Resonator having a tuning fork for a mechanical clock movement

A watch movement and resonator technology, applied to electromechanical clocks, mechanically driven clocks, clocks, etc., can solve problems such as unfavorable precise operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

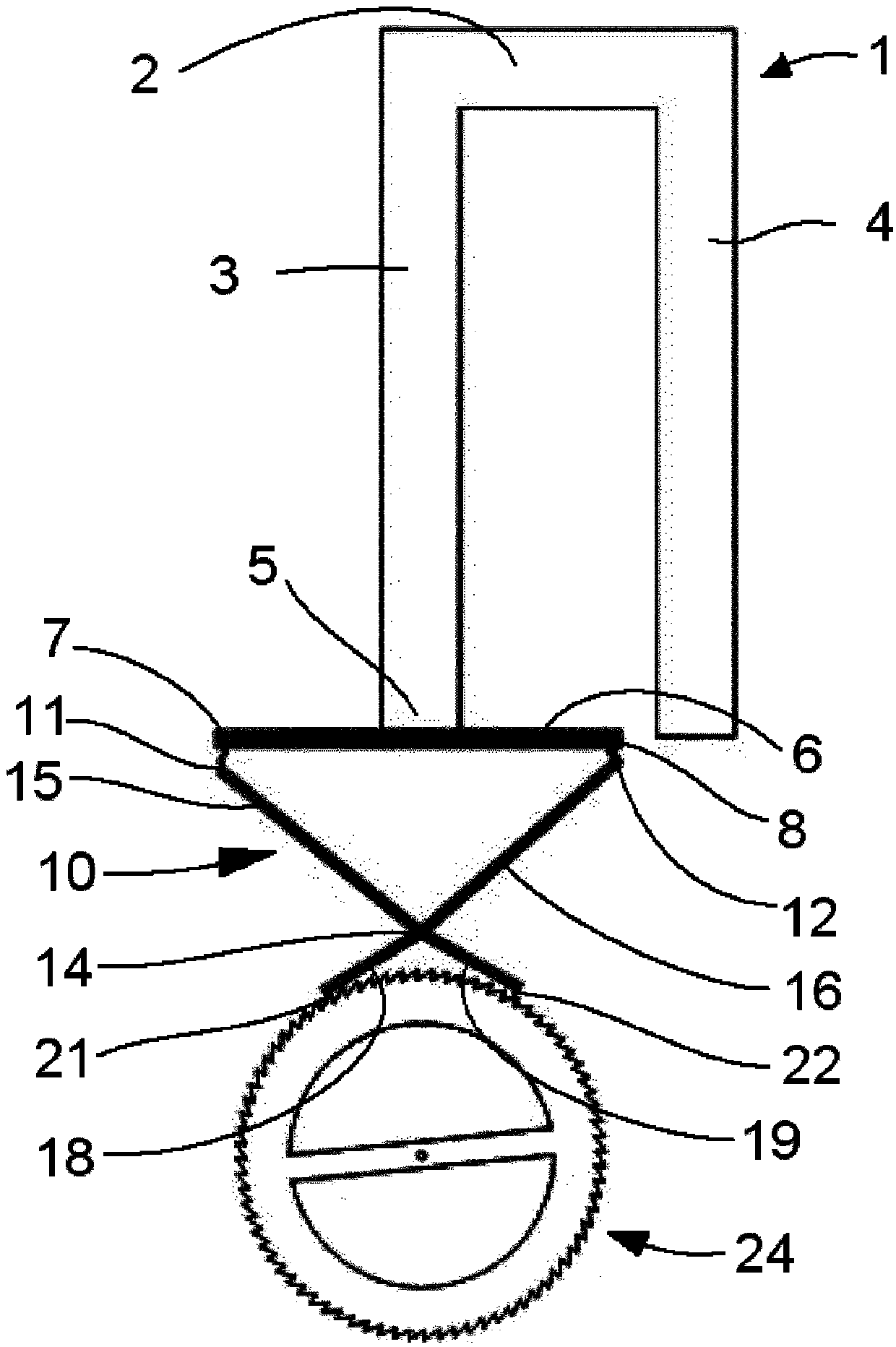

Embodiment Construction

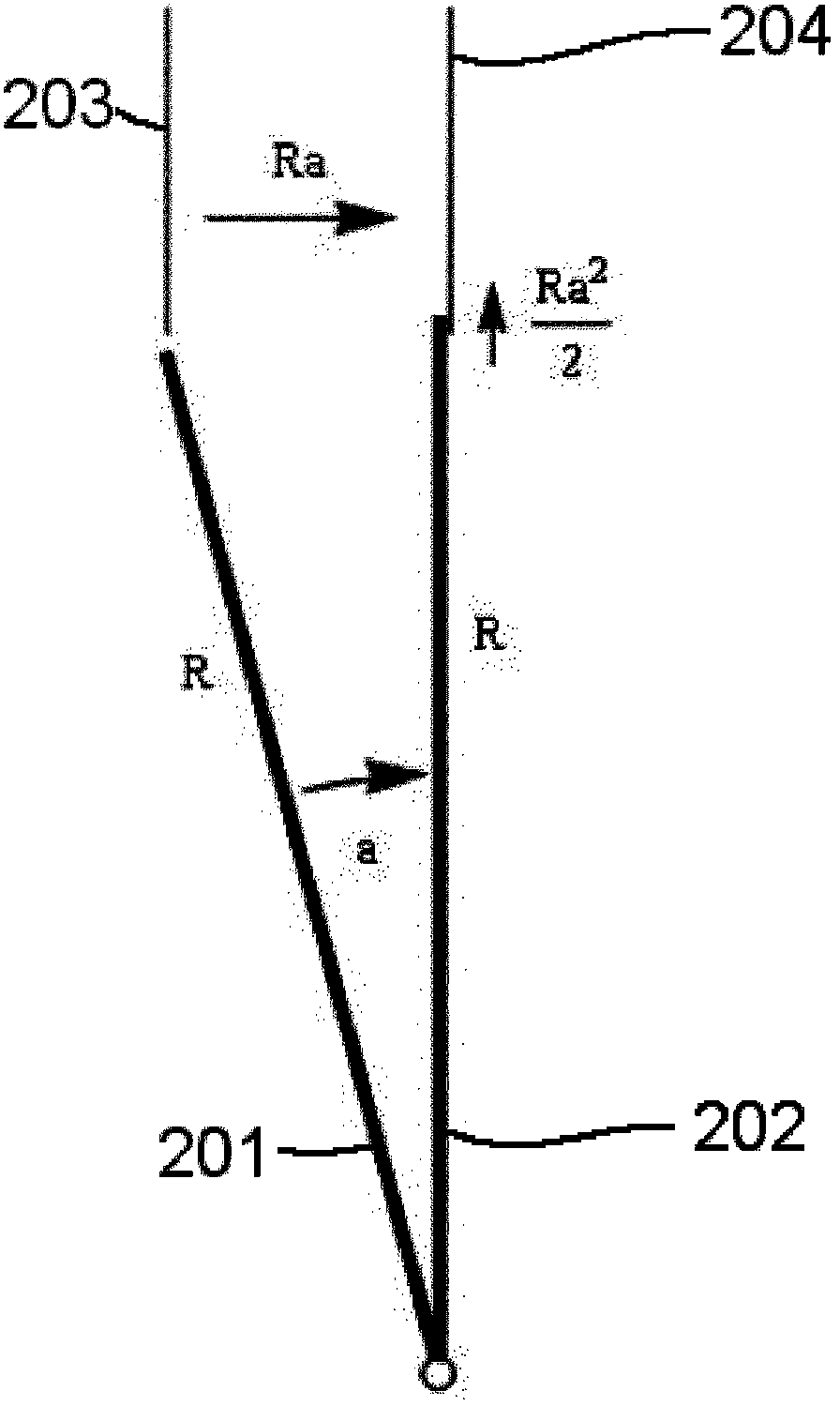

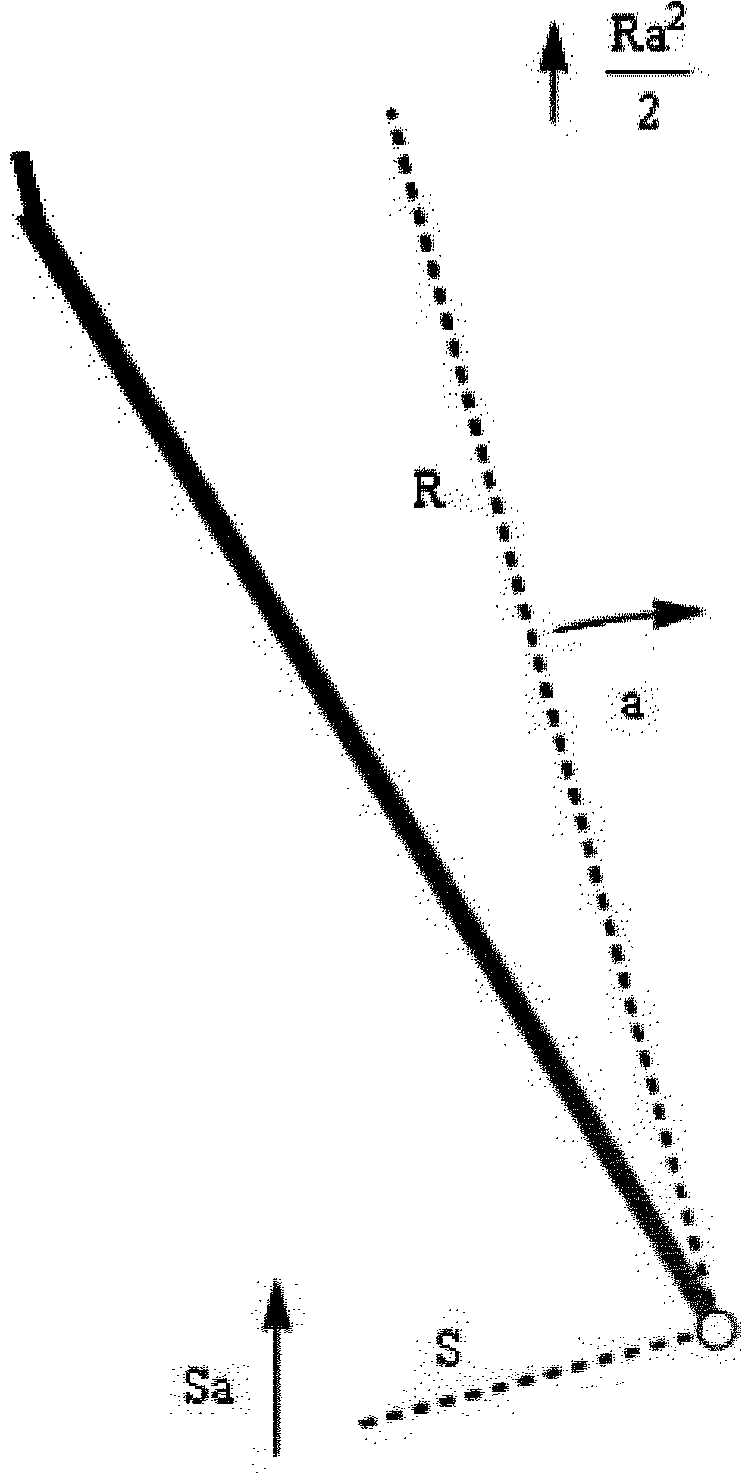

[0051] Figure 1a and 1b A schematic diagram of the limitations considered when implementing the invention, more particularly in terms of geometry, ensuring the correct cooperation between the tuning fork prong and the escapement pallet assembly fork.

[0052] Figure 1a The movement of a pallet assembly of radius R is roughly illustrated to determine the movement of its tip between the angles of rotation it covers, between the first and second radii, in the direction of the second radius, i.e. approximately What relationship exists along the axis of the tuning fork fork.

[0053] Thick lines 201 and 202 illustrate the first and second positions, generally indicated by thin lines 203 and 204 , that the pallet assembly can adopt when it pivots in response to a push transmitted by the tuning fork tine.

[0054] More specifically, when the pallet assembly is in position on line 201, the tuning fork prong (line 203) needs to be able to move past the first of its tines without tou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com