Laser linear array type 3D printing equipment and molding method thereof

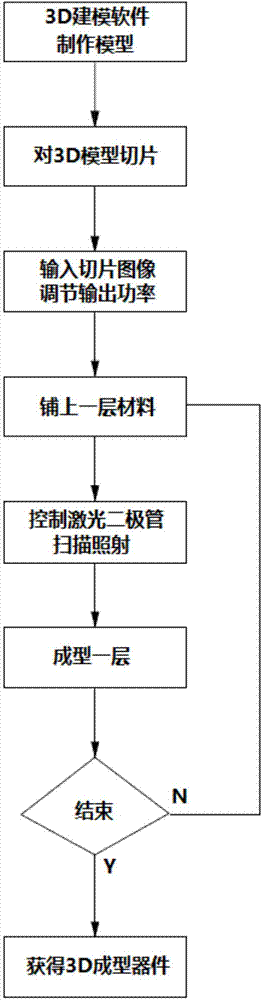

A 3D printing and array technology, applied in the field of 3D molding, can solve the problems of long manufacturing time and achieve the effects of reducing time spent, increasing molding speed, and precise molding production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

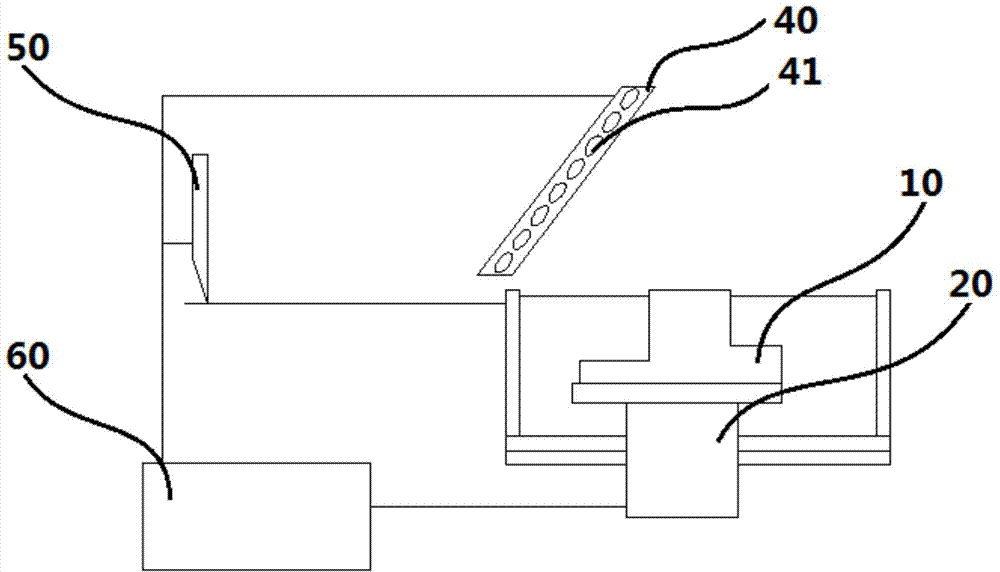

[0023] Hereinafter, the laser line array 3D printing device and the forming method thereof of the present invention will be further described in detail with reference to the drawings and specific embodiments of the present invention.

[0024] The invention can theoretically realize the unlimited expansion of the processing breadth. Limited by the experimental conditions, the laser diode line array with a length of about 200mm is prepared by using 1000 laser diodes LD with a distance between the diodes of 0.1mm. The 1mm diameter of the laser diode chip lamp bead not only breaks through the limitation of large-format processing, but also ensures the molding accuracy. In addition, there are many kinds of laser diode power and wavelength, according to the used power and wavelength combined with the molding material, it can meet different molding requirements.

[0025] The laser line array 3D printing equipment includes a computer controller 60, a forming pallet 10, a storage box 30, a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com