Novel intelligent suppressor for unstable combustion

A combustion instability and suppressor technology, applied in the direction of burners, gas fuel burners, combustion chambers, etc., can solve the problems of single control frequency, increase the working frequency range, narrow working frequency band, etc., and achieve the effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and effect of the present invention clearer and clearer, the following examples are given to further describe the present invention in detail. It should be pointed out that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

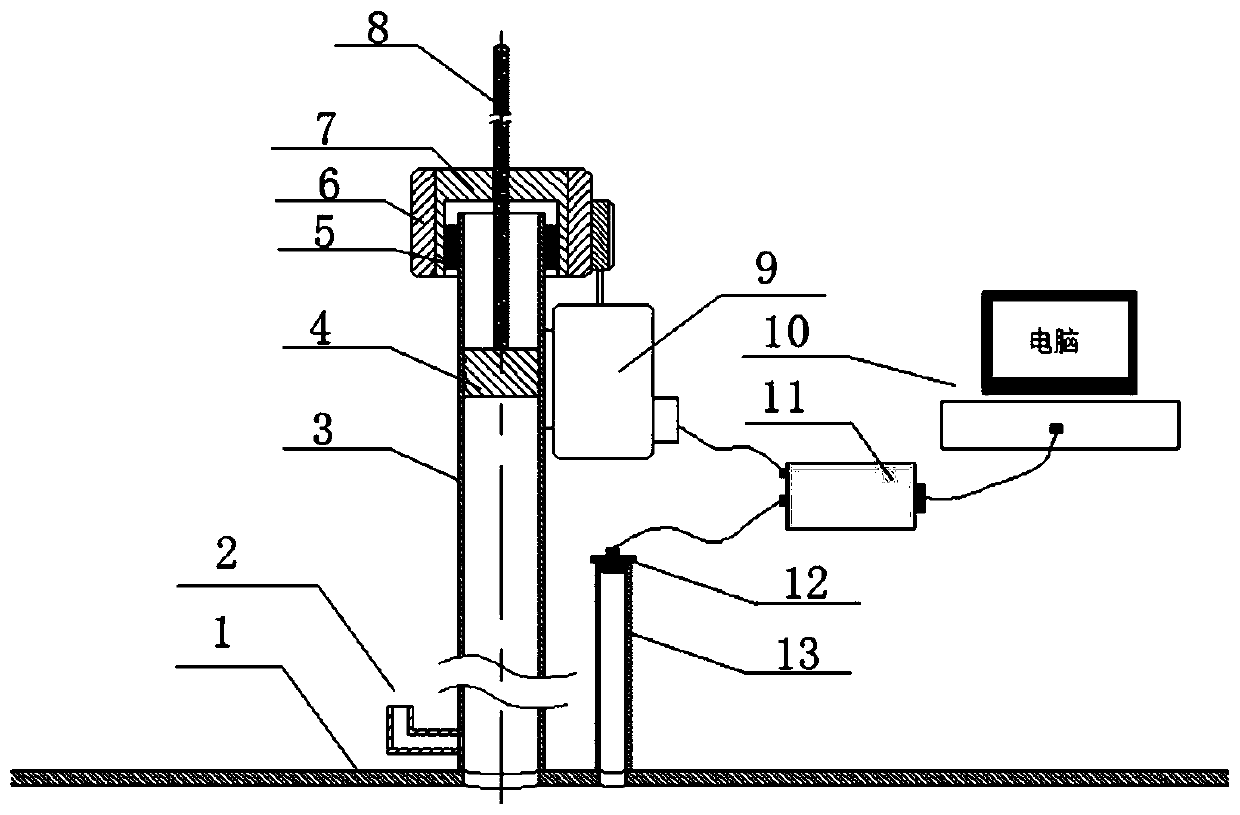

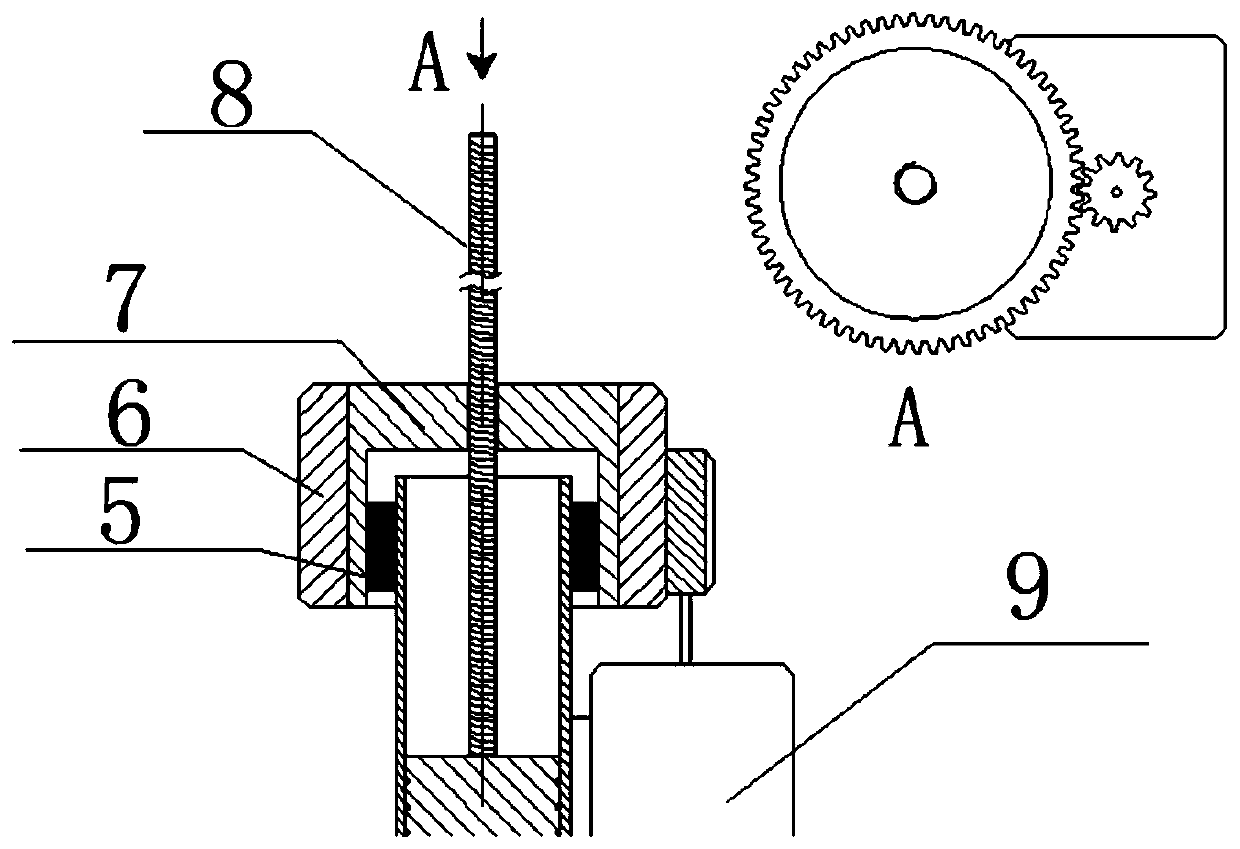

[0023] Such as Figure 1~2 As shown, the combustion instability intelligent suppressor designed by the present invention is mainly composed of sound-absorbing pipeline 3, sealing piston 4, transmission device, stepper motor 9, oscillation pressure sensor 12, oscillation pressure measurement pipeline 13 and control system. Usually the combustion is confined in a closed space, such as the combustion in the boiler is limited in the furnace, and the combustion in the gas turbine is limited in the combustion chamber. Therefore, the wall surface 1 of the combustion device in the present invention represents the wall surface of a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com