Steady optimal distributing method for geometric accuracy of multi-shaft machine tool

A multi-axis machine tool and machine tool technology, applied in special data processing applications, instruments, electrical digital data processing, etc., to achieve the effect of improving work efficiency and reducing machine tool manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

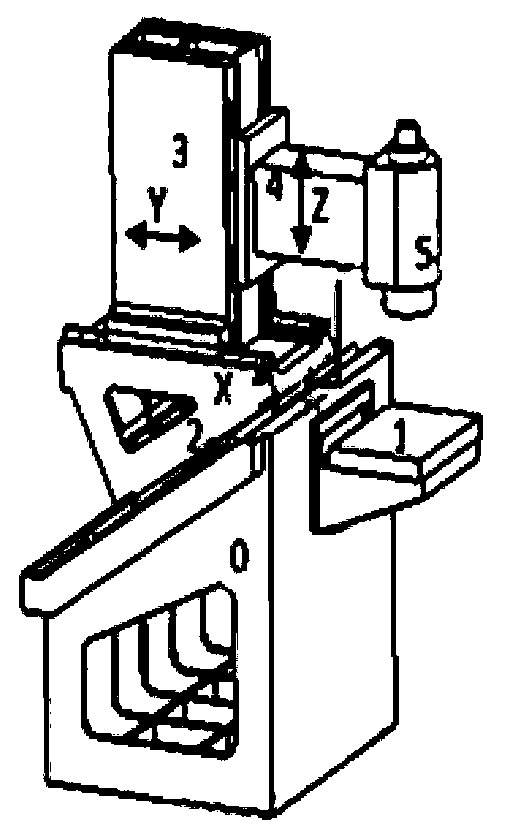

[0068] In order to achieve a balance between the cost and precision of the machine tool, the present invention takes a certain type of three-axis vertical machine tool as an example to verify the above-mentioned robust optimization design method. The technical indicators of the three-axis vertical machining center are: the size of the worktable is 320mm×460mm; the strokes of X, Y, and Z are 300mm, 250mm, and 300mm respectively; The fast moving speed is 48m / min; the positioning accuracy is ≦0.003mm in the case of full closed loop, and the repeat positioning accuracy is ≦0.0015mm. Its structure diagram is as follows image 3 . The three-axis machine tool mainly has three translational units of X, Y, and Z axes and a spindle unit. The present invention mainly considers the static error of the machine tool, so the machine tool has 21 geometric errors in total, including six basic errors of X, Y, and Z ( Δx x ,Δy x ,Δz x ,Δα x ,Δβ x ,Δγ x ,Δx y ,Δy y ,Δz y ,Δα y ,Δβ y ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com