Processing technique for top surface of rail

A surface processing and rail top technology, applied in metal processing equipment, manufacturing tools, details of milling machine equipment, etc., can solve the problems of rail top straightness, hat shape deviation, uneven bright band in the transition range, and achieve a perfect fit. , to ensure product processing accuracy, the effect of good machined surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

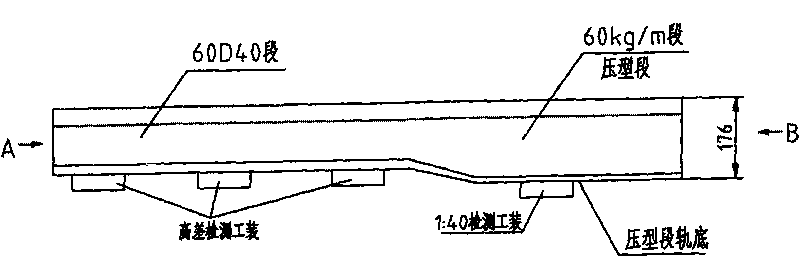

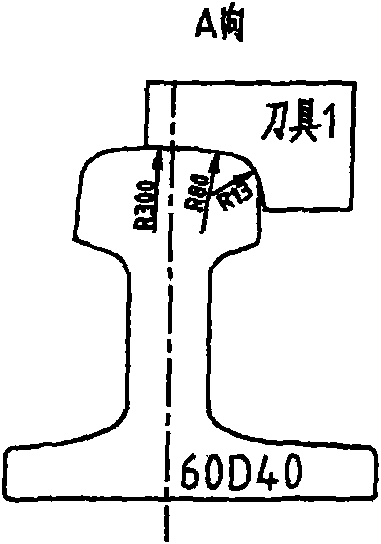

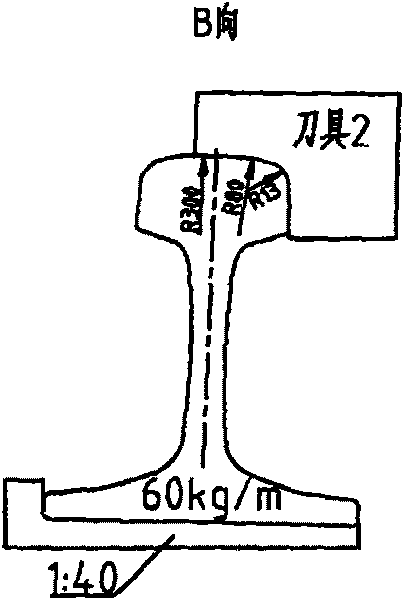

[0010] The present invention is suitable for the full-length processing of the top surface of 60D40 rails, and its technological process is as follows: one-time blanking→saw cutting→pressing→secondary blanking→straightening→milling and pressing the rail bottom of the profiled section→fine adjustment→drilling→milling Rail bottom and rail waist bolt groove → milling rail head working side and non-working side → milling rail top reduction value → quenching → correction.

[0011] Program implementation steps and control points:

[0012] 1. Cutting and sawing: take the 60D40 rail of the required length;

[0013] 2. Pressing section pressing: press the 60D40 rail pressing section into a 60kg / m rail for easy connection with the guide rail.

[0014] 3. Straightening: Because forging belongs to hot processing, after the forging is completed, the rough adjustment process of the rail must be completed on the top bender, because there is a certain machining allowance on the rail head and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com