Prism longitudinal bend composite vibrator linear supersonic motor

A technology of linear ultrasonic motor and composite vibrator, which is applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc. It can solve the problem of large thrust and large stroke linear ultrasonic motor with little research, etc. problems, to achieve the effect of convenient design and debugging, improving motor efficiency and increasing thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

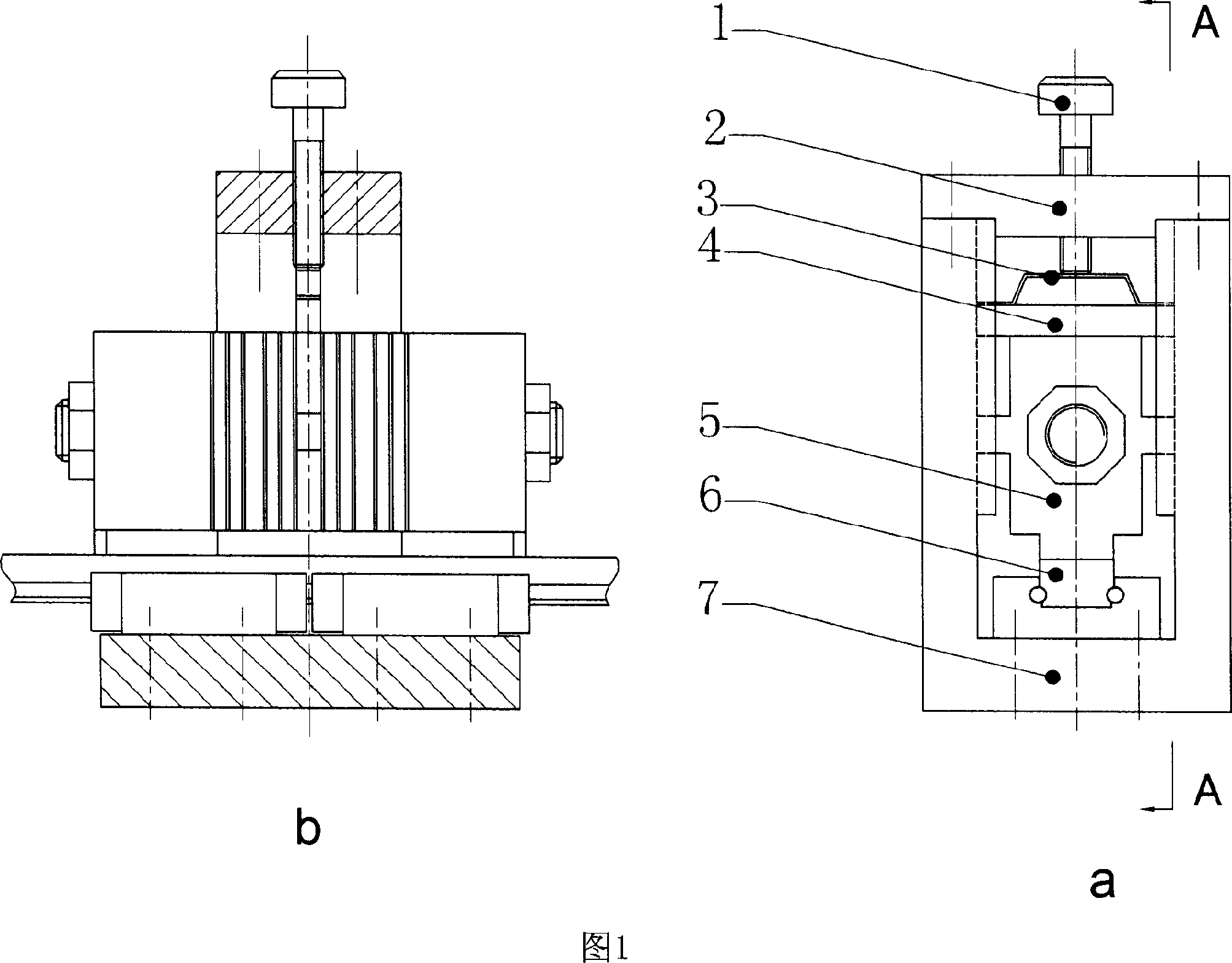

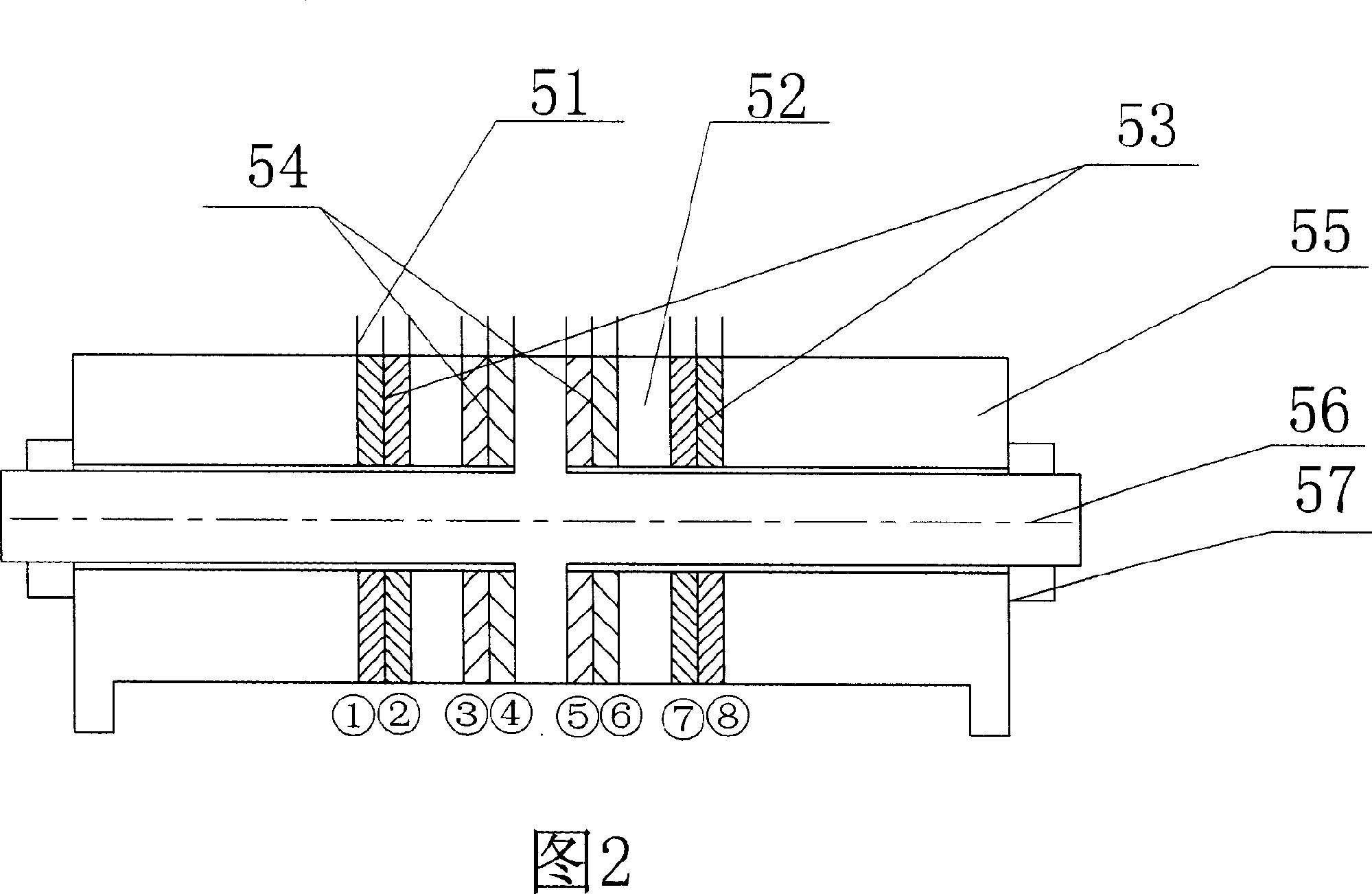

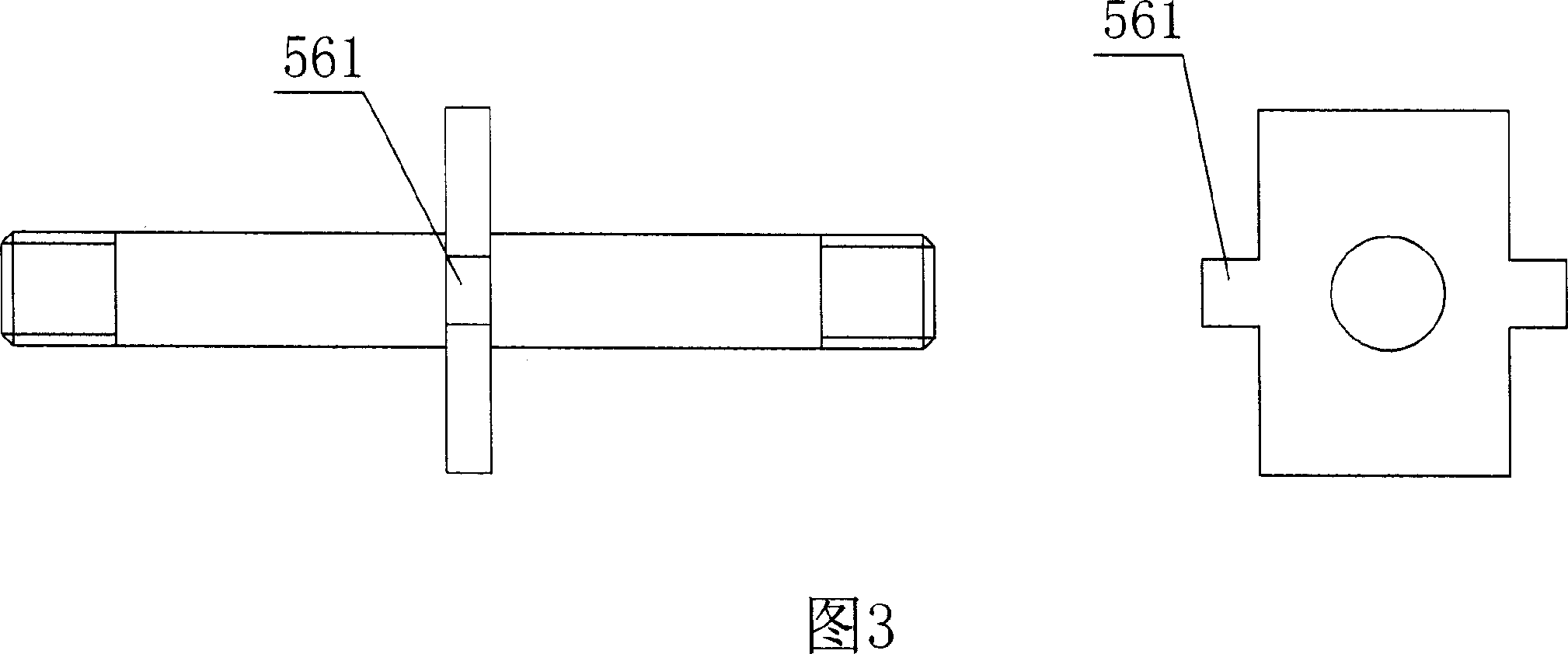

[0028] The structure schematic diagram of the present invention is shown in accompanying drawing 1, mainly by preloading screw 1, upper cover plate 2 of frame, preloading spring 3, mass block 4, stator 5 (being driving vibrator), mover 6, frame 7 Composed of seven components. The pre-tightening screw 1, the upper cover plate 2 of the frame, the pre-tightening spring 3 and the frame 7 constitute the pre-tightening force applying mechanism of the motor. By changing the feeding depth of the pre-tightening screw 1 and the elastic deformation of the pre-tightening spring 3, the Give the stator 5 a certain preload. The mover 6 is a linear slider with a guide groove on one side, and the slider is fixed on the bottom of the frame 7 . Both side plates of the frame 7 are provided with guide grooves, and the shoulders of the stator 5 can be placed in the frame 7 along the guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com