Grinding and polishing industrial robot offline programming method based on workpiece three-dimensional graph

A technology of industrial robots and three-dimensional graphics, which is applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of high grinding and polishing process requirements for teaching personnel, certain requirements for operators, and inapplicable programs, etc., and achieve offline programming process simplified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

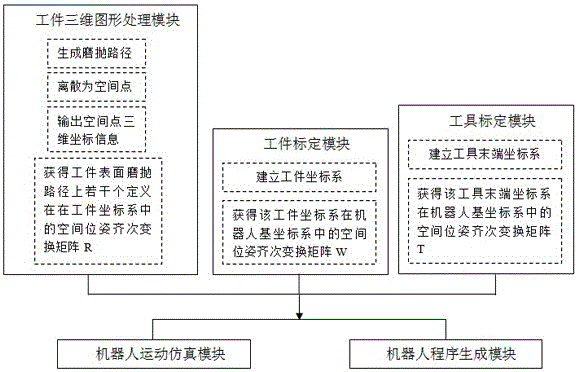

[0050] Such as Figure 1~6 As shown, a method of off-line programming for grinding and polishing industrial robots based on three-dimensional graphics of workpieces in this embodiment includes the following steps:

[0051] Step S0: Obtain the three-dimensional graphics of the workpiece 2 by three-dimensional software;

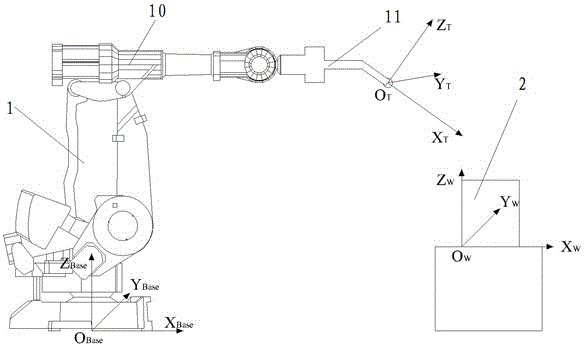

[0052] Step S1: use the workpiece calibration module to establish a workpiece coordinate system OW on the workpiece 2, and calibrate to obtain the homogeneous transformation matrix W of the spatial pose and orientation of the workpiece coordinate system OW in the robot base coordinate system OBase;

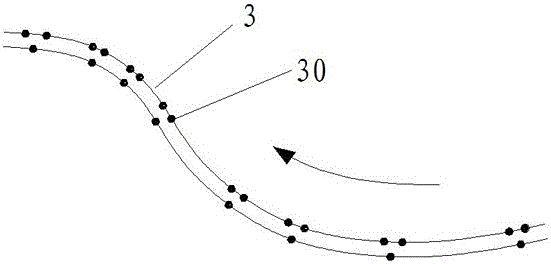

[0053] Step S2: use the workpiece three-dimensional graphics processing module to generate the grinding and polishing path 3 on the three-dimensional graphics surface of the workpiece 2, discretize the grinding and polishing path 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com