Interval theory-based geometric precision optimization allocation method for precision horizontal machining center

A technology of geometric precision and interval theory, applied in the direction of geometric CAD, electrical digital data processing, special data processing applications, etc., can solve the dependence on machine tools, cannot form a scientific, theoretical, and systematic design method, and cannot directly guide high-end Problems such as the manufacturing and assembly process of CNC machine tools to achieve the effect of reducing production costs and improving production and assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be described in further detail:

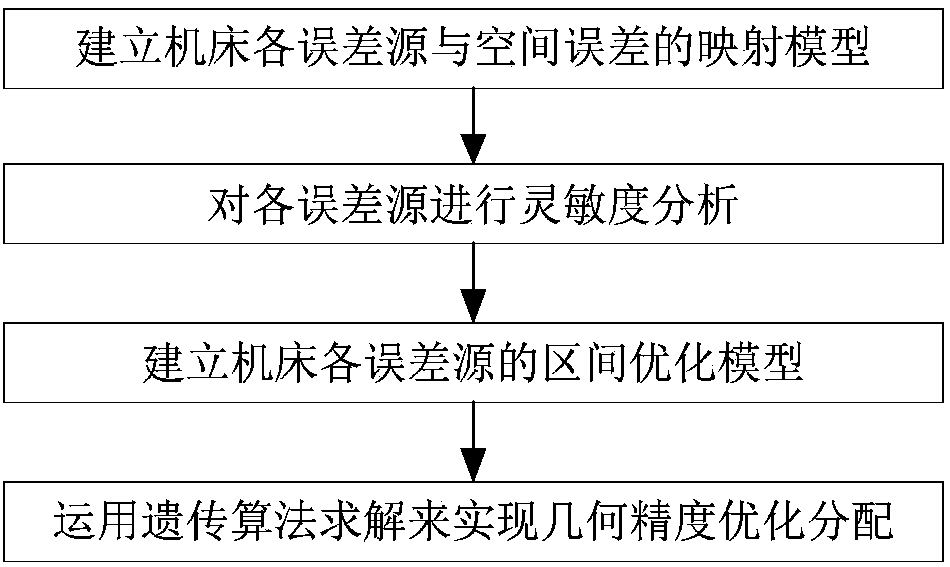

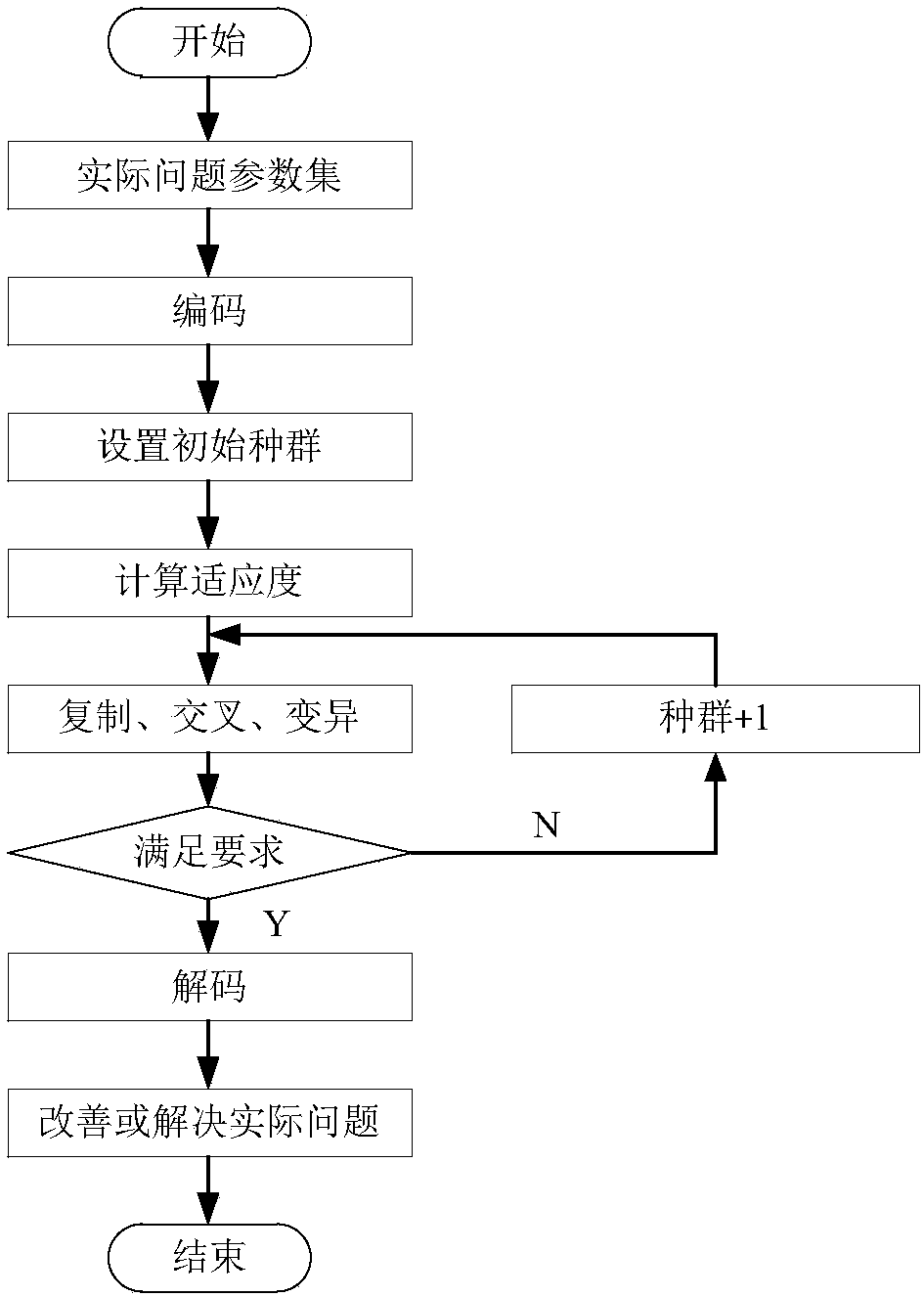

[0019] Such as figure 1 As shown, the method for optimizing the distribution of geometric accuracy of precision horizontal machining centers based on interval theory provided by the present invention includes the following steps:

[0020] (1) Establish a mapping model between each geometric error of the machine tool and the space error of the machine tool;

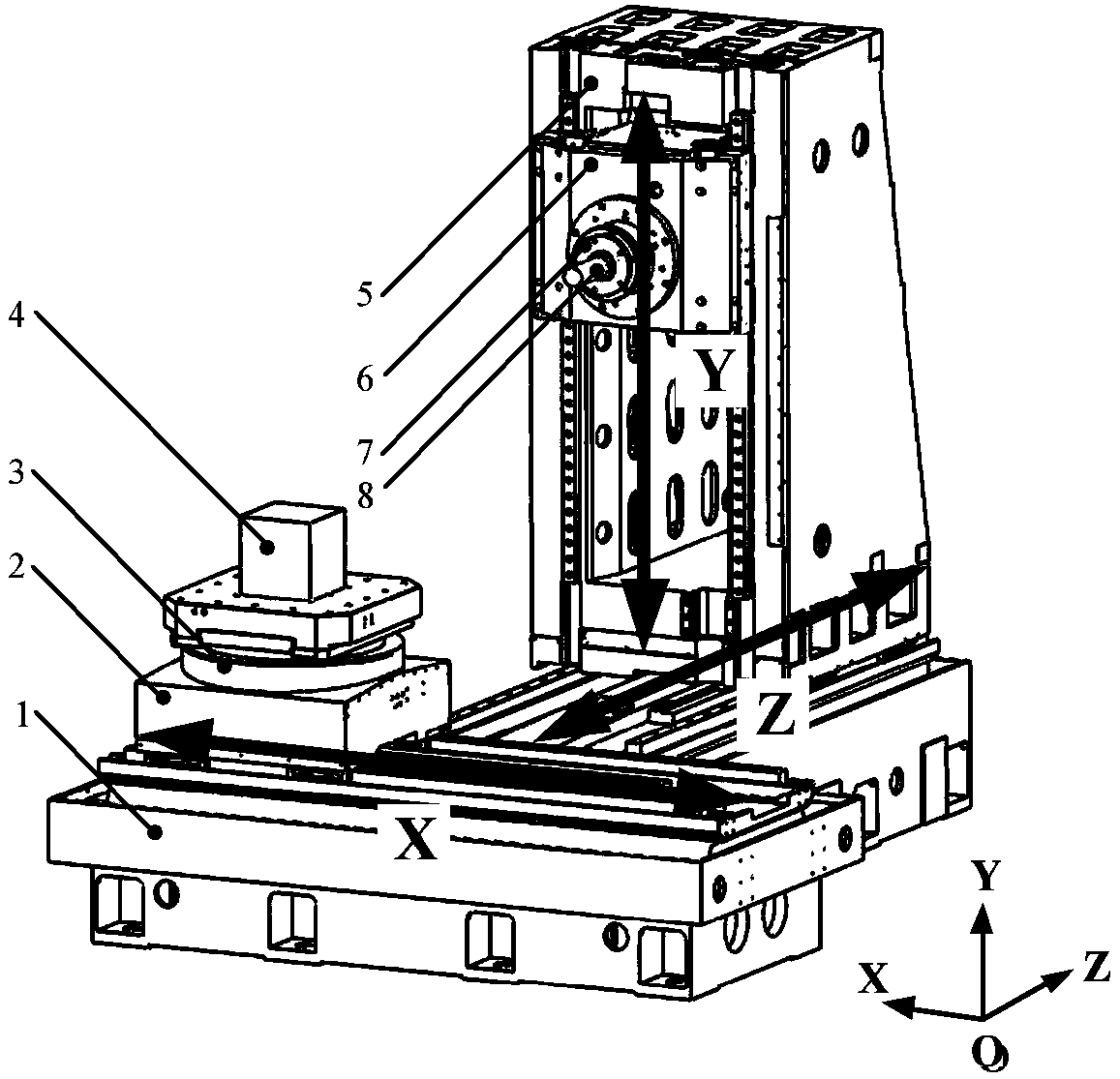

[0021] The geometric errors of CNC machine tools can be divided into position-dependent geometric errors (PDGEs) and position-independent geometric errors (PIGEs) according to whether they are related to the motion position of the machine tool. This invention takes u2000 / 800H precision horizontal machining center as an example, the model is as follows figure 2 As shown, the method of the present invention is described. The above-mentioned machining center has 21 geometric errors in the case o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com