Double-ball-bar-based geometric error recognition method for five-axis machine tool front sway

A technology of geometric error and double ballbar, which is applied in the field of CNC machine tools, can solve the problems of few identification methods of swinging heads of five-axis CNC machine tools, many sources of geometric errors, and inability to provide machining accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The method of the present invention specifically comprises the following steps:

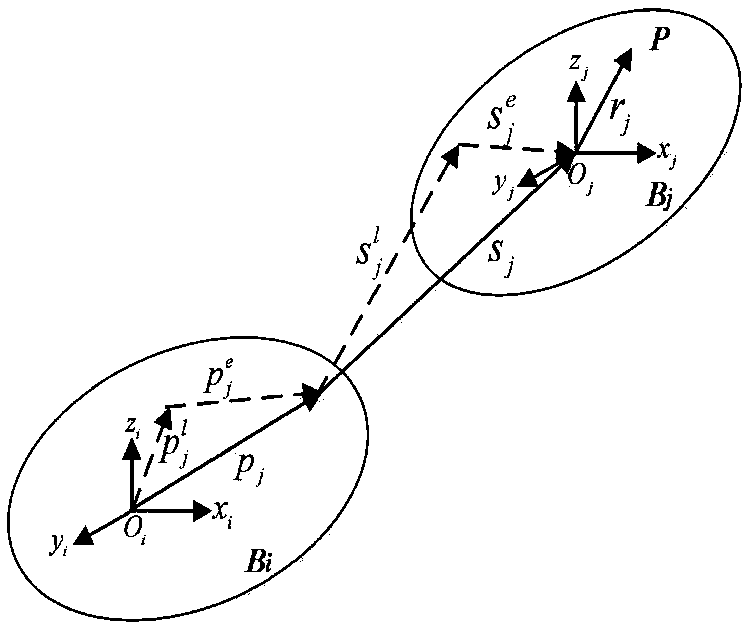

[0080] Step 1, based on the multi-body theory, establish the equation of motion relationship between adjacent two bodies

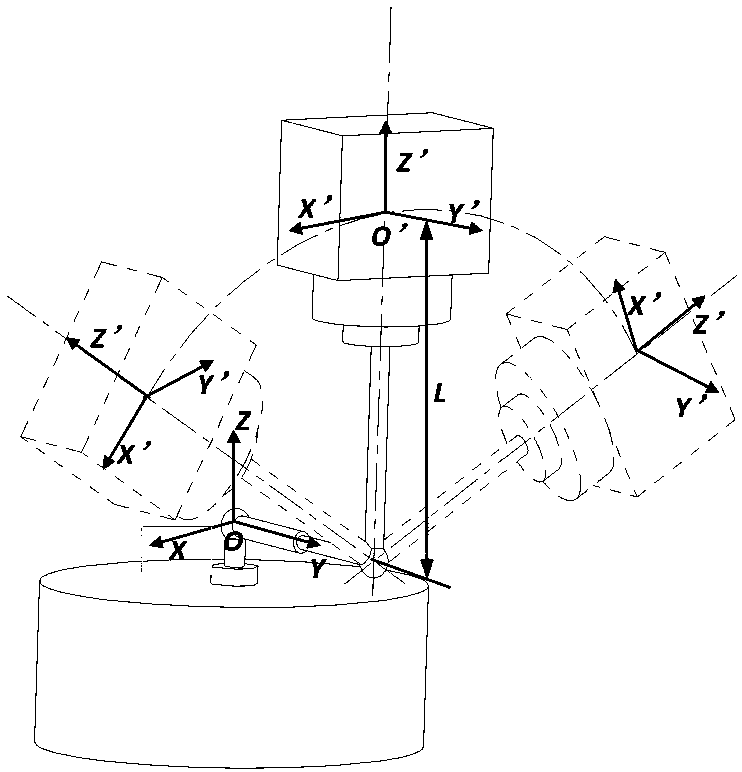

[0081] Step 2, by analyzing the geometric error parameters of the swing head of the machine tool, according to the working principle of the double ballbar, identify the geometric error parameters of the swing head in the three measurement modes of X, Y, and Z of the machine tool. By establishing a reference coordinate system and a motion coordinate system on the workbench, the position coordinates of points A, C, and D are respectively obtained.

[0082] Step 3, according to the above analysis, in the measurement mode in the Y direction, identify the geometric error parameters, and establish the relationship between the position equation of the actual point D' and the theoretical point D in O-XYZ and the change in the length of the rod in the Y direction , identify ε ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com