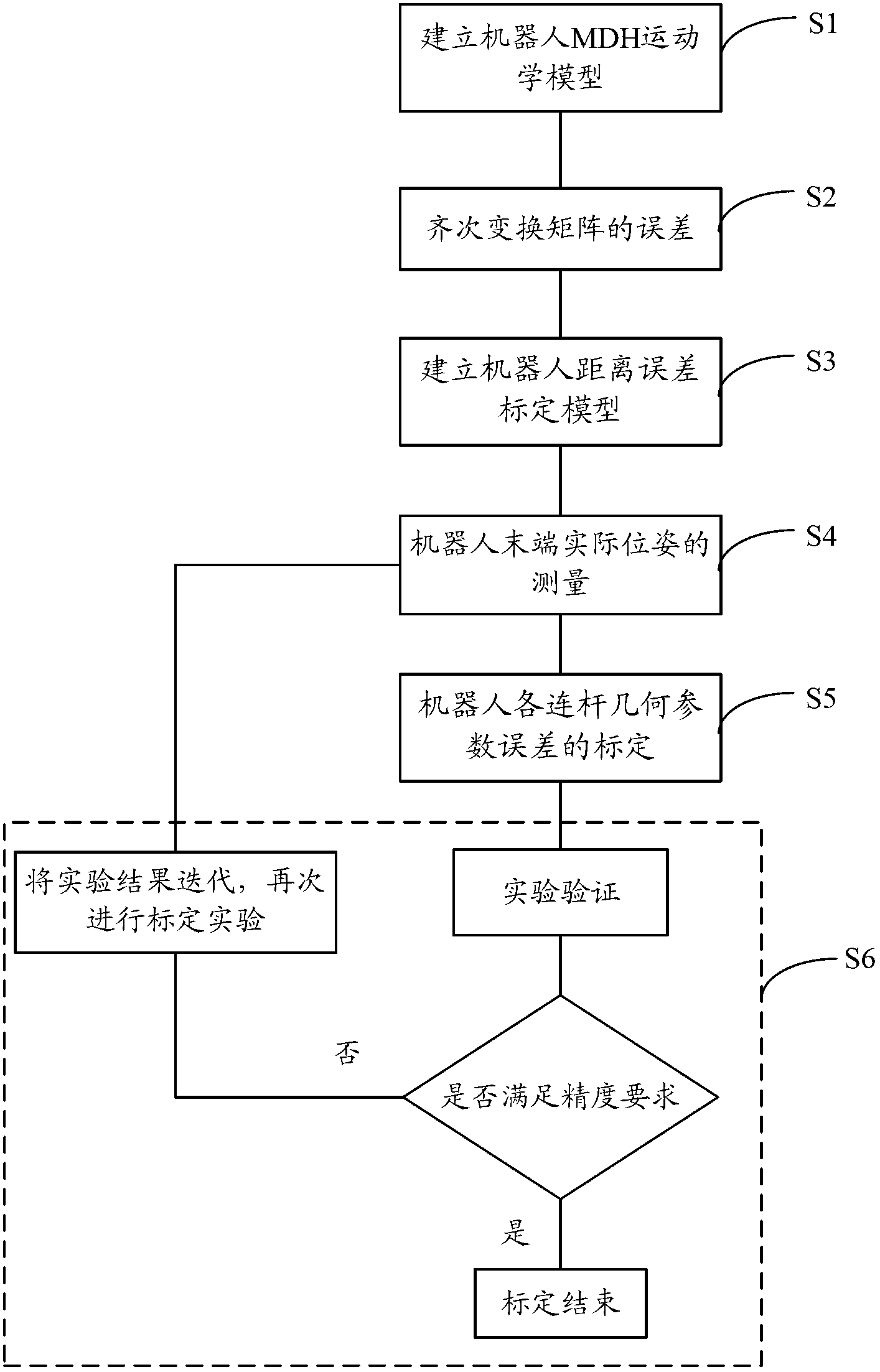

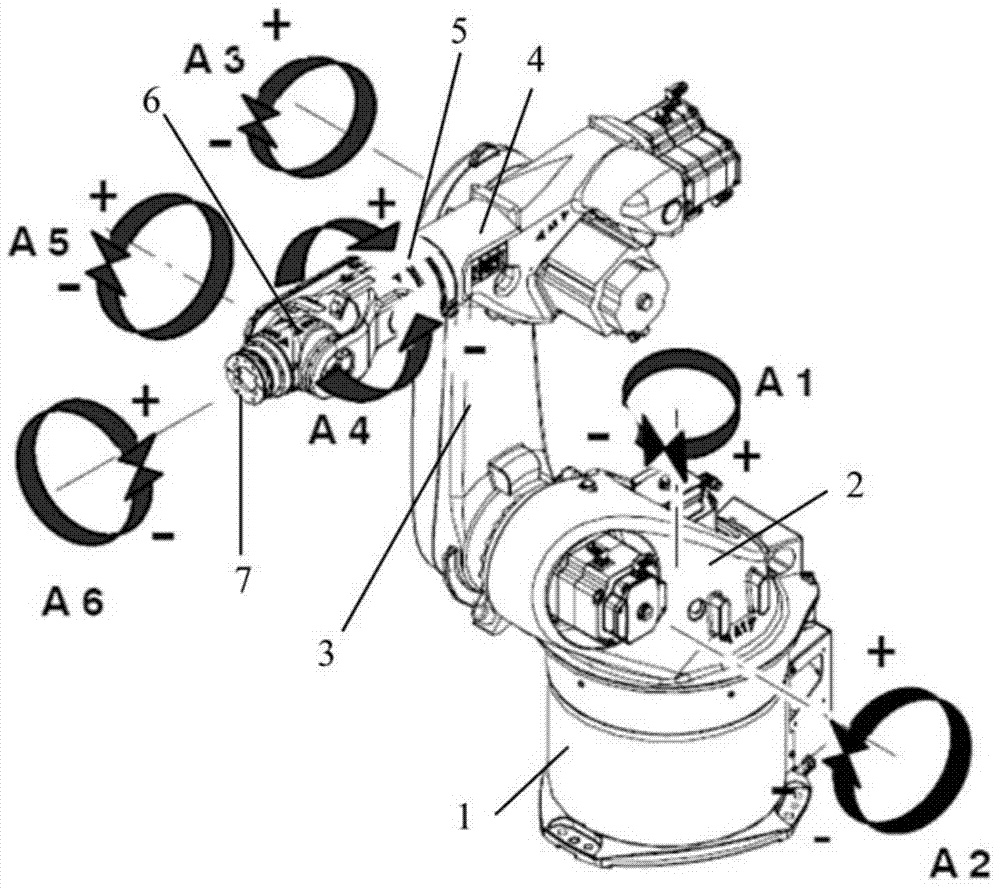

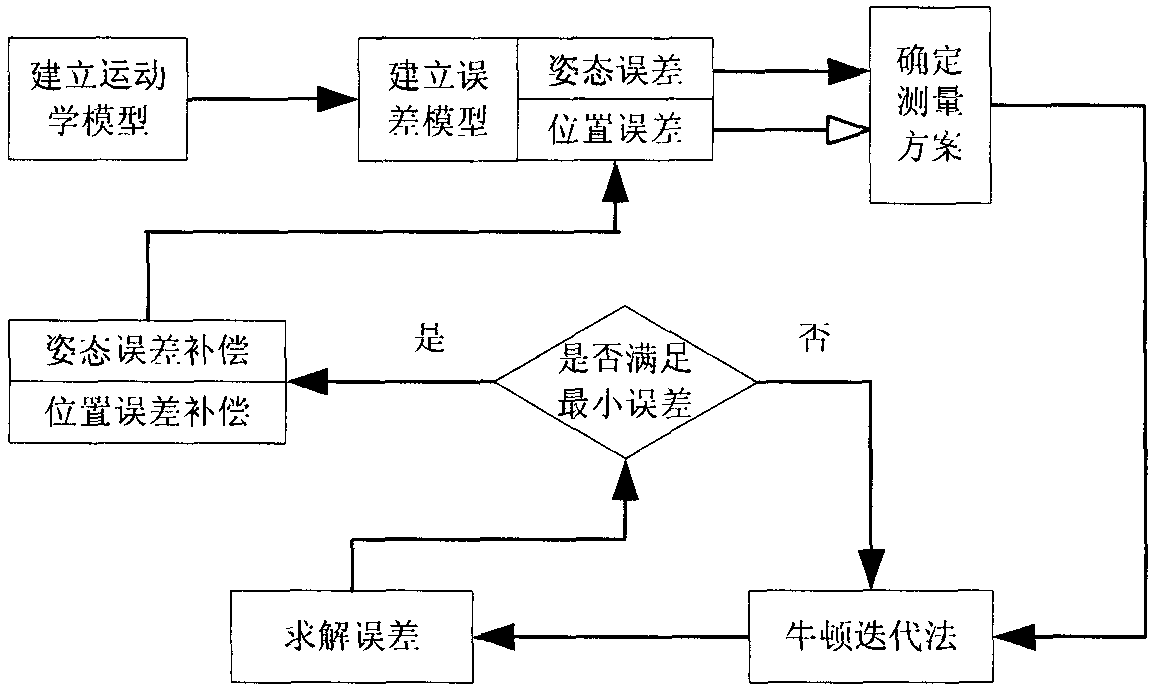

Industrial robot calibration method based on distance error models

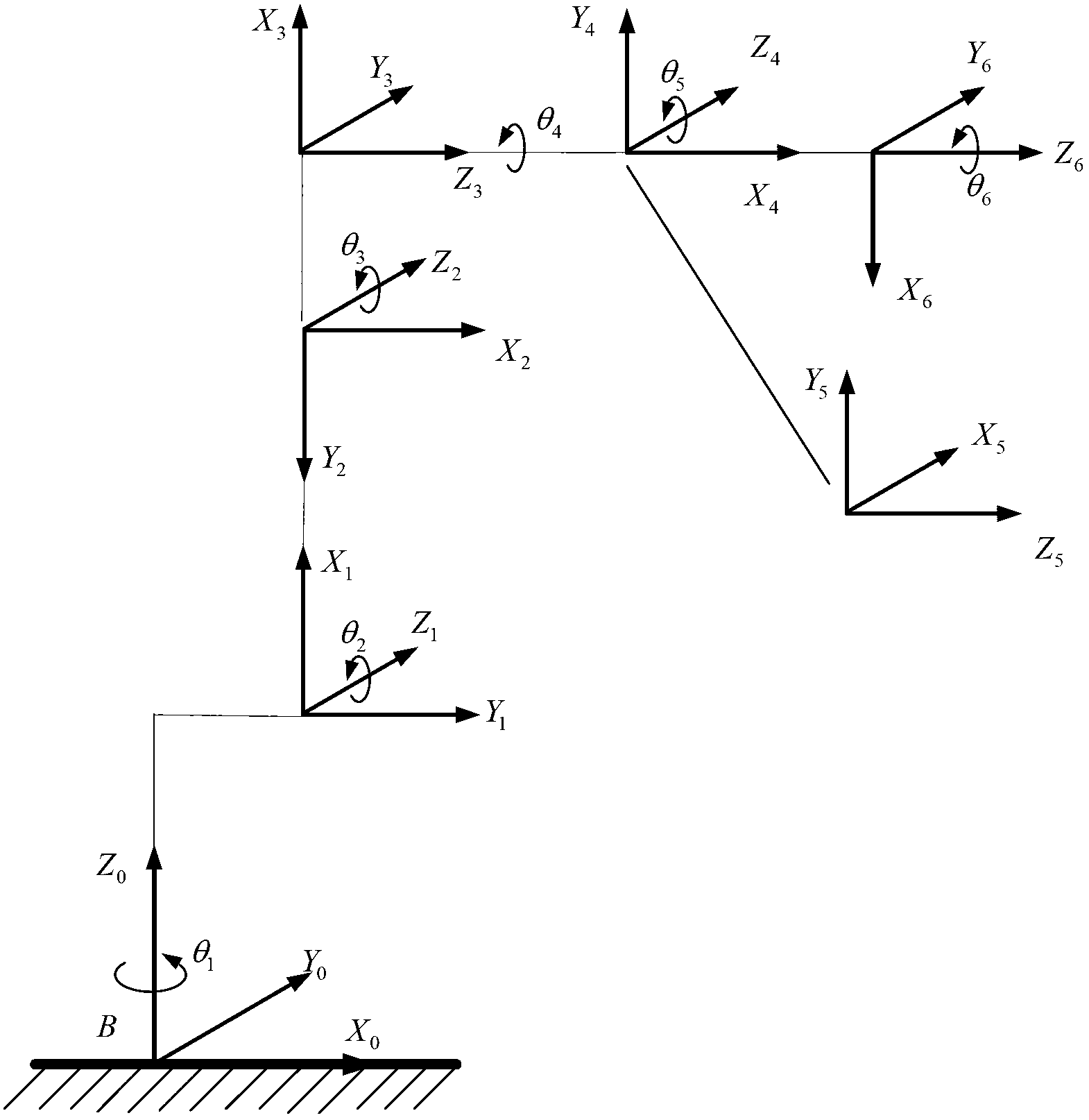

InactiveCN103231375ACalibration method is simpleThe calibration method is practicalProgramme-controlled manipulatorSimulationHomogeneous transformation matrix

The invention discloses an industrial robot calibration method based on distance error models. The method comprises: establishing a robot MDH (modified Denavit-Hartenberg) kinematic model; subjecting the errors of a matrix to homogeneous transformation; establishing a robot distance error calibration model; measuring the end actual pose of a robot; calibrating geometrical parameter errors of every connecting rod of the robot; and performing experimental verification. The industrial robot calibration method based on the distance error models has the advantages of being simple, practical, high-efficiency and rapid, is applicable to any series articulated robots, has a strong commonality, and can improve the positioning accuracy and the distance accuracy of an industrial robot simultaneously.

Owner:SUZHOU UNIV

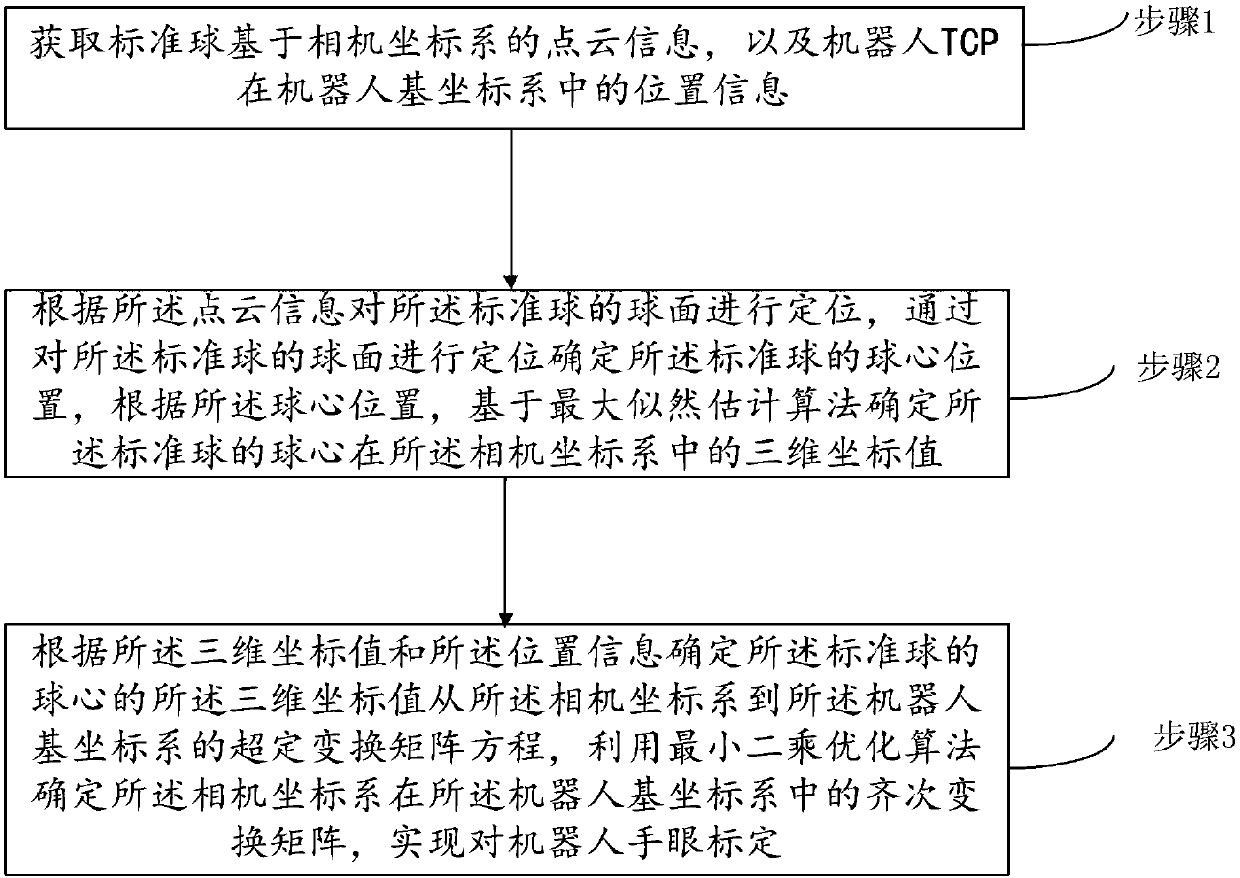

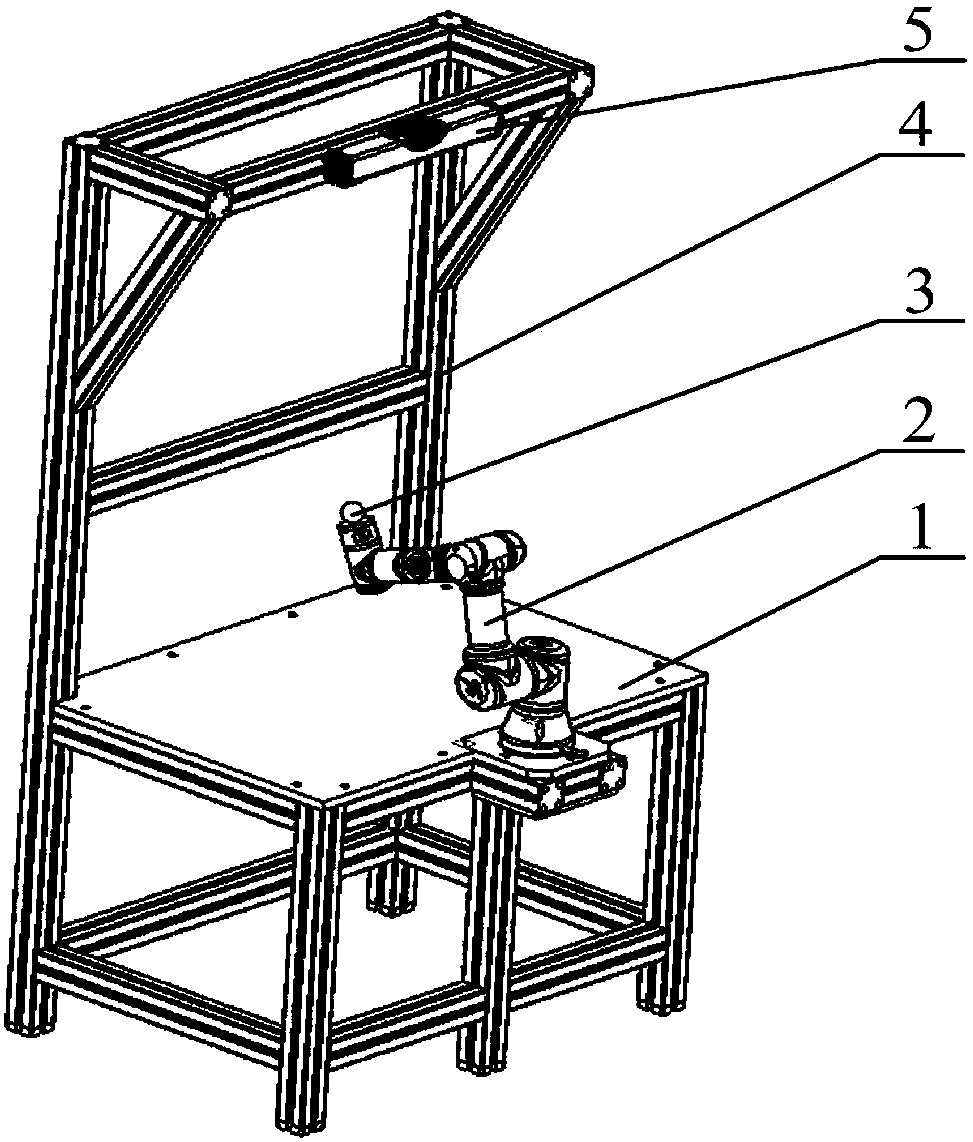

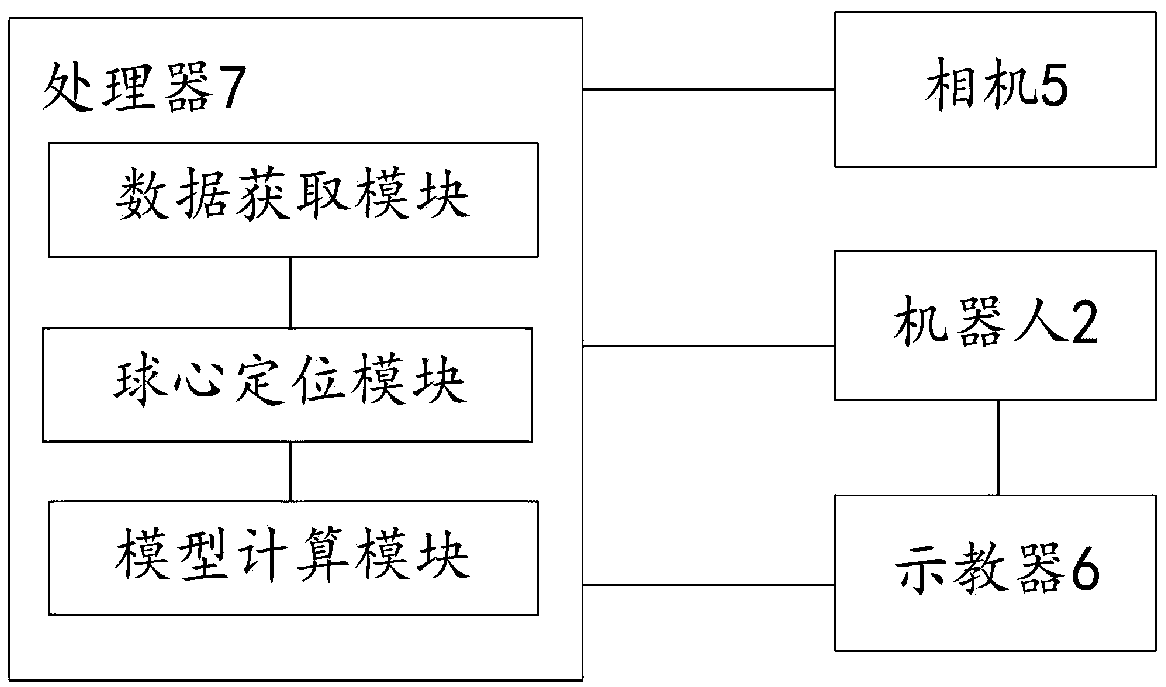

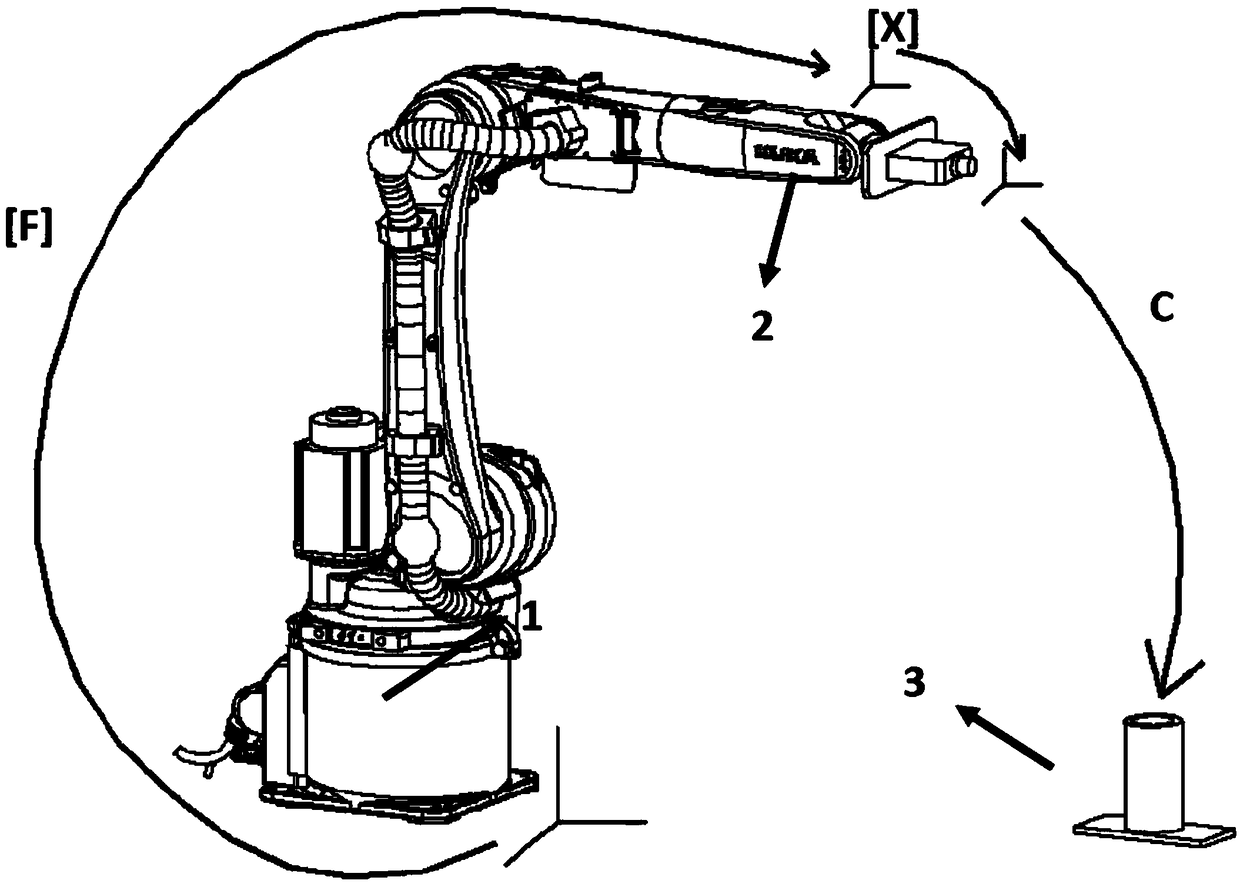

Robot hand eye calibration method and device based on standard ball

InactiveCN108582076AReduce workloadHigh utility valueProgramme-controlled manipulatorRobot handPoint cloud

The invention relates to a robot hand eye calibration method and a robot hand eye calibration device based on a standard ball. The method comprises the steps of acquiring point cloud information of the standard ball based on a camera coordinate system, and position information of a robot TCP in a robot-based coordinate system; positioning a ball surface of the standard ball according to the pointcloud information, determining a ball center position of the standard ball, and determining a three-dimensional coordinate value of the ball center of the standard ball in the camera coordinate systembased on a maximum likelihood estimation algorithm according to the ball center position; and determining an overdetermined transformation matrix equation of the three-dimensional coordinate value from the camera coordinate system to the robot-based coordinate system, and utilizing a least square optimization algorithm for determining a homogeneous transformation matrix of the camera coordinate system in the robot-based coordinate system, so that robot hand eye calibration is realized. According to the robot hand eye calibration method and the robot hand eye calibration device based on the standard ball provided by the invention, the robot hand eye calibration is realized by adopting the standard ball, no internal parameters of a camera is required to be calibrated, and the calibration method is simple, high in efficiency and suitable for hand eye calibration operation of various robots.

Owner:武汉库柏特科技有限公司

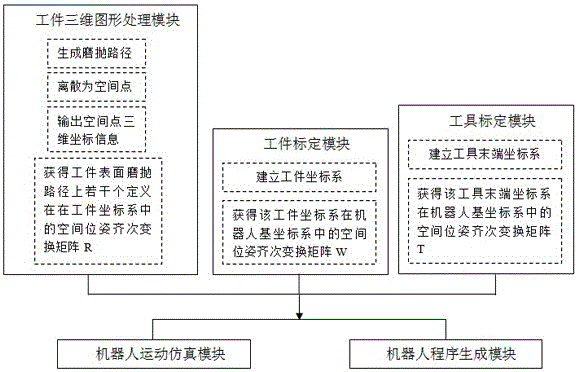

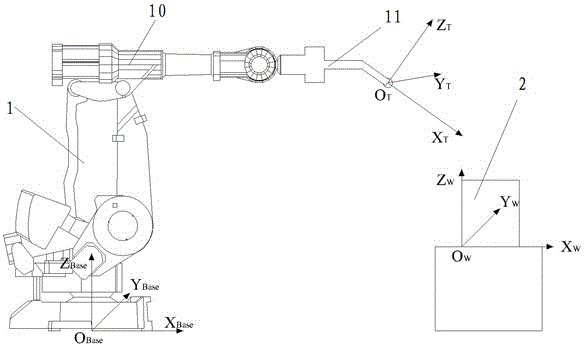

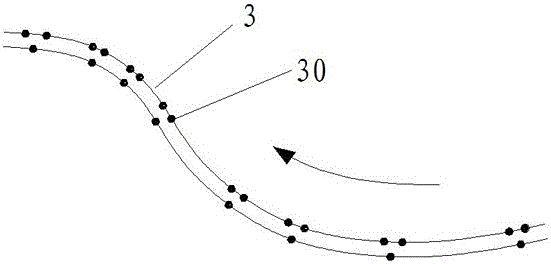

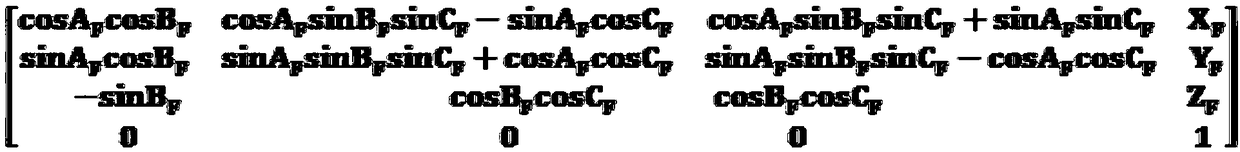

Grinding and polishing industrial robot offline programming method based on workpiece three-dimensional graph

InactiveCN106182018ASimplified offline programming processQuick buildProgramme-controlled manipulatorGraphicsContact position

The invention relates to an off-line programming method for grinding and polishing industrial robots based on the three-dimensional graphics of workpieces. Through the workpiece calibration module, the homogeneous transformation matrix W of the spatial position and orientation of the workpiece coordinate system OW in the robot base coordinate system OBase is obtained through calibration; through the three-dimensional workpiece The graphics processing module discretizes the grinding and polishing path into several spatial points, outputs the three-dimensional coordinate information of each spatial point, and calculates several spatial pose homogeneous transformation matrices defined in the workpiece coordinate system OW on the grinding and polishing path of the workpiece surface R; through the tool calibration module, establish the tool end coordinate system OT at the contact position between the robot tool end and the workpiece, and calibrate to obtain the space pose homogeneous transformation matrix T of the tool end coordinate system OT in the robot base coordinate system OBase, to realize The robot is programmed offline. The invention has the beneficial effect of simplifying the off-line programming process of the grinding and polishing industrial robot without relying on off-line programming software of the robot.

Owner:FUZHOU UNIV

Camera and robot relative pose calibration method based on pixel space optimization

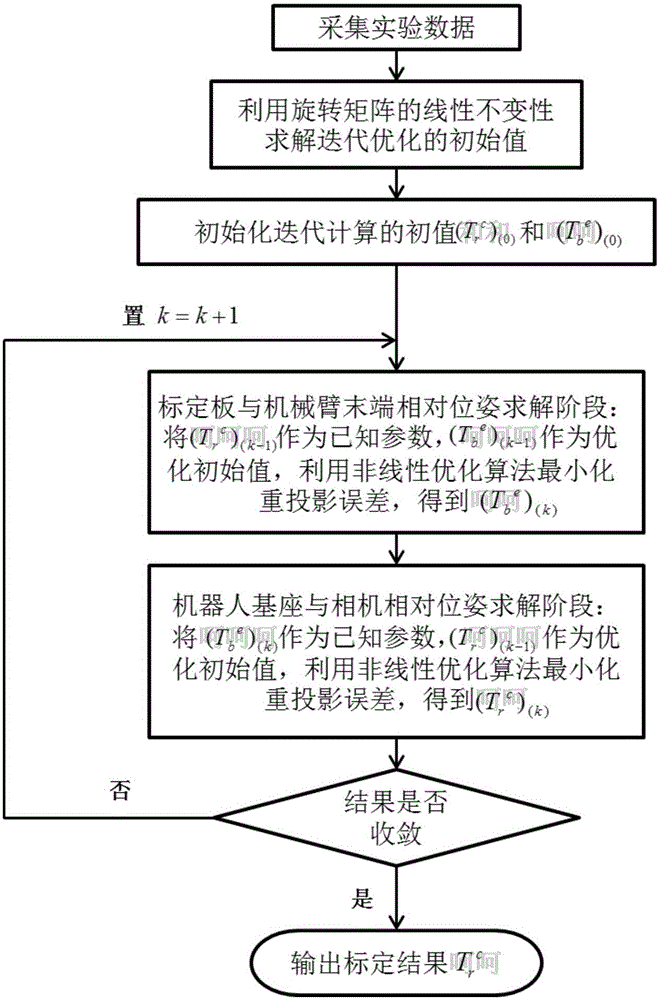

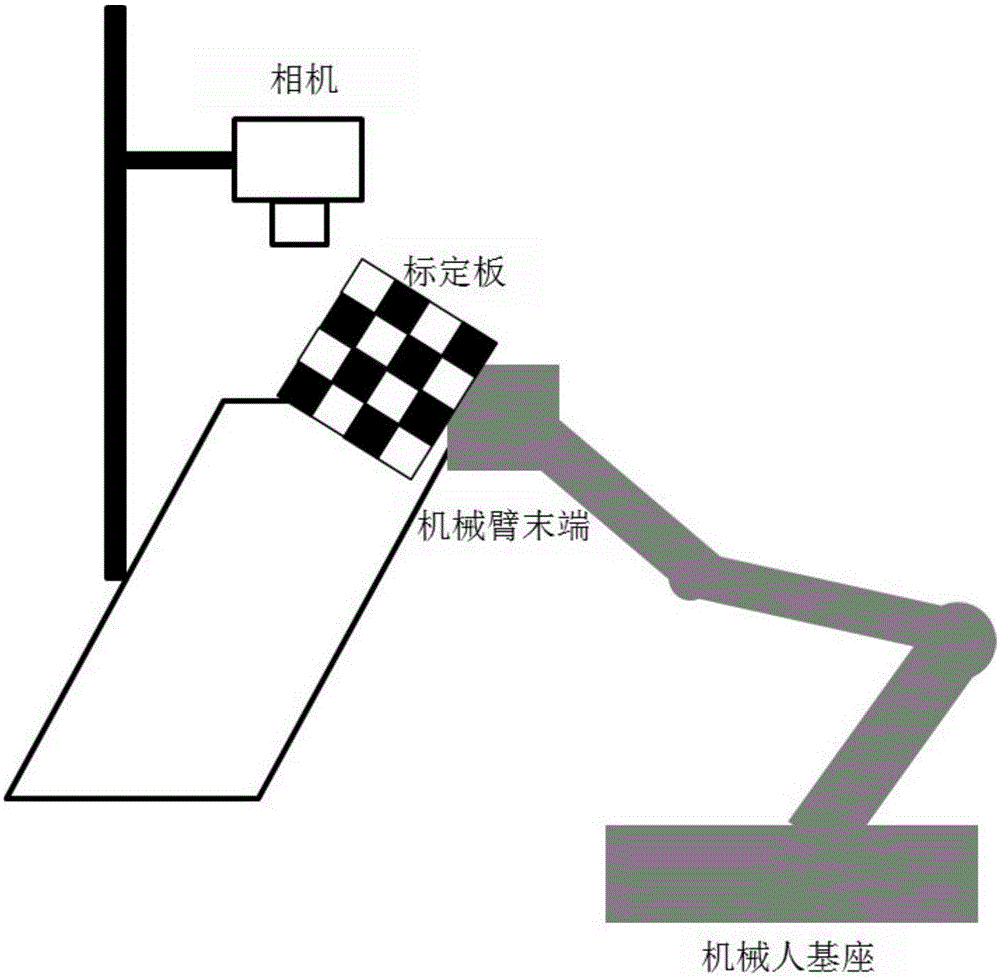

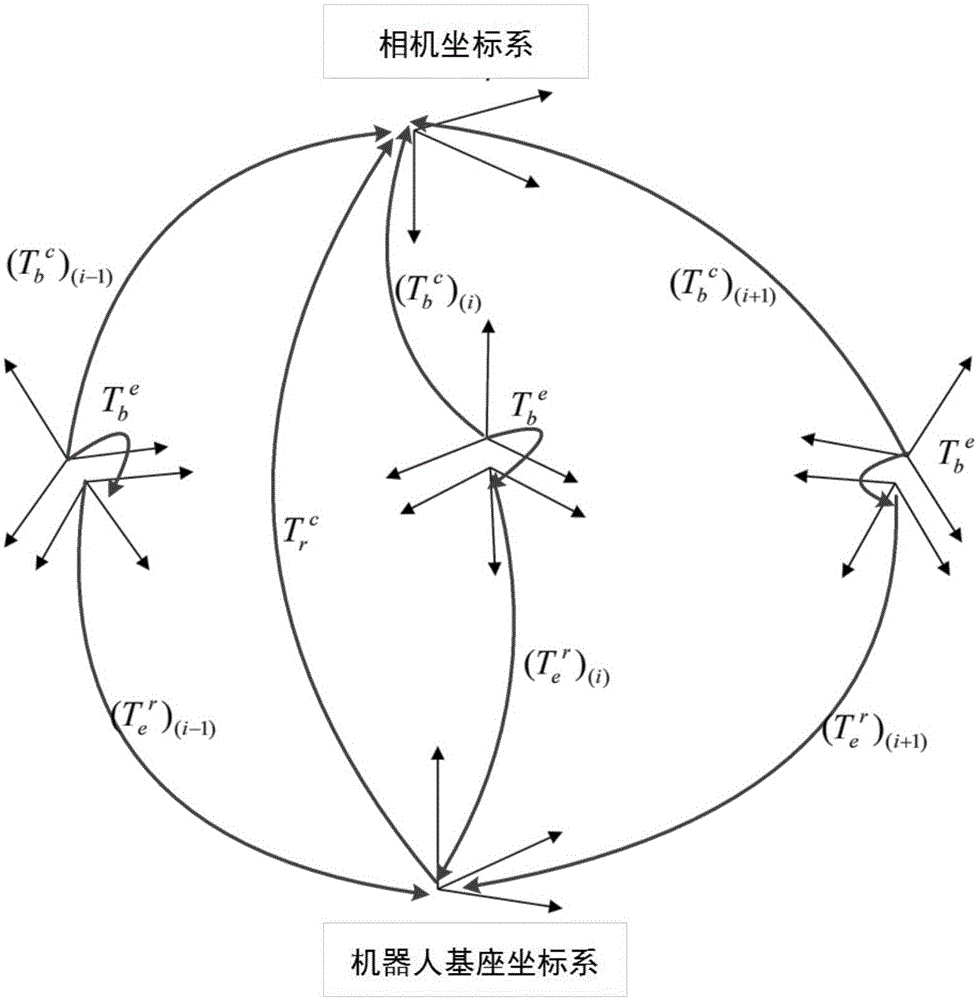

ActiveCN105014667AHigh precisionSmall reprojection errorProgramme-controlled manipulatorCalibration resultReprojection error

The invention discloses a camera and robot relative pose calibration method based on pixel space optimization. According to the method, a calibration board carried at the tail end of a robot is adopted for moving inside the range of the view of a fixed camera, and space motion constraint information of the calibration board is utilized for calibration to obtain the optimal relative pose relation between the camera and a robot base. Firstly, linear invariance of a rotating matrix is utilized for solving a homogeneous transformation matrix to obtain a preliminary calibration result; then, the preliminary calibration result is used as an initial optimization value for optimization of pixel space, so that a reprojection error is made to the minimum. According to the camera and robot relative pose calibration method, the iterative optimization algorithm is adopted, no precision external measurement equipment is needed, model constraints of the image pixel space are utilized, the effective optimization initial value obtaining method is combined, the calibration result with the higher precision is obtained, and the requirement of a visual servo robot for completing positioning and grabbing working in industrial application can be met.

Owner:ZHEJIANG UNIV

Online offset correction method and device for robot hand-eye calibration

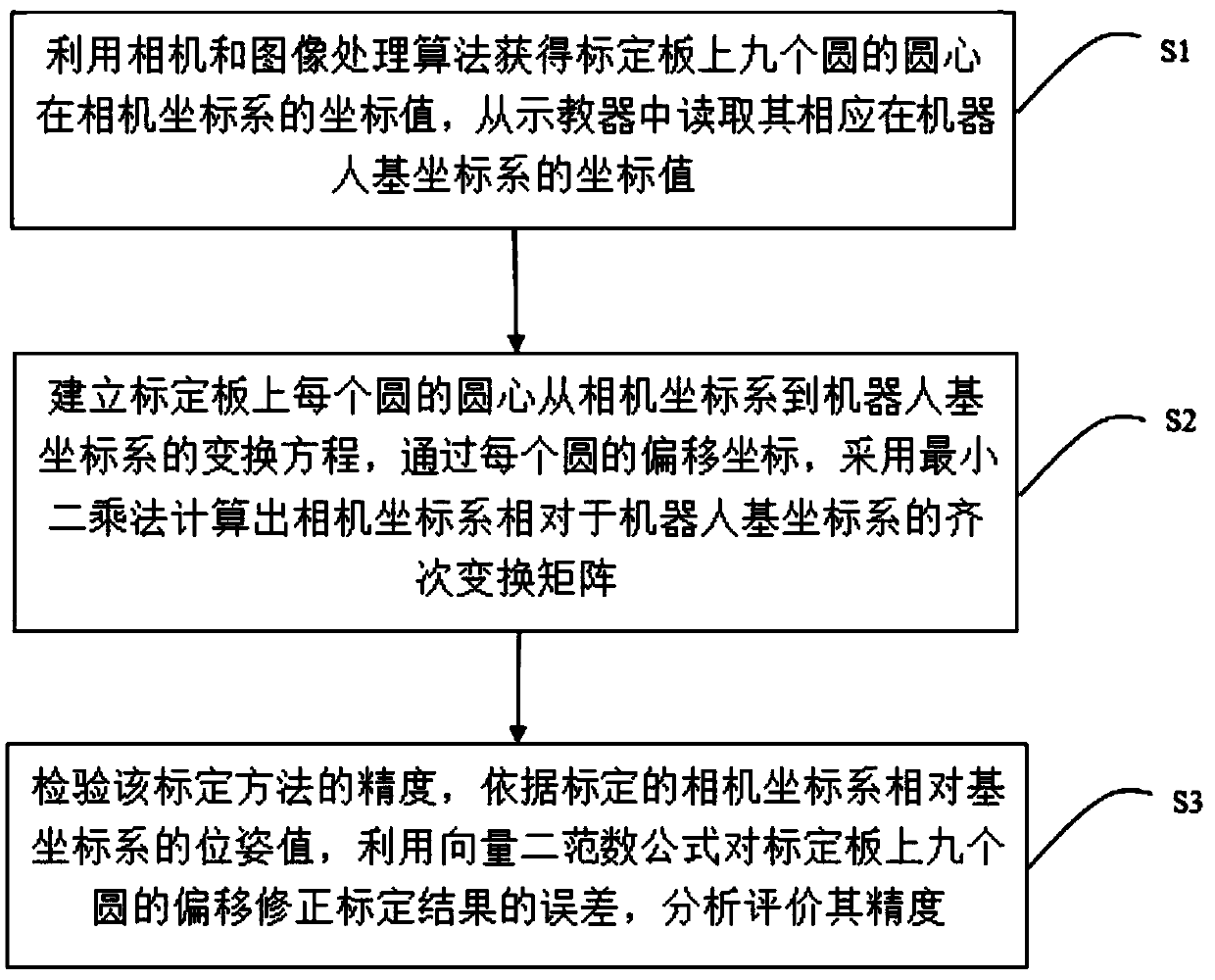

ActiveCN108818536AEasy and Accurate AcquisitionPrecision AdjustmentProgramme-controlled manipulatorProduction lineRobot hand

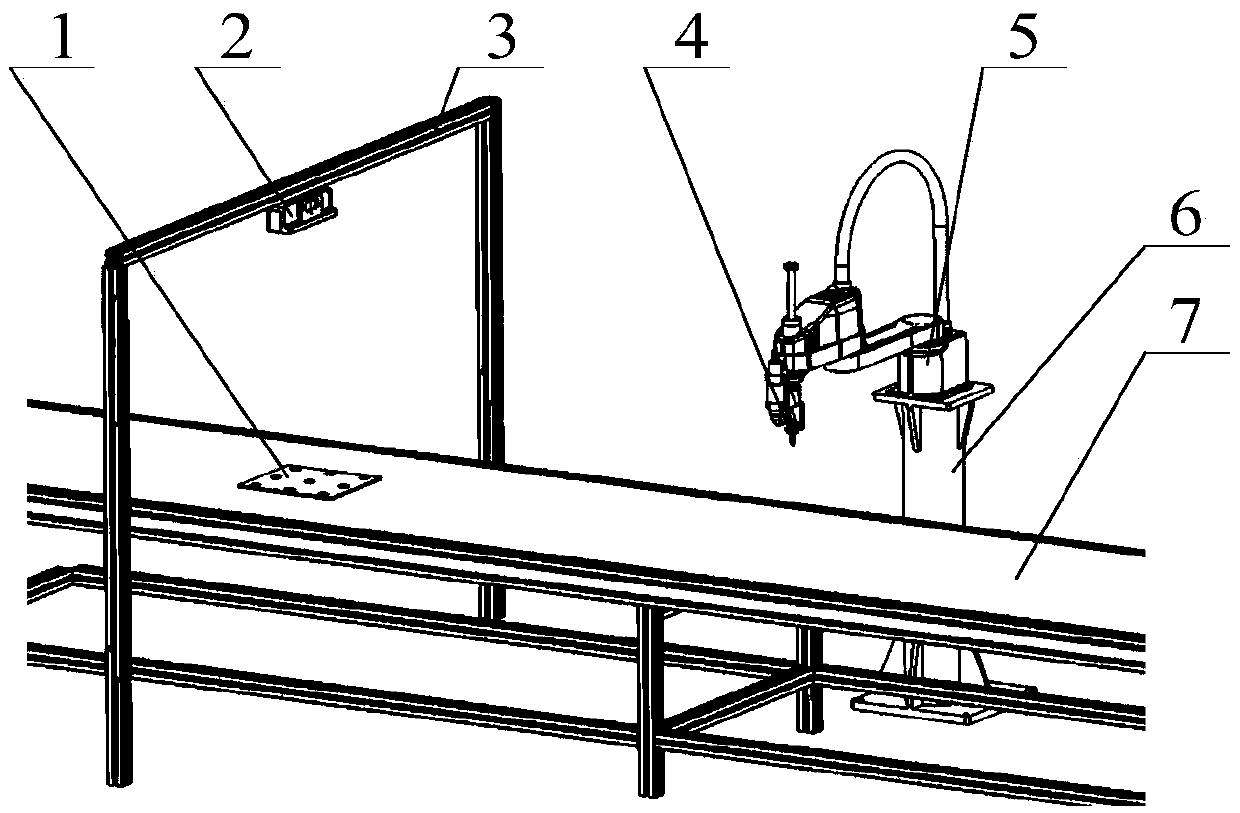

The invention relates to an online offset correction method and device for robot hand-eye calibration. The online offset correction method comprises the steps that coordinate values of the circle centers of nine circles on a calibration plate in a camera coordinate system and a base coordinate system are obtained; a transformation equation of the circle center of each circle on the calibration plate from the camera coordinate system to the robot base coordinate system is established, through offset coordinates of each circle, the least square method is adopted to calculate a homogeneous transformation matrix of the camera coordinate system relative to the robot base coordinate system; and according to calibrated pose values of the camera coordinate system relative to the base coordinate system, errors of the offset correction calibration results of the nine circles on the calibration plate are analyzed through a vector two-norm formula, and thus the precision of the online offset correction method is evaluated. According to the online offset correction method and device for robot hand-eye calibration, offset in the robot hand-eye calibration process is corrected, flexible, preciseand rapid adjustment on a production line can be achieved, high-repeatability and precise grabbing operation can be achieved, the online offset correction method and device can be applied to operationof an SCARA robot hand-eye device, and the simple, efficient and high-precision effects are achieved.

Owner:武汉库柏特科技有限公司

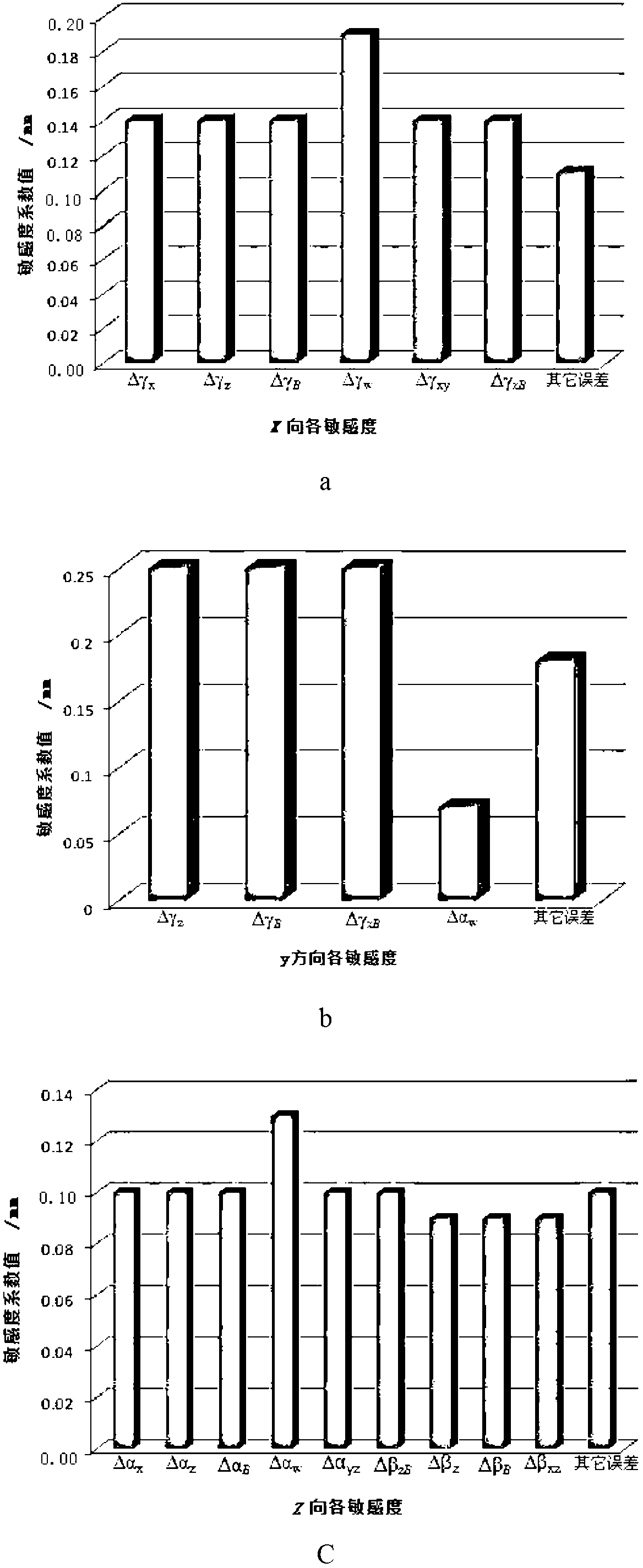

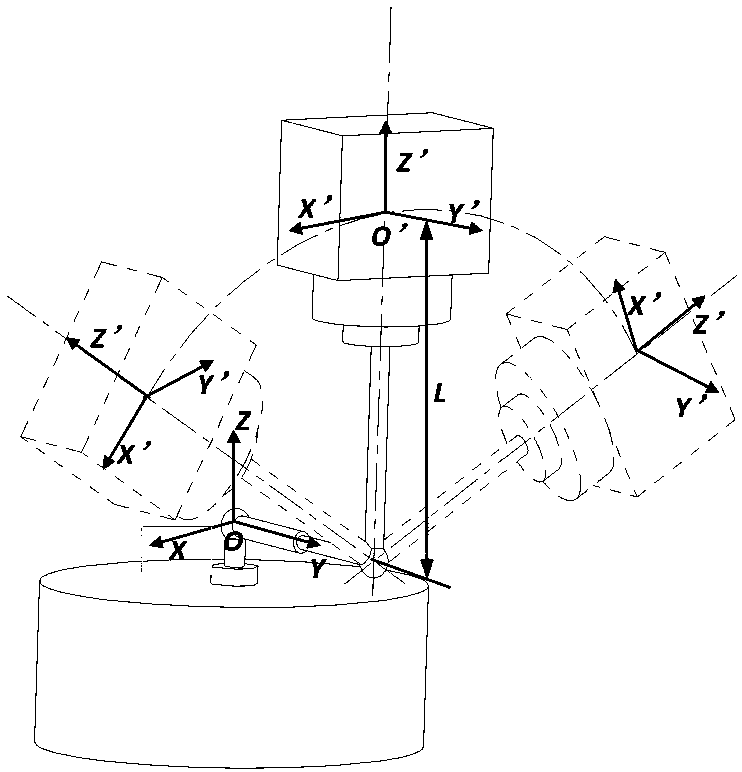

Recognition method of critical geometrical error source of machine tool

The invention discloses a recognition method of a critical geometrical error source of a machine tool and belongs to the technical field of machine precision designing. The recognition method of the critical geometrical error source of the machine tool is characterized by comprising the steps that the machine tool is abstracted into a multi-body system according to the structure and motion characteristics of the machine tool, relevance of parts of the machine tool is described by a topological structure and a low-order body array, a generalized coordinate system is built in the multi-body system, coupling relationship of error amounts of parts of the machine tool is described by a homogeneous transformation matrix, a characteristic matrix and a motion equation of the relative movement between two adjacent bodies of the machine tool are elicited, a precision model of a machining center is built, an ordinary mathematical model used for error sensitivity analysis of a four-shaft machine tool is built with a matrix differential method according to the precision model of the precision horizontal machining center, influence degrees on the whole space error of all error elements are compared by calculating the geometrical error sensitivities of all parts, and finally the critical error source influencing the machining precision of the machine tool is recognized.

Owner:BEIJING UNIV OF TECH +1

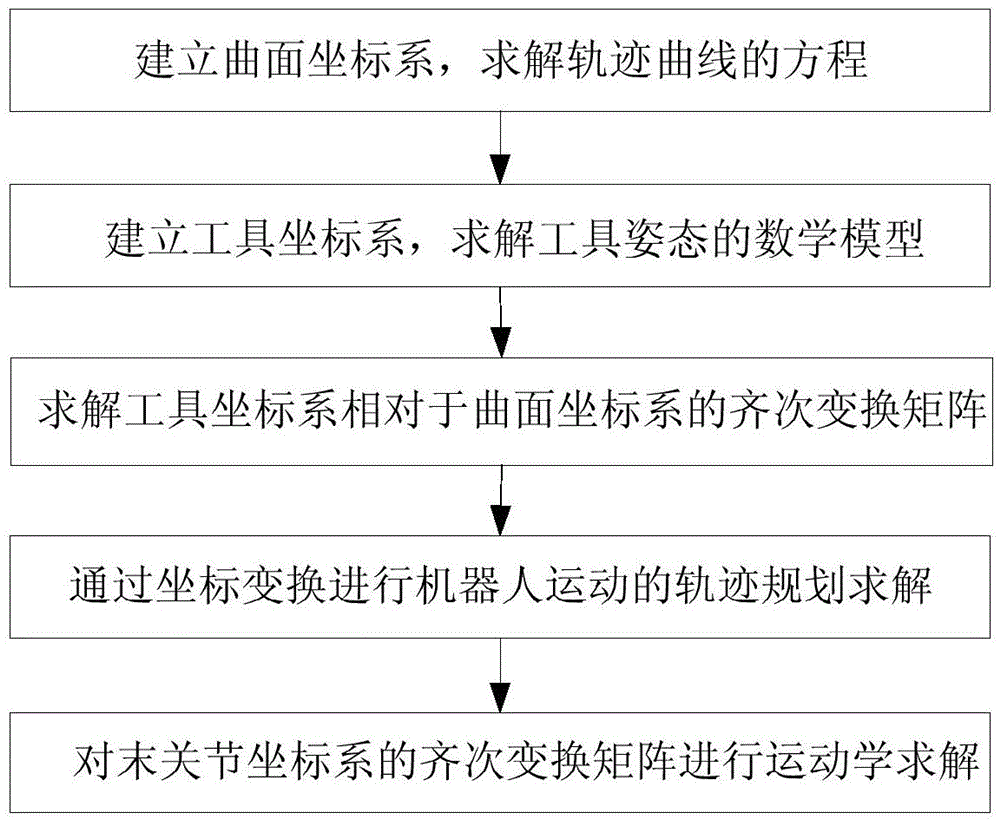

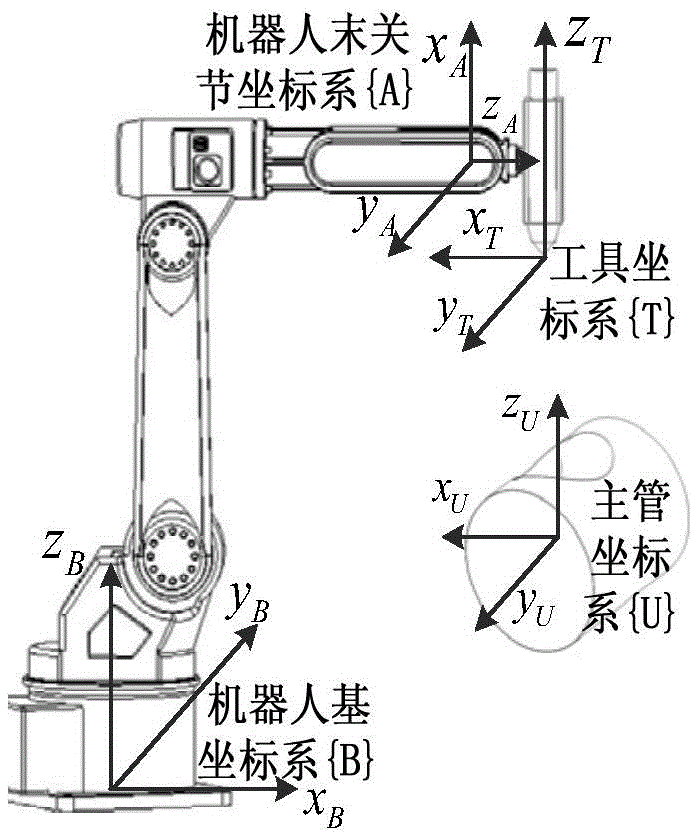

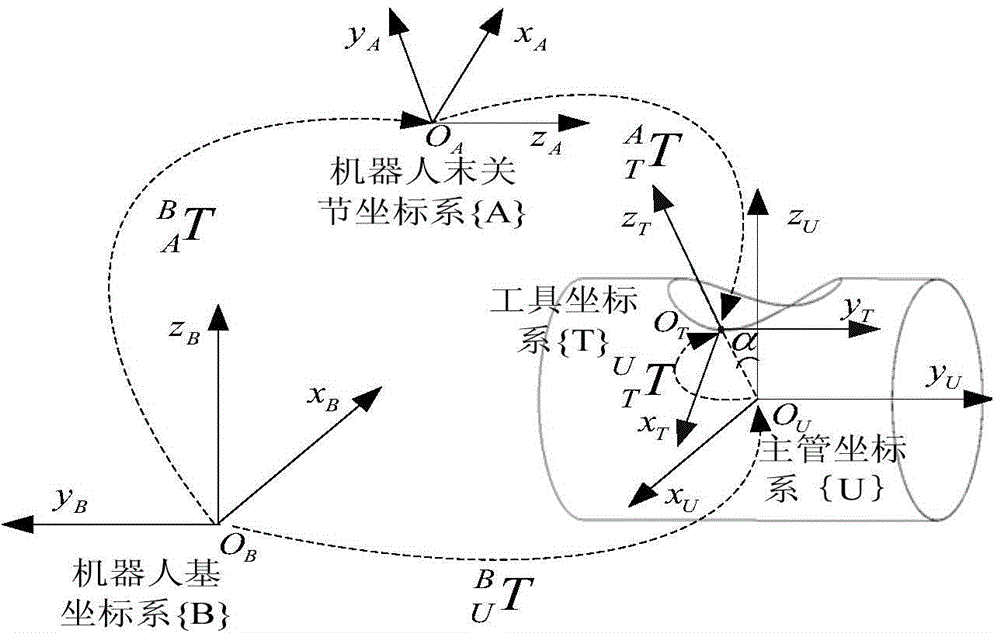

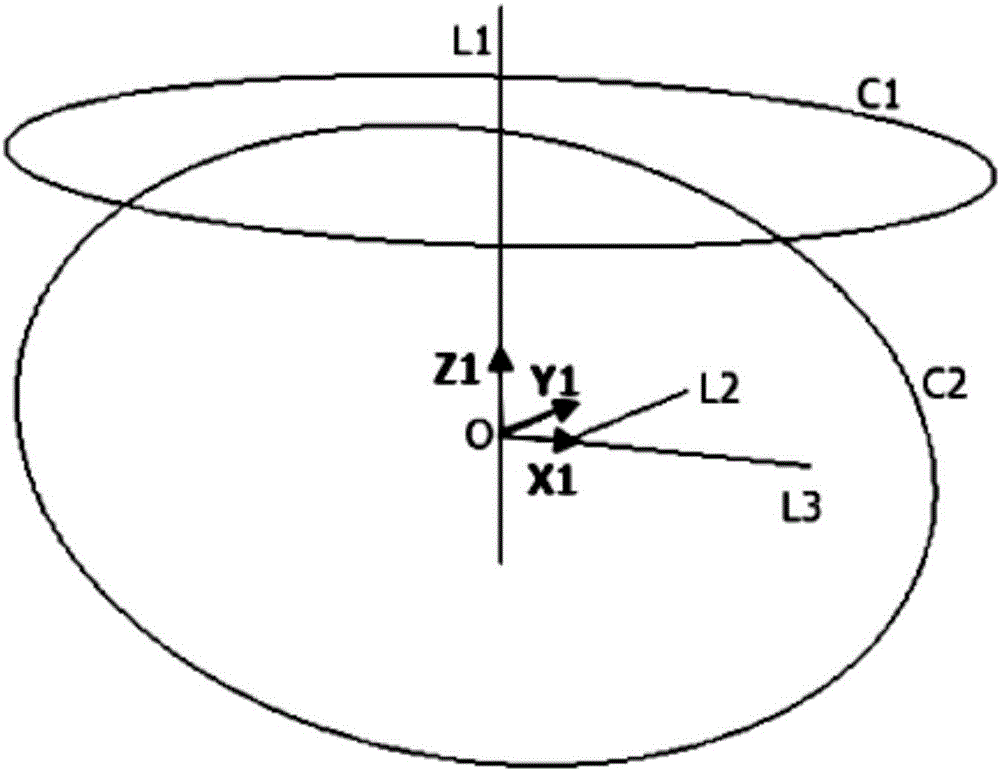

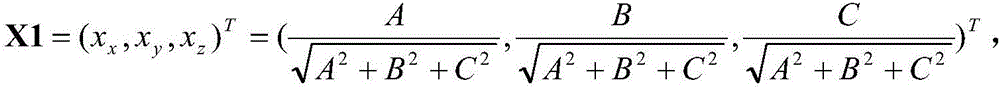

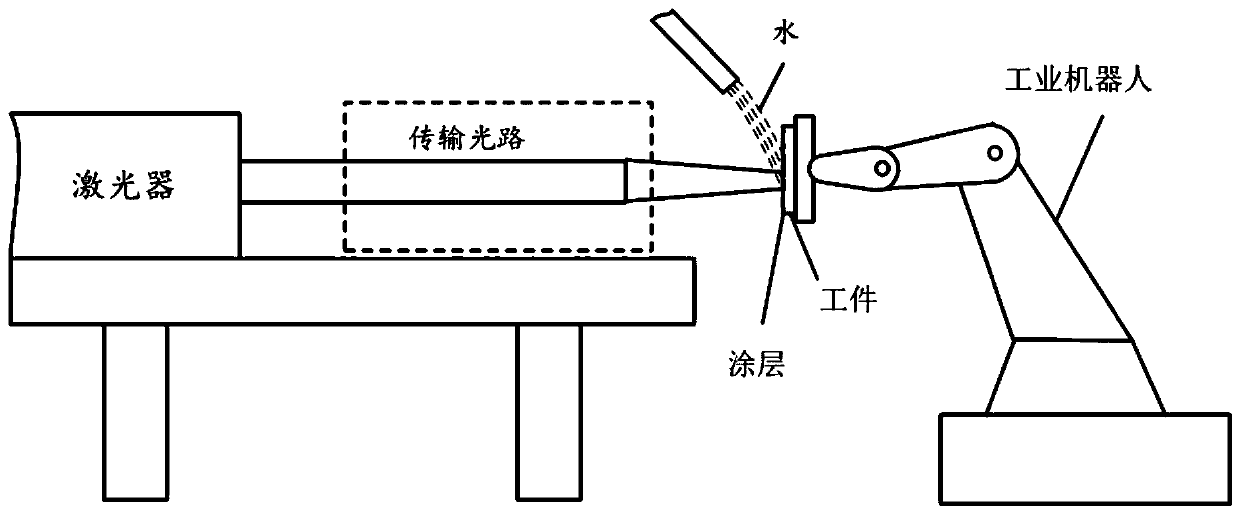

Pipeline insertion intersecting line track planning method orientated to laser machining robot

InactiveCN104827479ASave imputation calculation timeReduce difficultyProgramme-controlled manipulatorMetal working apparatusLaser processingMathematical model

The invention discloses a pipeline insertion intersecting line track planning method orientated to a laser machining robot. According to the method, through coincidence of the axis of a laser head of the laser machining robot and the normal vector of a curved surface of a workpiece, it is guaranteed that the laser machining head and the surface of the workpiece are perpendicular, a mathematic model of the position and the posture of the laser machining head in the pipeline insertion intersecting line cutting process is established, a homogeneous transformation matrix of a tail joint coordinate system relative to a robot base coordinate system is acquired when the laser machining robot cuts an intersecting line, and finally the position of the intersecting line is rapidly calibrated through a position interpolation algorithm for determining the intersecting line track. By the adoption of the track planning method, the position and the posture of the laser machining head can be effectively controlled in the intersecting line cutting process of the laser machining robot, compared with a traditional track planning method, the track planning method can greatly shorten operation time of track planning of a motion controller and the responding speed of a whole system is increased.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

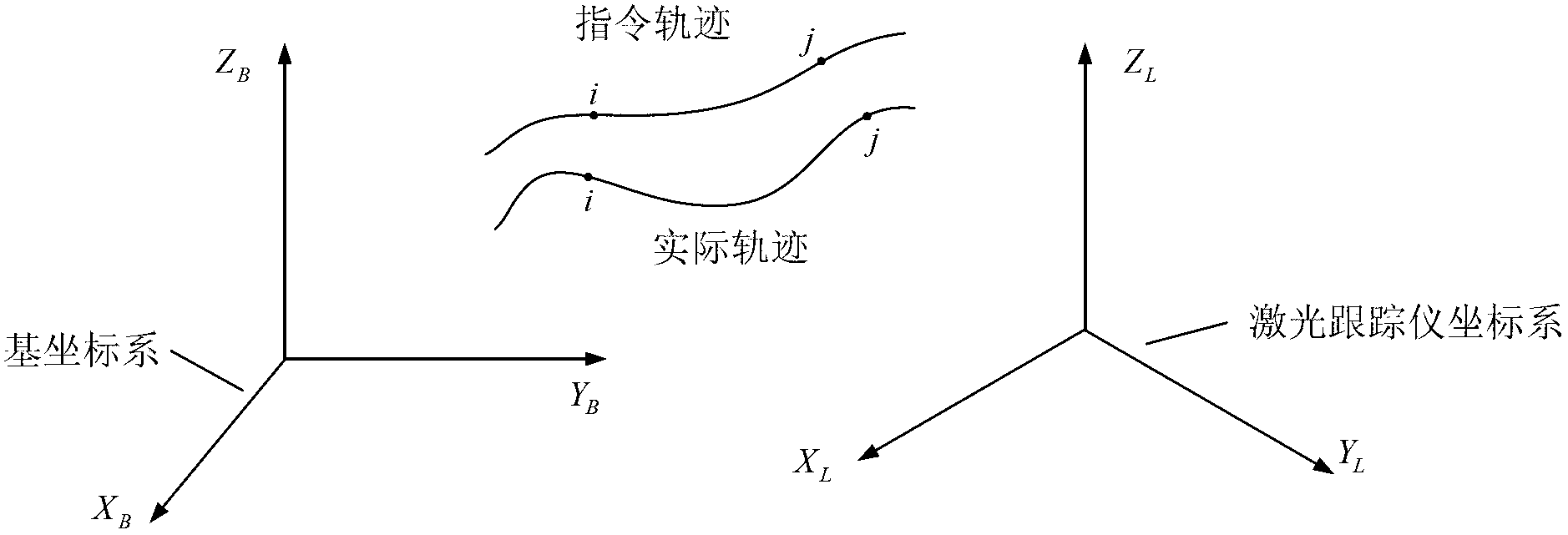

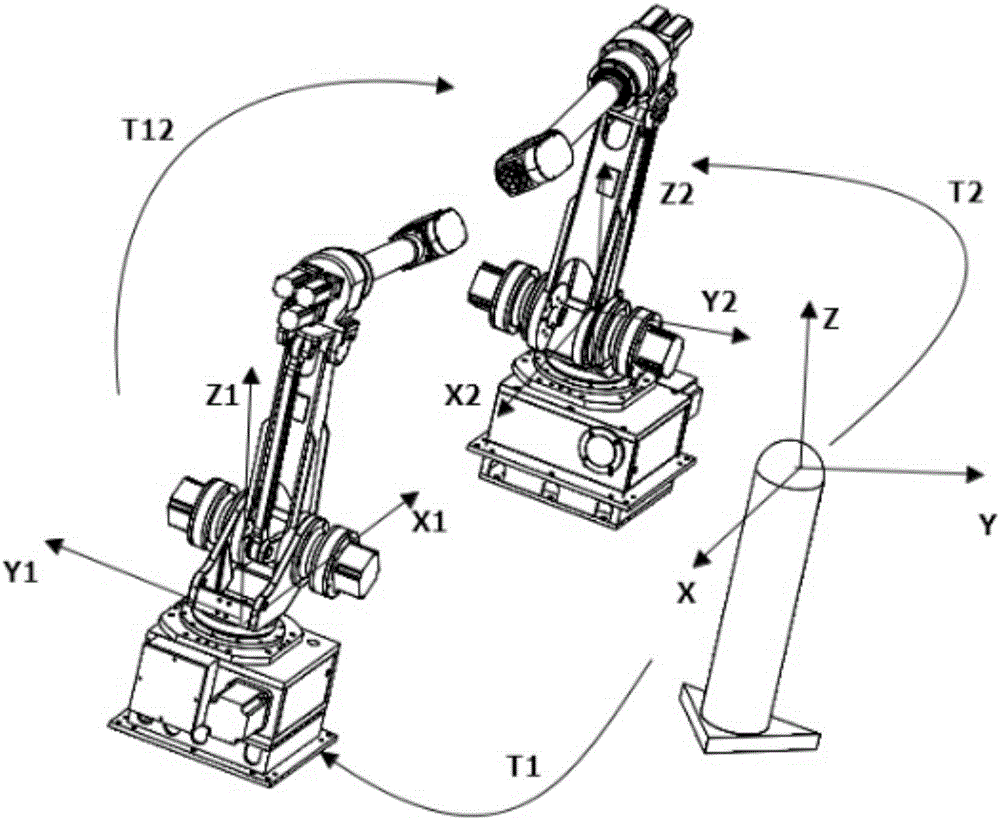

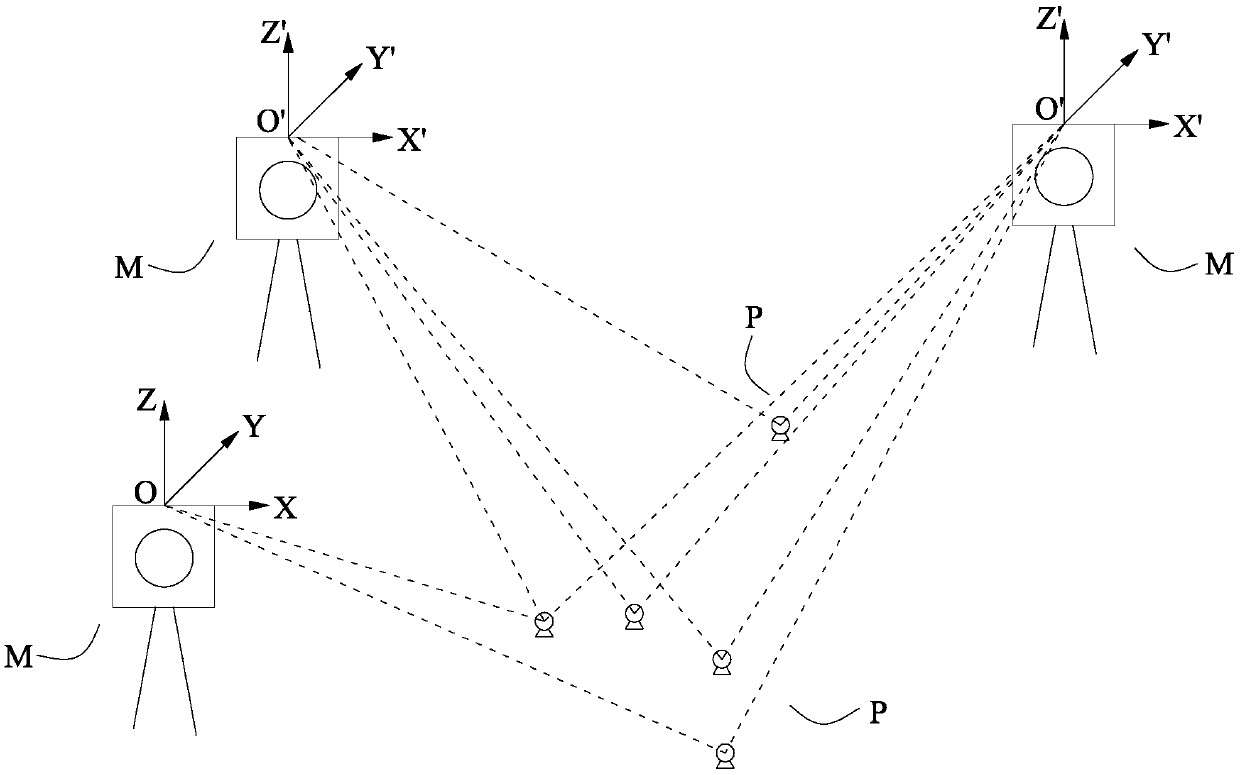

Double-robot base coordinate system calibration method based on laser tracker

InactiveCN106595474AReduced operating requirementsAvoid Calibration Accuracy ImpactUsing optical meansCalibration resultLaser tracker

The invention discloses a double-robot base coordinate system calibration method based on a laser tracker. For two robots with the cooperation relation, the method employs a high-precision laser tracker measurement system to determine a homogeneous transformation matrix of each robot base coordinate system relative to a laser tracker coordinate system, and achieves the determining of the relative posture relation between the two robot base coordinate systems through a coordinate transformation method. The method is simple in operation, and the calibration process exerts low requirements on the operation of the robots. The calculation process of the calibration method does not refer to the readings of internal coders of the robots and joint angle values, thereby avoiding the calibration precision impacts from an operation error and a robot error. Meanwhile, the method employs the advantage that a laser tracker device is high in measurement precision, so the calibration result is high in precision. The method provided by the invention is simple in operation, remarkably shortens the time, and improves the calibration efficiency.

Owner:SOUTH CHINA UNIV OF TECH +1

Method for automatically determining relation between robot base coordinate system and world coordinate system

ActiveCN104729407AAutomatically determineHigh degree of automationUsing optical meansInternal variableClassical mechanics

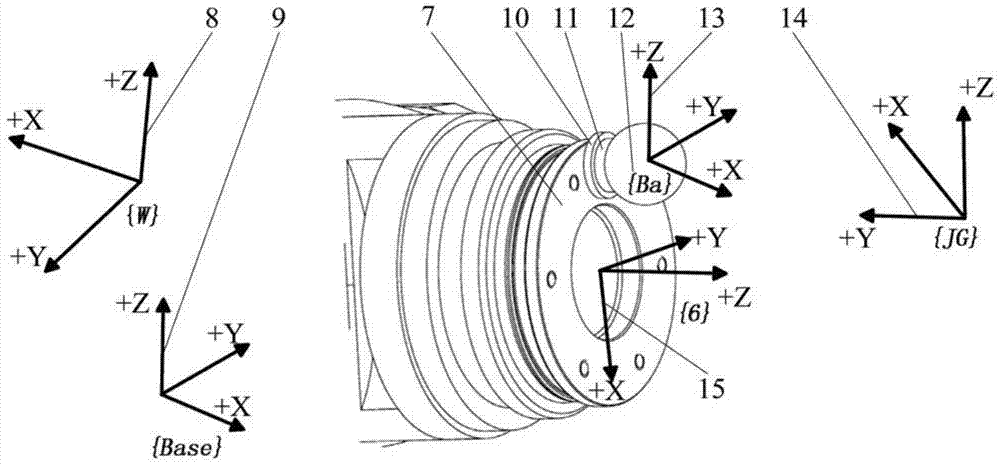

The invention discloses a method for automatically determining the relation between a robot base coordinate system and a world coordinate system. The method includes the following steps that a specified tool is mounted; a homogeneous transformation matrix of a robot tail end flange coordinate system {6} relative to the robot base coordinate system {Base} is determined; a homogeneous transformation matrix of the robot tail end flange coordinate system {6} relative to a target sphere coordinate system {Ba} is determined; a homogeneous transformation matrix of the target sphere coordinate system {Ba} relative to a laser tracker coordinate system {JG} is determined; a homogeneous transformation matrix of the world coordinate system {W} relative to the laser tracker coordinate system {JG} is determined; a homogeneous transformation matrix of the world coordinate system {W} relative to the robot base coordinate system {Base} is determined. According to the method, the advantage of high-precision measurement of the laser tracker is utilized, the internal variable of a robot is read, a coordinate conversion method is used for automatically determining the relation between the robot base coordinate system and the world coordinate system, the degree of automation is high, the speed is high and the precision is also high.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

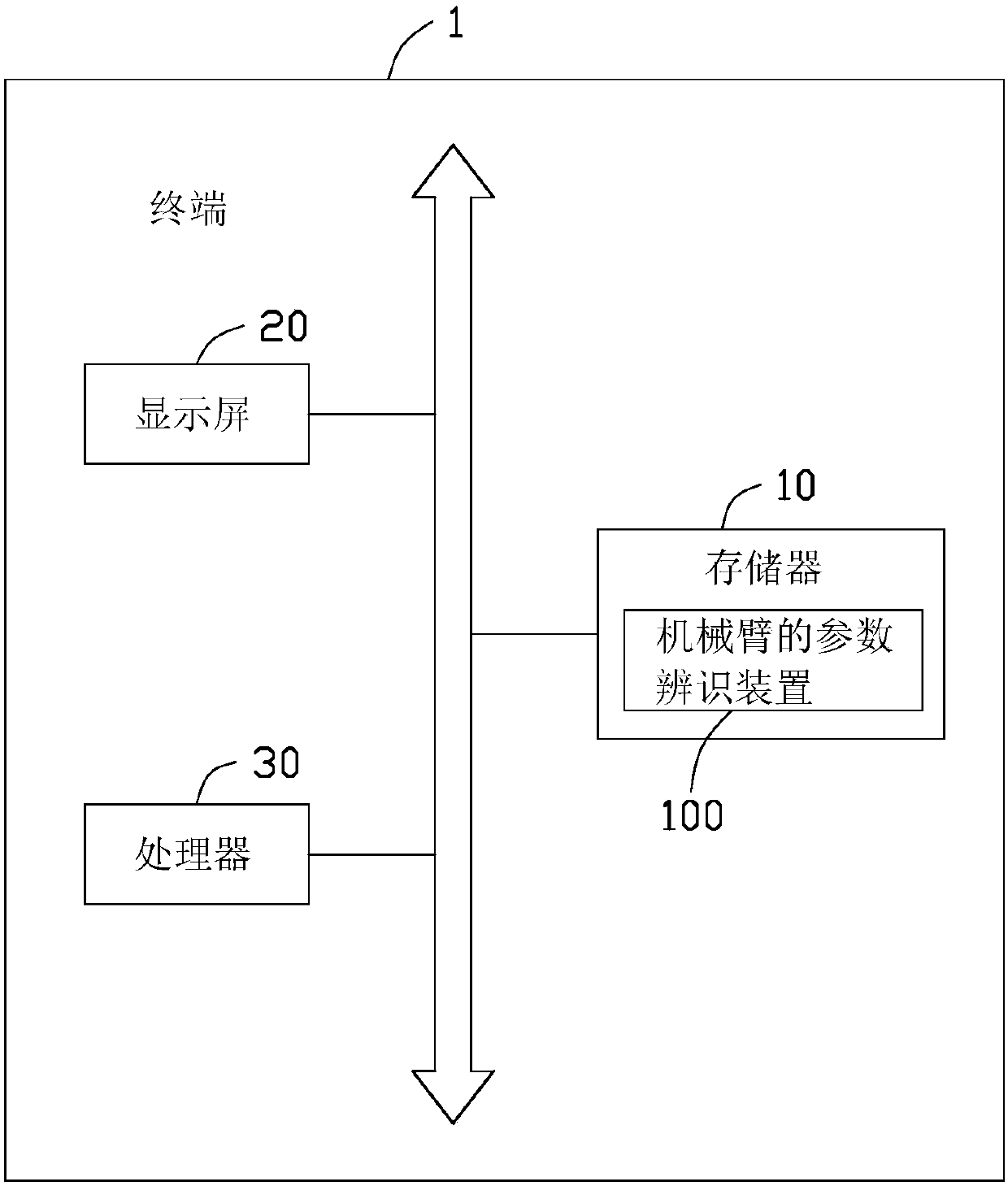

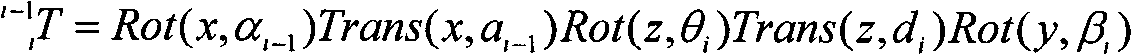

Parameter measurement and identification method and device of mechanical arm, terminal, and storage medium

InactiveCN108527373AHigh precisionProgramme-controlled manipulatorMeasurement deviceJoint coordinates

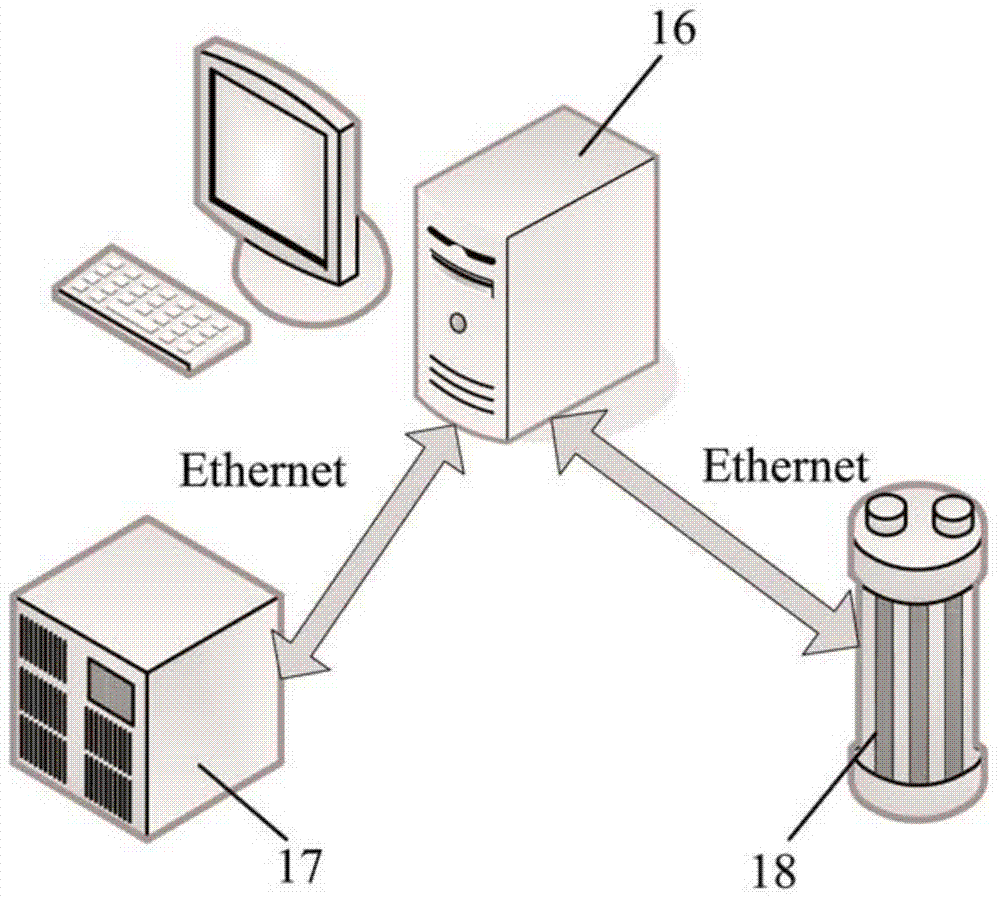

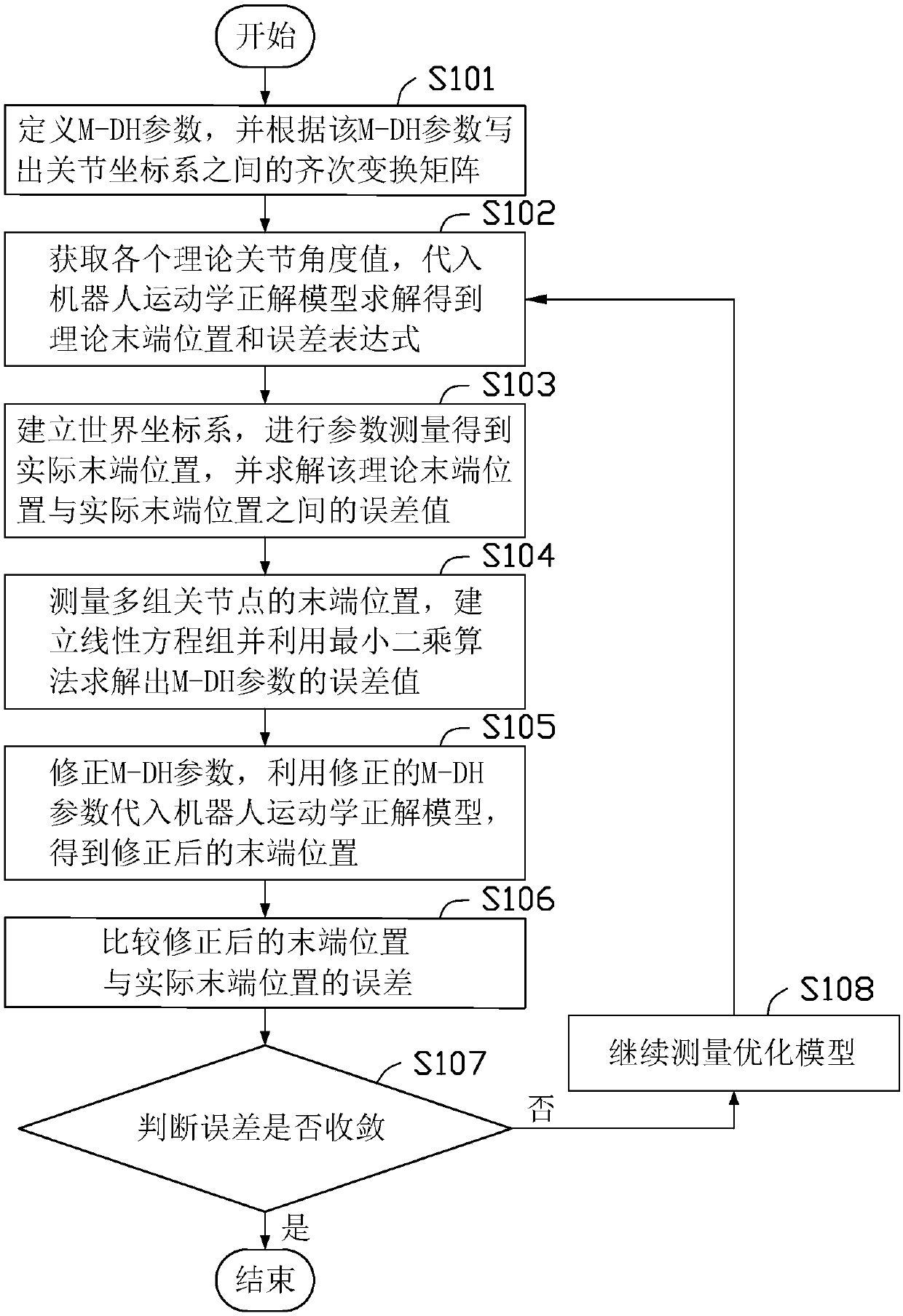

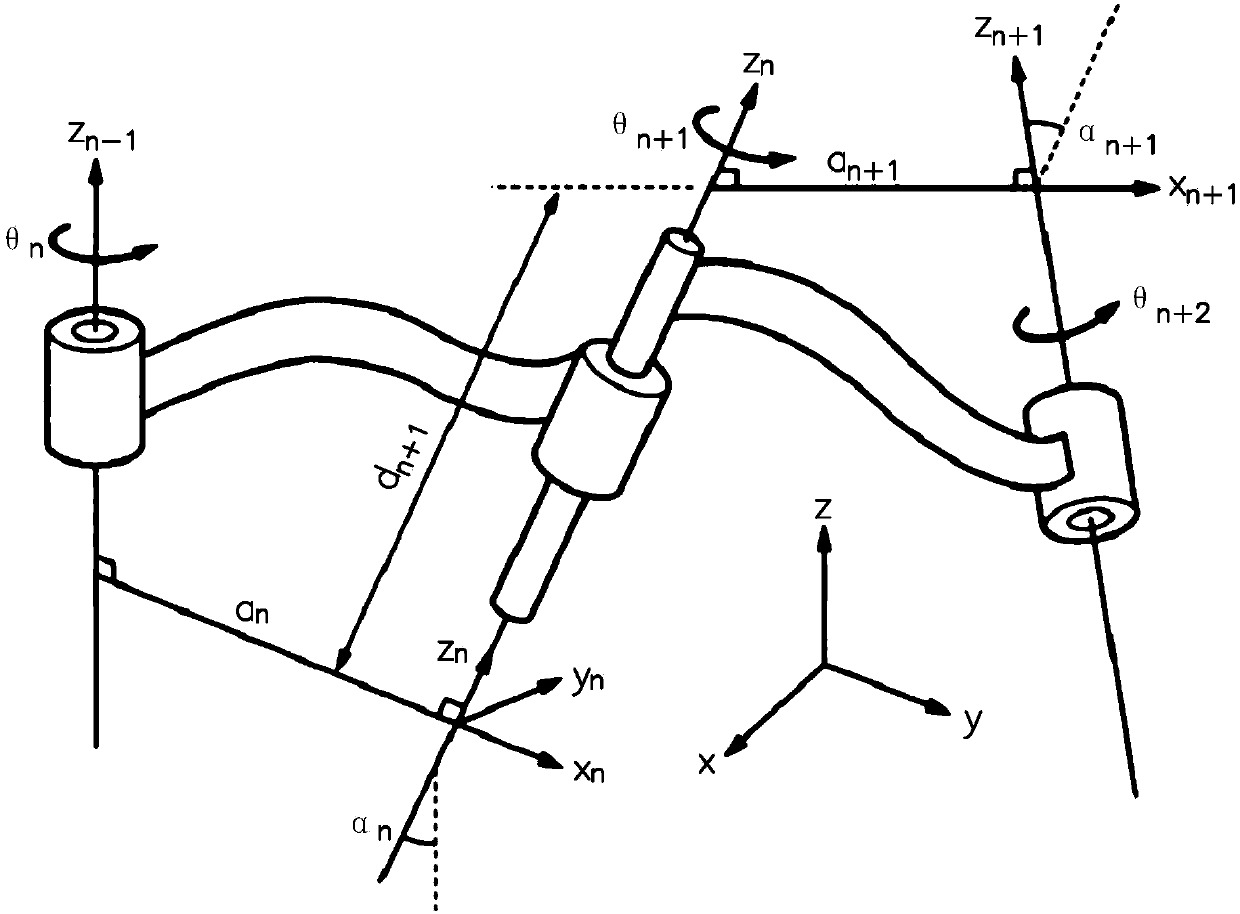

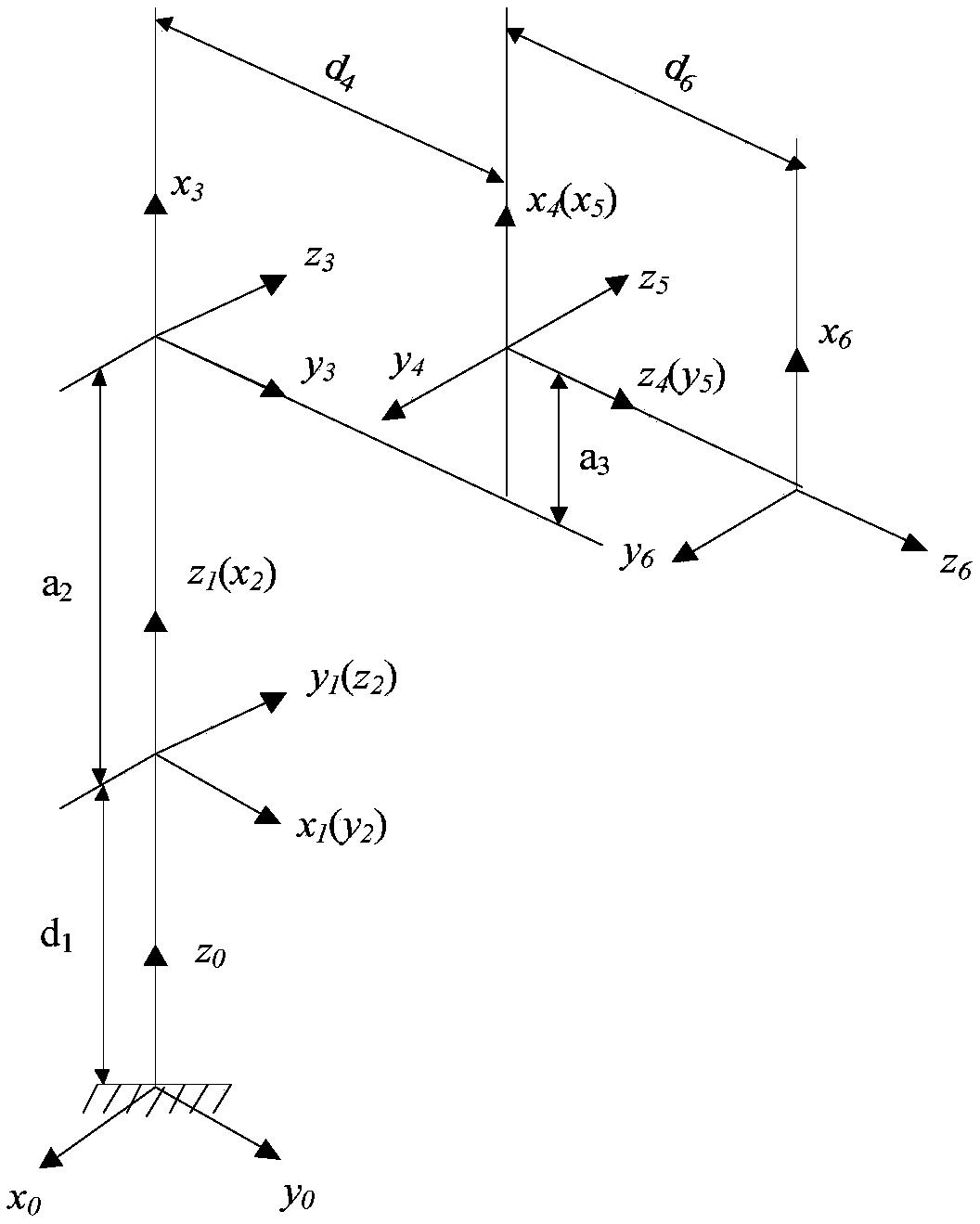

The invention provides a parameter identification method of a mechanical arm. The parameter identification method of the mechanical arm comprises the steps of defining an M-DH parameter, and writing out a homogeneous transformation matrix between joint coordinate systems; acquiring each theoretical joint angle value, substituting into a robot kinematics forward analysis model, and solving to obtain a theoretical terminal position and an error expression; measuring a practical terminal position, and solving an error value between the theoretical terminal position and the practical terminal position; measuring terminal positions of multiple groups of joint points, building a system of linear equations, and utilizing a least squares algorithm for solving an error value of the M-DH parameter;correcting the M-DH parameter, and utilizing the corrected M-DH parameter to obtain a corrected terminal position; and judging whether an error between the corrected terminal position and the practical terminal position is converged or not, and if yes, finishing the flow. The invention further provides a parameter measurement method and a parameter measurement device of the mechanical arm, a parameter identification device of the mechanical arm, a terminal device and a storage medium. By utilizing the embodiment of the invention, the parameter identification accuracy can be improved.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN

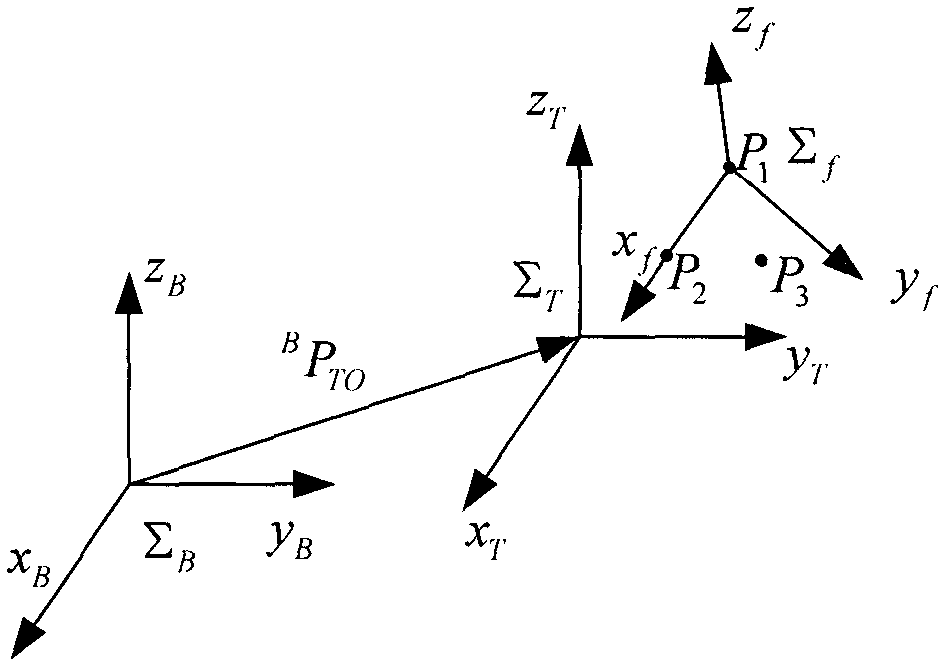

Oppositely-closing attitude-adjusting method based on multi-laser tracker measuring field

ActiveCN109613519ALess constraints on location selectionFlexible position selection constraintsWave based measurement systemsLight beamGlobal optimization

The invention provides an oppositely-closing attitude-adjusting method based on a multi-laser tracker measuring field. The oppositely-closing attitude-adjusting method comprises the steps that S1, anideal assembly model is established; S2, the multi-laser tracker measuring field is constructed; S3, a bundle adjustment method is adopted for iterative computation, and a homogeneous transformation matrix between any two laser trackers is solved; S4, coordinates of all enhanced reference systems (ERS) under an overall coordination system are calculated; and S5, target workpiece tools are assembled onto standard workpiece tools. Position selection of the ERSs is small in constraint and more flexible, drifting of the relative positions between all the ERSs is avoided, and the measuring precision is improved. Station transferring computation adopts the bundle adjustment method based on an overall optimization idea, station transferring computation between the multiple laser trackers can be completed at a time, and the station transferring precision is improved. Meanwhile, actually measured data of the laser trackers are adopted to guide attitude adjusting, the influence of placing errorof target measuring points on the position estimation result of the target measuring points is reduced, and the measuring precision is improved.

Owner:TSINGHUA UNIV

Method for separating and identifying kinematical parameters of mechanical arm

InactiveCN102314690AAvoid submersionAvoid measurement errorsImage analysisUsing optical meansEngineeringActuator

The invention relates to a method for separating and identifying kinematical parameters of a mechanical arm. On the basis of a laser tracking instrument position measurement principle and a mechanical arm differential kinematics principle, a D-H (Denavit-Hartenberg) parameter identifying method of the mechanical arm without counting joint position errors is provided by separating a posture matrix from a position vector in a homogeneous transformation matrix of an end effector. The method for separating and identifying the kinematical parameters of the mechanical arm comprises the following steps of: firstly identifying a posture parameter by measuring the posture matrix of the end effector in a basic system; secondly, identifying the separated position parameters by utilizing the identified posture parameter and the practically-measured end position; and finally realizing the identification of the kinematical parameters of the mechanical arm.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Three-dimensional vision sensor

InactiveUS8295588B2Avoid performanceCancel noiseImage enhancementImage analysisTransformation parameterThree dimensional measurement

Owner:ORMON CORP

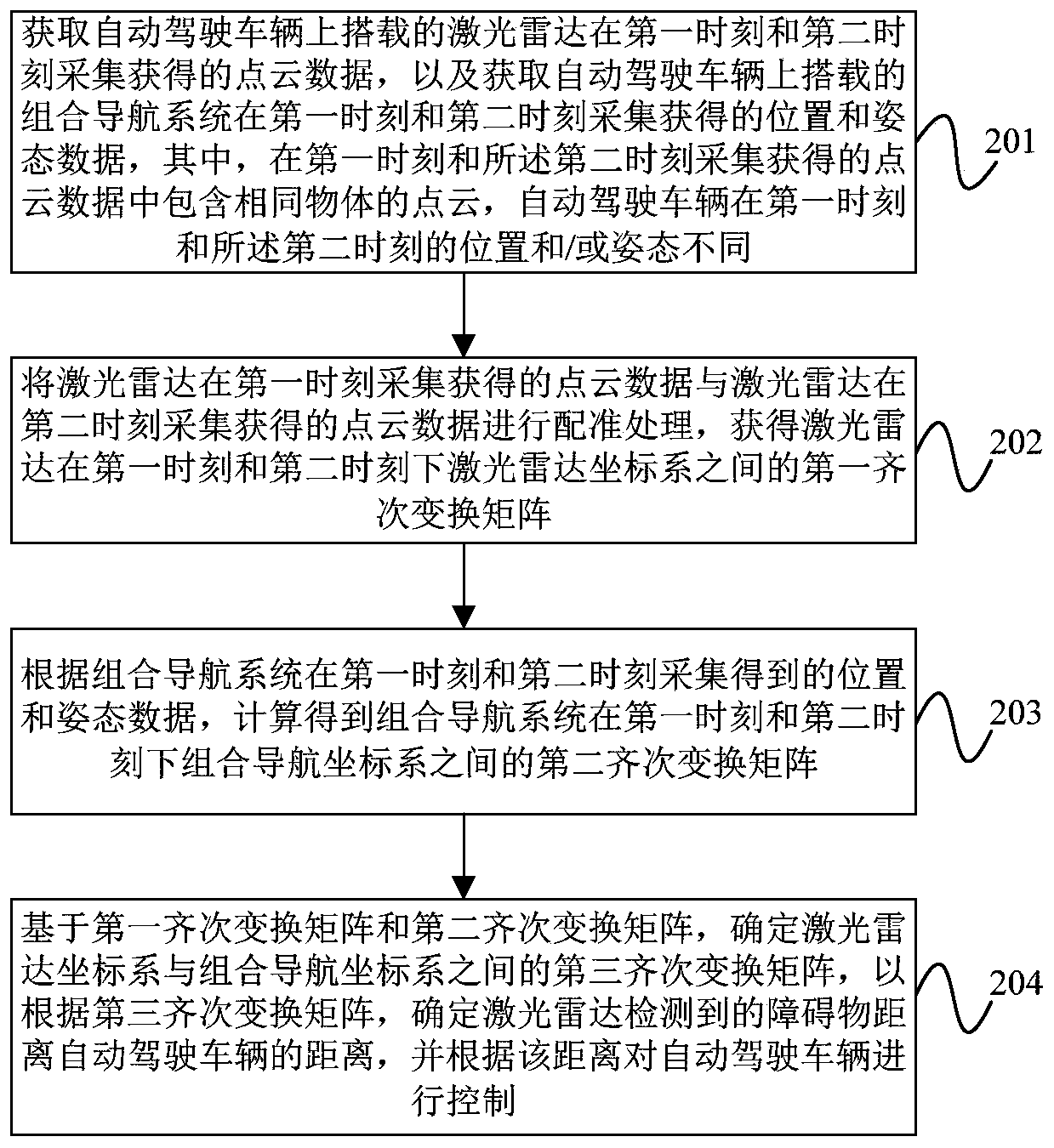

Joint calibration method of radar and integrated navigation system, device, equipment and medium

ActiveCN110673115ALower requirementCalibration results have little effectSatellite radio beaconingPoint cloudRadar

The embodiment of the application provides a joint calibration method of a radar and an integrated navigation system, a device, equipment and a medium. The joint calibration method of the radar and the integrated navigation system comprises the following steps: obtaining point cloud data collected by the lidar on an automatic driving vehicle at a first moment and a second moment, and position andattitude data collected by the integrated navigation system at the first moment and the second moment; performing registration processing on the point cloud data obtained by the lidar to obtain a first homogeneous transformation matrix; calculating a second homogeneous transformation matrix according to the position and attitude data obtained by the integrated navigation system; and completing thejoint calibration between the lidar and the integrated navigation system according to the first homogeneous transformation matrix and the second homogeneous transformation matrix. For the joint calibration of the radar and the integrated navigation system, the scheme provided by the embodiment of the application has lower requirements on environmental conditions, which weakens the impact of the environmental conditions on the accuracy of the calibration and improves the accuracy of the calibration.

Owner:HANGZHOU FABU TECH CO LTD

Robot calibrate error compensation method based on fuzzy nerve network

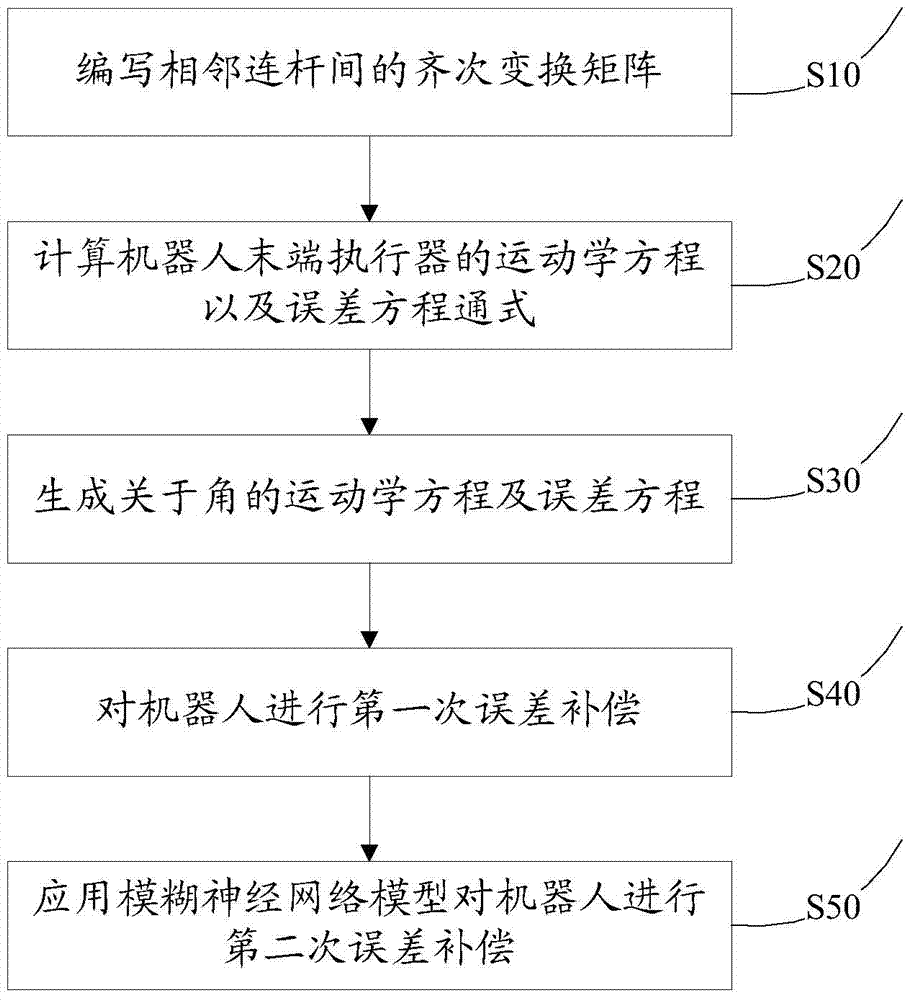

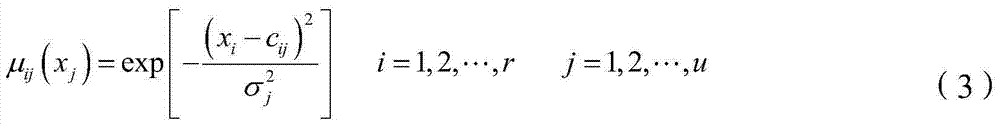

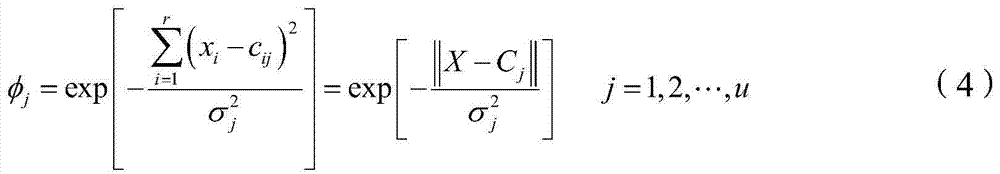

InactiveCN104516268AStrong self-learning functionImprove robustnessAdaptive controlNerve networkKinematics equations

The invention discloses a robot calibrate error compensation method based on a fuzzy nerve network; the method comprises the following steps: compiling a homogeneous transformation matrix between adjacent link rods; calculating a kinetics equation and an error equation general formula of a robot end performer according to the transformation matrix; generating a kinetics equation and an error equation of an angle [theta i] according to a geometry parameter nominal value, the kinetics equation and the error equation general formula; compensating a first error compensation for the robot according to the kinetics equation and error equation; applying a fuzzy nerve network model to carry out a second error compensation for the robot; the method can enable the robot error compensation model to be faster, and more accurate with strong robustness.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

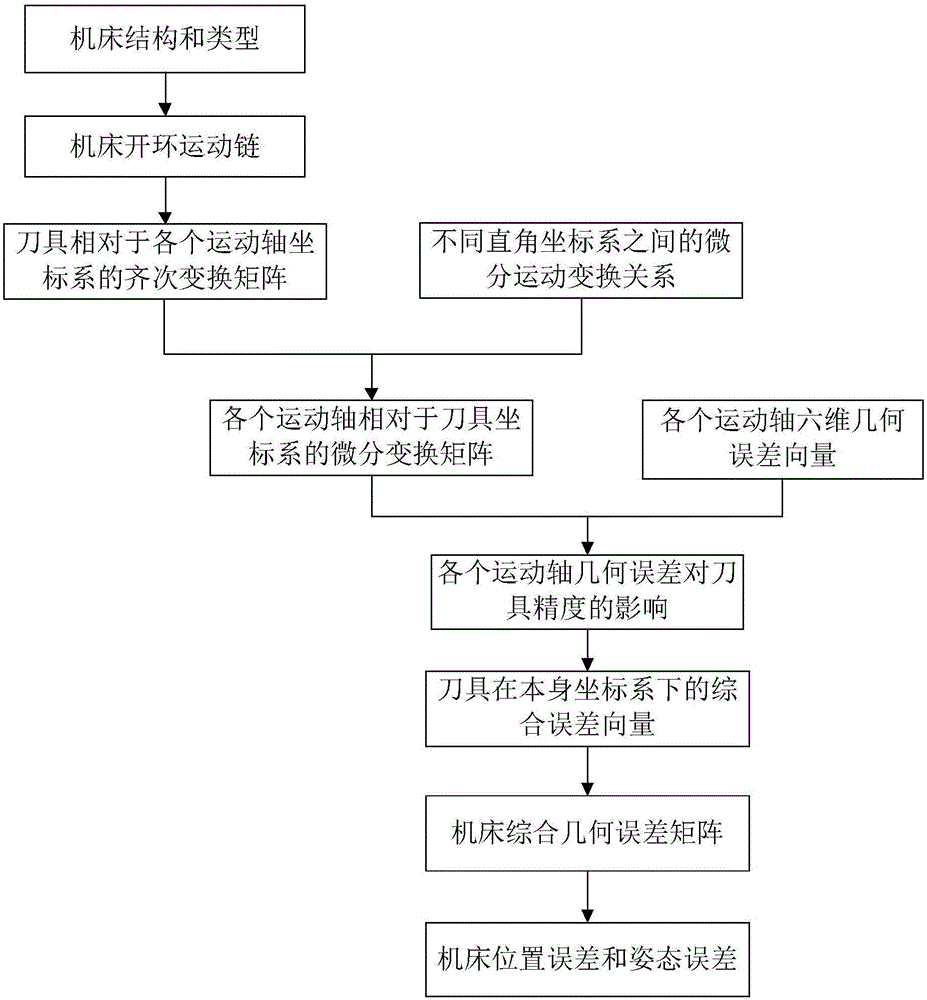

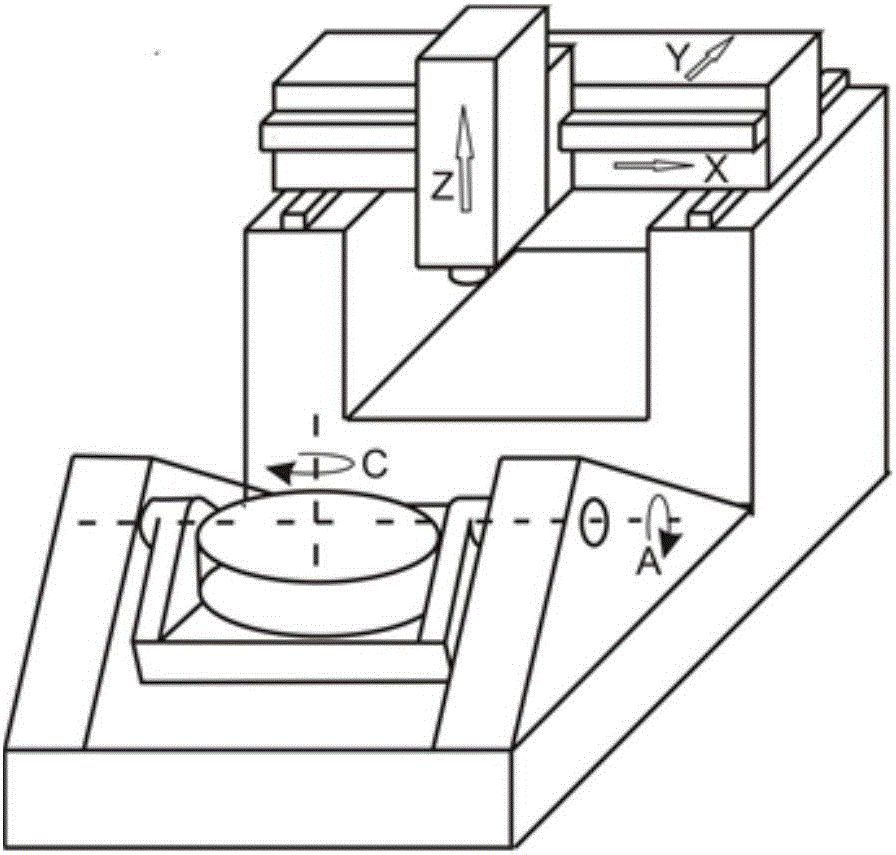

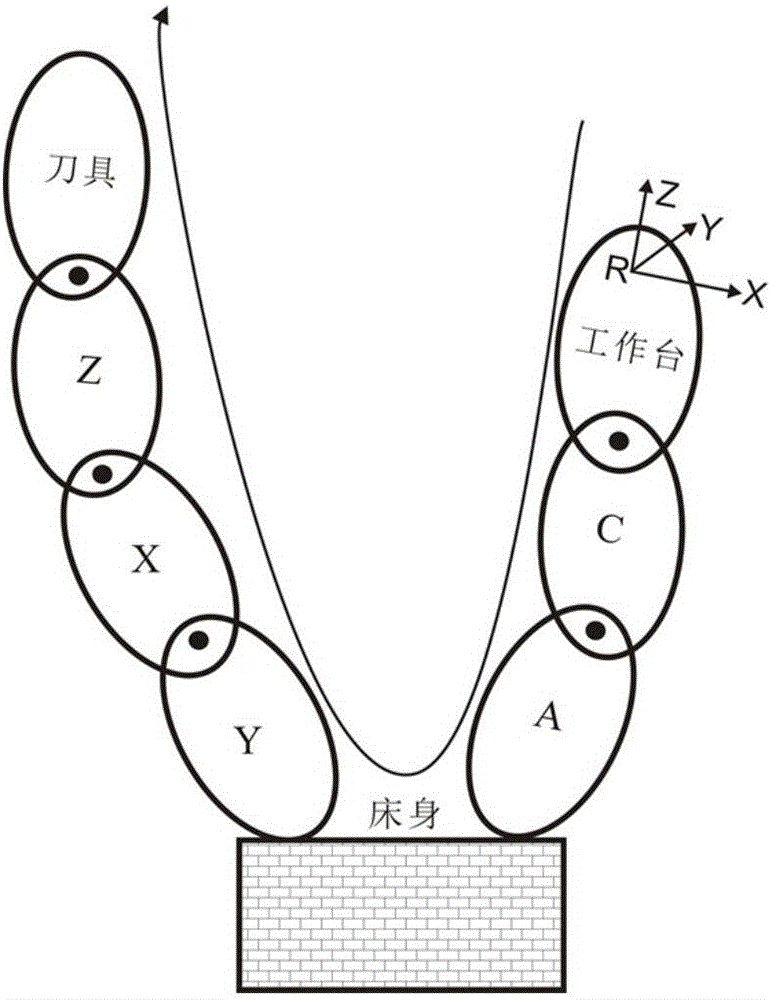

Geometric error modeling method for numerically-controlled machine tool

InactiveCN106502203AGood for error compensationSimple designProgramme controlComputer controlNumerical controlGeometric error

The invention, which belongs to the technical field of the numerically-controlled machine tool processing, discloses a geometric error modeling method for a numerically-controlled machine tool. The method comprises the following steps that: a machine tool topological structure and an opened-loop kinematic chain are established according to a machine tool structure and type; on the basis of differential kinematic conversion relation between different rectangular coordinate systems, a conversion relationship between a differential kinematic matrix and a homogeneous transform matrix between the coordinate systems is established; homogeneous transform matrixes of the machine tool relative to all motion shafts are established successively; differential kinematic matrixes of all motion shafts relative to a cutting tool are established; six-dimensional geometric error vectors of all motion shafts are established; influences on the cutting tool precision by the geometric errors of all motion shafts are calculated; adding is carried out to obtain a comprehensive error vector of the cutting tool; and according to the homogeneous transform matrix of the cutting tool relative to a work bench, the comprehensive error vector of the cutting tool is converted into a comprehensive error matrix of the machine tool, thereby obtaining position errors and attitude errors of the machine tool and the cutting tool. Therefore, the method is mainly used for obtaining influences on the machine tool precision by all motion shaft errors, so that the processing precision is improved.

Owner:SOUTHWEST JIAOTONG UNIV

Laser processing visual matching method and system and medium

InactiveCN110355464AImprove machining accuracyImprove processing stabilityImage analysisLaser beam welding apparatusVisual matchingLaser processing

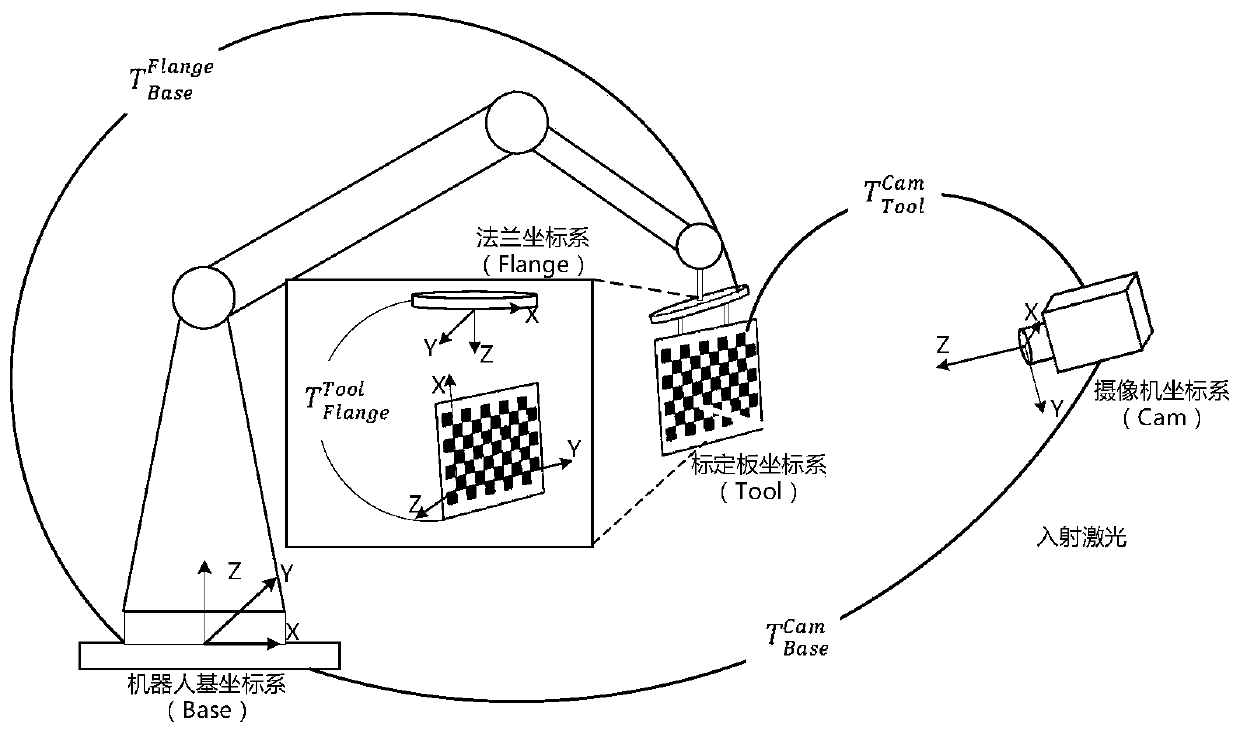

The invention provides a laser processing visual matching method and system and a medium. The laser processing visual matching method comprises a device fixing step, wherein a calibration plate is fixed on a flange of an industrial robot, and a camera is fixedly placed at a first preset position of an external space of the industrial robot; a coordinate system construction step, wherein a base coordinate system Base, a flange coordinate system Flange, a calibration plate coordinate system Tool and a camera coordinate system Cam of the industrial robot are constructed; and a matrix acquisitionstep, wherein a closed kinematic chain equation between the four coordinate systems is established, and a homogeneous transformation matrix of the calibration plate coordinate system and the flange coordinate system is obtained. Shortcomings in the prior art are overcome, the vision-based matching method with simple operation and high precision is provided, and guarantees are provided for high-precision and high-stability operation for follow-up laser processing.

Owner:SHANGHAI JIAO TONG UNIV

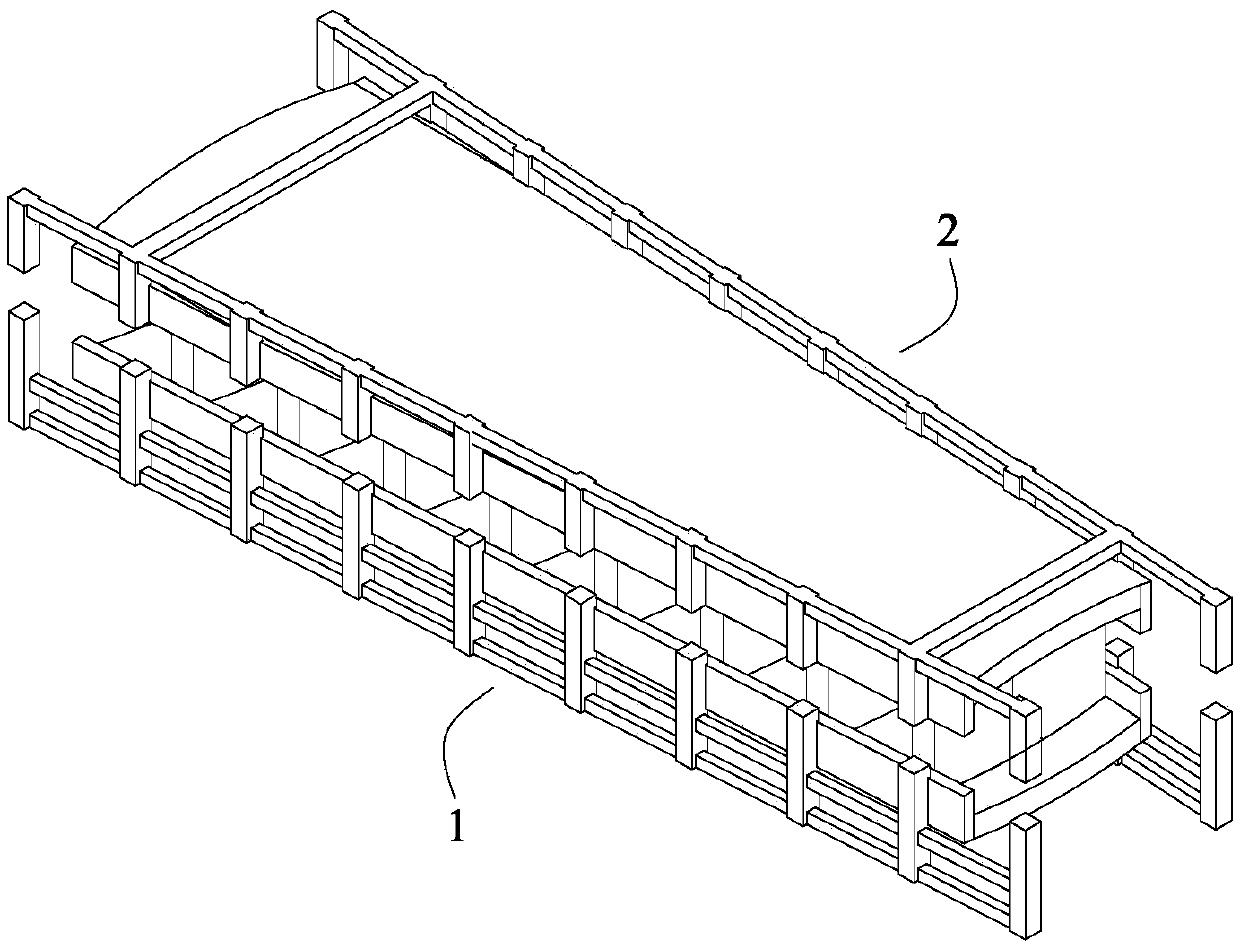

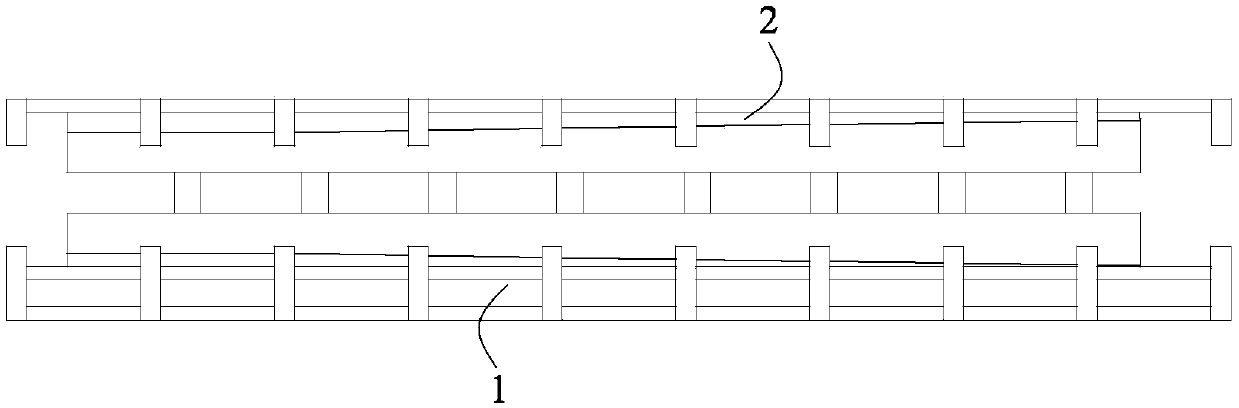

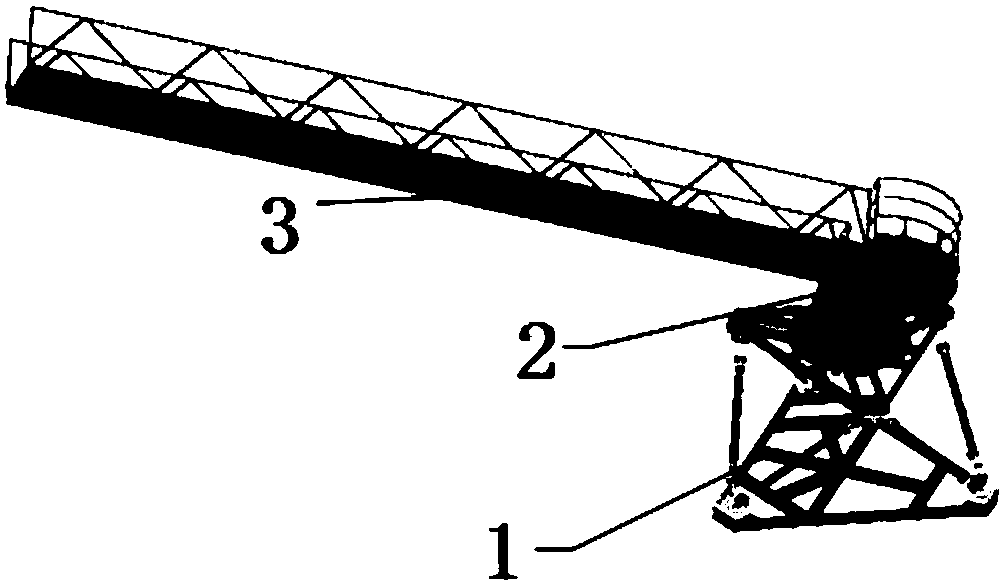

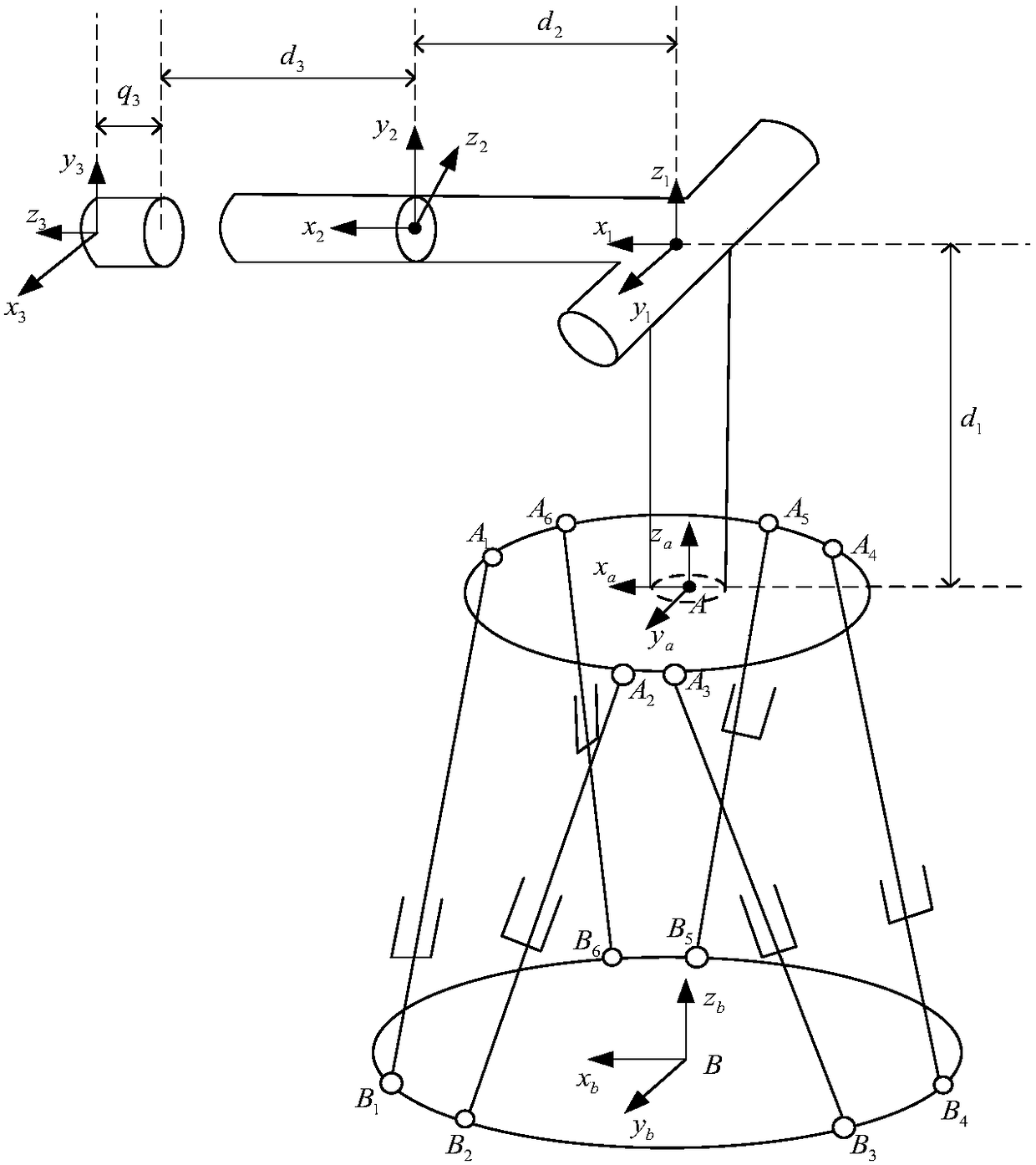

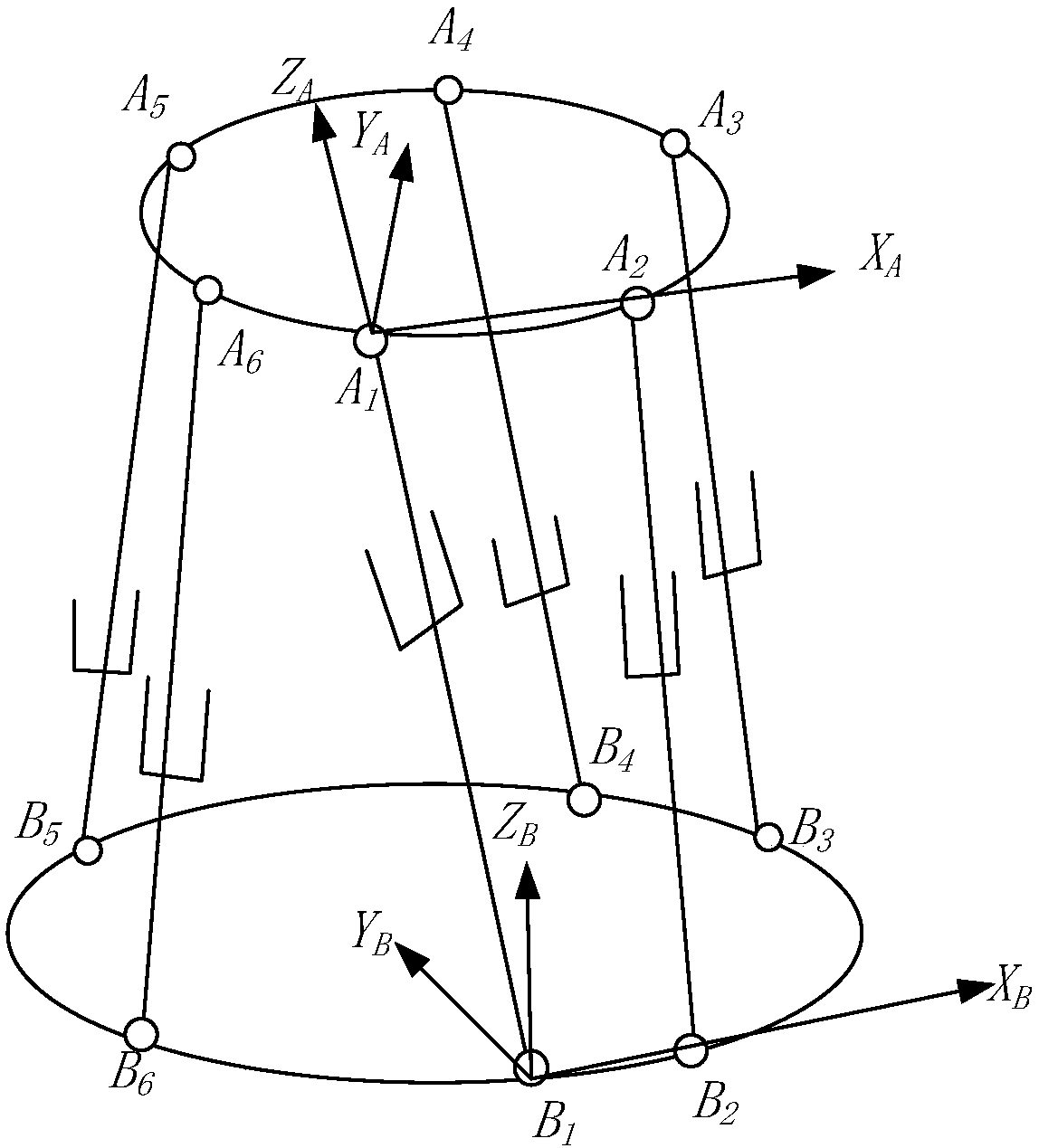

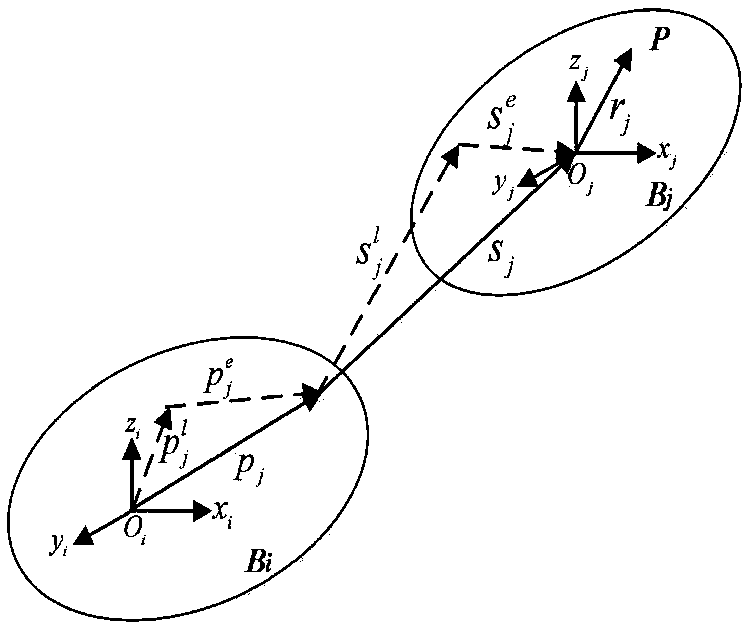

Hybrid mechanism-based kinematic solution method for active wave compensation systems

ActiveCN108446425AMake up for sports limitCompensatory improvementDesign optimisation/simulationComplex mathematical operationsActive heave compensationSimultaneous equations

The invention provides a hybrid mechanism-based kinematic solution method for active wave compensation systems. The method comprises the following steps of: in an inverse kinematic process, solving aposition and a posture, in a space, of a mobile platform through a pose parameter of a target point at the tail end of an upper platform, solving the displacement of each rod length, namely, each mobile pair, and inputting an obtained joint motion amount into a compensation platform controller to realize motion control; and in a forward kinematic process, solving a direction cosine matrix and a position vector, in a static coordinate system, of a mobile coordinate system through 6 input rod lengths, a constraint equation of the rod lengths and a system of simultaneous equations, solving a homogeneous transformation matrix at the tail end of an accommodation ladder of the upper platform, and inputting an obtained pose, in the space, of the tail end of the accommodation ladder into the compensation platform controller to realize motion control. The method is capable of enabling the calculation process to be relatively rapid, simple, correct, efficient and convenient to apply, providing basis for the motion control of active wave compensation systems, and satisfying the work demands of the active wave compensation systems of engineering.

Owner:HARBIN ENG UNIV

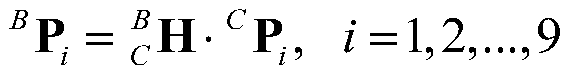

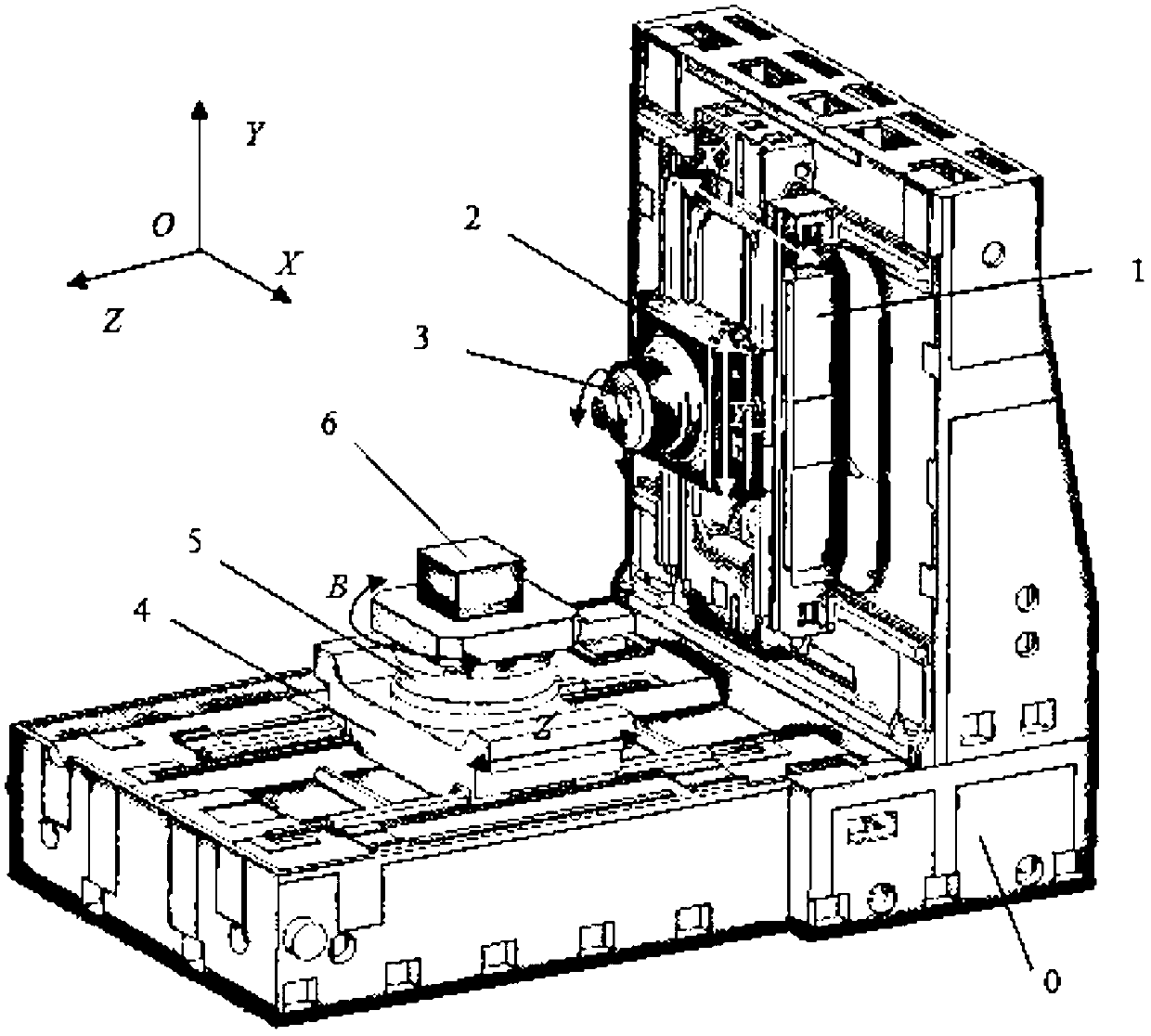

Method for detecting position-independent geometric errors of double rotating shafts of five-axis numerical control machine tool

ActiveCN109732401ASolve the identification problemSolve asynchronicityMeasurement/indication equipmentsGeometric errorRotational axis

The invention discloses a method for detecting position-independent geometric errors of double rotating shafts of a five-axis numerical control machine tool. The method is characterized in that a ballbar is adopted as experimental equipment for identifying the position-independent geometric errors (PIGEs) of the swing shaft B and the rotating shaft C in the five-axis numerical control machine tool; a new measurement track is provided; the problem that asynchronism is caused between the resultant velocity formed when the swing shaft B and the rotating shaft C re in coordinated movement and theacquisition speed of the ball bar is solved; a homogeneous transformation matrix in the rigid body kinematics is combined, and a simulation model is established; and the simulation model is combinedwith experiments, and the position-independent geometric errors of the double rotating shafts of the five-axis numerical control machine tool can be identified and measured. By means of the method, the position-independent geometric errors of the double rotating shafts of the five-axis numerical control machine tool can be rapidly and effectively detected; and the precision is high, and the practicability is good.

Owner:TIANJIN POLYTECHNIC UNIV

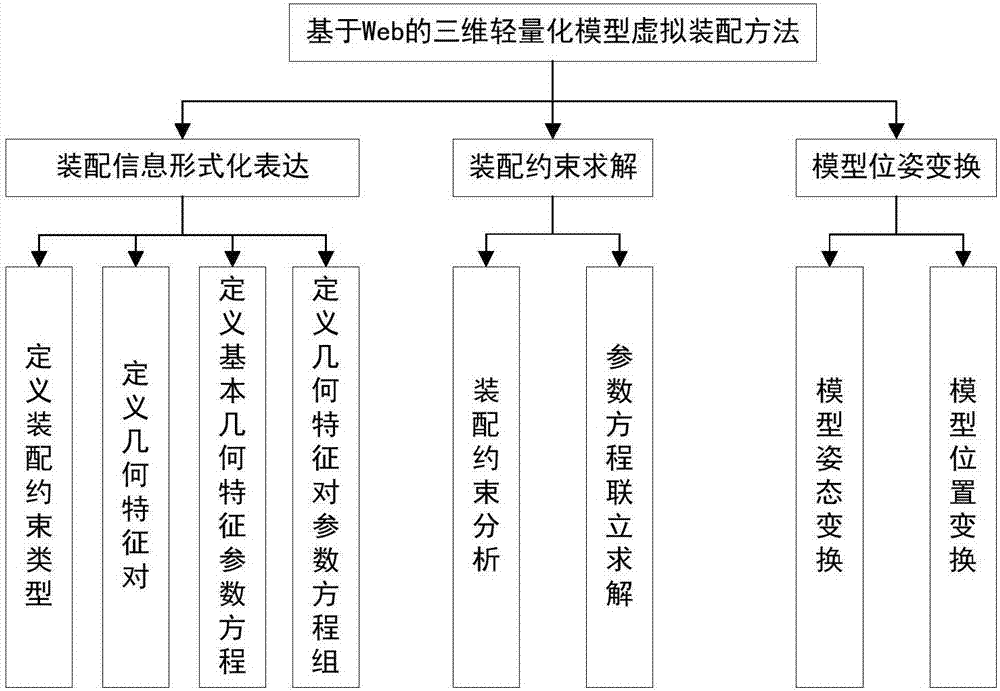

Web-based three-dimensional lightweight model virtual assembly method and device thereof

ActiveCN107247832AVirtual assembly implementationAvoid the problem of not being able to complete virtual assemblyDesign optimisation/simulationSpecial data processing applicationsComputer visionObjective model

The invention discloses a Web-based three-dimensional lightweight model virtual assembly method. The Web-based three-dimensional lightweight model virtual assembly method comprises the following steps: expressing assembly information in a formalized manner; defining an assembly restraining type and geometric feature pairs, and representing geometric features of a three-dimensional lightweight model and establishing a simultaneous parameter equation set through a parameter equation which comprises vector quantity information according to defined assembly restraining type and geometric feature pairs; assembly restraining solving: solving the parameter equation set to meet an assembly restraining requirement according to the geometric feature pairs corresponding to the different assembly restraining types; and model pose transformation: carrying out pose transformation on the three-dimensional lightweight model through a homogeneous transform matrix, and enabling the three-dimensional lightweight model to move to a specific location of a target model to finish virtual assembly. By the Web-based three-dimensional lightweight model virtual assembly method and the method thereof, virtual assembly of the three-dimensional lightweight model in a Web environment is realized.

Owner:WUHAN UNIV OF TECH

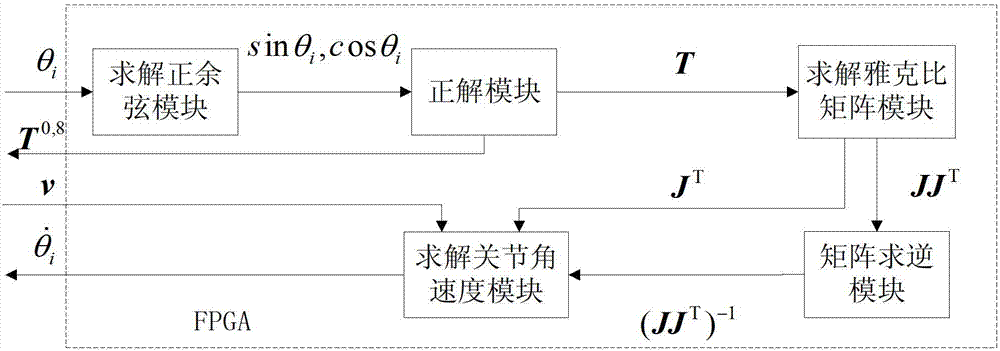

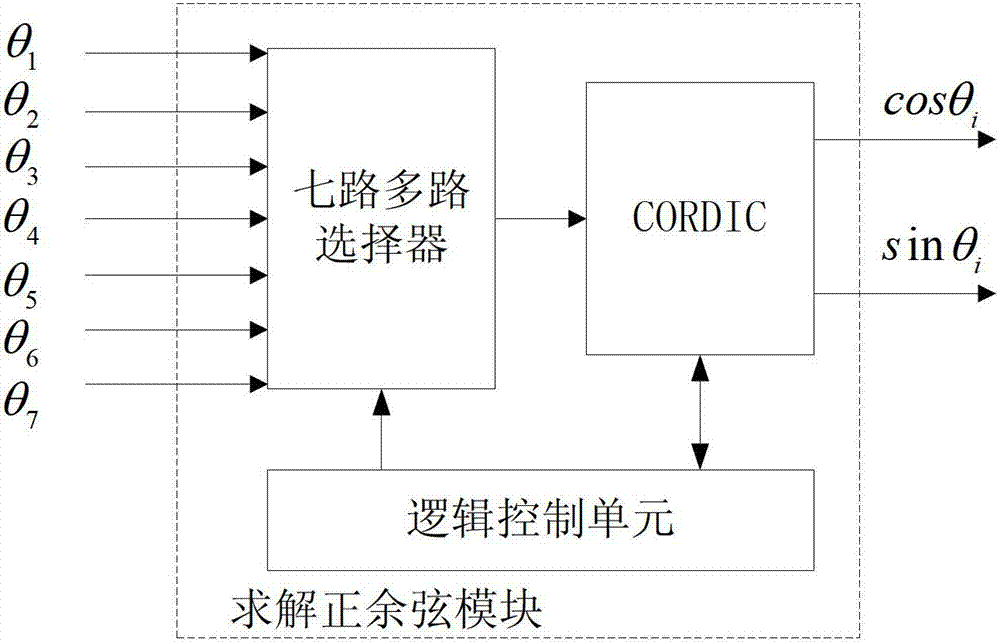

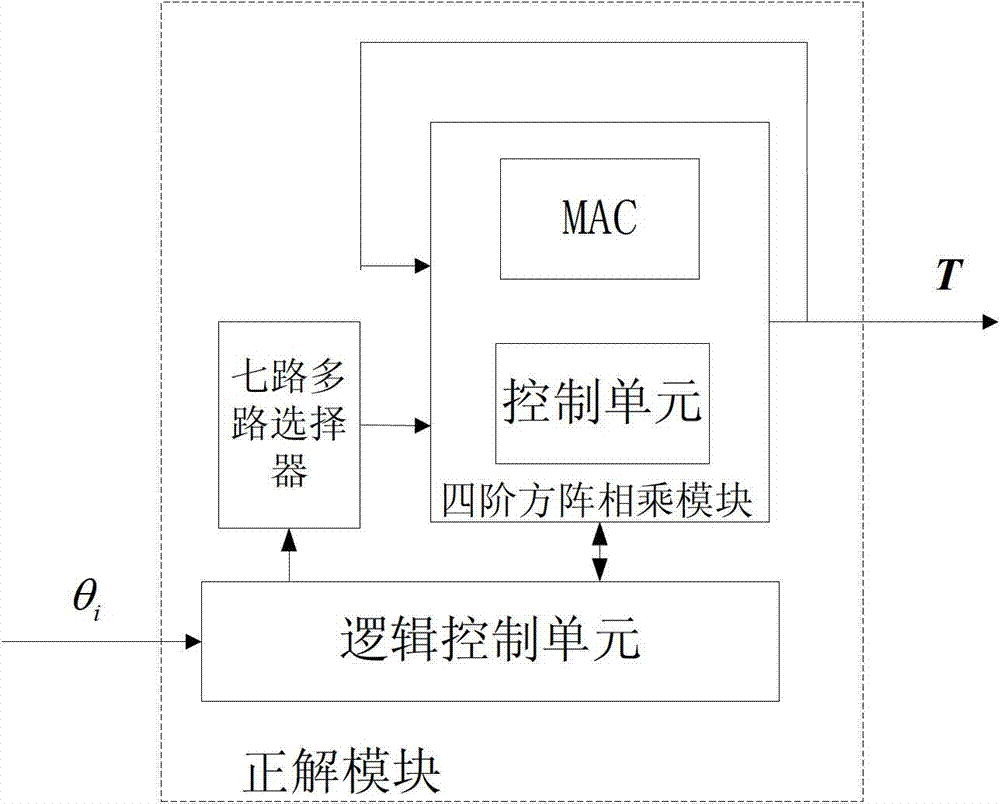

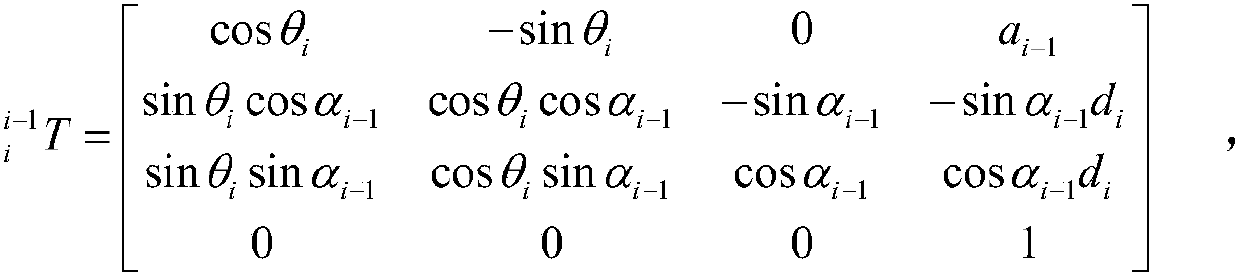

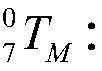

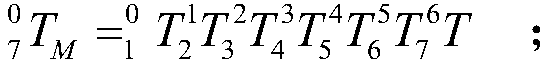

Kinematics real-time solving method based on seven-DOF space manipulator of FPGA

The invention discloses a kinematics real-time solving method based on a seven-DOF space manipulator of an FPGA. The kinematics solving method is related to five function modules, respectively, a sine and cosine solving module, a positive solution module, a Jacobian matrix solving module, an inversion module and a joint angular speed solving module. The sine and cosine solving module is used for computing sine and cosine values of each joint angle of the manipulator and inputting the sine and cosine values of each joint angle of the manipulator to the positive solution module to solve a homogeneous transformation matrix, then, the Jacobian matrix solving module is used for computing each line of a Jacobian matrix relative to a tail end coordinate system through the homogeneous transformation matrix to obtain a Jacobian matrix and a full rank matrix relative to a reference coordinate system through computation and outputting the full rank matrix to the inversion module for inversion. When inversion operation is completed, the full rank matrix is output to the joint angular speed solving module and is multiplied with a transpose of the Jacobian matrix relative to the reference coordinate system, then, pseudo-inversion of the Jacobian matrix can be obtained, finally, the angular speed of each joint can be obtained by multiplying the tail end speed, and the whole kinematics solving can be completed.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Modeling method for simplified kinematic model of minimally invasive surgical robot

ActiveCN107374727AMeeting the needs of controlled motionComputer-aided planning/modellingDesign optimisation/simulationSimulationPosition control

The invention discloses a modeling method for a simplified kinematic model of a minimally invasive surgical robot. The method includes the steps of creating a homogeneous transformation matrix of a main wrist point based on a basic coordinate system of a main hand; according to the homogeneous transformation matrix of the main hand, a preset basic coordinate rotation mapping matrix and a proportion mapping coefficient of the main hand and a subordinate hand, obtaining the position of a writ point of the subordinate hand based on a basic coordination system of the subordinate hand; according to the homogeneous transformation matrix of a position control movement joint of the subordinate hand and the position of the wrist point, creating an equation, and figuring out an angle value and / or position value of the position control movement joint of the subordinate hand; according to the one-to-one corresponding relation between a posture angle of the main hand at the position of the wrist point and the posture angle of the subordinate hand at the wrist point of the subordinate hand, creating an equation, and then figuring out the angle value and / or position value of a posture control movement joint of the subordinate hand. According to the method for the simplified kinematic model of the minimally invasive surgical robot, on the basis of an idea of separating the position from the posture, the complex degree of kinematic calculation can be simplified, and the real-time index of a control system is improved.

Owner:CHONGQING JINSHAN MEDICAL ROBOTICS CO LTD

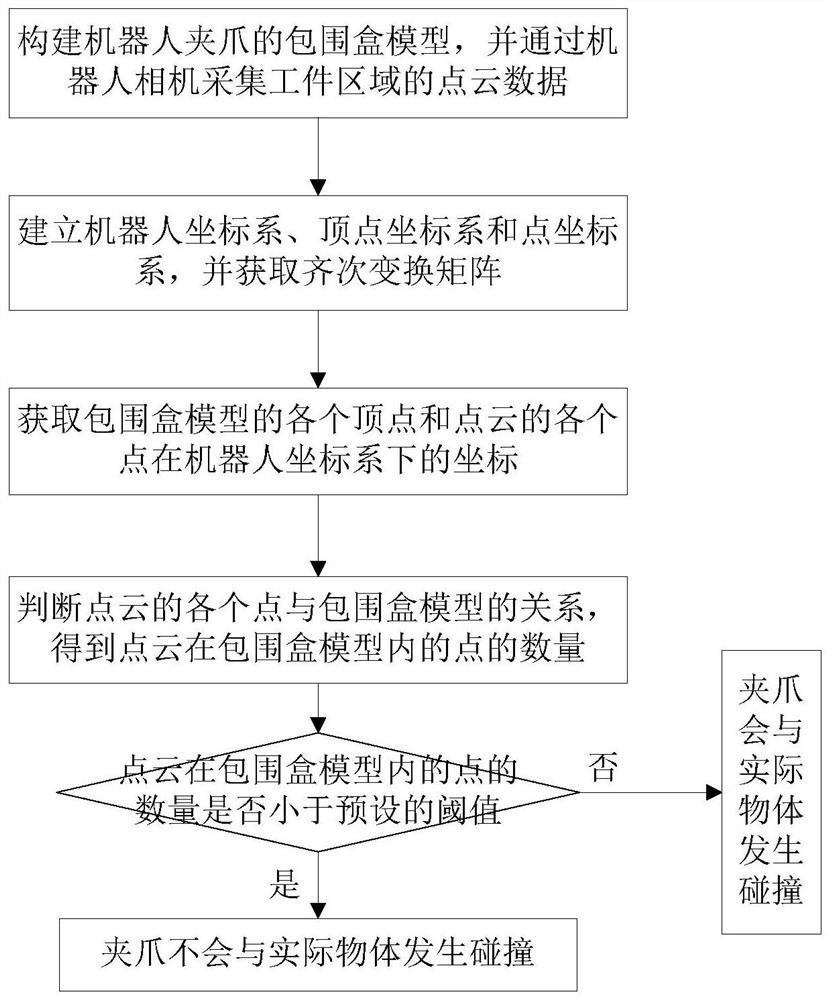

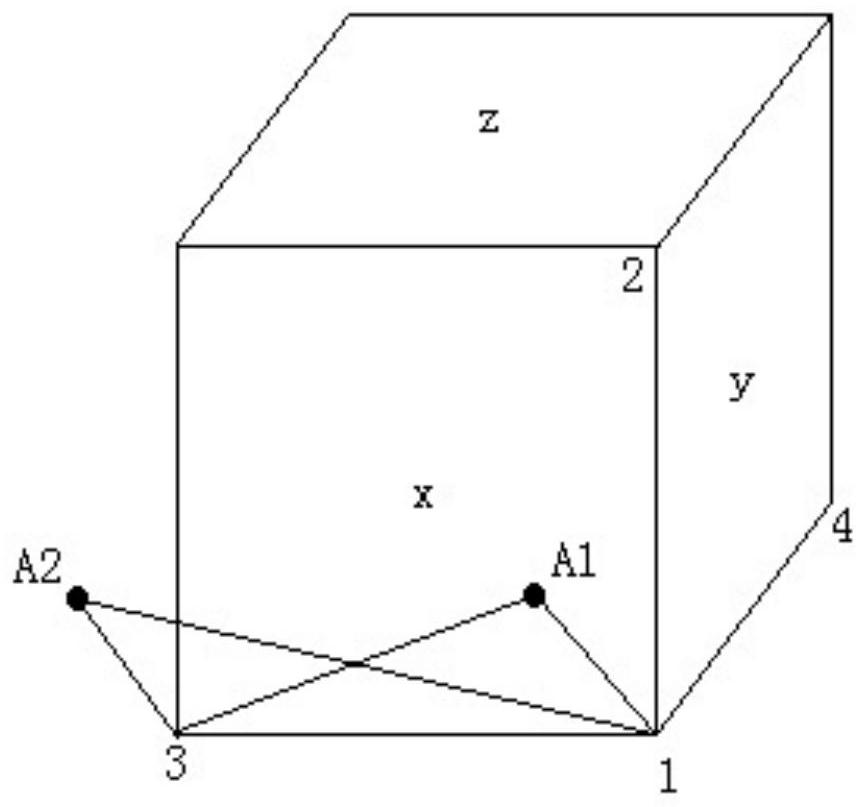

Point cloud collision detection method applied to robot grabbing scene

ActiveCN112060087AProgramme-controlled manipulatorImage enhancementPoint cloudComputer graphics (images)

The invention provides a point cloud collision detection method applied to a robot grabbing scene. The method comprises the following steps of S1, constructing a bounding box model of a robot clampingjaw, and collecting point cloud data in a workpiece region; S2, establishing a robot coordinate system, a vertex coordinate system and a point coordinate system, and obtaining a homogeneous transformation matrix; S3, obtaining the coordinates of each vertex of the bounding box model and the coordinates of each point of a point cloud under the robot coordinate system respectively according to thehomogeneous transformation matrix; S4, judging the relationship between each point of the point cloud and the bounding box model, and obtaining the quantity of the points, in the bounding box model, of the point cloud; and S5, comparing the quantity of the points, in the bounding box model, of the point cloud with a preset threshold so as to detect whether the clamping jaw collides with an actualobject or not in advance. According to the point cloud collision detection method applied to the robot grabbing scene, the problem of unstable grabbing caused by a collision conflict between a clamping jaw and other workpieces touched by the clamping jaw in the workpiece grabbing process of a robot currently is solved.

Owner:FOSHAN LONGSHEN ROBOT

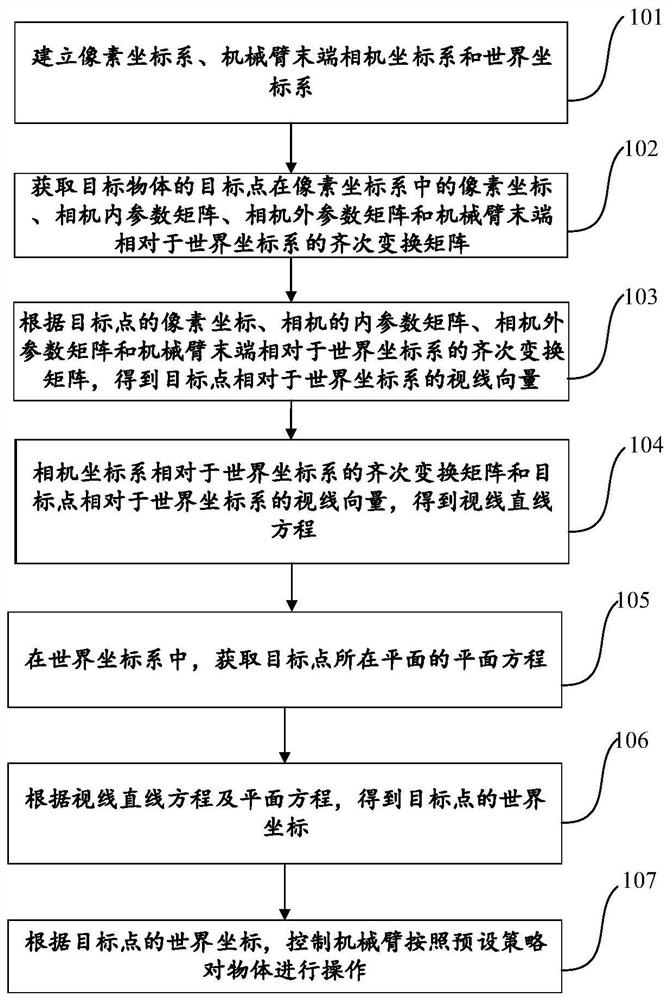

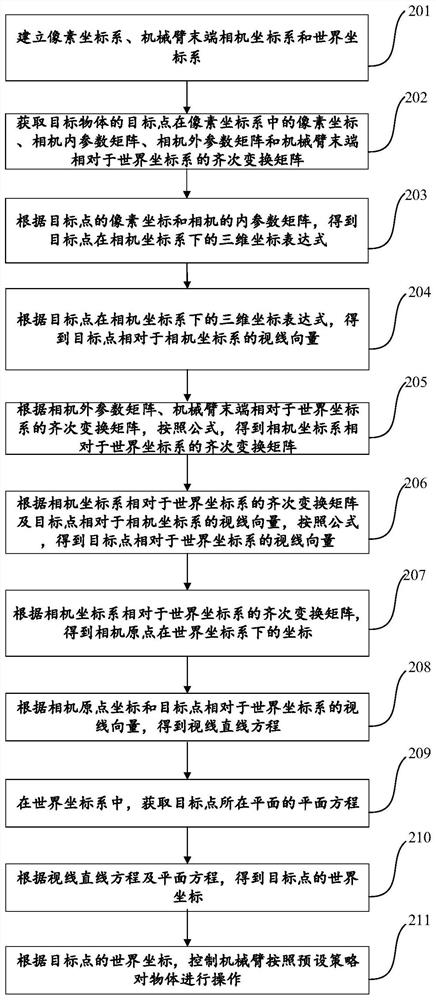

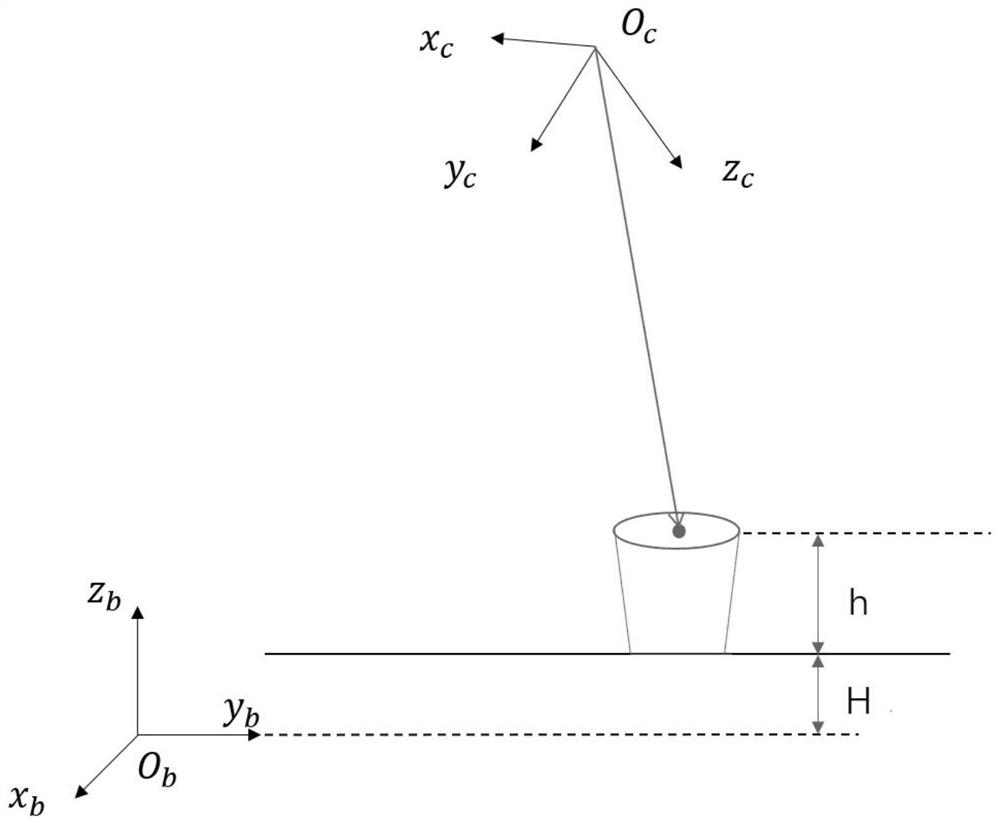

Control method and device for manipulator arm based on monocular vision positioning

InactiveCN111673735ANo matching involvedNo distance involvedProgramme-controlled manipulatorImage analysisRadiologyNuclear medicine

The present invention provides a control method and device for a manipulator arm based on monocular vision positioning. First, pixel coordinates of a target point of a target object in a pixel coordinate system are obtained, then the transformation is carried out by using a homogeneous transformation matrix of a camera coordinate system relative to the end of the manipulator arm and the homogeneous transformation matrix of the end of the manipulator arm relative to a world coordinate system. Then line of sight equations are obtained. Finally, in the world coordinate system, the plane equationof the plane where a target point is located is obtained, and the target point is obtained through the line of sight equations and the plane equations. Therefore, compared with the prior art, the embodiment of the invention does not need two monocular cameras, simplifies the positioning system, and has simple operation, and does not involve the matching of image feature points and the calculationof optimal distance, simplifies the processing algorithm and reduces the requirements for hardware equipment.

Owner:PING AN TECH (SHENZHEN) CO LTD

Double-ball-bar-based geometric error recognition method for five-axis machine tool front sway

InactiveCN109375580AAvoid couplingImprove accuracyProgramme controlComputer controlRelative displacementGeometric error

The invention discloses a double-ball-bar-based geometric error recognition method for a five-axis machine tool front sway. On the basis of motion conditions of an inclination head of a five-axis machine tool, three kinds of measurement modes of an X direction, a Y direction and a Z direction are put forward respectively; relative displacement equations of two DBB balls under three kinds of measurement modes are established respectively based on a HTM and a multibody system (MBS) theory; and a geometric error parameter of the inclination head is fully recognized. According to the invention, all error terms of the front sway are identified and the coupling phenomenon among parameters is avoided. Moreover, the identification precision and the universality are high; and the reference is provided for error recognition of the five-axis machine tool front sway.

Owner:BEIJING UNIV OF TECH

Hand and eye calibration method based on 3D vision

The invention discloses a hand and eye calibration method based on 3D vision. The method comprises the following steps of: installing a 3D visual sensor at the tail end of a manipulator; placing a measuring workpiece on the ground; calculating a homogeneous transformation matrix of a manipulator tail end flange coordinate system relative to a robot based coordinate system; moving a robot to different positions, and reading different three-dimensional positions (X, Y, Z) of the circle center of a circular hole of the measuring workpiece in a ceramic coordinate system by virtue of the 3D visualsensor; and solving the homogeneous transformation matrix between the manipulator flange coordinate system and the 3D visual sensor coordinate system by adopting a least square method based on the system of simultaneous equations. The method disclosed by the invention acquires the homogeneous transformation matrix between manipulator flange coordinates and the 3D visual sensor coordinates by calculation and by reading the internal variable values of the robot and the 3D visual sensor, is simple and high in accuracy value and can provide conversion basis for three-dimensional point cloud precise reconstruction of a large-size component.

Owner:JIANGSU JICUI MICRO NANO AUTOMATION SYST & EQUIP TECH RES INST CO LTD

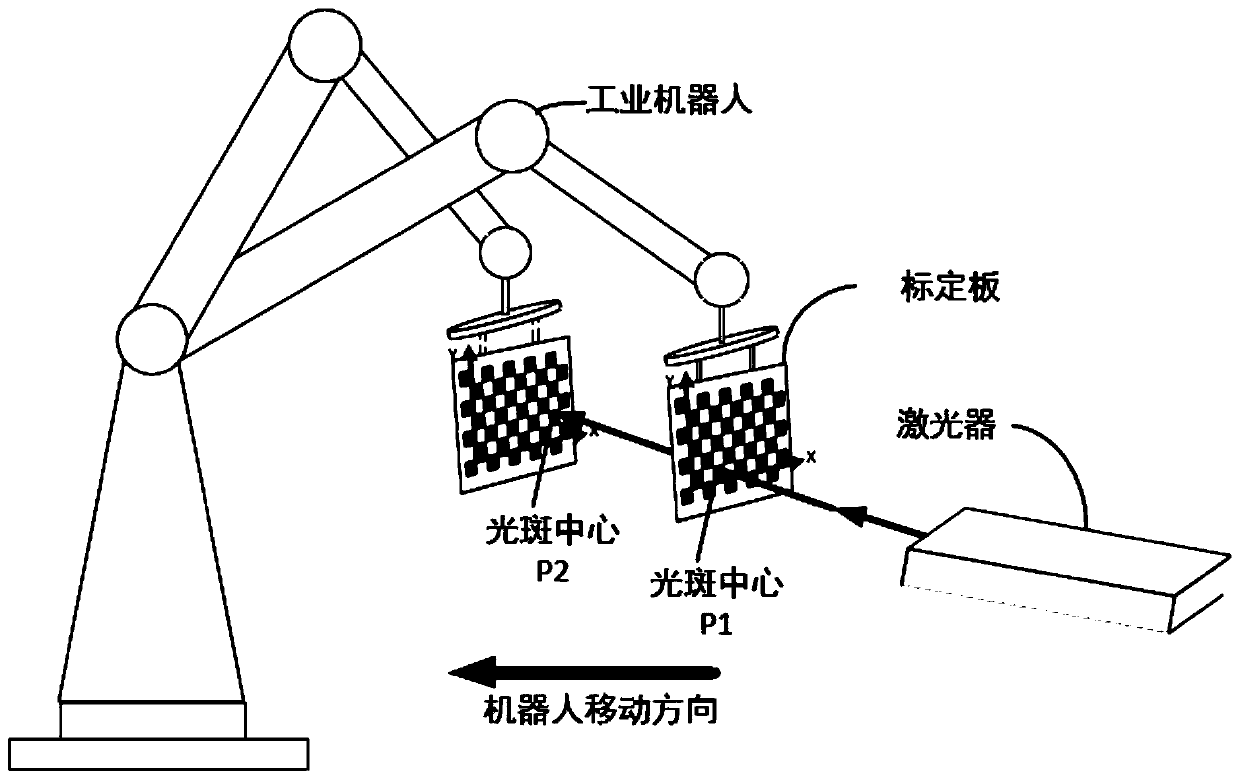

Hand-eye calibration method of robot linear structured light vision measurement system

The invention discloses a hand-eye calibration method of a robot linear structured light vision measurement system. According to the method of the invention, the movement relationships of a robot are demonstrated through establishing a coordinate system according to the movement features of the robot; the movement of the tail end of the robot is controlled, and homogeneous transfer matrix principles are used in combination, and the movement quantity of a camera before and after the movement of the robot is obtained, and then, a final hand-eye relation matrix can be obtained according to a hand-eye relation model. According to the hand-eye calibration method of the invention, a round replacement standard ball in the prior art is adopted as a target, and therefore, only the linear features of structural light are needed to be extracted, and thus, calculation amount can be reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Geometrical calibration tool and method for multi-robot base coordinate system

PendingCN109278066AEasy to operateImprove calibration accuracyManipulatorKinematics equationsEngineering

The invention relates to a geometrical calibration tool and method for a multi-robot base coordinate system. The method comprises the steps that the calibration tool is adjusted to arrive at a plurality of calibration points, and a line pull measuring device is connected with the tail ends of robots to be calibrated; the robots to be calibrated are controlled by a demonstrator to move to a plurality of demonstration points in sequence, and the tail end positions of the multiple robots to be calibrated and the rope lengths between the multiple calibration points and the demonstration points areacquired; kinematical equations are simultaneously established according to the tail end positions of the multiple robots to be calibrated and the multiple rope lengths, and the positions of the multiple calibration points relative to the to-be-calibrated robot base coordinate system are calculated; and homogeneous transformation matrix equations are simultaneously established according to the positions of the multiple calibration points relative to the to-be-calibrated robot base coordinate system, and a first posture transformation matrix of the calibration tool relative to the to-be-calibrated robot base coordinate system is acquired. The portable calibration tool and the quick calibration method for the multi-robot base coordinate system are provided, and are simple in structure, lowin cost, easy to operate and high in universality.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

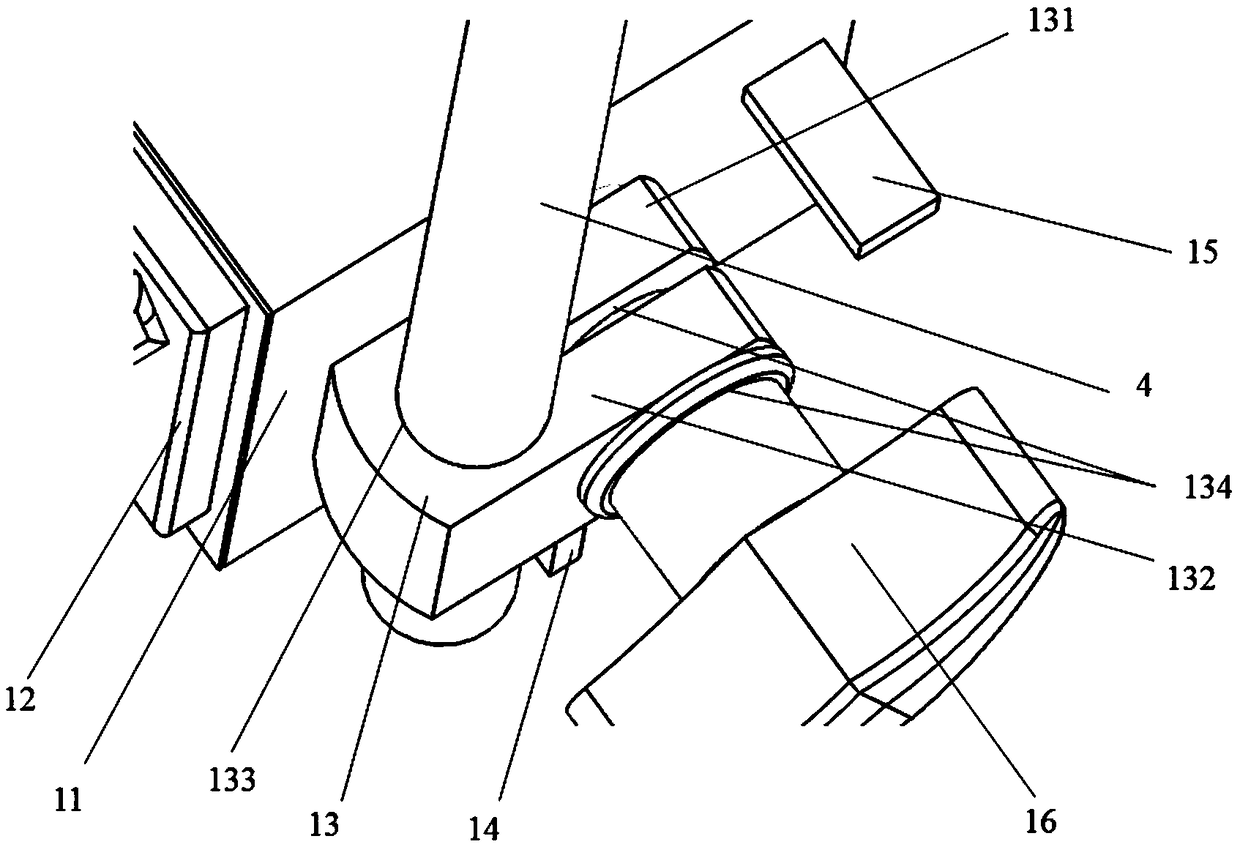

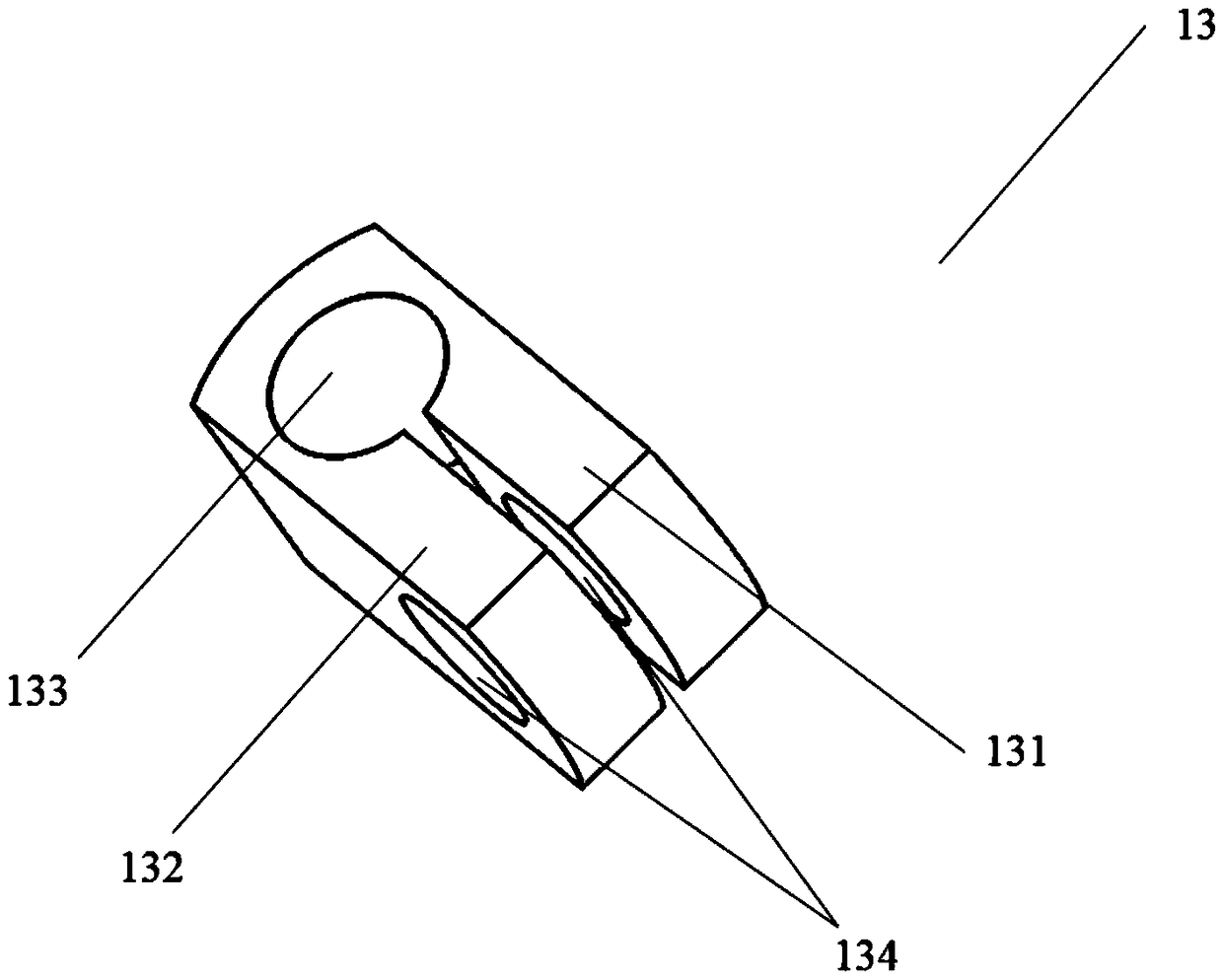

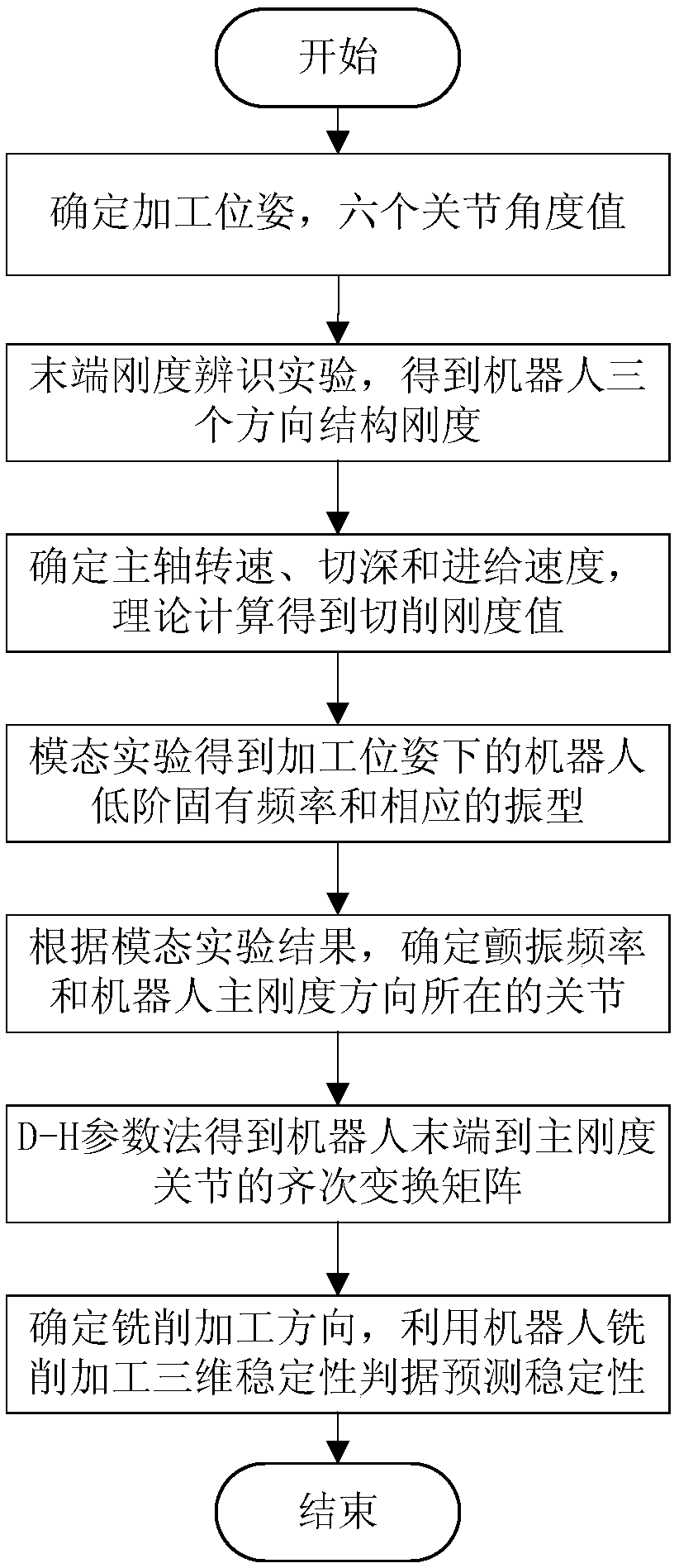

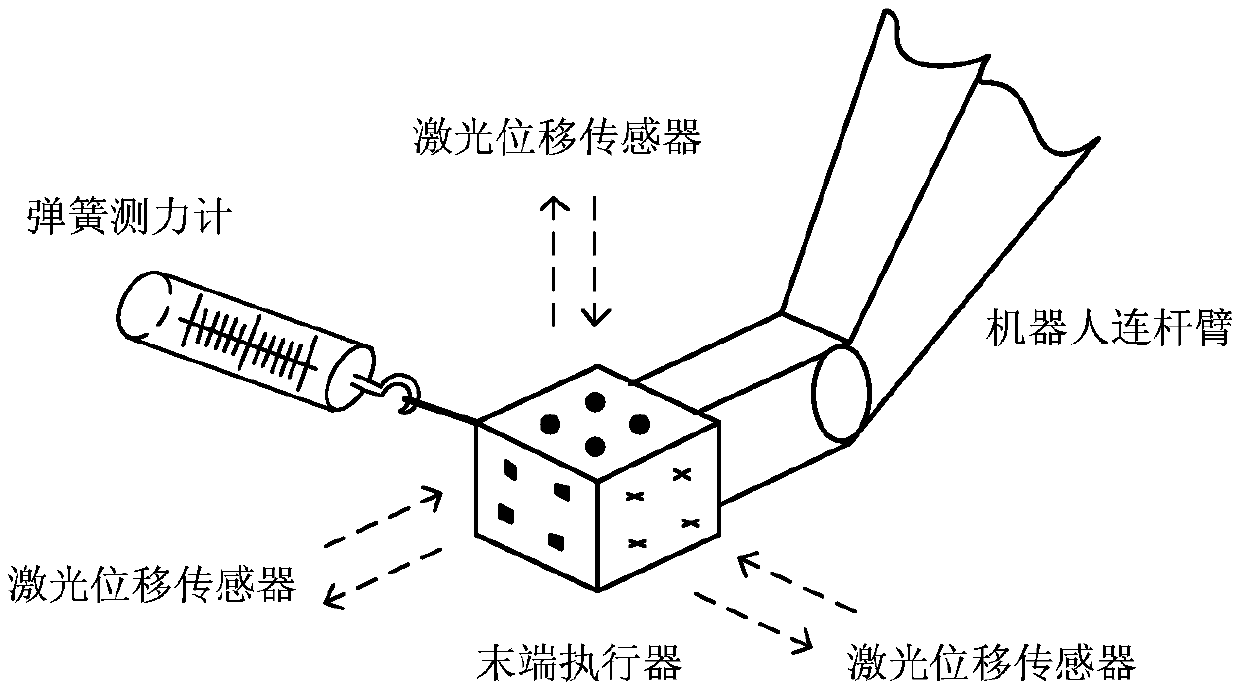

Milling three-dimensional stability forecasting method of six-freedom-degree series robot

ActiveCN108638076AAvoid Mode-Coupled FlutterImprove machined surface qualityProgramme-controlled manipulatorMachined surfaceStochastic matrix

The invention provides a milling three-dimensional stability forecasting method of a six-freedom-degree series robot and relates to the technical field of robot machining application. By means of themethod, the machining posture of the six-freedom-degree series robot is determined firstly, and the angle value of each joint of the robot is obtained; then the structural rigidity of the robot in three directions is obtained, and the milling cutting rigidity value of the robot is calculated and obtained; a homogeneous transformation matrix among all kinematics coordinate systems is obtained; theinherent frequency of various orders and corresponding modal shapes of the robot are obtained through analysis; the main rigidity direction of the robot is obtained, and the transfer matrix from cutting force to the main rigidity direction of the robot is determined; and finally, the machining direction is determined, and robot milling three-dimensional stability is used for judging and forecasting stability. By means of the milling three-dimensional stability forecasting method of the six-freedom-degree series robot, the machining feeding direction can be selected in advance, modal coupling fluttering in the milling process is avoided, and the quality of the machined surface is improved.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com