Patents

Literature

115 results about "Surface mode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

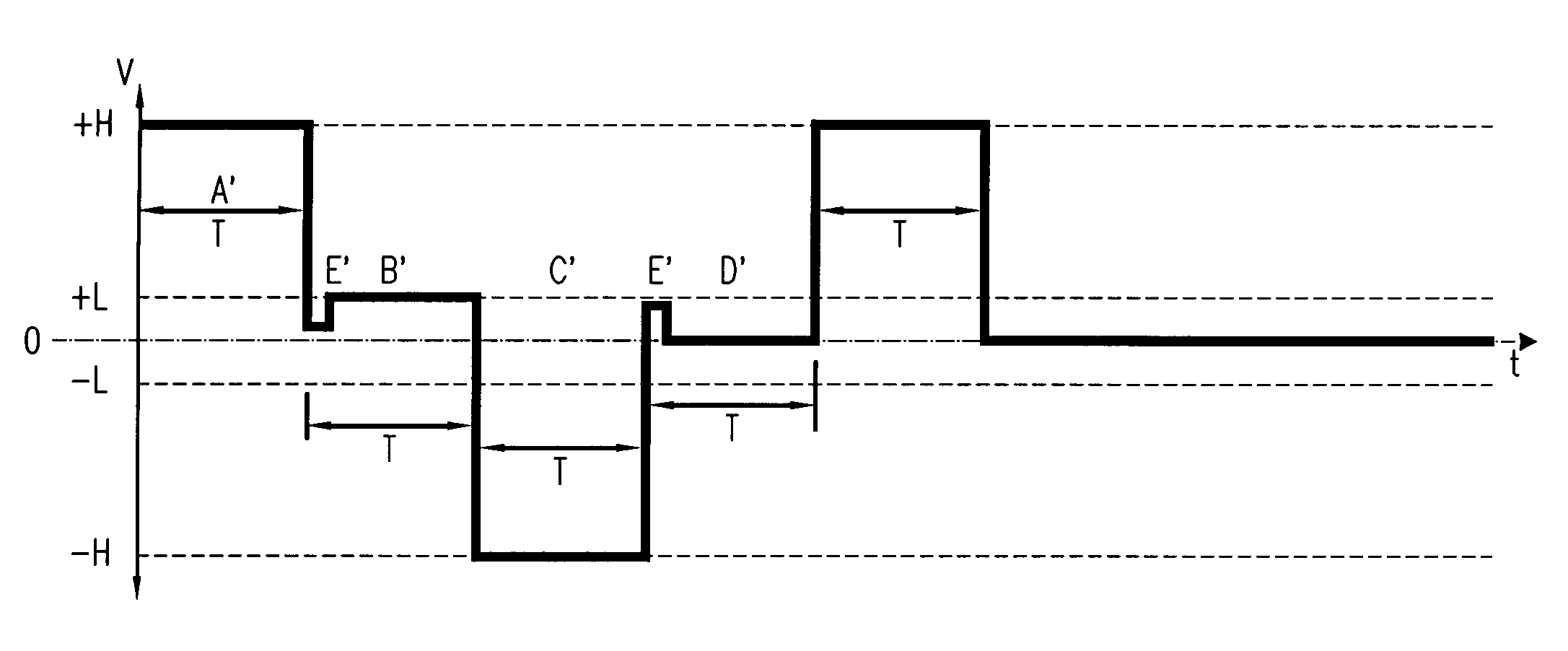

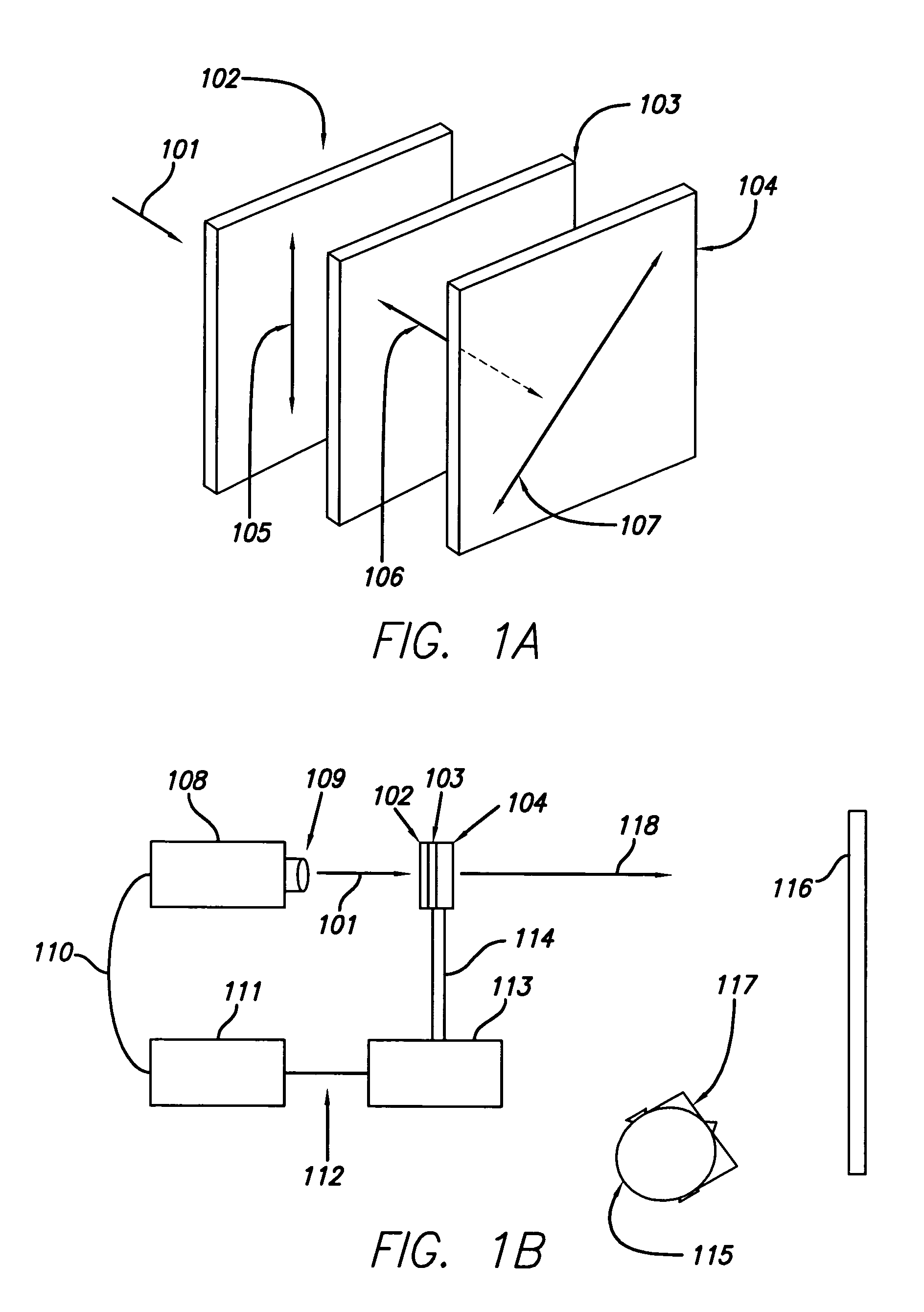

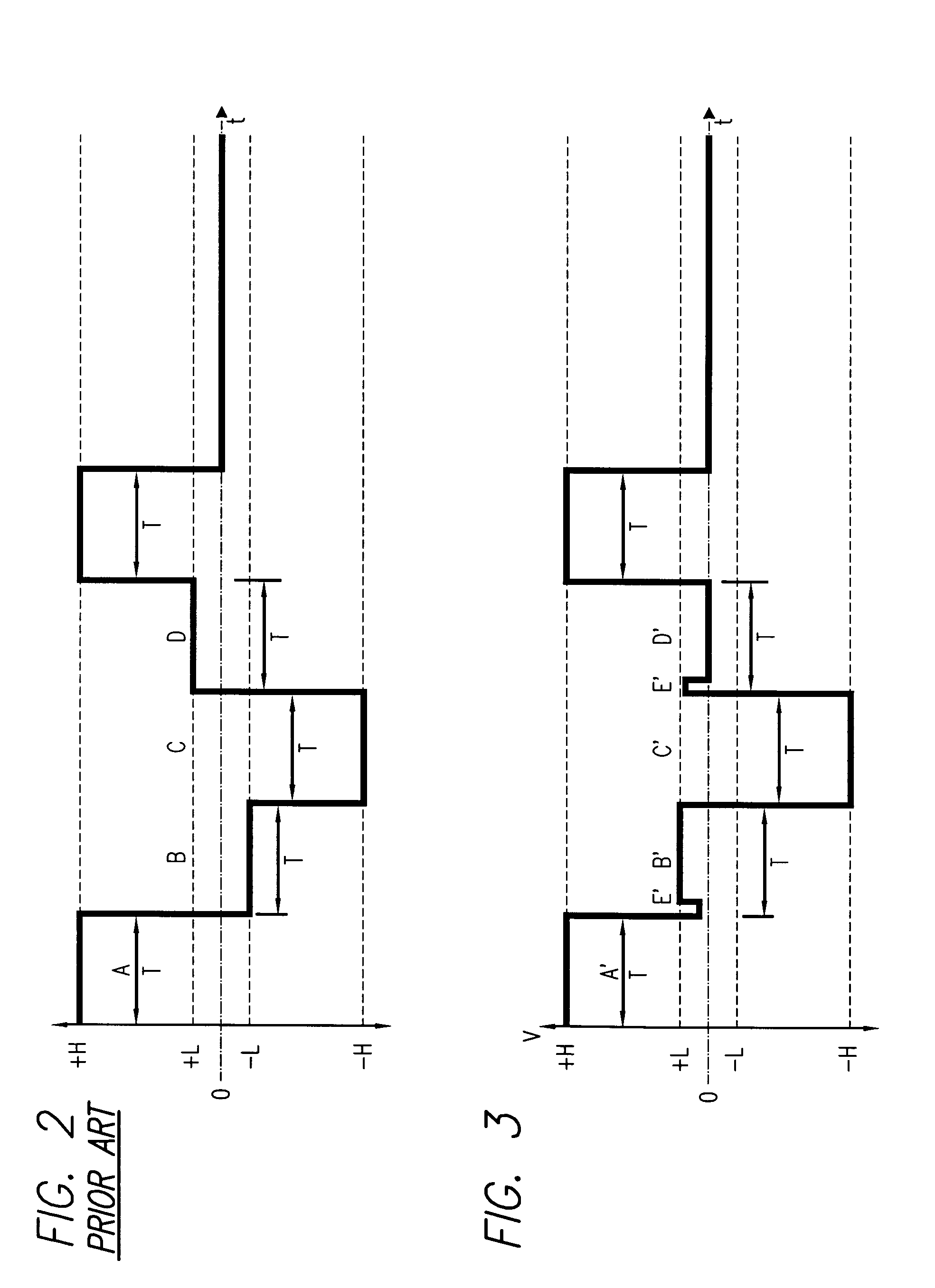

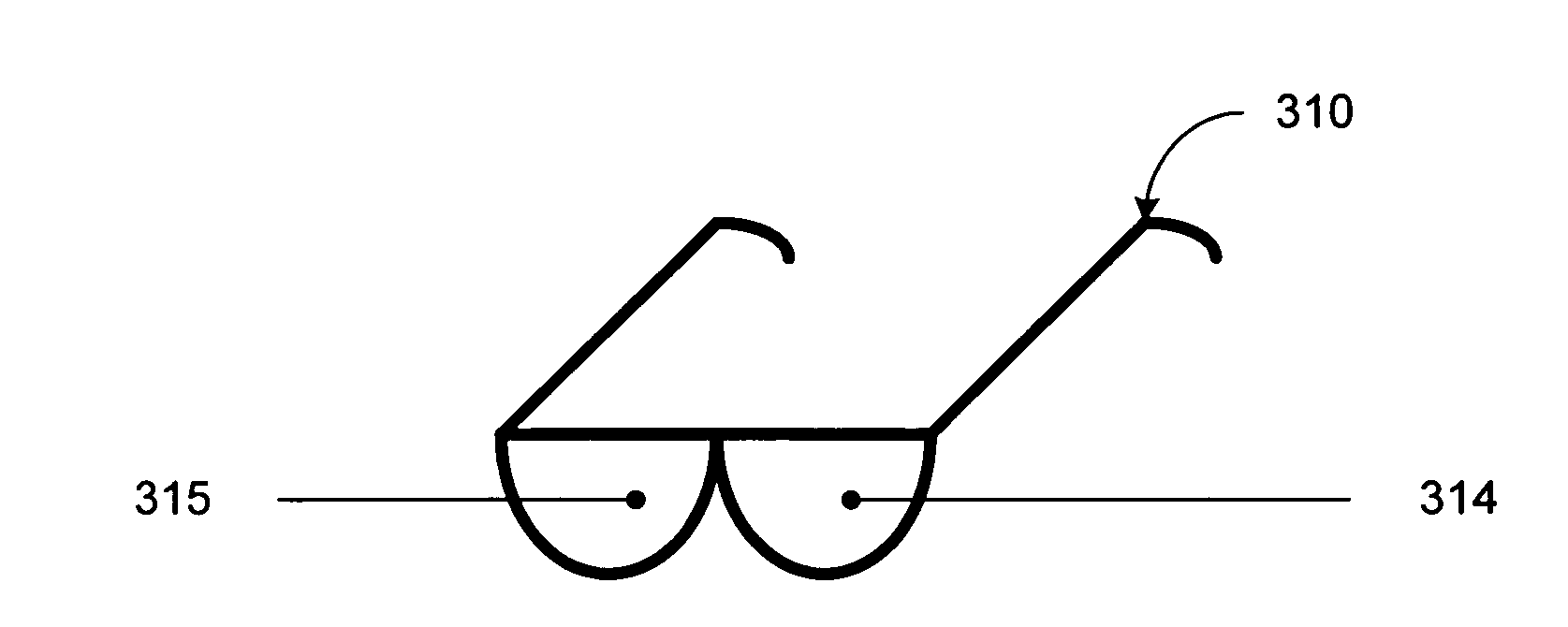

Enhanced ZScreen modulator techniques

Owner:REAID INC

Steady state surface mode device for stereoscopic projection

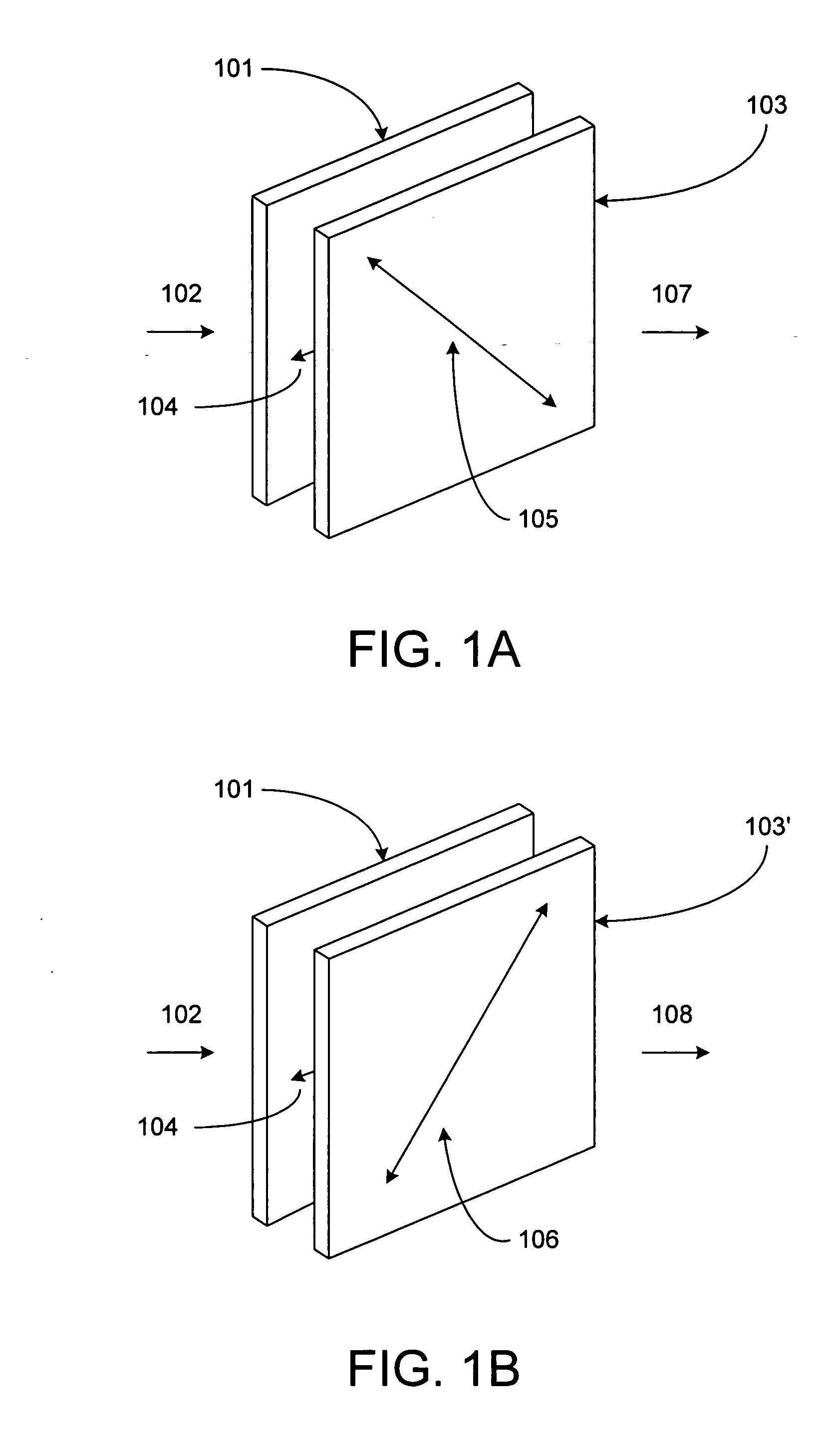

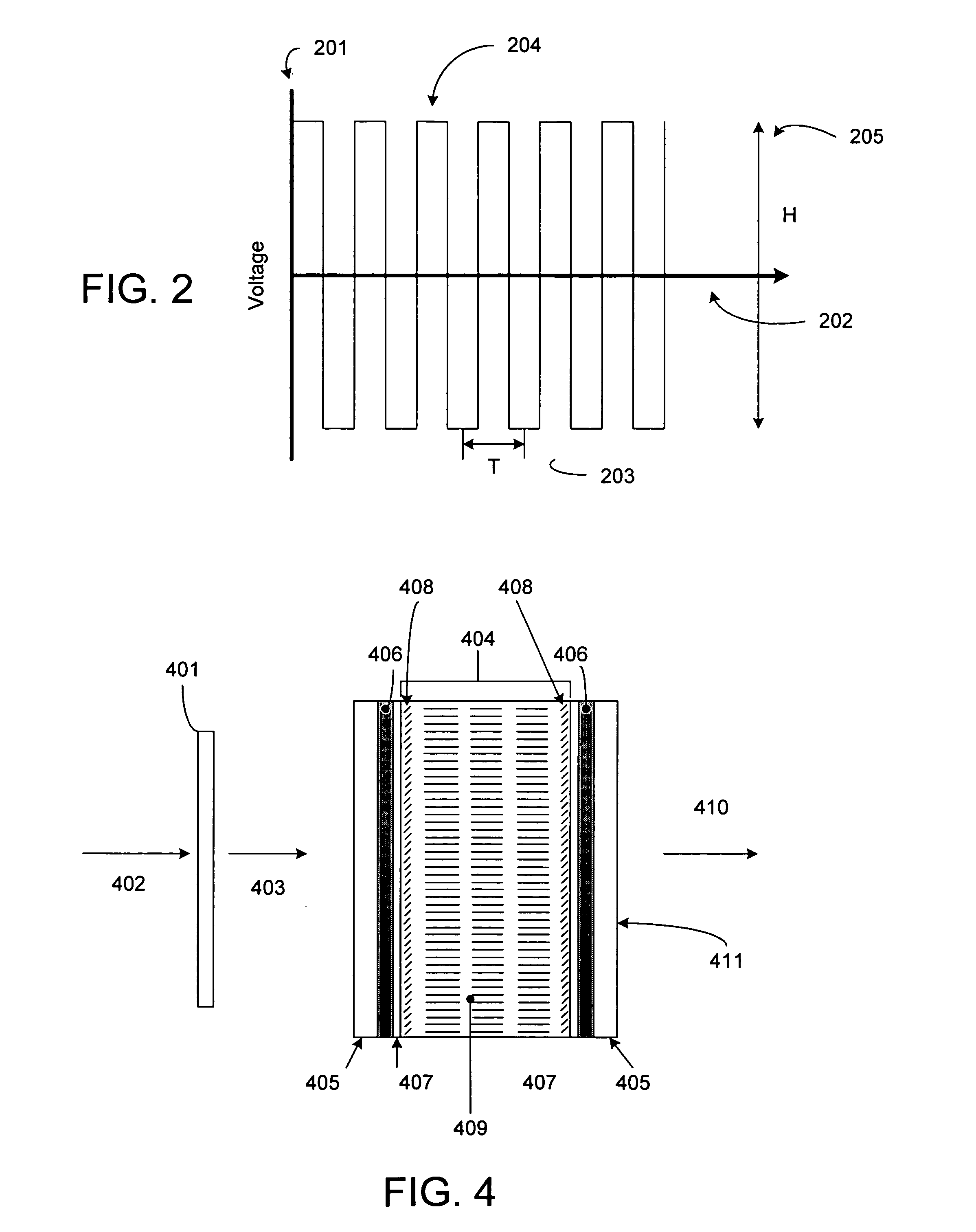

A modulator and system used to display motion pictures is provided. The design comprises a sheet polarizer and a SMD electro-optical modulator configured to operate in a steady state (non-switching) mode. The modulator is formed from two substantially parallel relatively clear plates, such as glass, two coatings of a transparent conductor, such as indium tin oxide, located between the two substantially parallel relatively clear plates, two polyamide layers located between the two coatings of the transparent conductor, and a film of liquid crystal material located between the two polyamide layers.

Owner:REAID INC

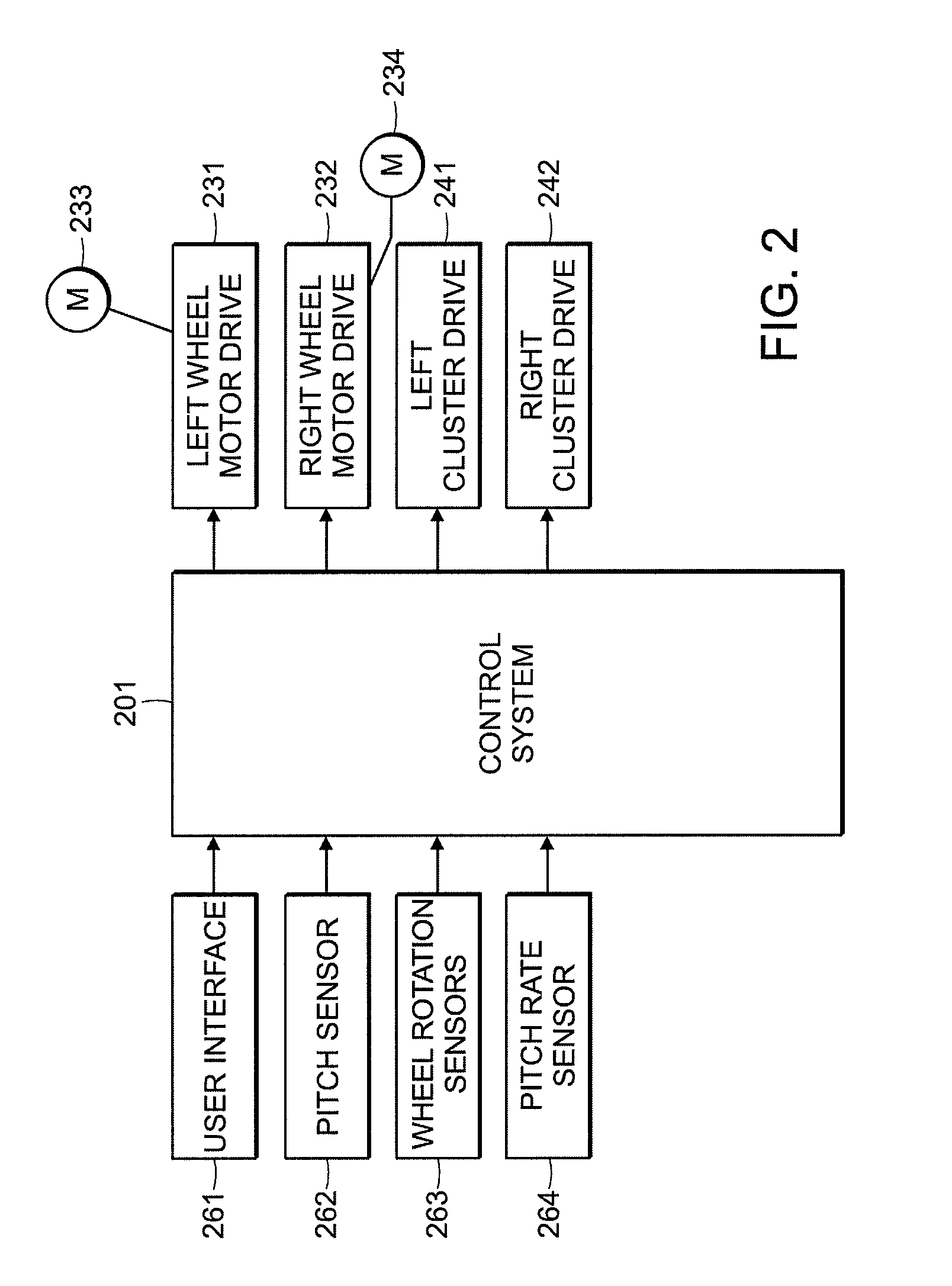

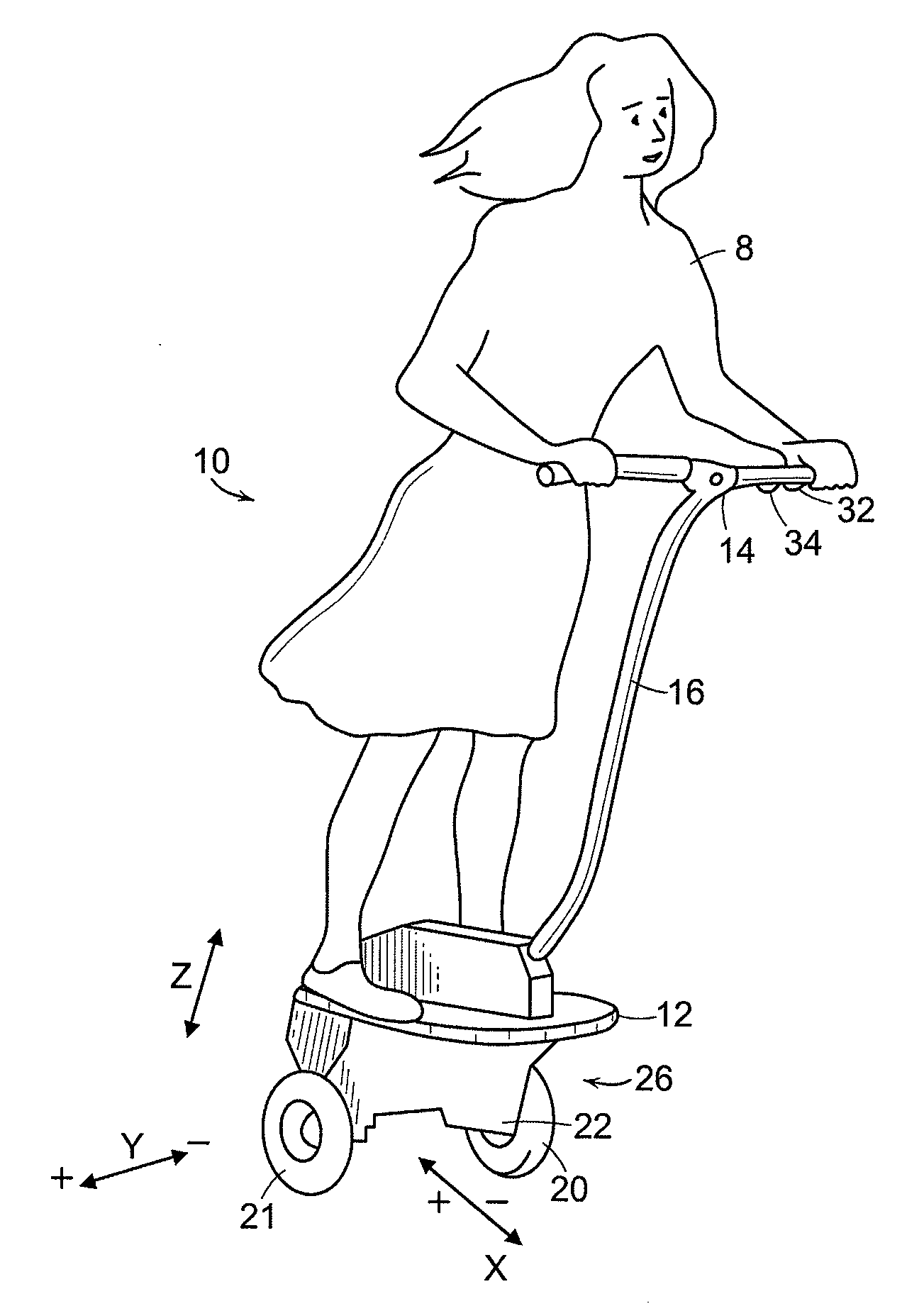

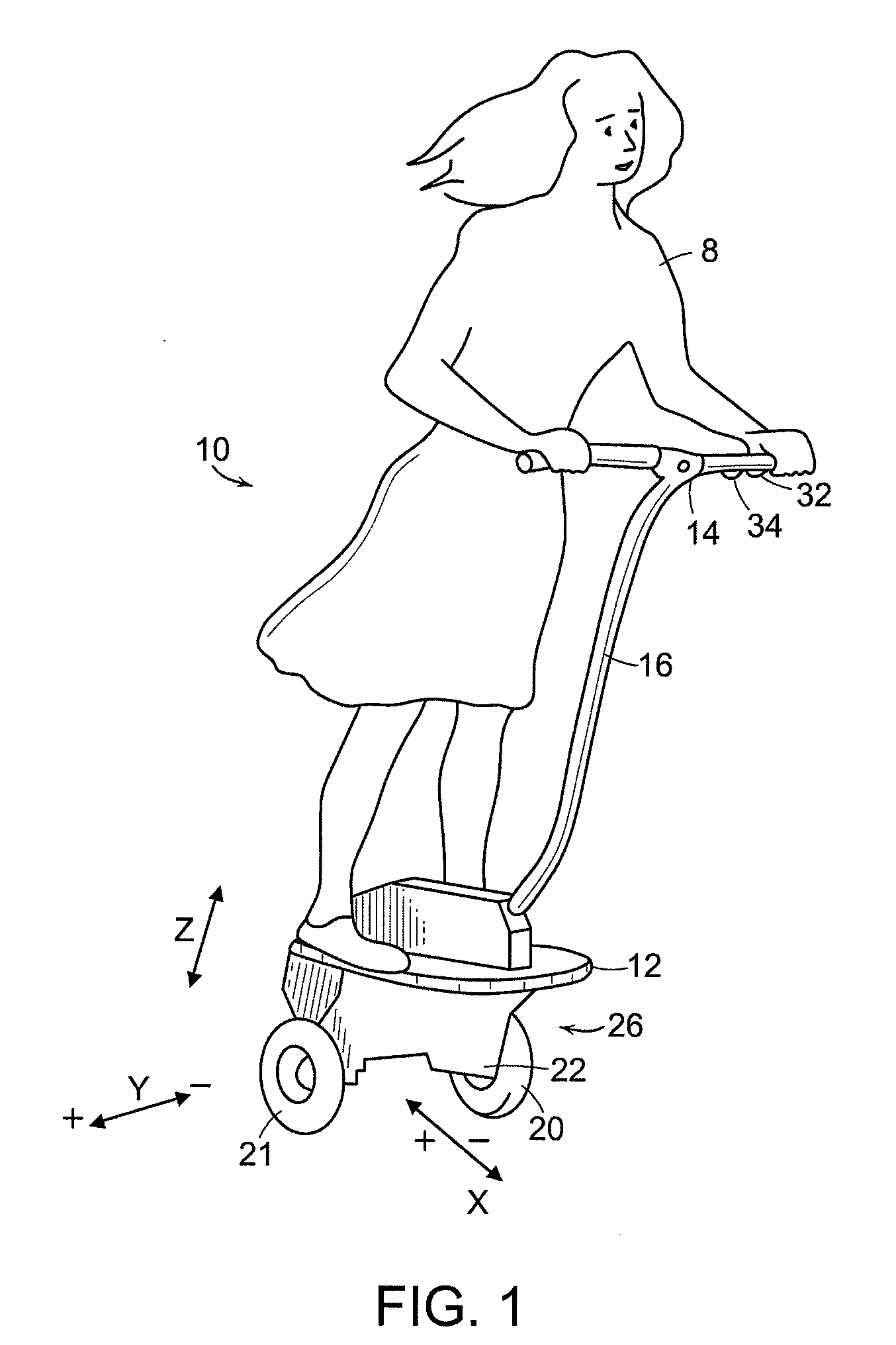

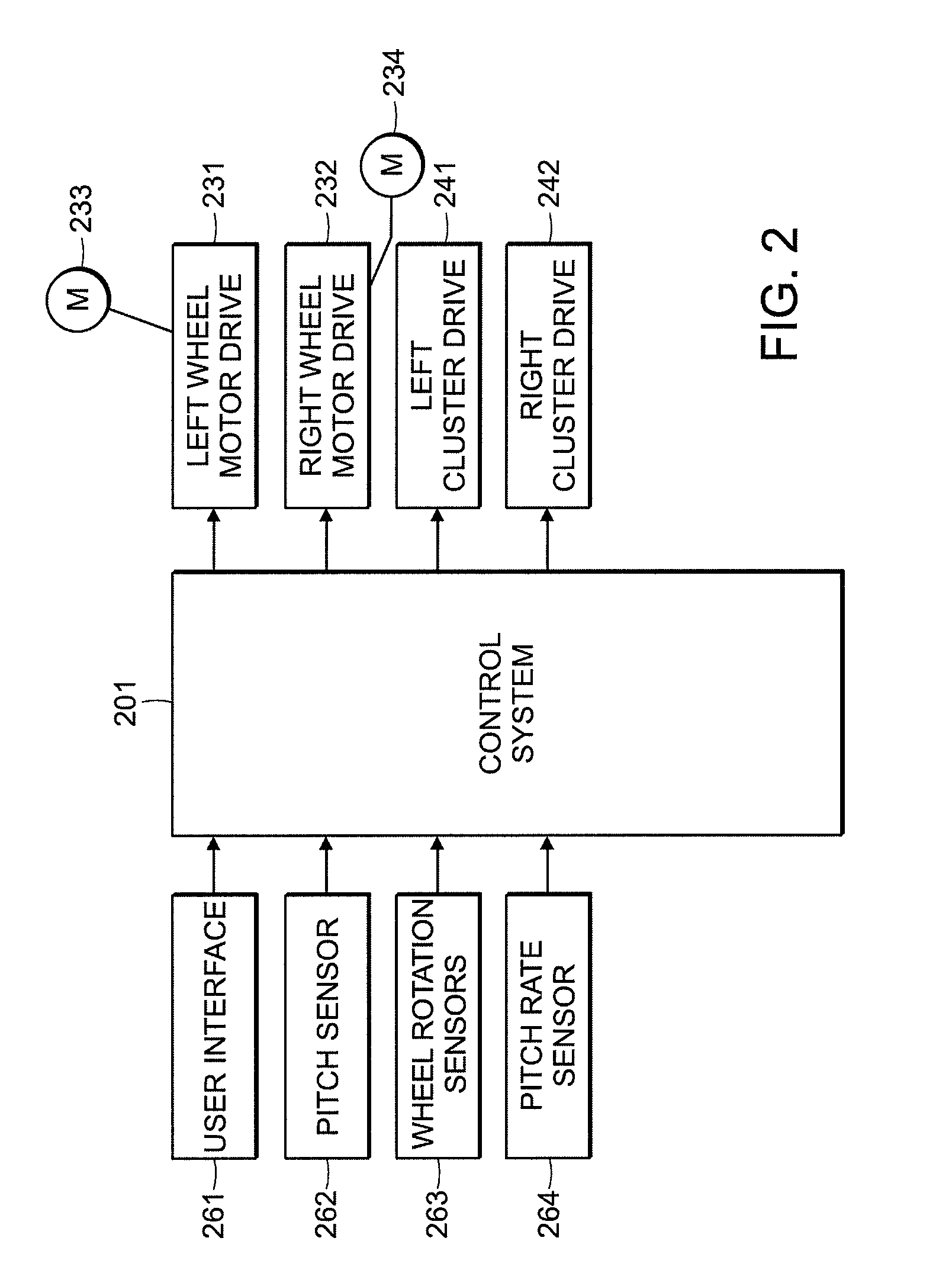

Methods and apparatus for moving a vehicle up or down a sloped surface

ActiveUS8146696B2Reduce amountIncreasing the amount of torqueHybrid vehiclesSpeed controllerGround contactSurface mode

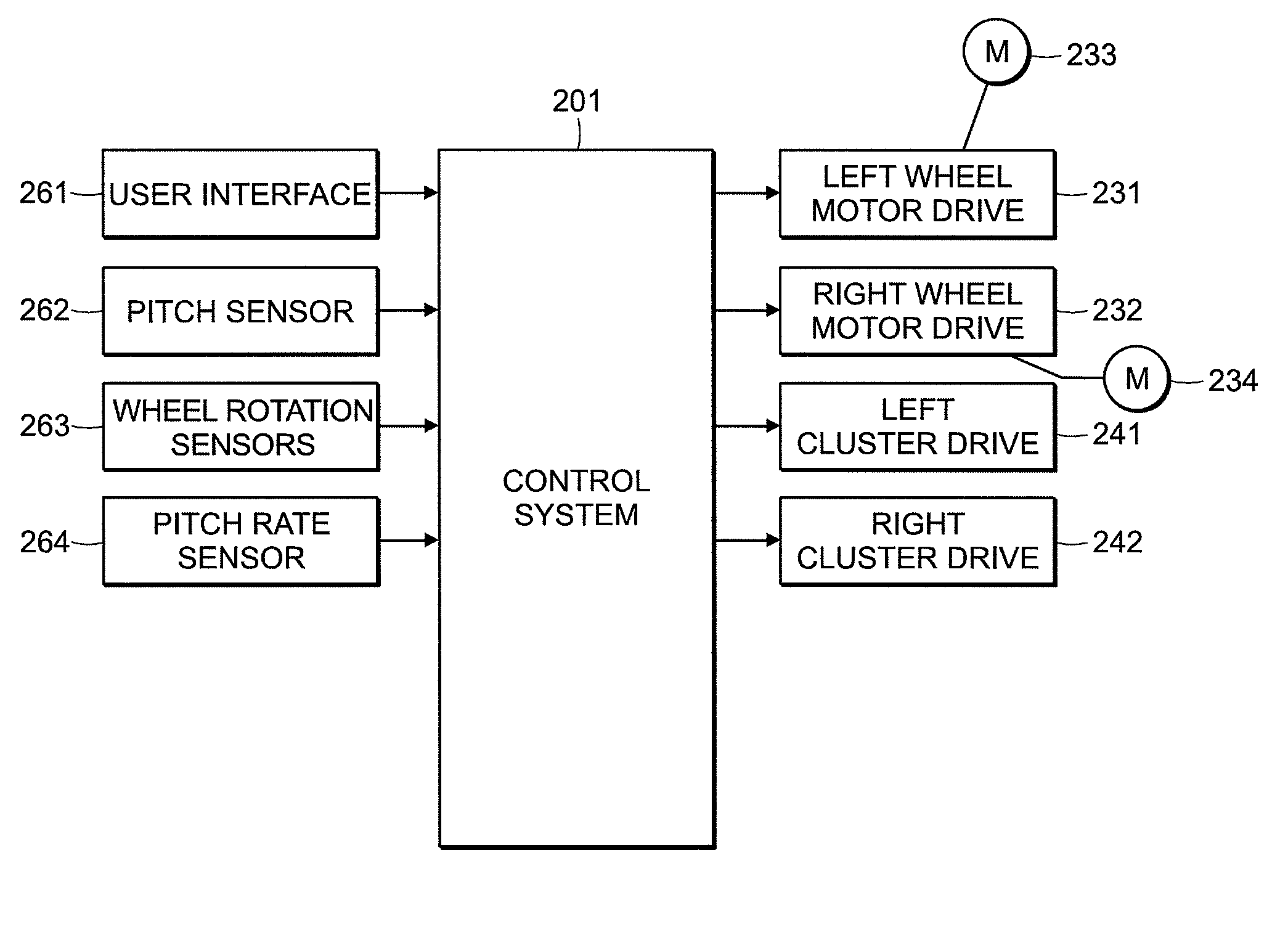

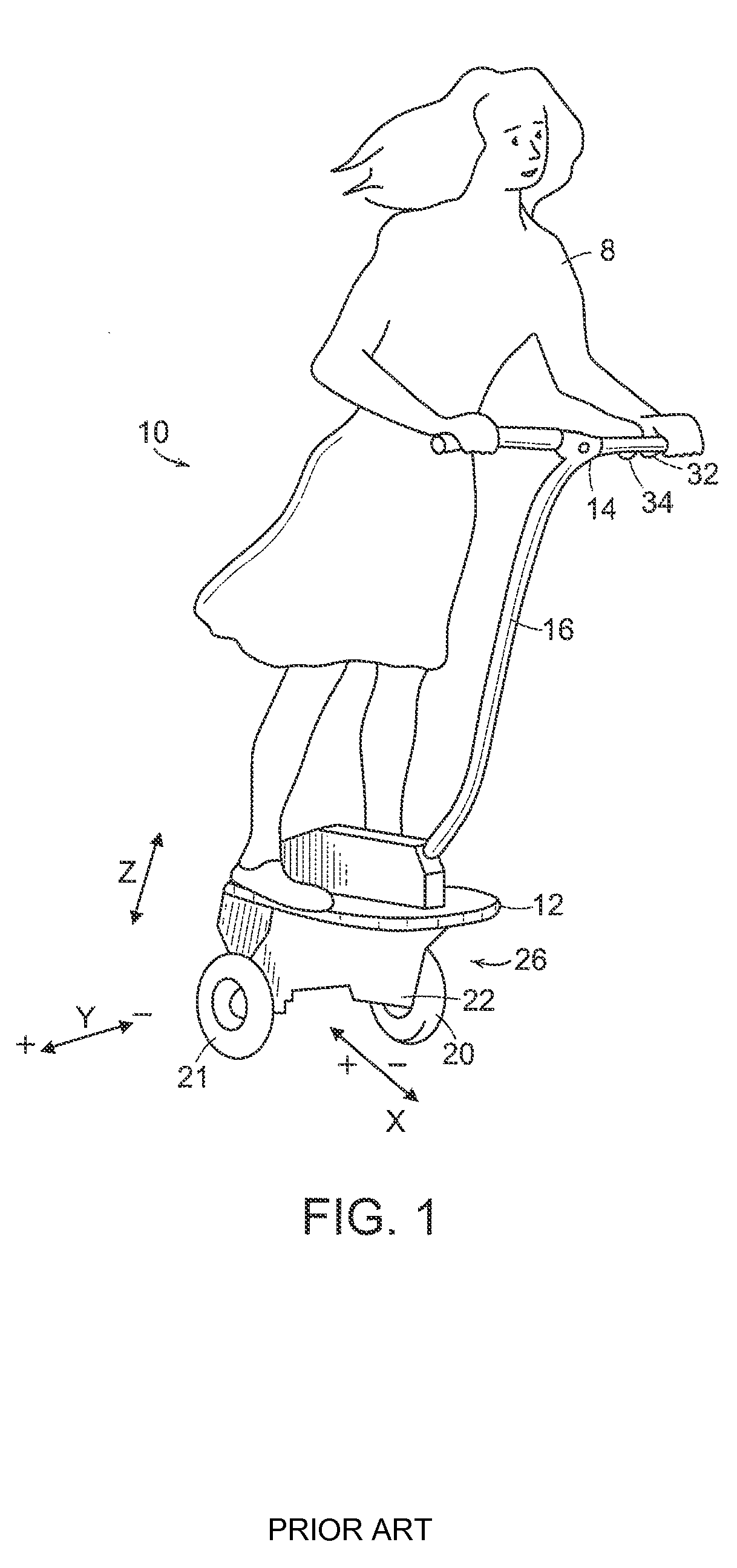

A system and method for safely moving a vehicle up or down a sloped surface is provided. In one embodiment, a method involves operating the vehicle in a sloped surface mode when at least one ground contacting element for moving the vehicle is on the sloped surface. An amount of torque is provided to the at least one ground contacting element to prevent the vehicle from uncontrollably moving down the sloped surface while in the sloped surface mode of operation. An assist mechanism can be coupled to the propulsion system to enable an operator to guide the vehicle.

Owner:SEGWAY INC

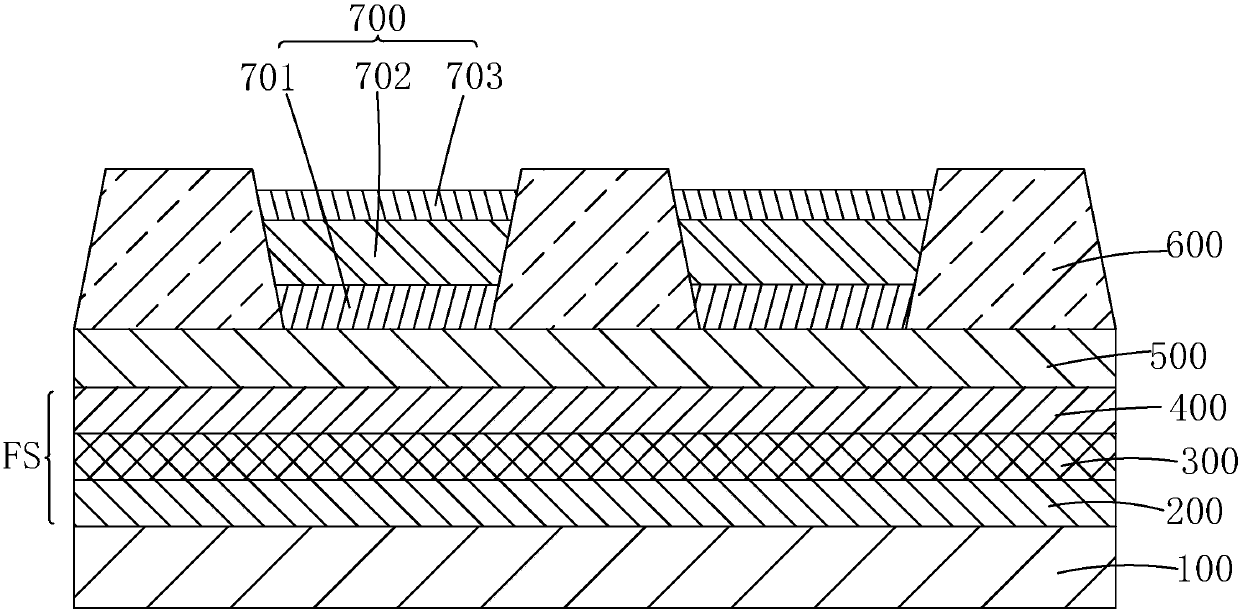

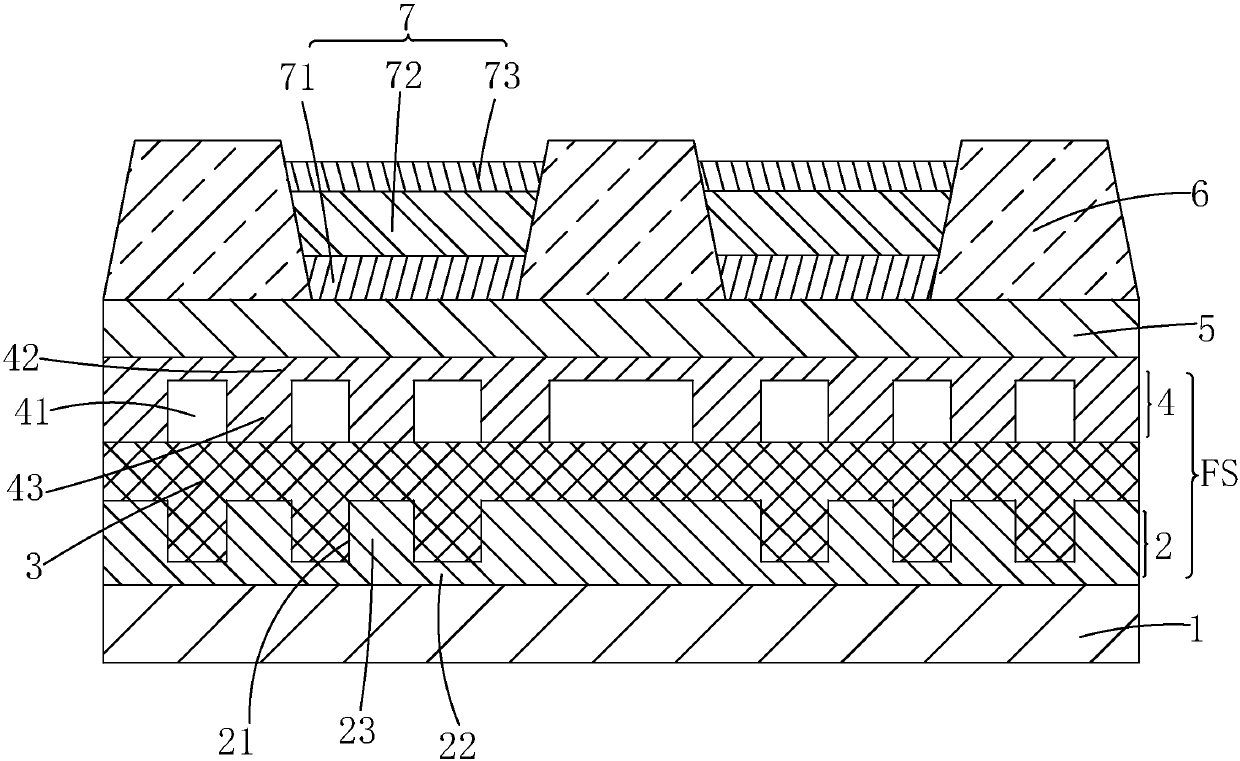

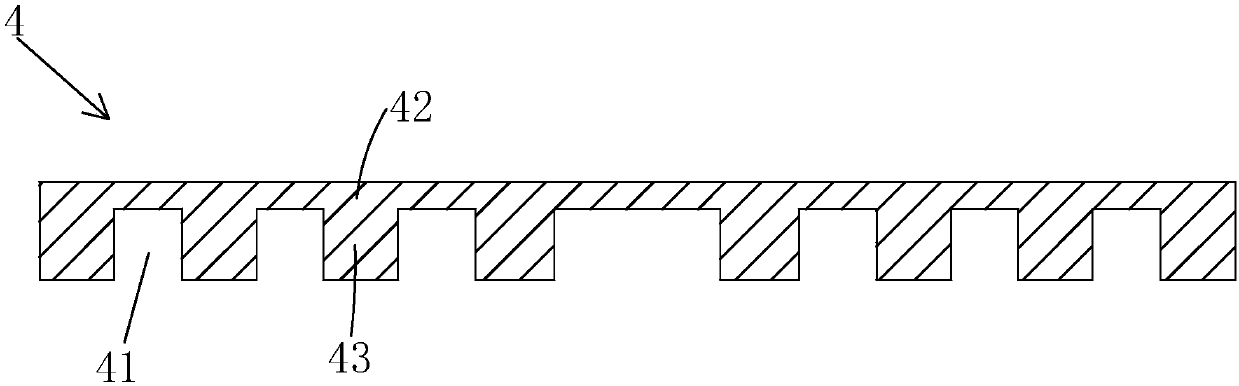

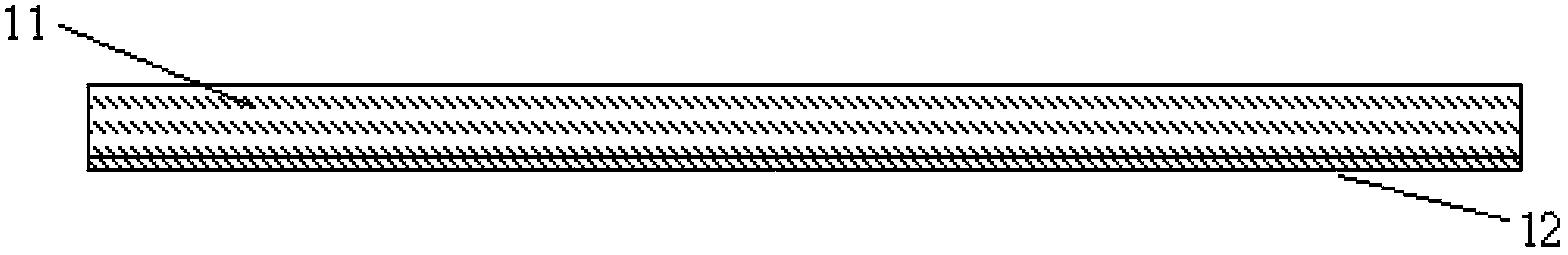

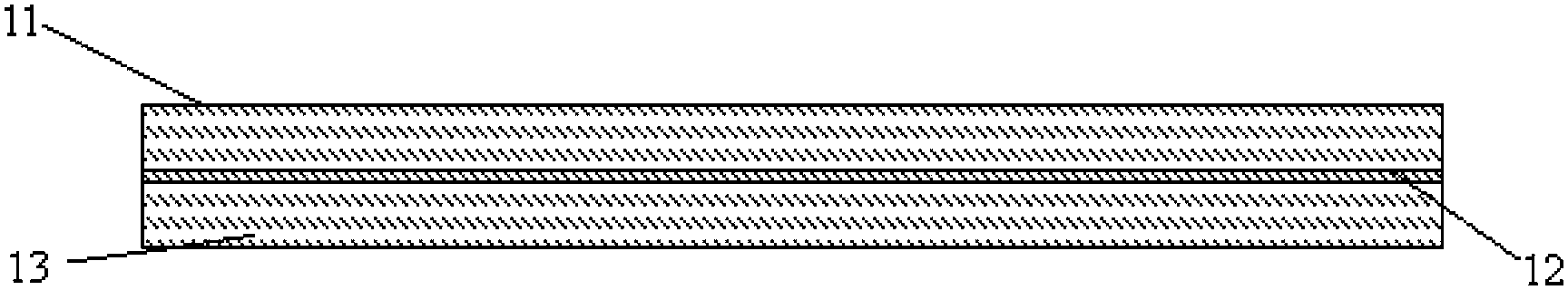

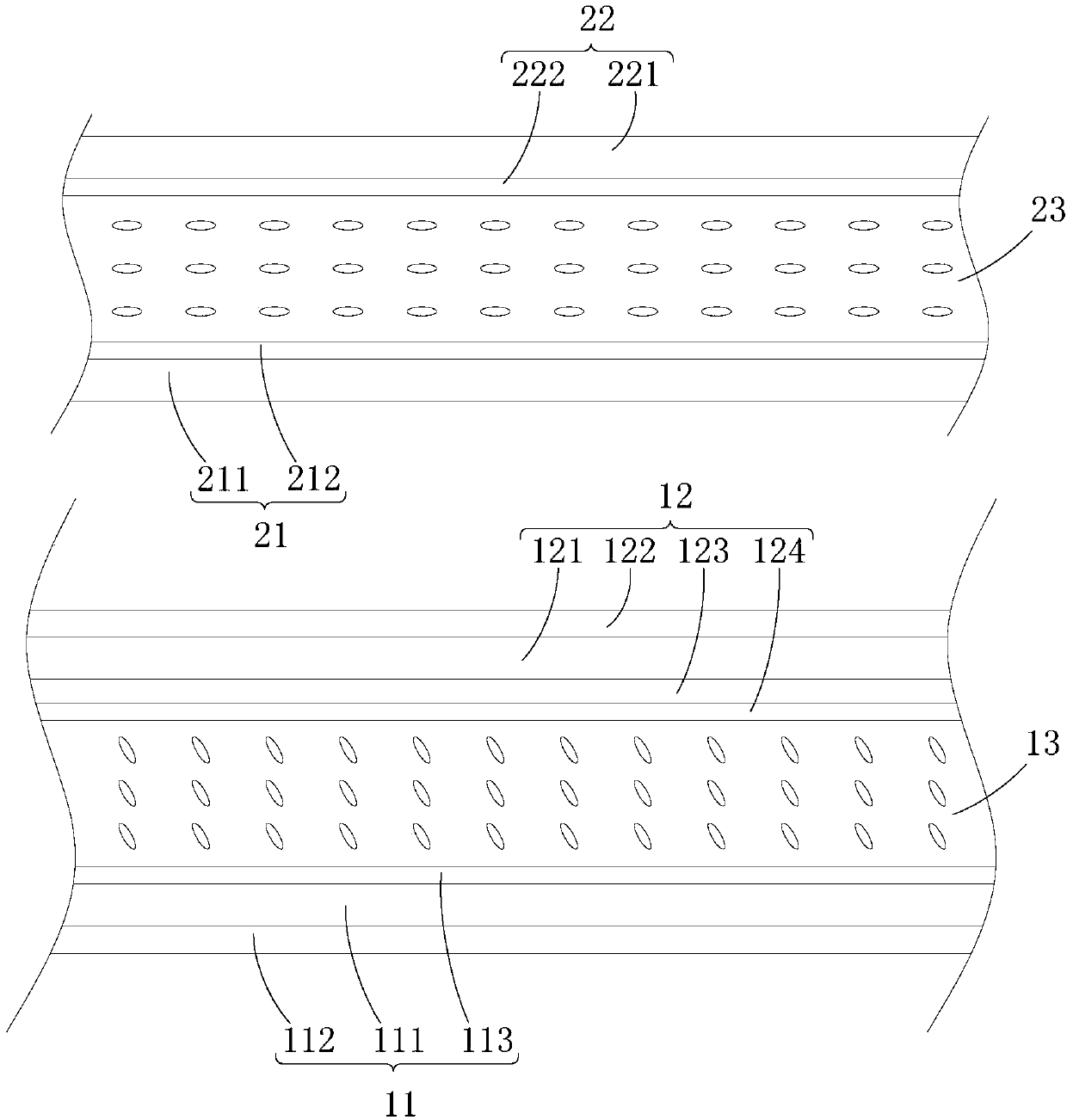

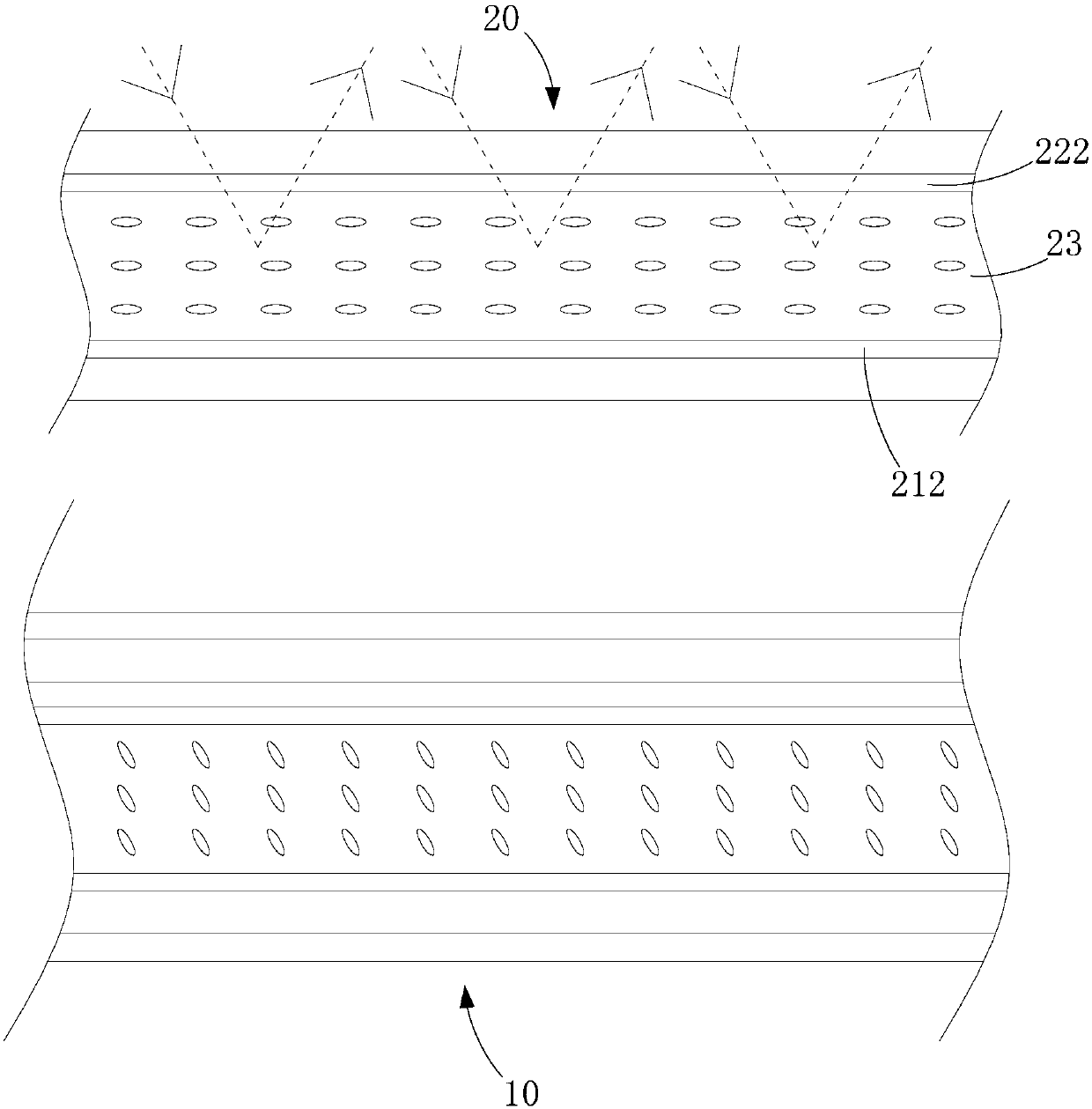

Flexible OLED (Organic Light Emitting Diode) display panel and production method thereof

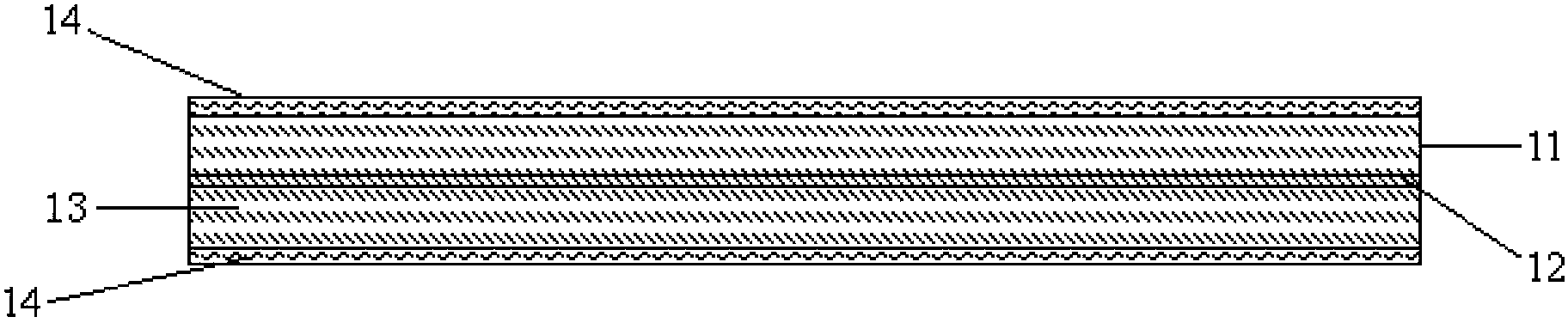

InactiveCN107611162AImprove bendabilityAvoid breakingSemiconductor/solid-state device detailsSolid-state devicesSurface modeEngineering

The invention provides a flexible OLED (Organic Light Emitting Diode) display panel and a production method thereof. A FS (Flexible Substrate) in the flexible OLED display panel comprises a patternedfirst flexible layer (2), a separation layer (3) covering the patterned first flexible layer (2) in a full-surface mode, and a patterned second flexible layer (4) arranged on the separation layer (3).When the flexible OLED display panel is bent, a bending stress is released through a plurality of first grooves (21) of the patterned first flexible layer (2) and a plurality of second grooves (41) of the patterned second flexible layer (4), so that bendability of the flexible OLED display panel can be reinforced, breakage of the flexible OLED display panel in the bending process is prevented, and yield of the flexible OLED display panel product is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

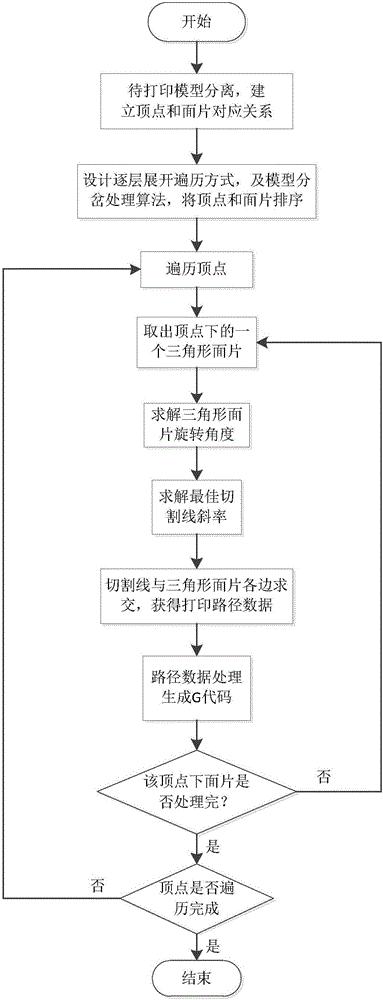

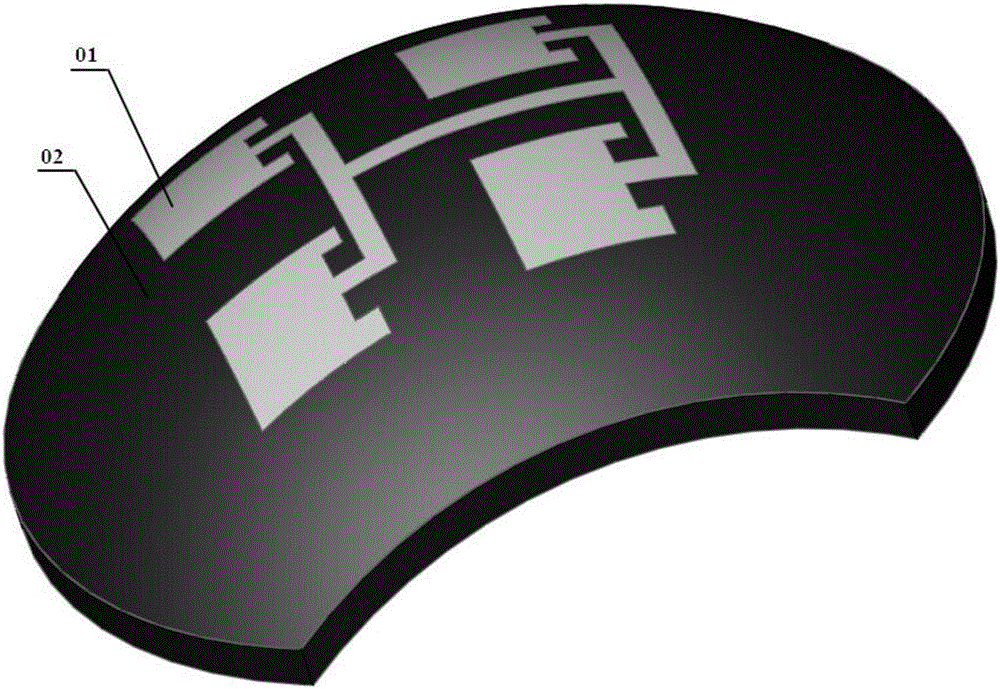

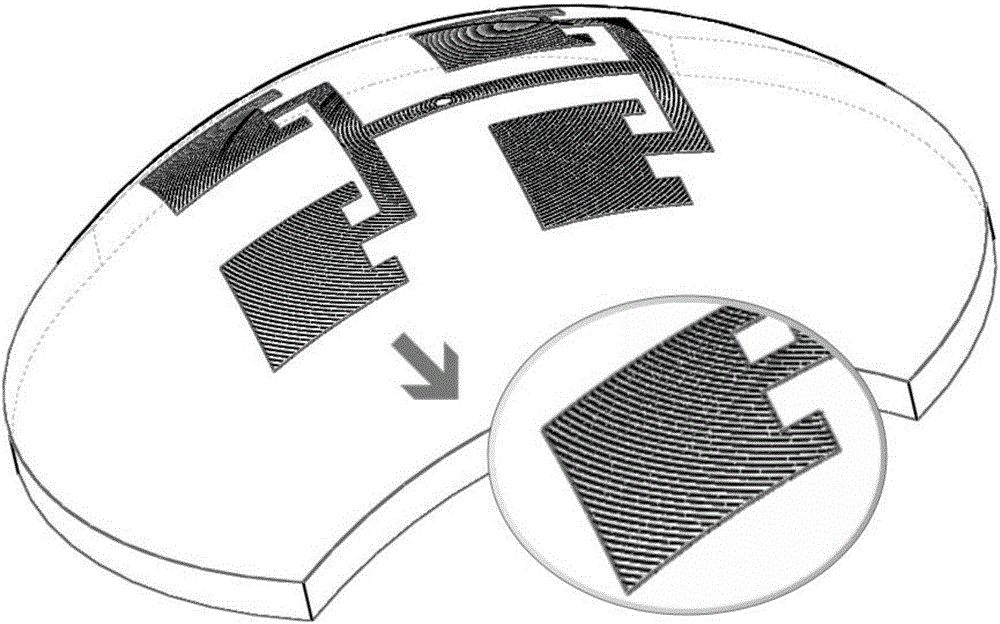

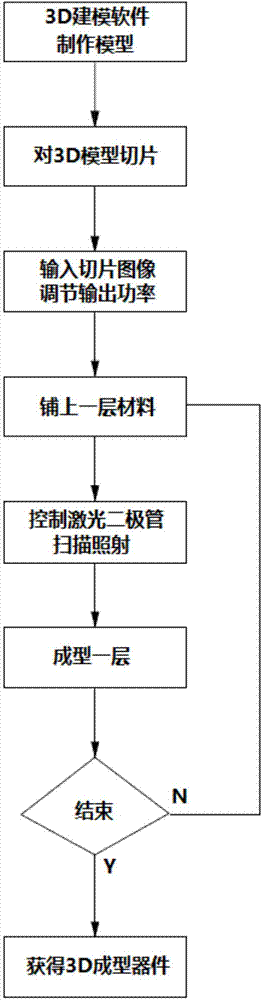

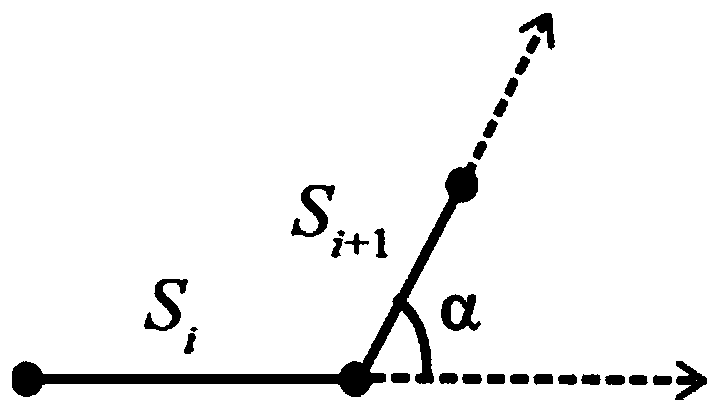

Slicing treatment method for surface model surface ink jet printing

ActiveCN106738864AImprove connectivityImprove qualityAdditive manufacturing apparatus3D object support structuresSurface modeData treatment

The invention discloses a slicing treatment method for surface model surface ink jet printing. The method comprises the following steps: a surface model to be printed is separated from a computer, and is preserved as a STL format for data processing to remove redundant data; a corresponding relation between a peak and a facet is built; a layer-by-layer unfolding traversal mode of the peak of the STL model and a fork processing algorithm are designed; the peak and the facet are arranged by a certain sequence; the peak is traversed; the facet included under the peak is read; an angle of rotating the facet to be printed to the horizontal position and an optimal cutting line slope are calculated; a printing error is reduced; a layering tangent line and each edge of the triangular facet are intersected to obtain printing path data; and all peaks and facets are traversed to obtain a complete G code of the model to be printed. The slicing treatment method can prevent the step effect of the forming surface of the surface model and the precision problem caused by ink flowing, and can improve the surface overall connectivity and the printing precision.

Owner:XIDIAN UNIV

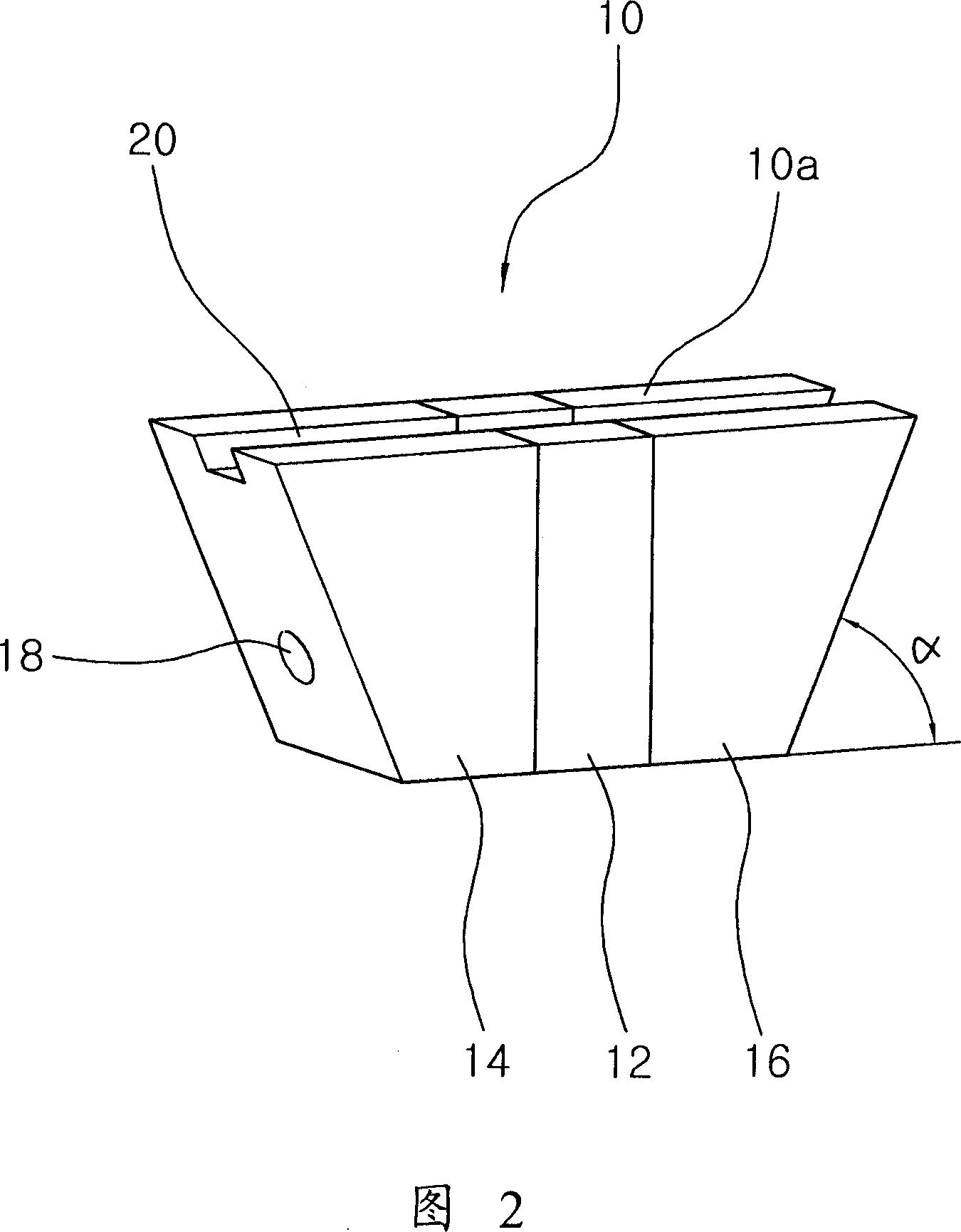

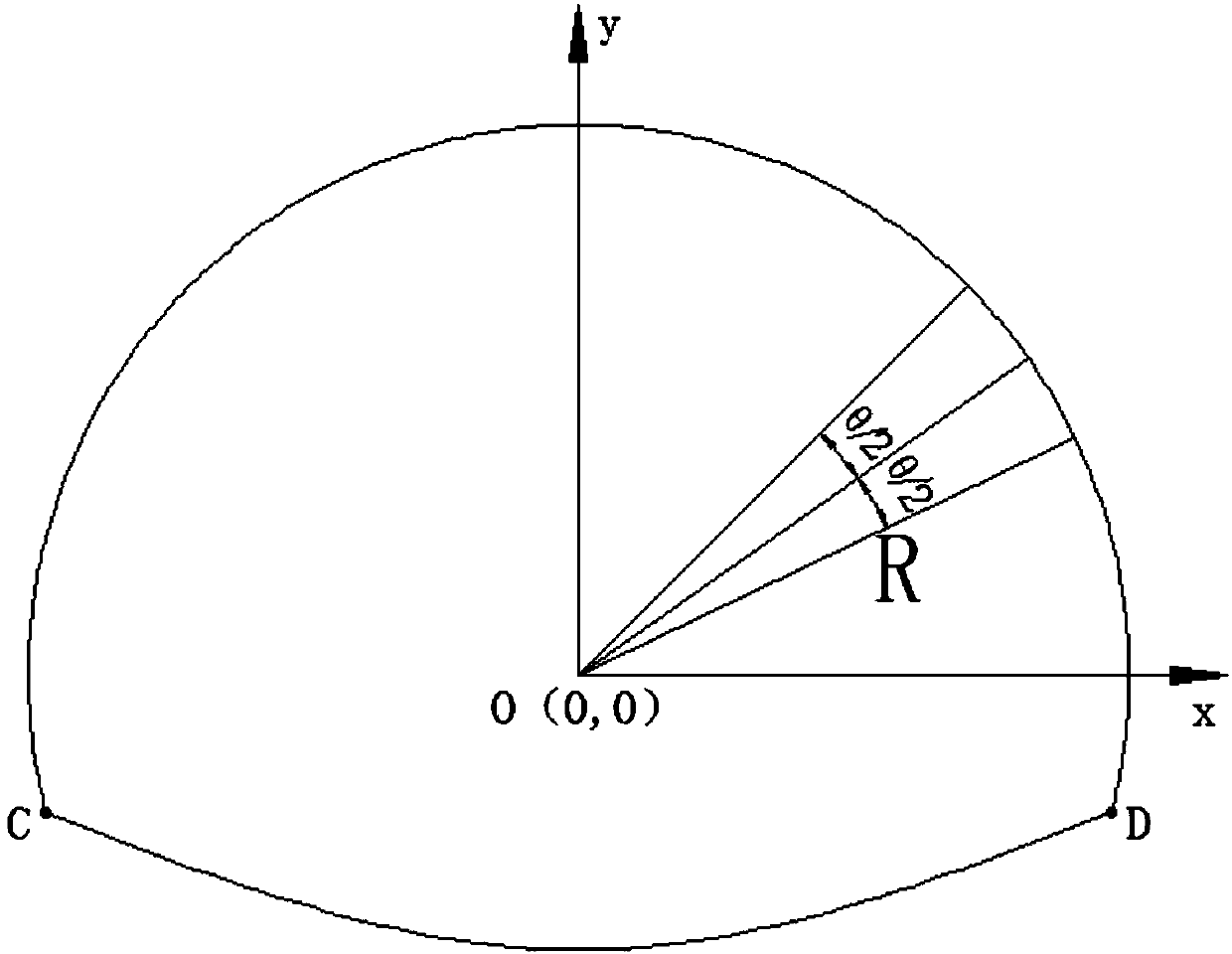

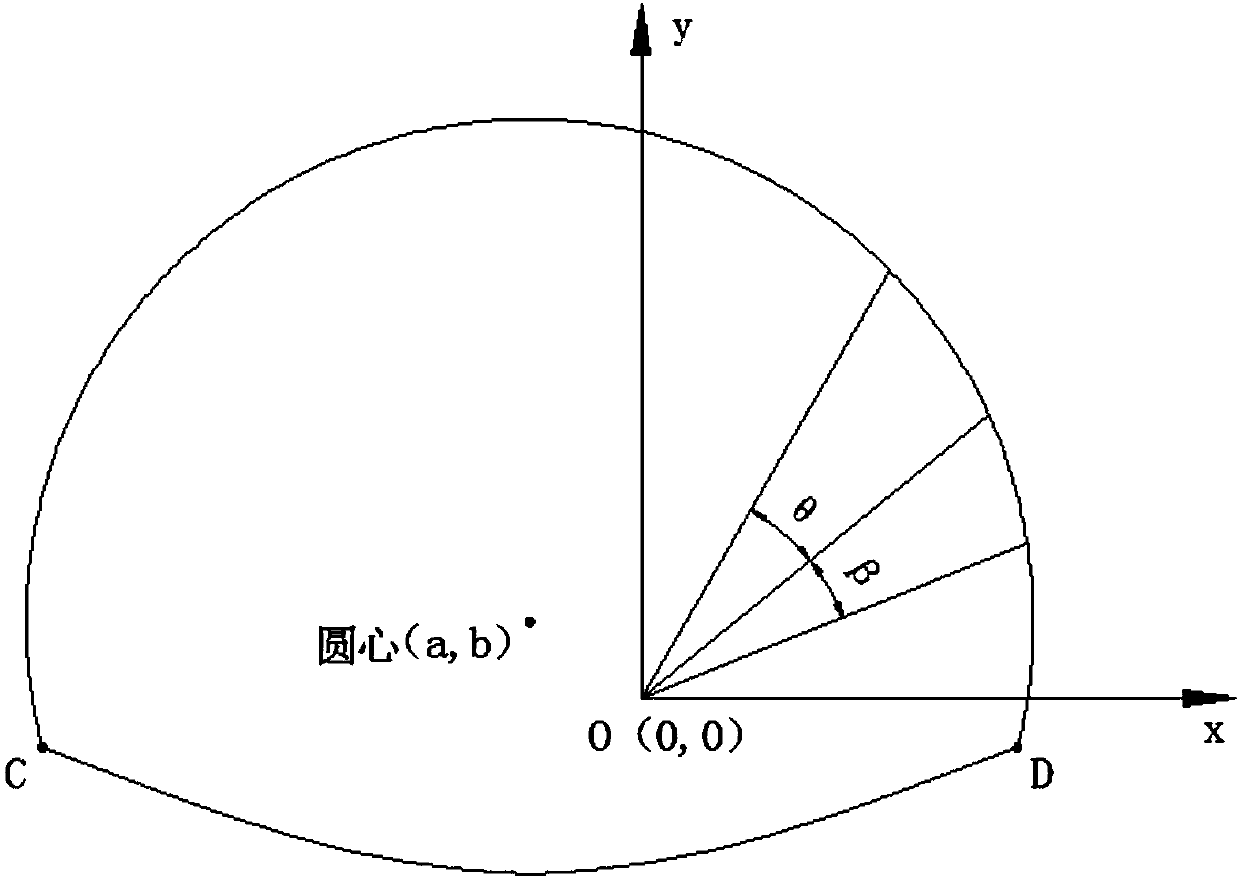

Synthetizing algorithm based on naked eye three-dimensional displaying technology

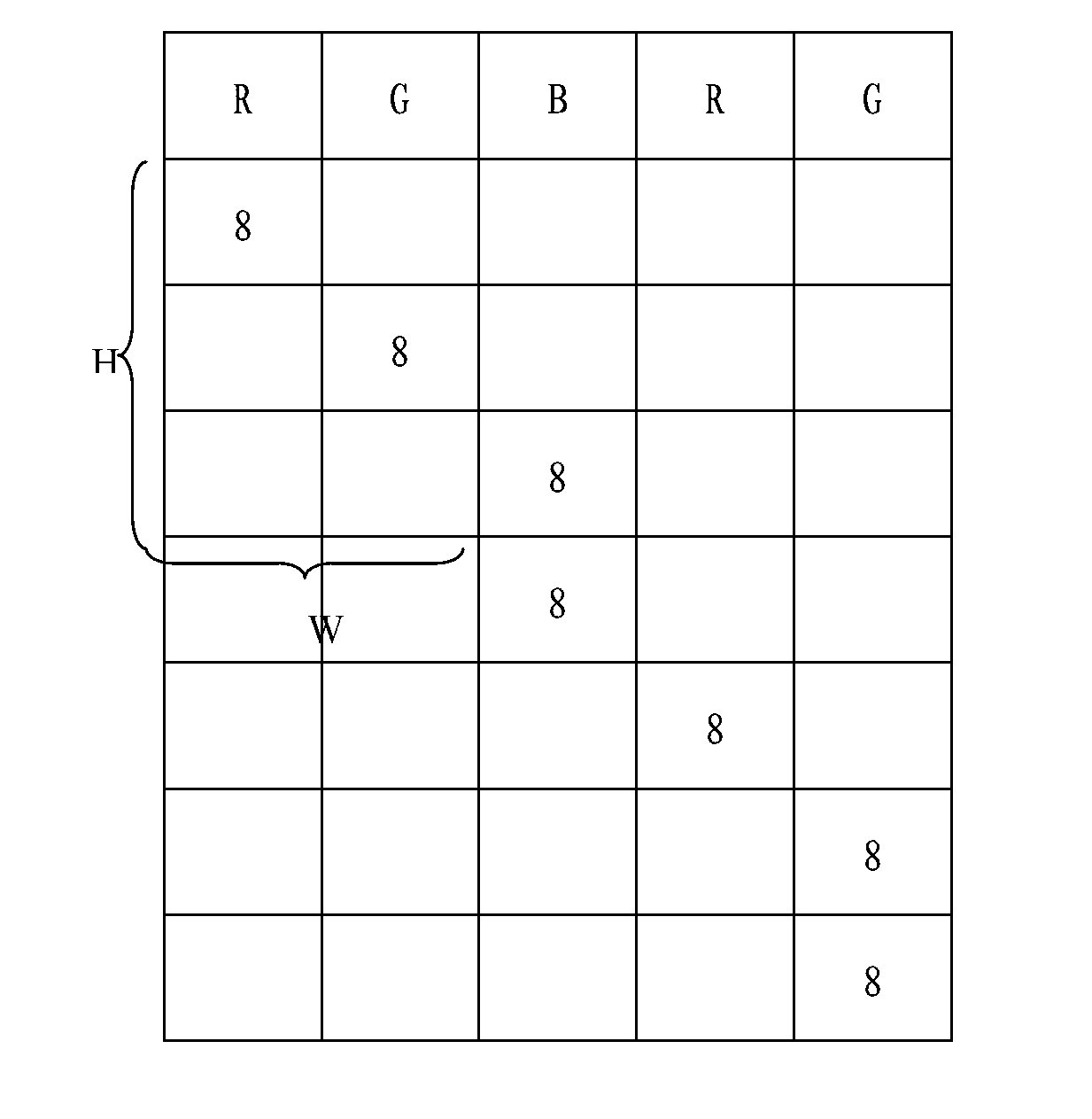

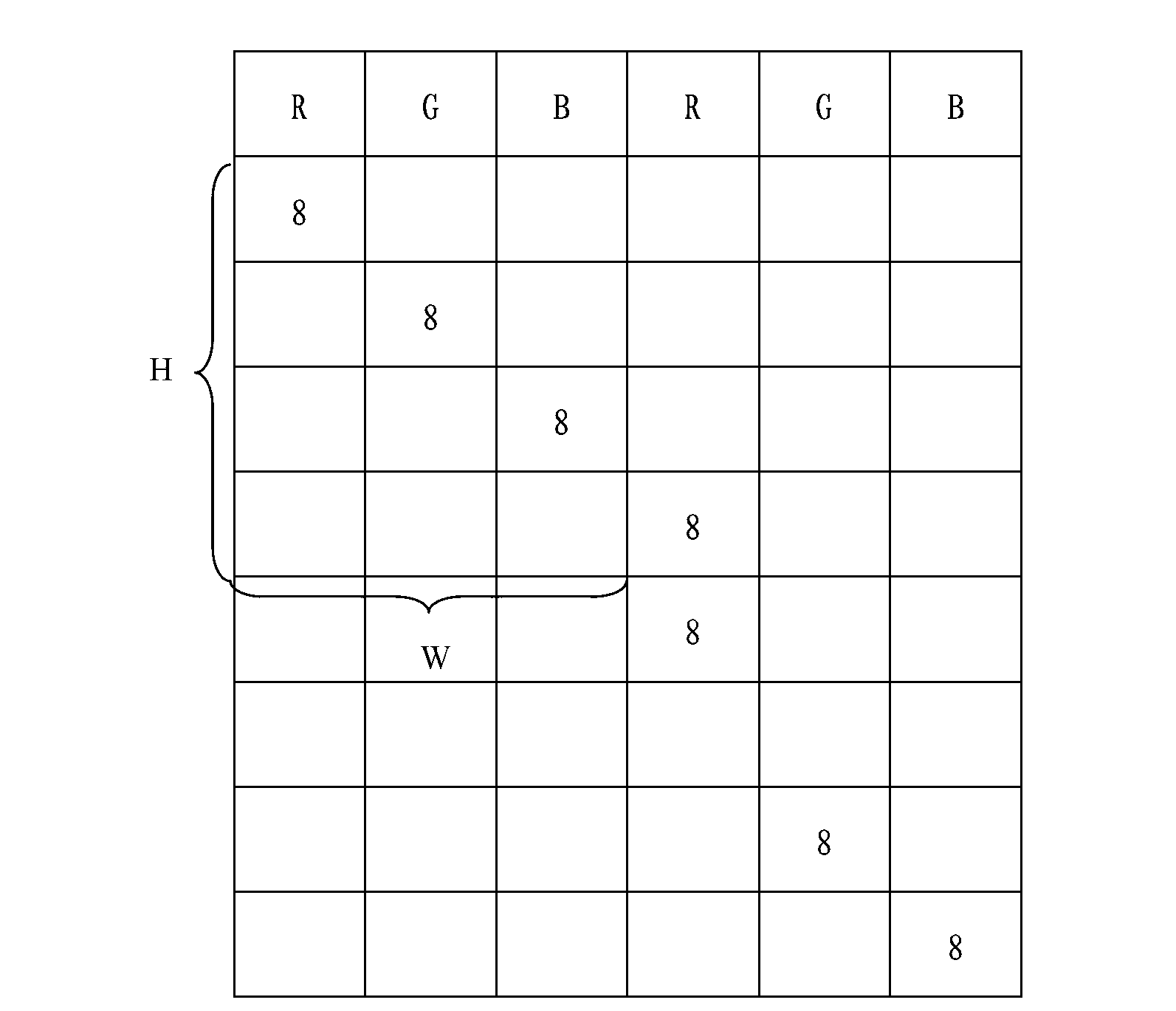

The invention relates to a naked eye free three-dimensional displaying technology, which arms at synthetizing corresponding three-dimensional images by meeting following requirements: 1, an included angle between surface-mounting direction of grating and the vertical direction is at an arbitrary value; and 2, the technology is suitable for a parallax barrier mode and a lens cylindrical surface mode, and simultaneously is capable of being applied to rectify angle error generated by grating surface-mounting. The technical scheme adopted by the synthetizing algorithm based on naked eye three dimensional displaying technology comprises the following steps: setting a dot pitch of a displayer as delta, a resolution ratio as W*H, a grating pitch as d, an inclination angle as alpha, and viewpoints as N, thus the initial arranged positions of sub-pixels of each row are determined to be consistent with initial positions of subsamplings: delta h equals to 3h*tan alpha equivalent to N (2); circulating for H times with row serving as a unit, and finally generating a three-dimensional composite image. The synthetizing algorithm based on naked eye three-dimensional displaying technology is mainly applied to free three-dimensional displaying.

Owner:TIANJIN UNIV

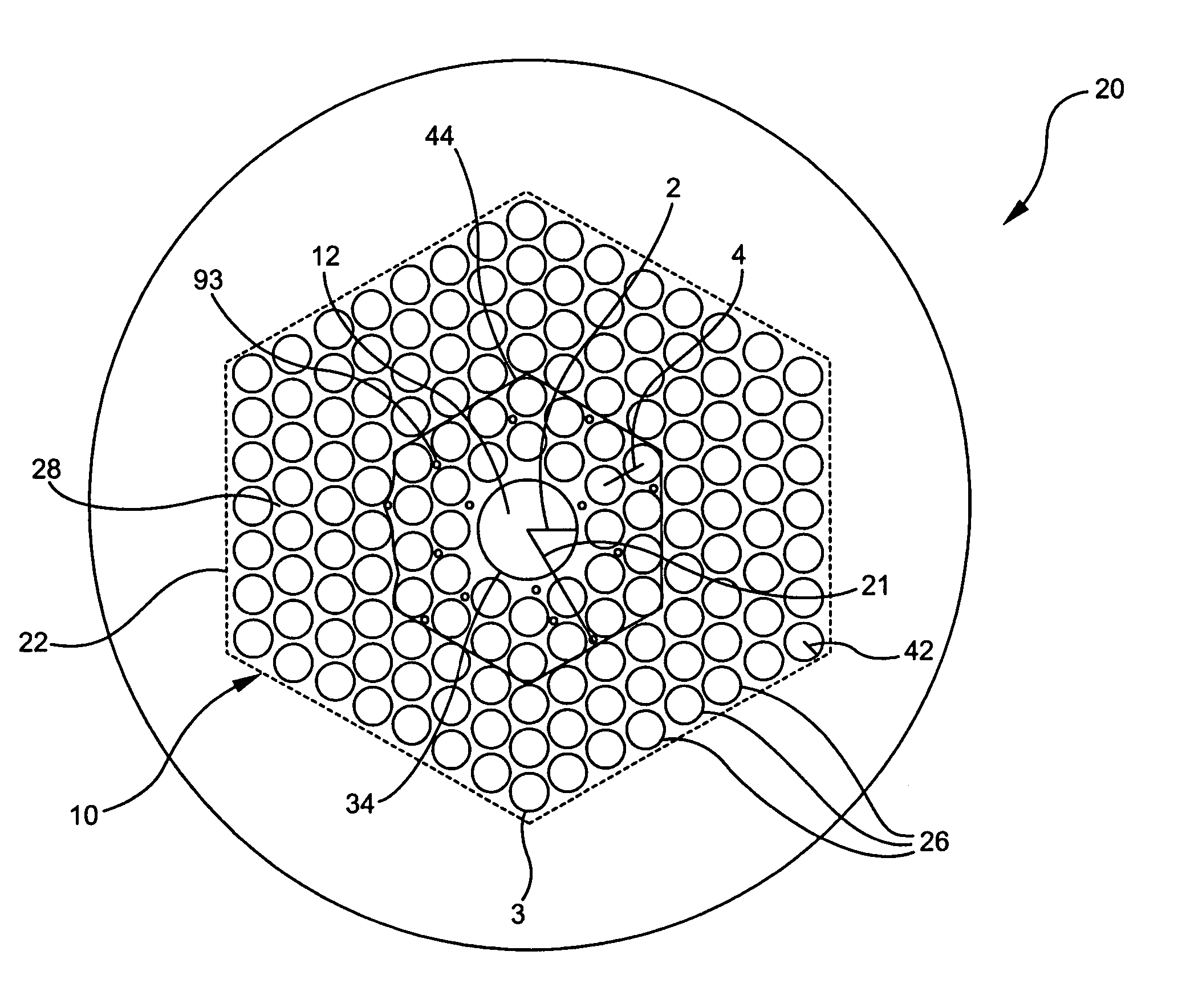

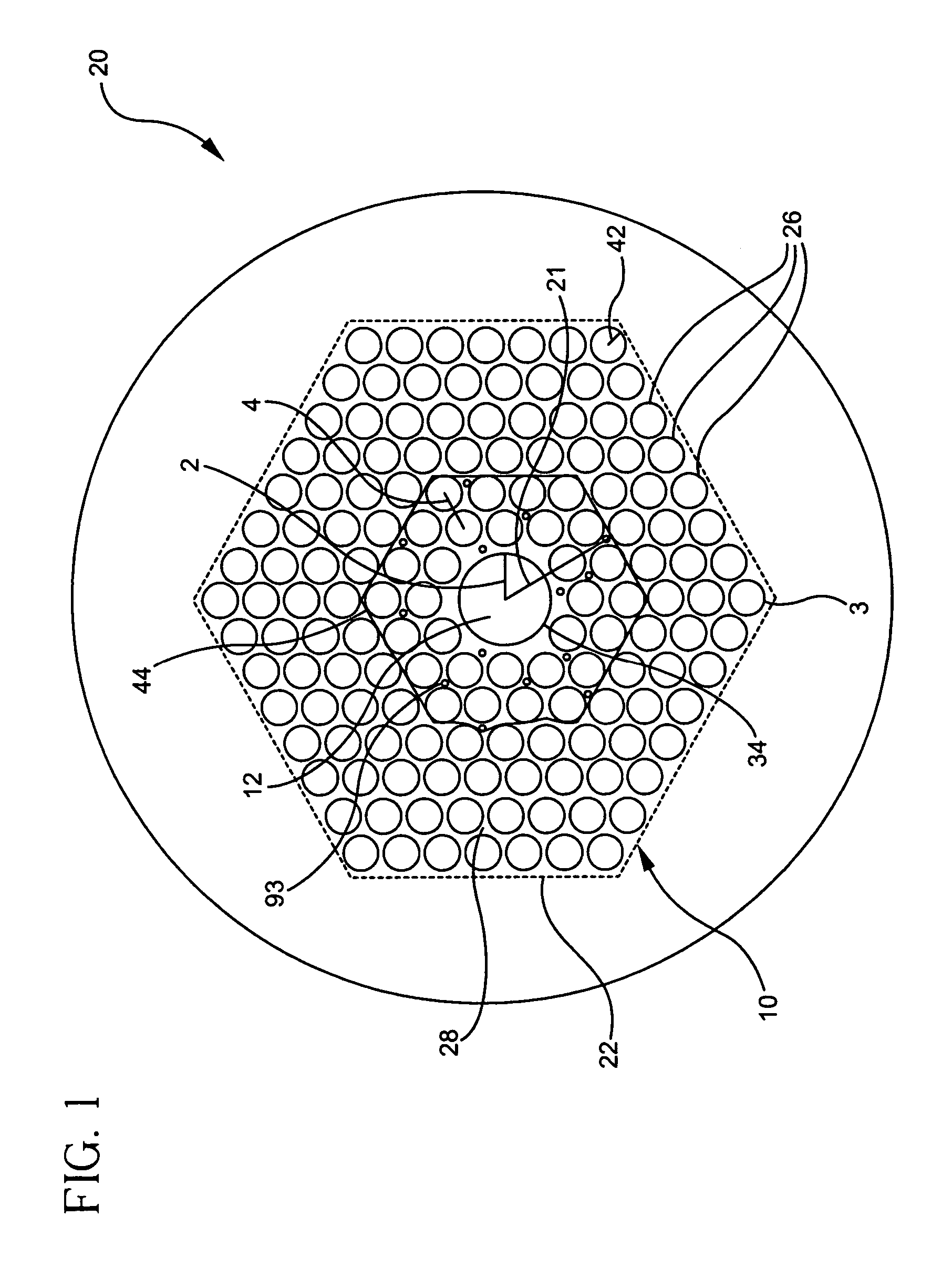

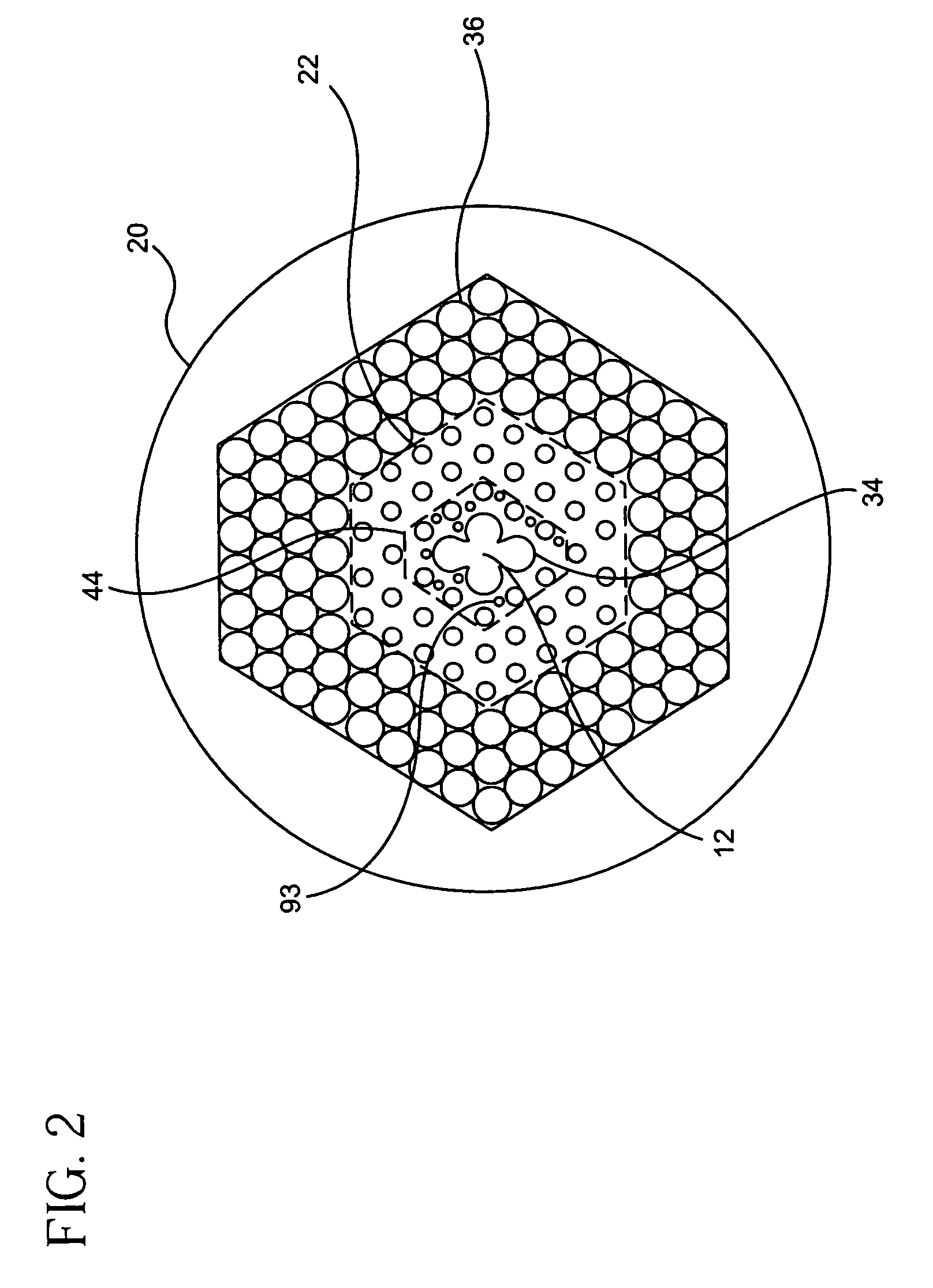

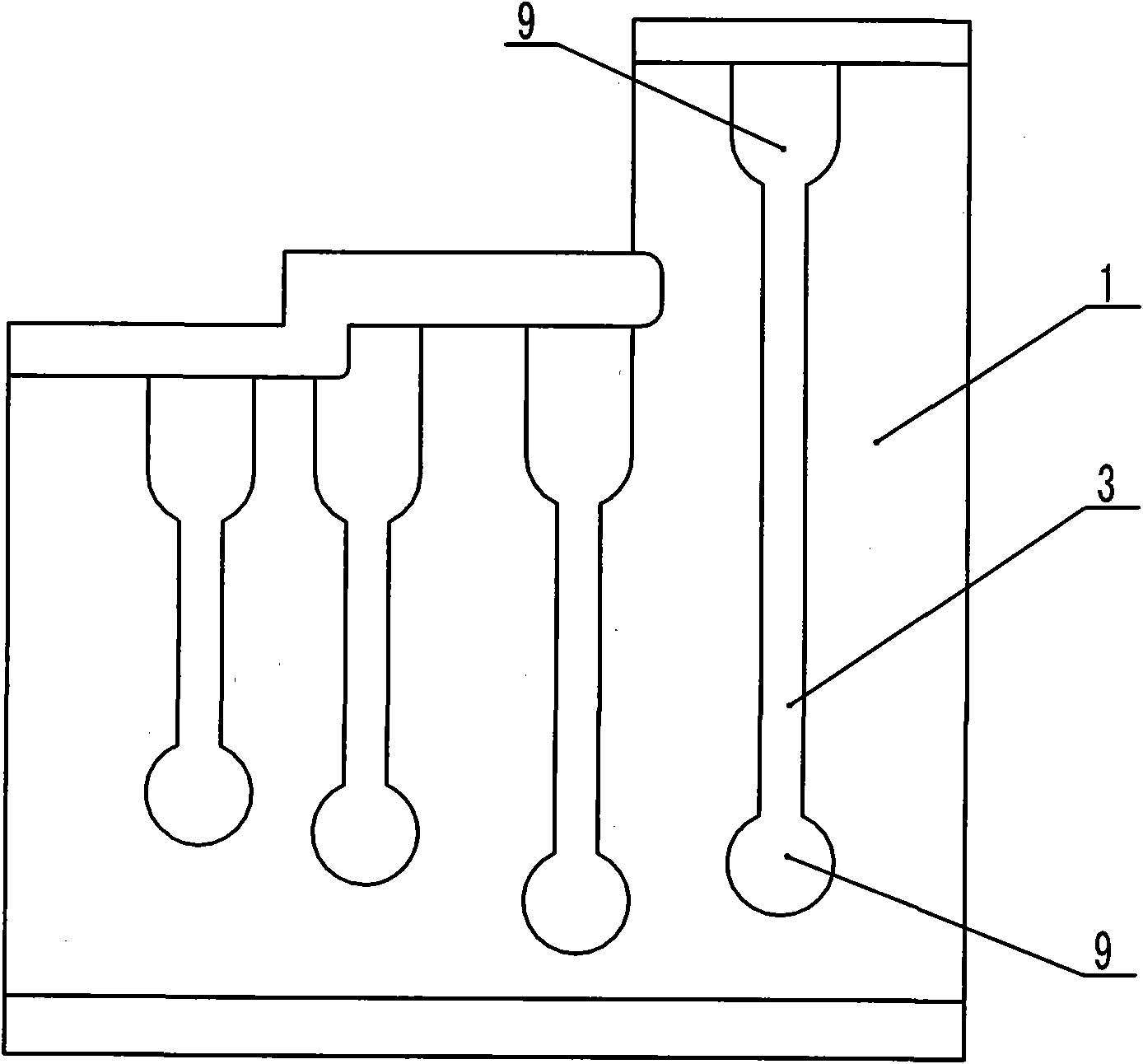

Active photonic band-gap optical fiber

A plurality of active gain material (93) is disposed in an active interface portion (44) of a dielectric band-gap cladding confinement region (22) adjacent to a dielectric core (12) of a photonic band-gap crystal fiber (20), wherein during operation, the plurality of active gain material (93) absorbs the pump energy and stores the pump energy as a potential energy storage for stimulation by EM energy in a second guided mode at a second frequency in a second range of frequencies for overlapping with the first guided mode of the core (12) such that the surface defined by an interface between the photonic band-gap cladding (22) and the dielectric core (12) that supports at least one surface mode propagating at that interface (44) overlaps the active interface portion of the dielectric cladding confinement region and a state associated with the dielectric core (12).

Owner:CORNING INC

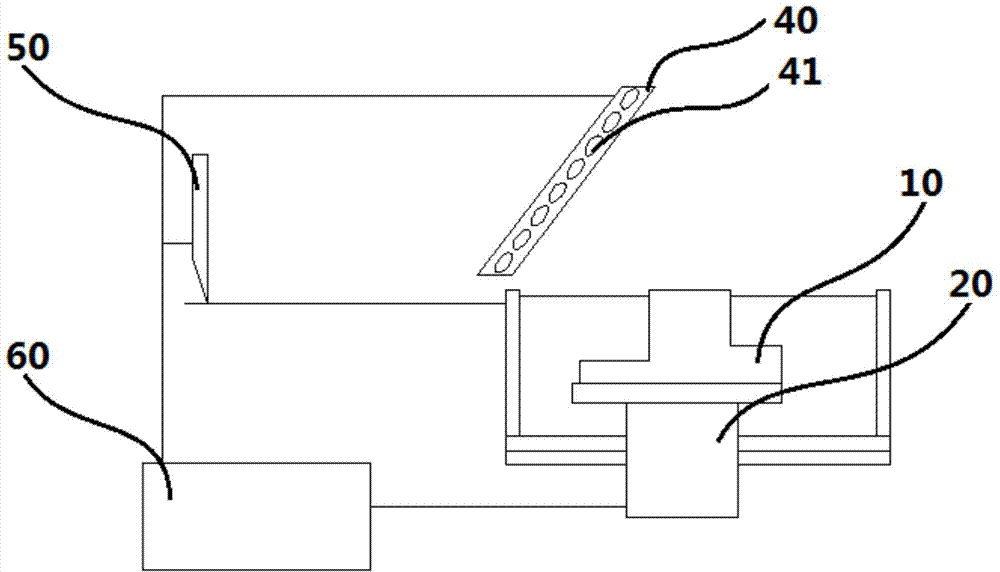

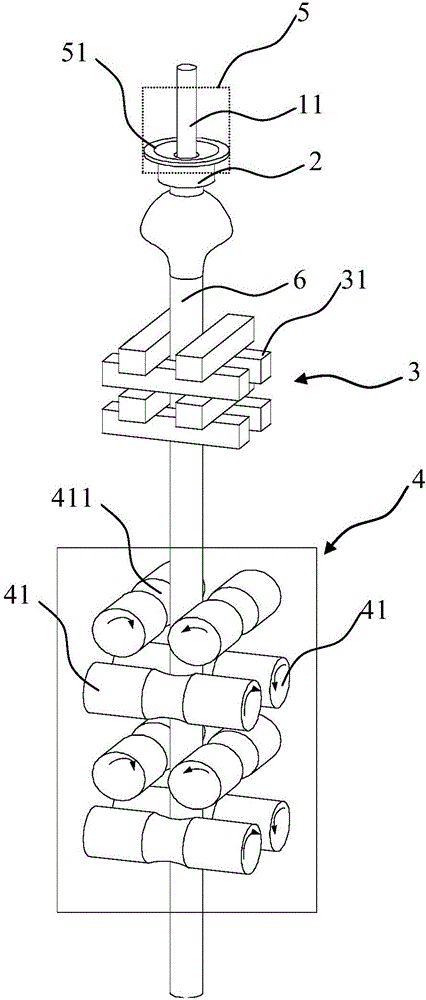

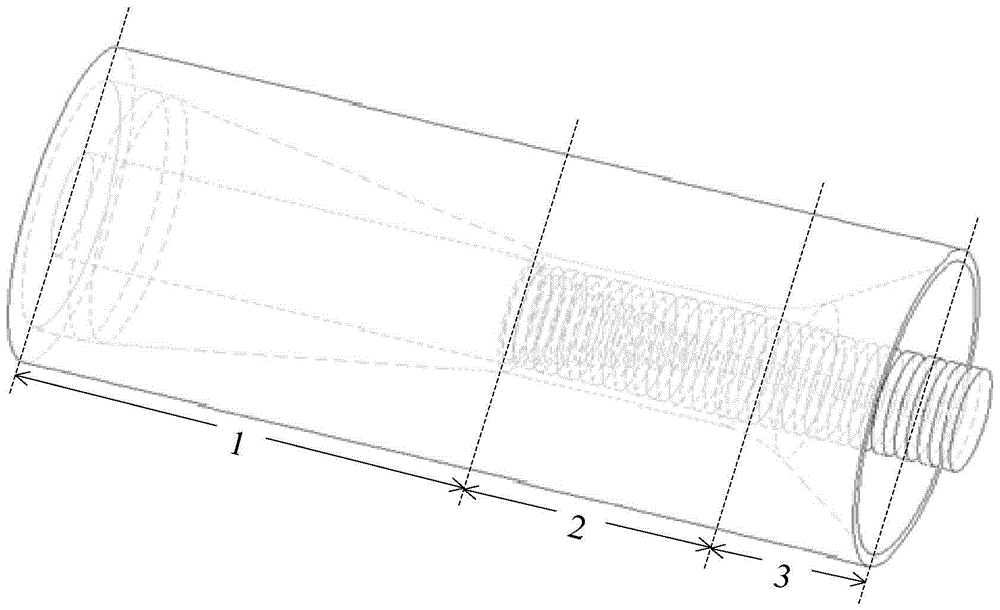

Laser linear array type 3D printing equipment and molding method thereof

InactiveCN104742376AEfficient molding productionPrecise moldingAdditive manufacturing apparatusSurface modeEngineering

The invention discloses laser linear array type 3D printing equipment which comprises a computer controller, a molding supporting plate, a storage box, a laser irradiator and a scraper, wherein a lifting mechanism is arranged below the molding supporting plate; the molding supporting plate and the lifting mechanism are integrally arranged in the storage box; a large quantity of to-be-used materials are arranged in the storage box; the liftable scraper and the laser irradiator are arranged above the molding supporting plate; and multiple laser diodes are arranged on the laser irradiator in a linear array manner. According to the equipment disclosed by the invention, the laser linear array irradiator is adopted based on a SLA technology, a large-scale image is scanned and molded from a linear mode to a surface mode, a large-scale large-size product can be efficiently and accurately molded and manufactured, the molding rate is increased, and the time consumed in the manufacturing process is reduced.

Owner:SHENZHEN LONGER3D SCI & TECH

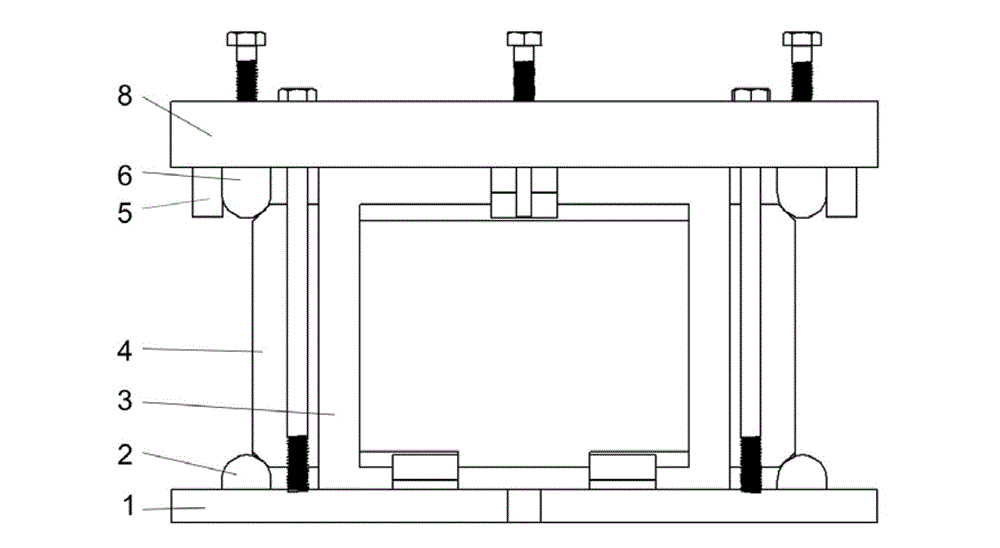

External airway type flat solid oxide fuel cell stack and assembling method

The invention discloses an external airway type flat solid oxide fuel cell stack and an assembling method, the cell stack comprises a pedestal, a core having a cube structure which is alternatively stacked by the flat solid oxide fuel cell and a bipolar plate, external airway type air feeding side covers which are fit with the side surfaces of the core, and a top board which is arranged on the top of the core and is fastened with the pedestal by passing through a bolt, wherein a plurality of locating pieces are fixedly arranged on the positions corresponding to each air feeding side cover, the locating piece is contacted with the air feeding side cover in an inclined plane or an arc surface mode for applying the pressure, slide blocks are provided on the positions where the lower part of the top board corresponds to each air feeding side cover, the slide blocks are fixed on the top board by adjusting the bolt, and can perform an up-down movement along a guide rail by adjusting the bolt, then connected with the air feeding side cover in the inclined plane mode for applying the pressure. According to the invention, the problems that the pressurization mode of the air feeding side cover is not reliable and the sealing performance is insufficient can be solved.

Owner:武汉华科福赛新能源有限责任公司

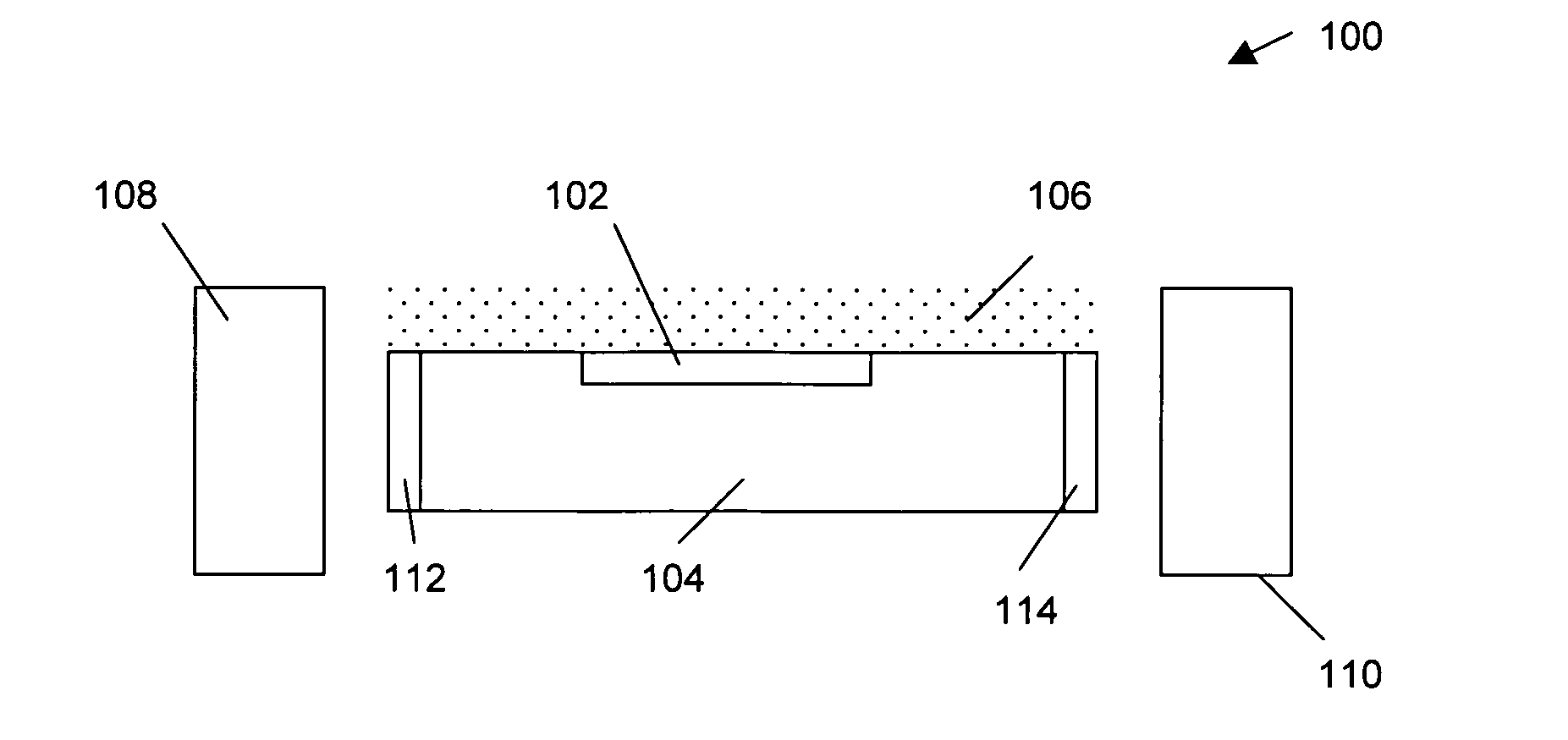

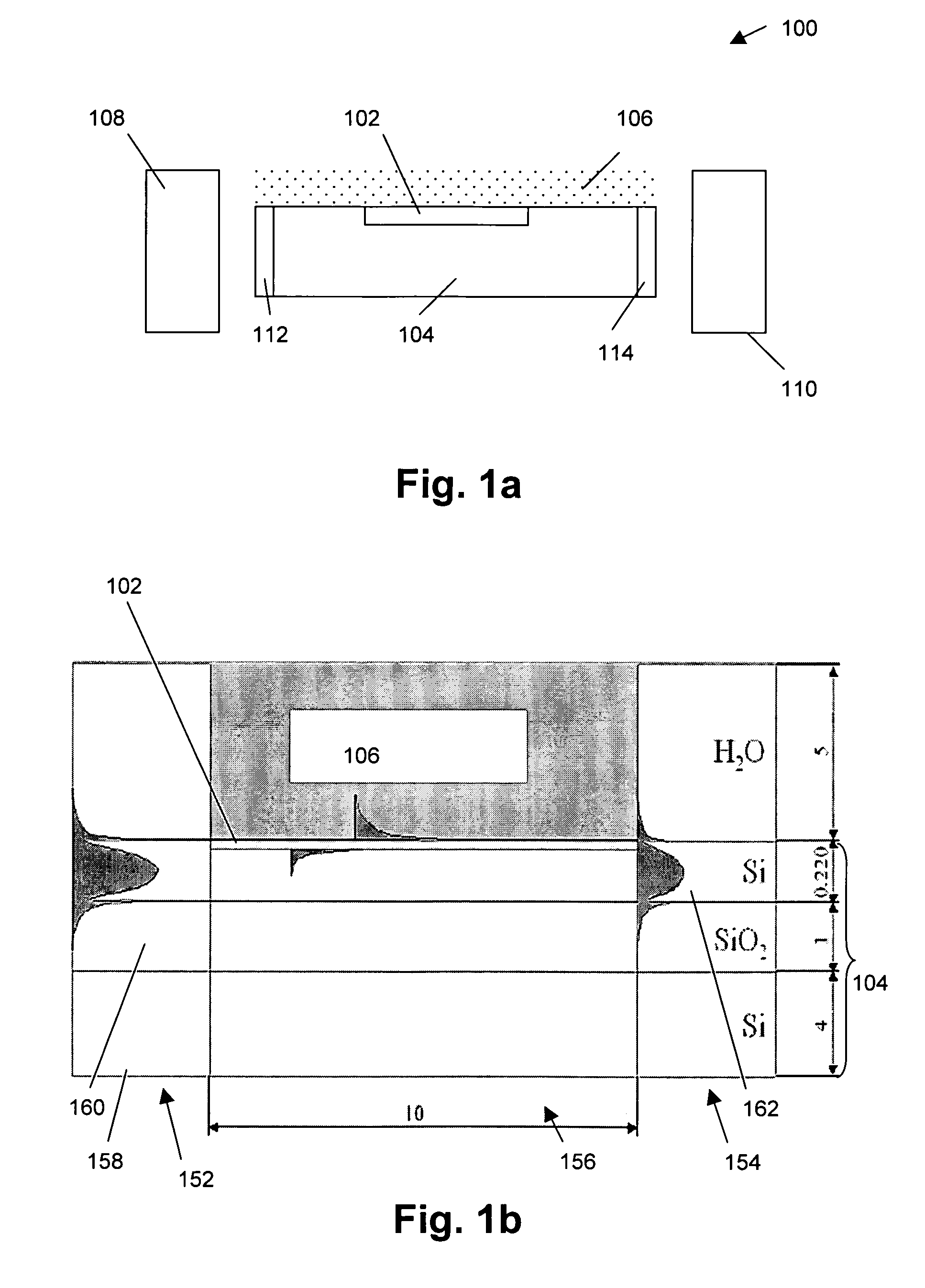

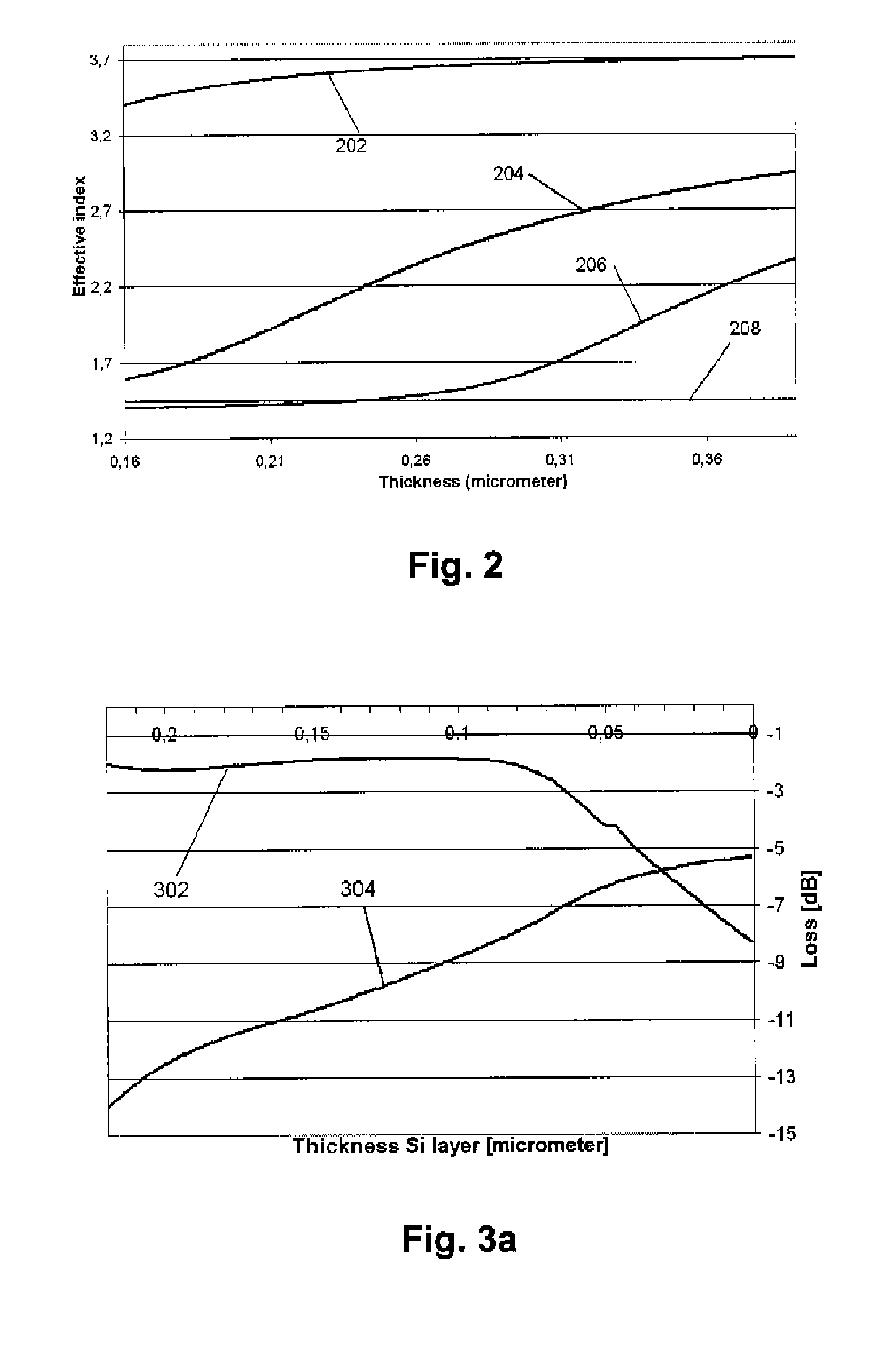

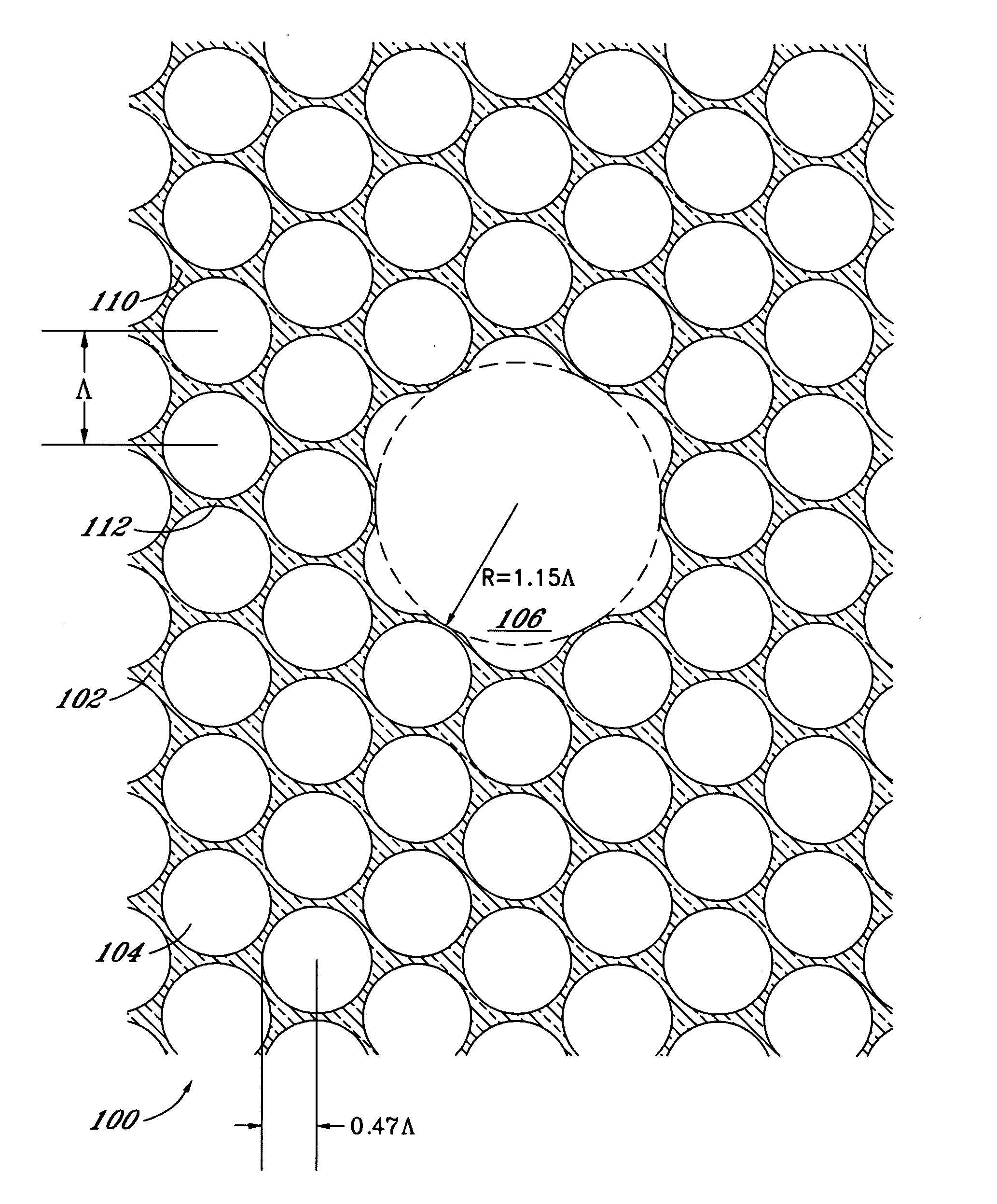

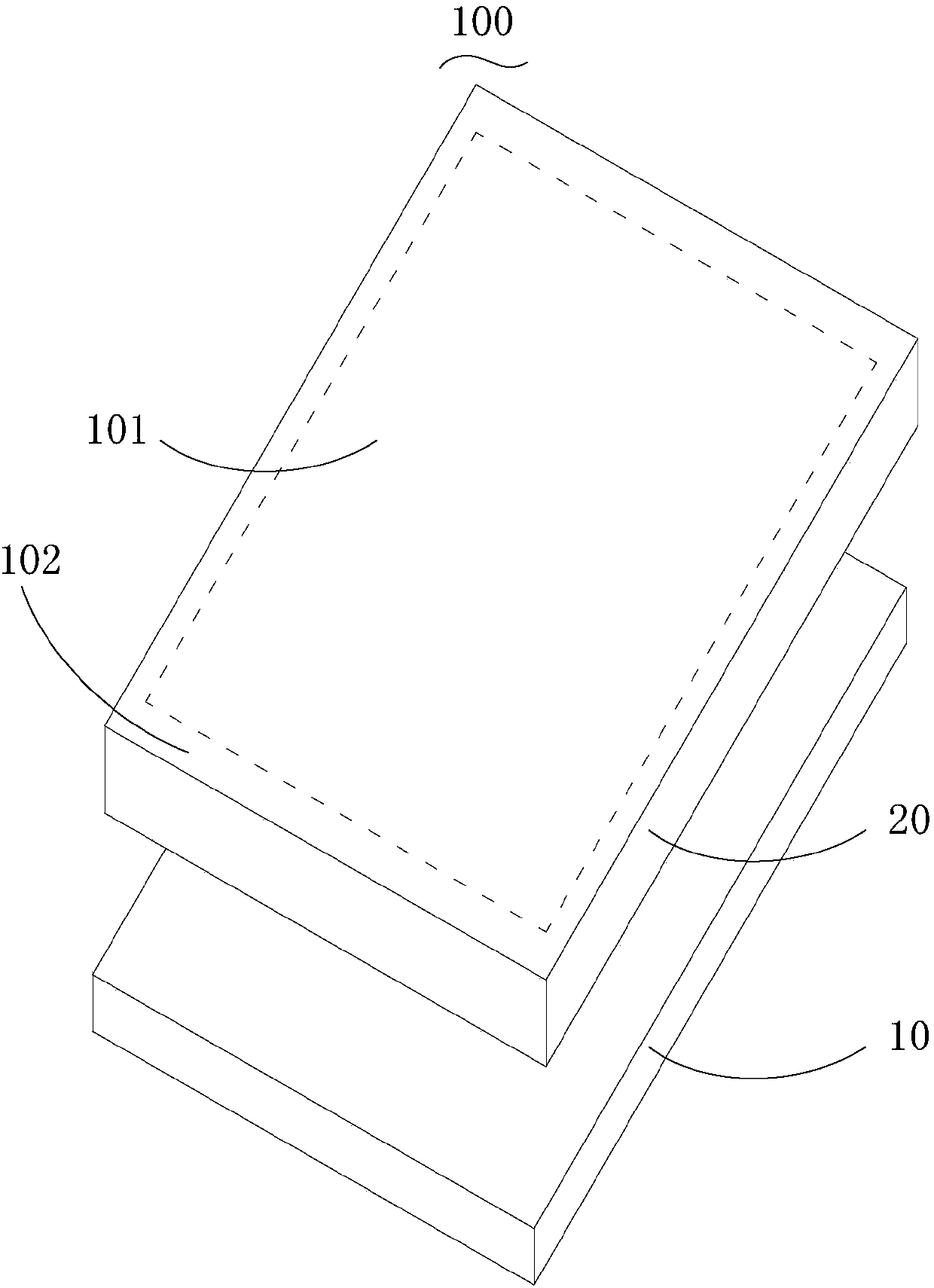

Integrated surface mode biosensor

InactiveUS20090103099A1Sensitive highEasy to manufactureScattering properties measurementsNanoopticsAnalyteSurface mode

An optical detection system (100) for detecting biological, chemical or bio-chemical particles is described. The optical detection system (100) typically comprises a surface mode interference means. The surface mode interference means may comprise a layer (102) such as for example a metal layer like e.g. a gold layer. The surface mode interference means furthermore typically is adapted to create an interference effect between optical interface modes of the layer to detect optical changes in the vicinity of the layer (102). In this way, sample (106) occurring in the vicinity of the surface may be detected. The present invention furthermore relates to a method for performing optical detection and to a method for setting up an optical detection system wherein parameters are selected for tuning the surface mode interference means to a desired wavelength range and / or to a desired range of analyte refractive indices.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW) +1

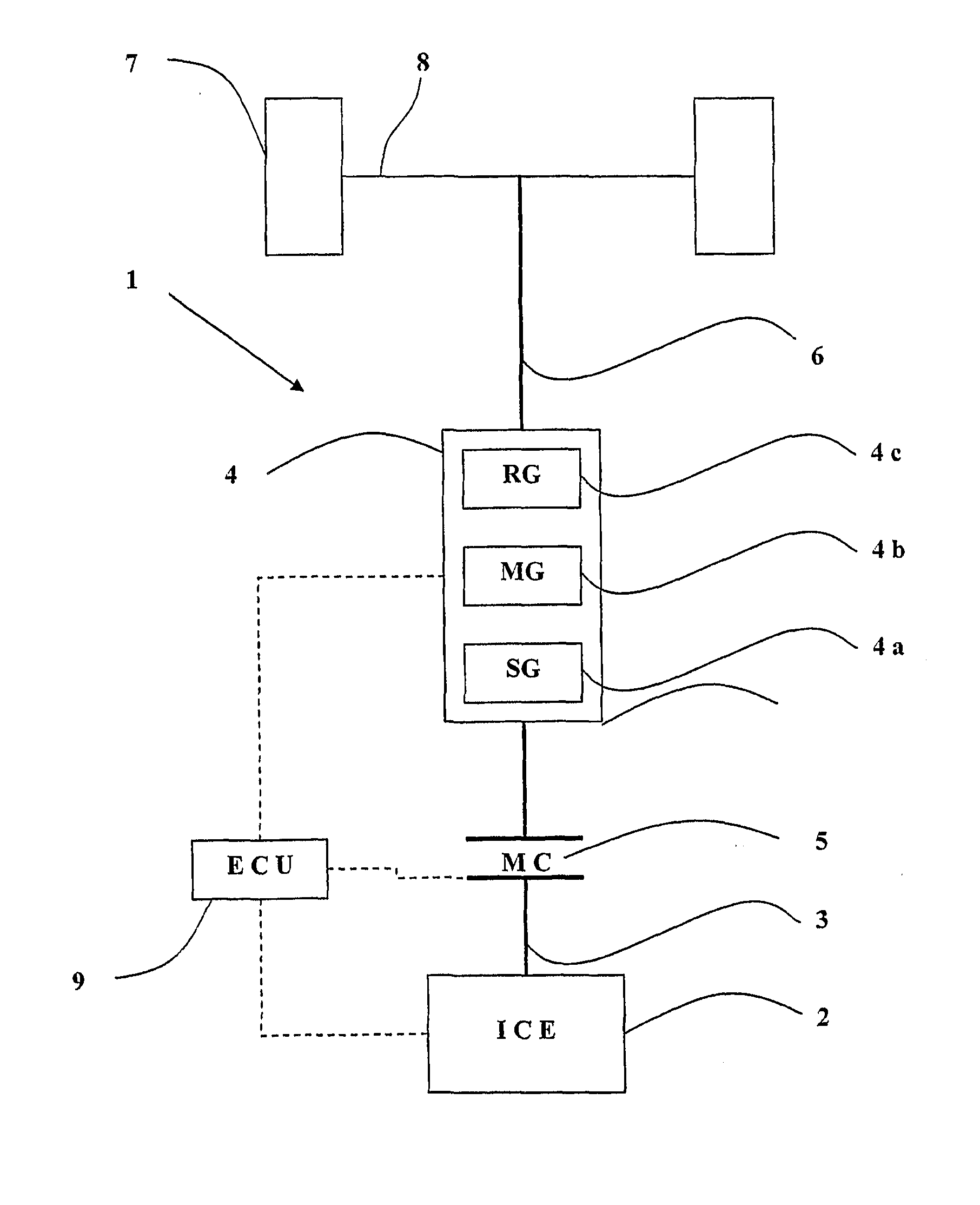

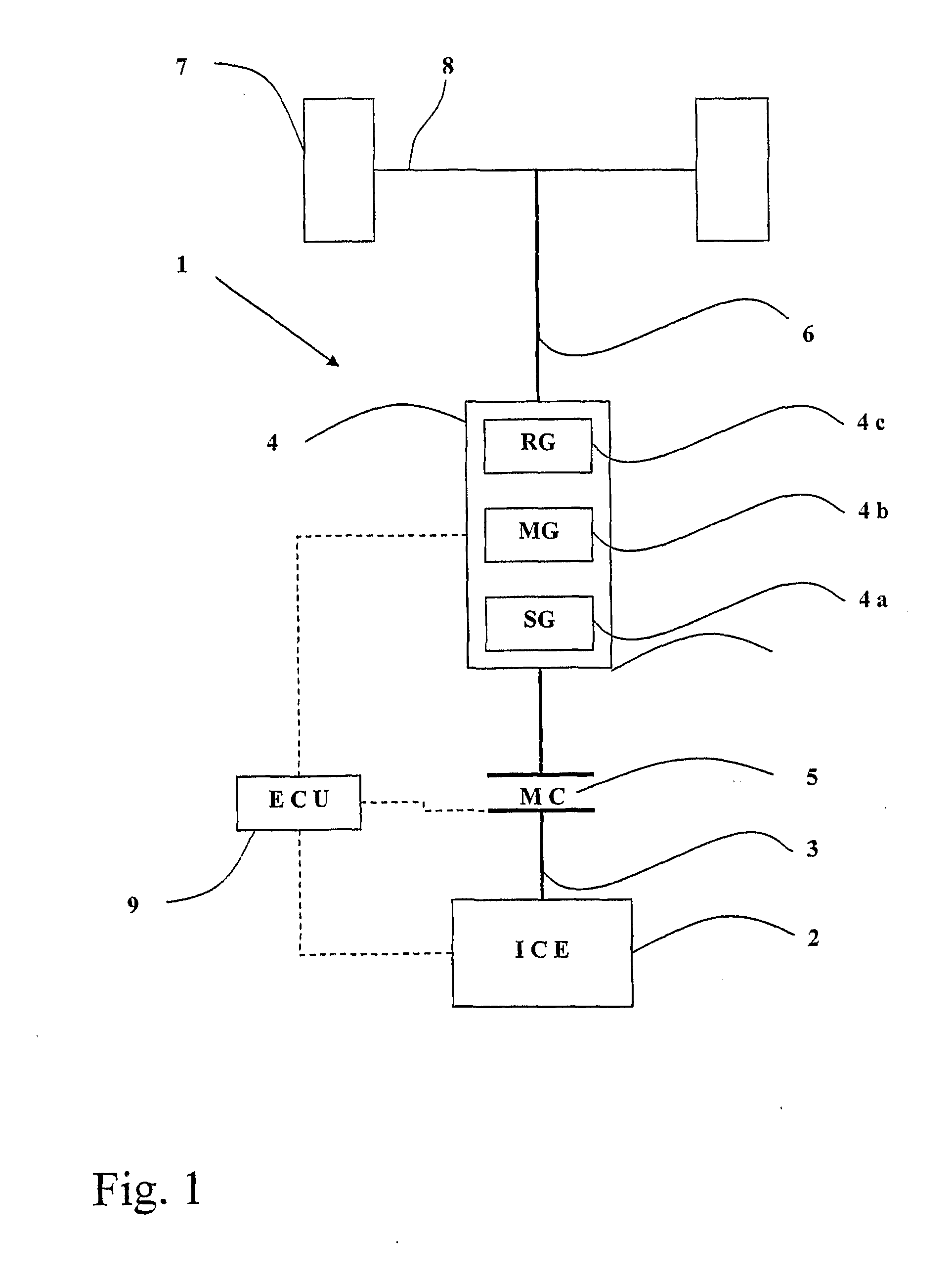

Method and system for controlling a vehicle powertrain

ActiveUS20110190993A1Shorten shift timeGood chance to succeedDigital data processing detailsGearing controlSurface modeNormal mode

A method and system for controlling a powertrain in a vehicle includes steps including registering a road condition. If the registered road condition corresponds to normal road conditions then a first gear selection control algorithm is used intended for driving the vehicle in a normal mode corresponding to the conditions on an ordinary road. If the registered road condition corresponds to soft surface road conditions then a second gear selection control algorithm is used intended for driving the vehicle in a soft surface mode corresponding to the conditions on an soft surface road. In this way, a vehicle can be adapted to be provided with an AMT to work in a satisfactorily way under an increased diversity of conditions.

Owner:VOLVO LASTVAGNAR AB

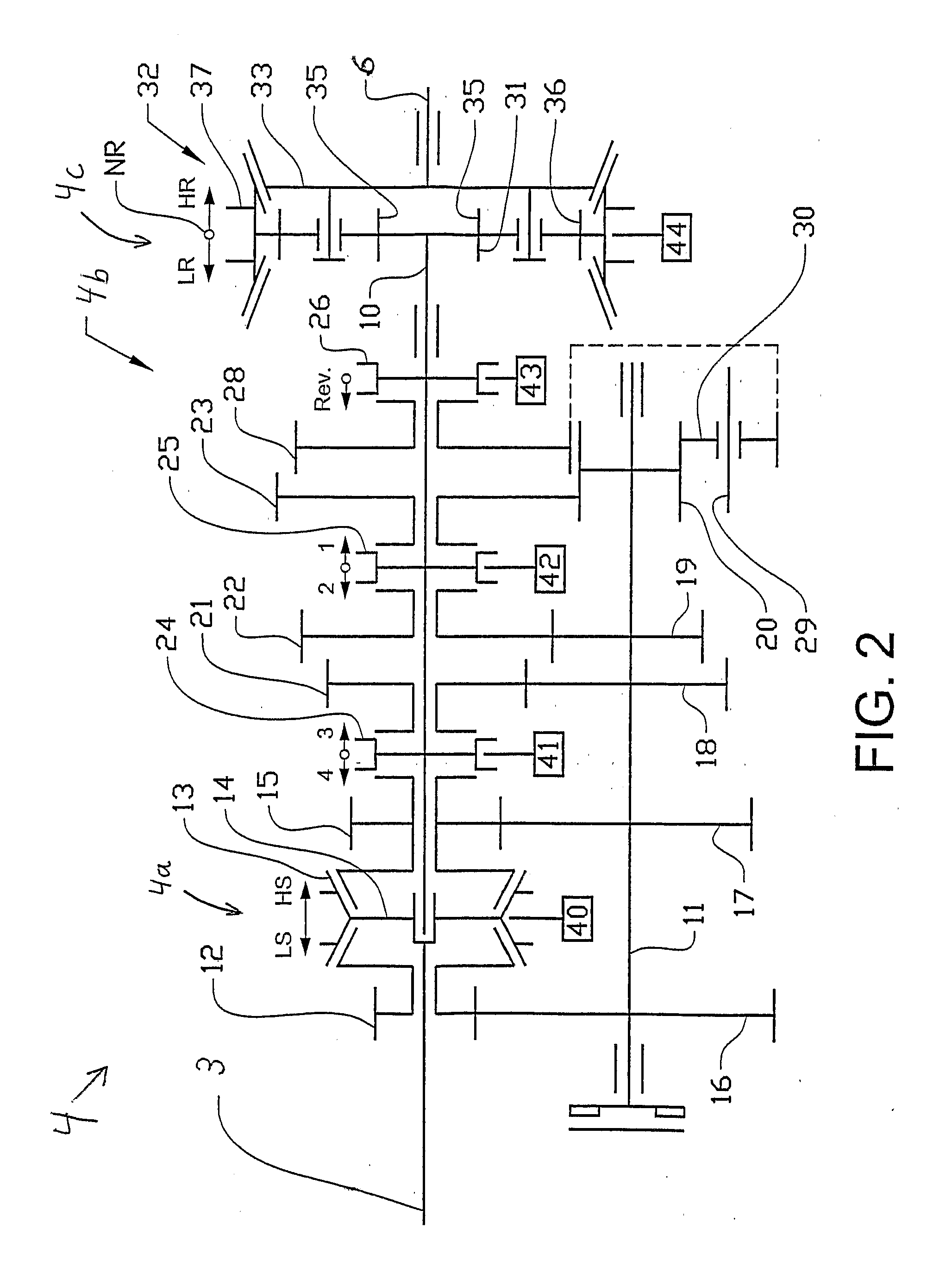

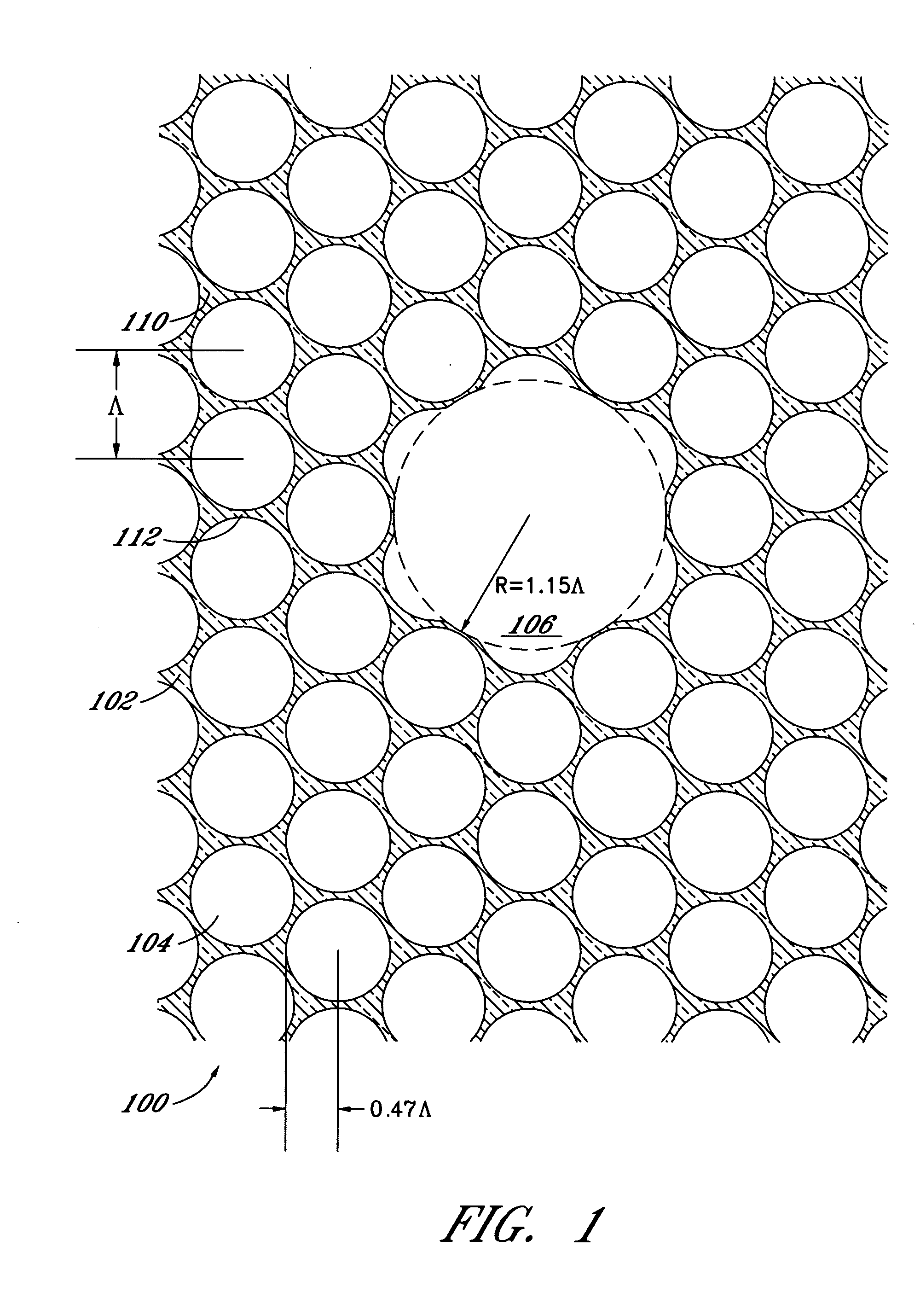

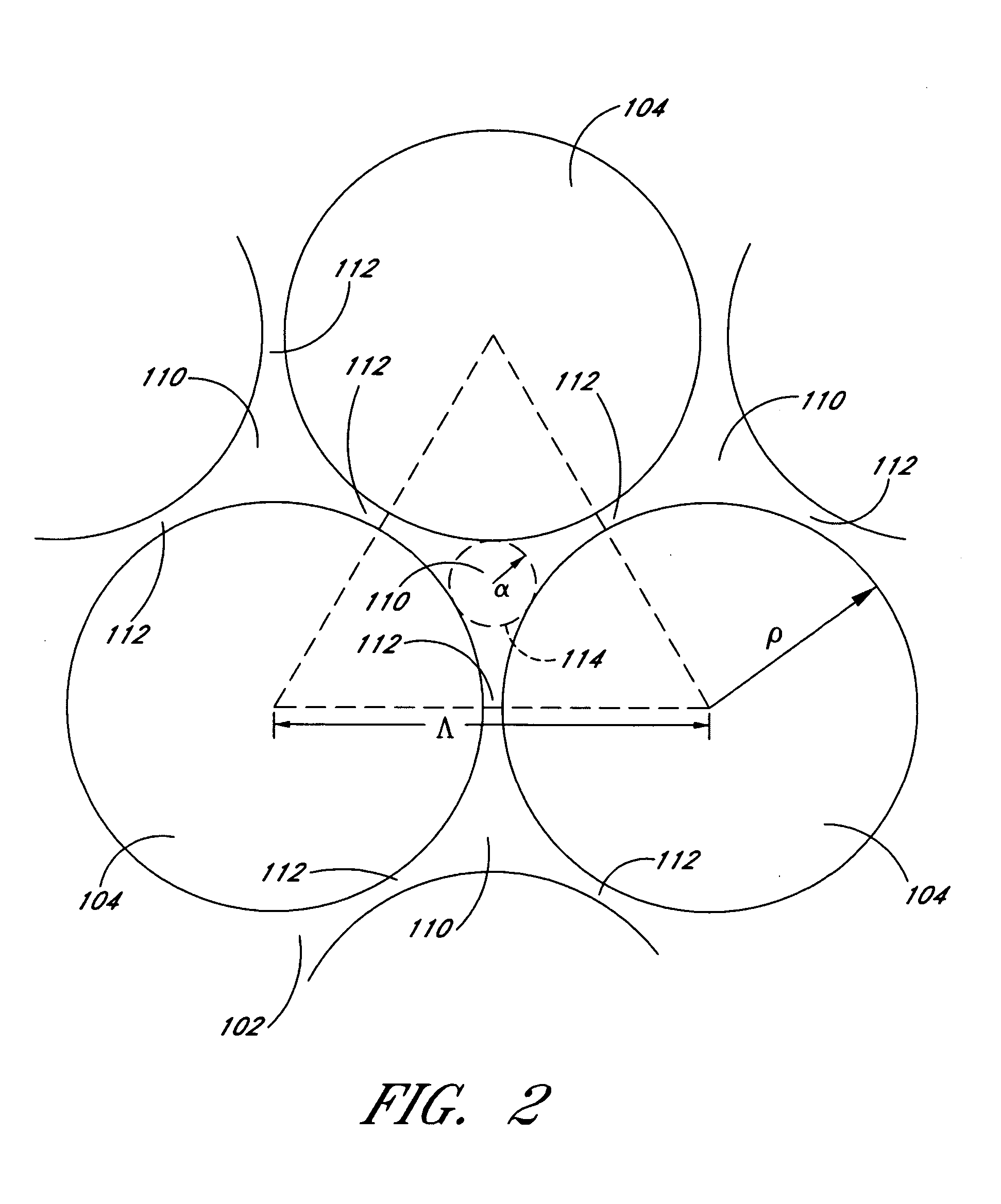

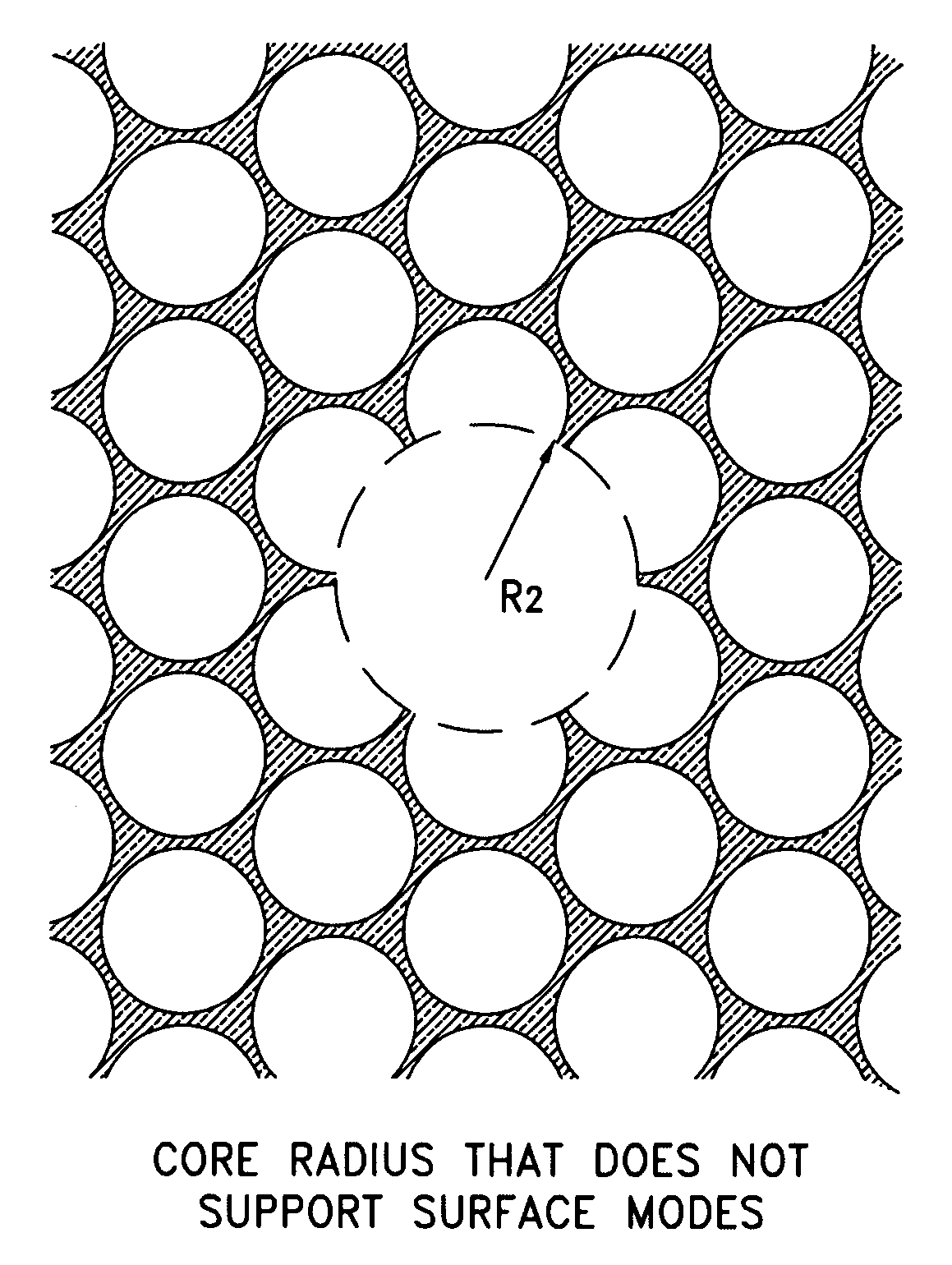

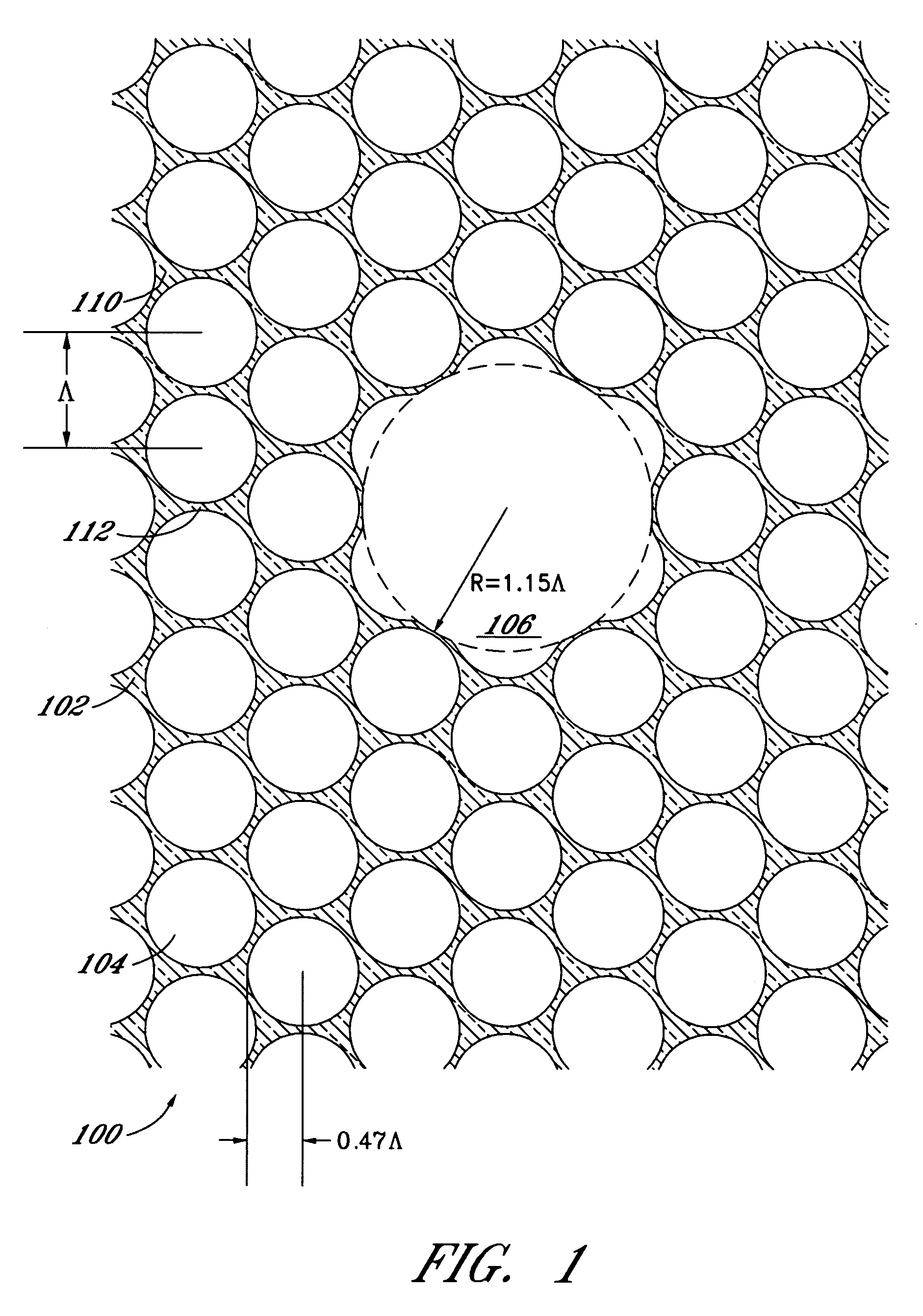

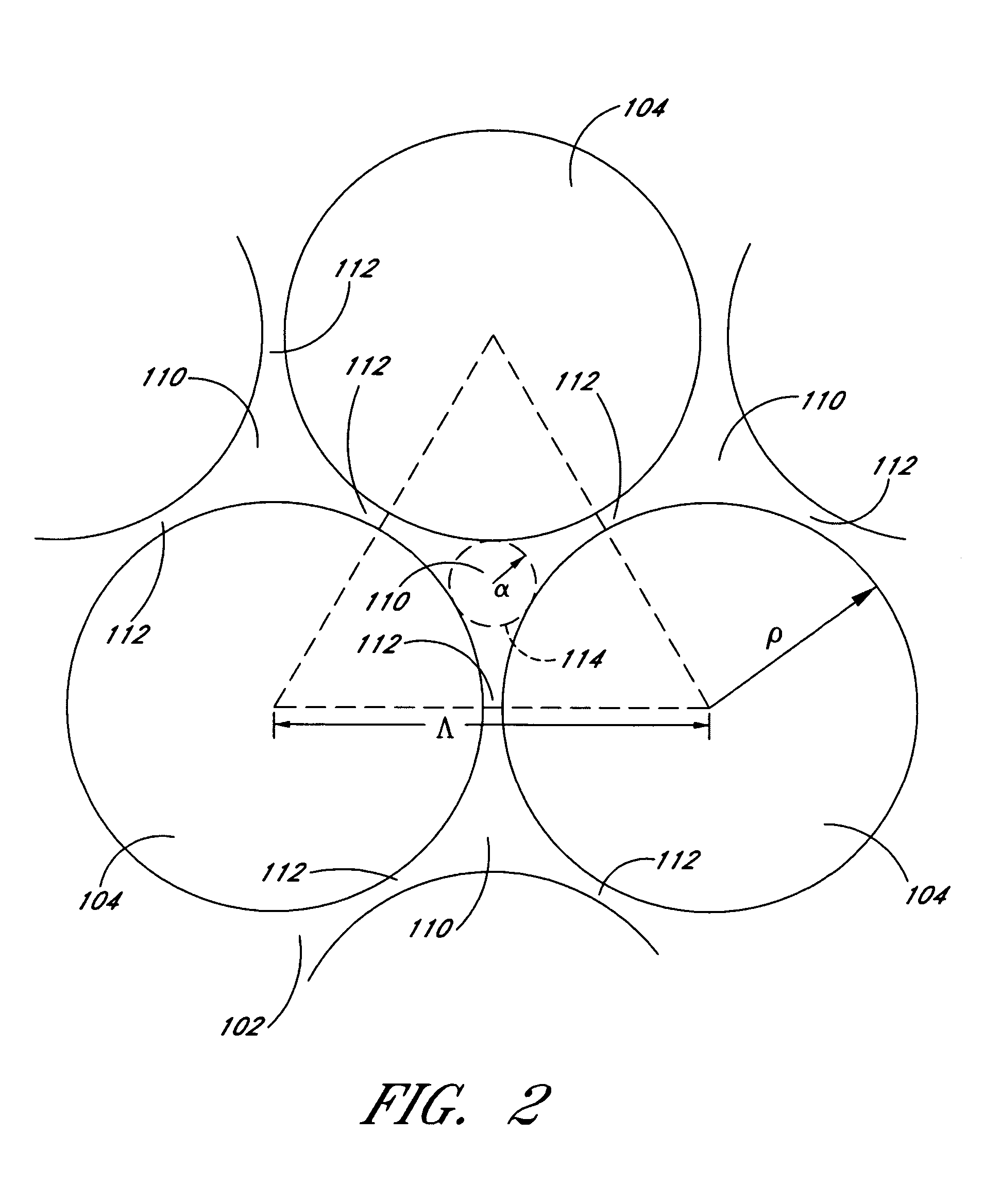

Method for configuring air-core photonic-bandgap fibers free of surface modes

ActiveUS20050118420A1Reduce lossQuicker and less complicatedOrganic active ingredientsCladded optical fibreSurface modePhotonic bandgap

Coupling of core modes to surface modes in an air-core photonic-bandgap fiber (PBF) can cause large propagation losses. Computer simulations analyze the relationship between the geometry and the presence of surface modes in PBFs having a triangular hole pattern and identify ranges of core characteristic dimensions (e.g., radii) for which the fiber supports no surface modes (i.e., only core modes are present) over the entire wavelength range of the bandgap. In particular, for a hole spacing Λ and a hole radius ρ=0.47Λ, the core supports a single mode and supports no surface modes for core radii between about 0.7Λ and about 1.05Λ, which suggests that such fibers should exhibit a very low propagation loss. The existence of surface modes can be predicted simply and expediently by studying either the bulk modes alone or the geometry of the fiber without requiring a full analysis of the defect modes.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

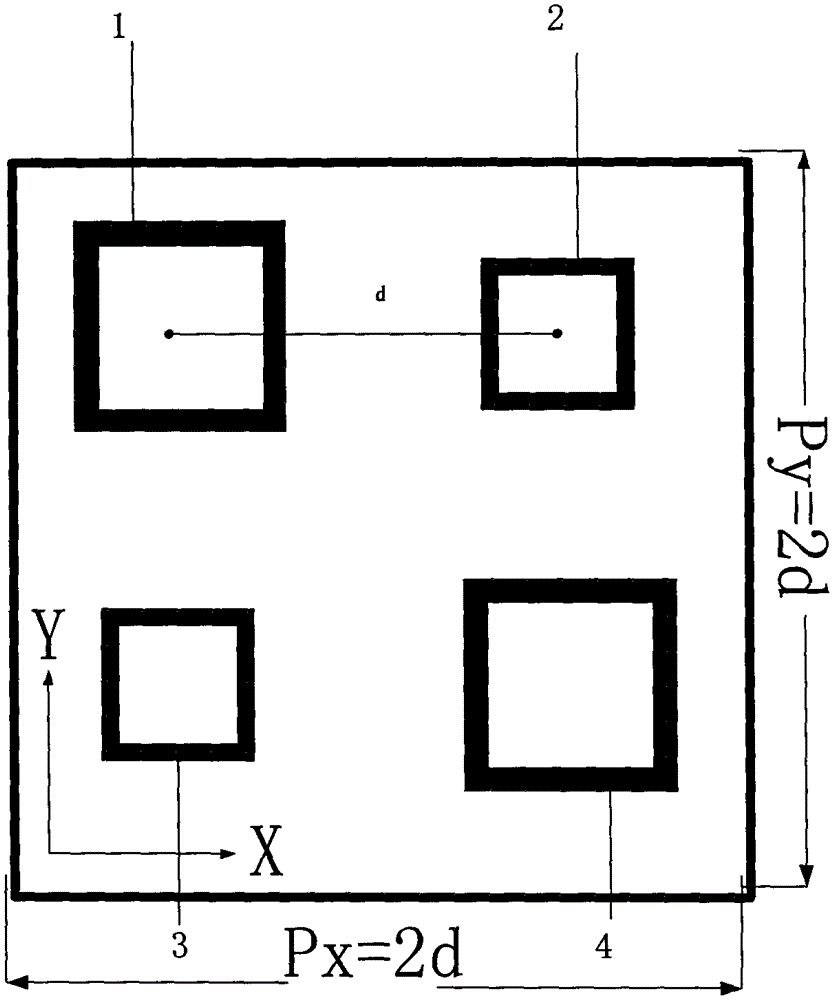

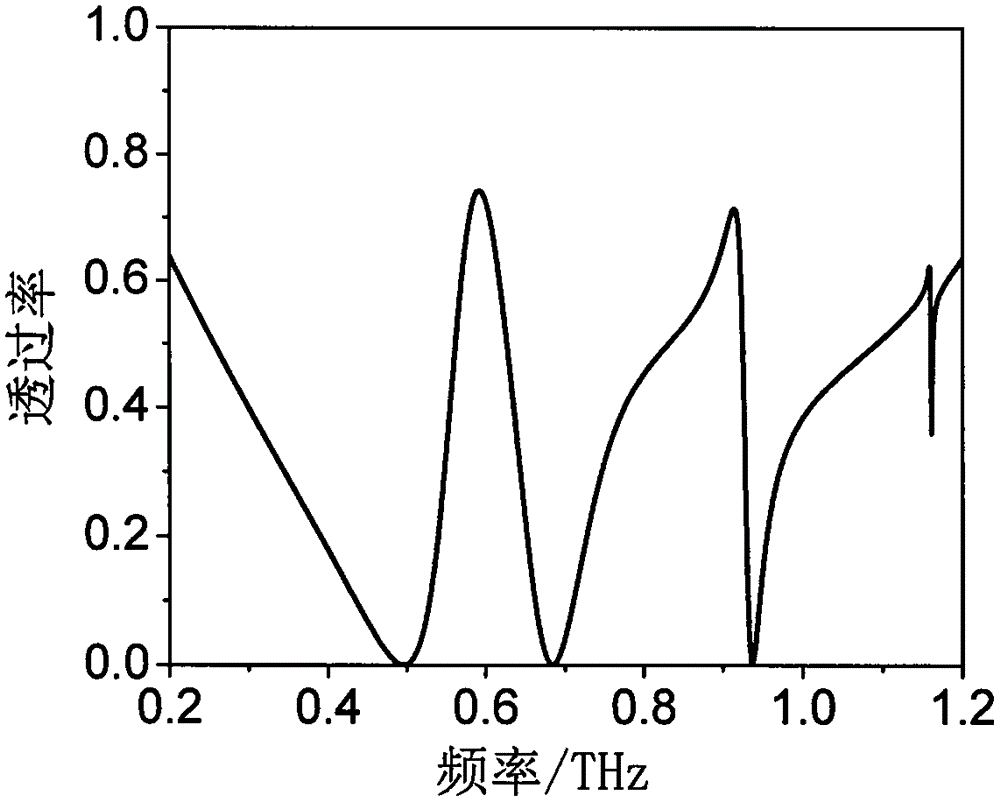

Polarization-insensitive meta-material resonance apparatus with adjustable guided-mode resonance quality factor

InactiveCN105633588AAchieving Electromagnetic Induction TransparencyAntennasDiffraction effectGrating

The invention discloses a polarization-insensitive meta-material resonance apparatus with an adjustable guided-mode resonance quality factor. The polarization-insensitive meta-material resonance apparatus comprises a planar waveguide and a meta-material unit that is arranged on the planar waveguide and is formed by a metal resonance unit. The meta-material resonance unit having a complex structure includes four metal resonance rings, wherein the four metal resonance rings is symmetric about the center of the resonance unit; and side lengths of the first metal resonance ring and the second metal resonance ring are not equal. Therefore, the resonance apparatus is not sensitive to the polarization. Besides, with the similar raster diffraction effect of the meta-material cladding layer, guided-mode resonance can be realized; and when the sizes of the metal resonance rings are changed, the quality factor of the guided-mode resonance can be adjusted and the mutual effect of the guided mode and the surface mode can be controlled, thereby realizing electromagnetic induction transparency.

Owner:CHINA JILIANG UNIV

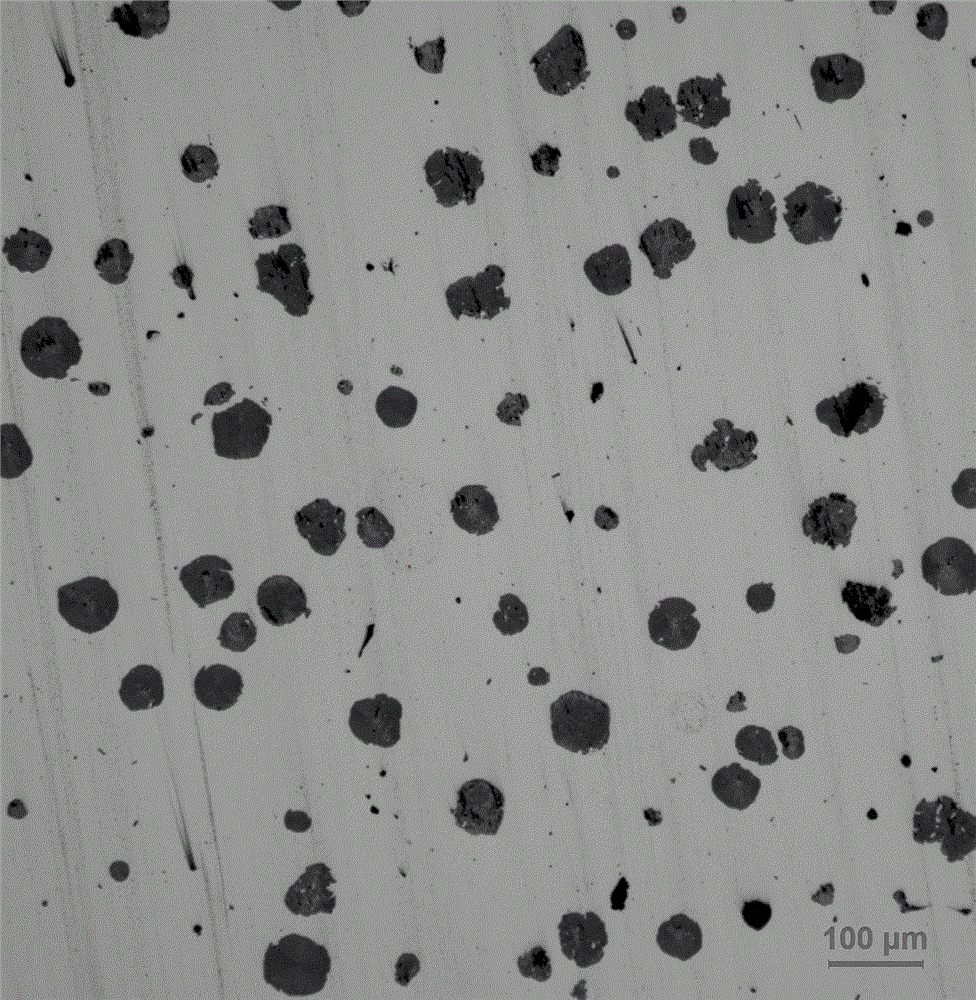

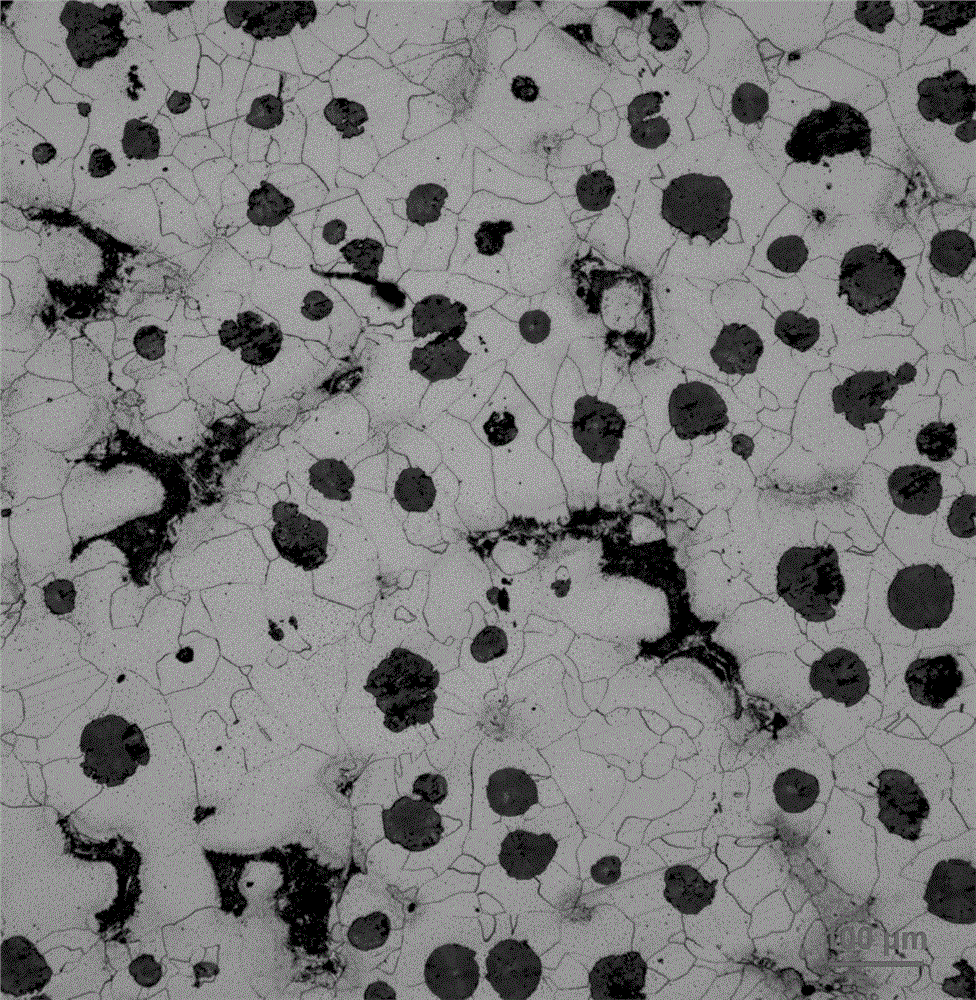

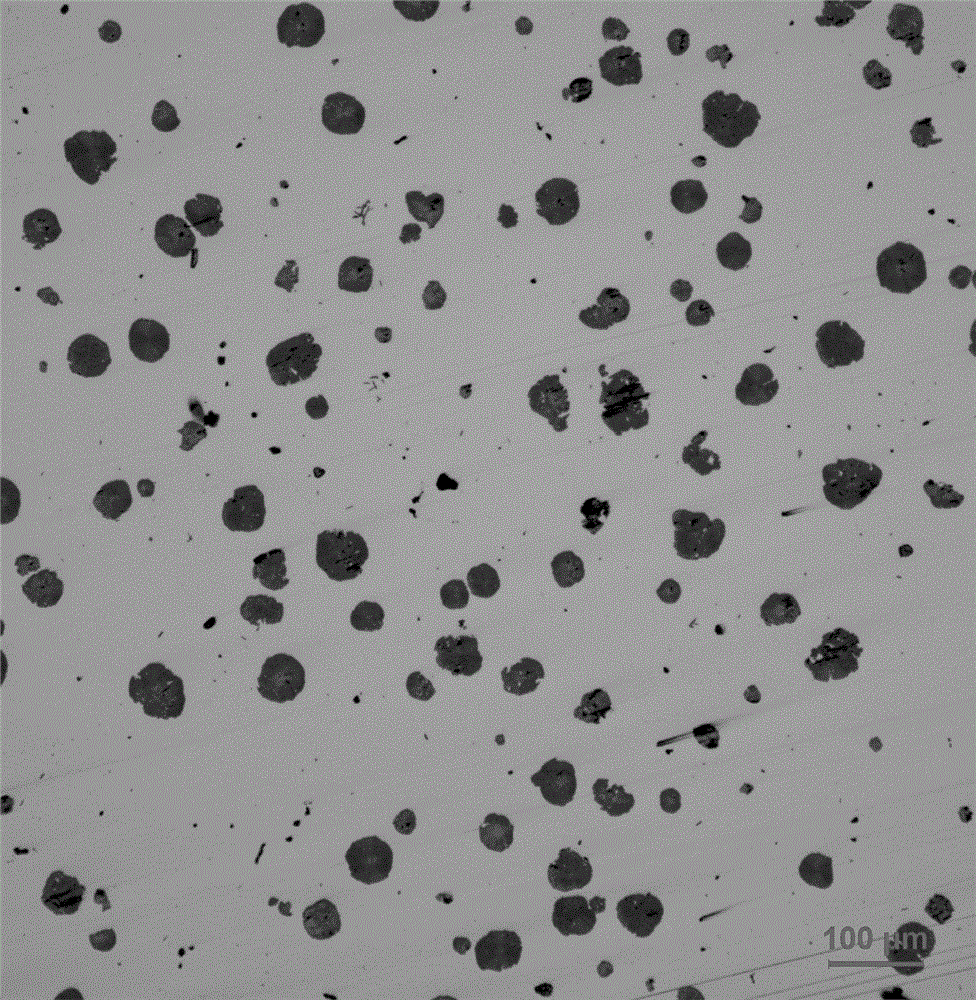

Synthesis and preparation process for high-silicon-molybdenum ductile iron material

The invention relates to a synthesis and preparation process for a high-silicon-molybdenum ductile iron material. The synthesis and preparation process specially comprises the following steps that raw materials are prepared, and the raw materials comprise, by mass, 60%-70% of scrap steel, 25%-35% of cast iron, 1%-1.2% of silicon iron, 1%-1.3% of ferro-molybdenum and 2%-2.5% of carburant; in the raw material melting process, furnace burdens are added in three batches; all the cast iron and 1 / 3 mass part of scrap steel are added in the first batch of furnace burdens, 5 / 11 mass part of carburant and 1 / 3 mass part of scrap steel are added in the second batch of furnace burdens, and 5 / 11 mass part of carburant and 1 / 3 mass part of scrap steel are added in the third batch of furnace burdens; after the third batch of furnace burdens are completely molten down, all the silicon iron and ferro-molybdenum are added, and when the temperature of molten iron rises to 1400-1410 DEG C, the remaining 1 / 11 mass part of carburant is added in a mirror surface mode after slagging-off impurity removal; and sampling analysis, blending, tapping, nodulizing and inoculation treatment are performed until pouring is completed. According to the process, the scrap steel is used as a main raw material, and the joint carbon adding mode of middle adding and mirror surface adding is adopted for preparing high-silicon-molybdenum ductile cast iron with high strength and high impact toughness.

Owner:KOCEL EQUIP

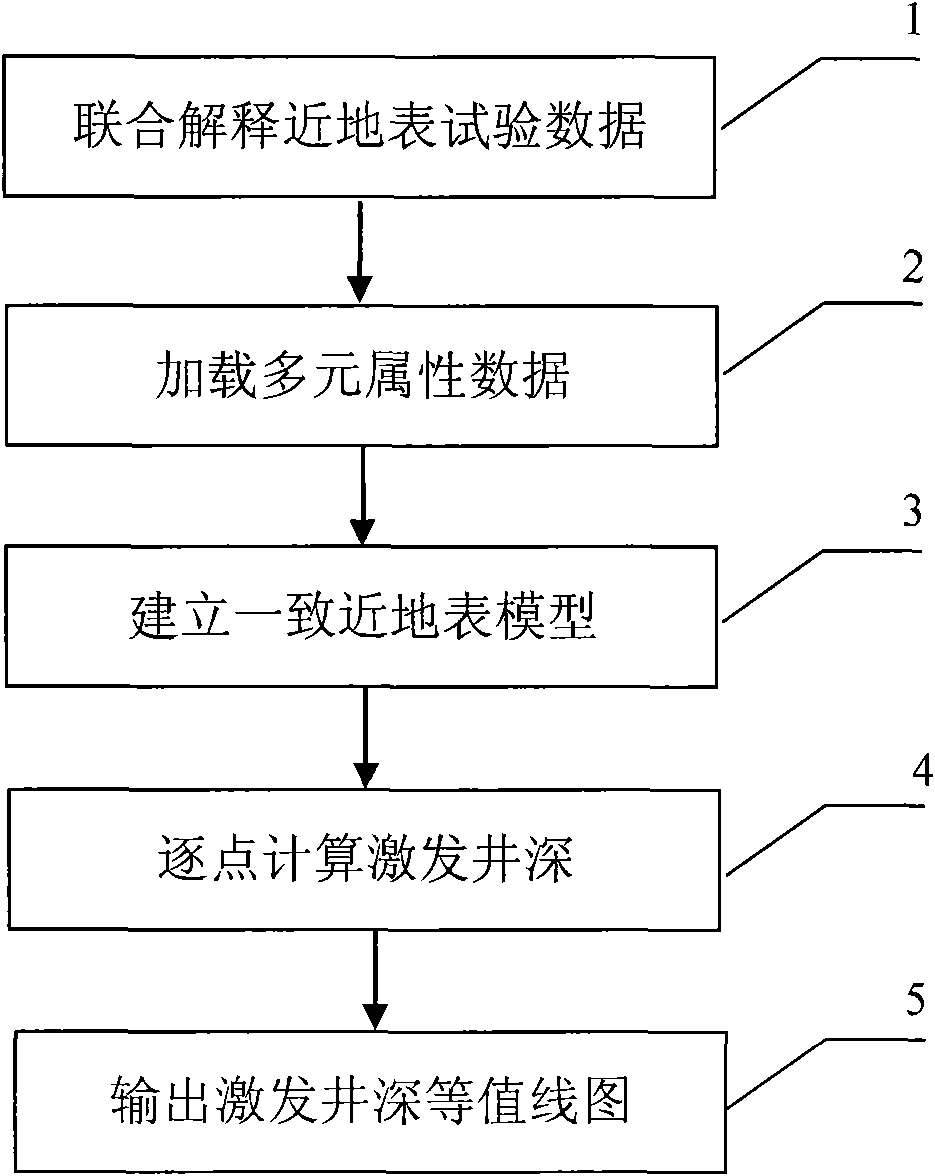

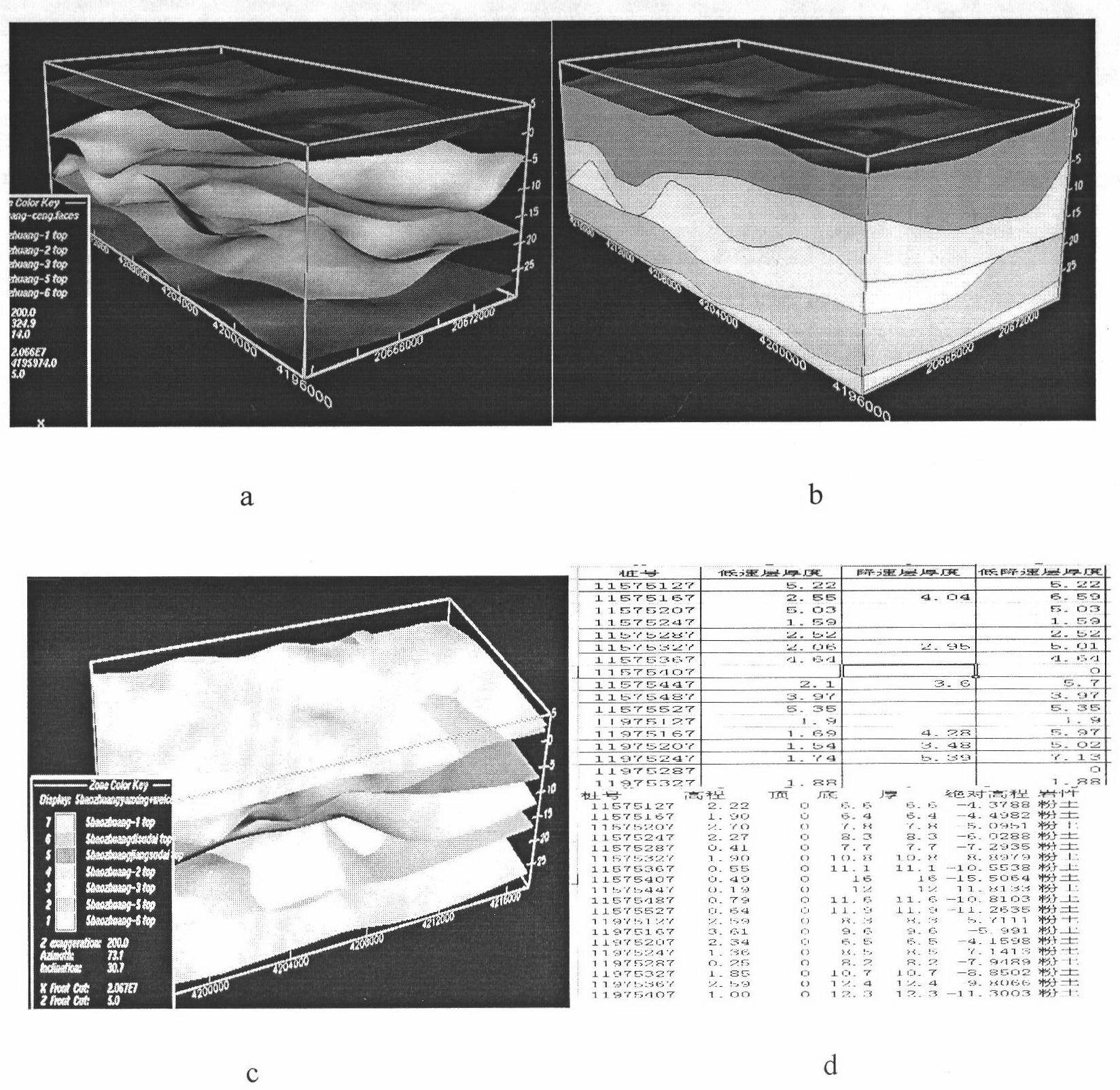

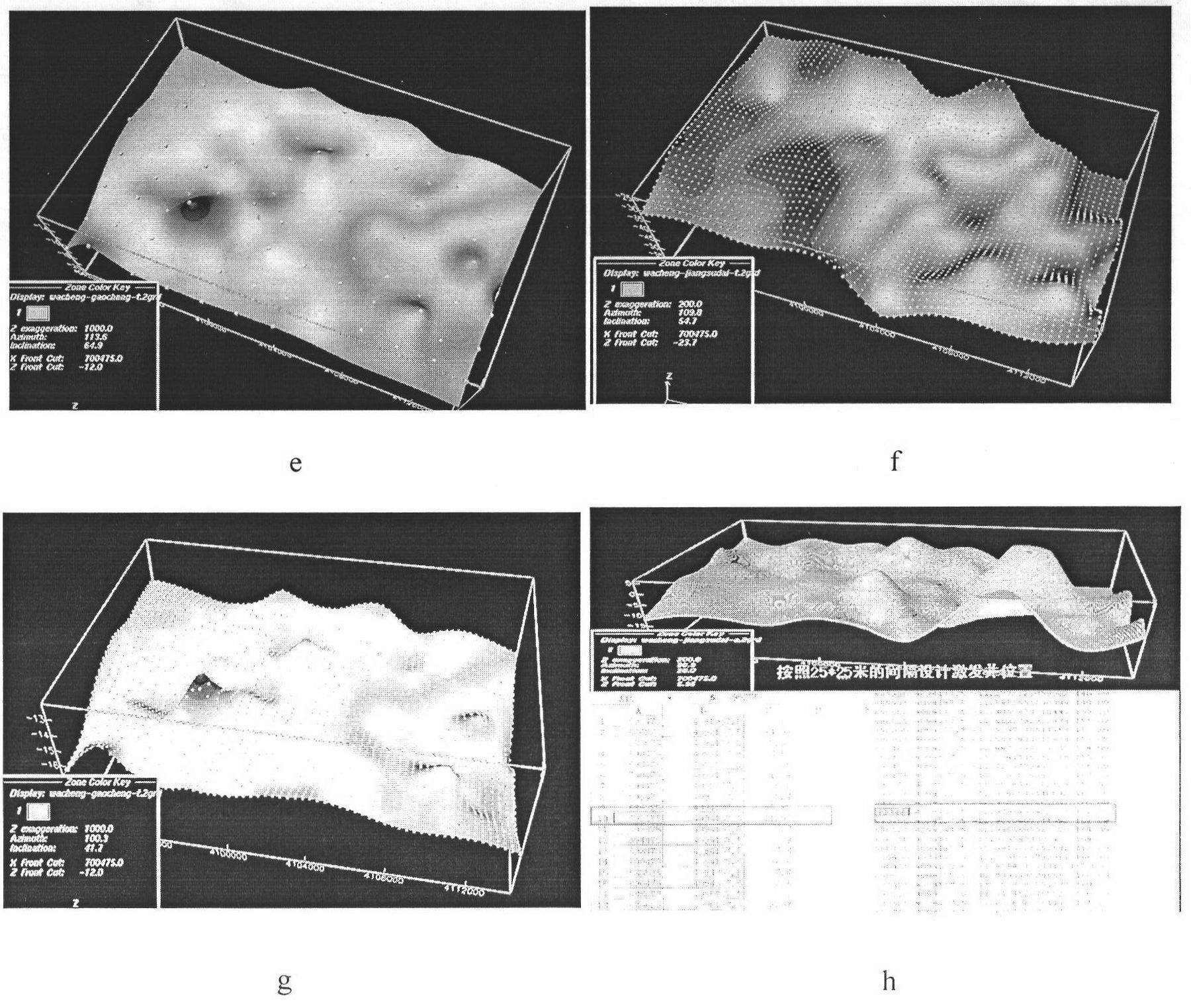

Point-by-point excitation well depth designing method based on uniform near-surface model

InactiveCN101788686ASimple designImprove recording signal-to-noise ratioSeismic signal processingSeismology for water-loggingLithologyDepth in a well

The invention discloses a point-by-point excitation well depth designing method based on a uniform near-surface model. The method comprises the following steps of: A. obtaining optimum lithological hierarchical data and optimum speed hierarchical data by combining interpretation; B. programming a data conversion interface program and loading multiple attribute data; C. establishing a comprehensive and uniform near-surface model according to the lithological hierarchical data and the optimum speed hierarchical data obtained after combining interpretation, data of the submersible surface and submersible well, speed data and absorption attenuation A values; D. carrying out point-by-point excitation well depth designing and static correction value calculation on the uniform near-surface model; and E. loading the generated excitation well depth dispersive point data into the system again to generate a contour map in a CGM (Computer Graphic Metafile)format, marking a position by using a small rectangular patters, displaying the depth value of the point, and plotting the processed result map by using a plotter. The invention can optimize the excitation well depth design, enhance the signal-to-noise ratio of the earthquake collecting single-shot record, and greatly improve the information quality.

Owner:CHINA PETROCHEMICAL CORP +1

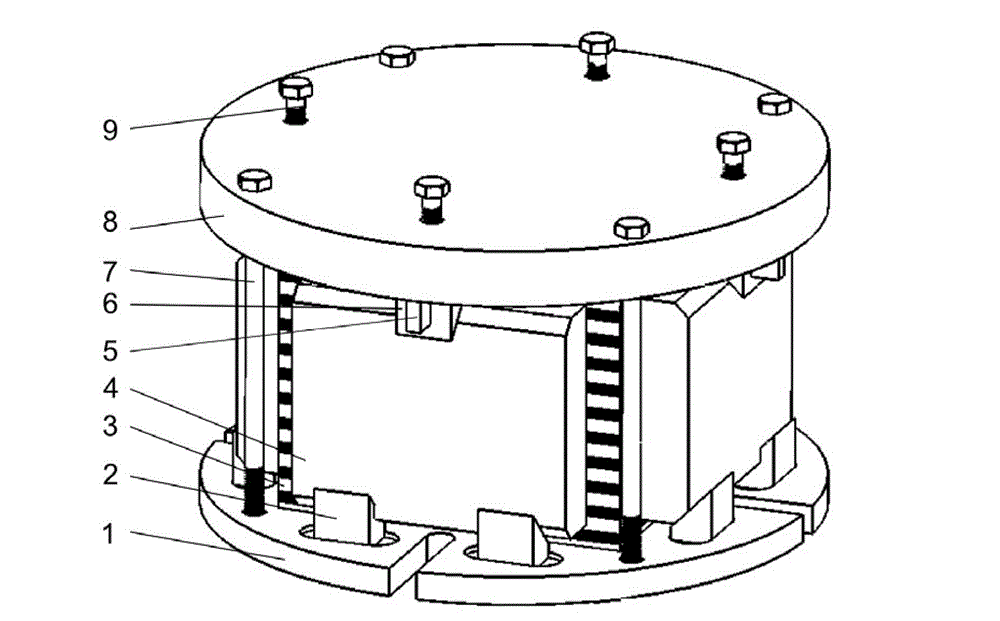

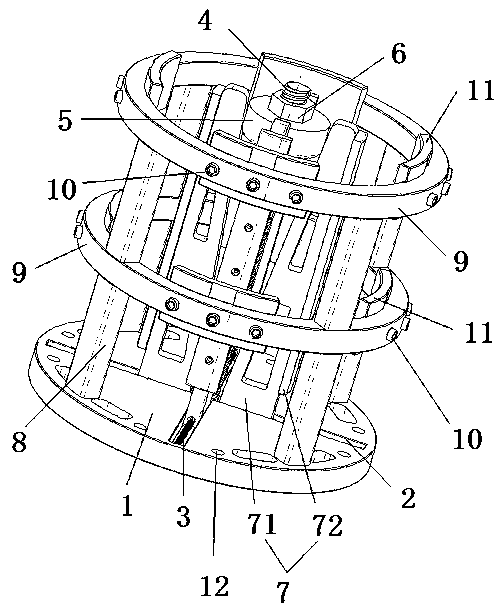

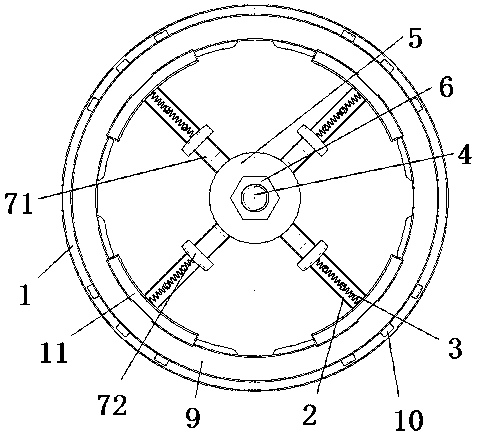

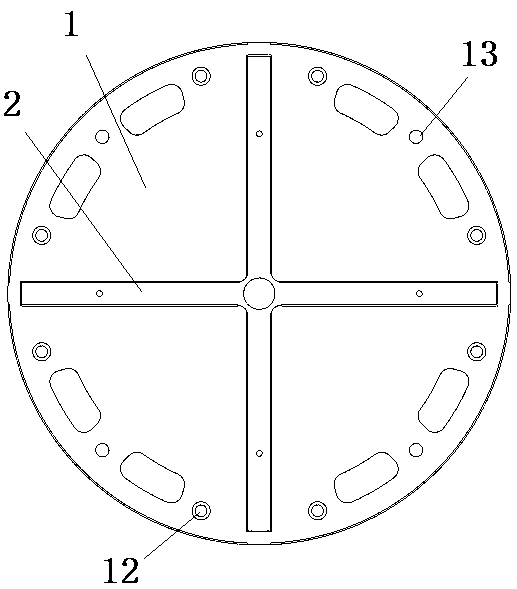

Vibration damping tool for machining thin-wall cylindrical workpieces

PendingCN110303358ASimple structureEasy to processPositioning apparatusMaintainance and safety accessoriesHydraulic cylinderSurface mode

The invention relates to a vibration damping tool for machining thin-wall cylindrical workpieces. The vibration damping tool for machining the thin-wall cylindrical workpieces comprises a tool base, wherein the tool base is provided with an inner supporting device, and the inner supporting device comprises workpiece inner wall support pieces, a support piece top pushing block and a pushing block drive unit; at least three or more workpiece inner wall support pieces are uniformly arranged around the axis of the tool base and movably arranged on the tool base along the radial direction of the tool base; the support piece top pushing block is arranged in a middle space enclosed by each workpiece inner wall support piece and matched with each workpiece inner wall support piece in a wedge surface mode; the pushing block drive unit is connected between the tool base and the support piece top pushing block, and used for the support piece top pushing block to move up and down so as to achievesynchronous movement of each workpiece inner wall support piece along the radial direction of the base through the wedge surface. Compared with a scheme that hydraulic cylinders are arrayed along thecircumferential direction of cylindrical workpieces to support the cylindrical workpieces, the vibration damping tool for machining the thin-wall cylindrical workpieces has the advantages of being simple in structure and low in cost.

Owner:LUOYANG PENGQI IND

Method for configuring air-core photonic-bandgap fibers free of surface modes

ActiveUS7110650B2Lower refractive indexReduce lossOrganic active ingredientsCladded optical fibreSurface modePhotonic bandgap

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

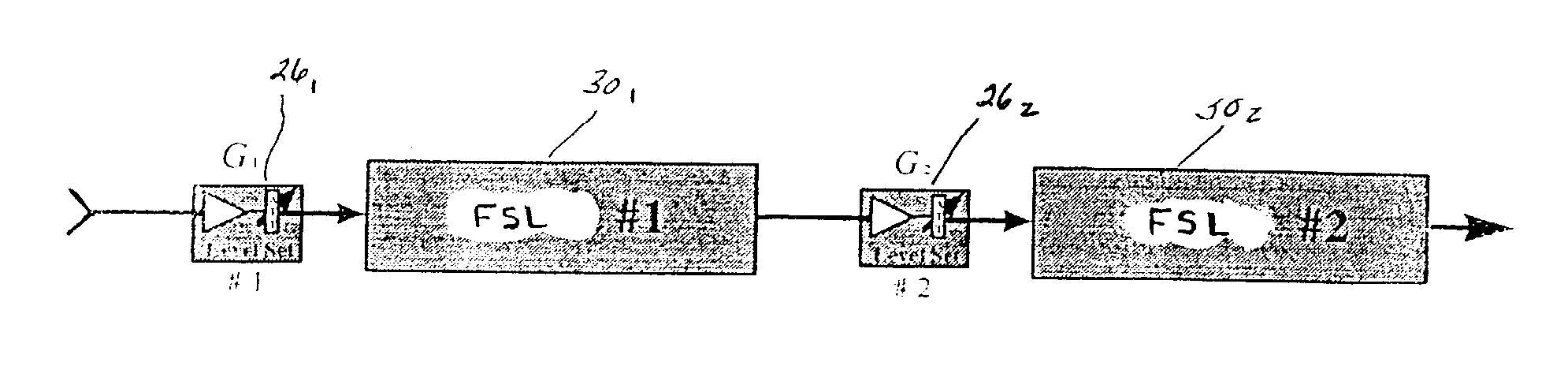

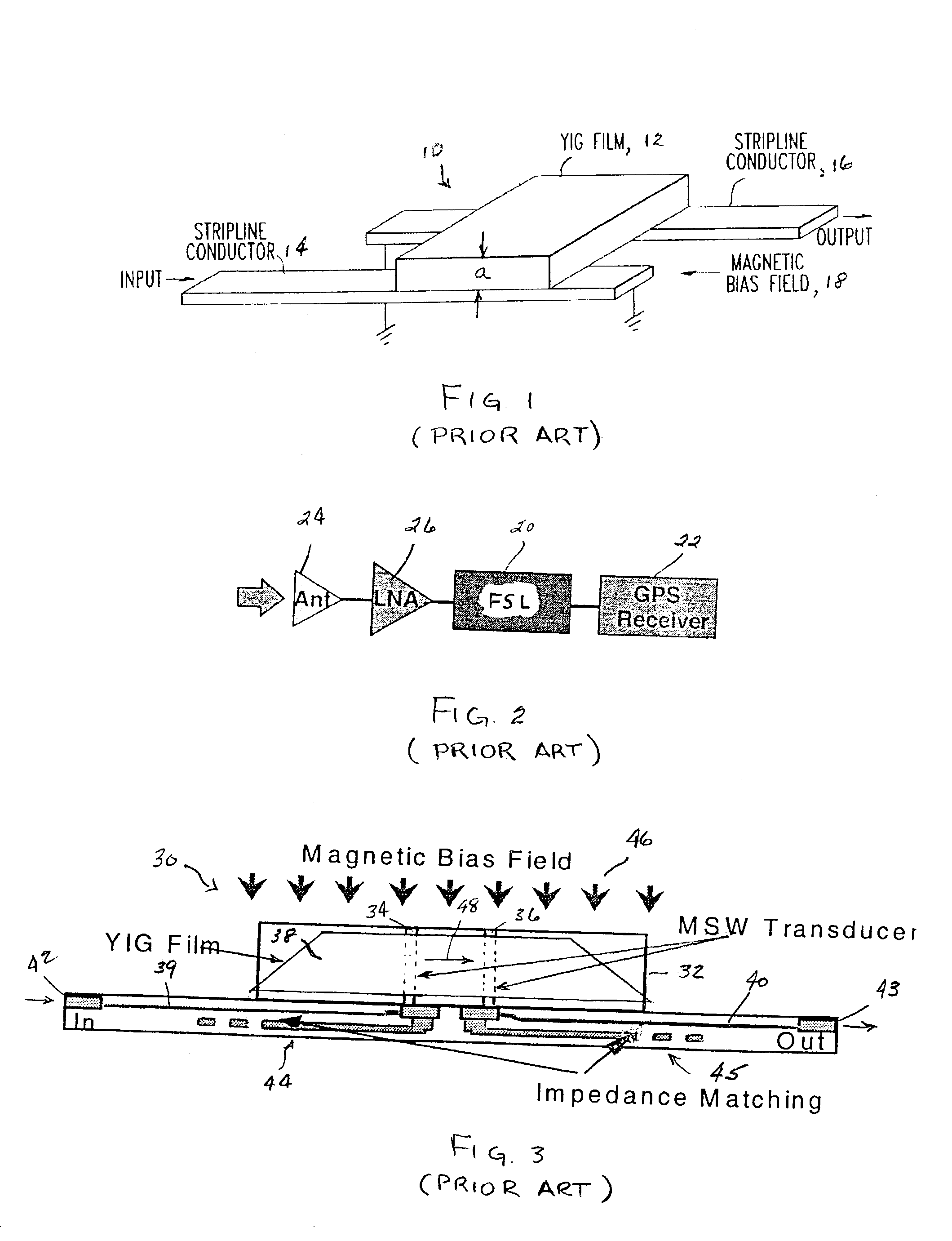

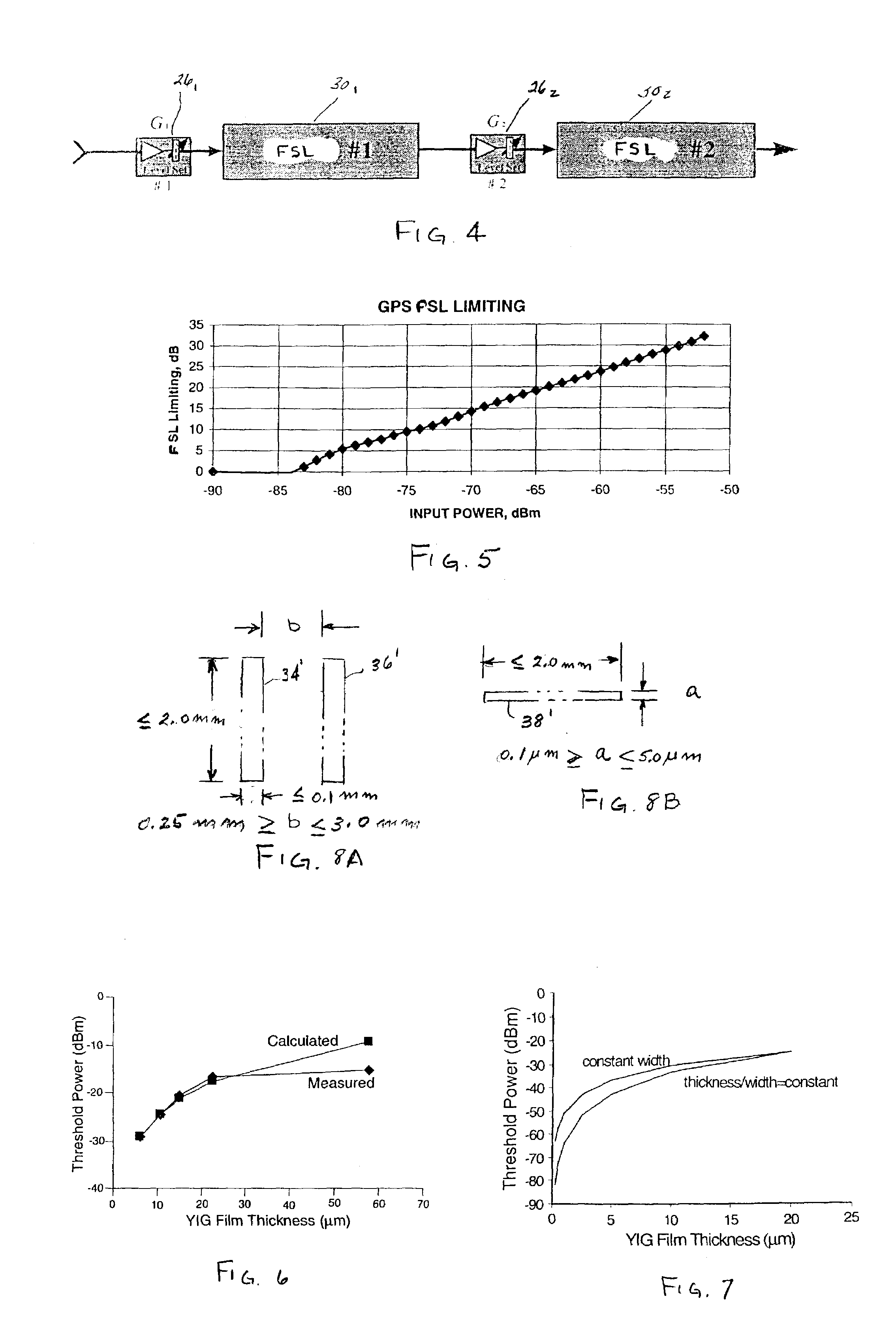

Low threshold power frequency selective limiter for GPS

InactiveUS6998929B1Suppress interferenceJam suppressionImpedence networksDynamo-electric converter controlSurface modeTransducer

A frequency selective limiter operative in a magnetostatic surface mode with a pair of parallel microstrip transducers formed on a substrate and having a length at least equal to the width of an overlaying YIG film ranging in thickness from about 0.1 μm and about 5.0 μm and having a width equal to or less than about 20. mm and which is biased by a permanent magnetic field applied in the plane of the film parallel to the transducers so that magnetostatic surface waves propagate therebetween in the YIG film so as to provide a limiter threshold level in the range of −75 dBm to −35 dBm. The transducers have specific spacings and dimensions.

Owner:NORTHROP GRUMMAN SYST CORP

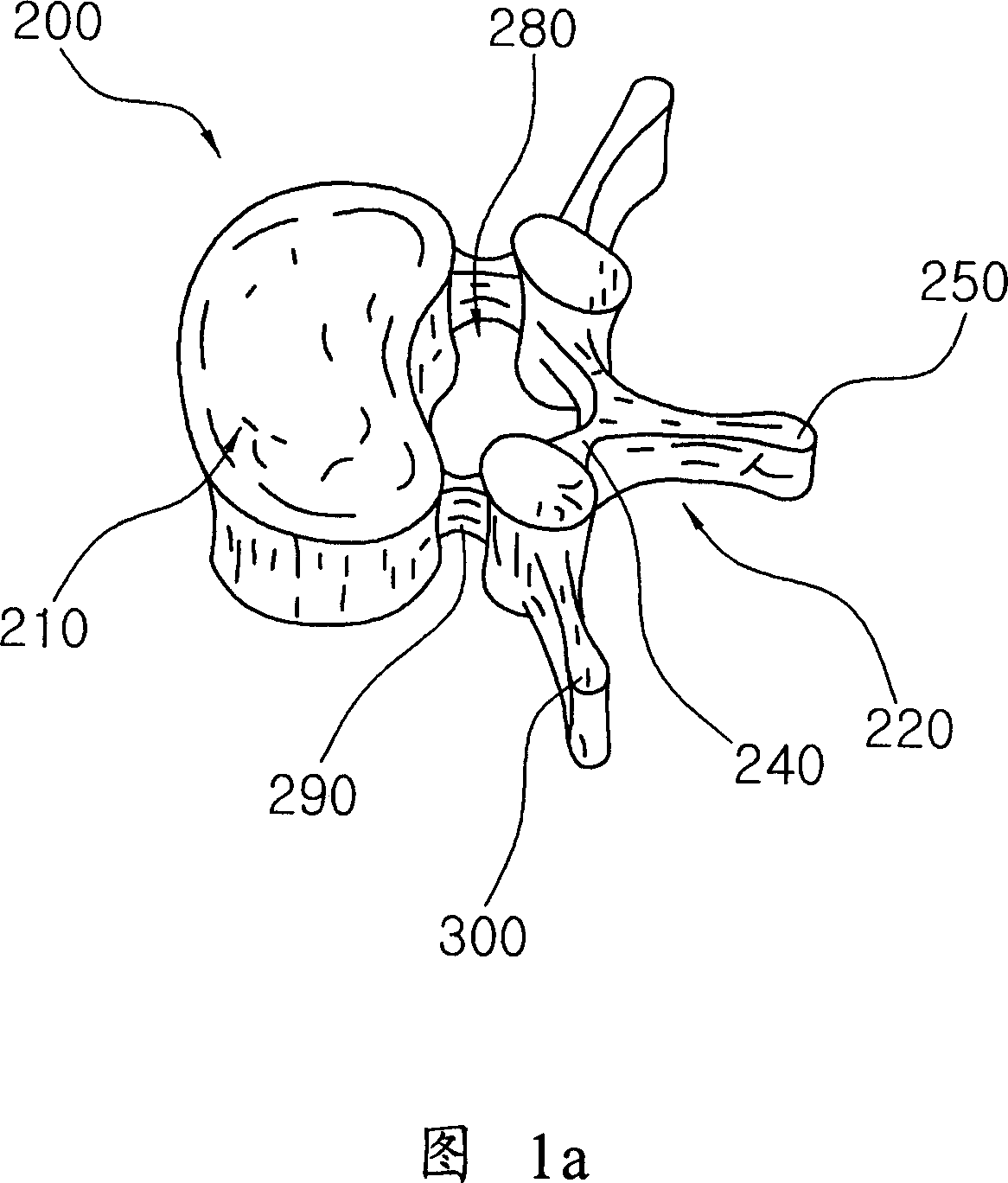

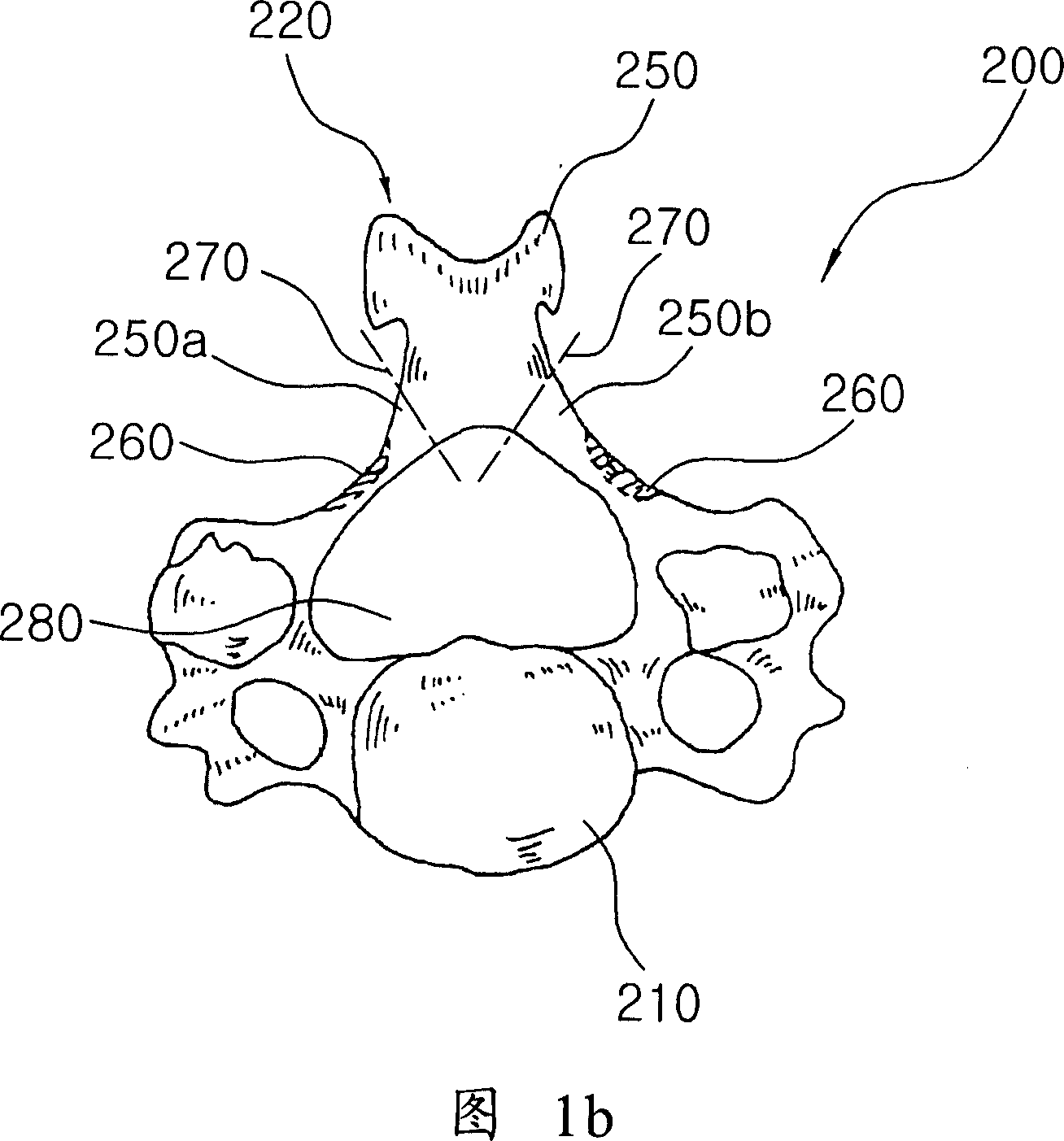

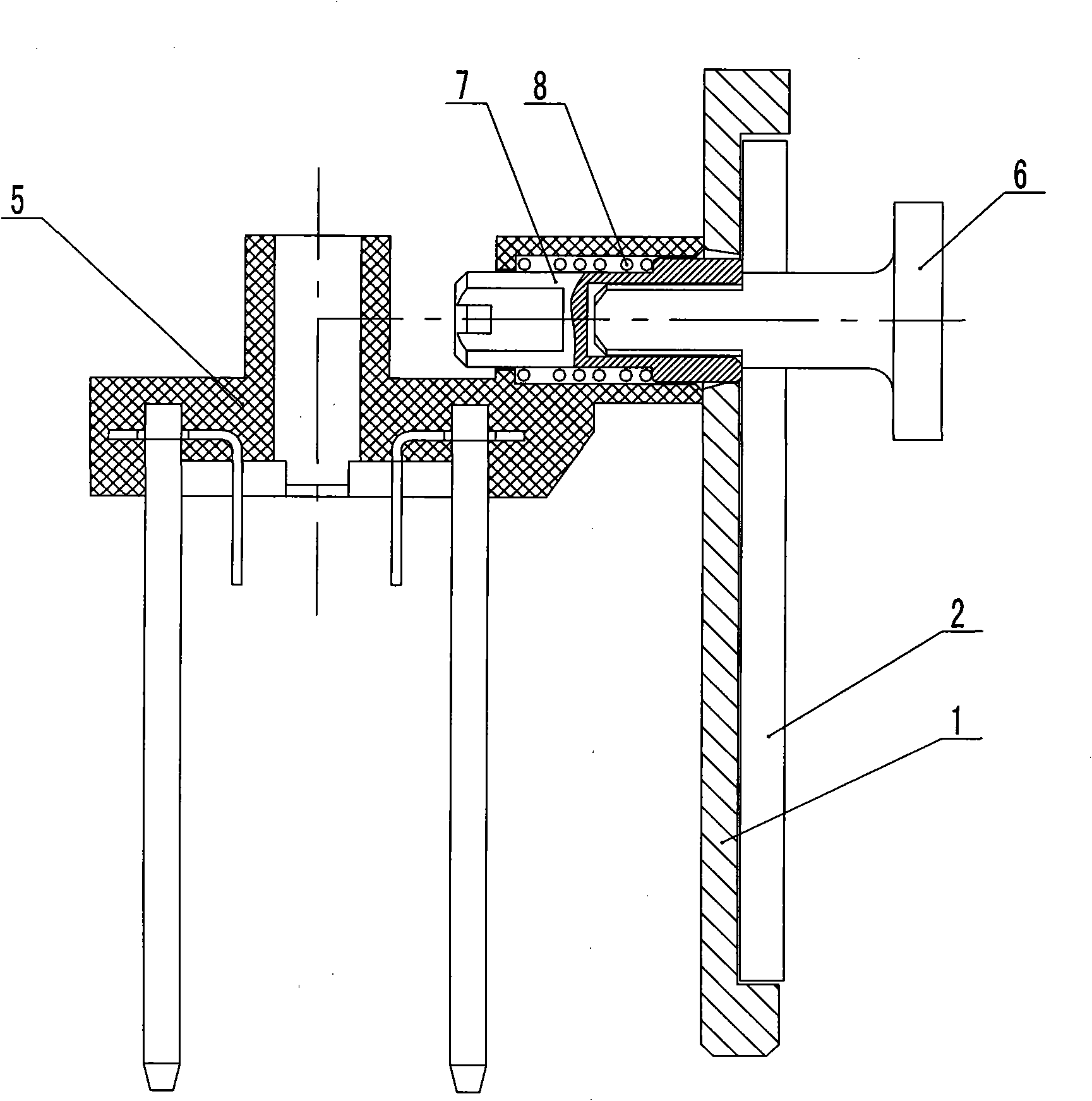

Vertebral arch positioning stent for cervical vertebra spinal canal enlargement operation

InactiveCN101049254AShorten the timeIncrease contact areaInternal osteosythesisSpinal implantsSurface modeSacroiliac joint

The present invention provides a vertebral arch orientation frame using for vertebral canal enlargement operation of the cervical vertebra body. The orientation frame includes springy deformation part which is setted in the middle and is composed of material with excellent spring. The first and the second combination part which connect to the two end of the given springy deformation part separately and combine with the dissected post-arch surface of the cervical vertebra body. This invention plays the articular function through the given springy deformation part, there is setted a pair of bone conductivity combination part composing of biological activity ceramic which can combine with the bone directly on the two end of the springy deformation part. The bone conductivity combination part can deform corresponding with the dissected post-arch surface mode with various angle and size when the post-arch of the cervical vertebra body forming so as to possess the larger contacting area with the dissected post-arch and implement combination completely.

Owner:BIOALPHA CORP

Methods and Apparatus for Moving a Vehicle Up or Down a Sloped Surface

ActiveUS20100051371A1Guaranteed to move normallyReduce amountVehicle fittingsDigital data processing detailsGround contactSurface mode

A system and method for safely moving a vehicle up or down a sloped surface is provided. In one embodiment, a method involves operating the vehicle in a sloped surface mode when at least one ground contacting element for moving the vehicle is on the sloped surface. An amount of torque is provided to the at least one ground contacting element to prevent the vehicle from uncontrollably moving down the sloped surface while in the sloped surface mode of operation. An assist mechanism can be coupled to the propulsion system to enable an operator to guide the vehicle.

Owner:SEGWAY INC

Method for manufacturing GaN epitaxial wafers or GaN substrates

InactiveCN104143497AAvoid crackingReduce manufacturing costSemiconductor/solid-state device manufacturingSurface modeLattice defects

The invention discloses a method for manufacturing GaN epitaxial wafers or GaN substrates. The method comprises the steps that (1) silicon oxide is grown on the back surface of a first silicon substrate; (2) the back surface of the first silicon substrate with the silicon oxide is bonded to the back surface of a second silicon substrate so that a third silicon substrate can be formed; (3) silicon nitride or silicon oxynitride are grown on the upper surface and the lower surface of the third silicon substrate; (4) the silicon nitride or silicon oxynitride on the third silicon substrate is etched in a double-surface mode so as to form required patterns; (5) GaN selective epitaxial growth is conducted on the double surfaces of the third silicon substrate; (6) the first silicon substrate and the second silicon substrate are stripped, so that the two GaN epitaxial wafers or the two GaN substrates are formed. According to the method for manufacturing the GaN epitaxial wafers or the GaN substrates, the GaN stress can be relieved effectively, GaN crazing and lattice defects can be overcome, and meanwhile the growth cost can be reduced.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

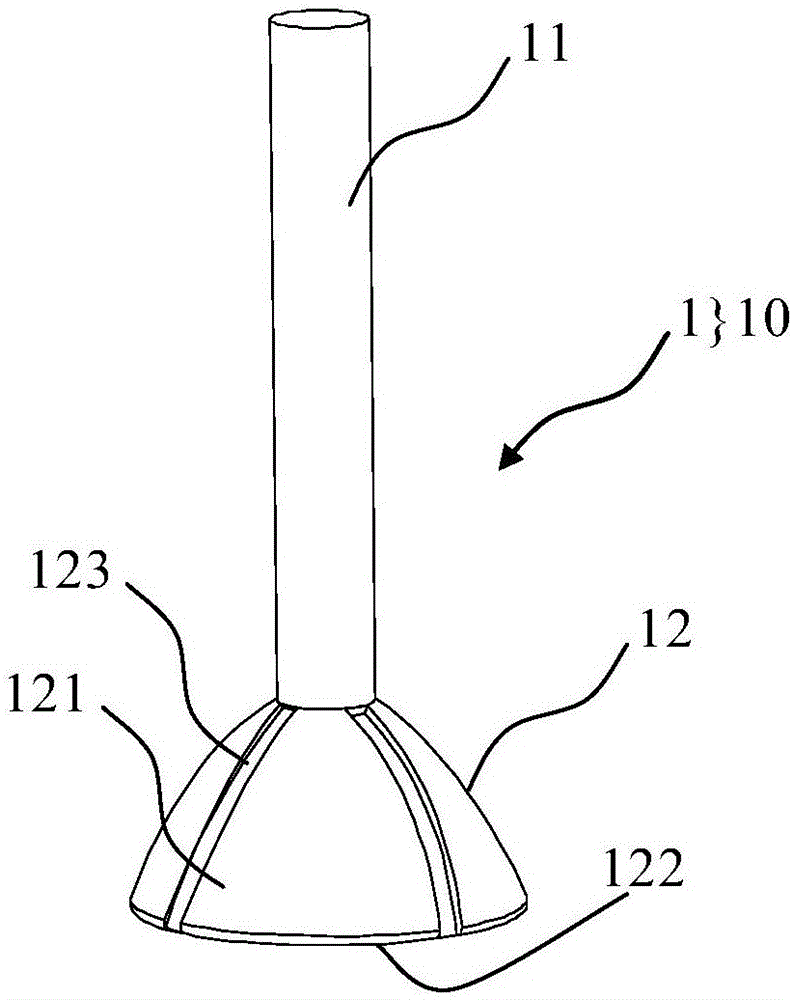

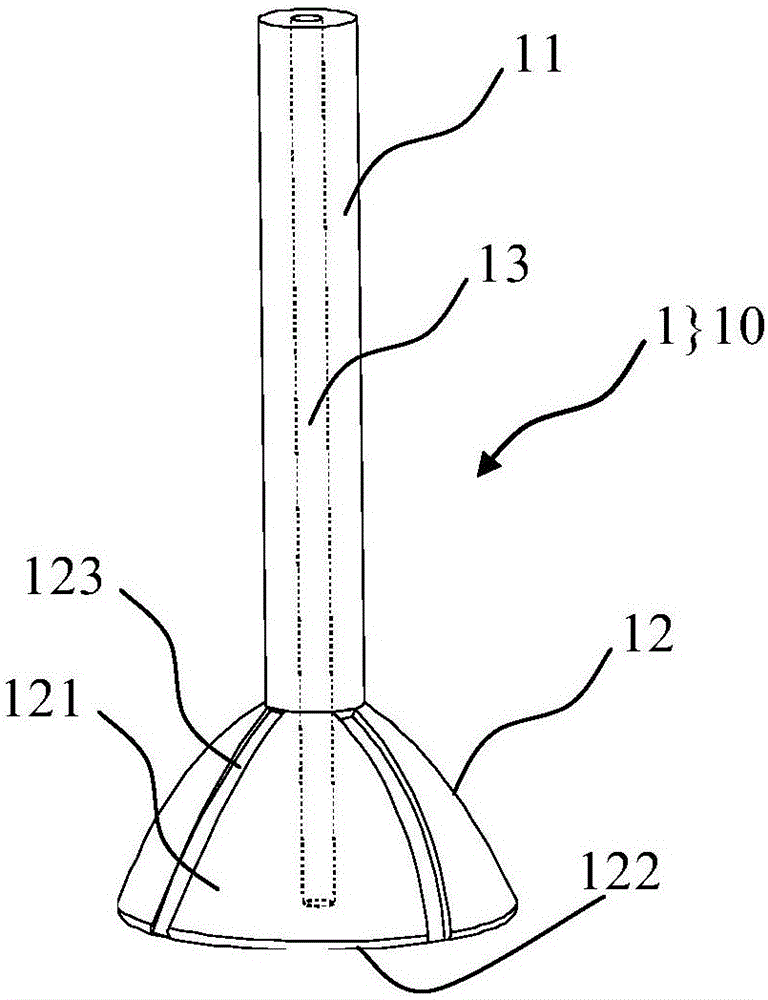

Glass tube molding mold, device and method

ActiveCN106495449AIntensity effectEasy to form internal ribsBioreactor/fermenter combinationsBiological substance pretreatmentsSurface modeManufacturing technology

The invention discloses a glass tube molding mold, device and method. The mold is installed at a discharge port of a molten glass material supply device and comprises an inner mold body, and the inner mold body is installed at the discharge port of the material supply device and comprises a connecting rod and a molding part; the molding part comprises a molding surface, the molding surface is the surface, facing the discharge port, of the molding part and is a spherical surface or conical surface or curved surface which protrudes towards the connecting rod, and at least one material groove is formed in the molding surface in a concaved mode and extends to the bottom of the molding surface from the corresponding joints. In the manufacturing technology, molten glass flows to the molding surface of the inner mold body through flow channel clearances formed in the discharge port, the molding surface guides the molten glass to be diffused in a curved surface mode to form a tube in the initial stage that the molten glass is converted from the flow state to the solidified state, inner ribs are formed by the molten glass flowing along the material grooves on the inner side of the tube, and then the glass tube is driven by a traction device to rotate, so that the inner ribs are in a spiral shape. Accordingly, the production problems in the prior art are solved, and the glass tube with the spiral ribs on the inner wall is produced.

Owner:GUOTOU BIO TECH INVESTMENT CO LTD

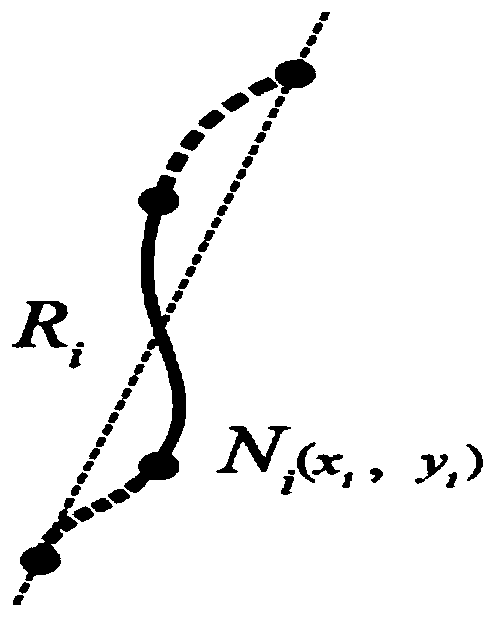

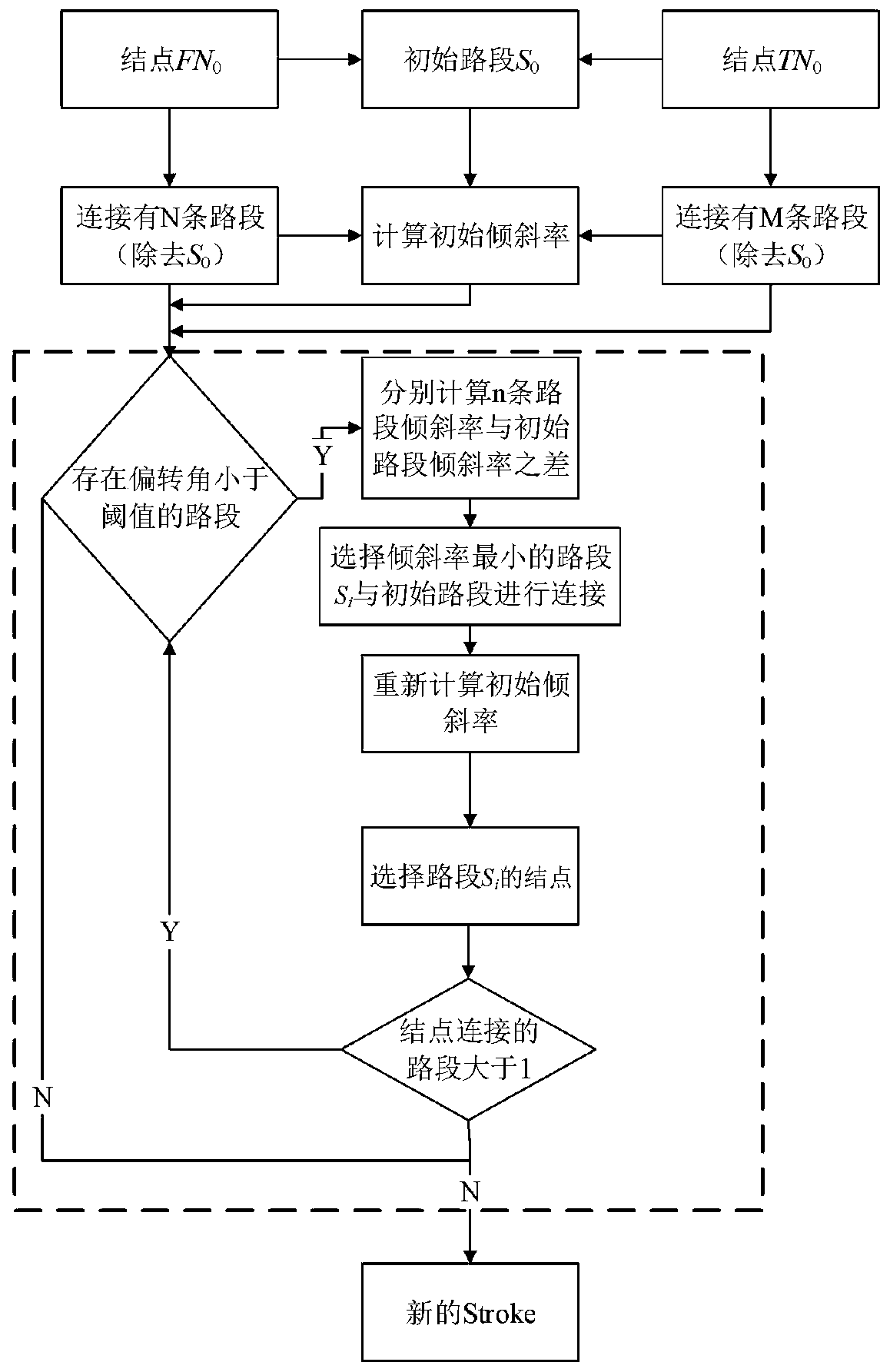

Road network selection method integrating line mode and surface mode

The invention discloses a road network selection method integrated with a line mode and a surface mode. The method comprises the steps of performing topology preprocessing on original road network data; generating a Stroke, evaluating the importance of the Stroke, and calculating four degrees; generating a weighted vomoni graph, and determining a road density threshold value; determining a selected length; carrying out sequencing according to the magnitude of the Stroke importance; selecting the Stroke with the maximum importance degree; judging whether the road density is smaller than a threshold value or not, if not, entering a queue Q, and if yes, performing road selection; whether the Stroke set is empty or not is judged, if yes, whether the total length of the Stroke is smaller than LS or not is judged, and if not, road connectivity processing is conducted; if the total length of the Stroke is smaller than LS, the Stroke is selected from the queue Q according to the importance degree until the selection length is determined, and then road connectivity processing is carried out; and evaluating the result after the selection is finished.

Owner:CAPITAL NORMAL UNIVERSITY

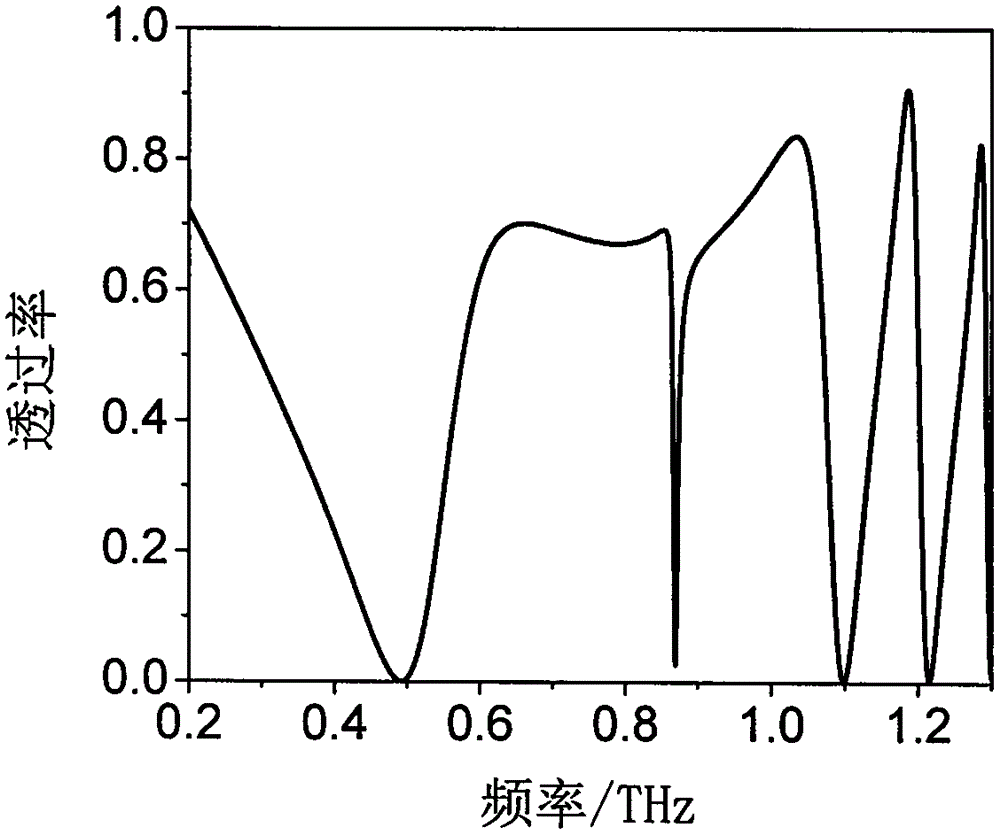

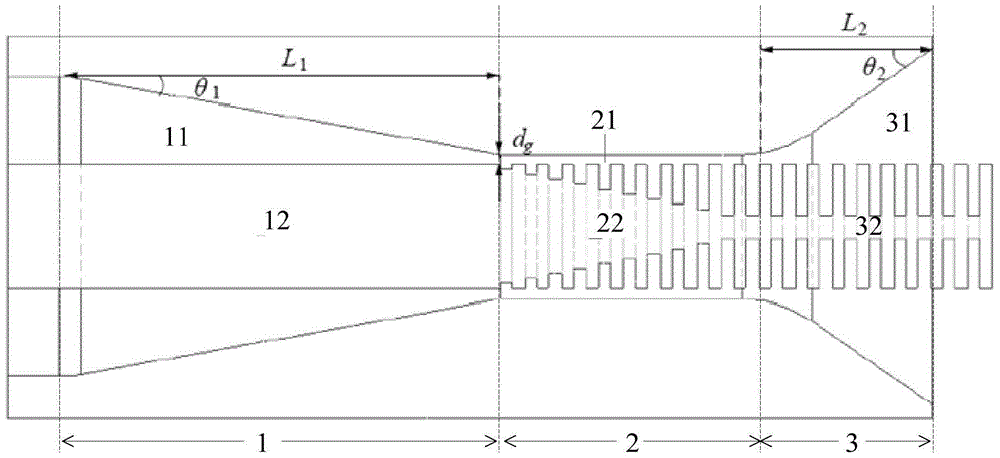

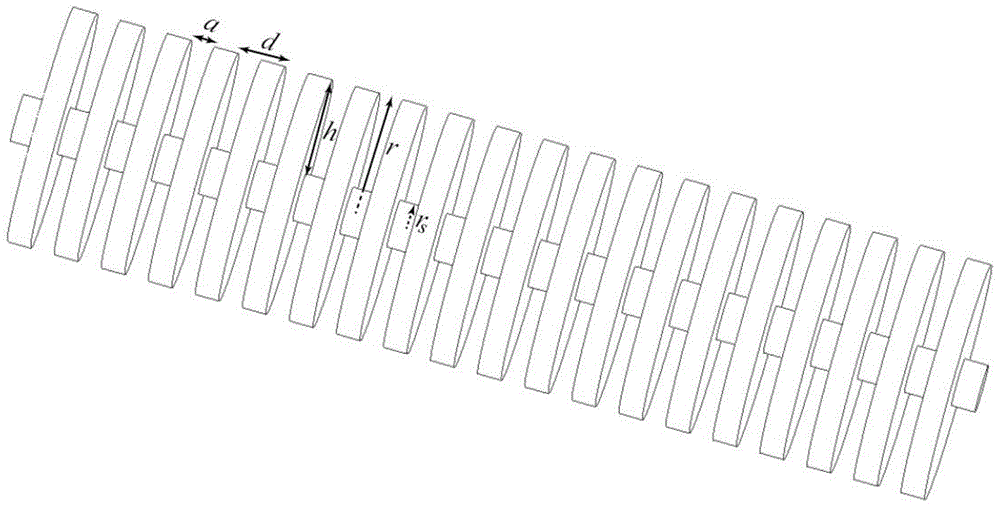

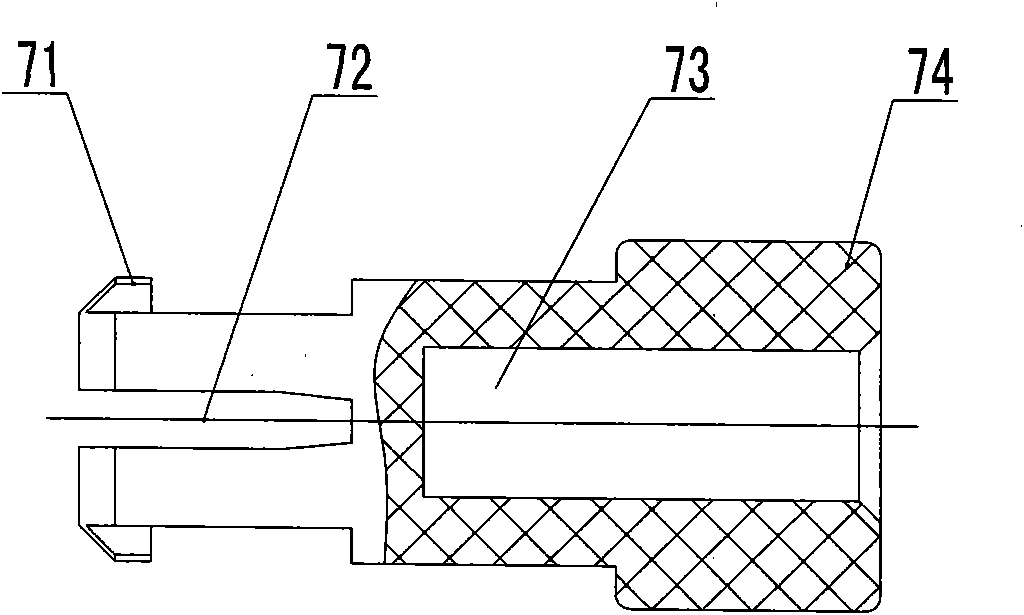

Ultra wide band terahertz class surface plasmon coupler and coupling method

The invention discloses an ultra wide band terahertz class surface plasmon coupler and a coupling method. In the invention, a TEM mode compressor, a mode matcher and a surface mode radiator are adopted. Parameters of the above three portions are reasonably selected. Conversion efficiency from a TEM mode to a class surface plasmon mode is greatly increased and simultaneously an excitation band width of the class surface plasmon mode is widened. The coupler and the coupling method play a powerful role in promoting practical application of a class surface plasmon waveguide which is a novel waveguide in a terahertz wave band. The coupler of the invention is a whole metal structure so that electromagnetic energy losses introduced by the coupler are reduced. Simultaneously, processing of the coupler is convenient and integration is easy to achieve.

Owner:PEKING UNIV

On-line monitoring method for failure state of metal and protection layer inter face

InactiveCN1657902ALife expectancyHigh sensitivityWeather/light/corrosion resistanceMaterial impedanceSurface modeTerminal equipment

This invention relates to the metal and the protector contact surface mode of failure on-line monitor method, in the design or the manufacture mechanical device metal base corrosion sensitive spot, prefabricated monitor contact surface corrosion change poking head in, uses the same material which cuts directly down from the equipment home position is the main body, after processes probe in to inlay the mechanical device metal base again the home position, probe in with the equipment metal base is the integrated union, states probe in to pass through the equipment wall, its rear part reserves in hardware exterior has the connecting lead the receptacle, when needs to gather the contact surface information, Will state the receptacle and the electrochemistry workstation with the wire and so on can gather electrochemistry data the and so on impedance spectrum monitor terminal device connects, and will use the CR transmission line model analysis electrochemistry impedance spectrum. The monitor can obtain in advance information, the monitor result analysis has the versatility, the uniformity and the objectivity: Increased the result reliable degree.

Owner:SHAOGUAN COLLEGE

Rapid detection method for tunnel lining crack

ActiveCN108596869AEasy maintenanceEasy to operateTelevision system detailsImage enhancementSurface modeEnvironmental geology

The invention, which belongs to the technical field of recording and repairing the inner surface of the tunnel lining, particularly relates to a rapid detection method for a tunnel lining crack. According to the method, the inner surface of a tunnel is shot along the axis of the tunnel quickly; according to a shooting result, a tunnel lining inner surface image is obtained; on the basis of combination of the shooting position, shooting azimuth information, and a clearance fracture surface mode in the tunnel, a shooting coordinate model is established and the shot image is analyzed; a mathematical mapping relationship between pixel points on the shot image and corresponding spatial points in an actual tunnel model is established; and on the basis of the mapping relationship, the shooting result is restored and expanded. The equipment is simple and is easy to operate; the damage reality of the inner surface of the tunnel lining is reflected by the adjusted photo; and thus the related staff is able to carry out tunnel maintenance timely and conveniently.

Owner:NORTHEASTERN UNIV

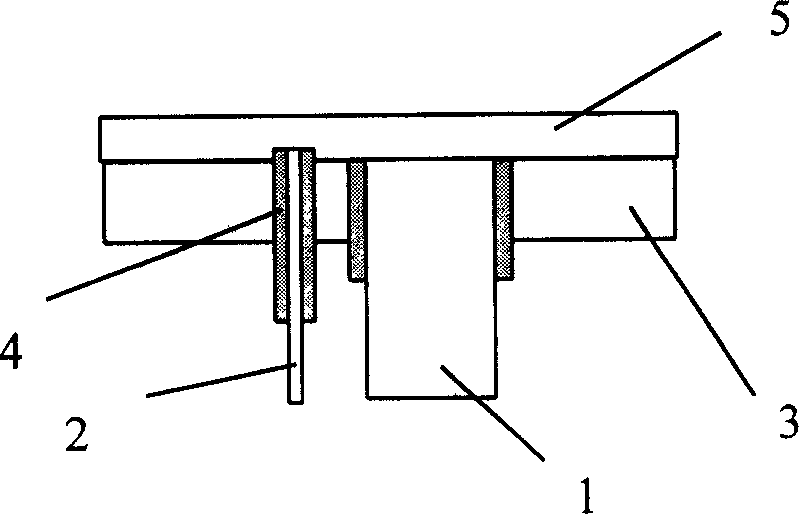

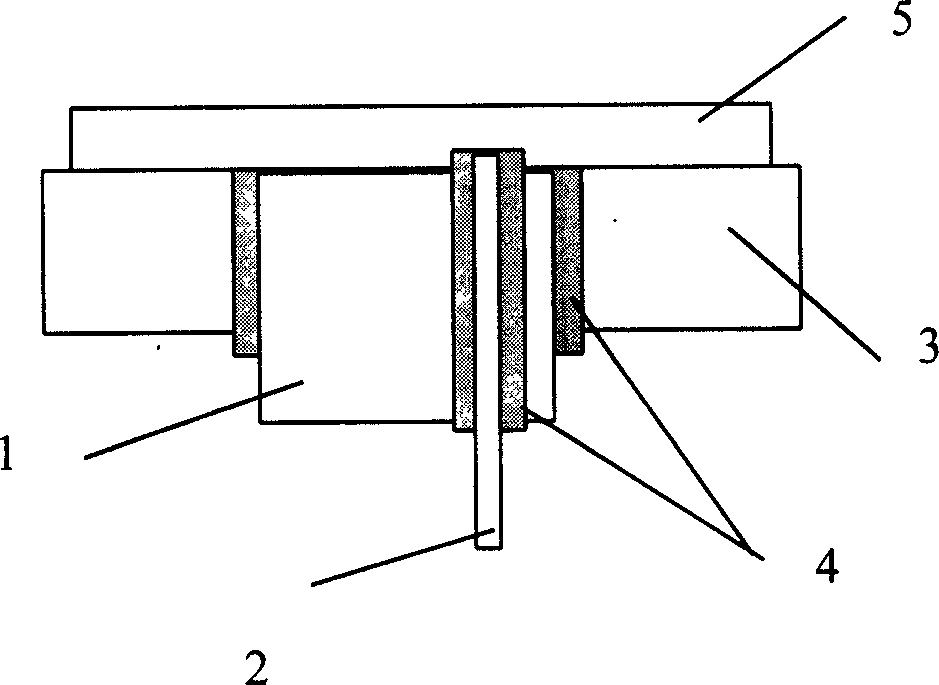

Plug dislocation interlocking apparatus used by general-purpose converter

ActiveCN102361201AImprove securityImprove reliabilityCoupling contact membersGeneral purposeSurface mode

The invention relates to a plug dislocation interlocking apparatus used by a general-purpose converter. The apparatus comprises a location plate and an interlocking slide block; a plurality of parallel linear grooves are opened on the location plate; folded grooves that are corresponded to the linear grooves are opened on the interlocking slide block; upper end spacings of the folded grooves are the same as spacings of the corresponded linear grooves of the location plate; a lower end spacing of each the folded groove is different from the spacing of the upper end groove of each the folded groove; and a central portion of the two ends of each the folded groove is in a sloped surface mode for transition; besides, handles that are connected with all plugs pass through the folded grooves of the interlocking slide block and can be moved up and down along the linear grooves on the location plate; and simultaneously, the interlocking slide block is driven to make translation movements left and right. According to the apparatus provided in the invention, it is utilized that spacings of the folded grooves and the linear grooves are not equal; therefore, when any type of plug is slipped off, an interlocking slide block is moved and dislocation of grooves and grooves is formed, so that other plugs are blocked by the slide block and can be slit downwardly; and thus the dislocation interlocking function is realized; moreover, a movable pin is utilized to realize position location, thereby improving security and reliability of the general-purpose converter.

Owner:BULL GRP CO LTD

Display device

The invention provides a display device which comprises a display panel and a mirror surface switcher. The mirror surface switcher is positioned on one side of the light emitting surface of the display panel and used for reflecting outside incident light, resisting display light emitted by display panel and switching the display device into a mirror surface mode, or the mirror surface switcher isused for penetrating the display light emitted by the display screen and switching the display device into a display module. The mirror surface switcher is arranged on the light emitting side of the display panel, reflects the outside incident light and resists the display light emitted by the display panel or is user for penetrating the display light emitted by display panel, so that the displaydevice has only one emitted light when displaying, and display images interfered by light reflected by reflective polarizers are avoided.

Owner:BOE TECH GRP CO LTD +1

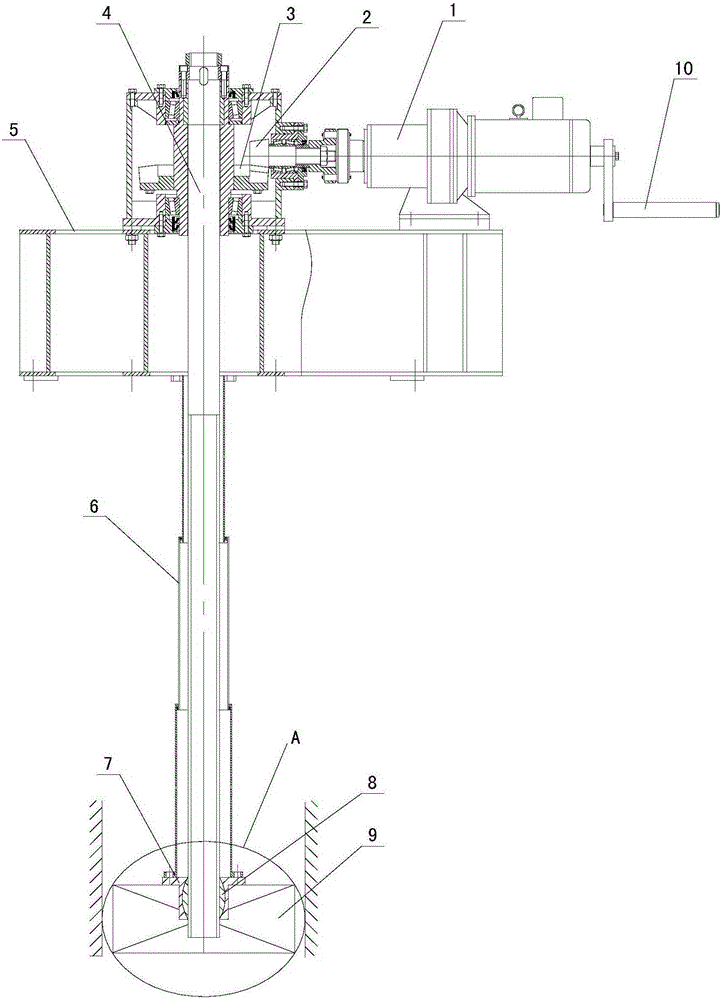

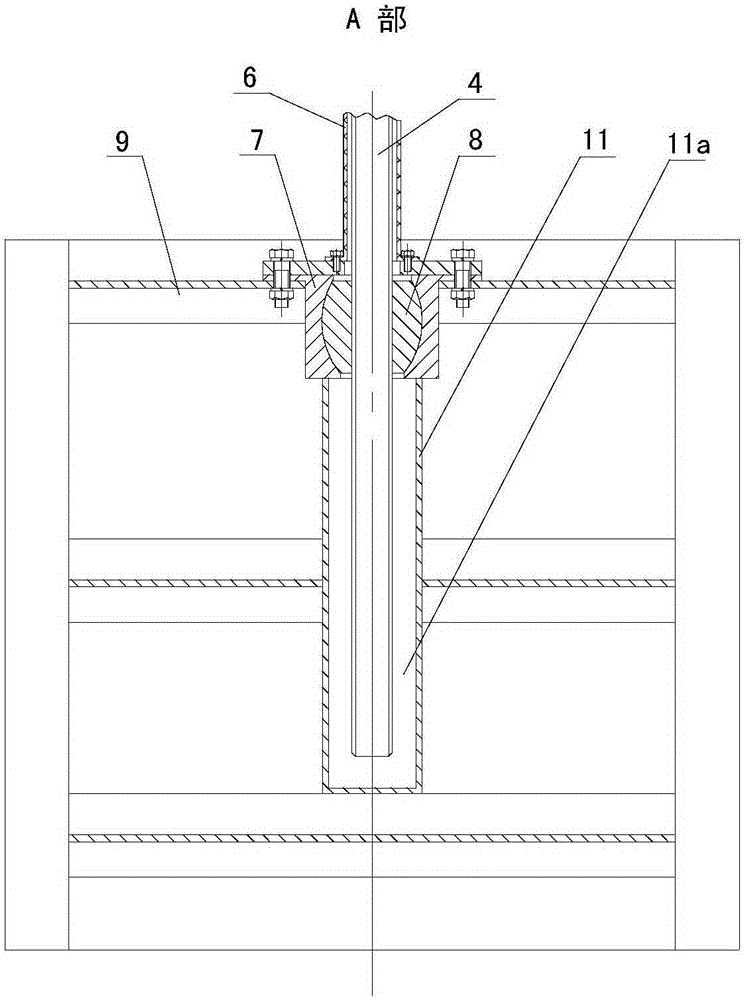

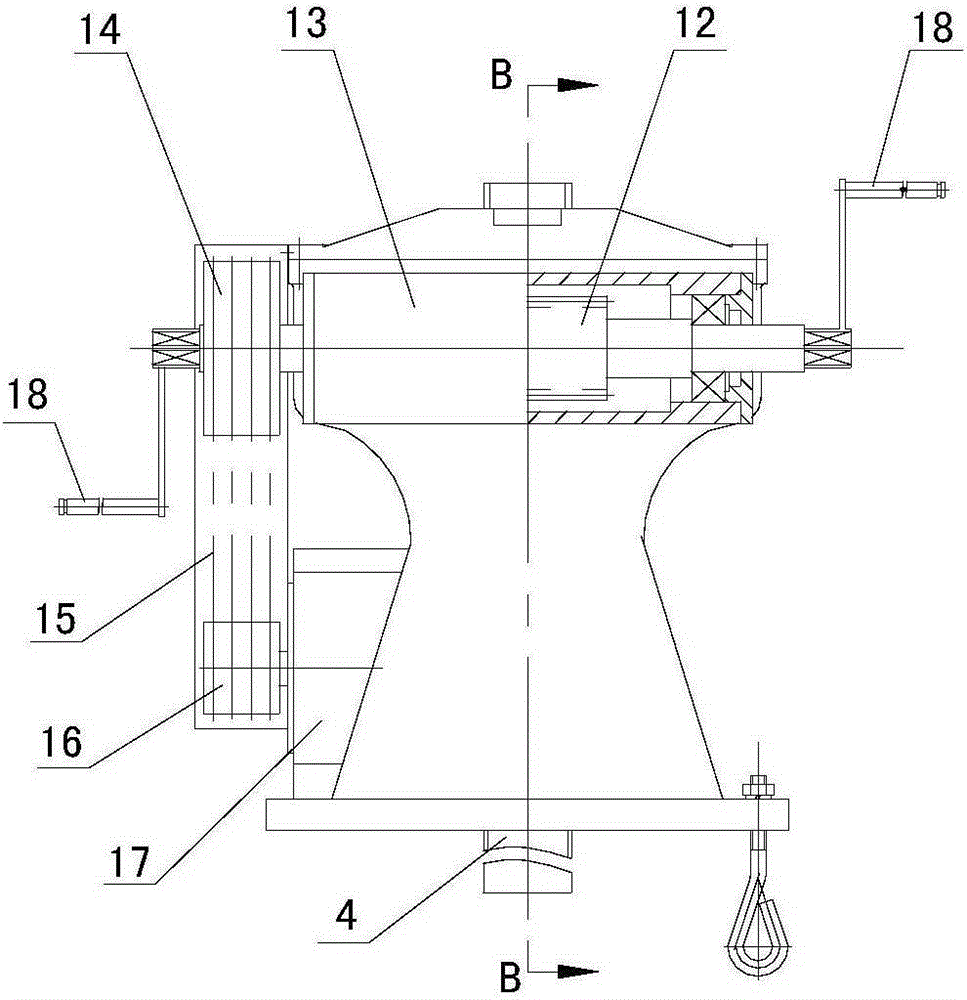

Rotating rod type gate hoist

A rotating rod type gate hoist is provided with a motor, a rack, a screw and a gate, wherein the screw is installed on the rack, a transmission mechanism is connected between an output shaft of the motor and the screw, a nut is connected to the gate, the screw is matched with the nut, a shaft sleeve is fixed to the gate, the nut is installed in the shaft sleeve, the outer side face of the nut and the surface of an inner hole of the shaft sleeve are spherical surfaces, and the outer side face of the nut is in interference fit with the inner hole of the shaft sleeve. The screw is sleeved with a multiple-section telescopic sleeve, the upper end of the sleeve is connected with the rack, and the lower end of the sleeve is connected with the gate or the shaft sleeve. Due to the fact that the outer side face of the nut is matched with the inner hole of the shaft sleeve in a spherical surface mode, the nut and the shaft sleeve can relatively deflect for compensation to avoid nut-screw friction increase caused by gate deflection when tiny deflection occurs in the vertical direction during vertical movement of the gate. The arranged sleeve can prevent floating objects on the water surface from being wound around the screw. The rotating rod type gate hoist is reasonable and compact in structure, stable in operation, small in resistance and long in service life.

Owner:ANHUI HEHAI WATER CONSERVANCY & HYDROPOWER MACHINE MAINTENANCE

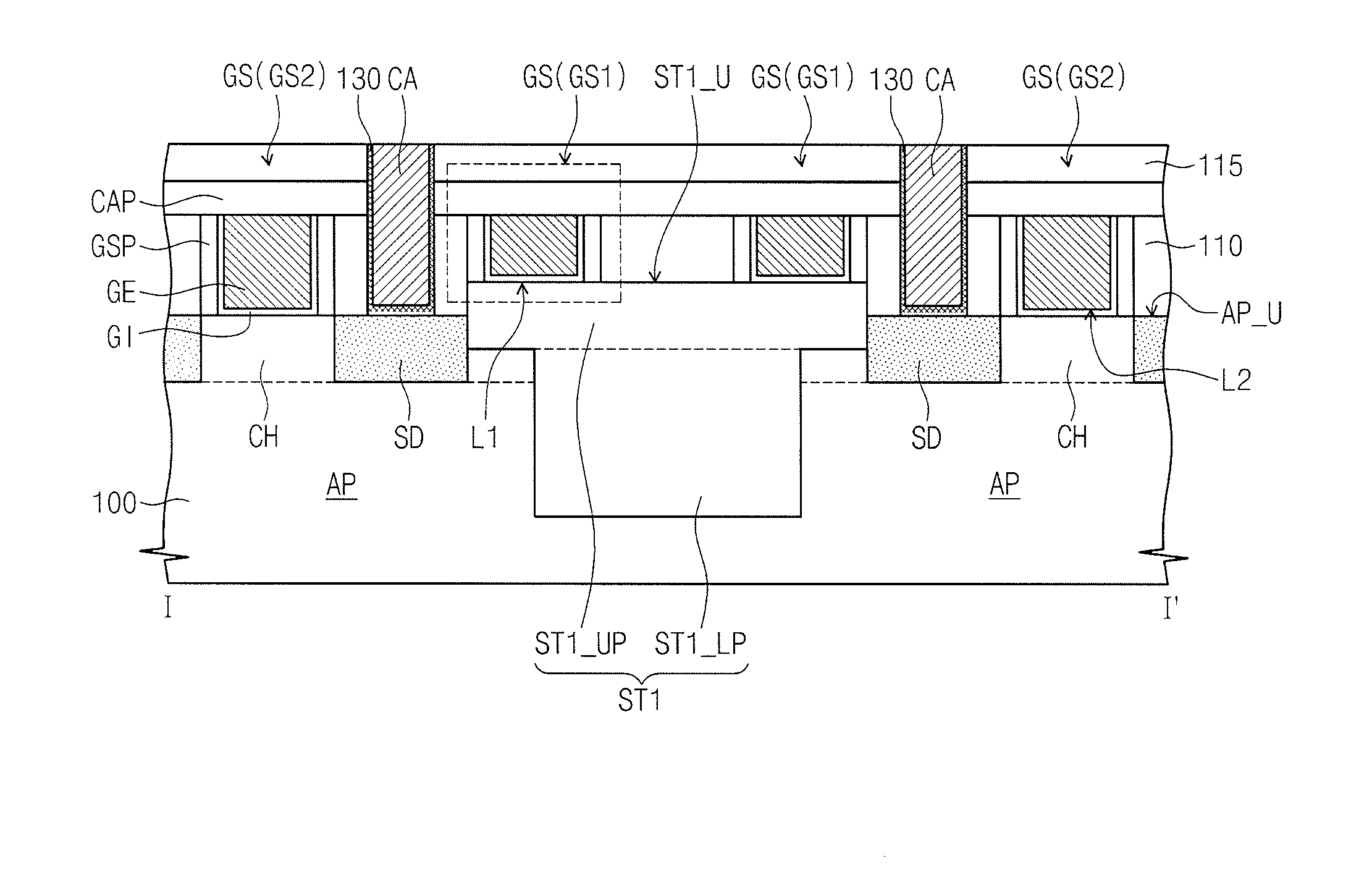

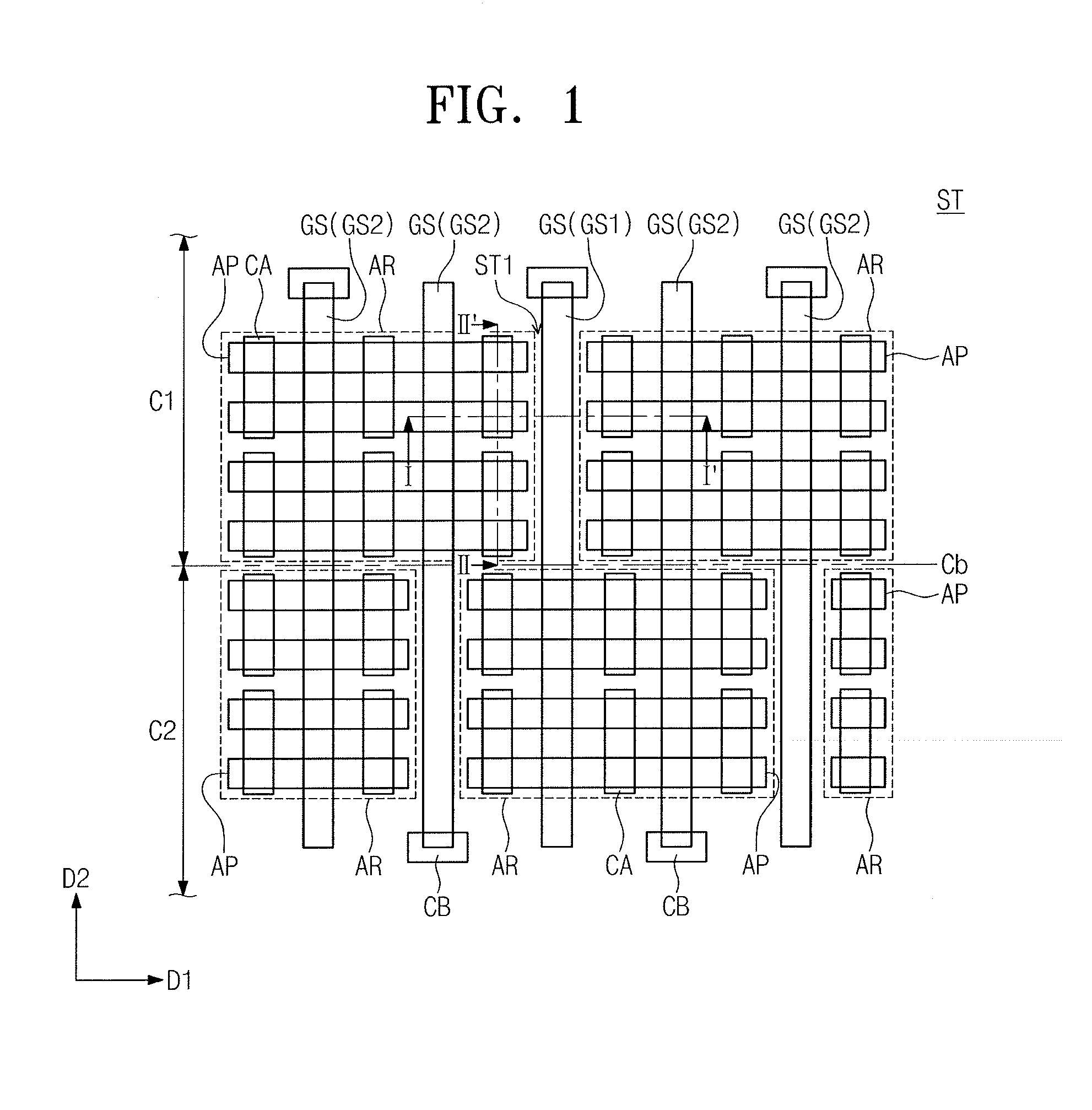

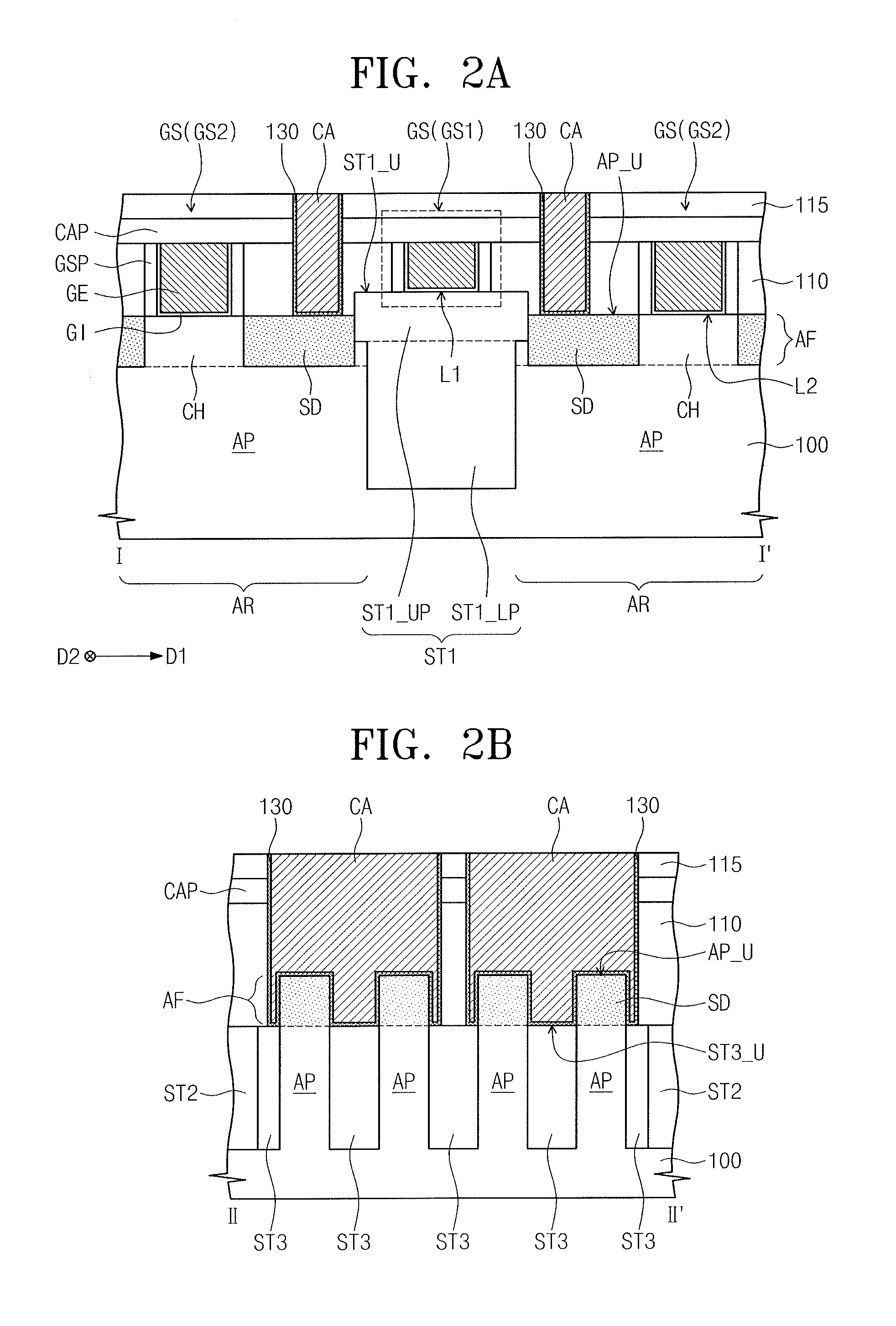

Semiconductor devices including field effect transistors

A semiconductor device includes a first device isolation layer defining active regions spaced apart from each other along a first direction on a substrate, second device isolation layers defining a plurality of active patterns protruding from the substrate, the second device isolation layers extending in the first direction to be spaced apart from each other in a second direction and connected to the first device isolation layer, a gate structure extending in the second direction on the first device isolation layer between the active regions, a top surface of the second device isolation layer being lower than a top surface of the active pattern, a top surface of the first device isolation layer being higher than the top surface of the active pattern, and at least part of a bottom surface of the gate structure being higher than the top surface of the active pattern.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com