Method for increasing movement stability of driving mechanism of spaceborne antenna with gap

A motion stability, spaceborne antenna technology, applied in the field of machinery, can solve the problems of ignoring the elastic deformation of the contact surface, unable to truly reflect the contact collision characteristics of the moving pair of the mechanism with gaps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

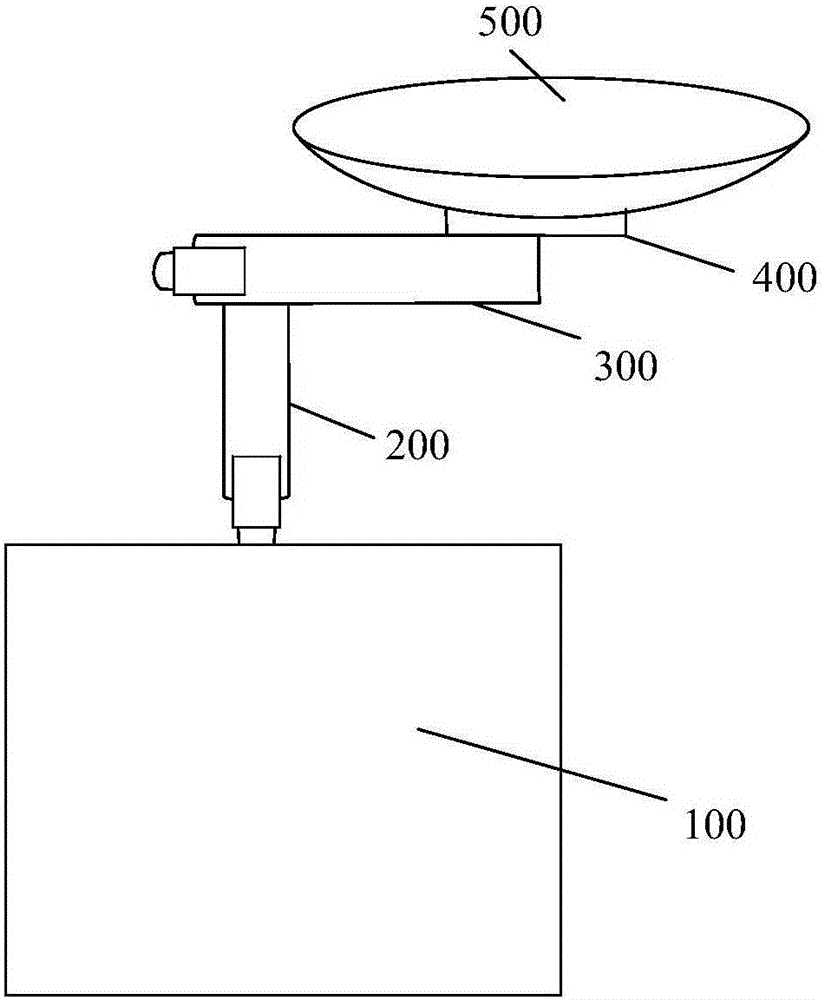

[0080] The present invention is applicable to various types of space-borne antenna drive mechanisms, and this embodiment only takes a certain type of space-borne antenna dual-axis drive mechanism as an example.

[0081] Such as image 3 As shown, the spaceborne antenna system with gaps in this embodiment is mainly composed of the satellite body 100, the azimuth axis 200, the pitch axis 300 and the flexible antenna reflecting surface 500, and the output end of the pitch axis 300 is directly reflected by the flexible antenna through the flange 400. Surface 500 is connected. Among them, the azimuth axis 200 and the pitch axis 300 constitute the dual-axis drive mechanism of the spaceborne antenna system. The dual-axis drive mechanism is divided into two rotation axes: rotation and azimuth. The antenna rotation axes are perpendicular to each other. Axis, vertical axis and horizontal axis are composed of exactly the same components and adopt the azimuth-pitch layout form, that is, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com