Gas sensor based on photoacoustic spectrometry

A technology of gas sensor and photoacoustic spectroscopy, which is applied in the direction of color/spectral characteristic measurement, instruments, scientific instruments, etc., can solve the problems that cannot be fully utilized effectively, and cannot realize the coupling of light-excited acoustic wave energy and tuning fork with maximum efficiency, and achieve Sensitivity-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

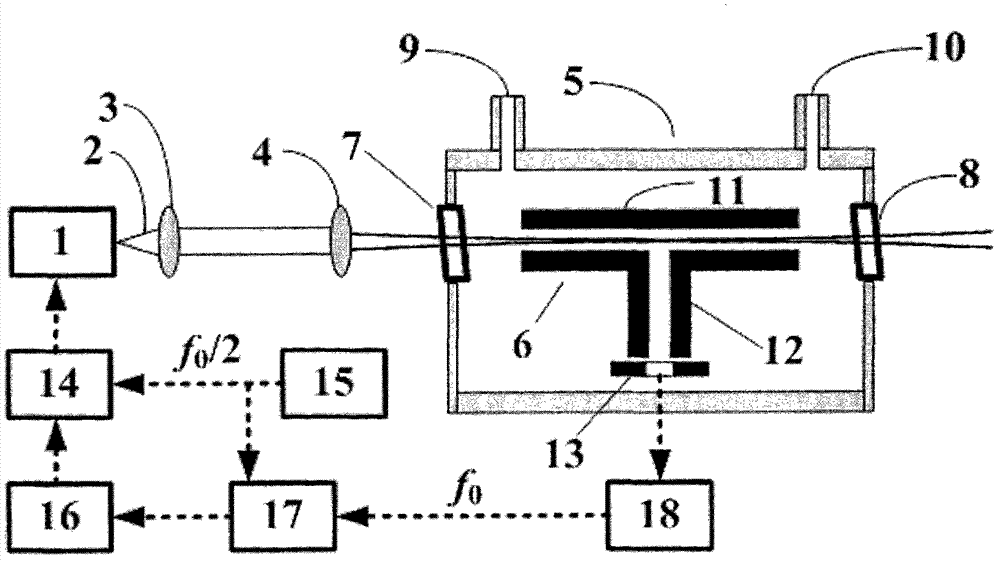

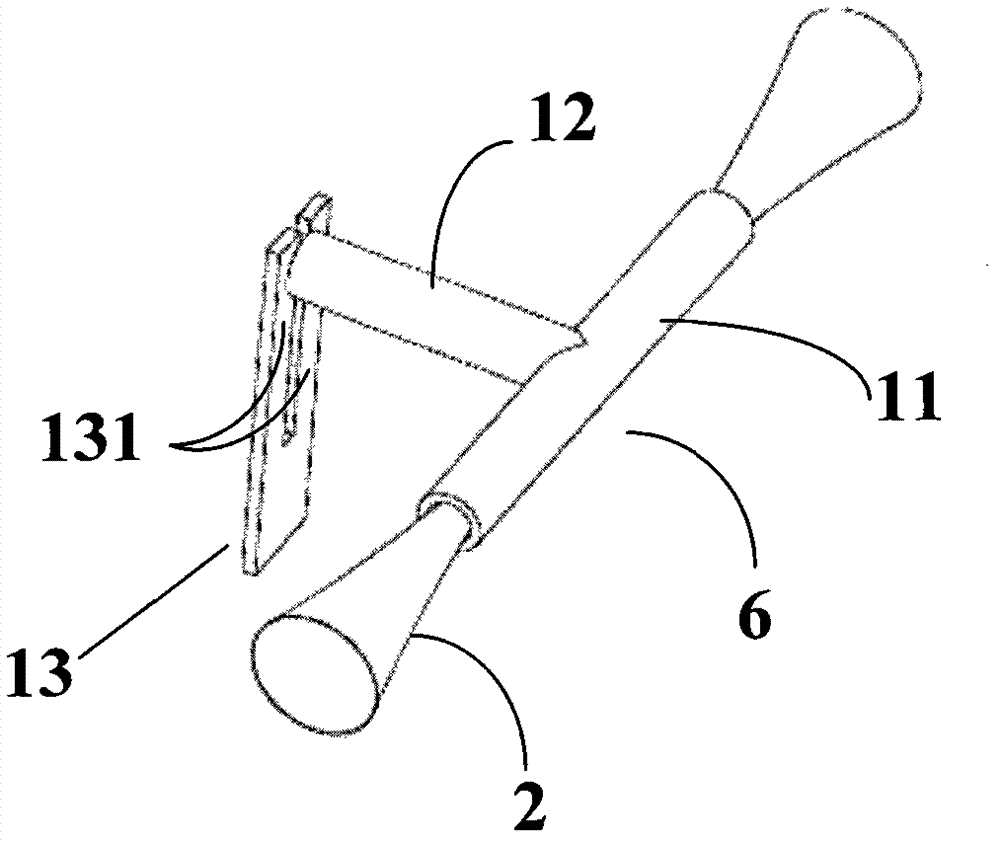

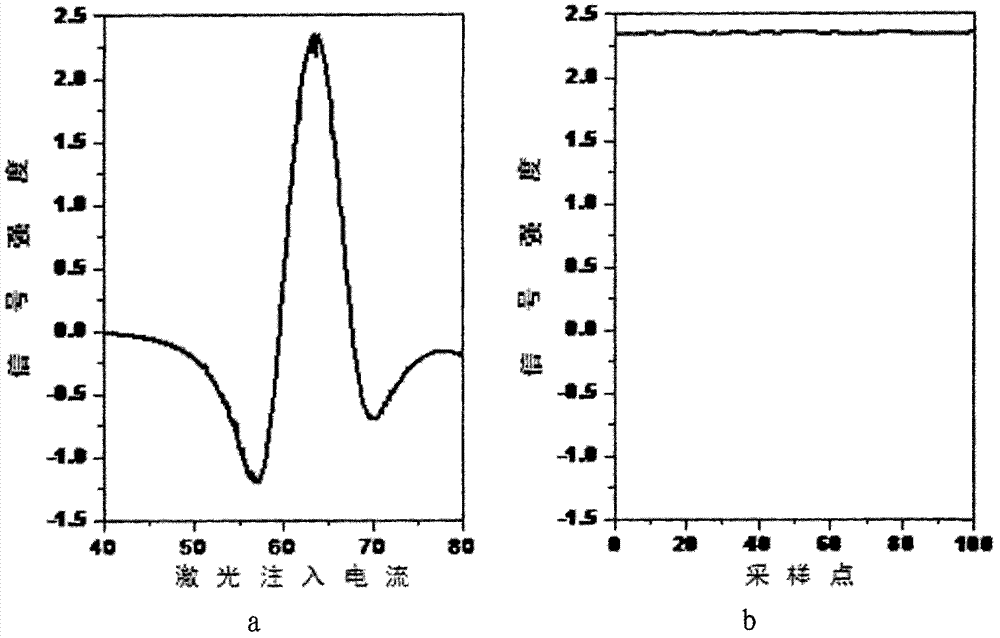

[0016] see figure 1 , figure 2 and image 3 , the composition of the photoacoustic spectrum gas sensor is as follows: a collimator lens 3, a focusing lens 4, an incident window 7 of the sample cell 5, an acoustic resonant cavity 6 and an exit window 8 of the sample cell 5 are sequentially arranged on the optical path 2 of the light source 1, and The circuit that the light source 1 and the quartz tuning fork 13 are connected to. in,

[0017] The wavelength of the light source 1 is the optical absorption wavelength of the gas to be measured, and a distributed feedback semiconductor laser (or quantum cascade laser) of the corresponding wavelength is now selected as the light source 1, and its input end is electrically connected with the output end of the laser controller 14, and the laser control The input terminal of the generator 14 is electrically connected with the output terminal of the function generator 15 and the output terminal of the computer 16 respectively.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com