Resonant pressure sensor and manufacturing method thereof

A pressure sensor and resonant technology, applied in the fields of micro-inertial sensors, resonant pressure sensors and their preparation, can solve the problems of accuracy being affected by co-vibration mass, increasing the difficulty of closed-loop control, unstable excitation and detection, etc. Stable excitation and detection, minimization of energy transfer, effect of energy transfer reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

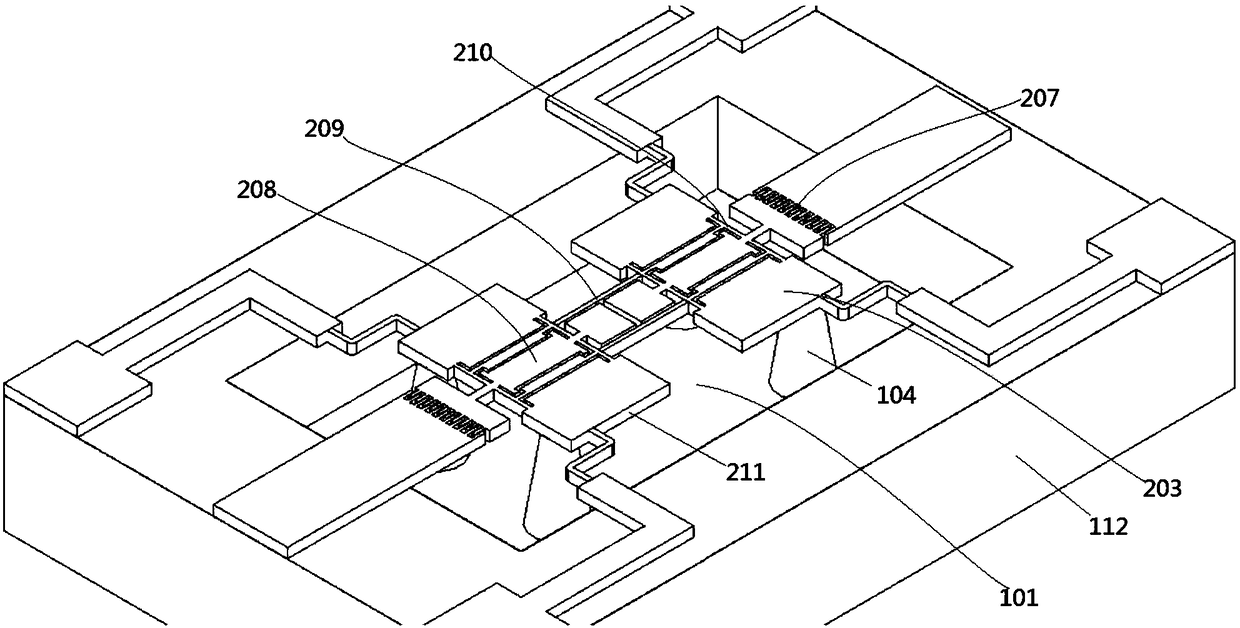

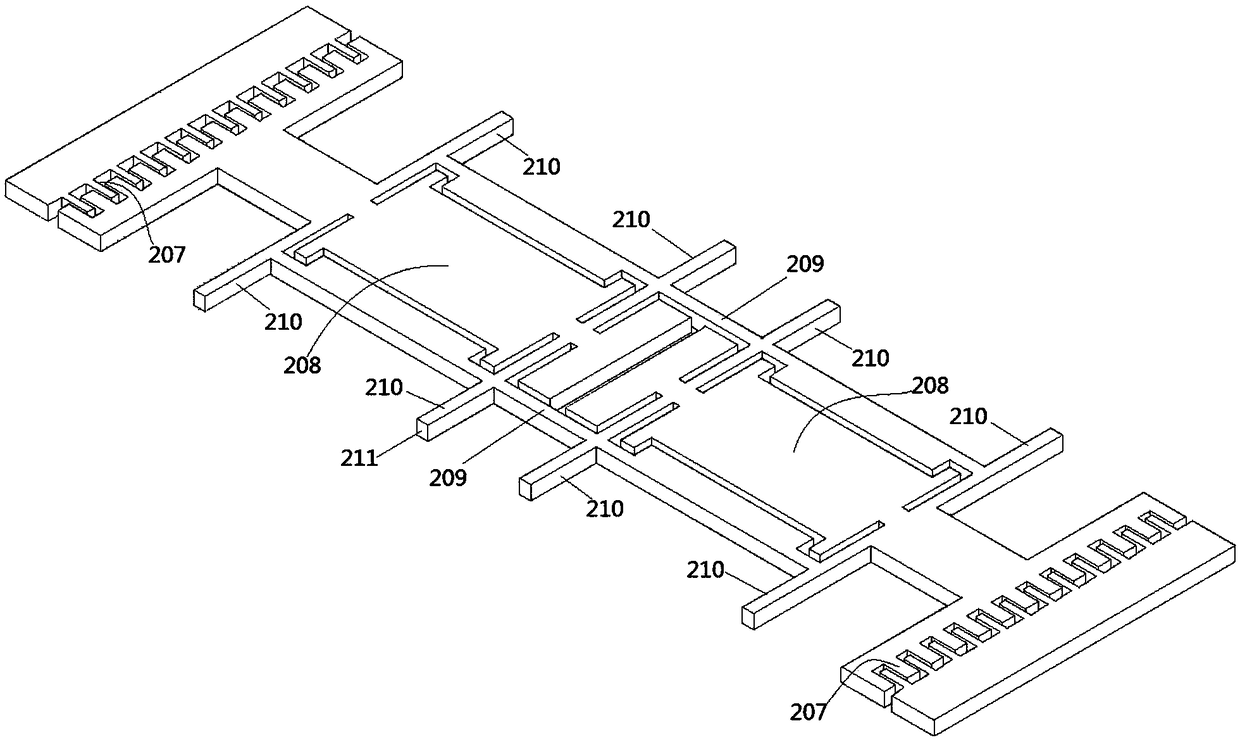

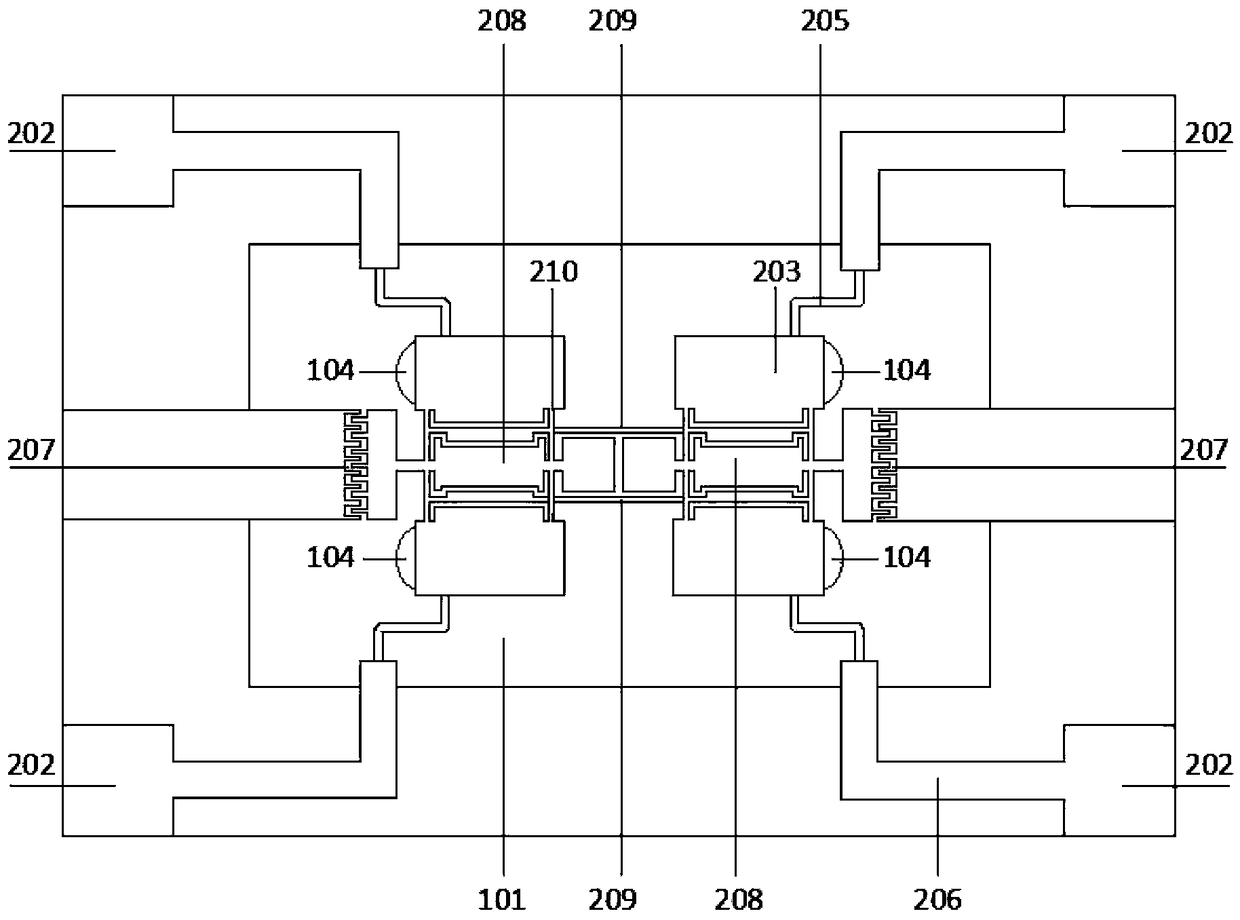

[0032] Such as figure 1 and image 3 As shown, a resonant pressure sensor includes: a rectangular bottom SOI wafer 112, the bottom SOI wafer 112 is in the shape of a zigzag, with a cavity in the middle. A layer of pressure detection sensitive film 101 is provided at the bottom of the cavity; four mutually symmetrical silicon islands 104 are provided in the cavity, and the silicon islands 104 are fixedly connected to the top surface of the pressure detection sensitive film 101 . In the present invention, the stress is transmitted through four silicon islands 104 , specifically, the four silicon islands 104 are symmetrically distributed on the diagonal of the pressure sensitive film 101 . The tops of the four silicon islands 104 are suspended with resonators 211; the four corners of the bottom SOI wafer 112 are provided with contact pads 202, and each contact pad 202 passes through the L-shaped track 206 and the S-shaped curved track 205 and the resonator 211 in turn. connect....

Embodiment 2

[0040] A method for preparing a resonant pressure sensor, comprising the steps of:

[0041] (1) Preparation: prepare two double-sided polished SOI silicon wafers, namely the first SOI silicon wafer 214 with a thickness of 475 um and the second SOI silicon wafer 214 with a thickness of 380 um.

[0042] (2) Etching: On the first SOI silicon wafer, etch the 1um thick wafer alignment key 122, the 325um high silicon island 104 and the 150um thick pressure detection sensitive thin film area to make the bottom SOI wafer 112. The etching in this step can adopt traditional KOH etching (wet etching). Such as Figure 6a shown.

[0043] (3) Silicon-silicon bonding: bonding the etched bottom SOI wafer 112 to the top layer of the second SOI silicon wafer 214 using a bonding technique. The bottom SOI wafer 112 and the second SOI silicon wafer are firstly cleaned by a standard cleaning method for silicon-silicon bonding, followed by bonding in a pure oxygen environment, and annealing at 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com