Three-axis micro-gyroscope based on tuning fork driving effect

A technology of micro gyroscope and gyroscope, which is applied in the direction of gyroscope/steering sensing equipment, gyro effect for speed measurement, instruments, etc. It can solve the problems of limiting the development and application of micro inertial devices, multi-channel drive loop signal crosstalk, and sensor volume increase, etc. problem, to achieve the effect of enhancing anti-interference ability, increasing output signal, increasing stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

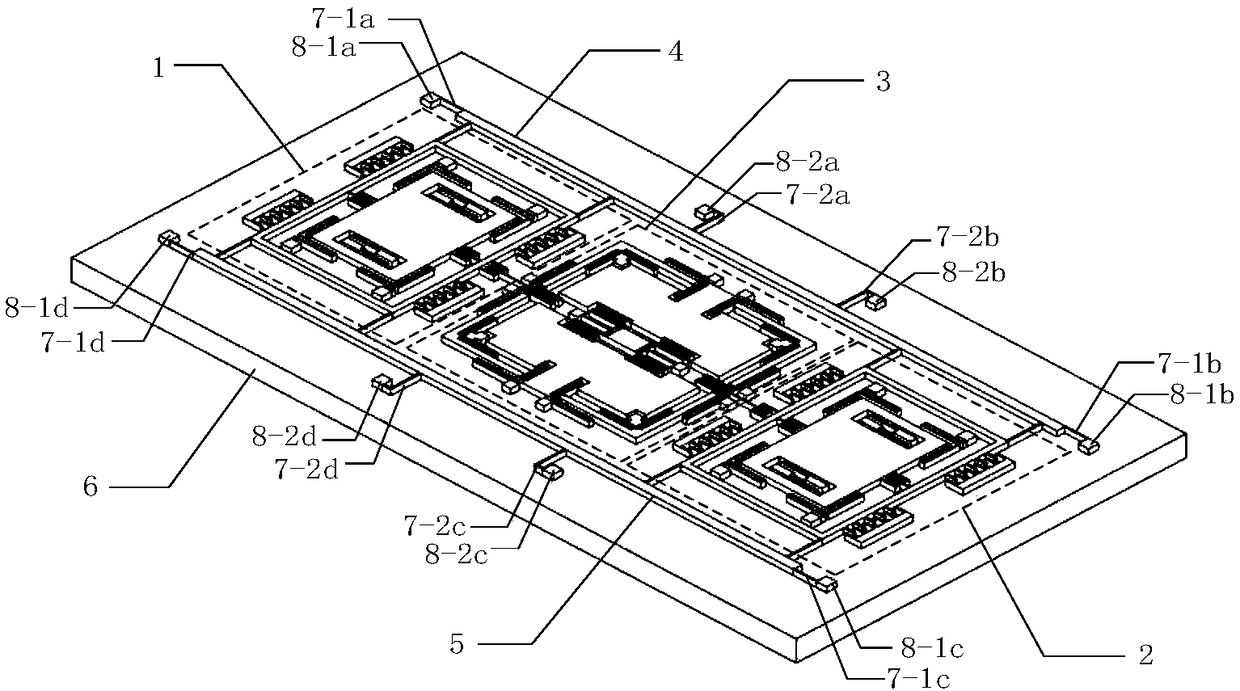

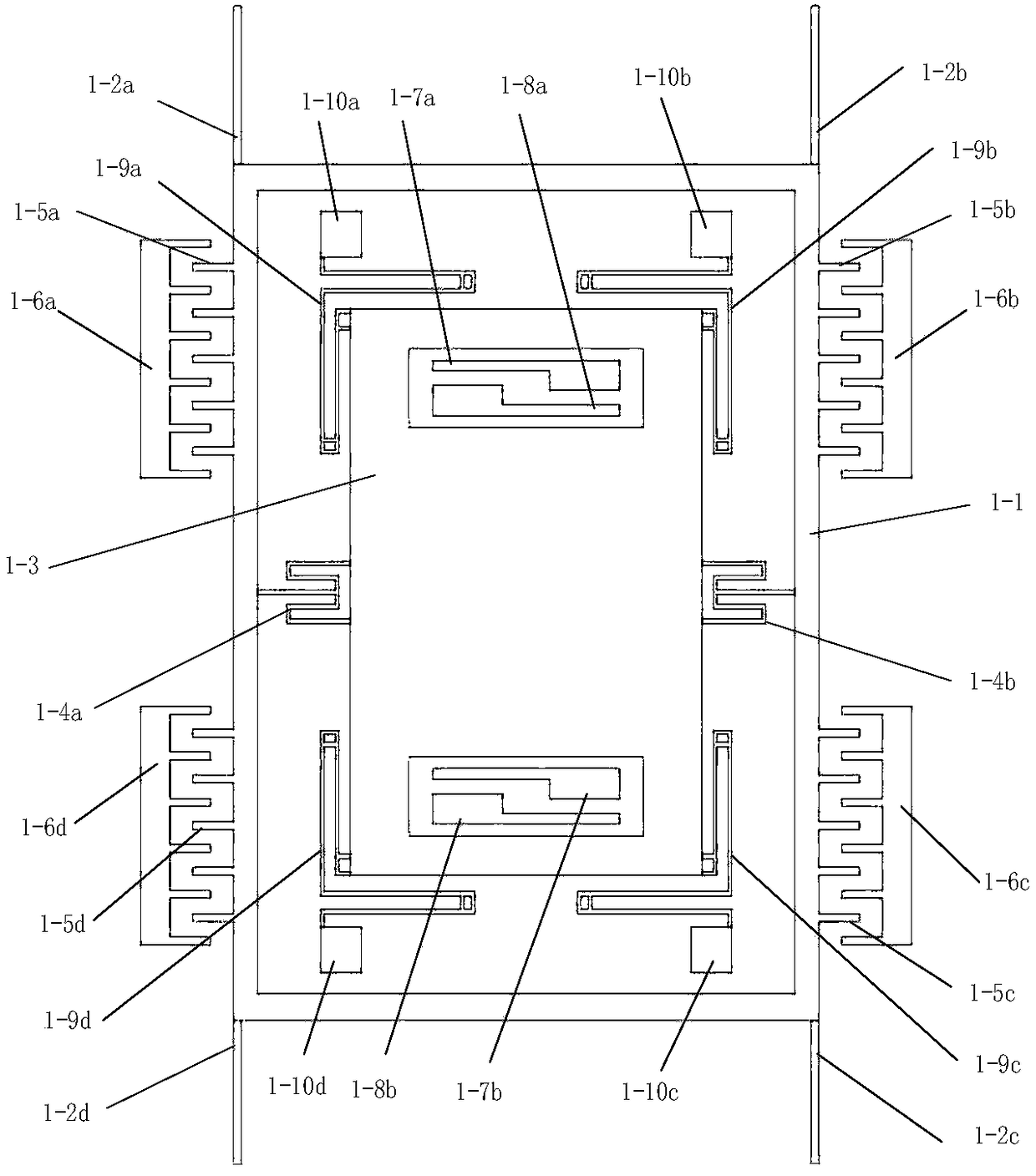

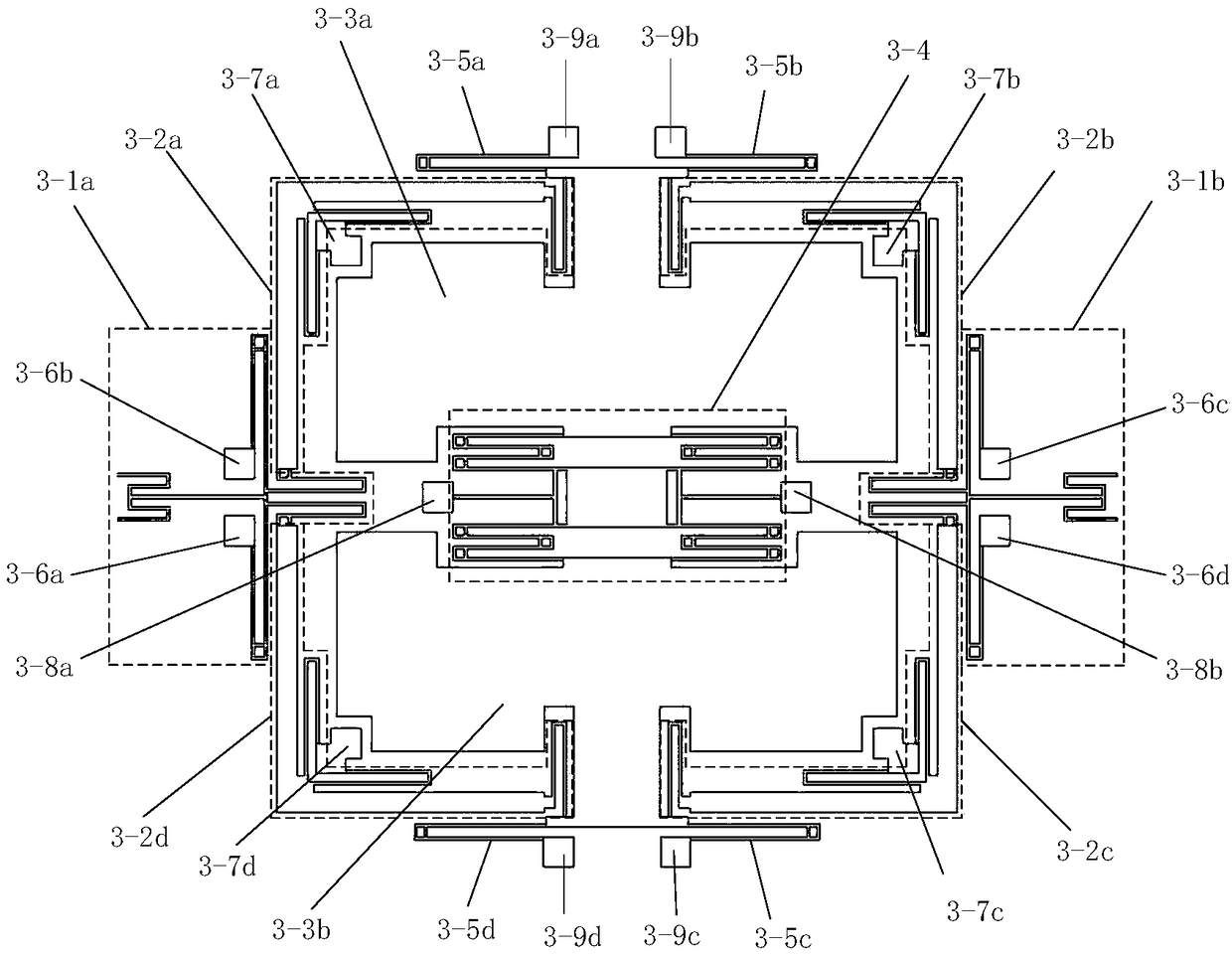

[0021] Such as figure 1 As shown, the three-axis micro-gyroscope based on the tuning fork driving effect of the present invention is used to measure the angular velocity input in the X, Y, and Z-axis directions. The upper layer is a silicon micro-gyroscope structure made of a single crystal silicon wafer, and the lower layer is a glass lining Bottom 6, the anchor points of the upper gyroscope structure are bonded to the lower glass substrate. Metal capacitor plates, signal leads and metal electrodes are arranged on the lower glass substrate. The upper gyroscope structure includes left mechanical structure 1, right mechanical structure 2, middle mechanical structure 3, upper beam 4, lower beam 5, short beams 7-1a, 7-1b, 7-1c, 7-1d, 7-2a, 7-2b, 7-2c, 7-2d, fixed anchor points 8-1a, 8-1b, 8-1c, 8-1d, 8-2a, 8-2b, 8-2c, 8-2d. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com