Patents

Literature

60 results about "Multibody system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multibody system is the study of the dynamic behavior of interconnected rigid or flexible bodies, each of which may undergo large translational and rotational displacements.

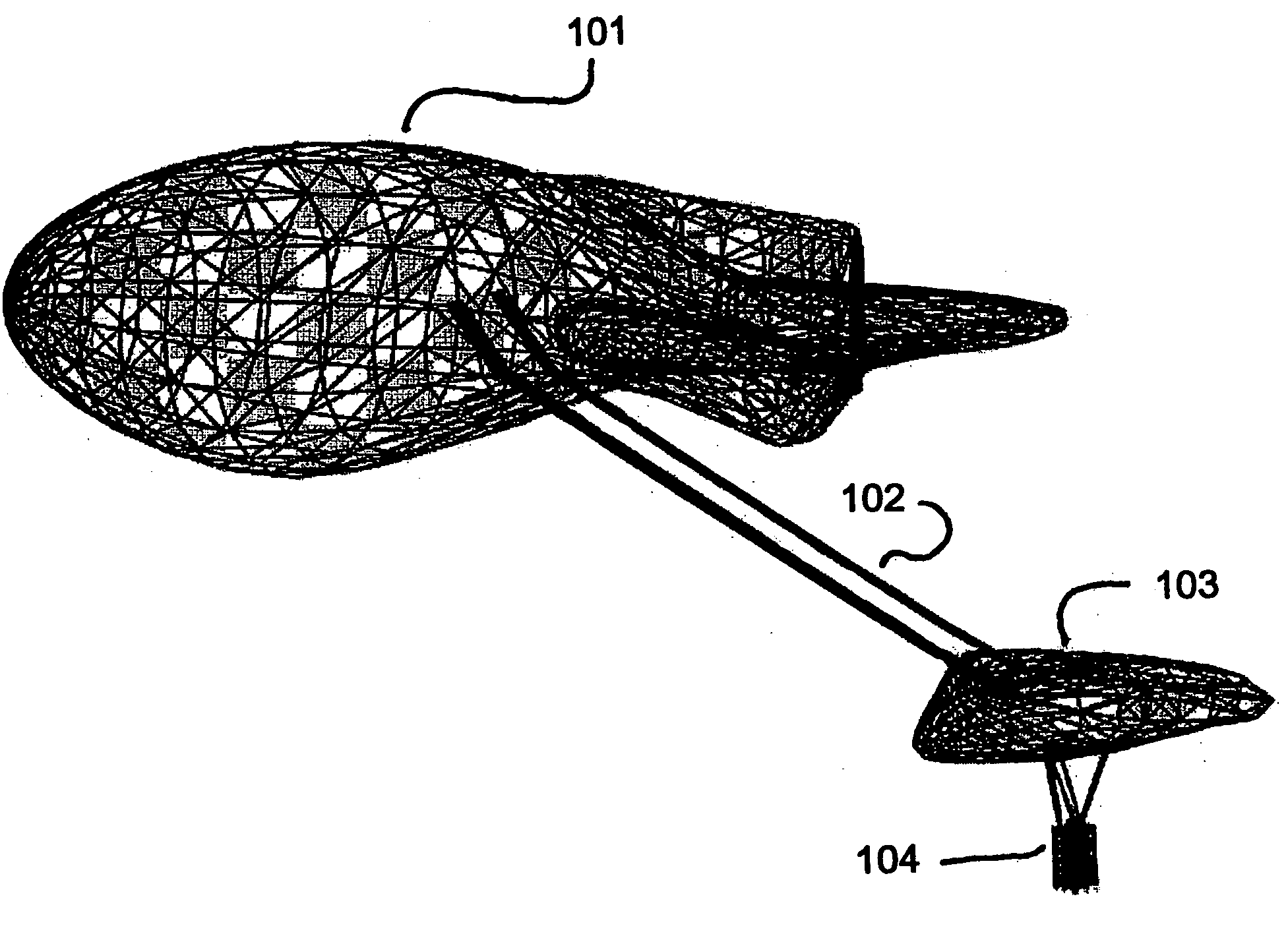

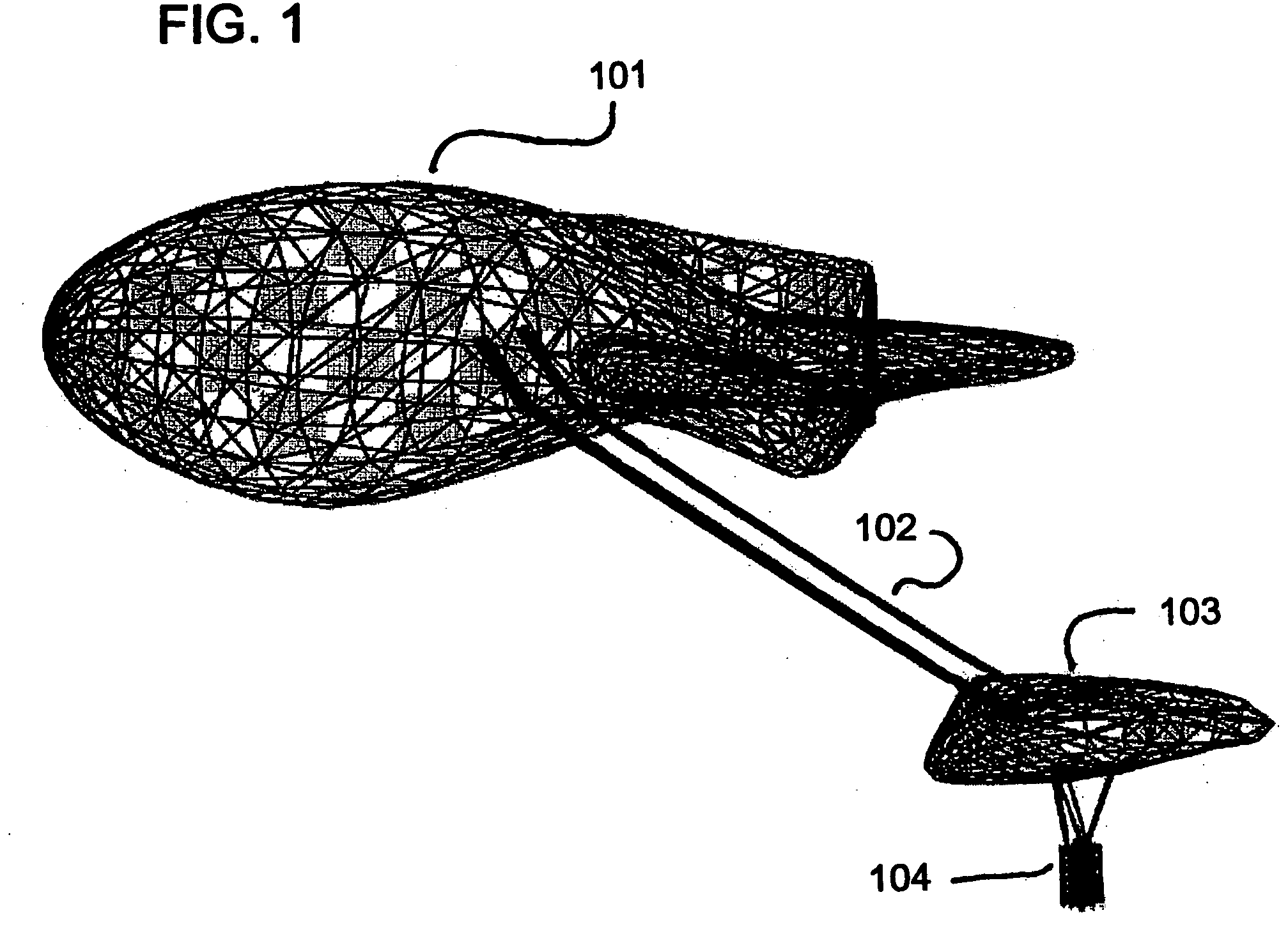

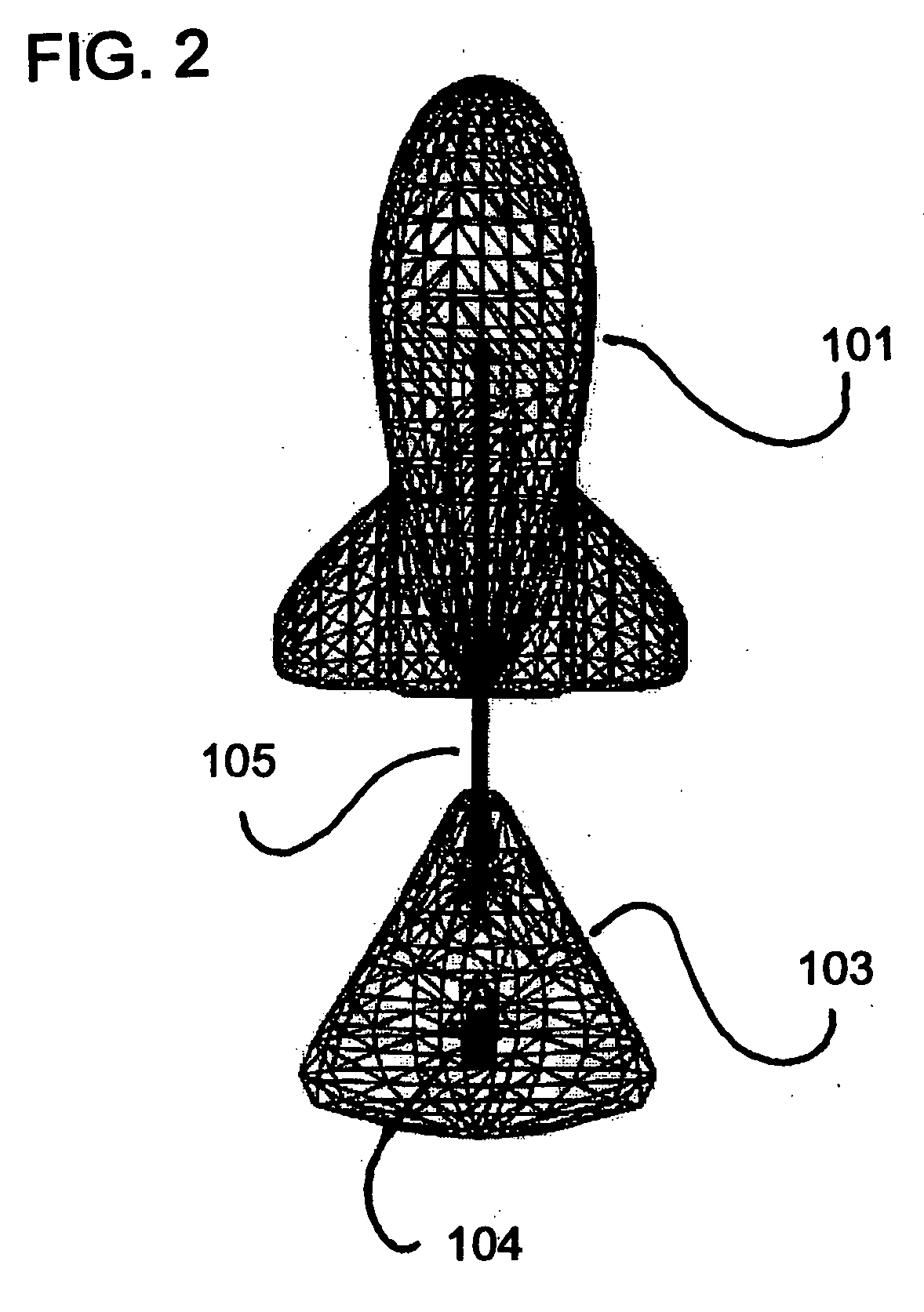

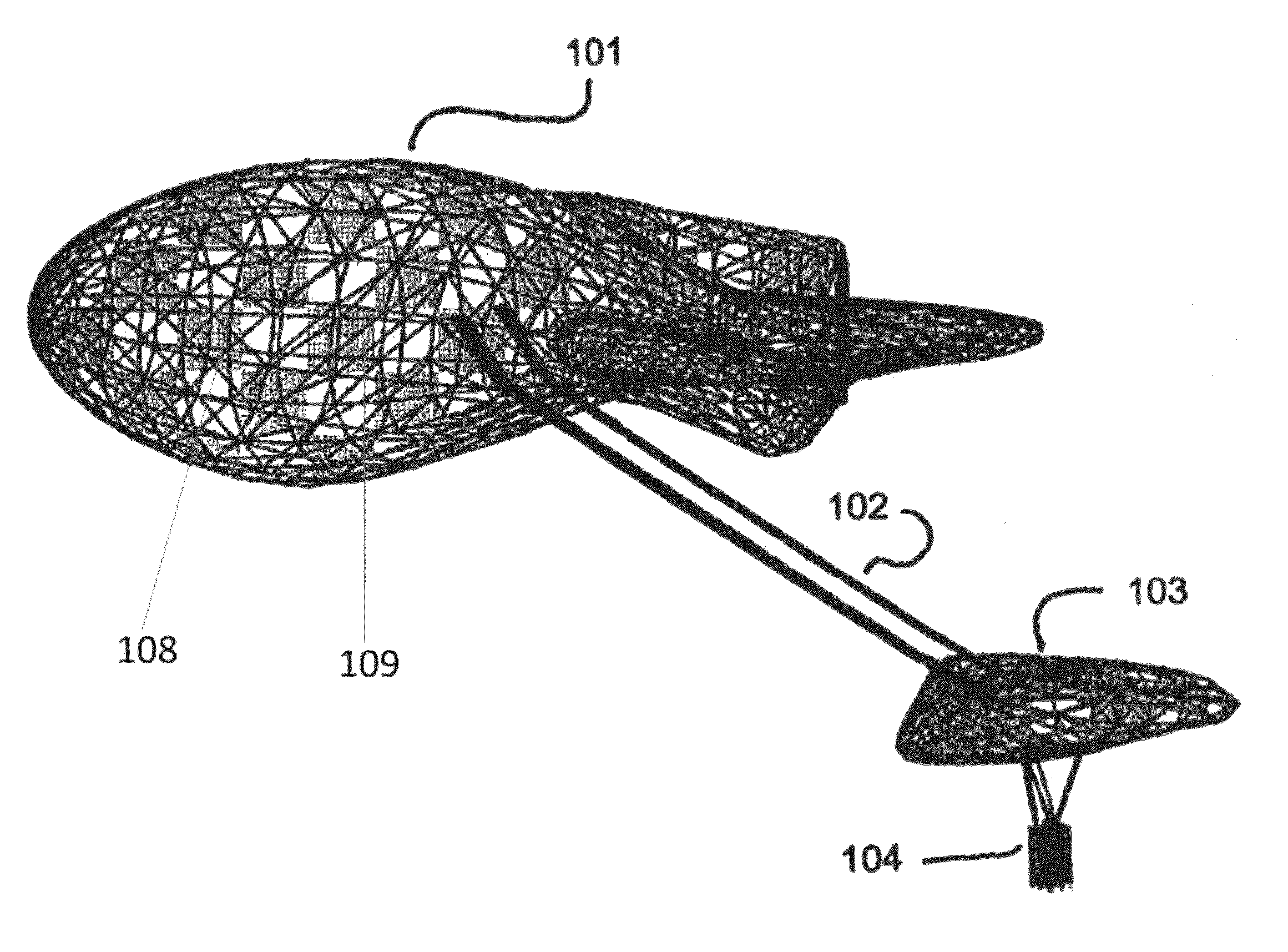

Multibody aircrane

InactiveUS20090152391A1Precise and timely point to point transferEfficient powerCargo handling apparatusPassenger handling apparatusLow speedControl line

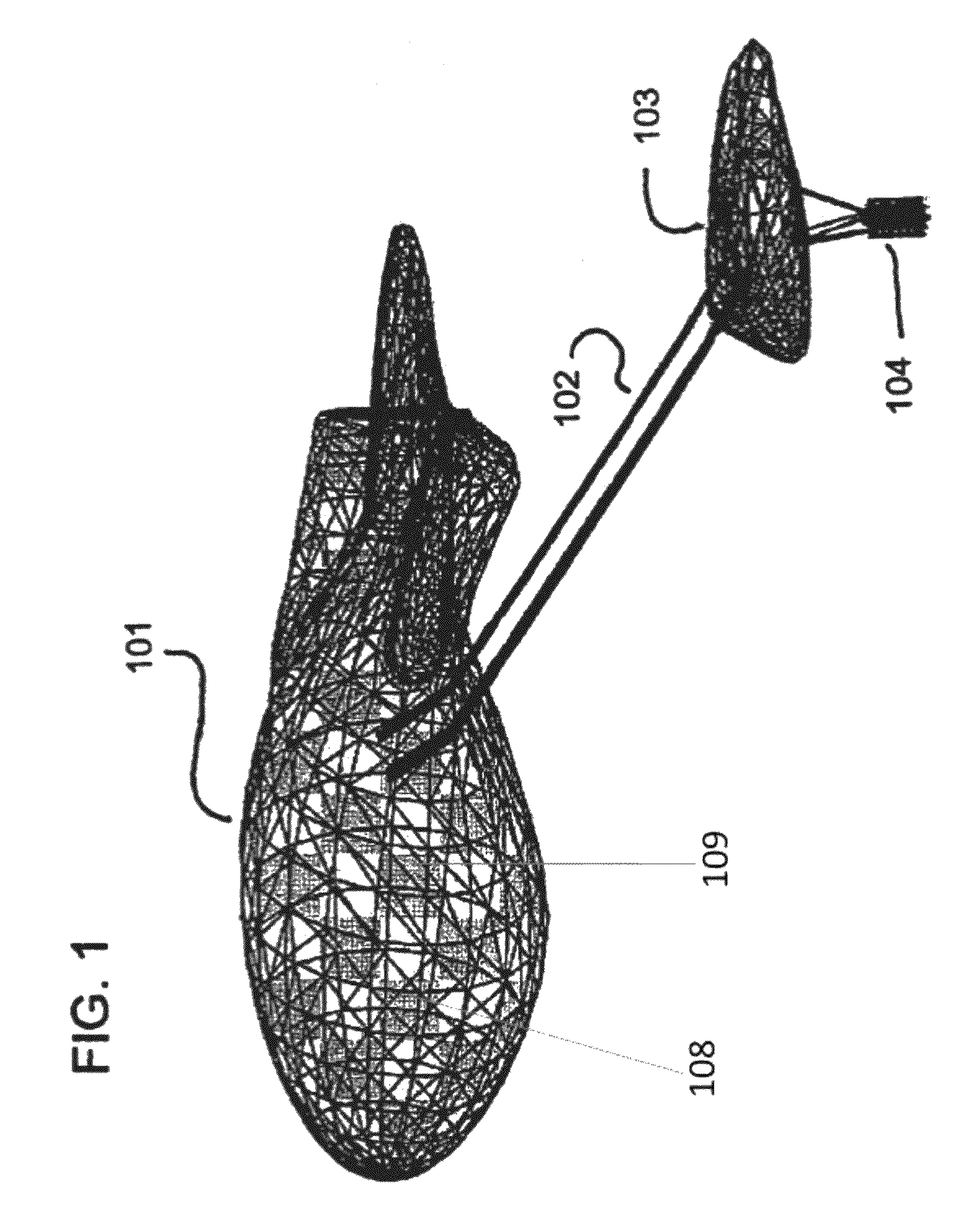

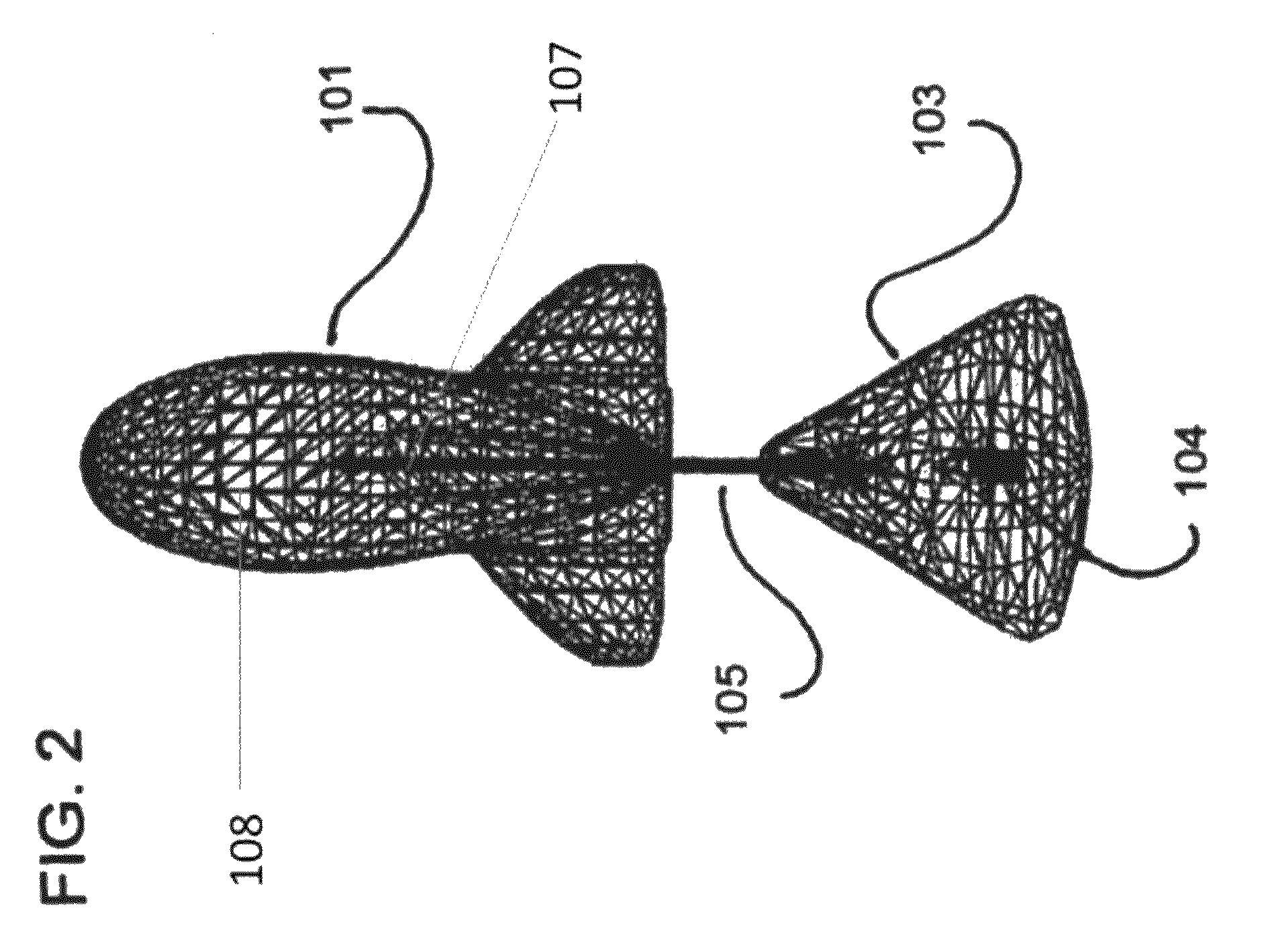

The MULTIBODY AIRCRANE performs relative positioning, predictive control, and ballast control to achieve very heavy-lifting tasks on land or sea. Such tasks allow station keeping and precise transfer of very heavy payloads between ships underway. This scalable multibody system features three subcomponents: AIRSHIP, SKYCRANE and LOADFRAME. This semi-autonomous system combines aerodynamic (kinetic) and aerostatic (buoyancy force) lift with efficient power and propulsion. During low-speed flight, the Airship and Skycrane are decoupled but linked via a reelable Tether Control Line. Beneath the Skycrane, centered on its hull, a patented NIST (National Institute of Standards and Technology) RoboCrane (featuring a computer controlled six degrees of freedom (DoF) cabling system,) is attached, to precisely suspend and control a Loadframe, with or without payload. During subsonic forward flight, these Airship and Skycrane are coupled as a single airframe (fuselage and delta wing.)

Owner:MCWHIRK BRUCE KIMBERLY

Multibody aircrane

This invention performs relative positioning, predictive control, and ballast control to achieve very heavy-lifting tasks on land or sea. Such tasks allow station keeping and precise transfer of very heavy payloads between ships underway. This scalable multibody system features three subcomponents: Airship, Skycrane and Loadframe. This semi-autonomous system combines aerodynamic (kinetic) and aerostatic (buoyancy force) lift with efficient power and propulsion. During low-speed flight, the Airship and Skycrane are decoupled but linked via a reelable Tether Control Line. Beneath the Skycrane, centered on its hull, a patented NIST (National Institute of Standards and Technology) RoboCrane, featuring a computer controlled six degrees of freedom (DoF) cabling system, is attached, to precisely suspend and control a Loadframe, with or without payload. During subsonic forward flight, these Airship and Skycrane are coupled as a single airframe: fuselage and delta wing.

Owner:MCWHIRK BRUCE KIMBERLY

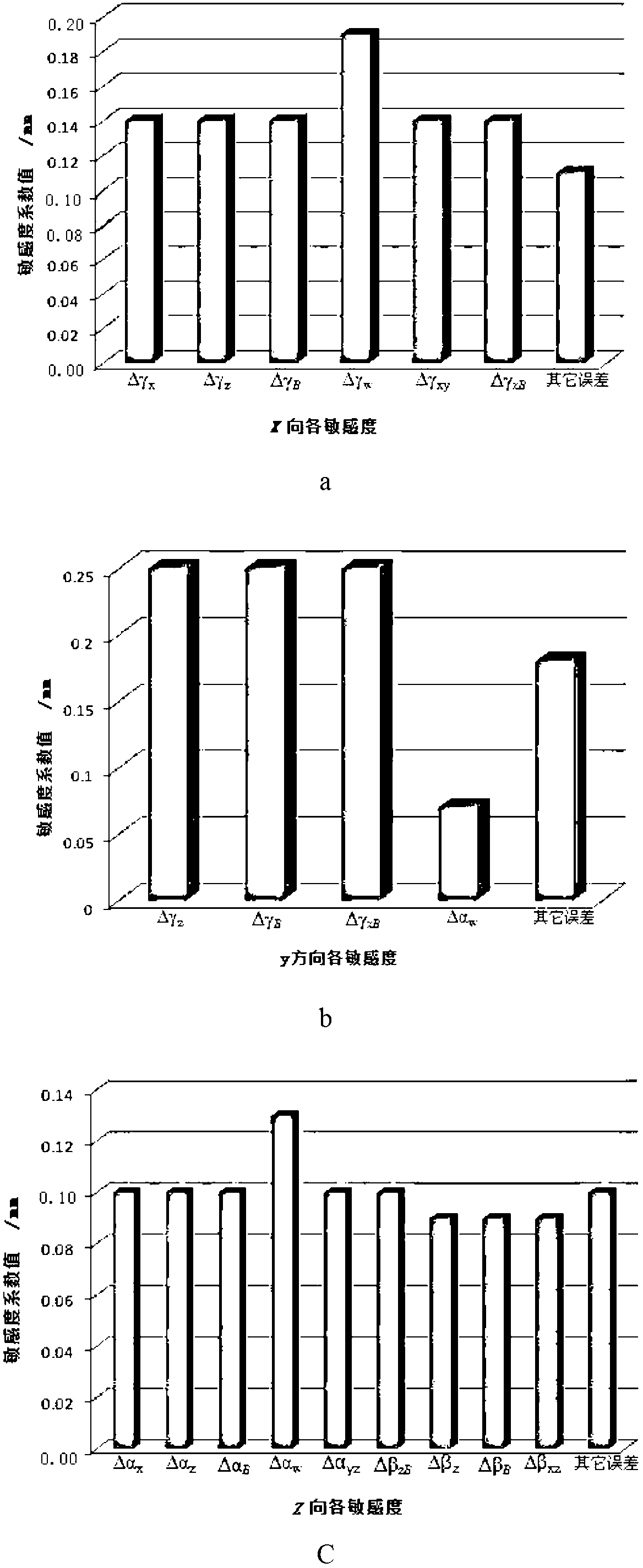

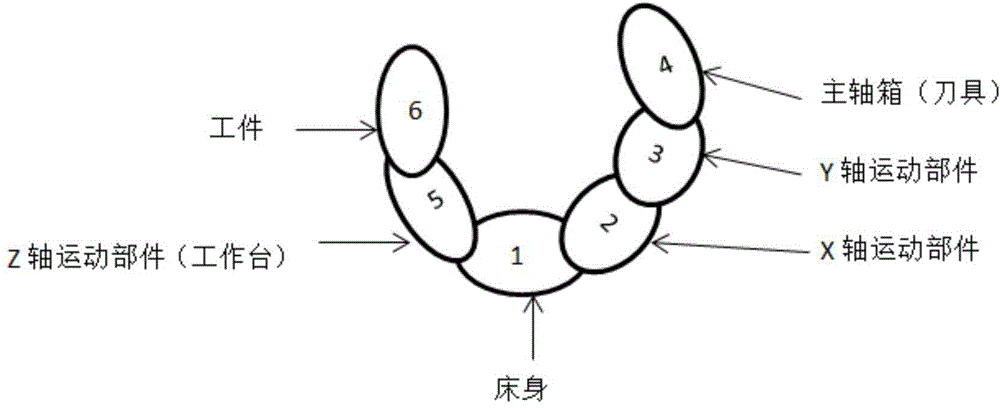

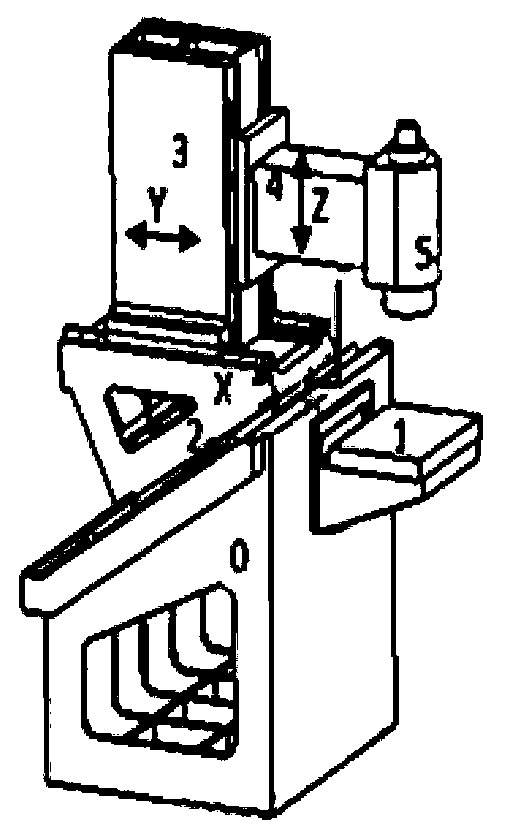

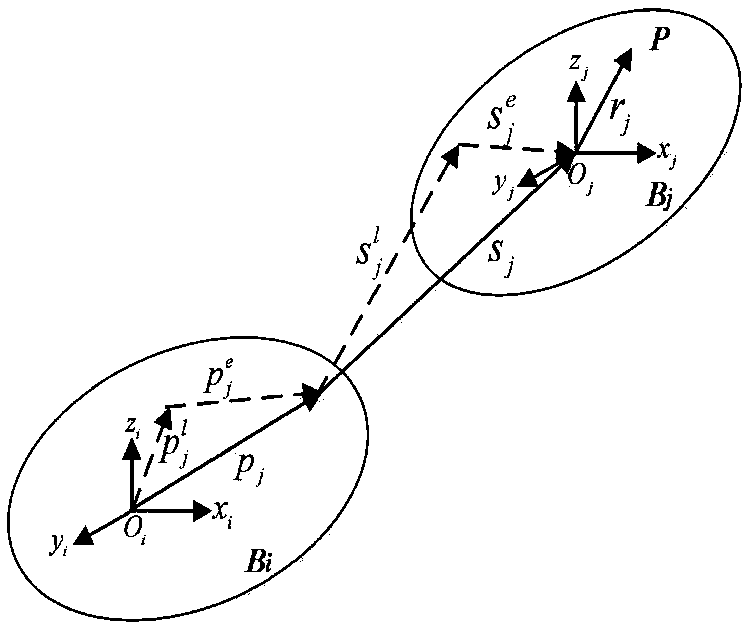

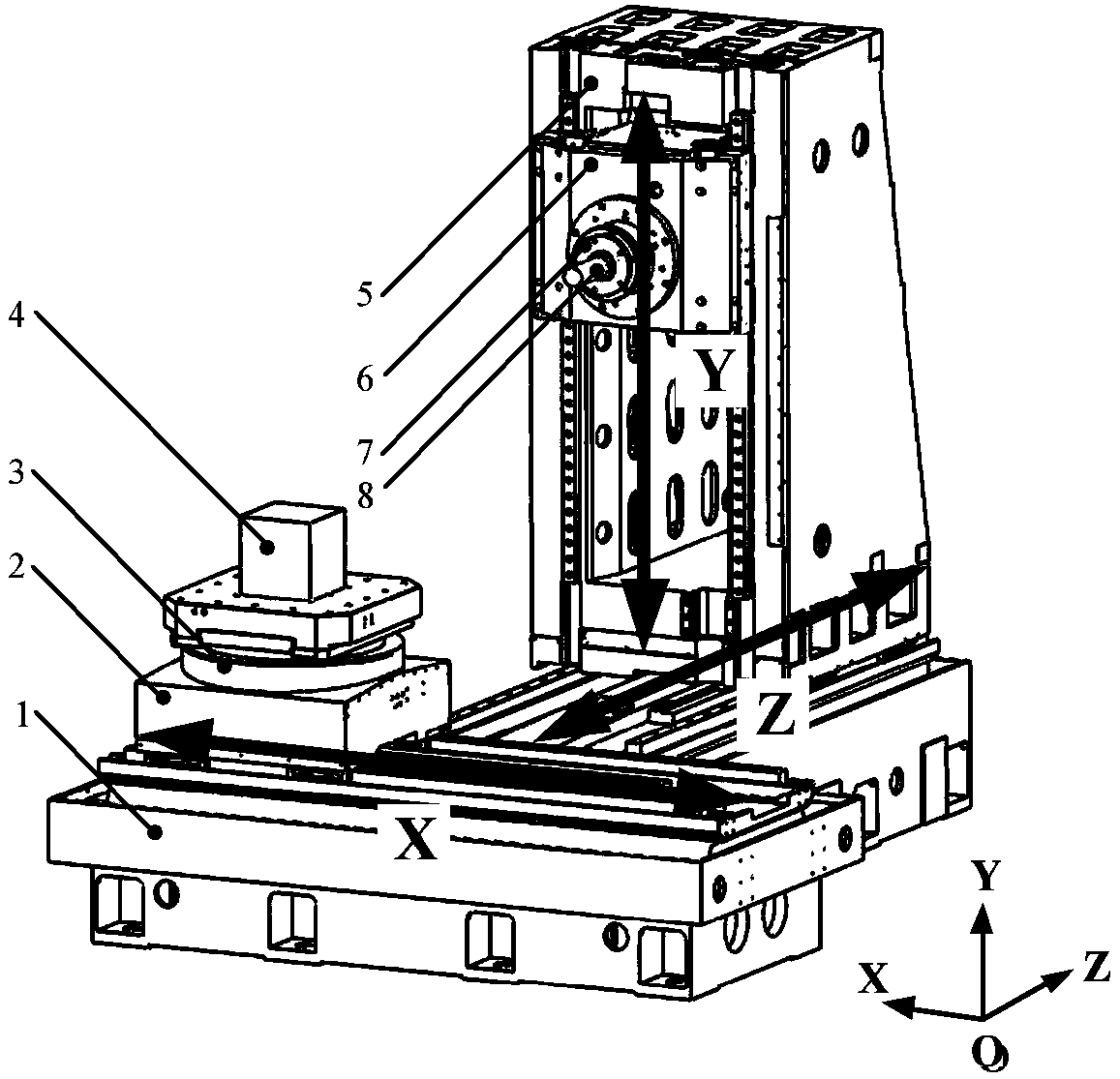

Recognition method of critical geometrical error source of machine tool

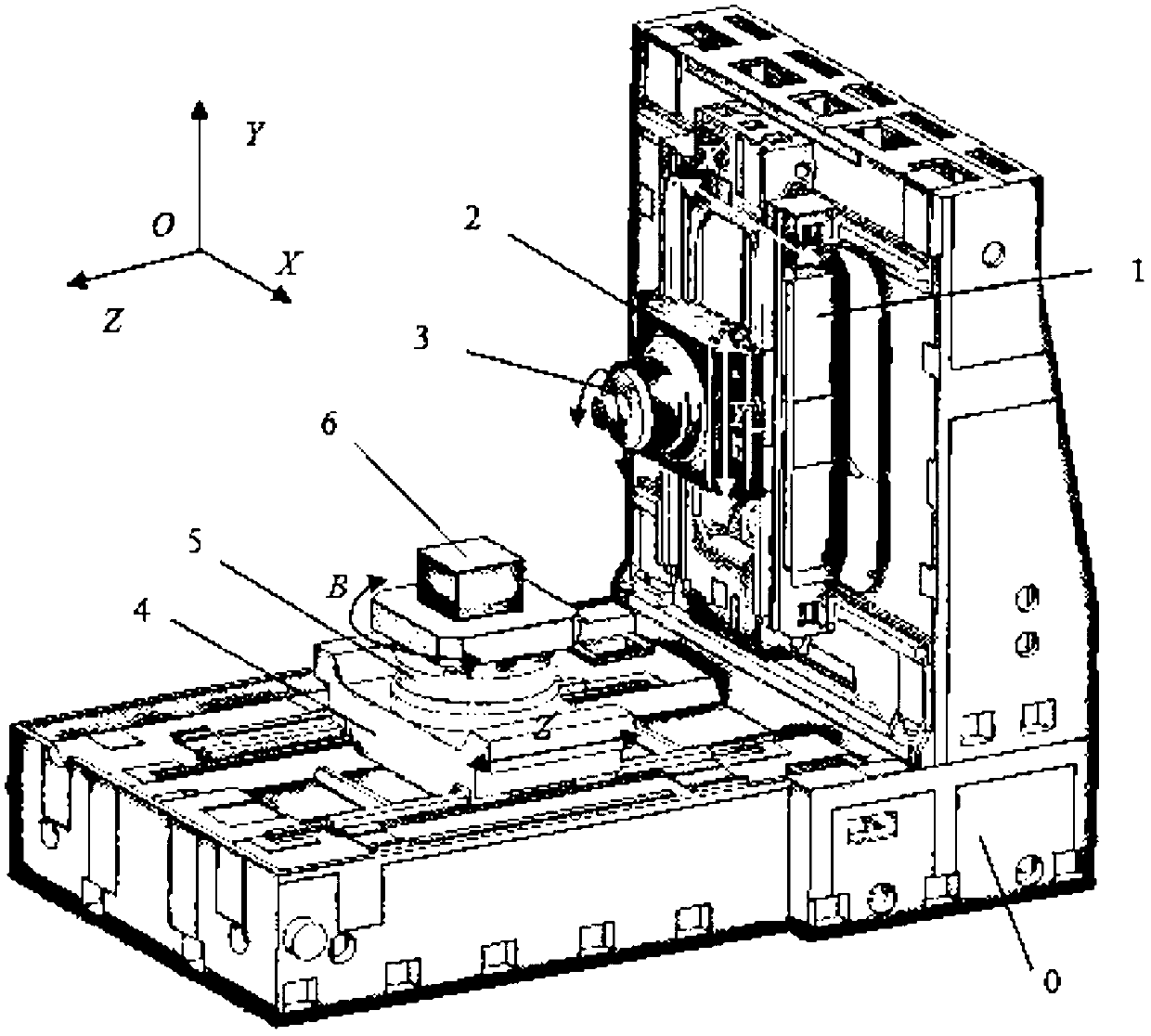

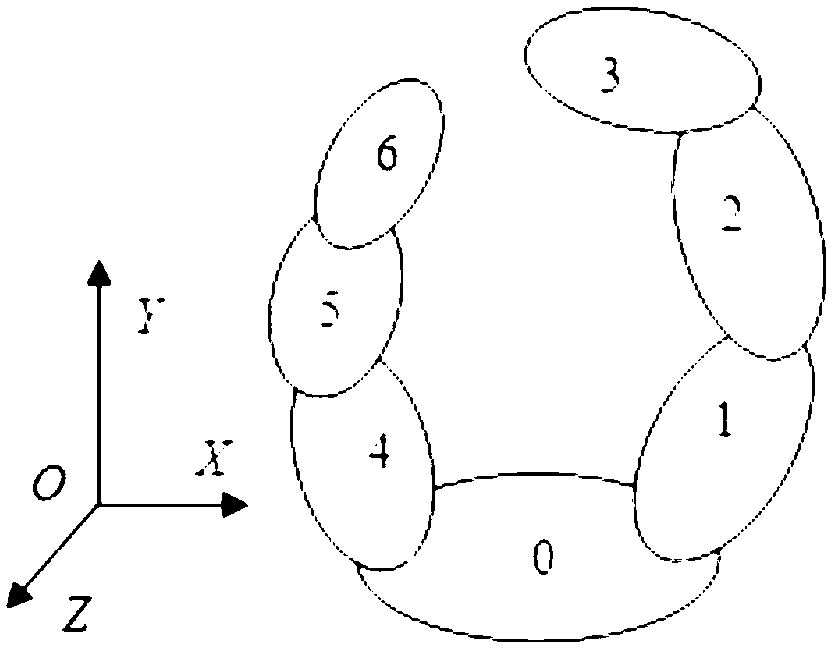

The invention discloses a recognition method of a critical geometrical error source of a machine tool and belongs to the technical field of machine precision designing. The recognition method of the critical geometrical error source of the machine tool is characterized by comprising the steps that the machine tool is abstracted into a multi-body system according to the structure and motion characteristics of the machine tool, relevance of parts of the machine tool is described by a topological structure and a low-order body array, a generalized coordinate system is built in the multi-body system, coupling relationship of error amounts of parts of the machine tool is described by a homogeneous transformation matrix, a characteristic matrix and a motion equation of the relative movement between two adjacent bodies of the machine tool are elicited, a precision model of a machining center is built, an ordinary mathematical model used for error sensitivity analysis of a four-shaft machine tool is built with a matrix differential method according to the precision model of the precision horizontal machining center, influence degrees on the whole space error of all error elements are compared by calculating the geometrical error sensitivities of all parts, and finally the critical error source influencing the machining precision of the machine tool is recognized.

Owner:BEIJING UNIV OF TECH +1

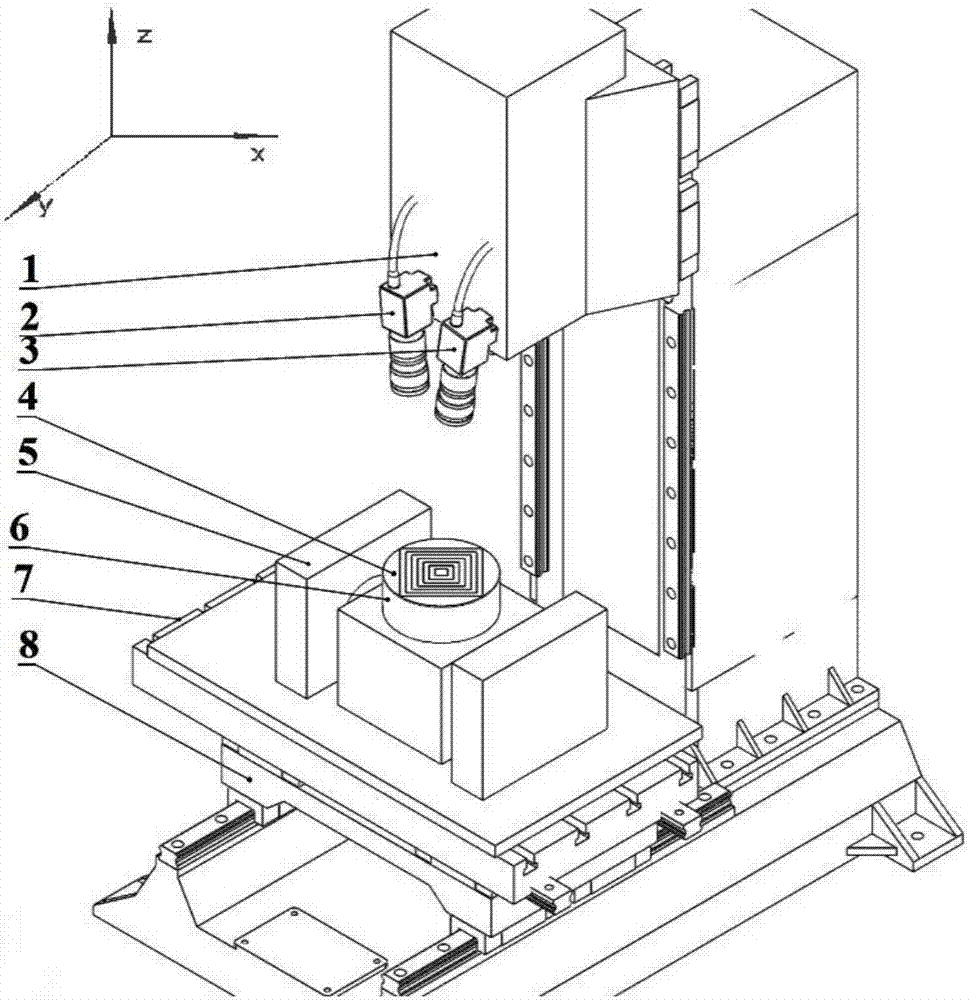

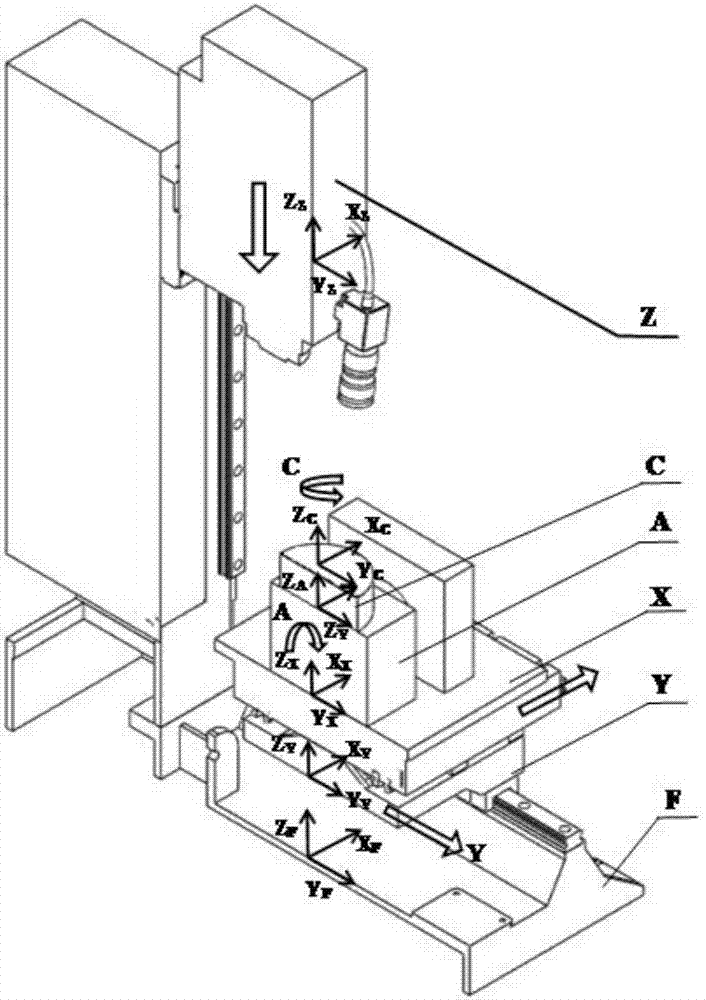

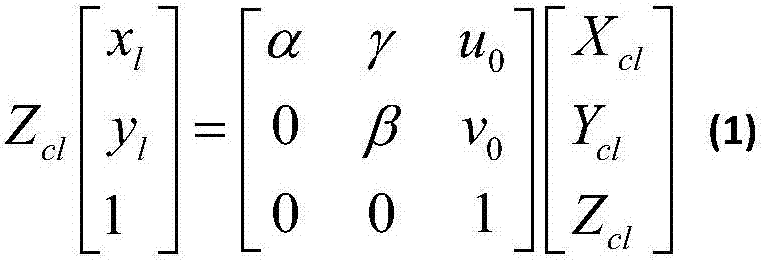

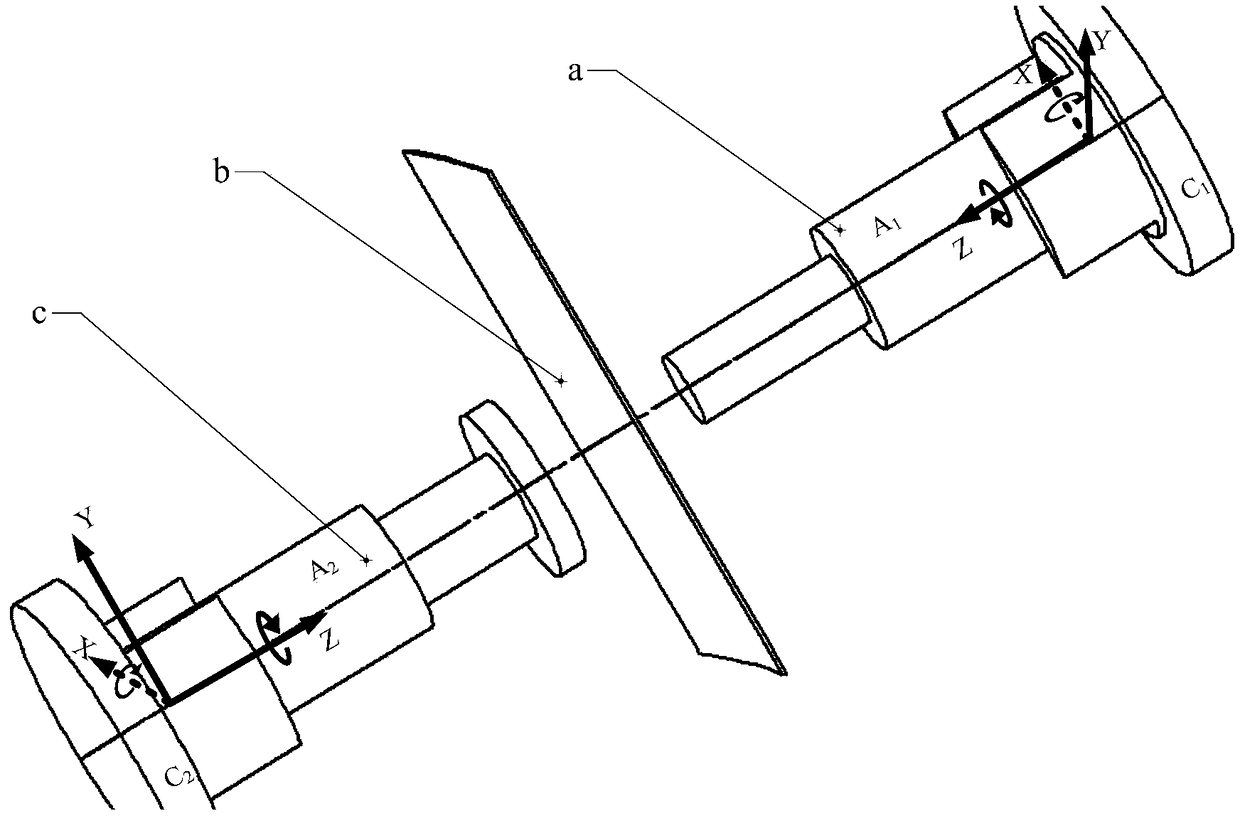

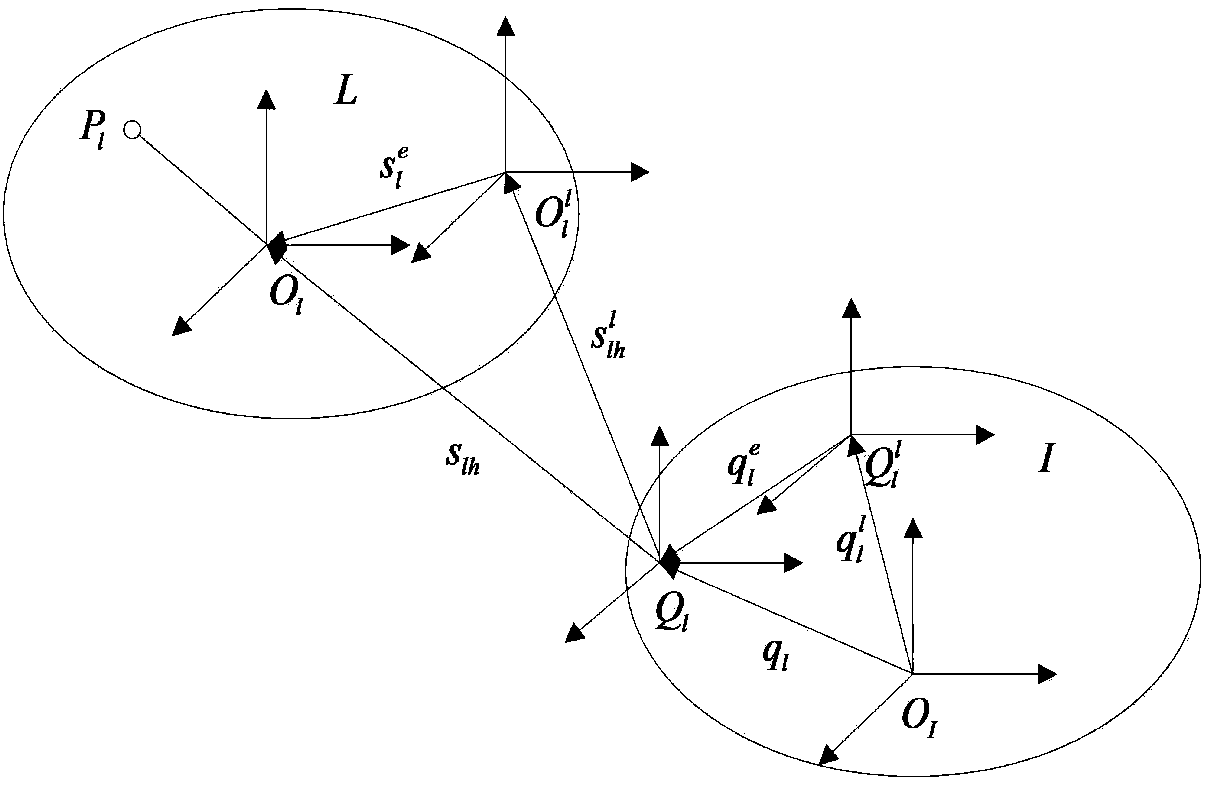

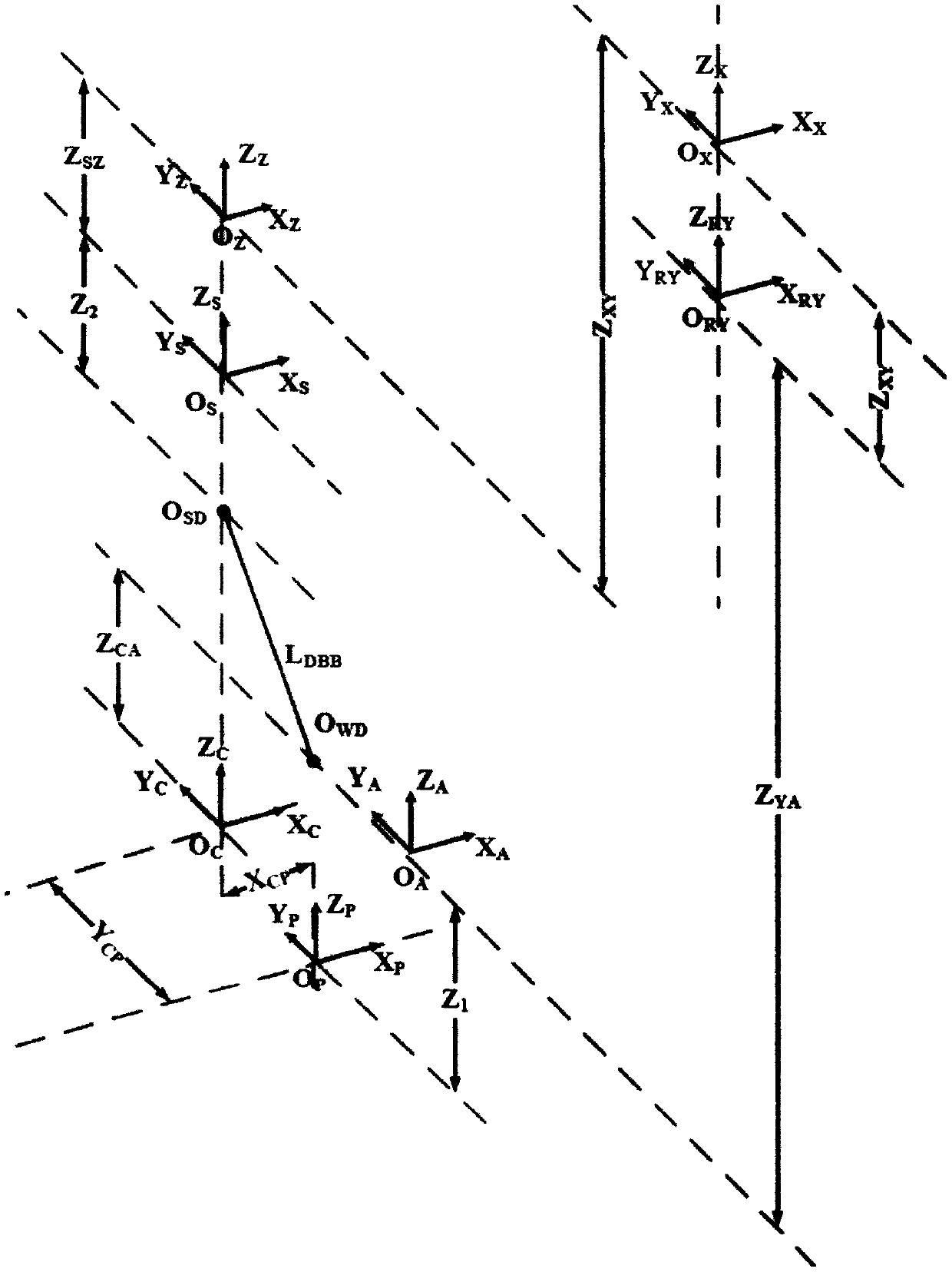

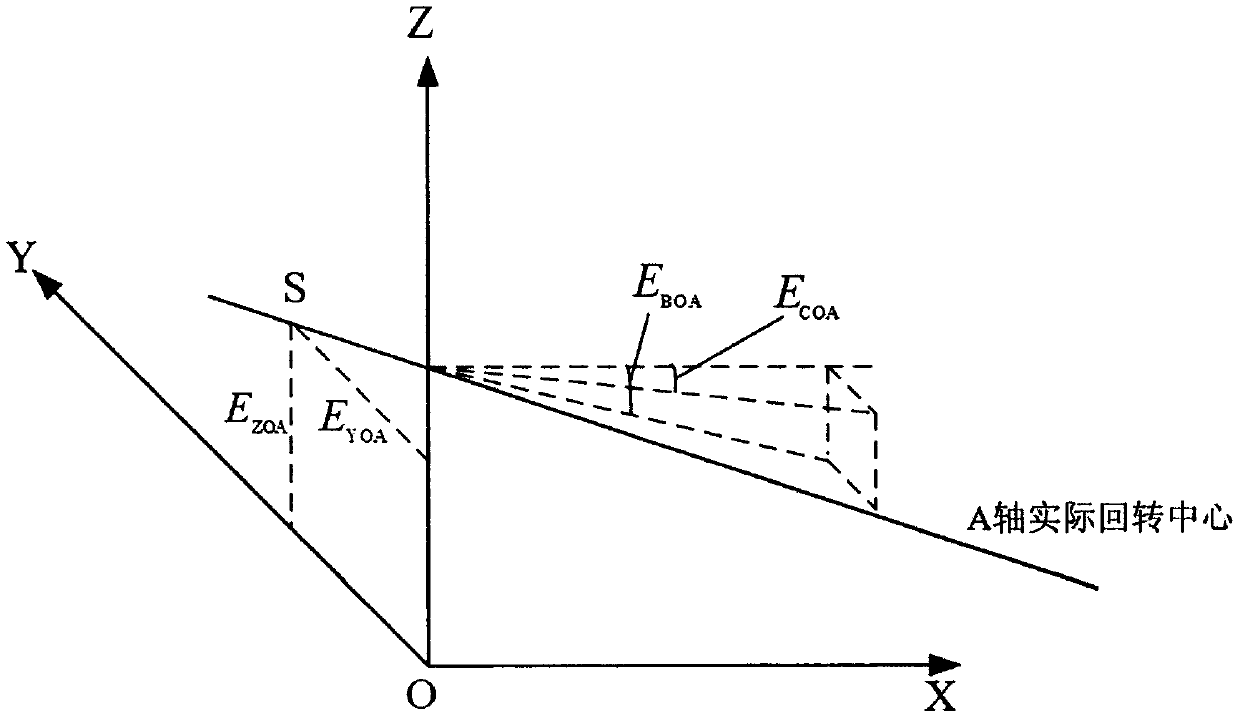

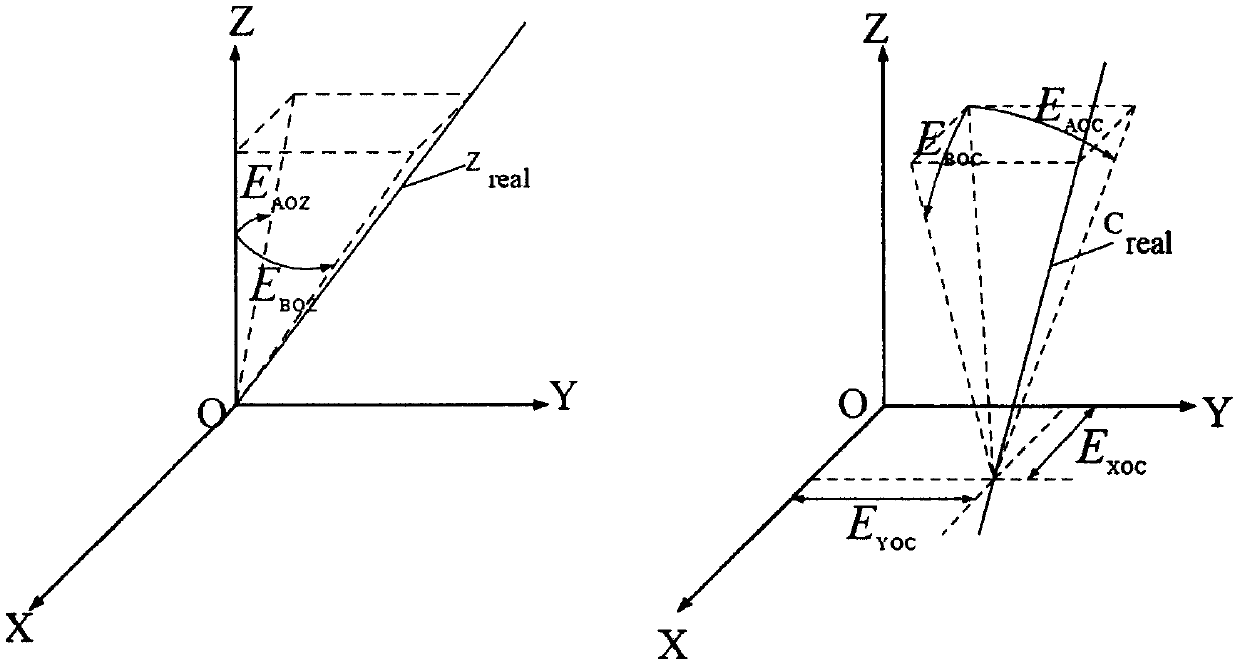

Detection method for geometrical errors of rotation shaft of five-axis numerical control machine tool

ActiveCN107186548ASolve internal and external parametersSolve the errorMeasurement/indication equipmentsNumerical controlImaging processing

The invention discloses a detection method for geometrical errors of a rotation shaft of a five-axis numerical control machine tool, belongs to the technical field of machine tool precision detection, and relates to a detection and identification method for the geometrical errors of the rotation shaft of the five-axis numerical control machine tool. The detection method comprises the steps that image information of a concentric target are collected by a binocular camera and used for representing the actual movement information of the rotation shaft, the three-dimensional coordinate information of a feature point is acquired finally through camera calibration and image processing, and the movement track represents the space movement track of one point on the rotation shaft; and through combination of a multi-body system theory of the machine tool and a subcoordinate transformation theory of the machine tool, the errors PIGE having no relation to the position of the rotation shaft and the errors PDGE having a relation to the movement position of the rotation shaft are identified and measured. The method effectively achieves detection and identification of the geometrical errors of the rotation shaft of the machine tool, the measurement process is simple and fast, and the measurement efficiency is high. The requirements for the operation track of the machine tool are simple in the measurement process, cooperation with other shafts is not needed, and other shaft linkage errors are avoided.

Owner:DALIAN UNIV OF TECH

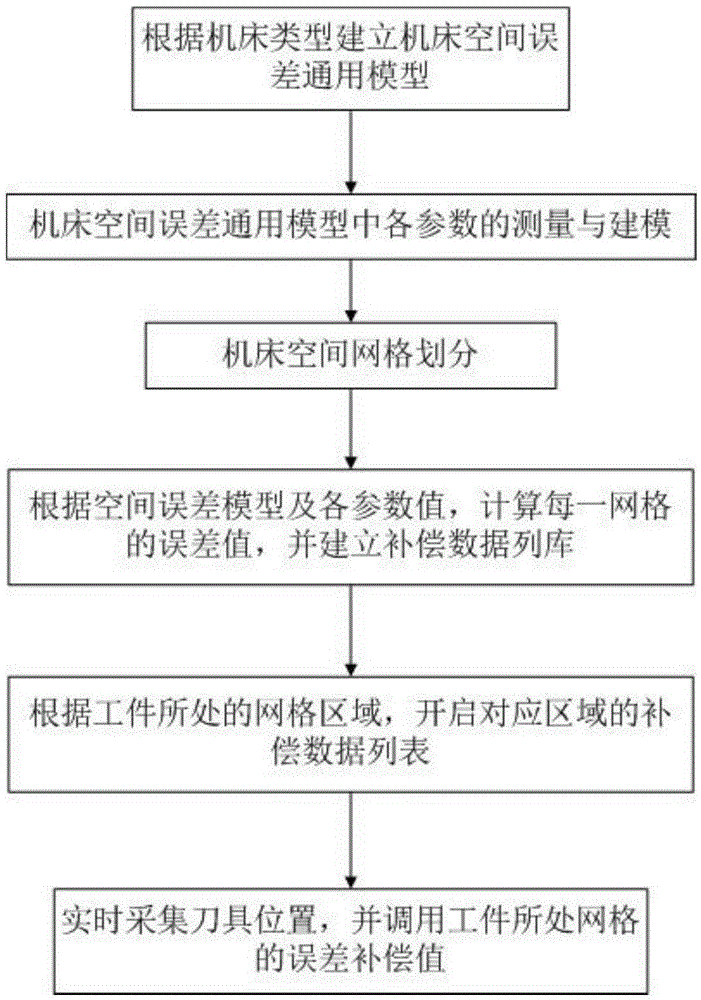

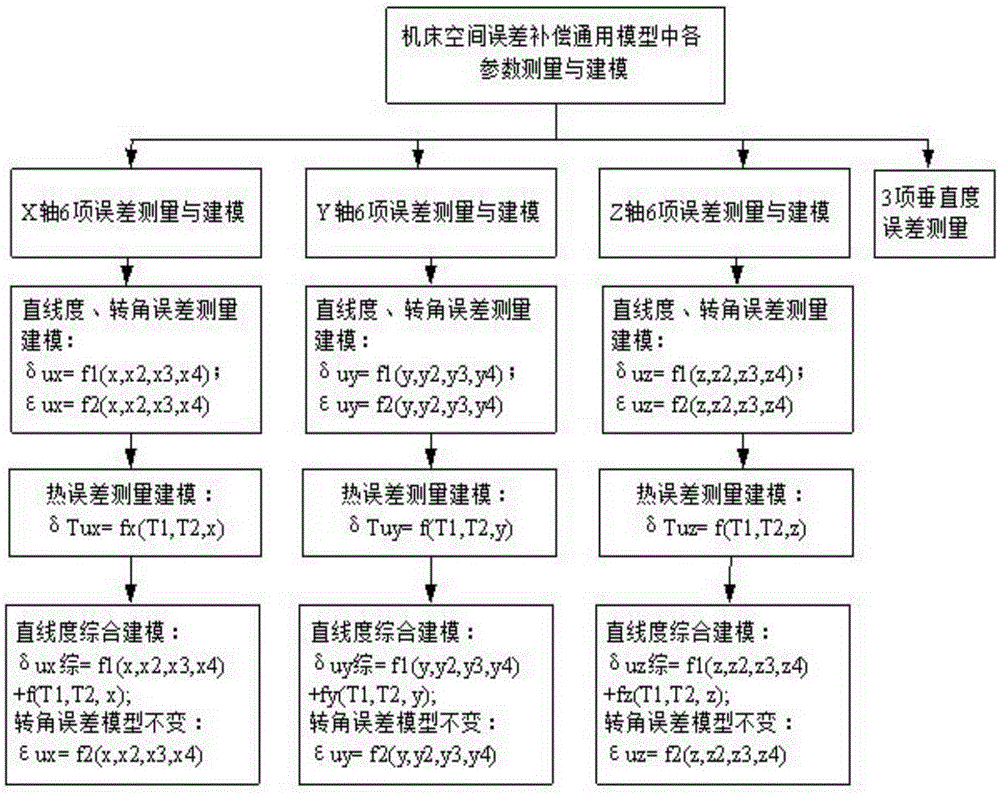

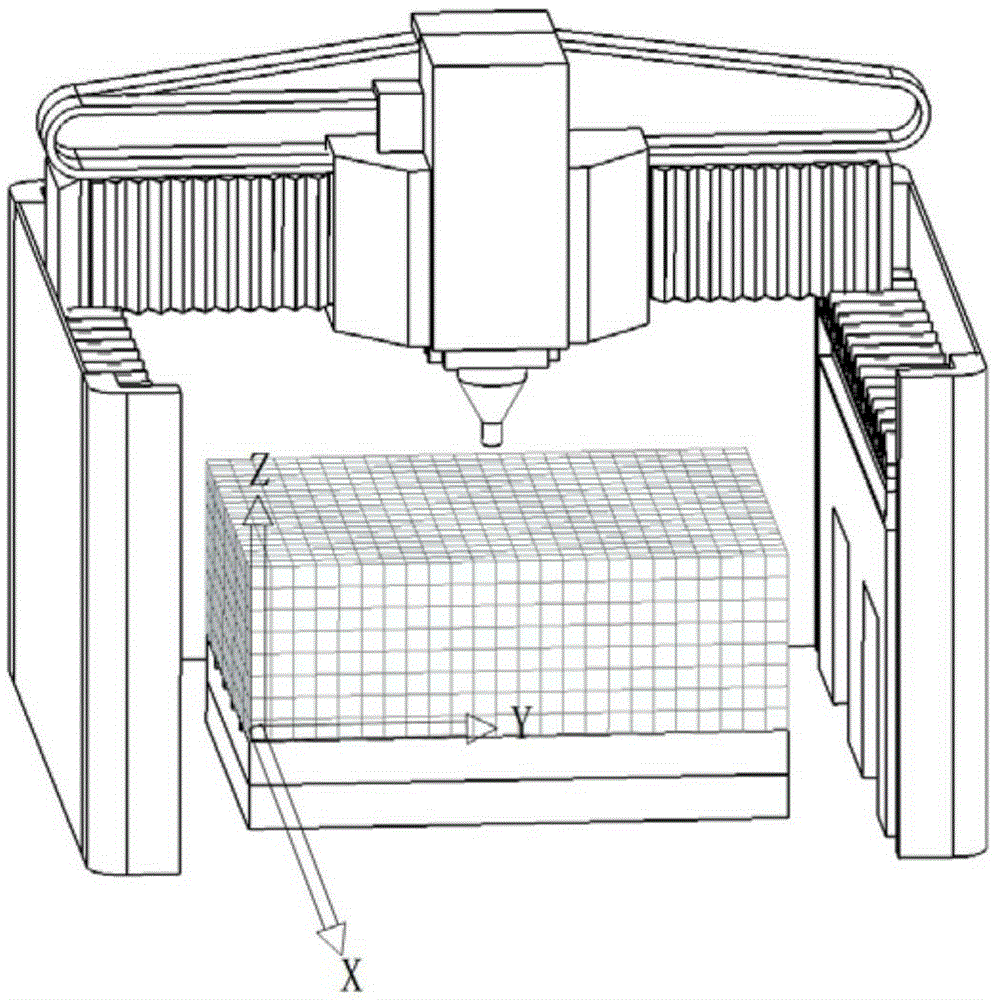

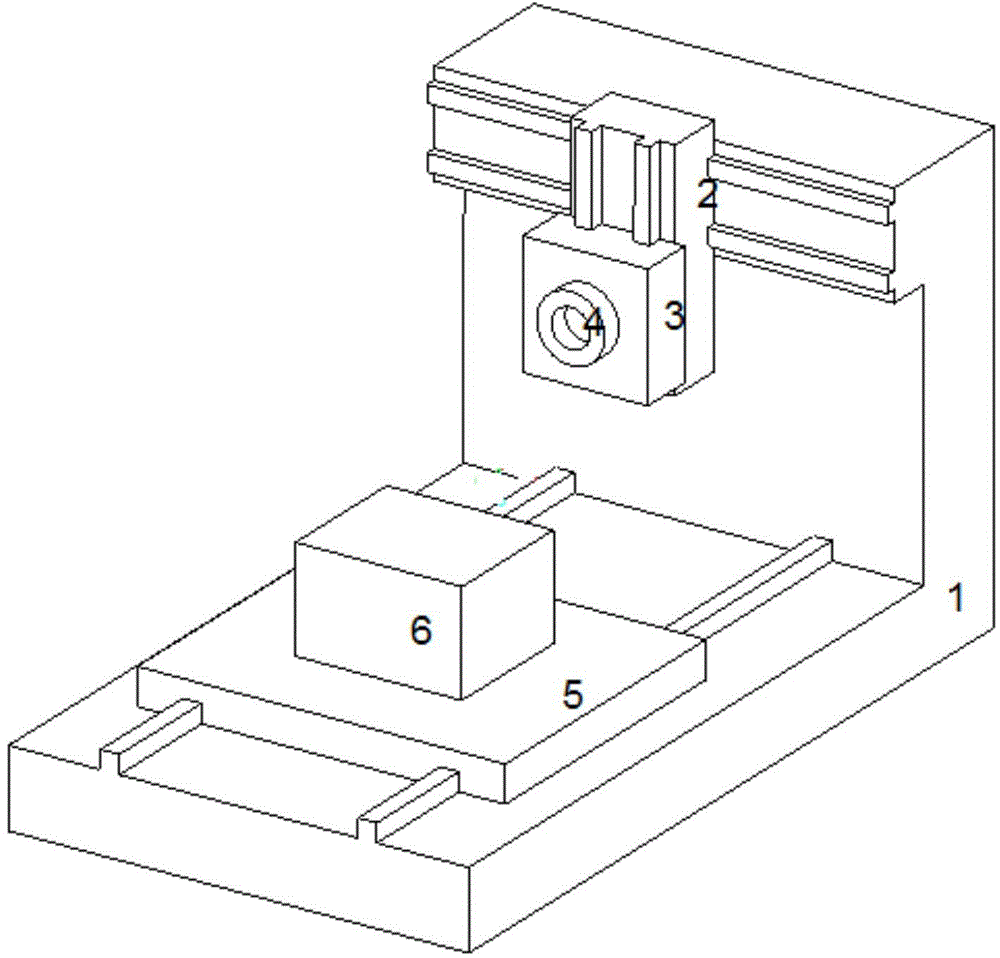

Numerical control machine tool space error modeling method based on space grid compensation mode

The invention discloses a numerical control machine tool space error modeling method based on a space grid compensation mode. The numerical control machine tool space error modeling method mainly comprises the following steps that step one, a three-axis numerical control machine tool space error universal model is established by utilizing a homogenous coordinate transformation method based on the multi-body system theory according to the type of a machine tool; step two, 21 geometric error elements in the model are measured by using a laser interferometer and modeling is performed; and step three, numerical control machine tool space error is compensated. According to the modeling method, static geometric error and dynamic thermal error modeling methods are integrated, a comprehensive model expression combination is separated into independent position influence terms and temperature influence terms, a space grid compensation list mode is adopted for the position error influence terms, and a real-time acquisition mode is adopted for the temperature error influence terms so that comprehensive compensation is realized. Therefore, the modeling method is scientific and effective and has the characteristics of being easy to compensate and convenient to apply.

Owner:HUBEI UNIV OF ARTS & SCI +1

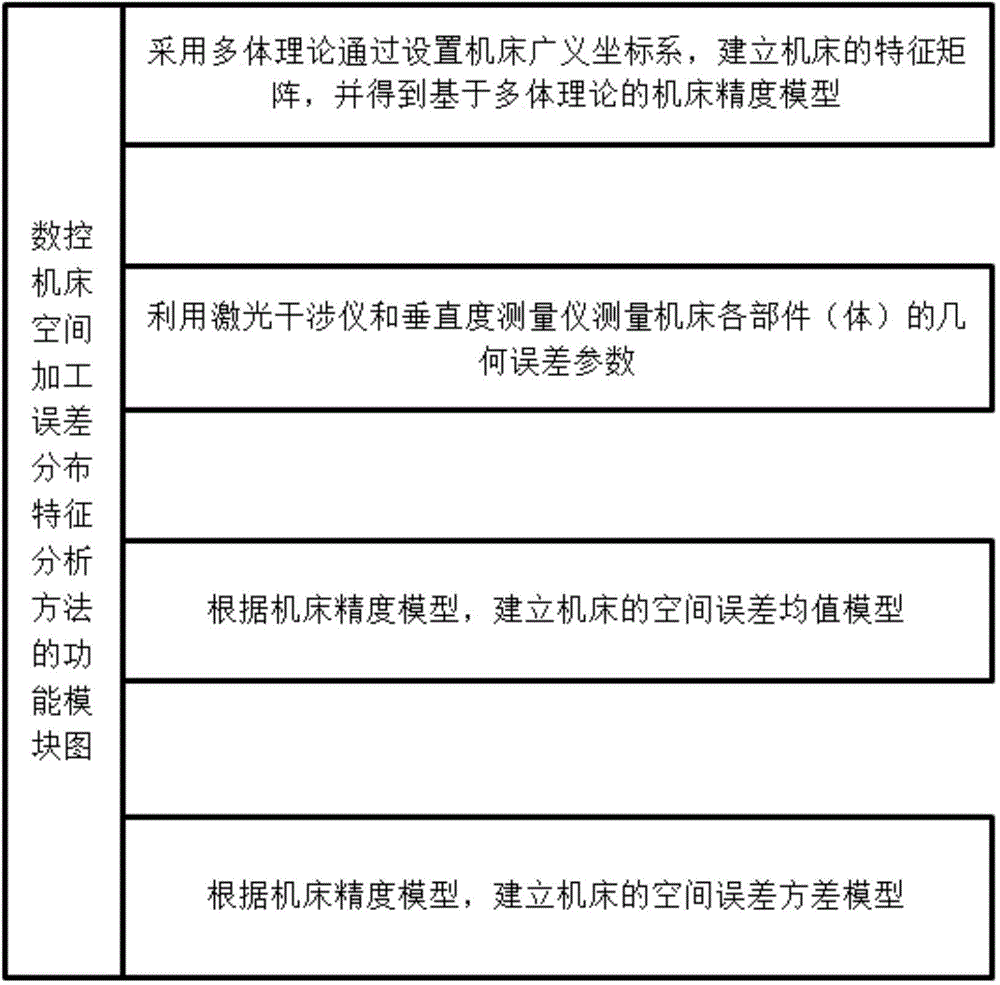

Analysis method on basis of distribution characteristics of space machining error of numerical control machine tool

ActiveCN104050316AReduce uncertaintySpecial data processing applicationsGeometric errorNumerical control

The invention discloses an analysis method on the basis of distribution characteristics of a space machining error of a numerical control machine tool, belongs to the field of accuracy design of a machine tool and particularly relates to an analysis method on the basis of the distribution characteristics of the space error. On the basis of space geometric error deterministic modeling and geometric error measurement which are established by a multibody system and the matrix total differential and random process principle, a space error deterministic analysis model of a precision horizontal machining center is established and the distribution characteristics of a geometric error and the space machining error of the machine tool are analyzed. The invention discloses a novel machine tool design concept and fundamentally solves the problem of accuracy of the machine tool. Guiding suggestions also can be given to actual assembling and machining, so that output of the error is reduced, machining accuracy of the numerical control machine tool is improved and the problem of accuracy of the machine tool is fundamentally solved.

Owner:BEIJING UNIV OF TECH +1

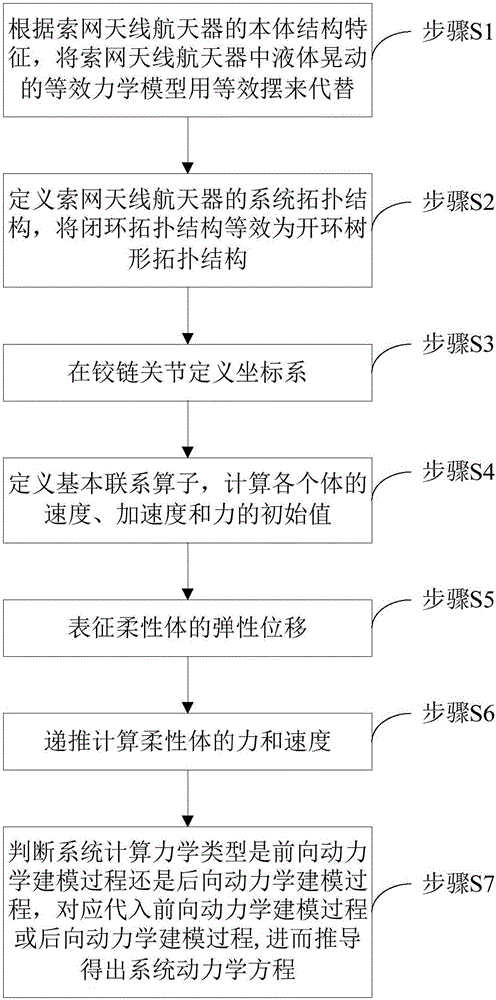

Spacecraft dynamics modeling method

ActiveCN105956348ASpeed up the development cycleSolve the problem of high-precision and high-efficiency kinetic modelingSpecial data processing applicationsDynamic modelsForward dynamic

The invention provides a spacecraft dynamics modeling method. The method comprises the following steps of: replacing a liquid sloshing equivalent mechanical model with an equivalent pendulum, enabling a closed loop topology structure to be equivalent to an open loop tree topology structure, defining a coordinate system at a hinge joint, defining a basic contact operator, characterizing elastic displacement of a flexible body, and performing recurrent calculation on the force and speed of the flexible body; and judging whether systematic calculation on a dynamics model is a forward dynamics modeling process or a backward dynamics modeling process, correspondingly substituting the forward dynamics modeling process or the backward dynamics modeling process, and deducing a system dynamics equation. The method provided by the invention is capable of not only meeting the precise modeling requirement, but also simplifying the design process, saving a lot of workload, accelerating the spacecraft development period, realizing high-precision high-efficiency dynamics modeling of a large flexible cable antenna spacecraft, achieving modeling of a flexible multi-body system capable of calculating closed loop spacecraft configuration in a simplest mode, and saving a lot of tedious and hard works.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

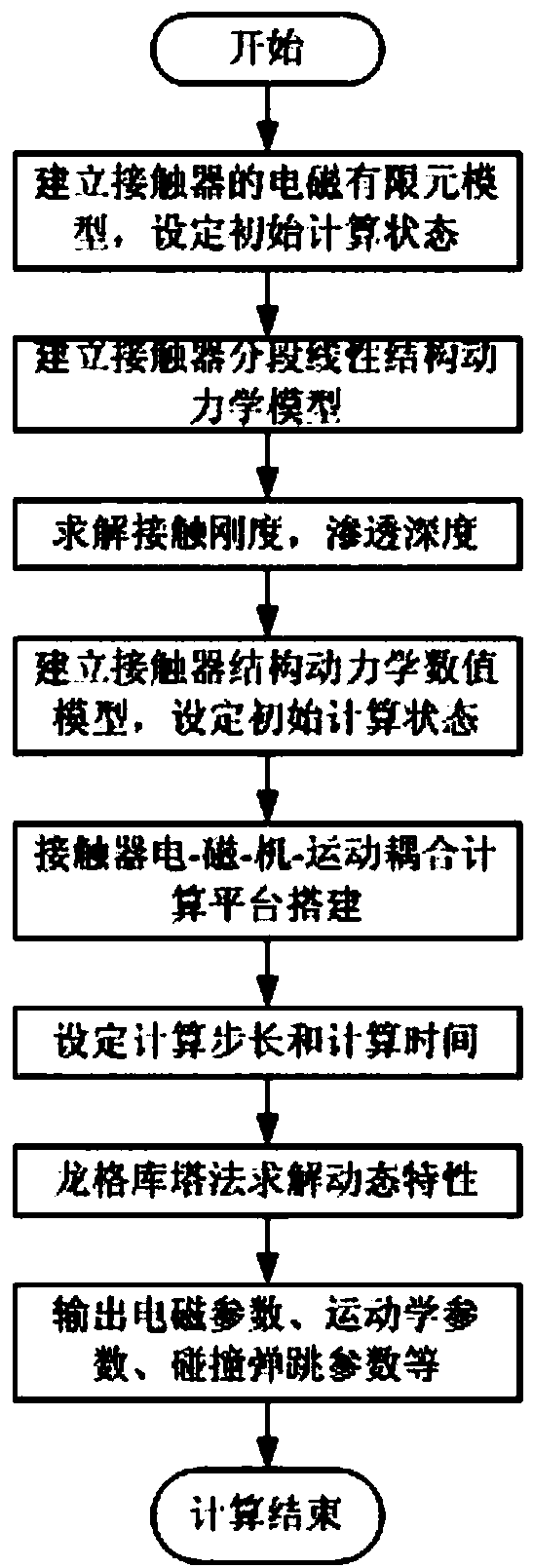

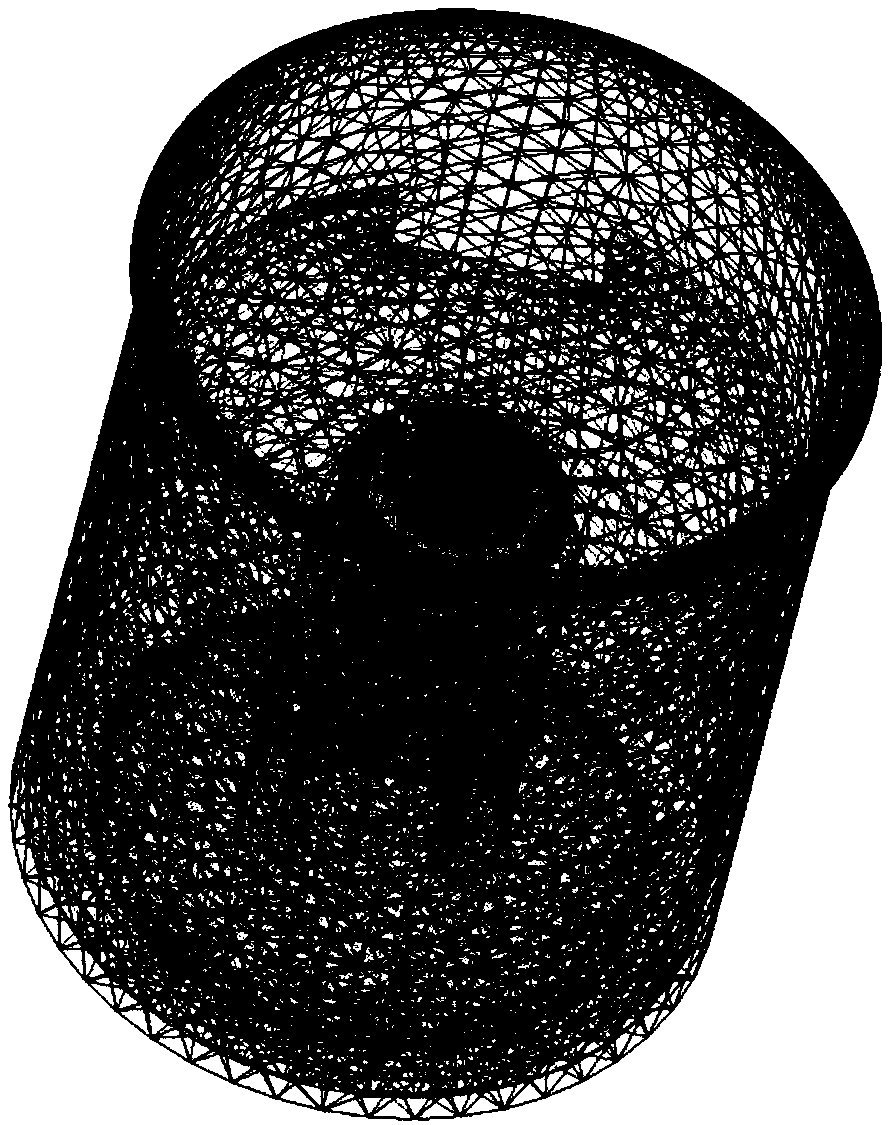

Method for calculating dynamic characteristics of contactor based on piecewise linear kinetic equation

ActiveCN107862127AResponse Electromagnetic Dynamic CharacteristicsVisualization of dynamic characteristic solution processGeometric CADDesign optimisation/simulationMagnetic tension forceDynamic method

Provided is a method for calculating dynamic characteristics of a contactor based on a piecewise linear kinetic equation, and belongs to the technical field of basic research design of general characteristics of contactors. The method comprises the steps that according to structural features of the contactor, segmentation is conducted on a contactor action process, plane collision and a continuouscollision force model with energy loss considered are used for being equivalent to a collision process, by means of the multi-body system kinematics based on a restrain method and a dynamic method, studying of the collision bounce situation of a contactor mechanical system under the action of external force is completed, and finally, dynamic characteristic calculation of the contactor with collision bounce considered is completed in combination of a coupling calculation method. The method has the advantages that the time-dependent situation of electromagnetic parameters such as the coil current and electromagnetic force in a working process of the contactor can be obtained, the electromagnetic dynamic characteristics of the contactor can be reflected more accurately, and errors are controlled within 5%; the bounce situation of an armature and a moving contact of the contactor can be reflected more really, and errors are controlled within 5%.

Owner:HARBIN INST OF TECH

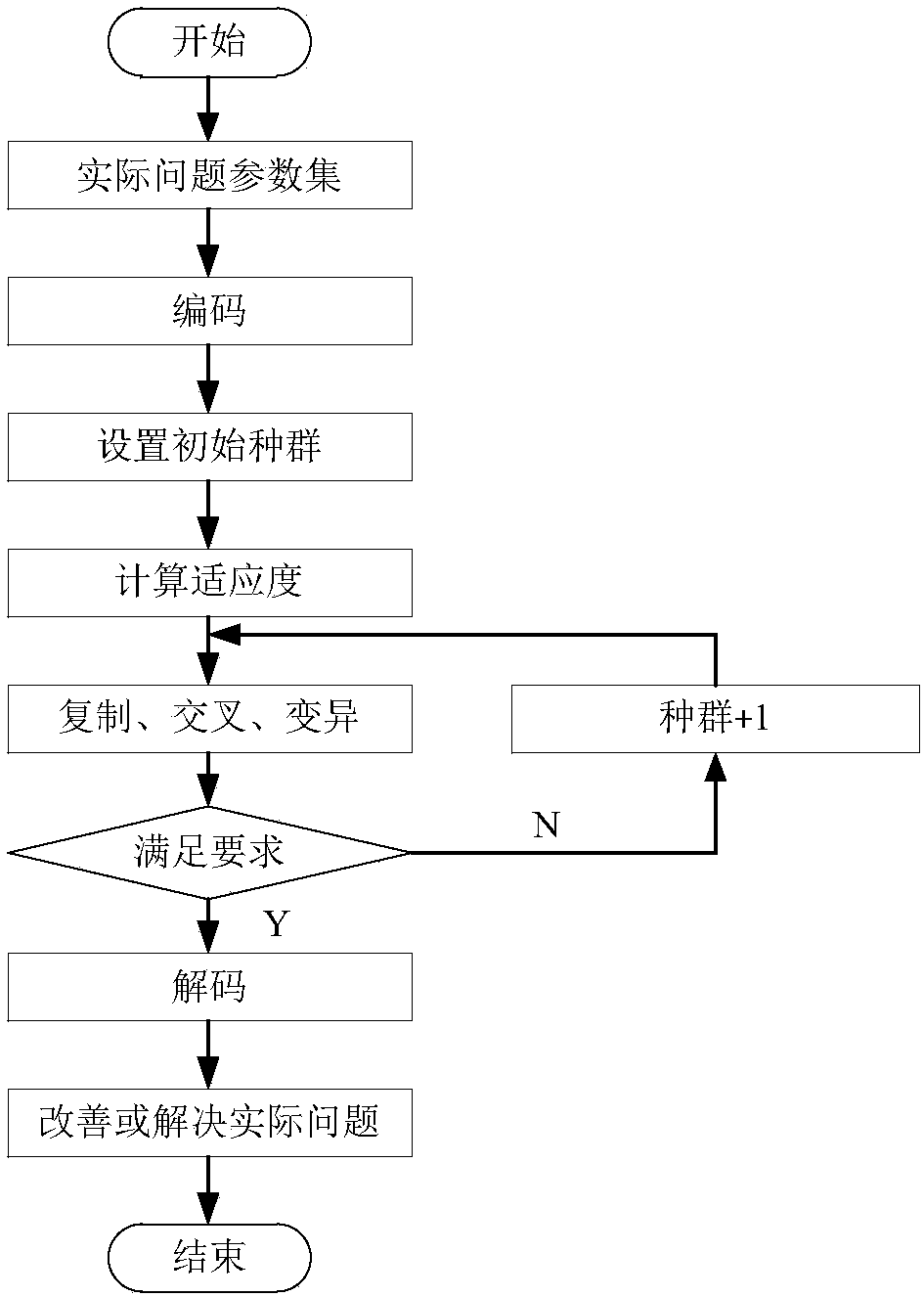

Steady optimal distributing method for geometric accuracy of multi-shaft machine tool

ActiveCN103390082AGuaranteed machining accuracyReduce manufacturing costSpecial data processing applicationsGeometric errorMultibody system

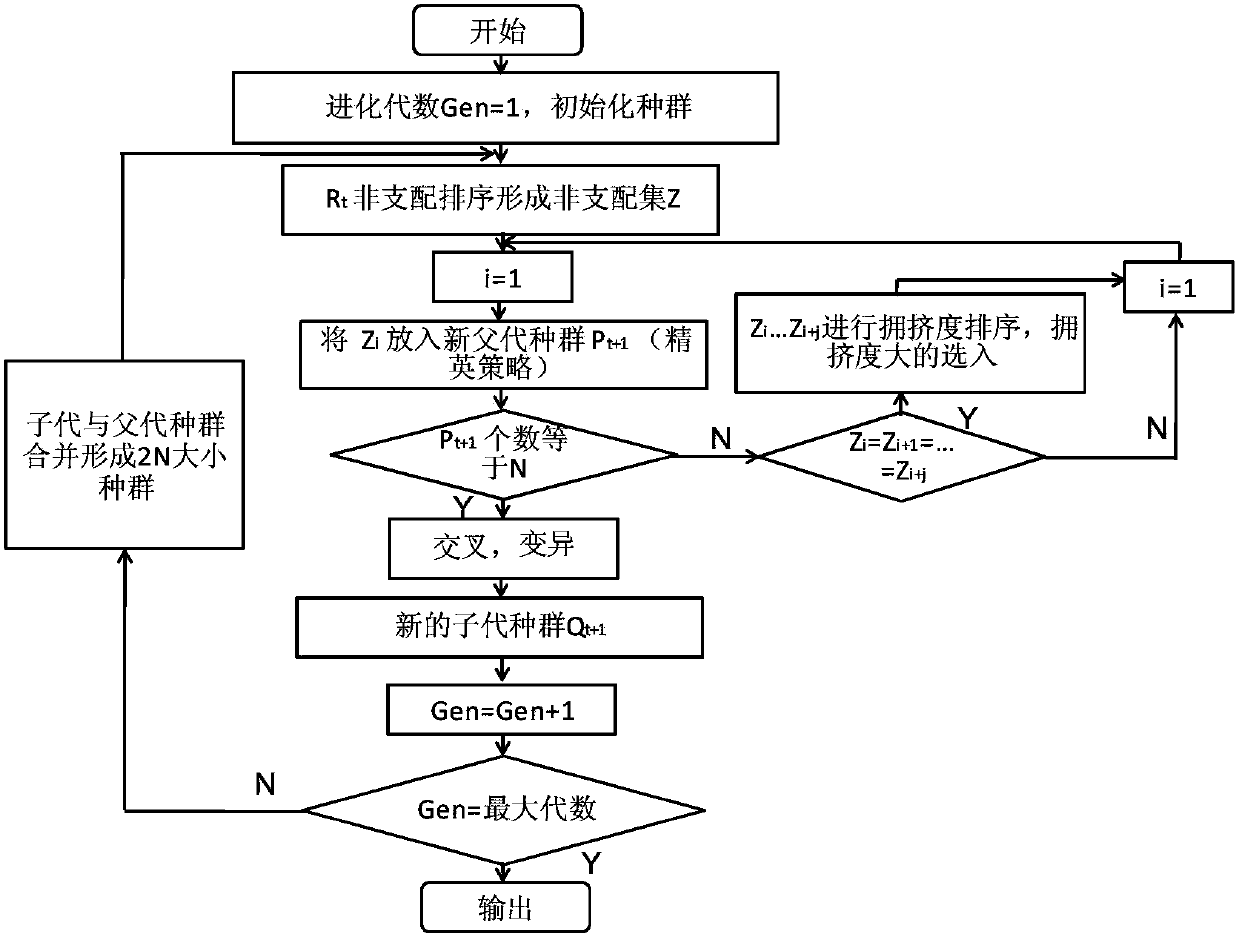

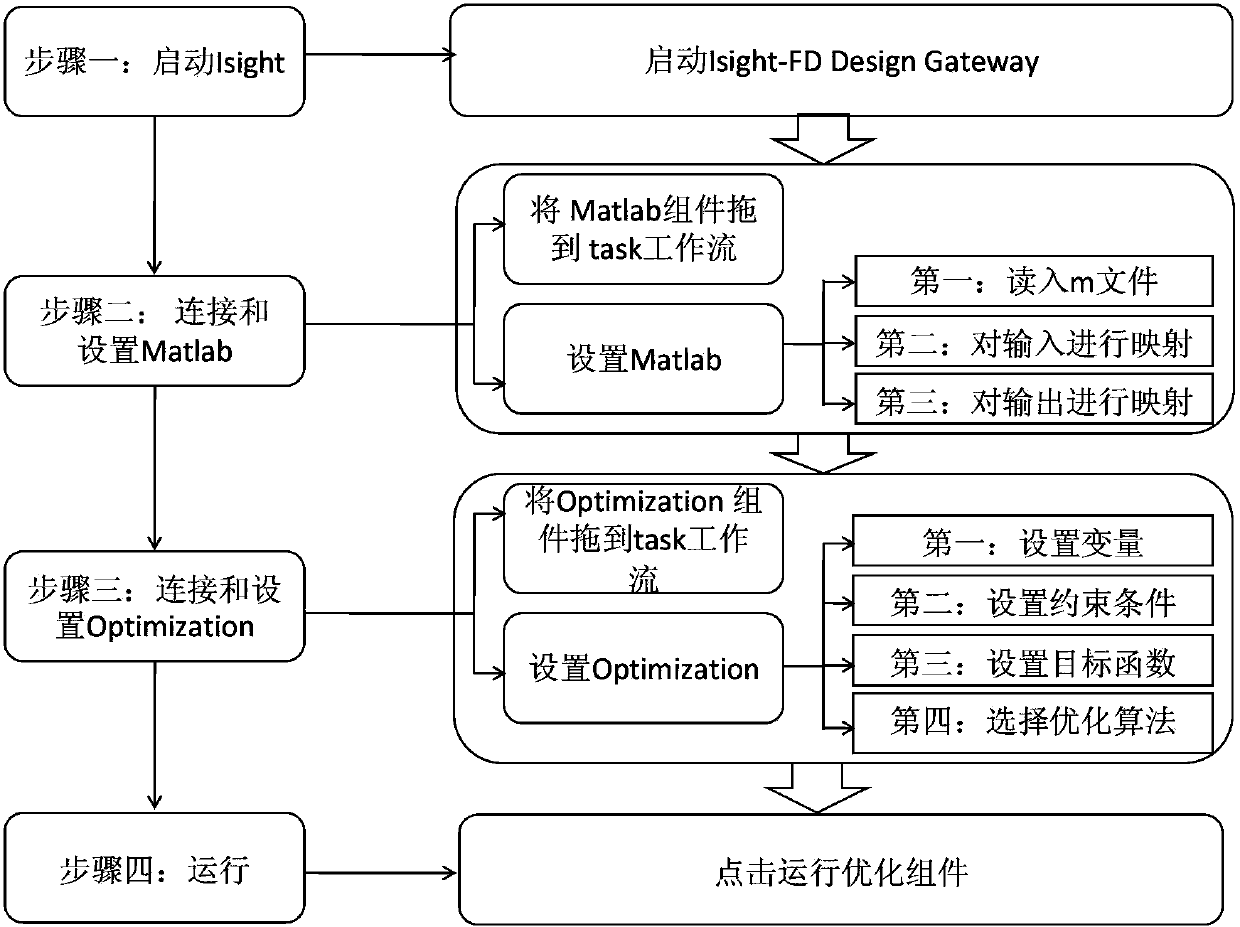

Along with increasing demand on machining precision, how to reasonably configure geometric error of a machine tool under the premise of ensuring the machining performance of the machine tool to balance the cost and machining precision is the problem demanding a prompt solution in manufacturing of the machine tool. The invention provides a novel multi-target optimal distributing method for geometric accuracy based on the manufacturing cost and quality loss of parts. The method comprises the following steps of: establishing a comprehensive spatial error model of geometric error of the machine tool by a multibody system theory; establishing a manufacturing cost model of a machine tool part according to the machining characteristic of the machine tool part which affects the geometric error to the maximum extent; meanwhile, combining the quality loss cost to establish a cost-based target function; establishing an optimal model associated to precise level of the part by identifying the geometric error, namely, maximizing European norms of all precision parameter variables as another target function; and realizing optimal distribution through Isight and Matlab integrated and combined with NSGA-II (Nondominated Sorting Genetic Algorithm-II).

Owner:BEIJING UNIV OF TECH +1

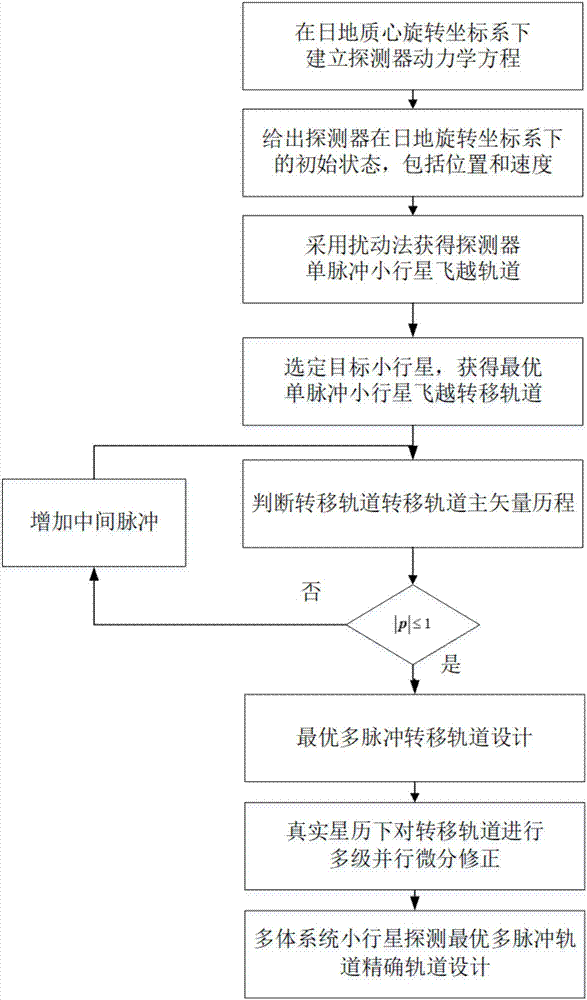

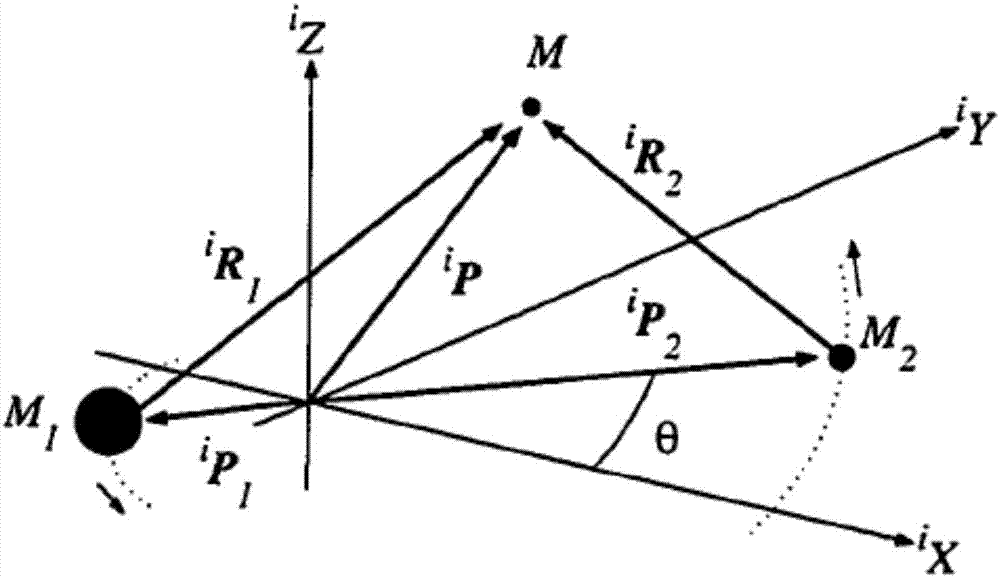

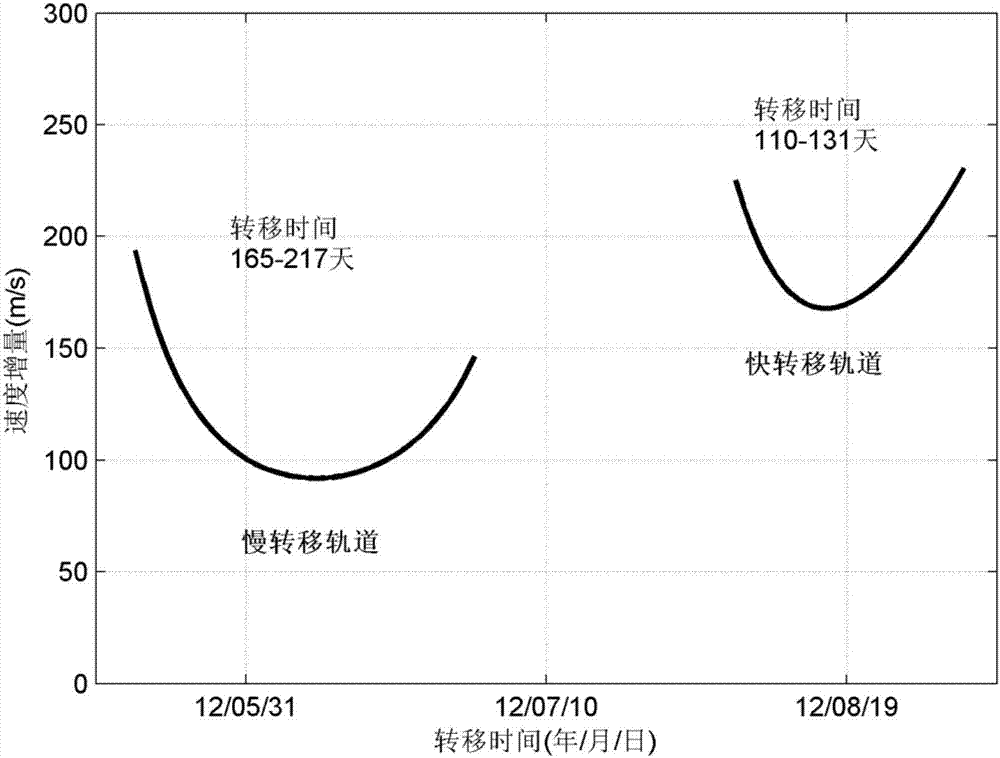

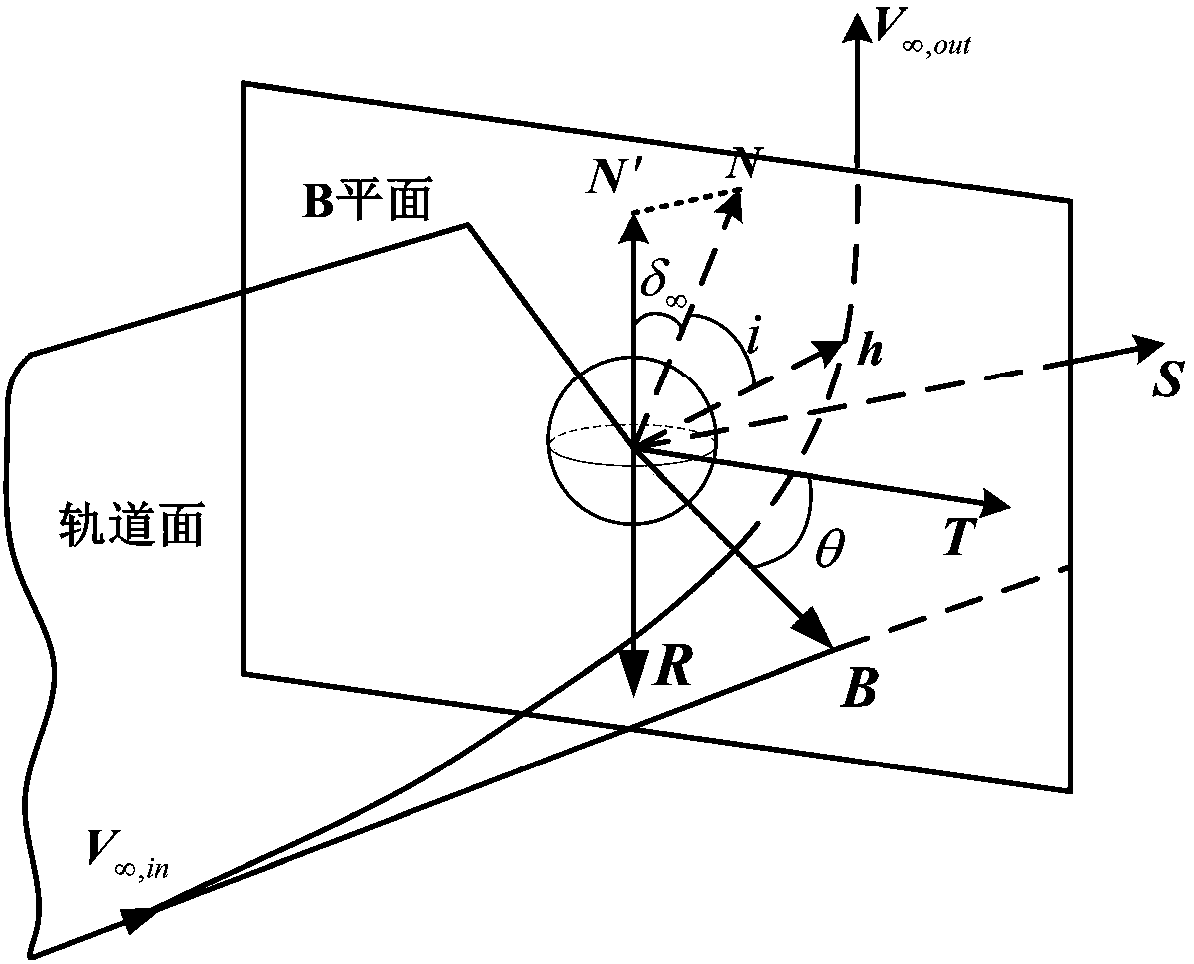

Minor planet detection optimal multi-impulse transfer method of interplanetary multibody system

InactiveCN107992682ASmall speed incrementOptimal velocity increment for asteroid detectionCosmonautic vehiclesDesign optimisation/simulationAviationVector theory

The invention discloses a minor planet detection optimal multi-impulse transfer method of an interplanetary multibody system, and belongs to the technical field of aerospace engineering. The method includes steps of firstly, building a detector kinetic equation under a geological core rotating system, namely, a high-precision kinetic model; selecting a target minor planet according to task restriction and providing an initial state of the detector under the geological core rotating coordinate system; applying a disturbance method to obtain a detector single-impulse minor planet flyover track;applying an optimization algorithm to obtain a single-impulse minor planet flyover transfer track with the minimum flyover distance; based on a main vector theory, performing a multi-impulse transfertrack design, and acquiring an optimal multi-impulse transfer track which meets the main vector condition; bringing the acquired optimal multi-impulse transfer track to the high-precision kinetic model to progressively induce; amending the transfer track by a multi-grade parallel differential amending method, and realizing the accurate track transfer of minor planet detection under a multi-celestial-body strong disturbance nonlinear environment. The minor planet detection optimal multi-impulse transfer method has the advantages of small speed increment, good applicability, and good astringency.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

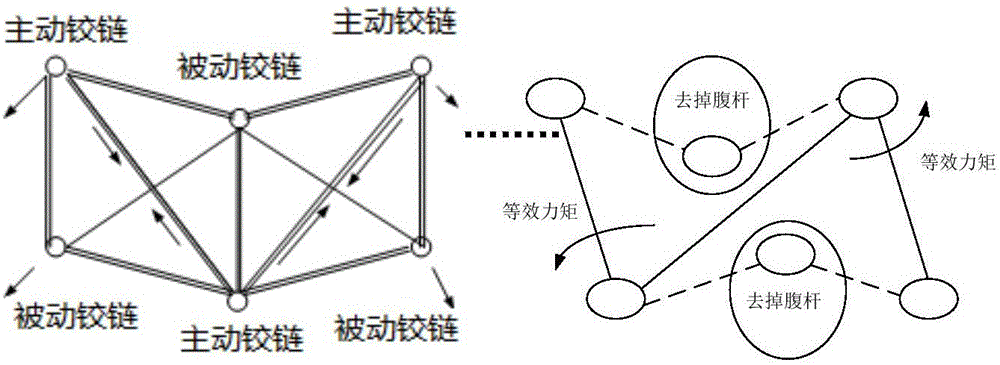

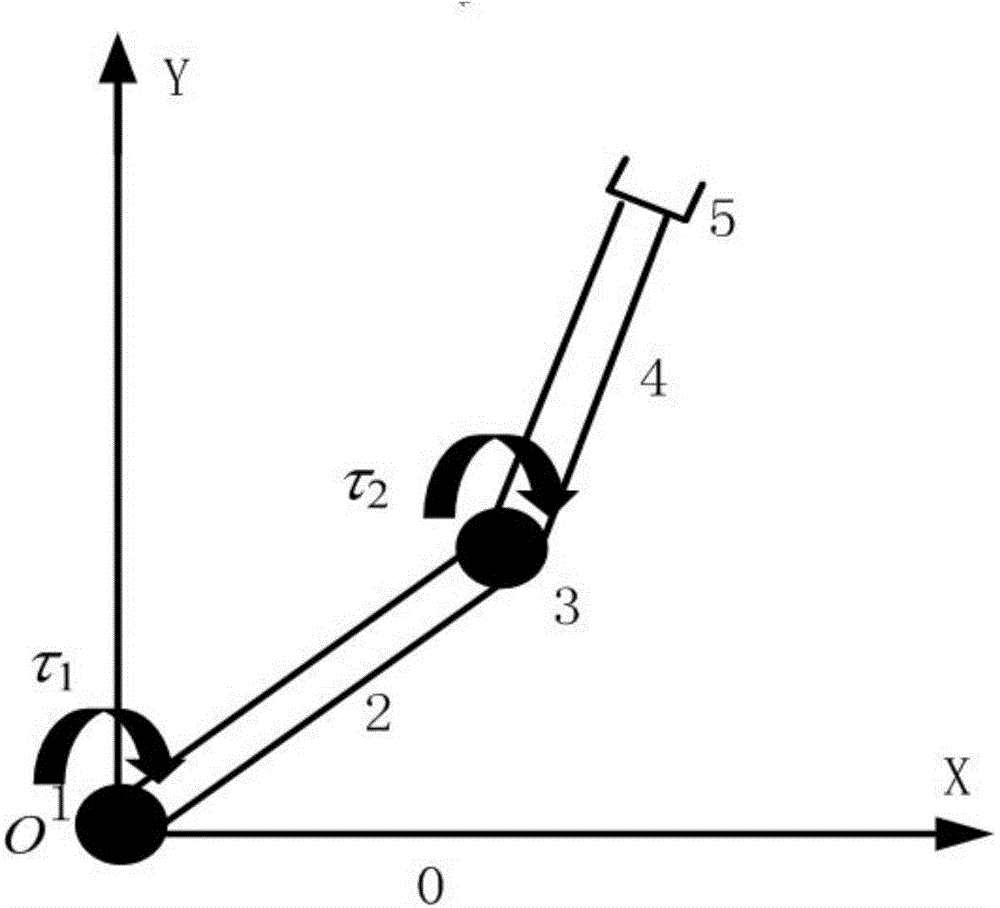

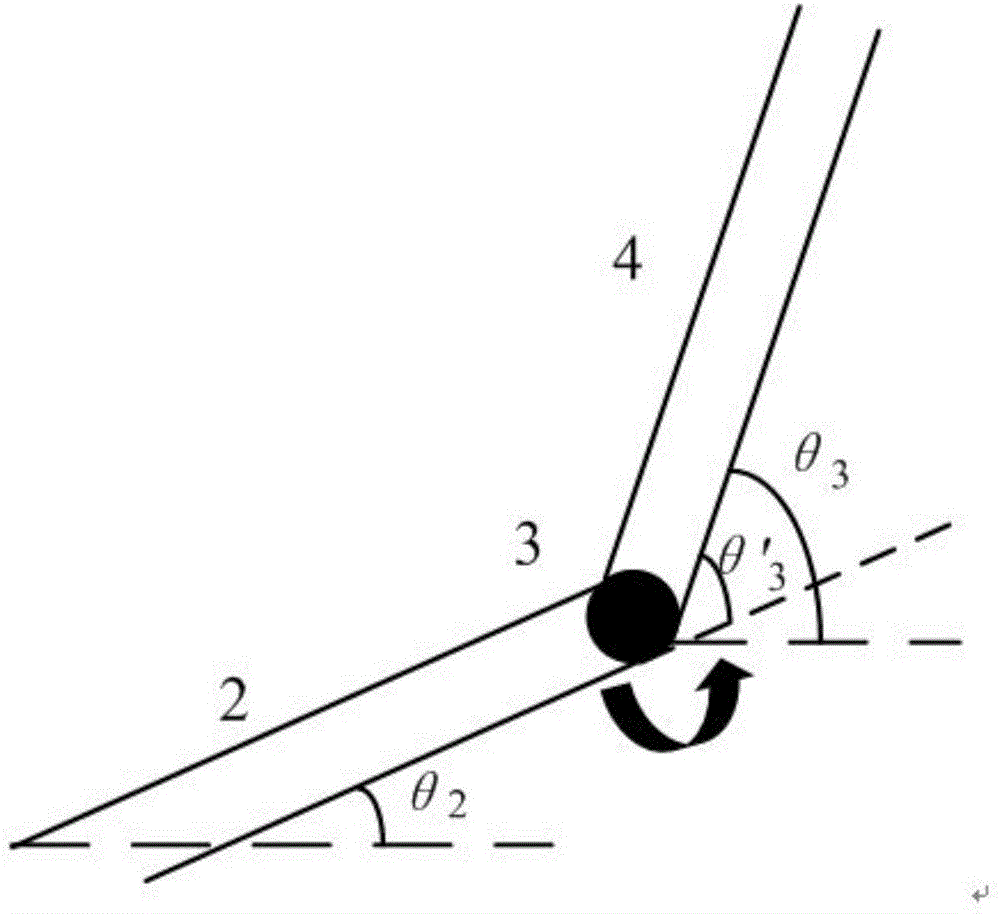

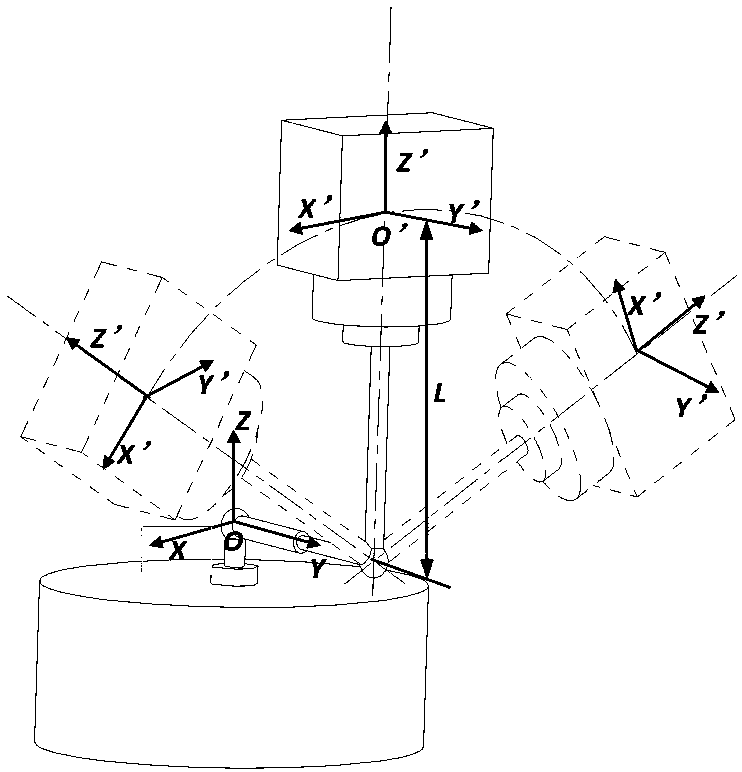

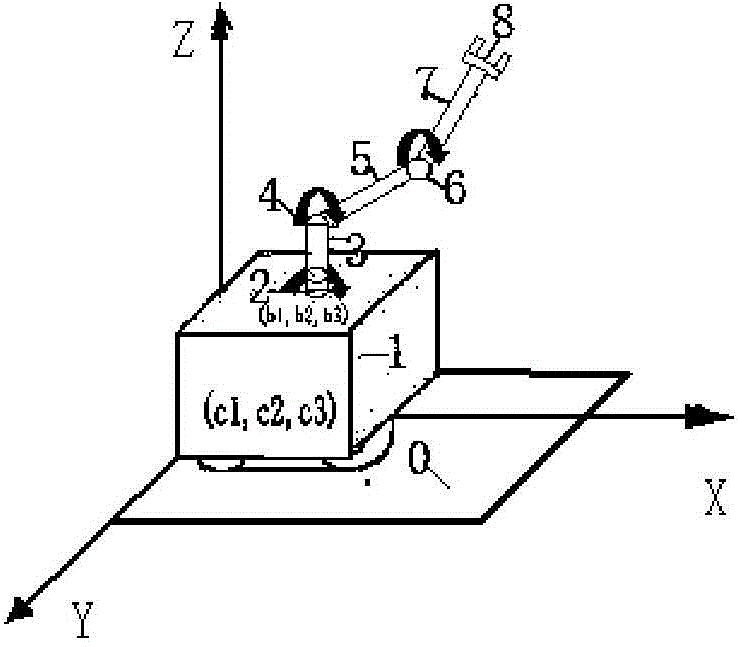

Mechanical arm modeling and solving method based on improvement of multi-body system transfer matrix

InactiveCN104573255ASimple modelLower orderSpecial data processing applicationsMathematical modelMatrix method

The invention discloses a mechanical arm modeling and solving method based on improvement of a multi-body system transfer matrix. The method is characterized in that a discrete time transfer matrix method of the multi-rigid-body system is improved according to the structure characteristics of a planar mechanical arm and the relation between motion transfer and force transfer, a unified model of an n-degree-of-freedom series mechanical arm is built, and kinematic and dynamic solving method and process of a system model is provided by setting the boundary condition according to the two acknowledged motion conditions between the joint space and the operation space of the mechanical arm. The method has the advantages of being flexile in modeling, small in calculation scale, capable of covering the kinematic and dynamic characteristics of the system and more effective compared with the traditional robot modeling method, showing the excellence of the new method, and achieving the aims of clear idea, simple programming and achievement easiness.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

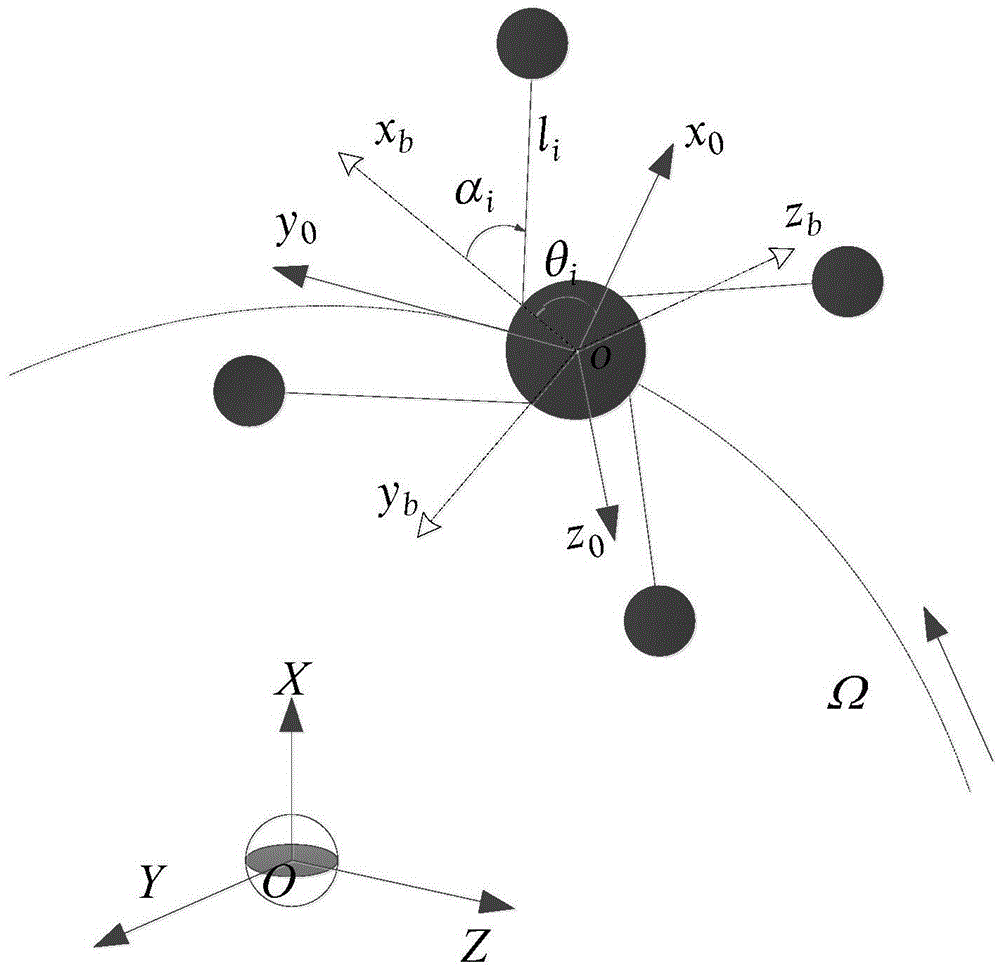

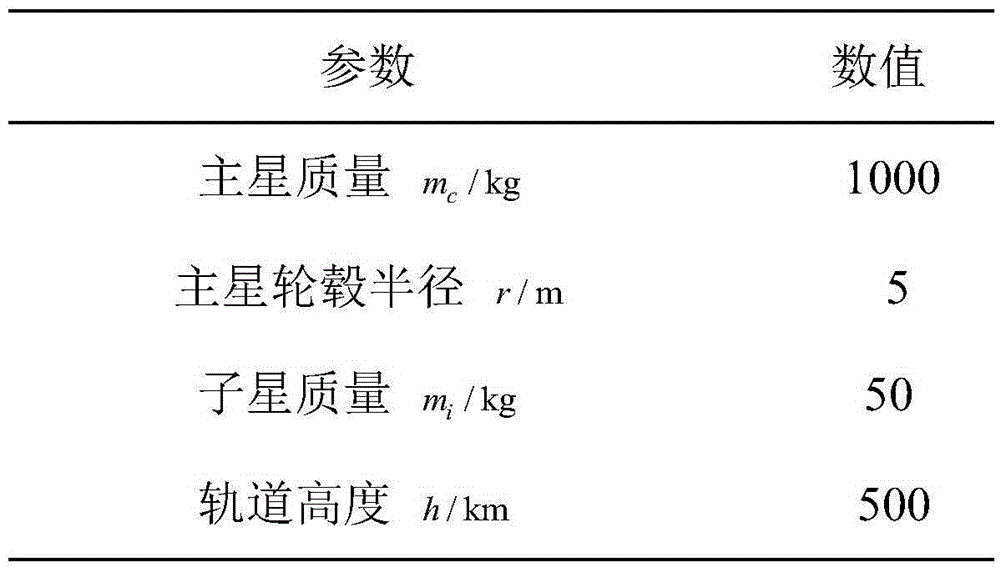

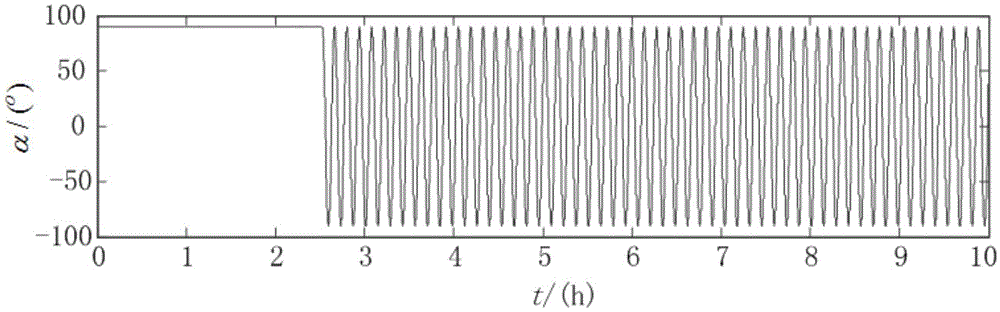

Radiation open loop tethered satellite formation constant speed spinning deployment control method

ActiveCN105468011AReflect stabilityReflect the characteristics of the movementCosmonautic vehiclesCosmonautic partsMassive gravityClosed loop

The invention discloses a radiation open loop tethered satellite formation constant speed spinning deployment control method, relates to a dynamics construction and control strategy design in which the tethered satellite formation is spun and deployed at a constant speed into a radiation open loop form and belongs to the field of spacecraft formation control. In view of the radiation open loop tethered satellite formation running on a circular Kepler track in an earth center gravitational field, in consideration of multi-body system movement characteristics and gravity gradient moment effects, system spinning deployment dynamics is built via a Lagrange equation; on the basis, a closed loop control strategy is designed, the main satellite is spun and deployed at a constant speed, compensation in view of the gravity gradient moment is carried out, damping is added to the tail section of the deployment to restrain system oscillation; the dynamics and the control method are simple, effective and easy to realize; and the whole process of controlling the tethered satellite system to deploy at a constant speed is smooth, safe and high in reliability.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

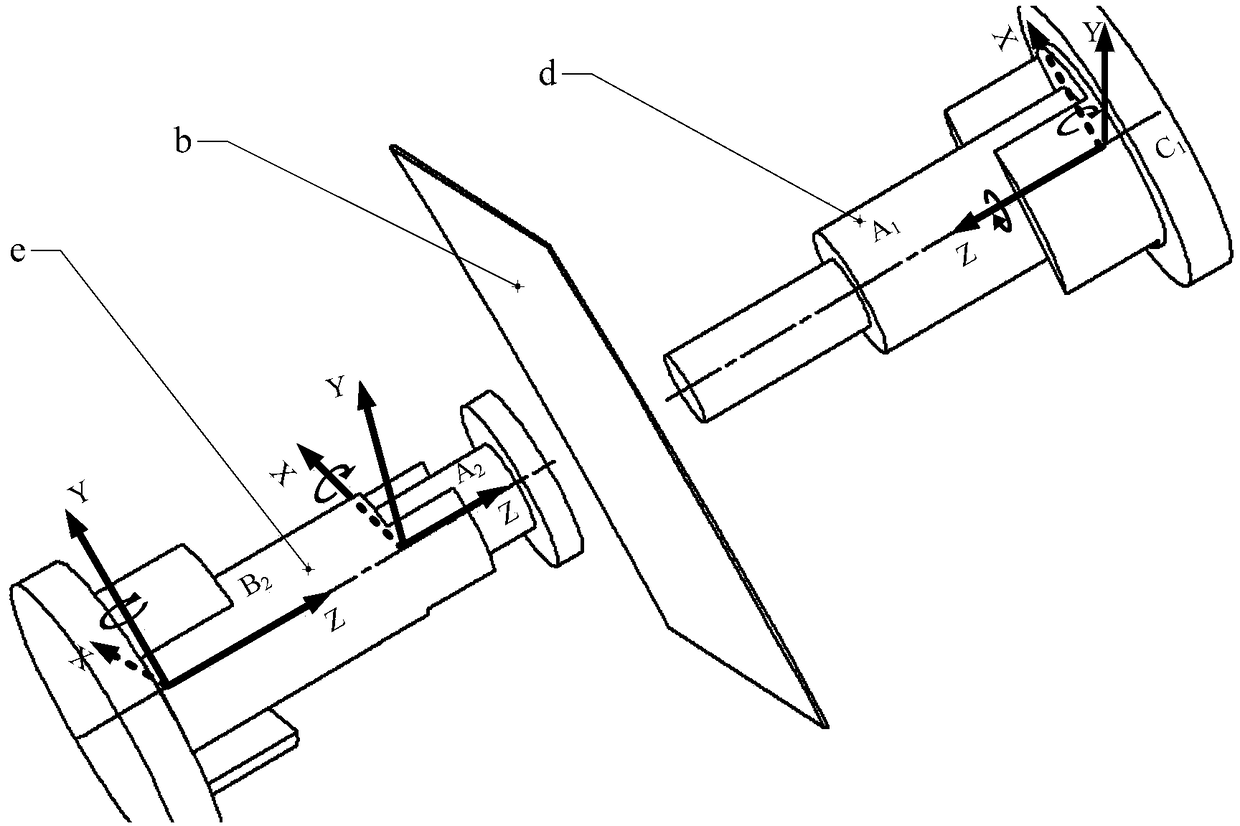

Five-shaft structure error measuring method of mirror image milling system, system and device thereof

The invention relates to five-shaft structure error measuring method of a mirror image milling system, a system and a device thereof. The method comprises the steps of constructing a geometric model,based on a multi-body system kinetic theory, constructing a geometric model of spatial positioning errors of a cutter central point P0 of a mill image milling processing area and a supporting centralpoint P1 of a supporting head in a motion process; acquiring pose data, through a displacement measuring device on a processing head of the mirror image milling system, acquiring pose (position and attitude) data of P0 and P1 in a preset measuring path; calculating a dynamic error, performing calculation processing on the acquired pose data of the P0 and P1, and obtaining a characteristic value ofthe motion error of the five-shaft structure; and performing data feedback adjustment, and based on the characteristic value of the five-shaft structure, performing feedback of the error compensationdata of the five-shaft structure to the control system of the image mirror milling system, making adjustment of the five-shaft structure according to error compensation data by the control system, sothat the supporting head performs synchronous movement with the processing head.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

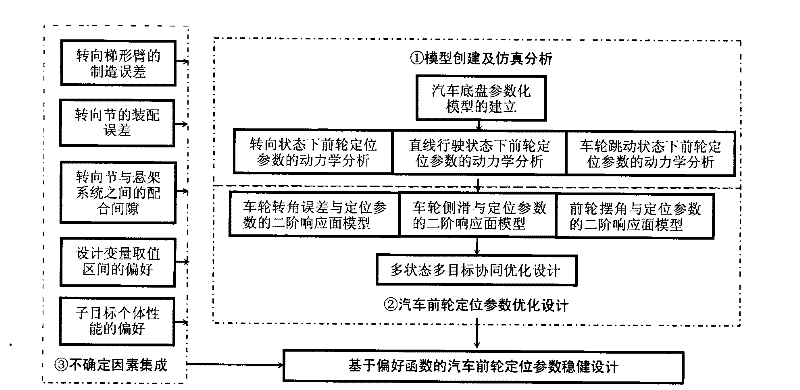

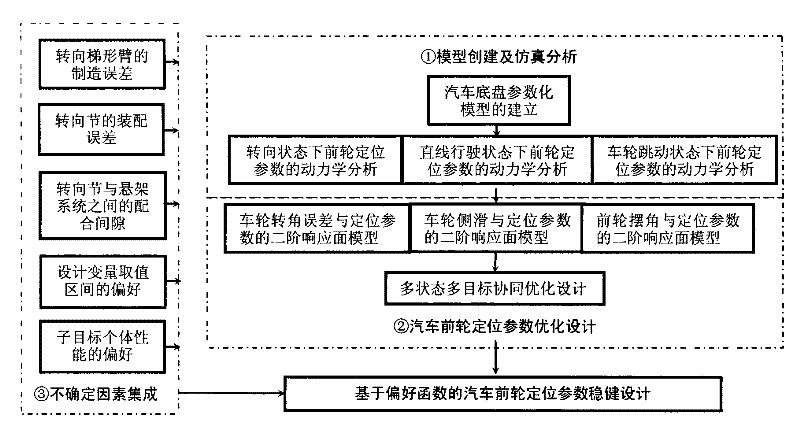

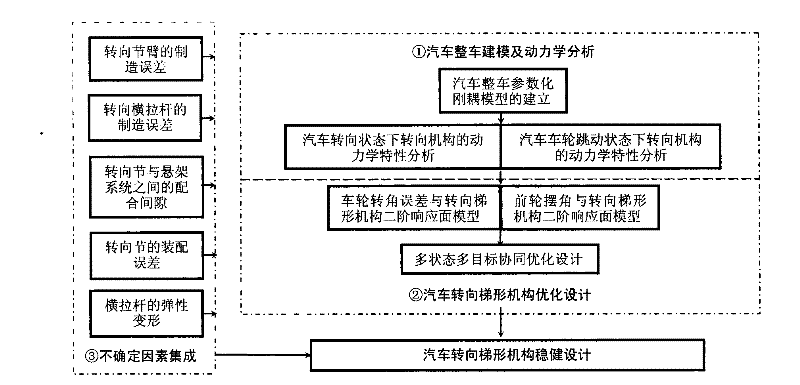

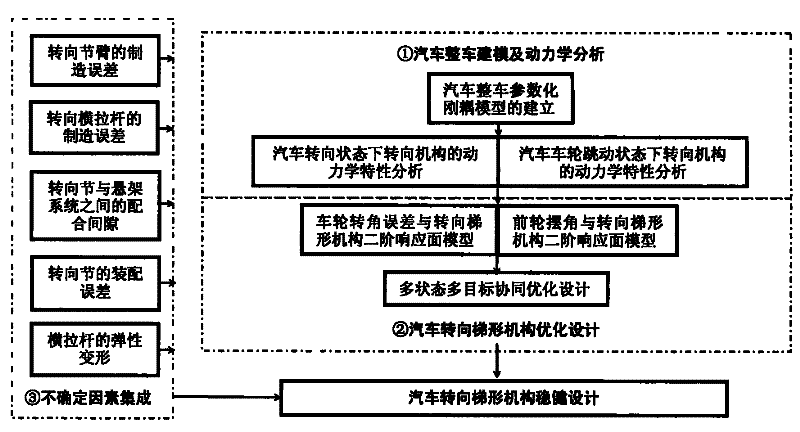

Robust design method for positional parameters of front vehicle wheels

InactiveCN102402636AImprove the design levelImprove handling stabilitySpecial data processing applicationsCamber angleNumerical range

The invention discloses a robust design method for positional parameters of front vehicle wheels. In the method, a robust design model for the positional parameters (a king pin inclination angle, a king pin caster angle, a front wheel camber angle, and a front wheel toe-in) of the front vehicle wheels is established by taking a multibody system dynamics theory as a basis, comprehensively considering the synergic relationship among a steering system, a drive system and a suspension system, analyzing the dynamics characteristics of the positional parameters of the front wheels under motor steering, straight running, wheel hopping and other various running states, integrating uncertain factors, such as the manufacturing errors of a steering trapezoidal arm, the assembling errors of a steering knuckle, a fit clearance between a steering mechanism and the suspension system, a designed variable numerical range, the preferences of all subgoal performances and the like, and taking the minimum angle turning error, the minimum sideslip during straight running and the minimum front wheel pivot angle during wheel hopping in a steering process as optimization goals. The robust design method disclosed by the invention has the advantage of improving the design level for the positional parameters of the front vehicle wheels in China, and can be widely applied to design of various types of vehicles.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

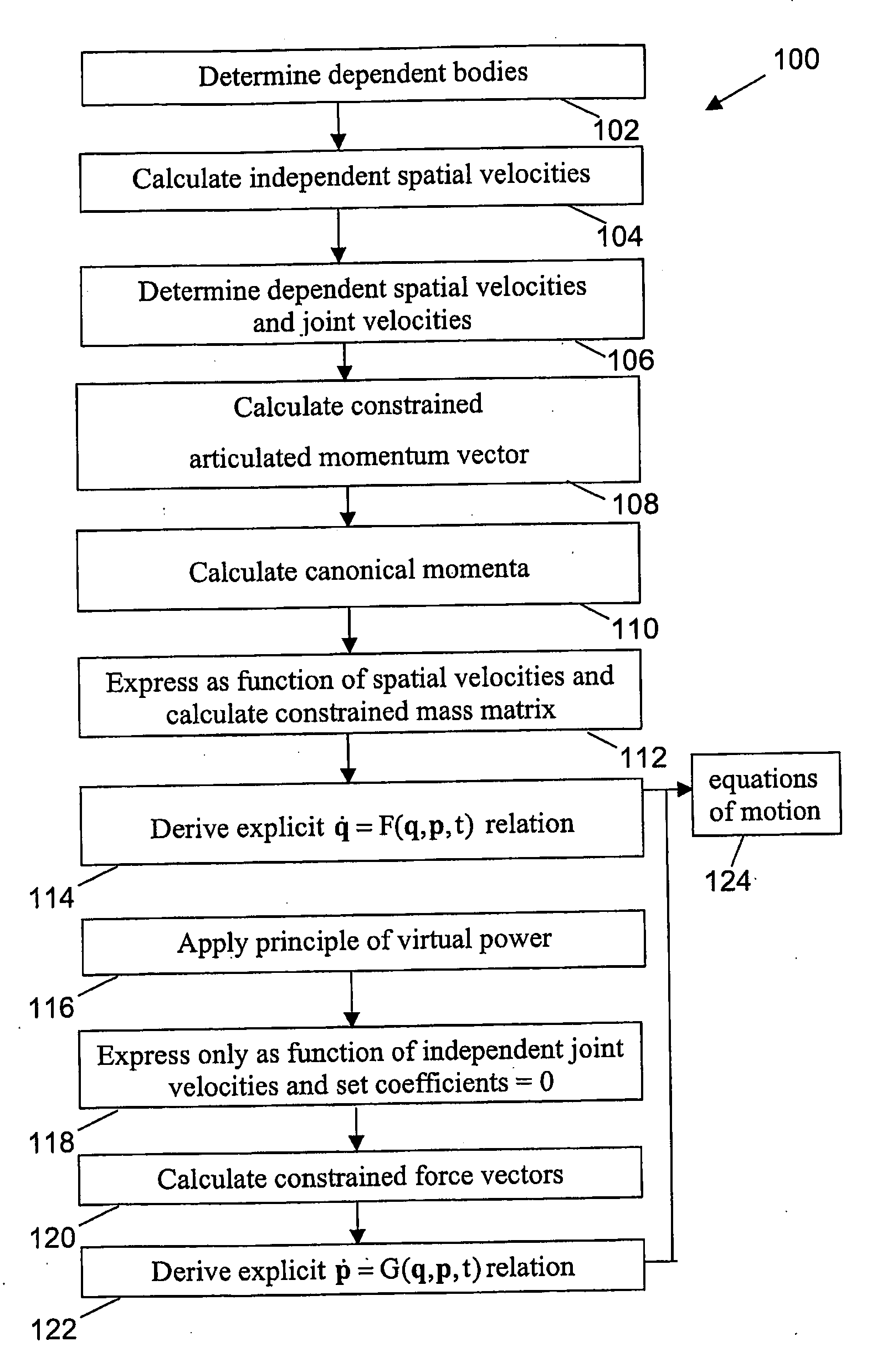

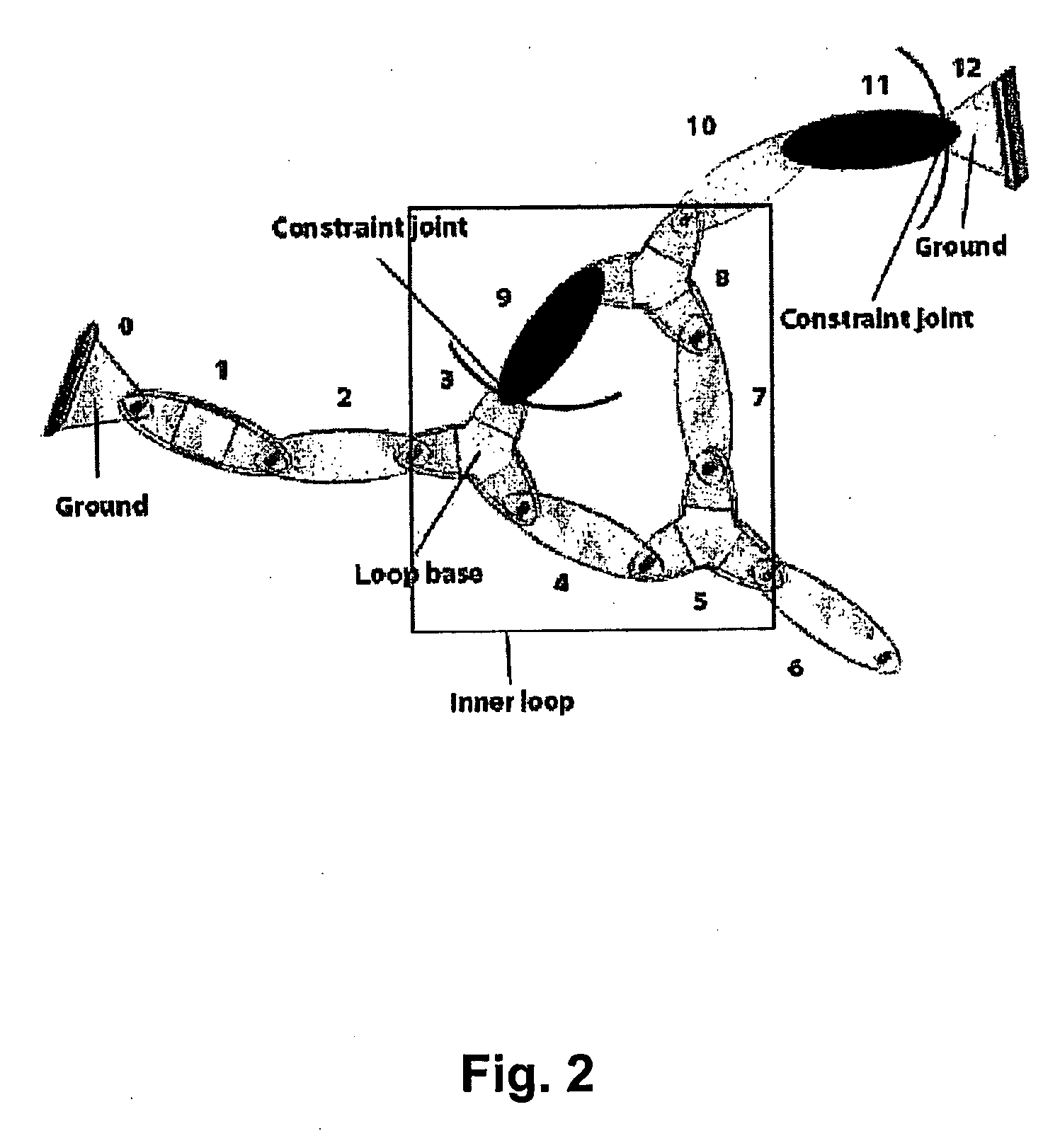

System and method for simulating motion of a multibody system

InactiveUS20090228244A1Great evolutionAvoid excessive errorComputation using non-denominational number representationDesign optimisation/simulationMomentumForward dynamic

The present invention relates to a method and system for describing the motion of a closed-loop multibody mechanism. In this case, equations of motion need to be obtained for constrained multibody systems. The invention is based on a forward dynamics formulation resulting in a recursive Hamiltonian formulation for closed-loop systems using generalised co-ordinates and conjugated canonical momenta. The method allows to limit the number of arithmetical operations necessary to obtain the equations of motion with a good evolution of the constraints violation errors. Calculations can be performed based on constrained articulated momentum vectors.

Owner:VRIJE UNIV BRUSSEL

Steady design method for vehicle steering trapezoid mechanism

InactiveCN102393861AImprove handling stabilityReduce abnormal wearSpecial data processing applicationsSteering angleMultibody system

The invention relates to a steady design method for a vehicle steering trapezoid mechanism. The method comprises the following steps of: based on multi-body system dynamics theory, applying methods, such as a virtual model machine technology, multi-body dynamics, elasticity mechanics, steady design and the like, comprehensively considering a synergic relationship between a steering system and a suspension system, analyzing dynamics characteristics of the steering trapezoid mechanism under operating conditions, such as vehicle steering, vehicle wheel jumping and the like, and integrating uncertain factors impacting on a steering angle and a steering mechanism stress, such as a manufacturing error of a steering tie rod, a manufacturing error of a steering knuckle arm, an assembling error of a steering node, fit clearance between the steering mechanism and the suspension system, elastic deformation of the tie rod, and the like. An optimizing aim that corner error during the steering process is minimum, and a swing angle for a front wheel during vehicle jumping is minimum can be achieved, and a steady design model for the vehicle steering trapezoid mechanism is built. The steady design method has the advantages that: a design level of vehicle front wheel parameters can be improved, and the method can be widely applied to vehicle design with various types.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

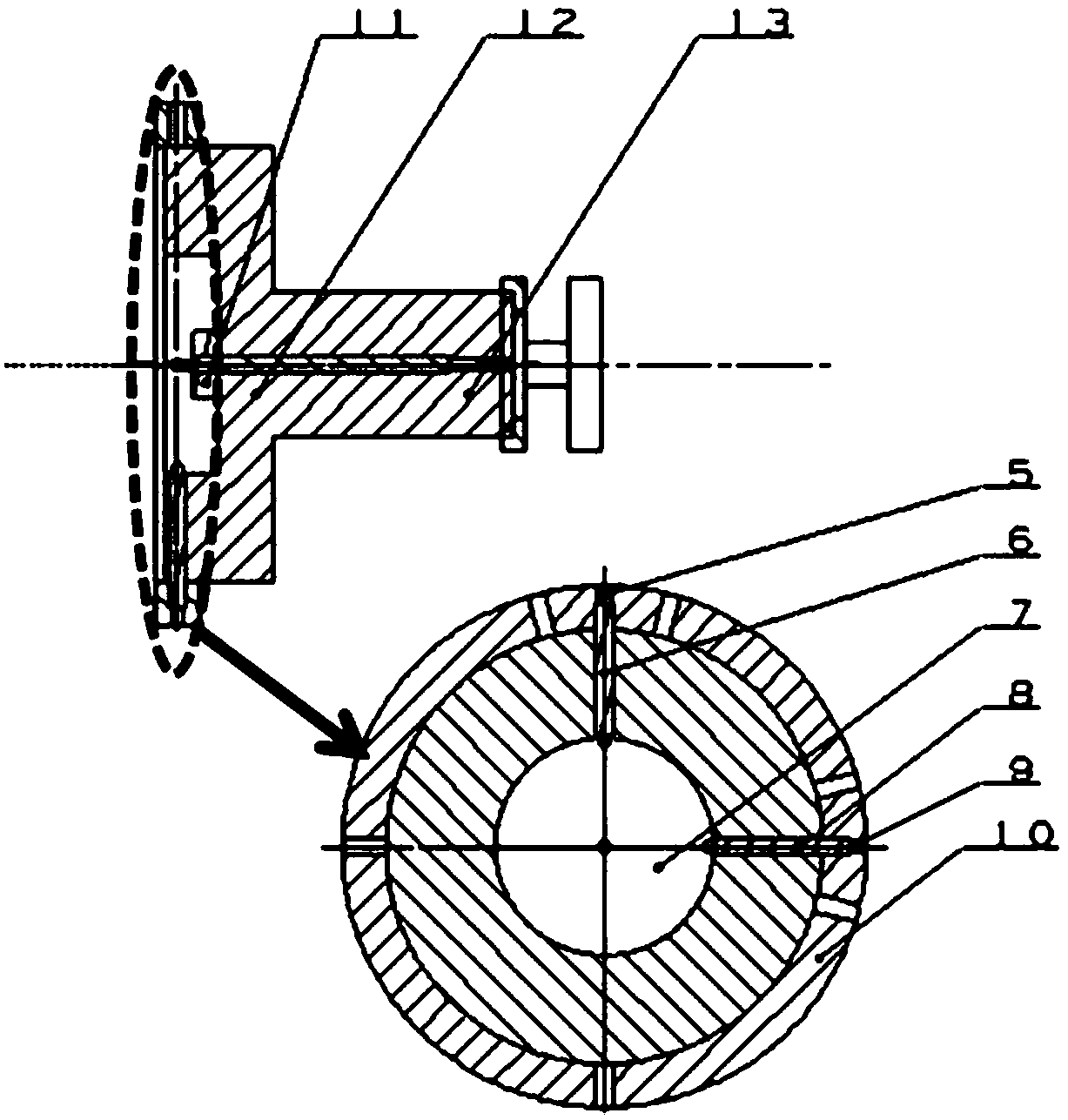

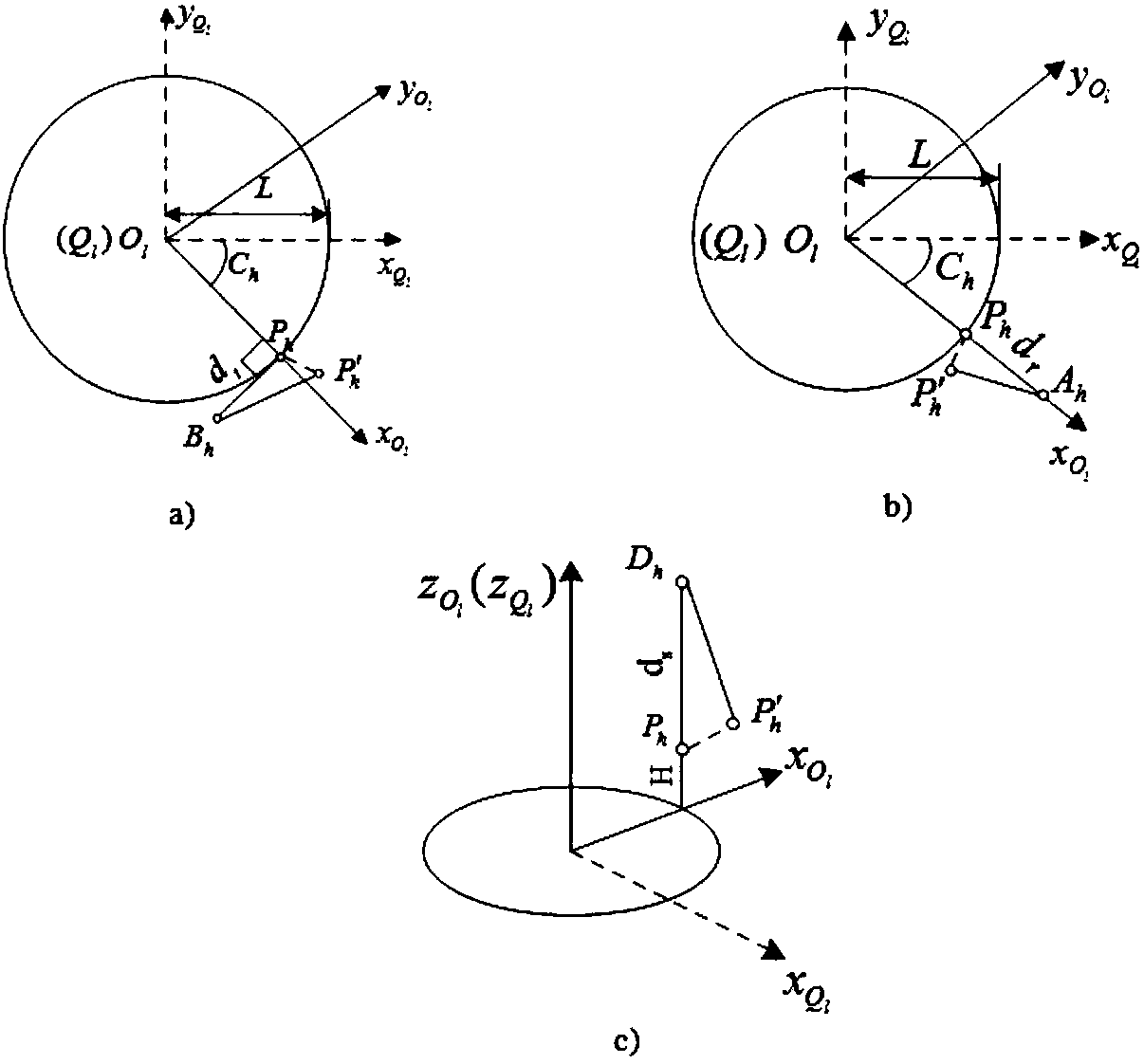

Double-ball-bar-based geometric error recognition method for five-axis machine tool front sway

InactiveCN109375580AAvoid couplingImprove accuracyProgramme controlComputer controlRelative displacementGeometric error

The invention discloses a double-ball-bar-based geometric error recognition method for a five-axis machine tool front sway. On the basis of motion conditions of an inclination head of a five-axis machine tool, three kinds of measurement modes of an X direction, a Y direction and a Z direction are put forward respectively; relative displacement equations of two DBB balls under three kinds of measurement modes are established respectively based on a HTM and a multibody system (MBS) theory; and a geometric error parameter of the inclination head is fully recognized. According to the invention, all error terms of the front sway are identified and the coupling phenomenon among parameters is avoided. Moreover, the identification precision and the universality are high; and the reference is provided for error recognition of the five-axis machine tool front sway.

Owner:BEIJING UNIV OF TECH

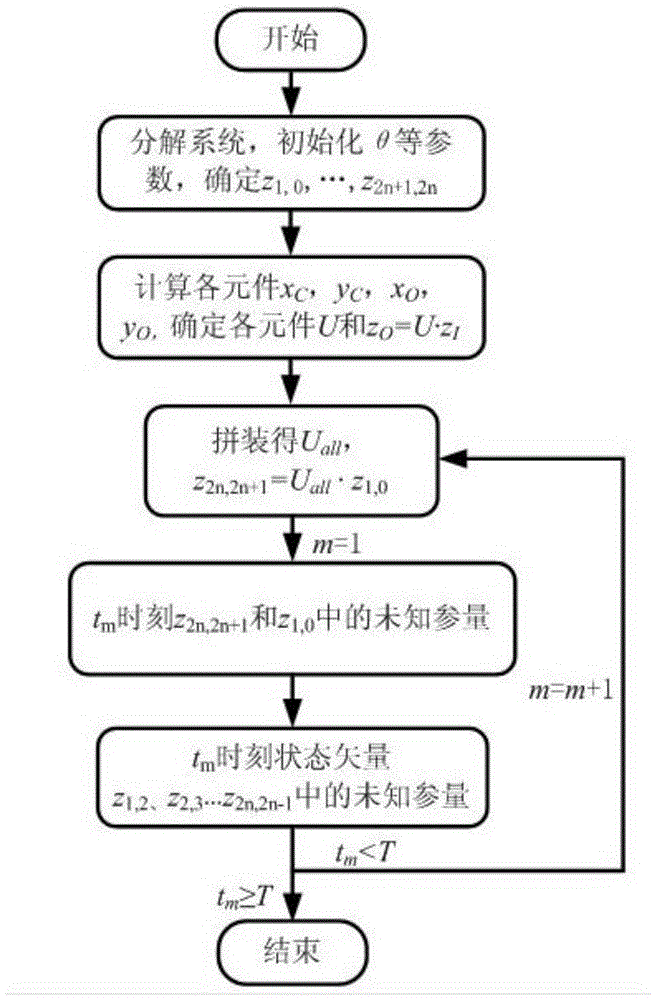

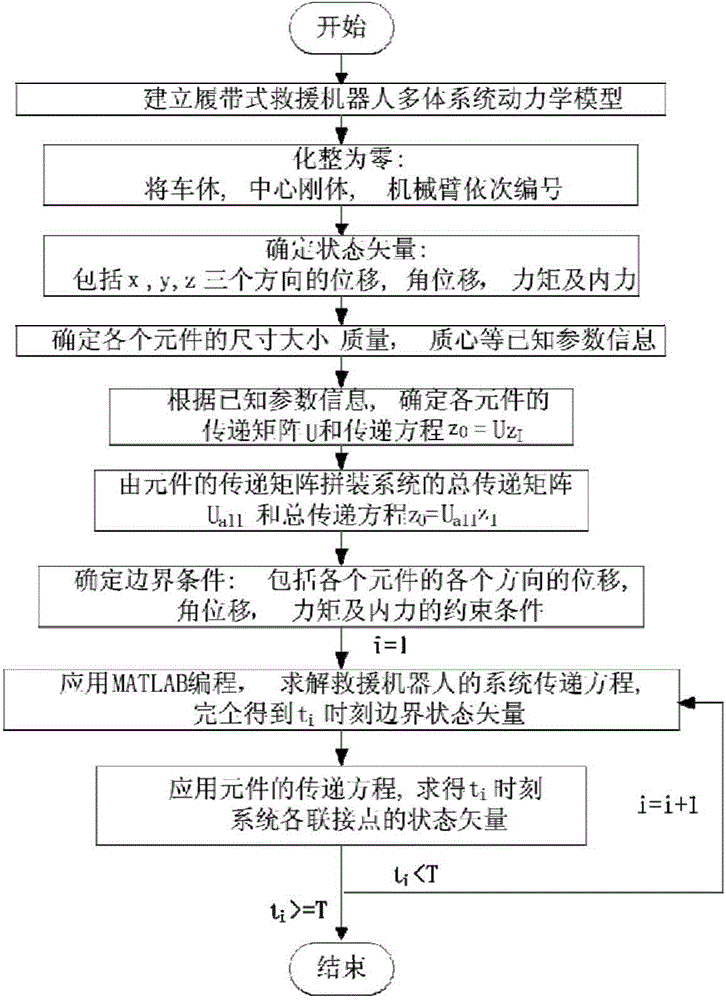

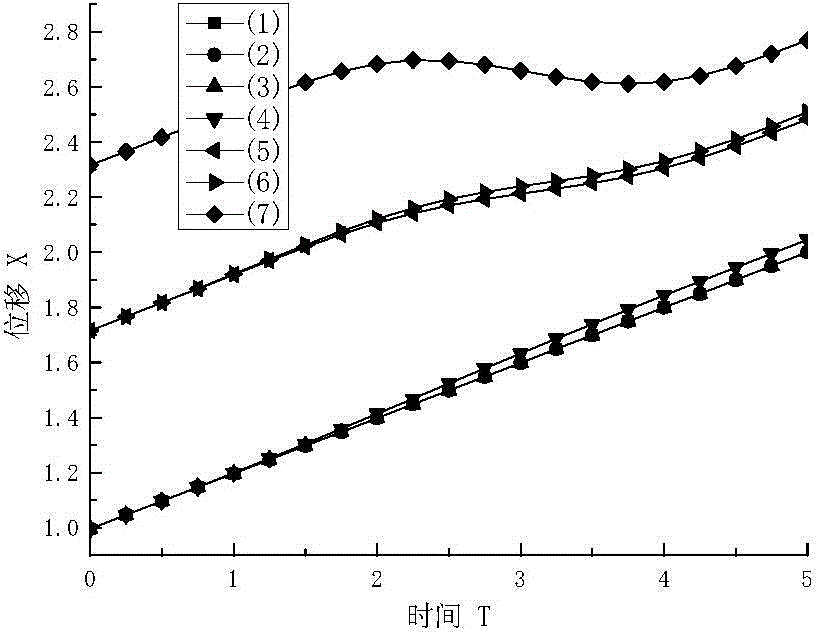

Robot dynamics modeling method based on multibody system discrete time transmission matrix method

InactiveCN104793497AOvercoming control difficultiesEasy to implementAdaptive controlMatrix methodDynamic models

The invention discloses a uniform dynamics modeling method based on a mmultibody system discrete time transmission matrix method and for a crawler-type moving robot. The method mainly includes: building a multibody system dynamics model for breaking up the whole into parts, and determining a state vector; determining a transmission matrix U and a transmission equation zO=UzI for each element; assembling the transmission matrixes of the elements to form a general transmission matrix Uall and a general transmission equation Uallzall=0 of a system; according to boundary conditions, solving the system transmission equation to acquire a boundary state vector of a moment ti; applying the transmission equations of the elements to solve a state vector of each connecting point of the system at the moment ti. By the method, the circumstance that errors caused by coupling and mutual influence are neglected during modeling of a moving platform and a mechanical arm when moving robots are studied in the past is avoided, the method is high in theoretical property, clear in thinking and easy in realization of programming, and the objective of accurate control on the moving robots can be achieved.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

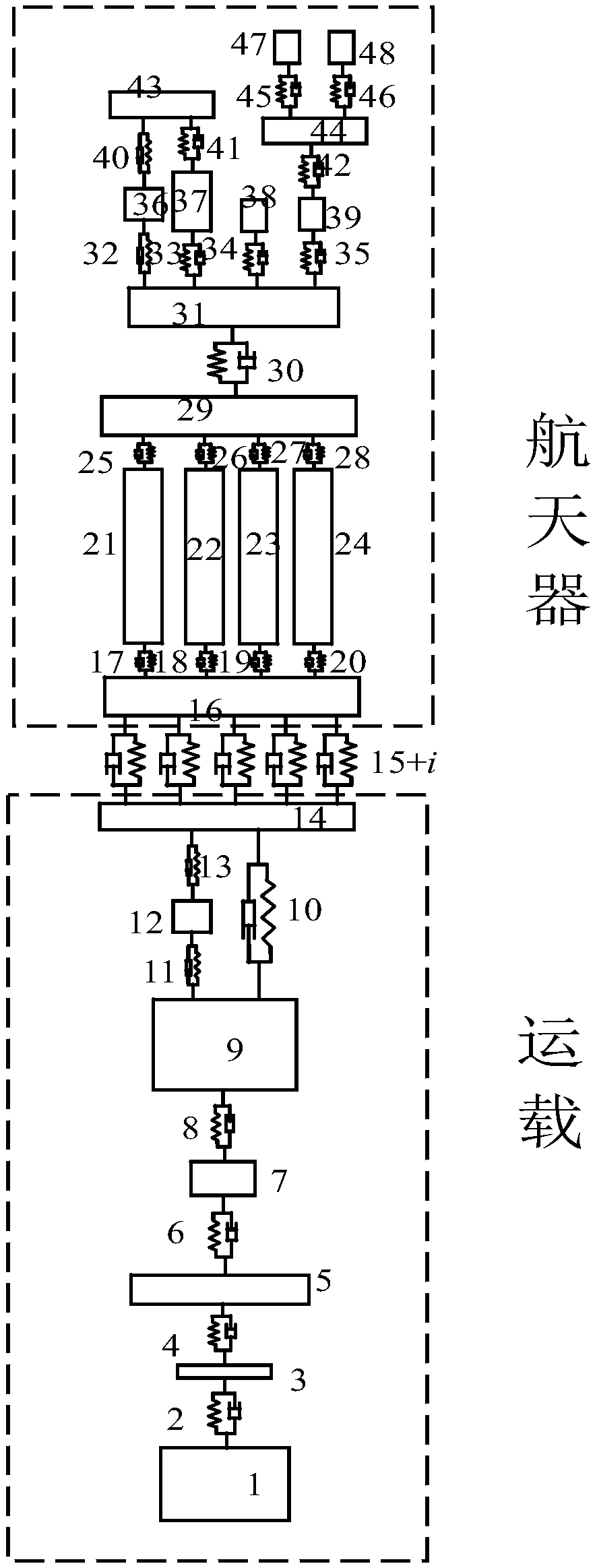

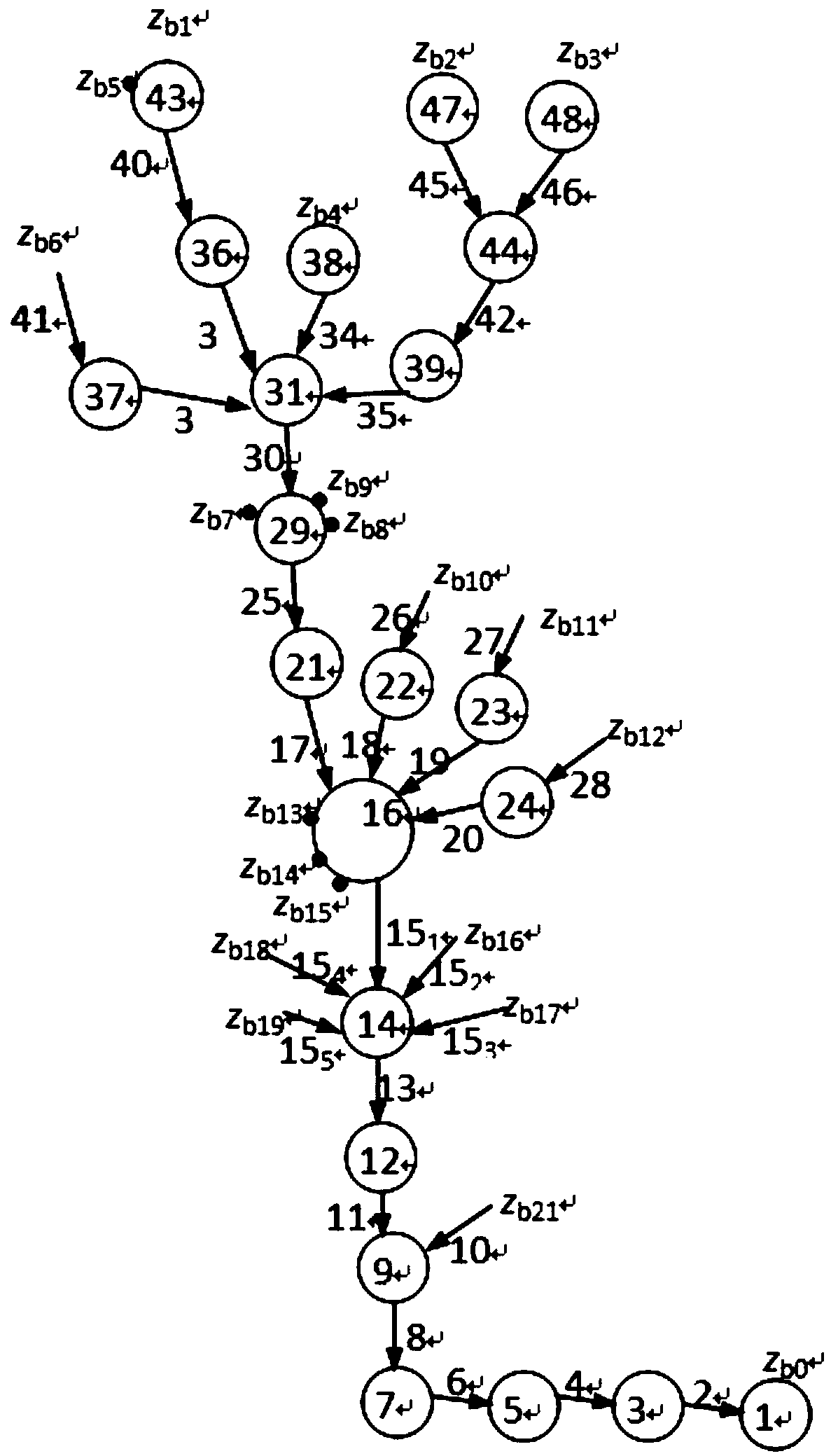

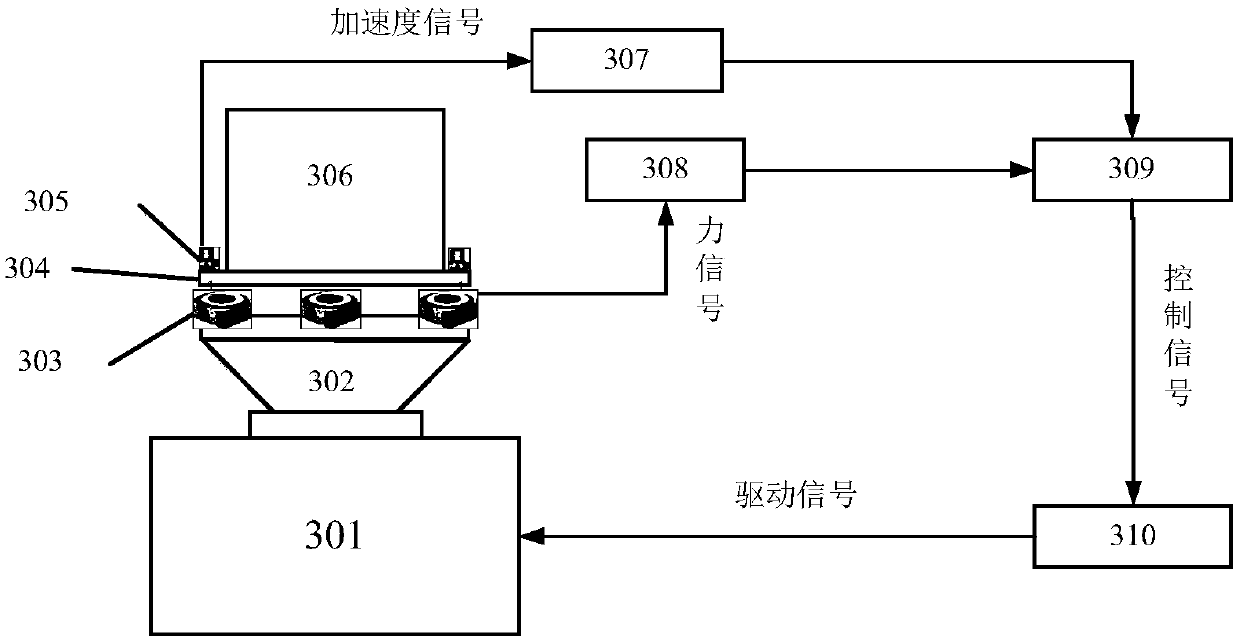

Rocket-spacecraft coupling multibody system dynamics calculation test method and system

ActiveCN109656149AFast and accurate coupled dynamic responseSimulate the realSimulator controlEngineeringRocket

The invention provides a rocket-spacecraft coupling multibody system dynamics calculation test method and system. The method comprises steps that physical mechanics model transformation and topological structure construction are performed; transfer matrixes and transfer equations of various components are established, a topological structure and supplementary conditions are utilized, a total transfer matrix and a total transfer equation of the system are obtained through assembling, the system is decoupled through proving orthogonality analysis, the modal analysis theory is utilized to analyzerocket-spacecraft coupling dynamics characteristics, and inherent characteristics of the system are obtained; according to the inherent characteristics of the system, rocket-spacecraft coupling dynamics response calculation is performed; through simulation calculation, the rocket-spacecraft connected interface force condition is obtained, the force spectrum input conditions of force limit controlare obtained, and the force limit test is performed. The method is advantaged in that the rocket-spacecraft coupling dynamics response is quickly and accurately obtained, the rocket-spacecraft interface force spectrum is obtained, the input conditions of the force limit vibration test is obtained, and the force limit vibration test can be quickly and accurately verified.

Owner:SHANGHAI INST OF SATELLITE EQUIP

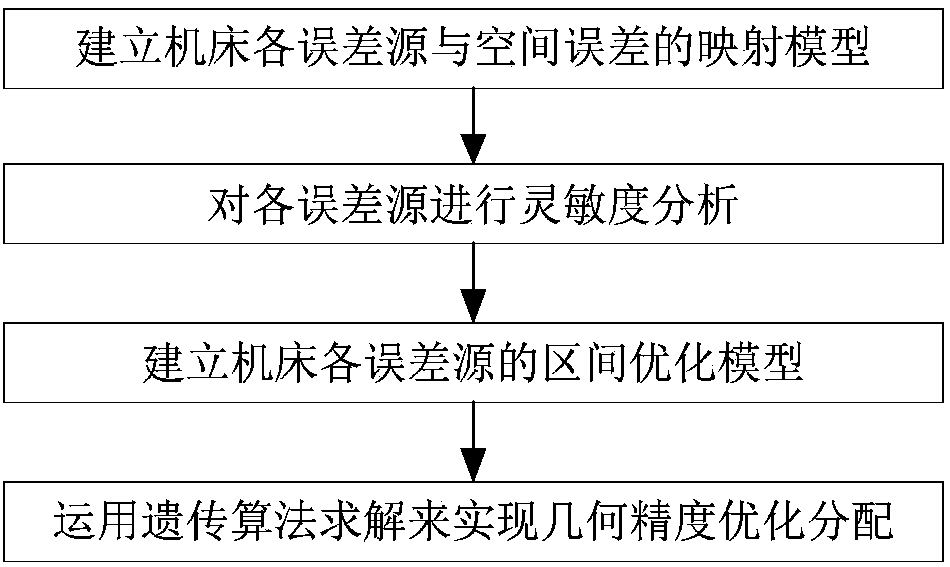

Interval theory-based geometric precision optimization allocation method for precision horizontal machining center

InactiveCN107368637AImprove production and assembly efficiencyReduce manufacturing costGeometric CADSpecial data processing applicationsGeometric errorKinematic theory

The invention discloses an interval theory-based geometric precision optimization allocation method for a precision horizontal machining center. The method comprises the following steps of (1) based on a multi-body system kinematics theory, building a mapping model between geometric errors and space errors of a machine tool; (2) based on an interval theory, performing sensitivity analysis on error sources; (3) based on the interval theory, building an interval optimization allocation model; and (4) based on a genetic algorithm, performing solving by applying MATLAB software to realize geometric precision optimization allocation. According to the method, the error sources difficult to realize are relaxed to a maximum feasible interval, so that the production cost is greatly reduced and the production and assembly efficiency of the machine tool is improved.

Owner:TIANJIN UNIV

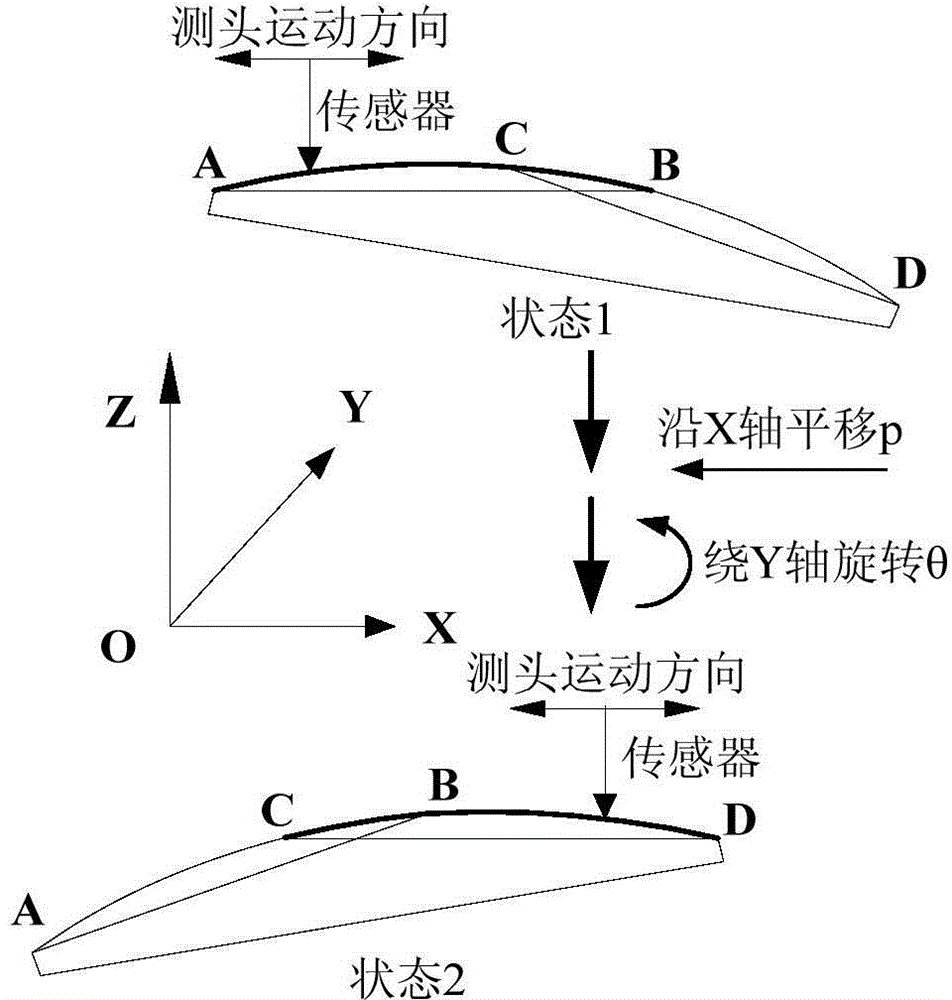

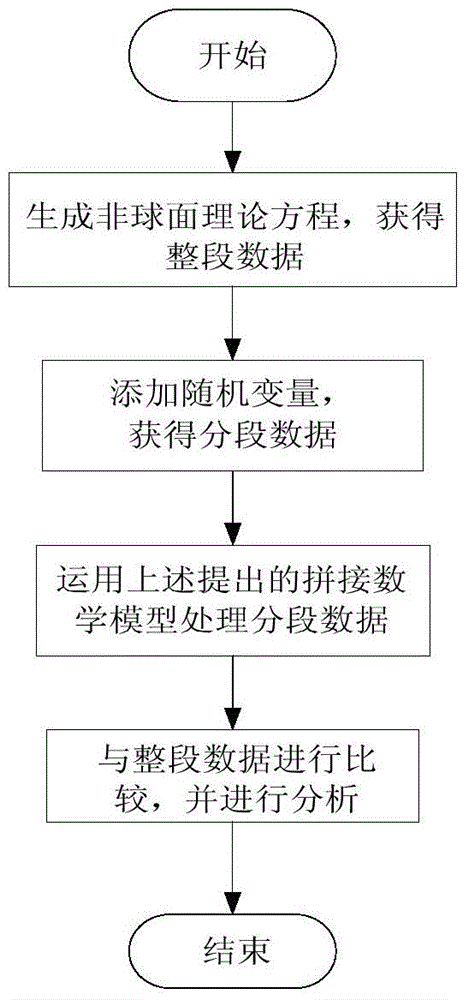

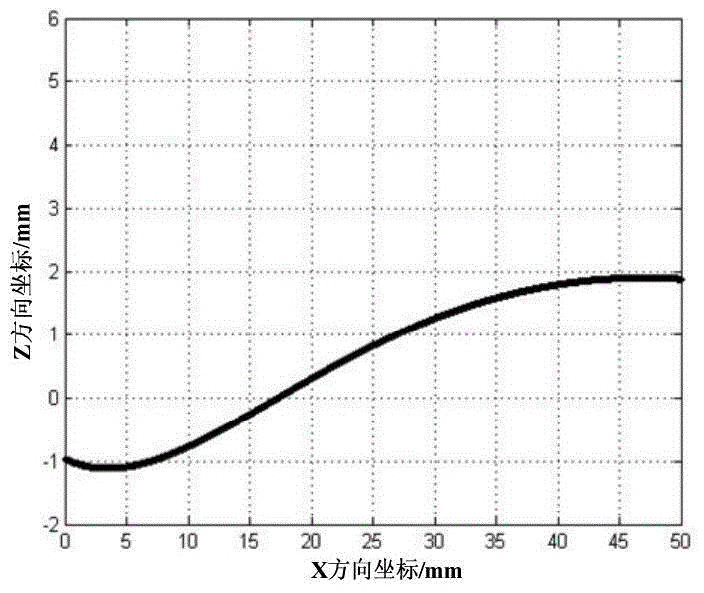

Splicing measurement method for two sections of profiles of large-caliber optical aspheric element

The invention relates to non-optical spherical elements, in particular to a splicing measurement method for two sections of profiles of a large-caliber optical aspheric element. The splicing measurement method includes providing a method of aligning data points of an overlapped area on the basis of a principle that radius of curvature is unchanged; building a preliminary optimized mathematic model for twp-section surface figure profile splicing according to a multibody system kinetic theory, a slope difference value and an inversion method; according to a simulation result of the preliminary splicing mathematic model, performing linear least square fitting on preliminary splicing errors, removing accumulated errors, and providing a final two-section splicing optimized algorithm. Experiments in which a Taylor Hobson contourgraph and an auxiliary measuring clamp are utilized to measure planar optical elements of 150mm and data processing by using the splicing optimized algorithm are performed, and results of the experiments show that maximum standard deviation of the splicing errors is 0.868 micrometer, and high-accuracy surface figure detection needs of optical elements at a grinding stage can be met.

Owner:XIAMEN UNIV

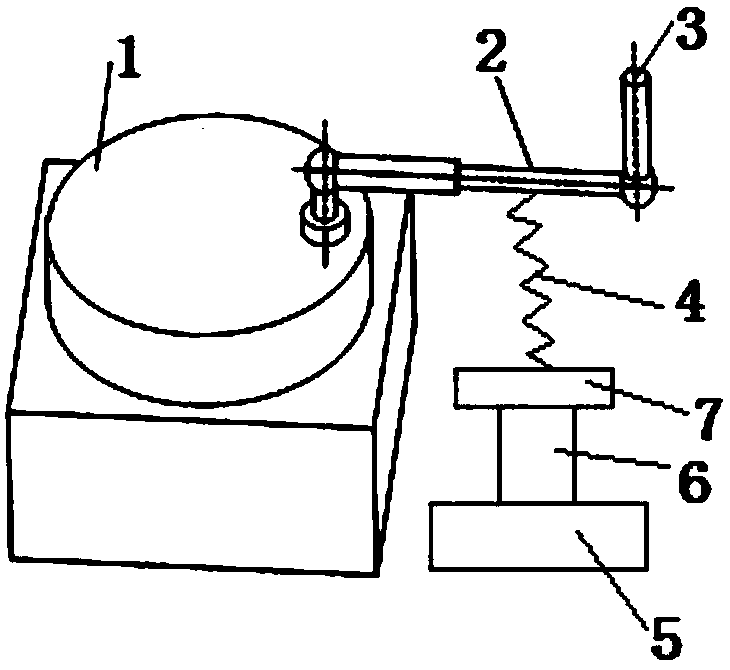

Multi-axis numerical control machine tool C-axis geometrical error measuring system and parameter identification method

PendingCN107066721ARealize identificationAvoid couplingGeometric CADSpecial data processing applicationsNumerical controlMultibody system

The invention relates to a multi-axis numerical control machine tool C-axis geometrical error measuring system and a parameter identification method. A motion equation with geometrical error and a motion equation under an ideal state are established under radial, tangential and axial three linkage modes by aiming at the structure and the characteristics of the multi-axis numerical control machine tool C-axis and by using a multibody system theory according to the working principle of a ball bar instrument, the two-end coordinates of the ball bar instrument are expressed into the same coordinate system separately through the variable quantity of the two-end positions of the ball bar instrument, and the actual distance between the two points is evaluated, so that the relation between a theoretical model and an actual measurement value is established and identification of eight geometrical error parameters of the C axis is realized. All the error items of the rotary C axis are identified, the coupling phenomenon existing in the geometrical error parameters is solved, accuracy and rapidness are realized, the identification precision is high, and important theoretical significance and practical significance in realizing the rest rotating shafts of the multi-axis numerical control machine tool are achieved.

Owner:BEIJING UNIV OF TECH

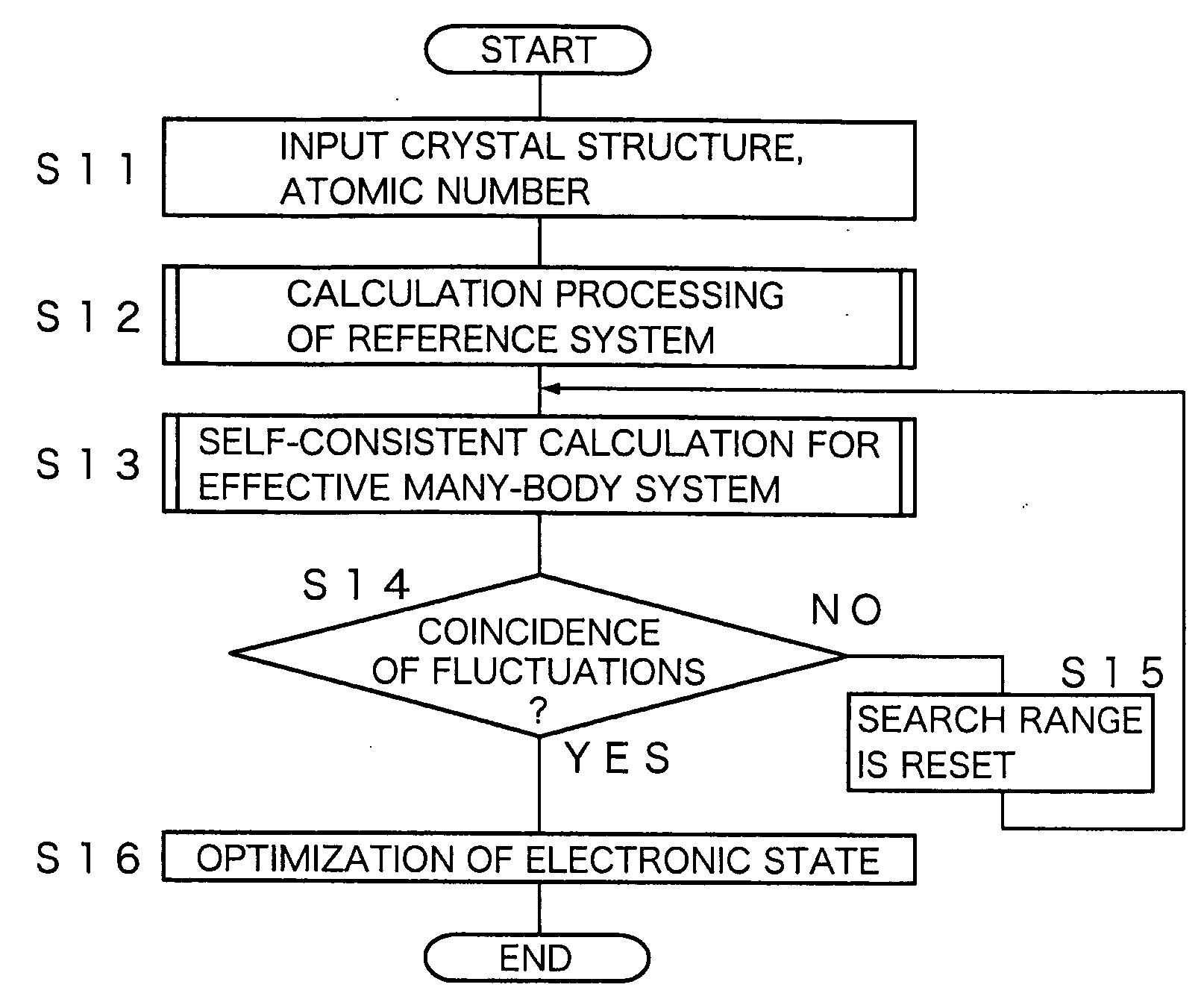

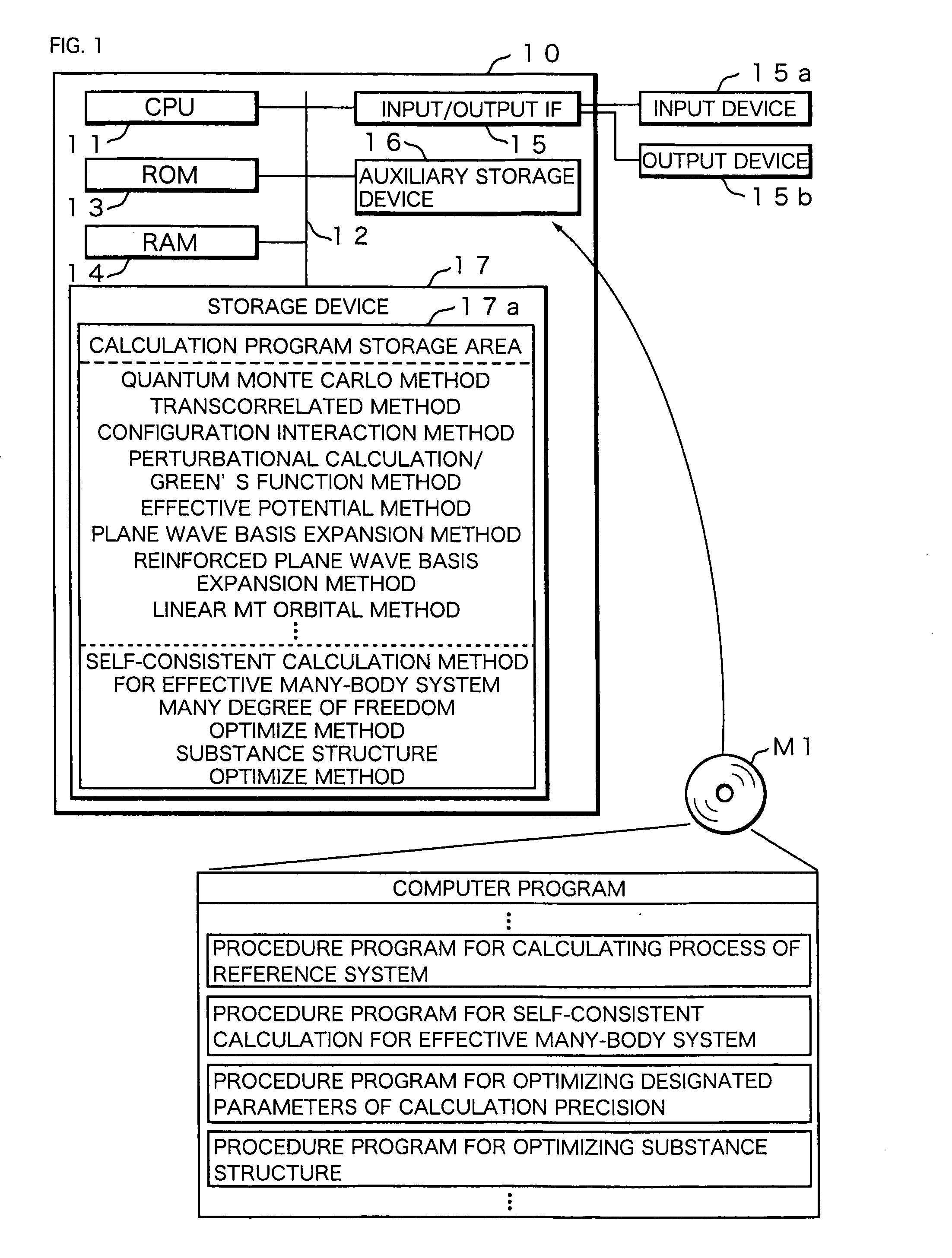

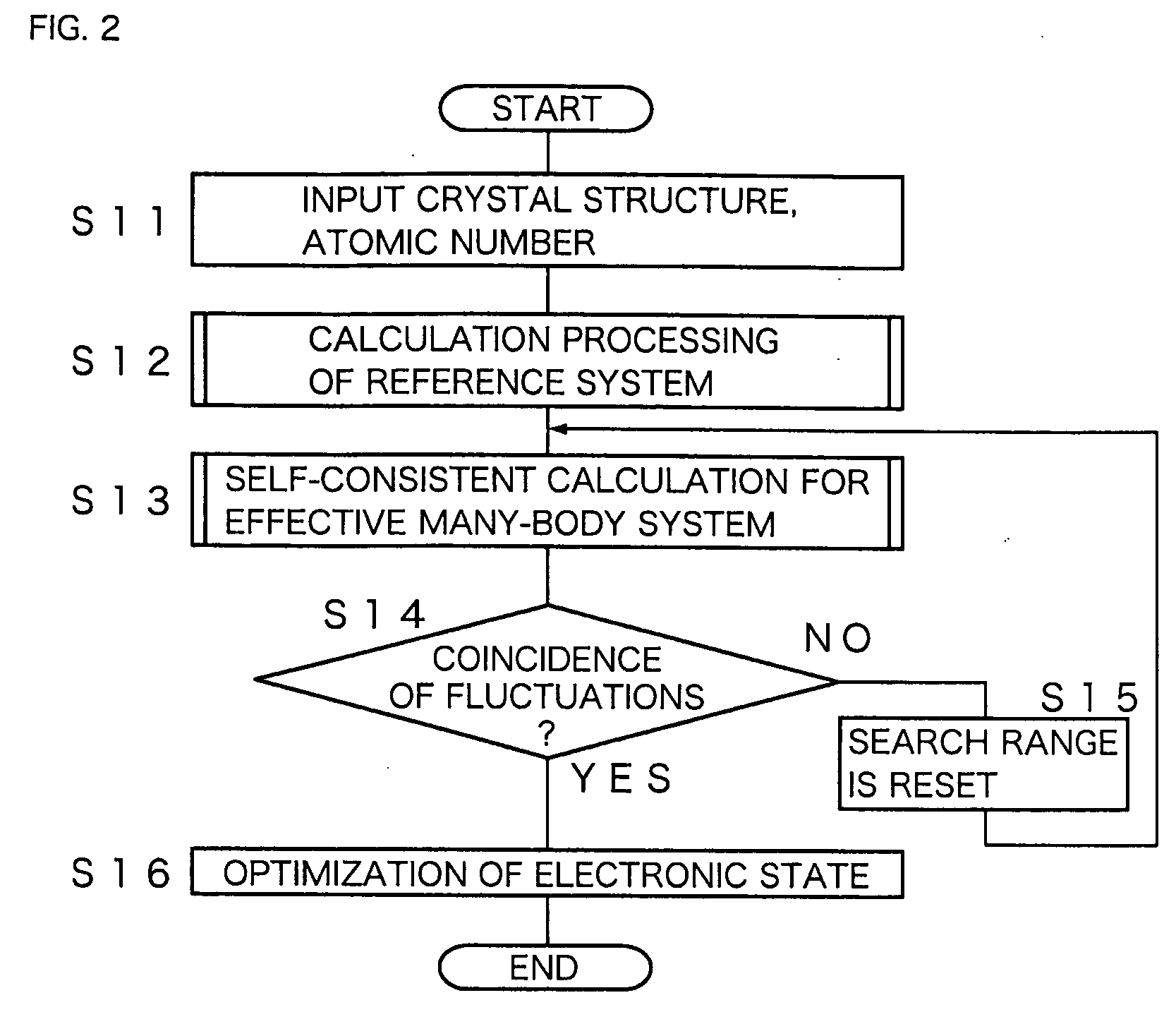

Electronic State Calculation Method, Electronic State Calculation Device, Computer Program, and Recording Medium

ActiveUS20090093973A1Guaranteed accuracyAnalogue computers for electric apparatusComputation using non-denominational number representationElectronic statesMultibody system

By receiving input of a crystal structure and atom numbers, and specifying an atom group that can generate fluctuations from an electronic state calculation of a normal Kohn-Sham theory, an electronic state calculation device calculates a reference system. Next, based on an extended Kohn-Sham theory, the electronic state calculation device performs self-consistent calculation for an effective many-body system, then determines whether or not density fluctuations obtained for the reference system and density fluctuations obtained by the self-consistent calculation coincide with each other, and in a case of coincidence, acquires parameters of an exchange correlation energy and a local interaction. By the acquired parameters, an effective Hamiltonian is decided, and optimization of an electronic state is performed for a known crystal structure.

Owner:OSAKA UNIV

Method for analyzing sensitivity of geometric errors of dual-rotation axes of five-axis CNC machine tool

InactiveCN110837246ASolve the identification problemEffective Geometric Error Sensitivity AnalysisProgramme controlComputer controlGeometric errorNumerical control

The invention proposes a method for analyzing sensitivity of geometric errors of dual-rotation axes of a five-axis CNC machine tool, and the method comprises the following steps of firstly constructing a mathematical model of geometric errors of the dual-rotation axes based on a multi-body system theory and a homogeneous transformation matrix; performing error parameter sampling by using a Monte Carlo method, and analyzing the sensitivity of the geometric errors of the dual-rotation axes of the CNC machine tool; finally performing sensitivity analysis on the error parameters based on the positions of the specific rotation angles of the dual-rotation axes, and calculating the first-order sensitivity and global sensitivity of each geometric error of the dual-rotation axes at this position bysetting the positions of five groups of specific rotation angles, wherein the Sobol sensitivity analysis method can be used to identify the key geometric error among the 20 geometric errors of the dual-rotation axes, and complete the identification of the geometric errors of the dual-rotation axes of the five-axis CNC machine tool. The method has the advantages of simple detection steps, convenient measurement and high identification accuracy.

Owner:TIANJIN POLYTECHNIC UNIV

Diesel engine air distribution system dynamic calculation method based on multi-body system transfer matrix

InactiveCN103034784ARealize kinetic performance calculationsEasy to set upSpecial data processing applicationsSystems researchMatrix method

The invention belongs to the field of diesel engine air distribution system researches and relates to a diesel engine air distribution system dynamic calculation method based on a multi-body system transfer matrix. The diesel engine air distribution system dynamic calculation method based on the multi-body system transfer matrix comprises the following steps of: building a cam profile Nth harmonic fitting function, selecting a state vector, a boundary condition, an initial input quantity and the like required by a multi-body system transfer matrix method, analyzing the mechanical properties of all components of an air distribution system, deducing a transfer matrix which reflects the mechanical properties, integrating all parameters to obtain a total transfer equation, solving the total transfer equation to obtain the dynamic response situation of each part, drawing the dynamic characteristic curve of each part and the like. The diesel engine air distribution system dynamic calculation method based on the multi-body system transfer matrix has the advantages that the mechanical response situations of all parts during the movement of the air distribution system can be intuitively reflected through the dynamic characteristic curves, the dynamic response results and the like of all parts, the method is suitable for air distribution systems of diesel engines with different speed types, the measuring and modeling time needed for building a three-dimensional model is greatly saved, and the obtained results are more effective than the results obtained through solution by using the traditional multi-rigid-body differential equation set.

Owner:FUZHOU UNIV

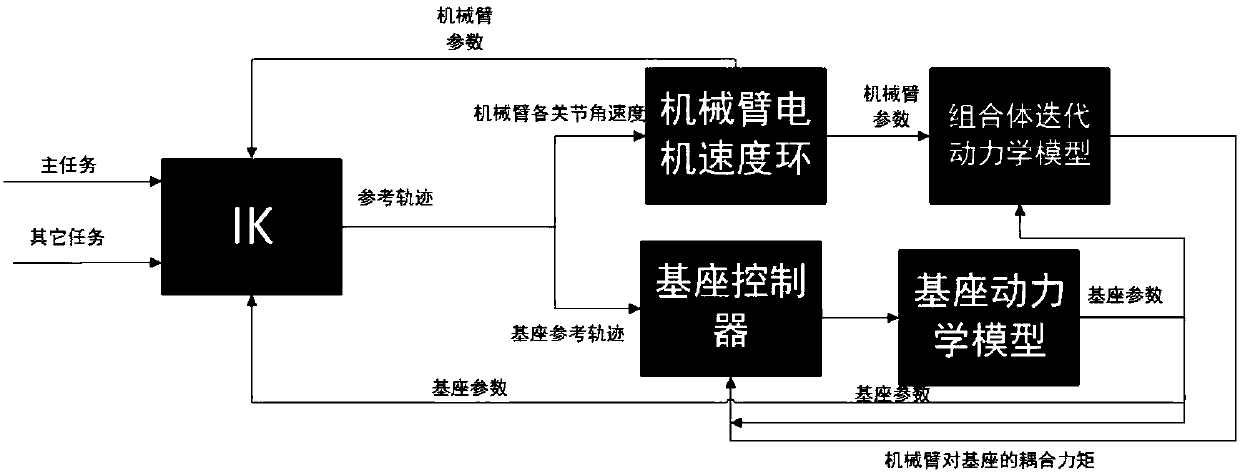

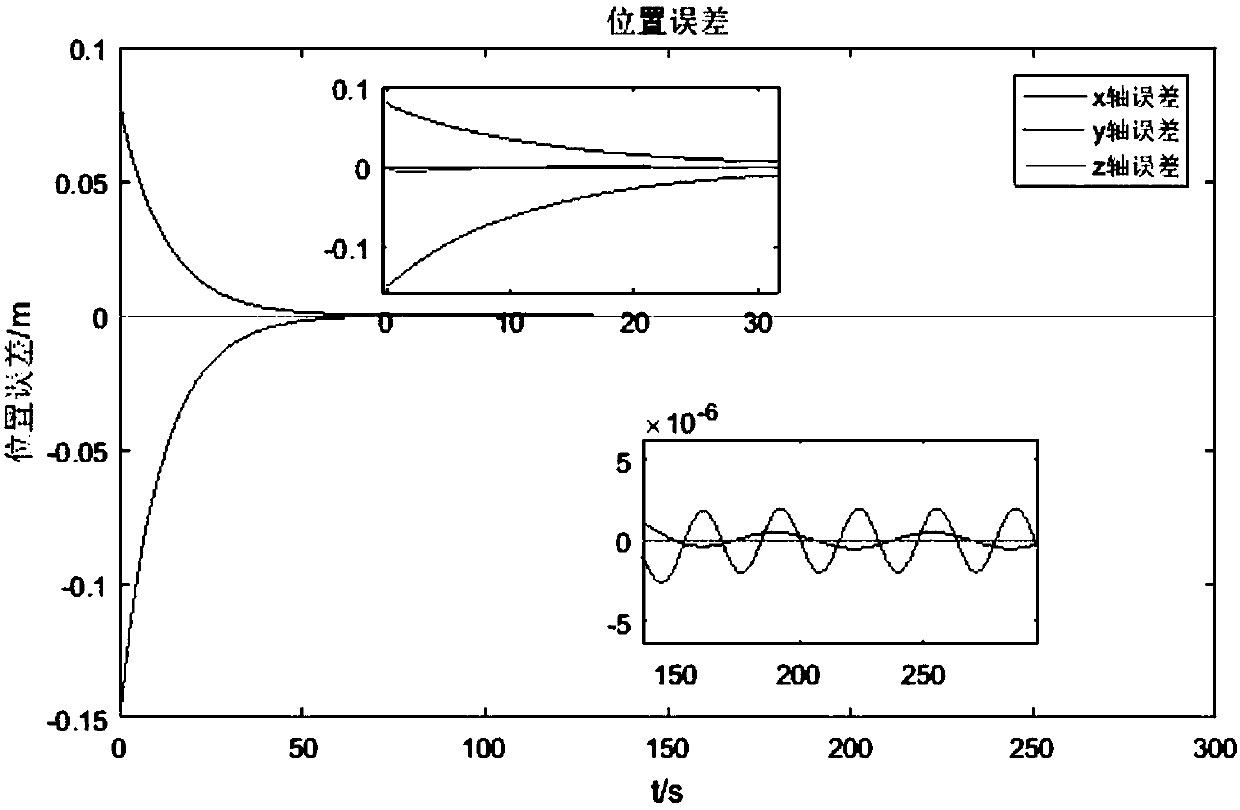

Underwater robot control method taking regard of multi-body coupling

ActiveCN107436605AStability Control PlatformImprove controlAltitude or depth controlKinematicsMultibody system

The invention discloses an underwater robot control method taking regard of multi-body coupling. The method comprises steps that 1), the multi-body system kinetics is utilized to realize control planning of reference tracks of an underwater robot base and an arm, and the reference tracks are respectively transmitted to the arm and the base in a speed signal mode; 2), the speed signal is received by a speed ring of the arm, and a position ring of the arm is formed by a kinetics control module; 3), the speed signal of the arm and base parameters are received by a combined body iteration dynamics module, and the coupling force of the arm for the base is outputted; and 4), the reference track of the base, a control error and the coupling force of the arm for the base are received by a base controller, and applied control force of the base is calculated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

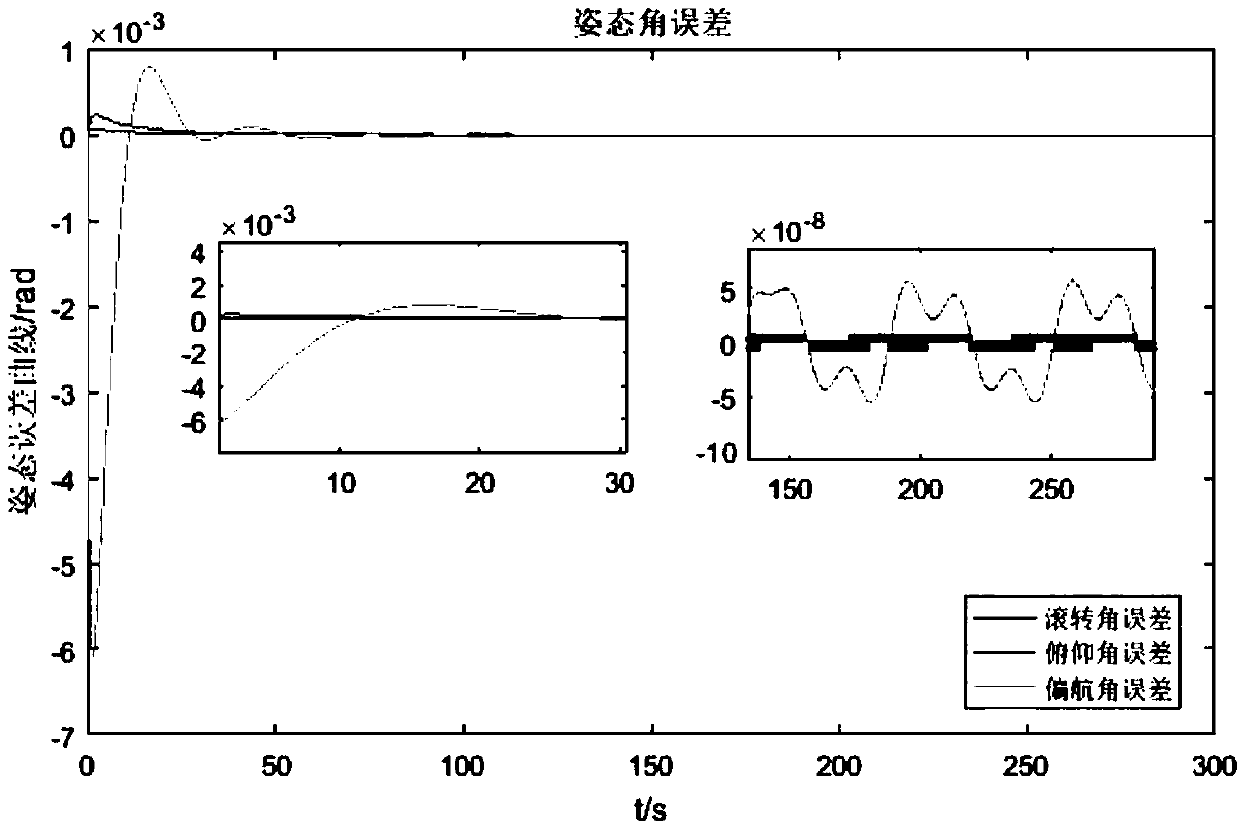

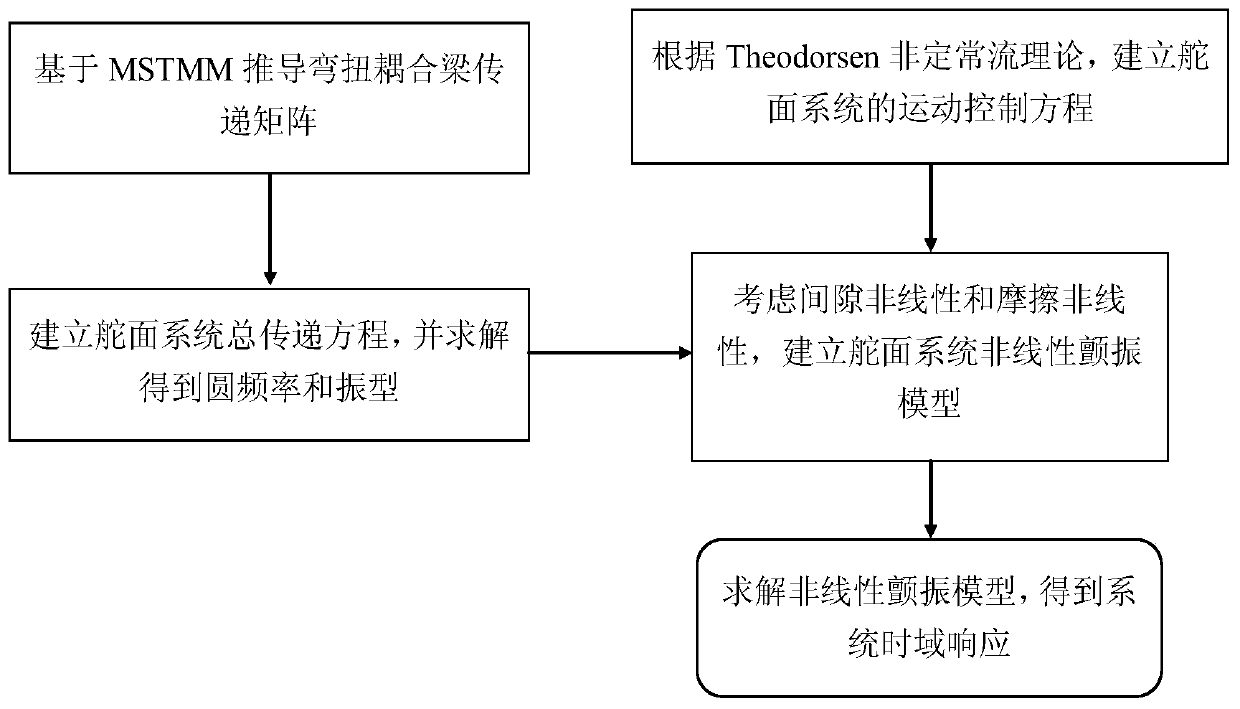

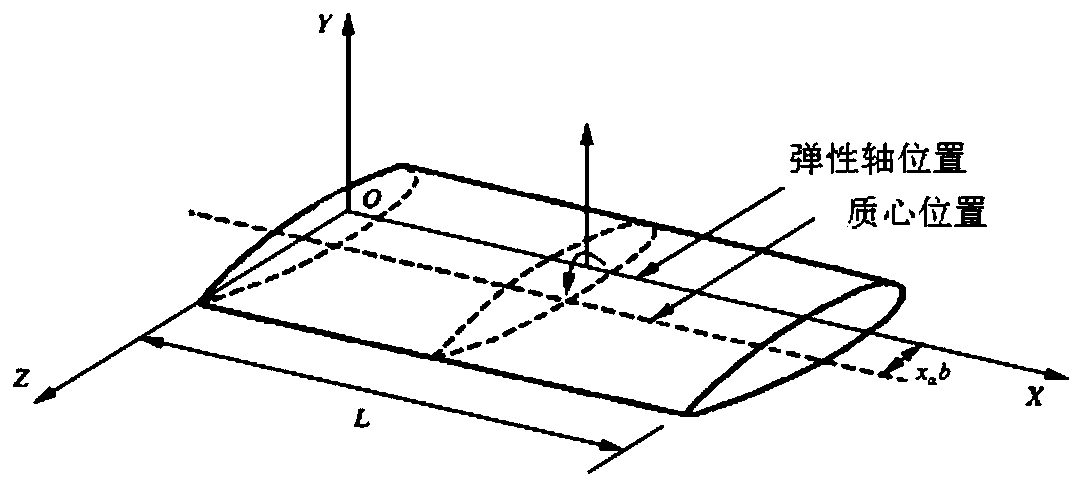

Control surface system nonlinear flutter model modeling method based on multi-body system transfer matrix method

ActiveCN110889169AMeet the needs of fast computingGeometric CADSustainable transportationKinetics equationEngineering

The invention discloses a control surface system nonlinear flutter model modeling method based on a multi-body system transfer matrix method. The control surface system nonlinear flutter model modeling method comprises the following steps: deriving a bending-torsion coupling beam transfer matrix based on the multi-body system transfer matrix method; establishing a total transfer equation of the system, and solving a circular frequency and a vibration mode; establishing a motion control equation of a control surface system by using a Theodorsen unsteady flow theory; considering gap nonlinearityand friction nonlinearity, establishing a body dynamics equation based on MSTMM, and obtaining a system nonlinear flutter model; and solving the nonlinear flutter model of the system to obtain the vibration time domain response of the control surface system. According to the method, the problem that a linear flutter calculation method cannot accurately predict the flutter response of the nonlinear system is solved, and the nonlinear flutter response of the control surface system is rapidly solved.

Owner:YANGZHOU UNIV

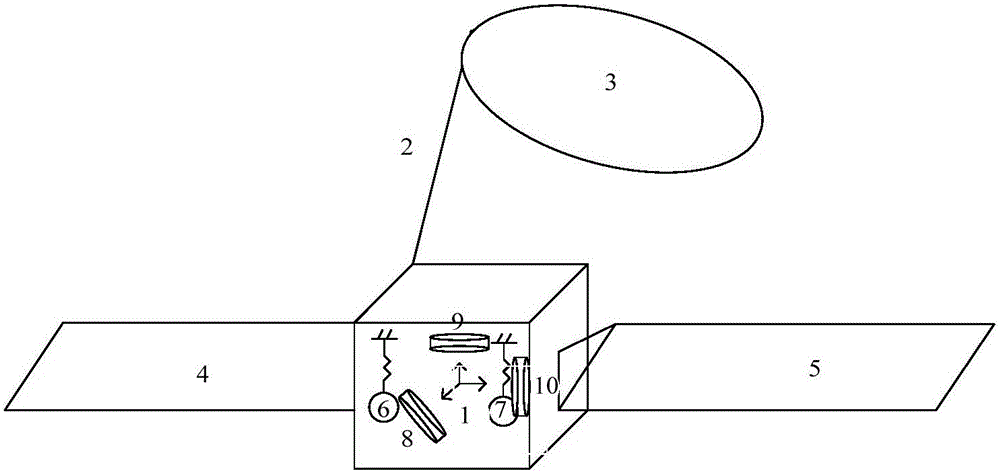

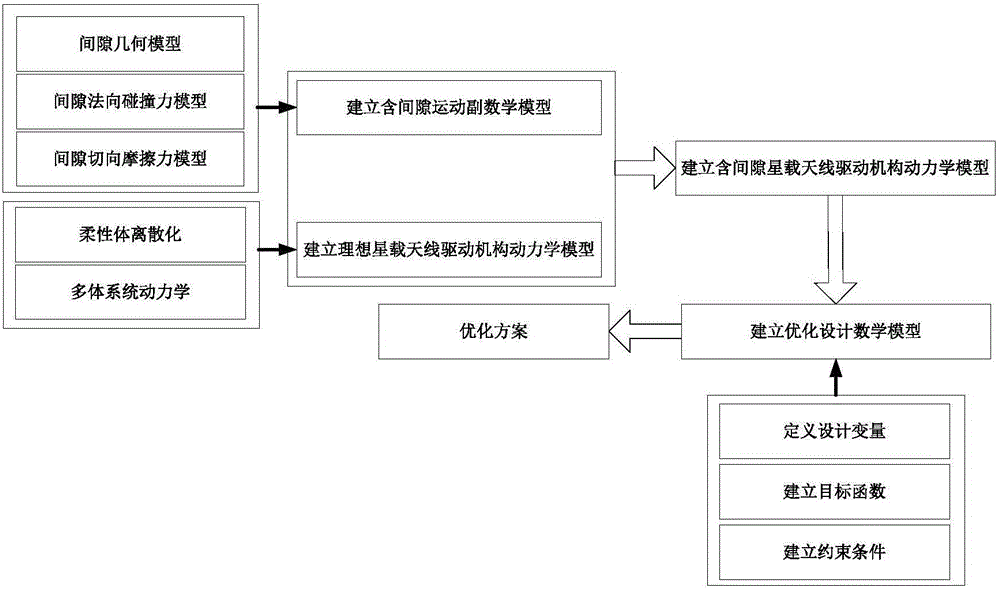

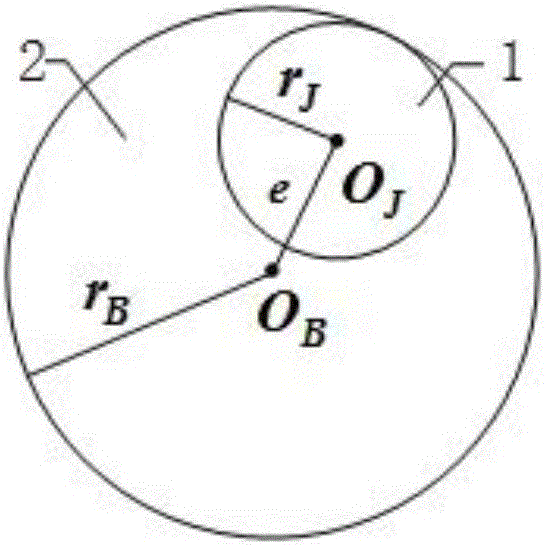

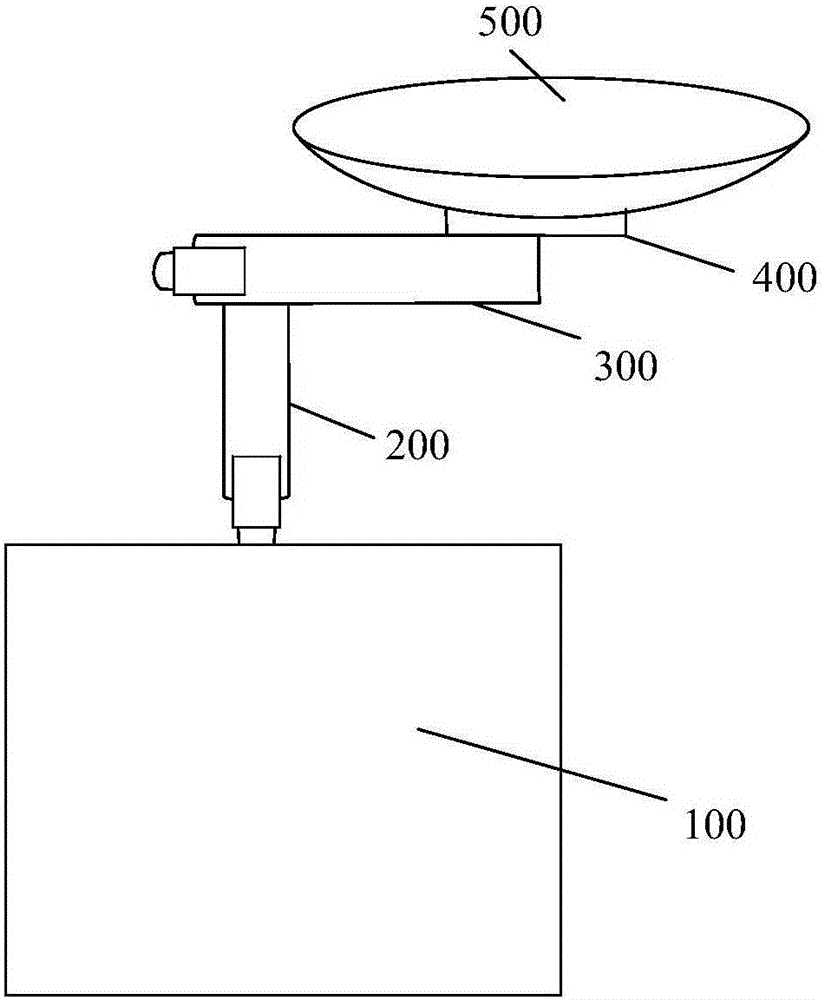

Method for increasing movement stability of driving mechanism of spaceborne antenna with gap

InactiveCN106066908AReduce the impact of motion stabilityReduce shockSpecial data processing applicationsKinematic pairMultibody system

The invention relates to a method for increasing the movement stability of a driving mechanism of a spaceborne antenna with a gap. The method is based on multibody system dynamics theories, flexible multibody system dynamics and a kinematic pair gap contact collision model. A spaceborne antenna driving mechanism dynamics model which taking a kinematic pair gap into consideration is established, and the influence of the gap on the dynamic characteristics of a reflecting plane of the spaceborne antenna is analyzed through value simulation. Minimizing the maximal peak value of movement acceleration jitter of the reflecting plane of the spaceborne antenna is taken as an optimization target. The element contact collision parameters of the kinematic pair with a gap are optimized without changing the basic structural parameters of the driving mechanism of the spaceborne antenna, and the auxiliary material of the elements of kinematic pair with a gap is selected to improve the movement stability of the driving mechanism of the spaceborne antenna. The element contact collision parameters of a kinematic pair with a gap are optimized, and proper auxiliary material of the kinematic pair is selected to substantially reduce the impact effect caused by gap contact collision of the kinematic pair, and reduce the influence of the gap on the movement stability of the driving mechanism of a spaceborne antenna. The method is simple, feasible and practical, and can be widely applicable to driving mechanisms of various spacecrafts.

Owner:HARBIN INST OF TECH AT WEIHAI

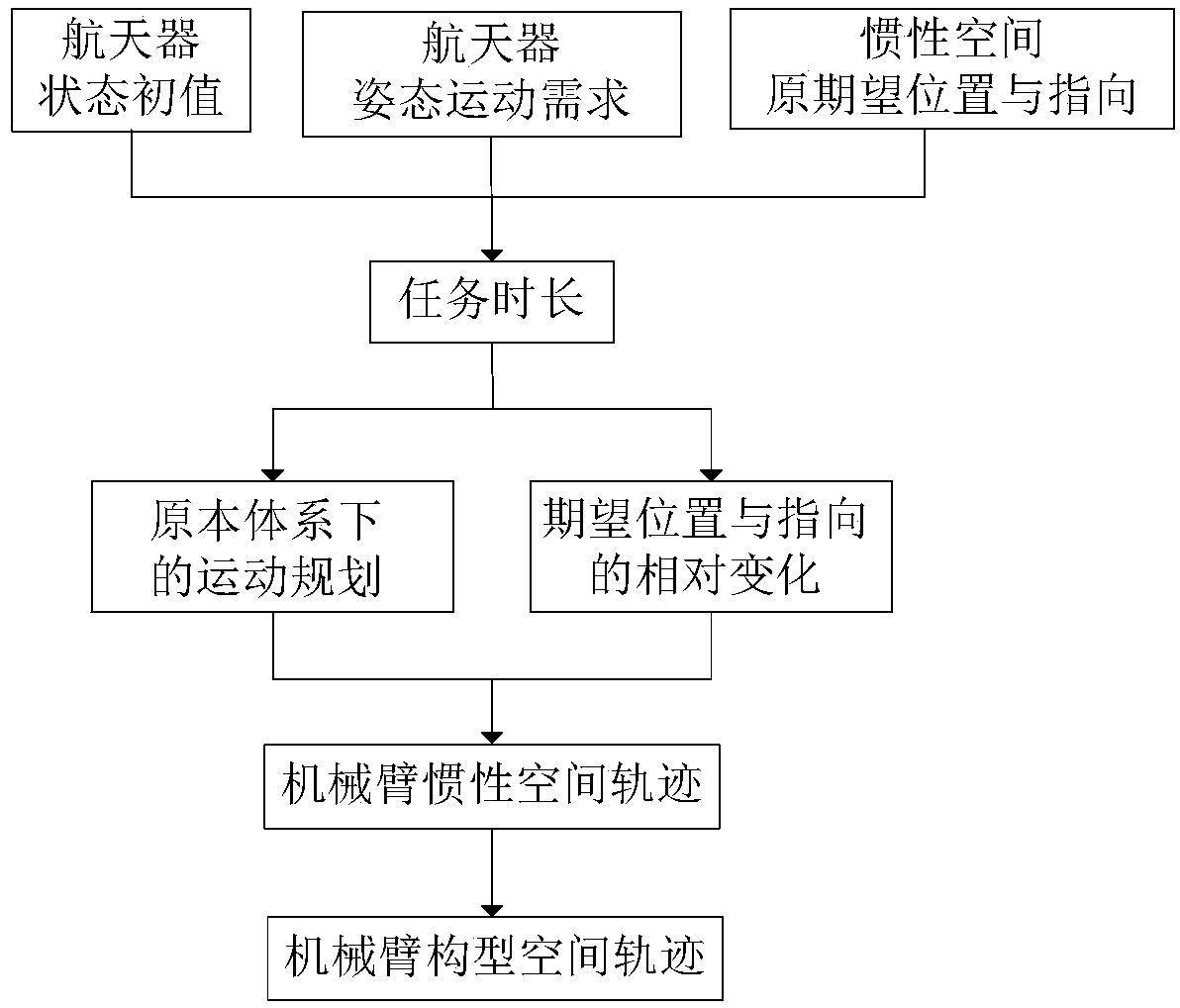

Mechanical arm track planning method considering spacecraft body attitude motion

ActiveCN109623812AReduce real-time computing pressureProgramme-controlled manipulatorOn boardMultibody system

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

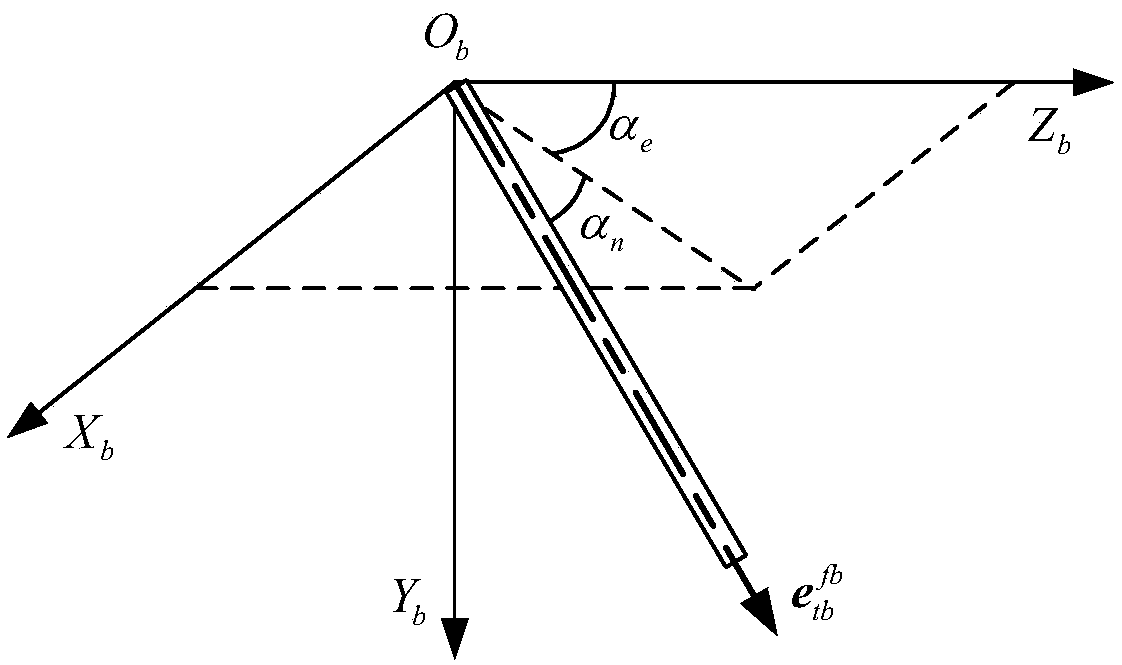

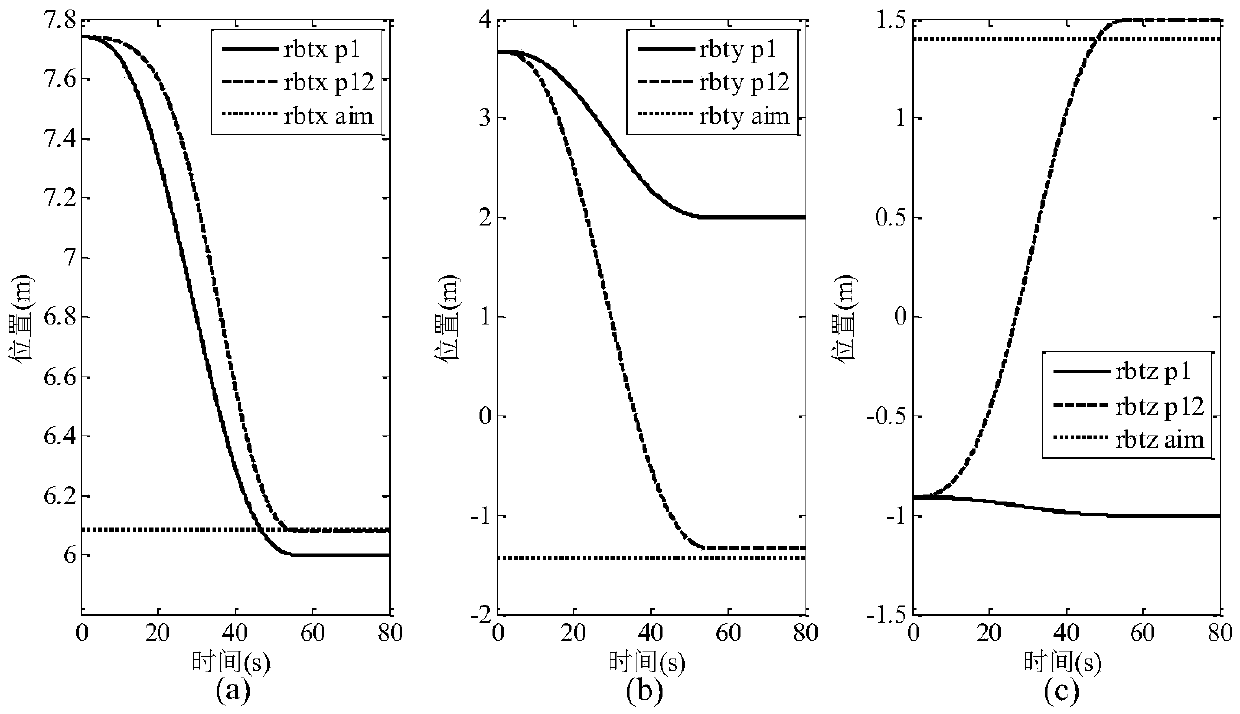

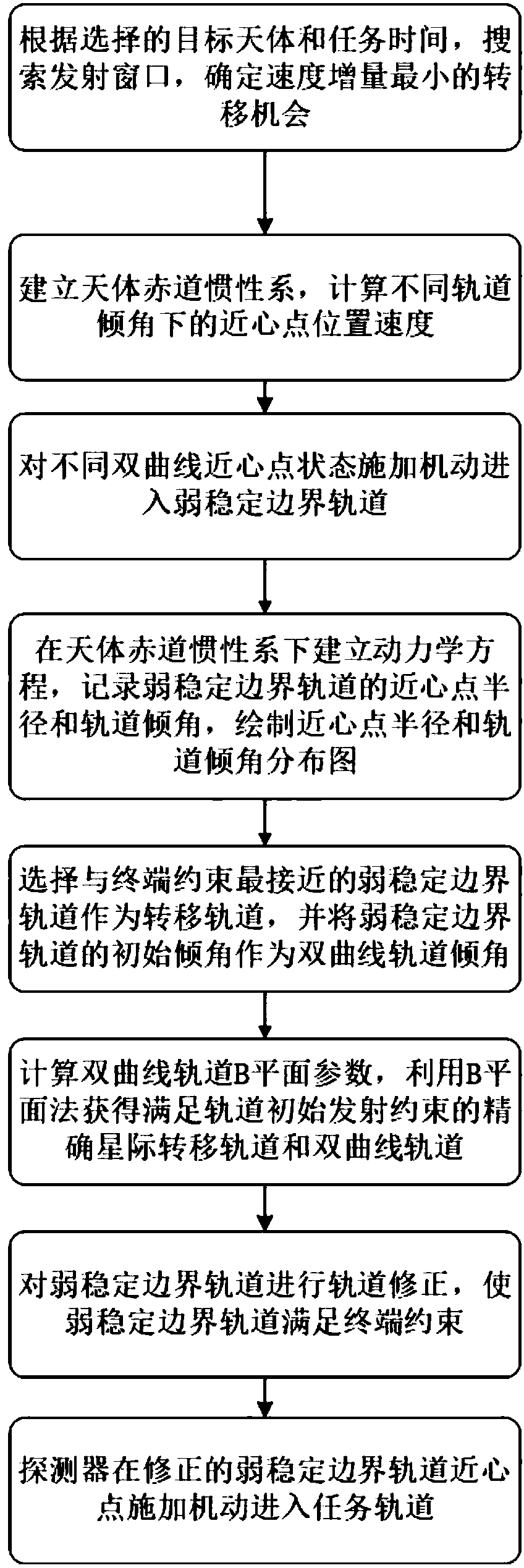

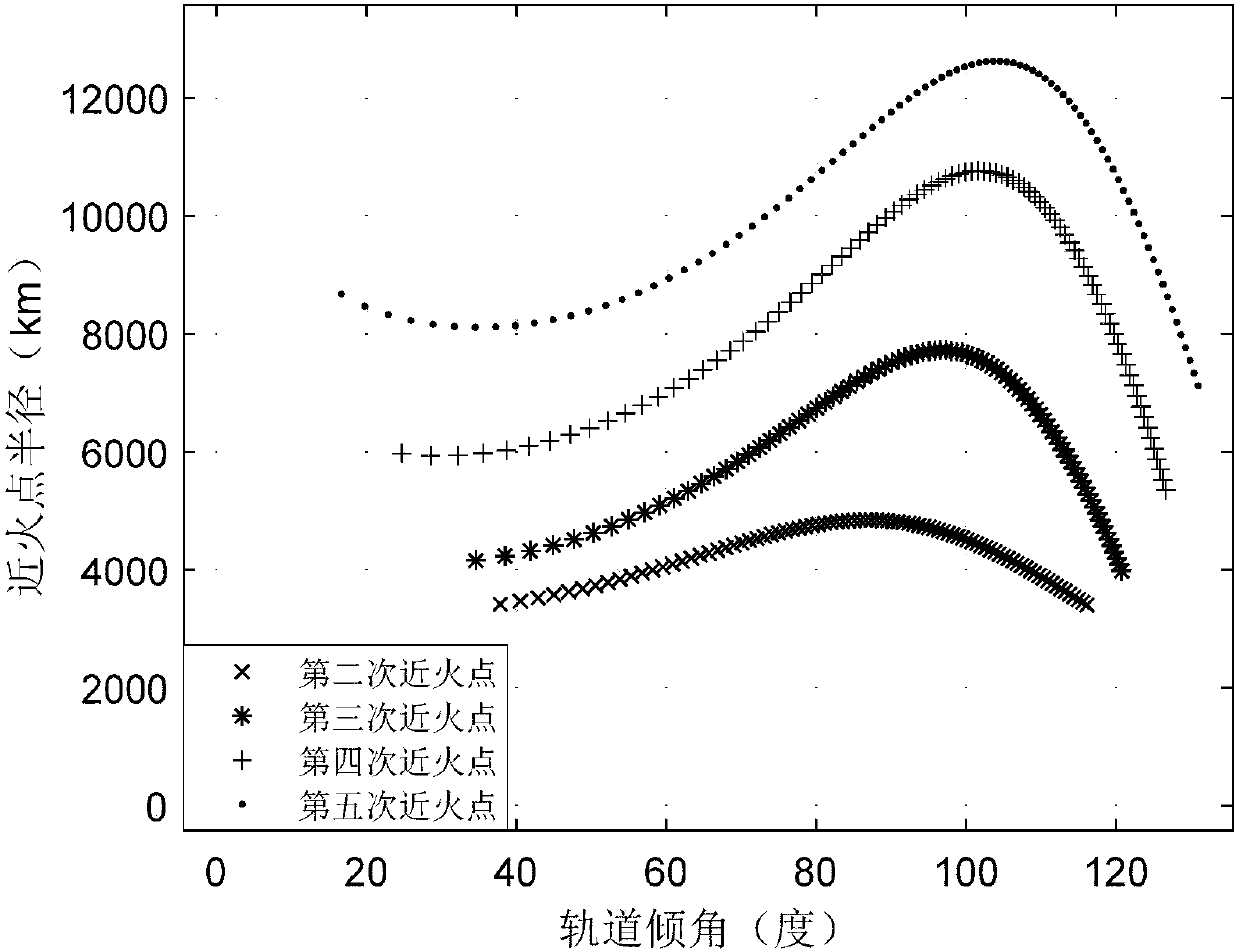

Low-energy orbit capture method for multi-body system taking into account initial and terminal constraints

ActiveCN108082538ASmall capture speed incrementsSave fuelCosmonautic vehiclesSpacecraft guiding apparatusAviationMultibody system

The invention discloses a low-energy orbit capture method for a multi-body system taking into account initial and terminal constraints and particularly relates to the low-energy orbit capture method for the multi-body system taking into account the constraints of initial and terminal states. The invention belongs to the technical field of aeronautics and astronautics. The low-energy orbit capturemethod for the multi-body system taking into account the initial and terminal constraints achieves the orbit capture design which satisfies the terminal constraints based on the multi-body system andthe theory of weak stability boundary, by virtue of the gravitational action of the sun for assisting planet capture and by screening the inclination of a hyperbolic orbit of an arrived celestial bodyand applying orbital correction. An interplanetary transfer orbit starting from the earth can be accurately matched with a weak stability boundary orbit by virtue of B-plane parameters. A detector can eventually enter a mission orbit through two-time braking and one-time orbital correction. The low-energy orbit capture method for the multi-body system taking into account the initial and terminalconstraints has the advantages of small required speed increment, wide application range and easy implementation of the method.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com