Patents

Literature

125 results about "Variable interval" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Interval Schedule. Interval schedules require a minimum amount of time that must pass between successive reinforced responses (e.g. 5 minutes). Responses which are made before this time has elapsed are not reinforced.

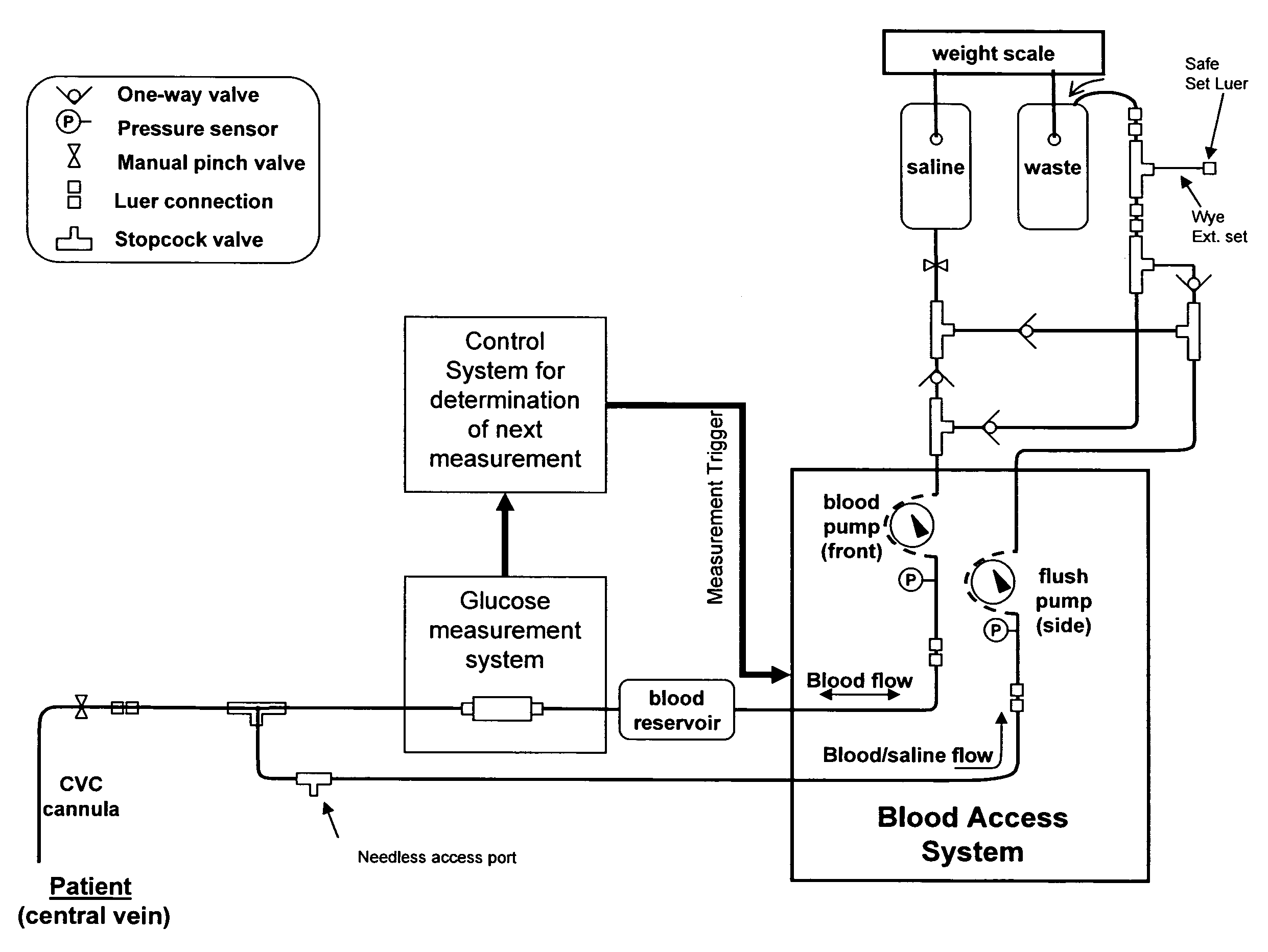

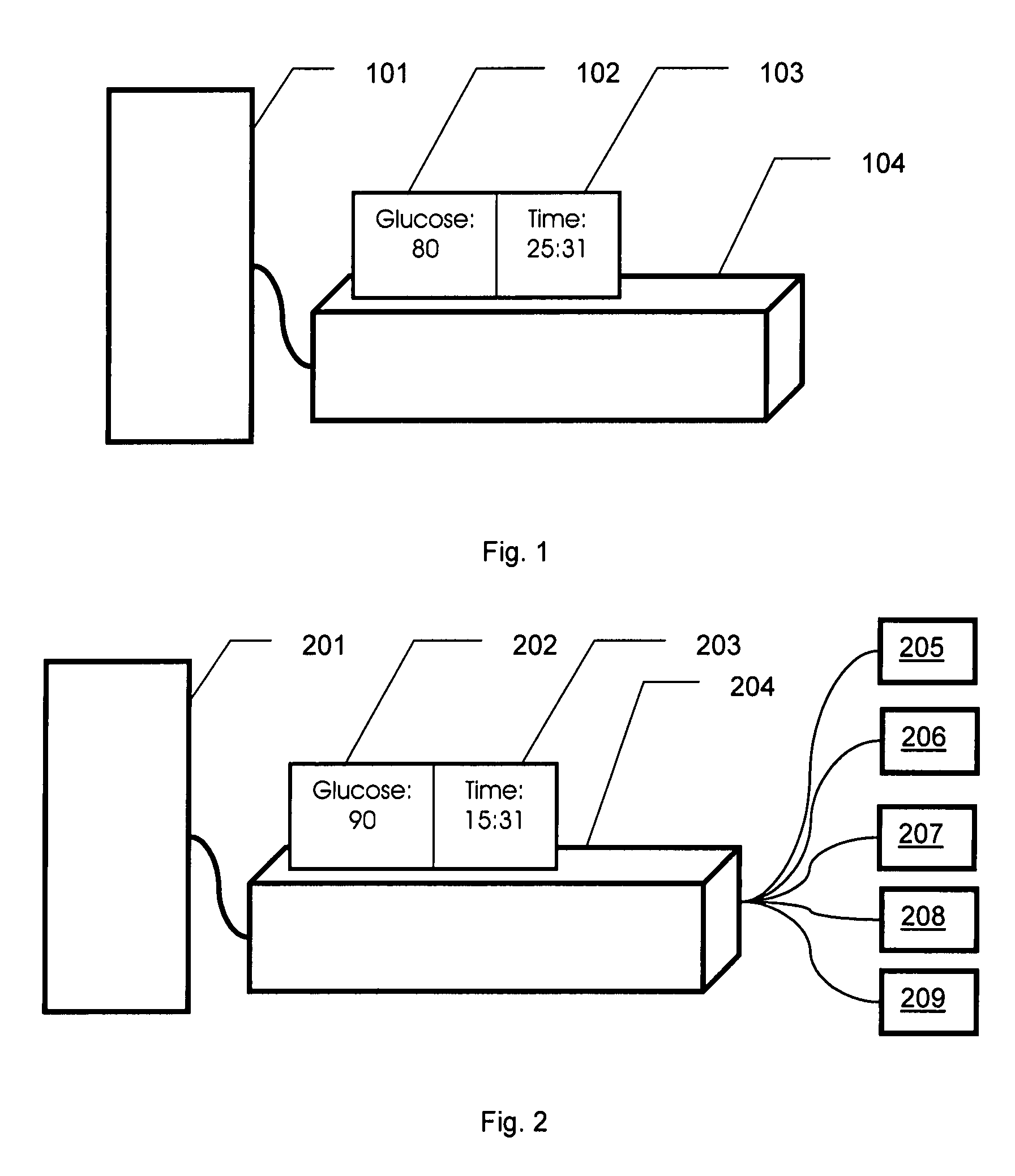

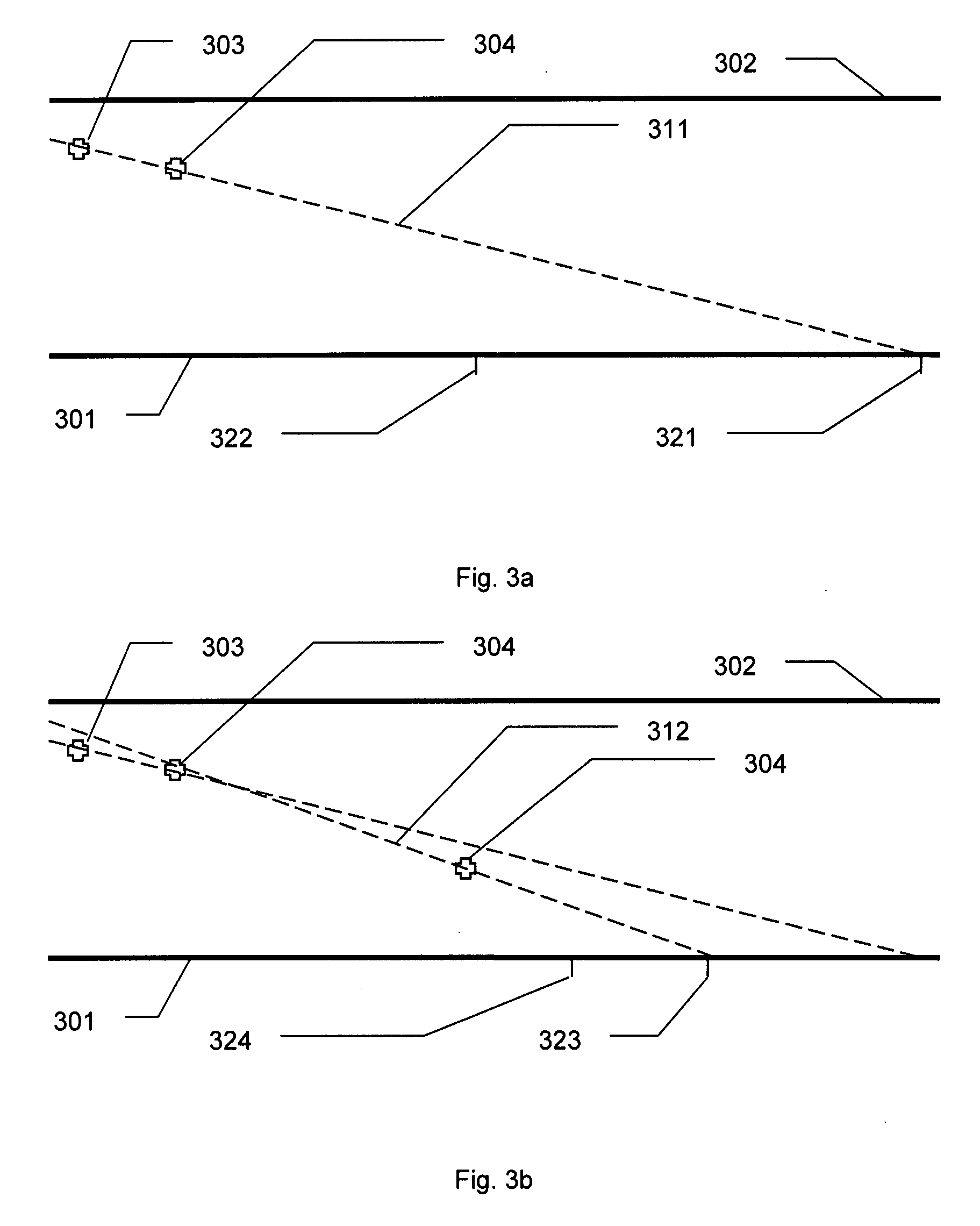

Variable Sampling Interval for Blood Analyte Determinations

InactiveUS20090054753A1Efficient measurementGreat patient safetyMedical simulationLocal control/monitoringAnalyteMedicine

The present invention provides methods and apparatuses that can provide measurement of glucose with variable intervals between measurements, allowing more efficient measurement with greater patient safety. A method according to the present invention can comprise measuring the value of an analyte such as glucose at a first time; determining a second time from a patient condition, an environmental condition, or a combination thereof; then measuring the value of the analyte at the second time (where the second time can be expressed as an interval after the first time, an absolute time, or a time indicated when certain patient or environmental conditions, or both, are reached or detected). The second time can be determined, as an example, from a comparison of the analyte value at the first time with a threshold. The interval between the first time and the second time can be related to the difference between the analyte value at the first time and the threshold; e.g., the closer to the threshold, the closer the two measurement times. The invention can be used with automated measurement systems, allowing the system to determine measurement times and automatically make measurements at the determined times, reducing operator interaction and operator error.

Owner:ROBINSON MARK RIES +2

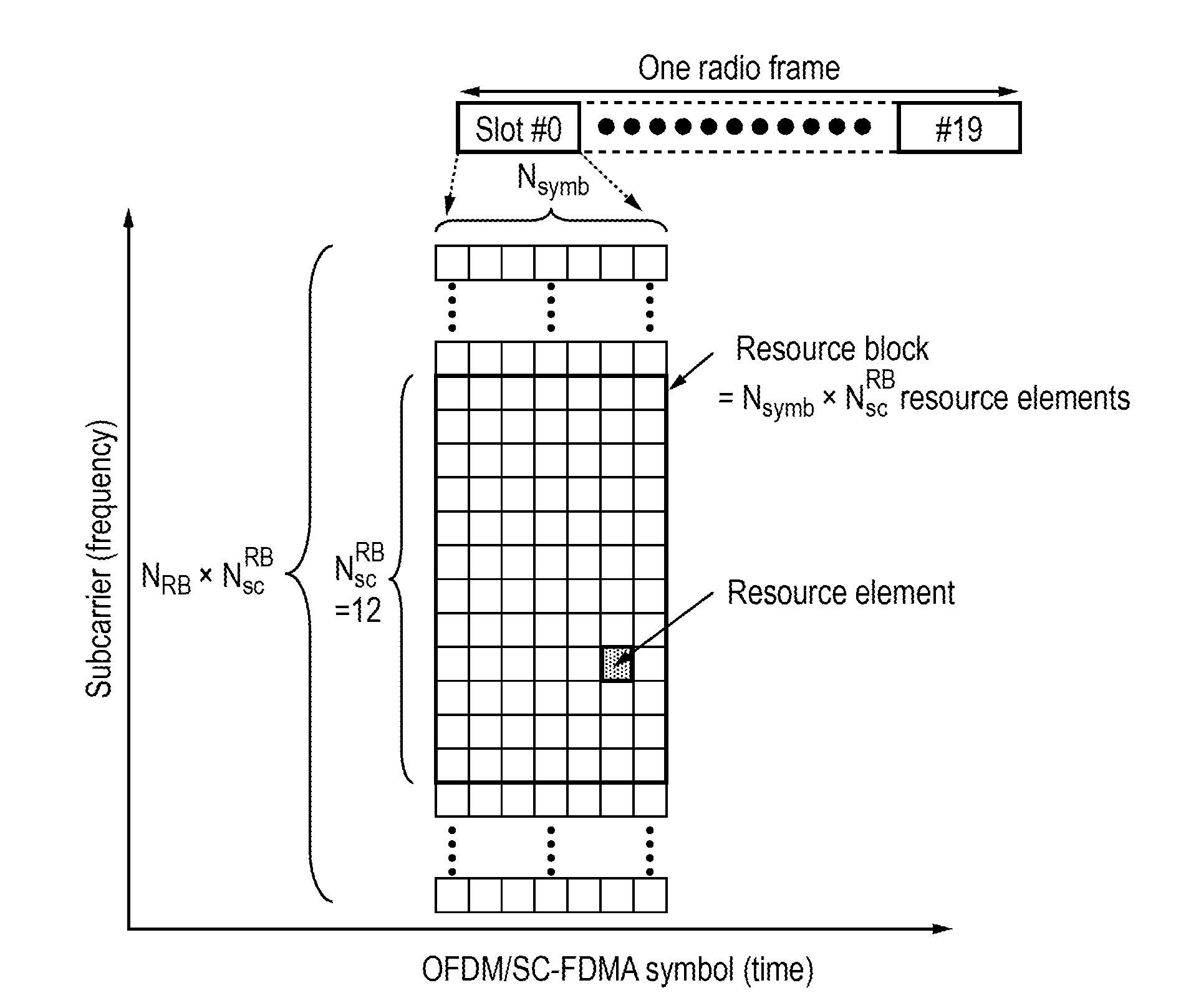

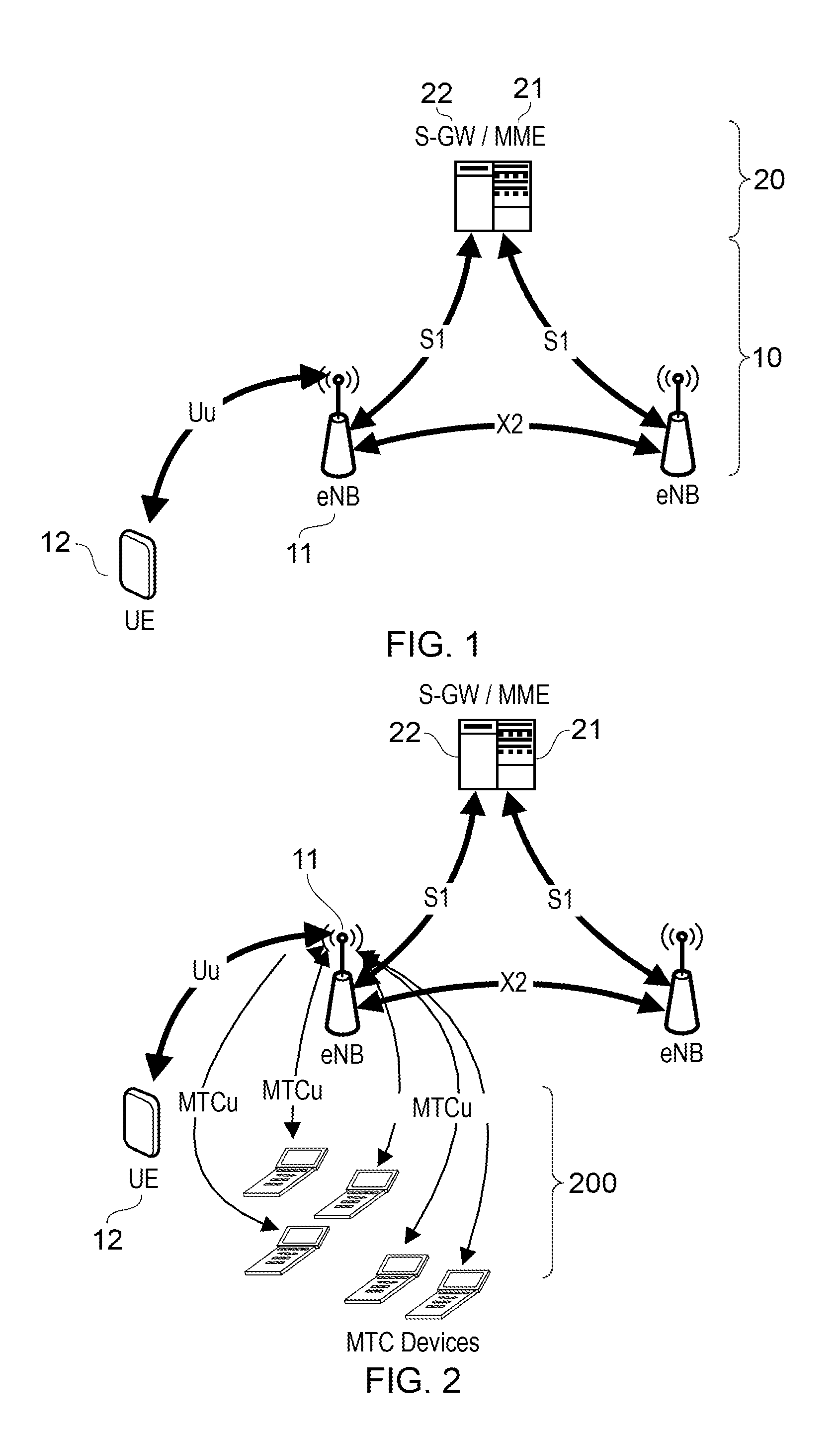

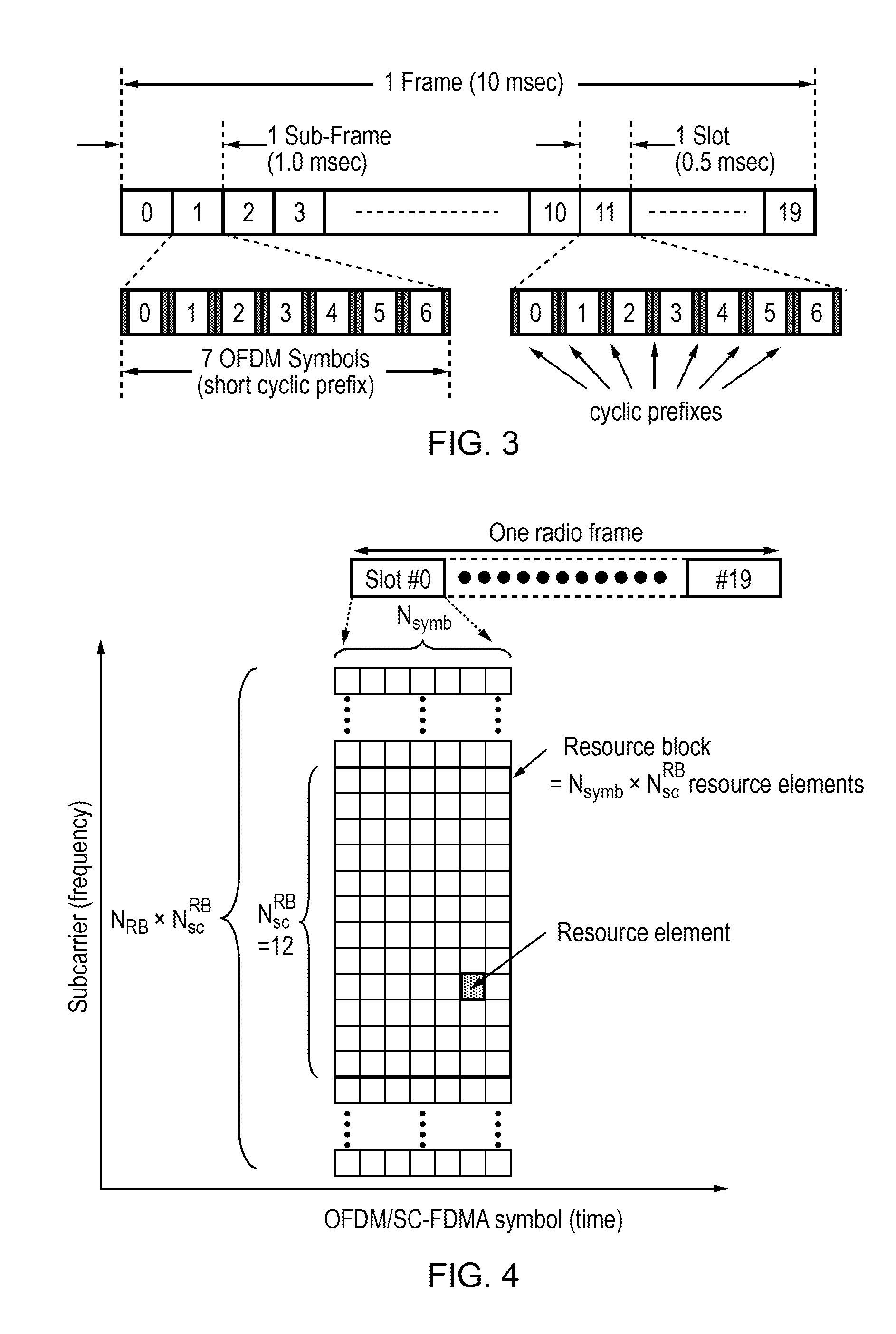

Control channel for wireless communication

ActiveUS20140105164A1Minimising additional decoding effortIncrease the number ofModulated-carrier systemsNetwork traffic/resource managementCommunications systemControl channel

A scheme for transmission of control channel information in a compact form intended to support SPS (Semi-Persistent Scheduling) in a wireless communication system. As applied to LTE, the scheme is to indicate a pre-configured UE-specific resource allocation in a Downlink Control Information (DCI) format containing information for multiple UEs in the same PDCCH. In order to avoid increasing the number of blind decodes, the DCI format size may be the same as an existing DCI format. Preferably the size of the new format is the same as that of DCI formats 0 / 1A / 3 / 3A. The number of required bits per UE is minimised by signalling only one of a limited set of DCI messages per UE. The scheme provides a means for re-configuring SPS resources for multiple UEs using a single PDCCH transmission, whilst enabling better support for variable packet sizes and variable intervals between packets than currently defined SPS.

Owner:FUJITSU LTD

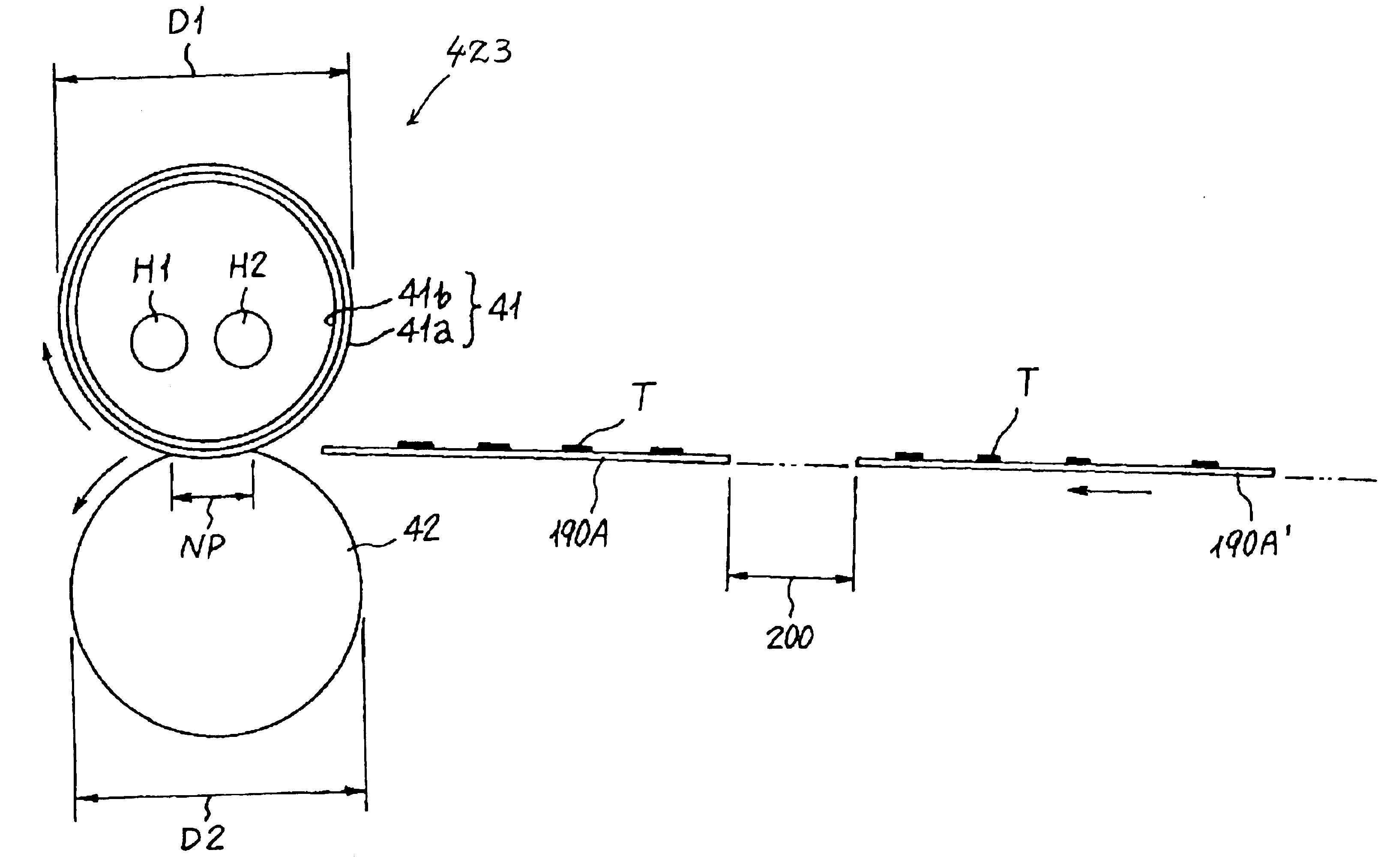

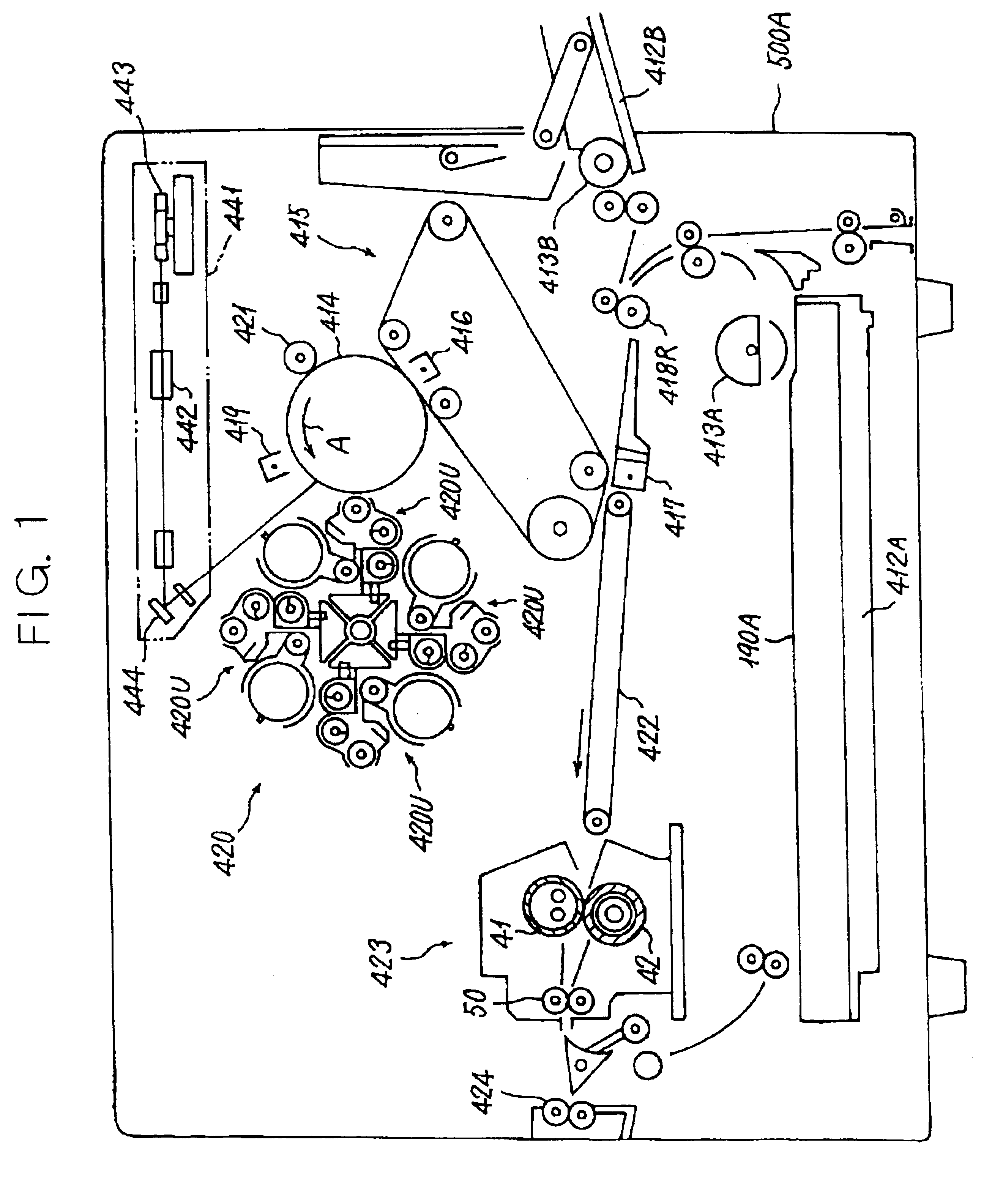

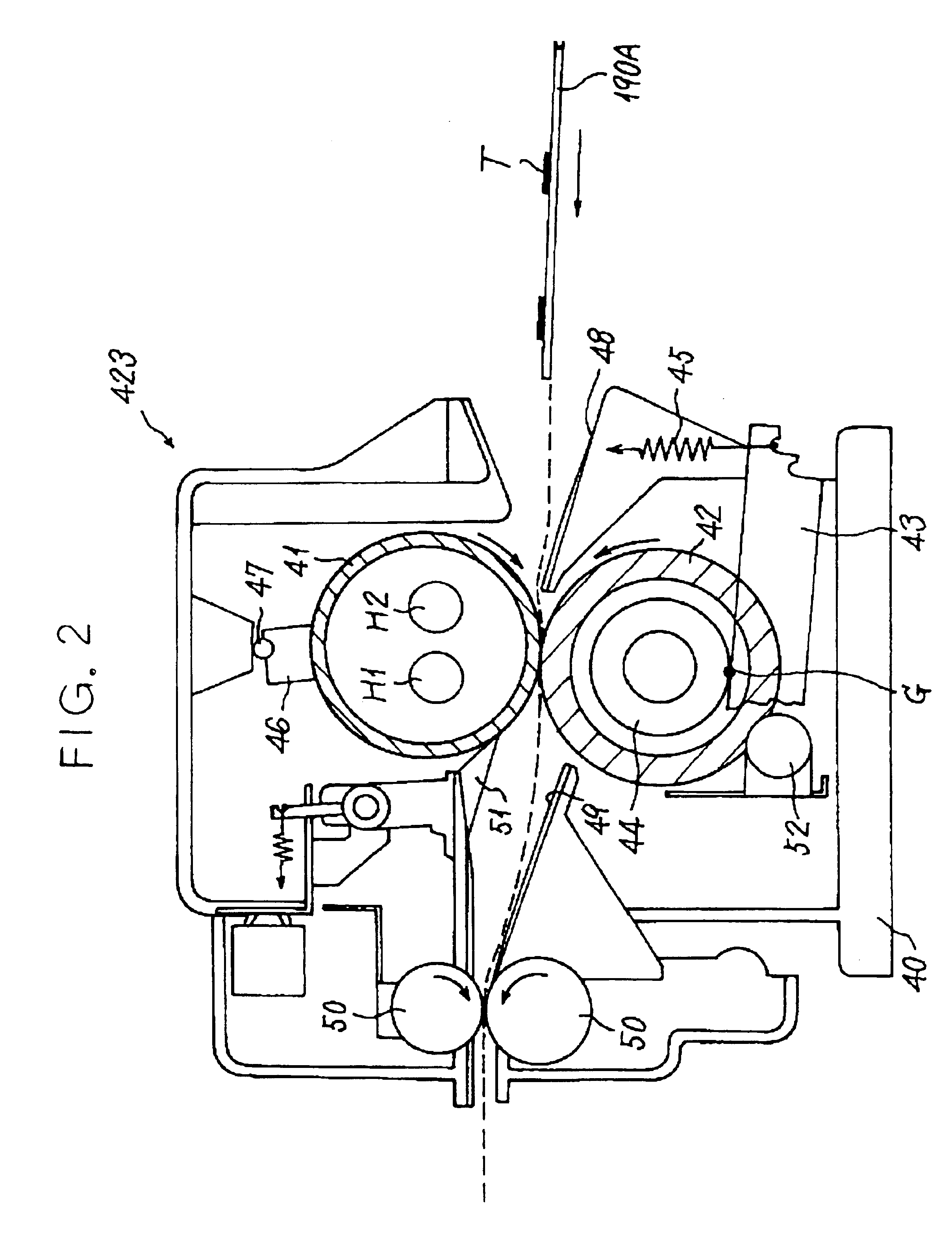

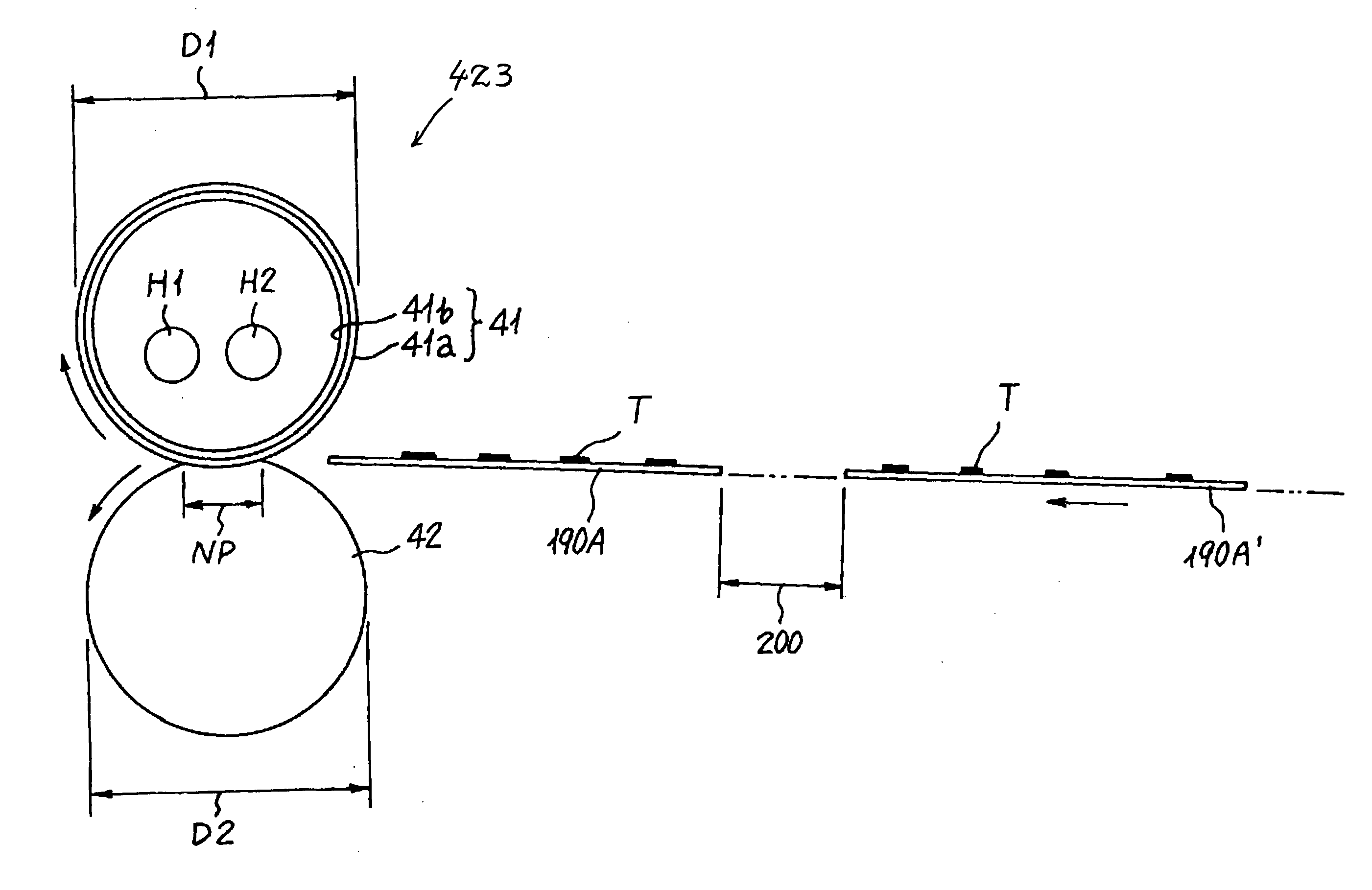

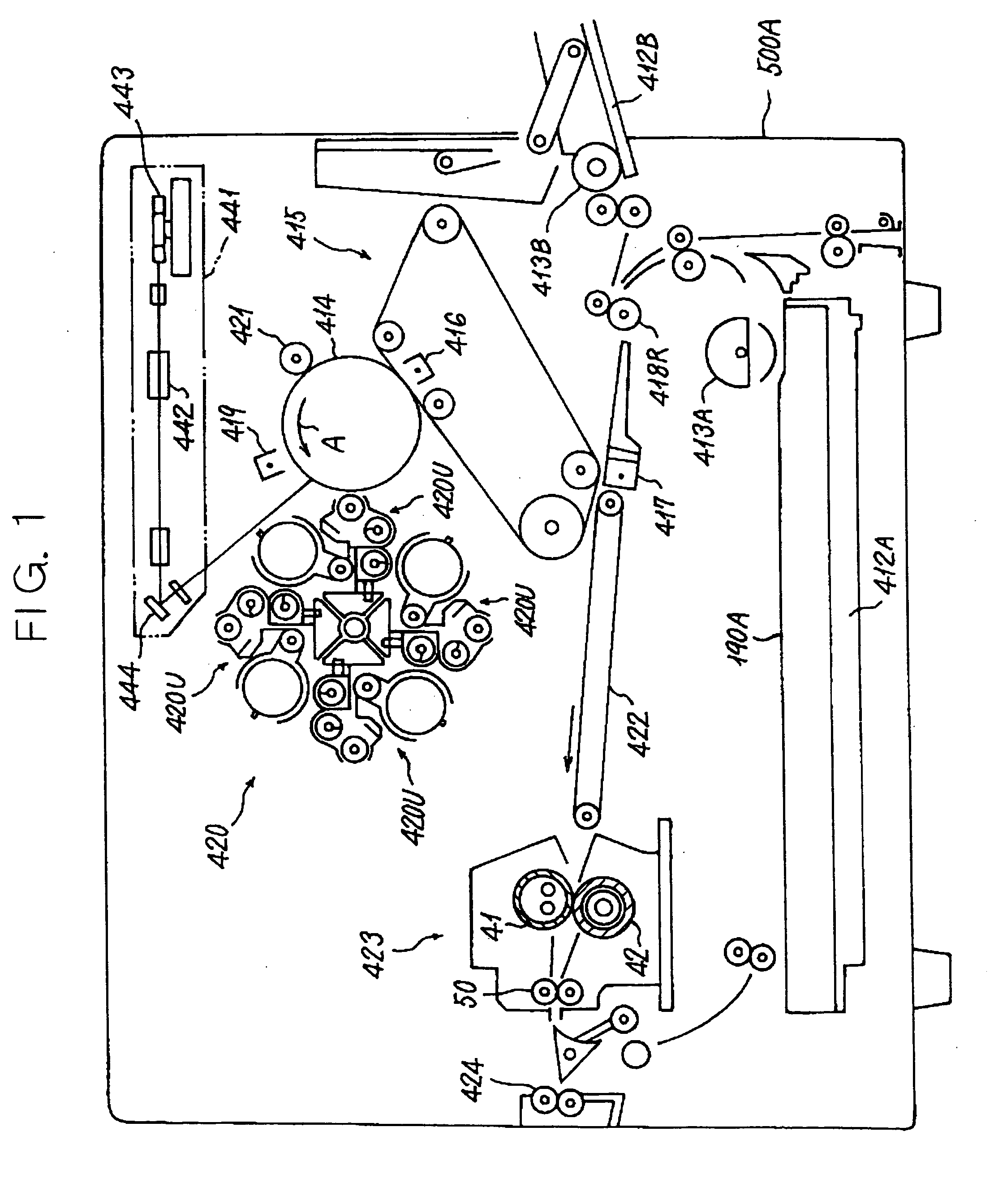

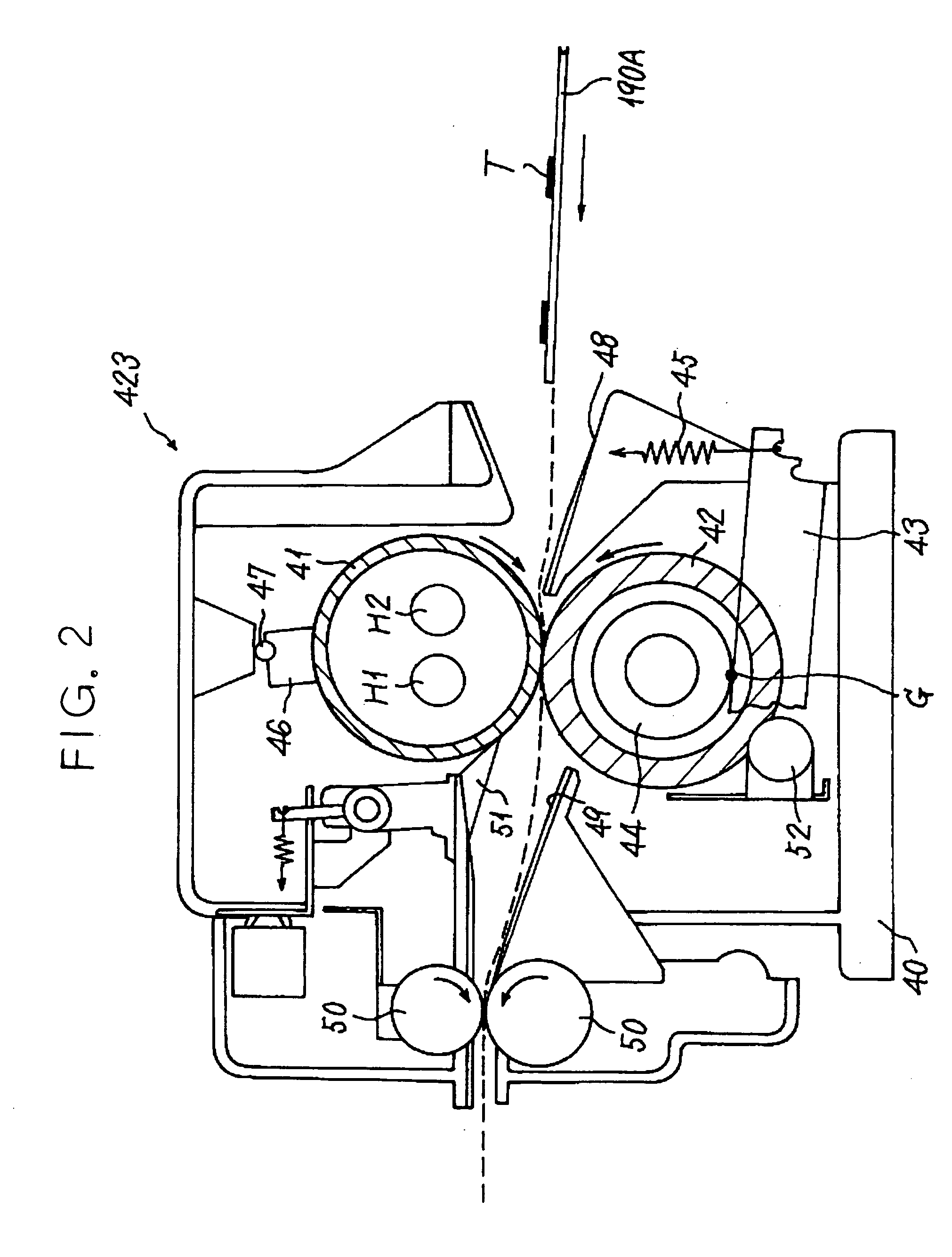

Fixing device and image forming apparatus including the same

InactiveUS6937827B2Shorten warm-up timeImprove qualityElectrographic process apparatusArticle feedersImage formationVariable interval

In accordance with the present invention, in an image forming apparatus including a fixing device for fixing a toner image on a sheet with heat at a nip between a fixing member accommodating a heat source and a pressing member not accommodating it, consecutive sheets are driven out of the fixing device at a variable interval without the number of sheets to be output within a preselected period of time being varied.

Owner:RICOH KK

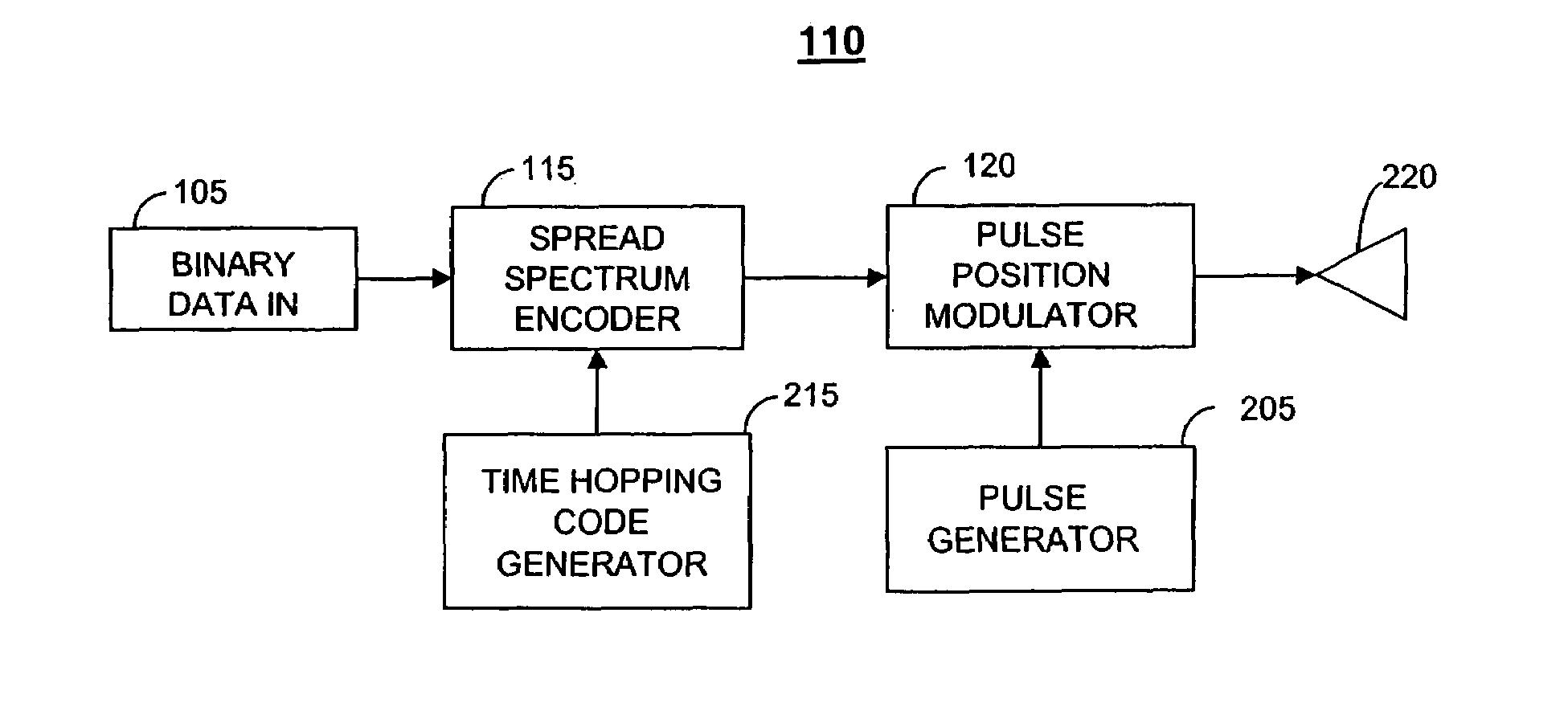

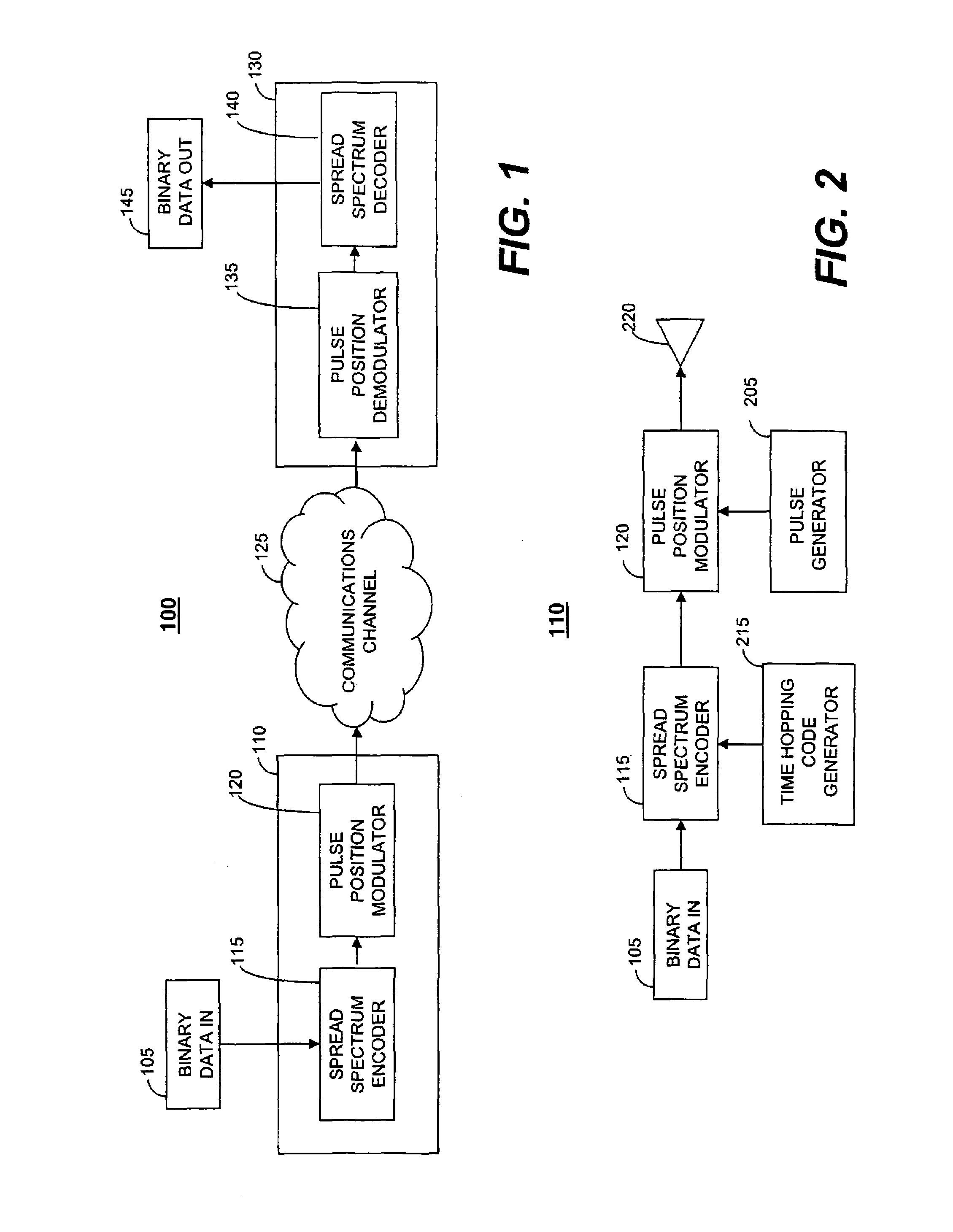

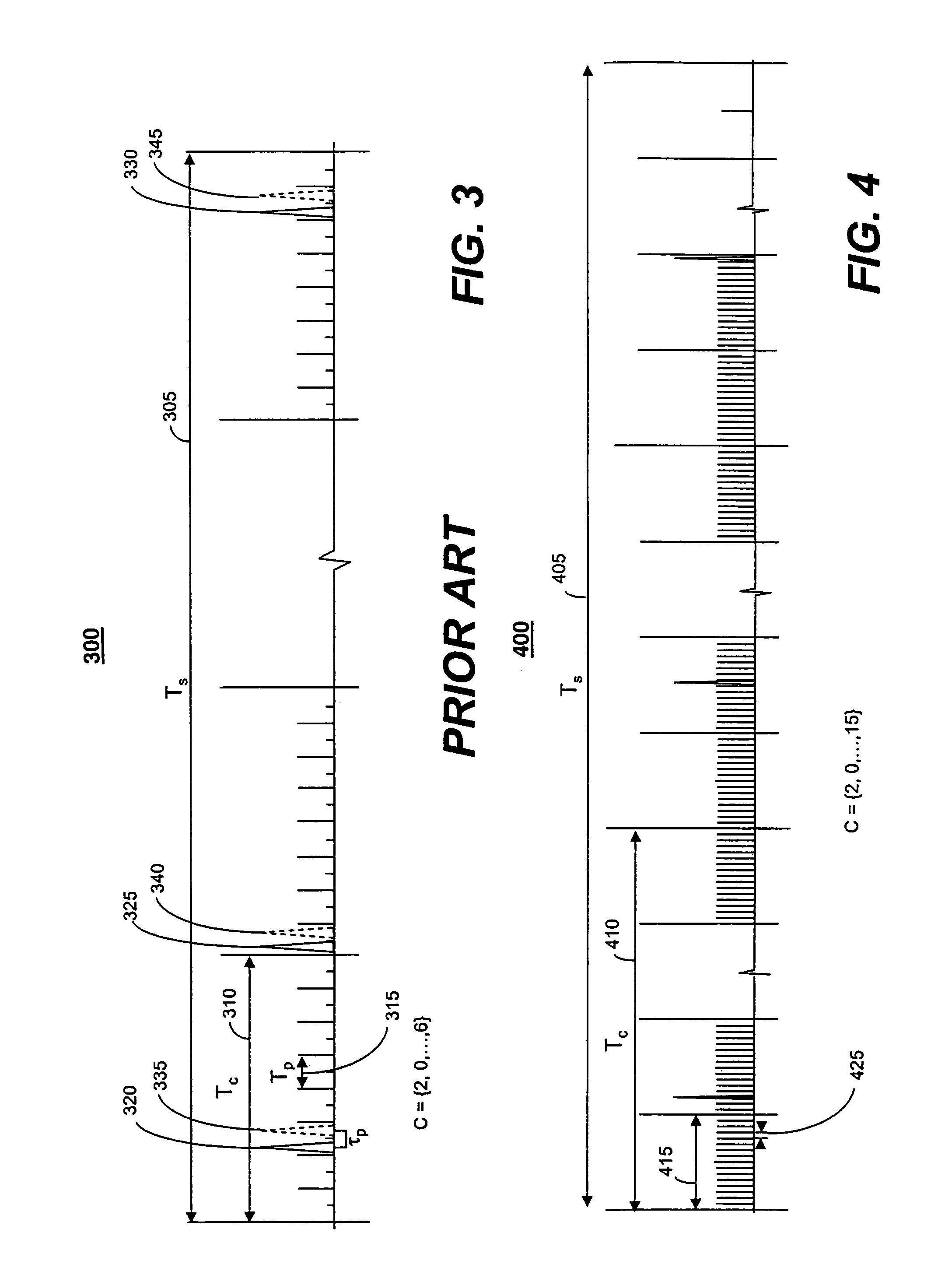

Variable spacing pulse position modulation for ultra-wideband communication links

ActiveUS7082153B2Improve throughputReduce riskFrequency/rate-modulated pulse demodulationPosition-modulated pulse demodulationUltra-widebandData stream

Methods and systems for generating a variable spacing pulse position modulated (VSPPM) signal for transmission across an ultra-wideband communications channel. The variable pulse position modulated spread spectrum signal is created by encoding every M input data bits from an input data stream into a symbol consisting of Nc chips. Each chip is divided into 2M sub-chips and each sub-chip is further divided into Np time slots. A pulse is transmitted for each chip in the symbol. During each chip period, the pulse is placed in the sub-chip corresponding to the binary M-tuple (or symbol) value. A time hopping code sequence consisting of Nc elements with a one-to-one chip association is then applied to each symbol so that the position of each pulse is shifted to the appropriate time slot that corresponds to the time hopping code value.

Owner:WSOU INVESTMENTS LLC +1

Fixing device and image forming apparatus including the same

InactiveUS20050074251A1Shorten warm-up timeImprove qualityElectrographic process apparatusArticle feedersImage formationVariable interval

In accordance with the present invention, in an image forming apparatus including a fixing device for fixing a toner image on a sheet with heat at a nip between a fixing member accommodating a heat source and a pressing member not accommodating it, consecutive sheets are driven out of the fixing device at a variable interval without the number of sheets to be output within a preselected period of time being varied.

Owner:RICOH KK

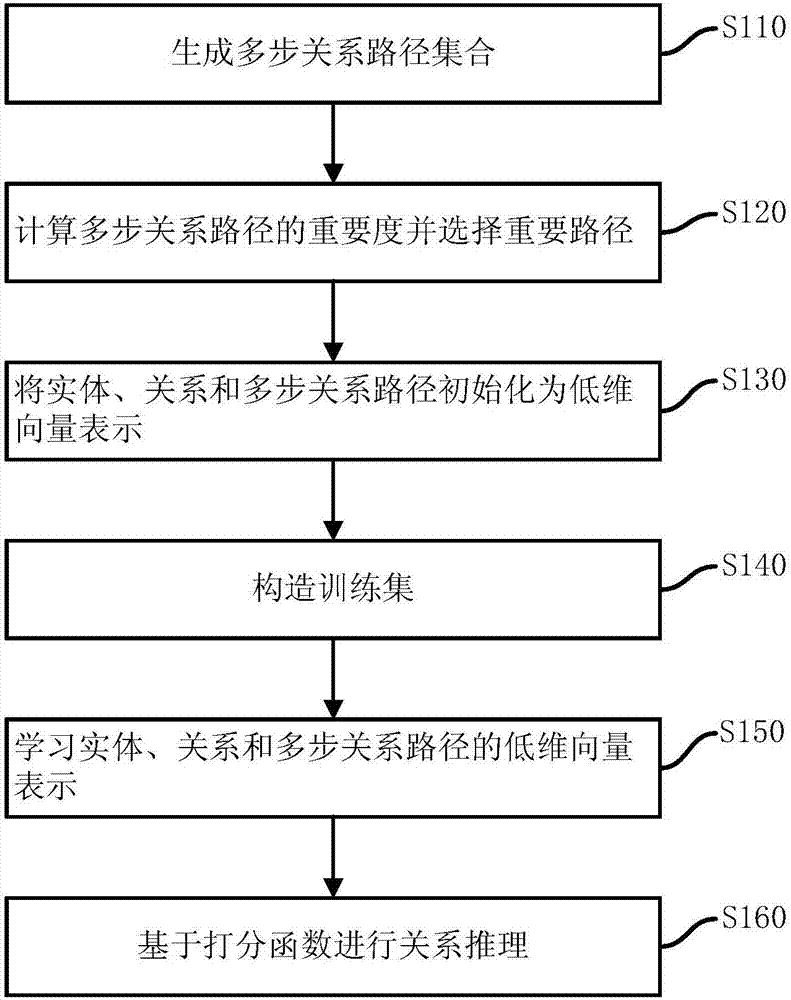

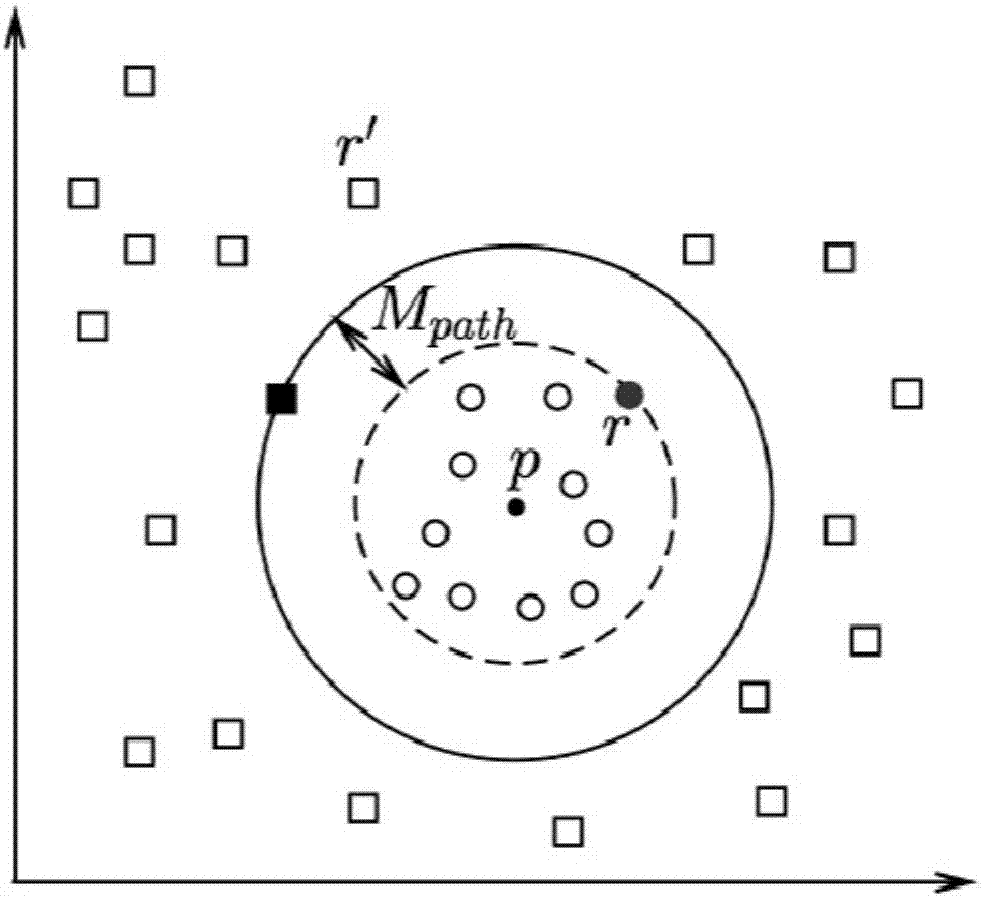

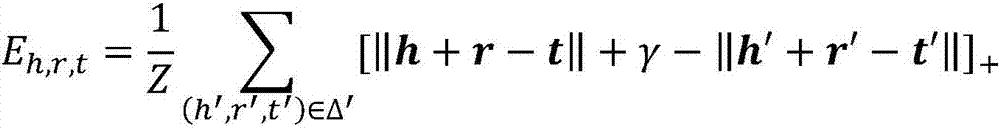

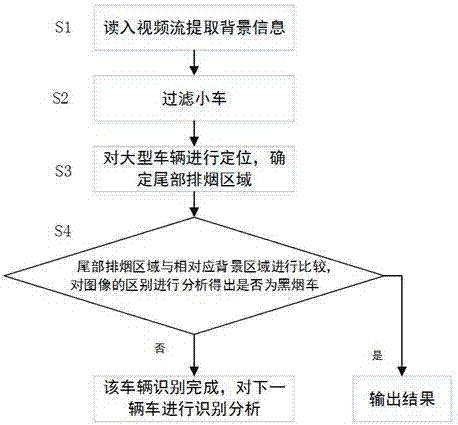

Vector representation method of knowledge mapping domain and inference method and system of knowledge mapping domain

InactiveCN106909622AHigh precisionImprove relational reasoningRelational databasesSpecial data processing applicationsPattern recognitionGraph spectra

The invention provides a vector representation method of a knowledge mapping domain. The method comprises the steps that the multi-step relation paths of the entity pairs in a knowledge mapping domain and between the relations and entity pairs are expressed as the initial low-dimensional vector; a model of the low-dimensional vector of the multi-step relation paths of the entity pairs and between the relations and the entity pairs is trained using a loss function with variable intervals. The model learned from the vector representation method is using for relation inferences to improve the accuracy of inferences in different knowledge mapping domains.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

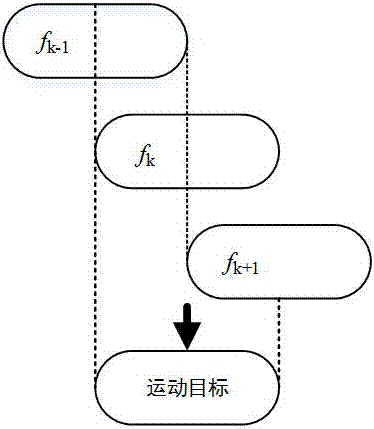

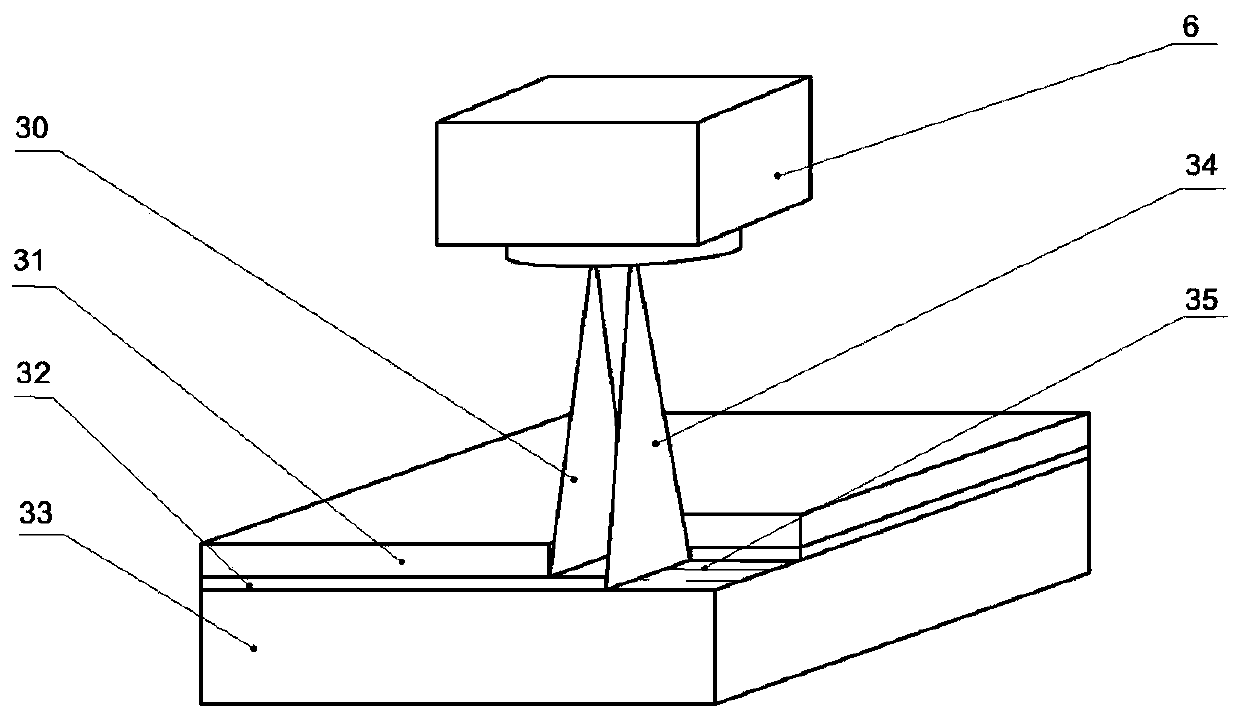

Intelligent monitoring and identification method for vehicles exhausting black smoke based on image processing technology

InactiveCN106951821AImprove efficiencyReduce data volumeCharacter and pattern recognitionData streamFilter algorithm

The invention discloses an intelligent monitoring and identification method for vehicles exhausting black smoke based on an image processing technology. The method comprises the following steps: S1, using a video capture card to collect a high-definition real-time video data stream of a traffic checkpoint; adjusting the time of interval sampling according to the degree of pavement change by use of a variable-interval background mean sampling technology, and extracting payment background information by use of a multi-frame image mean algorithm; S3, according to the collected video stream, removing small vehicles and non-motorized vehicles from each frame of image in real time by use of a small vehicle filtering algorithm, so as to reduce the amount of data of image processing and improve the efficiency of the algorithm; S4, positioning tail flue gas of large vehicles in each frame of image; and S5, comparing the data of a positioning area image and the data of a background area image of exhaust gas emission to judge whether the vehicles are vehicles exhausting black smoke. The intelligent monitoring and identification method for vehicles exhausting black smoke disclosed by the invention can improve the detection efficiency. Whether a vehicle exhausts black smoke is judged by use of the computer technology.

Owner:XIANGTAN UNIV

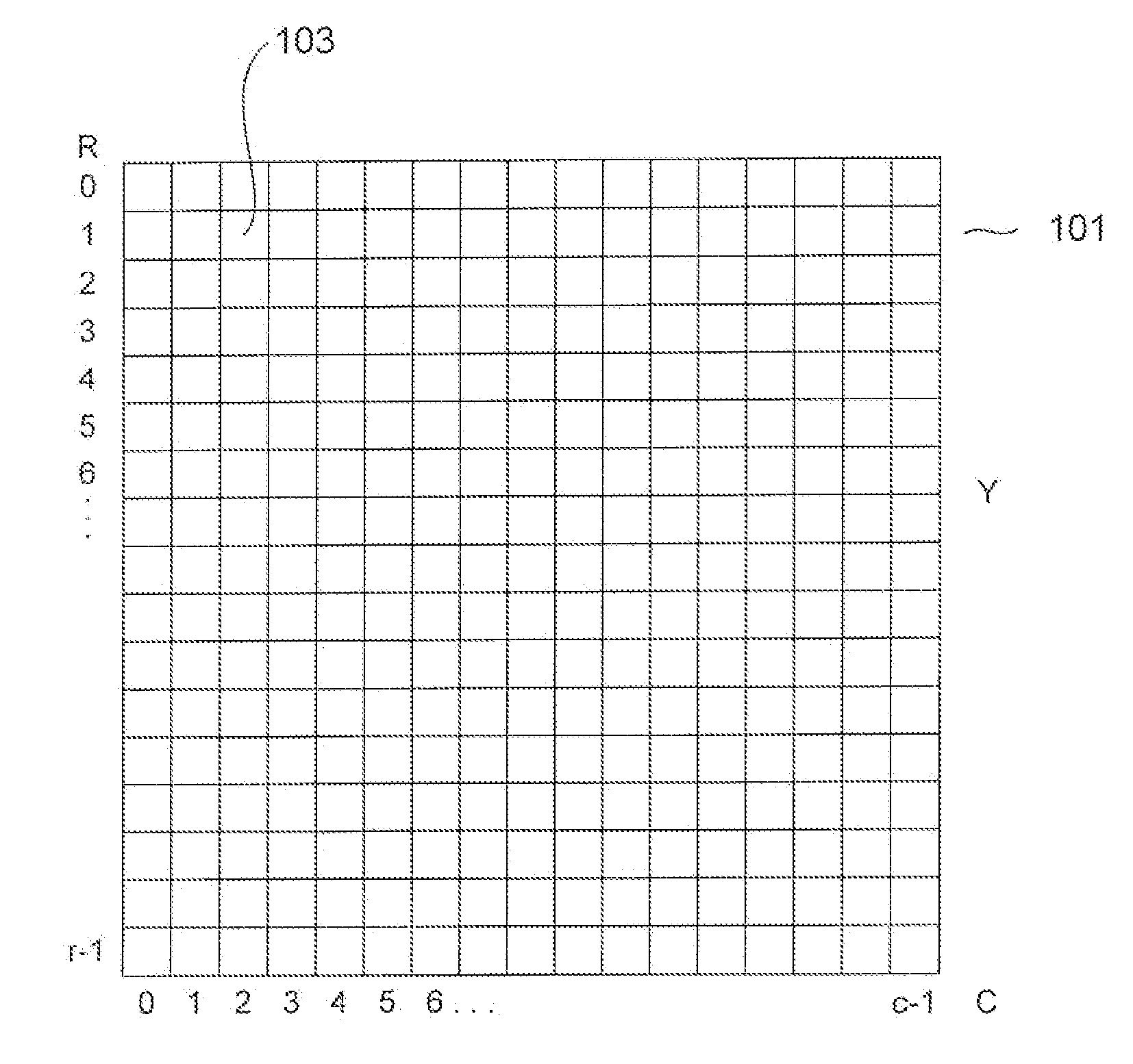

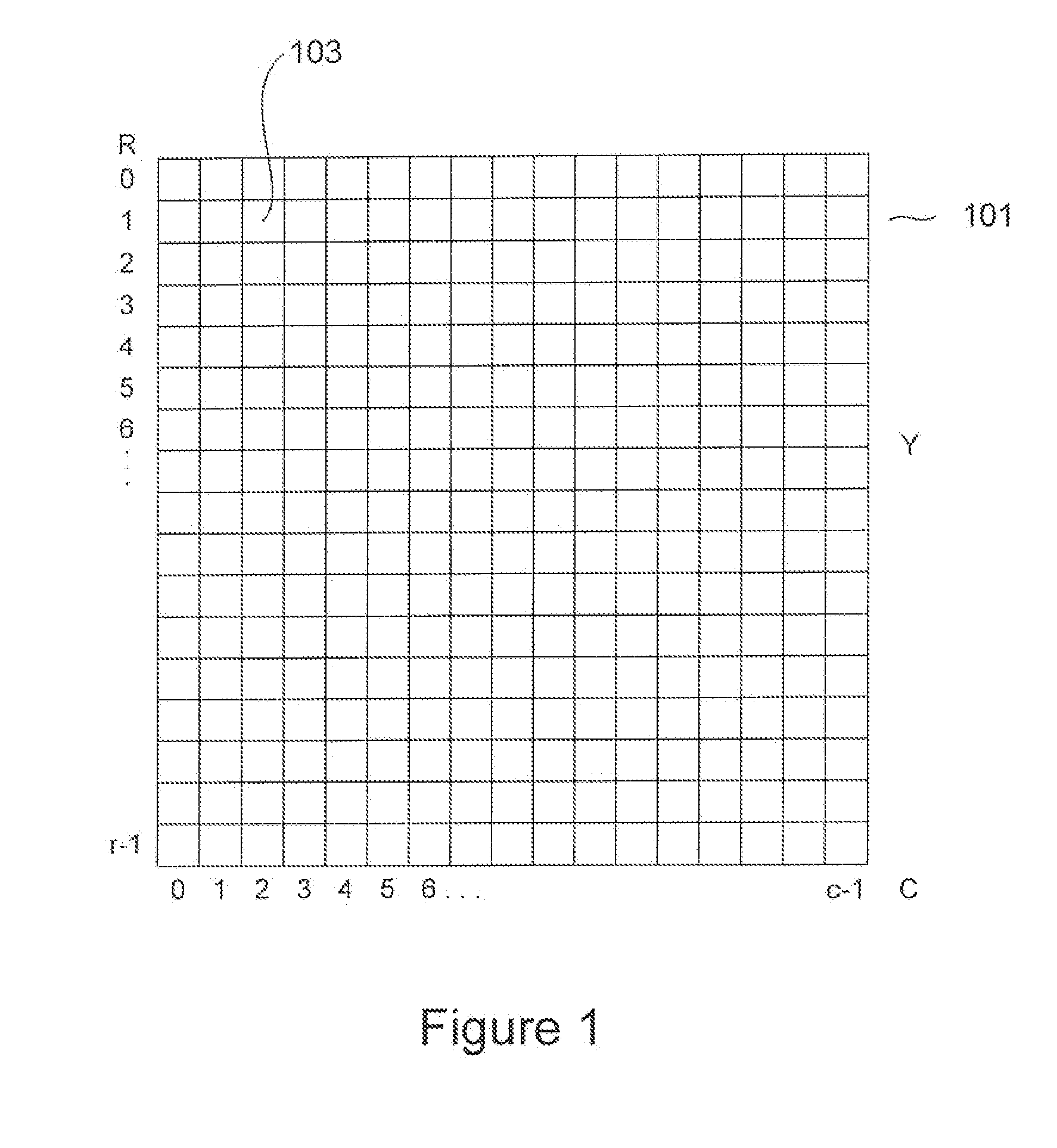

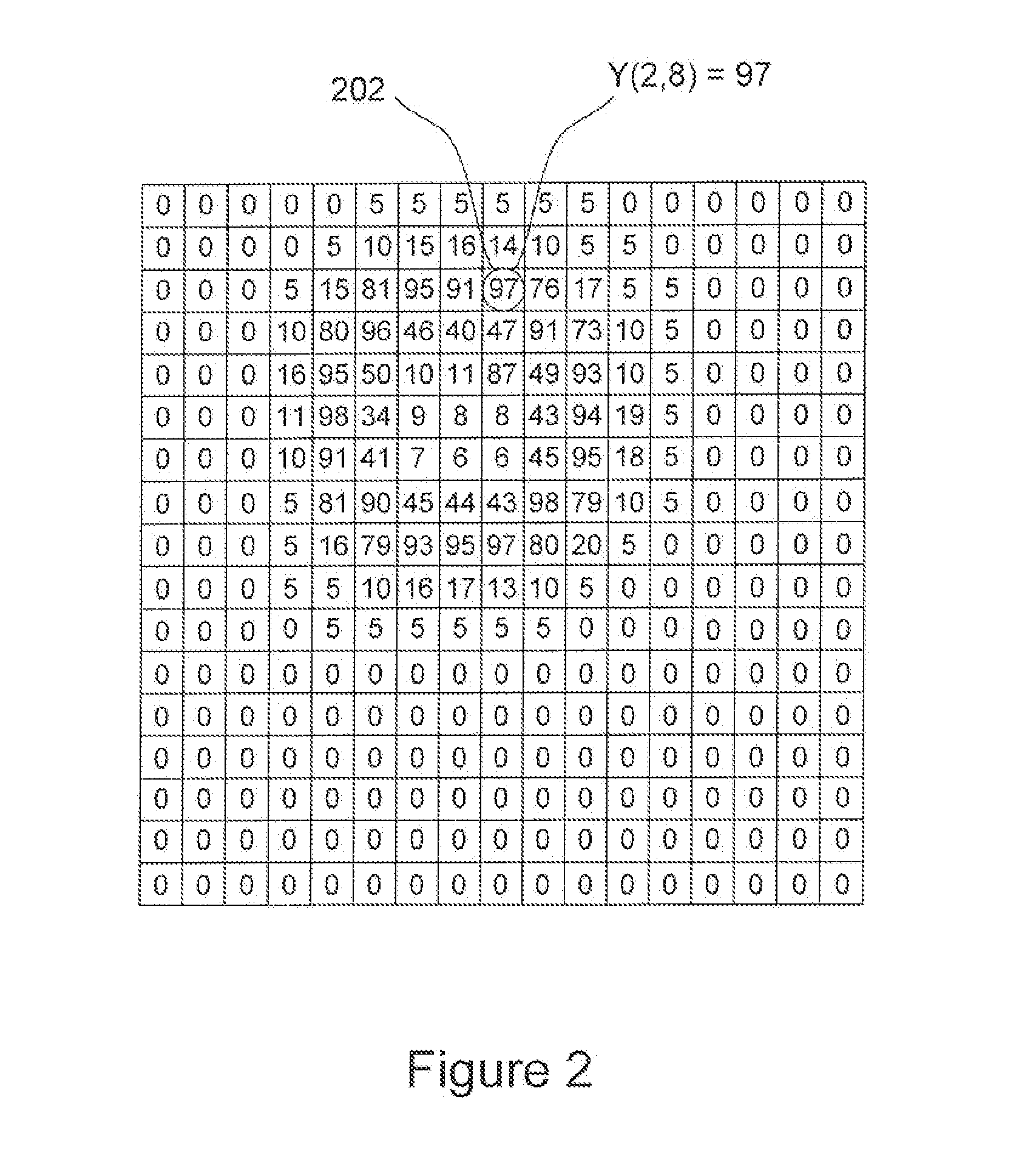

Method and system for efficient video processing

Embodiments of the present invention are directed to efficient video processing methods and systems for computationally efficient denoising, sharpening, contrast enhancement, deblurring, and other spatial and temporal processing of a stream of video frames. Embodiments of the present invention separate statistics-related calculations, including estimation of pixel-value-associated variances, standard deviations, noise thresholds, and signal-contrast thresholds, carried out on only a small percentage of video frames selected at a fixed or variable interval from the video stream, from various spatial and temporal processing steps carried out on each frame of the video stream. In certain embodiments of the present invention, the statistics-related calculations are carried out by the general processor or processors of a computer system, while the frame-by-frame spatial and temporal processing is carried out by one or more specialized graphics processors within the computer system.

Owner:HEWLETT PACKARD DEV CO LP

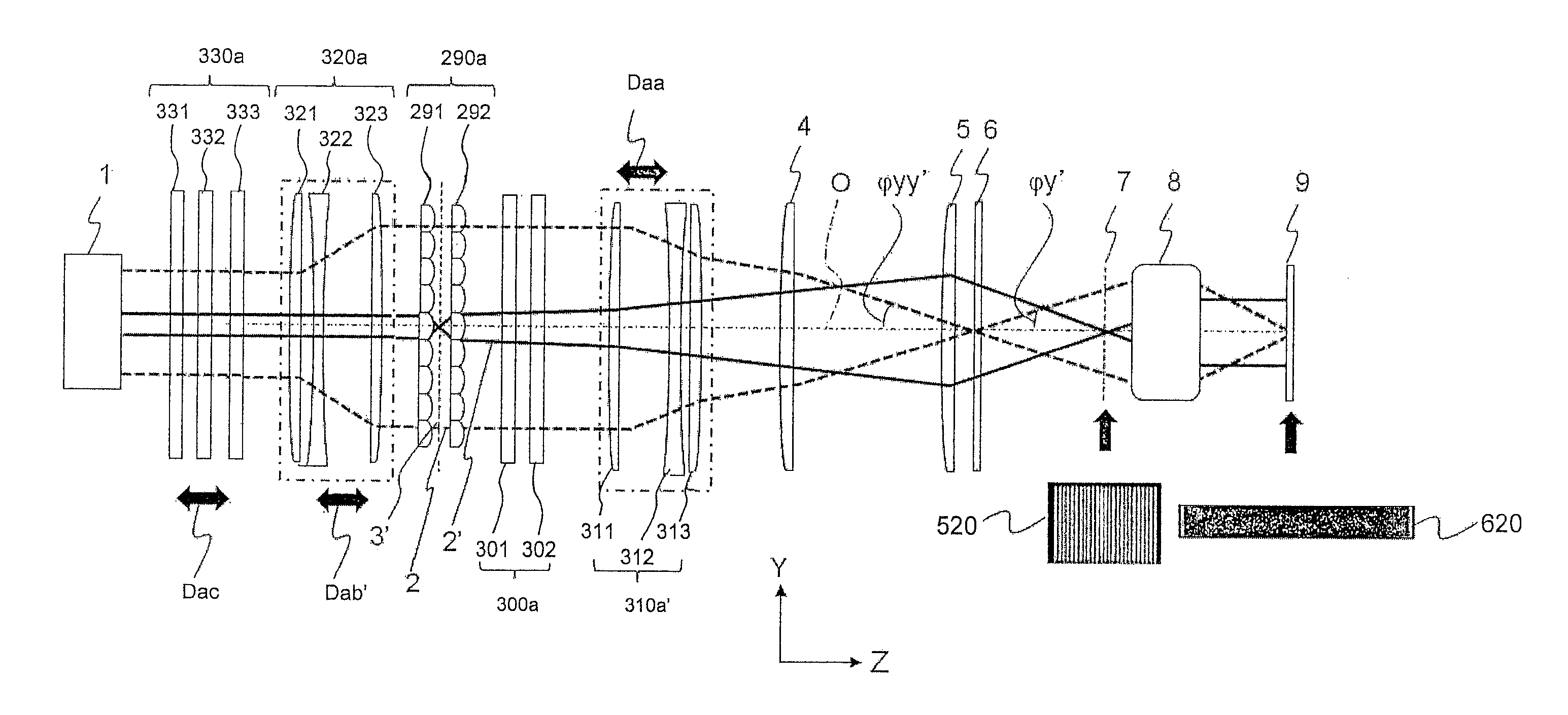

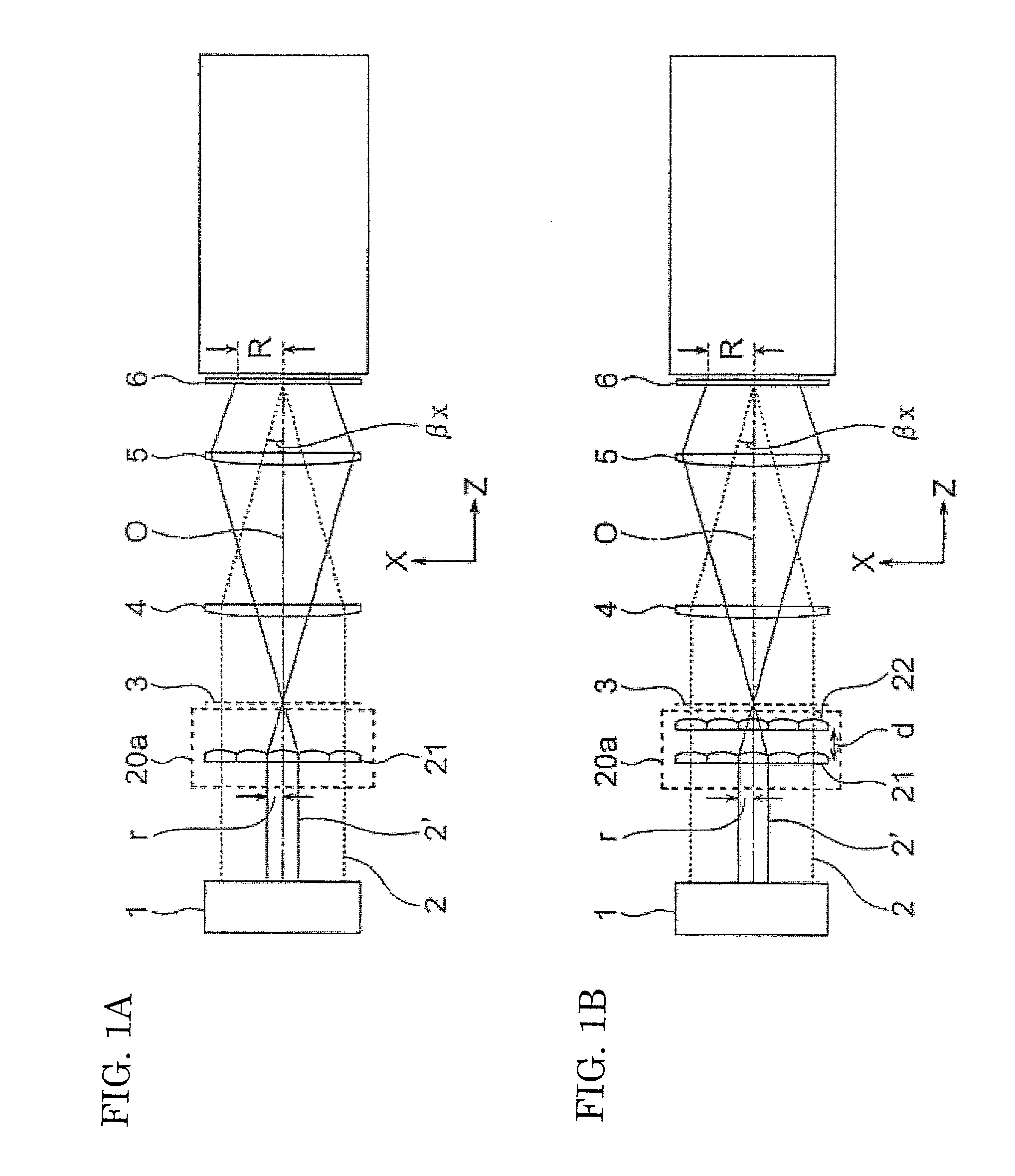

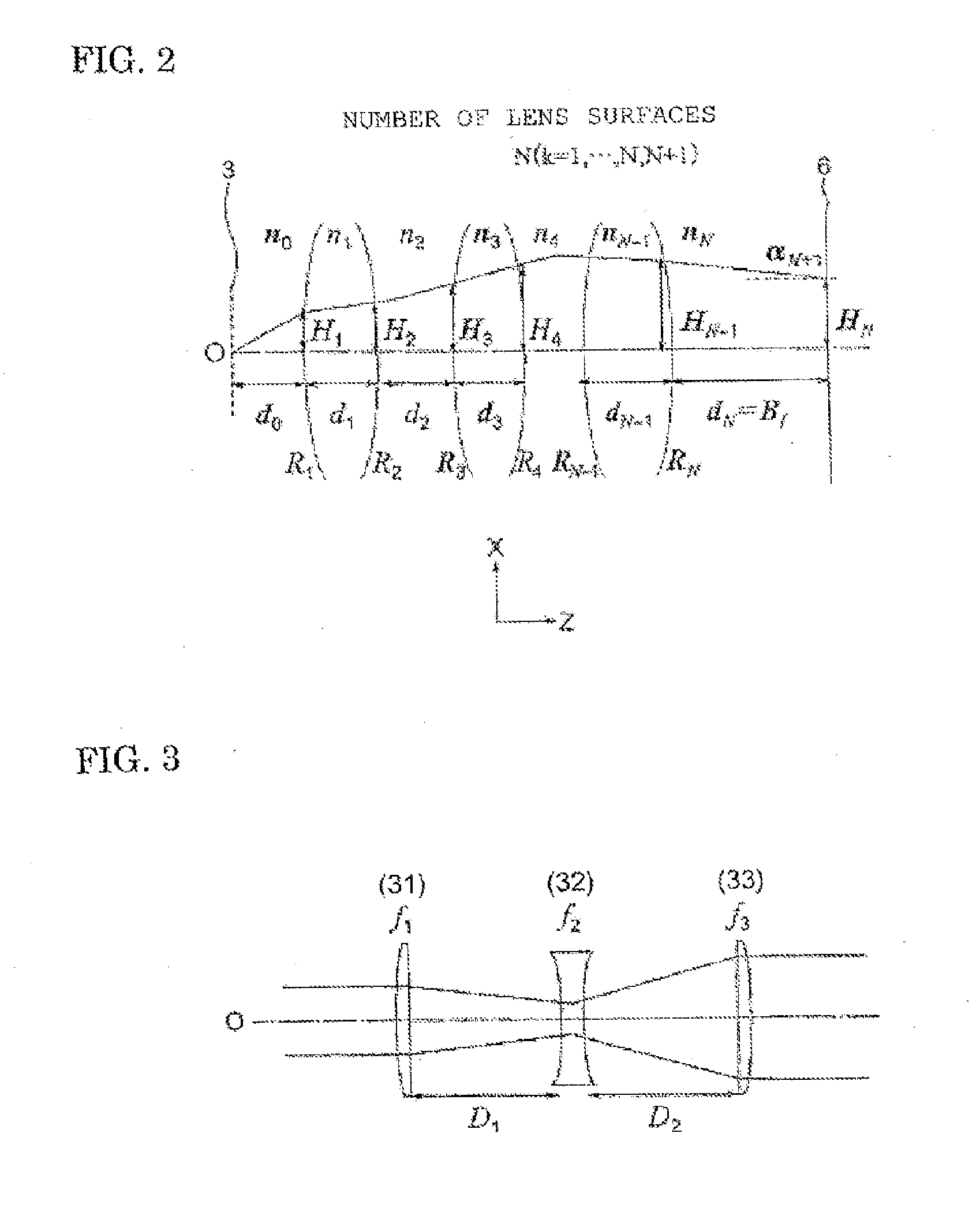

Adjustable Beam Size Illumination Optical Apparatus and Beam Size Adjusting Method

InactiveUS20110228537A1Small sizeUniform strengthCondensersLaser beam welding apparatusLight beamOptoelectronics

An adjustable beam size illumination optical apparatus includes a beam size adjusting optical system which includes groups of cylindrical array lenses disposed correspondingly to the long and short axis directions respectively and having variable intervals among the lenses, and a group of cylindrical telescope lenses disposed correspondingly to one of the long and short axis directions and having variable intervals among the lenses, and adjusts parallel light from a light source in size in accordance with the two axis directions orthogonal to each other. The lens interval of one of the cylindrical array lens groups and the cylindrical telescope lens group is changed to adjust a beam size on a projection surface in accordance with the long axis direction or the short axis direction. Thus, it is possible to adjust the beam size in accordance with the long axis direction and the short axis direction individually, and it is possible to make irradiation with the beam with uniform intensity.

Owner:HITACHI SEIKO LTD

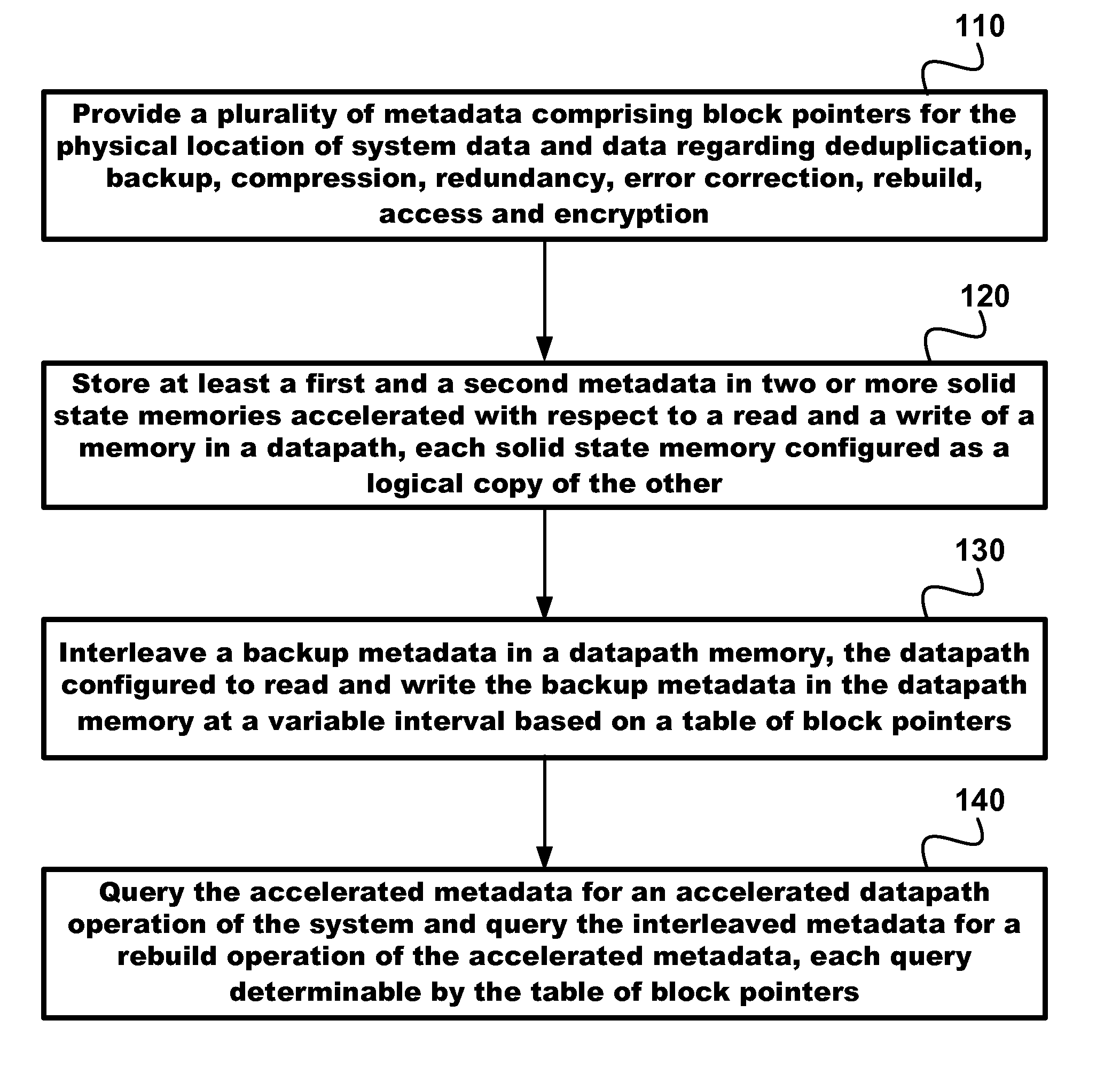

Scalable metadata acceleration with datapath metadata backup

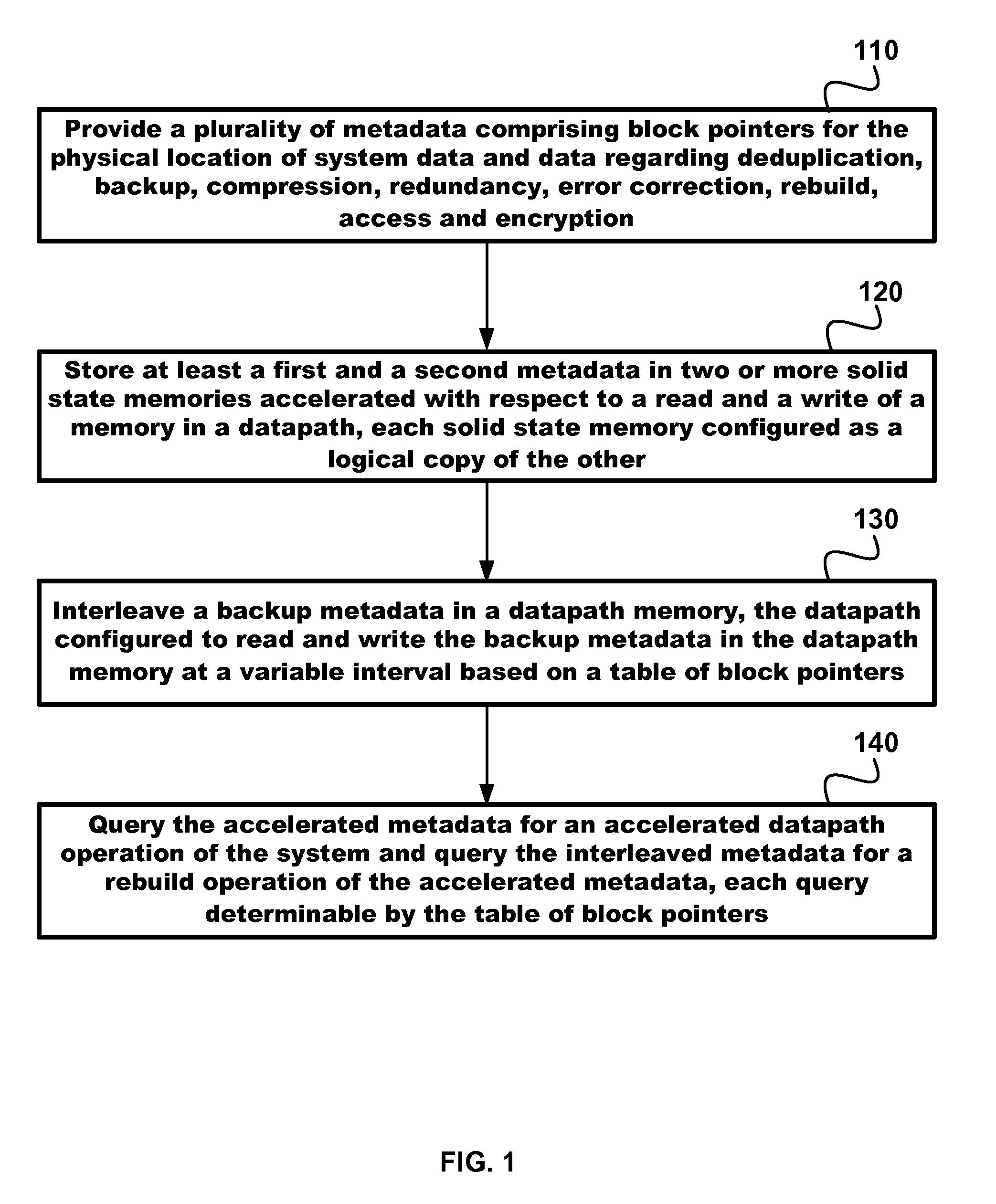

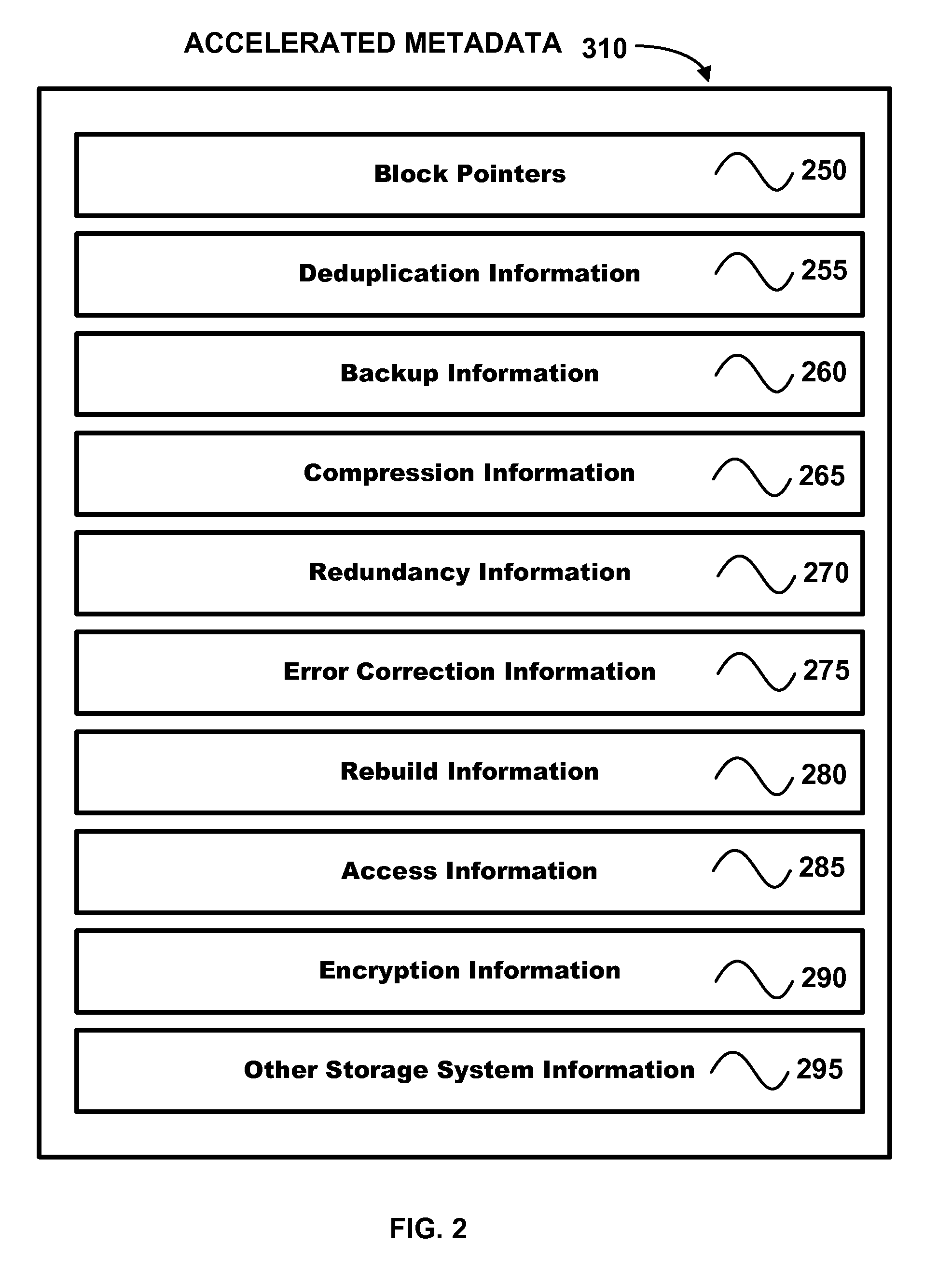

A system, method and computer program product for scalable metadata acceleration with datapath metadata backup as disclosed includes providing a plurality of metadata comprising variable block pointers for the physical location of system data. The method also includes storing at least a first and a second metadata in two or more solid state memories accelerated with respect to a read and a write of a memory in a datapath, each solid state memory configured as a logical copy of the other. The method additionally includes interleaving a backup metadata in a datapath memory at a variable interval based on a table of block pointers. The method further includes querying the accelerated metadata for an accelerated datapath operation of the system and querying the interleaved metadata and / or a logical mirror of the accelerated metadata for a rebuild operation of the accelerated metadata, each query determinable by the table of block pointers.

Owner:INTELLIFLASH BY DDN INC

BRT (bus rapid transit) combined dispatching method capable of achieving variable bus departure intervals

ActiveCN105448082ASolve the problem of concentrationAvoid \"cross-traffic\"Road vehicles traffic controlSeating capacityStop time

The invention belongs to the technical field of public transport dispatching and optimization, and especially relates to a BRT (bus rapid transit) combined dispatching method capable of achieving variable bus departure intervals. The method comprises the steps: determining the total number of stops and the total number of bus departure times, and obtaining the driving time of vehicles among stops, passenger flow information, the get-on time of passengers, the get-off time of passengers, and stopping time of vehicles; obtaining the number of get-on and get-off passengers at each stop, so as to determine the type of the stop as a BRT stop or common stop; taking a combination mode and a departure interval as decision variables; building a bus dispatching model, calculating the stop time and the number of get-on and get-off passengers of each vehicle at each stop, solving a target function expression, i.e., calculating the mean waiting time of passengers, the mean on-bus time of passengers, and the mean seating capacity of the vehicles; solving and obtaining a dispatching scheme through employing a particle swarm optimization algorithm, wherein the mean waiting time of passengers and the mean on-bus time of passengers are as short as possible in the scheme, the mean seating capacity of the vehicles are as large as possible in the scheme, and the scheme comprises a departure interval and a departure type.

Owner:TSINGHUA UNIV

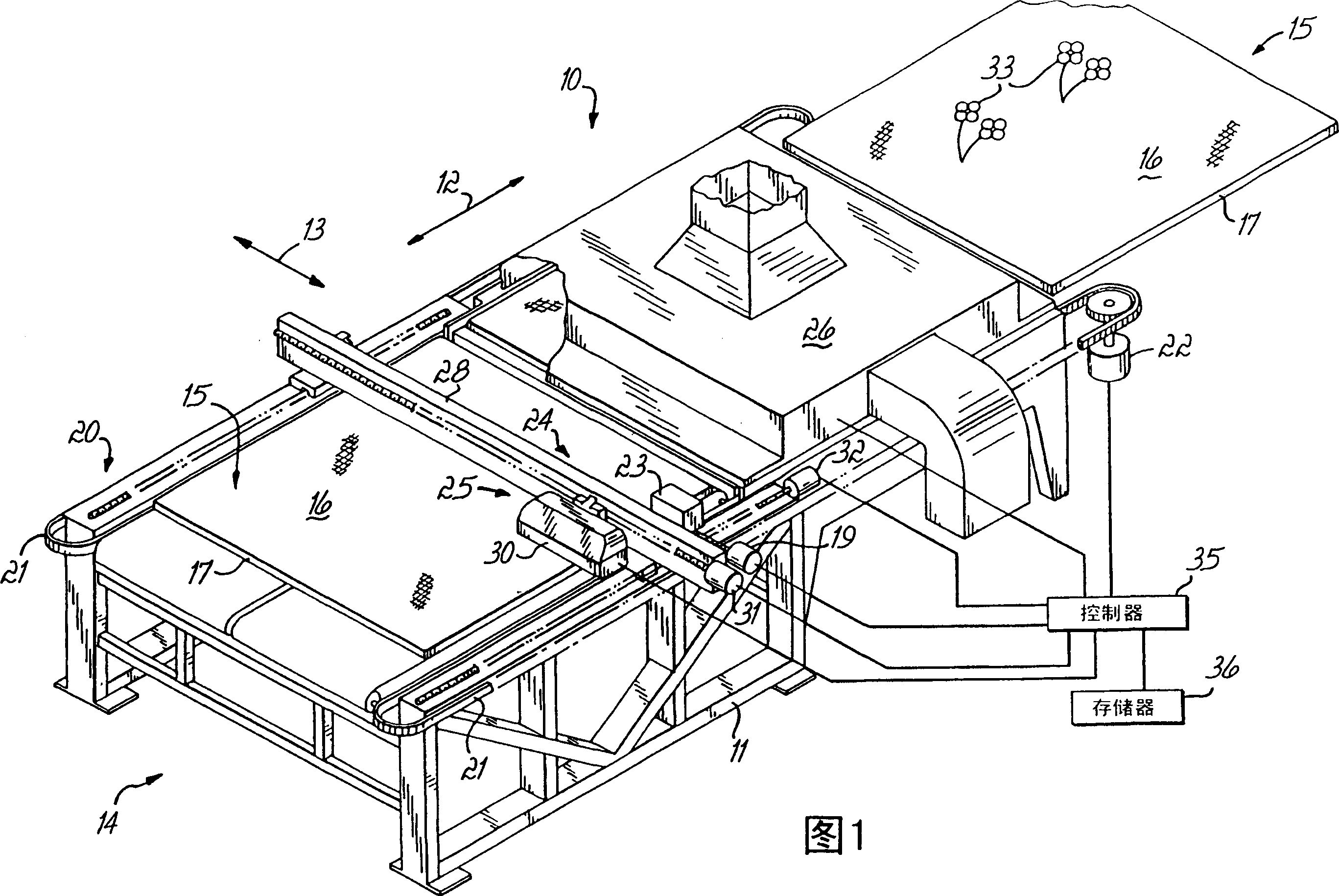

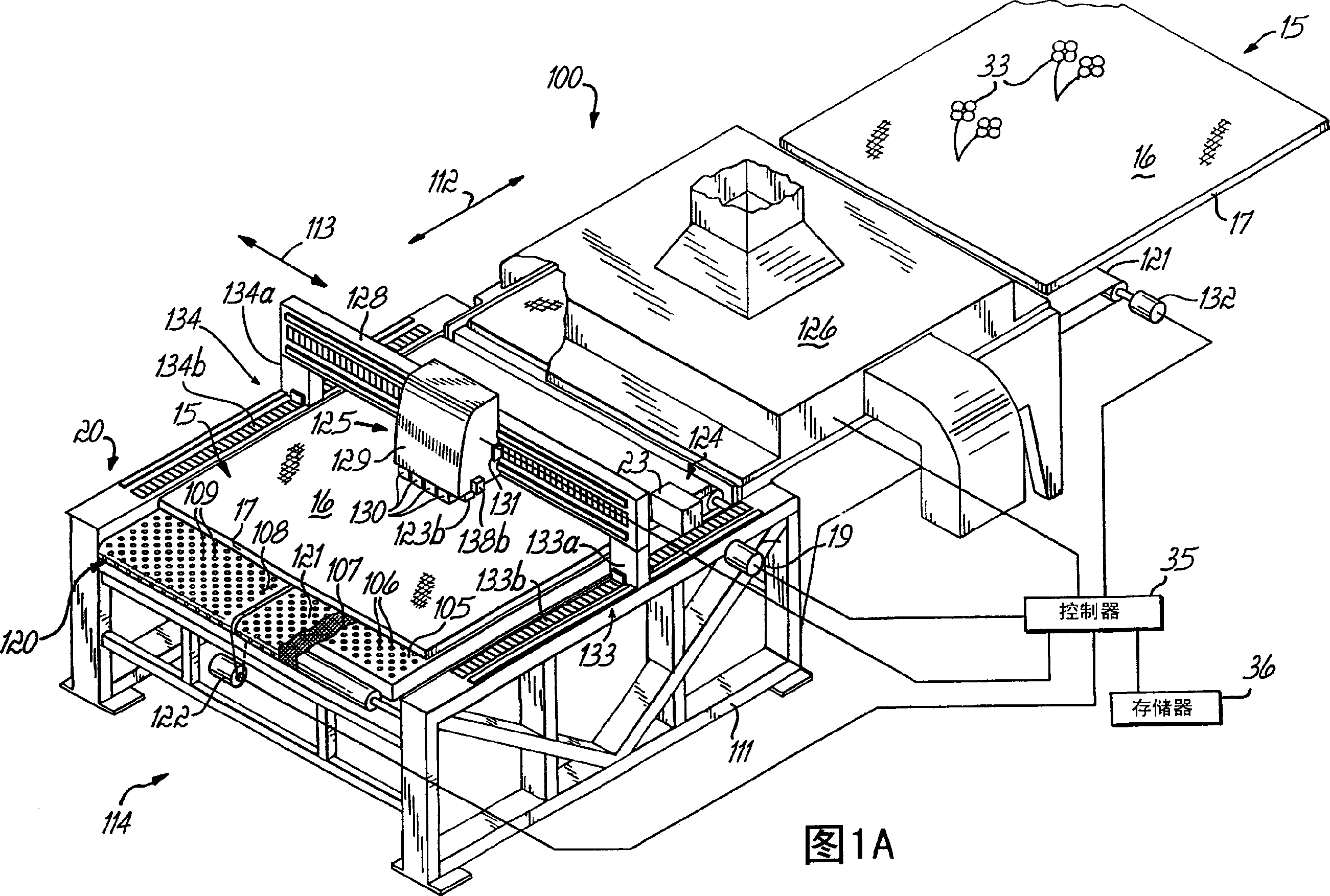

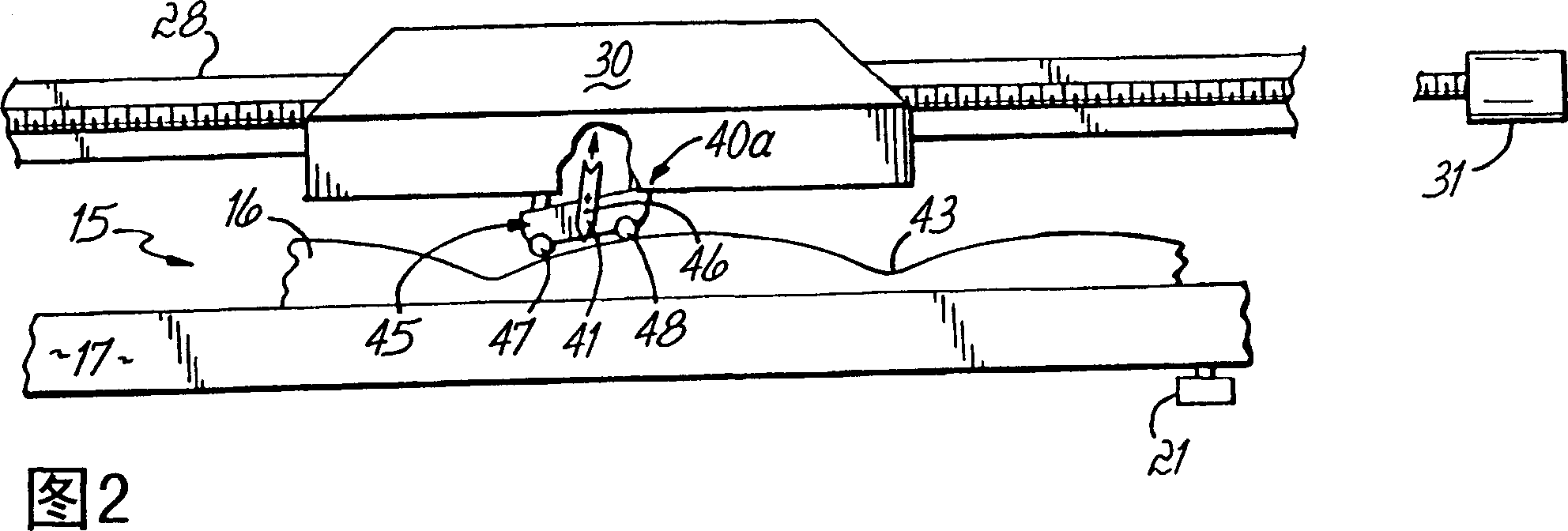

Method and apparatus for printing on rigid panels and other contoured or textured surfaces

Ink jet printing is provided onto rigid panels (15) such as office clapboard which may have contoured, textured surface (16) made from three-dimensional material, or other surfaces having variable interval from rigid panels, the distance between printing elements (30, 130, 130a-130d) and position which surface will printing on thereof is not alaways or exactly predicted. Panels (15) are printed using ultraviolet light curable ink, first at least part of ink are cured by UV light, and maybe more completely cure and dry the ink to remove by using heating step, thereby removing uncured monomer through evaporating, furtherly curing or other maners. The surface (16) of rigid panels have contoured shape via sewing or moulding technics. Printhead to panel spacing is adjustable to maintain a predetermined constant distance from the printing element to the surface of the panel. Each of printheads (130a-130d) independently moveable to control the spacing of the printheads from the substrate. Sensors (40, 138) set on printhead carriage (129) measure the distance from the printhead to the surface of the substrate. Positions or focus of UV curing heads (23, 123) are variable to keep UV light focus on ink on contoured surface of substrate. UV curing heads may be located on the printhead carriage, every side of printhead has a light curing head, so that alternating work when the carriage reciprocating, spot curing and coagulating ink points immediately after ink deposited on the substrate. Cold UV sources may be used to prevent heat deformation of flat or contoured substrates, thereby making spot curing on heat-sensitive substrates.

Owner:L & P PROPERTY MANAGEMENT CO

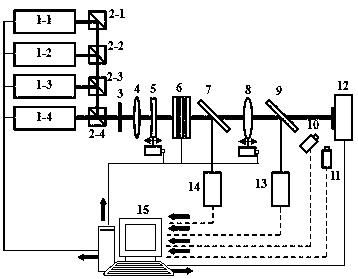

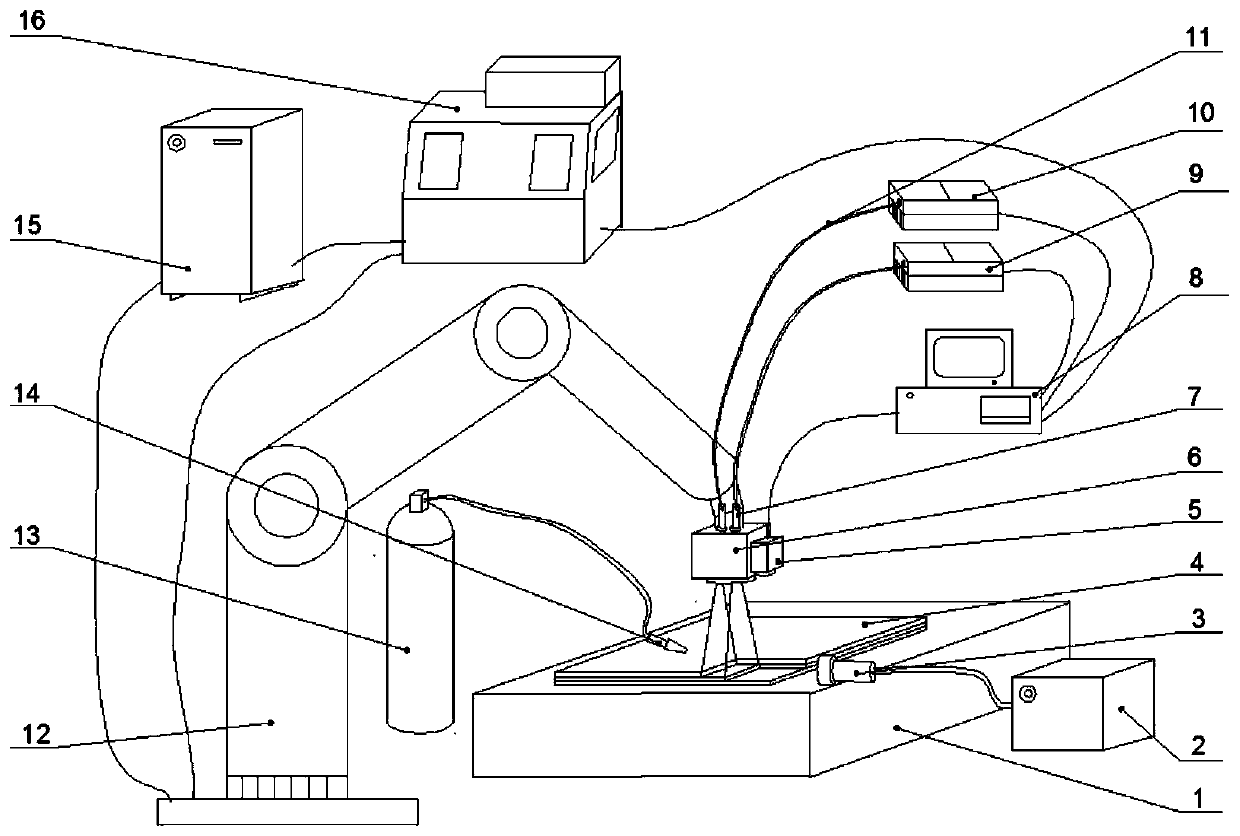

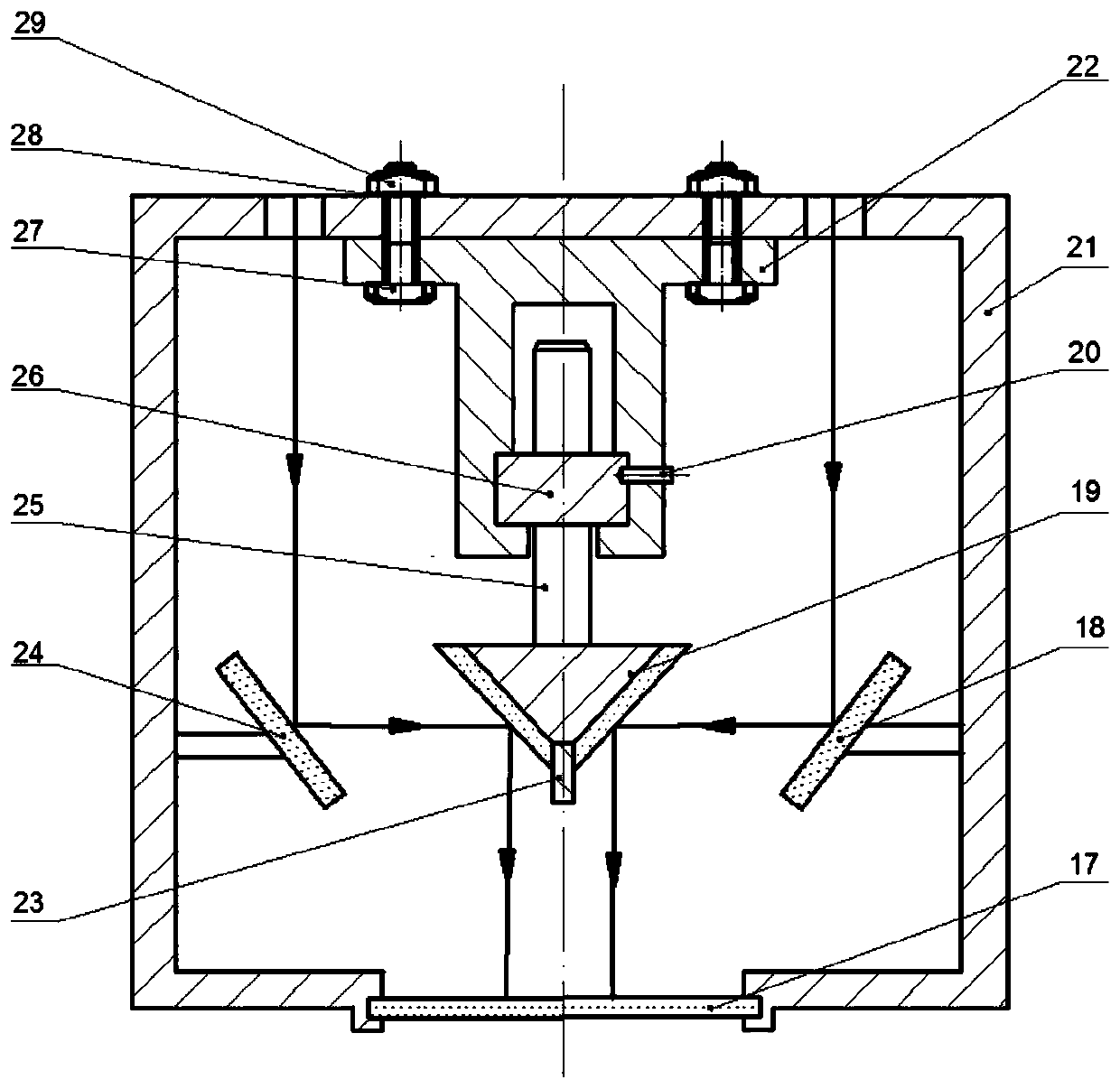

Multi-beam coaxial laser damage threshold test device and realization method

The invention discloses a multi-beam coaxial laser damage threshold test device and a realization method. According to the multi-beam coaxial laser damage threshold test device, four high-energy pulsed lasers are adopted, reflected by corresponding prisms and then enter a coaxial optical system, four light beams use one set of system and a computer control processing system, a variable-interval positive lens and a variable-interval negative lens are utilized to constitute a beam expanding system, the optical interval of the beam expanding system is adjusted, and thus collimated beam expandingof laser beams with different wavelengths can be achieved; and a stepper motor is adopted to precisely control the position of a focusing lens, and focal lengths of the different laser wavelengths arecompensated, so that it is ensured that laser is transmitted to the test surface, and the size and defocusing amount of a light spot are constant. According to the multi-beam coaxial laser damage threshold test device, integration, automation and intellectualization of a test system are achieved, thin film damage can be judged quickly and accurately in real time online, and laser damage thresholds of the various different wavelengths can be measured through the same test device.

Owner:XIAN TECH UNIV

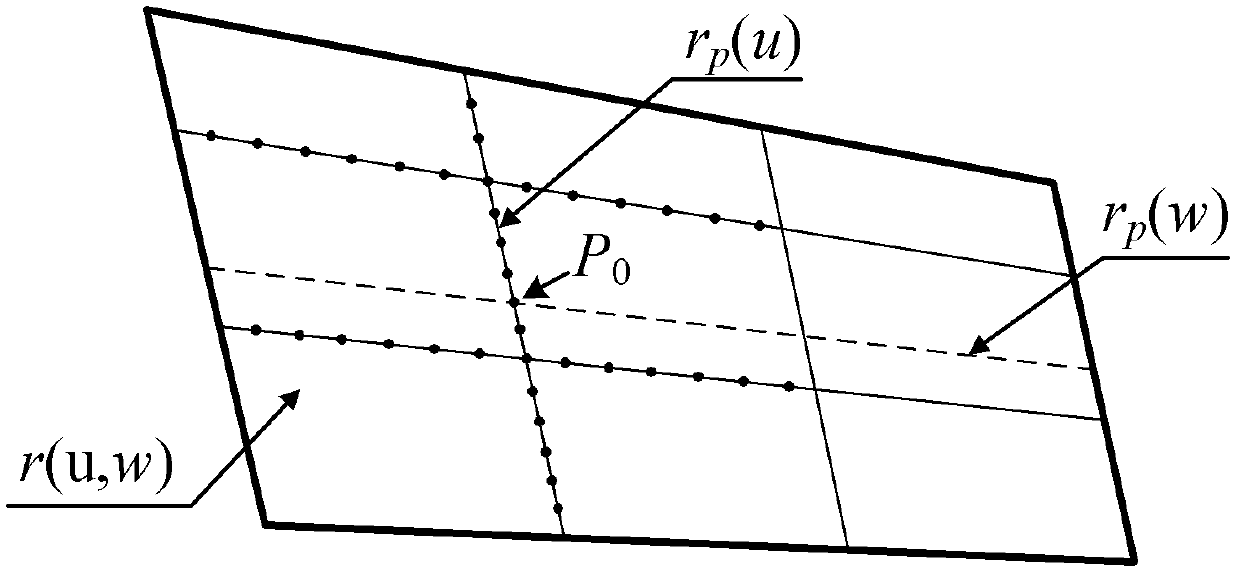

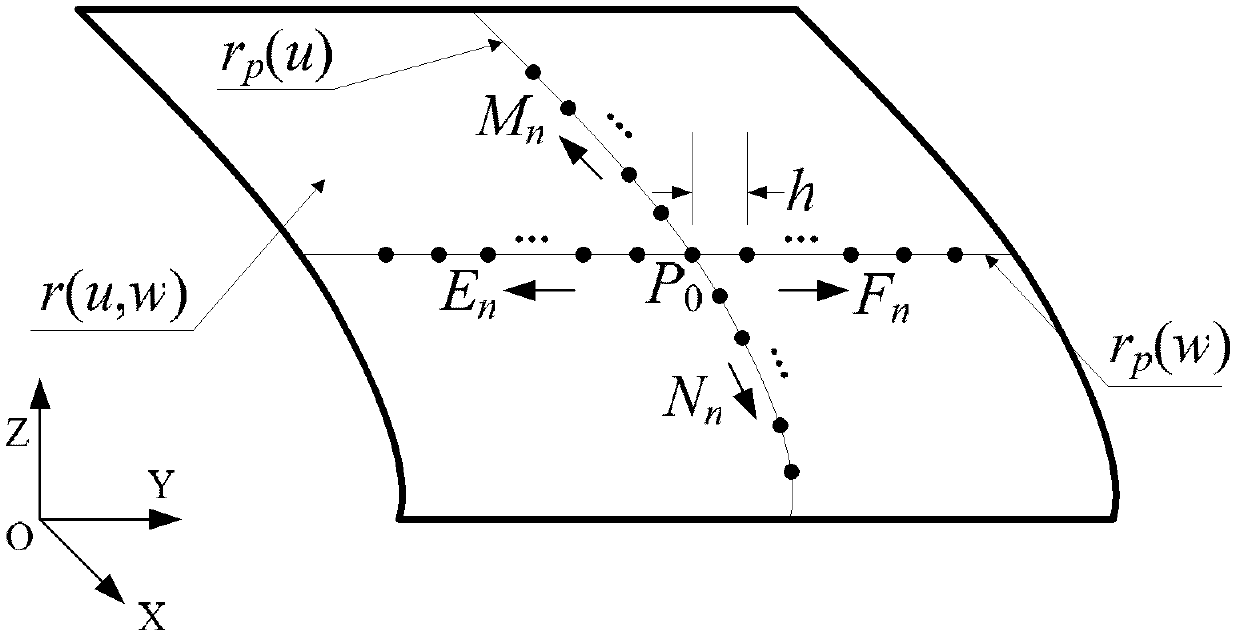

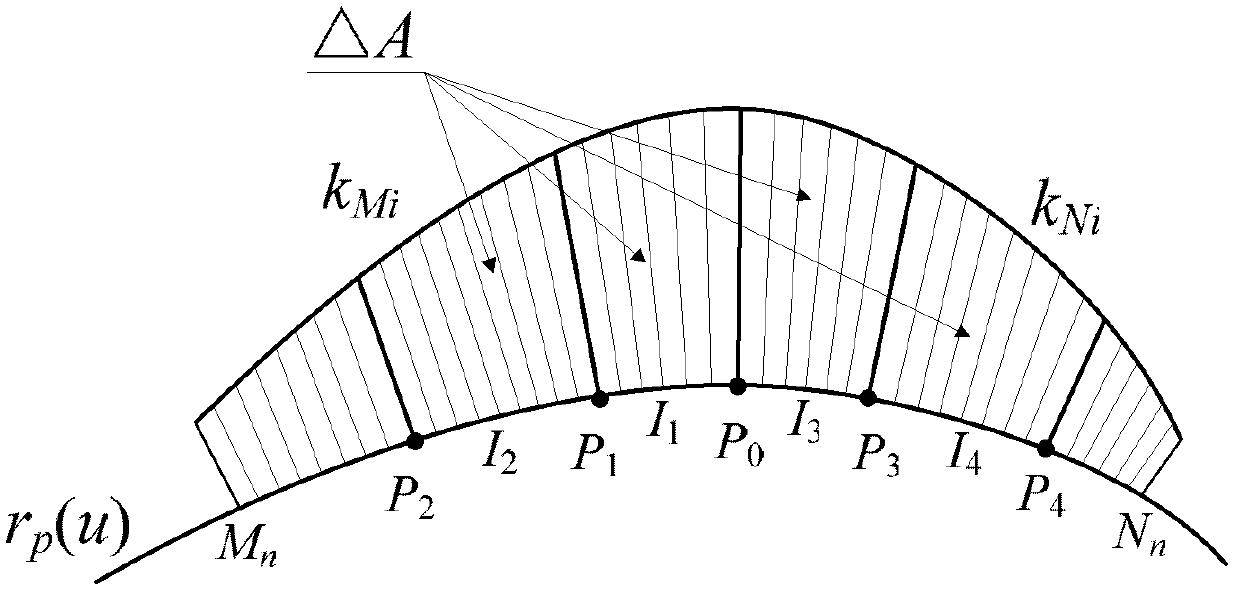

Variable-interval self-adaptive measuring point-searching aircraft panel normal vector determination method

InactiveCN102607484AImprove the accuracy of normal vector solutionGuarantee processing qualityMeasurement devicesMeasurement pointMathematical model

The invention provides a variable-interval self-adaptive measuring point-searching aircraft panel normal vector determination method, which can utilize the equicurvature integration method to self-adaptively search measuring points and interpolate two cubic B-spline curves on the measuring points according to the theoretical mathematical model of a panel, so as to determine the normal vector of the curved surface. Compared with the conventional method, the method utilizes the beneficial mathematical parameters provided by the theoretical mathematical model of the curved surface of the panel and adopts the equicurvature integration method to search the measuring points, thus ensuring that the density of the measuring points can be increased or decreased as the curvature of the curve is increased or decreased, the precision of solving the normal vector of the curved surface of the panel is increased by optimizing the distribution of the positions of the measuring points, the solution result can be used for guiding automatic drilling and riveting equipment to drill and rivet the panel, can be used in the analysis and estimation of panel deformation, and as a basis for the detection of the shape of the panel, the method is significant for the guarantee of aircraft panel-machining quality.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Electronic fish tank capable of automatically cleaning dirt

An electronic fish tank capable of automatically cleaning dirt comprises a tank body (1), a filter net (2) is arranged at the bottom of the tank body, a water turbidity monitor (3) and a sewage pump (4) are arranged under the filter net (2), a water inlet pipeline (5) is arranged on the upper portion of the tank body, excrement of fishes is deposited at the bottom of the tank body after penetrating through the filter net (2), the water turbidity monitor (3) is used for detecting the bottom water quality condition at variable intervals, and when water is judged to be dirty and needs to be replaced, the sewage pump (4) is started to clean dirt, and fresh water is supplemented through the water inlet pipeline (5); the water turbidity monitor (3) is a light perspective detection device; a reminding device (6) is arranged, reminding information is sent when water needs to be replaced, the condition of excrement at the bottom of the fish tank can be dynamically monitored, and excrement treatment and tank water replacing are automatically carried out.

Owner:丁宇栋

Large-scale ecological grazing pig cultivation method

InactiveCN102771444AStrong disease resistanceGrow fastFood processingAnimal feeding stuffAnimal scienceCichorium

The invention discloses a large-scale ecological grazing pig cultivation method, and belongs to the technical field of animal husbandry cultivation. A female miniature pig is hybridized with a female Taihu pig; a hybridized first generation young sow is selected as a female parent, and hybridized with two male black pigs as male parents; and the hybridized second generation is ecologically cultivated. A luxuriant grass is taken as a sports ground type grazing district; renascent herbs are mixed sown on the grass; various pastures are mixed sown on the grass every year; an ecological hog house is built; strains, fermented grass and natural nutrition healthcare pills or the like are prepared; when the pigs are cultivated, one or more of black wheat, cyperus esculentus, prepared soybean, endive, alfalfa, fermented grass meal and natural nutrition healthcare sugared pills are fed to the pigs in the hog house in variable interval; after the pigs freely eat, the pigs are driven to the sports yard to graze in a short time. Various pastures are planted on the sports yard until the sports grass per Mu can allow more than 100 pigs to be cultivated, and thus the large-scale ecological cultivation is achieved.

Owner:周建设

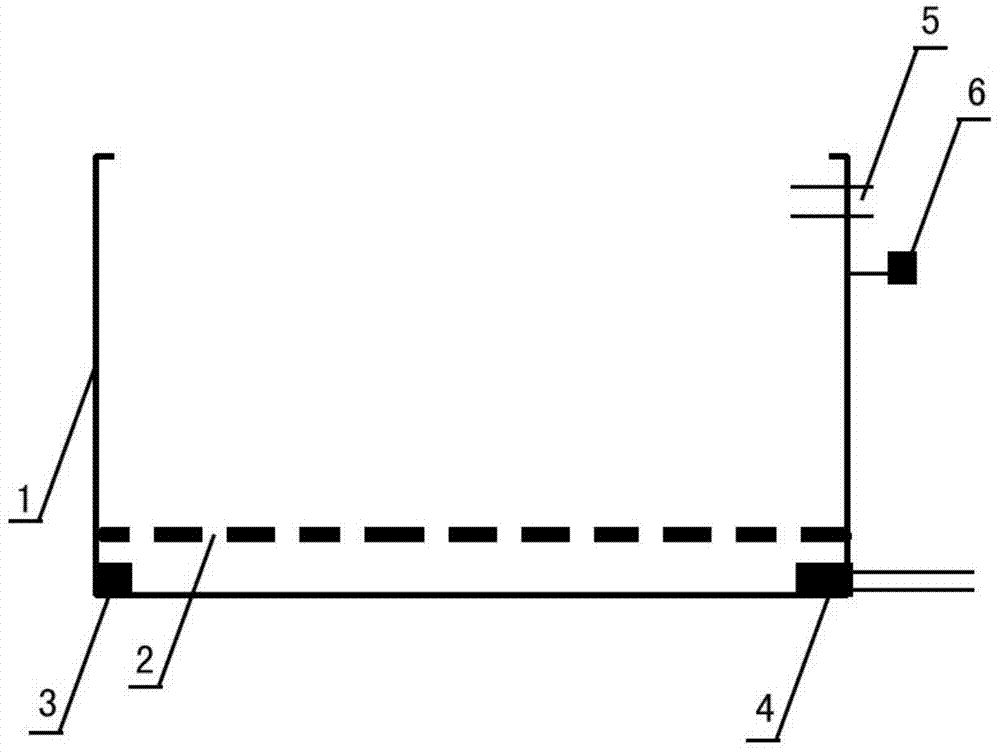

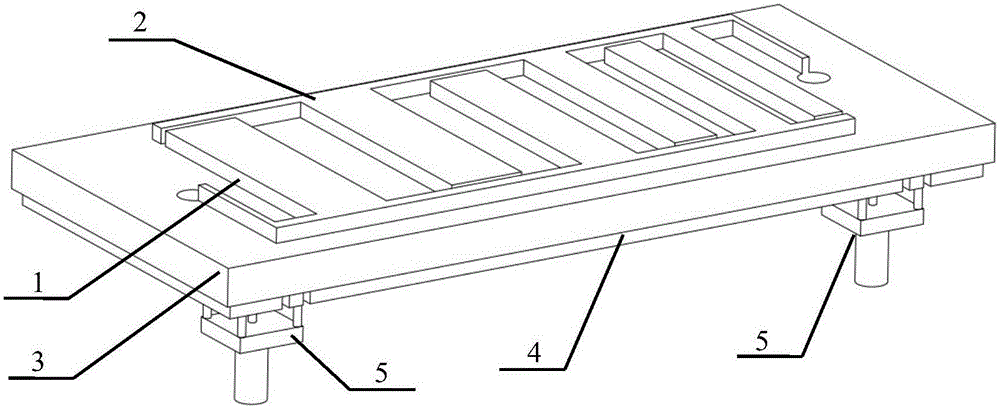

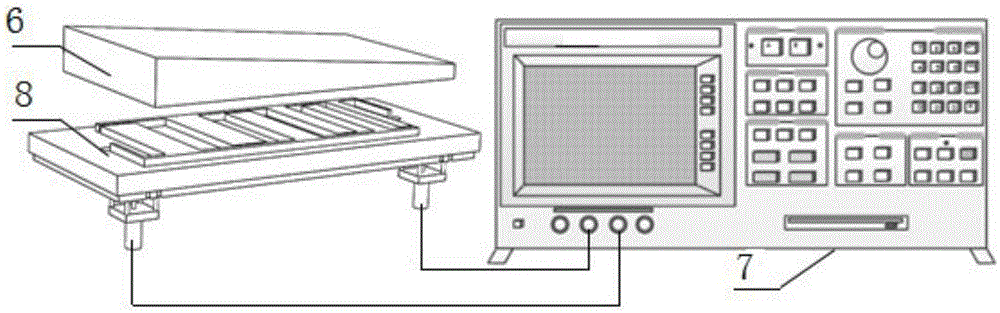

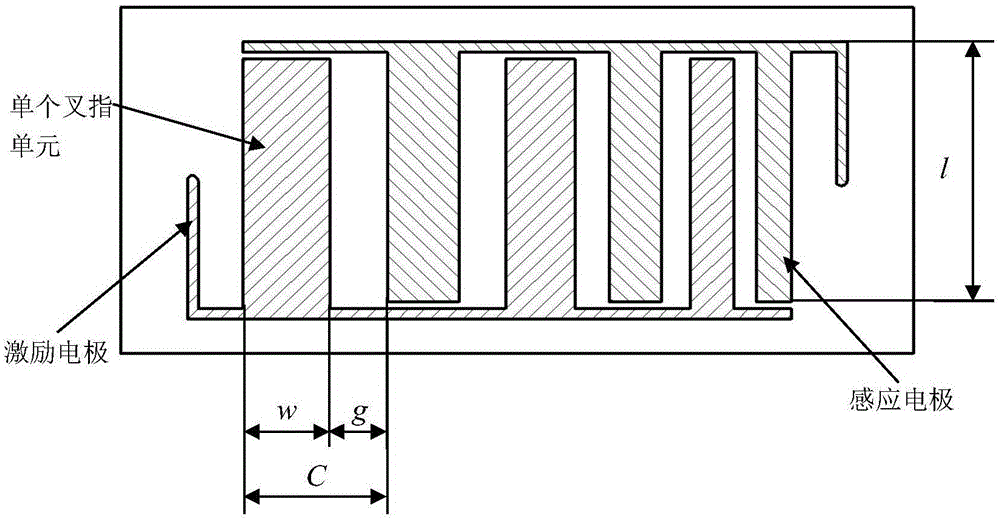

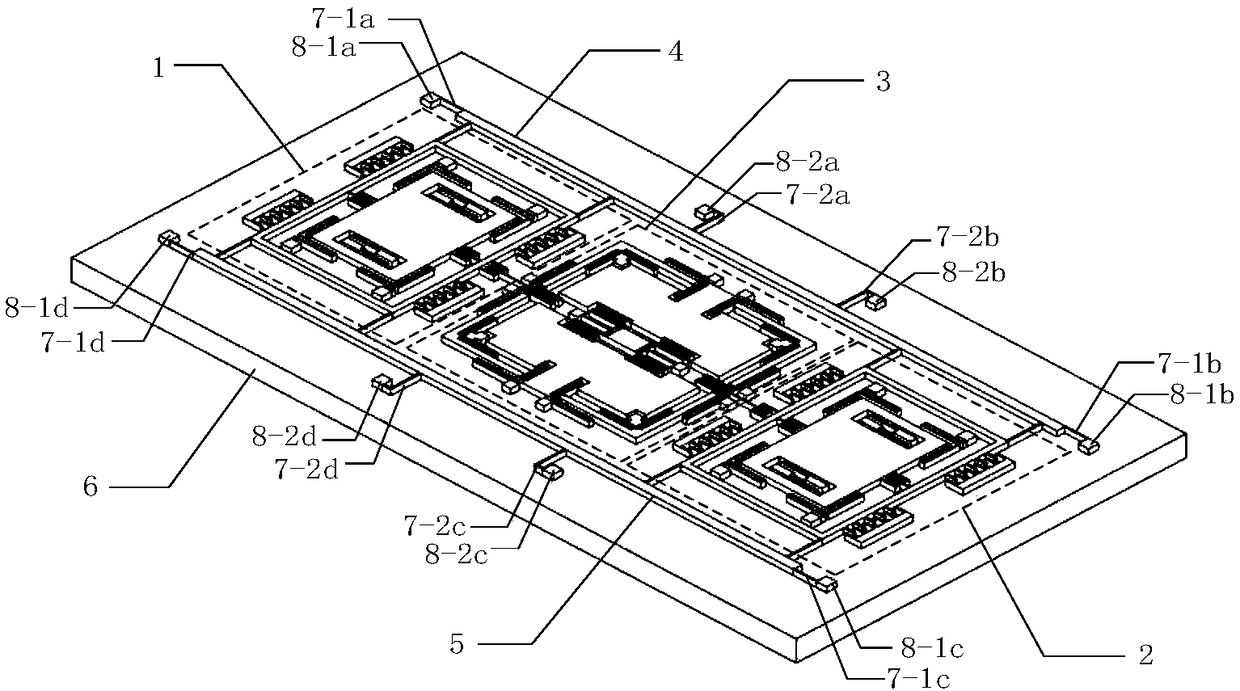

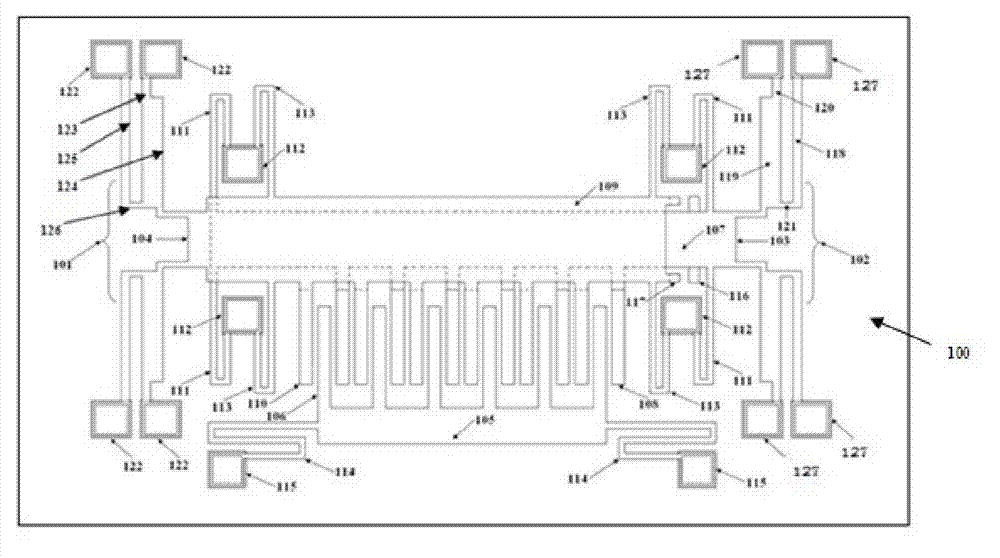

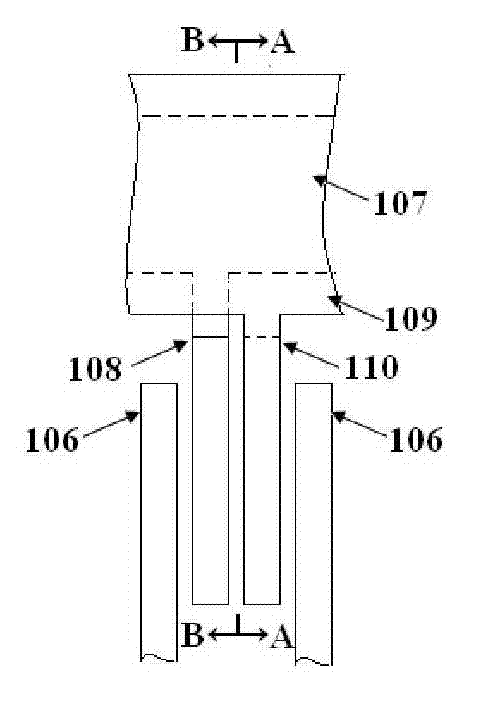

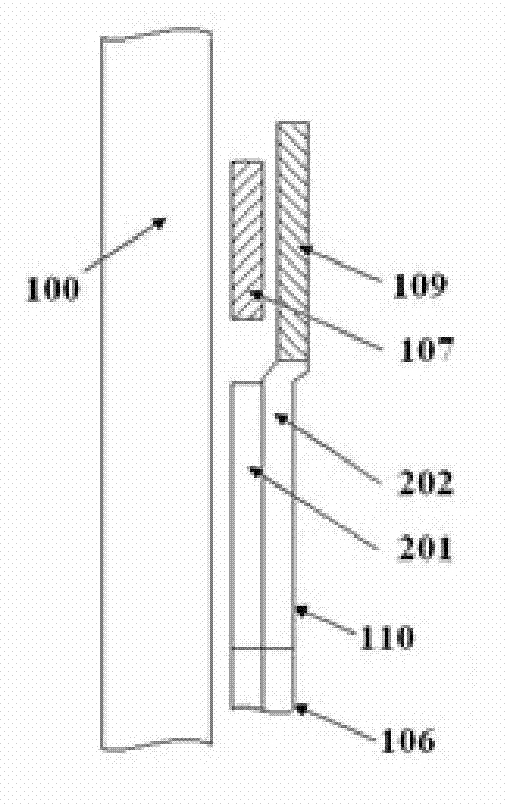

Variable-interval interdigitated adjacent capacitive sensor

ActiveCN105158582AIncrease the effective electrode areaMeasuring Electrical PerformanceCapacitance measurementsElectronic switchingVariable thicknessVariable interval

The invention provides a variable-interval interdigitated adjacent capacitive sensor, which is used for detecting dielectric properties of variable-thickness high polymer materials, and belongs to the field of nondestructive detection. The variable-interval interdigitated adjacent capacitive sensor is mainly composed of an excitation electrode, a sensing electrode, a substrate, a shielding layer, lead wire joints and the like. The excitation electrode and the sensing electrode are characterized by each comprising a plurality of interdigitated units, independent optimization design is carried out on width and intervals of each interdigitated unit that forms the interdigitated sensor electrodes according to a thickness variation rule of a structure to be detected, that is, the width of the electrodes is as large as possible on the premise of ensuring penetration depth, thus maximum signal intensity and detection sensitivity can be obtained. Compared with the traditional equal-interval interdigitated adjacent capacitive sensor, the variable-interval interdigitated adjacent capacitive sensor enlarges the effective electrode area, and enhances signal intensity and detection sensitivity.

Owner:BEIJING UNIV OF TECH

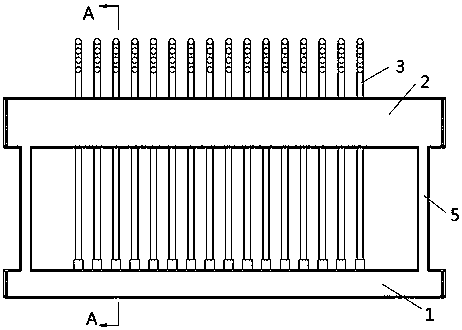

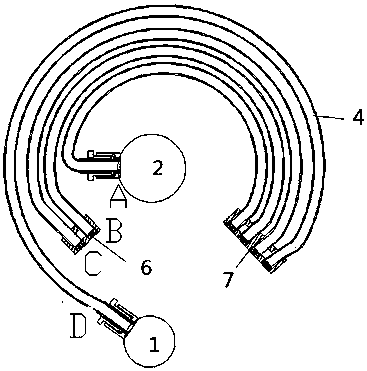

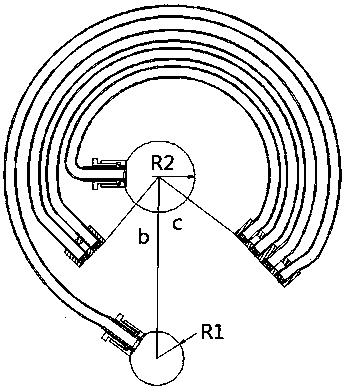

Variable-interval multi-heat-exchanging-pipe heat pipe

ActiveCN107631653AImprove heat transfer performanceImprove heat transfer effectIndirect heat exchangersHeat transfer modificationVariable intervalEngineering

The invention provides a heat pipe. The heat pipe comprises a lower collecting pipe, an upper collecting pipe, and pipe bundles through which the lower collecting pipe is communicated with the upper collecting pipe; the number of the pipe bundles is one or more; each pipe bundle comprises a plurality of arc-shaped heat exchanging pipes; the end portions of the adjacent heat exchanging pipes are communicated, and the heat exchanging pipes are made to form a series connection structure; the center lines of the arc-shaped heat exchanging pipes are an arc of concentric circles; and the larger thedistance away from the concentric circle center is, the larger the distance between the adjacent heat exchanging pipes is. The invention provides the novel type heat pipe; and due to the optimizationarrangement, the heat exchanging efficiency can be further improved, and the heat exchanging uniformity is improved.

Owner:青岛酒店管理职业技术学院

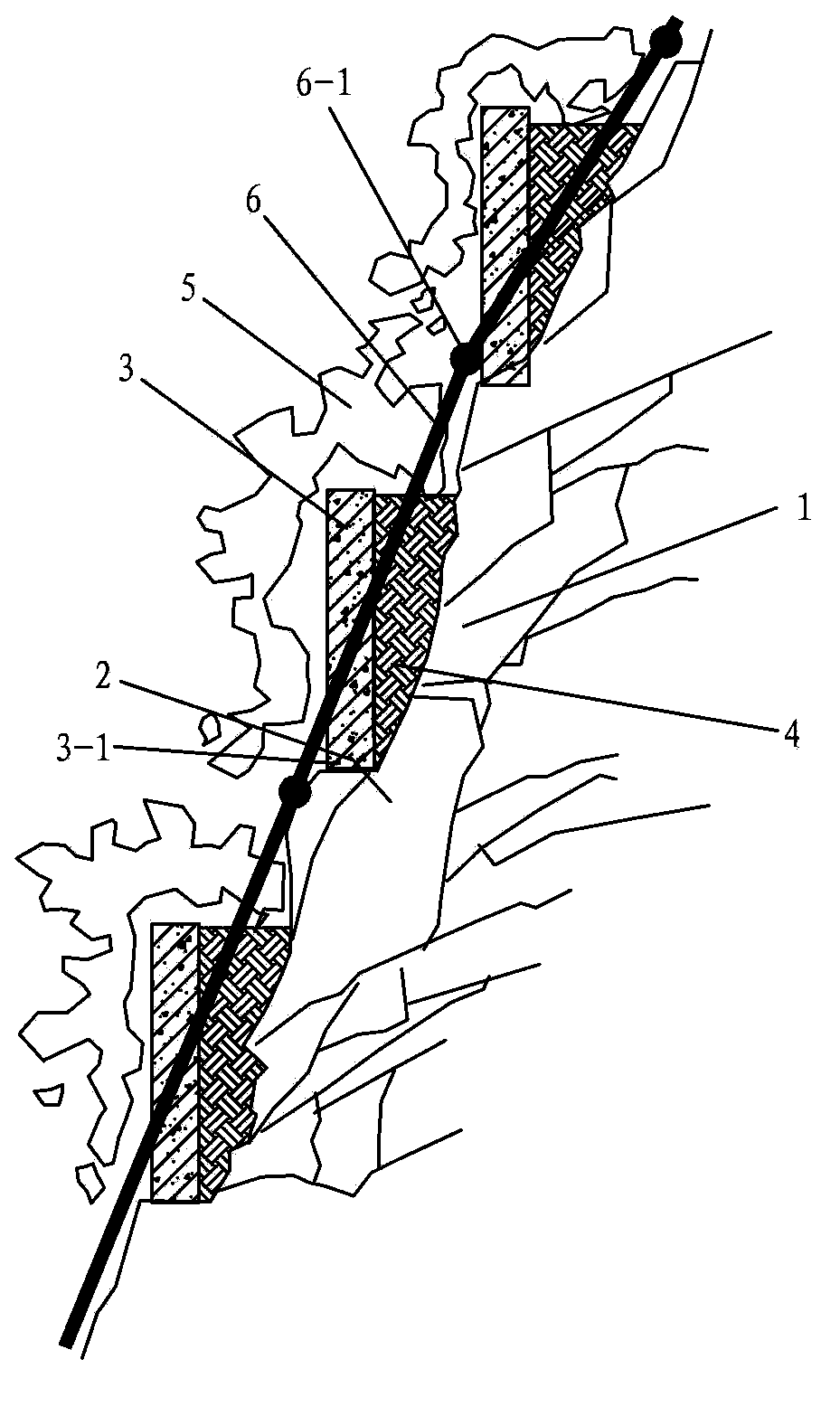

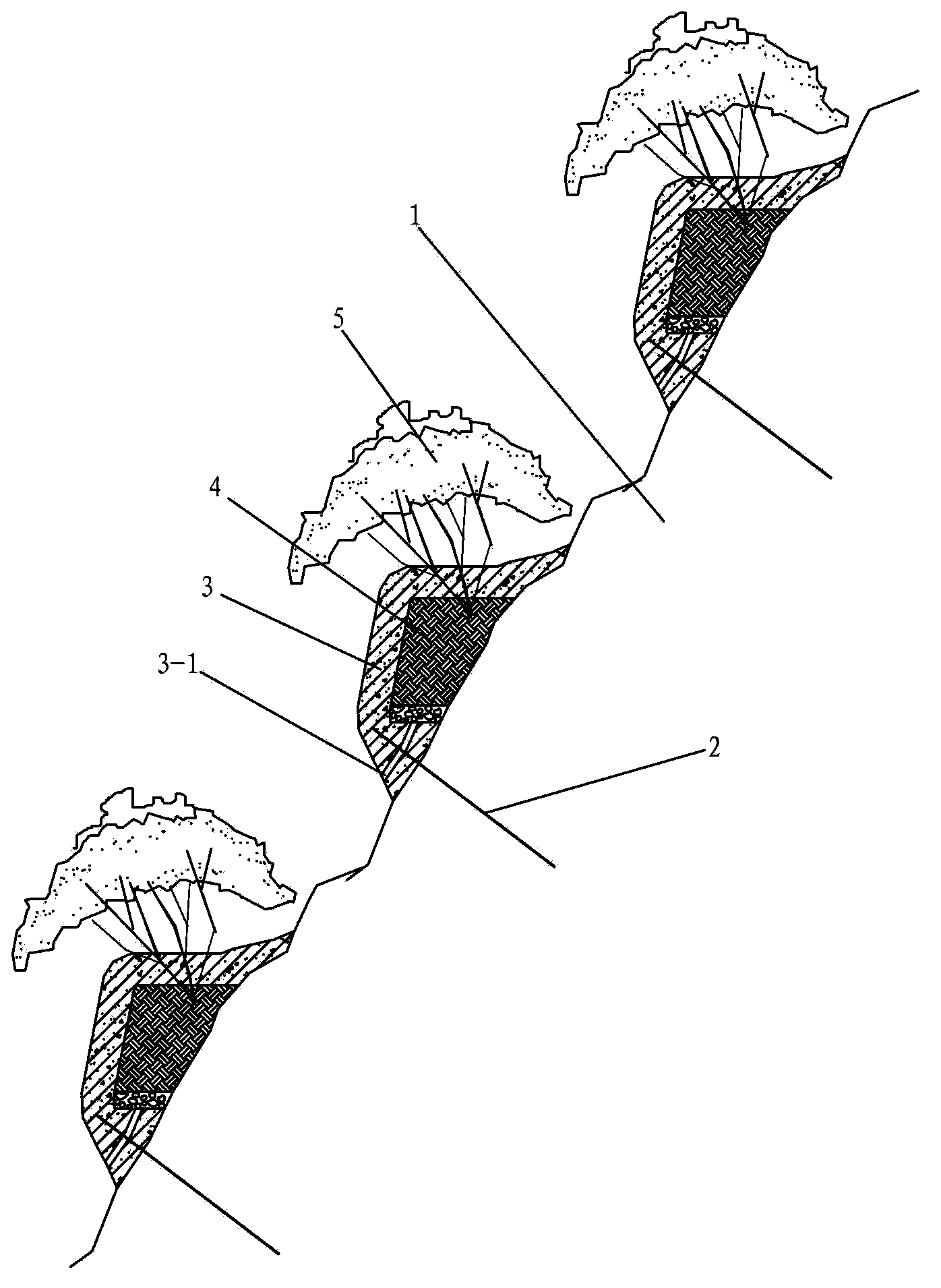

Method and architectural structure for planting virescence on rock mountain body

ActiveCN103430731AEnsure safetySimple structure, safe and reliableExcavationsCultivating equipmentsEcological environmentNormal growth

The invention relates to a method and an architectural structure for planting virescence on a rock mountain body. The method for planting virescence on the rock mountain body is characterized by comprising the following steps of: (1) drilling blind holes according to the set specification and interval on the slope of a rock mountain body, inserting reinforcing steel bars into the blind holes, fixing the reinforcing steel bars into the blind holes and solidifying with the rock mountain body by cement or concrete; (2) taking the reinforcing steel bar extending out of the slope of the rock mountain body as a support, and constructing bags on the slope of the rock mountain body by the concrete; (3) filling planting soil into the bags, and planting plants in the planting soil; (4) overlaying a water pipe from top to bottom along the slope of the rock mountain body, arranging water injection nozzles on the water pipe, which are positioned on the bags, and enabling the water injection nozzles to be positioned above the bags; (5) continuously watering the plants in fixed time or at an variable interval to provide water required by plant growth so as to ensure the normal growth of the plant. According to the invention, an anchor rod is arranged on the slope of the rock mountain body to form a connection structure by taking the reinforcing steel bars as the support; the bags are evenly constructed from top to bottom on the slope of the rock mountain body by concrete, soil is filled into the bags, and plants are planted; therefore, multi-layer ecological composite virescence is formed on the slope; the purposes of slope protection, virescence and ecological environment protection are achieved.

Owner:广州市设计院集团有限公司

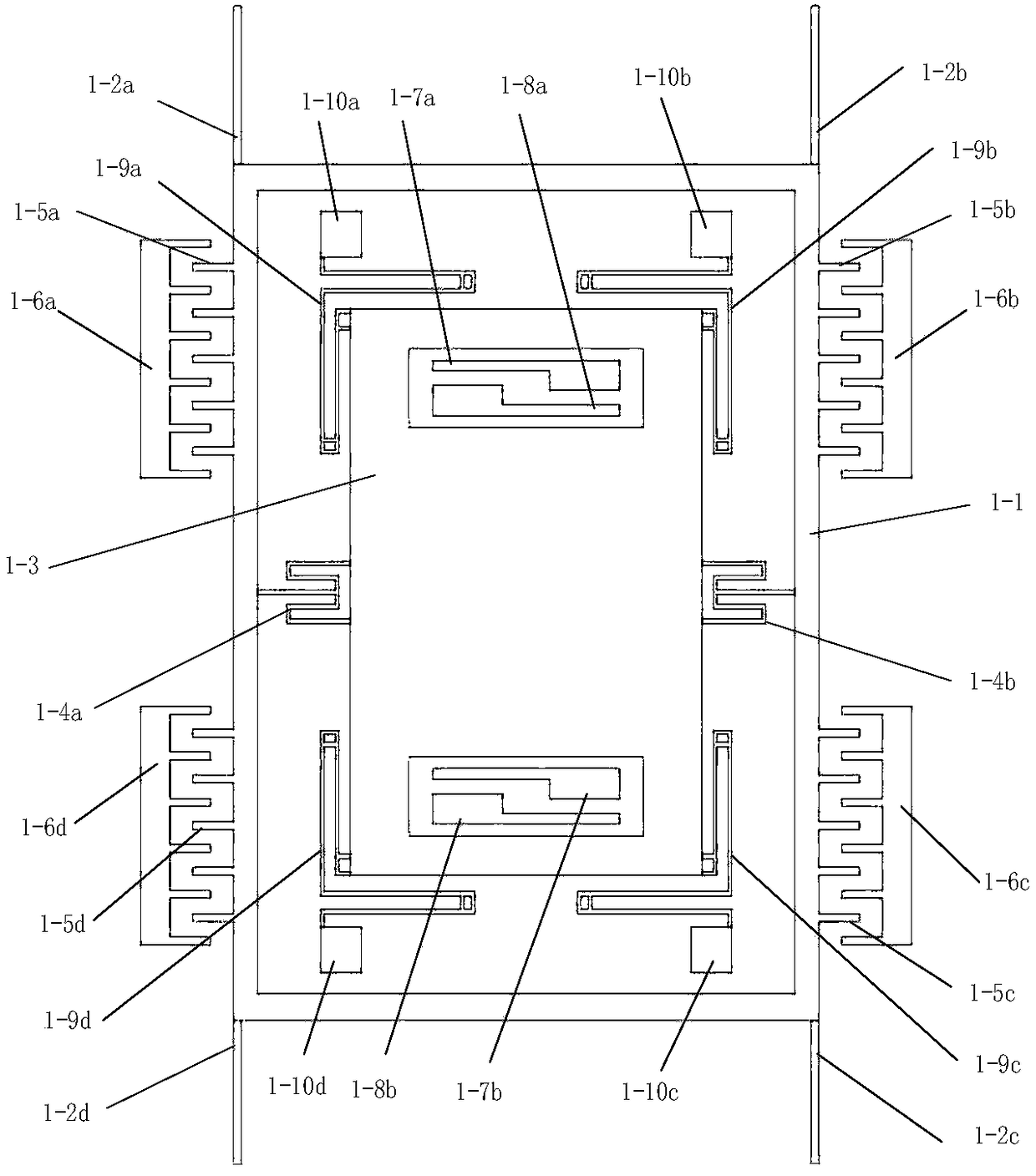

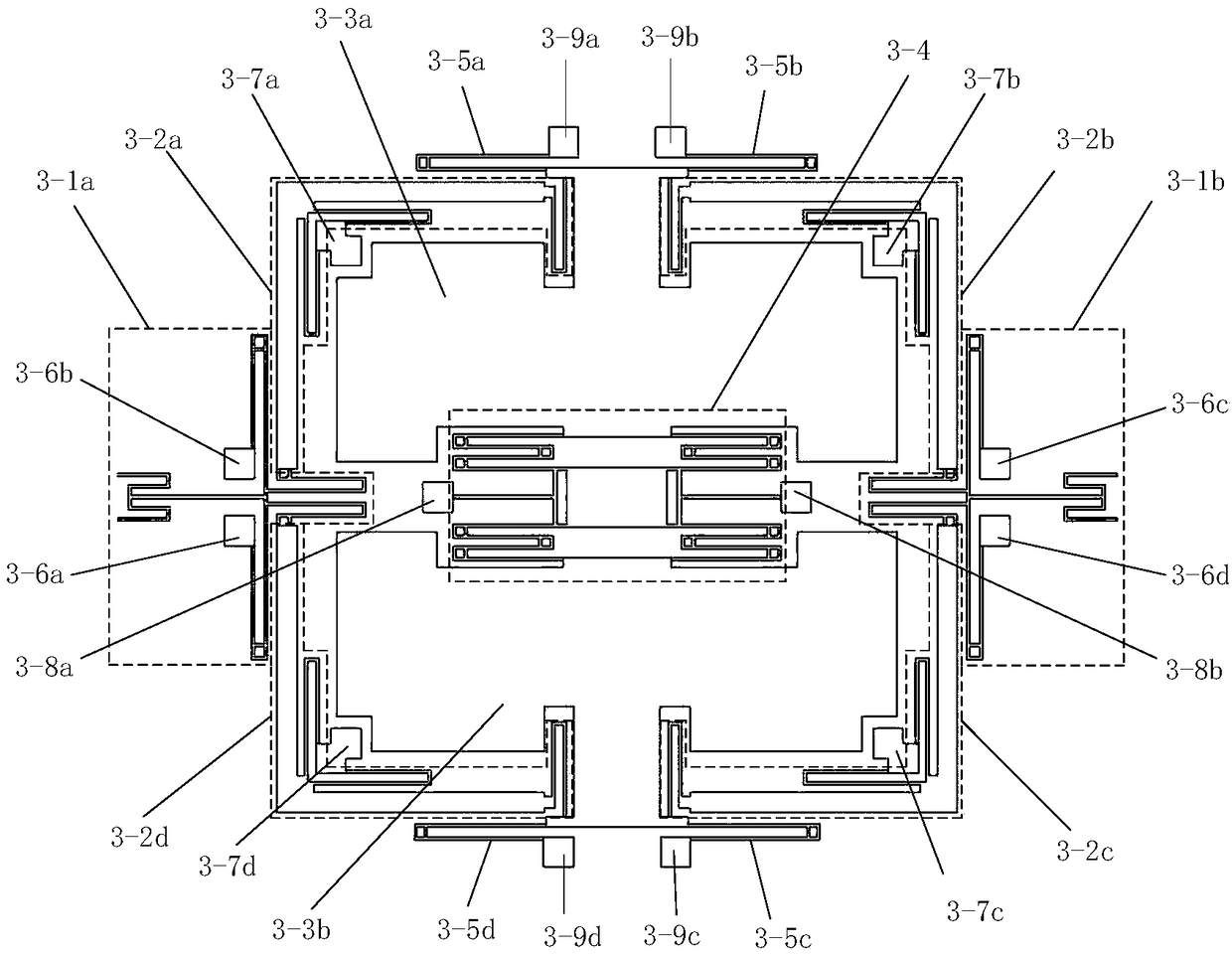

Three-axis micro-gyroscope based on tuning fork driving effect

ActiveCN108225295AImprove stabilityImprove reliabilitySpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesCapacitanceGyroscope

The invention discloses a three-axis micro-gyroscope based on a tuning fork driving effect, which comprise an upper-layer gyroscope structure and a lower-layer glass substrate, the upper-layer gyroscope structure comprises a left mechanical structure, a right mechanical structure, a middle mechanical structure, an upper crossbeam, a lower crossbeam, short beams, and anchor points, a turning mechanism based on tuning fork driving is designed in the middle mechanical structure, X-axis simple harmonic driving and Y-axis simple harmonic driving of sensitive weights of the middle mechanical structure are realized by the X-axis unidirectional driving of the left mechanical structure and the right mechanical structure, and thereby the consistency of driving frequencies between different axes is ensured. When angular velocity is inputted from outside, the sensitive weights receives Coriolis force to shift. By adopting a double-sensitive weight design and variable-interval capacitance differential detection, the three-axis micro-gyroscope can inhibit the common-mode interference of temperature, structural stress, acceleration and the like; the structure of the three-axis micro-gyroscope issymmetrically arranged, the stability is good, and the anti-interference capability is high.

Owner:SOUTHEAST UNIV

Software test method applying interval operation

InactiveCN101286133AReduce false alarm rateImprove accuracySoftware testing/debuggingReference typeSoftware engineering

The invention relates to the field of software testing technique. The invention can solve the technical problems of ineffective calculation of the unreachable path and insufficiently used variable value information in a program state test to some extent. The invention provides the concept of interval set, defines a set operation and a four arithmetic operation in the numerical variable interval set and defines an interval calculation method for Boolean typed variables, reference typed variables and expression. The method of the invention collects the value and expression range information of the variable in the prophase of software testing processing, and applies the information to the sentence nodes of a control flow graph; experiments show that the software testing method with interval operation added has lower false alarm rate of the testing results and higher testing accuracy than the original software testing method without interval information added.

Owner:BEIJING UNIV OF POSTS & TELECOMM

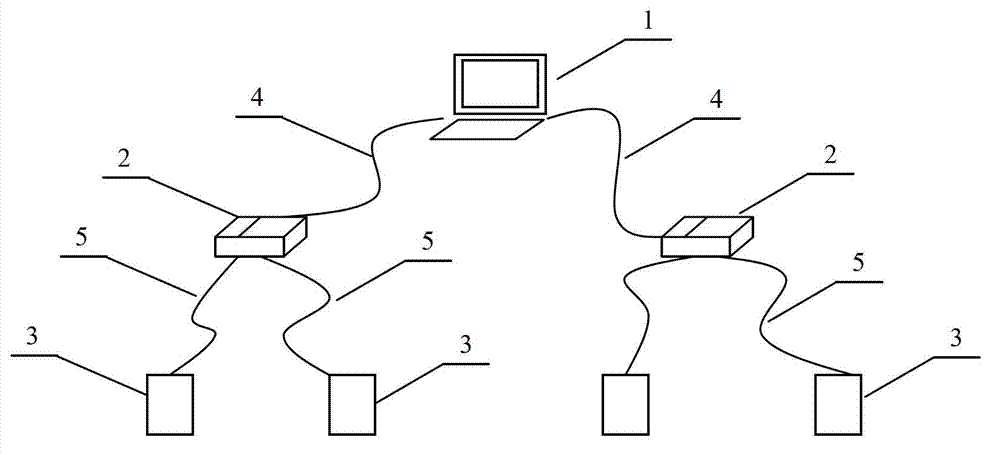

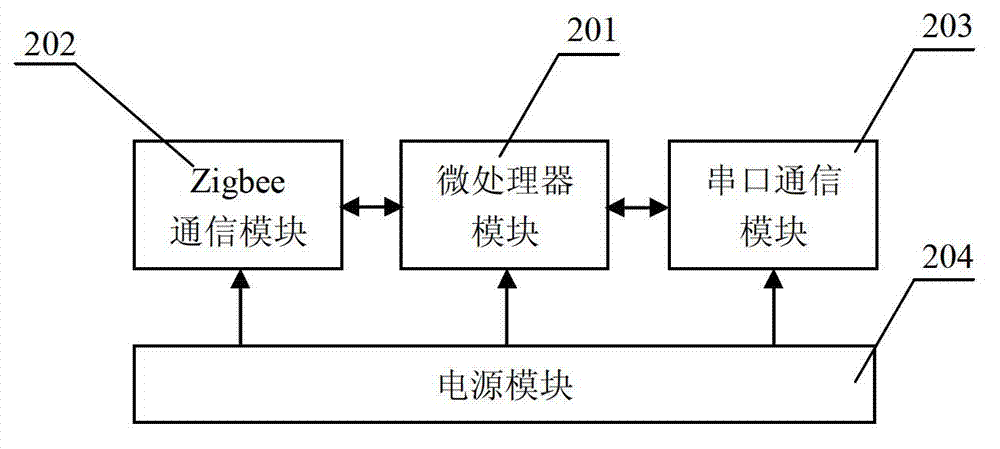

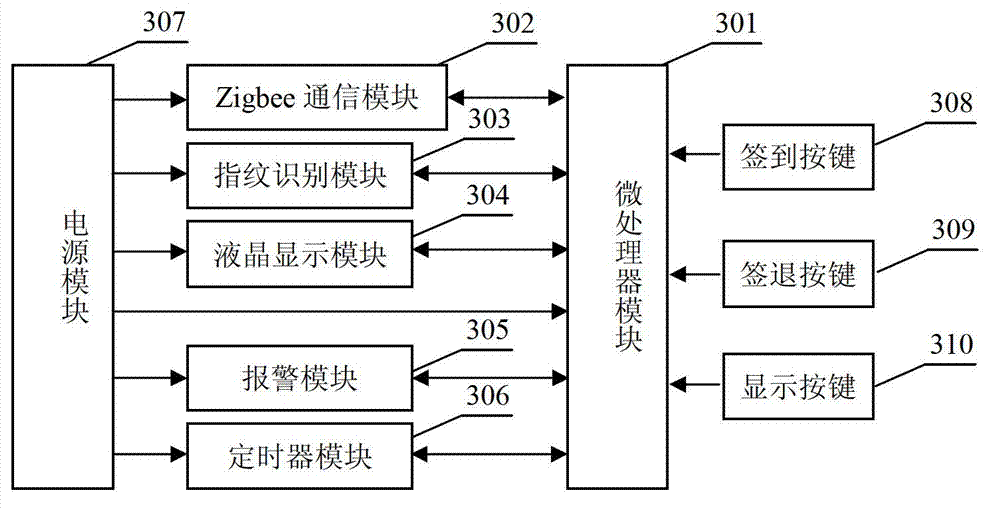

Non-contact attendance information system based on Zigbee technology

InactiveCN102855545AImprove attendance efficiencyEnergy efficient ICTNetwork topologiesElectronic identificationShortest distance

The invention discloses a non-contact attendance information system based on a Zigbee technology, comprising a central management computer, a plurality of reader-writers and a plurality of electronic identification cards, wherein the central management computer is in communication connection with the reader-writers through a serial port; the reader-writers are connected with the electronic identification cards through the Zigbee technology; when the electronic identification cards are located in the communication range of some reader-writer, the short-distance wireless communication between the electronic identification cards and the reader-writers is realized through the Zigbee technology; and a reader can be communicated with the plurality of electronic identification cards at the same time. The electronic identification cards have the function of identifying fingerprints, in order to avoid checkingattendance for a person. The system provided by the invention can realize the functions of inspecting the duty at variable intervals, sending notices and tracing temporary visitors, and provide the functions of alarming attendance failure and inquiring attendance information. The system provided by the invention adequately utilizes the low power comsumption characteristic of the Zigbee technology and combines the radio frequency identification technology to realize attendances of multiple users at the same time and thus effectively improves the attendance efficiency and intelligent management level.

Owner:JIANGSU UNIV OF SCI & TECH

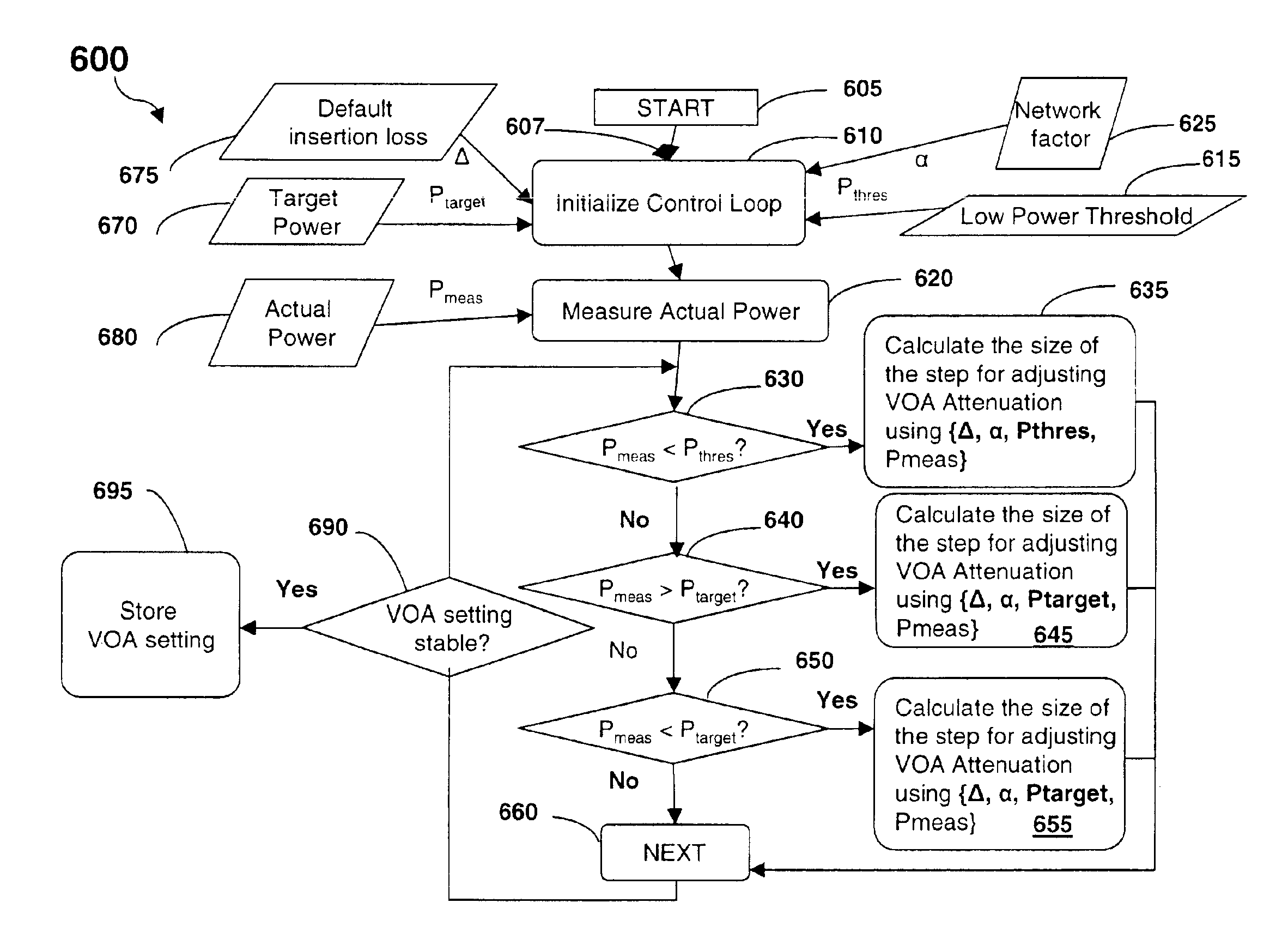

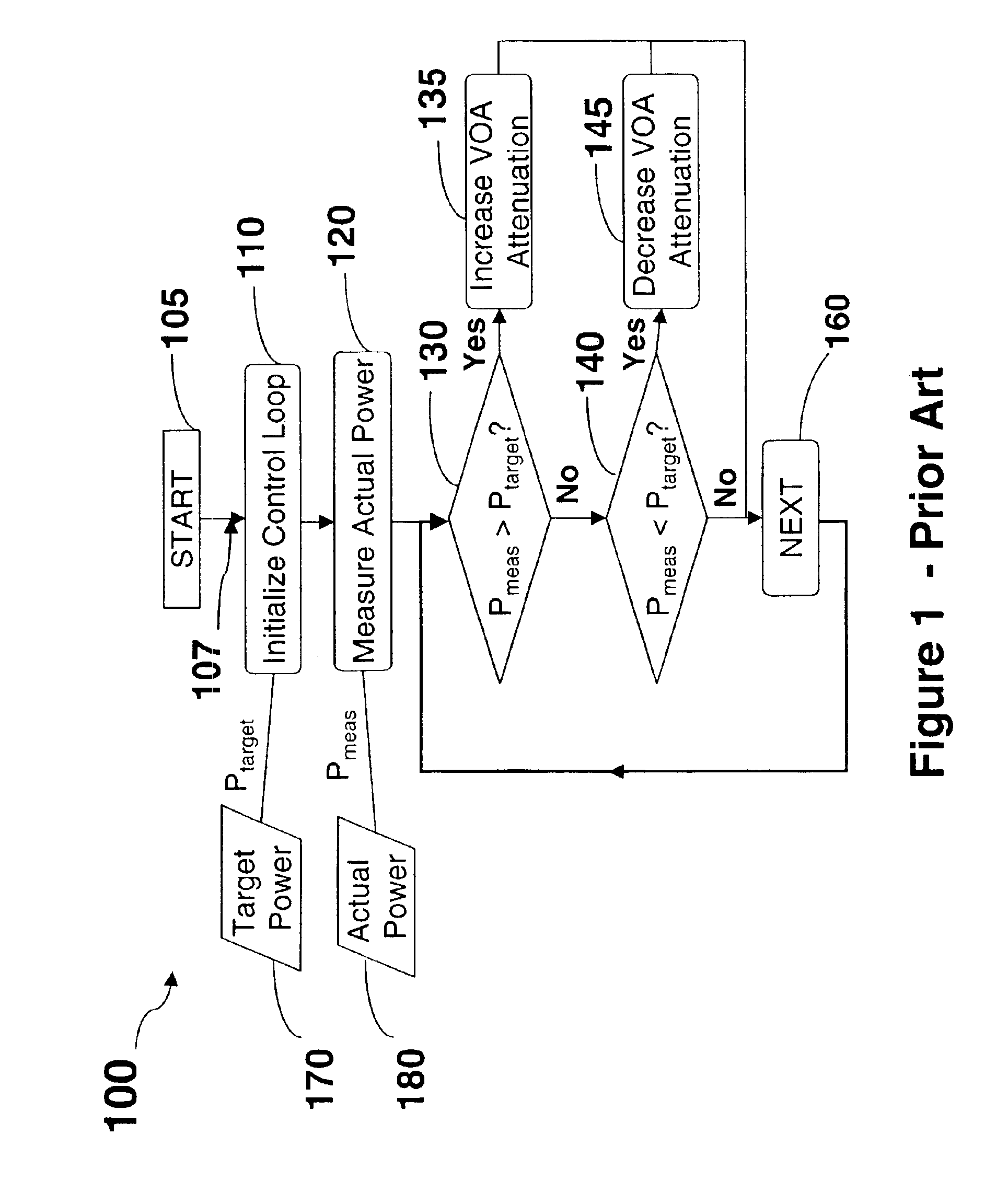

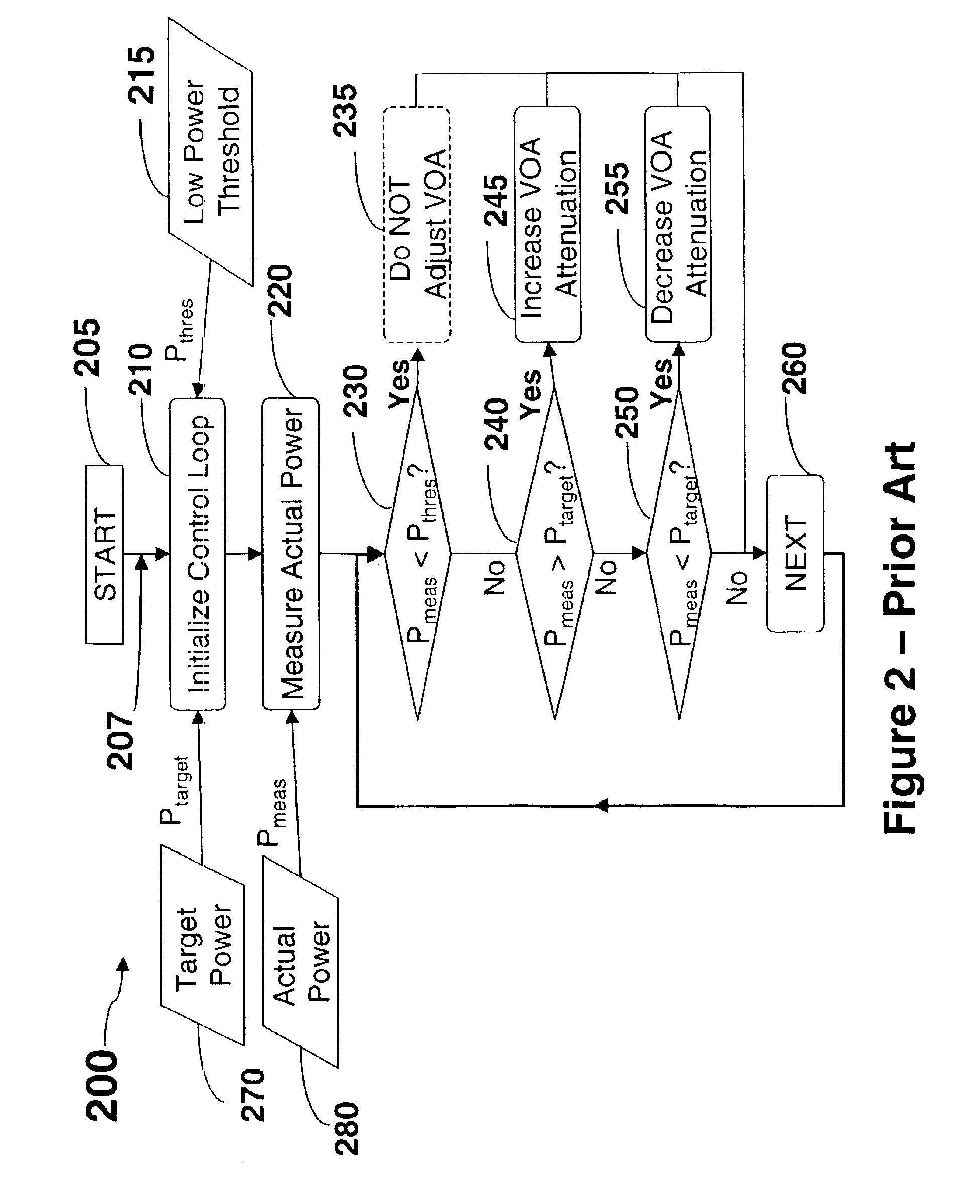

Method and apparatus for controlling a variable optical attenuator in an optical network

ActiveUS6987922B2Speed up the descentAdjust moreMultiple-port networksWavelength-division multiplex systemsUltrasound attenuationVariable interval

This invention describes a method for controlling attenuation for a variable optical attenuator (VOA) inserted in an optical path of an optical signal propagating in an optical network, comprising the steps of measuring power of the optical signal at the VOA; comparing the measured power with a target power; and if the measured power differs from the target power, changing the attenuation of the VOA in one or more variable size intervals (VSI) so that the power of the optical signal substantially equals to the target power, wherein the VSI being a function of the measured power and target power. The method further comprises the step of comparing the measured power with a Loss-of-signal (LOS) power threshold, and if the measured power is less than the LOS power threshold, changing the attenuation of the VOA in one or more variable size intervals so that the power of the optical signal substantially higher than the LOS power threshold, wherein the size of the variable interval being a function of the measured power and the LOS power threshold. The method dynamically computes a VSI, updates the VOA setting by said VSI, and manages a combination of open and closed VOA control loops to maintain the target power attenuation of the VOA The corresponding apparatus for controlling the VOA is also provided.

Owner:WSOU INVESTMENTS LLC +2

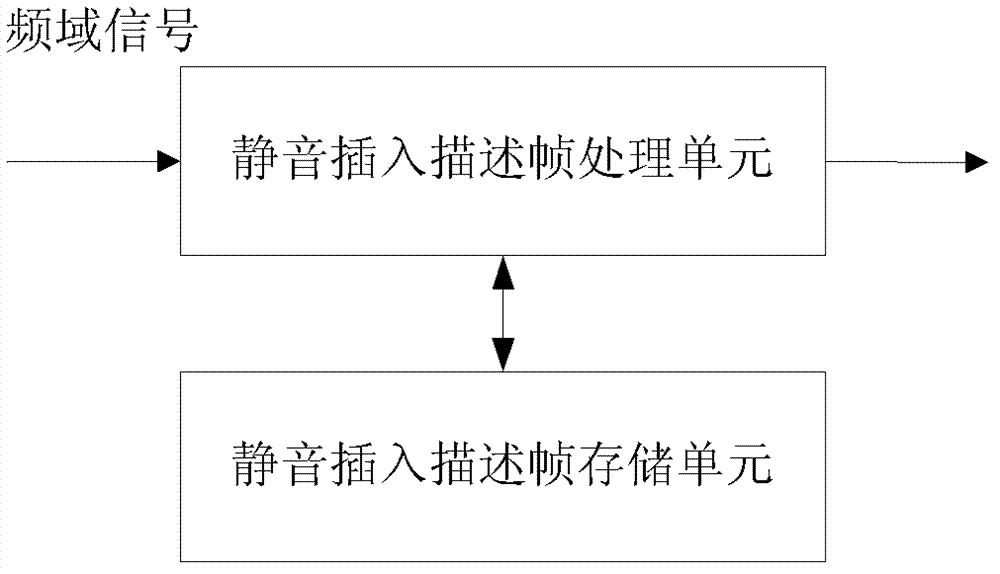

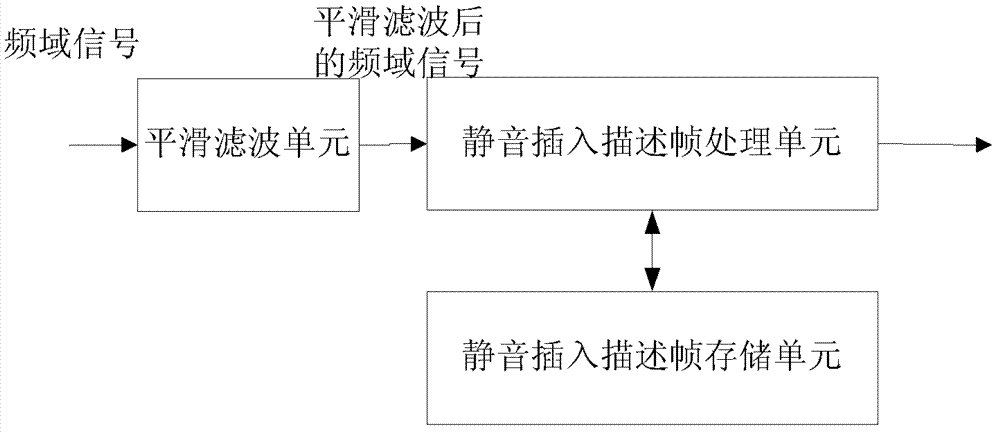

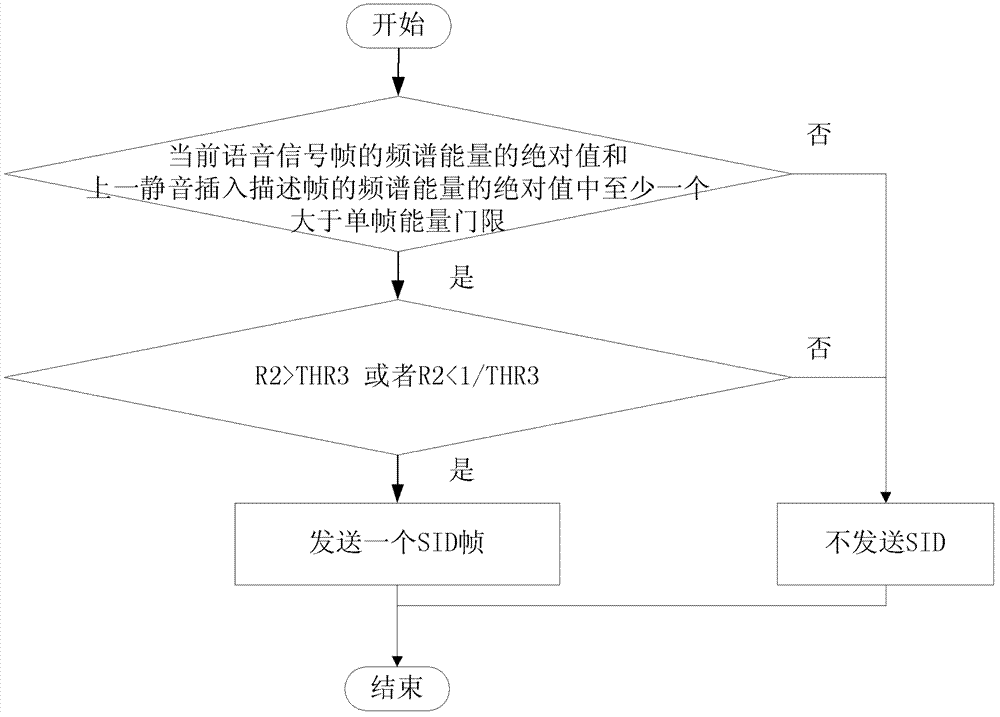

Method and device for adaptive discontinuous voice transmission

ActiveCN102903364AOvercome the disadvantage of high computational complexityEasy to trackSpeech analysisComputation complexityFrequency spectrum

The invention discloses a method and a device for adaptive discontinuous voice transmission. The method includes: during adaptive discontinuous voice transmission, determining whether to transmit a silence insertion descriptor or not according to a current voice signal frame and spectral information of a previous silence insertion descriptor. By the method and device, the problems that flexibly monitoring signal change by means of fixed intervals fails in the prior art and necessity of computation on multiple parameters such as linear prediction for the use of the means of variable intervals causes high computation complexity can be solved. Transmission is directly performed frequency domains by the method and device, signal change can be well tracked, and acoustic fidelity is guaranteed while low average bitrate is kept.

Owner:ZTE CORP

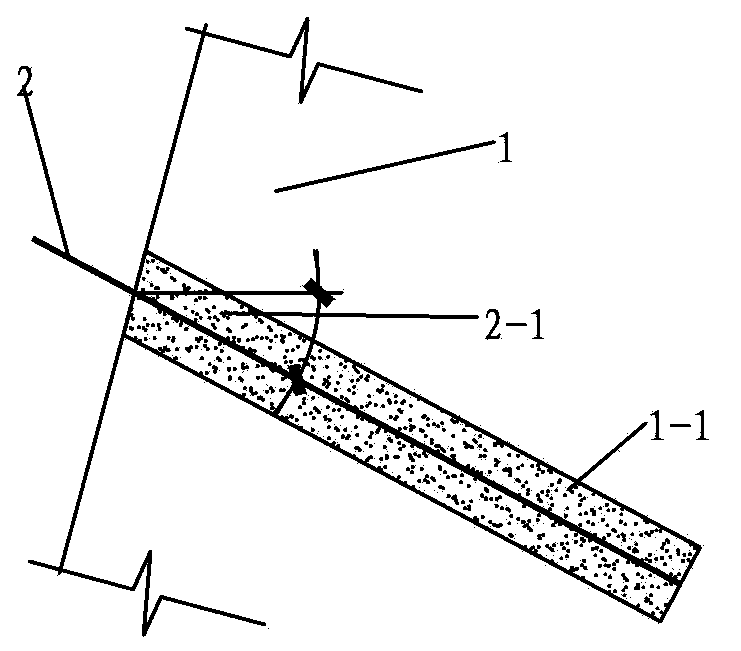

Double-laser cleaning device and method thereof

ActiveCN109719086AAvoid ablationPrecise control of laser cleaning effectCleaning using gasesPrismOptoelectronics

The invention provides a double-laser cleaning device. The double-laser cleaning device comprises a double-laser-beam dynamic combination device, wherein two laser beams are input into the double-laser-beam dynamic combination device, and the double-laser-beam dynamic combination device is used for outputting variable-interval parallel lasers which are emitted into the surface of a workpiece. Thetwo laser beams are emitted into a prism reflector through a first reflector and a second reflector, and the parallel lasers with variable intervals are output through the prism reflector in a translation mode. According to the double-laser cleaning device, the complex to-be-removed object on the surface of a substrate is efficiently removed through the two laser beams with different pulse widths,the first laser beam is used for cleaning most of the surface to-be-removed objects by using the long pulse width laser parameters, the second laser beam is used for using the short pulse width laserparameters, and the residual object to be removed is completely cleaned by utilizing the heat accumulation of the first laser beam, so that the laser cleaning efficiency is greatly improved, the energy is saved, the surface of the ablated substrate is effectively prevented from being ablated, and the surface quality of the substrate after laser cleaning is remarkably improved.

Owner:JIANGSU UNIV

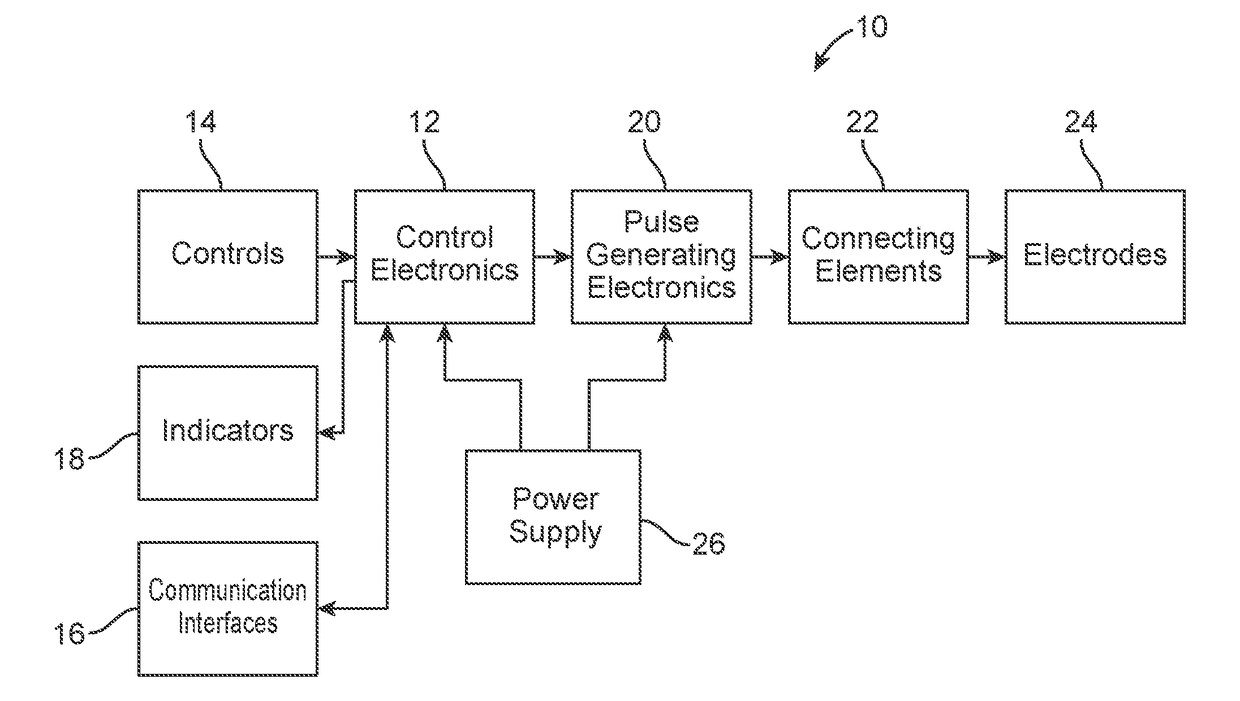

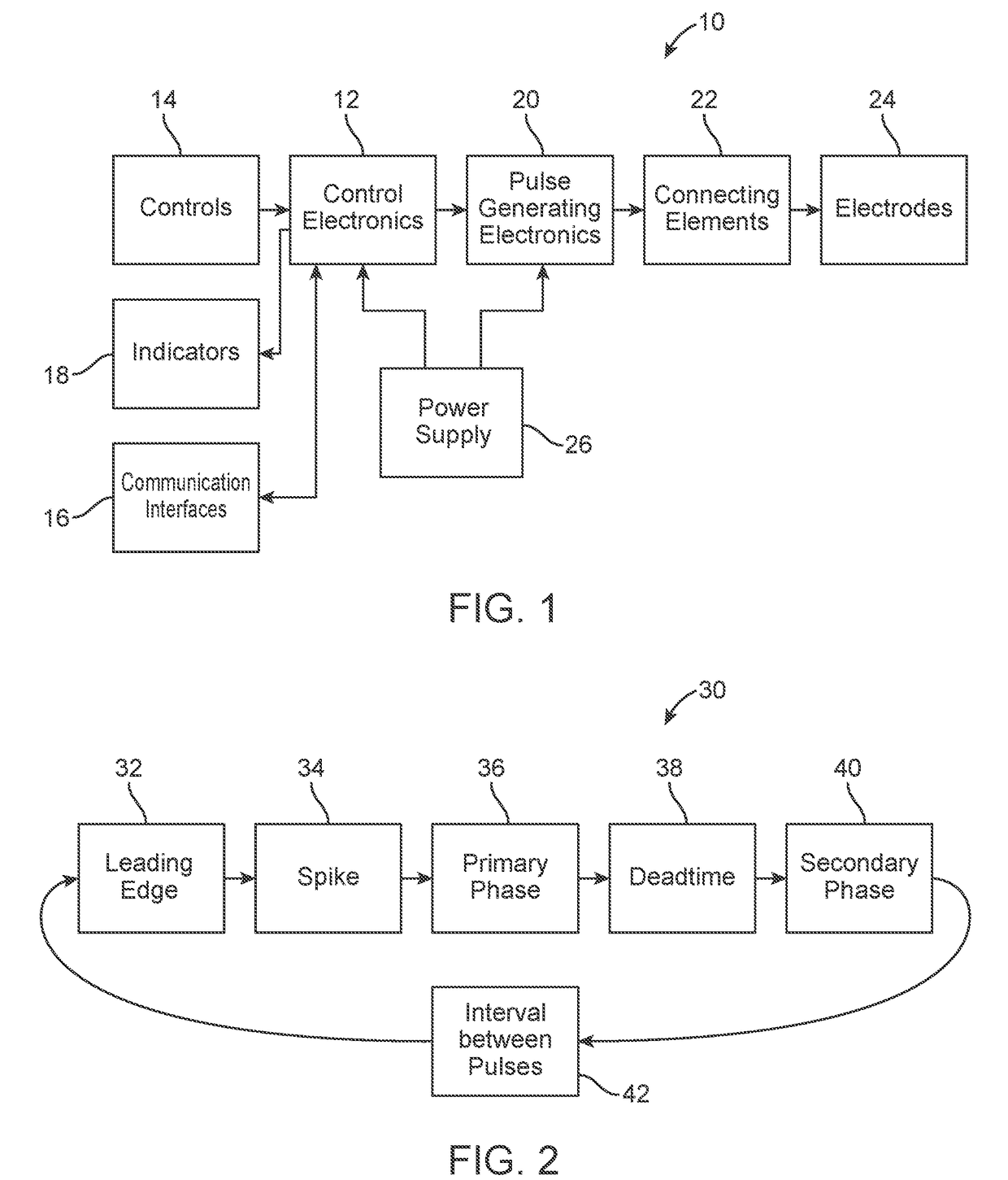

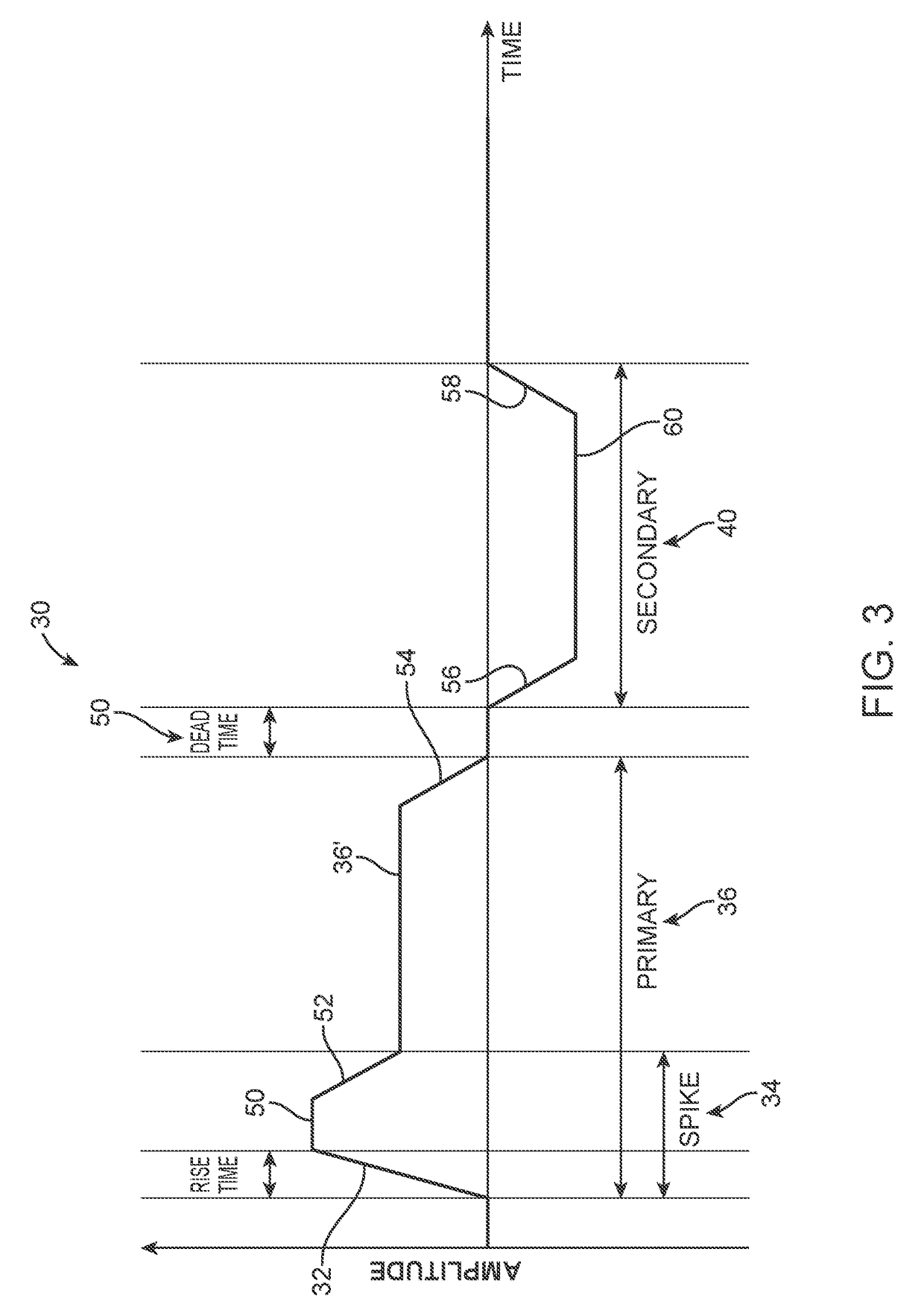

Neuromodulation device and method for use

ActiveUS20180154147A1Prevent habituationEnabling longer-term application of treatmentsExternal electrodesArtificial respirationTherapeutic DevicesCell membrane

Neuromodulation devices and methods of their use are described in which a therapeutic device is configured to generate a treatment for treating pain such as the reduction of the symptoms of chronic and acute pain as well as for treating other conditions. The neuromodulation device generates an output electrical signal in the form of pulses with a fast rise-time spike waveform followed by a longer-duration, lower amplitude primary phase waveform. The output signal includes a broad range of frequency components, with time constants tuned so as to interact with specific cell membrane or cellular components. The output signal may be conducted to the patient via electrodes. The pulses are triggered at variable intervals which prevent habituation.

Owner:HINGE HEALTH INC

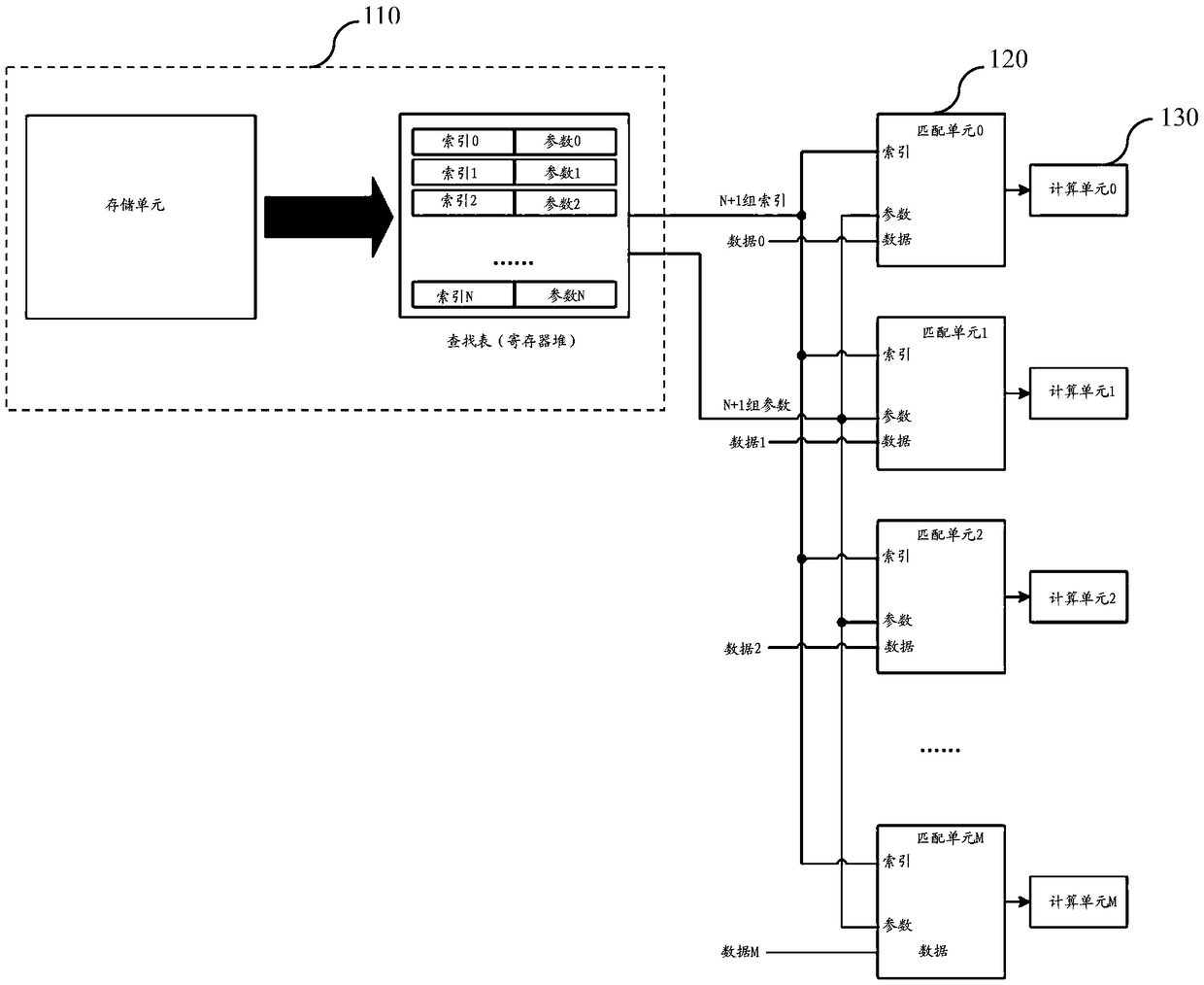

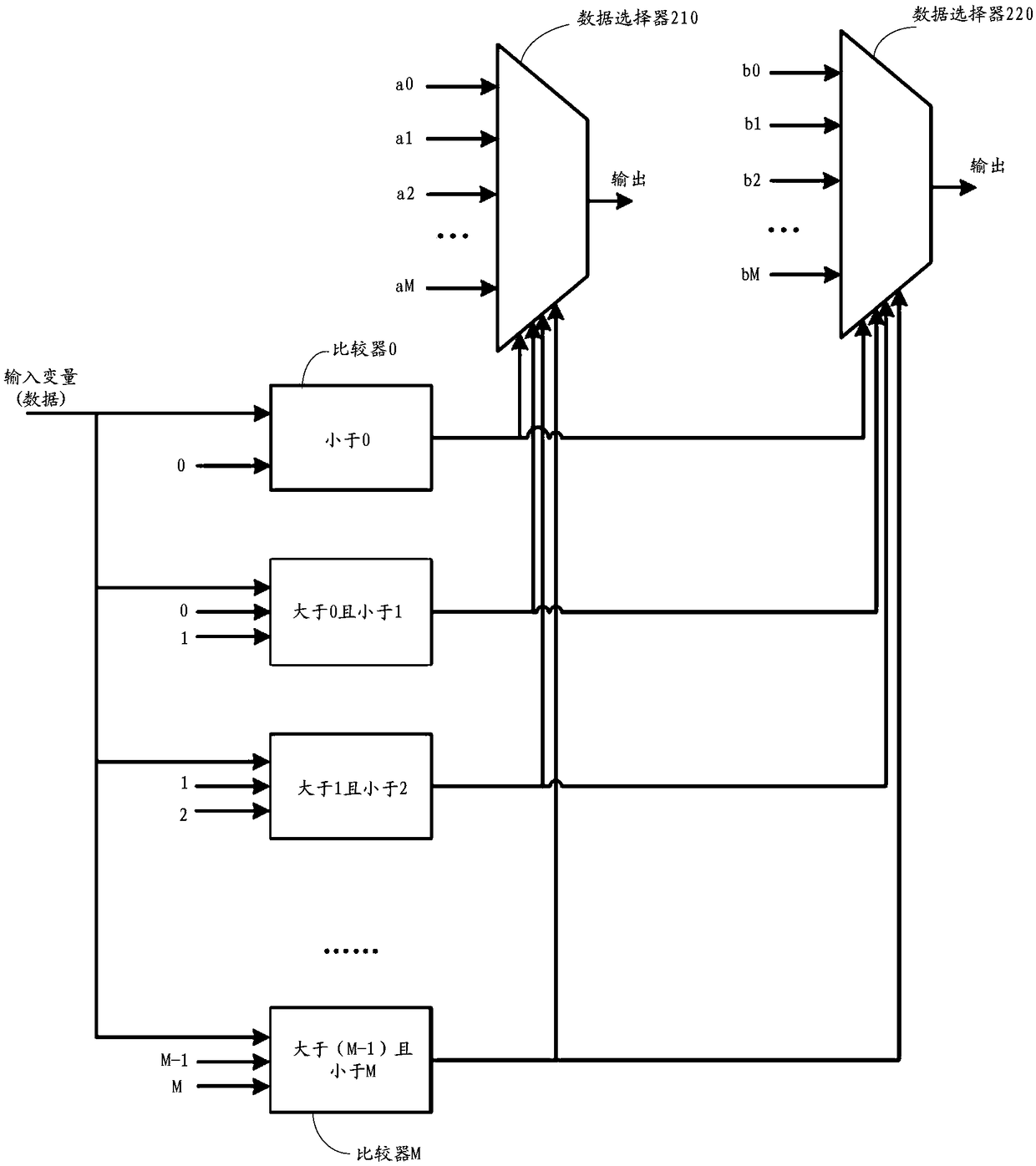

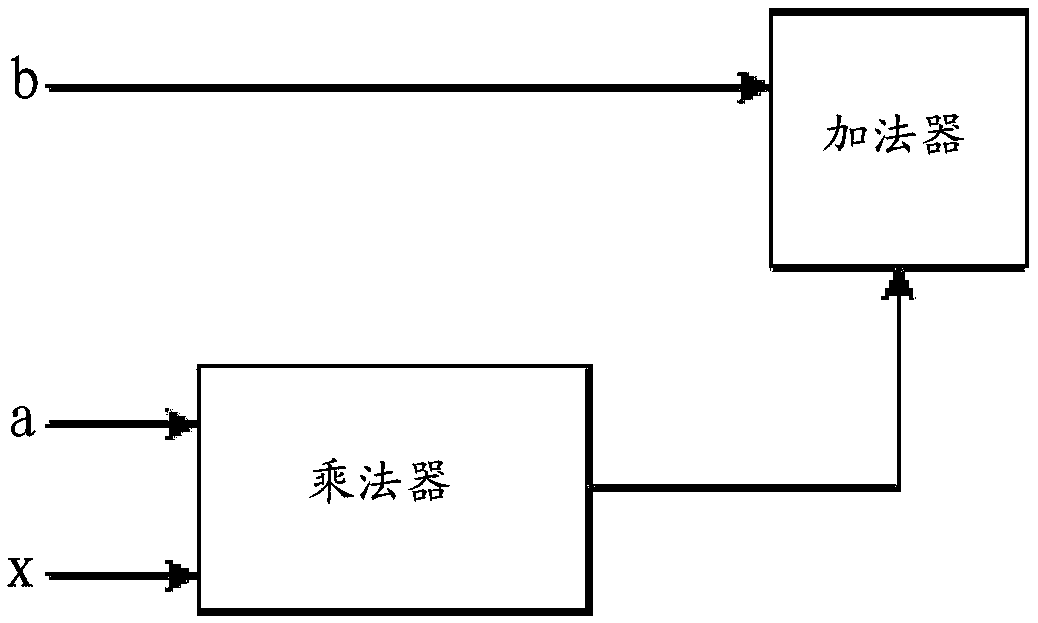

Activation processing device applied to neural networks

InactiveCN108898216AReduce volumeReduce performanceNeural architecturesPhysical realisationActivation functionNerve network

The invention provides an activation processing device applied to a neural network. The activation processing device includes a searching table unit, a plurality of matching units and a plurality of calculation units; the searching table unit is used for storing a variable interval reflecting an activation function in a neural network and a mapping relationship between corresponding fitting linearfunction parameters, wherein the linear function parameters include the intercept and slope for defining linear functions; the plurality of matching units are configured to output a linear function parameter corresponding to an input variable of an activation function to be calculated on the basis of the searching table; the plurality of calculation units are one-to-one correspondingly connectedwith the plurality of matching units; and each of the plurality of calculation units is used for completing a linear operation for the input variable of the activation function to be calculated according to a linear function parameter output by the corresponding matching unit. The activation processing device of the invention can improve the activation processing efficiency of the neural network and reduce the power consumption.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

Electro-thermal-driven micro-electro-mechanical comb tooth mechanism for regulating variable intervals of teeth

InactiveCN102951593AAchieving AMIncrease the sensor detection signal amplitudePiezoelectric/electrostrictive devicesFlexible microstructural devicesElectrothermal actuatorRight shift

The invention discloses an electro-thermal-driven micro-electro-mechanical comb tooth mechanism for regulating variable intervals of teeth. The electro-thermal-driven micro-electro-mechanical comb tooth mechanism comprises a left-shift electrothermal actuator, a right-shift electrothermal actuator, a fixed tooth, a moving tooth, four first anchor regions and an insulating substrate, wherein the fixed tooth consists of a left-shift fixed tooth and a right-shift fixed tooth; the left-shift electrothermal actuator is connected with one end of the left-shift fixed tooth, and the two ends of the left-shift fixed tooth are respectively connected to the first anchor regions; the right-shift electrothermal actuator is connected with one end of the right-shift fixed tooth, and the two ends of the right-shift fixed tooth are respectively connected to the first anchor regions; the left-shift fixed tooth comprises a first wide beam, a left-shift comb tooth and four first folding beams; the right-shift fixed tooth comprises a first wide beam, a right-shift comb tooth and four second folding beams; the moving tooth comprises a quality block, a moving tooth comb tooth, two second anchor regions and two third folding beams; and a left-shift stop block is arranged on the first wide beam, and a right-shift stop block is arranged on the second wide beam. Under the driving of an electrothermal driving force, the micro-electro-mechanical comb tooth mechanism regulates the intervals of the teeth to enable a signal generated by micro-electro-mechanical vibration to be strong.

Owner:SOUTHEAST UNIV

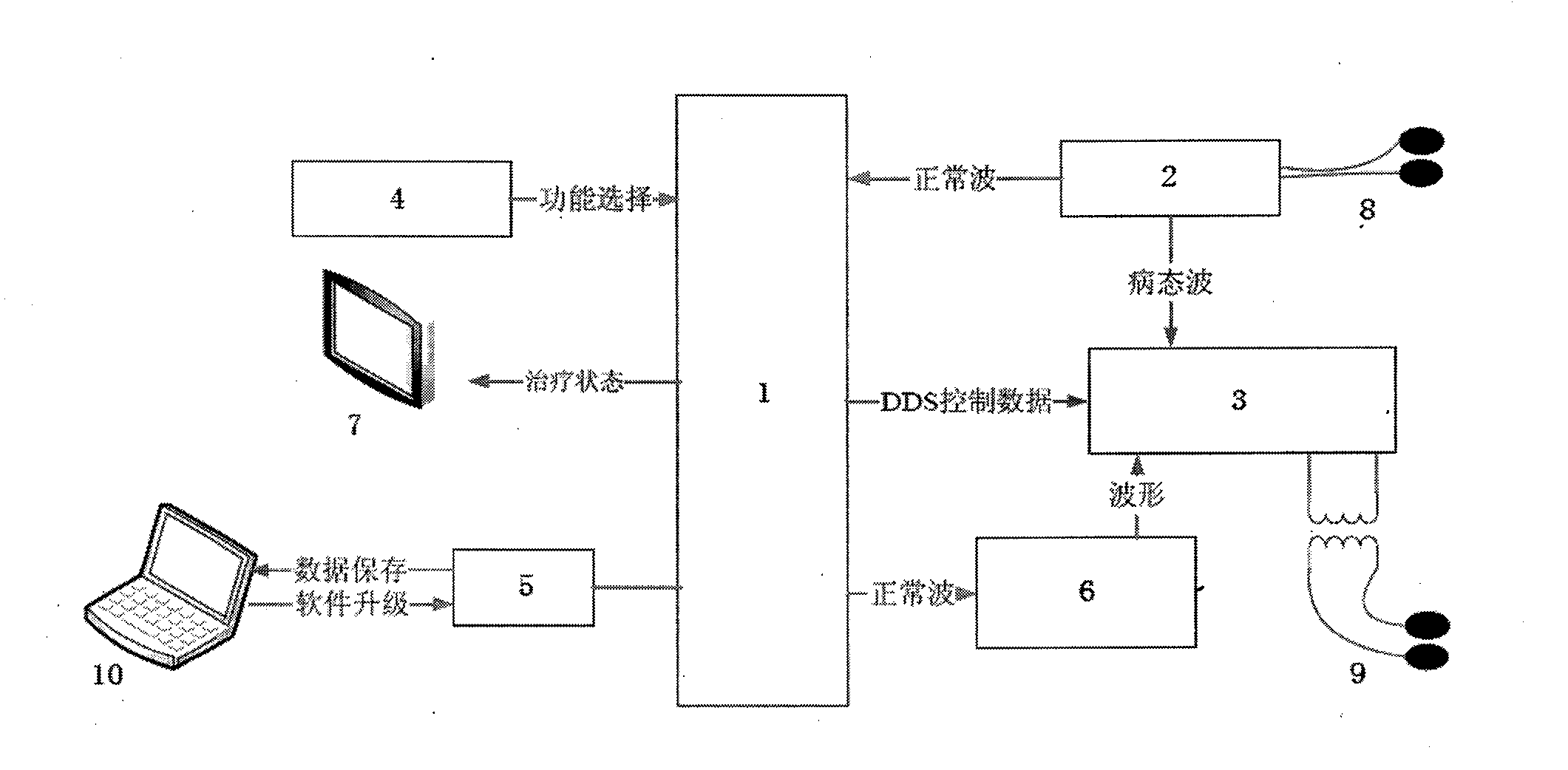

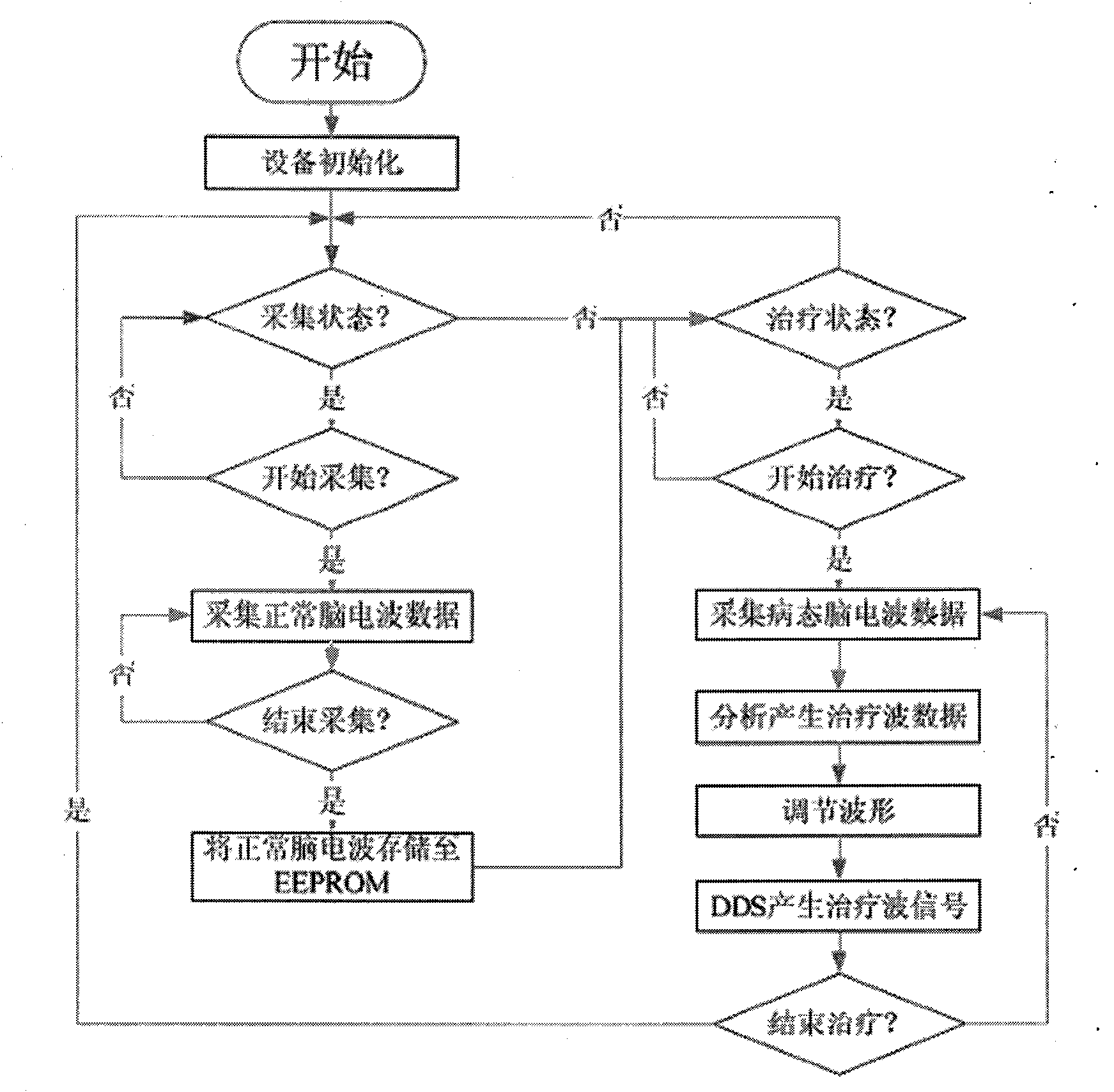

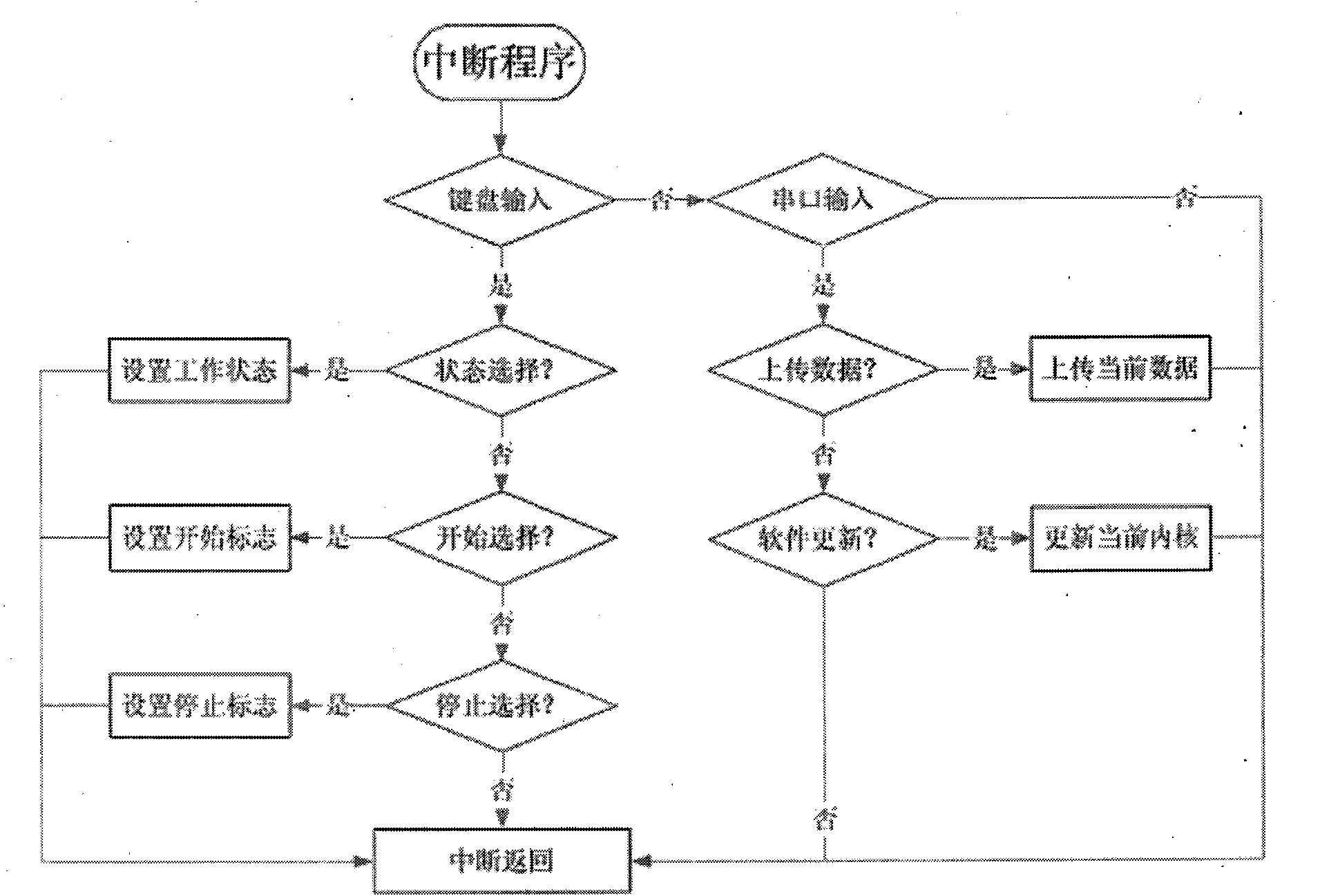

Drug-detoxifying apparatus based on brain wave biofeedback

InactiveCN101927052ATargetedWith a clear purposeSleep inducing/ending devicesDigital signal processingMicrocontroller

The invention discloses a drug-detoxifying apparatus based on brain wave biofeedback. The drug-detoxifying apparatus comprises the following modules: a serial port receiving module 1, a singlechip processing module 2, a DDS healing wave transmitter module 3, a treatment clock module 4, an LCD display module 5, a keyboard input module 6, an automatic acupoint searching module 7 and an auricular point sticking piece 8. The apparatus combines a traditional acupuncture principle and an advanced digital signal processing technology to generate dilatational wave in a specific frequency range to stimulate corresponding auricular points of a patient, so that plasma cortisol and plasma enkaphalin substance in the patient are adjusted to be restored to in a normal level, and simultaneously, auricular point sticking cowherb seed and the other medicine adjuvant therapy modes are used to achieve the purpose of giving up tobacco and relieving abstinence syndrome. The apparatus is provided with a precise automatic acupoint searching device and a treatment clock, thereby decreasing the problems that low treatment effect, increased relapse rate and the like are caused by incorrect automatic acupoint search and regular treatment at variable interval.

Owner:王志忠

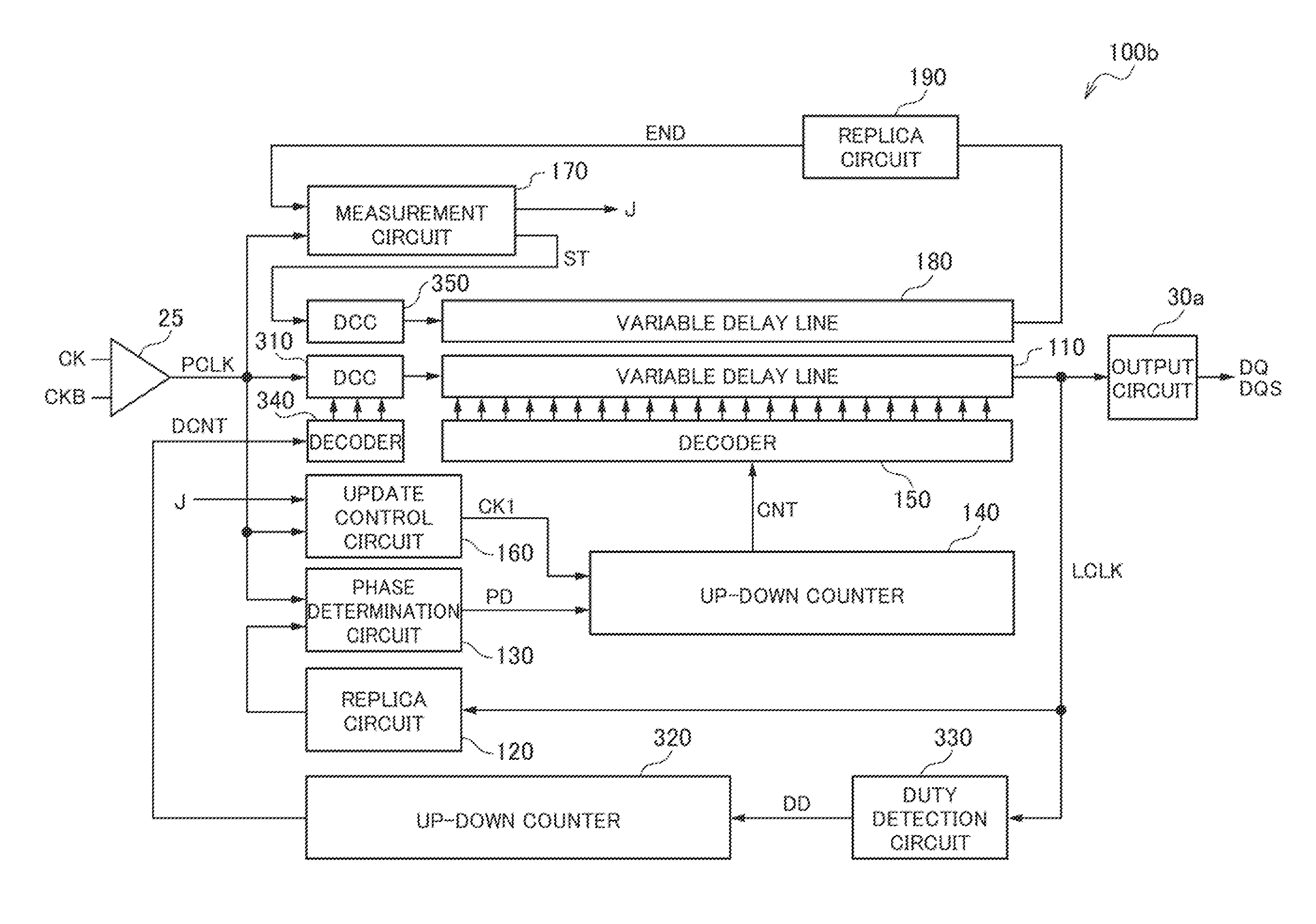

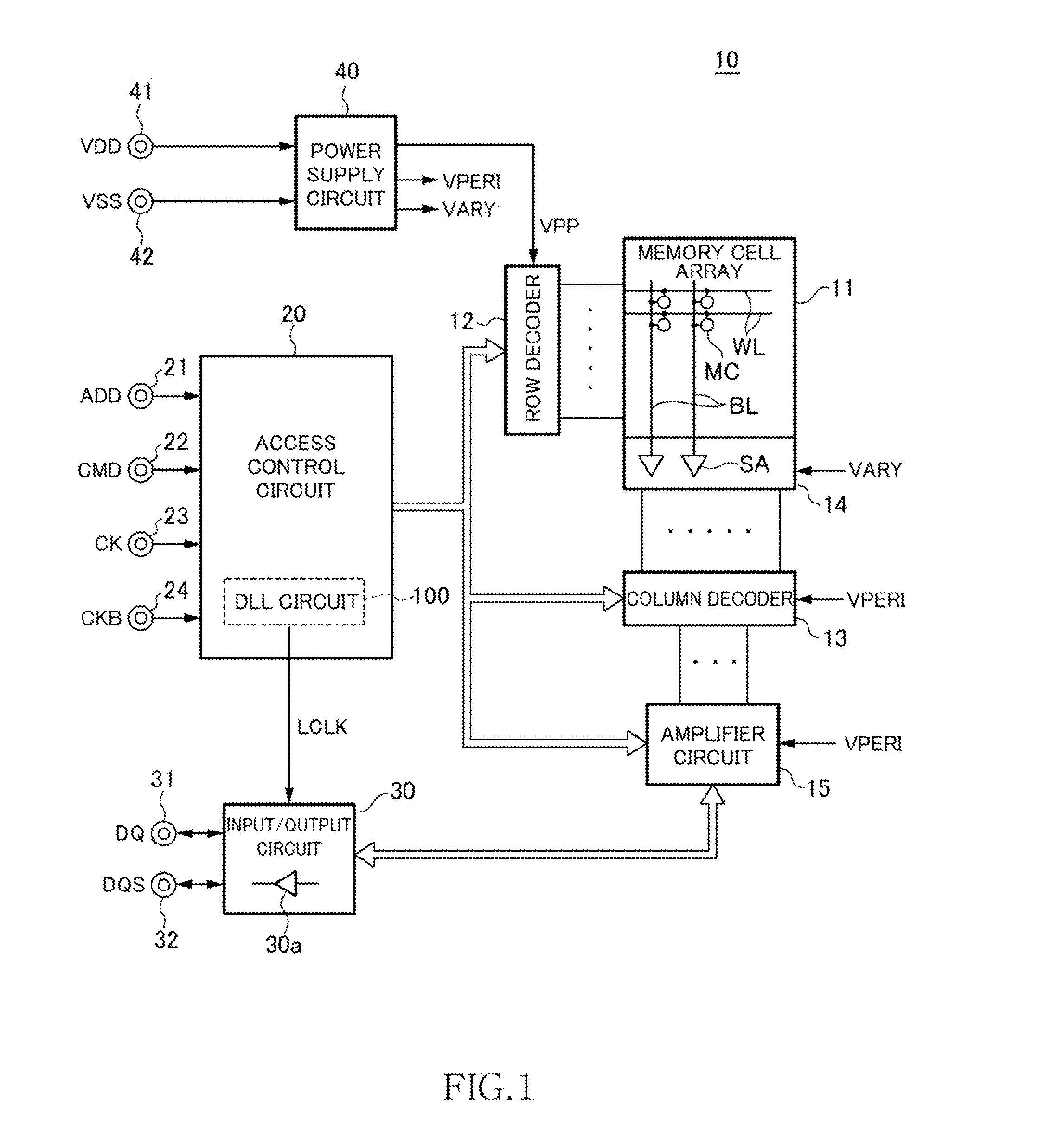

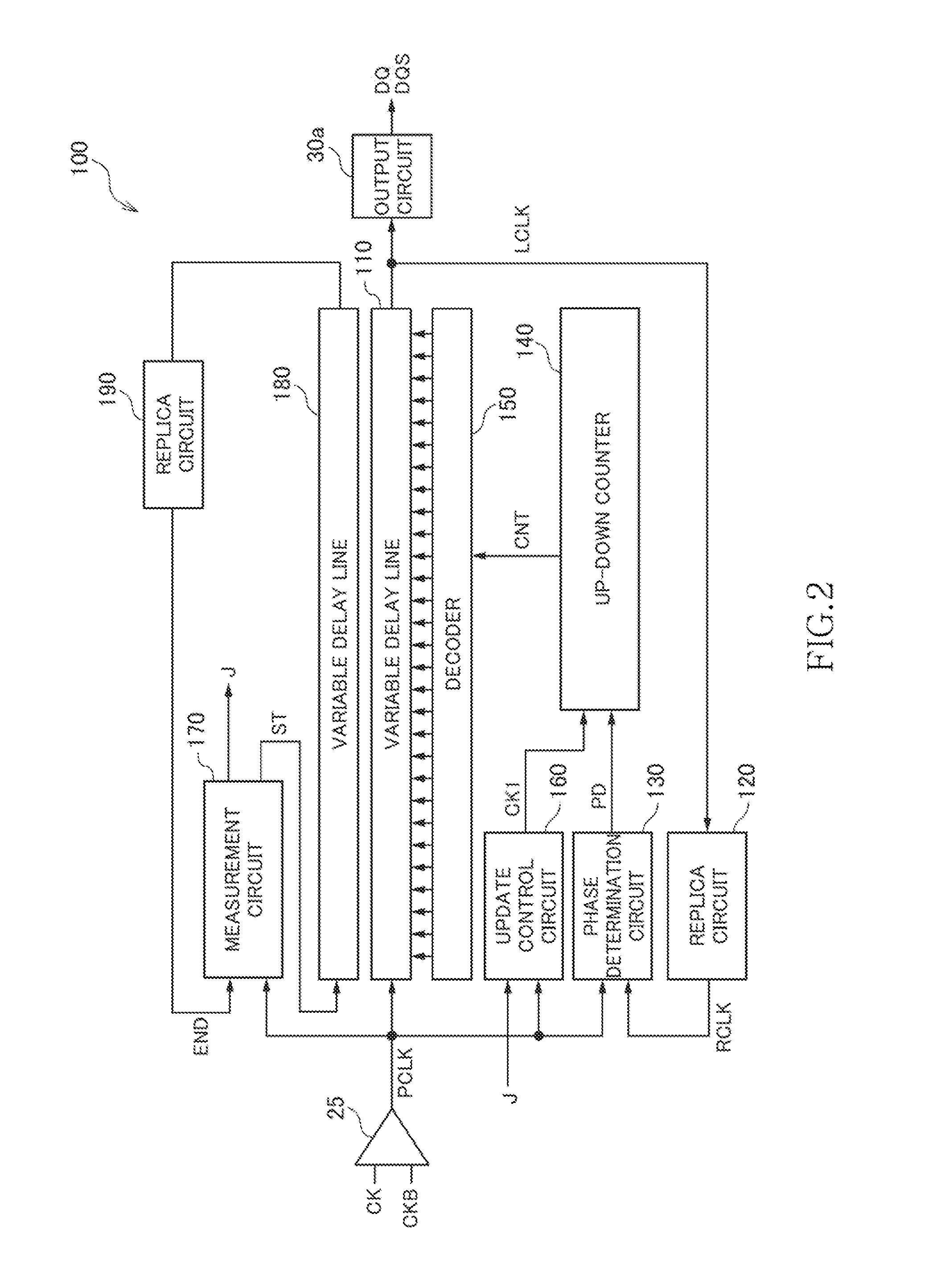

Semiconductor device having dll circuit

ActiveUS20150002196A1Fast transferShift a DLL circuitPulse automatic controlPower semiconductor deviceCircuit delay

Disclosed herein is a device includes a first delay circuit delaying a first clock signal according to a count value to generate a second clock signal, a phase determination circuit comparing a phase of the first clock signal with a phase of the second clock signal to generate a phase determination signal, an up-down counter updating the count value according to the phase determination signal each time an update signal is activated, and an update control circuit generating the update signal at a variable interval.

Owner:MICRON TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com