Splicing measurement method for two sections of profiles of large-caliber optical aspheric element

A measurement method and aspheric surface technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve problems such as the lack of alignment solutions for splicing algorithms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

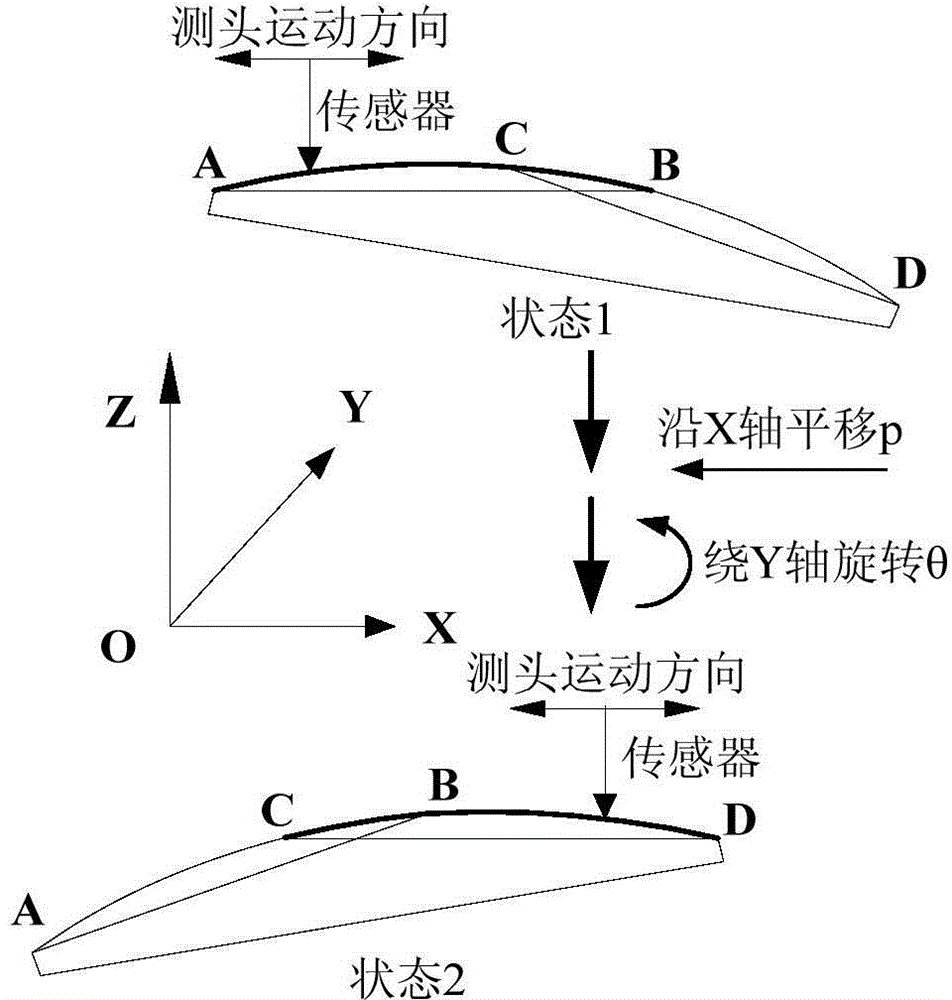

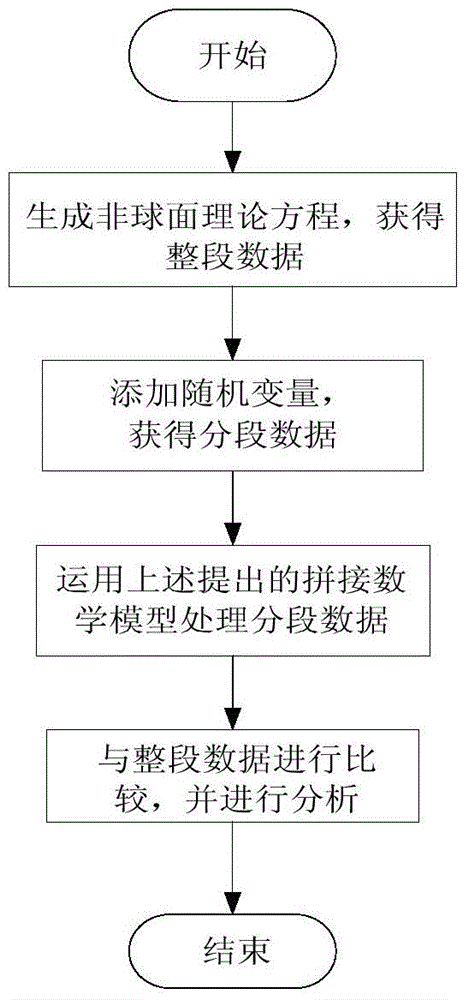

[0042] Such as figure 1 As shown, the surface profile of the measured workpiece is divided into AB segment and CD segment. The X direction is the horizontal movement direction of the profiler sensor, and the Z direction is the vertical measurement direction of the profiler sensor. First, measure the profile of segment AB in state 1; then translate and rotate the workpiece around the coordinate axis to state 2, so that the workpiece returns to the range of the sensor, and measure the profile of segment CD; and ensure that there is a certain overlapping area between the two profiles, It is the CB segment; finally, the segmented contours are stitched together through the overlapping area surface shape to reconstruct the surface shape profile of the workpiece under test. During the measurement process, due to the rotation and translation of the workpiec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com