Patents

Literature

38results about How to "Precise molding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

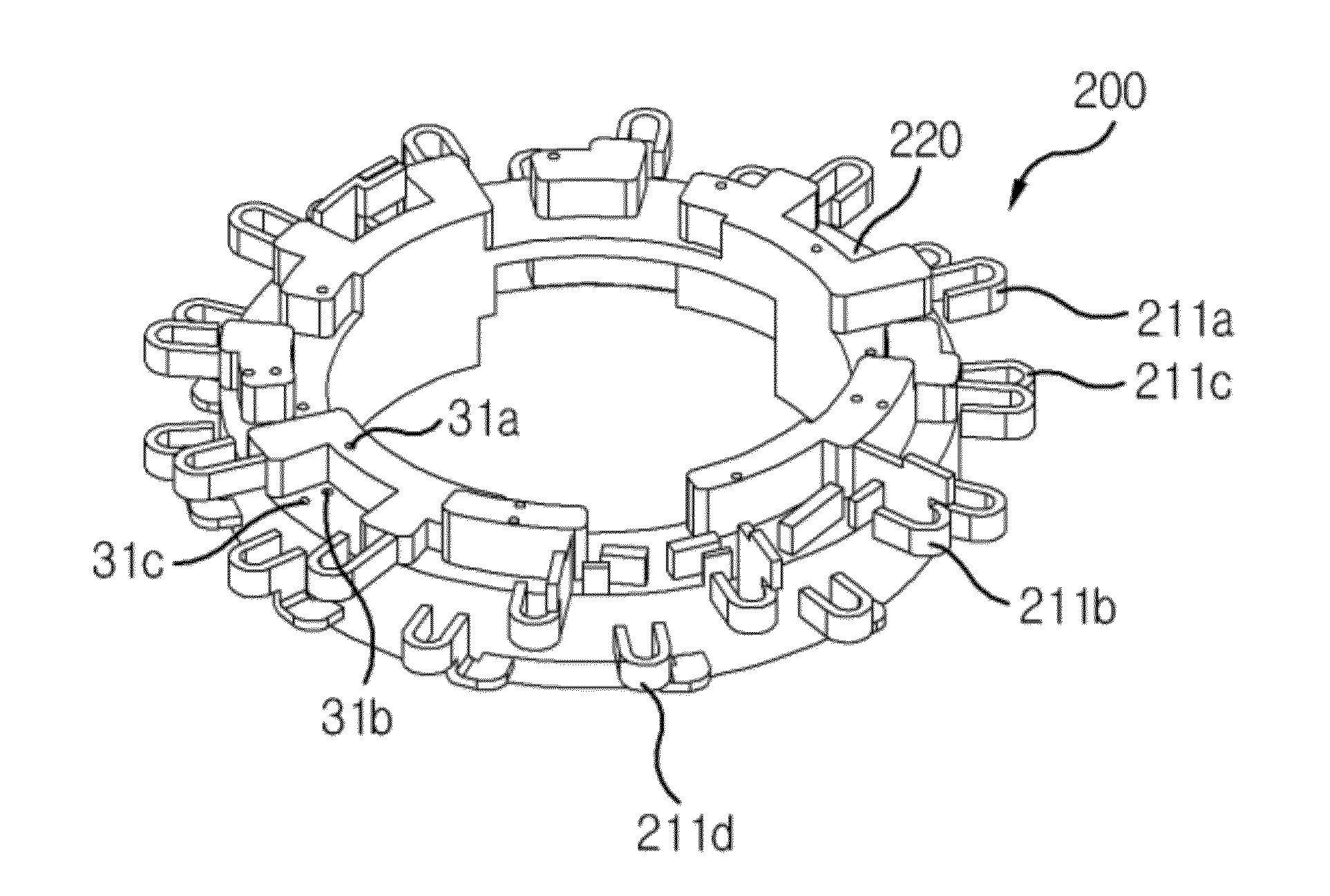

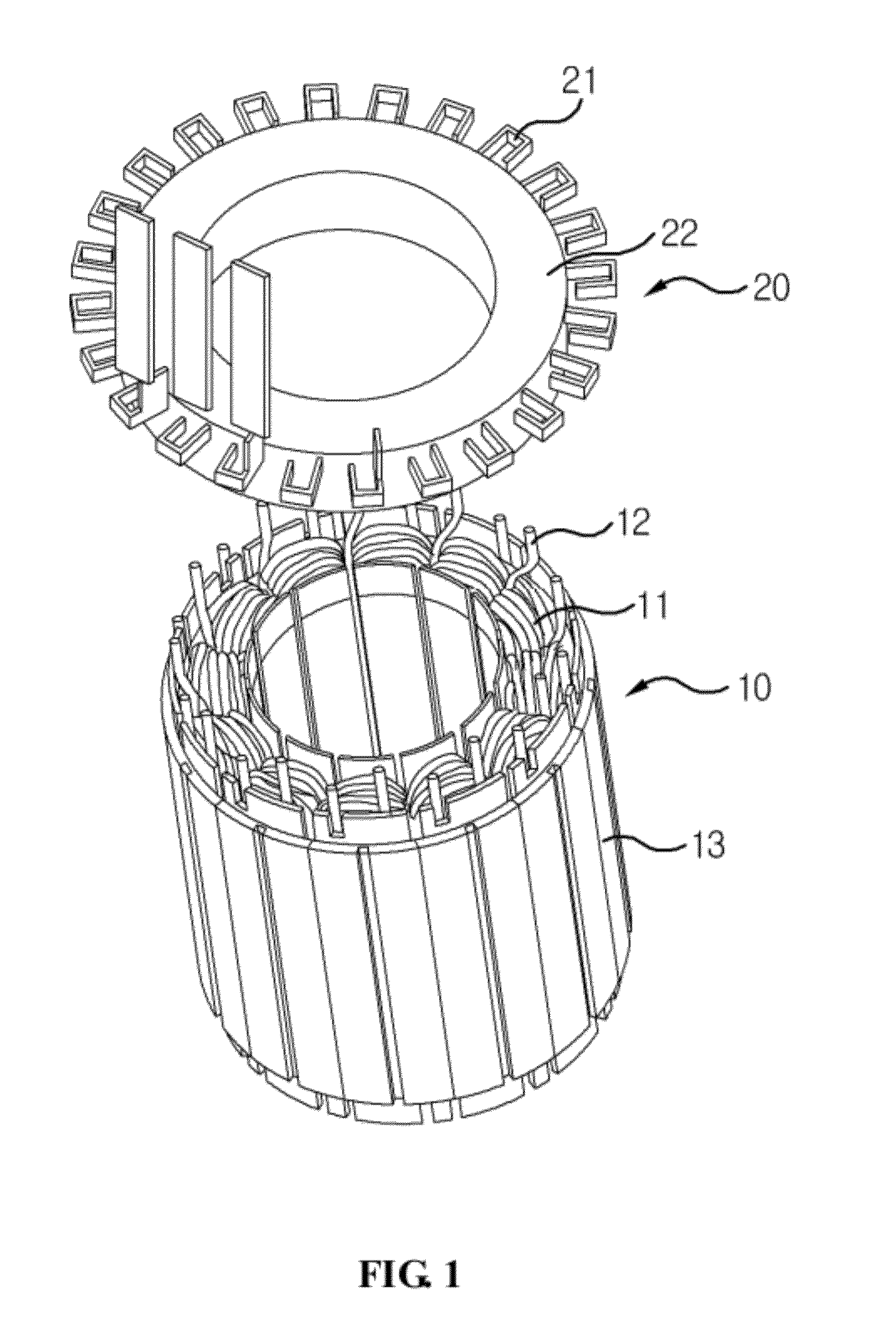

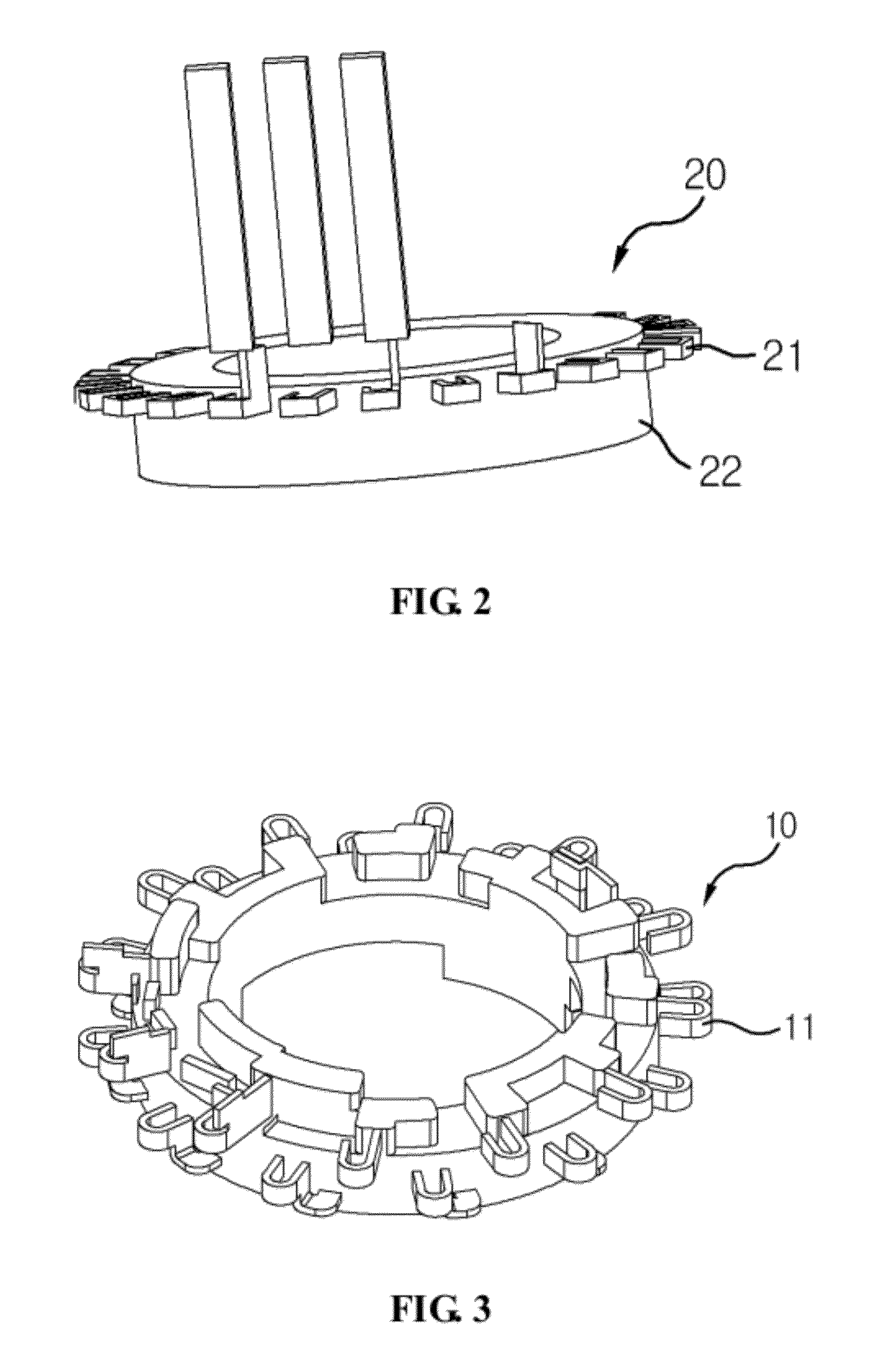

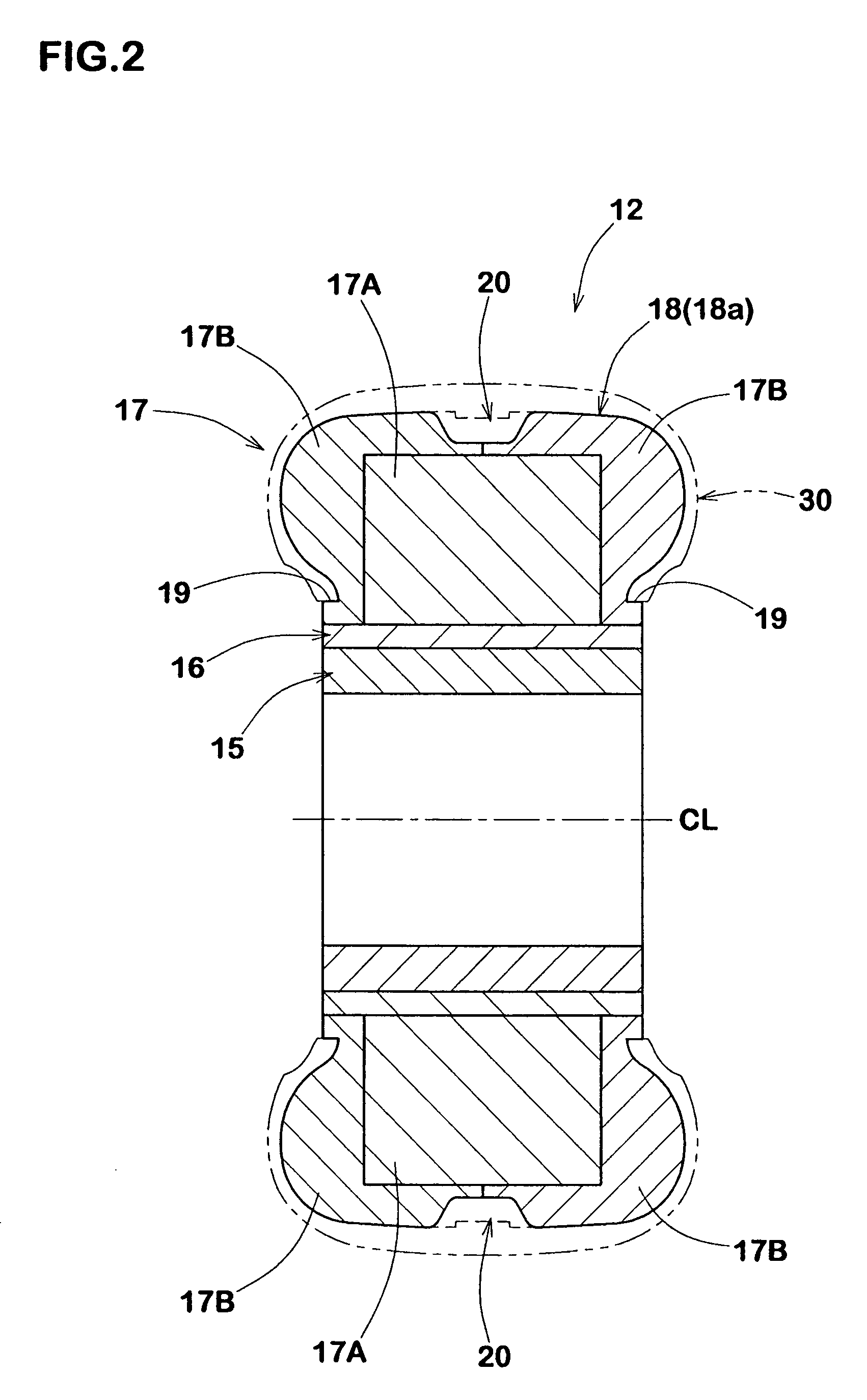

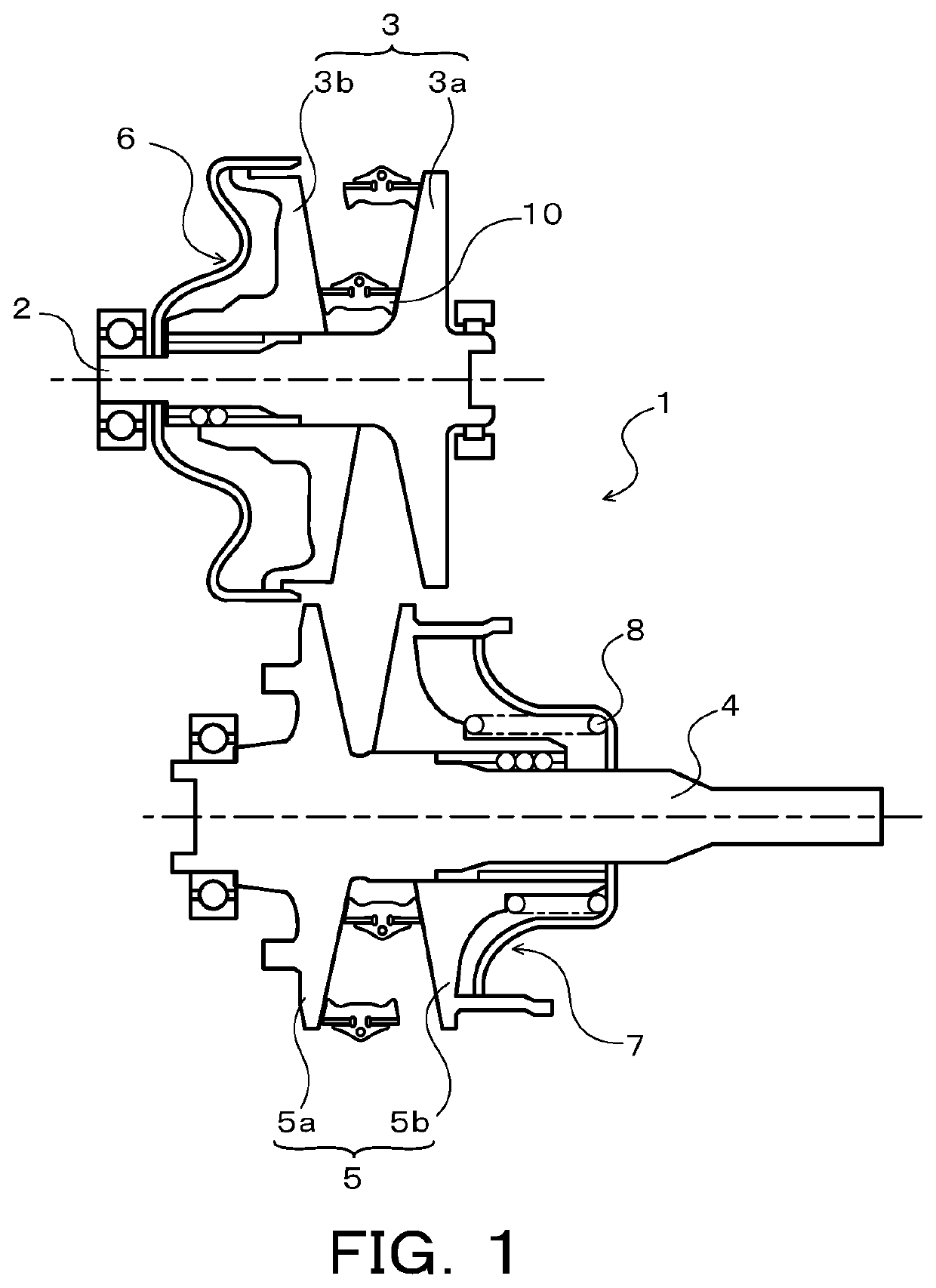

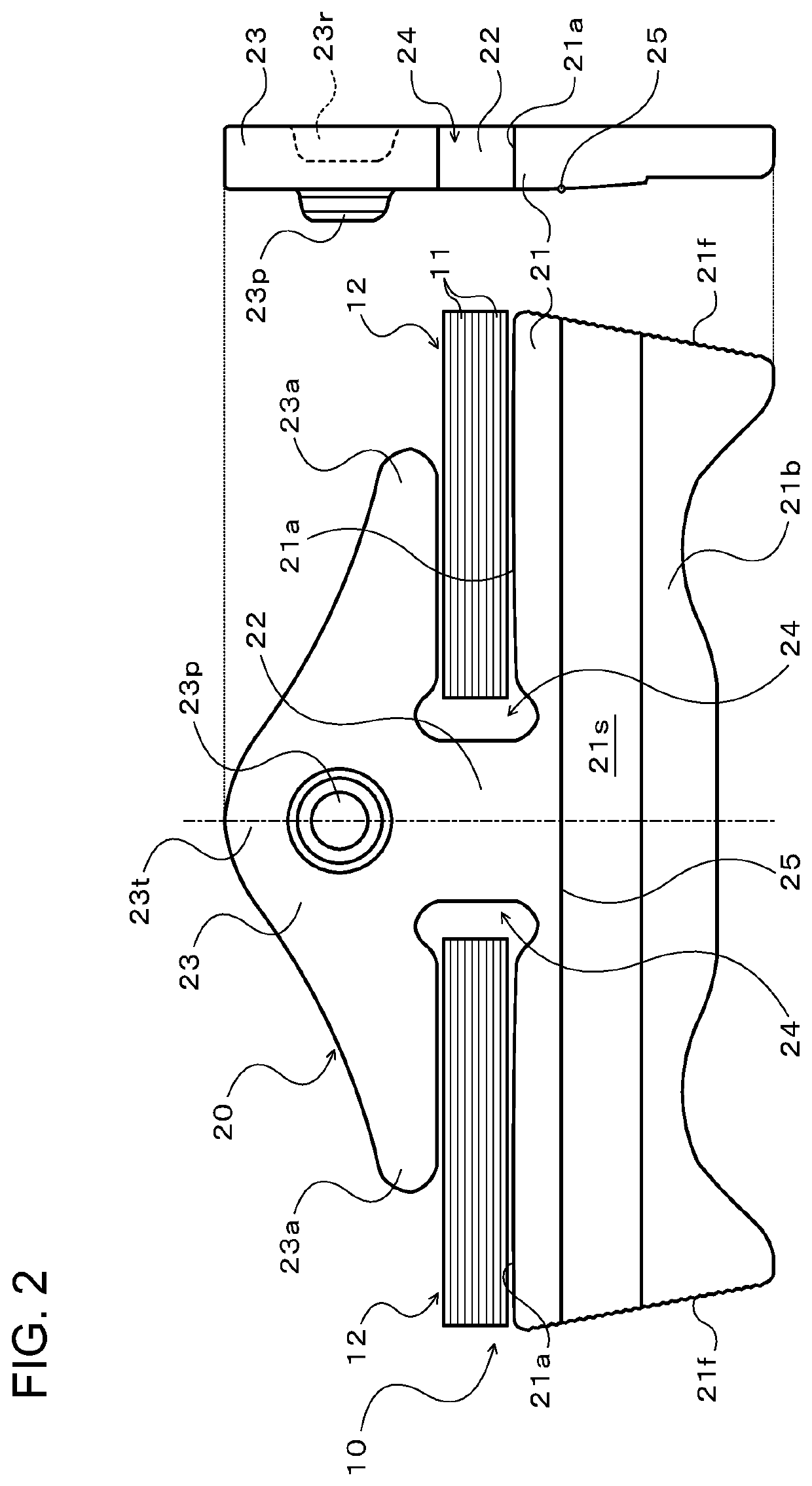

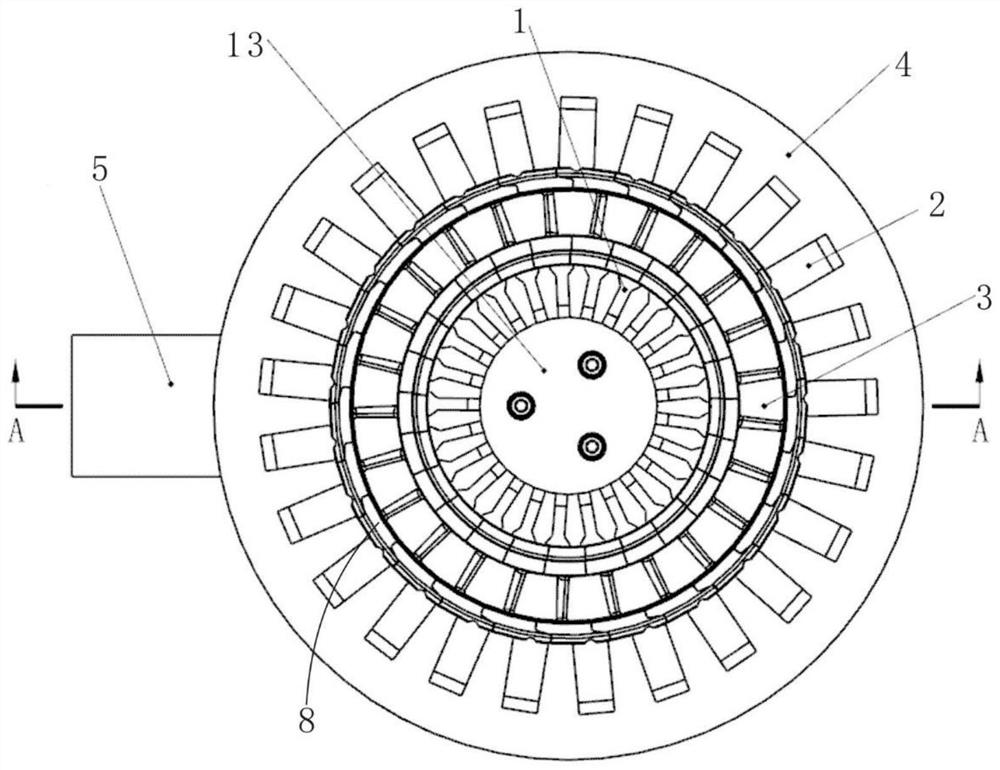

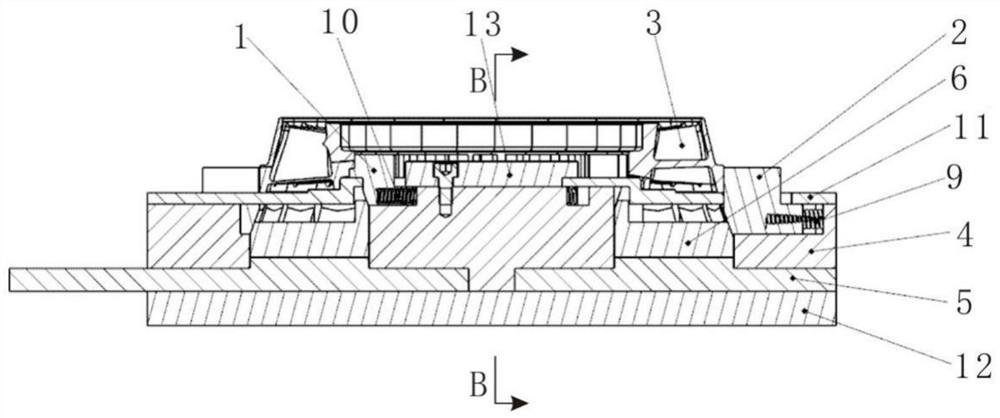

Bus bar of eps motor

ActiveUS20120112582A1Fixed and accurateConvenience to workWindings insulation shape/form/constructionTailstocks/centresStator coilEmbedded system

Disclosed is a bus bar of an EPS motor configured to improve a terminal structure of a bus bar to enable an easy assembly between a stator and the bus bar, whereby assemblage and operational reliability can be enhanced, the bus bar that is connected to a stator coil of the EPS motor, the bus bar including: an insulator made of insulation materials that forms a body of the bus bar; a lower terminal protrusively formed at a lower side of a periphery of the insulator, and connected to the stator coil; and an upper terminal protrusively formed at an upper side of the periphery of the insulator, and connected to the stator coil, whereby the terminals of the bus bar are divided to an upper terminal and a lower terminal to enhance assemblage and operational reliability by further obtaining a broader mutually discrete gap.

Owner:LG INNOTEK CO LTD

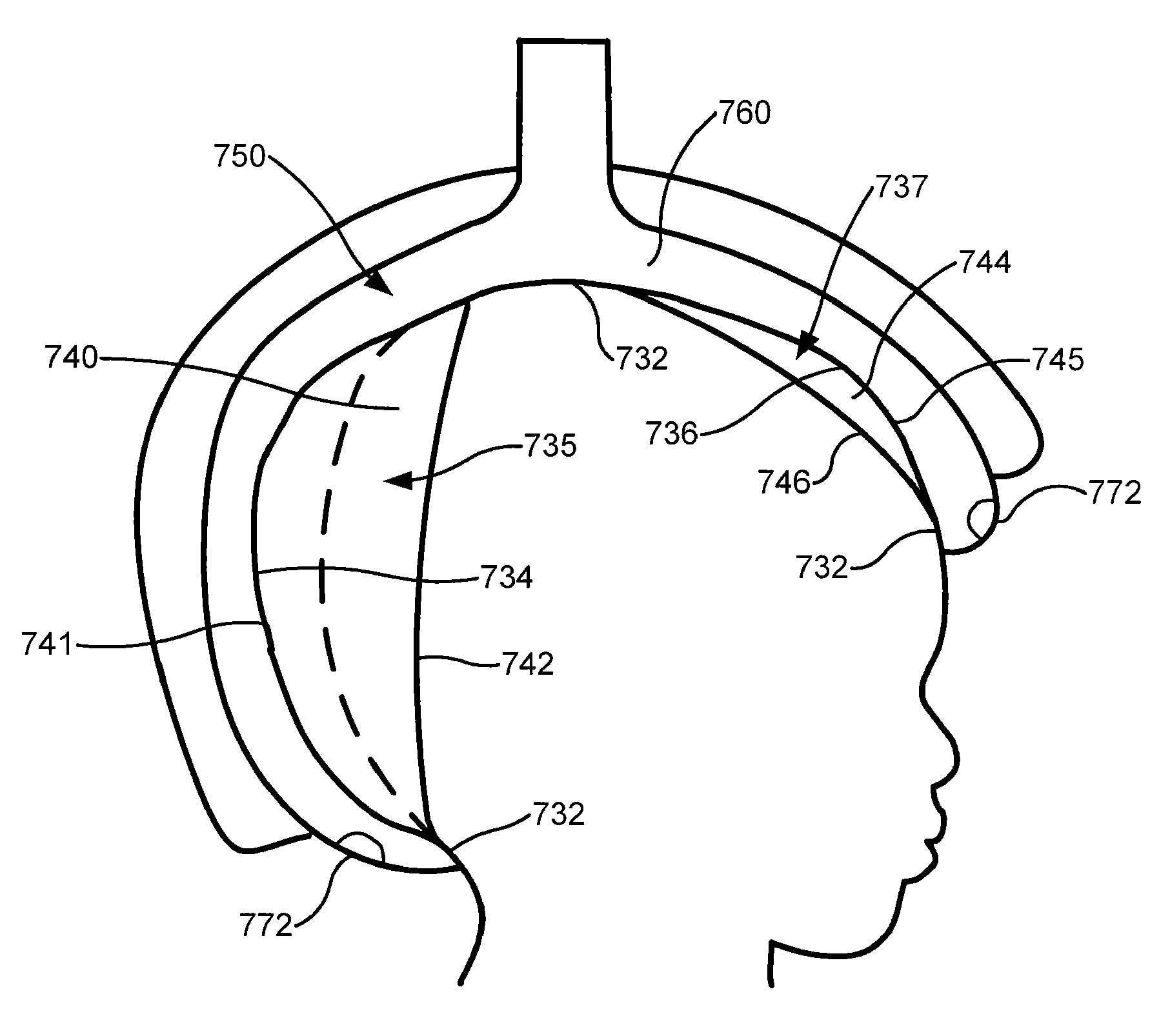

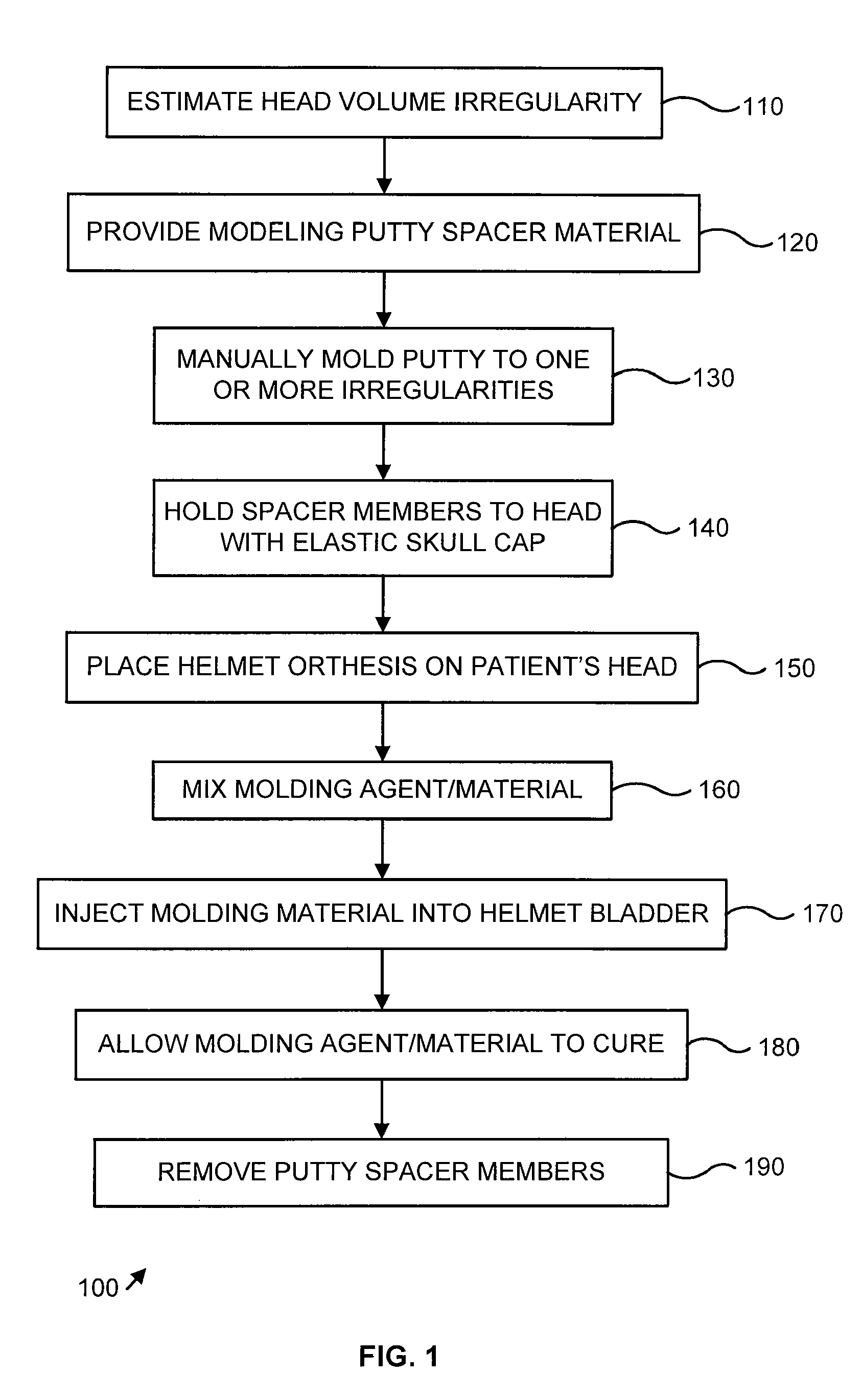

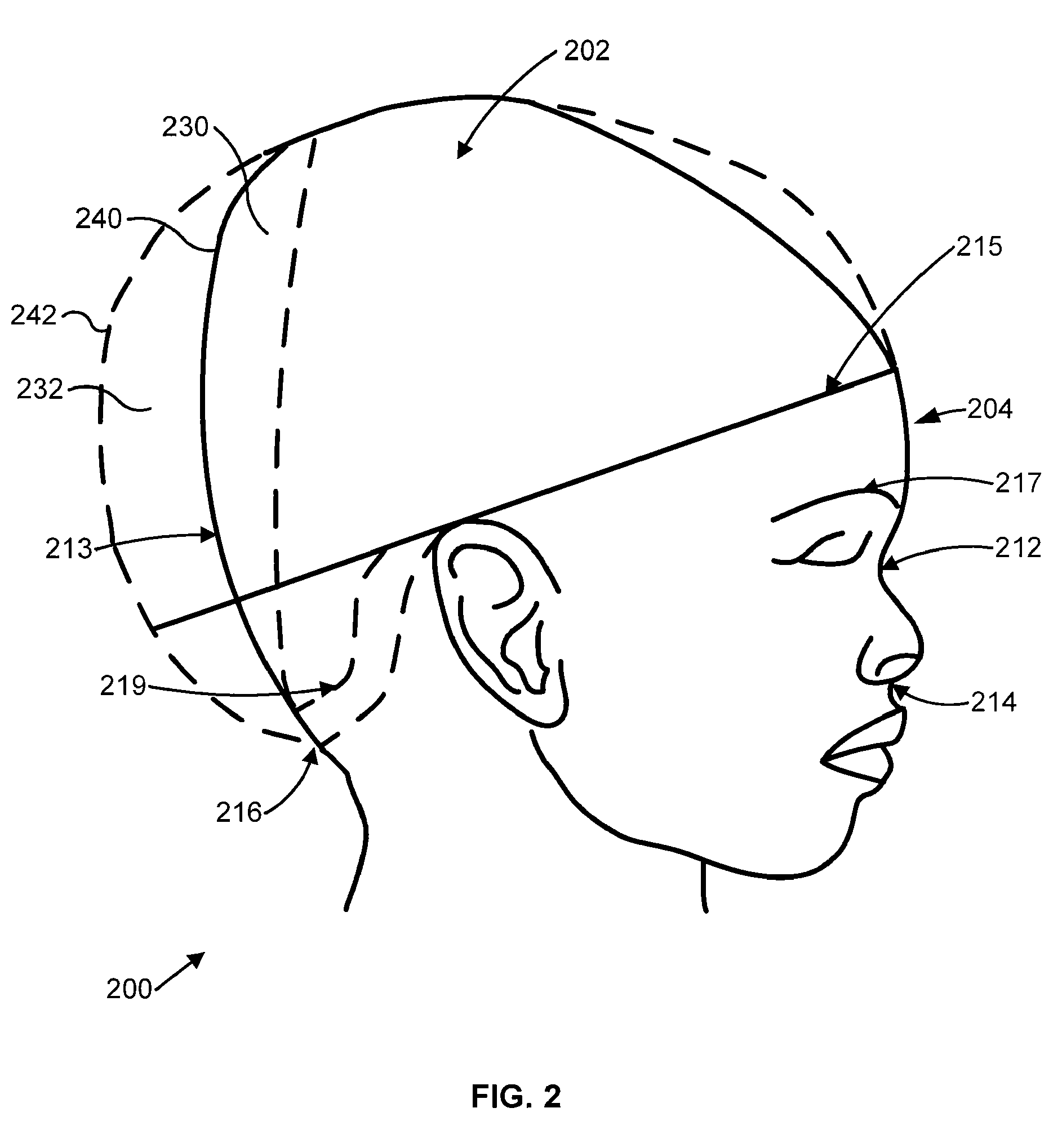

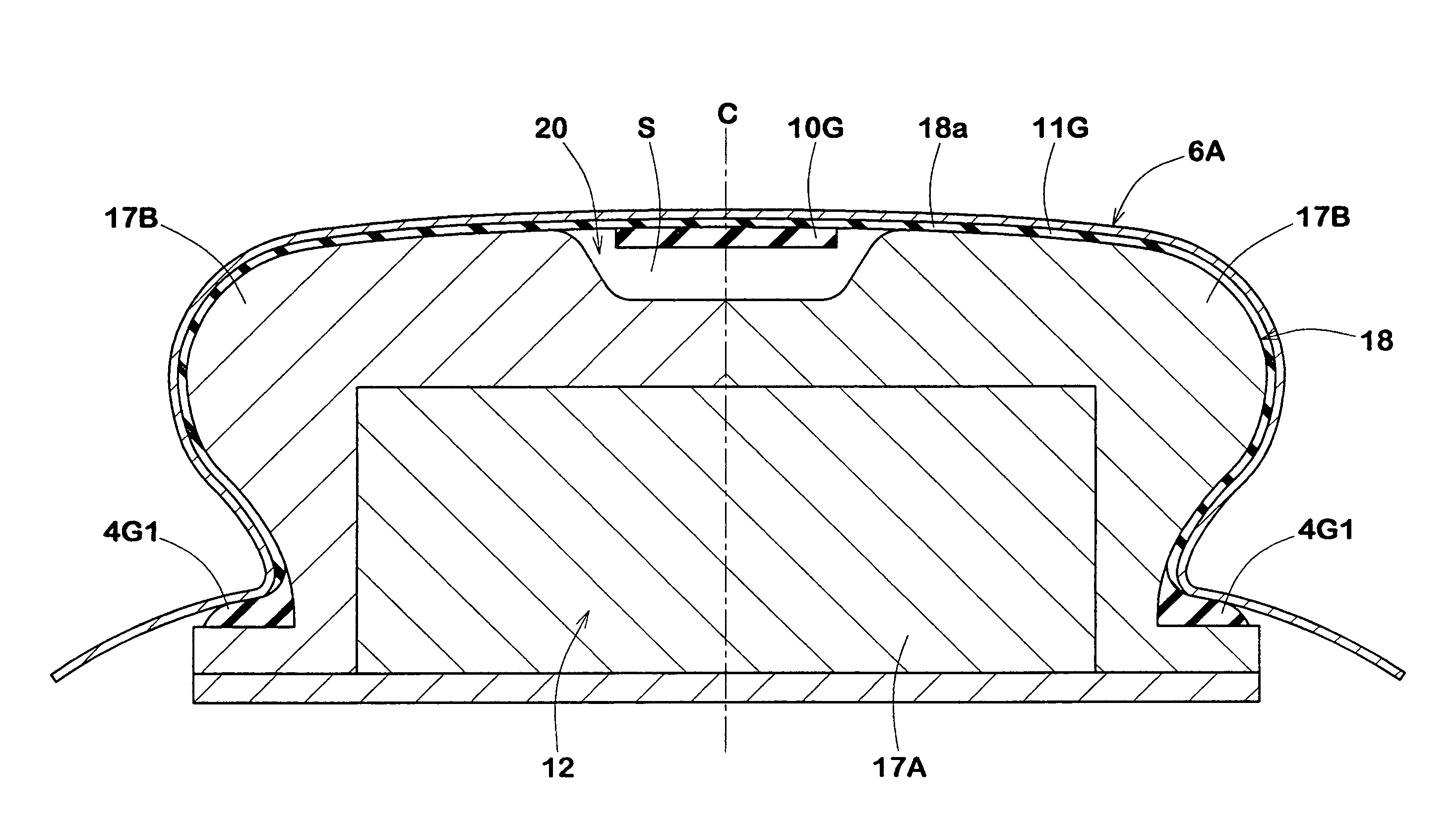

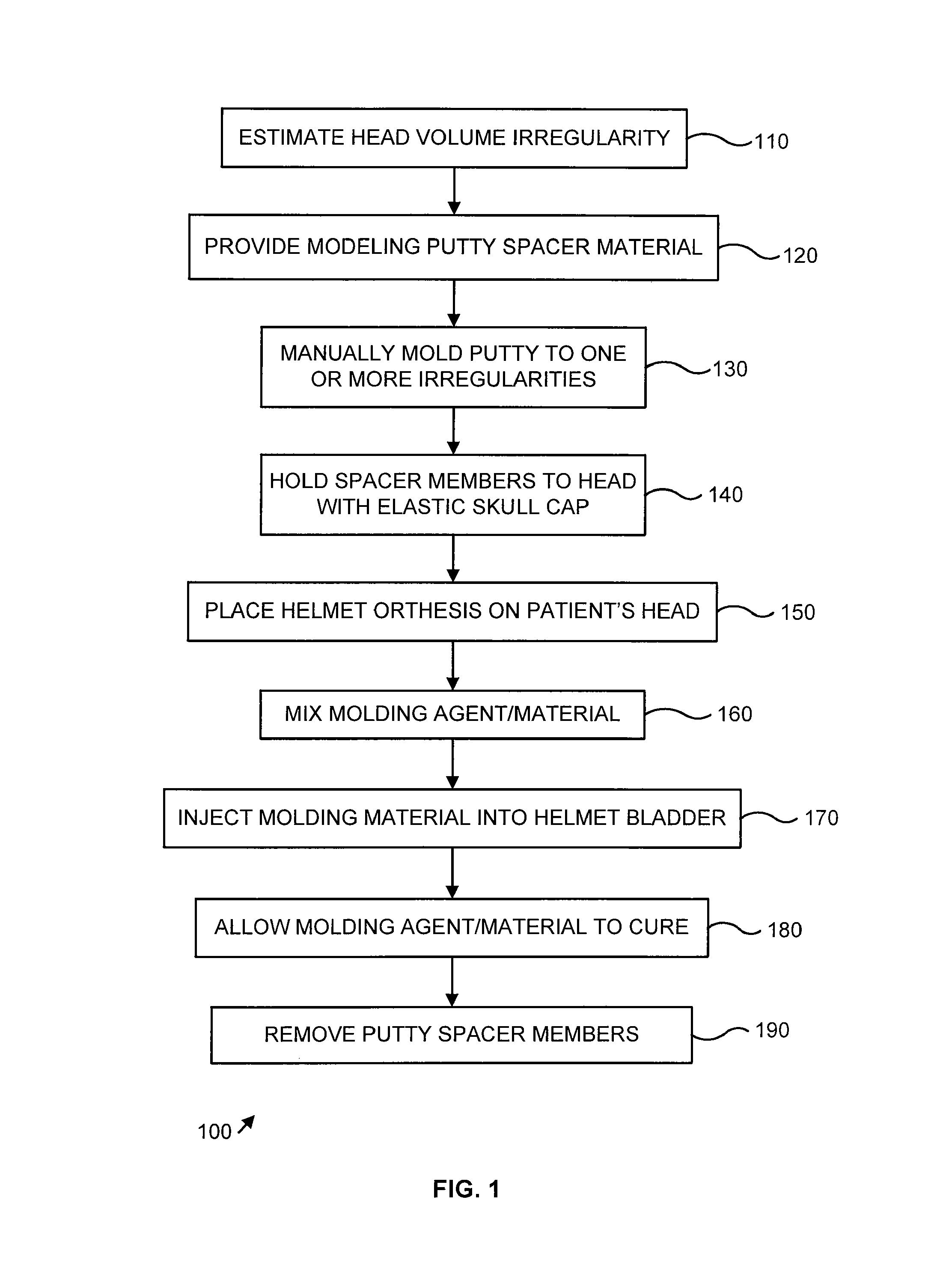

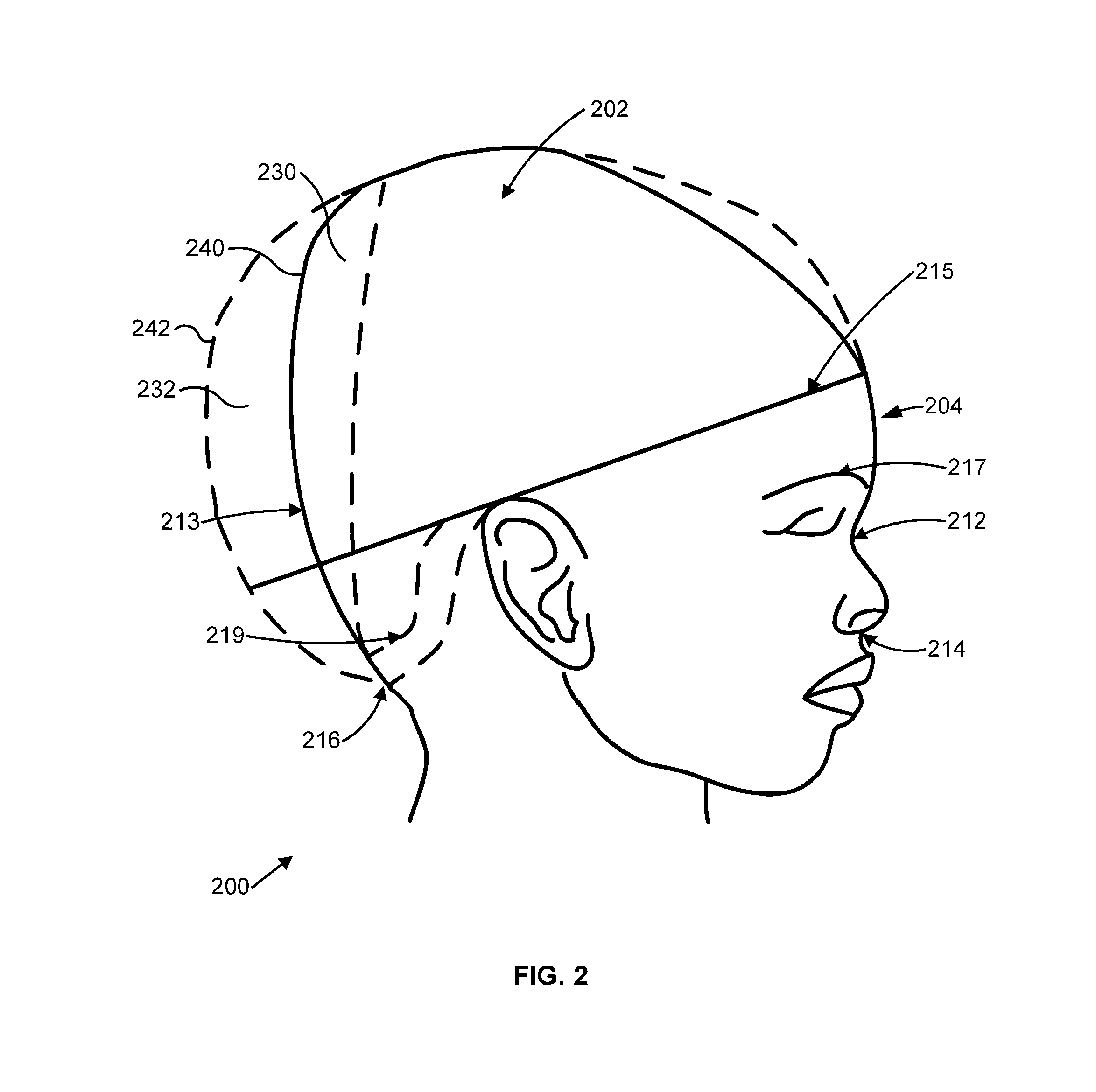

In situ molded orthotic and method for its fabrication

ActiveUS20120296249A1Low costAvoid complexityRestraining devicesFractureOrthotic helmetCranial growth

An orthotic helmet and methods for fabrication and use thereof. The orthotic is molded in situ on a growing infant's head for the treatment of plagiocephaly, postsurgical cranial molding, or other desired treatment plans. The helmet makes contact in areas where cranial shape and volume are adequate, and no contact in areas of planned cranial growth. The helmet includes a shell, a bladder system which can be filled with a viscoelastic expandable foam, a fastener and a retaining strap. In the areas of deficient cranial volume, a volume of modeling putty equivalent to the target growth volume is placed against the cranium, manually molded until the planned target volume and form have been attained, and the helmet is molded in place over this spacer material. The spacer is then removed, and the helmet is then worn continuously until resolution of the deformity or attainment of planned form is reached.

Owner:PPOD ORTHOTICS INC

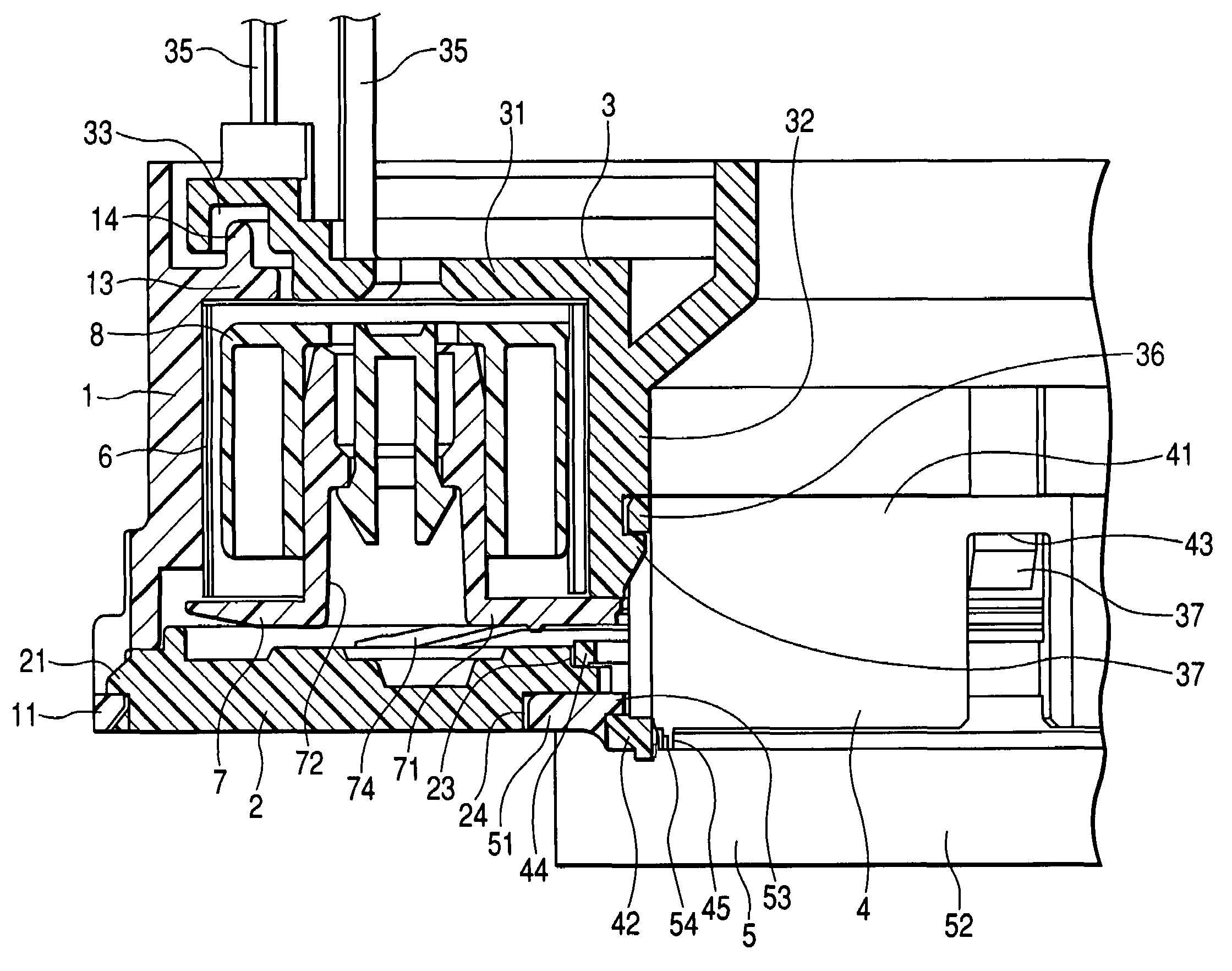

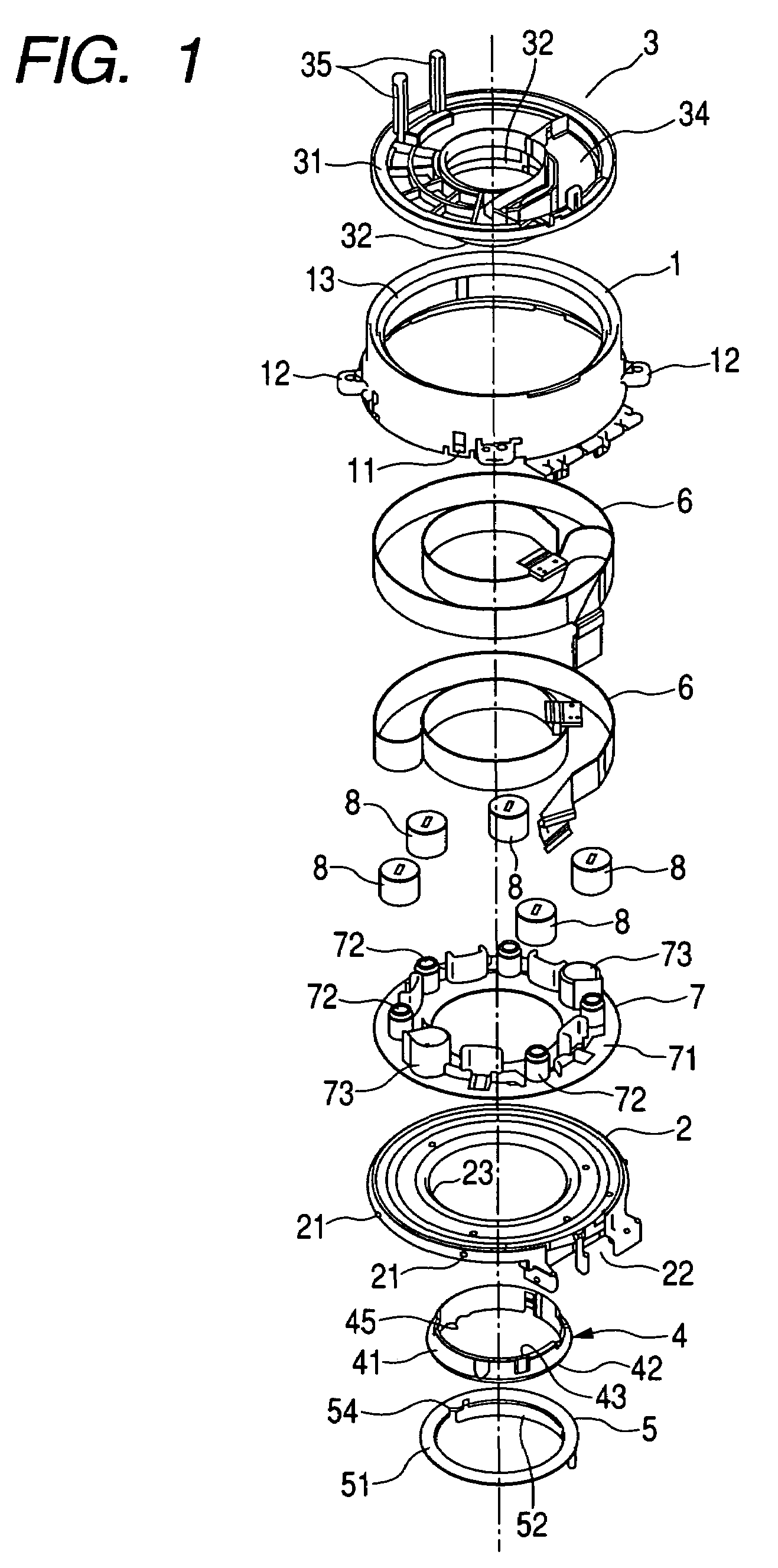

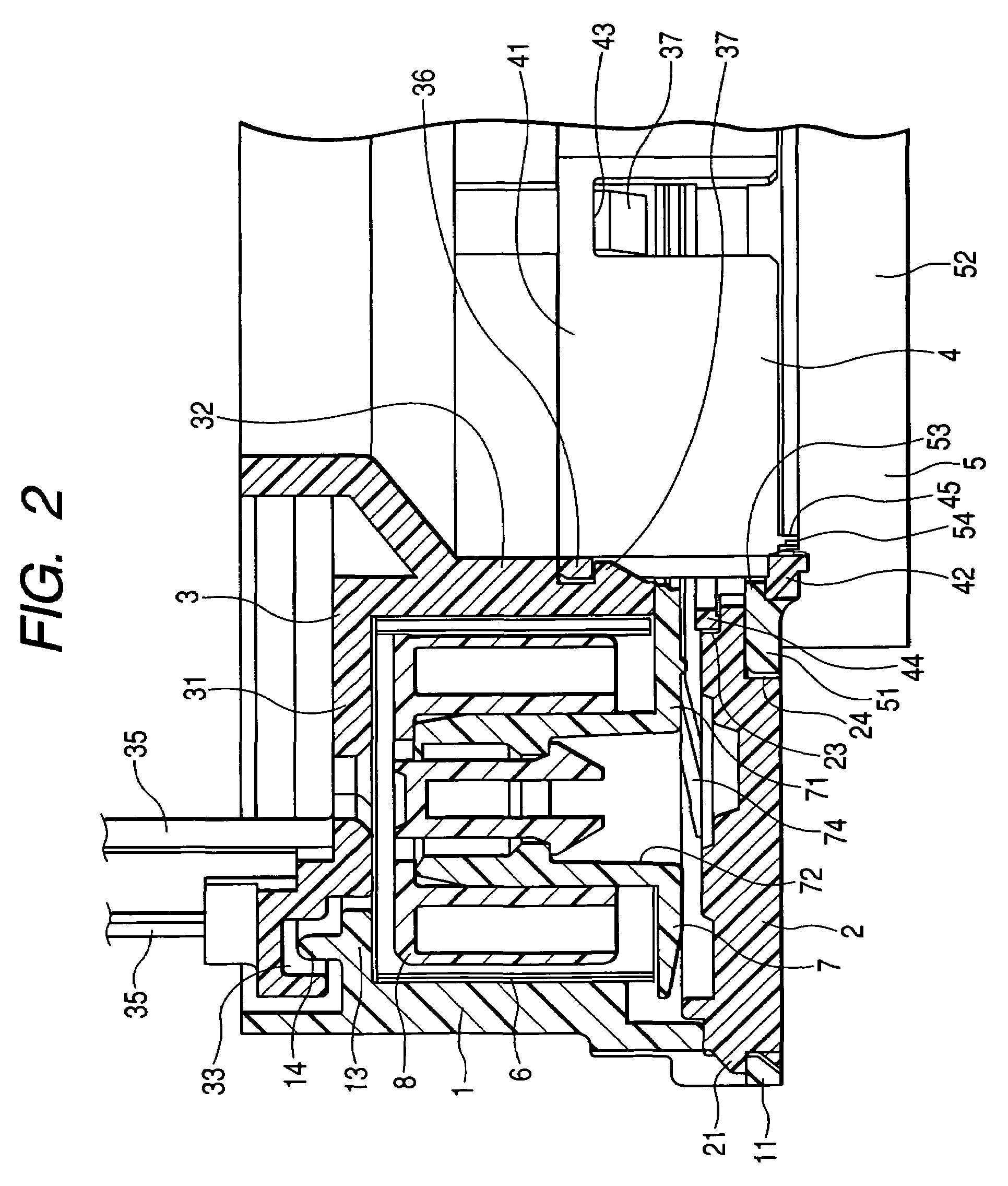

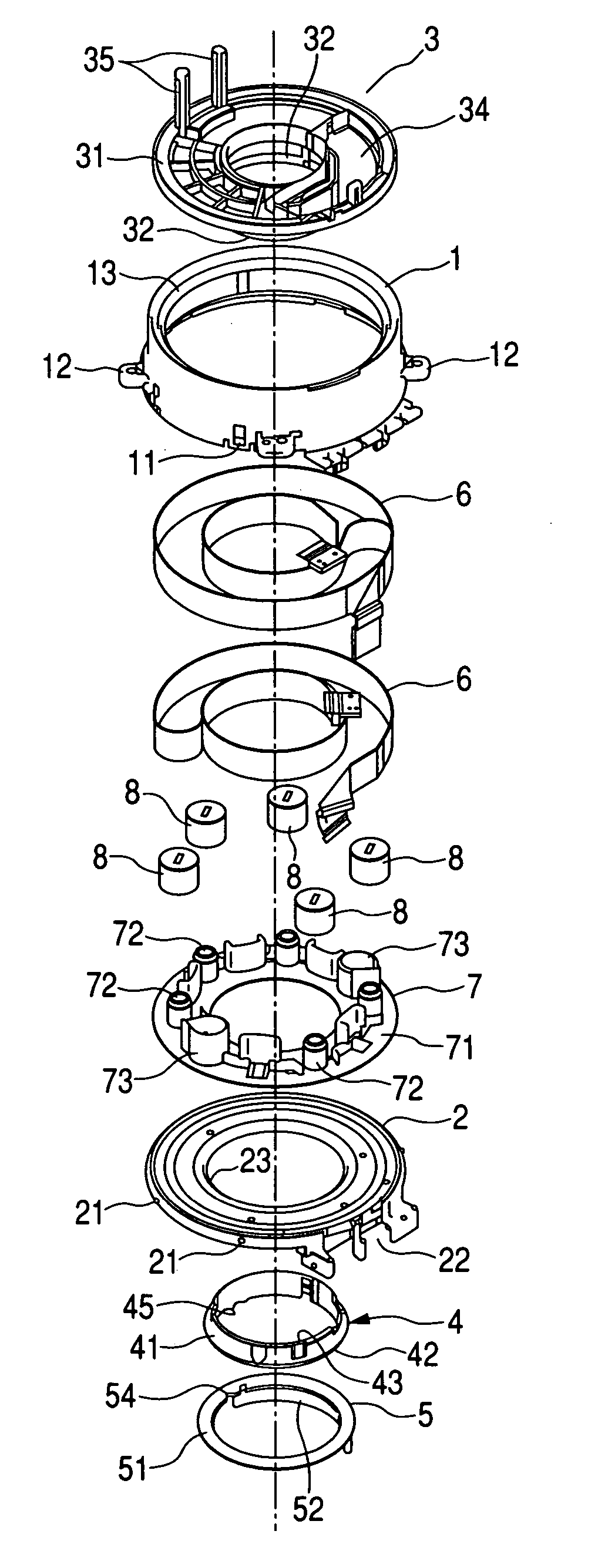

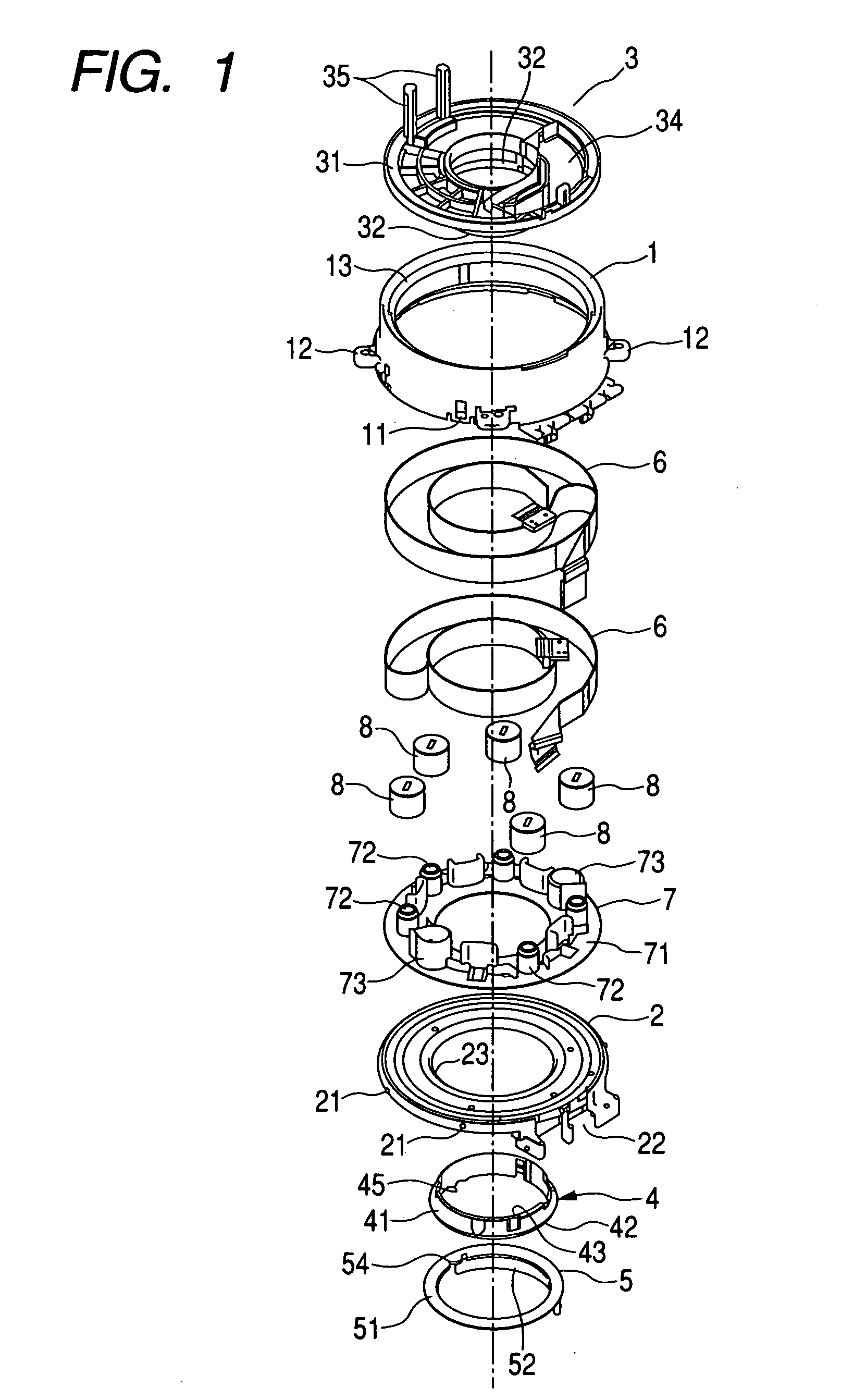

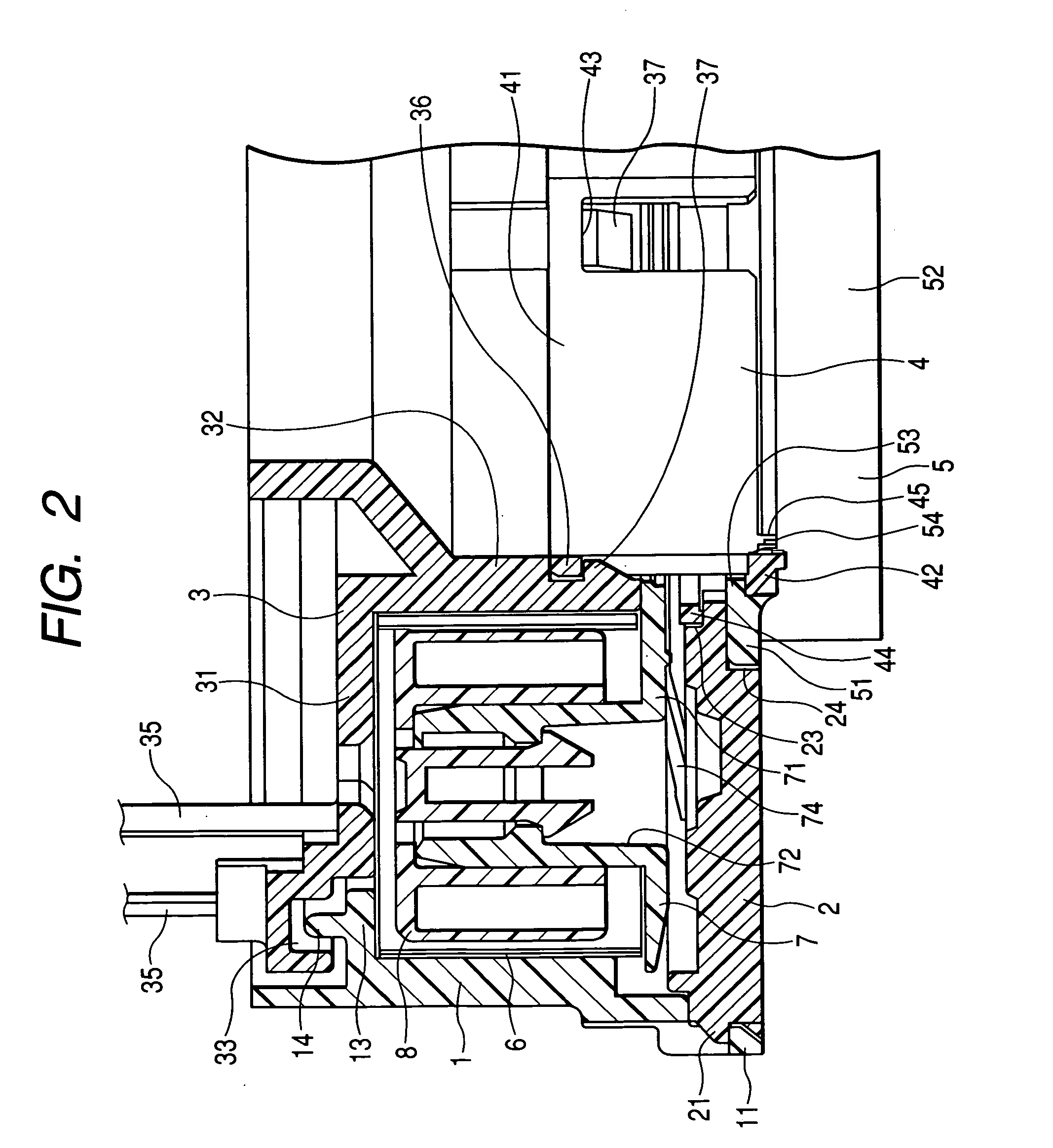

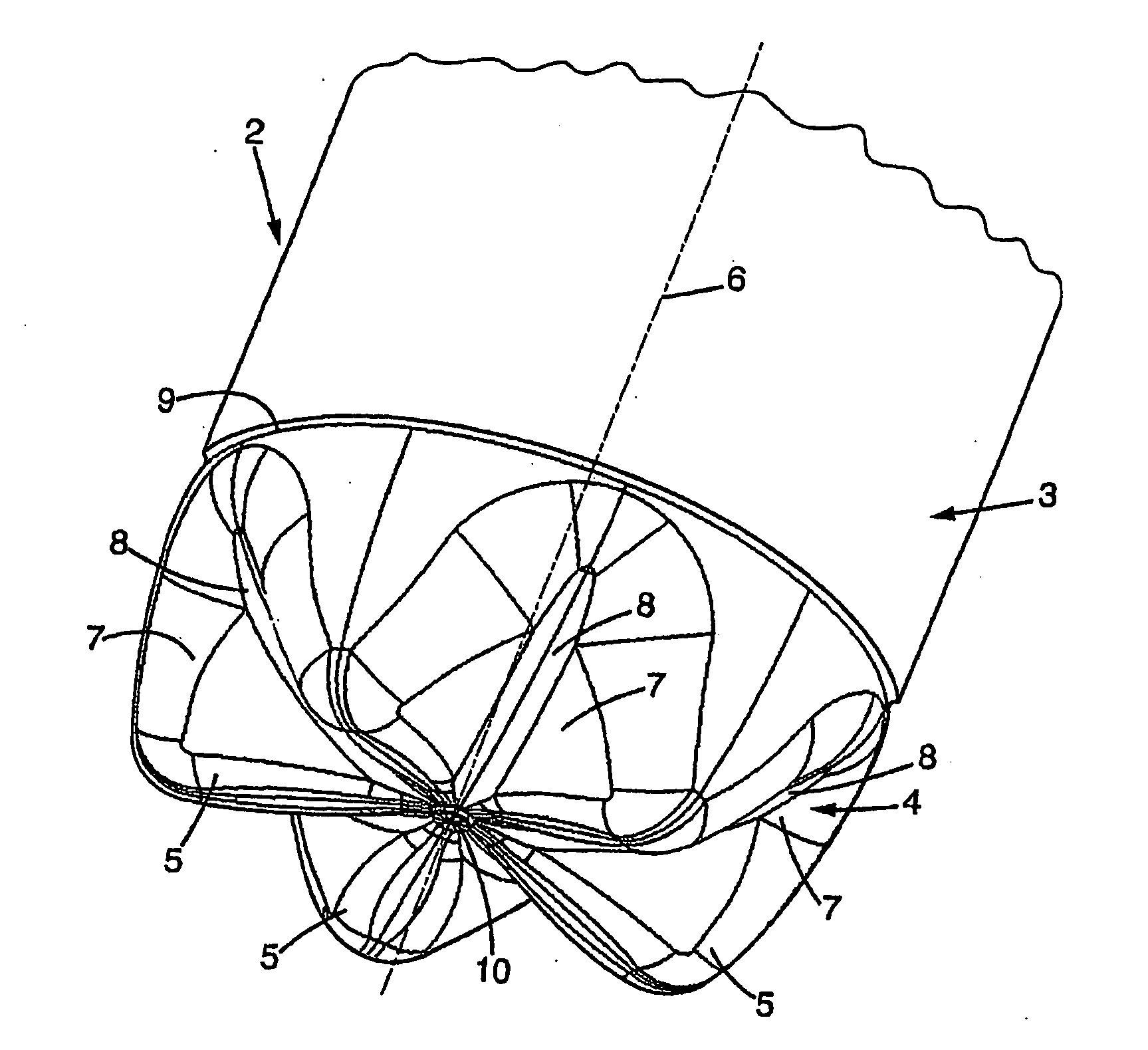

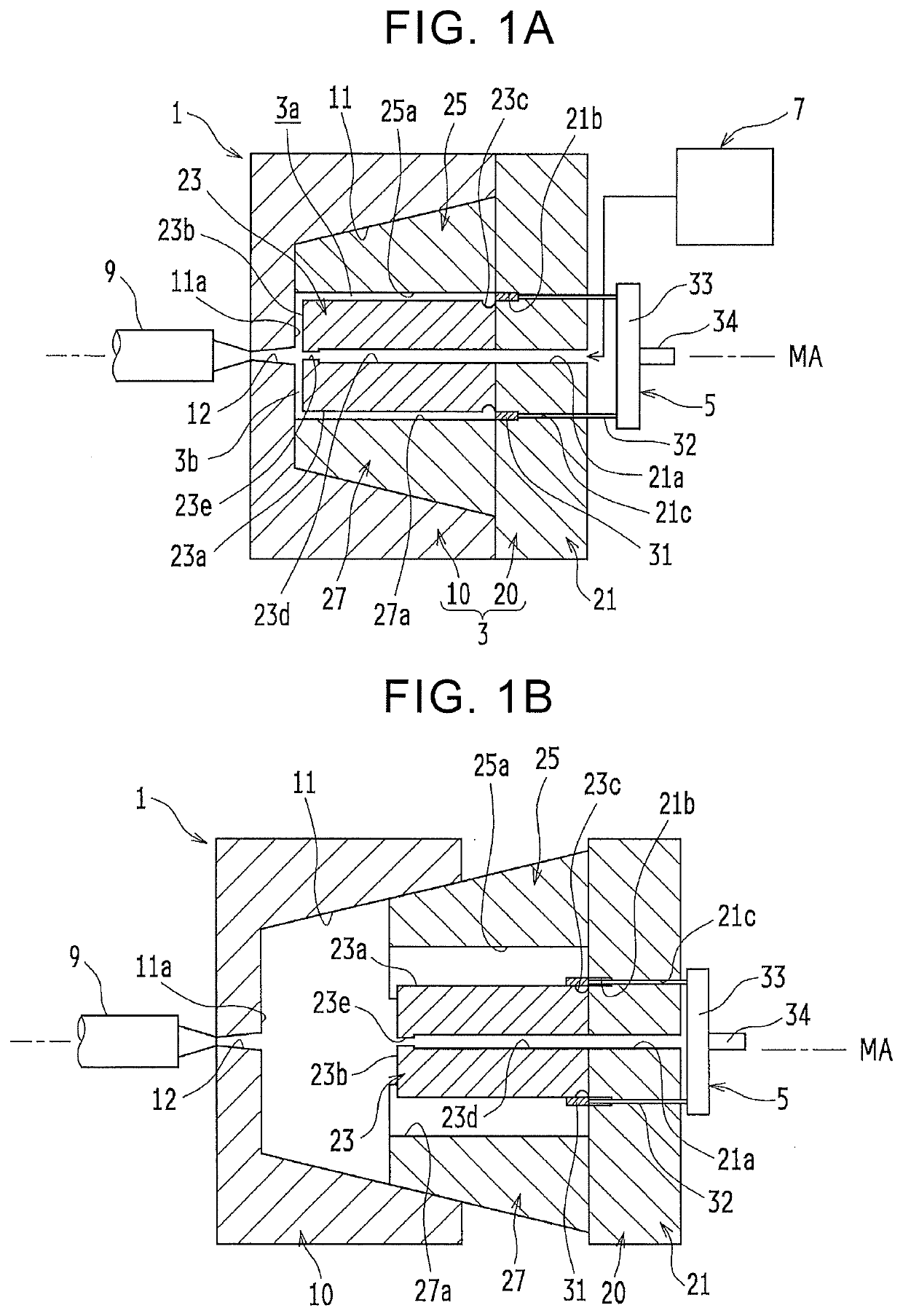

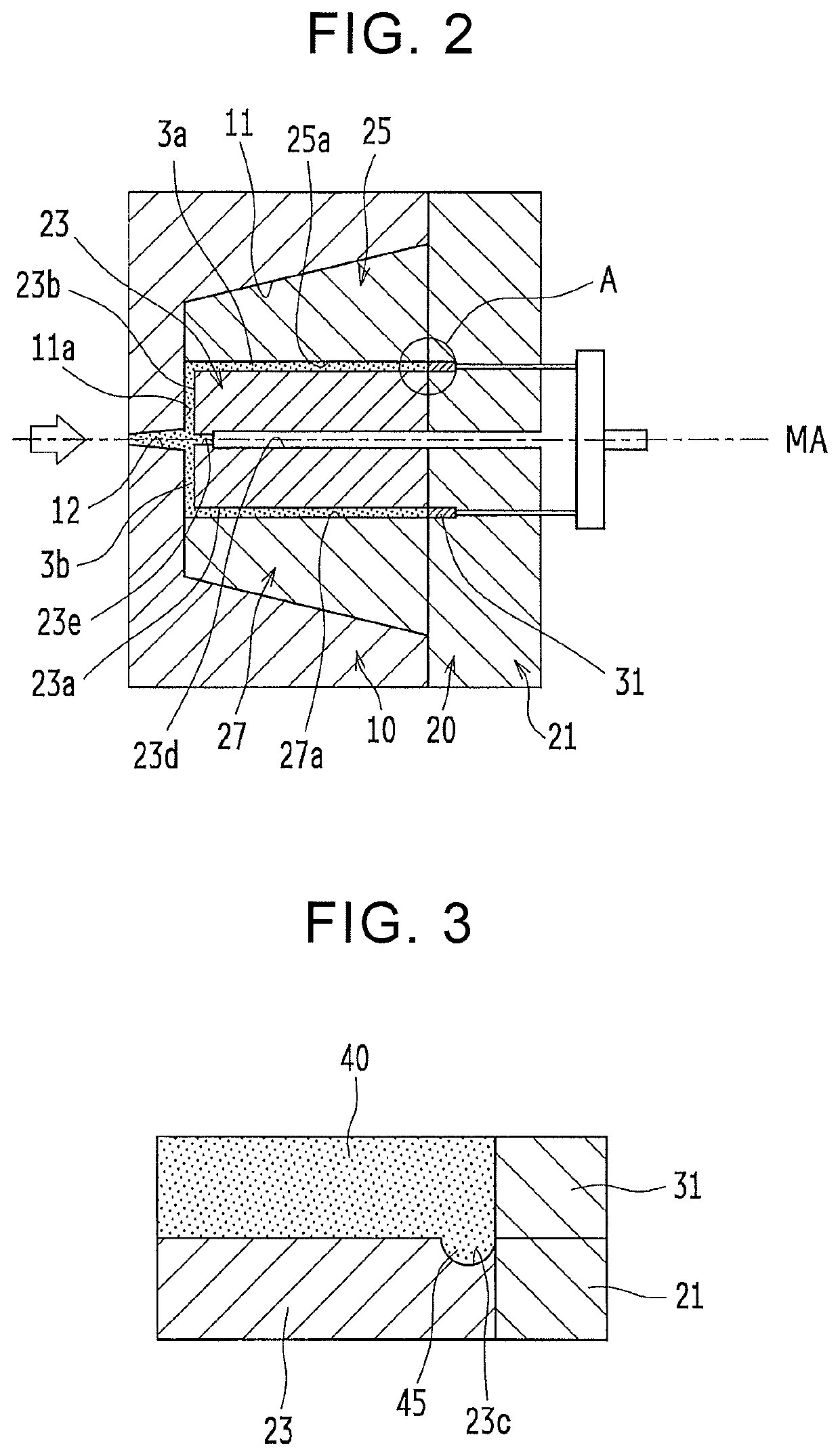

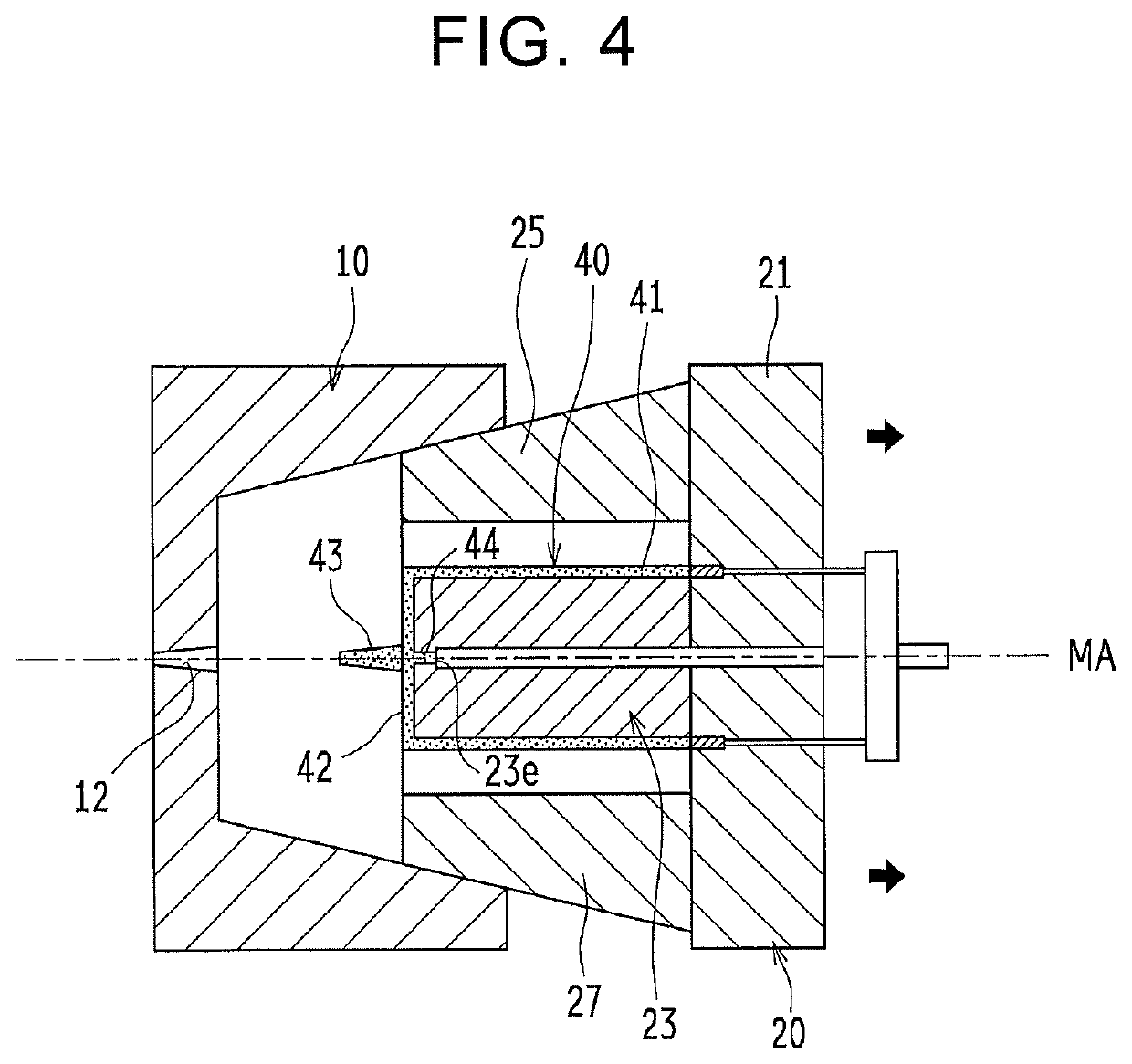

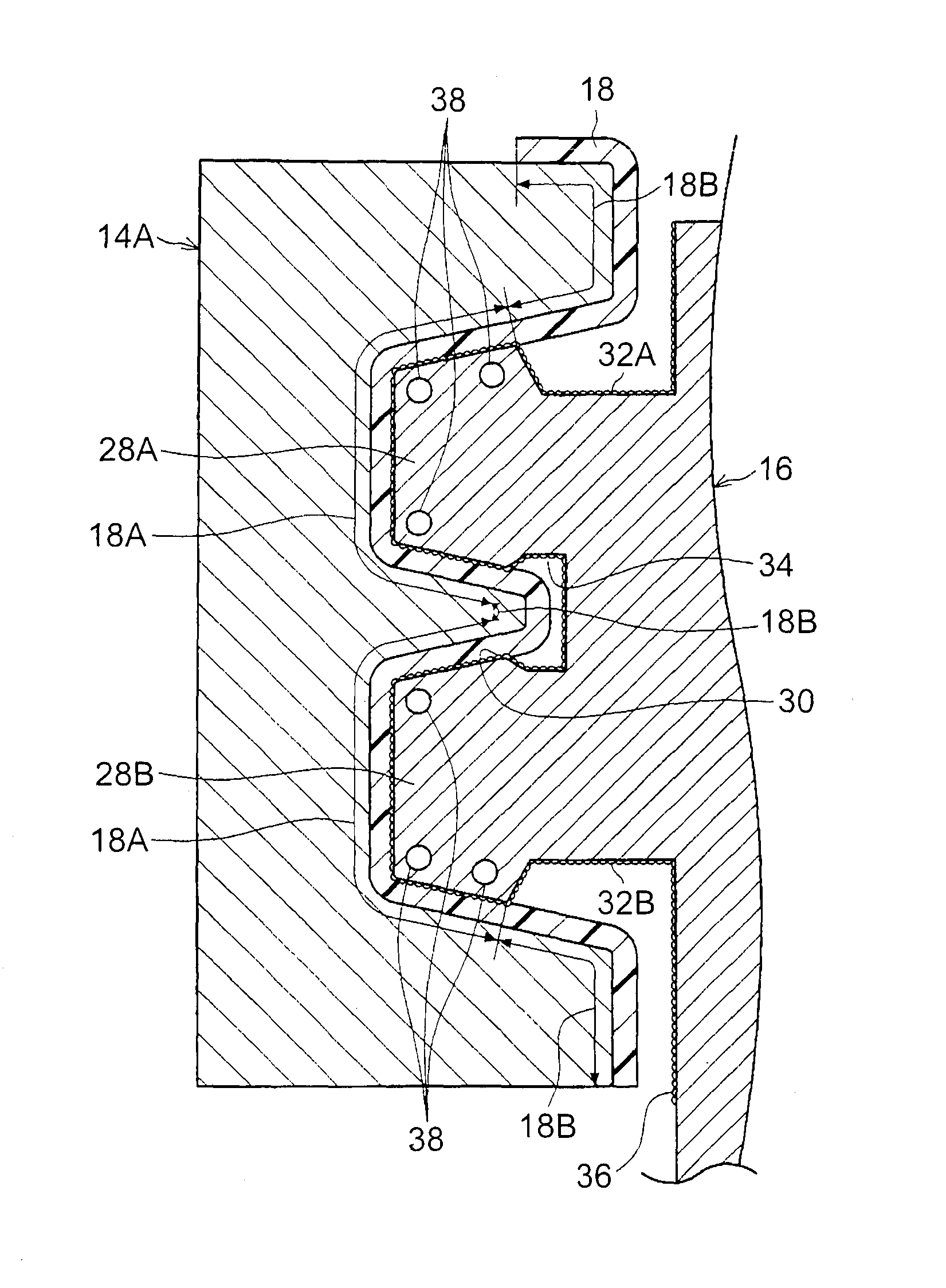

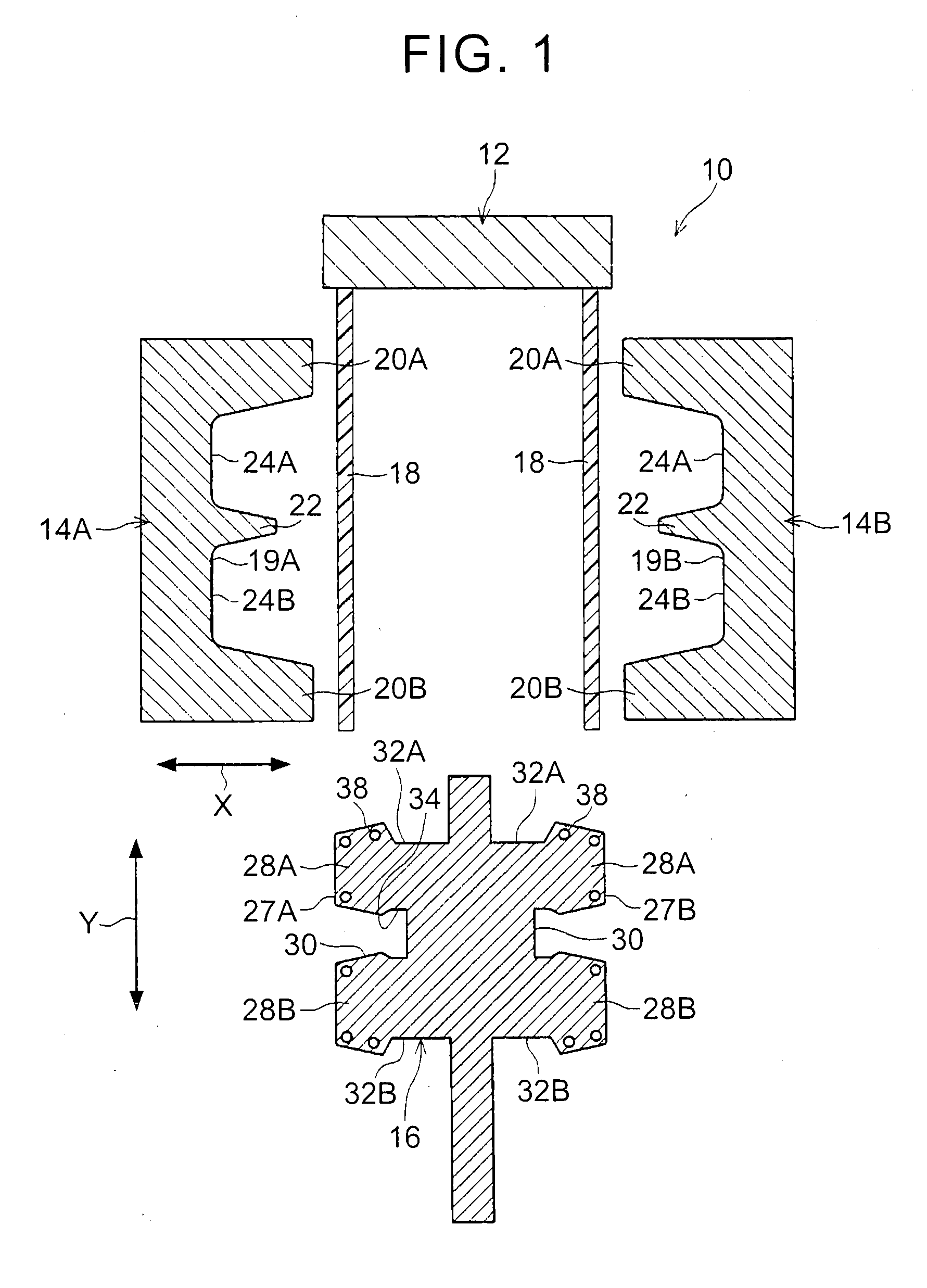

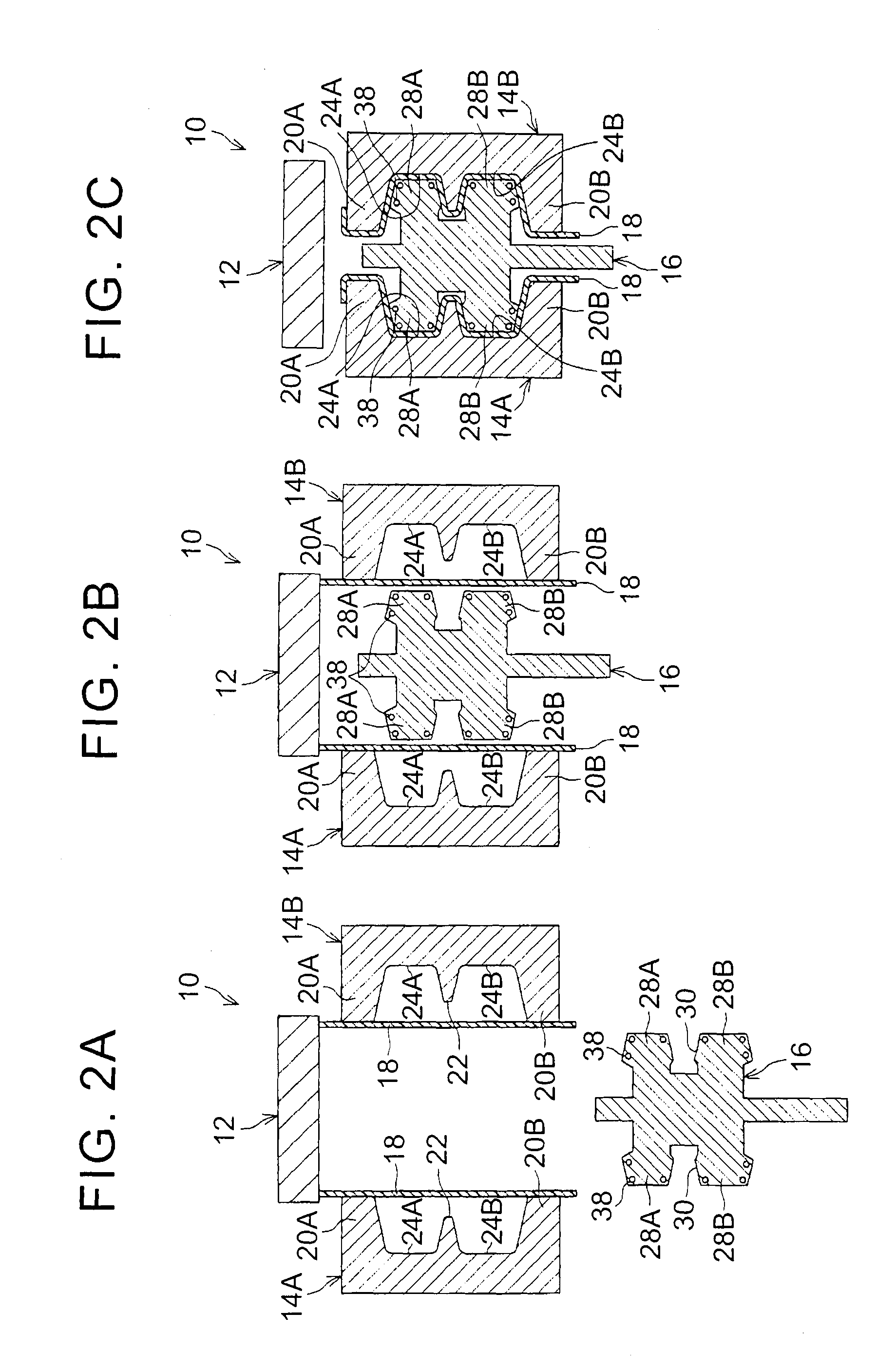

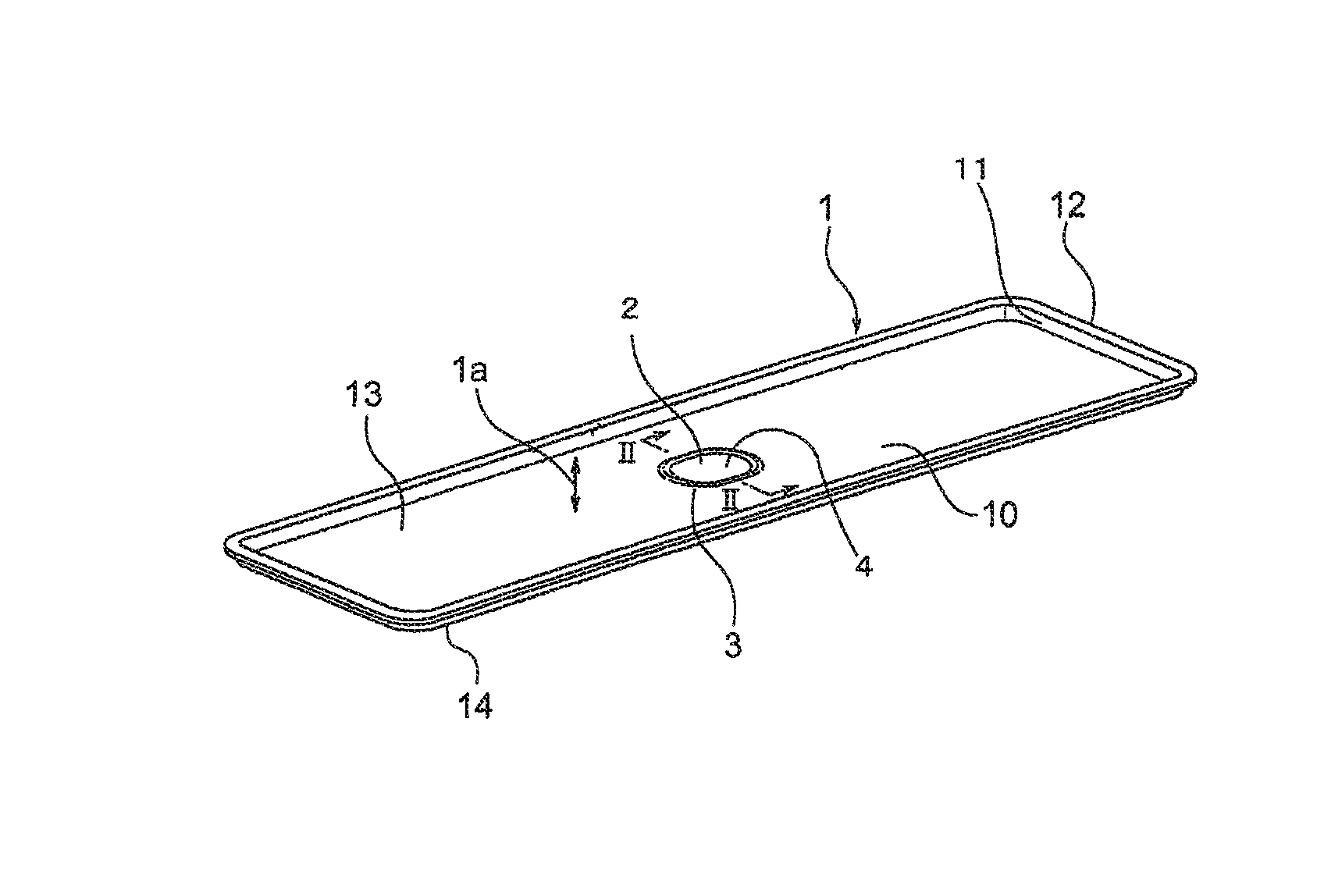

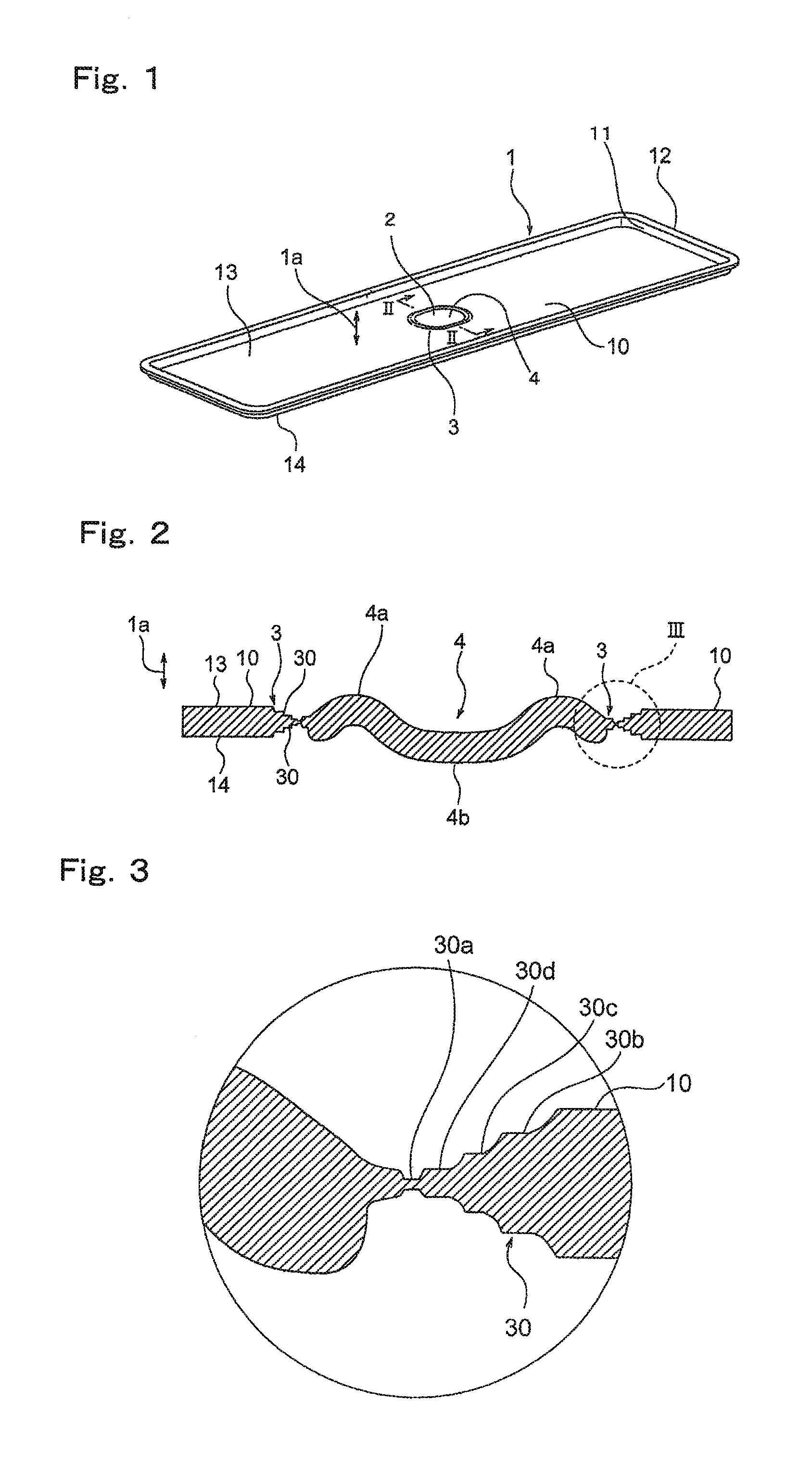

Rotary connector

ActiveUS7104821B2Precise moldingElectrically conductive connectionsRotary current collectorEngineeringFlexible cable

Owner:ALPS ALPINE CO LTD

Rotary connector

ActiveUS20060057863A1Precise moldingRotary current collectorElectrically conductive connectionsEngineeringFlexible cable

Owner:ALPS ALPINE CO LTD

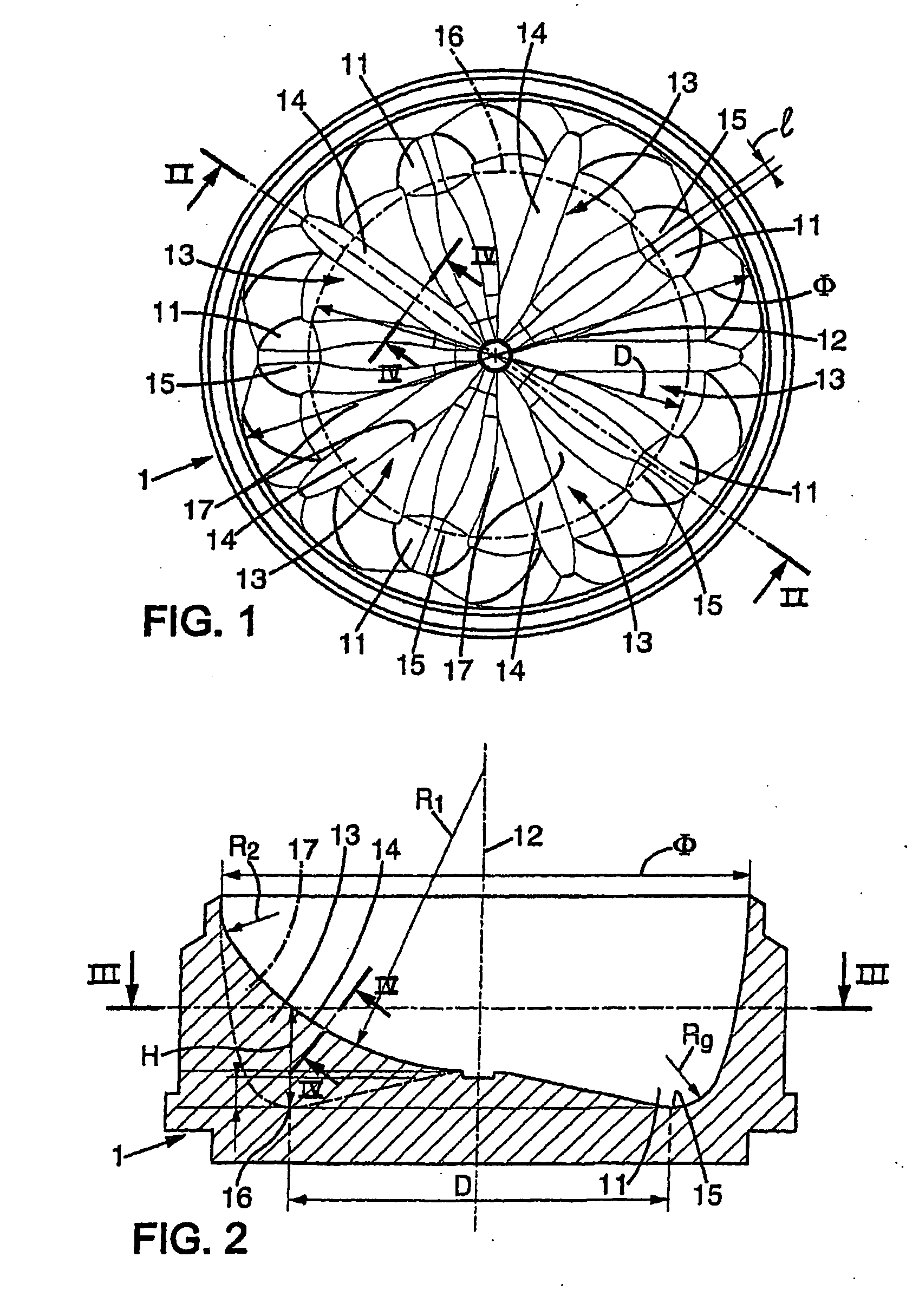

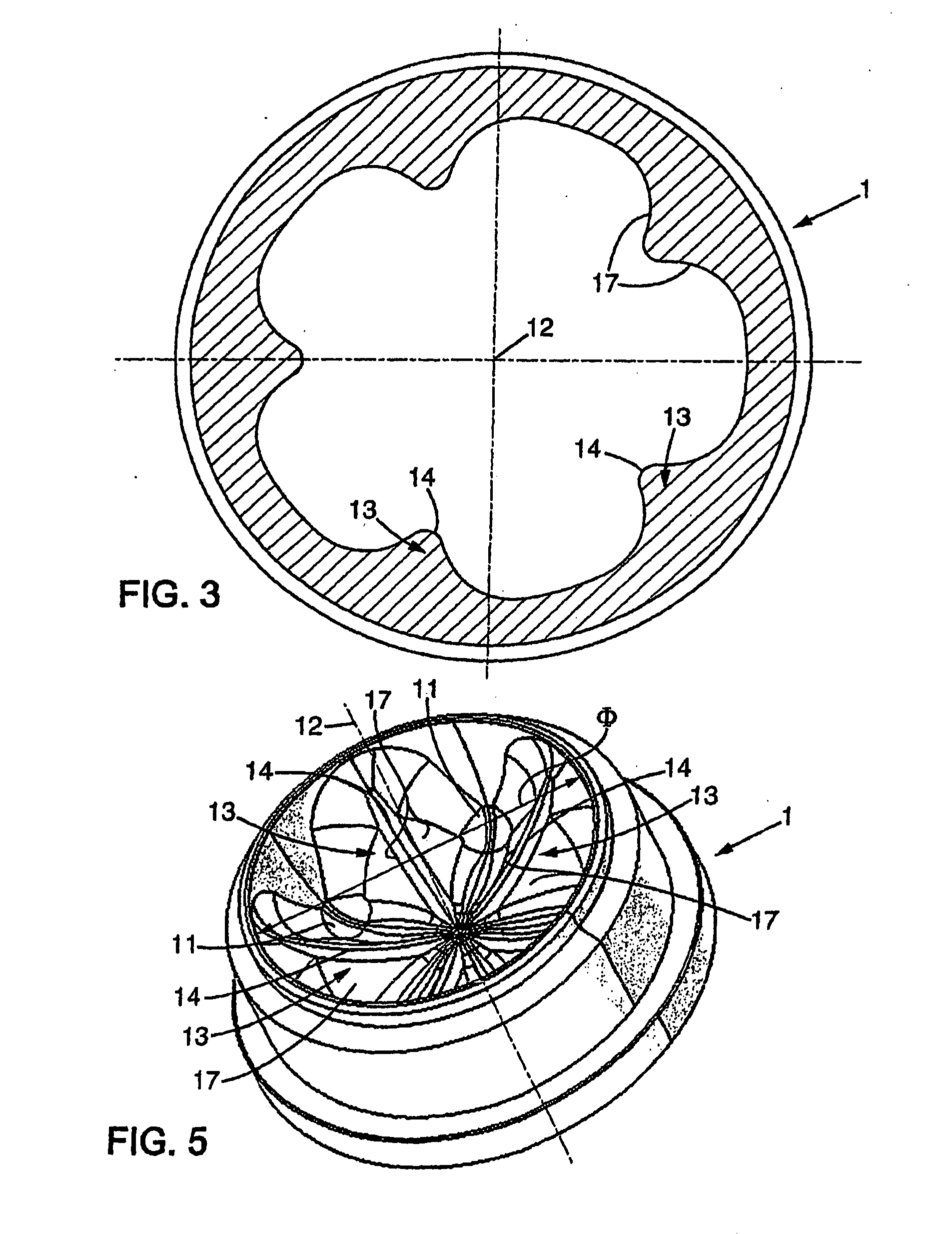

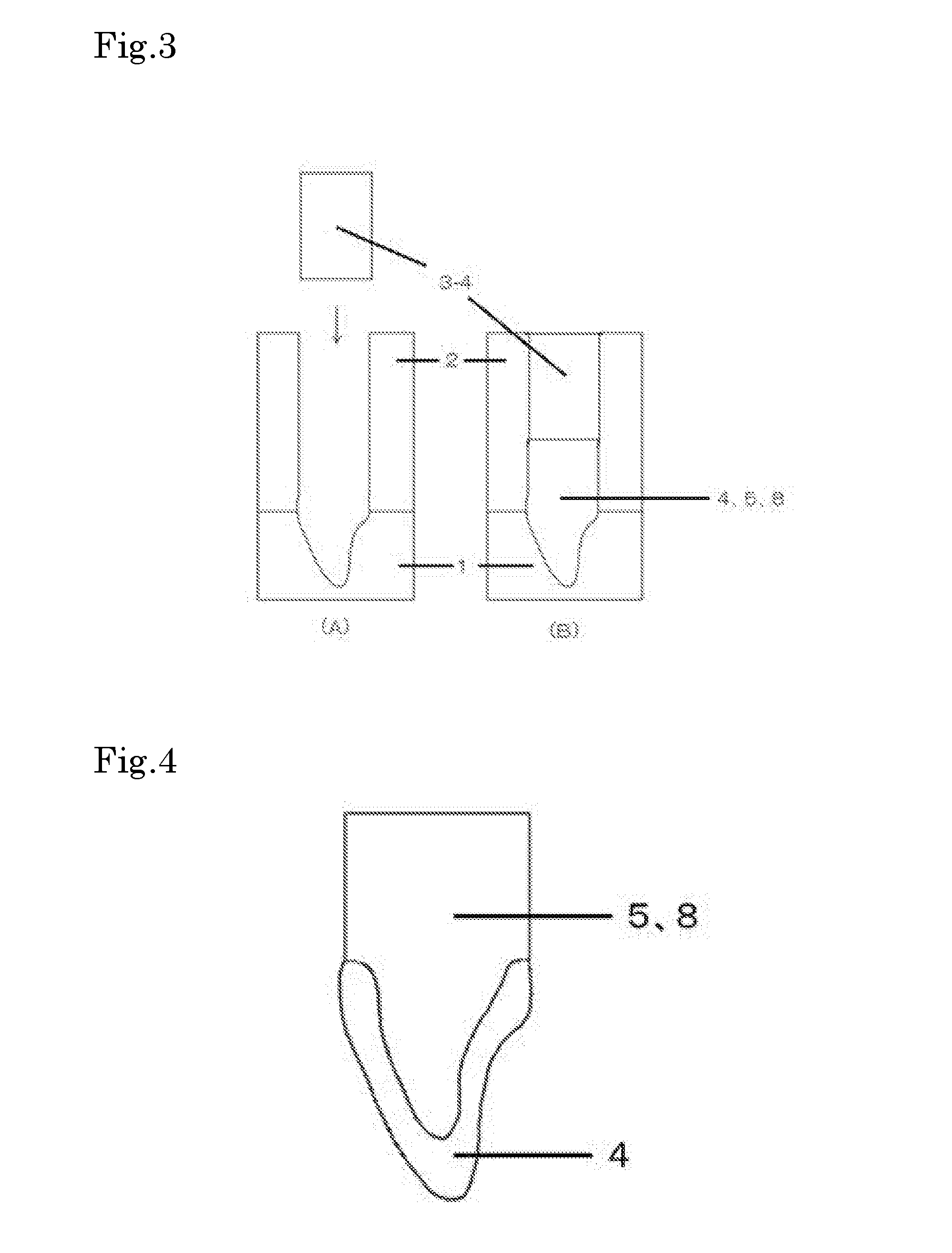

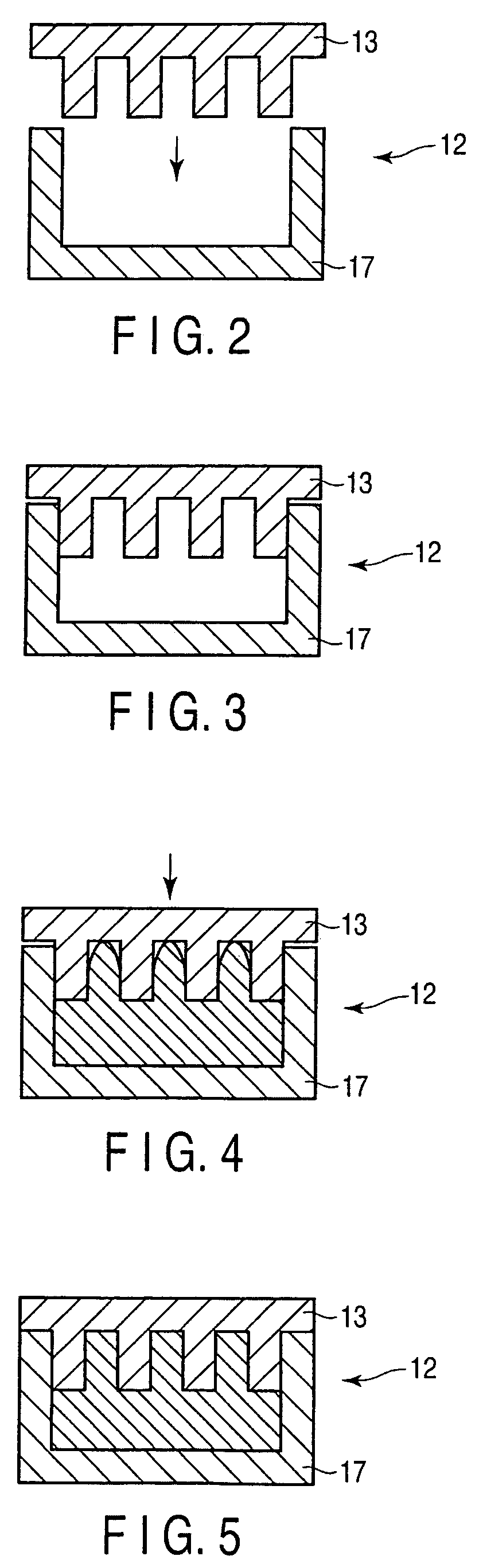

Mold Base for Mold Manufacturing Thermoplastic Containers, and Molding Device Equipped With At Least One Mold Provided With Such a Base

InactiveUS20090263534A1Easy to disassembleLarge base widthConfectioneryCeramic shaping apparatusTO-18Blow molding

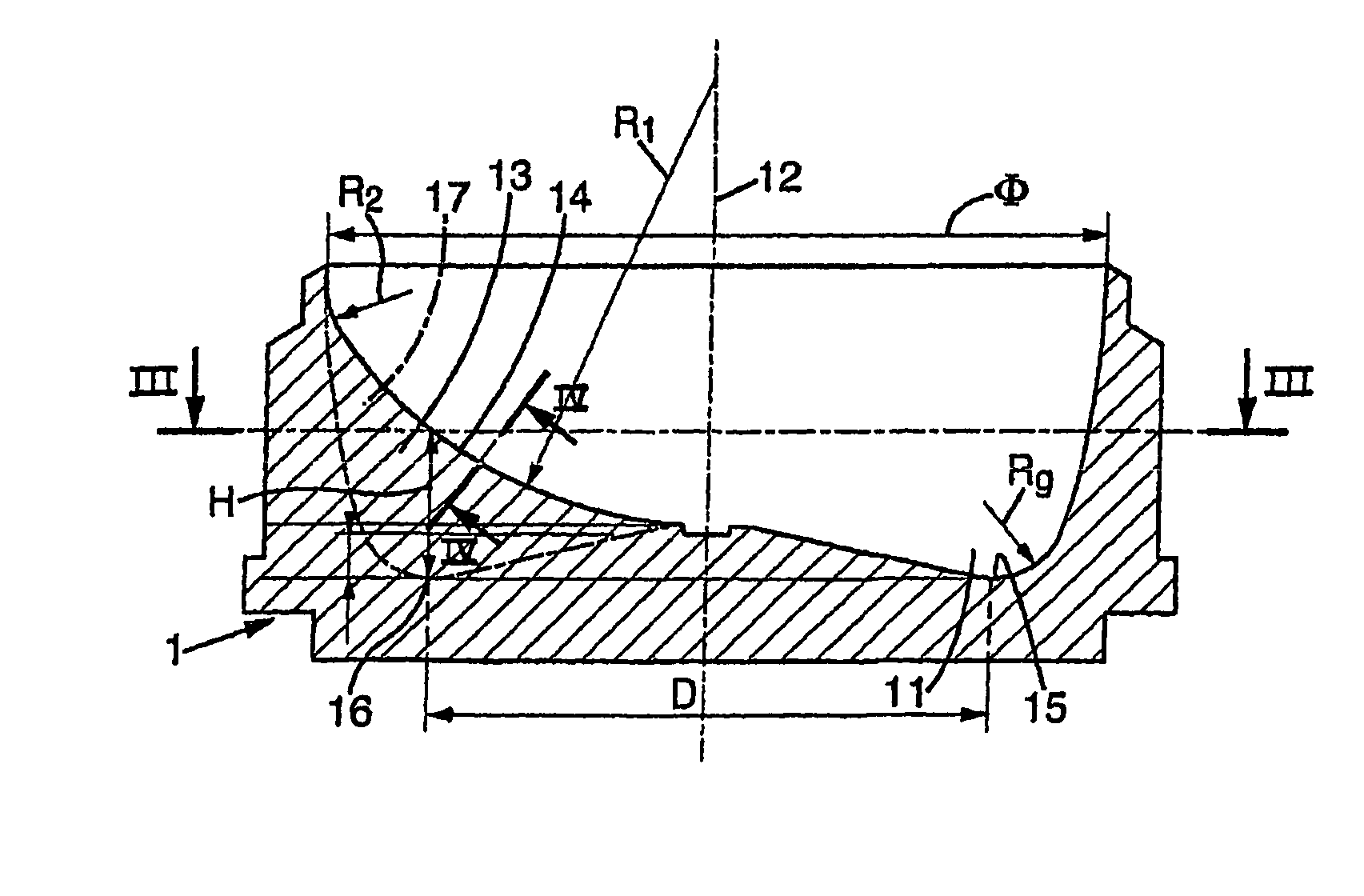

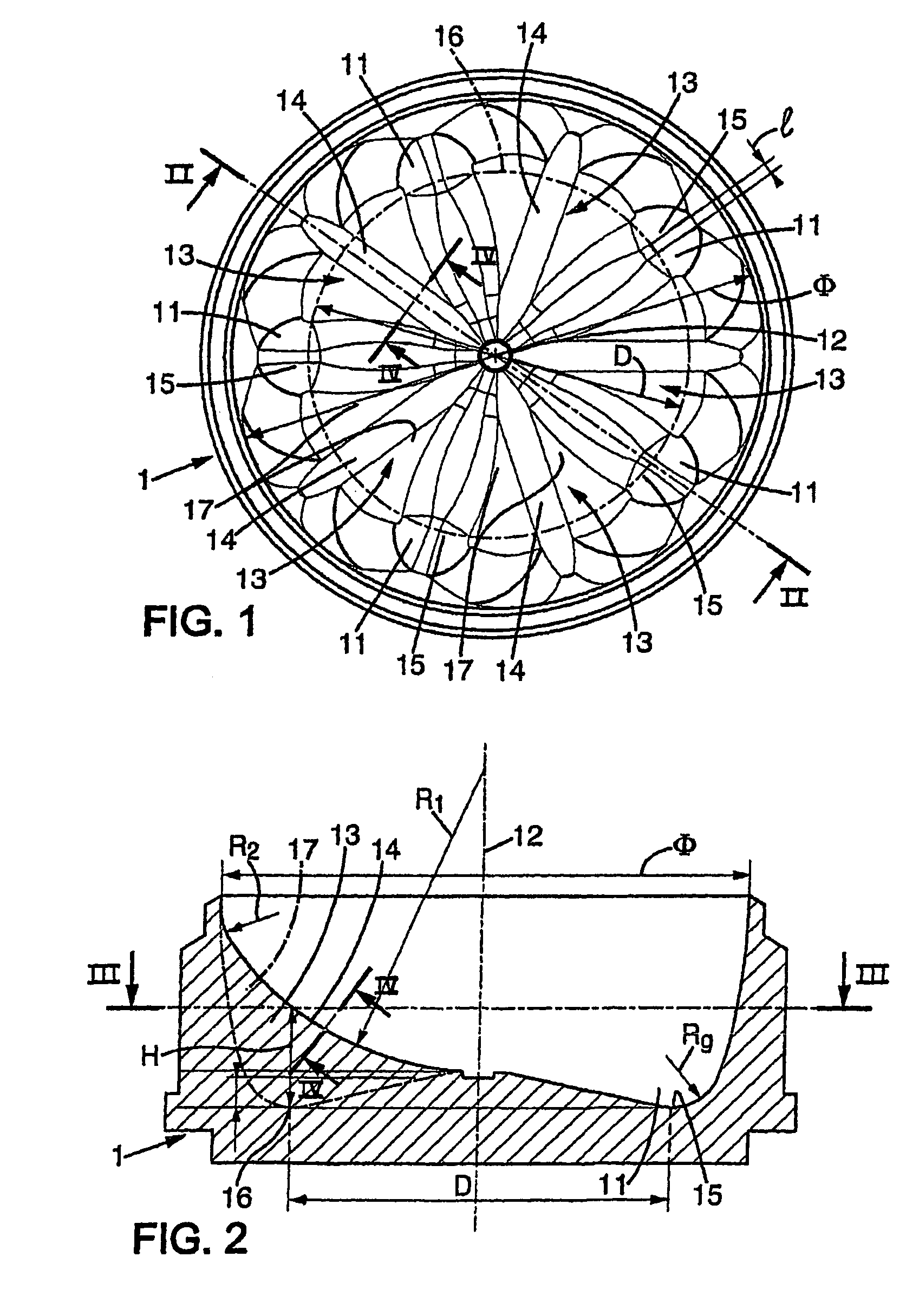

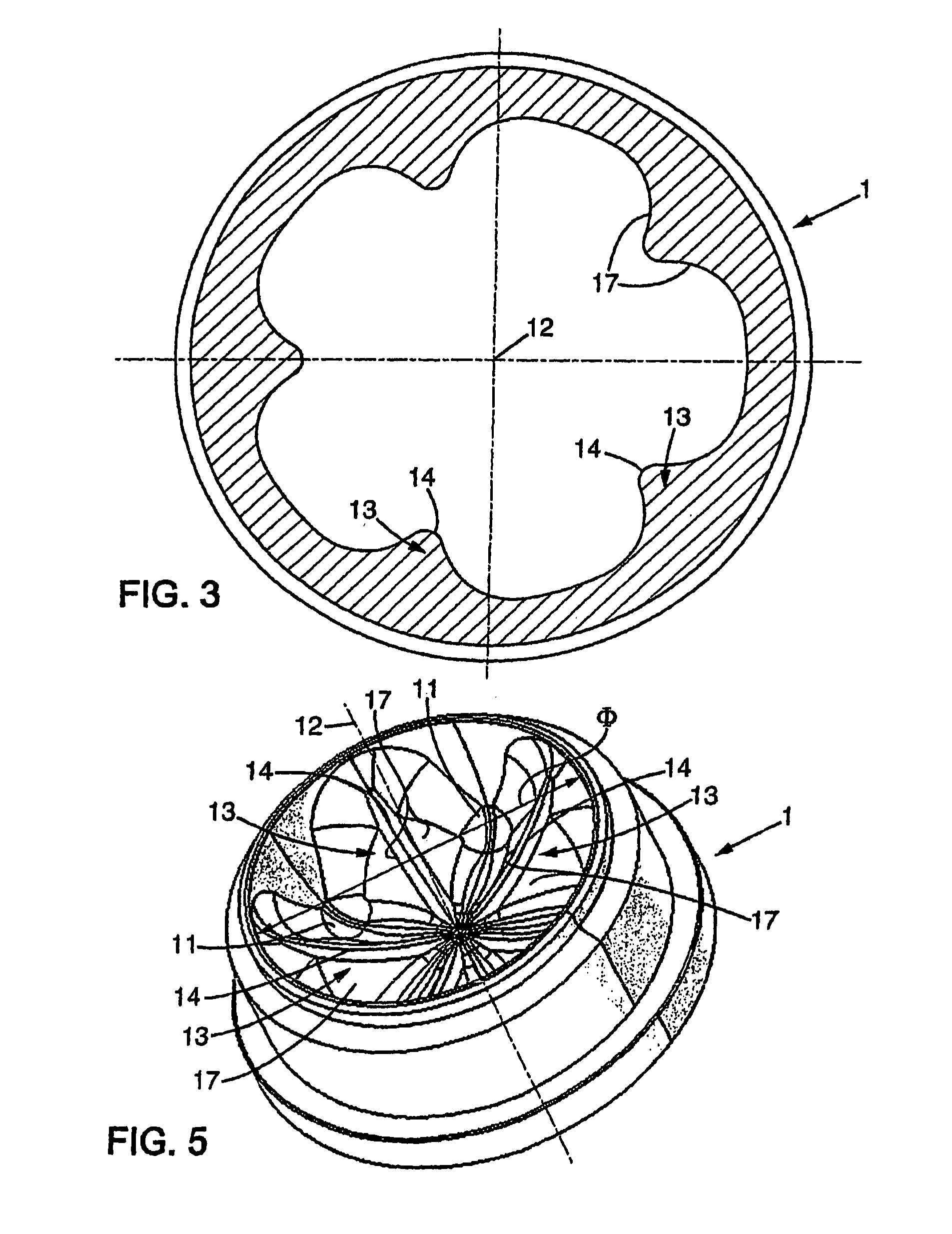

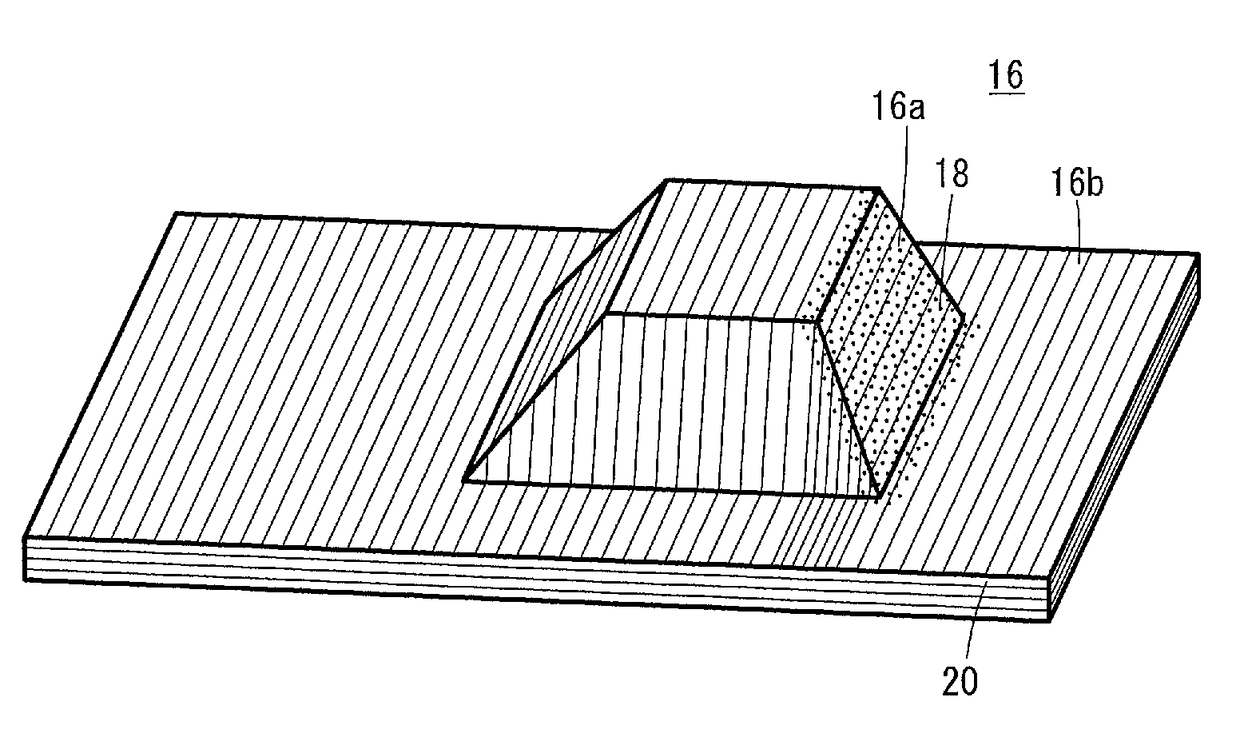

The invention concerns a mold base (1) for a blow- or stretch-blow molding of thermoplastic containers having a petaloid base with 5 stems which are separated by radiating troughs with convex radially curvilinear base, said base being connected to a body with a diameter Φ of 85 to 95 mm; the base comprises 5 cavities (11) separated by radiating ridge lines (13) with concave radial ridge (4) having a radius of 2 to 5 mm; the bases (15) of the cavities (11) have each a width of 1.5 to 3.5 mm and are distributed over a circular contour (16) of diameter of base D of 60 to 66 mm; the height (H) of the ridge line is 16.5 to 18 mm; the flanks (17) of the ridge lines are axially concave and the tangent planes at origin form an angle of 52° to 88°.

Owner:SIDEL PARTICIPATIONS SAS

Fluorine-containing resin composition for parts of electronic and electrical equipment and same parts

InactiveUS6245845B1Low dielectric constantImprove heat resistancePlastic/resin/waxes insulatorsCoatingsThermoplasticHeat resistance

To provide a fluorine-containing resin composition useful as a molding material for parts of electronic and electrical equipment which assures well-balanced enhancement of dielectric property, heat resistance, mold-processability (precise processability) and mechanical properties and the parts of electronic and electrical equipment. The fluorine-containing resin composition for parts of electronic and electrical equipment comprises 70 to 95% by weight of (I) fluorine-containing resin mixture comprising (a) a fluorine-containing resin containing polytetrafluoroethylene not to be fibrillated and (b) a thermoplastic resin other than the fluorine-containing resin and 5 to 30% by weight of (II) a metal compound whisker having a single bond strength of not less than 190 KJ / mol calculated from a dissociation energy of bond between a metal element and oxygen. The parts of electronic and electrical equipment which are obtained from the composition have a dielectric constant of not more than 3.5.

Owner:DAIKIN IND LTD

Rubber forming method and die for sheet metal frame parts with different-direction flanges

ActiveCN111229914AReduce in quantityImprove forming efficiencyShaping toolsEngineeringMechanical engineering

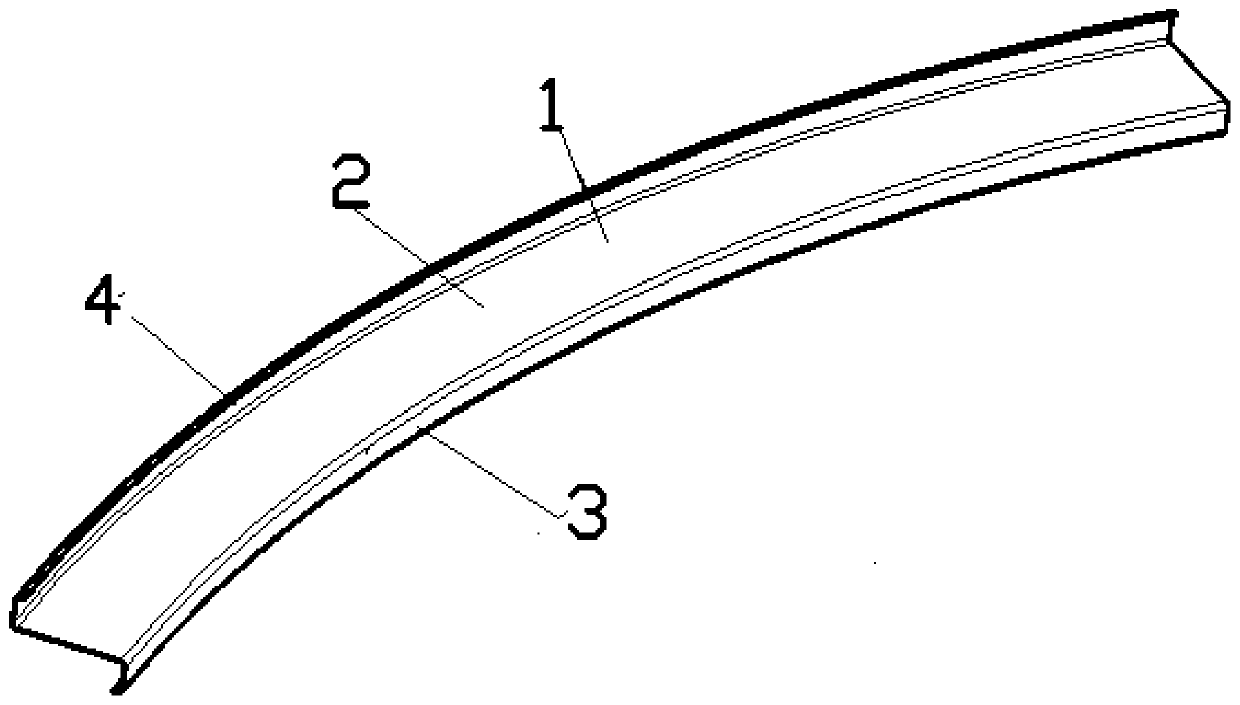

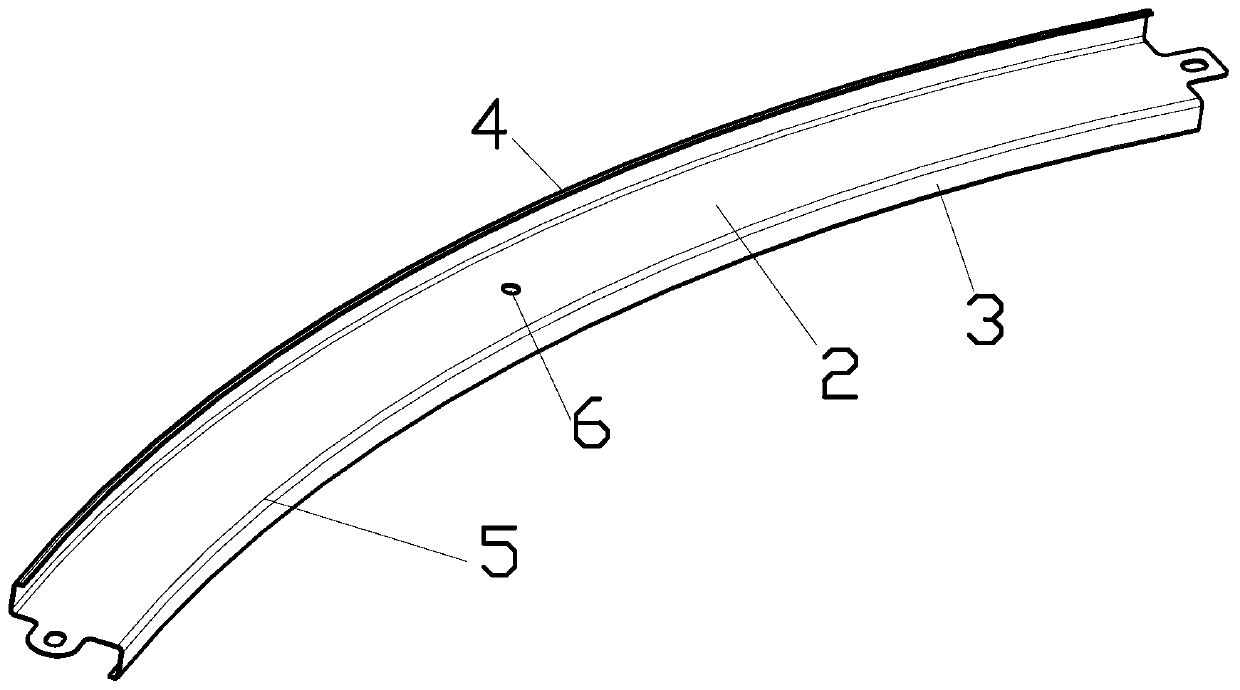

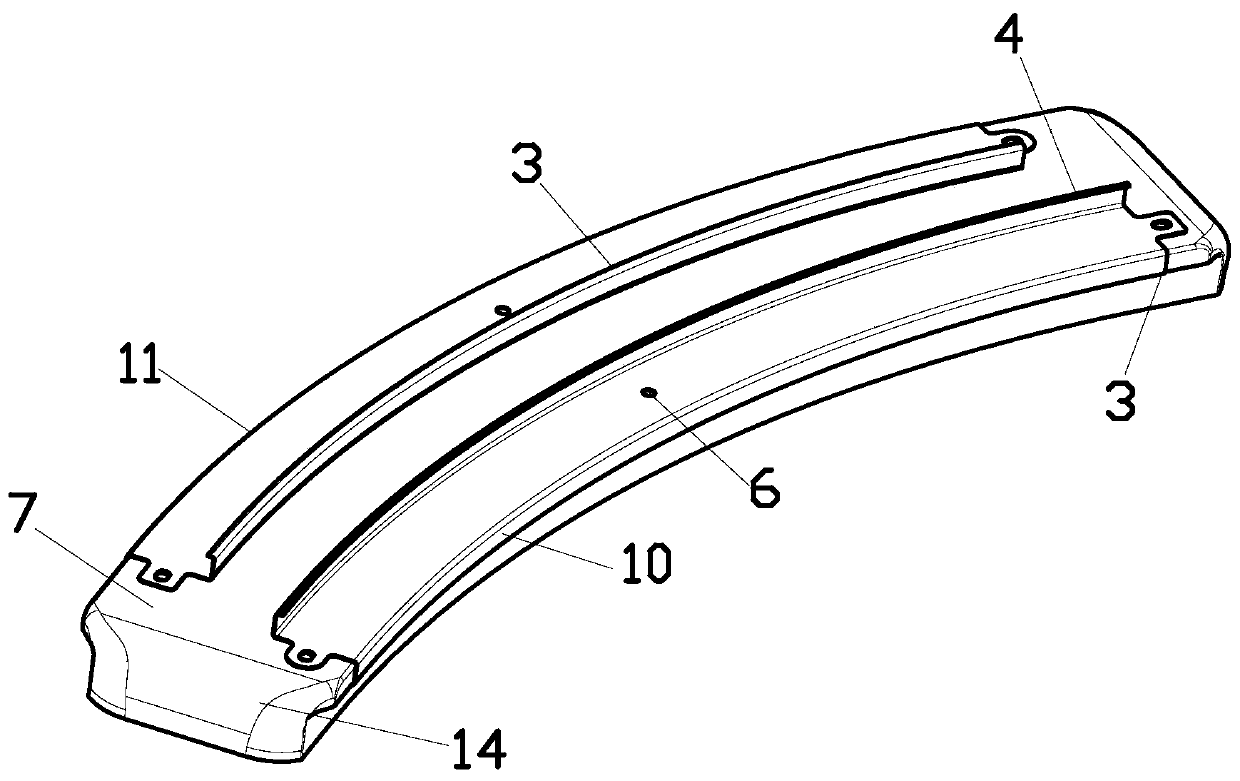

The invention discloses a rubber forming method and die for sheet metal frame parts with different-direction flanges. A model of the sheet metal frame parts comprises an equal-curvature arc-shaped webplate, the first flange and the second flange, wherein the first flange and the second flange are symmetrical; and the forming die comprises a carcass and a cover plate matched with the carcass, thecarcass comprises two forming stations, the first forming station matched with the first flange is arranged on the inner side of the carcass, the second forming station matched with the second flangeis arranged on the outer side of the carcass, an arc-shaped avoiding groove is formed in the inner surface of the cover plate, an expanded sheet of the first sheet metal frame part is placed on the first forming station of the carcass for positioning, an expanded sheet of the second sheet metal frame part is placed on the second forming station of the carcass for positioning, first rubber formingis performed, then the first sheet metal frame part is turned over and placed on the second forming station of the carcass, the second sheet metal frame part is turned over and placed on the first forming station of the carcass, and second rubber forming is performed.

Owner:XIAN AIRCRAFT IND GROUP

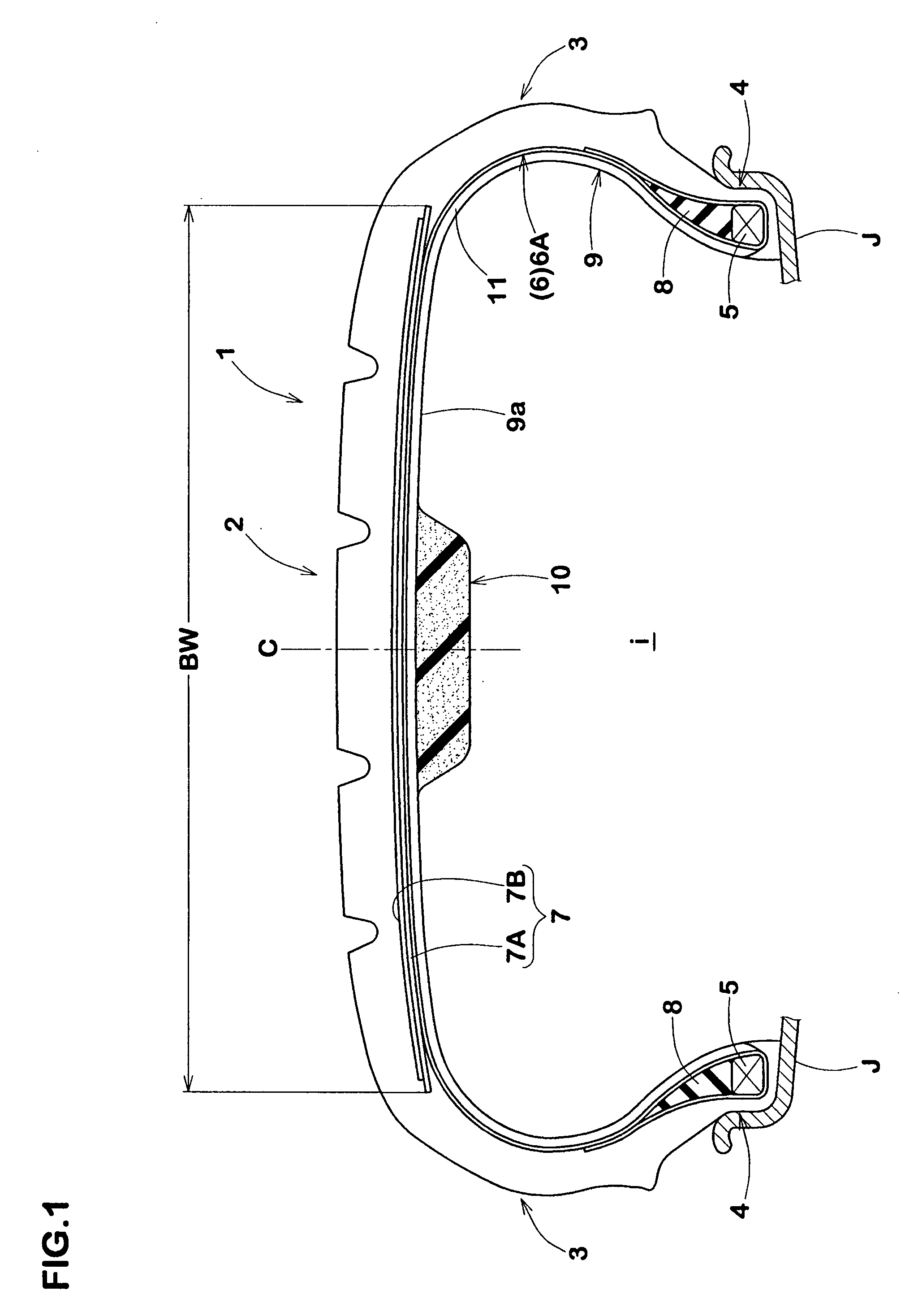

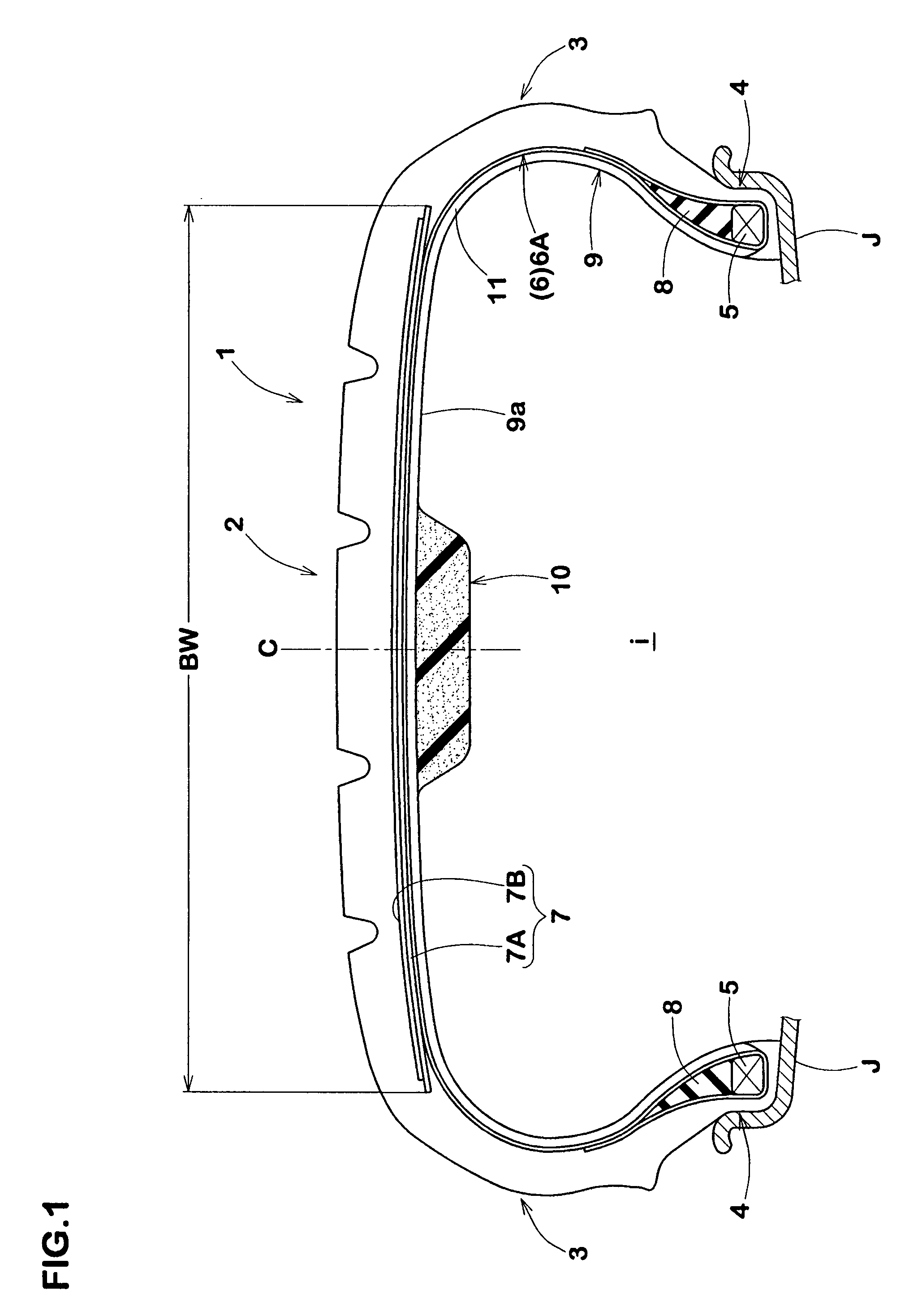

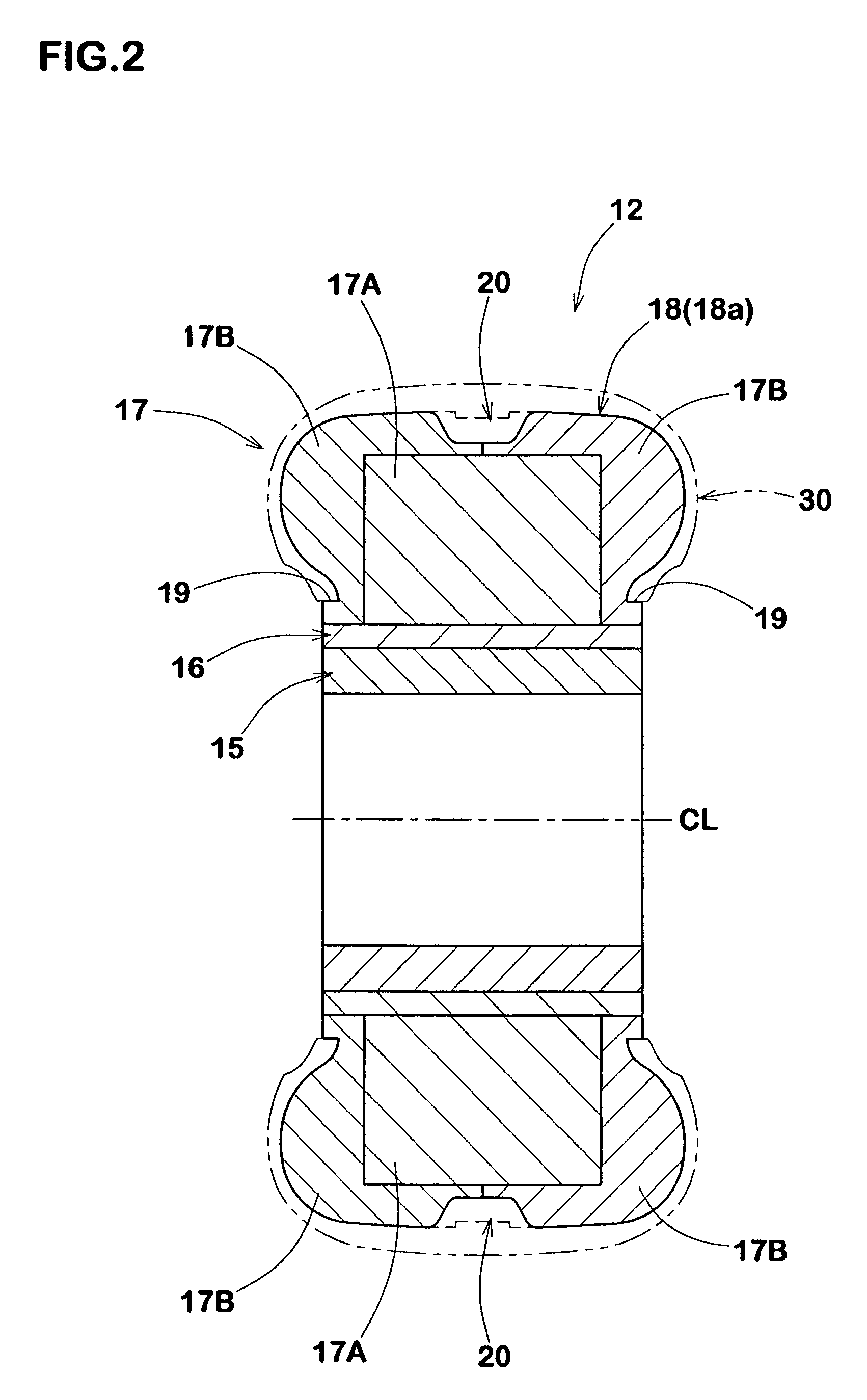

Method for manufacturing pneumatic tire

InactiveUS20080087368A1Effective noise damperExpand accurately and sufficientlyTyresInflatable tyresEngineeringMechanical engineering

A method for manufacturing a pneumatic tire with a noise damper on the inside of the tread portion, comprises the steps of: building a raw tire on an annular tire building core; placing the raw tire within a vulcanizing mold together with the core; and heating the raw tire in the mold. The tire building core has a molding face for molding an inner surface of the tread portion. The molding face is provided with a groove extending in the tire circumferential direction. In the step of building the raw tire, an expandable damper material is placed in the groove. During heating the raw tire to be vulcanized, the damper material expands in the groove, whereby the expanded material forms the noise damper integrated into the radially inside of the tread portion.

Owner:SUMITOMO RUBBER IND LTD

Compression molded tooth

InactiveUS20160293056A1Easy to produceAccurate shapeArtificial teethDentistry preparationsDentistryPolysaccharide

The compression molded tooth used for practicing dental cutting treatment of the present invention comprises a composition containing a powder or powders of saccharide, polysaccharide, protein, and / or glycoprotein each having a particle size of 1 to 100 μm.

Owner:SHOFU INC

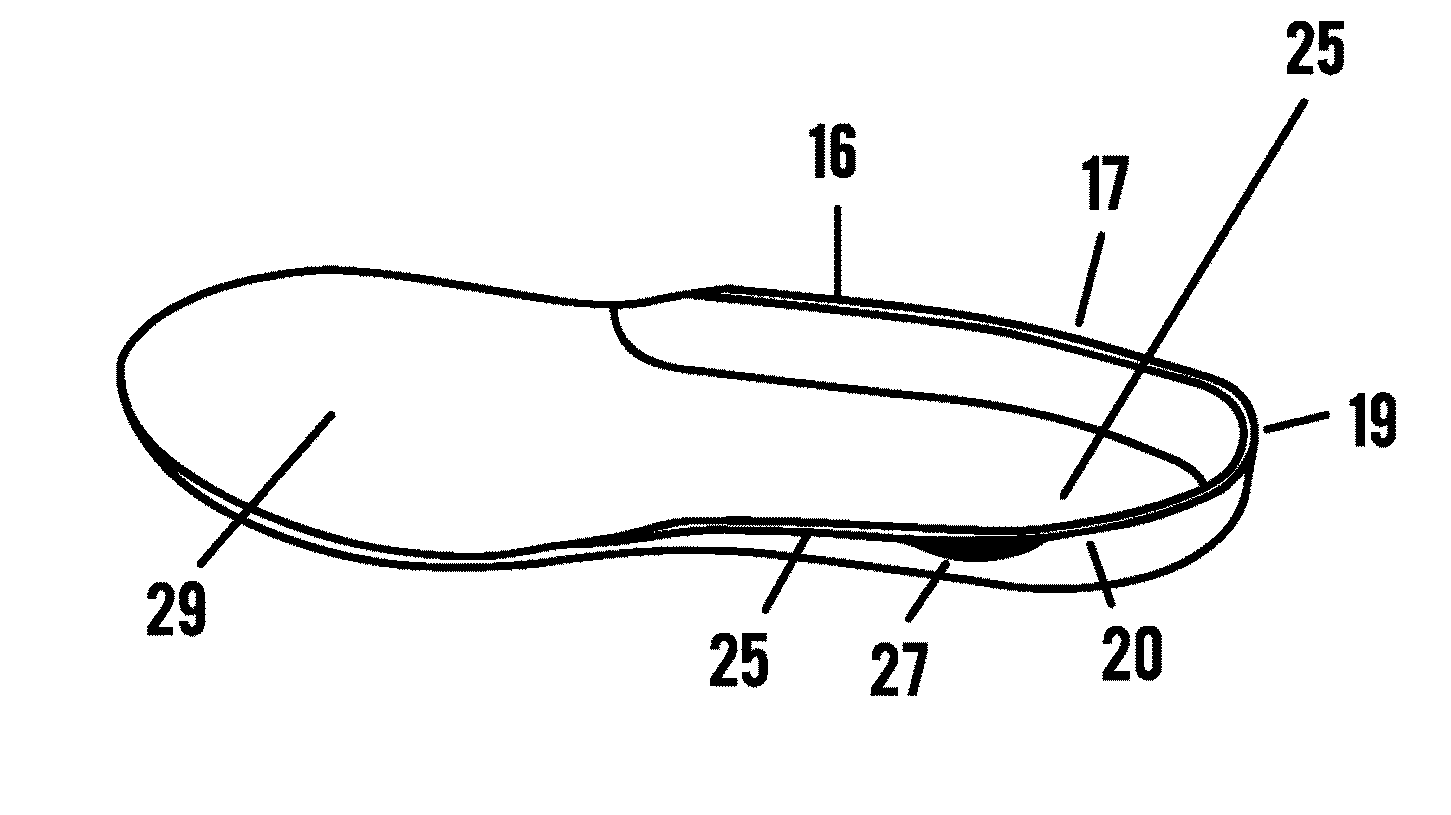

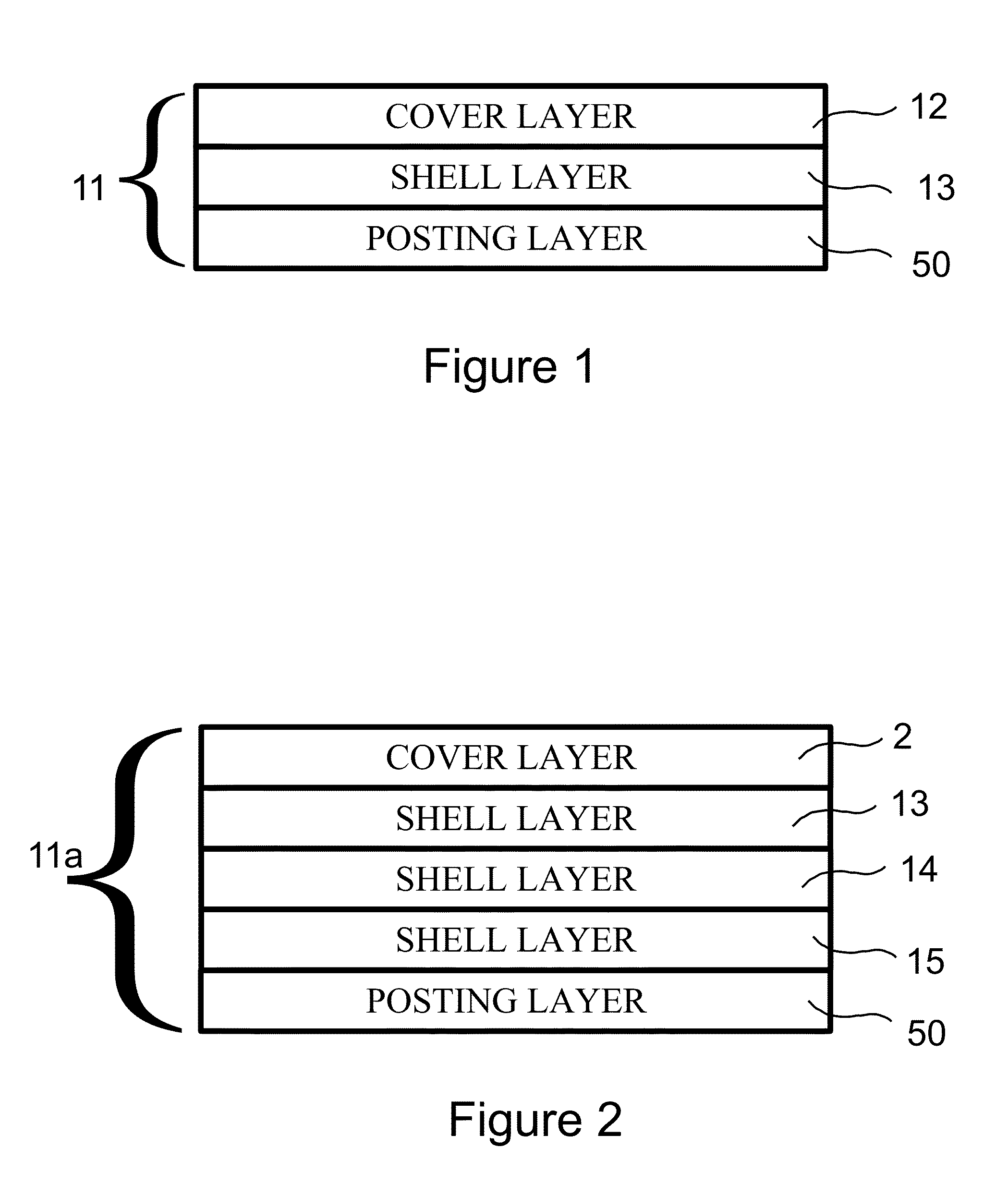

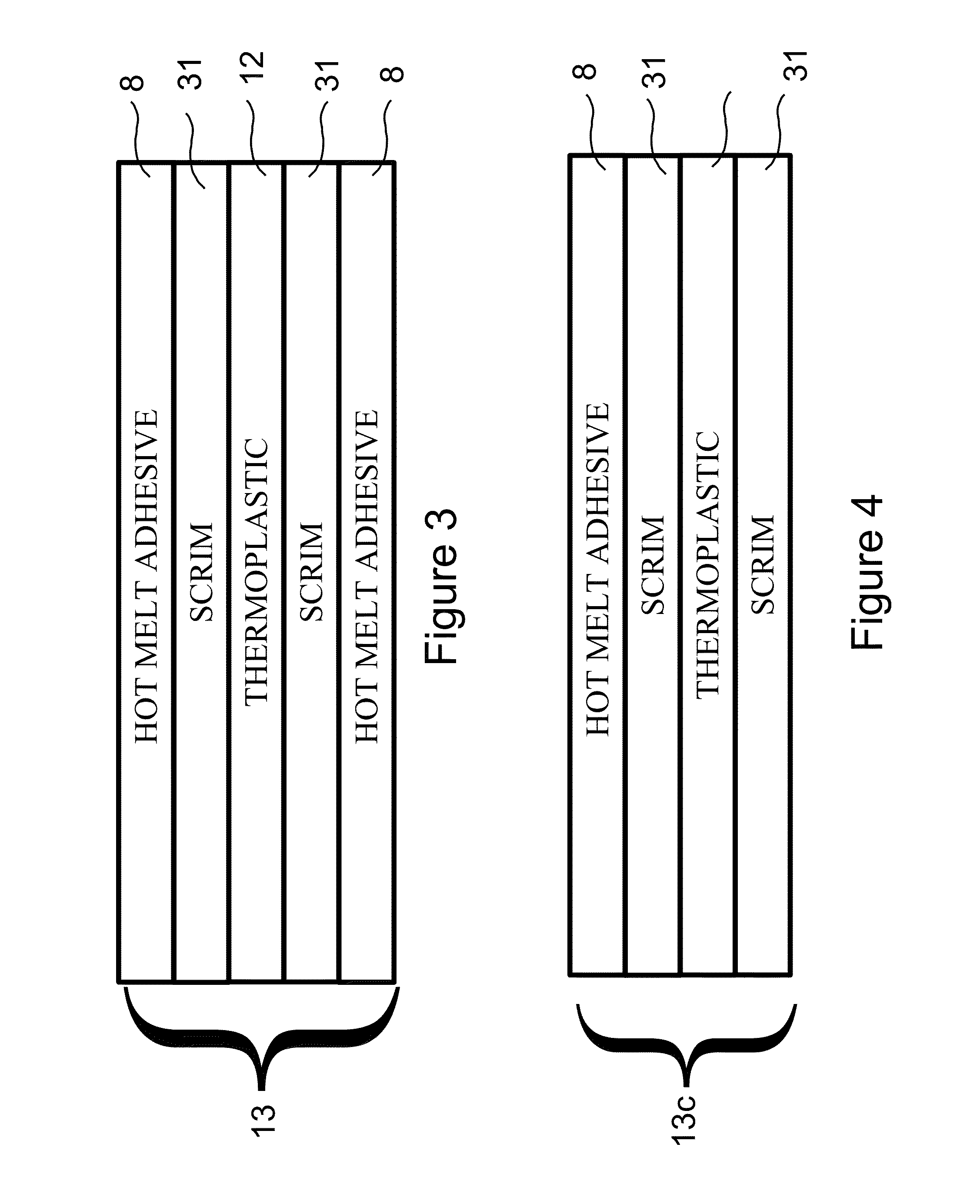

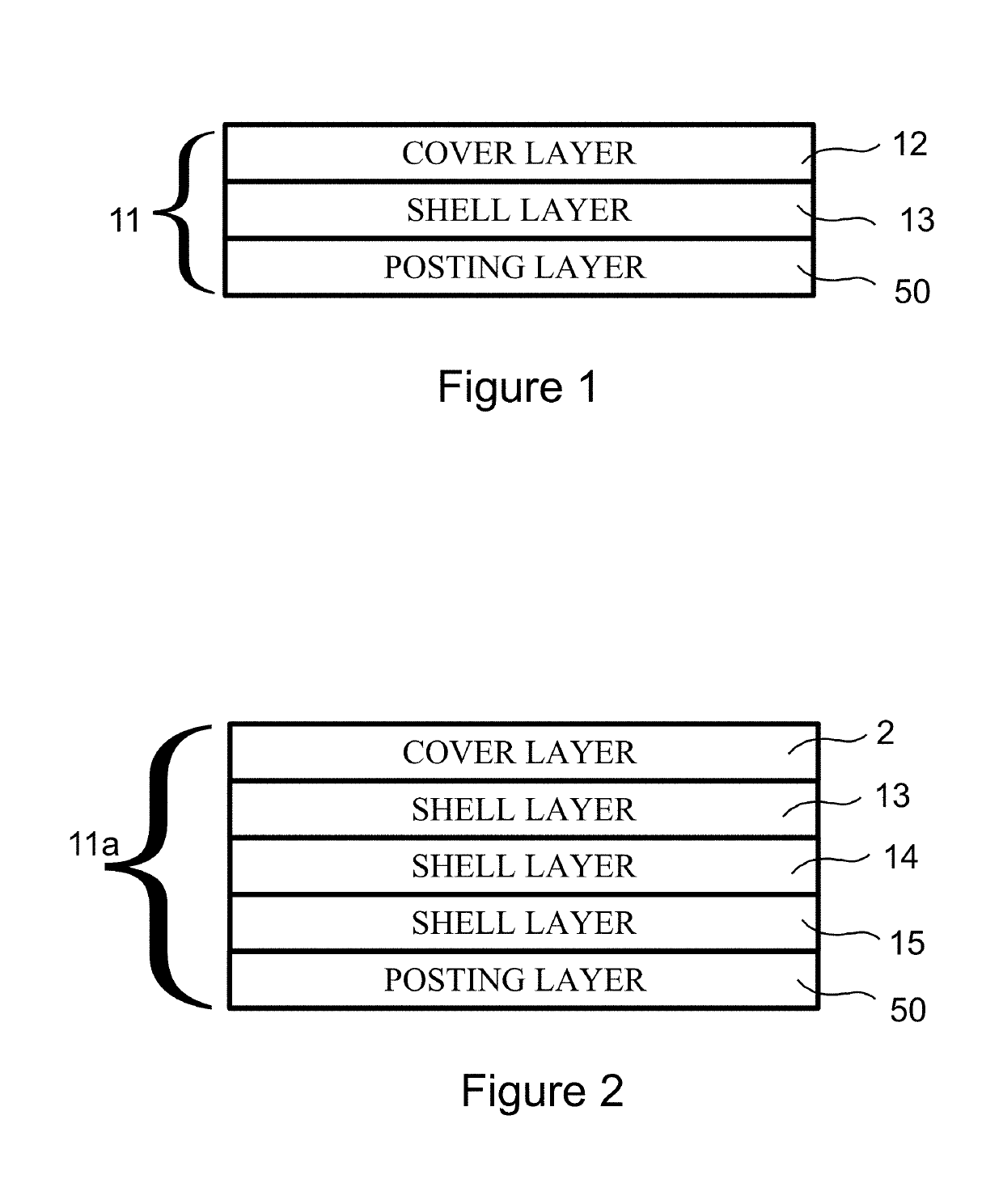

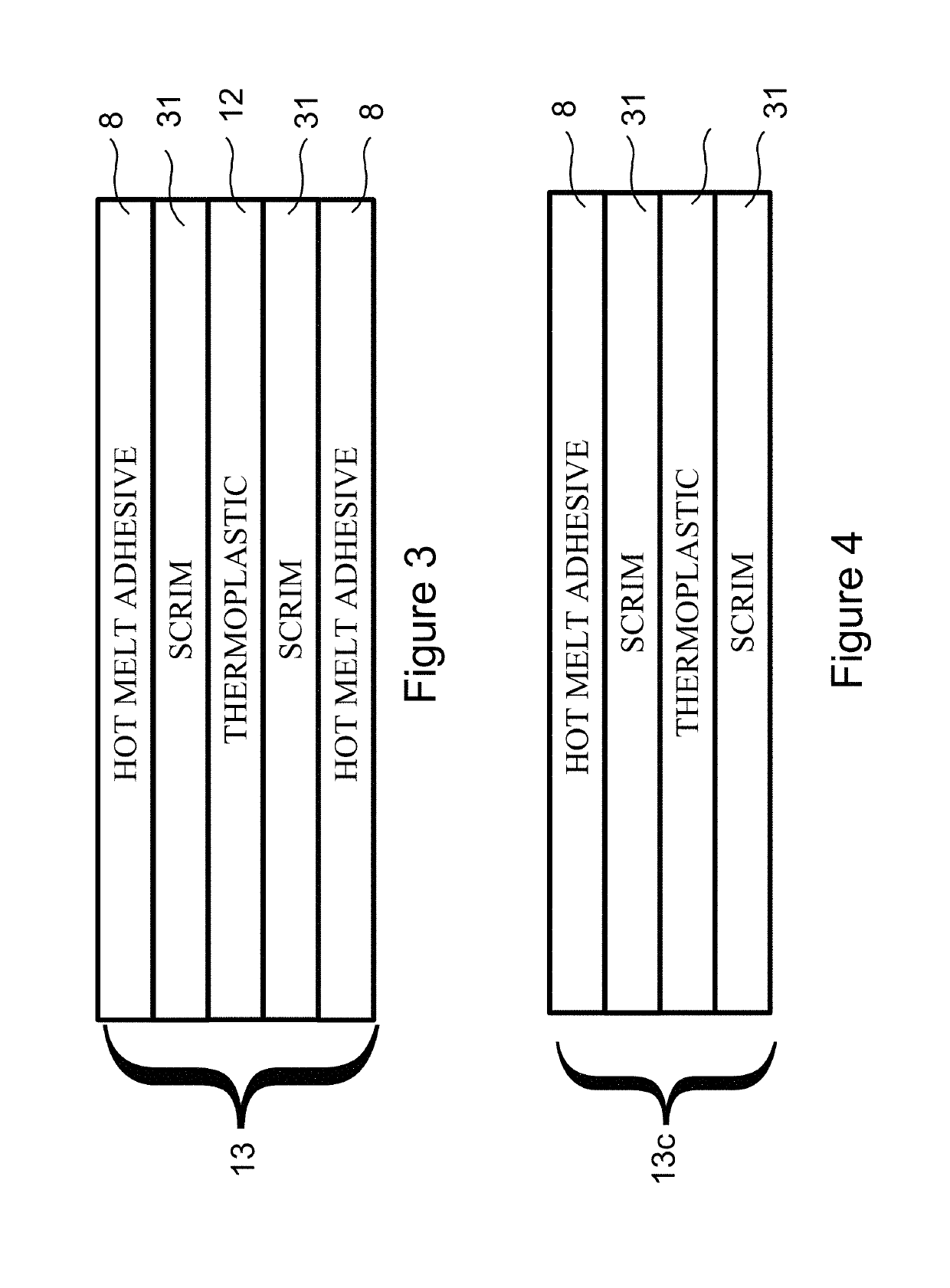

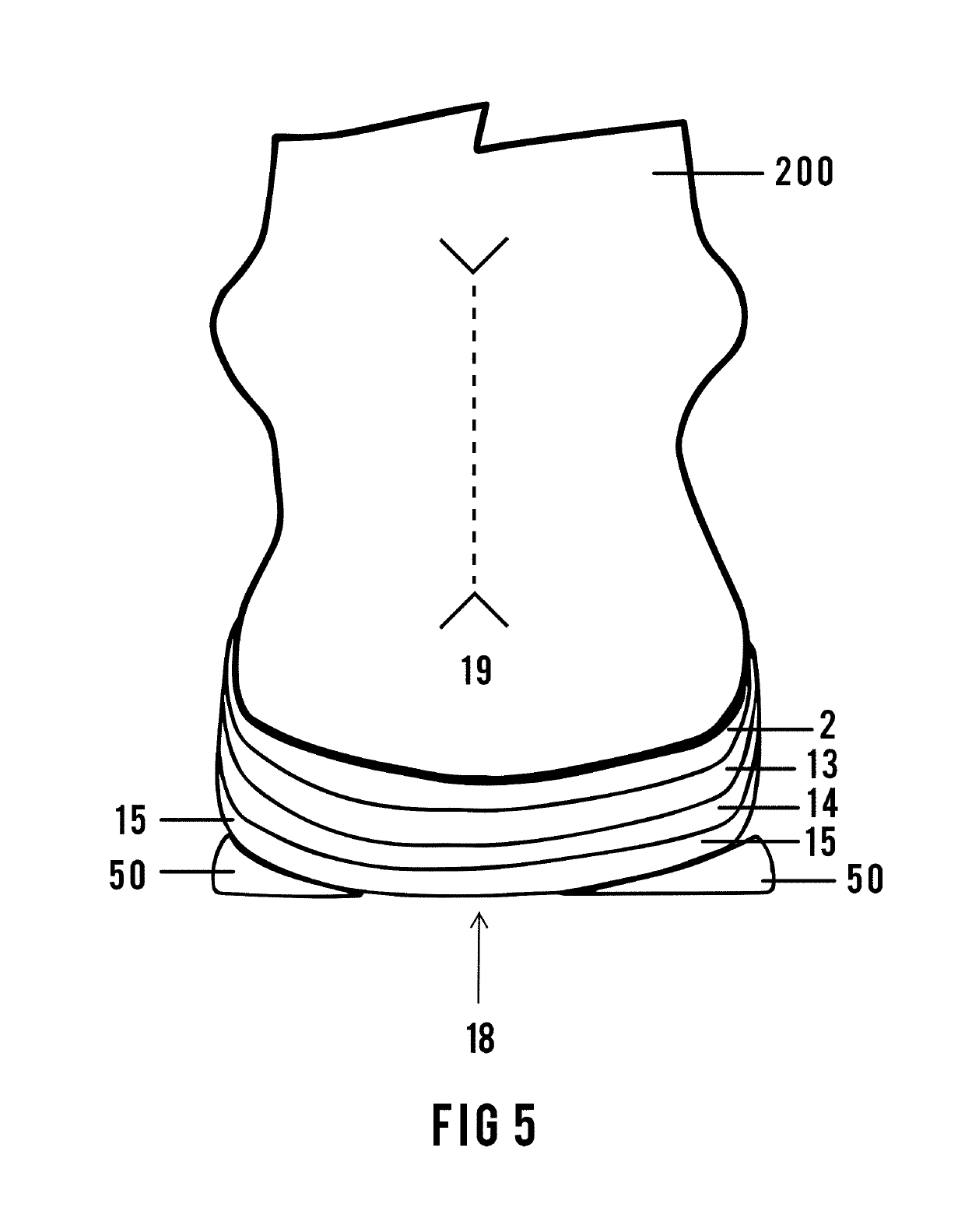

Custom multi-layered orthotic/orthosis, and method for forming

ActiveUS20160095737A1Avoid swingingEasy to understandInsolesNon-surgical orthopedic devicesThermoplasticPolyester

A multilayer orthotic / orthosis has a cover layer, a shell layer and a posting layer. The shell layer is formed of a thermoplastic having a moldable temperature. The rigidity of the shell layer, and in particular the rigidity of the thermoplastic is chosen to be of a magnitude to support the portion of the individual at temperatures below the moldable temperature. The shell layer, preferably the thermoplastic, has a flexibility above the moldable temperature to mold the shell layer into a shape to support the portion of the individual. The shell layer has two layers of woven polyester fibers (“scrim”) on the top and bottom. The scrim gives the plastic strength and prevents it from stretching excessively when molding. These unique properties make the material well suited for stacking multiple layers without having excessive bulking of material top lines. Both sides of the shell layer are coated with a layer of hot melt cement / glue / adhesive for easy attachment of various layers or other materials. One side of the shell layer is connected to one side of the cover layer. A posting layer is arranged on a side of the shell layer diametrically opposite the cover layer, and provides support for the orthotic / orthosis in order to prevent rocking, especially when the orthotic / orthosis is for the foot of the individual.

Owner:MASTERFIT ENTERPRISES

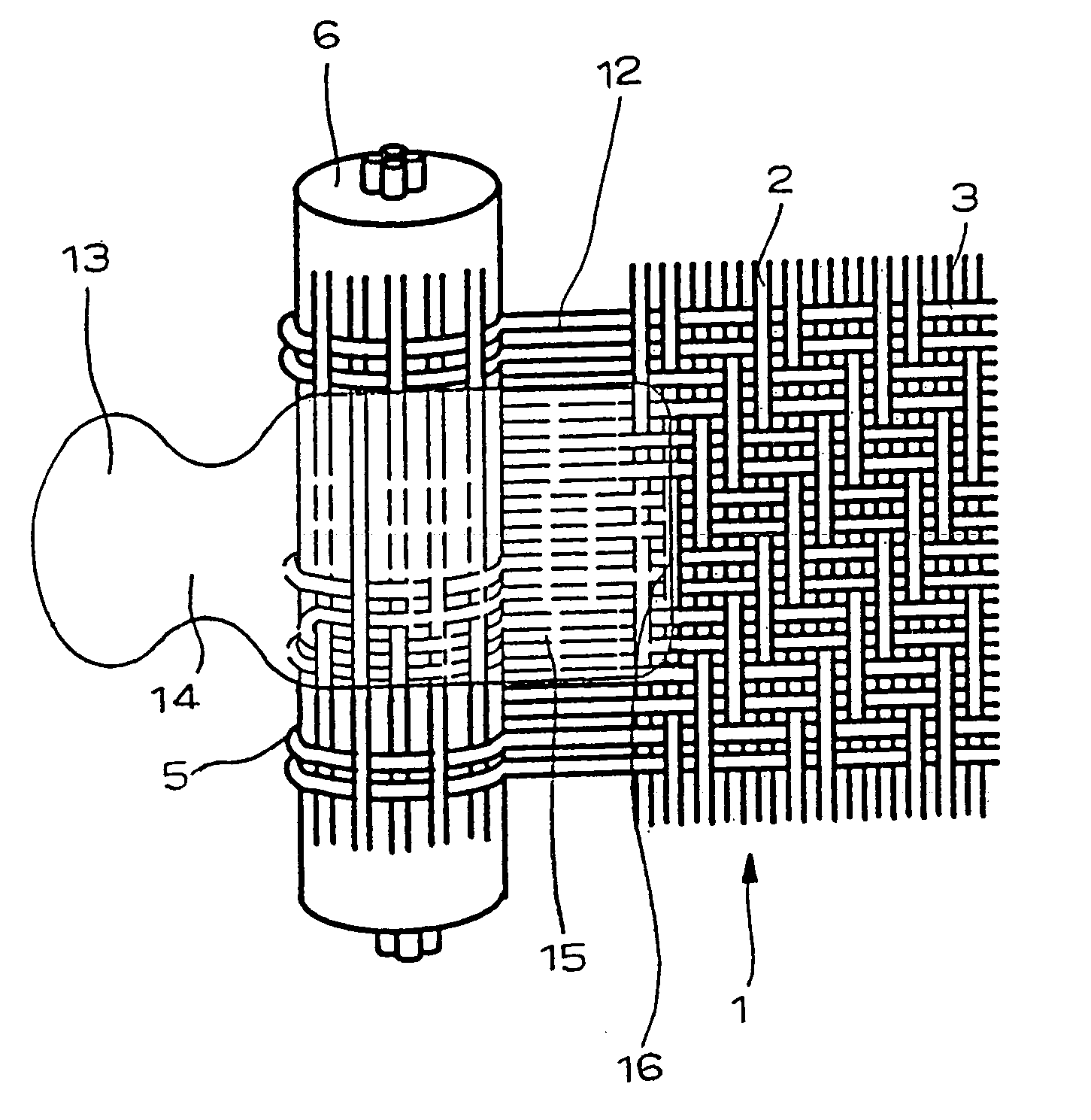

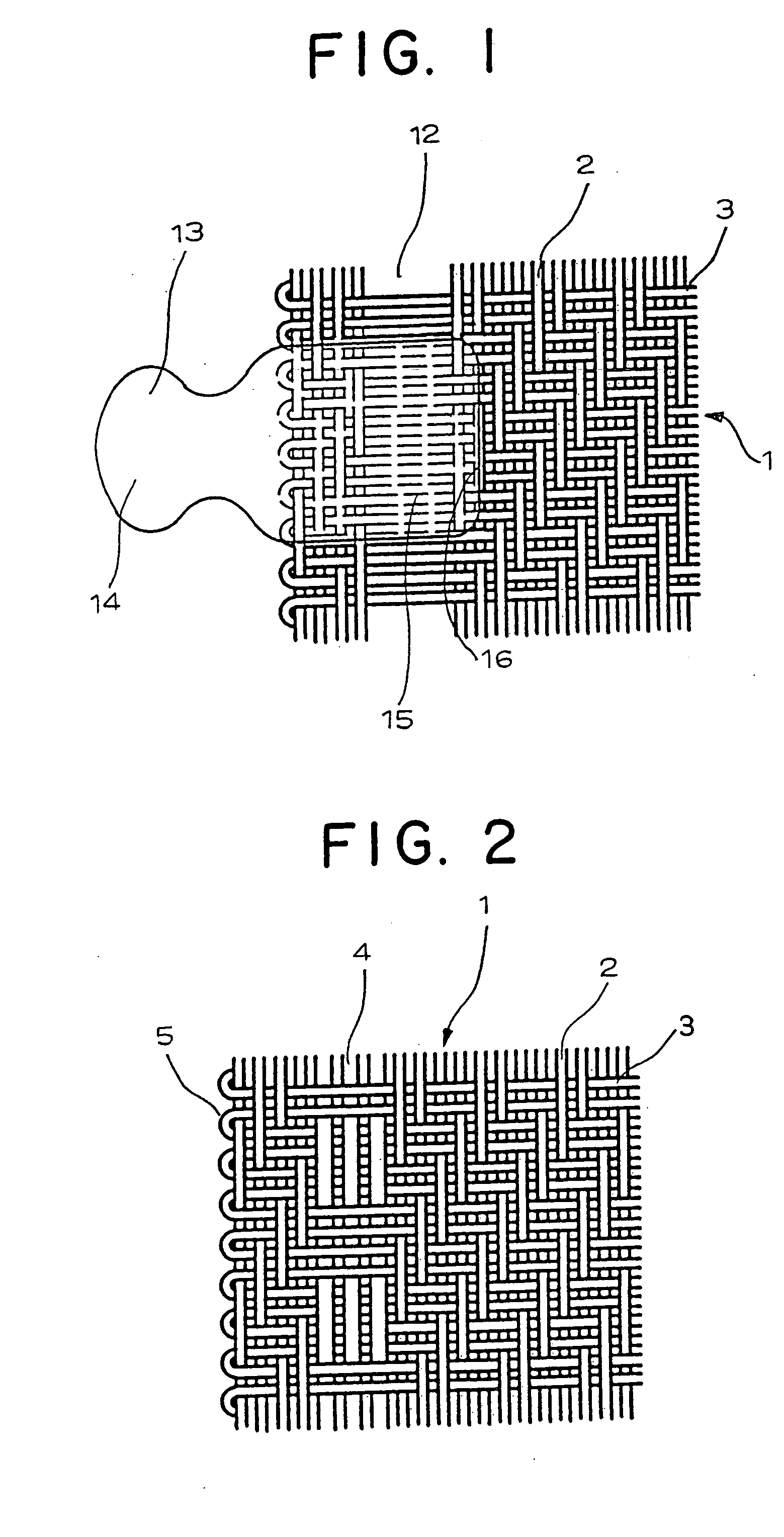

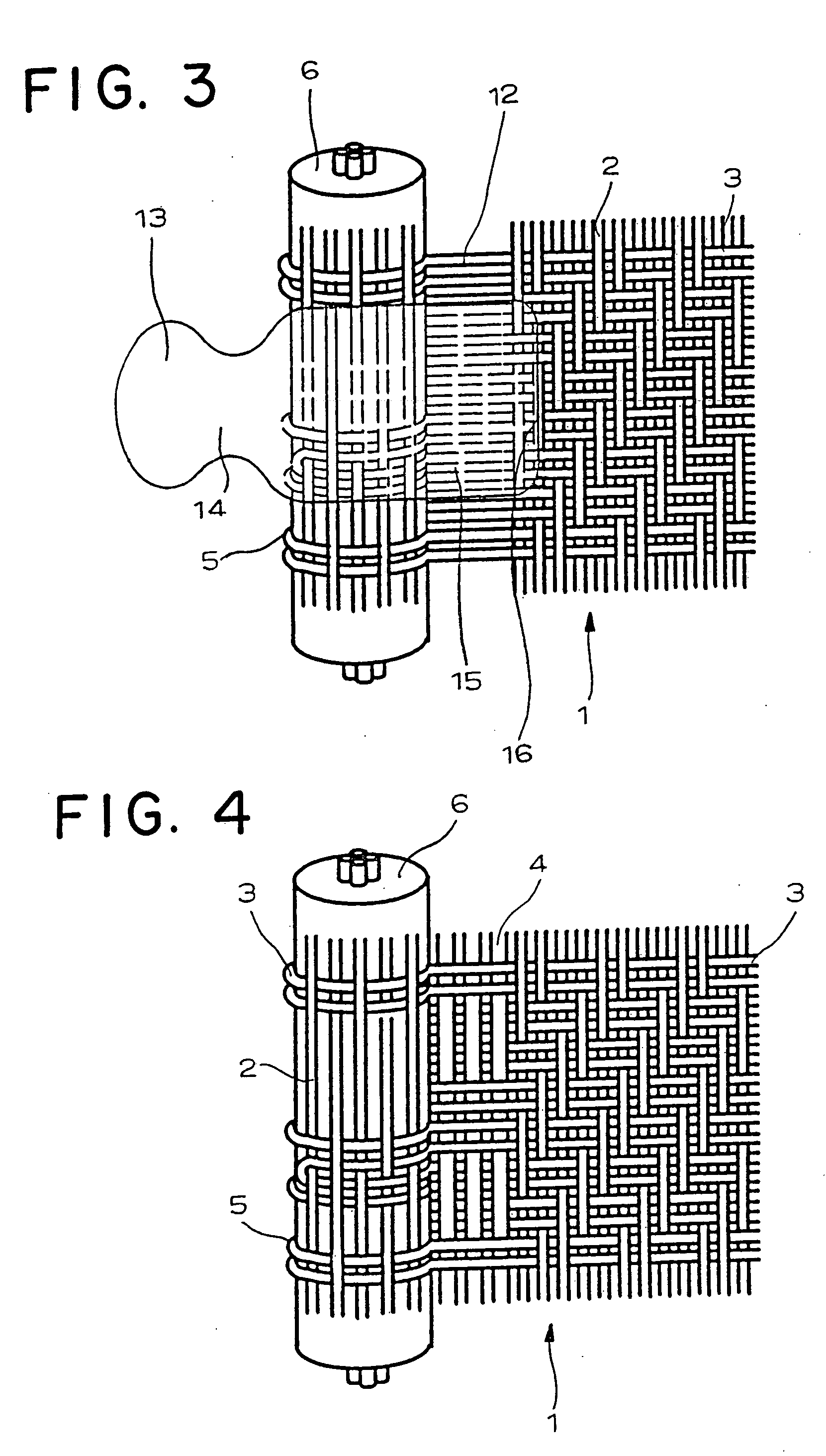

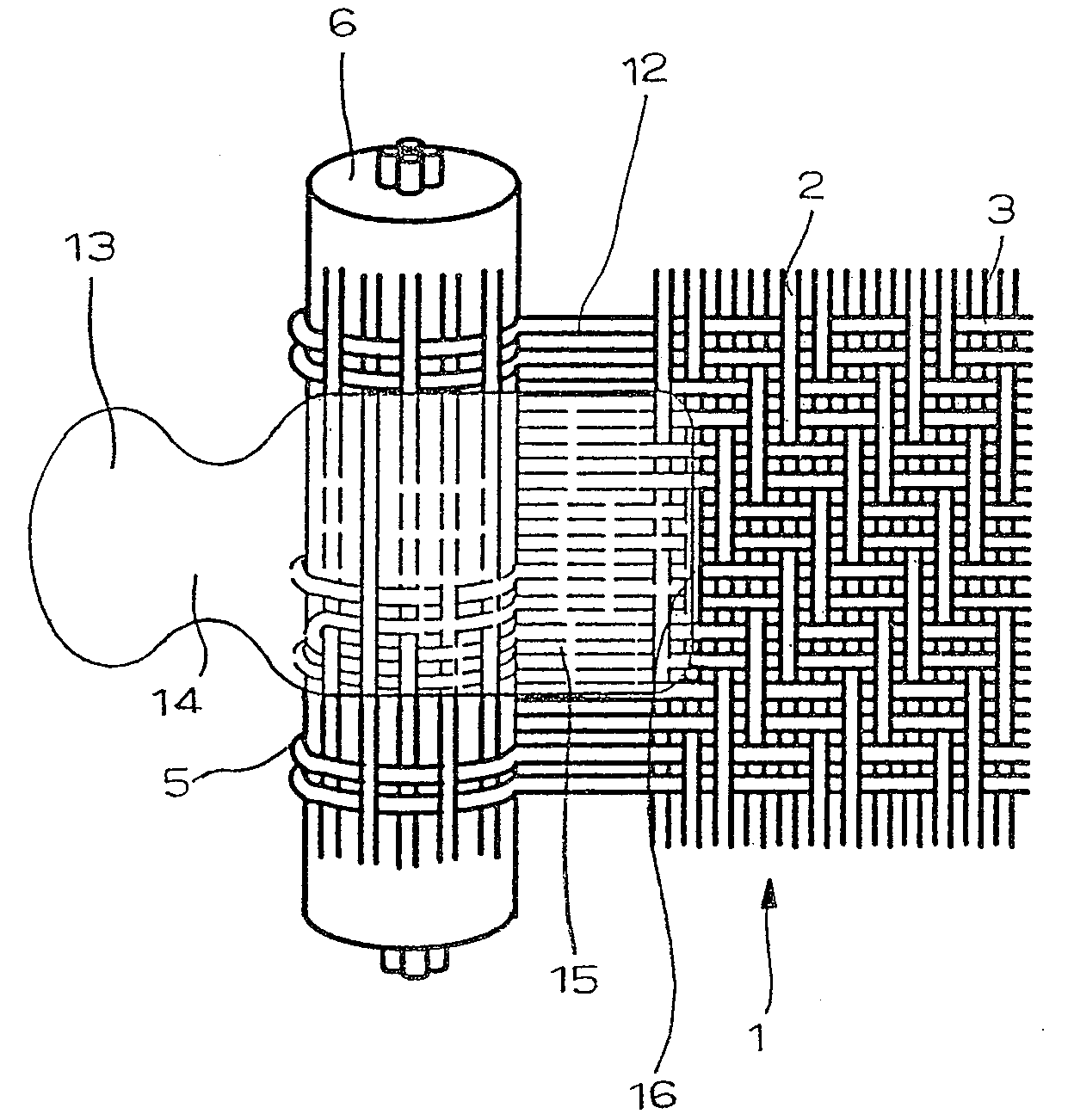

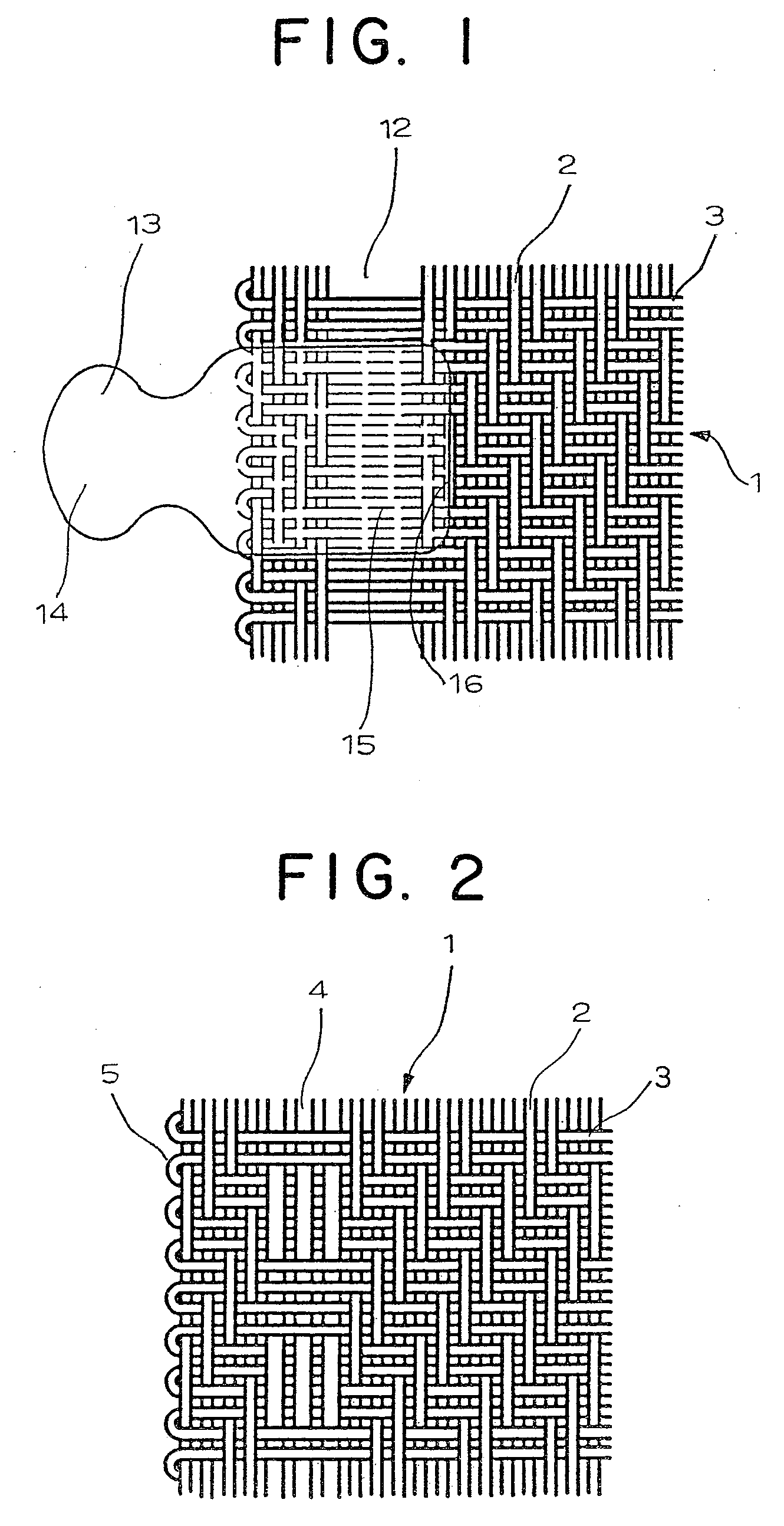

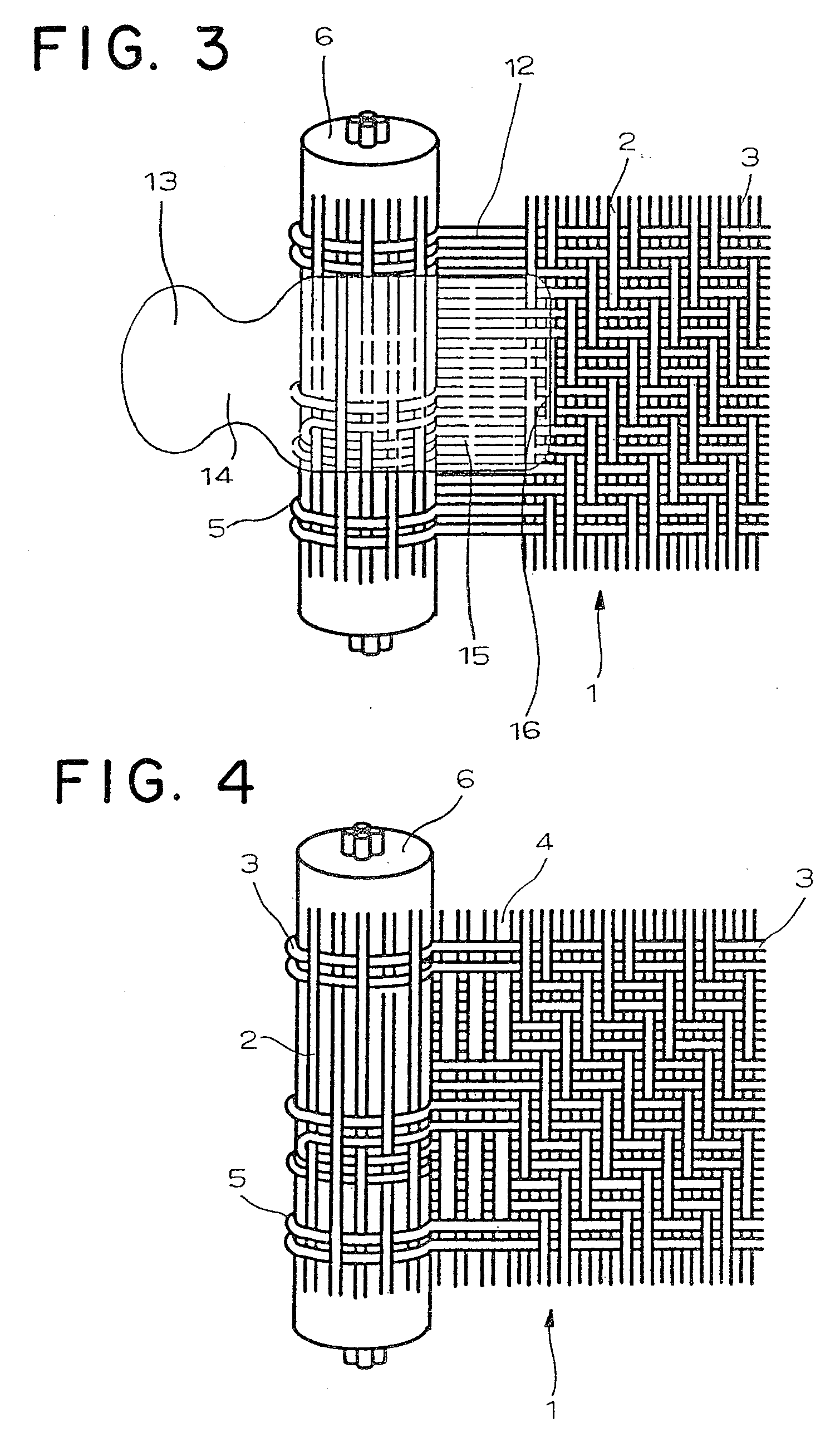

Slide fastener stringer and method of manufacturing the same

InactiveUS20060016052A1Good lookingEasy to installSnap fastenersSlide fastenersEngineeringWater soluble

A slide fastener stringer easily manufactured by a series of manufacturing steps with molding fastener elements in a warp yarn exclusion area formed on one side edge of a fastener tape, wherein a fastener tape is produced by weaving with warp yarns and weft yarns of synthetic fiber yarn; plural pieces of water soluble fiber yarns are disposed inside over plural pieces of the warp yarns from the side edge of the tape; in a dying step in a process for manufacturing a fastener stringer, the water soluble fiber yarns are dissolved to form the warp yarn exclusion area; and by molding the fastener elements by using the warp yarn exclusion area, the fastener stringer is manufactured in an easy sequential manufacturing process without applying any special processing.

Owner:YKK CORP

Slide fastener stringer and method of manufacturing the same

InactiveUS20080257442A1Good lookingEasy to installSlide fastenersWoven fabricsWater solubleEngineering

Owner:YKK CORP

Method for manufacturing pneumatic tire

InactiveUS7857926B2Expand accurately and sufficientlyEffective noiseLaminationTyresEngineeringMechanical engineering

A method for manufacturing a pneumatic tire with a noise damper on the inside of the tread portion, comprises the steps of: building a raw tire on an annular tire building core; placing the raw tire within a vulcanizing mold together with the core; and heating the raw tire in the mold. The tire building core has a molding face for molding an inner surface of the tread portion. The molding face is provided with a groove extending in the tire circumferential direction. In the step of building the raw tire, an expandable damper material is placed in the groove. During heating the raw tire to be vulcanized, the damper material expands in the groove, whereby the expanded material forms the noise damper integrated into the radially inside of the tread portion.

Owner:SUMITOMO RUBBER IND LTD

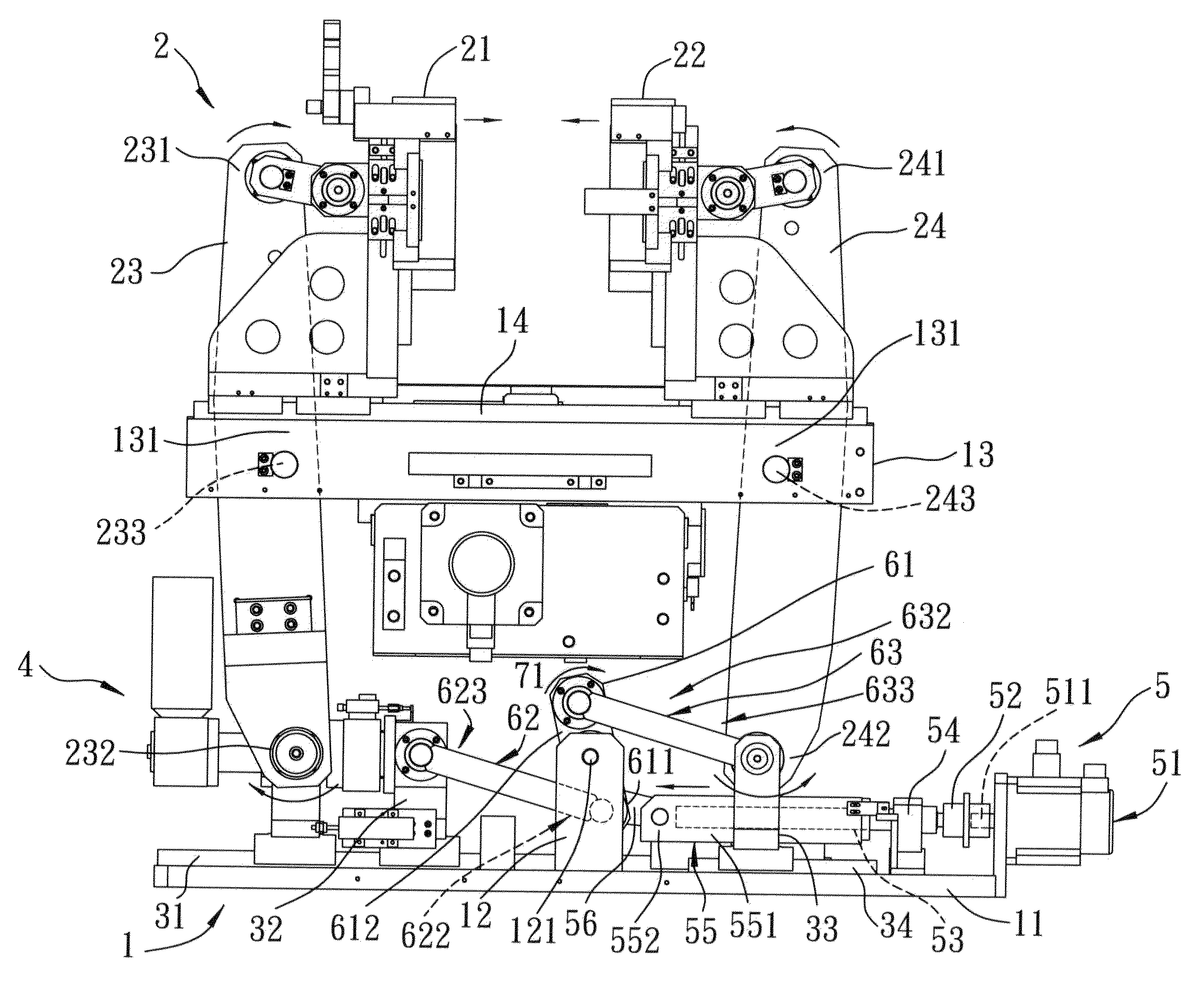

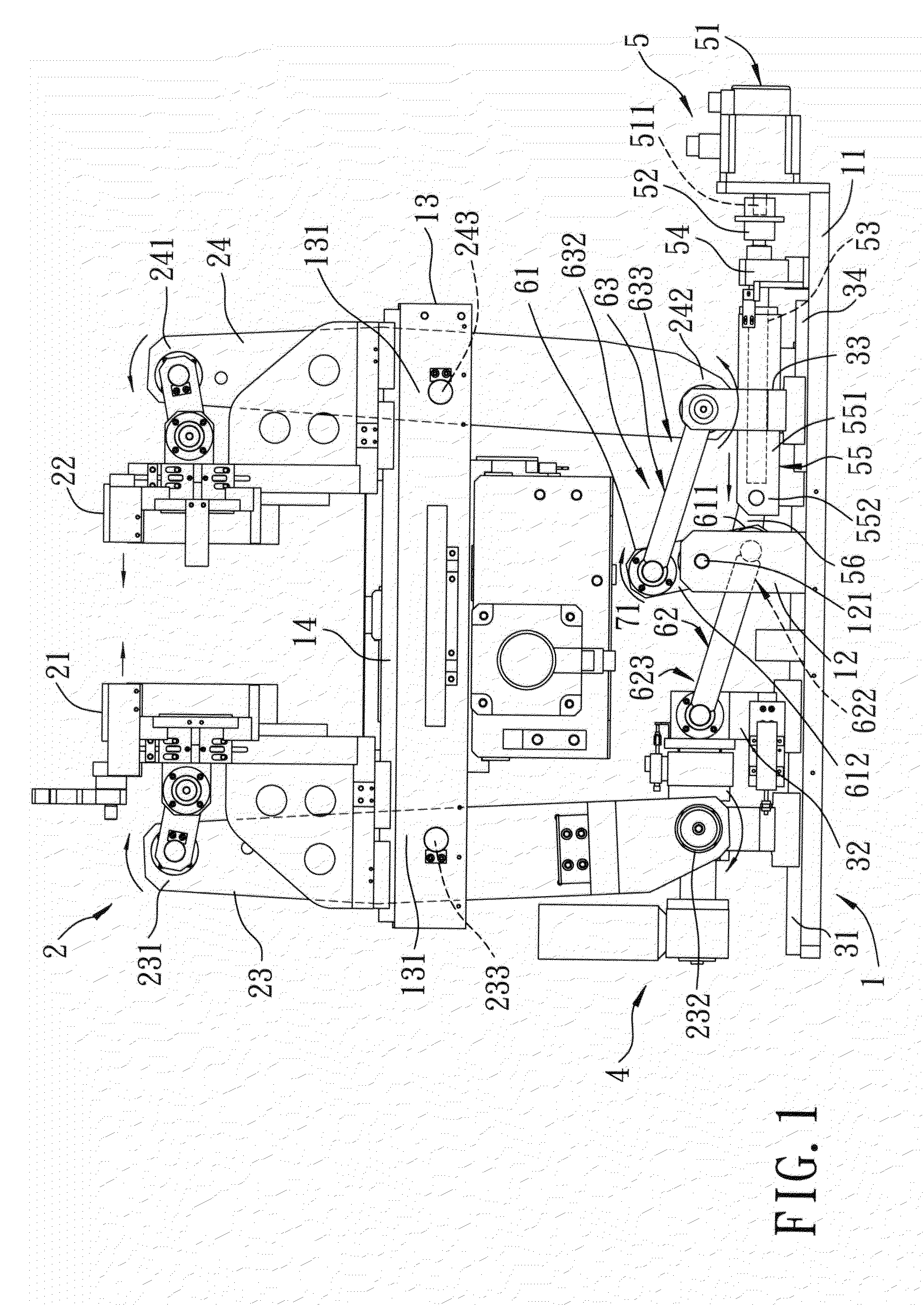

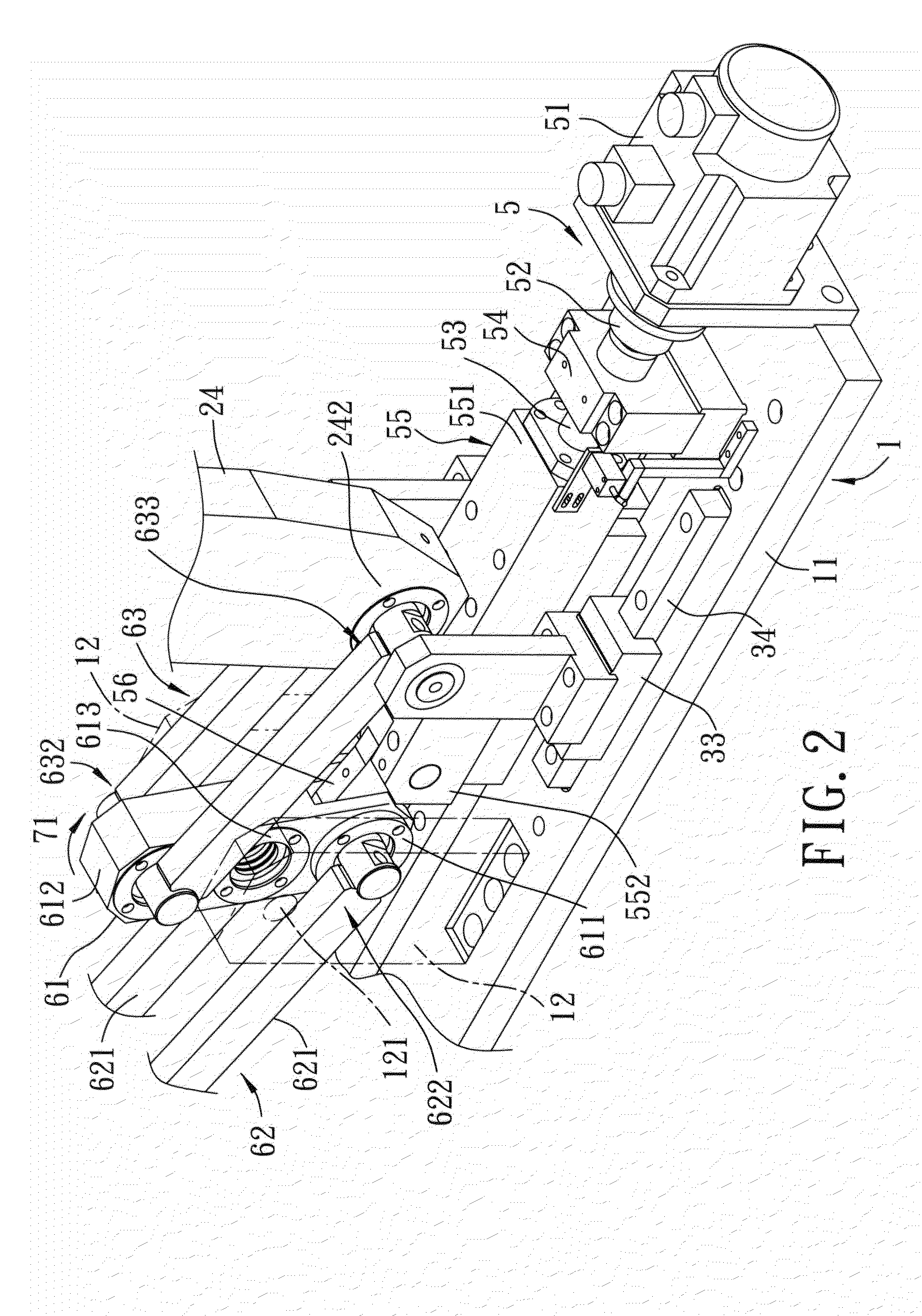

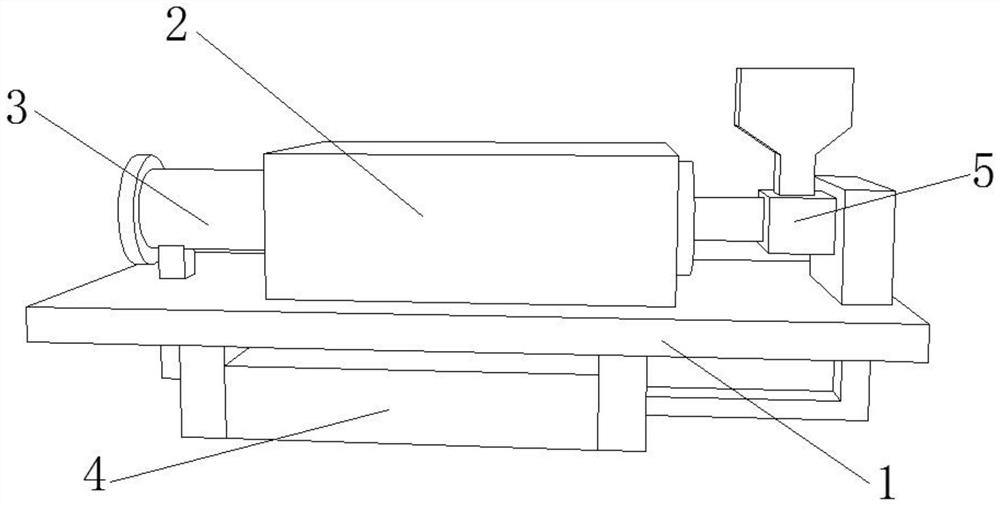

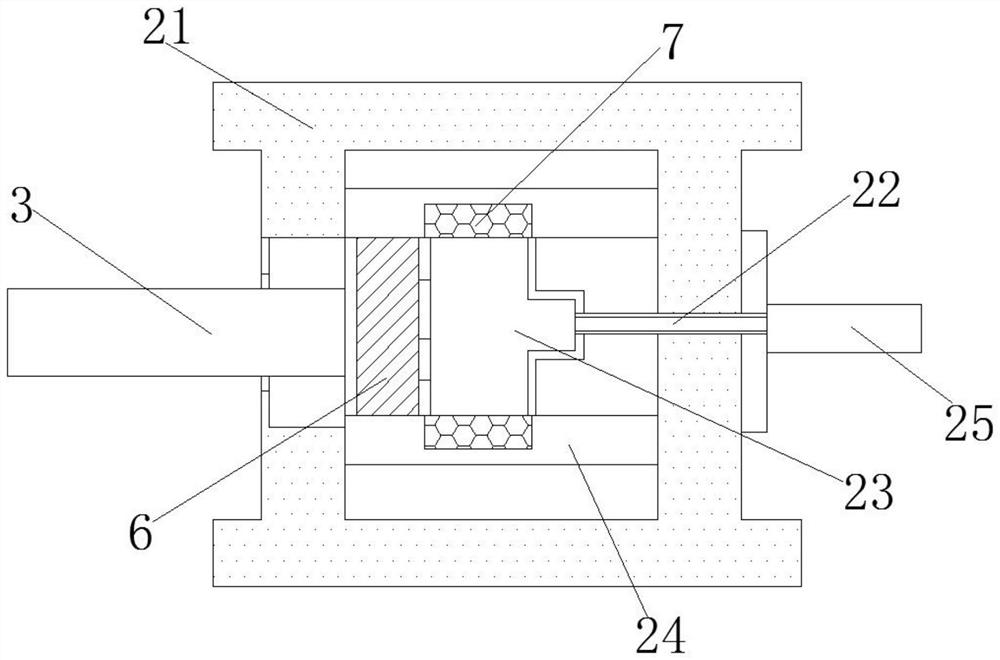

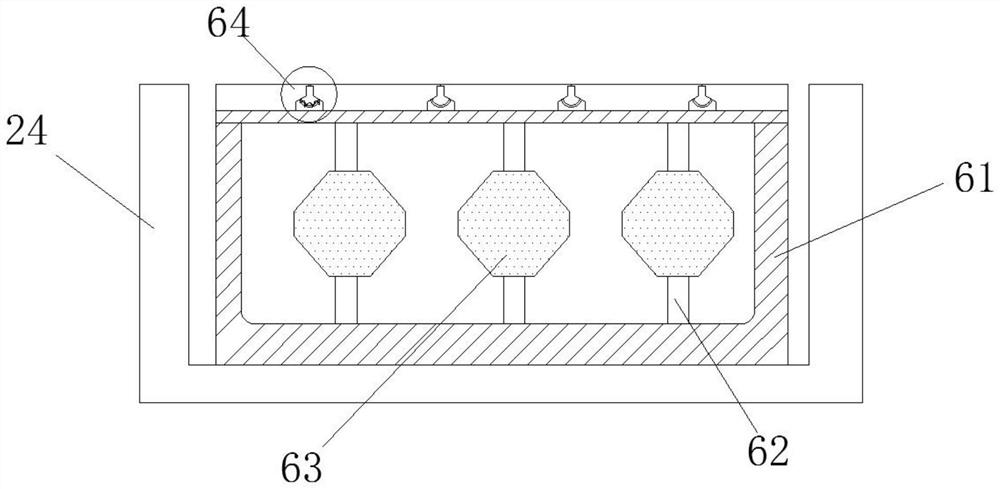

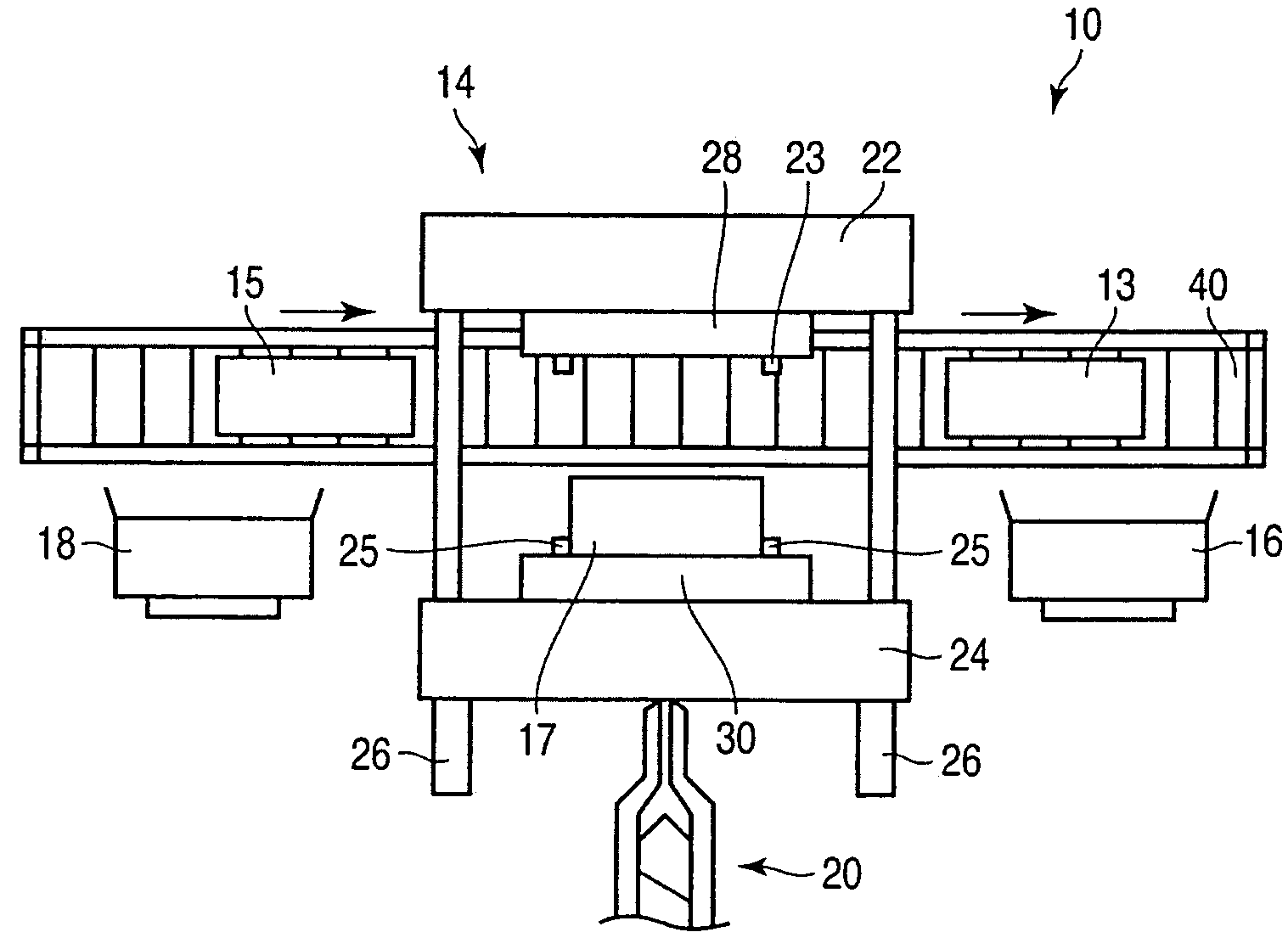

Molding machine

A molding machine includes two holding arms mounted on a base unit, connected respectively to two molds, and operable to move the molds between a mold closing state and a mold opened state. The molding machine further includes an adjusting seat mounted on the base unit and movable relative to a threaded shaft that is rotated by a power supply, a swing arm connected pivotally to the adjusting seat, a linkage unit having opposite end parts that are connected pivotally and respectively to a pivot portion of the swing arm and one of the holding arms, and another linkage unit having opposite end parts that are connected pivotally and respectively to another pivot portion of the swing arm and the other one of the holding arms. The swing arm is swingable through the movement of the adjusting seat so as to swing the holding arms by virtue of the linkage units.

Owner:JIH HUANG MACHINERY INDAL

Custom multi-layered orthotic/orthosis, and method for forming

Owner:MASTERFIT ENTERPRISES

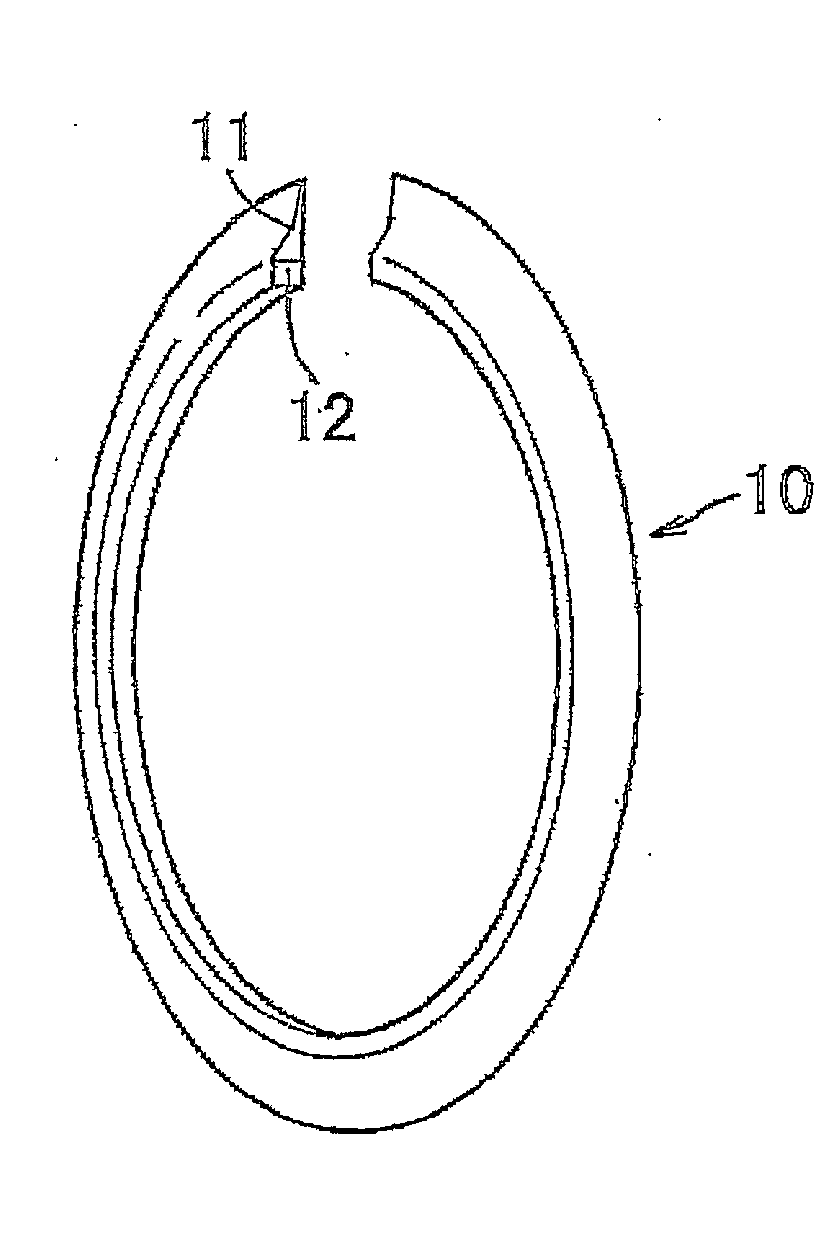

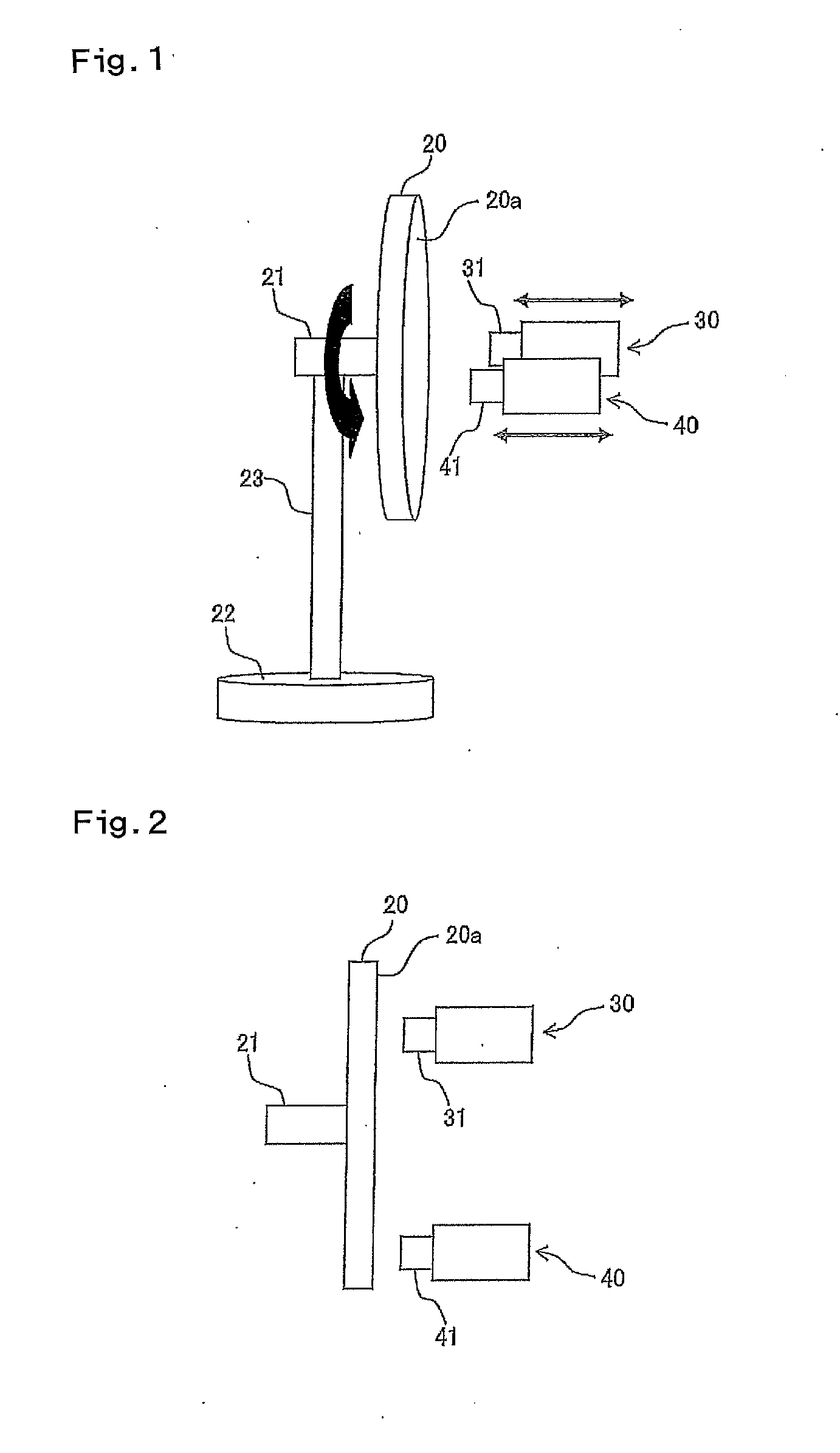

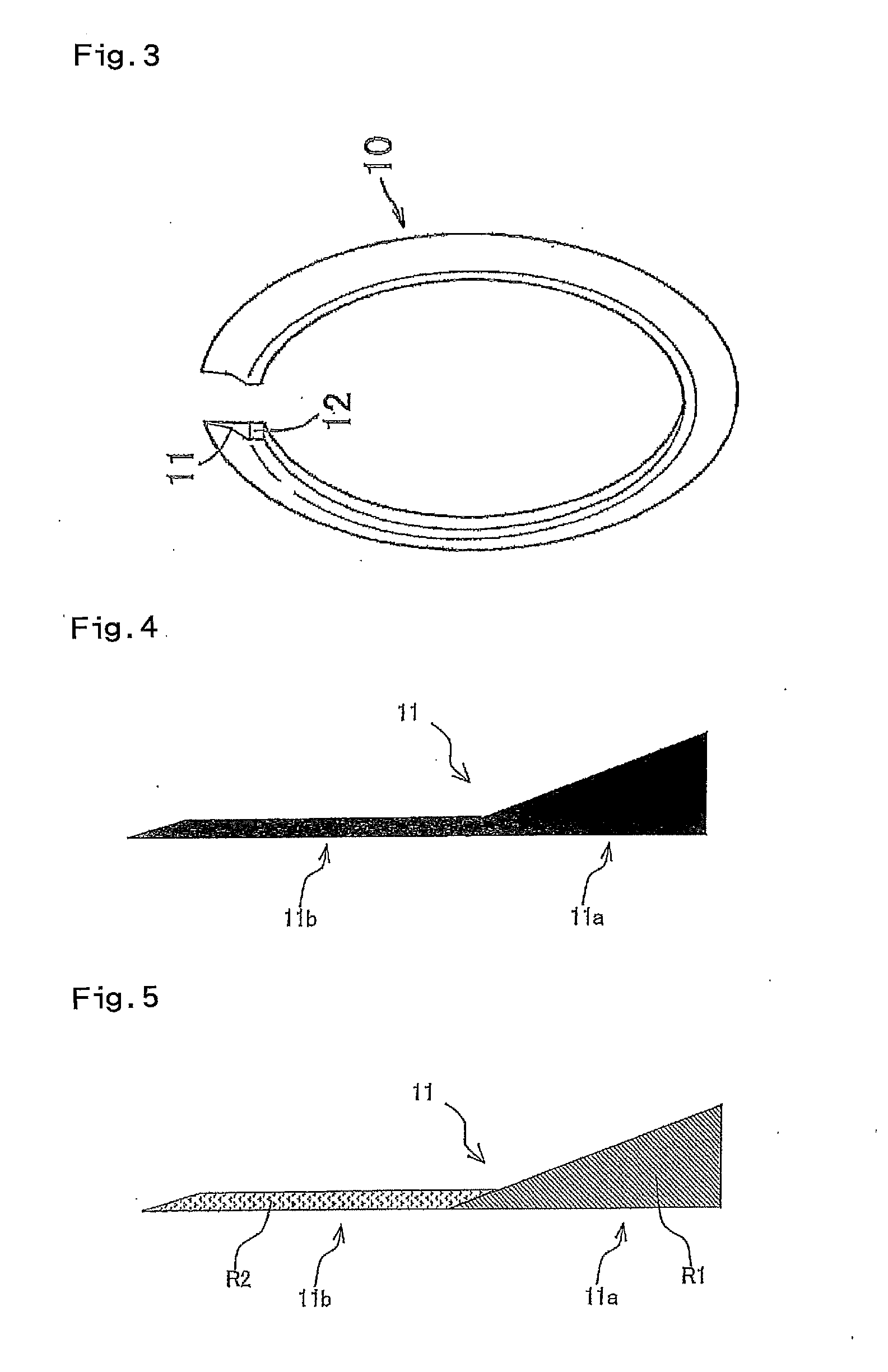

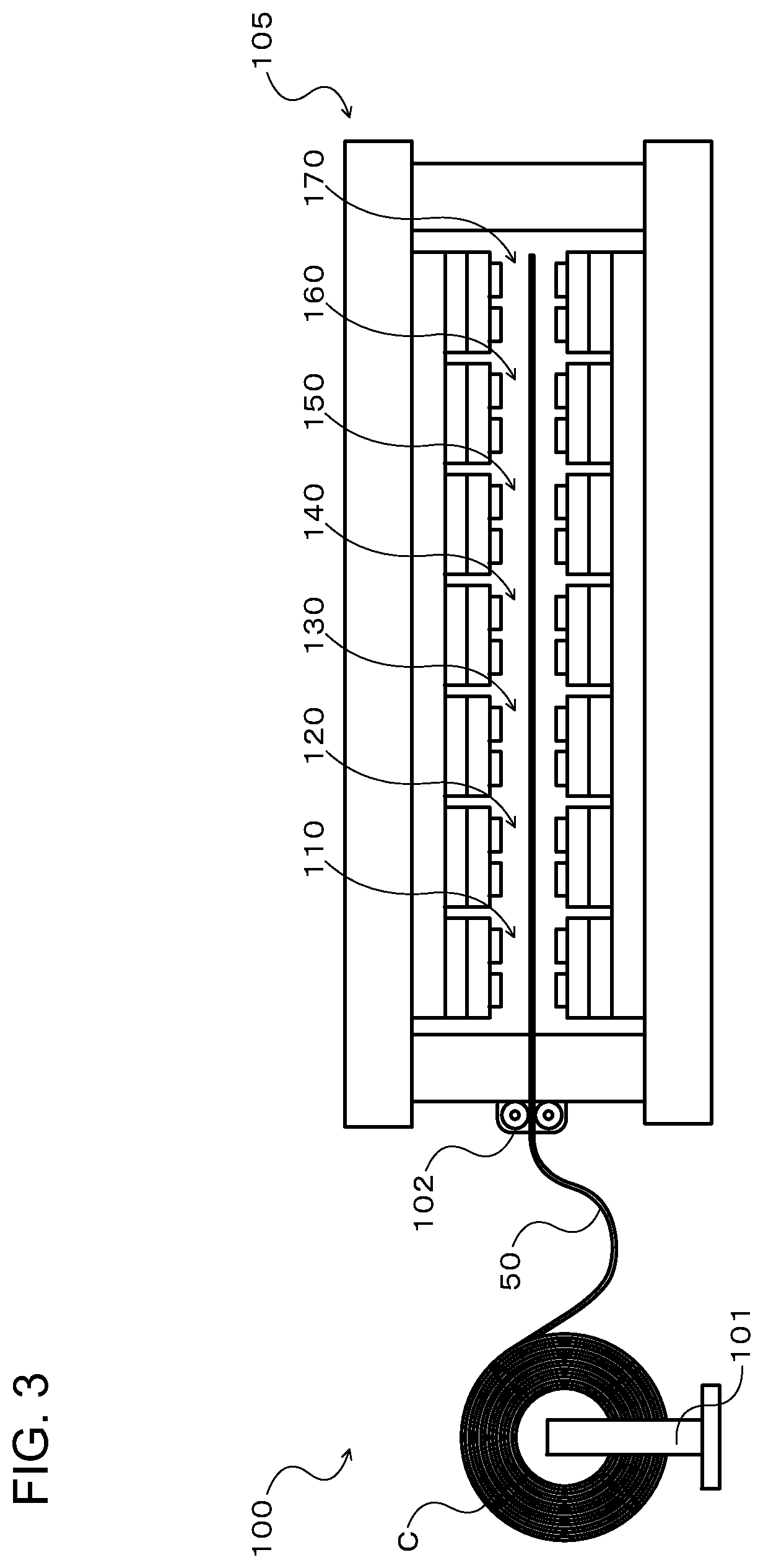

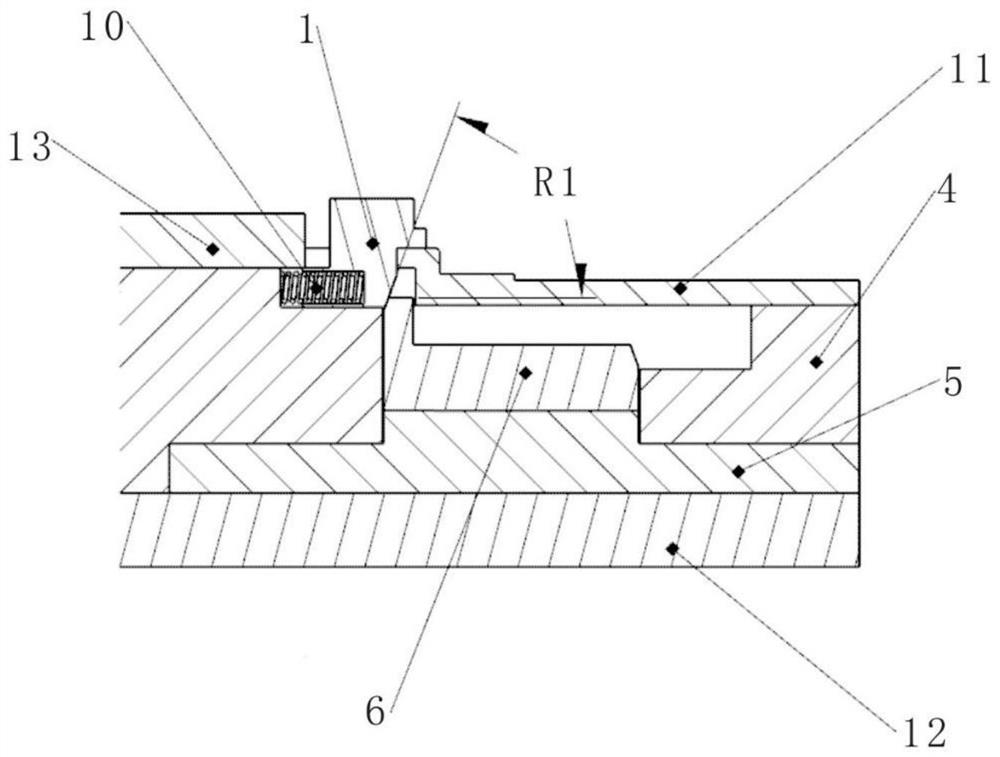

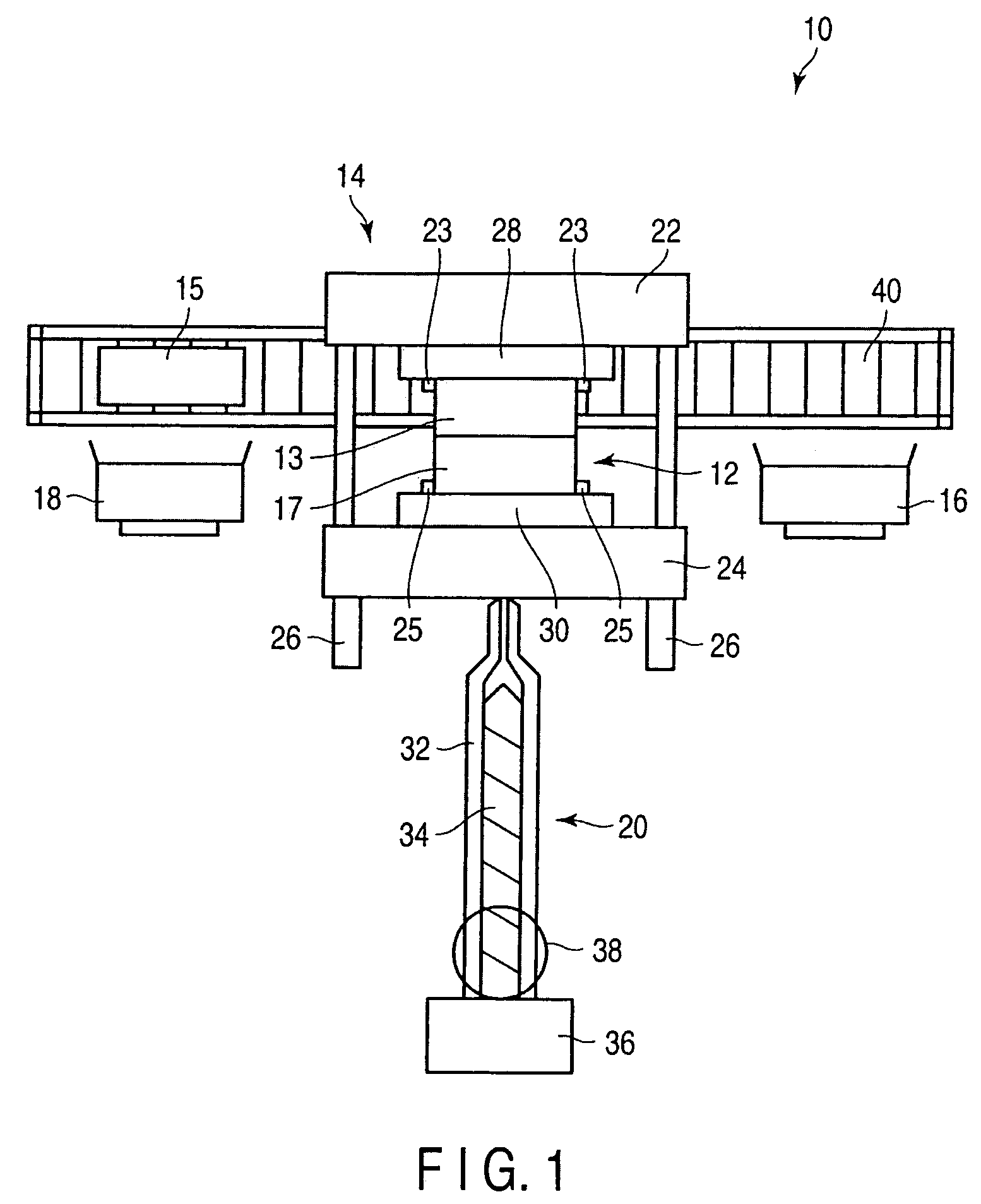

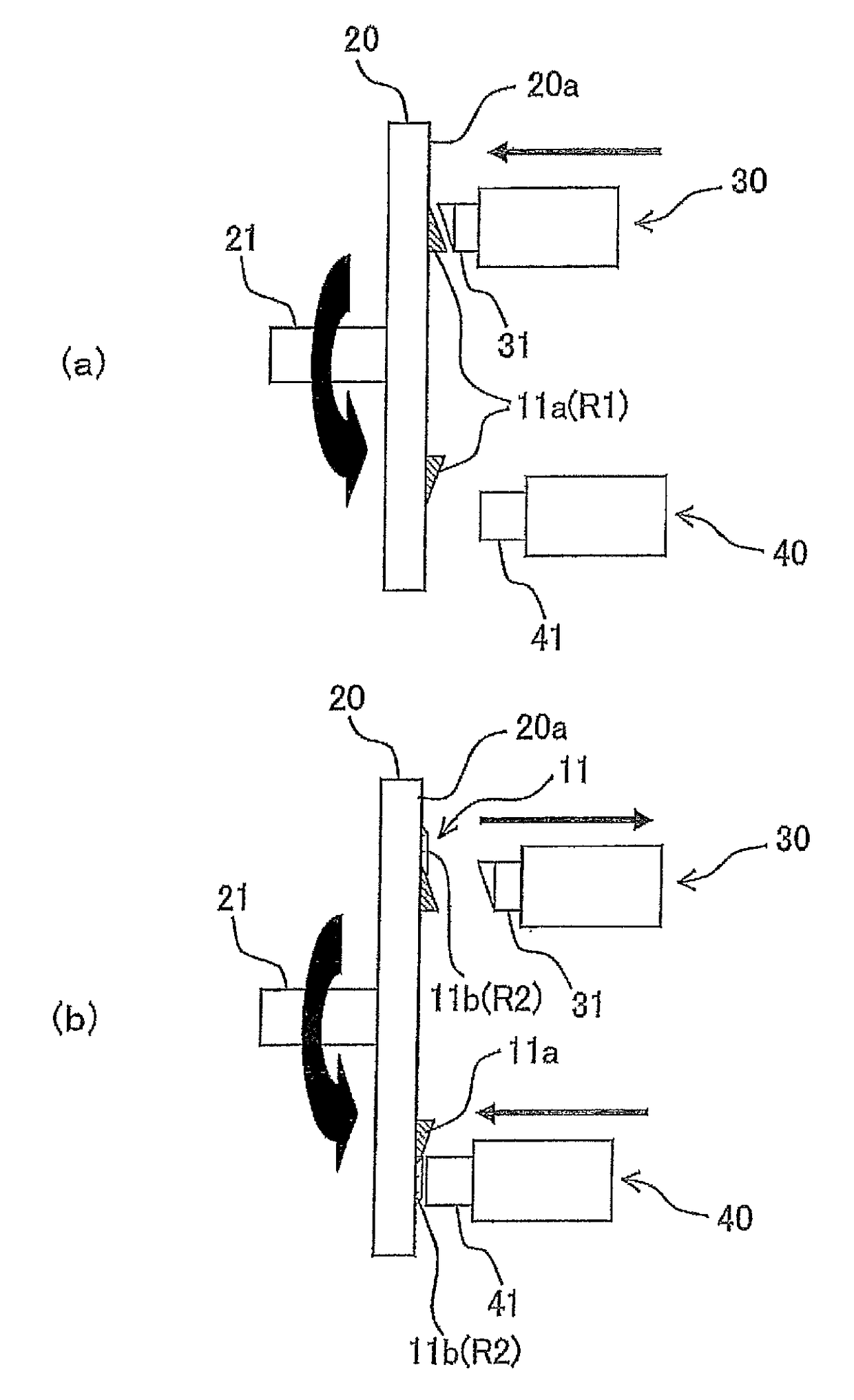

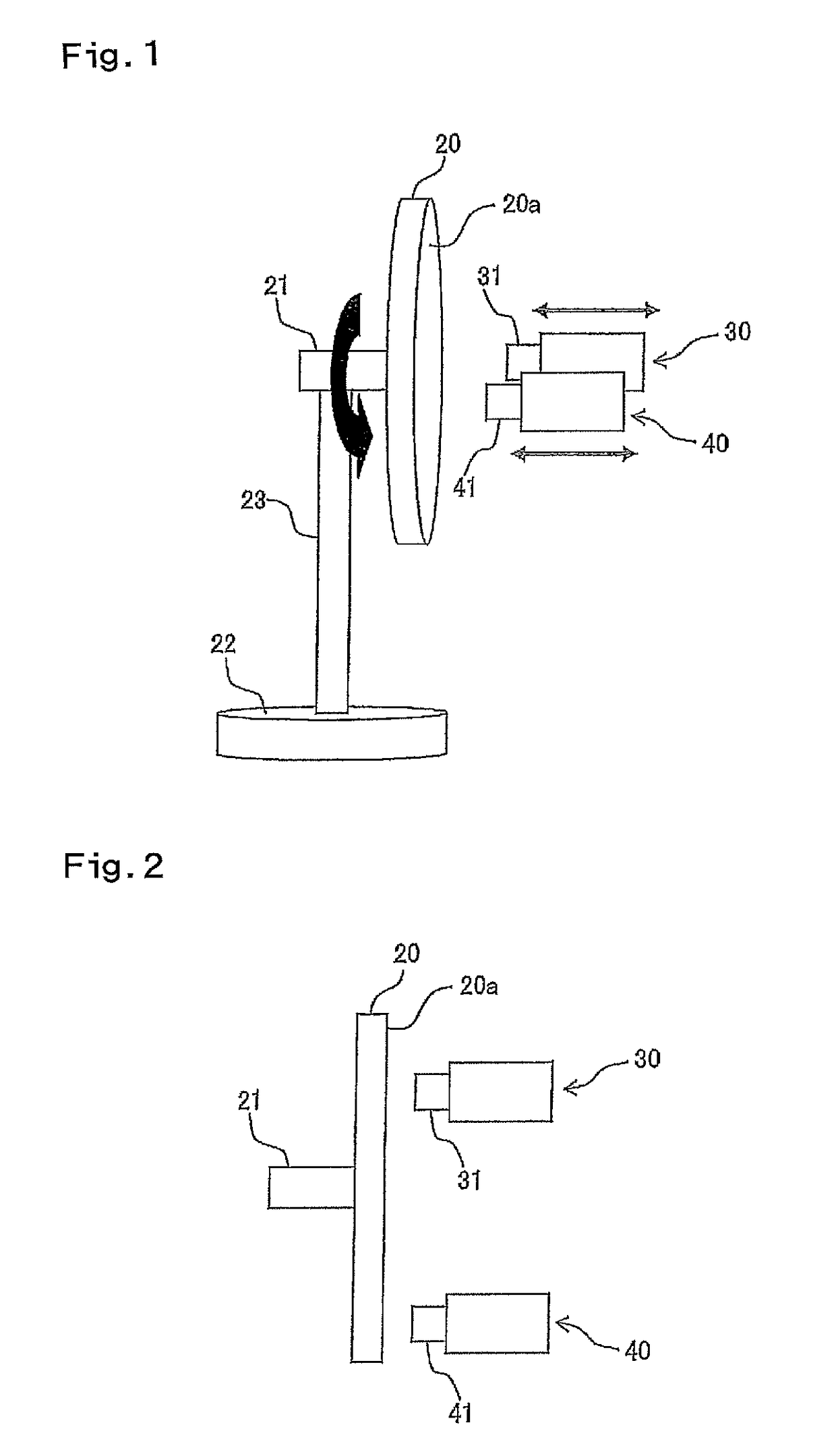

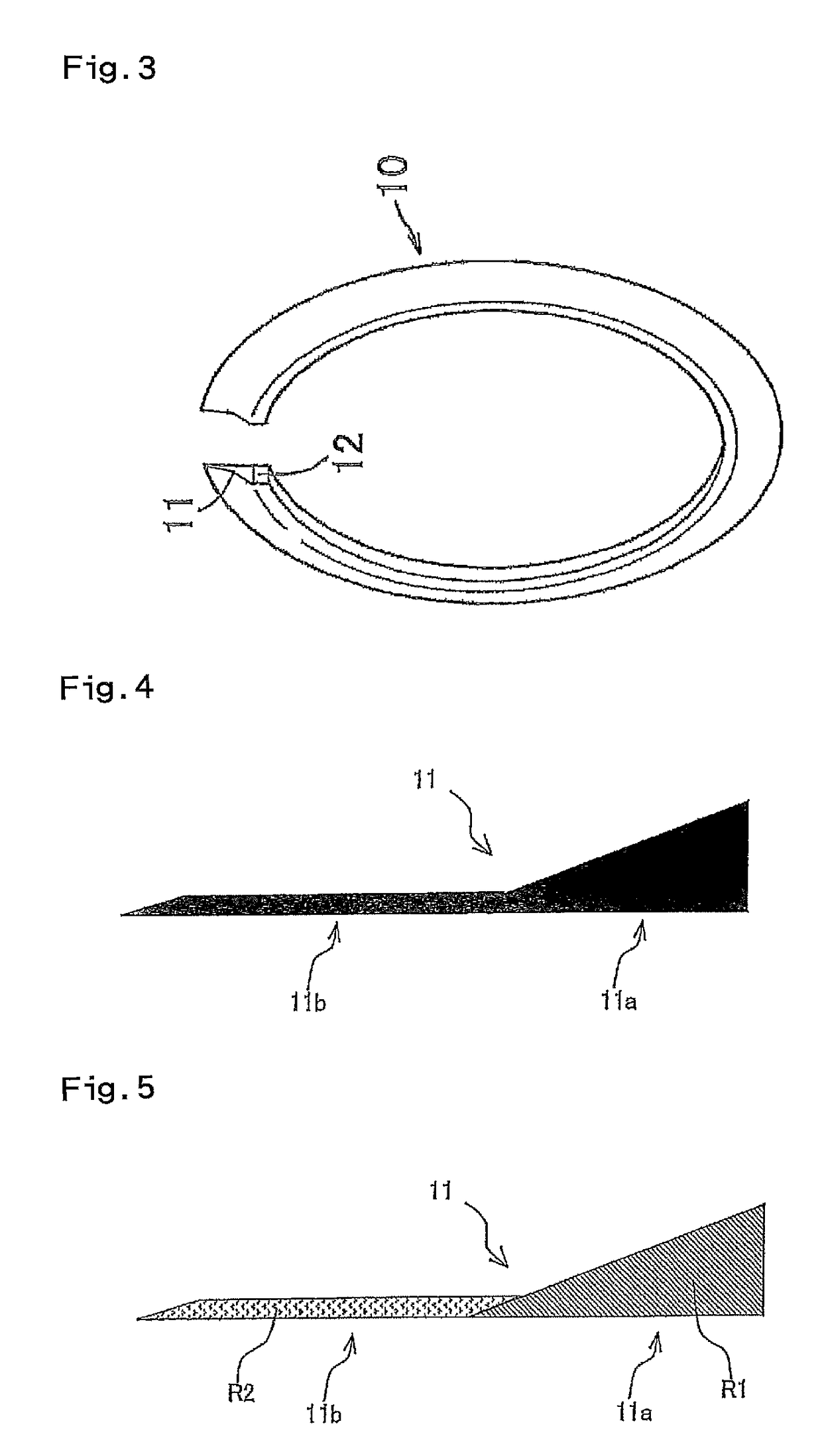

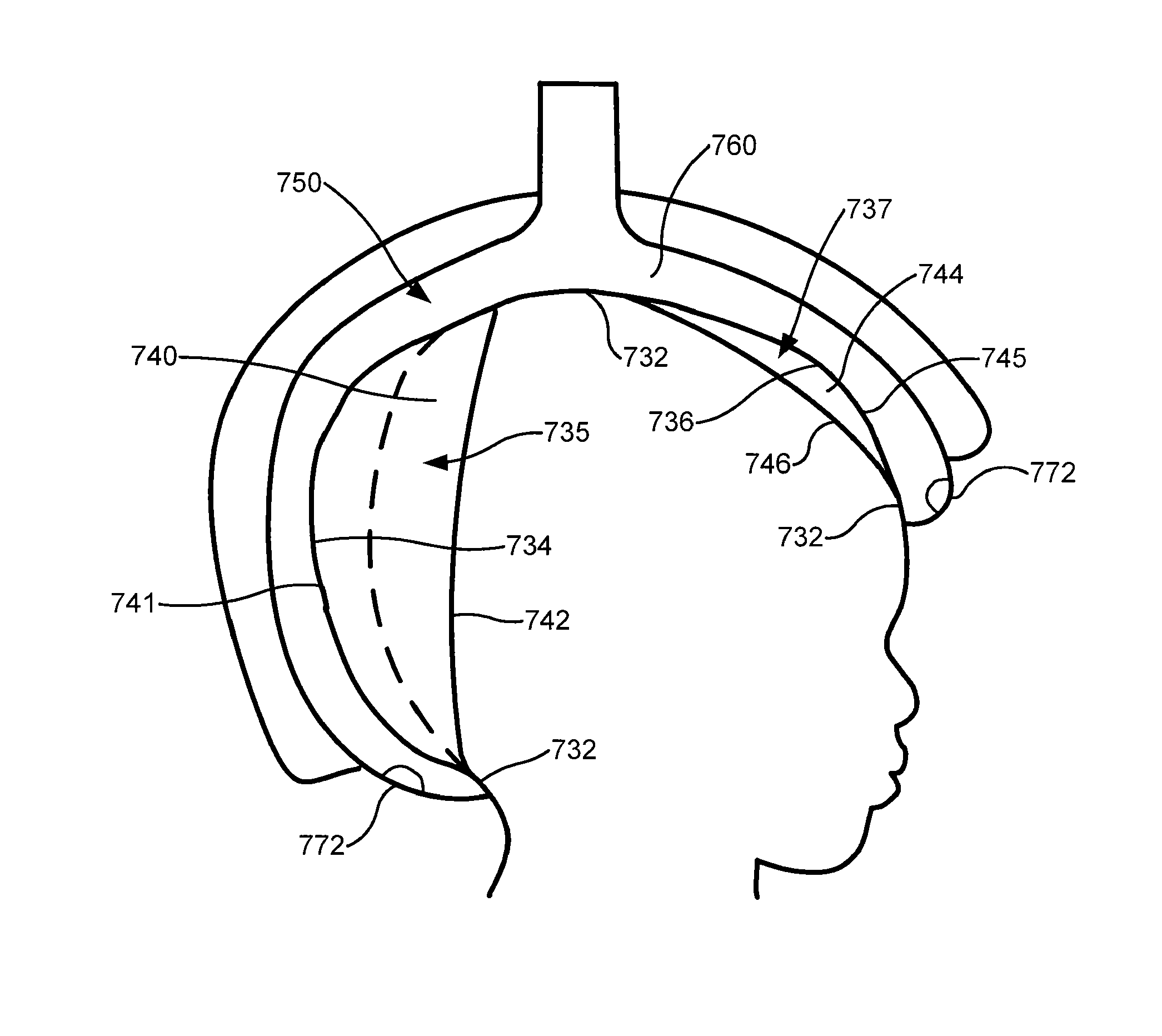

Method for molding annular member and apparatus for molding annular member

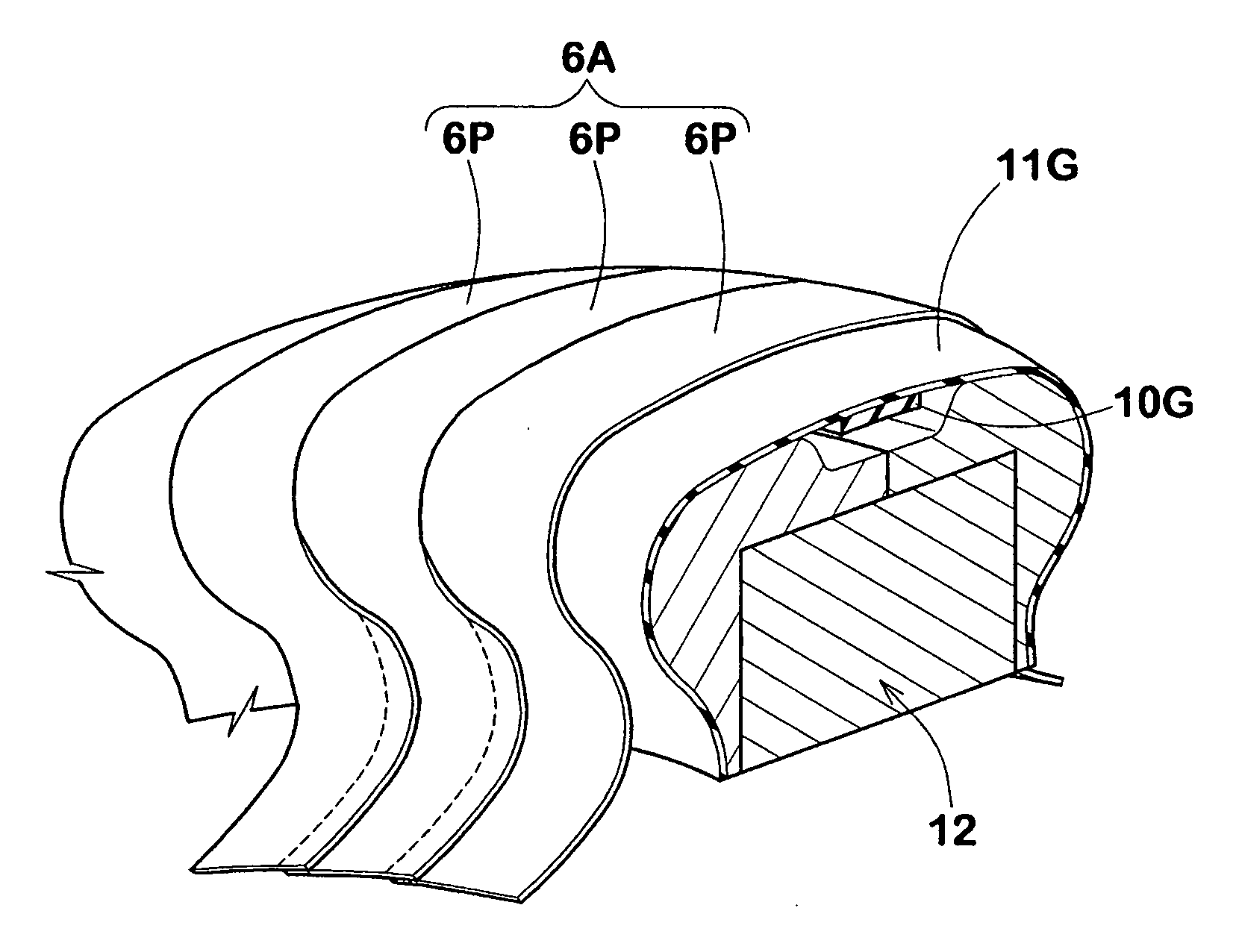

The object of the present invention is to provide a method and an apparatus for molding an annular member capable of accurately molding an annular member into a predetermined cross-sectional shape even if the annular member has a thick-walled inner peripheral part and a thin-walled outer peripheral part. The method for molding a bead filler (11) including a thick-walled inner peripheral part (11a) and a thin-walled outer peripheral part (11b), the method comprising the steps of extruding, into an annular shape, rubber (R1) by a first extruder (30) onto a molding table (20) through a first die (31) provided with an opening having the same cross-sectional shape as that of the inner peripheral part (11a) while the molding table (20) is rotated, and molding the inner peripheral part (11a); and extruding, into an annular shape, rubber by a second extruder (40) onto the molding table (20) through a second die (41) provided with an opening having the same cross-sectional shape as that of the outer peripheral part (11b) while the molding table (20) is rotated, and molding the outer peripheral part (11b).

Owner:TOYO TIRE & RUBBER CO LTD

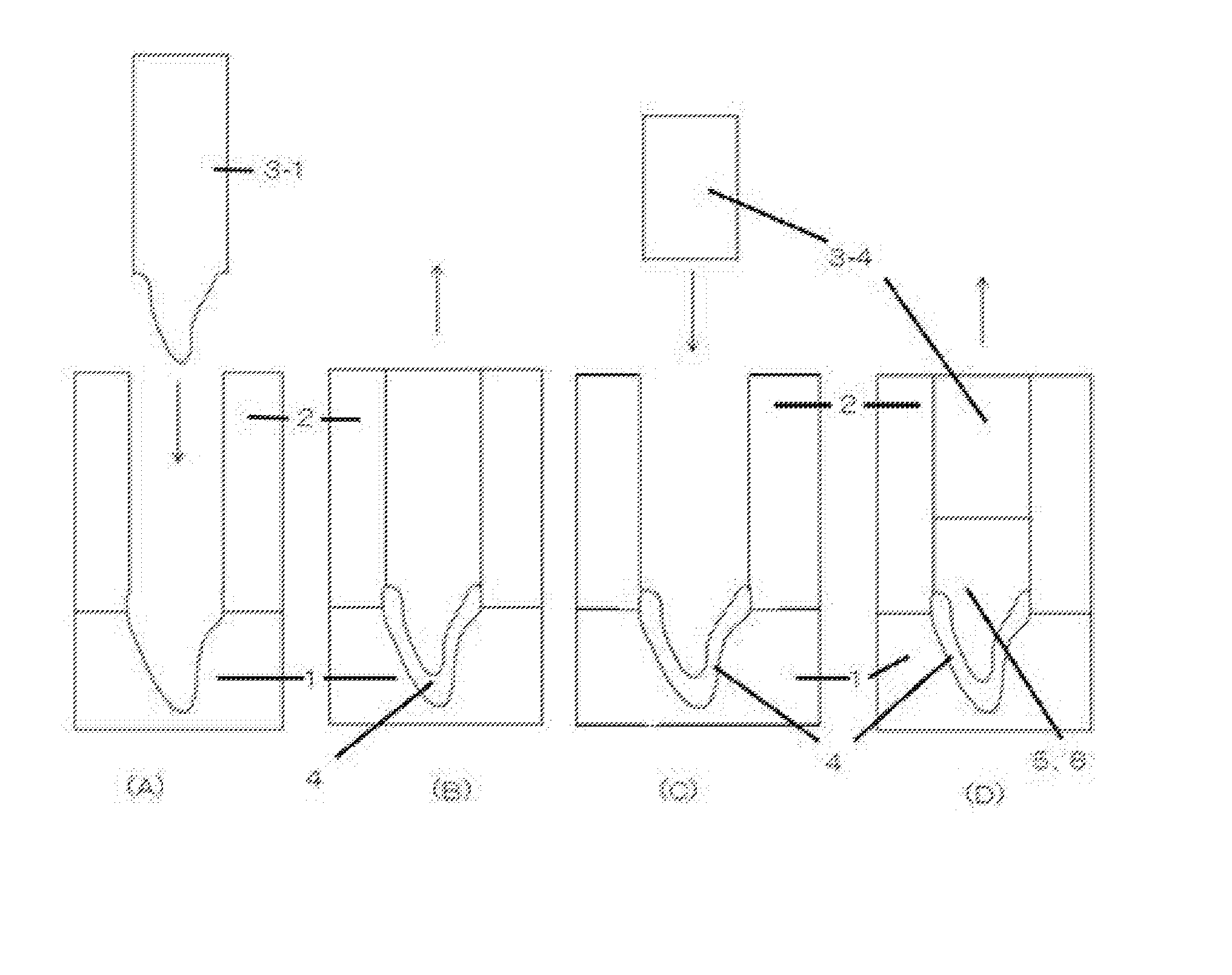

Manufacturing method and manufacturing device of element

PendingUS20220134408A1Improve production yieldPrecise moldingShaping toolsV-beltsPunchingTransmission belt

An element manufacturing method for a transmission belt of a continuously variable transmission having a thick wall portion and a thin wall portion formed by sequentially feeding a material having a strip shape with a uniform thickness to each press position and performing press working on the material at the press position. The method includes, as the press working performed at the press position: a preliminary punching step in which a portion other than a connecting portion is cut off from surrounding material and the cut off portion is punched so as not to overlap with the surrounding material in a plate thickness direction; a crushing step of compressing and crushing a region of the thin walled cut off portion, after the preliminary punching step; and a punching step of punching the cutting off portion into an outer shape corresponding to the element, after the crushing step.

Owner:AISIN CORP +1

Injection molding die, injection molding system, and injection molding method

InactiveUS20200039132A1Reduce damageSimple configurationTubular articlesHollow articlesComposite materialPolymer chemistry

An injection molding die is an injection molding die for molding a resin hollow body including a straight tubular portion having an inner peripheral surface that does not have a tapered portion for die removal. The injection molding die includes a core having a cylindrical portion configured to form the inner peripheral surface of the straight tubular portion. The core has a groove recessed inwardly in the radial direction and formed over a whole circumference of the cylindrical portion in an end portion of the core on a first side in the axial direction, the end portion corresponding to a rear end portion of the resin hollow body in the die-removal direction.

Owner:TOYOTA JIDOSHA KK

Mold base for mold manufacturing thermoplastic containers, and molding device equipped with at least one mold provided with such a base

A mold base for a blow- or stretch-blow molding of thermoplastic containers having a petaloid base with 5 stems which are separated by radiating troughs with convex radially curvilinear base, the base being connected to a body with a diameter Φ of 85 to 95 mm; the base includes 5 cavities separated by radiating ridge lines with concave radial ridge having a radius of 2 to 5 mm; the bases of the cavities have each a width of 1.5 to 3.5 mm and are distributed over a circular contour of diameter of base D of 60 to 66 mm; the height of the ridge line is 16.5 to 18 mm; the flanks of the ridge lines are axially concave and the tangent planes at origin form an angle of 52° to 88°.

Owner:SIDEL PARTICIPATIONS SAS

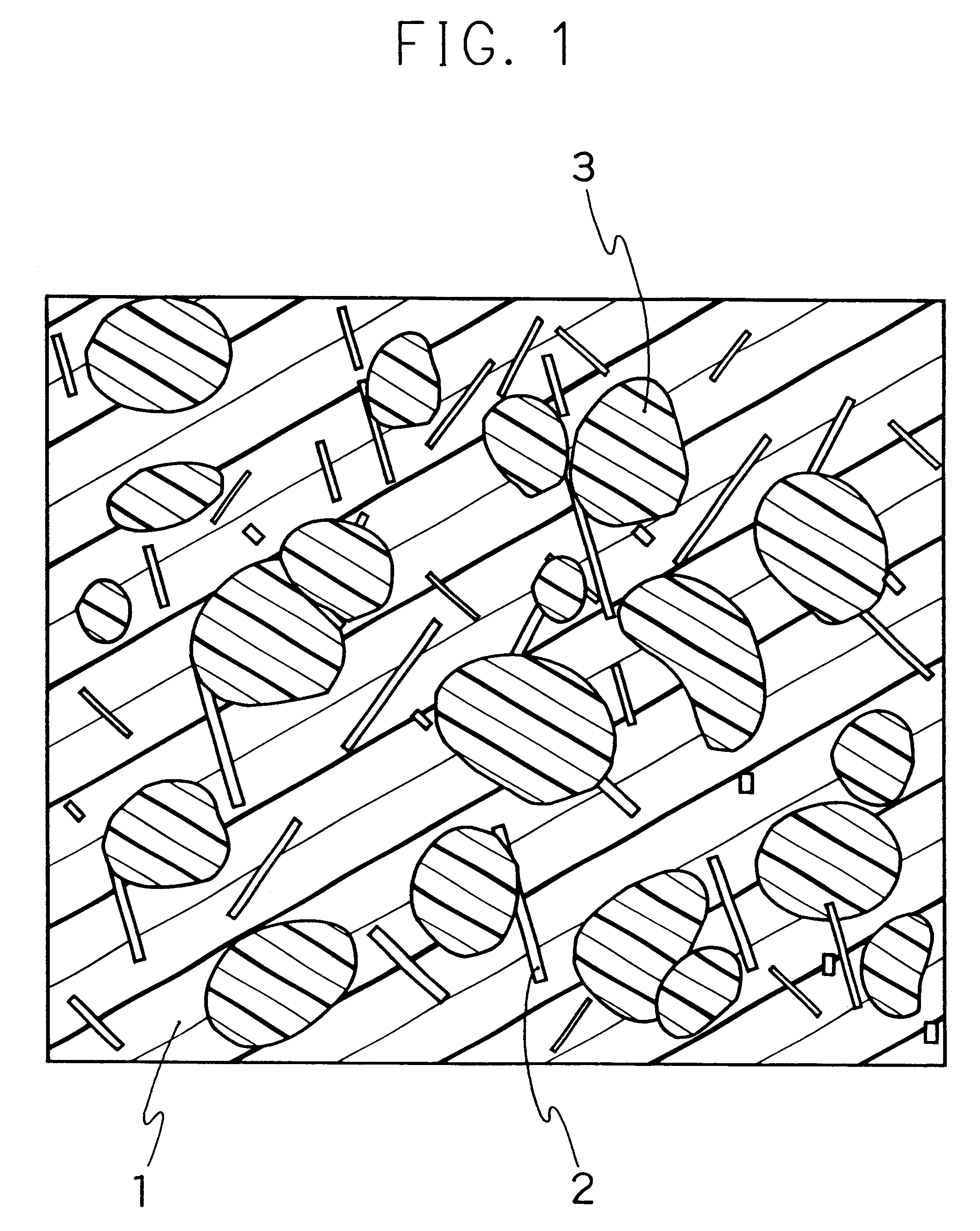

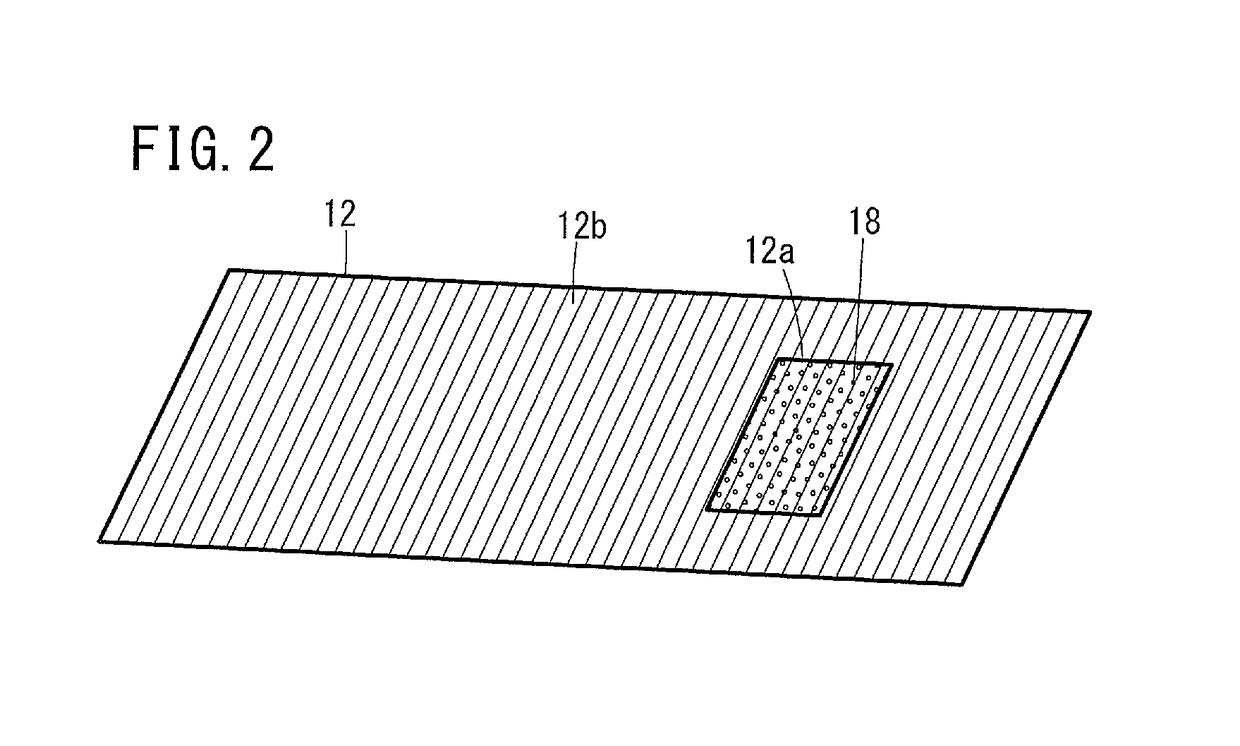

Fiber-reinforced composite material and method for manufacturing same

A fiber-reinforced composite material and a method for manufacturing the same. A first binder resin is applied to a first portion for forming a deformed part of a fiber base material, and a second binder resin is applied to a second portion excluding the first portion. The fiber base material is then heated so that the degree of melting of the first binder resin during shaping is less than the degree of melting of the second binder resin, and the second binder resin is softened. Shaping is then performed so that a deformed part is formed in the fiber base material, and a preform is obtained. A fiber-reinforced composite material is obtained using the preform as a molding precursor.

Owner:HONDA MOTOR CO LTD

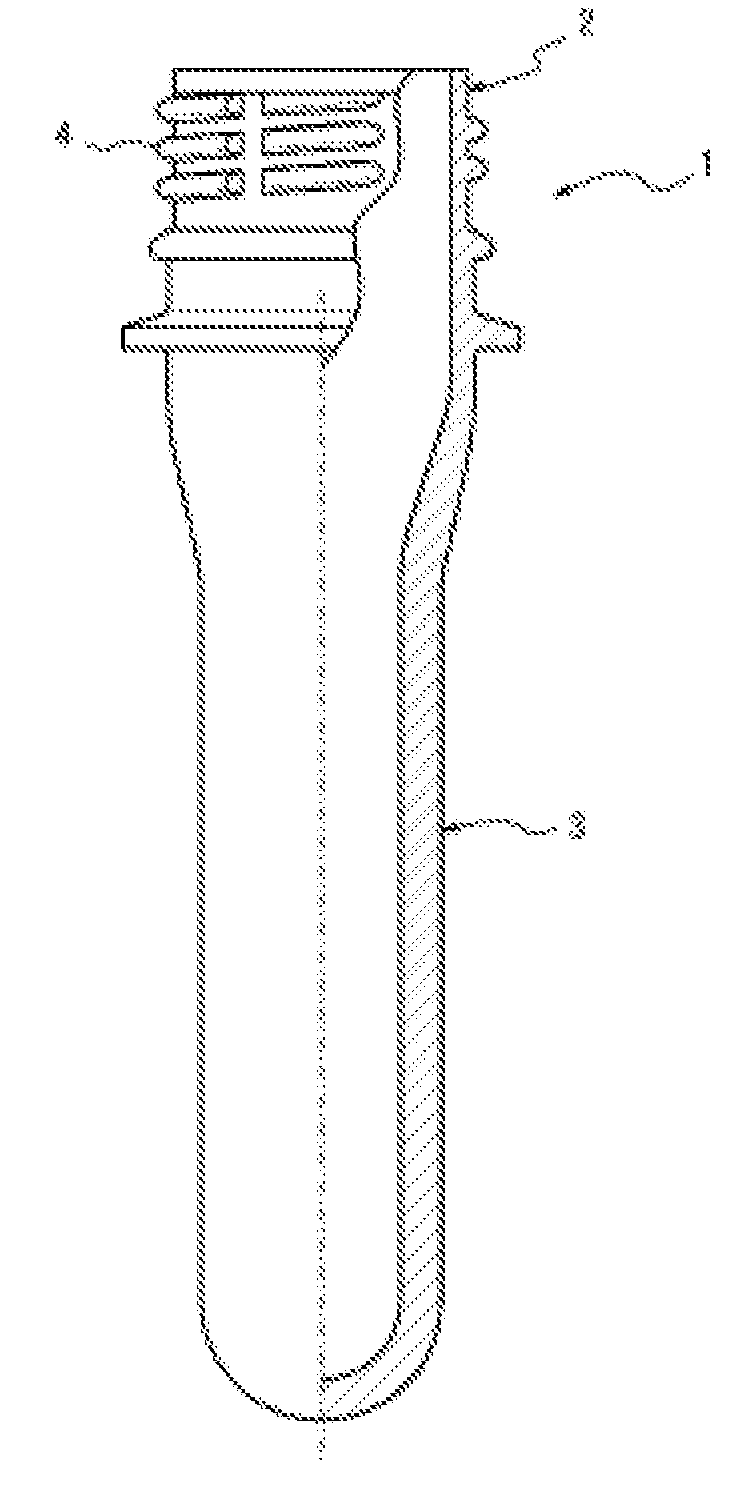

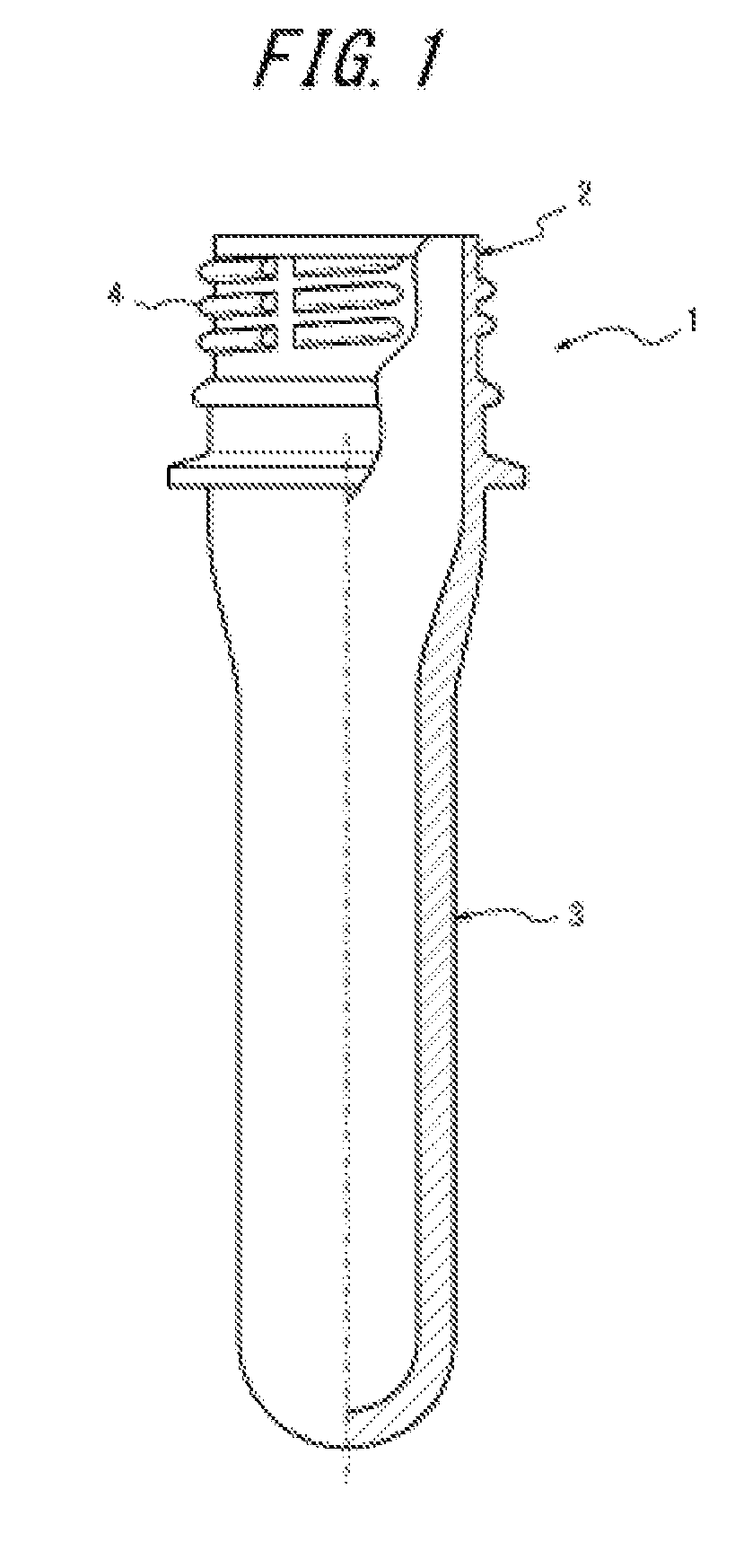

Preform for liquid blow molding

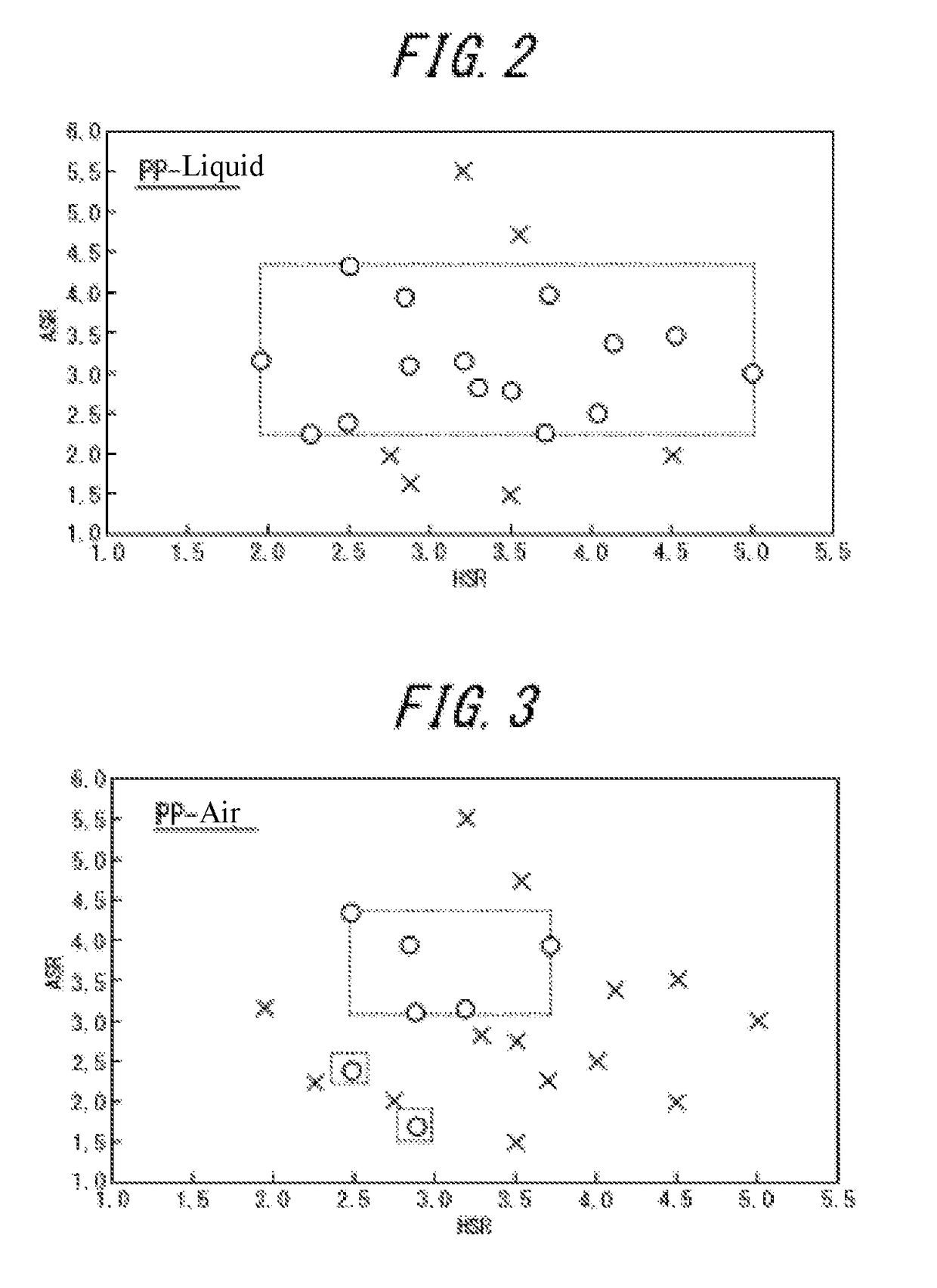

InactiveUS20170312972A1Precise moldingHigh densityDomestic articlesBlow moldingLow-density polyethylene

A preform formed from polypropylene or high density polyethylene and with which a container of a desired shape can be precisely molded by liquid blow molding. When formed of polypropylene as a closed-bottom cylinder shape having an open end section and a body section, the preform is molded into the container by stretching the body section in the axial direction by a stretch ratio of 2.25-4.34, inclusive, and in the radial direction by a stretch ratio of 1.95-5.00, inclusive. When formed of high density polyethylene as a closed-bottom cylinder shape having an open end section and a body section, the preform is molded into the container by stretching the body section in the axial direction by a stretch ratio of 1.69-2.50, inclusive, and in the radial direction by a stretch ratio of 2.26-5.07, inclusive.

Owner:DISCMA

Method of manufacturing resin molded product and manufacturing device thereof

InactiveUS20160243751A1Improve cooling effectSuppression of temperature gradientsDomestic articlesFuel tankEngineering

A manufacturing device of a resin fuel tank can efficiently cool molded bodies when a cooling mold is inserted on the inside of the sheet-like molded bodies and shaping molds are closed. Here, semispherical convex portions are tightly formed on a surface of the cooling mold, and a contact area of the convex portions with the molded body gradually decreases in a boundary region of the molded body in which transition from an contact portion, with which the cooling mold contacts, to a non-contact portion, with which the cooling mold does not contact, is made. Thus, a temperature gradient of the molded body is suppressed in the boundary region, and formation of a groove in the boundary region can be suppressed.

Owner:TOYOTA JIDOSHA KK

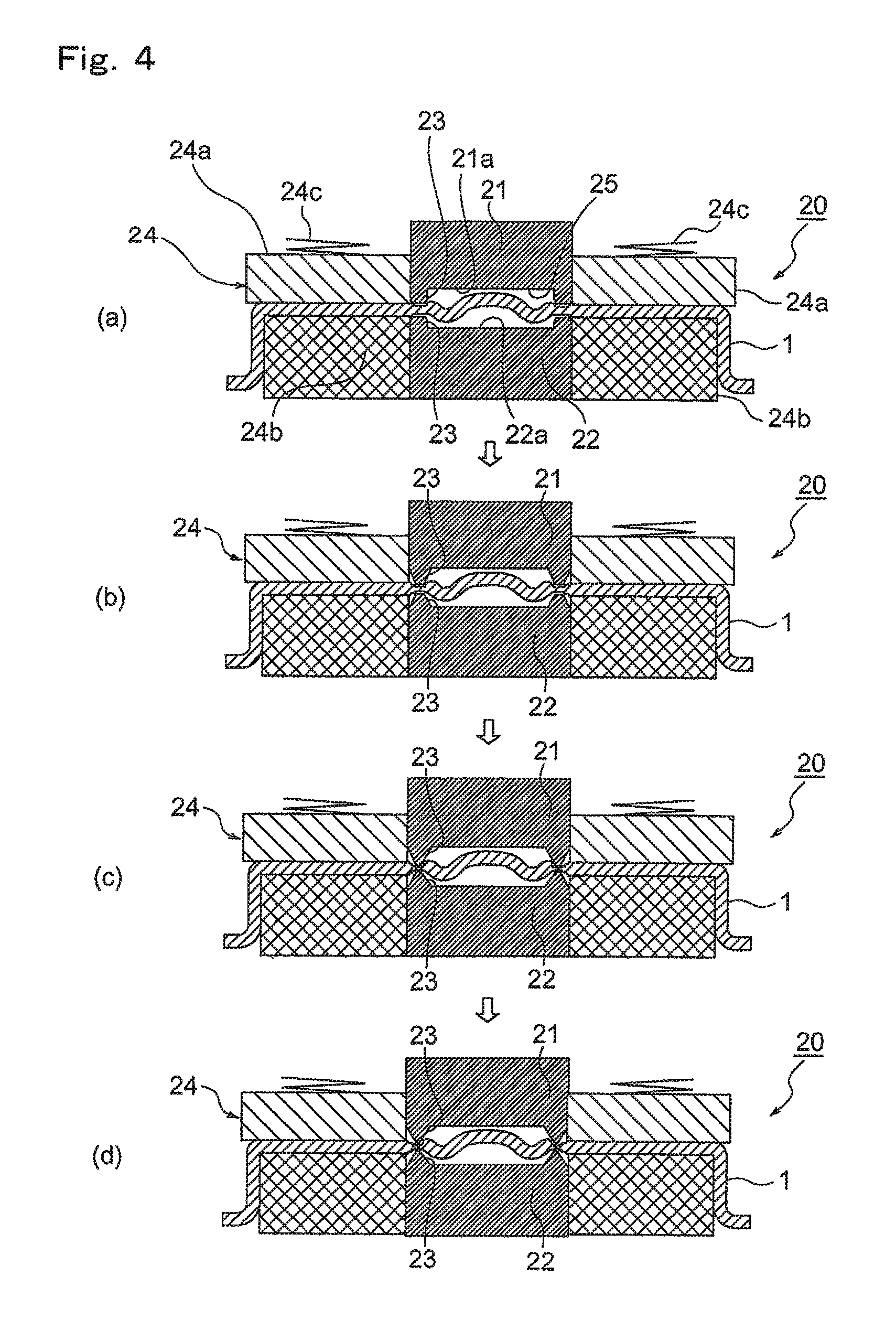

Method and apparatus for manufacturing a battery safety valve, a battery safety valve, and method for manufacturing a battery case lid

ActiveUS9508968B2Extend your lifePrecise moldingFinal product manufactureVent arrangementsEngineeringMetal sheet

In a method for manufacturing a battery safety valve according to the present invention, a stainless steel metal sheet is used, and an thin annular portion constituting an edge portion of a safety valve is formed in a lid by simultaneously pressing annular projecting portions provided respectively on a punch and a die so as to oppose each other, against respective surfaces of the lid.

Owner:NISSHIN STEEL CO LTD

High-efficiency injection molding machine

The invention discloses a high-efficiency injection molding machine, and relates to the technical field of injection molding, the high-efficiency injection molding machine comprises an operation table, an injection mechanism is fixedly connected to the upper surface of the operation table, the injection mechanism comprises a treatment box shell, and the bottom of the treatment box shell is fixedly connected to the upper surface of the operation table; and the lower surface of the operation table is fixedly connected with a motor box, the outer surface of the treatment box shell is slidably connected with a push rod, and the outer surface of the push rod penetrates through the treatment box shell and extends into the inner cavity. According to the high-efficiency injection molding machine, molten plastic is injected into the mold through the hot runner, the high-temperature plastic enables gas in the air bag to absorb heat and expand, the first circular ring is driven to move and be connected with the outermost side of the plastic, when a cooling system is started, the gas in the air bag and the plastic are cooled to contract, the first circular ring is firstly separated from the plastic, and the rapid separation effect is achieved; the compression ball and the elastic strip play a buffering role to avoid breakage caused by excessive contraction of the airbag.

Owner:李卫新

A mold assembly tool for a single blade wax mold of a turbine guide

ActiveCN112620579BPrecise moldingHigh mold opening pass rateFoundry moulding apparatusEngineeringTurbine

The invention discloses a mold-assembling tooling for a turbine guider single-blade wax mold, which comprises a wax mold fitted between an inner positioning block and an outer positioning block, the inner positioning block and the outer positioning block are installed on a track base, And it can move horizontally relative to the track base to clamp, position and release the wax mold; the non-clamping ends of the inner and outer positioning blocks are connected with the elastic mechanism to realize the inner and outer positioning blocks The elastic clamping and reset of the track base; the lower end of the track base is equipped with a rotating handle, which can rotate around the axis; the track base is equipped with an ejection structure that can move up and down. The structure is in contact with the inner positioning block and the outer positioning block in the form of an inclined surface, and the ejection structure and the rotating handle are in contact with a helical surface, and the ejecting structure moves up and down under the rotation of the rotating handle. The mold set tool can accurately and efficiently combine a group of individual blade wax patterns into a full ring guide wax pattern.

Owner:成都晨发泰达航空科技股份有限公司

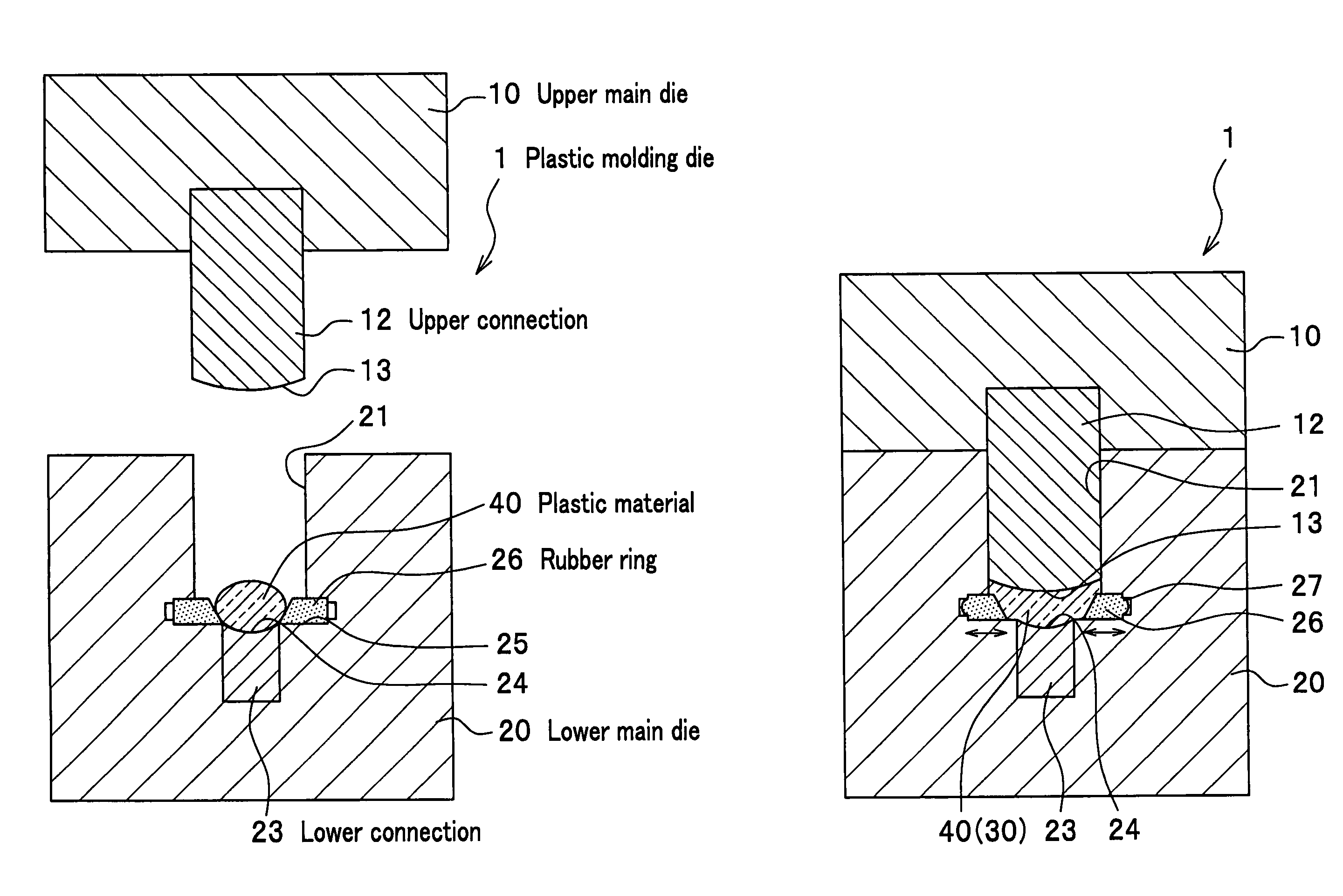

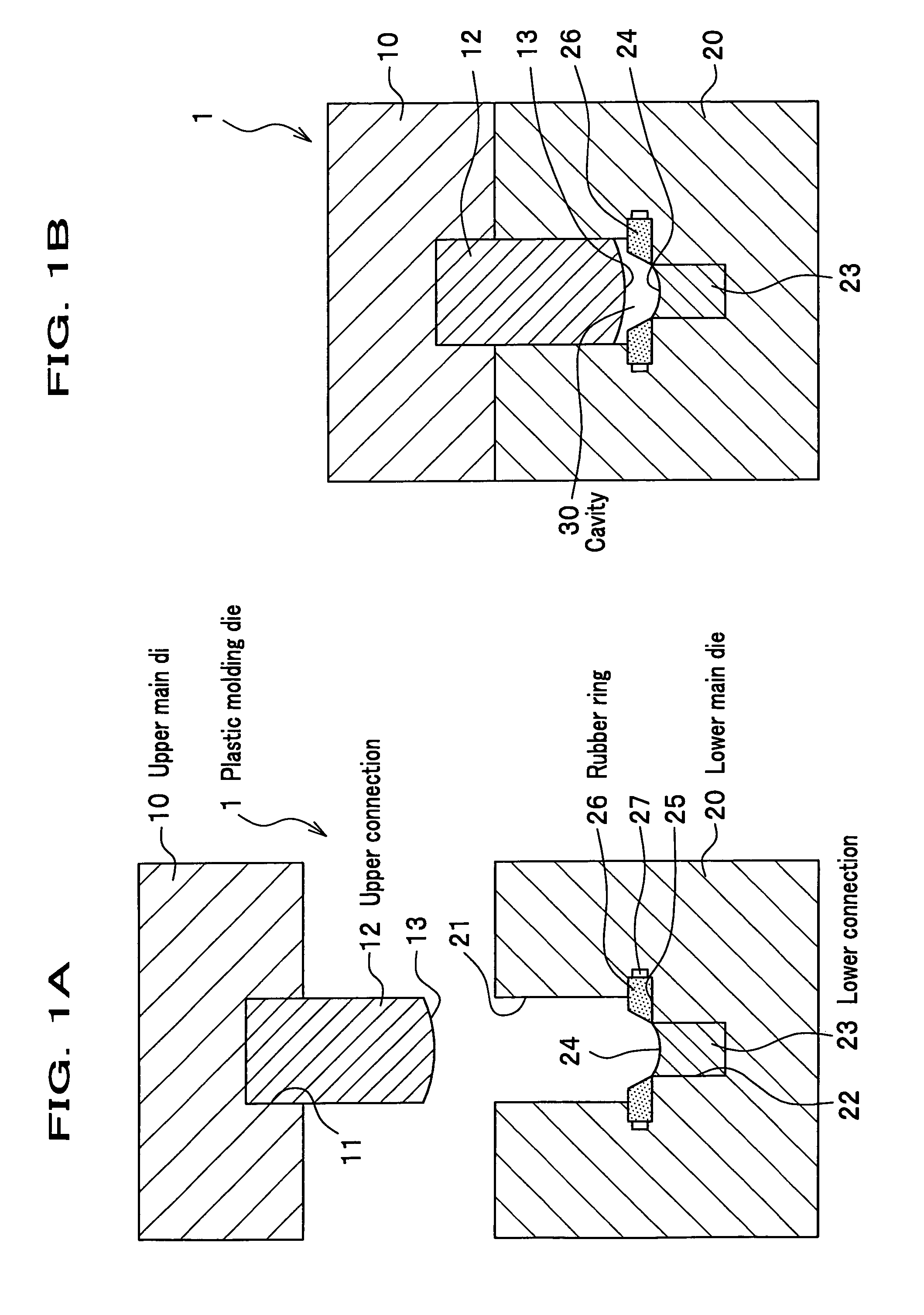

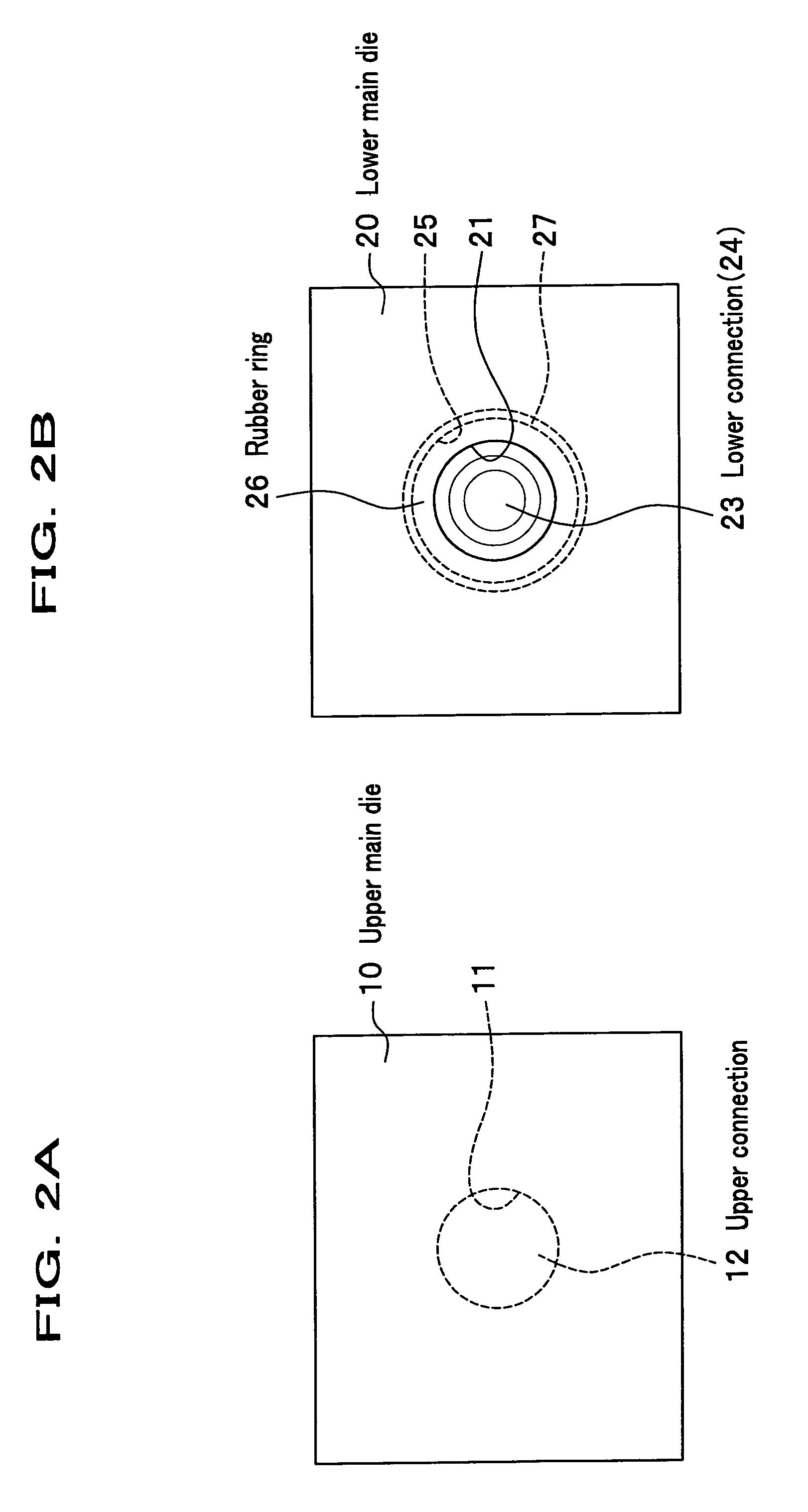

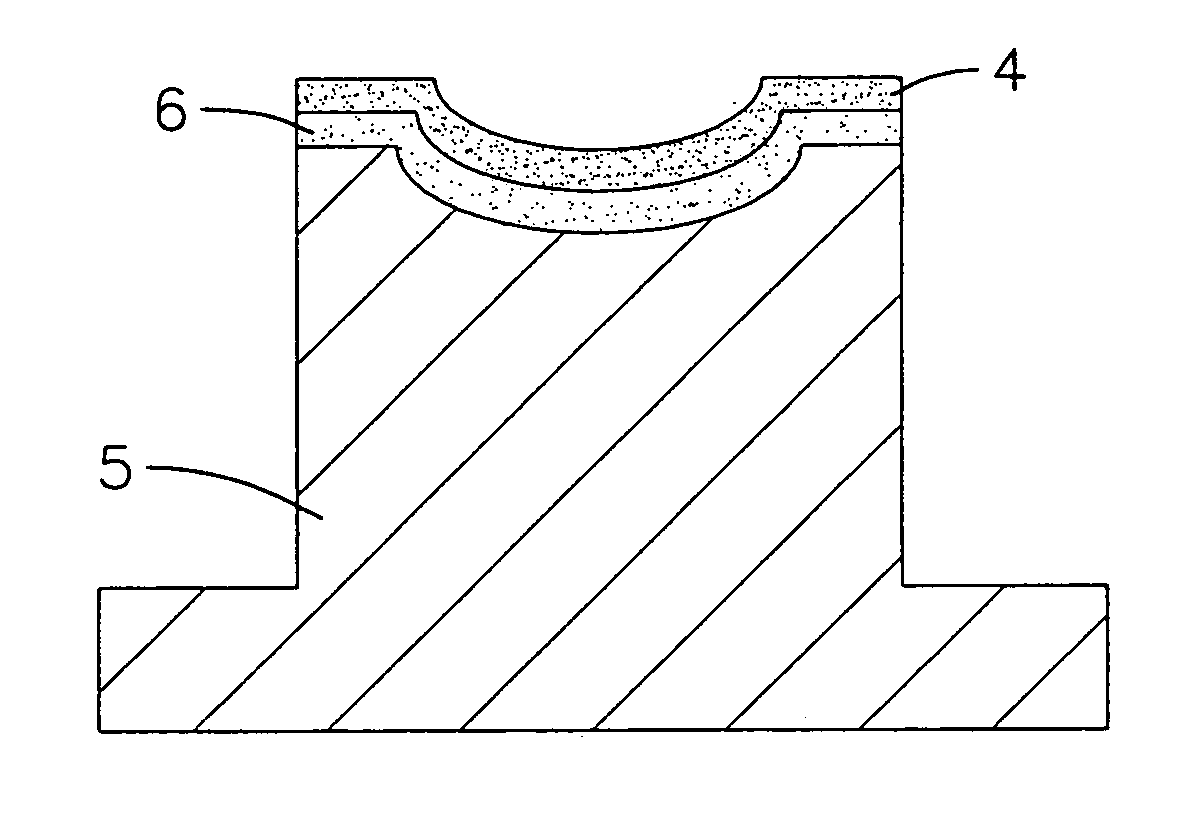

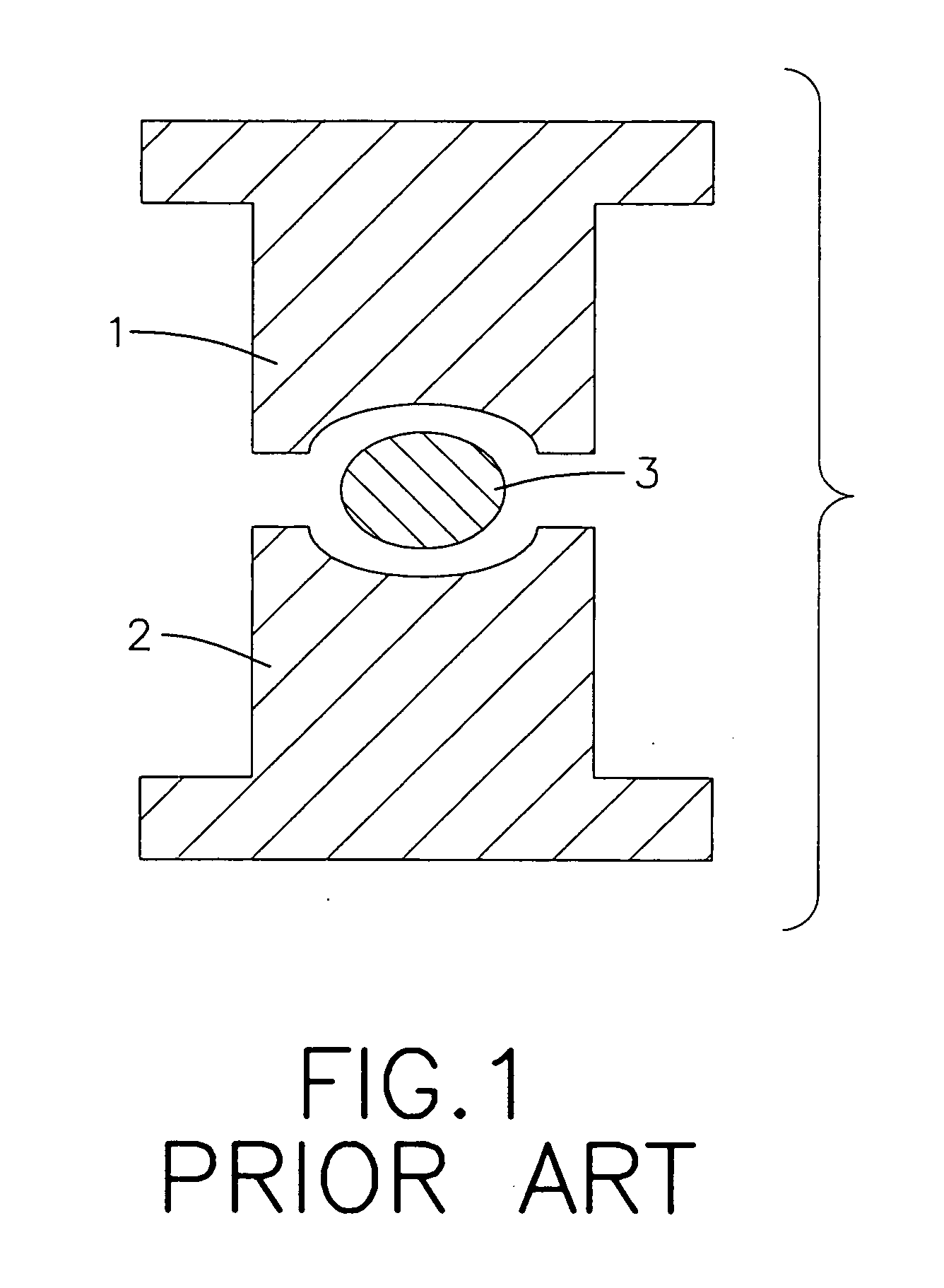

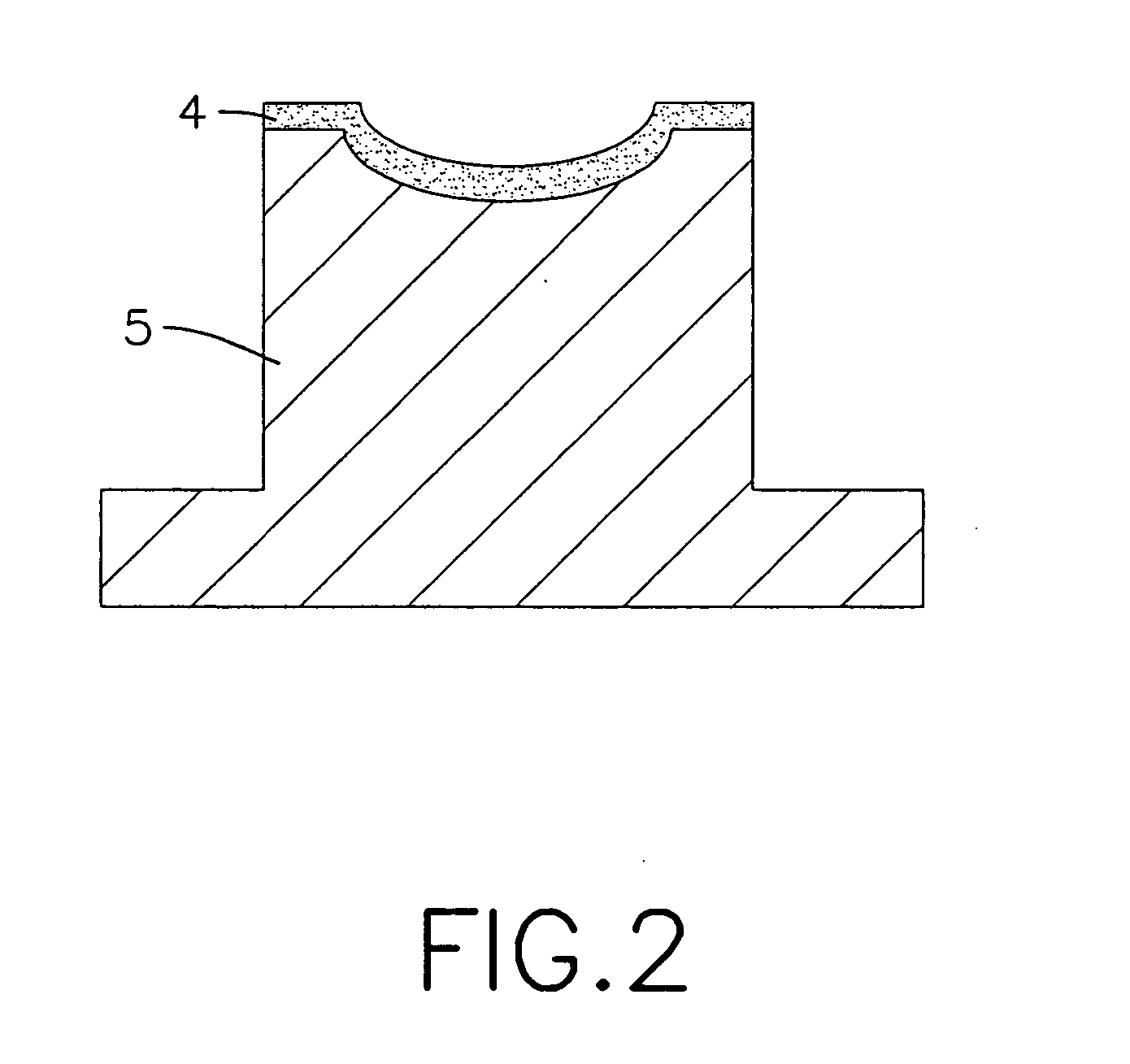

Plastic molding die

InactiveUS7845934B2Reduce cavity volumeKeep in touchSemiconductor/solid-state device detailsConfectioneryCompression moldingElastomer

A plastic molding die provided with a cavity where a plastic material is put in, wherein a part of an inner surface of the cavity is configured with an elastic body. A molding portion corresponding to a molding surface of a molded product is disposed on the inner surface of the cavity, and the elastic body is arranged on a portion other than the molding portion of the inner surface of the cavity. The plastic molding die may be a molding die for compression molding. The elastic body is made of rubber, and has an upper temperature limit higher than a glass-transition temperature of the plastic material. The degree of rubber hardness of the elastic body is from 50 to 100.

Owner:FUJIFILM CORP +1

Minute shape molding method and apparatus thereof

InactiveUS7820084B2Precise moldingShorten the timeOther chemical processesMouldsShell moldingEngineering

Owner:TOSHIBA MASCH CO LTD

Method for molding annular member and apparatus for molding annular member

The object of the present invention is to provide a method and an apparatus for molding an annular member capable of accurately molding an annular member into a predetermined cross-sectional shape even if the annular member has a thick-walled inner peripheral part and a thin-walled outer peripheral part. The method for molding a bead filler (11) including a thick-walled inner peripheral part (11a) and a thin-walled outer peripheral part (11b), the method comprising the steps of extruding, into an annular shape, rubber (R1) by a first extruder (30) onto a molding table (20) through a first die (31) provided with an opening having the same cross-sectional shape as that of the inner peripheral part (11a) while the molding table (20) is rotated, and molding the inner peripheral part (11a); and extruding, into an annular shape, rubber by a second extruder (40) onto the molding table (20) through a second die (41) provided with an opening having the same cross-sectional shape as that of the outer peripheral part (11b) while the molding table (20) is rotated, and molding the outer peripheral part (11b).

Owner:TOYO TIRE & RUBBER CO LTD

In situ molded orthotic and method for its fabrication

An orthotic helmet and methods for fabrication and use thereof. The orthotic is molded in situ on a growing infant's head for the treatment of plagiocephaly, postsurgical cranial molding, or other desired treatment plans. The helmet makes contact in areas where cranial shape and volume are adequate, and no contact in areas of planned cranial growth. The helmet includes a shell, a bladder system which can be filled with a viscoelastic expandable foam, a fastener and a retaining strap. In the areas of deficient cranial volume, a volume of modeling putty equivalent to the target growth volume is placed against the cranium, manually molded until the planned target volume and form have been attained, and the helmet is molded in place over this spacer material. The spacer is then removed, and the helmet is then worn continuously until resolution of the deformity or attainment of planned form is reached.

Owner:PPOD ORTHOTICS INC

Mold for glass

InactiveUS20070186590A1Extend your lifePrecise moldingGlass pressing apparatusGlass press-moulding apparatusA diamond

Owner:KINIK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com