Film stretching device and film stretching method for production of vibrating films of electret microphones

A technology of electret microphone and stretch film, which is applied in the direction of sensor, diaphragm fixation/tightening, electrical components, etc. It can solve the problems of inconsistency and achieve the effect of consistent tension, consistency assurance and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

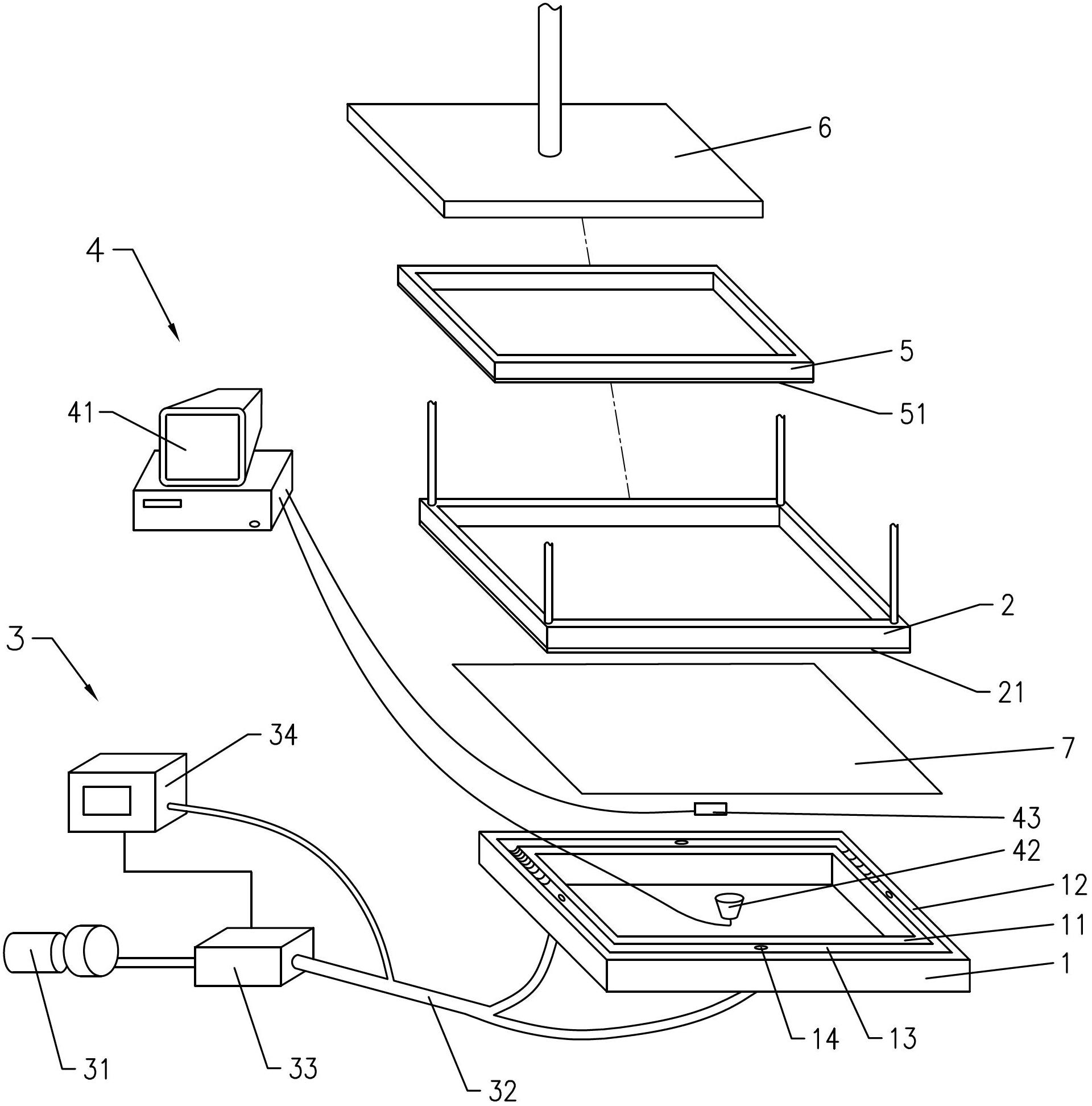

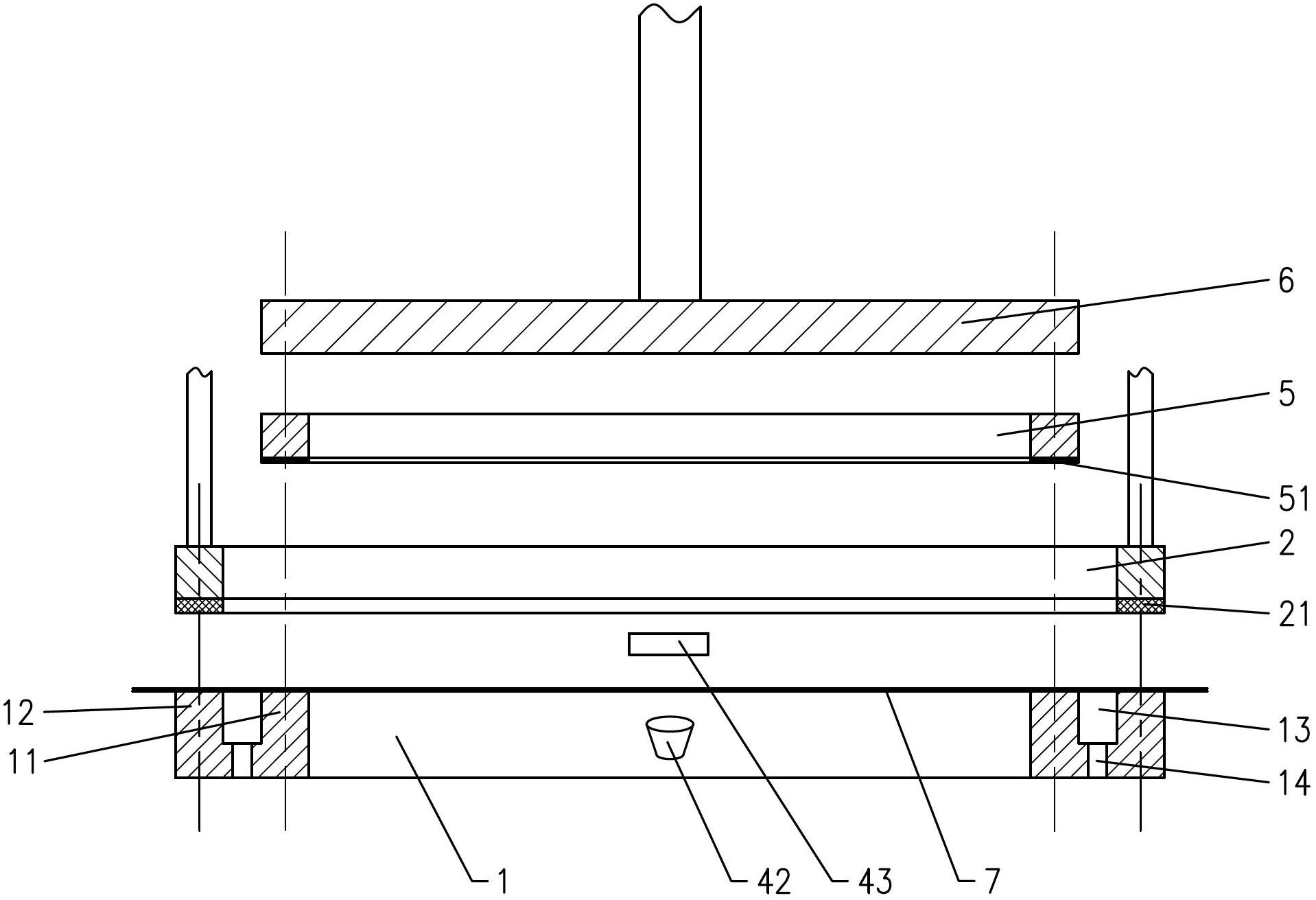

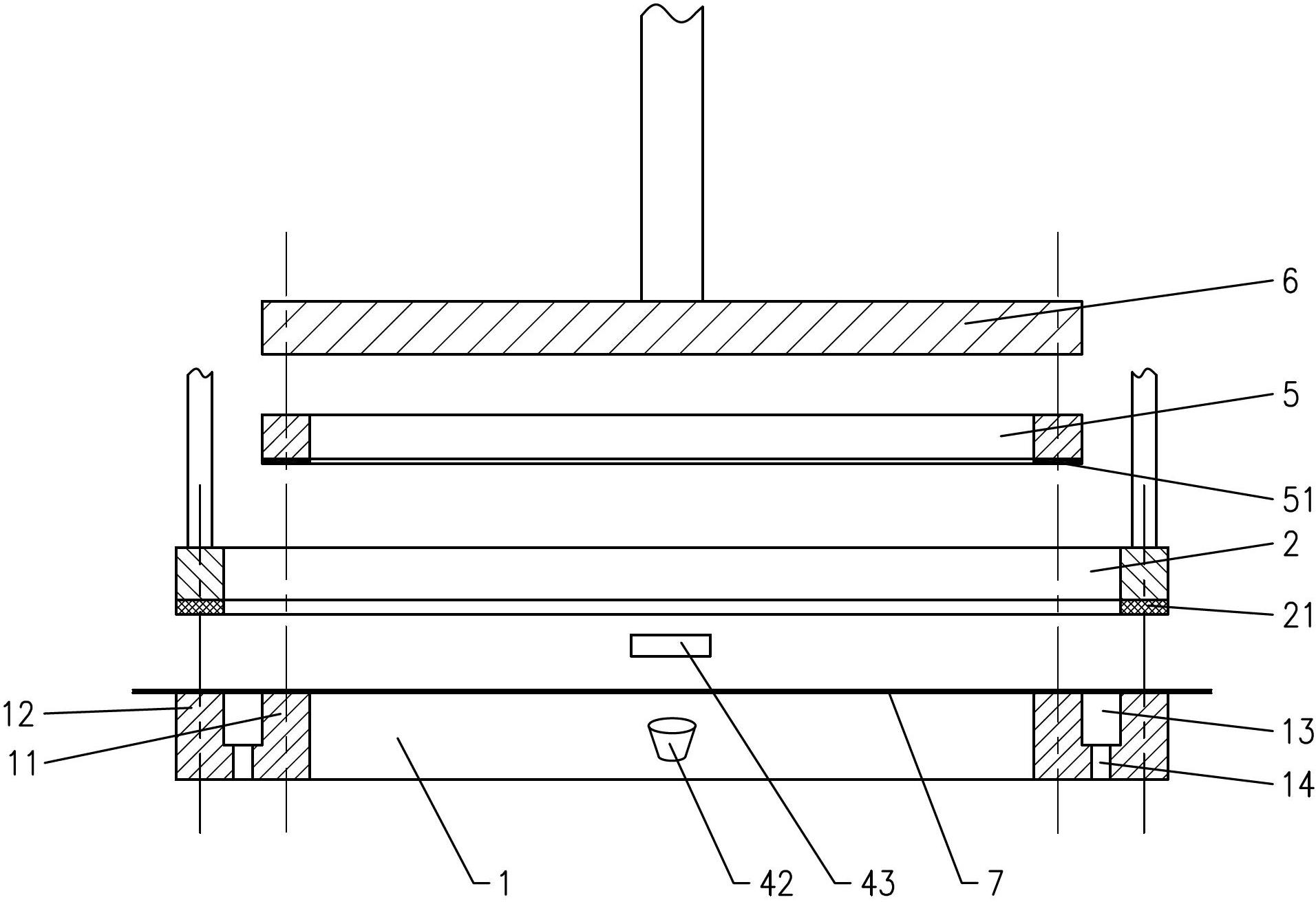

[0030] Such as figure 1 and figure 2 As shown in the figure, the stretch film device for the production of the electret microphone diaphragm is applied in the mass production process of the diaphragm. Membrane operation.

[0031] The stretch film device comprises a square annular lower pressure ring 1, and a square annular vacuum groove 13 is arranged on the top of the lower pressure ring 1. The vacuum groove 13 divides the top of the lower pressure ring 1 into the inner top 11 of the lower pressure ring and the lower pressure ring. The top 12 outside the ring is provided with a pumping hole 14 at the bottom of the vacuum tank 13 , and the vacuum device 3 is connected to the pumping hole 14 for vacuuming the inside of the vacuum tank 13 .

[0032] Wherein, the vacuum device 3 comprises: a vacuum pump 31, which is connected with the air extraction hole 14 by a pipeline 32 and a control valve 33; a vacuum tester 34 for measuring the degree of vacuum in the vacuum tank 13, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com