Detection method for geometrical errors of rotation shaft of five-axis numerical control machine tool

A technology of numerical control machine tools and detection methods, applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of long measurement period, high cost of measurement equipment, high cost of laser target balls, etc., and solve geometric errors The identification and detection, the machine tool running trajectory requirements are simple, and the effect of avoiding other axis linkage errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

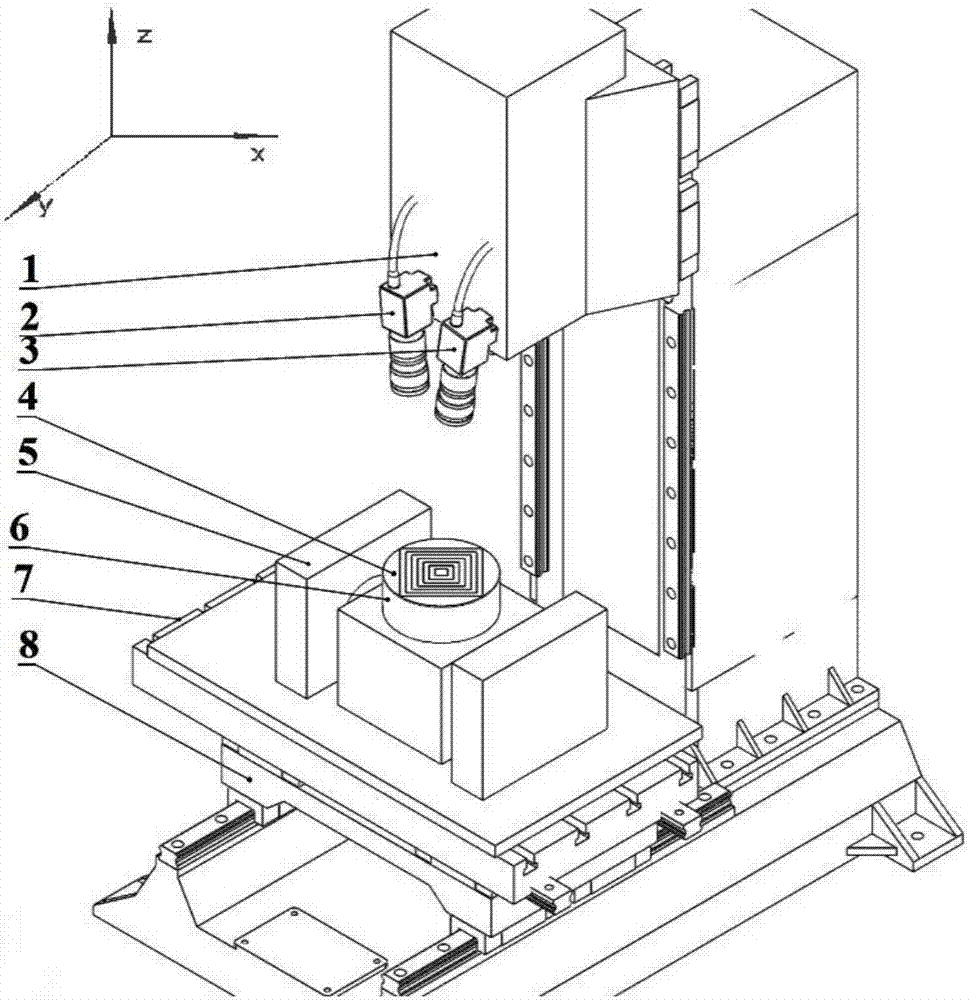

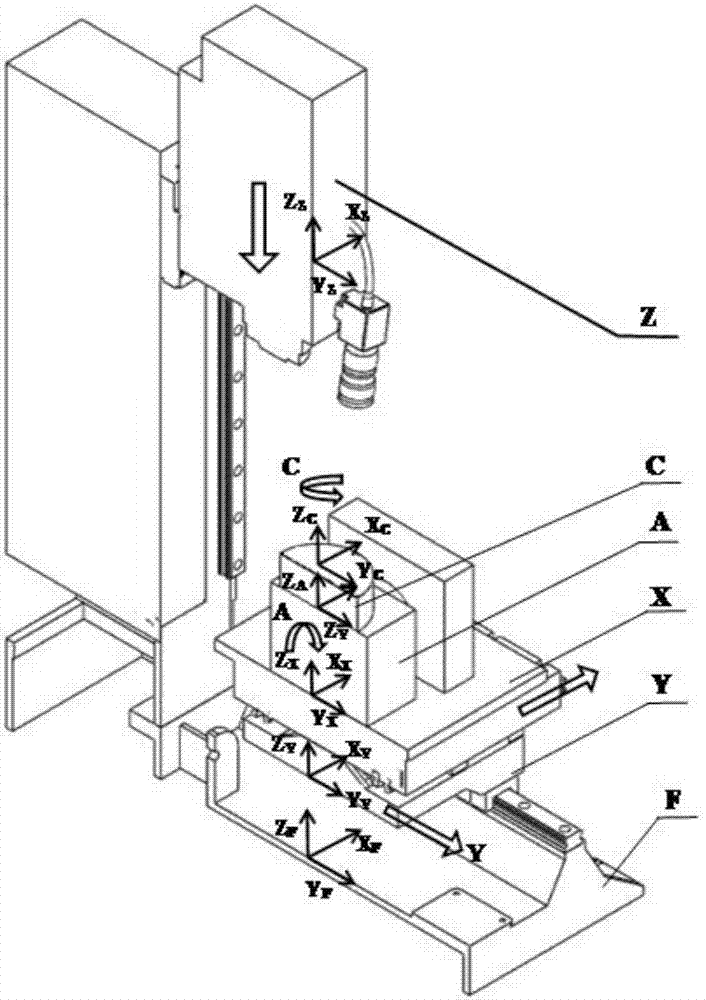

[0041] The present invention uses a binocular camera to measure the C-axis geometric error of the machine tool, such as figure 1 As shown, the left camera 2 and the right camera 3 are installed on the Z-axis 1 of the machine tool, and the "Hui"-shaped target is attached to the C-axis 6 of the machine tool. The binocular camera is used to collect the three-dimensional coordinates of its corners to characterize the movement characteristics of the C-axis of the machine tool. First adjust the left and right cameras to form a certain angle, the range is between 30°-60°, so that the common field of view is suitable, and the selected public field of view of the present invention is 200mm × 200mm.

[0042] The specific steps of the detection method are as follows:

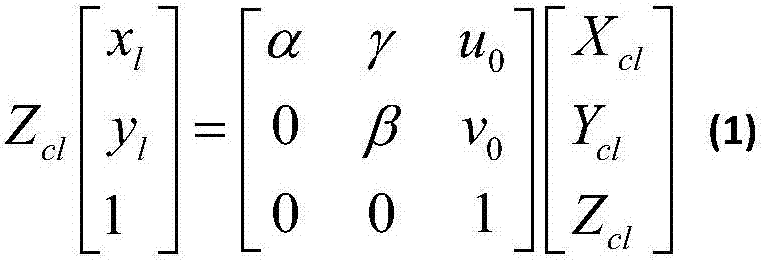

[0043] The first step is to build a binocular measurement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com