Variable-interval self-adaptive measuring point-searching aircraft panel normal vector determination method

An aircraft panel and determination method technology, applied in the field of measurement and detection, can solve the problems of high calculation efficiency, low normal vector accuracy, small data collection amount, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Describe the present invention below in conjunction with specific embodiment:

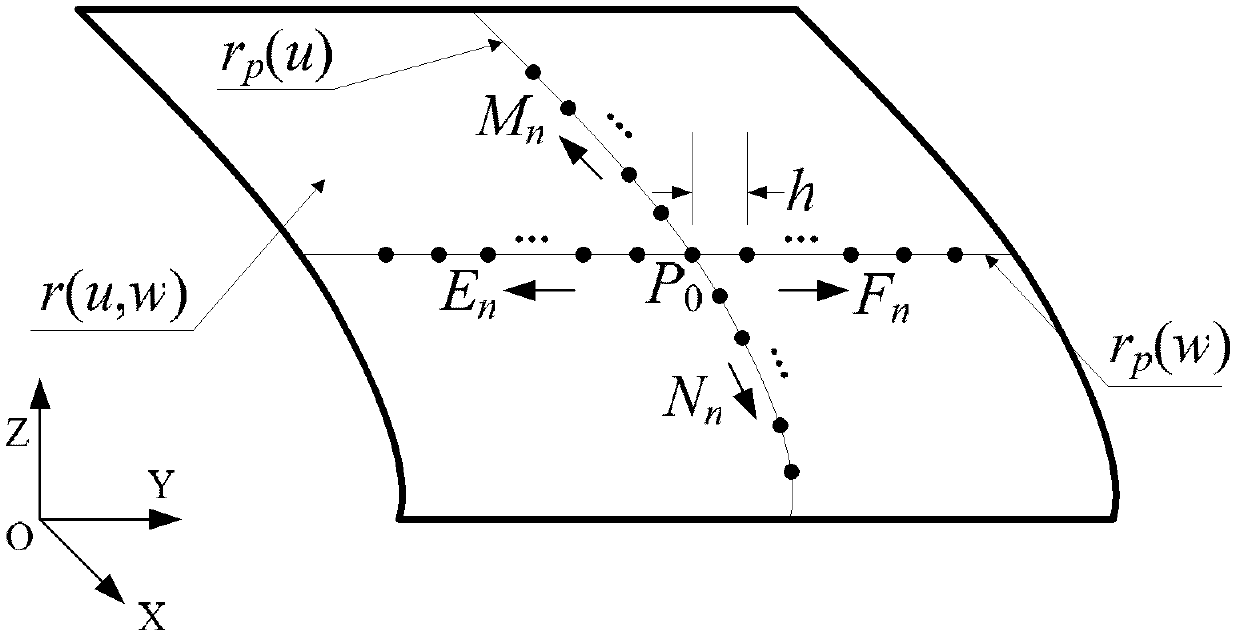

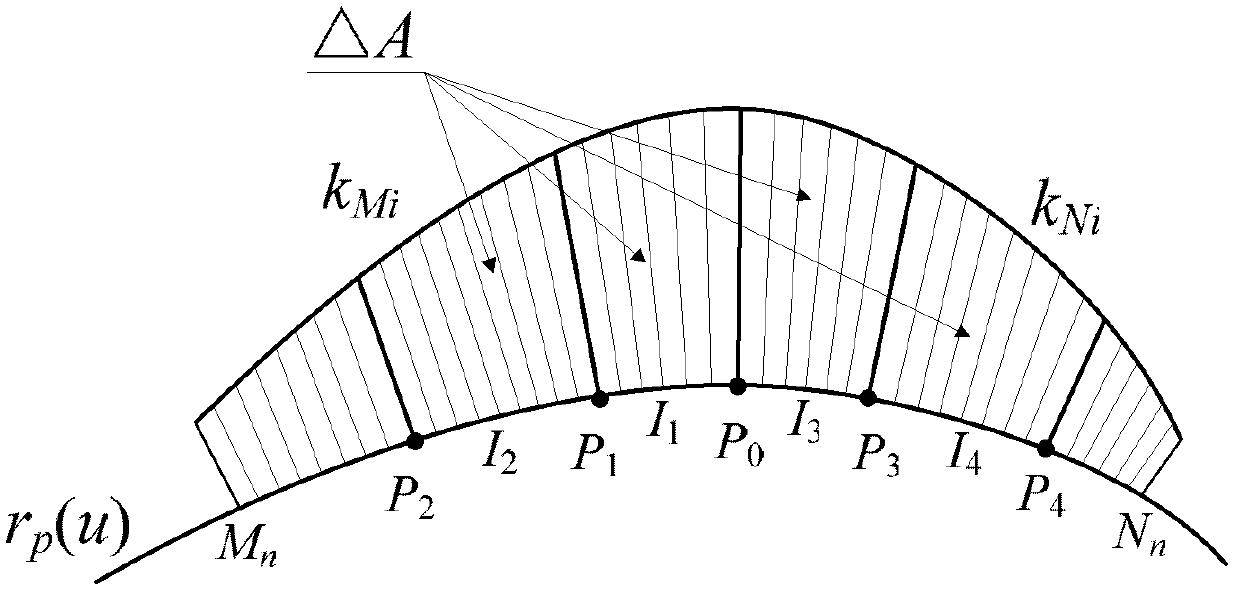

[0039] This embodiment is to measure the drilling and riveting point P to be measured on the leading edge panel of a certain type of aircraft wing. 0 Since most of the modern aircraft panels are free and complex curved surfaces, in order to quickly and accurately measure and calculate the normal vector at the point to be measured, the method proposed by the present invention is used in this embodiment to determine The normal vector of the point to be measured comprises the following steps:

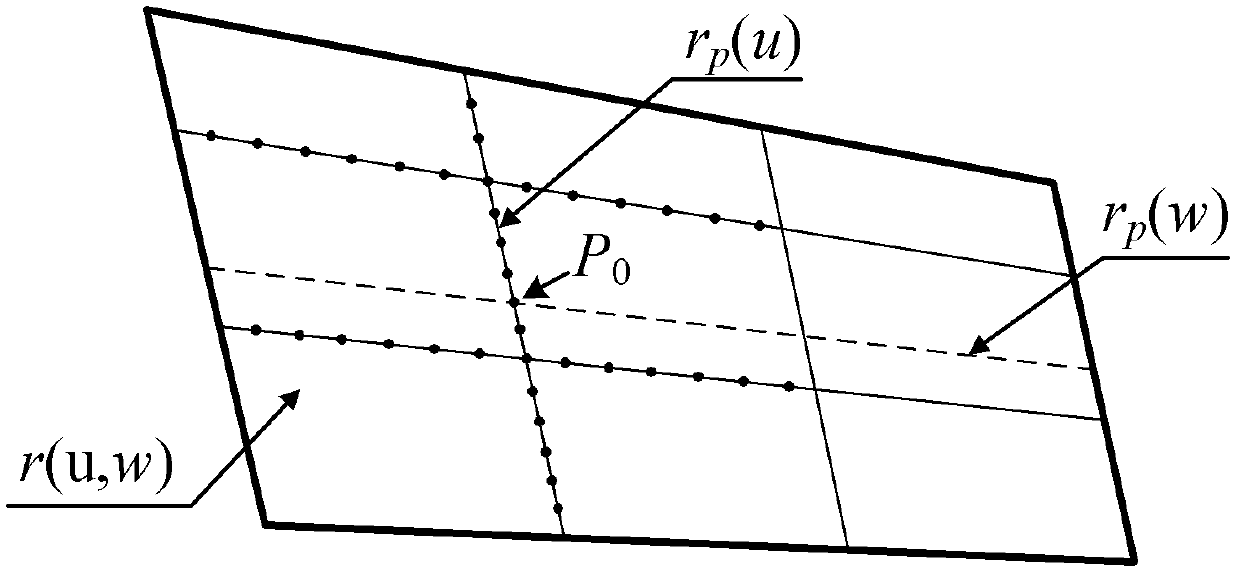

[0040] Step 1: As attached figure 1 As shown, in the CATIA V5 three-dimensional environment, the point P to be measured is extracted according to the theoretical mathematical model of the wall panel 0 Space coordinates, P 0 The surface equation r(u, w) of the wall surface where the point is located, and the P 0 Point's spanning curve equation r p (u) and over P 0 The chord curve equation of a point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com