Patents

Literature

438 results about "Fork tuning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A tuning fork is an acoustic resonator in the form of a two-pronged fork with the prongs (tines) formed from a U-shaped bar of elastic metal (usually steel).

Connector

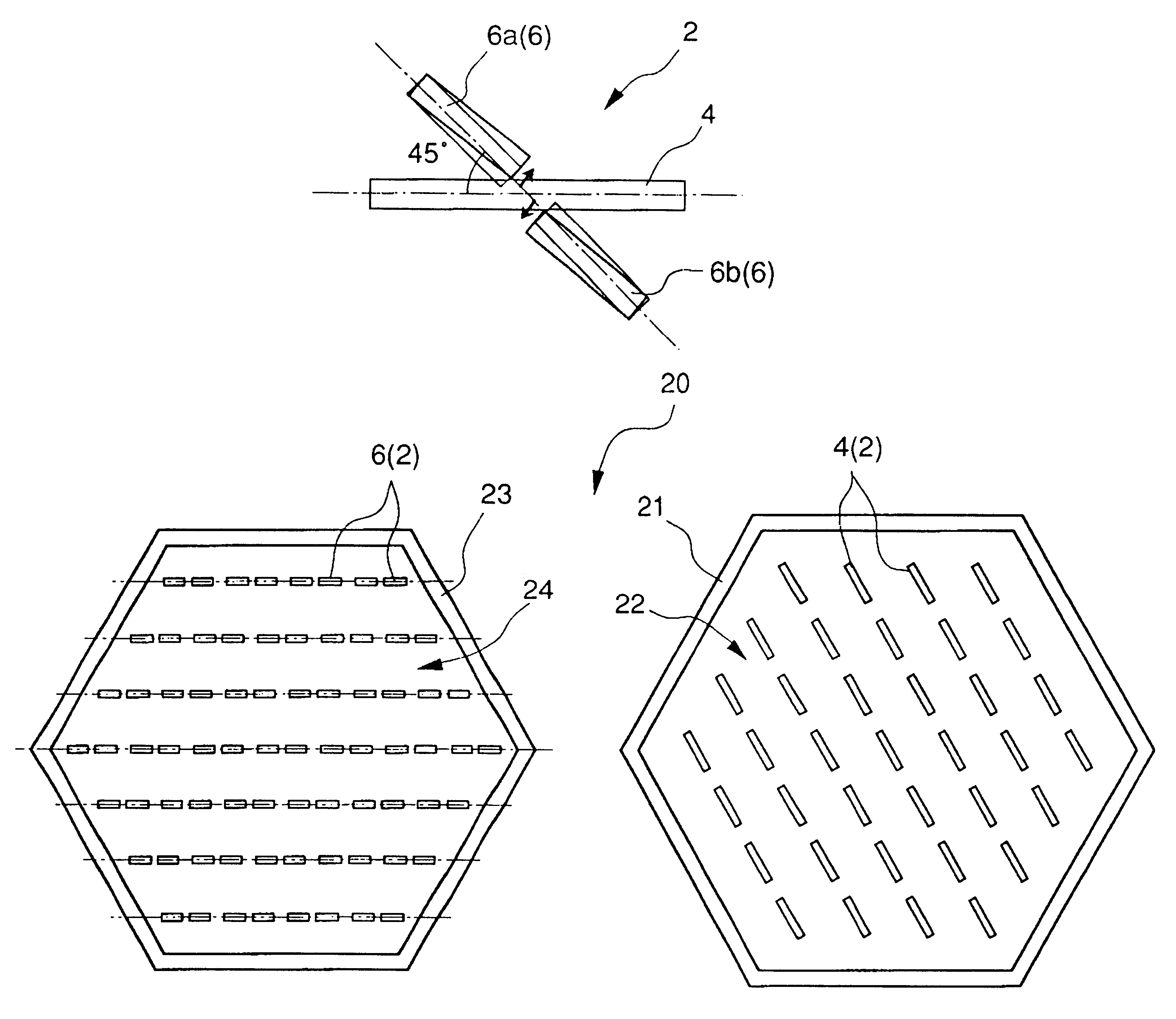

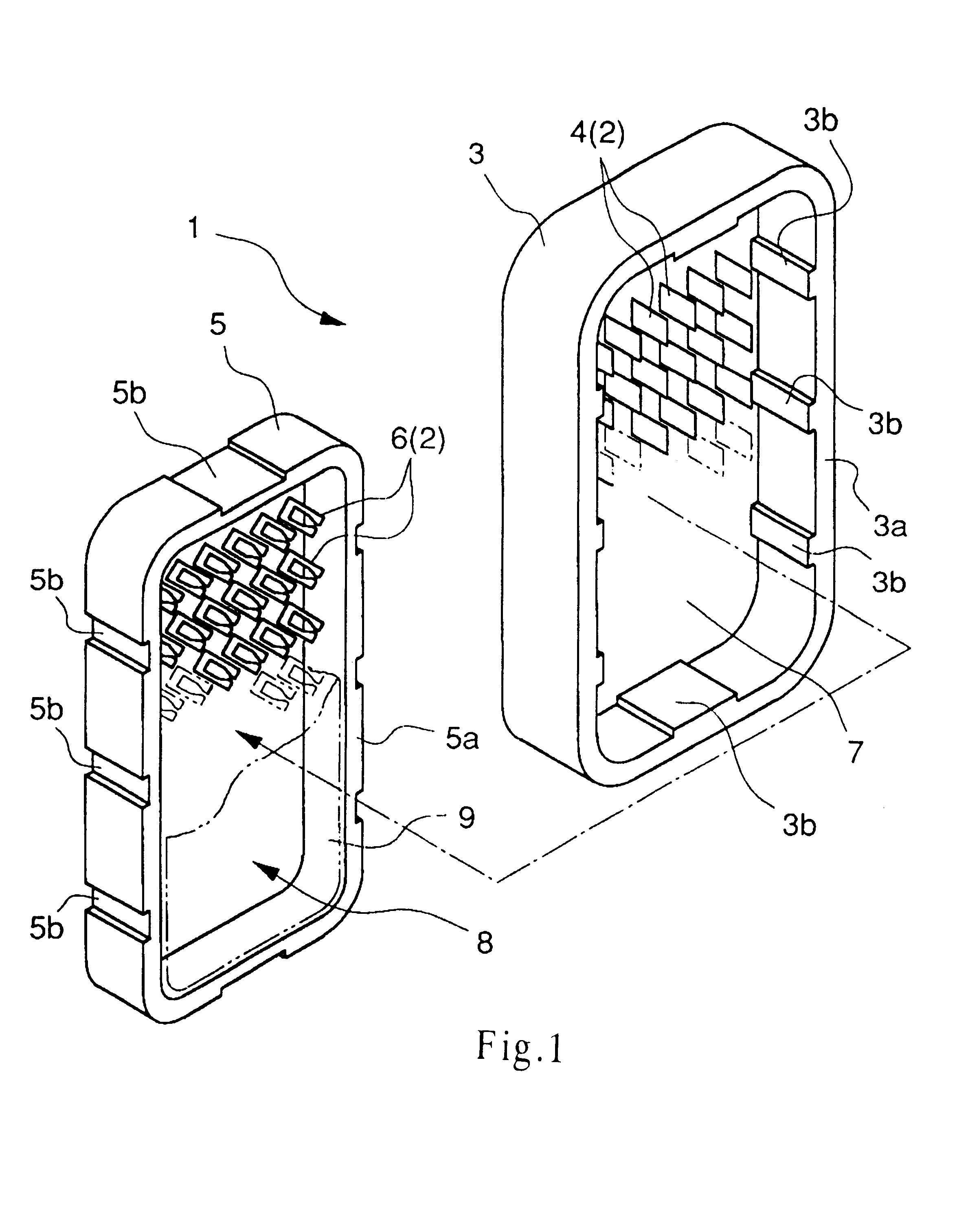

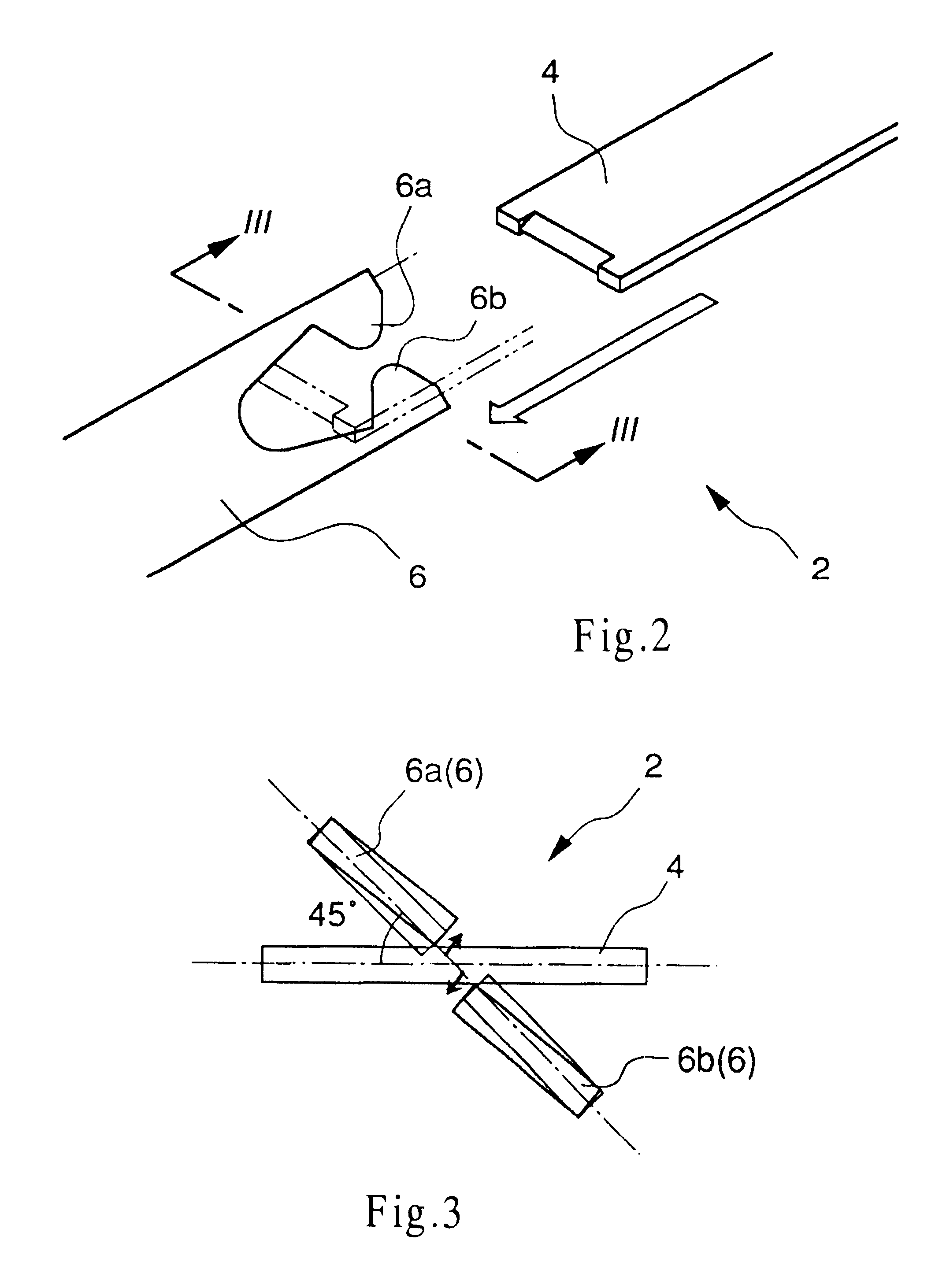

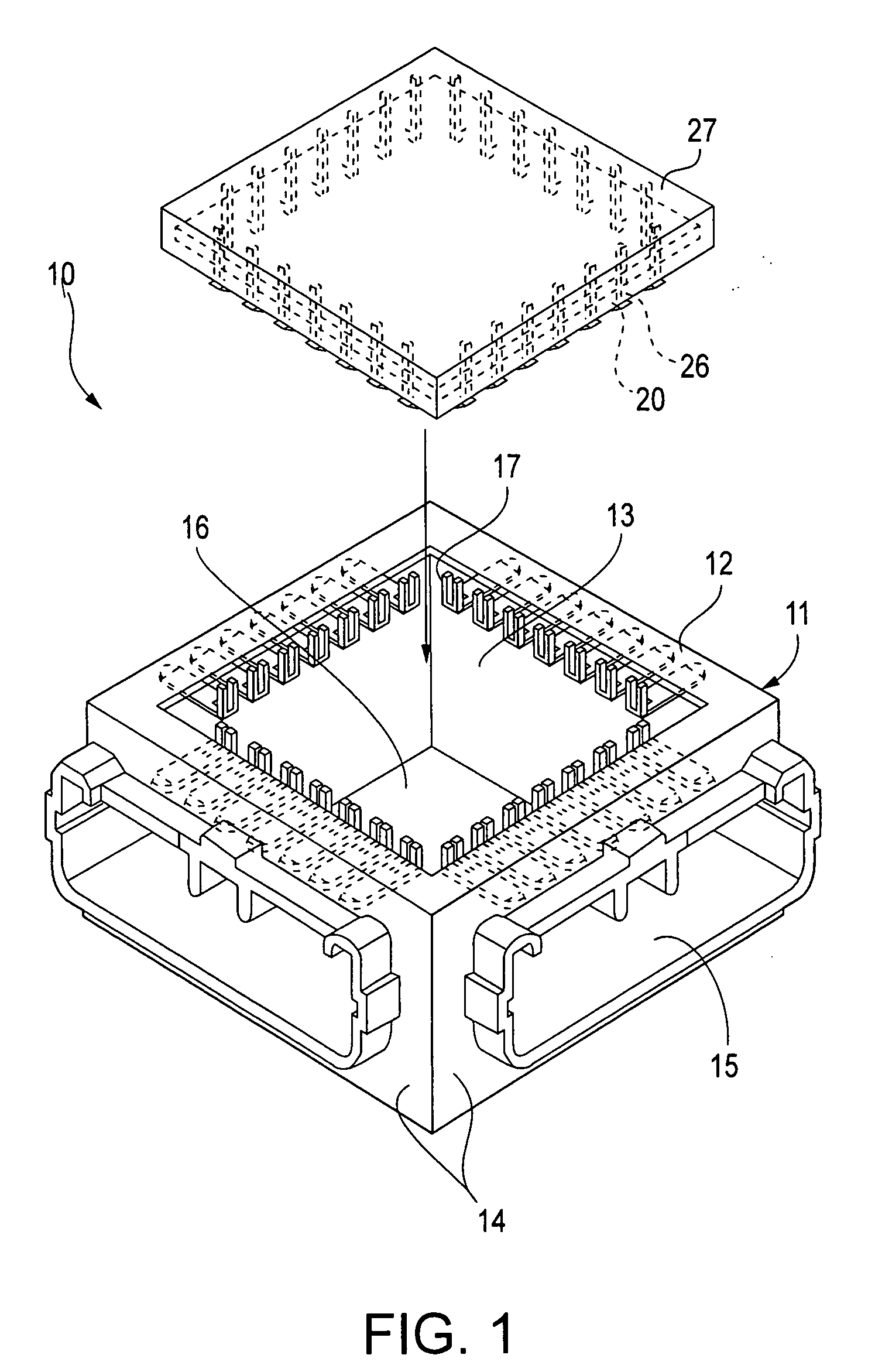

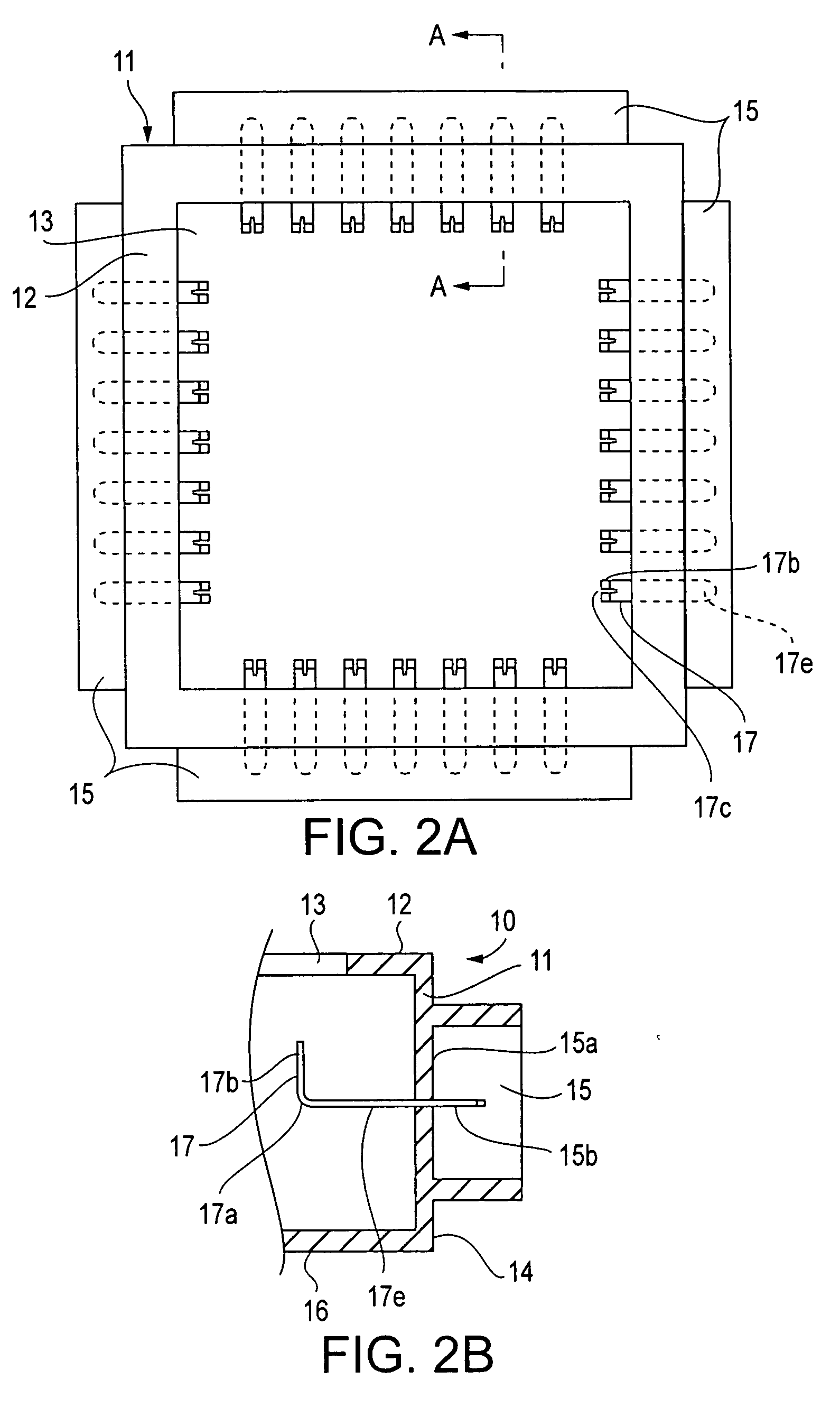

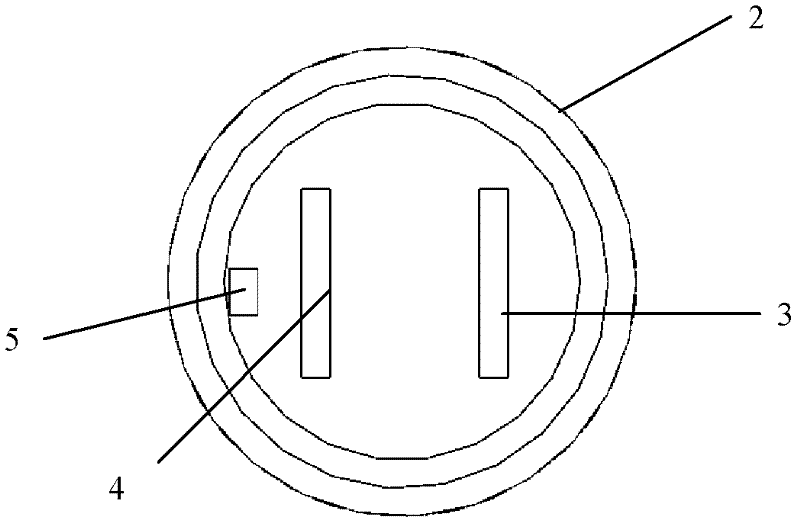

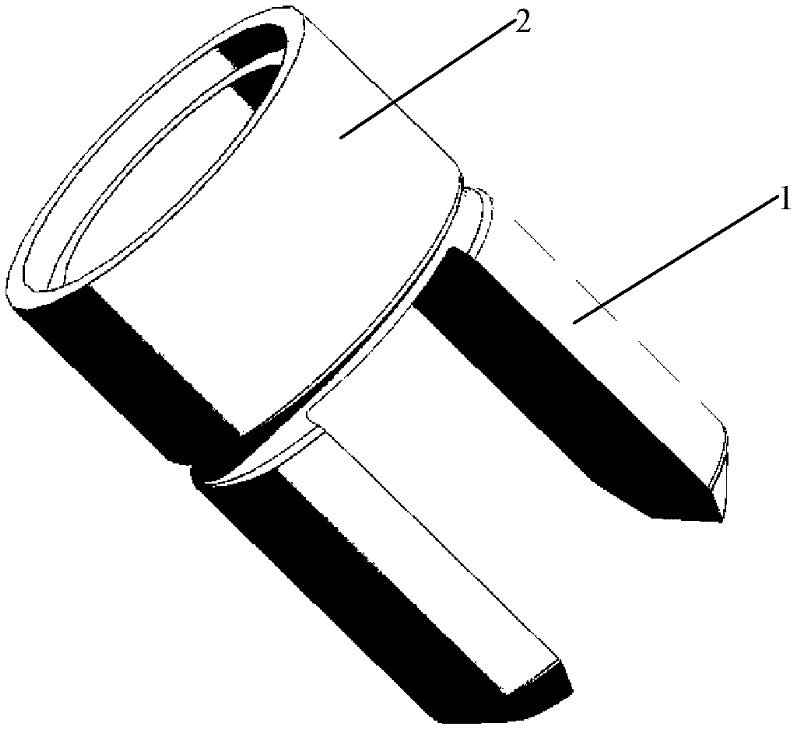

A suitable contact state is attained by an always stable contact pressure between a male contact and a female contact which form a tuning fork type contact. For a contacts providing a tuning fork type contact 2 that attains a contact state by inserting a male contact 4 between a pair of beams 6a and 6b provided on a female contact 6, in the connected state, male contact 4 and female contact 6 are arranged so as to maintain a state wherein the width direction of the male contact is angled relative to the direction of separation of the beams 6a and 6b.

Owner:FCI AMERICAS TECH INC (US)

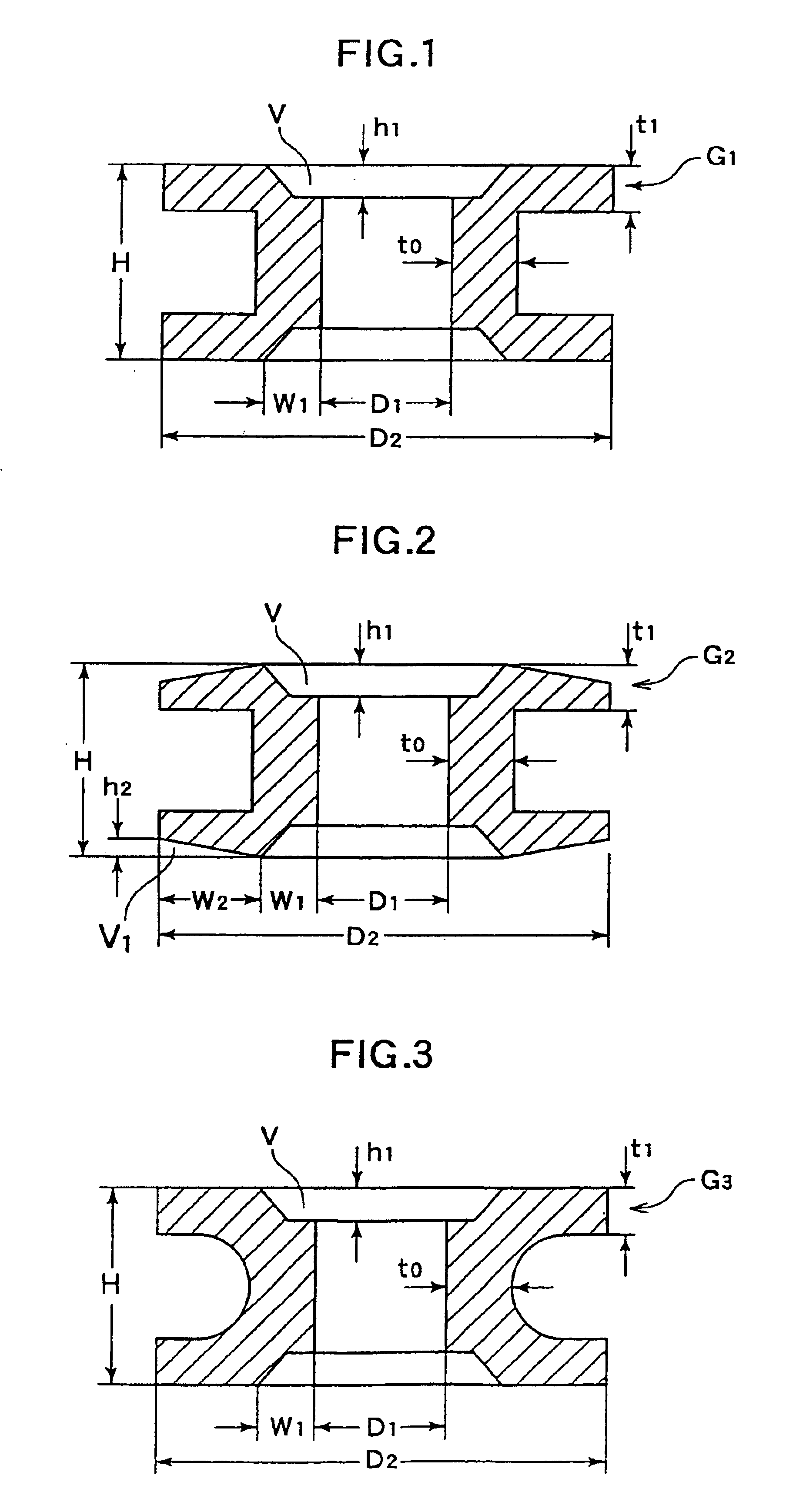

Metal gasket

ActiveUS6905125B2Small tightening forceUltra-high vacuumEngine sealsFluid pressure sealed jointsEngineeringMetal

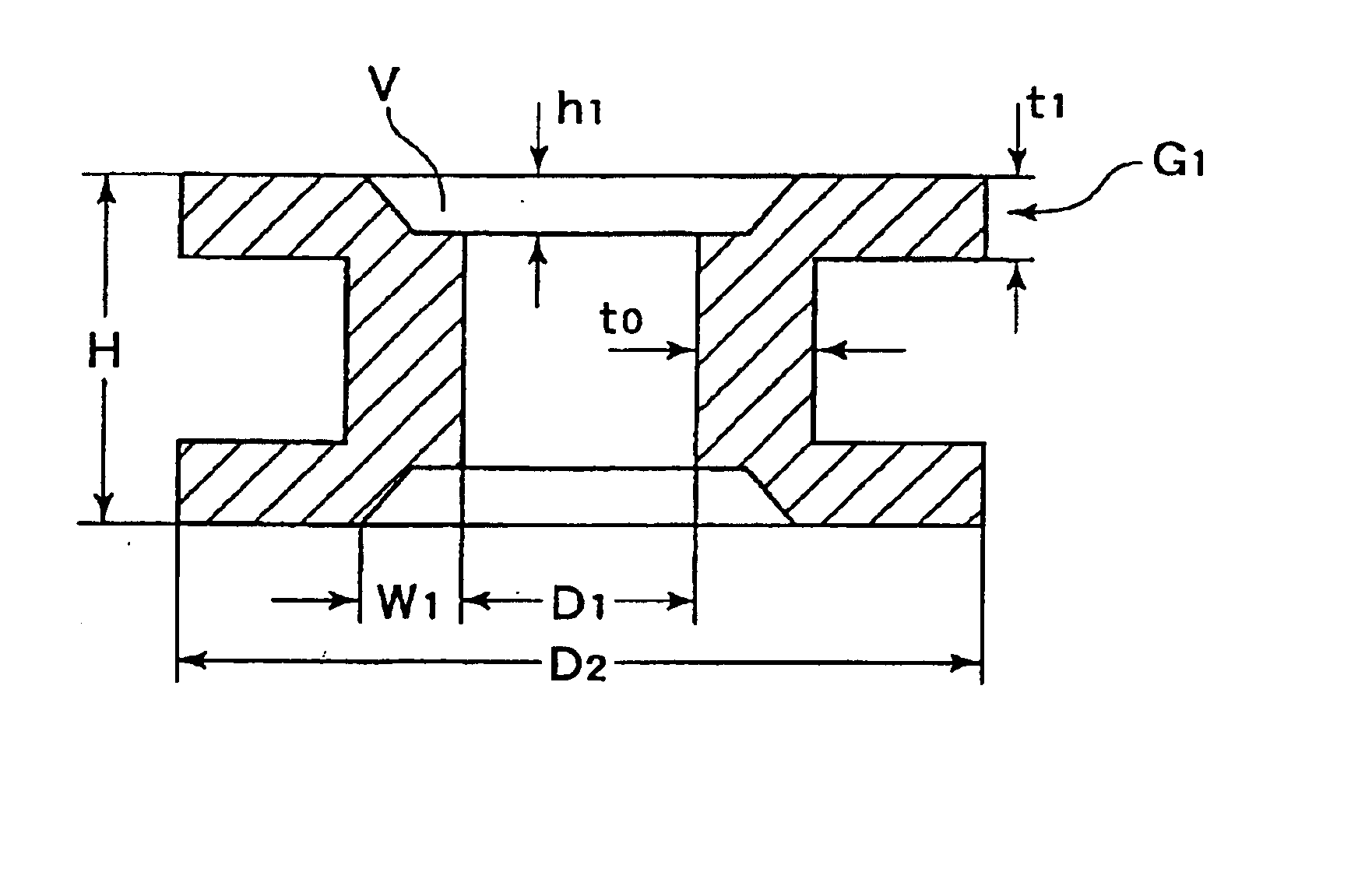

An annular-shaped metal gasket, which can reduce a tightening force necessary to a seal and easily manage the manufacturability and the characteristics thereof, the metal gasket, in an annular-shaped metal gasket having a cross section provided with an outer circumferential opening and formed in one of a laterally U-shape, voids are formed to the innermost circumferential portions on the two confronting flat sealing surfaces of the metal gasket that are in contact with opponent surfaces, each void having a width equal to or more than 40% of the central wall thickness t0 of a bight section and a height equal to or more than 5% of the height H of the gasket, wherein the cross section of the gasket is formed in a tuning-fork shape. A tightening force necessary to the seal can be reduced by forming the cross section of the metal gasket in the tuning-fork shape and providing the voids with the surfaces of the metal gasket in contact with the opponent surfaces.

Owner:NICHIAS CORP

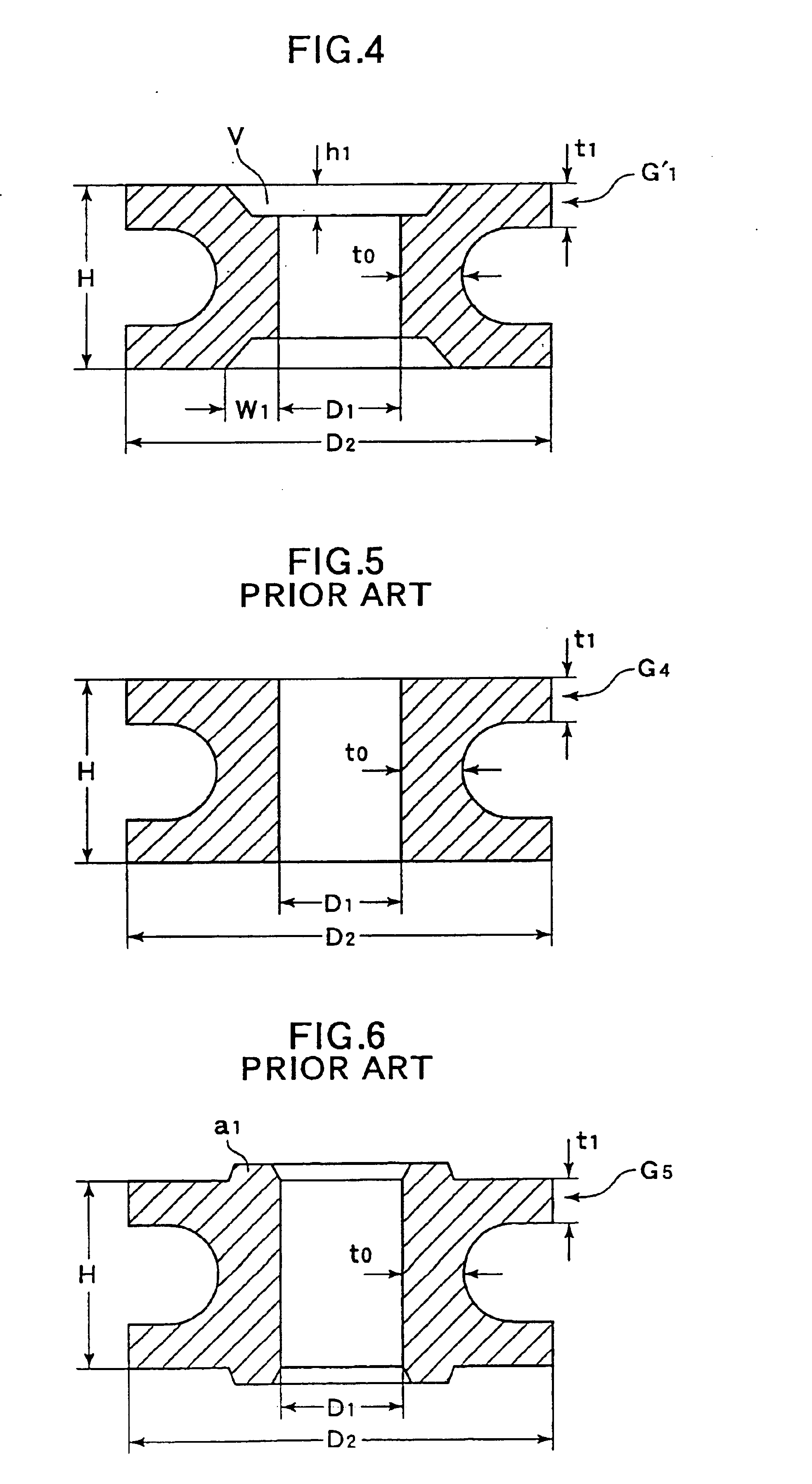

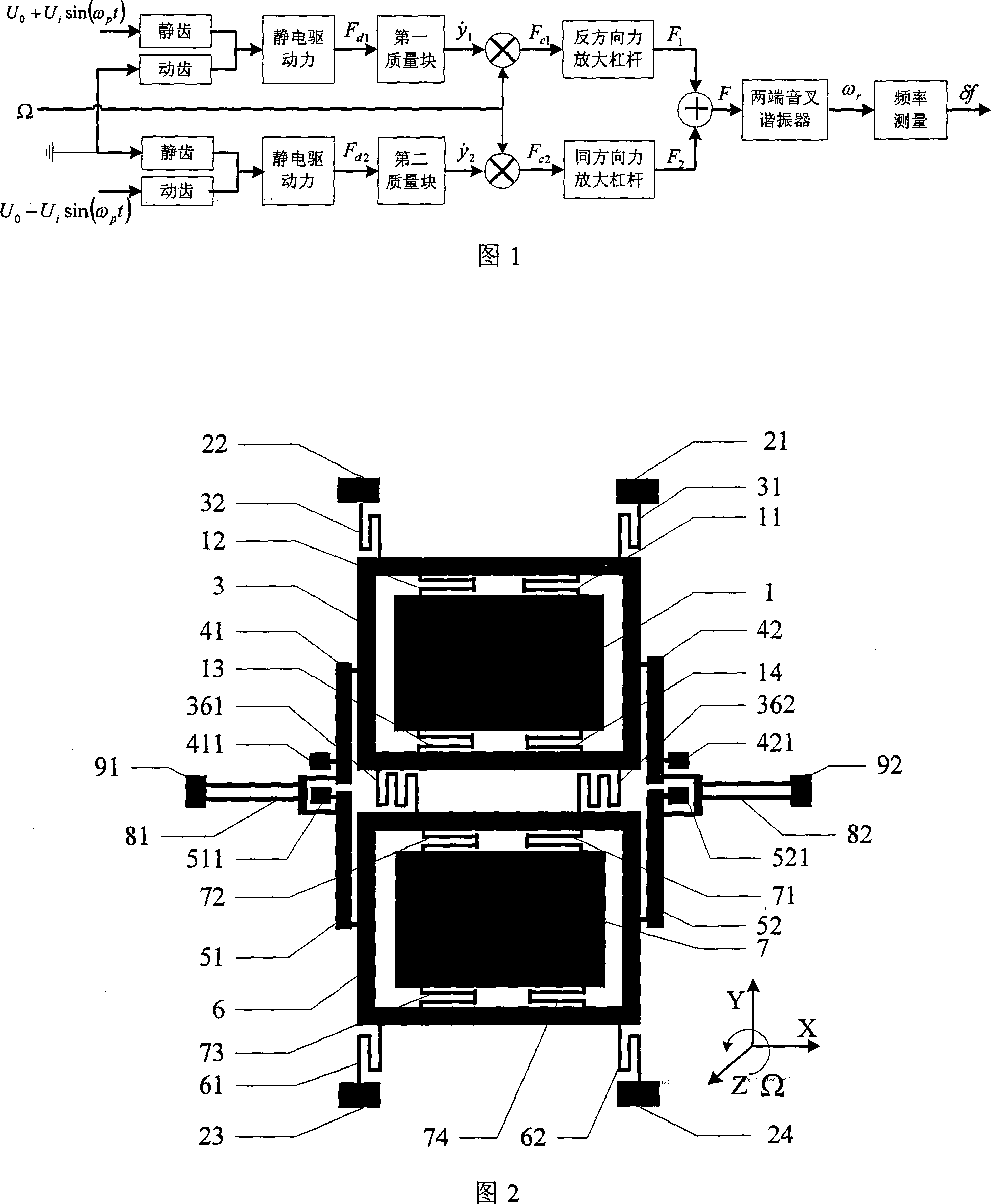

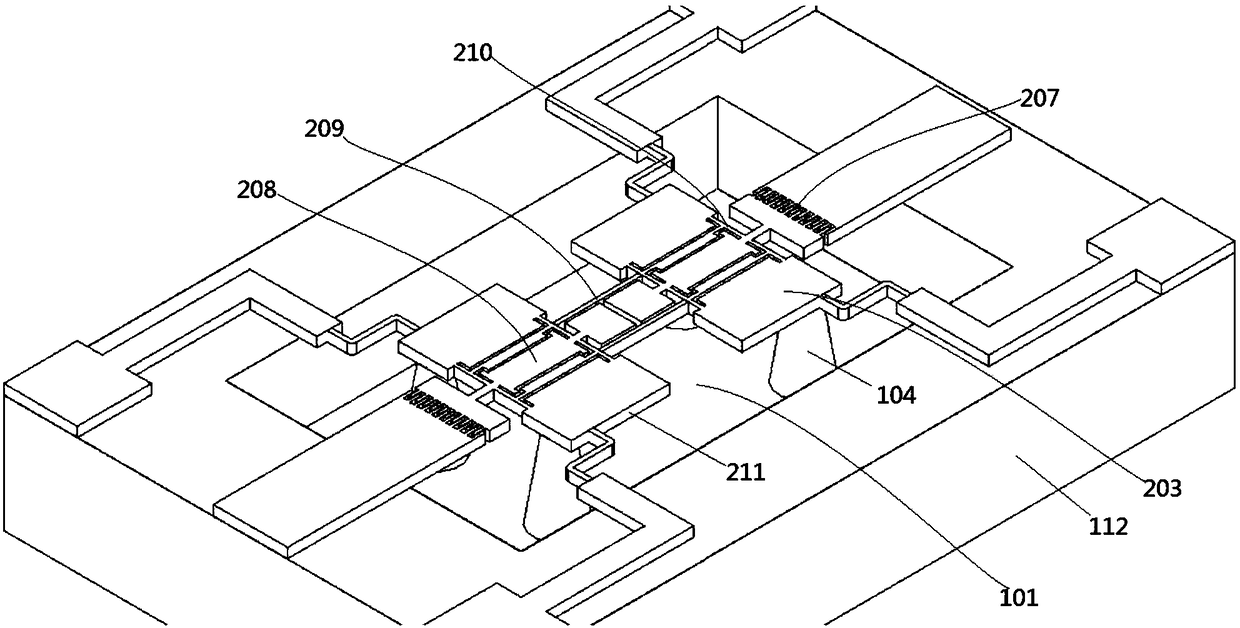

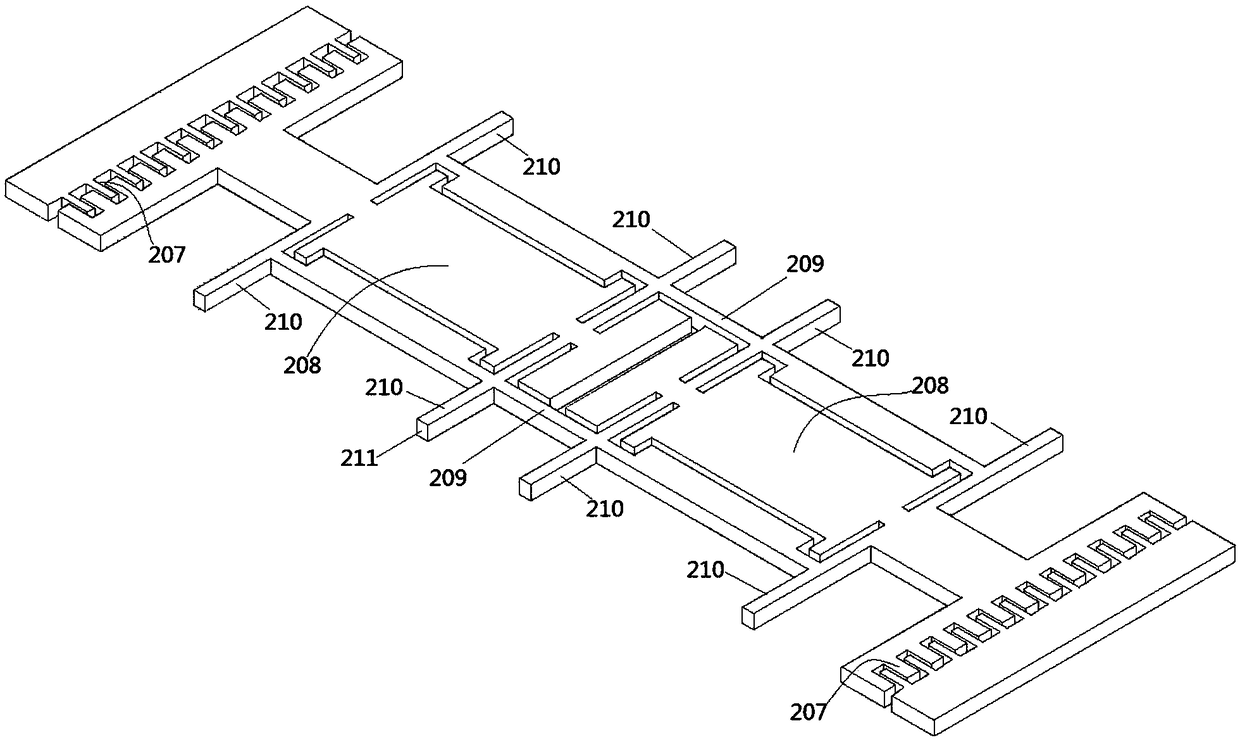

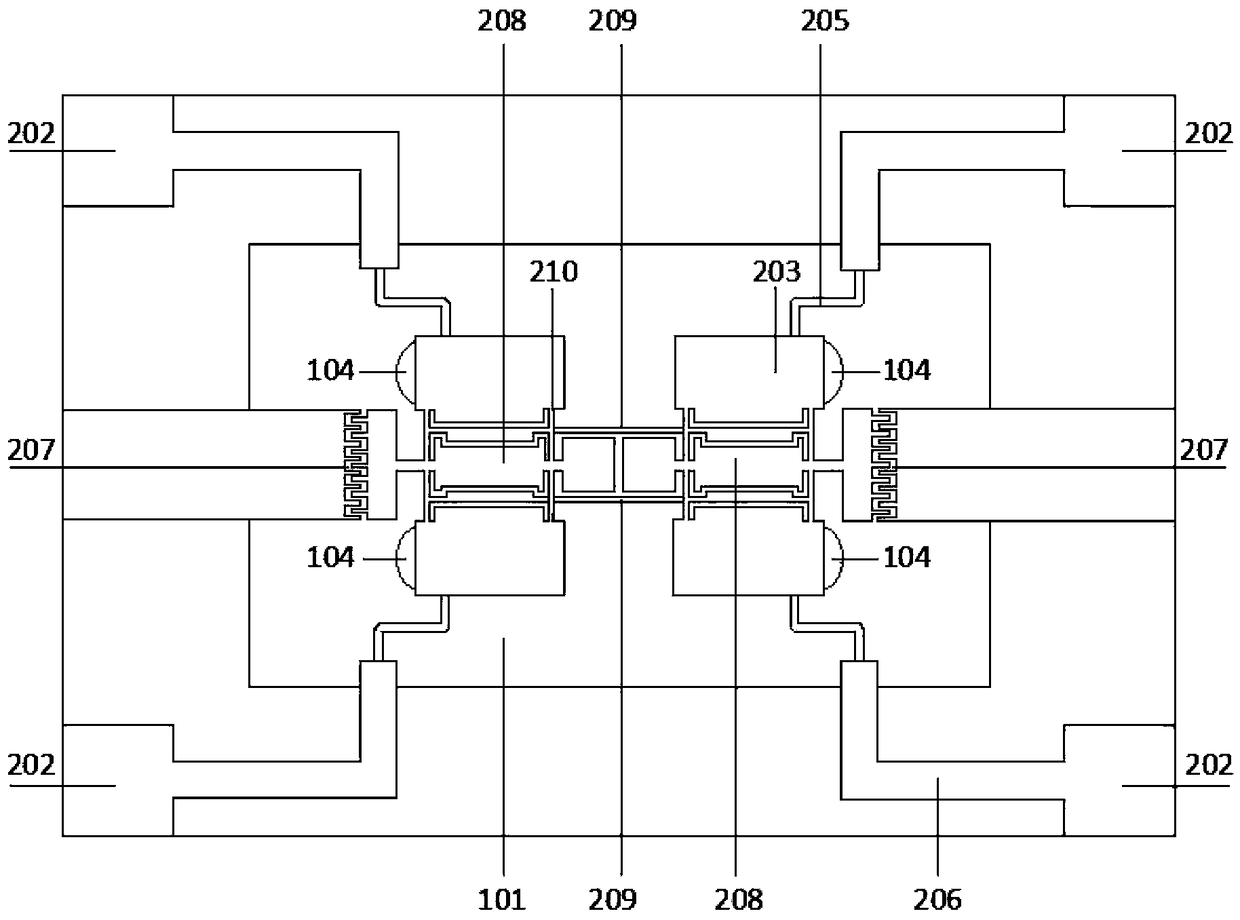

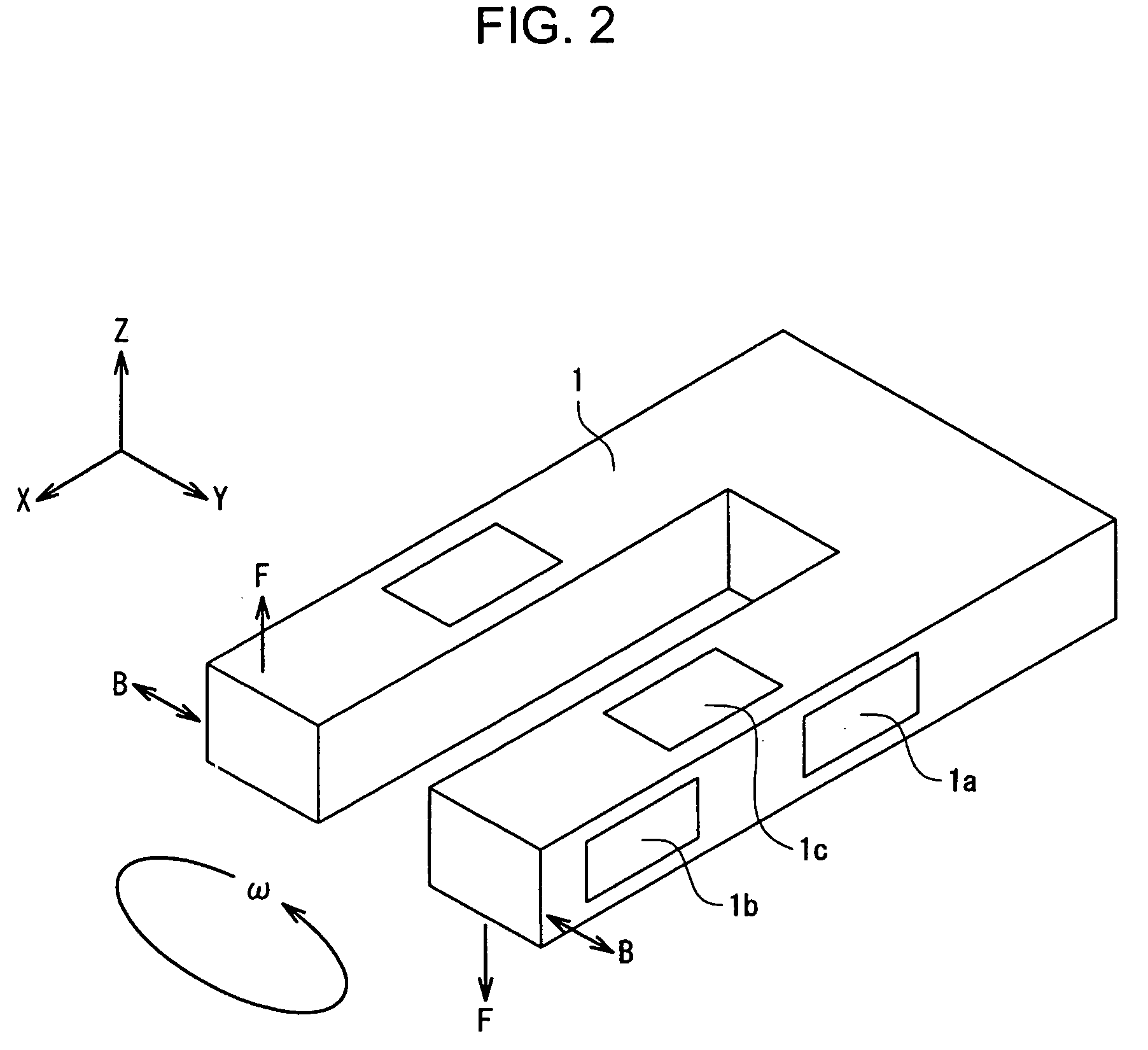

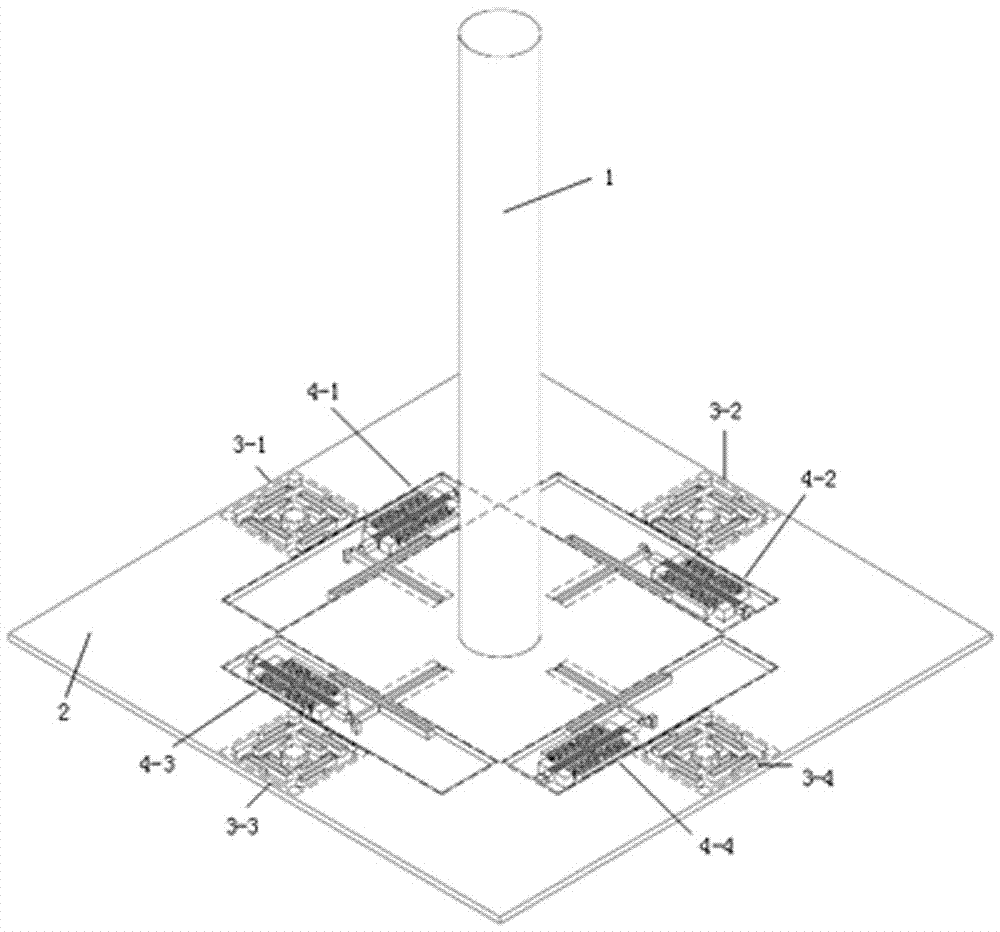

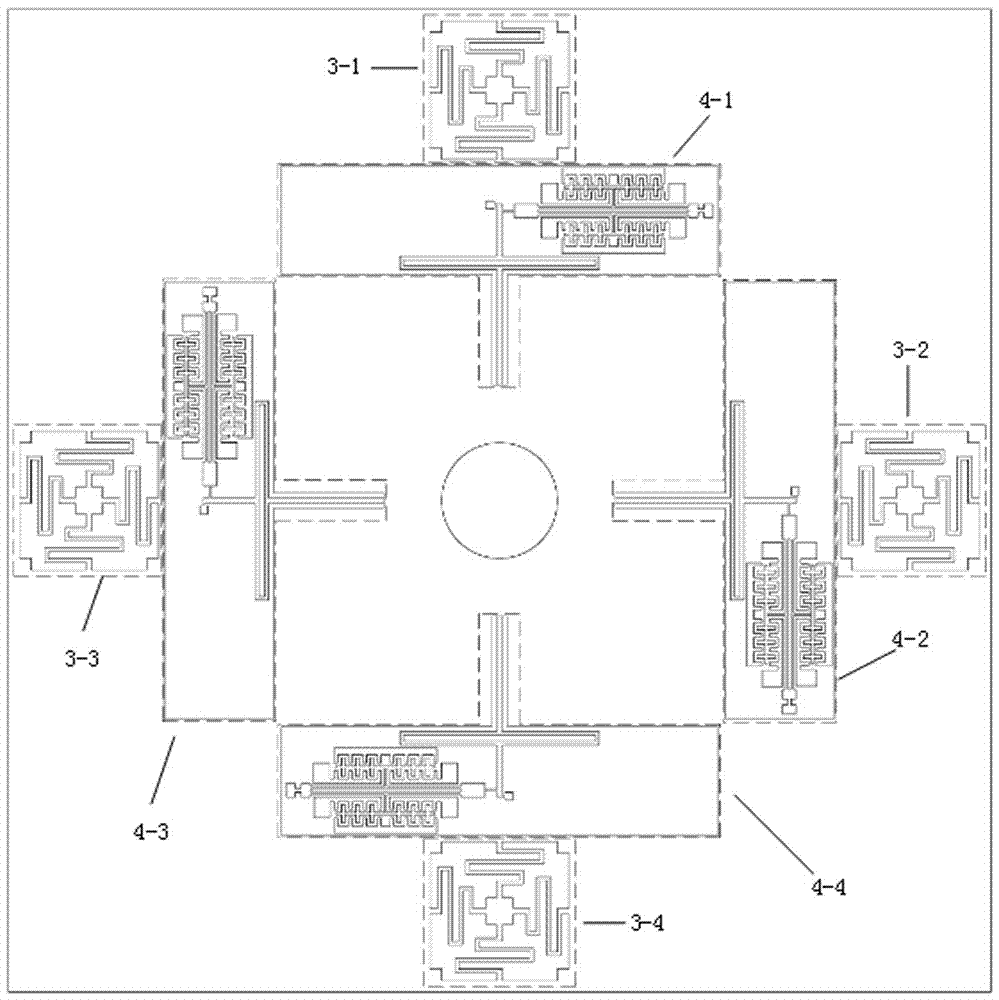

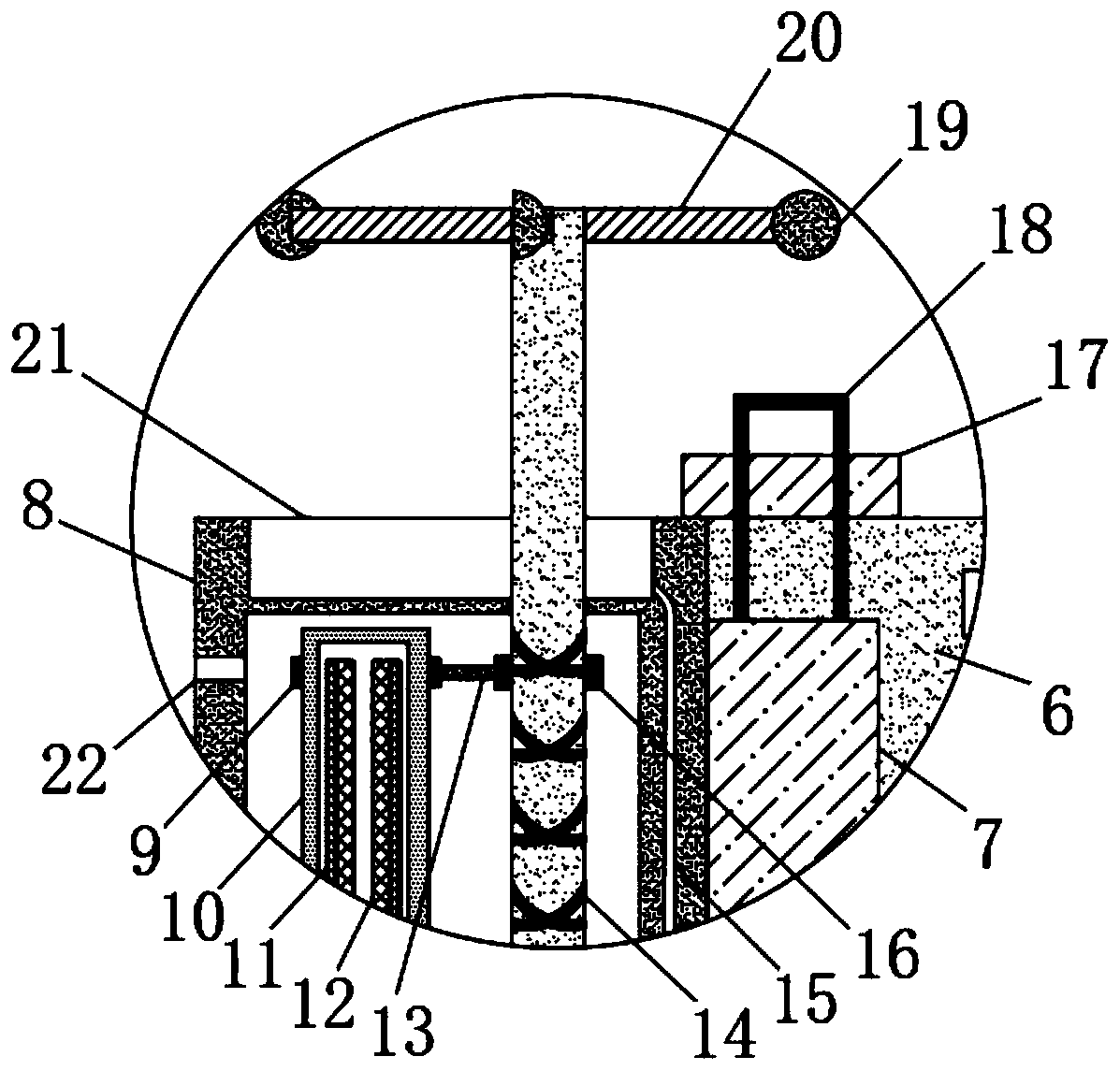

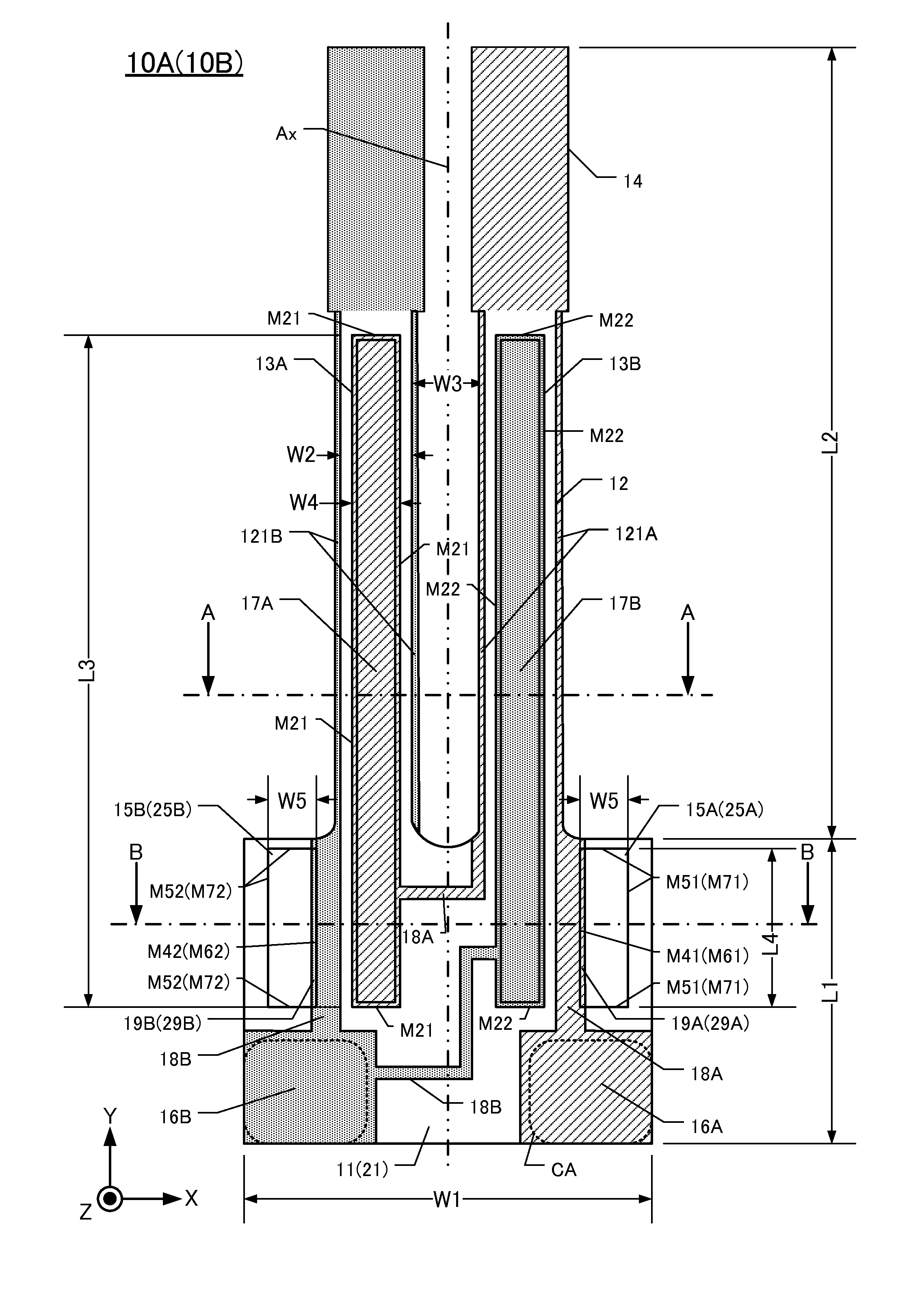

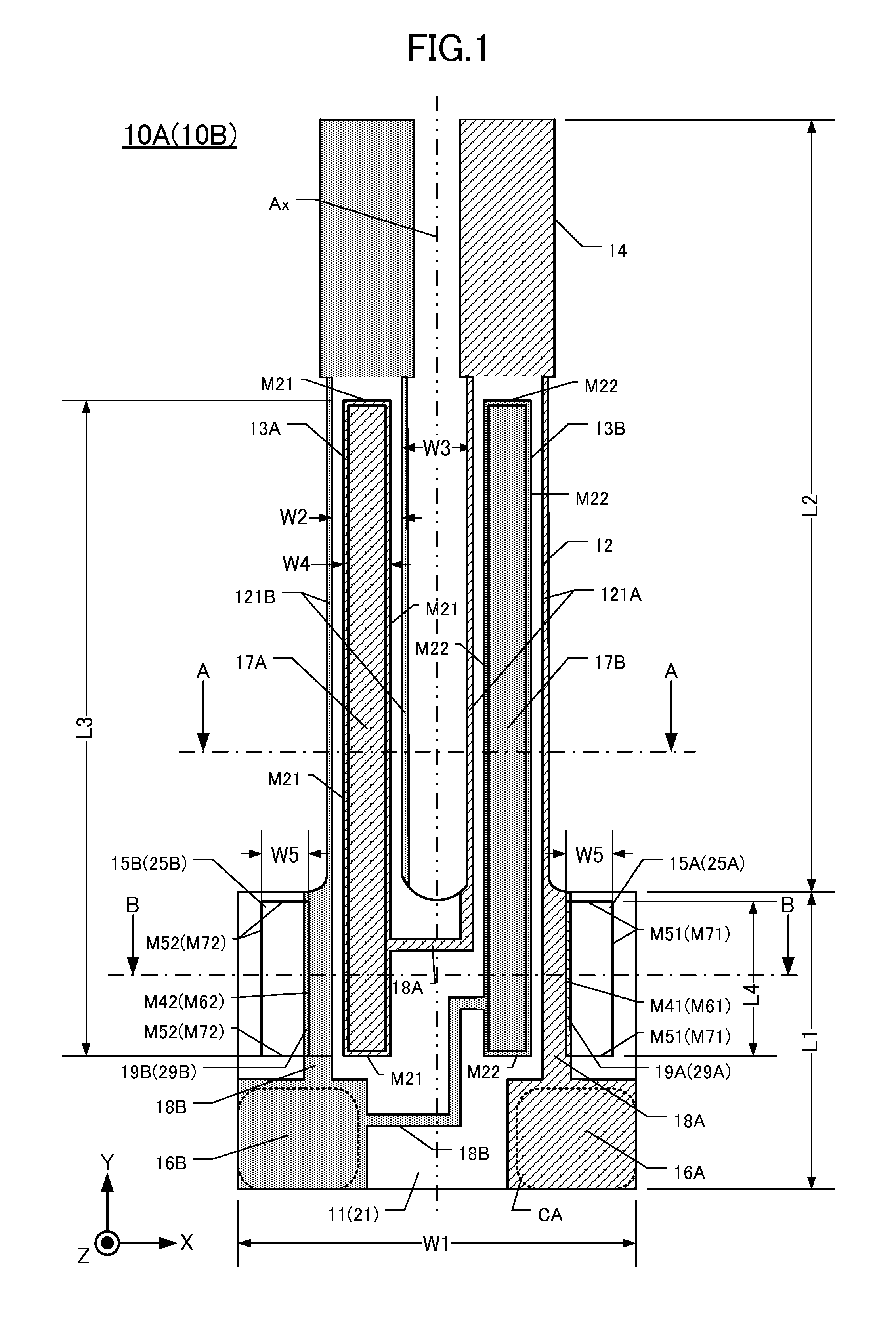

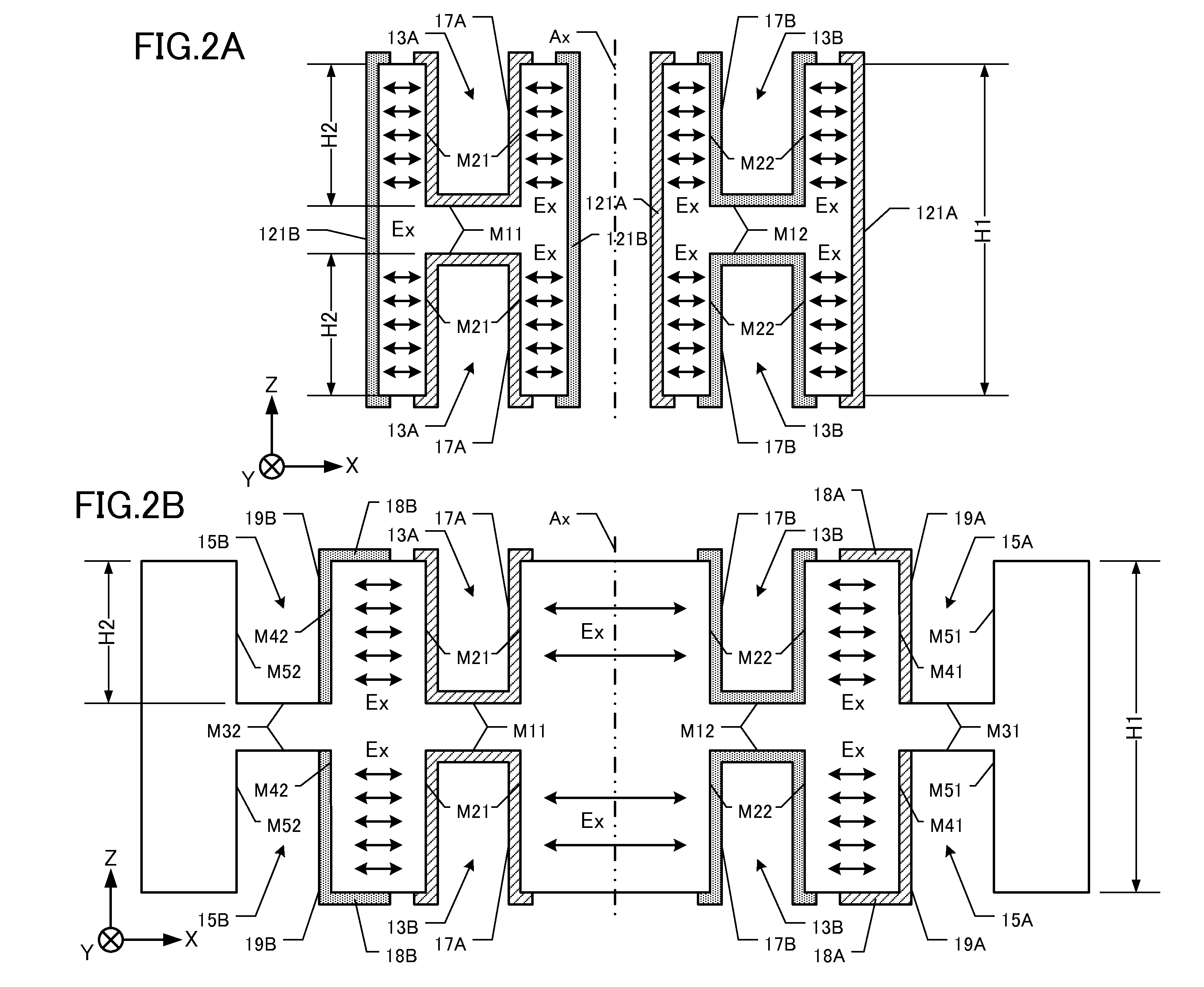

Double quality blocks attune output type silicon MEMS gyroscopes

ActiveCN101135563AReduce vibration and noiseReduce energy lossTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesGyroscopeResonance

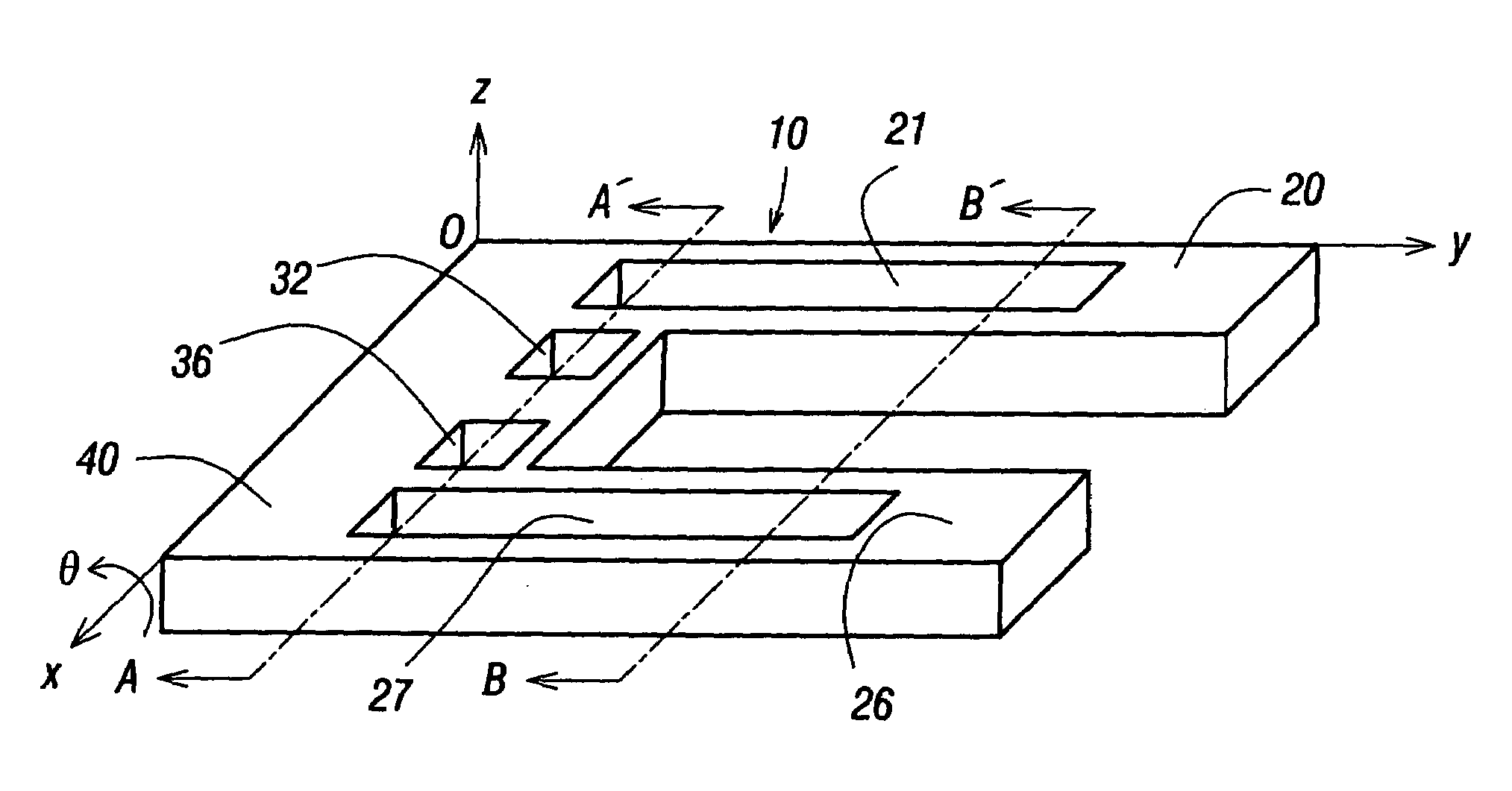

The gyroscope comprises: fixed teeth, movable teeth, two mass blocks, two outer frames, two pairs of leavers and two tuning fork resonators. The first mass block and second mass block are respectively connected to the first outer frame and second outer frame through four infolding beams; two outer frames are respectively secured on the anchor point through the outer supporting beam; two outer frames are connected through a pair of folding beams; both right and left sides of the first outer frame are connected to the free end of two tuning fork resonators via the opposite direction force amplifying leaver; the both right and left sides of the outer frame are connected to the free end of two tuning fork resonators via the same direction force amplifying leaver; by testing the resonance frequency of tuning fork resonator at both ends, calculating the rotating speed inputted from outside.

Owner:BEIHANG UNIV

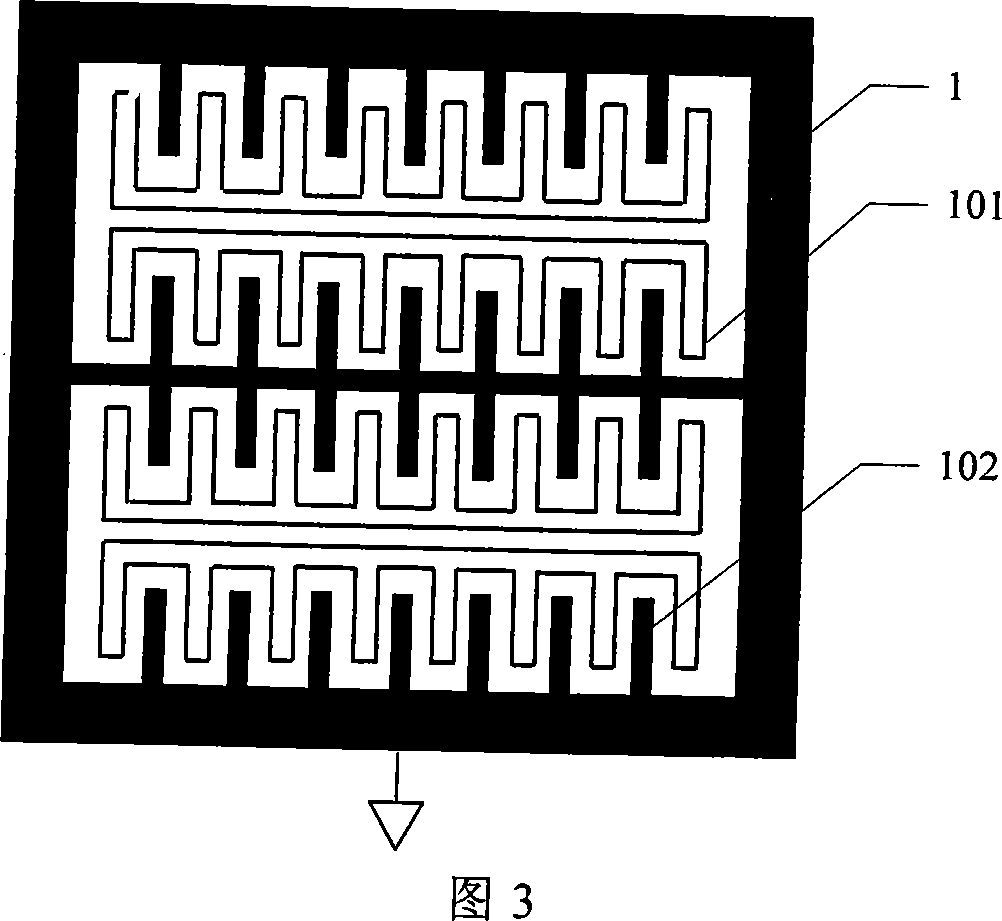

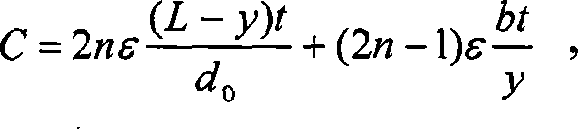

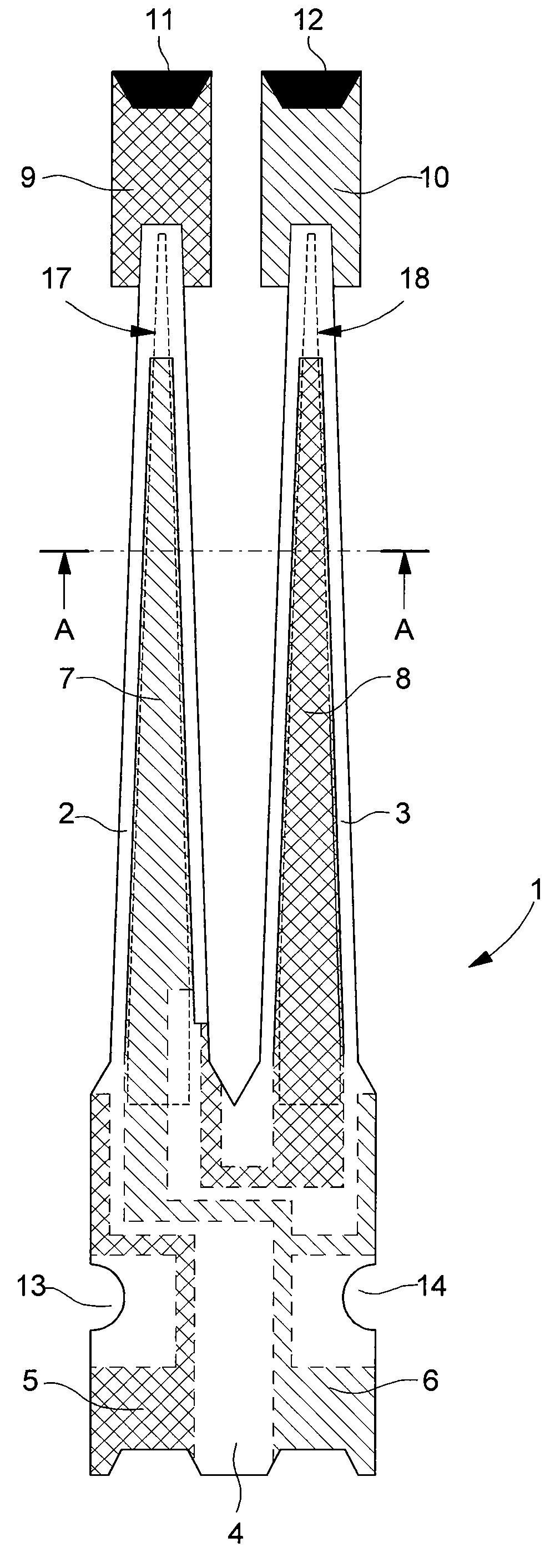

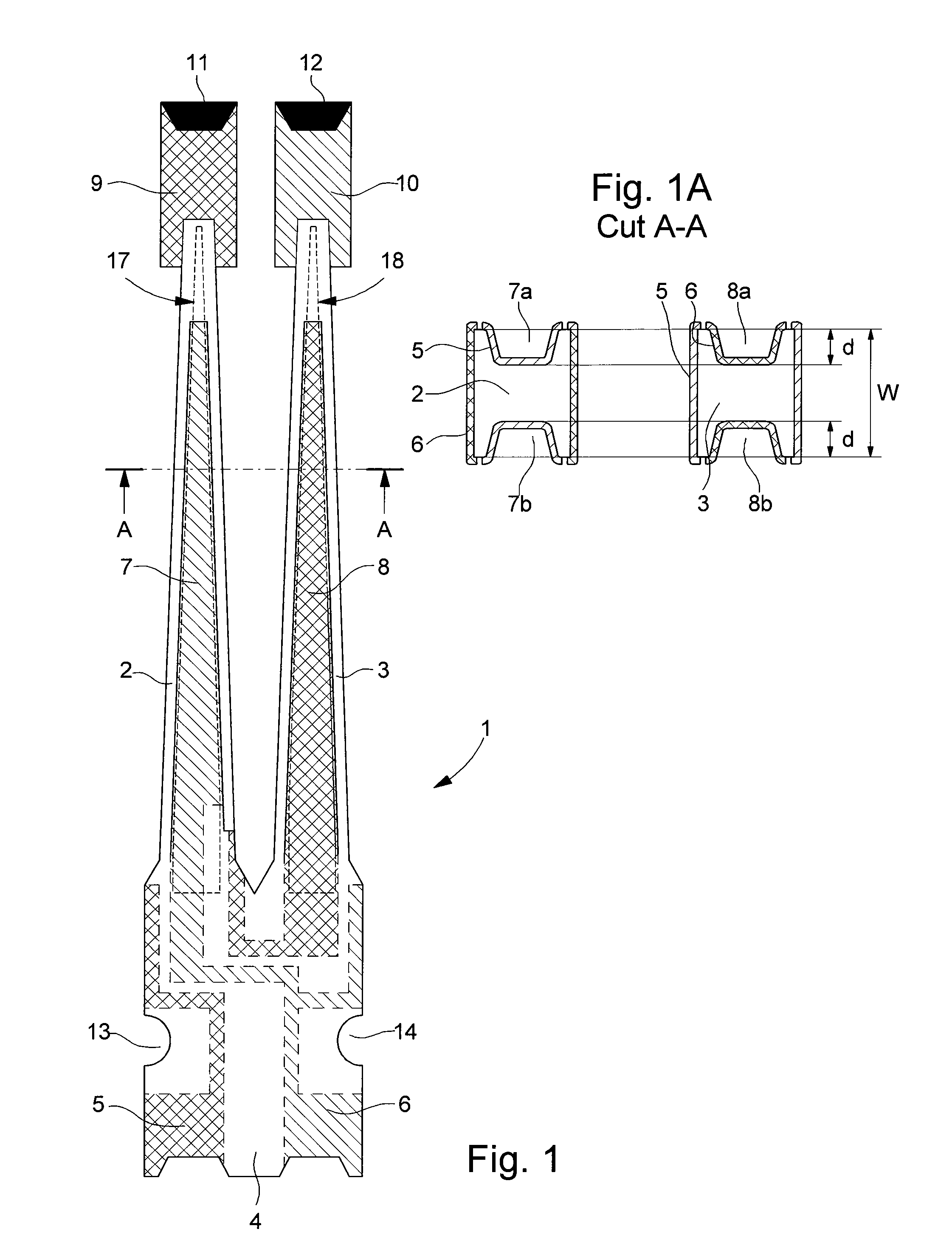

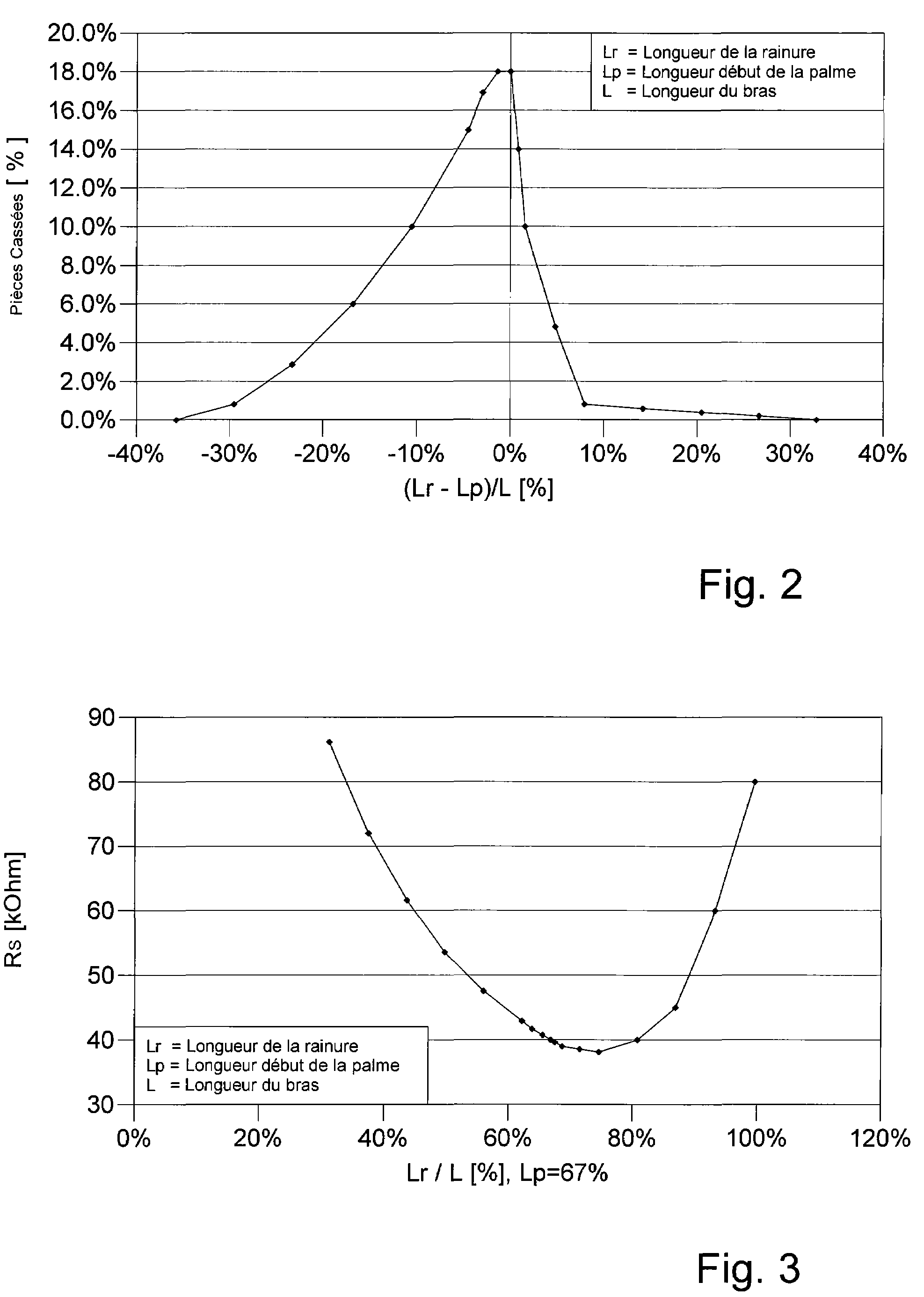

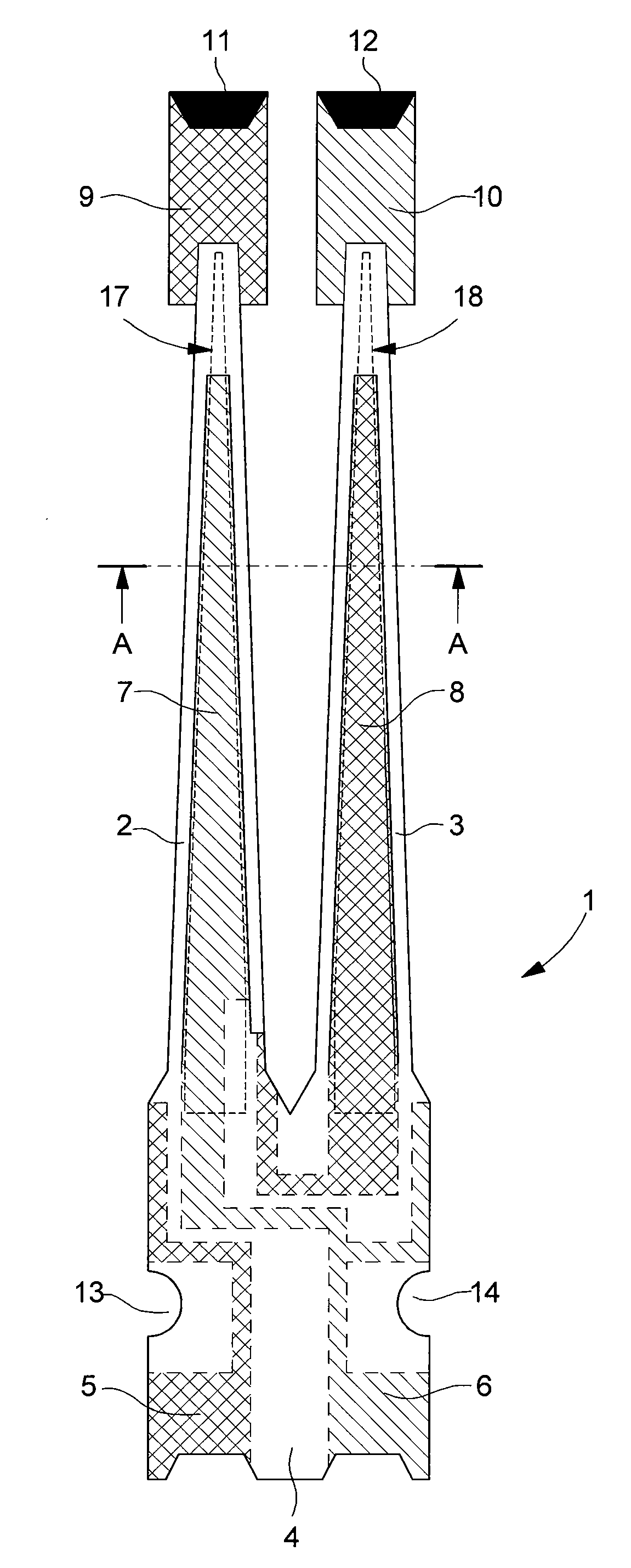

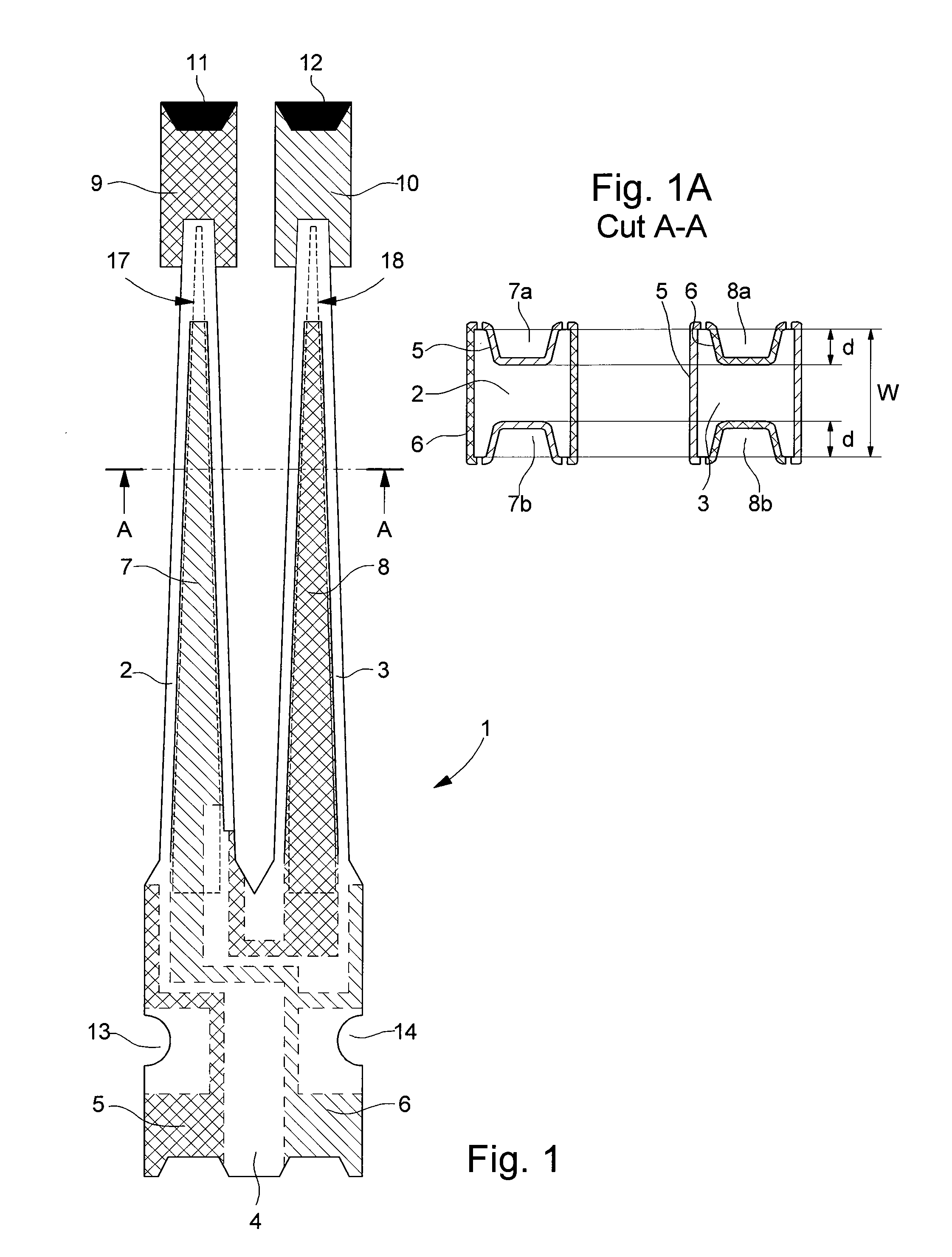

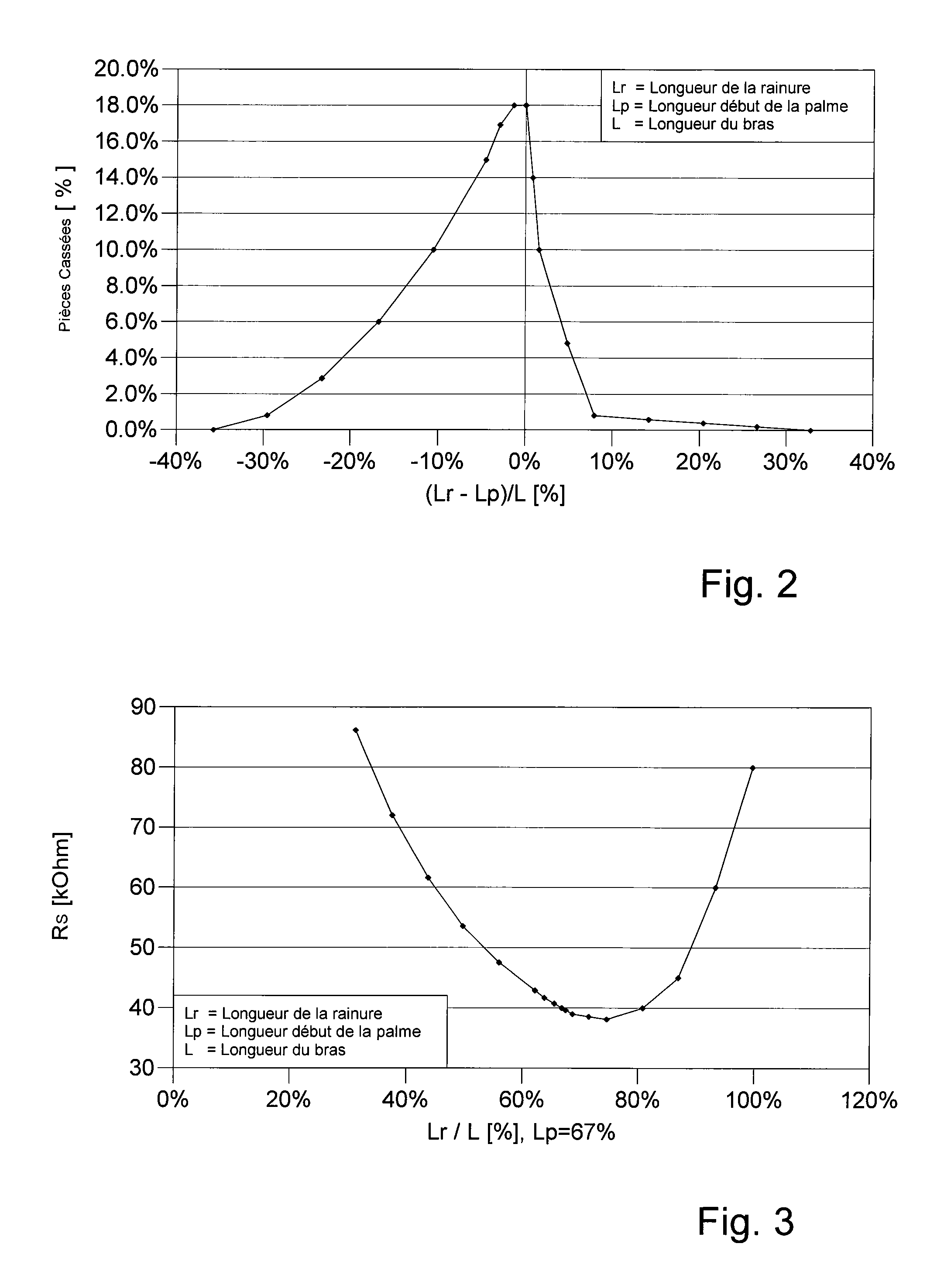

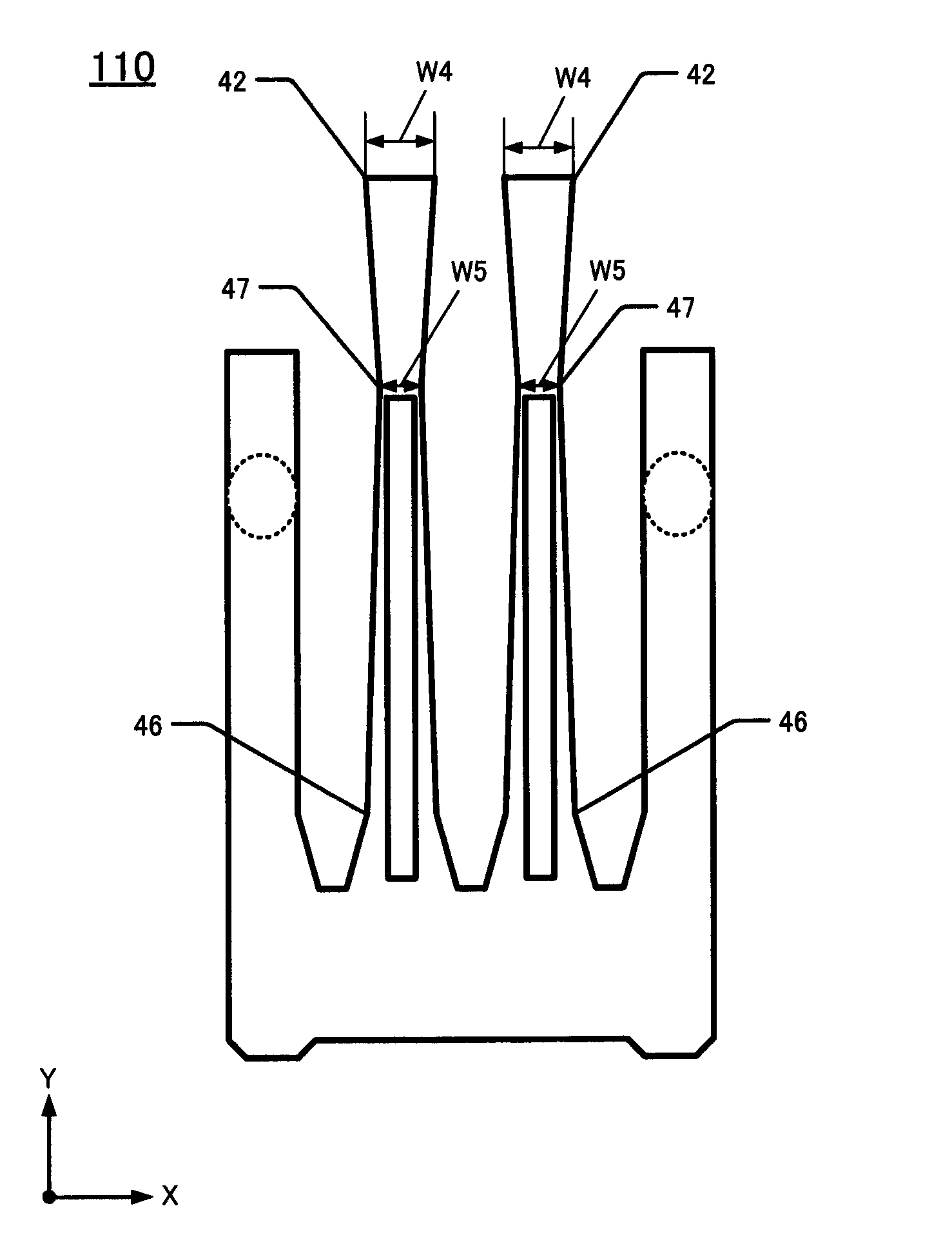

Piezoelectric resonator with optimised motional capacitances

ActiveUS7626318B2Improve stress conditionImprove seismic performancePiezoelectric/electrostriction/magnetostriction machinesImpedence networksCapacitanceShock resistance

The tuning fork resonator (1) includes a base (4) from which first and second parallel vibrating arms (2, 3) extend, carrying a set of excitation electrodes (5, 6) for vibrating the arms at a fundamental frequency. Grooves (7, 8) are formed on at least one of the top or bottom surfaces of each of said arms. The vibrating arms have a generally tapered shape, and are extended by an enlarged flipper shaped portion (9, 10) which forms the free end of each arm. The groove (7, 8) is extended in the direction of the free end of an arm to beyond the start of the flipper (9, 10) so as to increase said first motional capacitance of the resonator for the fundamental frequency, to decrease said second motional capacitance of the resonator for the partial frequency and to ensure better distribution of mechanical stress along the vibrating arms and to increase shock resistance.

Owner:ETA SA MFG HORLOGERE SUISSE

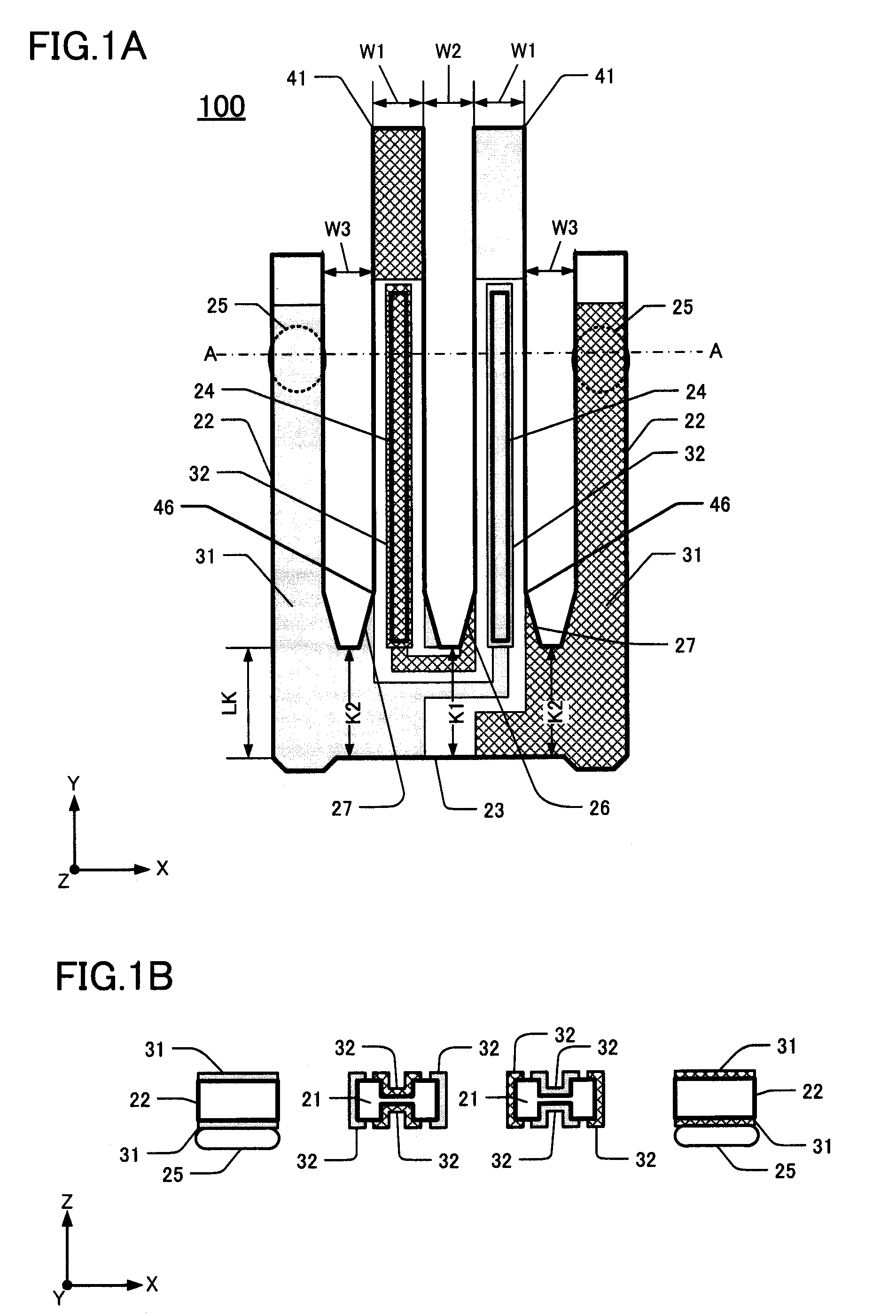

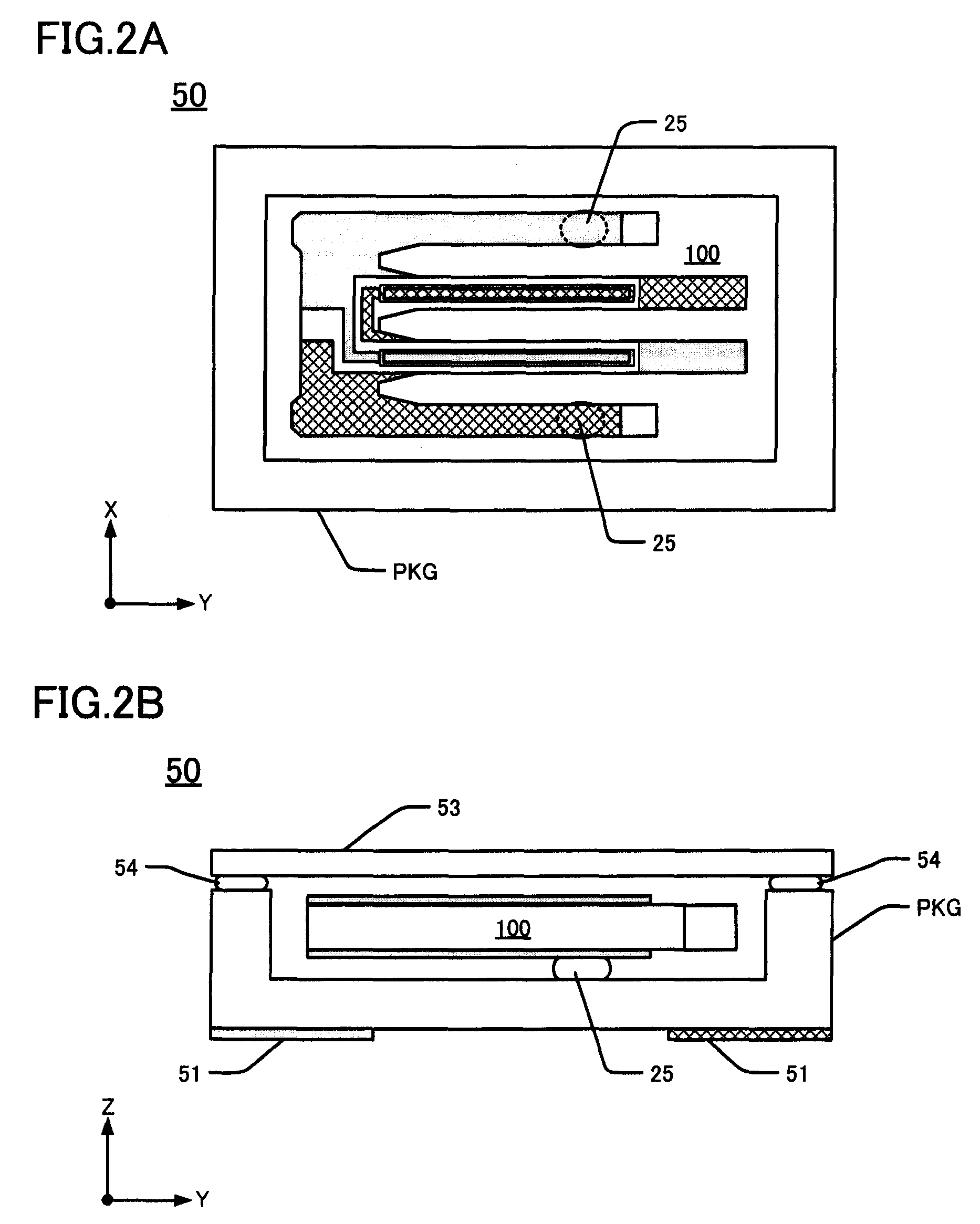

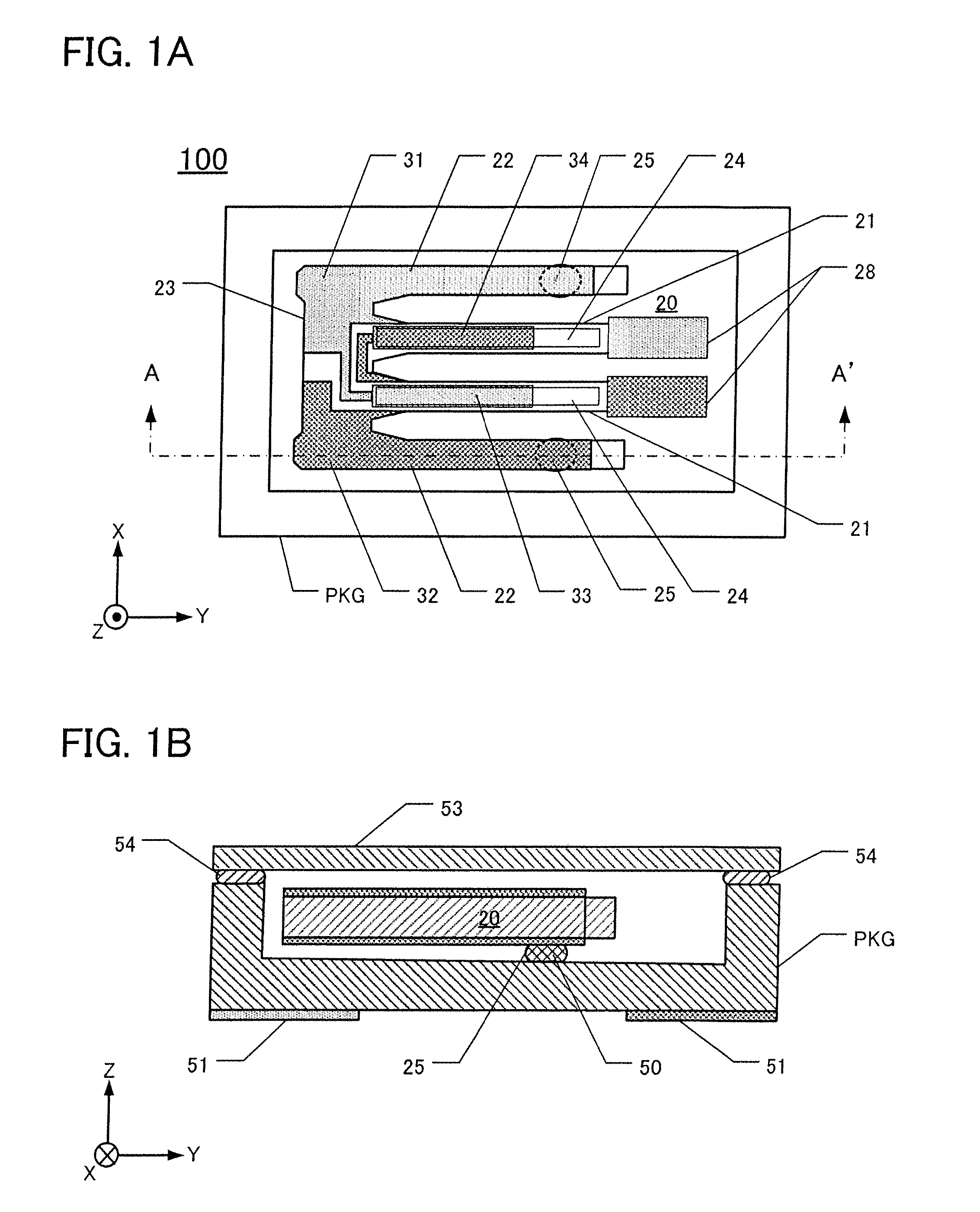

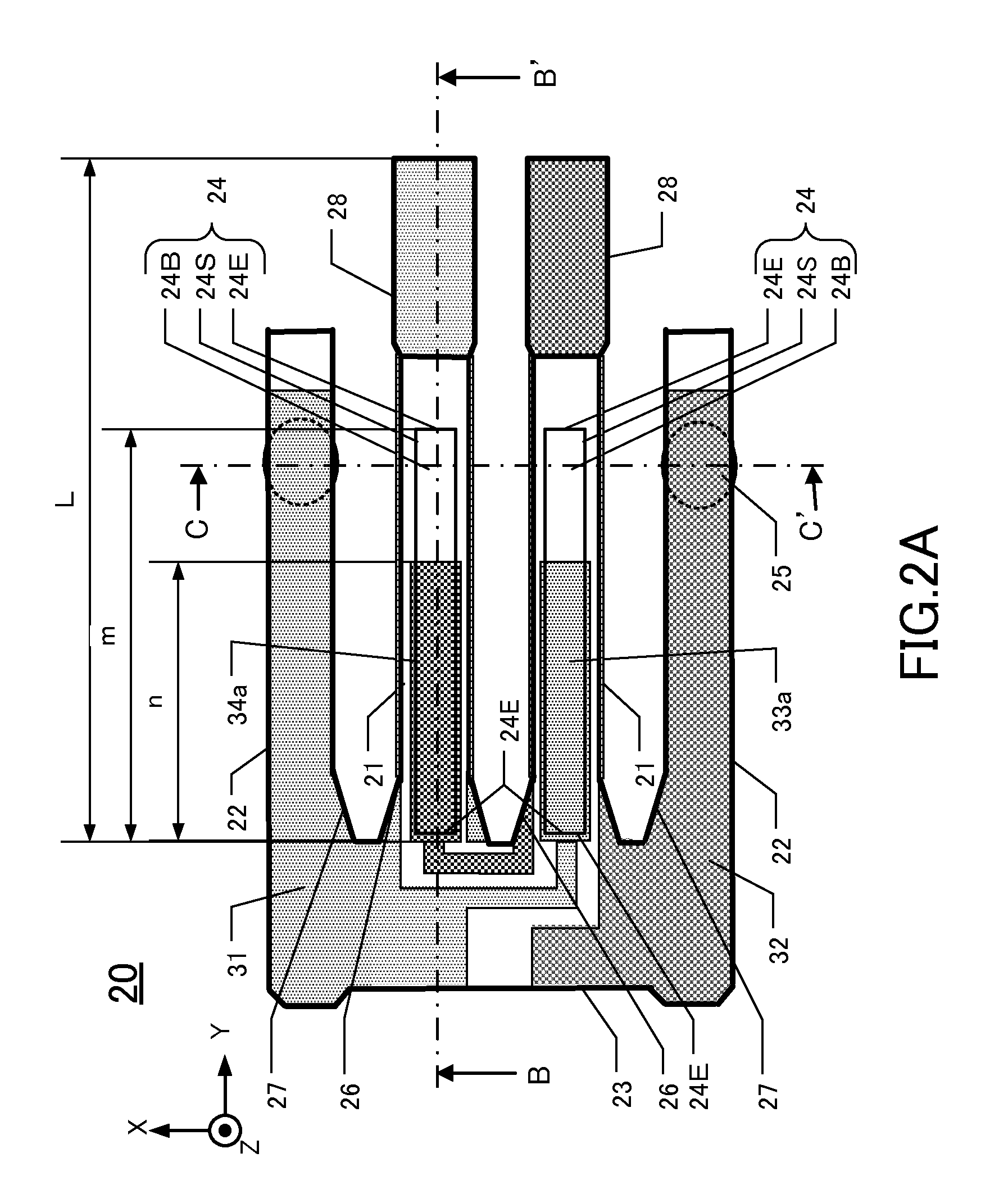

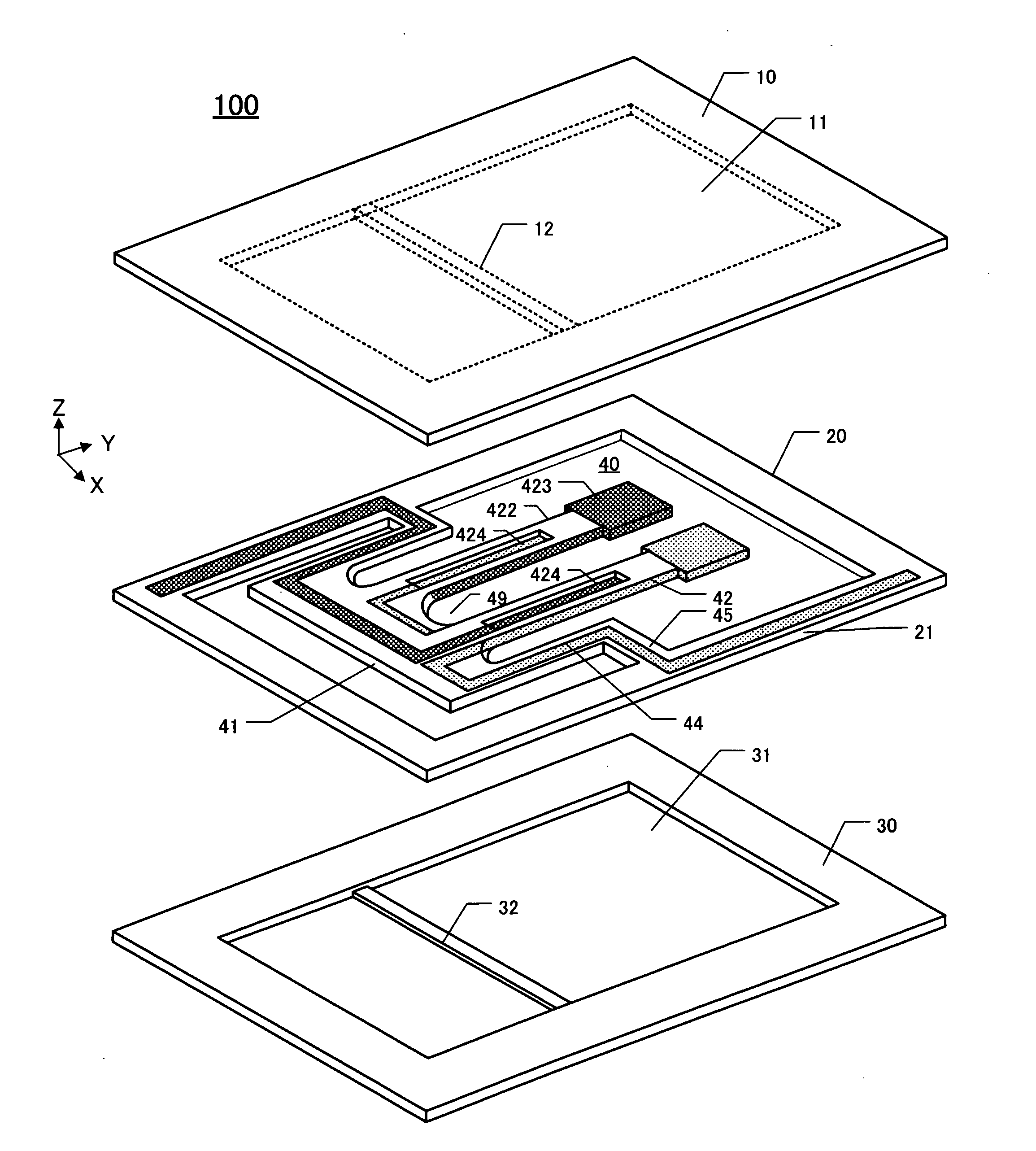

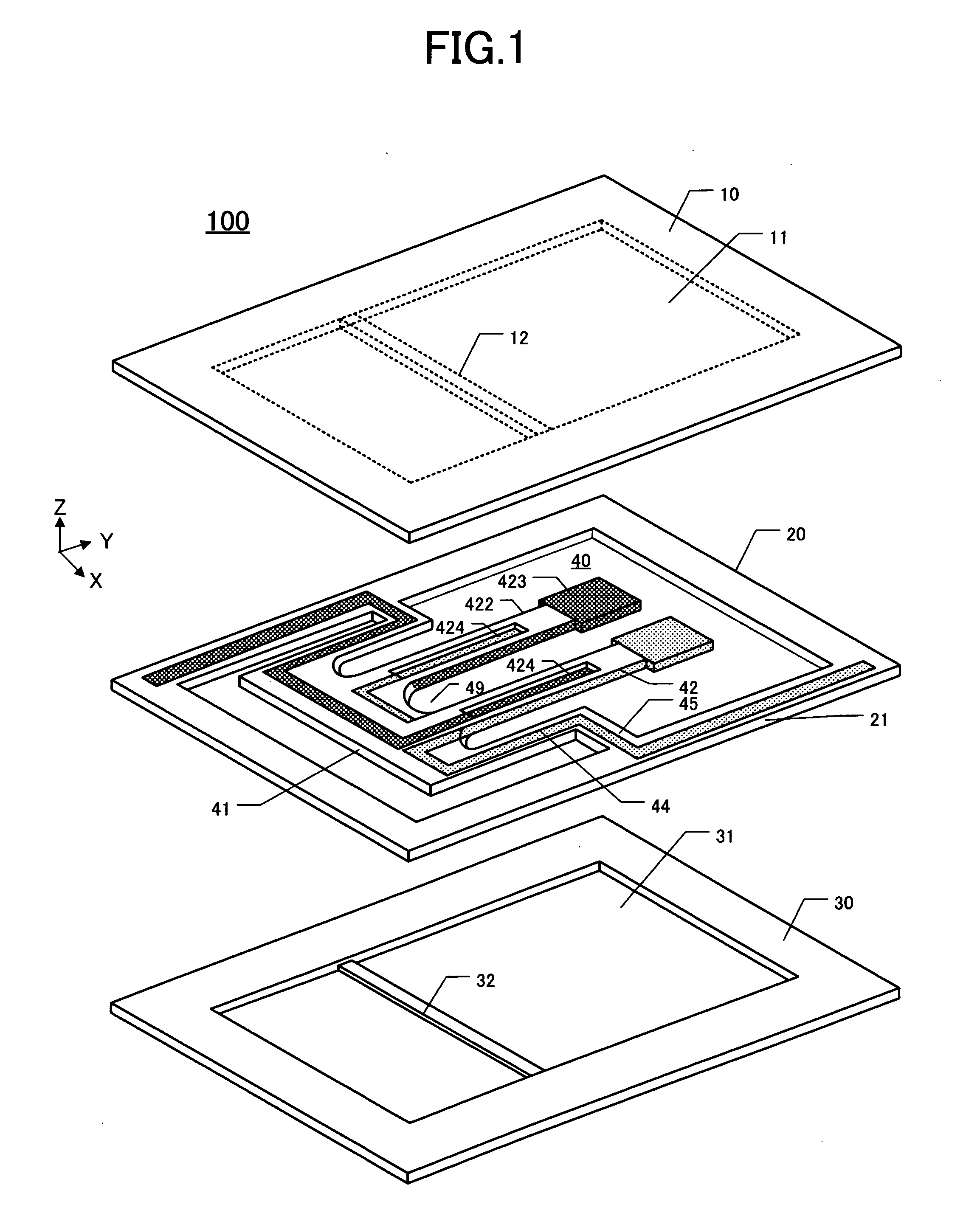

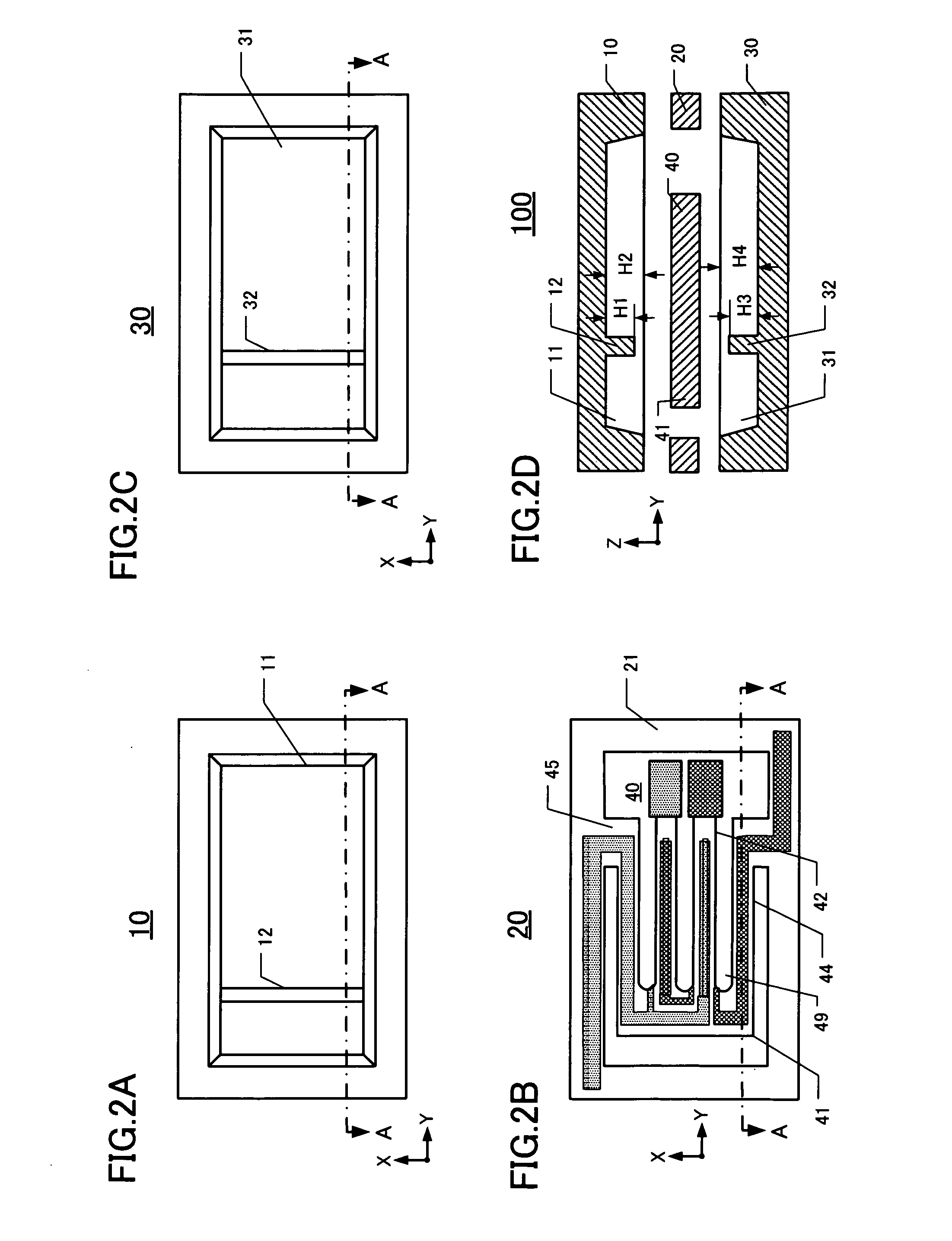

Piezoelectric devices and methods for manufacturing same

InactiveUS20100201221A1Improve sealingPrevent intrusionPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksConductive materialsFrequency regulation

An exemplary piezoelectric vibrating device includes a piezoelectric frame that supports and surrounds a tuning-fork type piezoelectric vibrating piece having a pair of vibrating arms. The device also includes a lid and a package base that are siloxane-bonded to the frame. The lid defines at least one frequency-adjustment hole extending through the thickness dimension of the lid from an inner major surface thereof (facing the frame) to an outer major surface of the lid. The package base defines at least one through-hole electrode passing via a respective electrode through-hole through the thickness of the base from an inner major surface thereof (facing the frame) to the outer major surface thereof. The electrode is connected to the piezoelectric vibrating piece. The lid and base include external electrodes, made of an electrically conductive material, that cover the through-holes and frequency-adjustment hole(s).

Owner:NIHON DEMPA KOGYO CO LTD

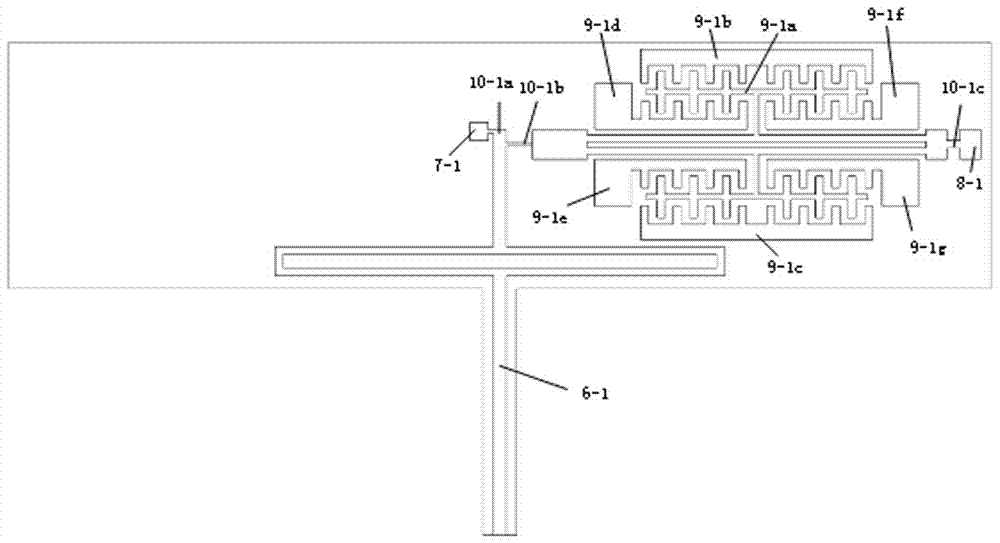

Resonant pressure sensor and manufacturing method thereof

ActiveCN108507709AReduced external energy transferReduce the impactForce measurement using piezo-resistive materialsCouplingAcoustics

The invention provides a resonant pressure sensor and a manufacturing method thereof. A resonator uses a resonator structure based on an SOI silicon-based silicon comb double-ended fixed tuning fork structure. A Wheatstone bridge is formed inside the resonator by two piezoresistive materials (silicon after process doping) and two equivalent resistors (undoped silicon). The resistance change of thepiezoresistive materials is changed by a pressure change to detect the change in resonant frequency. Based on the silicon island structure, the pressure sensor structure is designed to transform thedeformation on a pressure-sensitive film into the plane vibration in the direction of the resonator through the silicon island structure, which not only reduces the mechanical coupling of the sensor,but also improves a quality factor and achieves a wide measurement range and high reliability.

Owner:HEFEI UNIV OF TECH

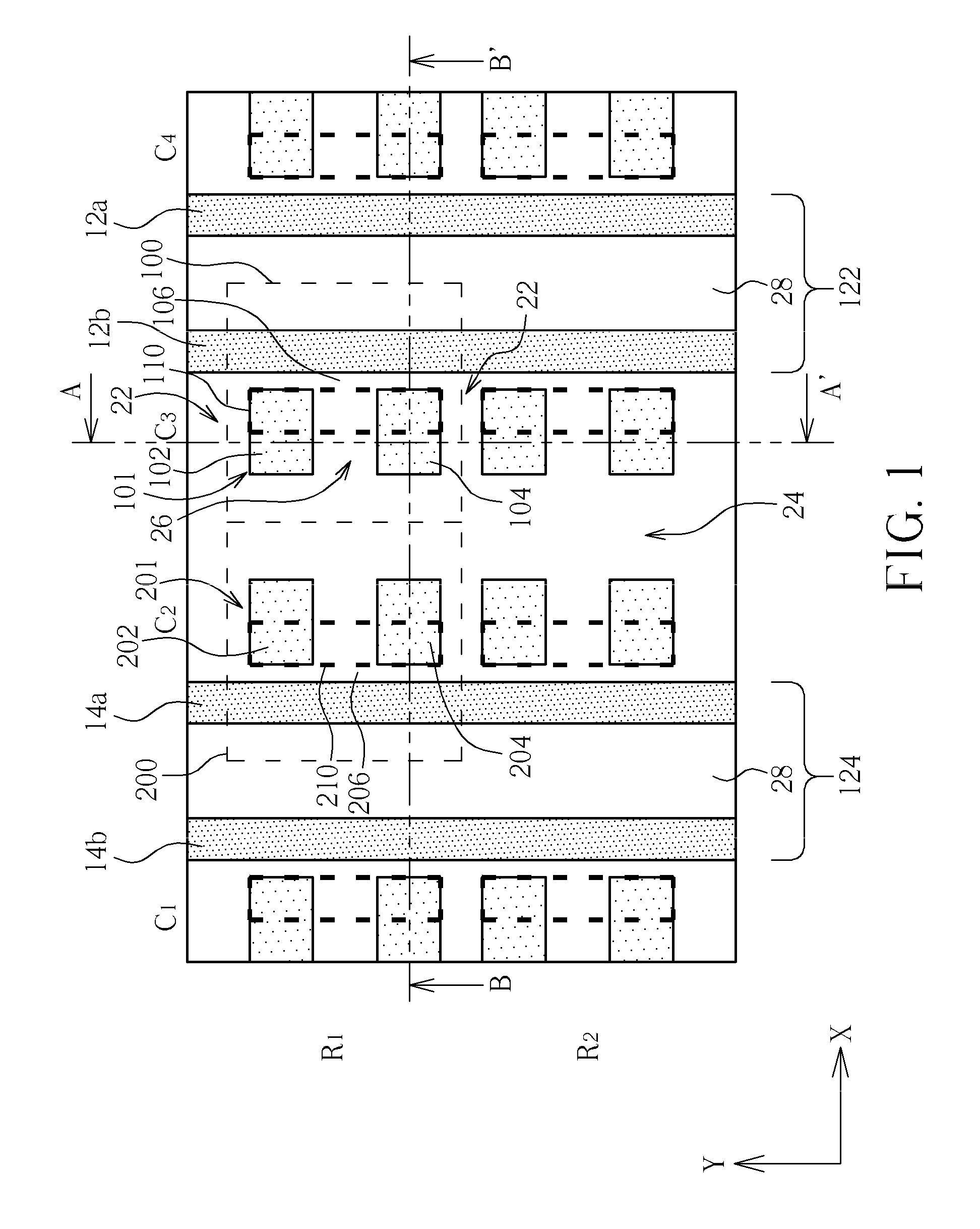

Single-gate finfet and fabrication method thereof

InactiveUS20110298041A1Resolving and eliminating coupling effectSolid-state devicesSemiconductor devicesUltra thin bodyEngineering

A single-gate FinFET structure includes an active fin structure having two enlarged head portions and two respective tapered neck portions that connect the enlarged head portions with an underlying ultra-thin body. Two source / drain regions are doped in the two enlarged head portions respectively. An insulation region is interposed between the two source / drain regions. A trench isolation structure is disposed at one side of the tuning fork-shaped fin structure. A single-sided sidewall gate electrode is disposed on a vertical sidewall of the active fin structure opposite to the trench isolation structure.

Owner:NAN YA TECH

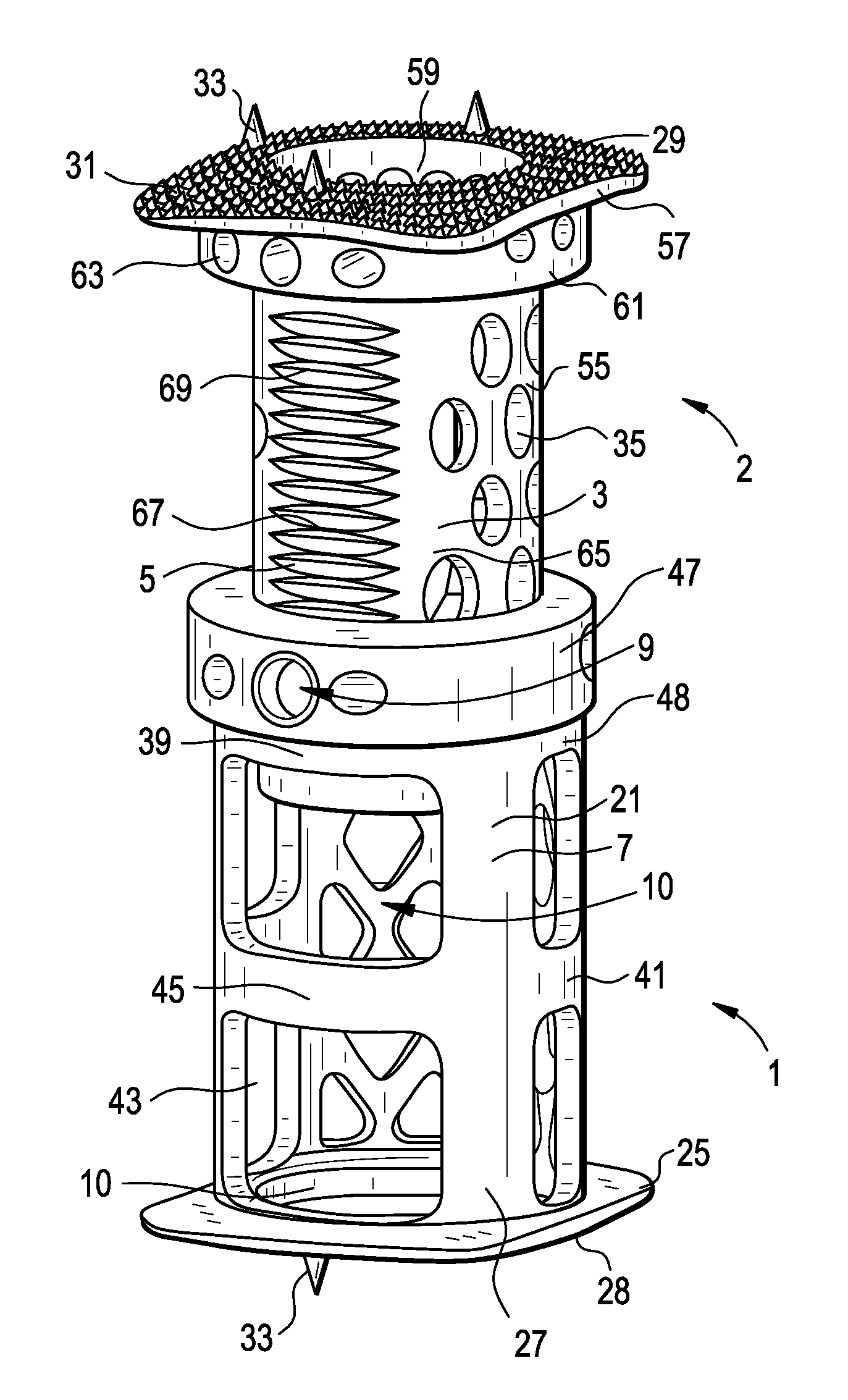

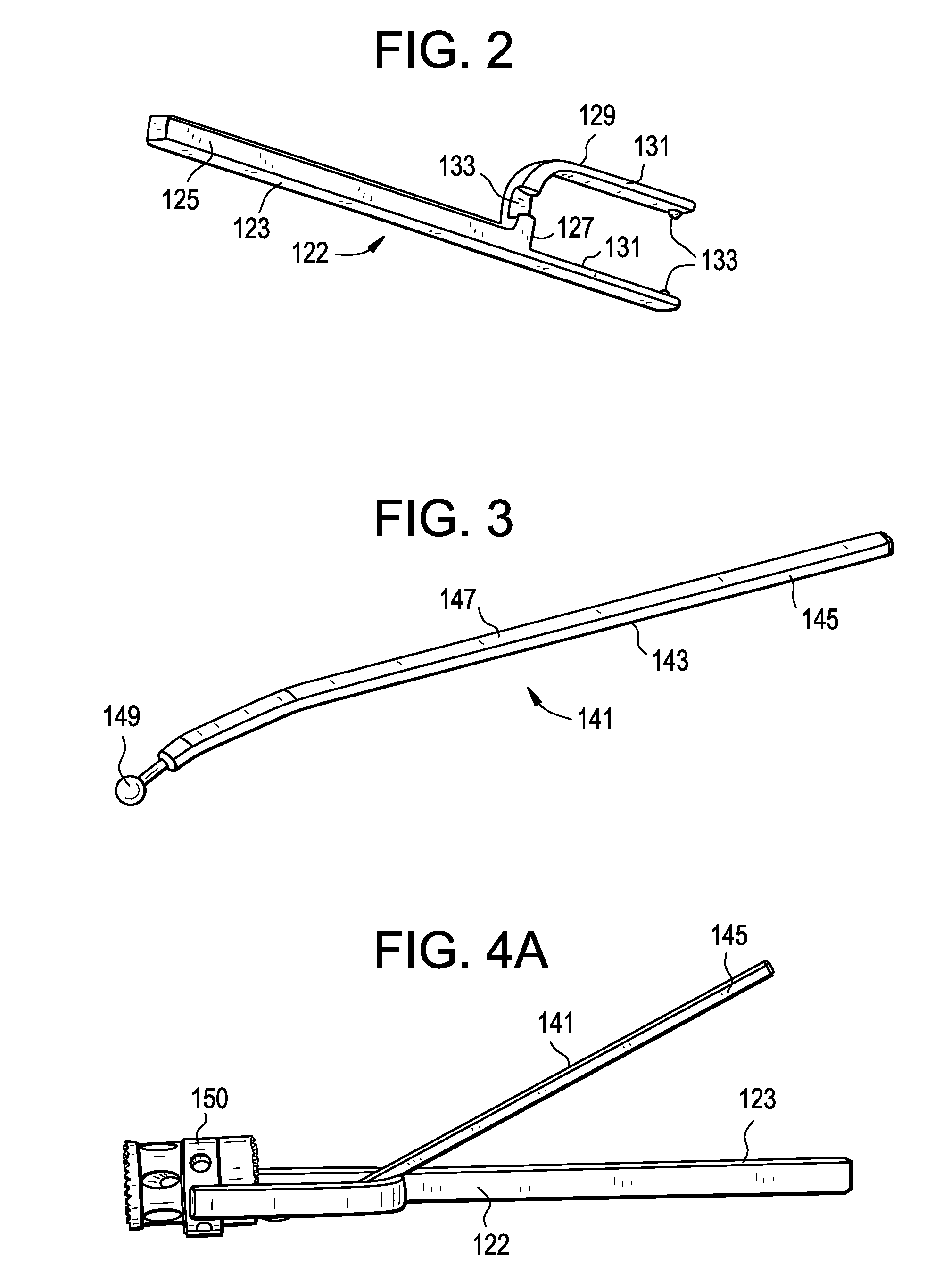

Minimally invasive corpectomy cage and instrument

ActiveUS20100280616A1Eliminate needSufficient external expansion mechanismSpinal implantsExpandable cageEngineering

An assembly comprising an expandable corpectomy cage and an insertion instrument, wherein the expandable cage comprises an instrument attachment features, including mating holes on the sides of the outer sleeve, and a ball-shaped pocket on the endplate of the inner sleeve, and the insertion instrument features a tuning-fork shaped holder, which attaches to the mating holes on the implant's outer sleeve using small bosses which mate with the holes under the spring tension of the fork, and a lever with a spherical end that mates with the ball-shaped pocket in the inner sleeve endplate.

Owner:DEPUY SYNTHES PROD INC

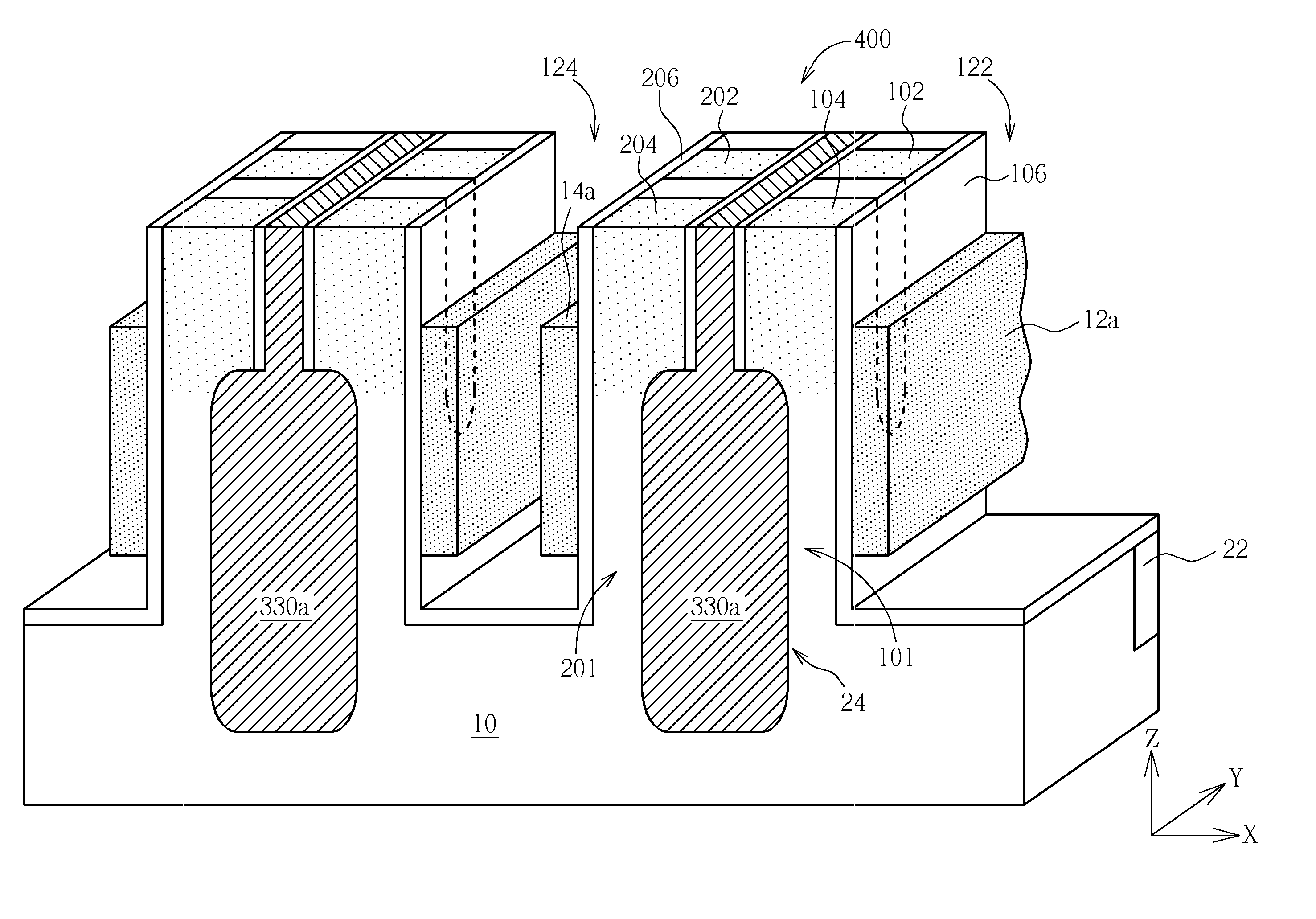

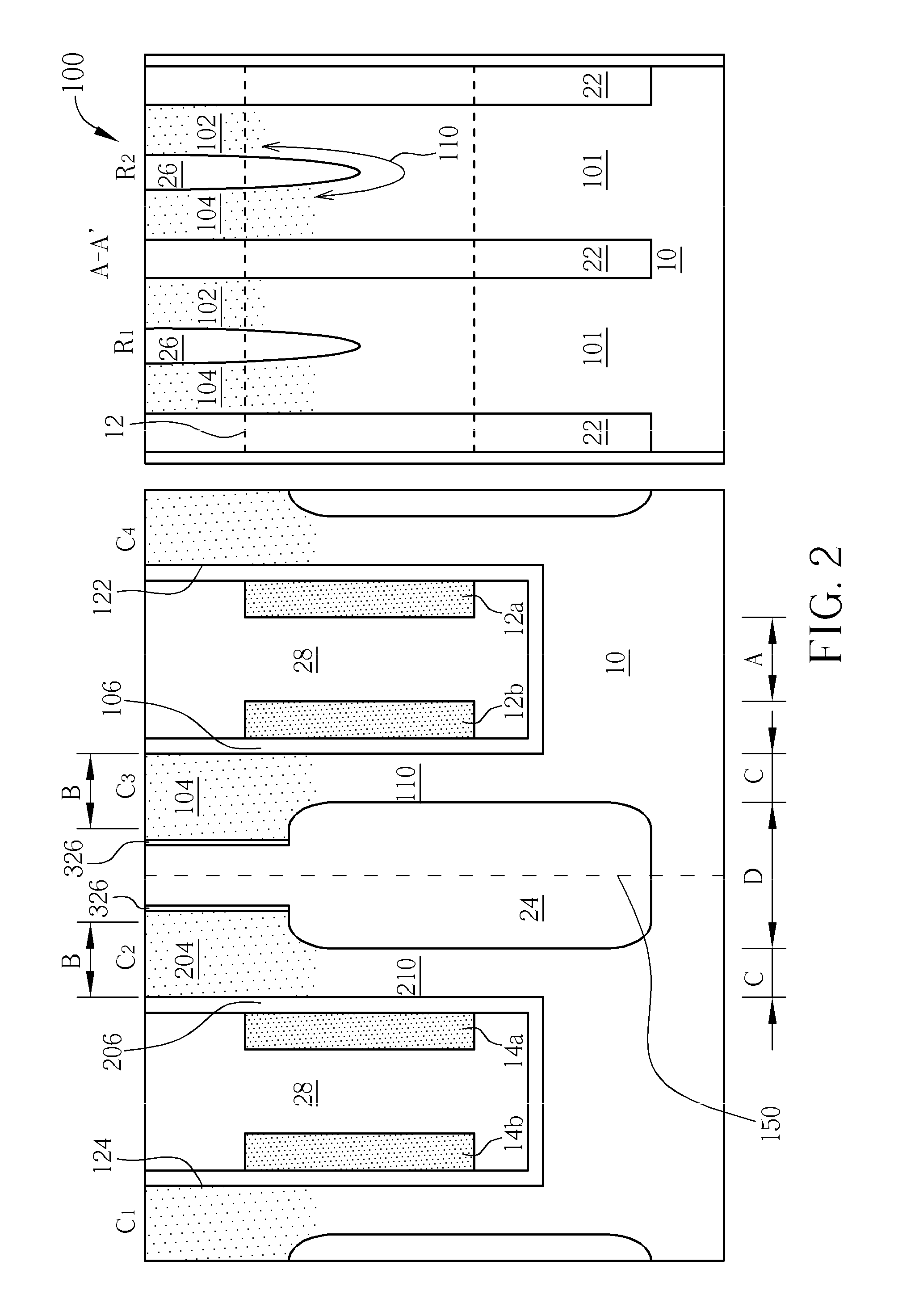

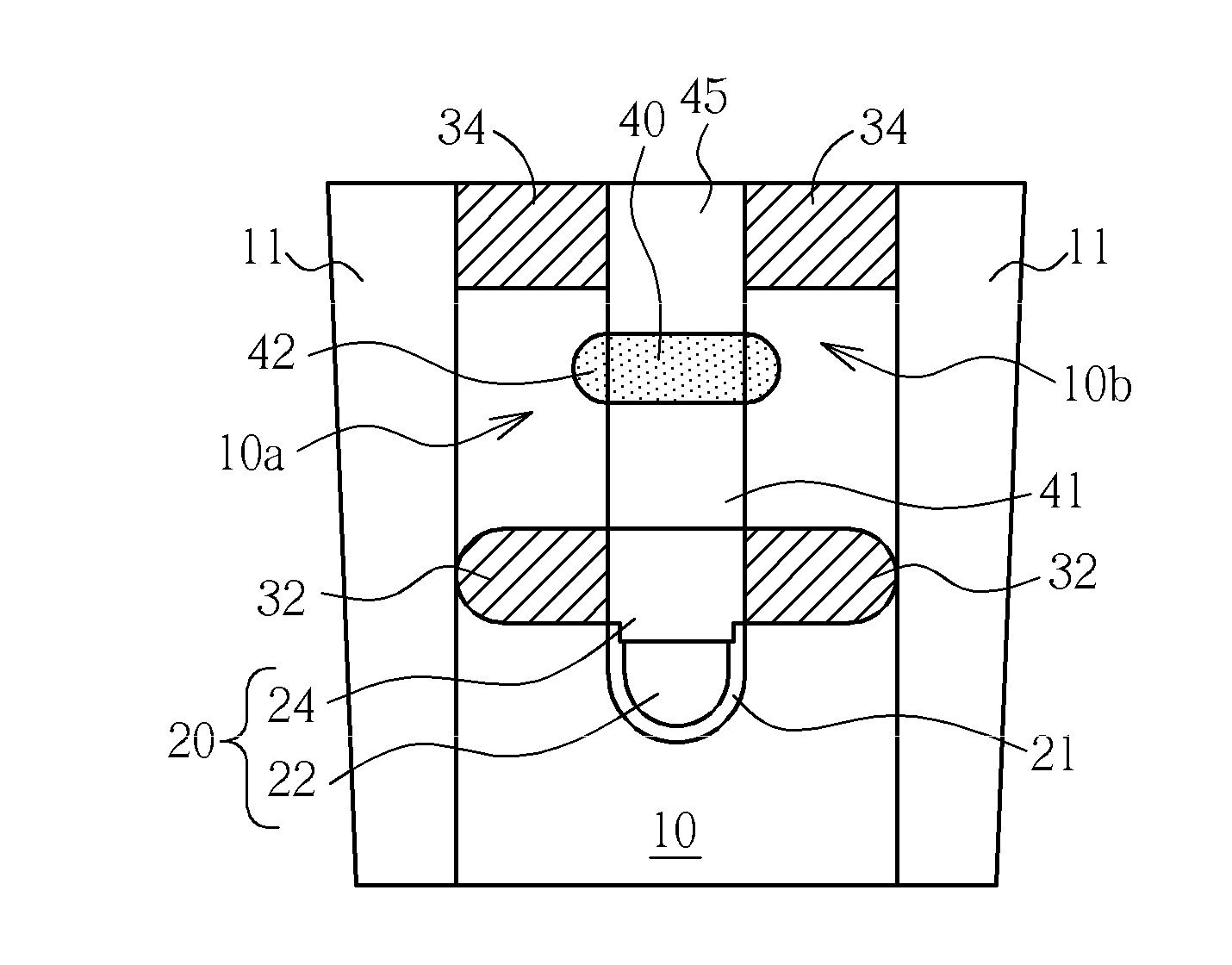

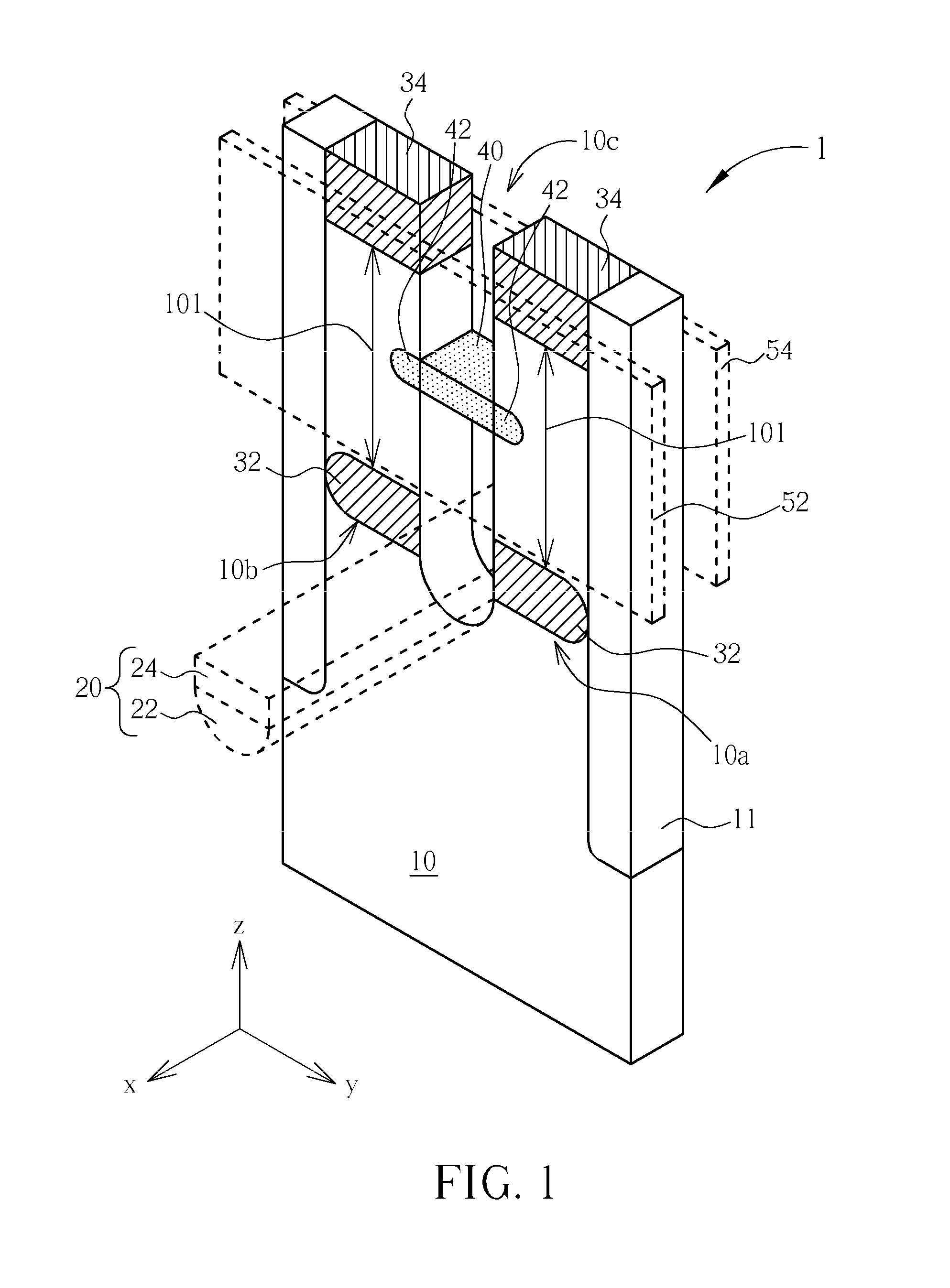

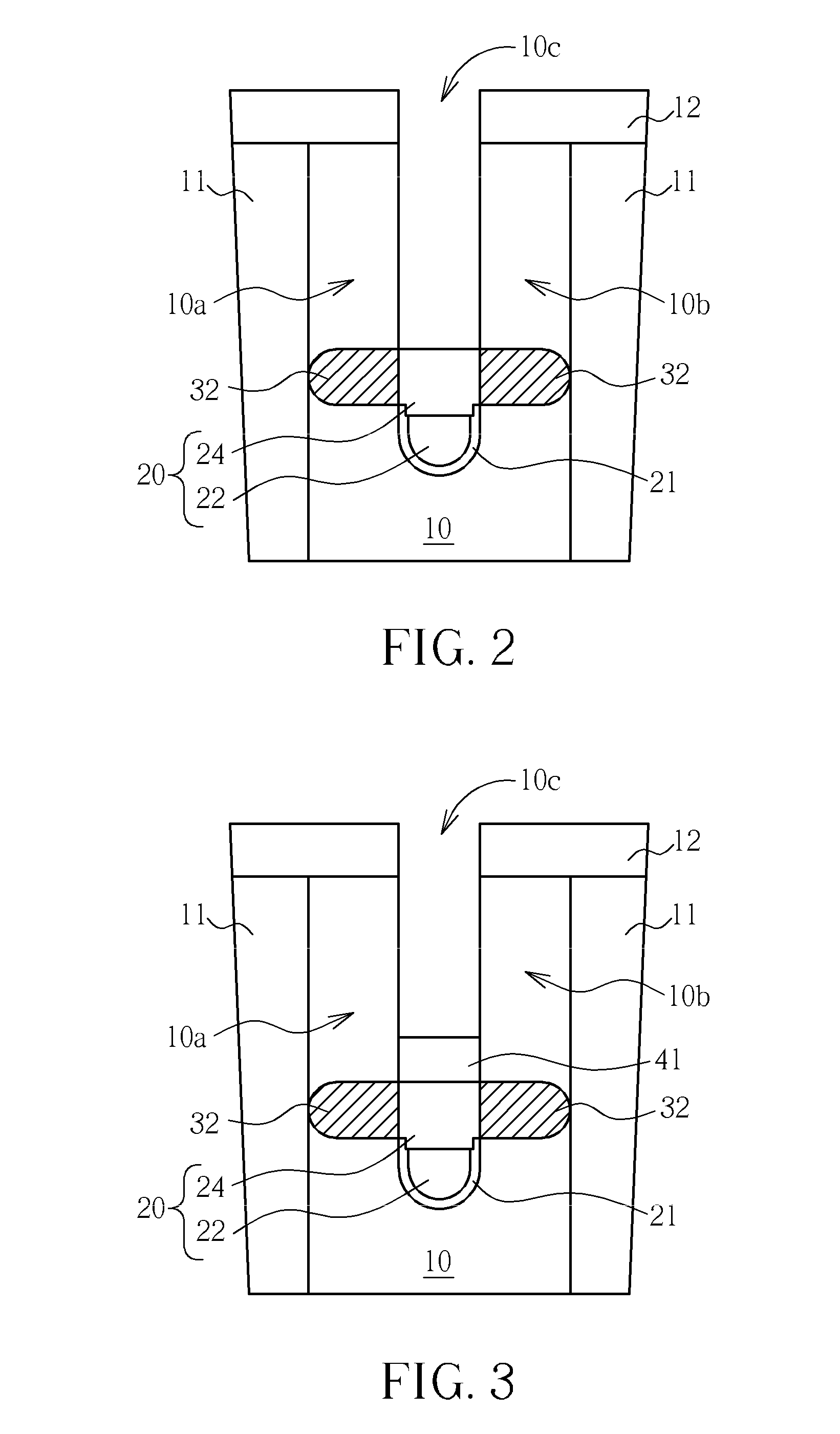

Dual vertical channel transistor and fabrication method thereof

A dual vertical channel transistor includes a tuning fork-shaped substrate body; a buried bit line embedded at a bottom of a recess between two prong portions of the tuning fork-shaped substrate body; an out-diffused drain region adjacent to the buried bit line in the tuning fork-shaped substrate body; a source region situated at a top portion of each of the two prong portions of the tuning fork-shaped substrate body; an epitaxial portion connecting the two prong portions of the tuning fork-shaped substrate body between the out-diffused drain region and the source region; a front gate situated on a first side surface of the tuning fork-shaped substrate body; and a back gate situated on a second side surface opposite to the first side surface of the tuning fork-shaped substrate body.

Owner:NAN YA TECH

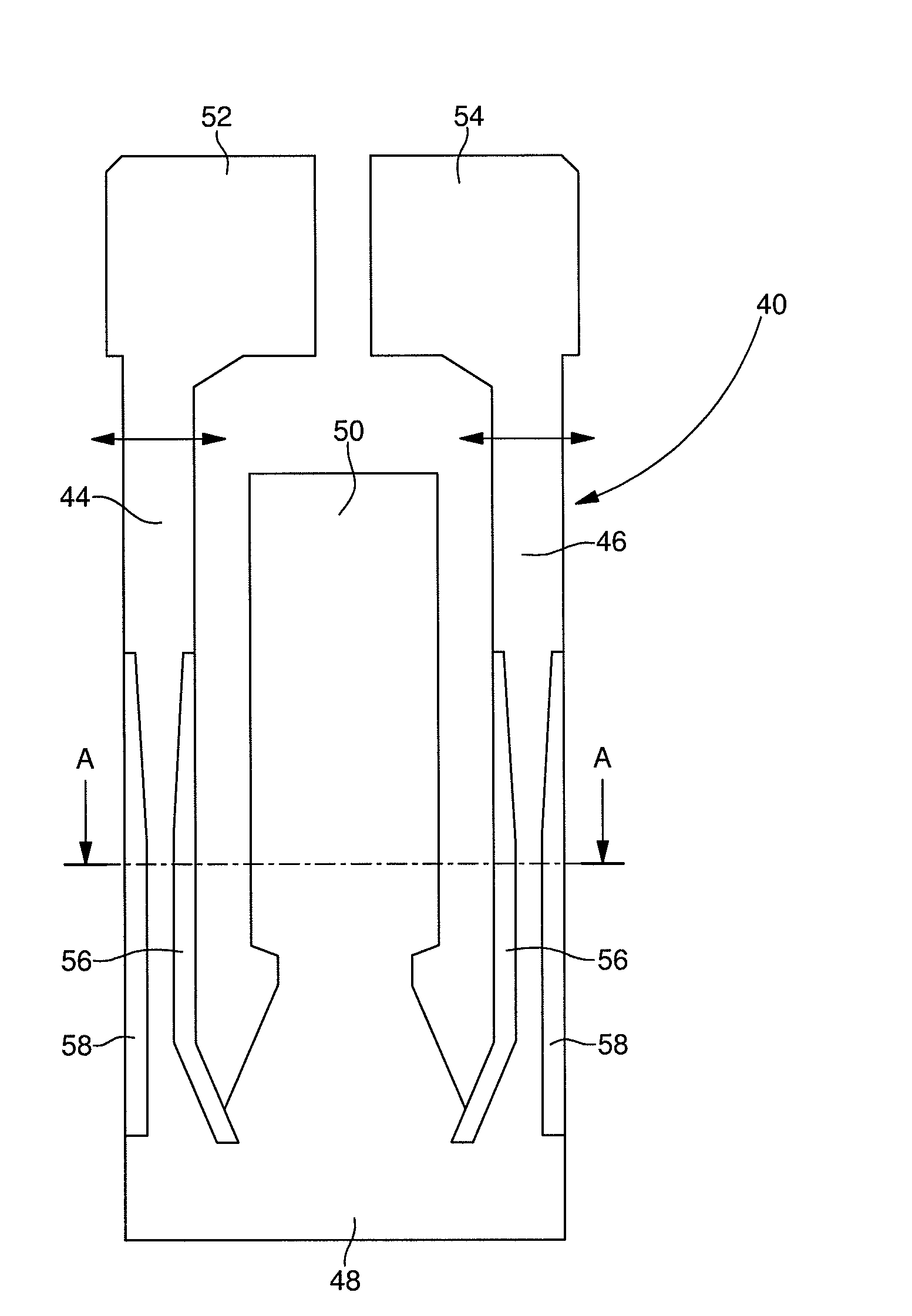

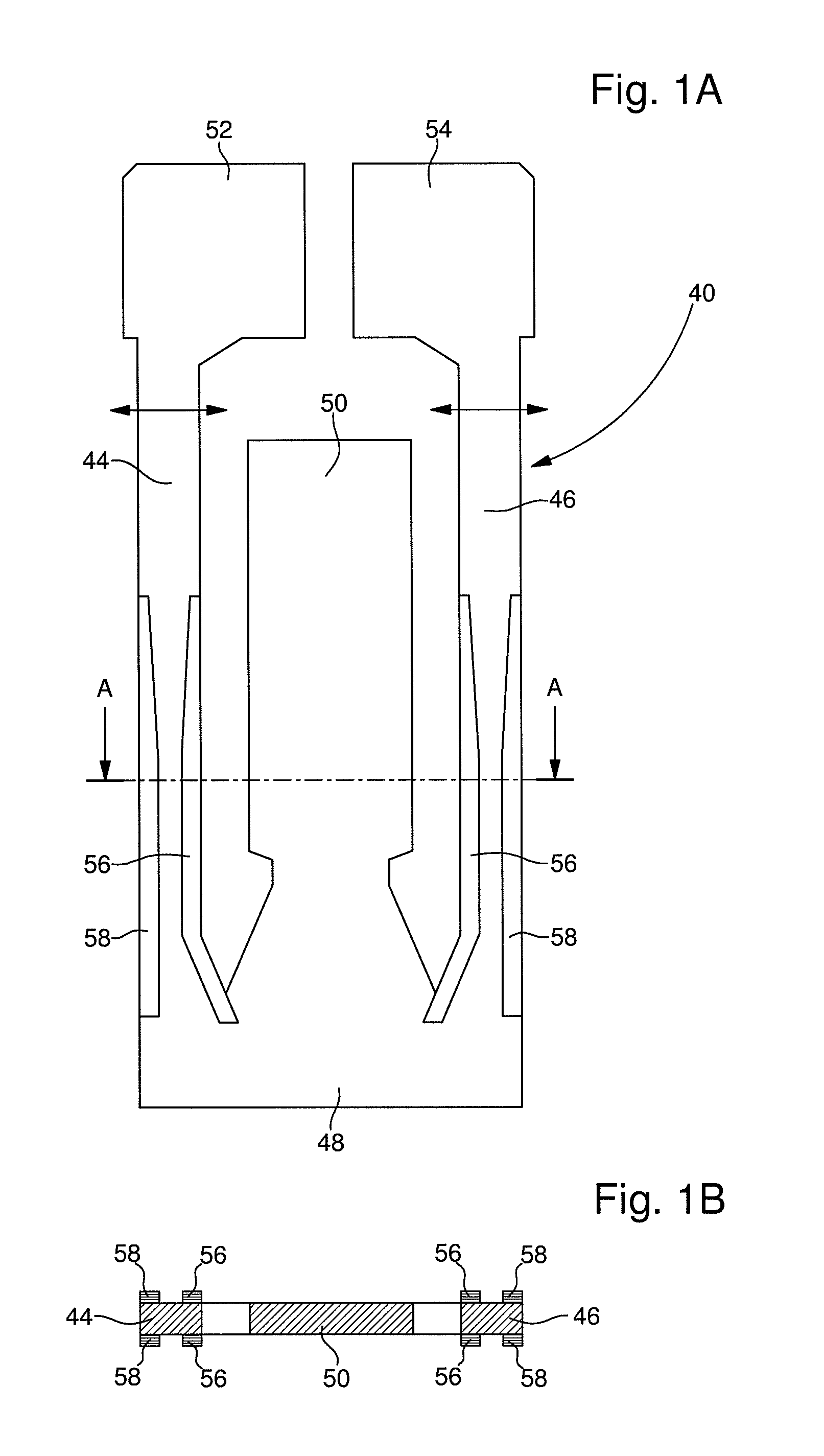

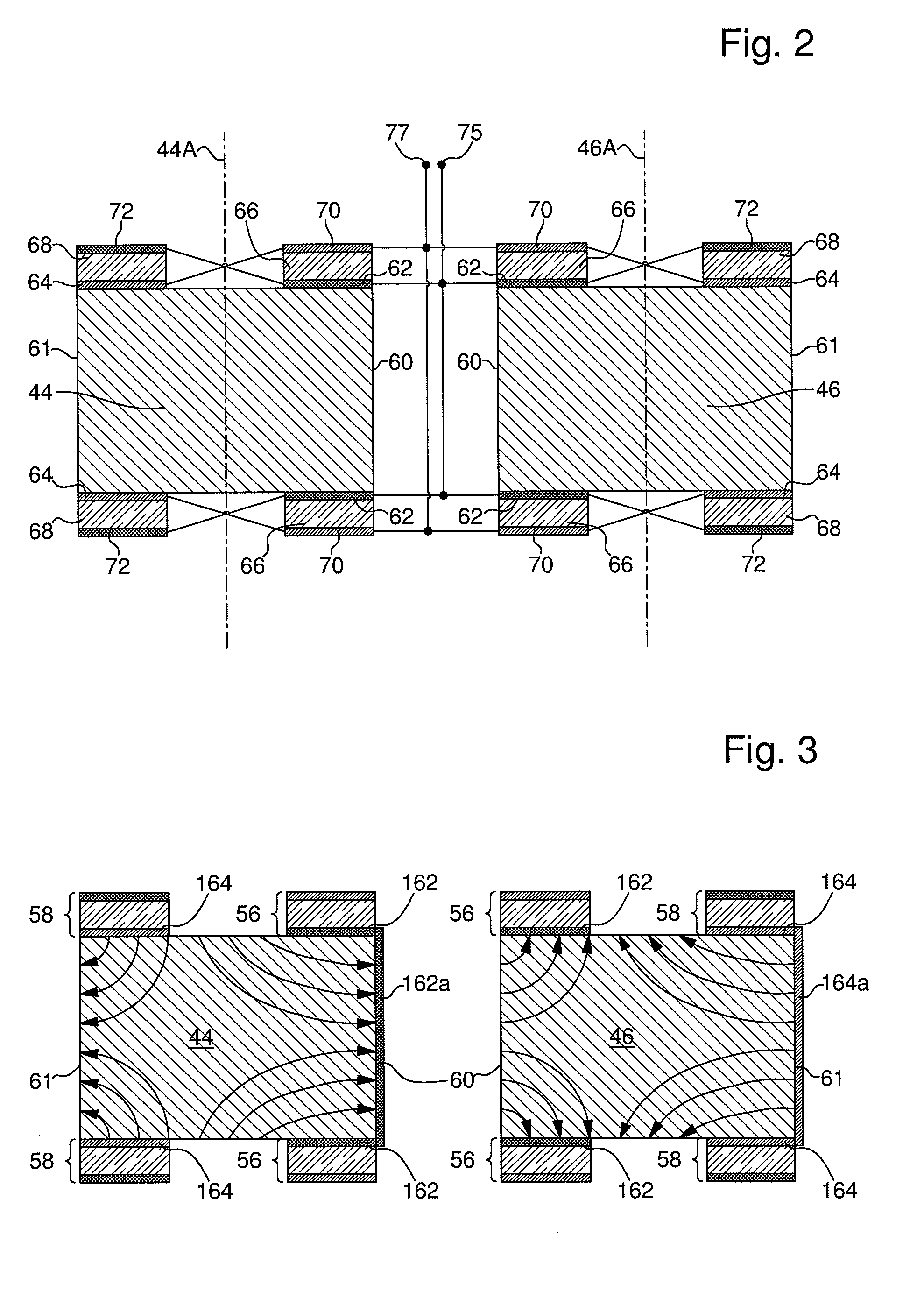

Piezoelectric thin-film tuning fork resonator

InactiveUS20110001394A1High quality factorIncreased polarizationImpedence networksPiezoelectric/electrostriction/magnetostriction machinesQuartzResonator

The piezoelectric thin-film tuning fork resonator (40) comprises an integral tuning fork made out of a quartz crystal. The tuning fork comprises a base (48) and a pair of parallel vibrating arms (44, 46) extending from the base. Each of the vibrating arms carries:first and second electrodes (62, 64) provided on at least one main surface of the arm, said first and second electrodes being formed respectively on an inner portion and on an outer portion of said one main surface, in such a way as to be spaced apart,first and second piezoelectric thin films (66, 68) formed over the first and second electrodes respectively,third and fourth electrodes (70, 72) formed over the first and second piezoelectric thin films respectively.

Owner:MICRO CRYSTAL

Piezoelectric generator with optimised motional capacitances

ActiveUS20090021120A1Improve securityInsufficient resistancePiezoelectric/electrostriction/magnetostriction machinesImpedence networksCapacitanceShock resistance

The tuning fork resonator (1) includes a base (4) from which first and second parallel vibrating arms (2, 3) extend, carrying a set of excitation electrodes (5, 6) for vibrating the arms at a fundamental frequency. Grooves (7, 8) are formed on at least one of the top or bottom surfaces of each of said arms. The vibrating arms have a generally tapered shape, and are extended by an enlarged flipper shaped portion (9, 10) which forms the free end of each arm. The groove (7, 8) is extended in the direction of the free end of an arm to beyond the start of the flipper (9, 10) so as to increase said first motional capacitance of the resonator for the fundamental frequency, to decrease said second motional capacitance of the resonator for the partial frequency and to ensure better distribution of mechanical stress along the vibrating arms and to increase shock resistance.

Owner:ETA SA MFG HORLOGERE SUISSE

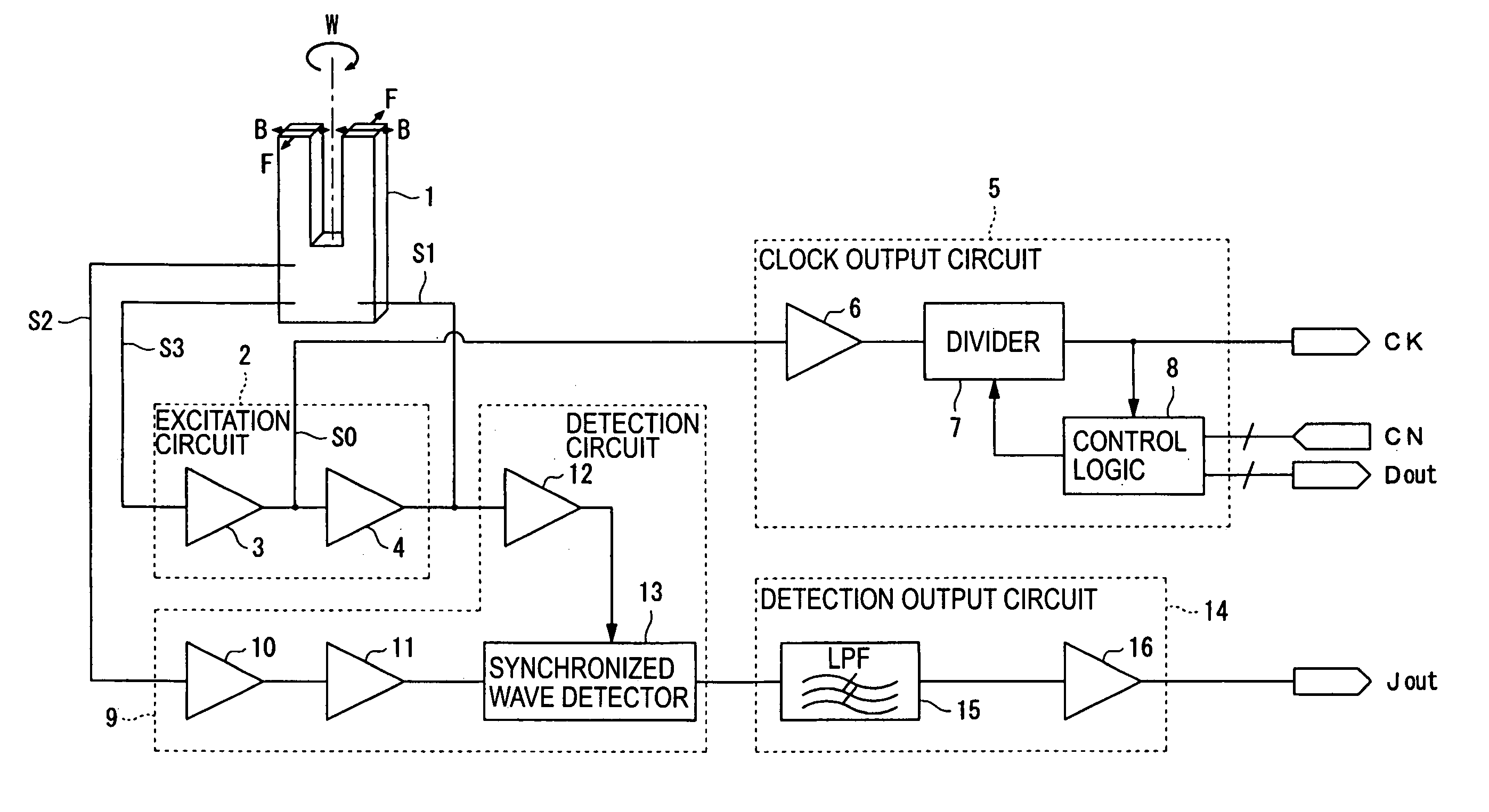

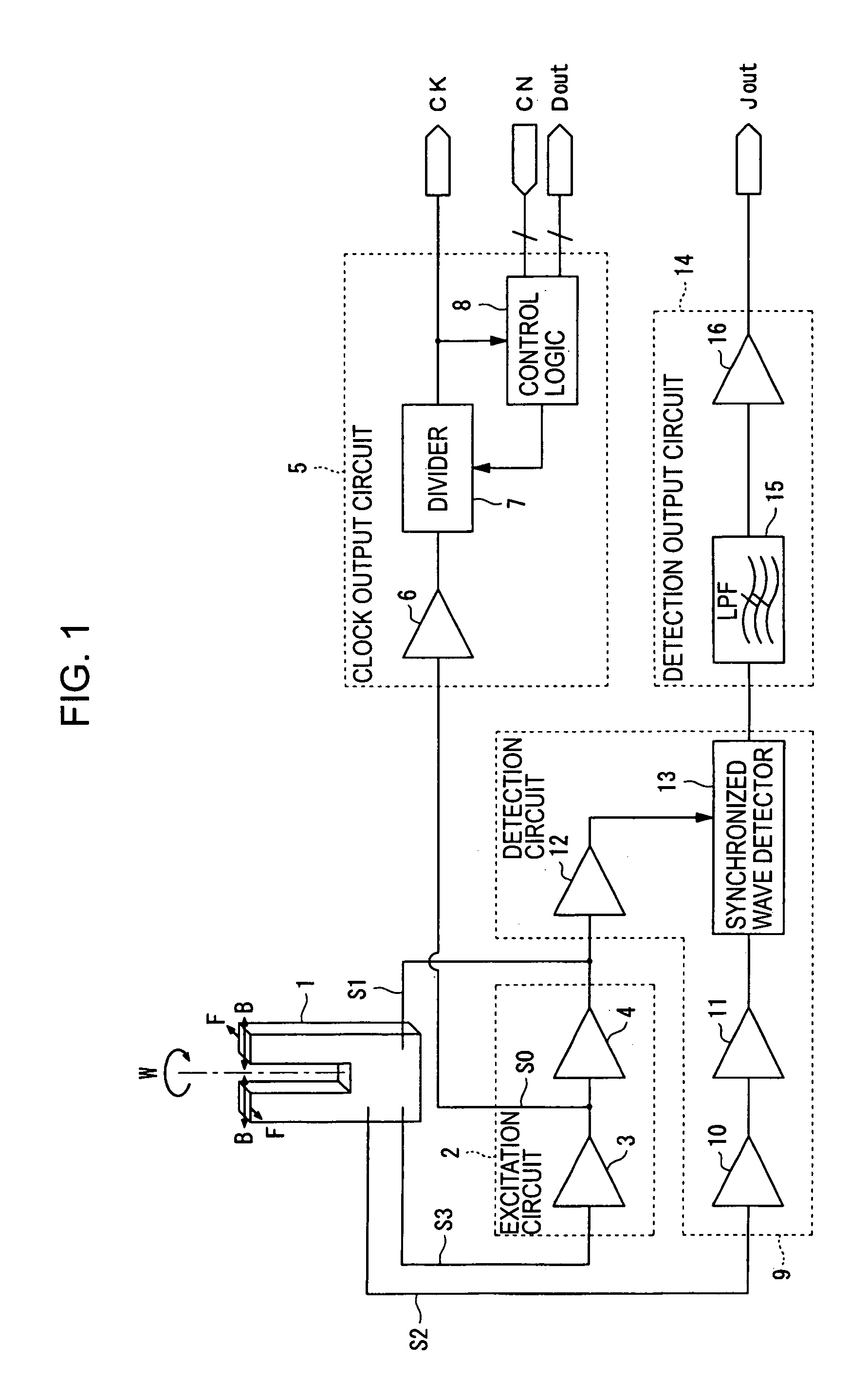

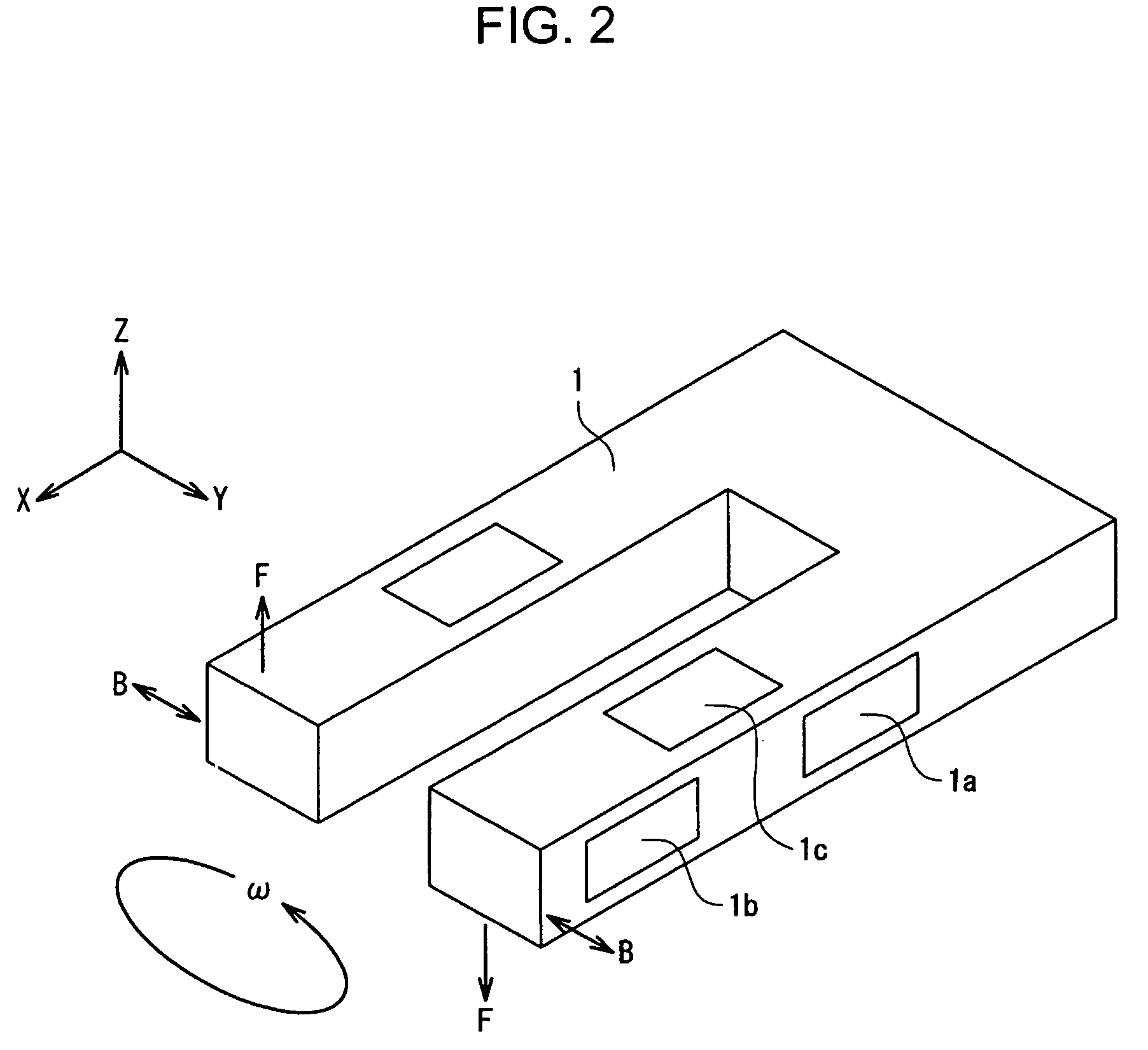

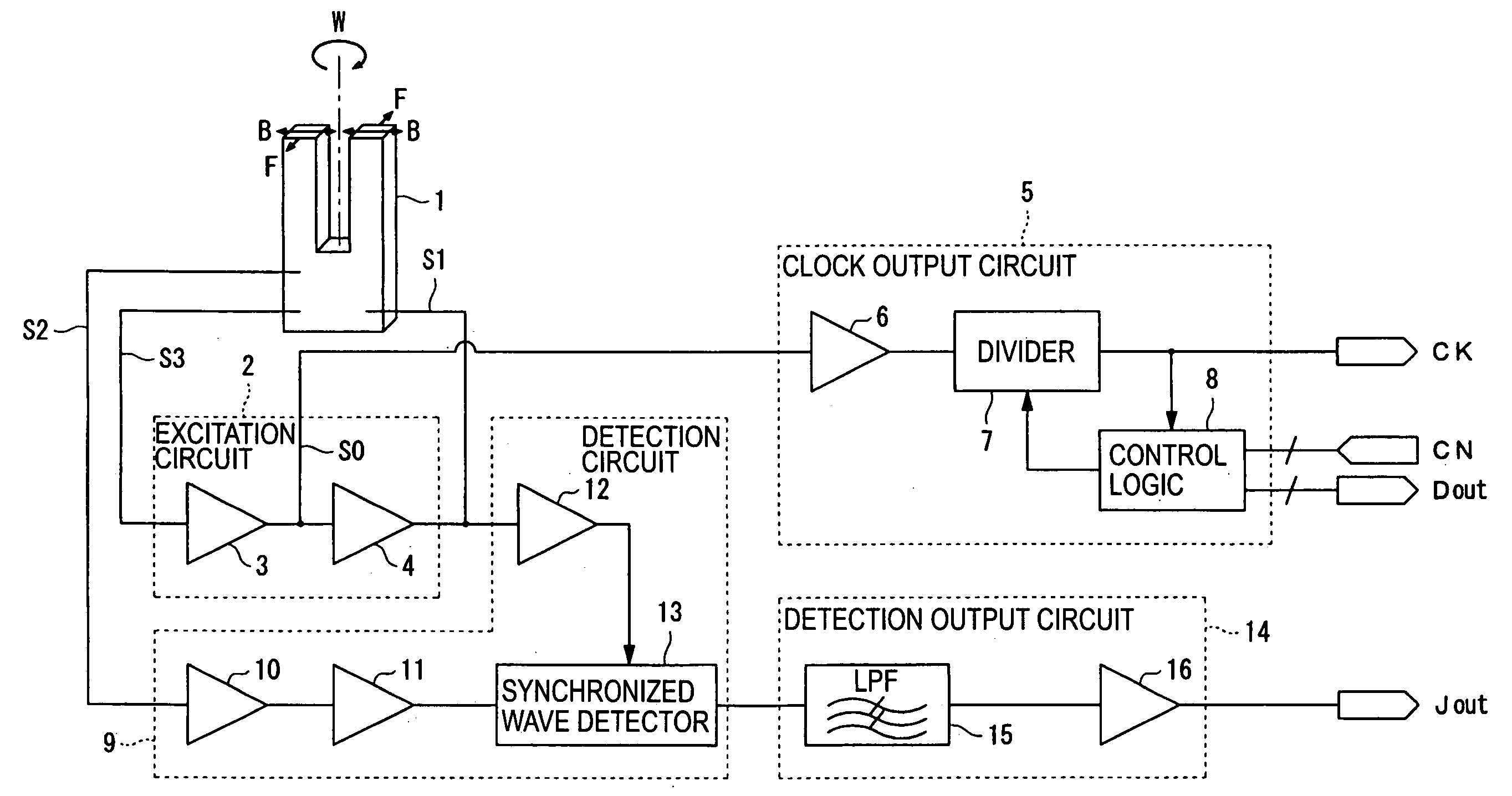

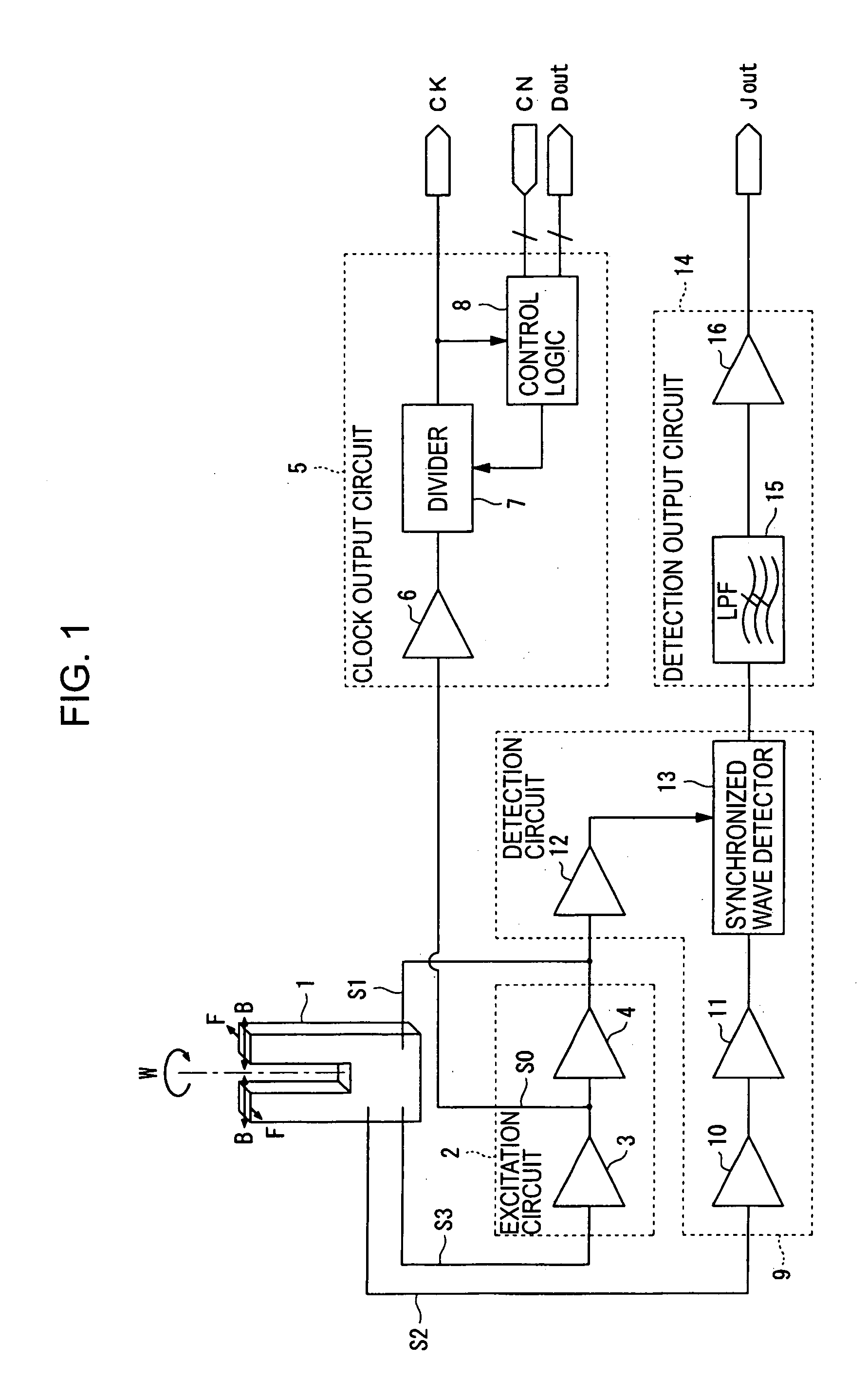

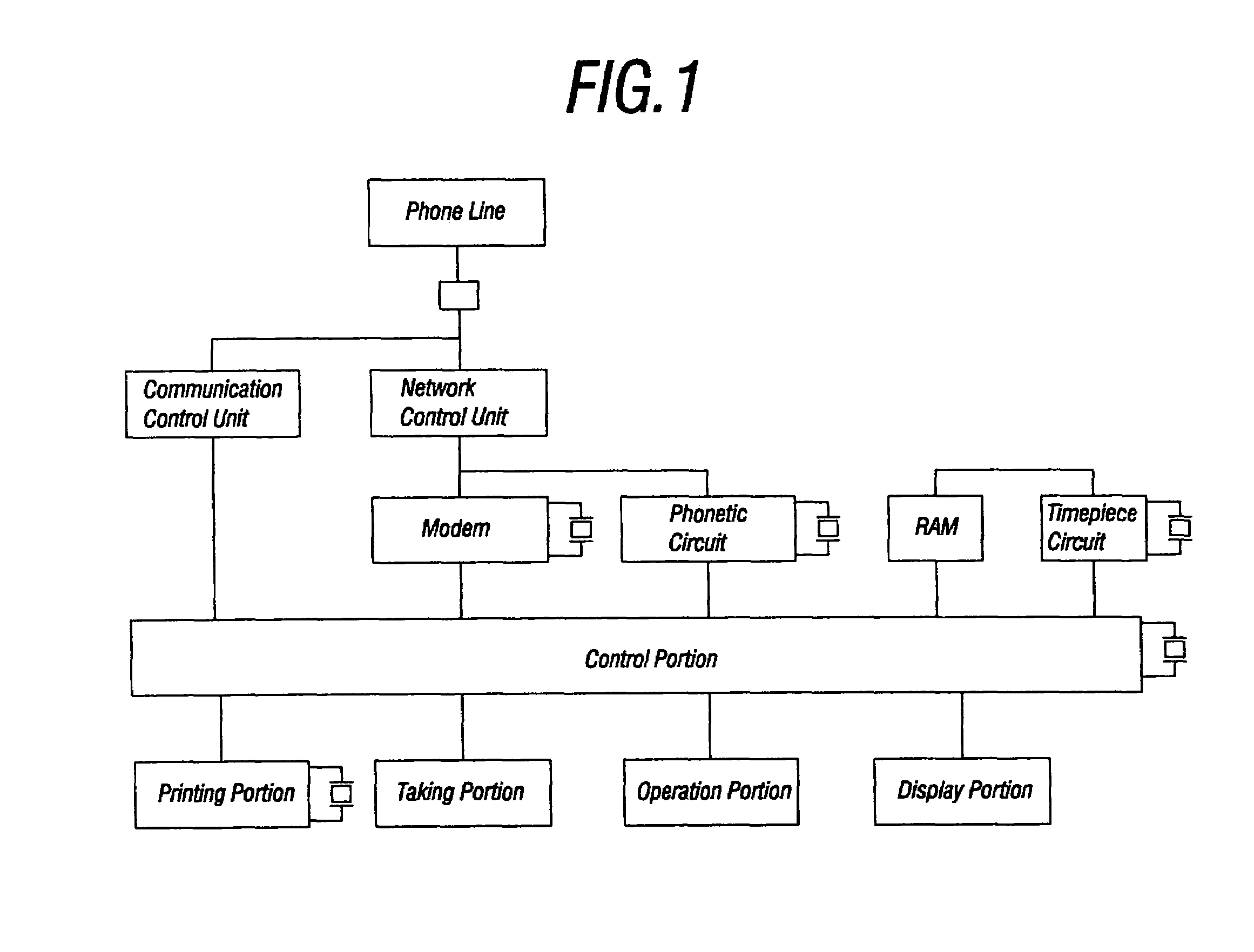

Clock generating device, vibration type gyro sensor, navigation device, imaging device, and electronic apparatus

InactiveUS7258009B2Suppressing the device from being largeSubject to movementTelevision system detailsInstruments for road network navigationTime informationGyroscope

A vibration gyro sensor is provided which is capable of generating time information and detecting an angular velocity. A driving signal for driving a tuning fork piezoelectric vibrating reed is generated based on an excitation signal generated by an oscillation circuit. An angular velocity signal is obtained based on a detection signal generated by a detection electrode of the tuning fork piezoelectric vibration reed. The excitation signal generated by the oscillation circuit is input to a divider such that a timer clock signal is generated.

Owner:SEIKO EPSON CORP

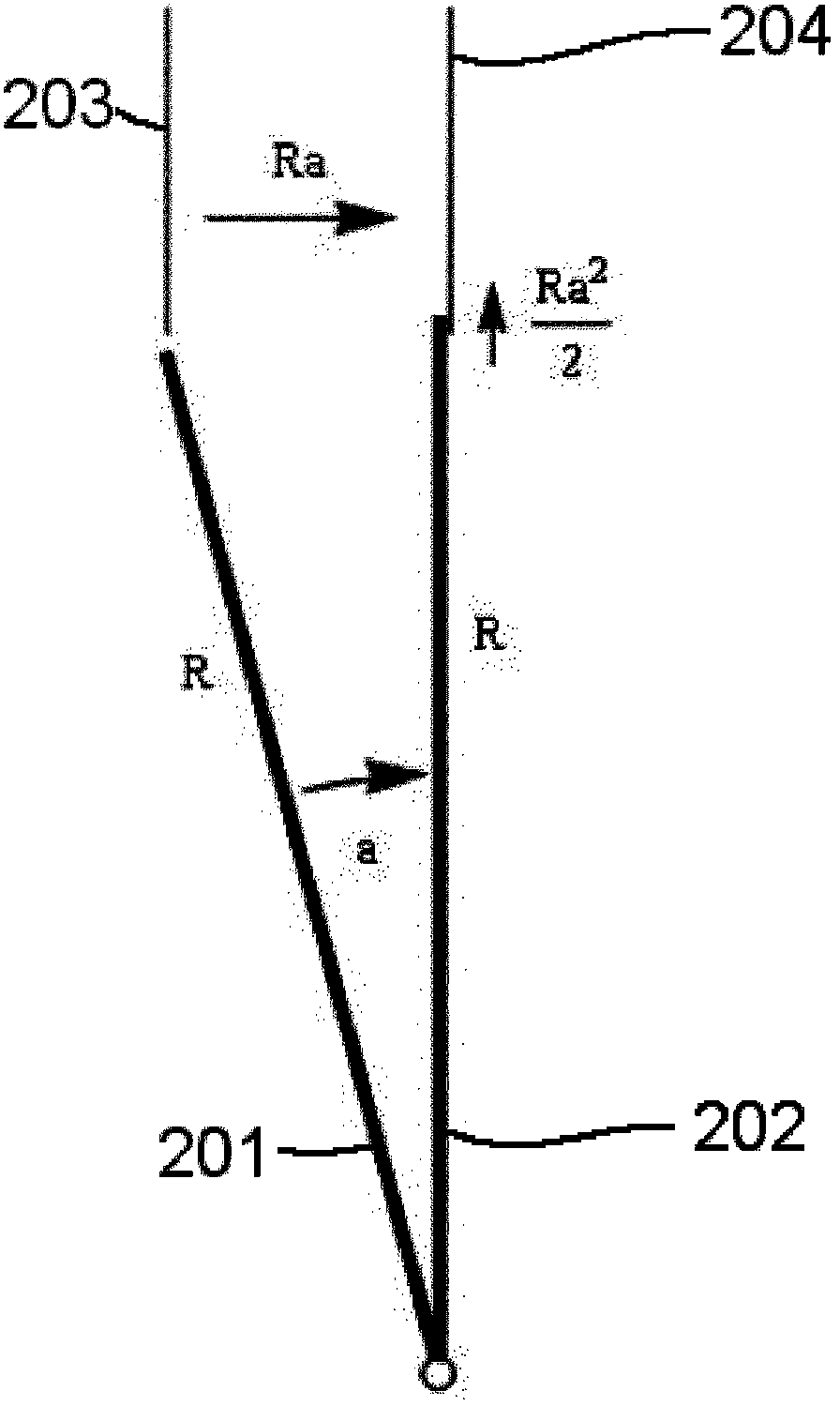

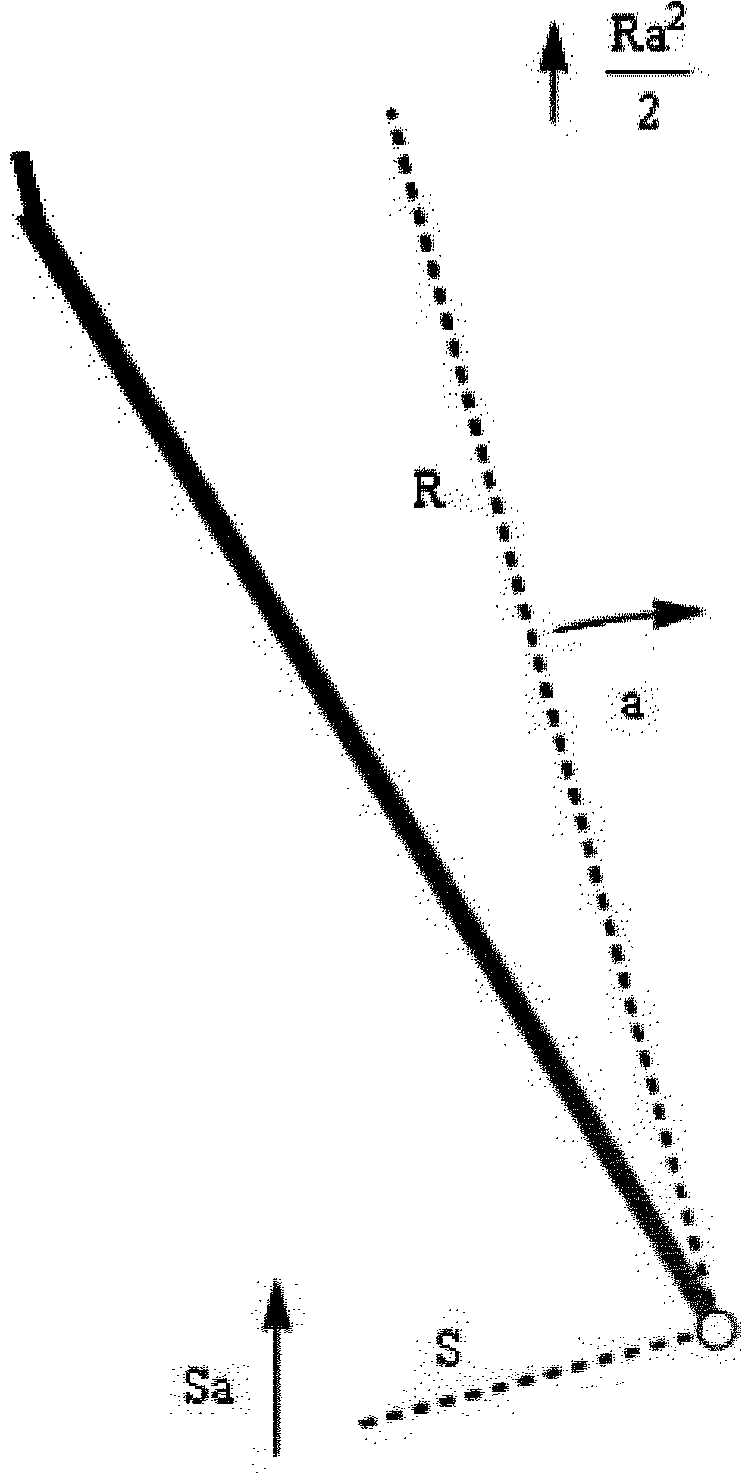

Tuning fork oscillator for timepieces

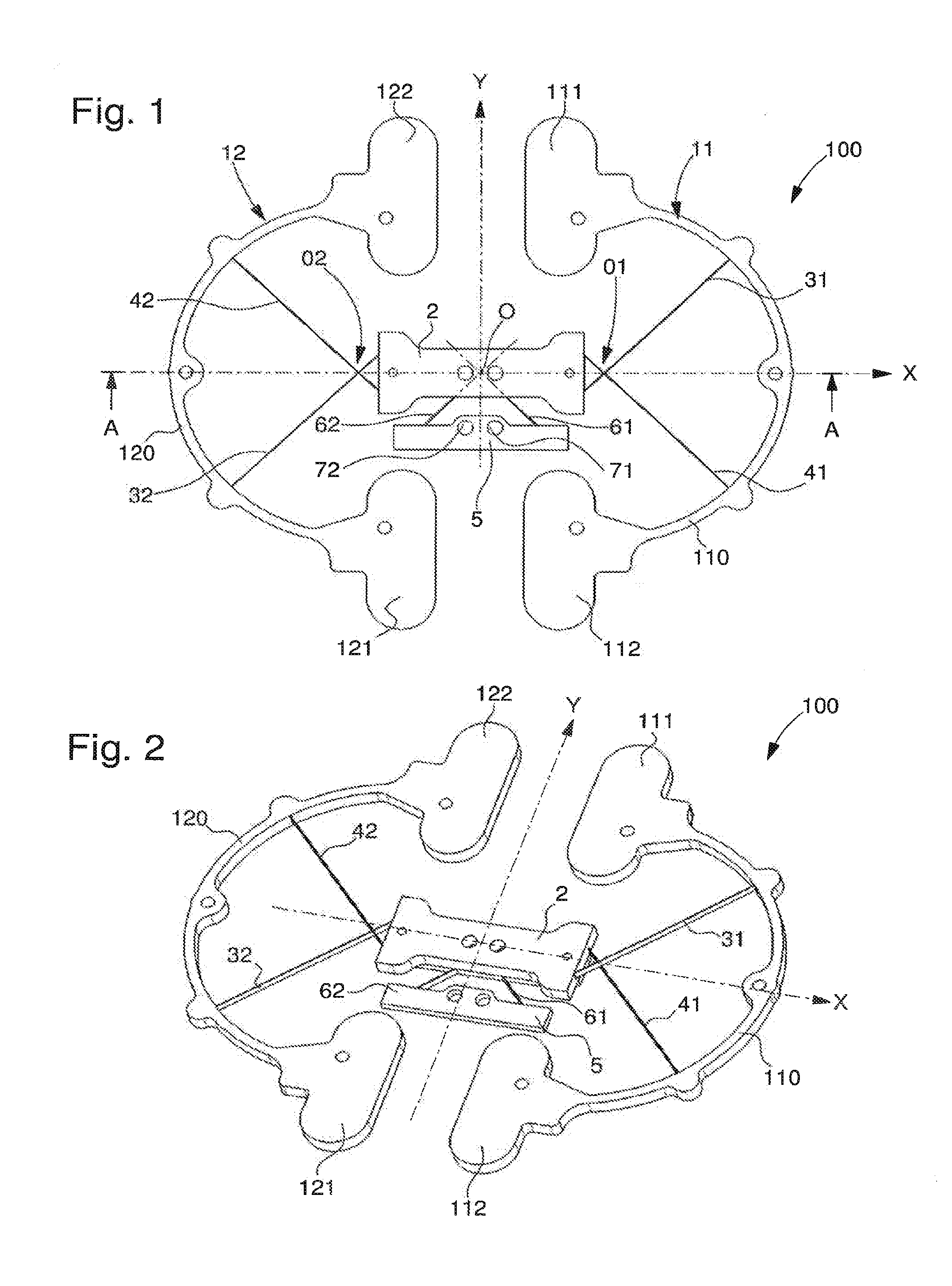

A timepiece oscillator including a resonator formed by a tuning fork which includes at least two mobile oscillating parts, fixed to a connection element by flexible elements whose geometry determines a virtual pivot axis having a determined position with respect to this connection element and around which the respective mobile part oscillates, and the center of mass of the mobile part coincides in the rest position with the respective virtual pivot axis, and, for at least one of the two mobile parts the flexible elements are formed of intersecting resilient strips extending at a distance from each other in two parallel planes, and whose directions, in projection on one of the parallel planes, intersect at the virtual pivot axis of the mobile part.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

Tuning fork oscillator for timepieces

ActiveUS20160179058A1Quality improvementImprove operating precisionEscapementsFrequency stabilisation mechanismRest positionResonator

A timepiece oscillator including a resonator formed by a tuning fork which includes at least two mobile oscillating parts, fixed to a connection element by flexible elements whose geometry determines a virtual pivot axis having a determined position with respect to this connection element and around which the respective mobile part oscillates, and the centre of masse of the mobile part coincides in the rest position with the respective virtual pivot axis, and, for at least one of the two mobile parts the flexible elements are formed of intersecting resilient strips extending at a distance from each other in two parallel planes, and whose directions, in projection on one of the parallel planes, intersect at the virtual pivot axis of the mobile part.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

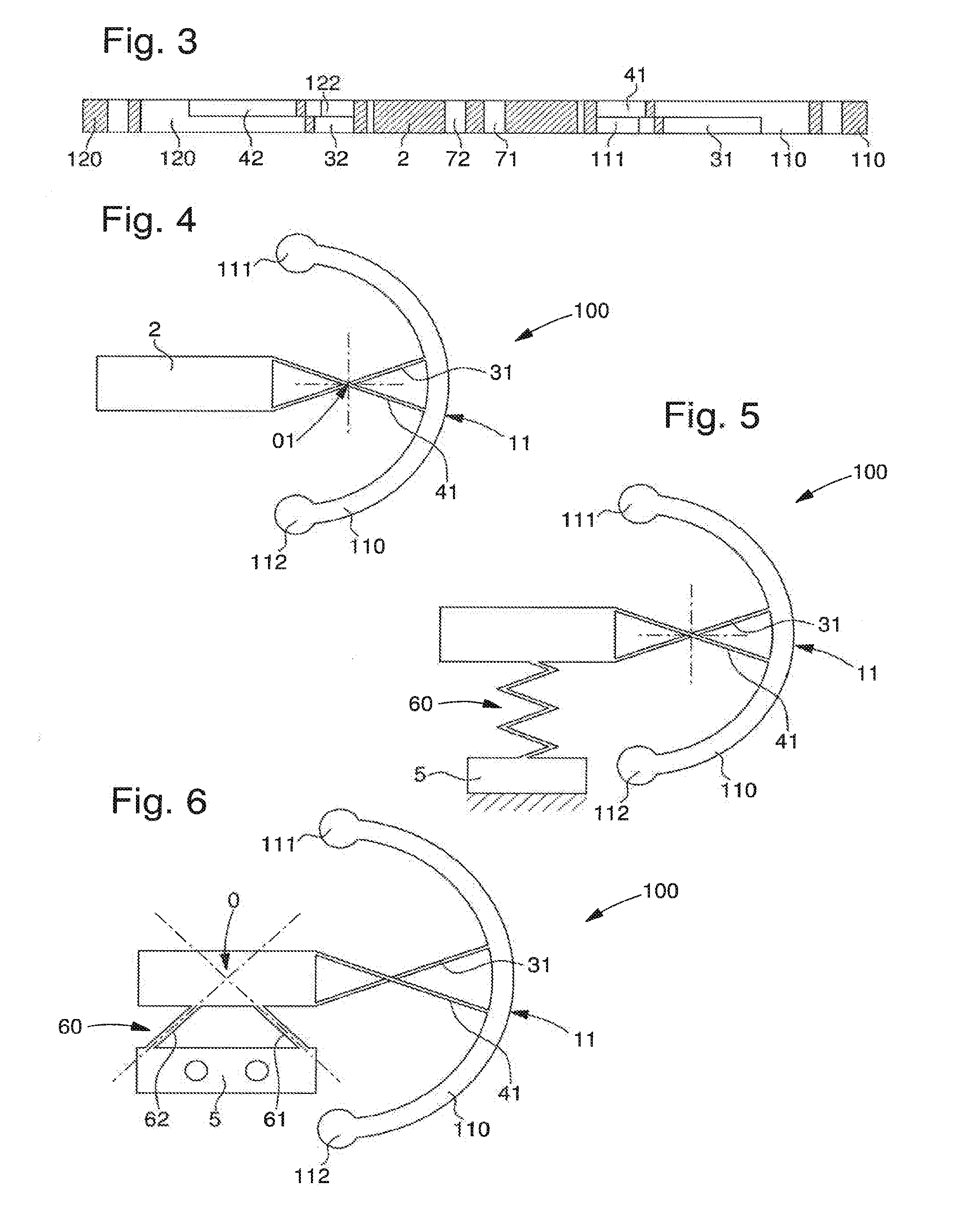

Gas sensor based on photoacoustic spectrometry

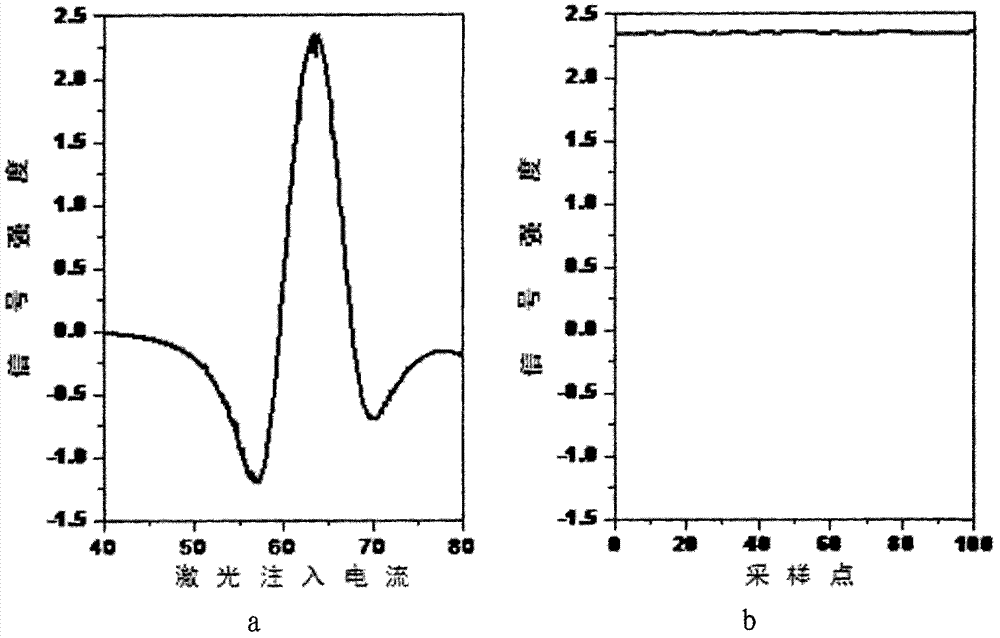

ActiveCN102954948AAchieve couplingHigh sensitivityColor/spectral properties measurementsAcoustic energyAcoustic wave

The invention discloses a gas sensor based on photoacoustic spectrometry, comprising a circuit matched and connected with a light source (1) and a quartz tuning fork (13). The gas sensor is characterized in that an acoustic resonator (6) is composed of a main tube (11) with a branch tube (12) which are communicated with each other vertically; the tube axis of the main tube (11) is coaxial with a light path (2), the tube length of the main tube (11) is 4.57-7.87 mm, and the tube inner diameter of the main tube (11) is 0.4-1.5mm; the tube length of the branch tube (12) is 1-2mm and the tube inner diameter of the branch tube (12) is 0.4-0.5mm; the focus of a focusing lens (4) is located at the communicated part of the main tube (11) and the branch tube (12); the plane and the slit centre of a tuning fork arm (131) of the quartz tuning fork (13) are vertical to and located in the axis of the branch tube (12) respectively, and the distance between the plane of the tuning fork arm (131) and the tail port of the branch tube (12) is 20-50mu m; and the slit width of the tuning fork arm (131) of the quartz tuning fork (13) is 0.28-0.32mm, and the resonant frequency of the tuning fork arm (131) of the quartz tuning fork (13) is 31.768-33.768kHz. The gas sensor based on photoacoustic spectrometry realizes coupling between a light-excited acoustic energy and the quartz tuning fork with the highest efficiency and can be used for the field of trace gas detection.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

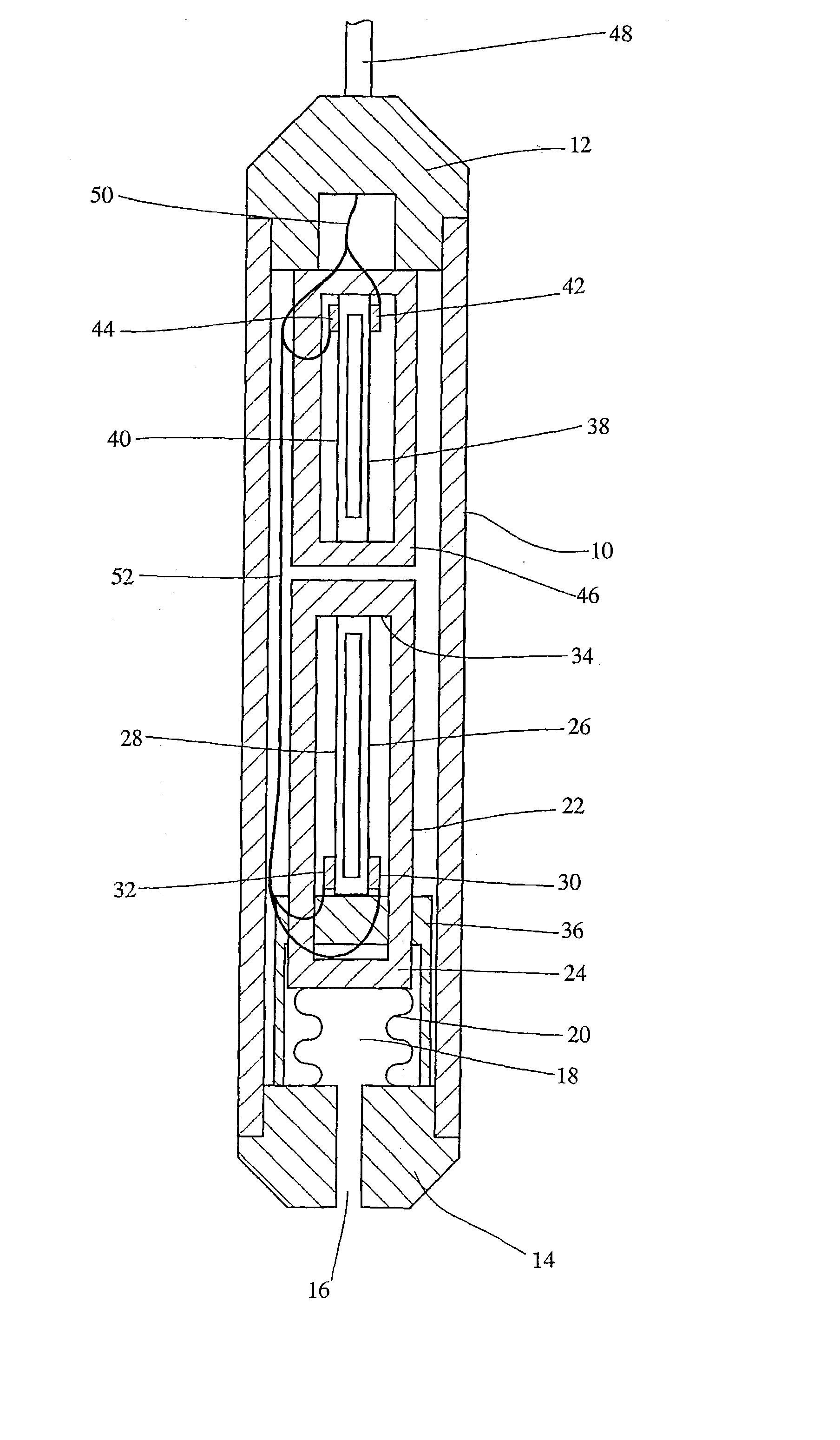

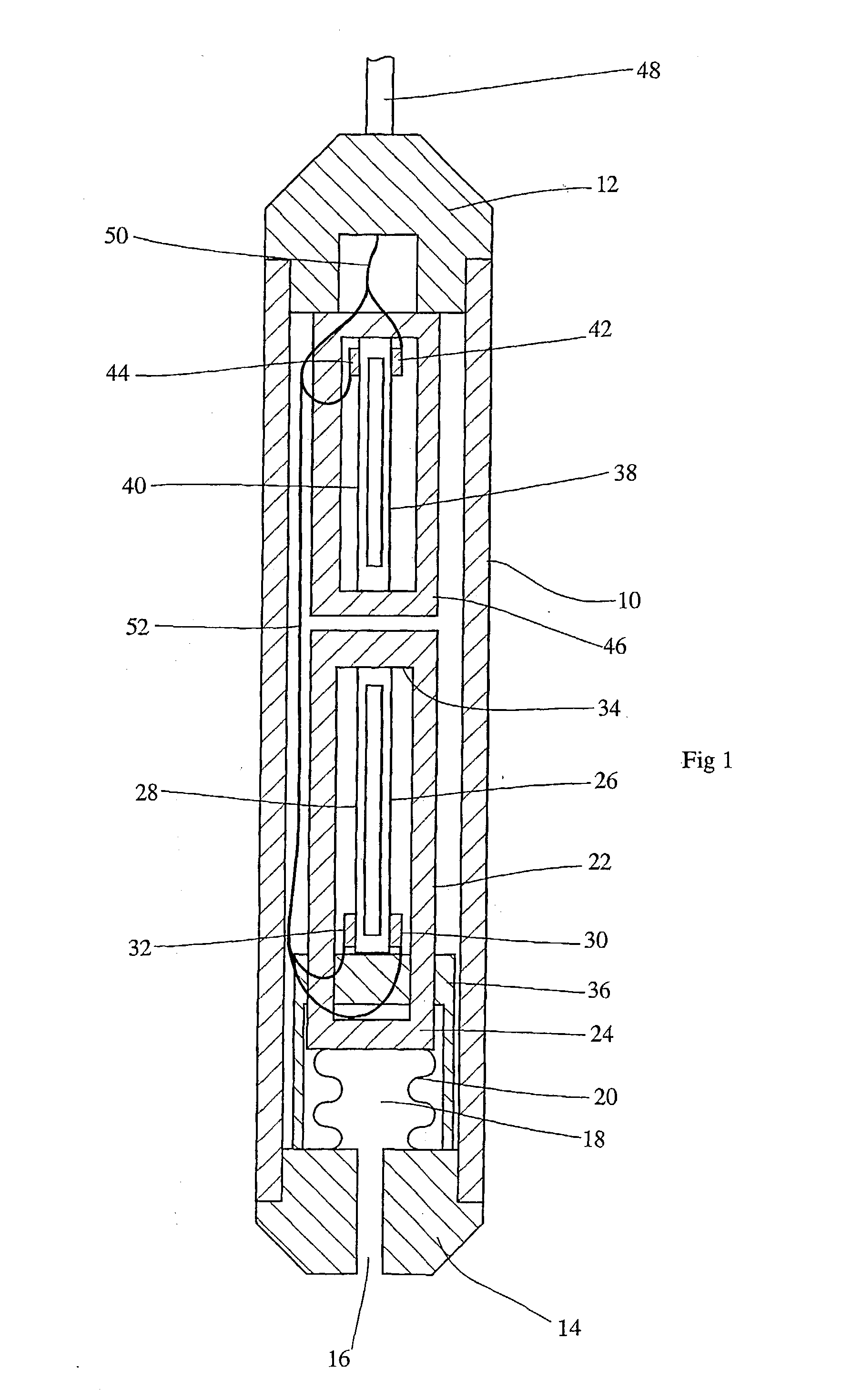

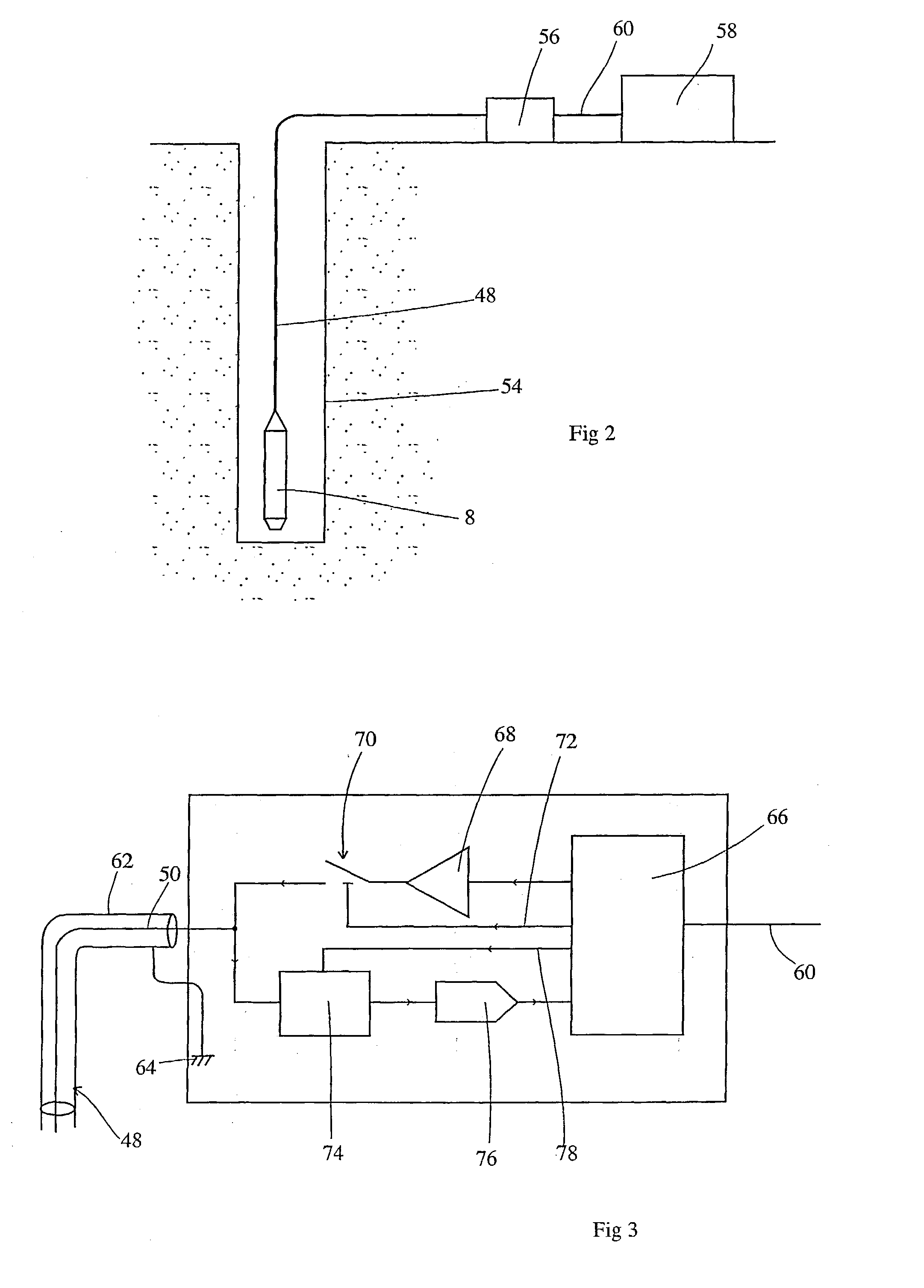

Sensor apparatus

InactiveUS20030101822A1Reduce impactHigh quality factorVibration measurement in solidsSurveyElectrical conductorSignal on

A measurement head particularly for borehole use can measure multiple parameters with no electronics in the head and only a single conductor cable. Double-ended tuning forks (26, 28 and 38, 40) in the head are arranged to respond to different parameters such as temperature and pressure by adjusting their resonant frequencies. A drive signal on the conductor (50) is applied to transducers (30, 32, 42, 44) on all the tuning forks and those whose instantaneous resonant frequency is close will resonate. The signal is removed and the transducers return a decaying signal at the resonant frequency along the conductor. Other drive frequencies are tried, to locate the other sensors whose frequency ranges are separate.

Owner:BAKER HUGHES INC

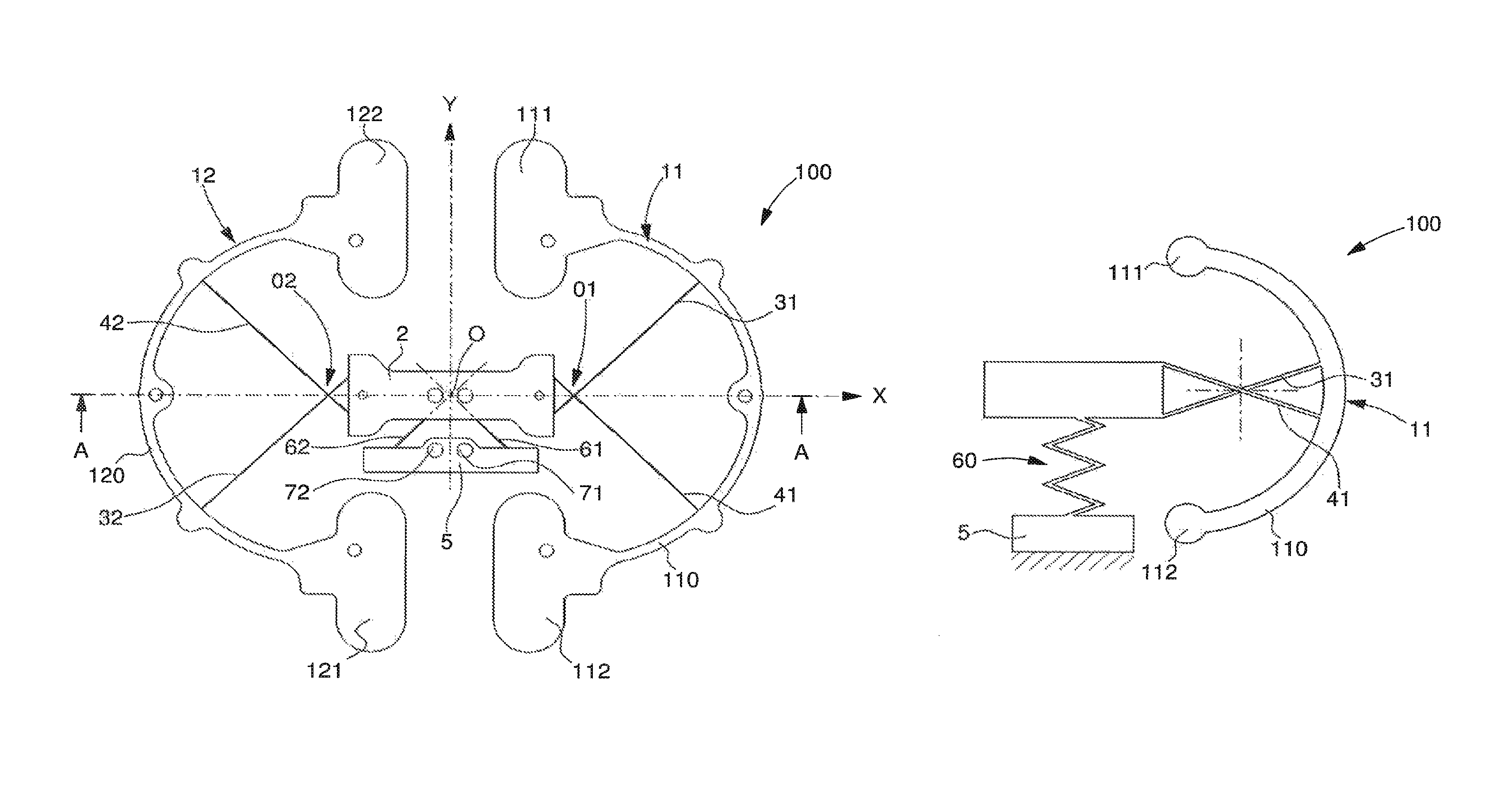

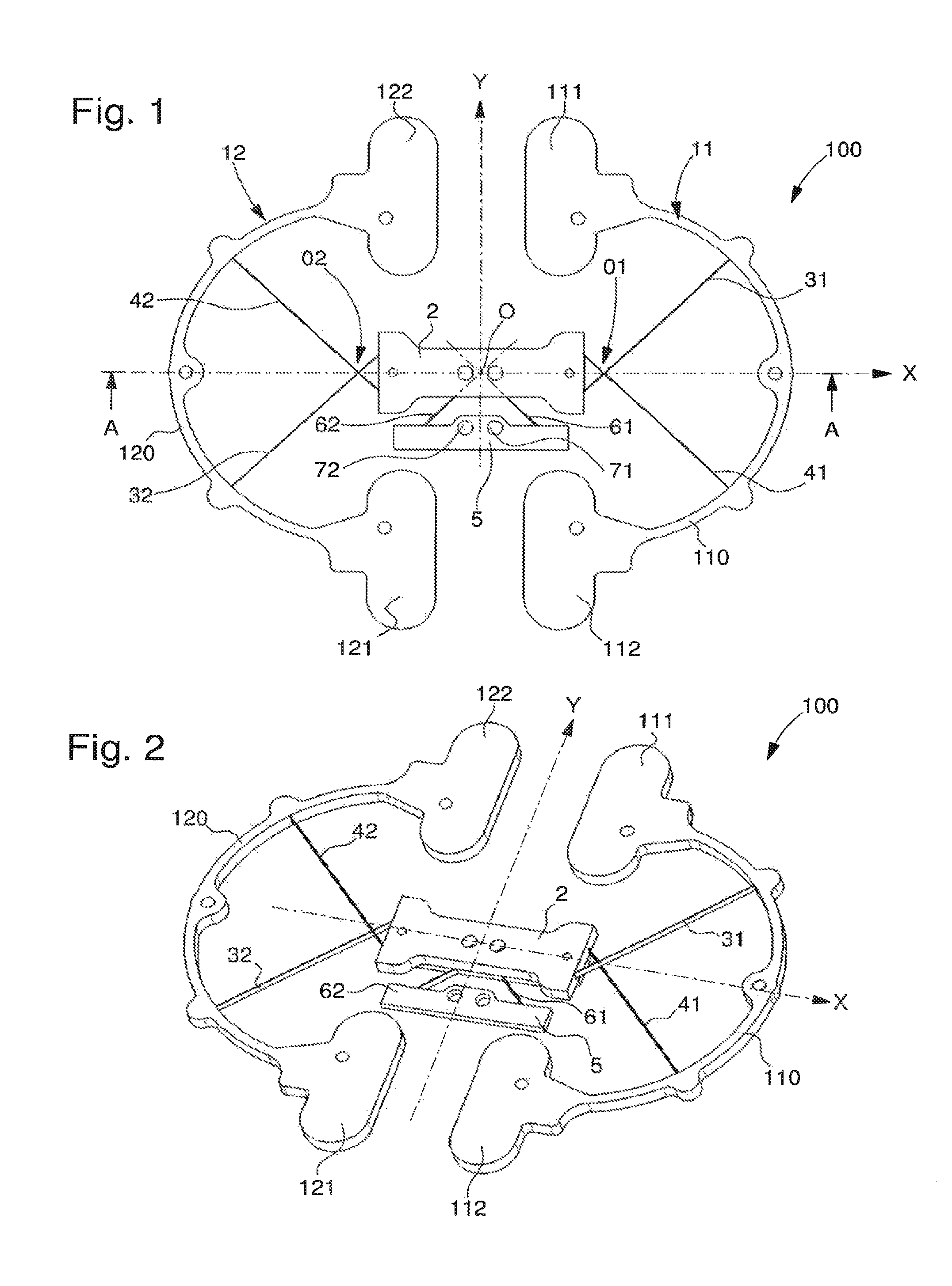

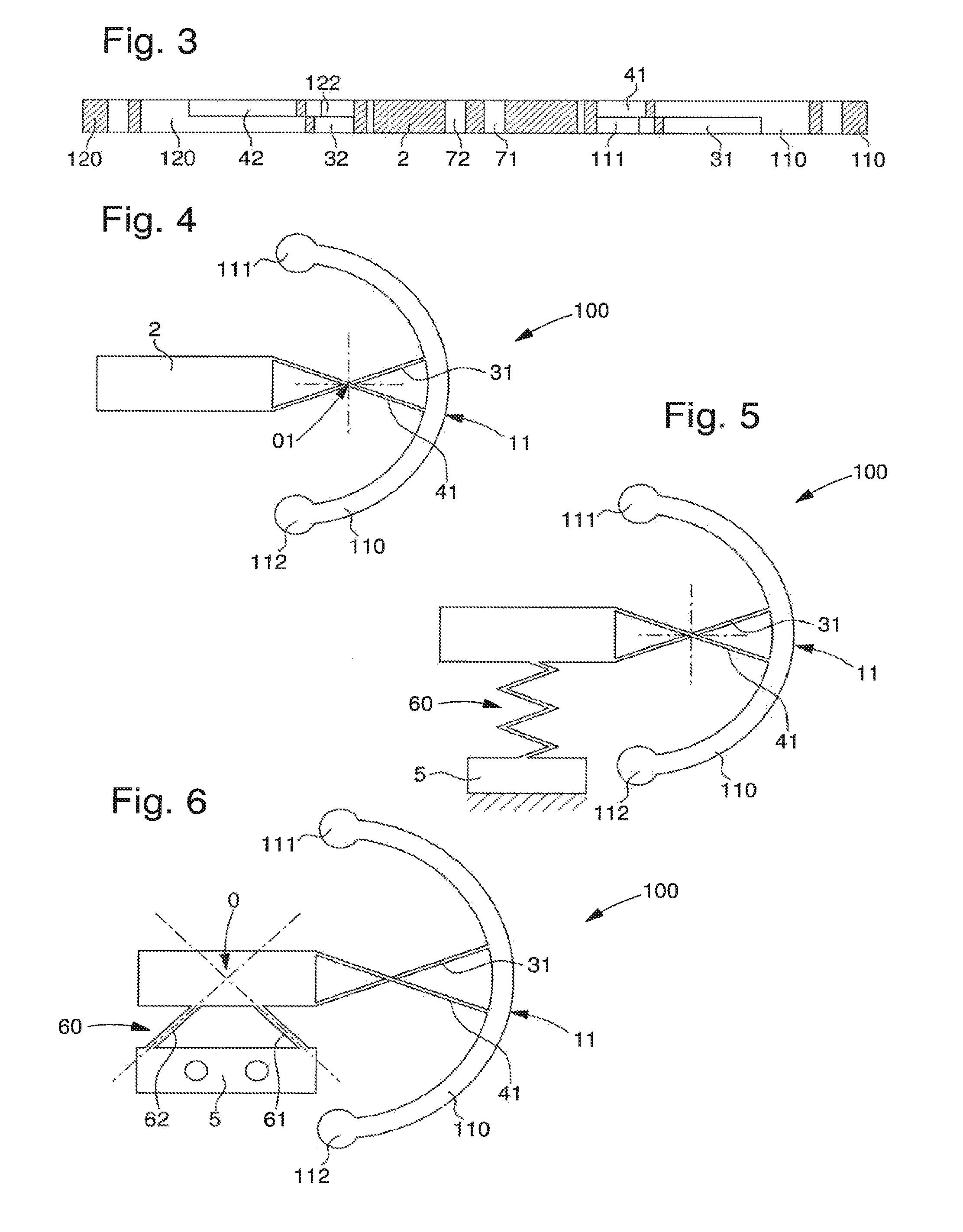

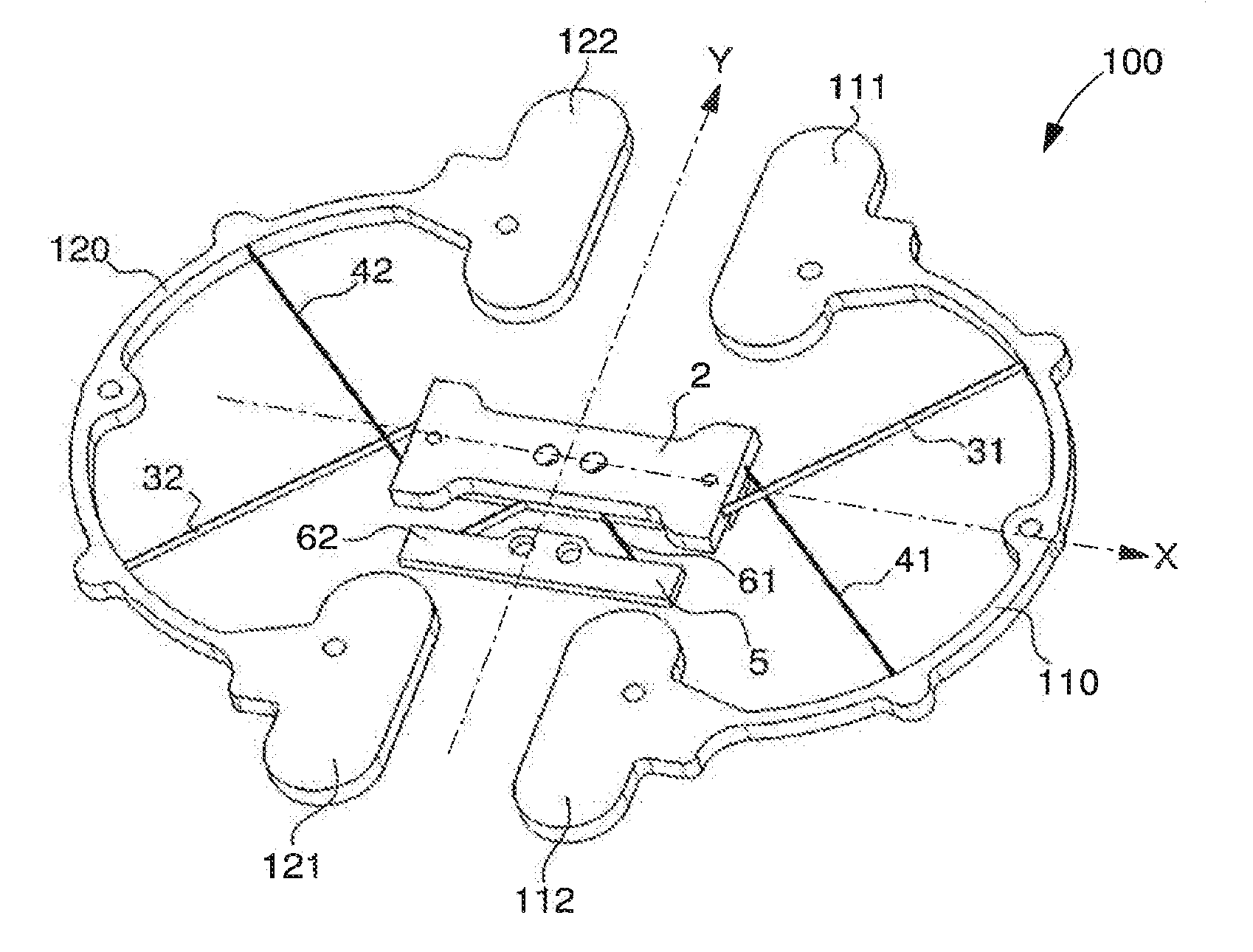

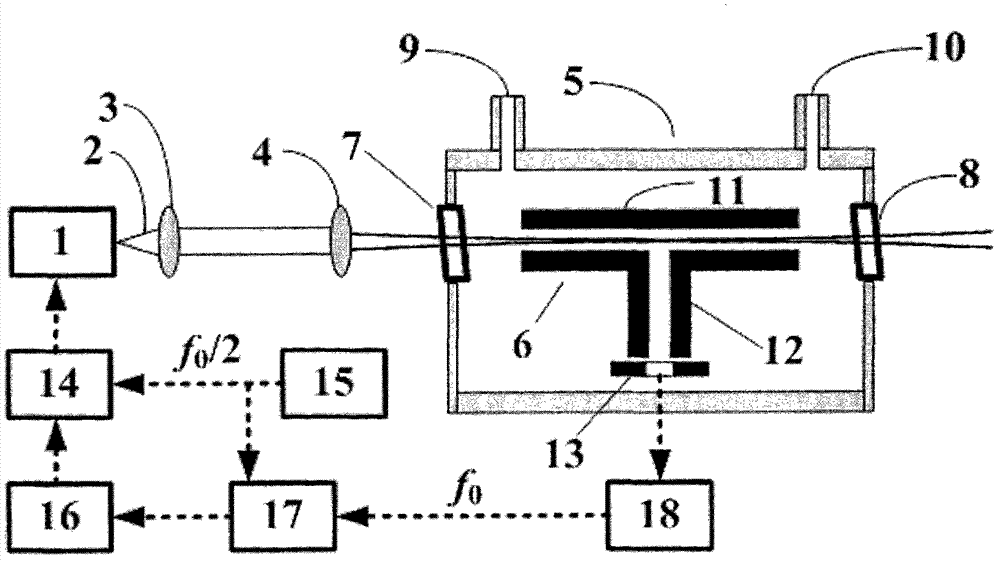

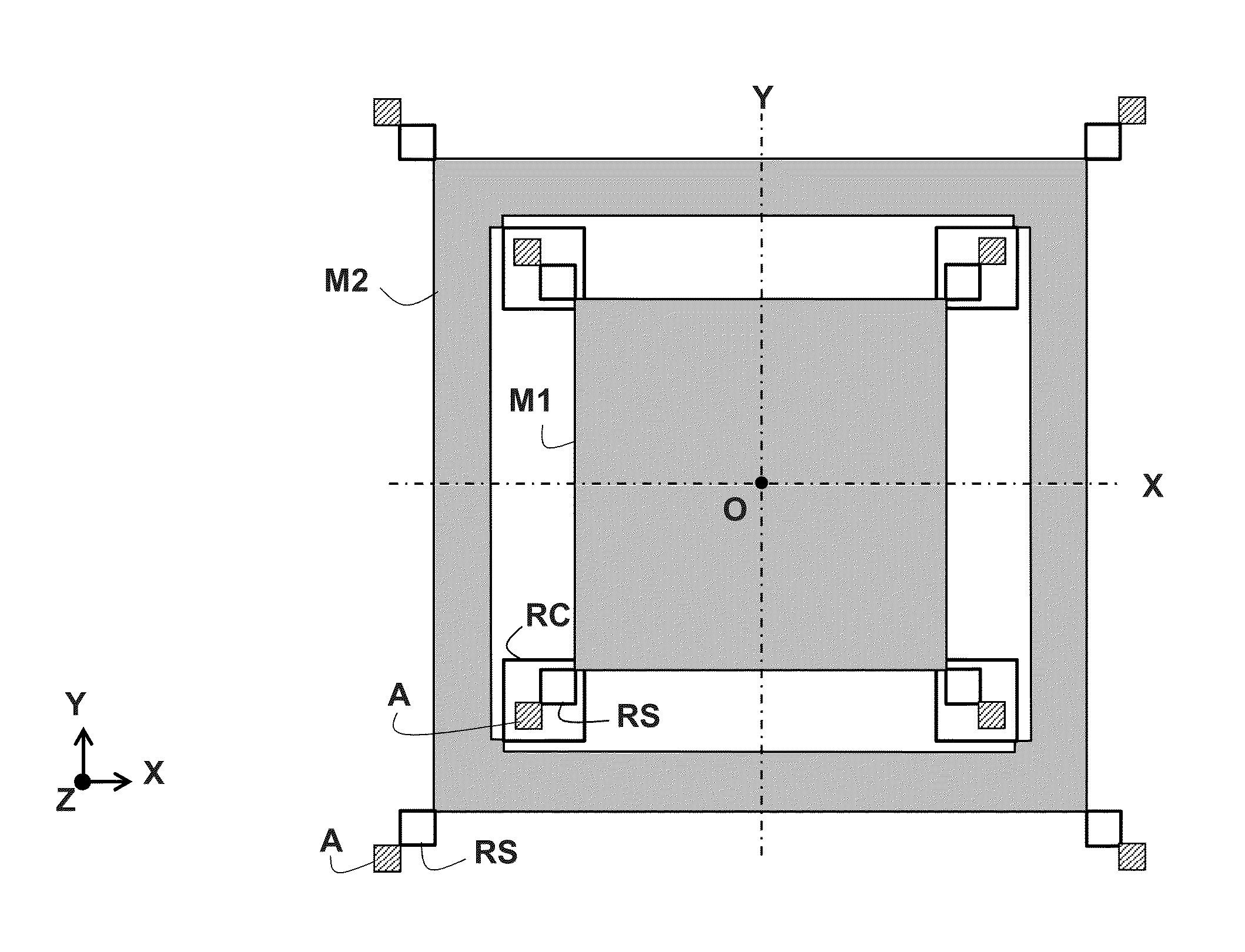

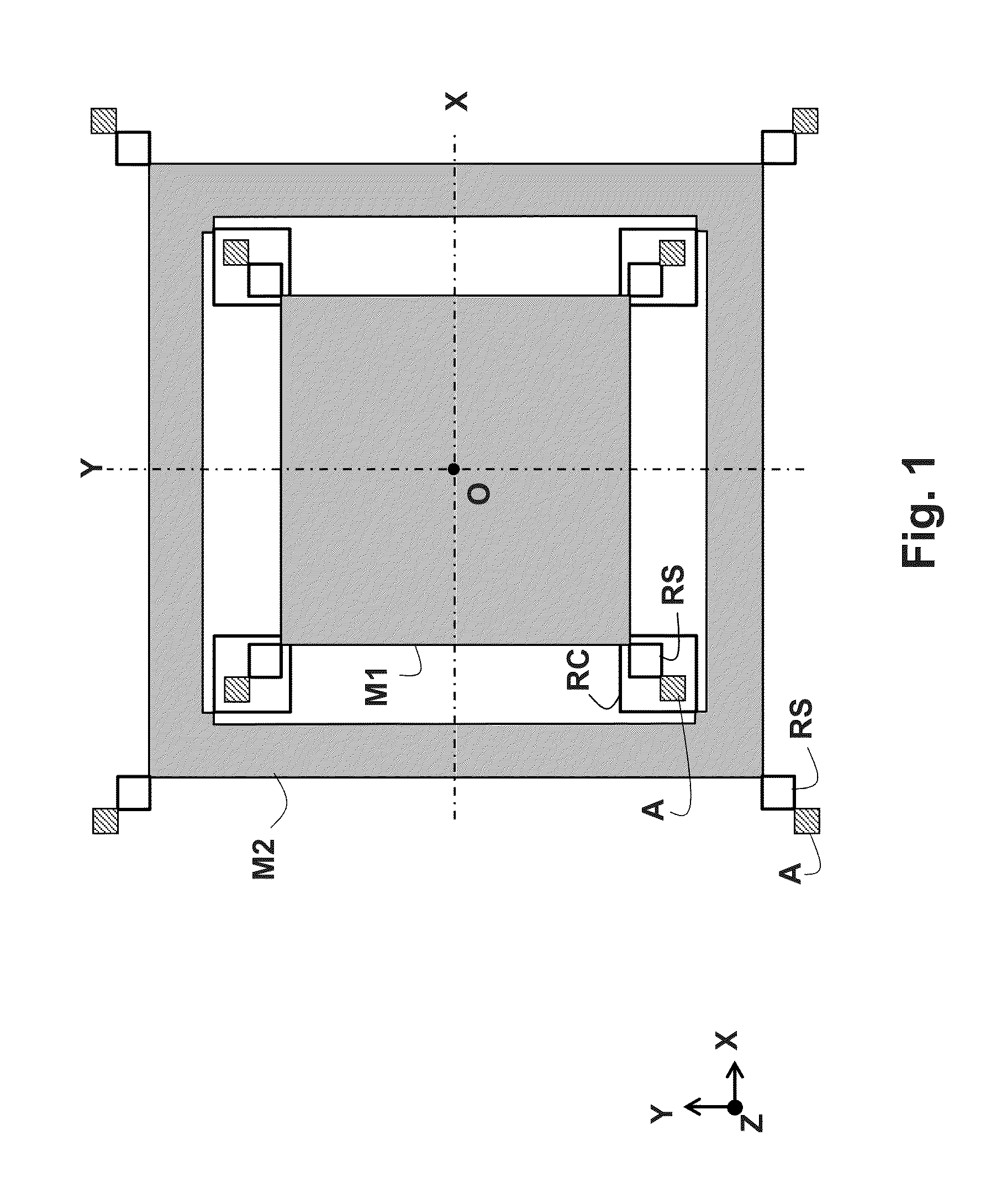

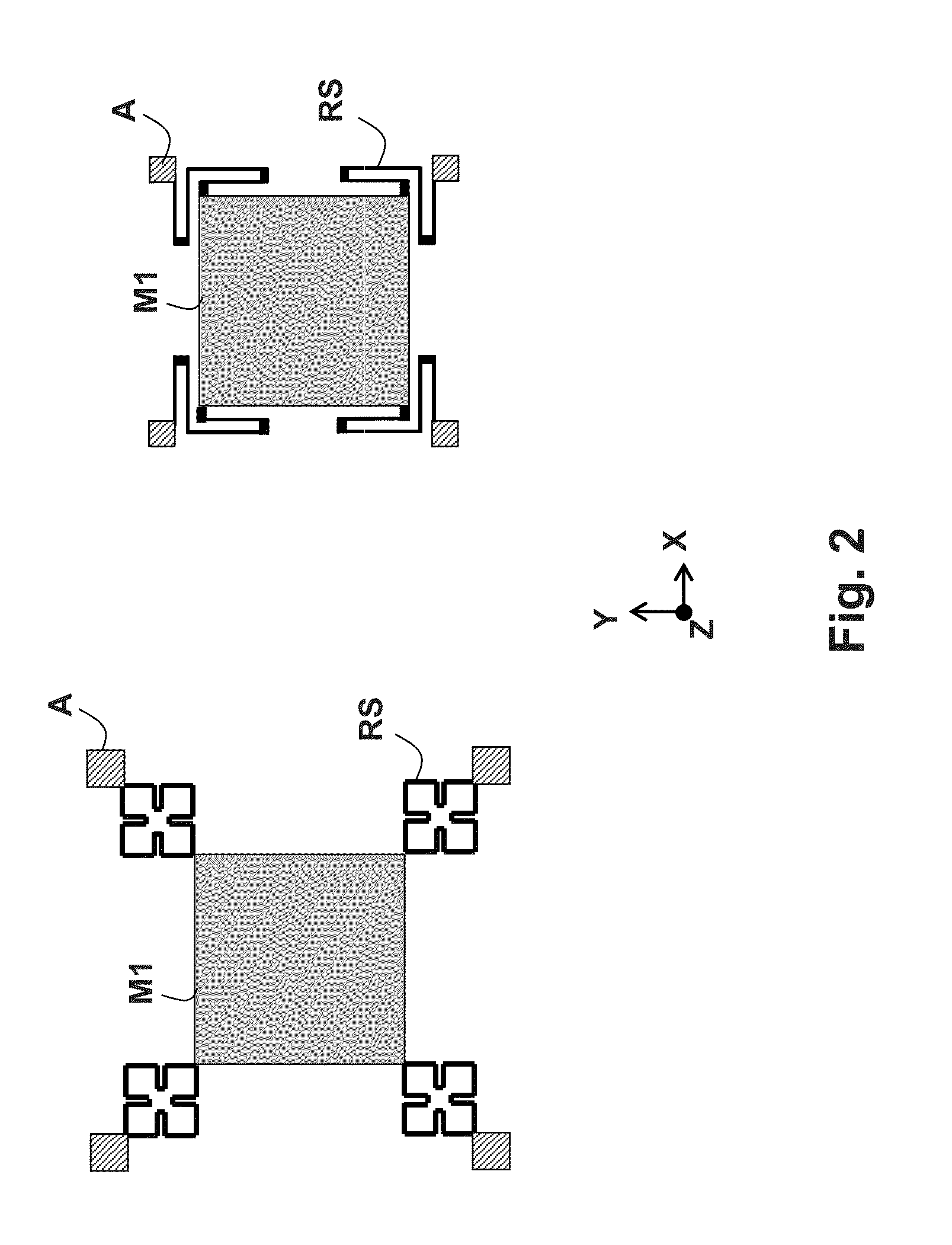

MEMS angular inertial sensor operating in tuning fork mode

ActiveUS20150377621A1Easy to separateHigh stiffness of couplingAcceleration measurement using interia forcesSpeed measurement using gyroscopic effectsTuning forkAxis of symmetry

A vibrating inertial sensor is provided, micro machined in a plane thin wafer, allowing the measurement of an angular position or of an angular speed. The sensor comprises two vibrating masses suspended by springs with identical stiffness in X and Y and coupled together by identical stiffness springs in X and Y, and at least excitation transducers and detection transducers disposed on at least one of the masses. The mobile assembly consisting of a vibrating mass and the parts of transducers fastened to this mass has a generally symmetric structure with respect to an axis of symmetry OX and with respect to an axis of symmetry OY.

Owner:THALES SA

Clock generating device, vibration type gyro sensor, navigation device, imaging device, and electronic apparatus

InactiveUS20050160813A1Subject to movementGood precisionTelevision system detailsInstruments for road network navigationTime informationGyroscope

A vibration gyro sensor is provided which is capable of generating time information and detecting an angular velocity. A driving signal for driving a tuning fork piezoelectric vibrating reed is generated based on an excitation signal generated by an oscillation circuit. An angular velocity signal is obtained based on a detection signal generated by a detection electrode of the tuning fork piezoelectric vibration reed. The excitation signal generated by the oscillation circuit is input to a divider such that a timer clock signal is generated.

Owner:SEIKO EPSON CORP

Tuning-fork type piezoelectric vibrating pieces having similarly shaped vibrating-root and supporting root portions

InactiveUS8134284B2Facilitate bisymmetric etchingIncrease valuePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesMechanical engineeringFork tuning

Owner:NIHON DEMPA KOGYO CO LTD

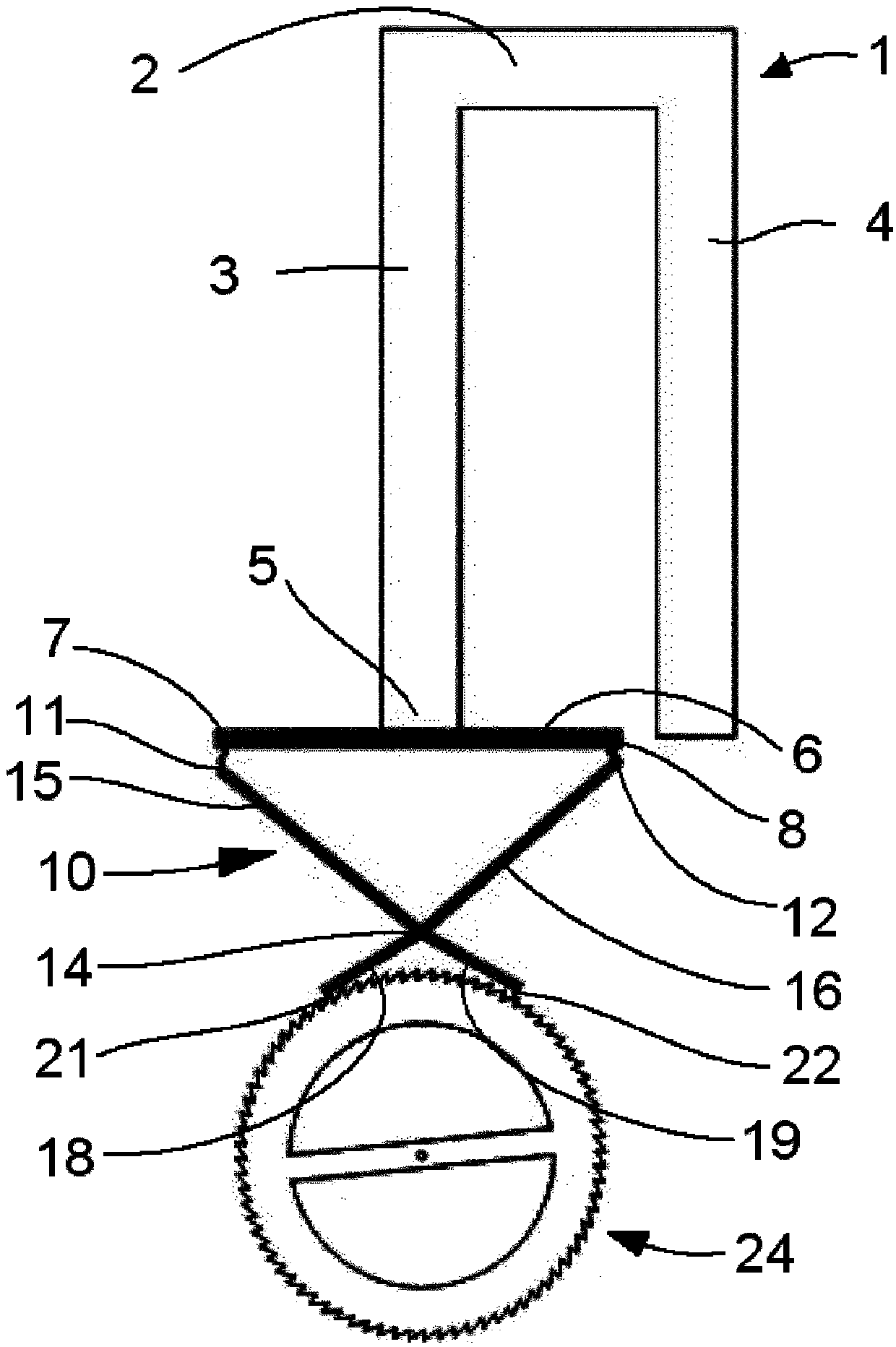

Resonator having a tuning fork for a mechanical clock movement

ActiveCN103858061AReduce disadvantagesHigh quality factorEscapementsFrequency stabilisation mechanismMechanical energyResonator

The invention relates to a mechanical resonator having a tuning fork for a clock movement having a lever escapement, comprising a tuning-fork oscillator (1), at least one first arm (3) of which is to be oscillated on either side of a first axis and has at least one first pin combined with at least one first fork tooth of an anchor (10, 100) so as to pivot the latter between first and second angular positions, and alternately lock and release an escape wheel (24). The resonator comprises a conversion member (6, 7, 8, 15, 16) which is secured to the first pin and which is arranged to: convert the oscillations of the first arm (3) of the oscillator (1) into rotational movements of the anchor (10, 100) by transmitting first pulses to the latter; and transmit mechanical energy from the anchor (10, 100) to the first arm (3) of the oscillator (1) in the form of pulses such that the first tooth has an amplitude of movement that is either axial or substantially in the direction of the first axis during the pivoting of the anchor, said amplitude of movement being greater than the amplitude of movement of the first pin substantially in the direction of the first axis.

Owner:THE SWATCH GRP RES & DEVELONMENT LTD

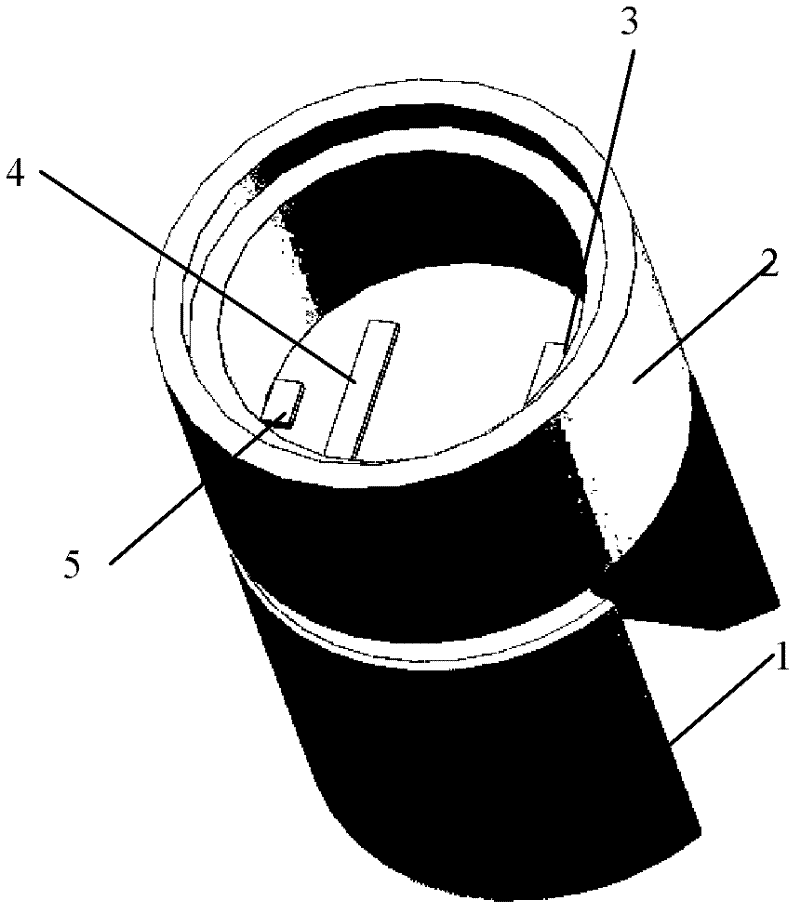

Bionic double-shaft hair sensor device

ActiveCN107421526ASuppression of swinging motionHigh detection sensitivitySpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesTuning forkImage resolution

The invention discloses a bionic double-shaft hair sensor device comprising a three-layer structure including metal aluminum alloy hair at an upper layer, a silicon microsensor at a middle layer and a glass substrate provided with a signal wire at a lower layer, wherein the metal aluminum alloy hair is adhered to a center position of the upper surface of the silicon microsensor; the microsensor is composed of a pedestal mass block, four swing suppression elastic structures and four resonator structures; the four resonator sub-structures are positioned in hollow areas on four sides of the pedestal mass block; and the four swing suppression elastic structures are positioned in hollow areas on the side surfaces of the four resonators. According to the device provided by the invention, variations of inherent frequency of fixed tuning fork resonant beams at two ends are detected, the sizes of axial forces suffered by the resonant beams are computed, so that sensitivity to flow speeds and accelerations in two directions in a plane is achieved, and the device has the advantages of small volume, light weight, compact structure and high resolution ratio and precision.

Owner:SOUTHEAST UNIV

Tuning-fork type quartz-crystal vibrating pieces and piezoelectric devices having low crystal impedance

ActiveUS20120248938A1Easy to adjustPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesEdge surfaceFront edge

Tuning-fork type quartz-crystal vibrating pieces are disclosed, of which the vibration frequency can be adjusted without increasing CI. An exemplary piezoelectric device has a pair of vibrating arms extending in a predetermined direction from a first edge of a base. Respective first grooves are defined in a first principal surface of the vibrating arms. The first grooves extend in the predetermined direction, and have first excitation electrodes extending from a back-edge surface but not completely to a front-edge surface of the grooves. Respective second grooves are defined in a second principal surface, opposite the first principal surface, of the vibrating arms. The second grooves extend in the predetermined direction, and have second excitation electrodes extending from a back-edge surface completely to a front-edge surface of the second grooves.

Owner:NIHON DEMPA KOGYO CO LTD

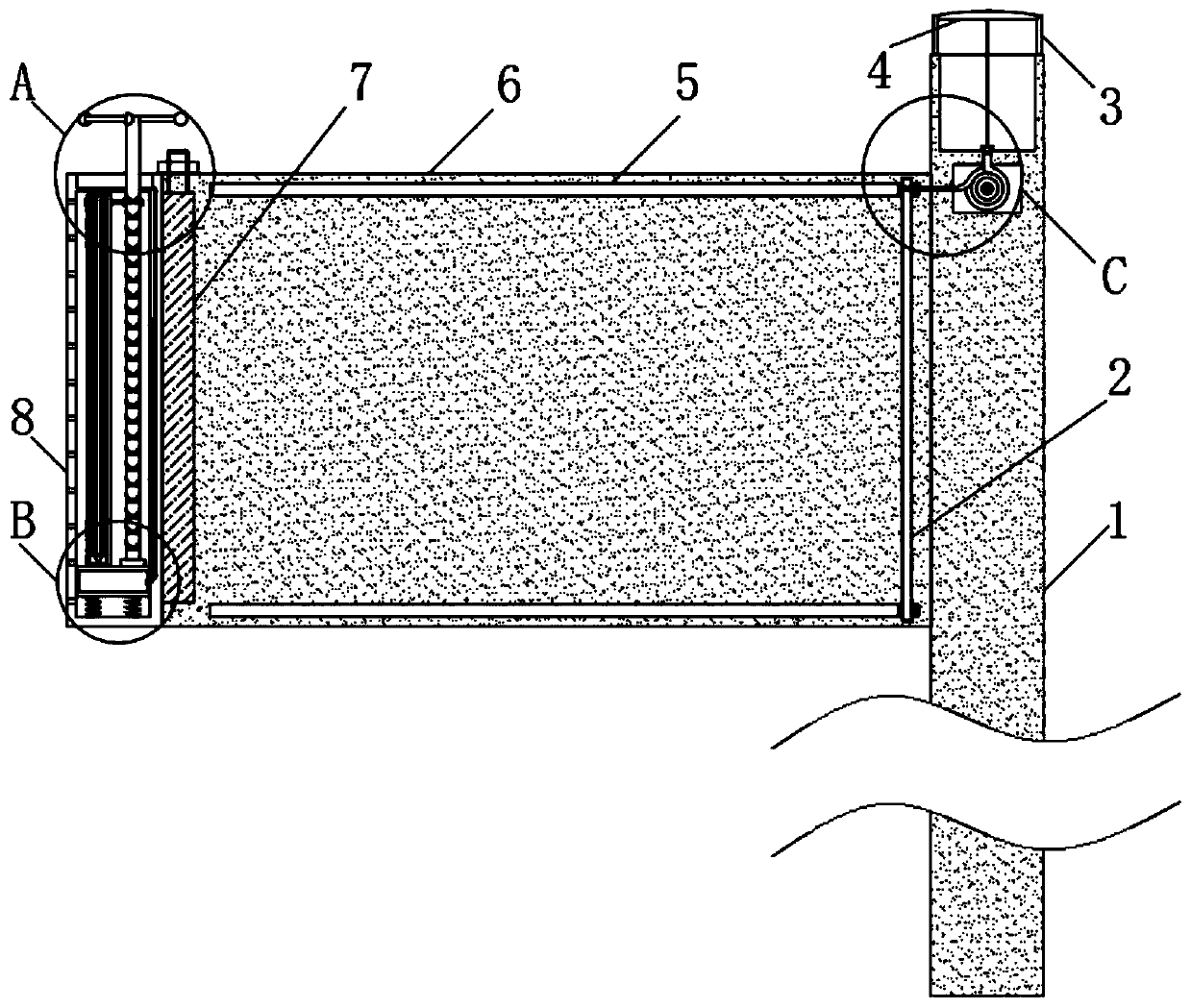

A sidewalk guardrail with dust removing function

ActiveCN109024383AHarm reductionReduce labor costsElectrostatic separationRoadway safety arrangementsFiberArchitectural engineering

The invention discloses a sidewalk guardrail with dust removing function, comprising two transverse bars and a hollow vertical bar arranged between the two transverse bars. A dust net is fixedly connected between the two transverse bars on one side close to a lane, and the side close to the lane and the sidewalk of the hollow vertical bar is provided with vertically arranged strip openings. A tuning fork, a chemical fiber material and a glass cylinder are arranged in the invention, the raised dust can be electrostatically adsorbed on the glass cylinder after the automobile passes through, andthe harm of the dust to pedestrians on both sides of the road is reduced; The dust on the glass cylinder can be cleaned by setting the scraper ring and the plate, so that the maintenance of the equipment is not needed, and the labor cost is reduced; A magnetic blade is arrange so that that magnetic blade intermittently attracts the dust screen when rotate, and the dust screen vibrates, and dust adsorbed on the dust screen can be shaken off by the vibration of the dust screen.

Owner:江西捷达交通工程有限责任公司

Municipal road indicating equipment for sponge city

ActiveCN110670502ALess quantityGuaranteed cleanlinessElectrostatic separationCleaning using toolsArchitectural engineeringMechanical engineering

The invention discloses municipal road indicating equipment for the sponge city. The municipal road indicating equipment for the sponge city comprises a support pillar, wherein an indicator plate is fixedly connected to the side wall of the support pillar; a dust prevention mechanism is arranged on the side wall of the indicator plate and comprises an installation box; the installation box is fixedly connected to the side wall of one end, far away from the support pillar, of the indicator plate; openings communicating with the outside are formed in the front side wall and the back side wall ofthe installation box; an installation rod is fixedly connected to the inner wall, close to the bottom end, of the installation box; a rubber barrel is fixedly connected to the upper wall of the installation rod; a tuning fork is fixedly connected into the rubber barrel; furs are fixedly connected to the side wall of the tuning fork; multiple ventilation holes are formed in the side wall of one end, far away from the indicator plate, of the installation box; and a reciprocating screw rod is rotatably connected to the upper wall of the installation rod through a bearing. According to the municipal road indicating equipment for the sponge city provided by the invention, the amount of dust attached to the side wall of the indicator plate can be greatly reduced, and the indicator plate can beautomatically cleaned, so that time and effort are greatly saved, and the personal safety of people and the normal passage of traffic are further ensured.

Owner:扬州市路安新型材料有限公司

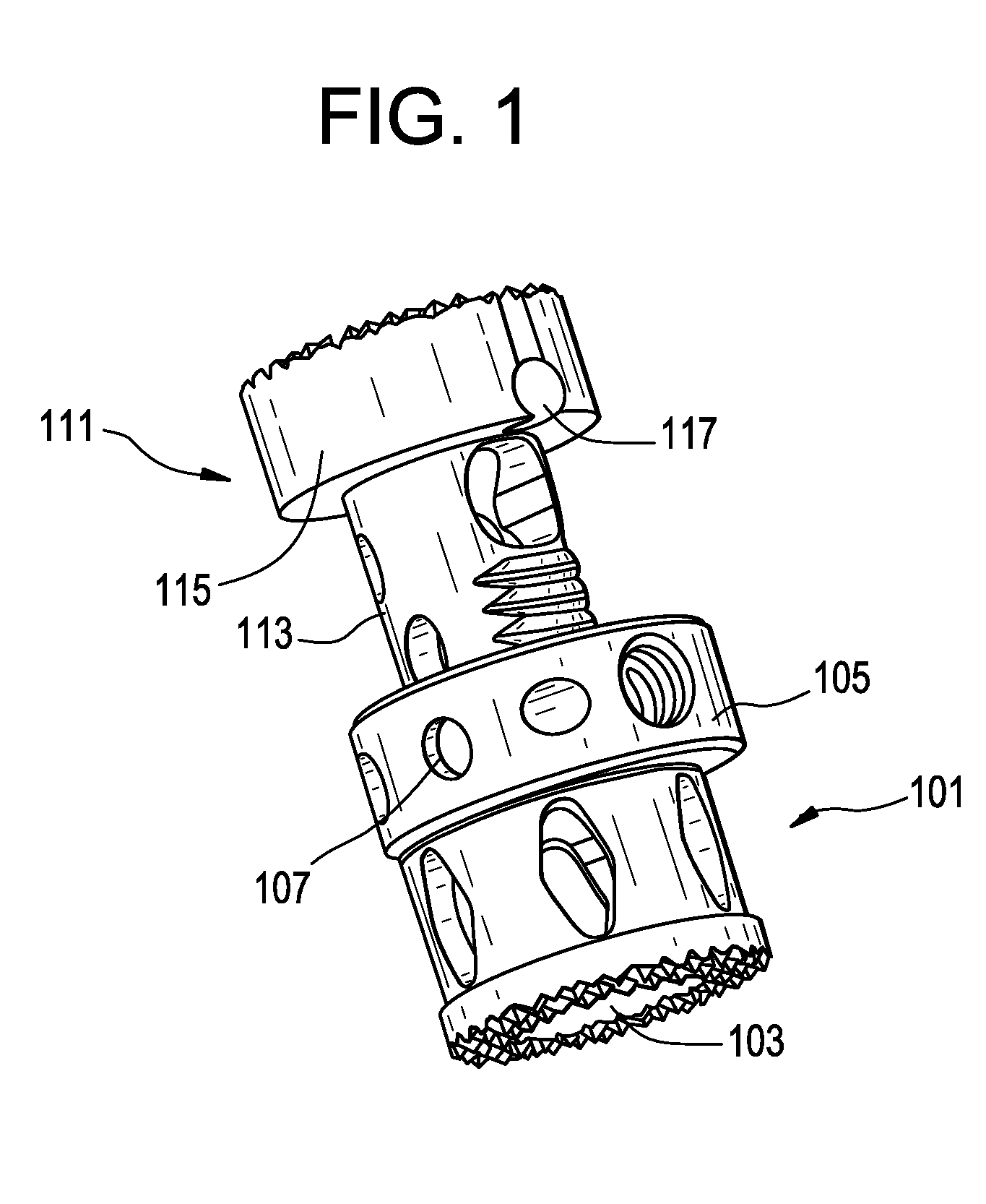

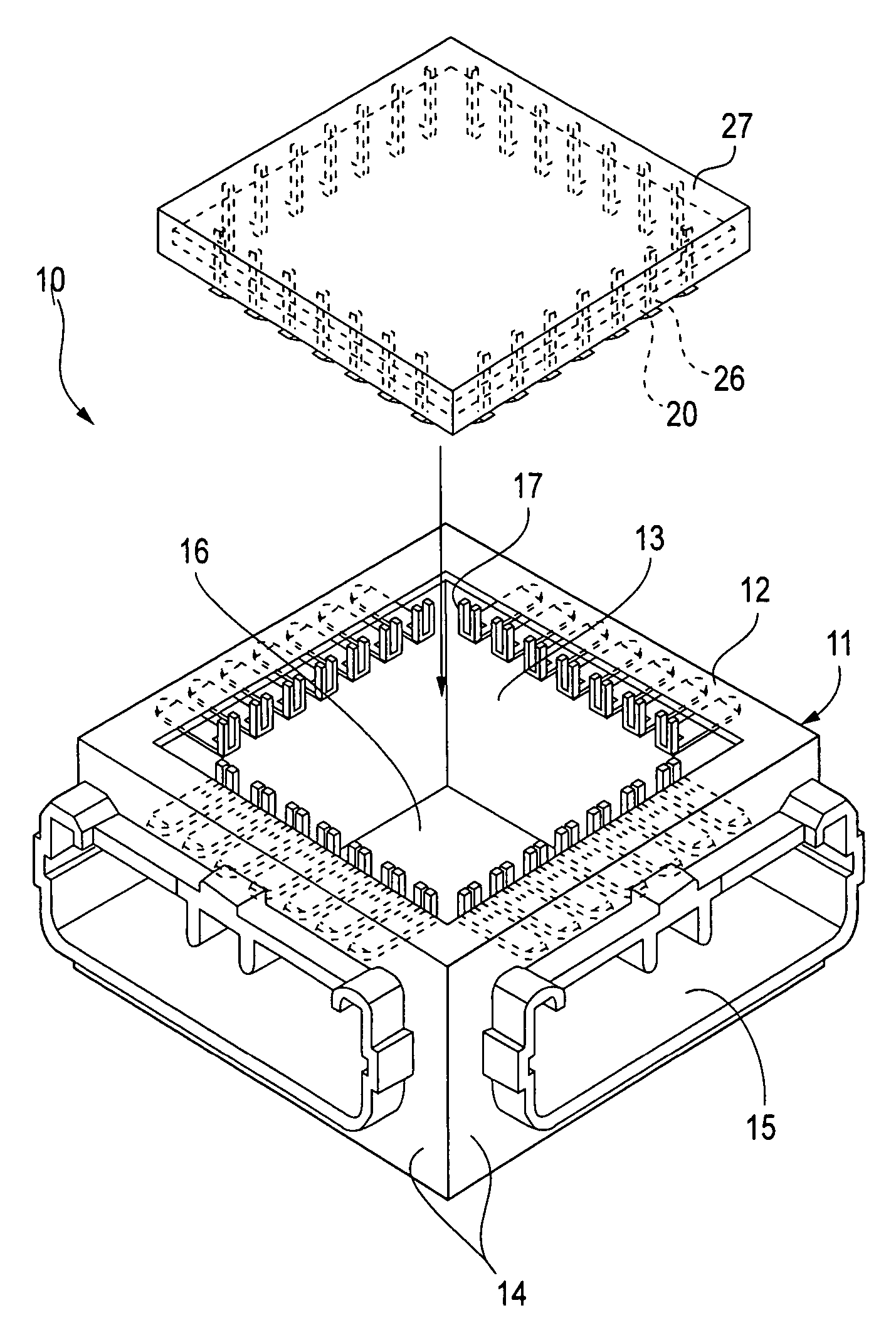

Electric junction box and connection structure of tuning fork terminal

InactiveUS20060035492A1Avoid connection failureAvoid deformationPrinted circuit aspectsPrinted circuit manufactureElectrical conductorElectrical connection

An electric junction box that can accommodate various circuit patterns in accordance with a combination of a printed-circuit board and a case housing the printed-circuit board. Connection pins connected to conductors are provided in a projecting position at intervals along the peripheral edge of a printed-circuit board. An opening corresponding to the printed-circuit board is formed in a central region of the upper side of a case. Connector joints are positioned on the peripheral walls of the four sides of the case, and L-shaped terminals are provided at the same intervals as for the connection pins along the opening. Additionally, a connection structure of a tuning-fork terminal includes a tuning-fork terminal at the end portion of a conducting plate base bent vertically and having a press connection slot in the center of the vertical portion; and a tab-shaped mating terminal electrically connected to contact portions projecting from inner sides of the slot.

Owner:SUMITOMO WIRING SYST LTD

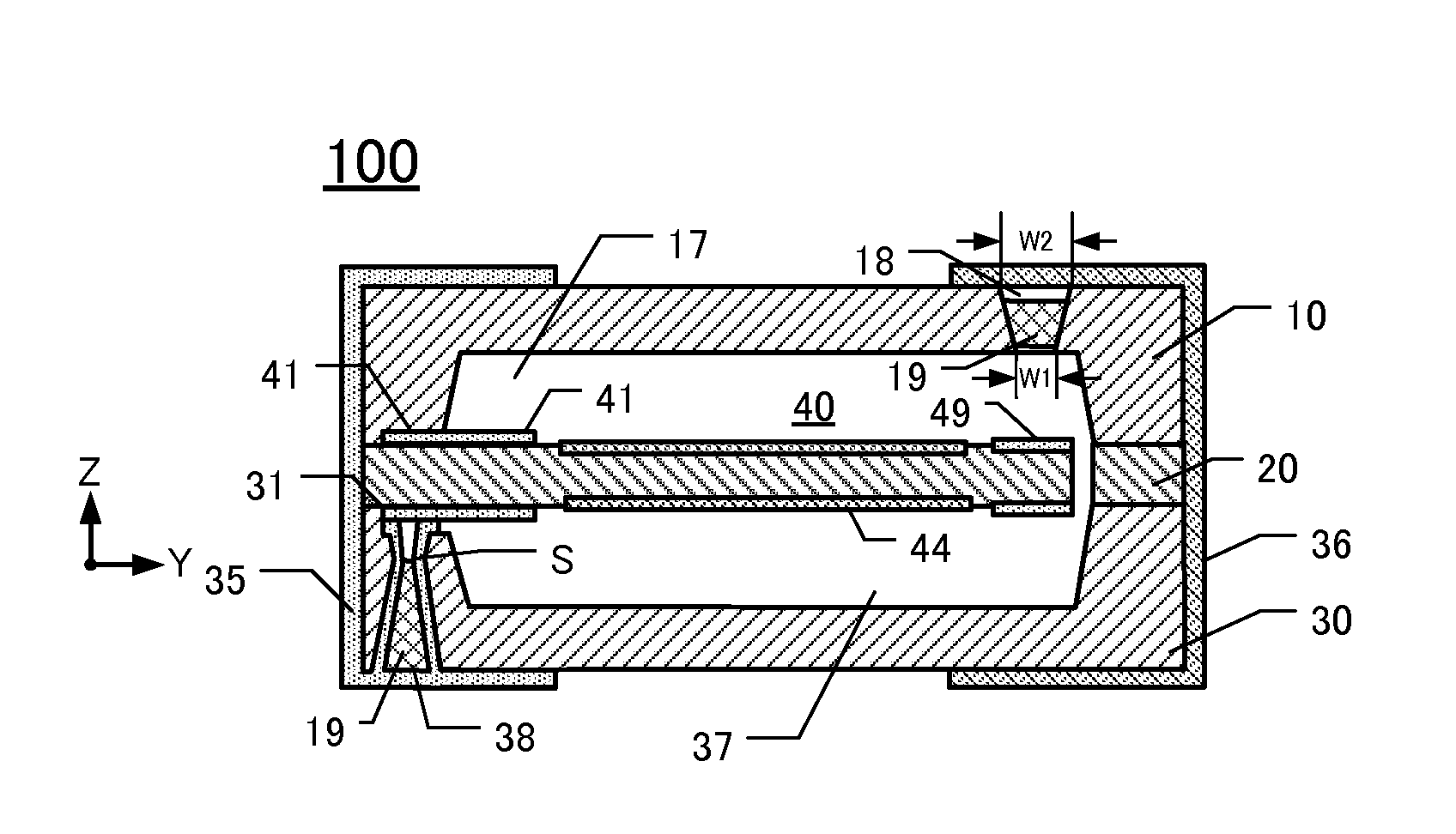

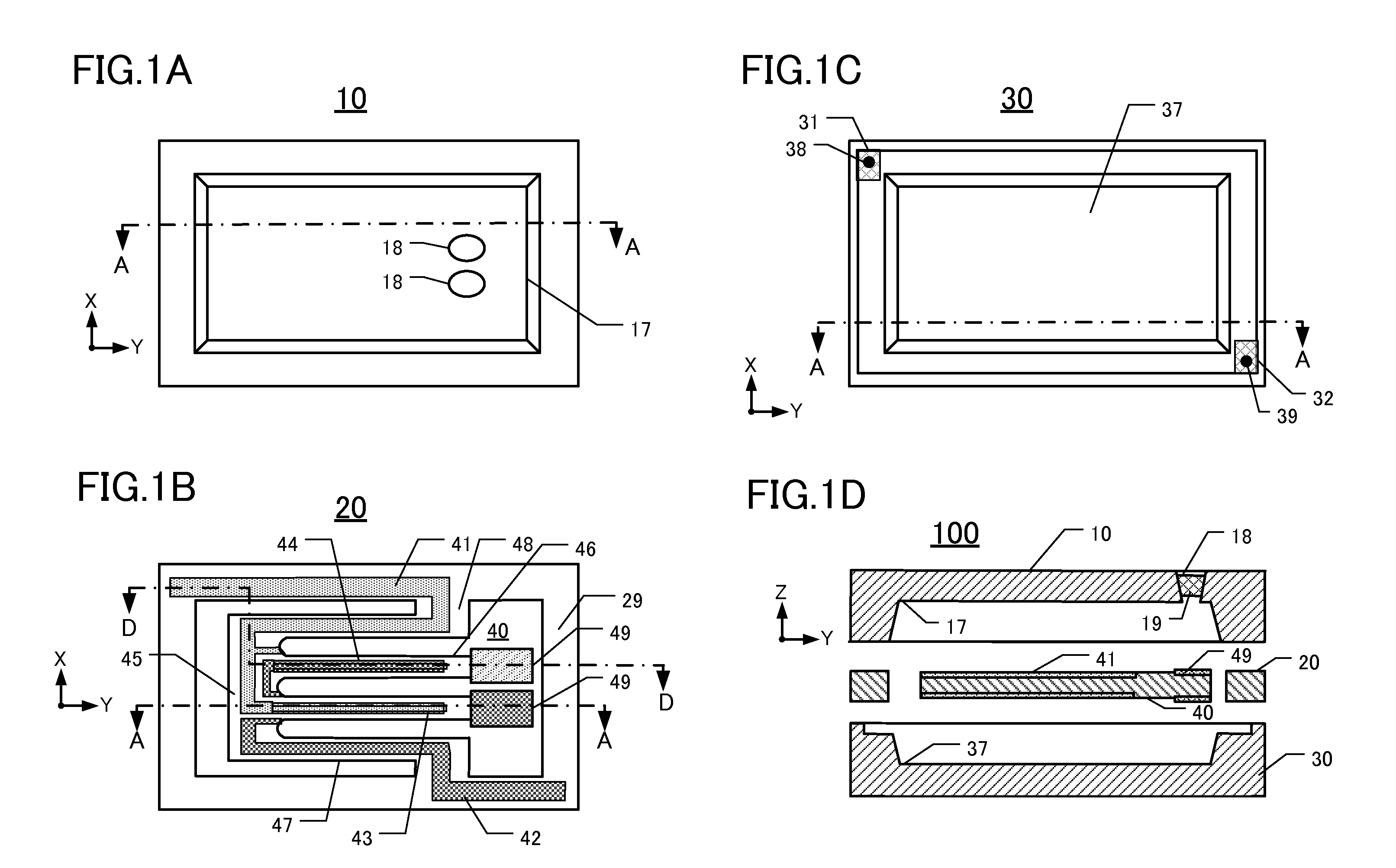

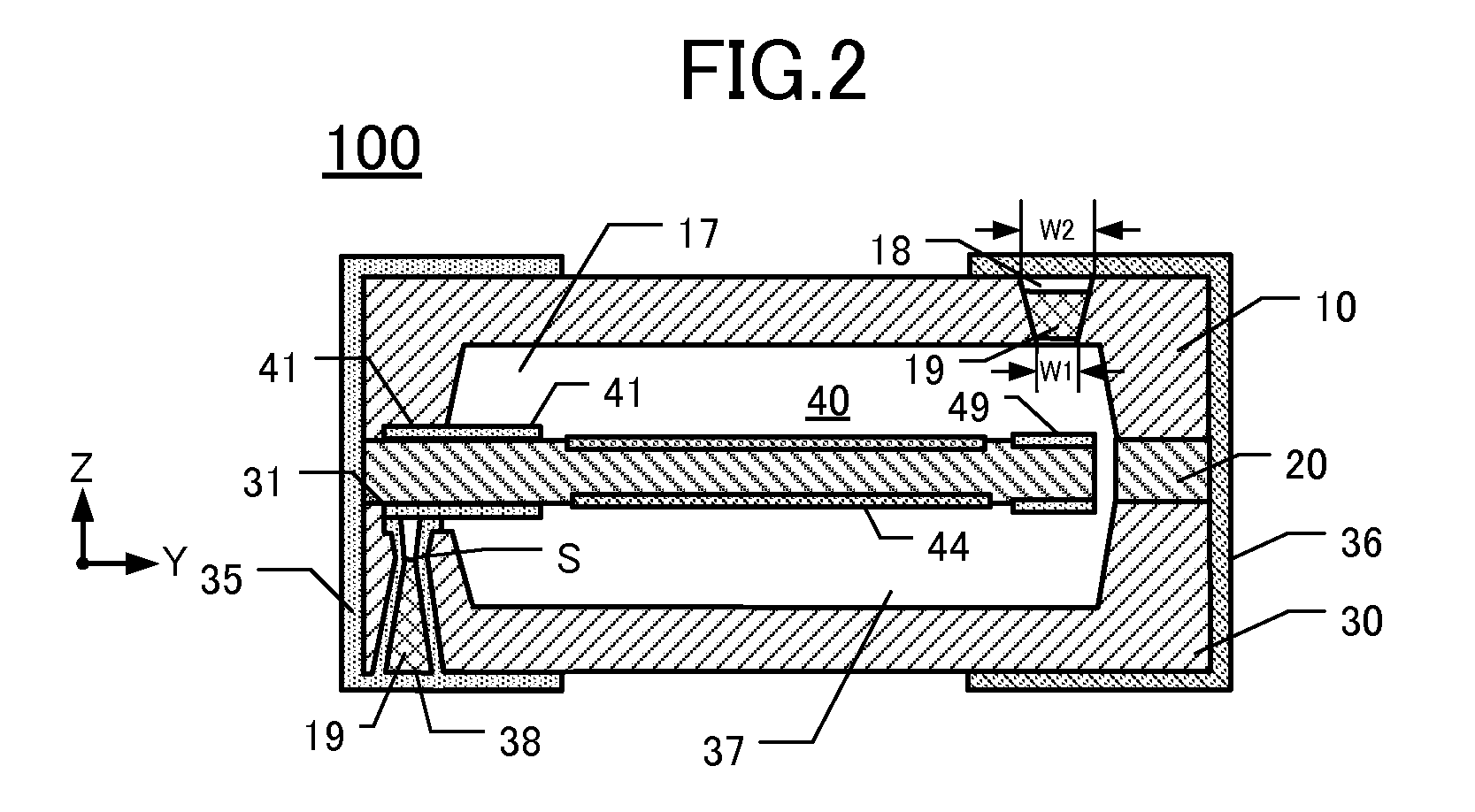

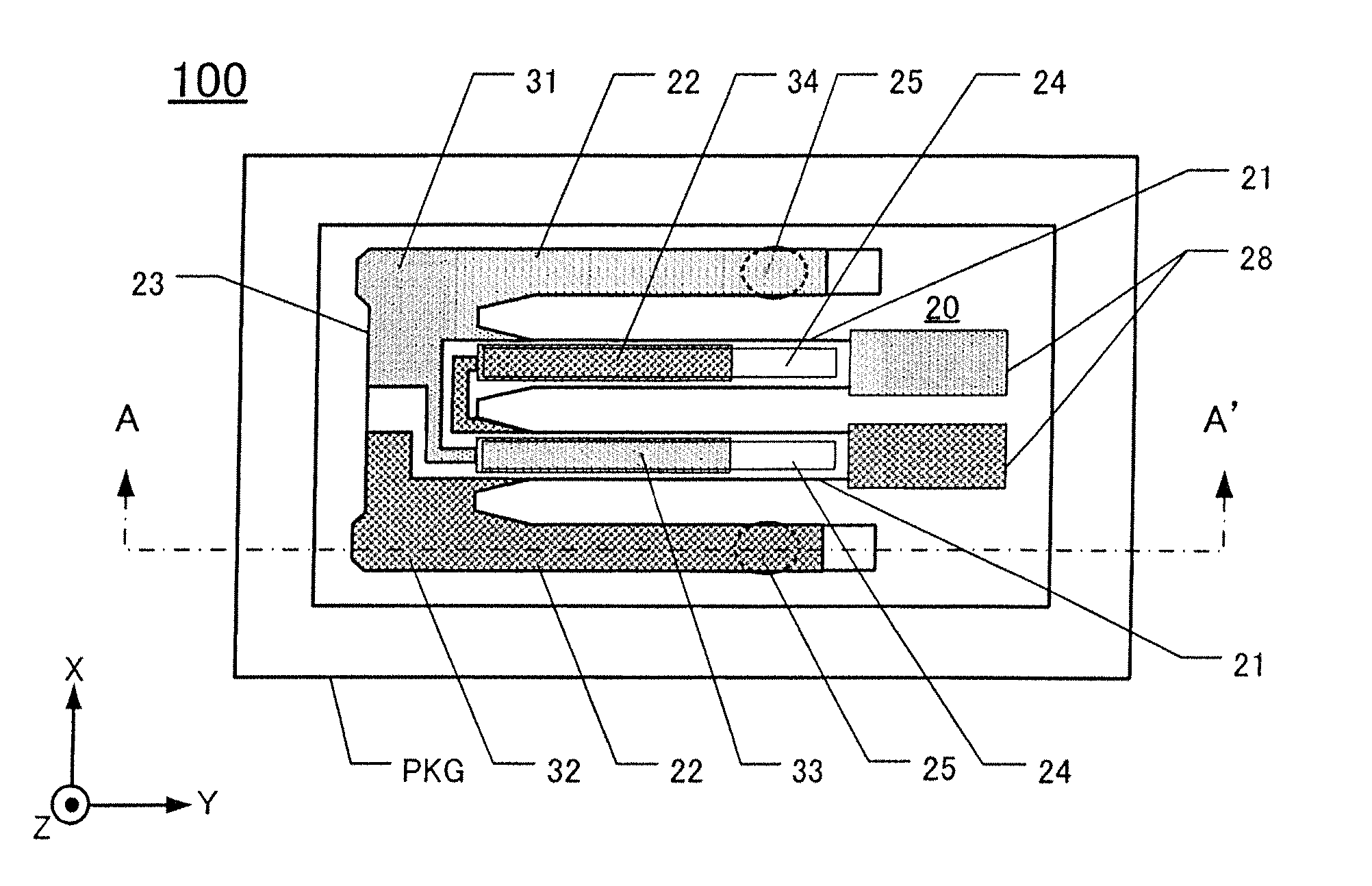

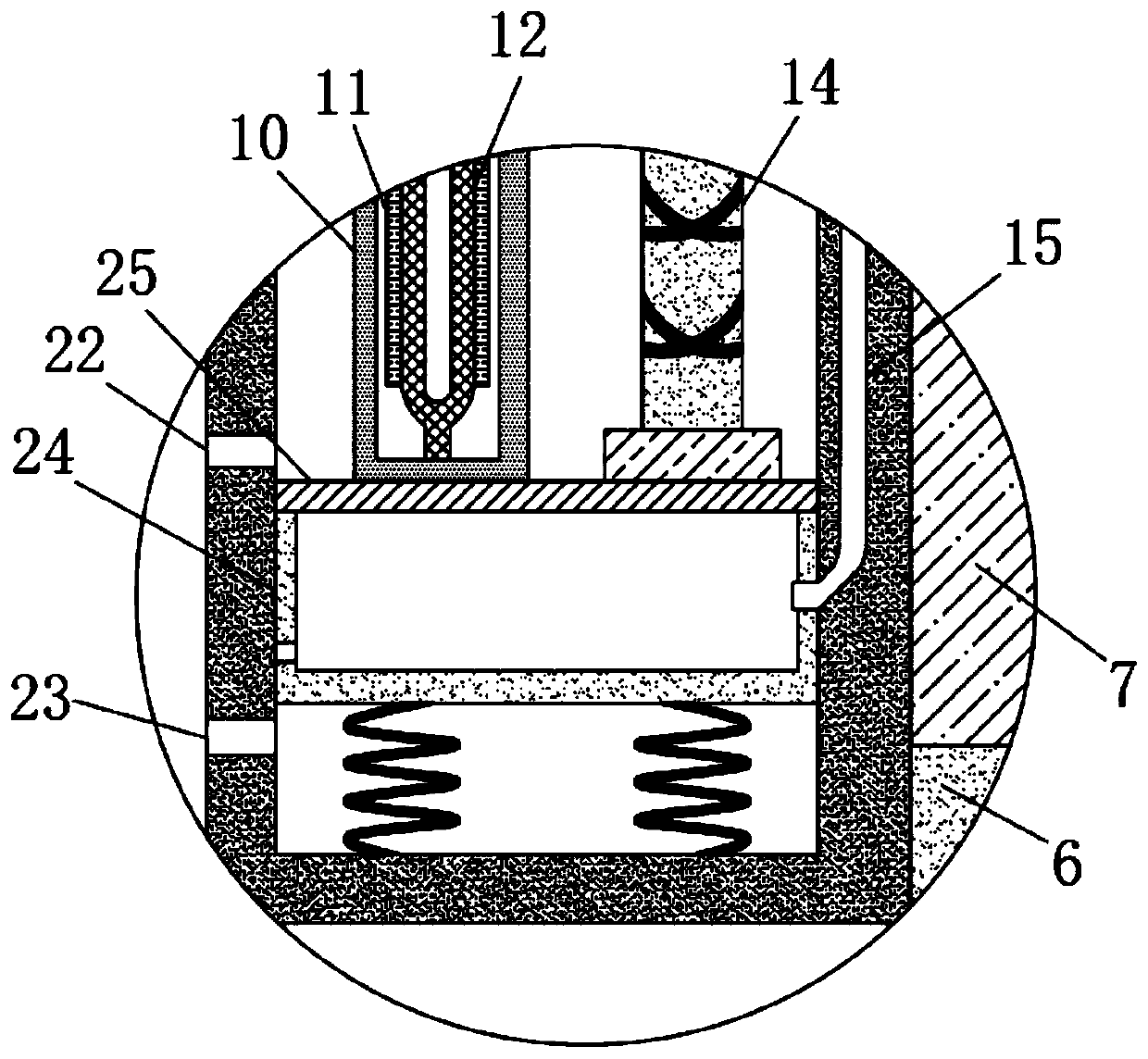

Impact-resistant piezoelectric devices

InactiveUS20100148634A1Reduce variationCompromise impact resistance can provideImpedence networksPiezoelectric/electrostriction/magnetostriction machinesEngineeringFork tuning

Piezoelectric devices are disclosed that include a chip plate sandwiched between a lid plate and a base plate. The chip plate includes a tuning-fork type piezoelectric vibrating piece surrounded by an outer frame. The lid plate includes a concavity on its inner major surface, and the base plate includes a concavity on its inner major surface. The lid plate, chip plate, and base plate are bonded together to form a package containing the piezoelectric vibrating piece. The tuning-fork type piezoelectric vibrating piece includes a base having an X-direction width and at least pair of vibrating arms extending from the base in a Y-direction. The tuning-fork type piezoelectric vibrating piece is coupled to the outer frame by supporting arms extending in the Y-direction outboard of the vibrating arms. The concavity of the lid plate includes at least one base-movement “buffer” extending in the X-direction at a location corresponding to the base of the vibrating piece. The concavity of the base plate includes at least one base-movement buffer extending in the X-direction at a location corresponding to the base.

Owner:NIHON DEMPA KOGYO CO LTD

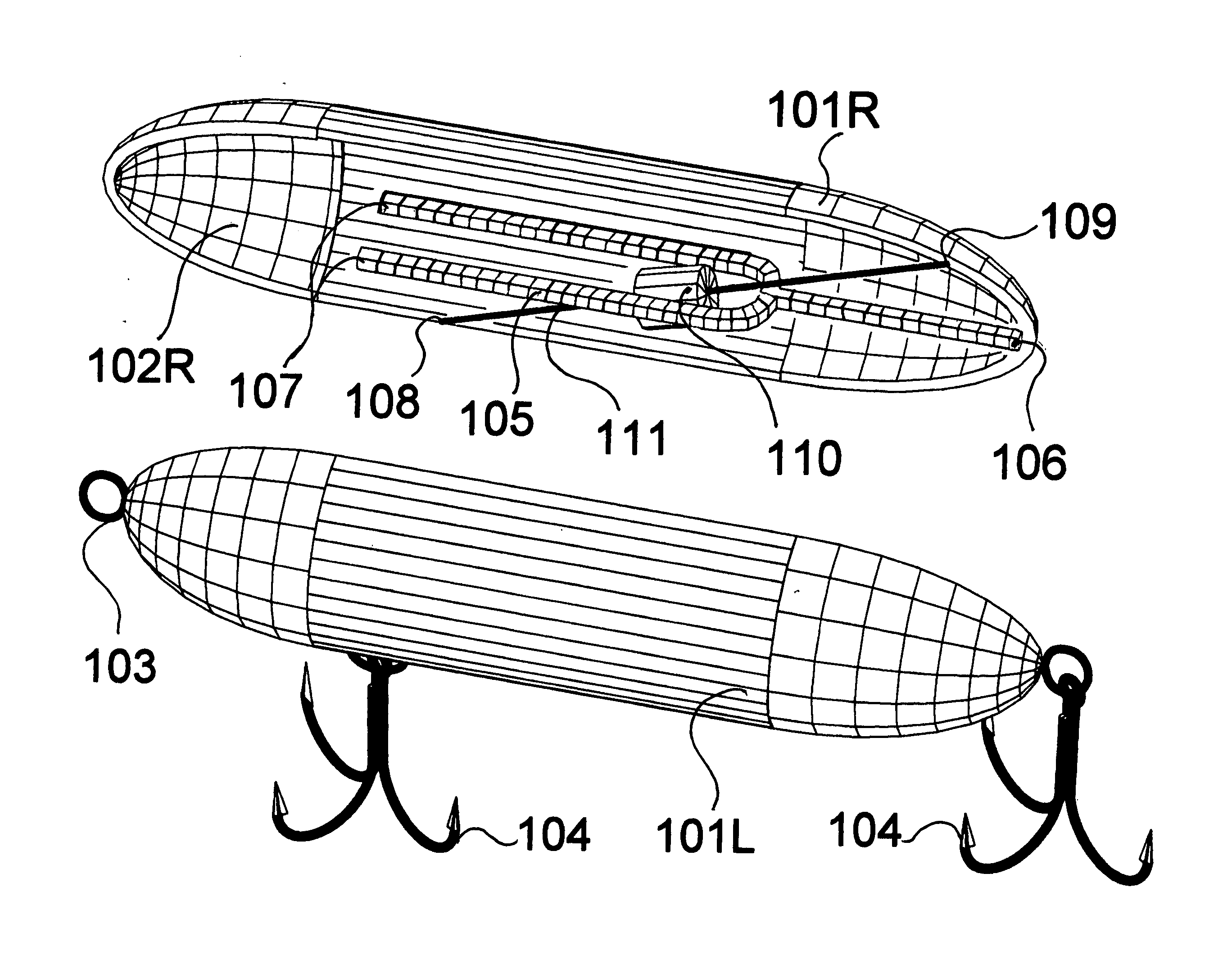

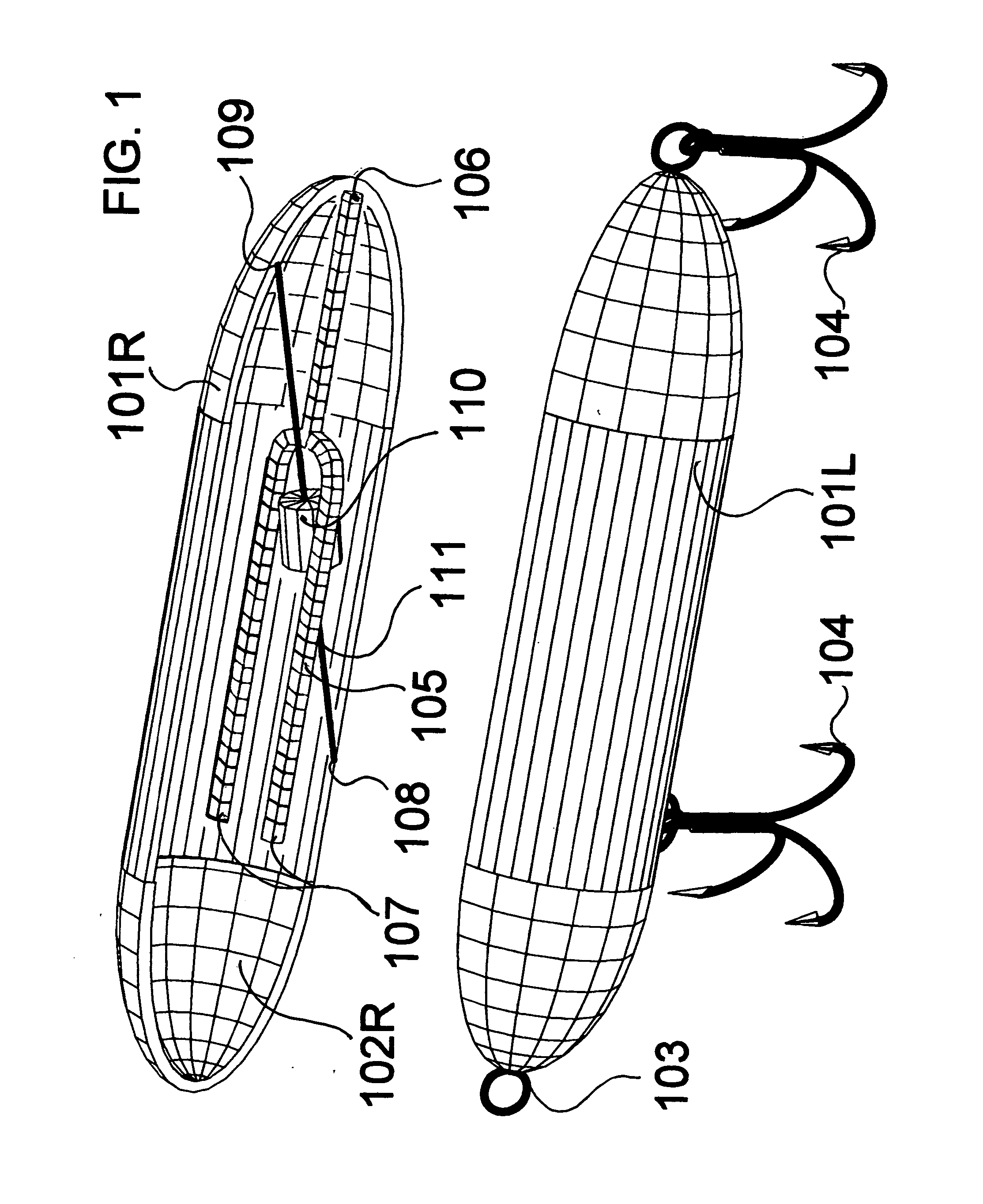

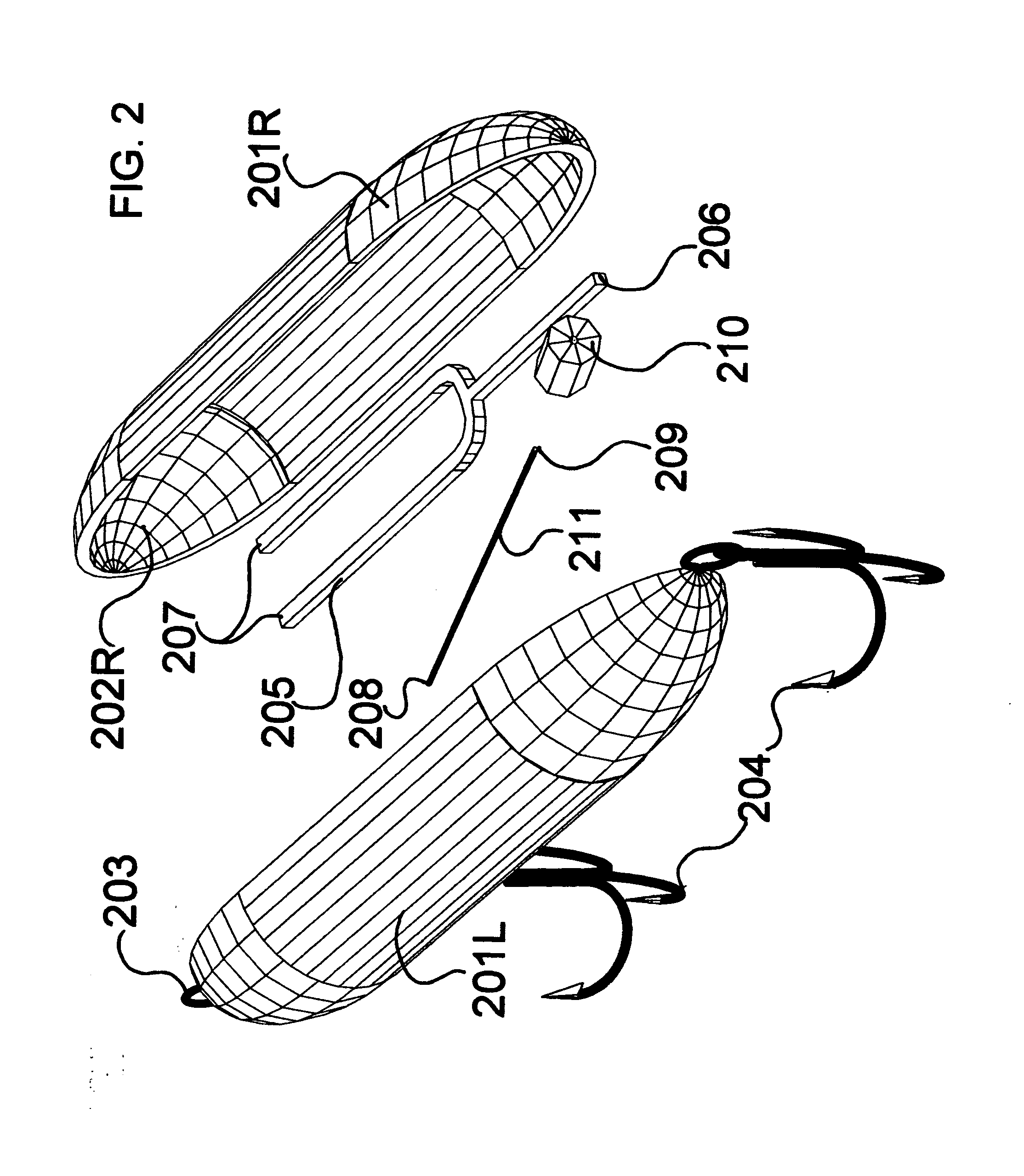

Sound Emitting fishing lure

The disclosed apparatus can be adapted to work in most fishing lures. The apparatus allows the manufacture to adjust the sound(s) emitted by said fishing lure over a wide range, from several thousand hertz down to tens of hertz or lower. The hertz produced by one embodiment of the apparatus can be lowered to the point that the targeted game fish can interpret the action induced into the fishing lure by the disclosed invention more as movement of the fishing lure rather than sound emitted from the fishing lure. The apparatus obtains the energy it requires to operate from the movement of the fishing lure. One embodiment of the disclosed invention comprises a generic shell (top water fishing lure shell), a tuning fork and a pendulum. The stem of tuning fork is mounted to the inside wall of the shell, the pendulum is rotatably mounted to the interior wall of the shell in such a manner as to allow the weighted end of the pendulum to strike the tuning fork while the fishing lure is in use.

Owner:DUGGER RANDLE LEE II

Piezoelectric vibrating pieces and piezoelectric devices comprising same

InactiveUS20110221311A1Not be reduceElectric field is not reducedPiezoelectric/electrostriction/magnetostriction machinesImpedence networksBiomedical engineeringTuning fork

An exemplary tuning-fork type piezoelectric vibrating piece has a rectangular base having upper and lower main surfaces and a pair of vibrating arms extending longitudinally from the base. The vibrating arms also have the upper and lower main surfaces. Each main surface of each vibrating arm defines a respective vibrating-arm groove extending longitudinally into the base. Each main surface of the base has at least one respective step-side surface situated outboard, in an X-axis direction, of each vibrating-arm groove. Each step-side surface is parallel with the respective vibrating-arm groove. A first electrode is situated on the vibrating-arm grooves of the first vibrating arm and on the at least one respective step-side surface on each main surface. A second electrode is situated on the vibrating-arm grooves of the second vibrating arm and on the at least one respective step-side surface on each main surface. The first and second electrodes are energized with different electrical polarities.

Owner:NIHON DEMPA KOGYO CO LTD

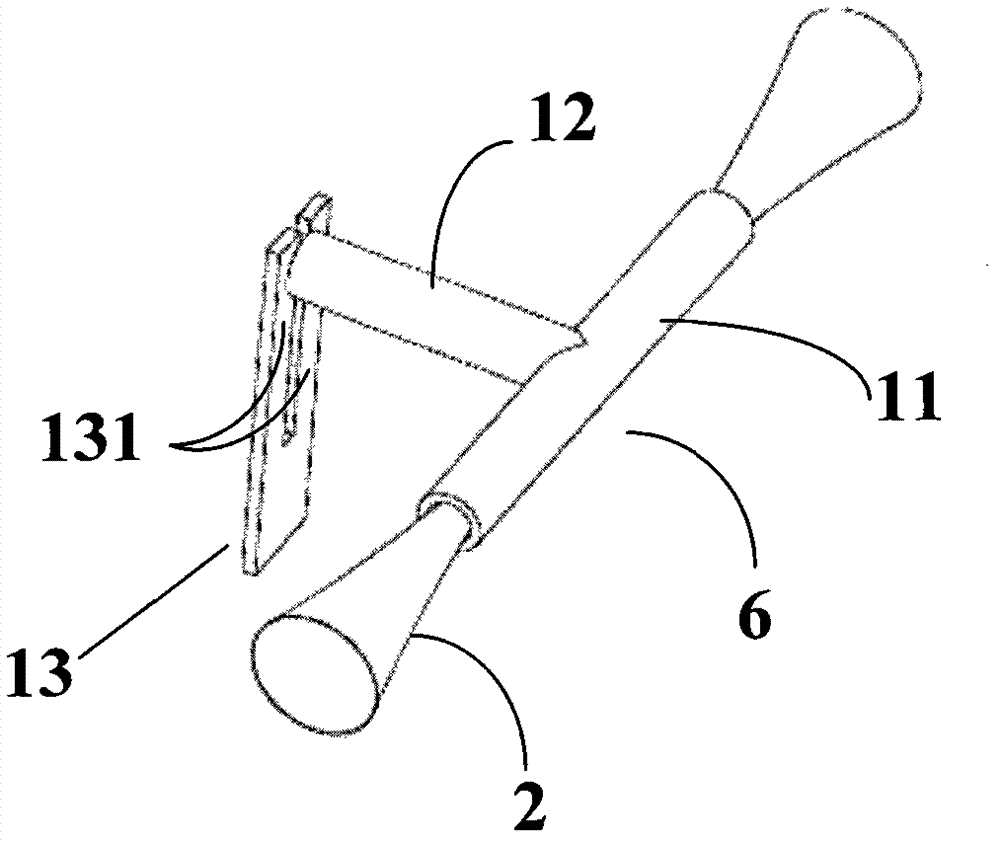

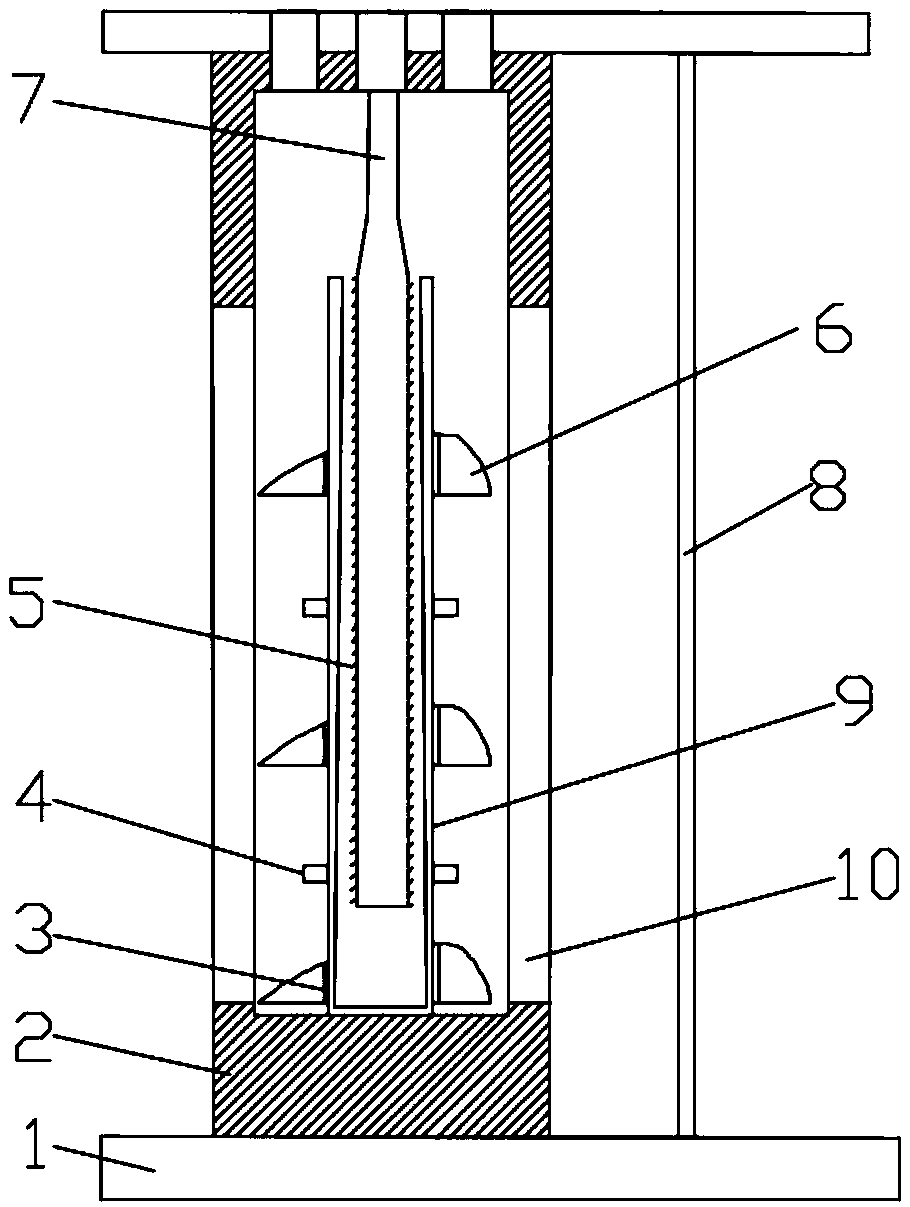

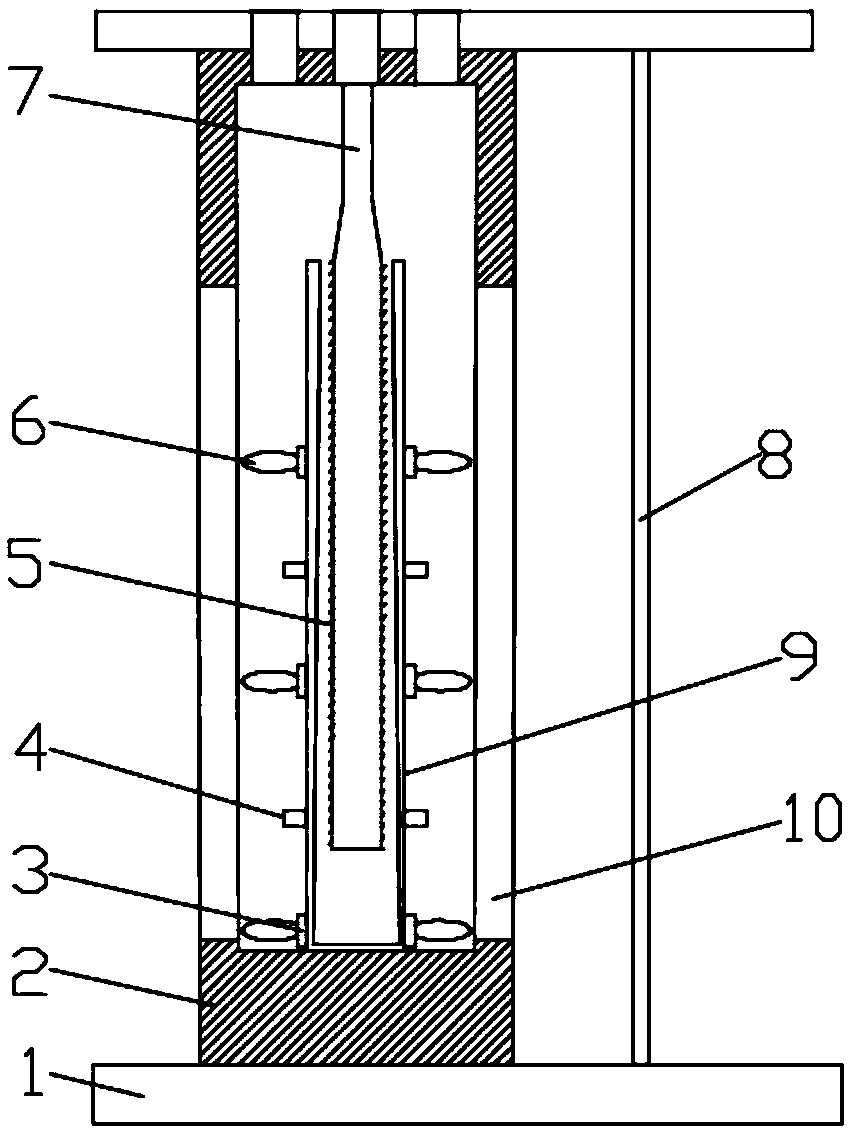

Resonant tuning fork liquid density sensor with piezoelectric actuation and piezoelectric detection

ActiveCN102353612AReal-time online measurementReal-time detectionSpecific gravity measurementLiquid densityPiezoelectric actuators

The invention discloses a resonant tuning fork liquid density sensor with piezoelectric actuation and piezoelectric detection, comprising a tuning fork body, a clamped body, a piezoelectric actuator, a piezoelectric vibration pickup, and a temperature sensor, wherein, the piezoelectric actuator and the piezoelectric vibration pickup are arranged on the clamped body, the generated alternating force is transmitted to the tuning fork body by the piezoelectric actuator to let the tuning fork body produce simple harmonic vibration with intrinsic frequency itself; when immersing the tuning fork body in a liquid under test, the additional mass of the tuning fork body changes so as to let the vibration frequency of the tuning fork body change; by picking up the vibration signal with the piezoelectric vibration pickup, the detection of the vibration frequency of the tuning fork body is realized; because the vibration frequency of the tuning fork body is a monotone function of the liquid density, thus the real-time on-line detection of the liquid density is realized; and the temperature sensor is arranged on the clamped body for real-time detection of the temperature of the liquid under test, and is used for compensating the variation of the elastic modulus of the tuning fork body. According to the invention, the high precision on-line detection of densities of various liquids at different temperature can be realized.

Owner:BEIHANG UNIV

Quartz crystal unit and method for manufacturing a quartz crystal unit and electronic apparatus

InactiveUS7845063B2High-frequency stabilityHigh quality factorPrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblyCapacitanceElectrical polarity

A method for manufacturing a quartz crystal unit comprises forming a quartz crystal tuning fork resonator that is capable of vibrating in a flexural mode of an inverse phase and that has a quartz crystal tuning fork base, and first and second quartz crystal tuning fork tines connected to the quartz crystal tuning fork base. An electrode is disposed on each of two of side surfaces of each of the first and second quartz crystal tuning fork tines so that the electrodes of the first quartz crystal tuning fork tine have an electrical polarity opposite to an electrical polarity of the electrodes of the second quartz crystal tuning fork tine, a motional capacitance C1 of a fundamental mode of vibration of the quartz crystal tuning fork resonator being greater than a motional capacitance C2 of a second overtone mode of vibration thereof.

Owner:PIEDEK TECHN LAB

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com